FANUC I/O Unit-MODEL A

CONNECTION AND MAINTENANCE MANUAL

B-61813E/04

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

B-61813E/04 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-1

B-61813E/04 PREFACE

PREFACE

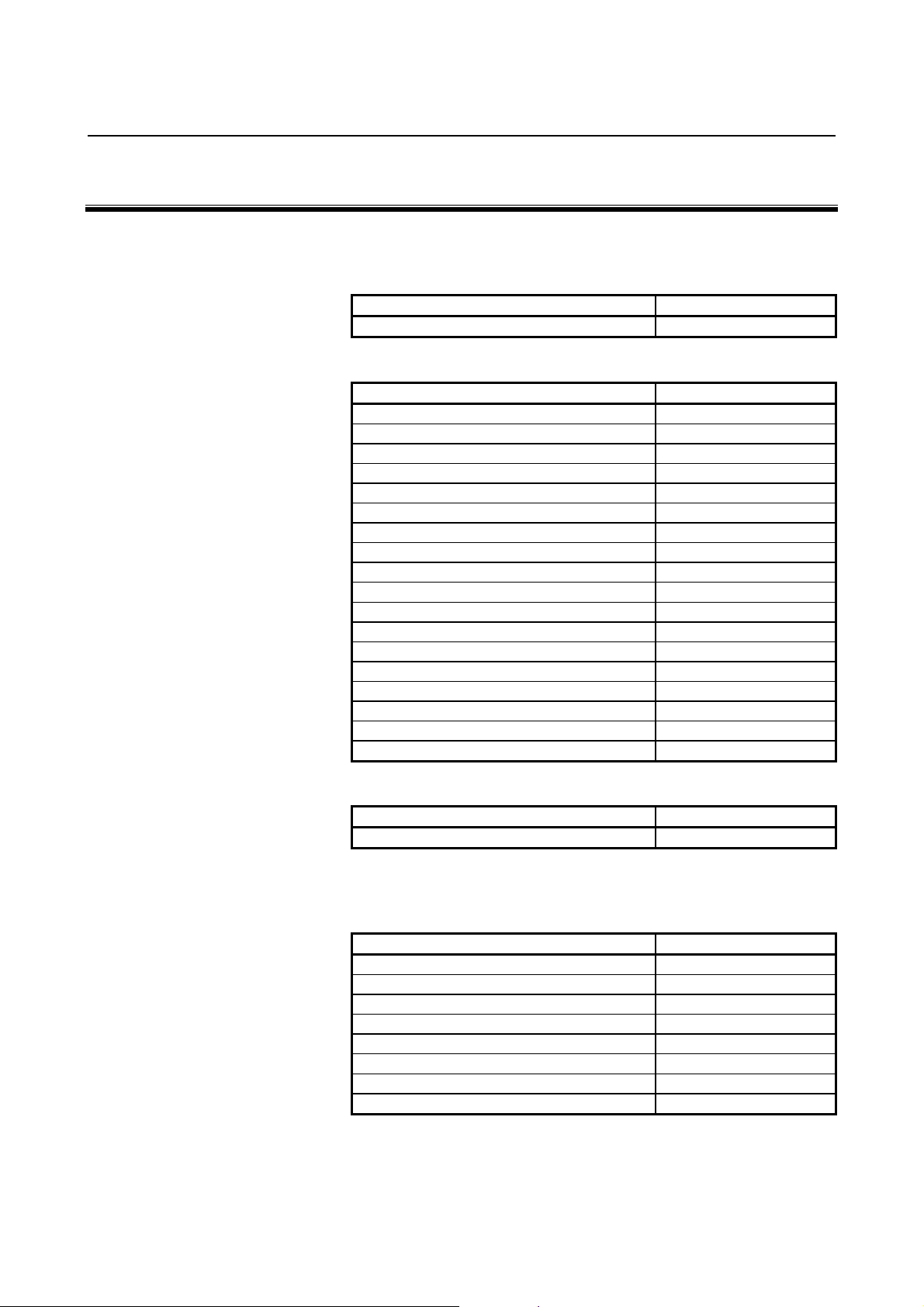

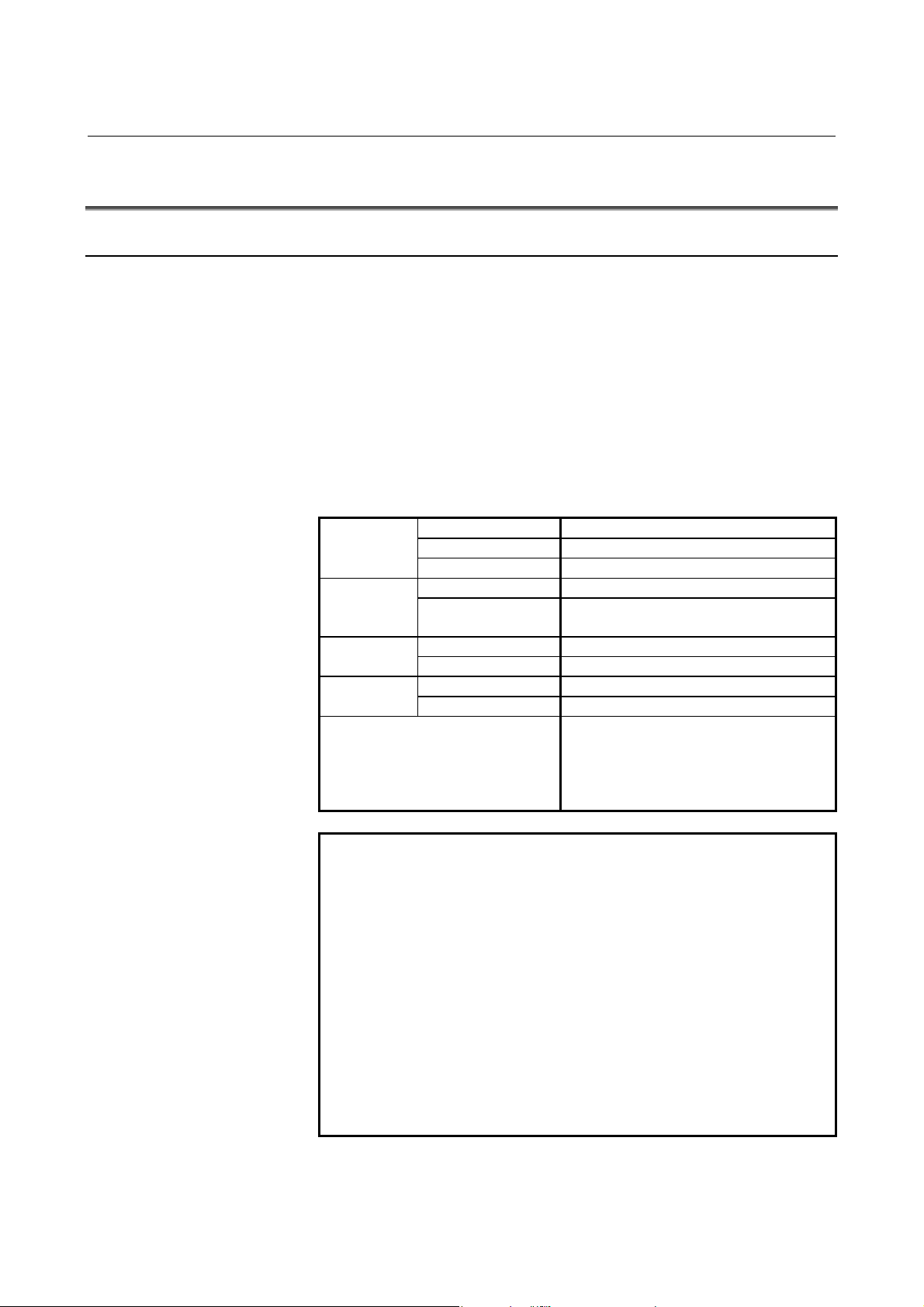

Applicable models

This manual describe the following products:

Name of products Abbreviation

FANUC I/O Unit-MODEL A I/O Unit-A

Applicable CNCs

Name of products Abbreviation

FANUC Power Mate Power Mate

FANUC Series 0 (MODEL C) Series 0-C

FANUC Series 15 Series 15

FANUC Series 16 Series 16

FANUC Series 18 Series 18

FANUC Series 20 Series 20

FANUC Series 21 Series 21

FANUC SYSTEM F-MODEL D Mate F-D Mate

FANUC Power Mate i Power Mate i

FANUC Series 0i Series 0i

FANUC Series 15i Series 15i

FANUC Series 16i Series 16i

FANUC Series 18i Series 18i

FANUC Series 20i Series 20i

FANUC Series 21i Series 21i

FANUC Series 30i Series 30i

FANUC Series 31i Series 31i

FANUC Series 32i Series 32i

Other related models

Name of products Abbreviation

FANUC I/O Unit-MODEL B I/O Unit-B

Abbreviations of manufacturer names used herein

This manual uses the following abbreviations for manufacturers of

products such as connectors.

Manufacturer name Abbreviation

Daito Communication Apparatus Co., Ltd. Daito

Fujitsu Limited Fujitsu

HIROSE ELECTRIC CO., LTD. HIROSE ELECTRIC

HONDA TSUSHIN KOGYO CO., LTD. HONDA TSUSHIN

Molex Incorporated Molex

Nihon Weidmüller Co., Ltd. Weidmüller

SORIAU JAPAN SORIAU JAPAN

Tyco Electronics AMP K.K. Tyco Electronics

p-1

B-61813E/04 TABLE OF CONTENTS

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE .................................s-1

PREFACE....................................................................................................p-1

I. CONNECTION

1 FANUC I/O Link ...................................................................................... 3

1.1 CONFIGURATION......................................................................................... 4

1.2 ALLOCATION OF I/O POINTS...................................................................... 5

2 I/O Unit CONFIGURATION.....................................................................7

3 INSTALLATION ......................................................................................8

3.1 ENVIRONMENT FOR INSTALLATION .........................................................9

3.1.1 Environmental Conditions outside the Cabinet........................................................9

3.2 DESIGNING CONDITION FOR A CABINET ............................................... 10

3.3 OUTER DIMENSION OF I/O Unit................................................................ 11

3.4 MOUNTING AND DISMOUNTING MODULES............................................15

4 CONNECTION....................................................................................... 16

4.1 GENERAL CONNECTION DIAGRAM......................................................... 17

4.2 CONNECTING INPUT POWER SOURCE .................................................. 18

4.3 GROUNDING ..............................................................................................19

4.4 REQUIRED CURRENT ............................................................................... 20

4.5 INTERFACE MODULE (AIF01A, AIF01A2, AIF01B) ................................... 21

4.6 INTERFACE MODULE (AIF02C) CONNECTION........................................ 24

4.6.1 Overview ................................................................................................................24

4.6.2 Connection .............................................................................................................25

4.6.3 Setting with the DIP Switch ...................................................................................27

4.7 CONNECTING WITH I/O MODULES.......................................................... 28

5 DIGITAL INPUT/OUTPUT MODULES .................................................. 30

5.1 LIST OF MODULES ....................................................................................31

5.2 CORRESPONDENCE BETWEEN I/O SIGNALS AND ADDRESSES IN A

MODULE .....................................................................................................34

5.2.1 Module with 16/32 Digital Inputs (DI) ..................................................................34

5.2.2 Module with 5/8/12/16/32 Digital Outputs (DO)...................................................34

5.2.3 AIO40A Module (Hybrid Module with 24 Input and 16 Output Points)...............35

5.3 SPECIFICATION FOR EACH MODULE ..................................................... 36

c-1

TABLE OF CONTENTS B-61813E/04

5.4 DETAILS OF I/O Unit CONNECTORS (HONDA TSUSHIN/HIROSE

ELECTRIC) AND TERMINAL BLOCK (WEIDMÜLLER).............................. 74

5.4.1 Modules Using the MR-50RMA Connector Manufactured by Honda Tsushin.....75

5.4.2 Modules Using the HIF3BB-50PA-2.54DS Connector Manufactured by

Hirose Electric........................................................................................................77

5.4.3 Modules Using the HIF4-40P-3.18DS Connector Manufactured by

Hirose Electric........................................................................................................79

5.4.4 Modules Using the Terminal Block BL3.5/24/90F Manufactured by

Weidmüller.............................................................................................................80

6 ANALOG INPUT MODULE................................................................... 81

6.1 12-BIT ANALOG INPUT MODULE (AAD04A)............................................. 82

6.1.1 Specifications .........................................................................................................82

6.1.2 Correspondence between Input Signals and Addresses in a Module .....................83

6.1.3 Connecting with Analog Input Module..................................................................85

6.2 16-BIT ANALOG INPUT MODULE (AAD04B)............................................. 86

6.2.1 Specifications .........................................................................................................86

6.2.2 Correspondence between Input Signals and Addresses in a Module .....................87

6.2.3 Connecting with Analog Input Module..................................................................89

7 ANALOG OUTPUT MODULE ............................................................... 90

7.1 12-BIT ANALOG OUTPUT MODULE (ADA02A)......................................... 91

7.1.1 Specification...........................................................................................................91

7.1.2 Correspondence between Output Signals and Addresses in a Module ..................92

7.1.3 Connection to Analog Output Module ...................................................................93

7.2 14-BIT ANALOG OUTPUT MODULE (ADA02B)......................................... 94

7.2.1 Specification...........................................................................................................94

7.2.2 Correspondence between Output Signals and Addresses in the Module ...............95

7.2.3 Connection between the Analog Output Module and Load ...................................96

8 HIGH-SPEED COUNTER MODULE .....................................................97

8.1 OUTLINE OF HIGH-SPEED COUNTER MODULE ..................................... 98

8.2 SPECIFICATIONS OF HIGH-SPEED COUNTER MODULE..................... 100

8.2.1 Pulse Counter .......................................................................................................100

8.2.2 Comparison Function ...........................................................................................100

8.2.3 Pulse Interface ......................................................................................................102

8.2.4 External Contact Input..........................................................................................105

8.2.5 External Contact Output.......................................................................................105

8.2.6 Marker Processing................................................................................................106

c-2

B-61813E/04 TABLE OF CONTENTS

8.2.7 LED indicators .....................................................................................................107

8.3 PMC INTERFACE .....................................................................................109

8.3.1 Mode A.................................................................................................................109

8.3.2 Mode B.................................................................................................................111

8.3.3 Details of PMC Interface Signals .........................................................................114

8.4 TOTAL CONNECTION OF HIGH-SPEED COUNTER MODULE.............. 117

8.4.1 Connection Diagram.............................................................................................117

8.4.2 Connector Signal List...........................................................................................117

8.4.2.1 C49 signal (for mode A).................................................................................. 118

8.4.2.2 C49 signal (for mode B) .................................................................................. 118

8.5 CONNECTION WITH PULSE GENERATOR ............................................119

8.5.1 Use of Phase A and B Pulses................................................................................119

8.5.2 Use of Positive/Negative Pulses...........................................................................120

8.6 CONNECTION WITH MACHINE (POWER MAGNETICS CABINET) .......121

8.6.1 Use in Mode A .....................................................................................................121

8.6.2 Use in Mode B......................................................................................................122

8.7 I/O SIGNALS CONVENTIONS .................................................................. 123

8.7.1 Solid State Relay Output Signals (OUT0 to OUT7) ............................................123

8.7.2 DC Input Signals (ME and CSP)..........................................................................124

8.7.3 +5-V Output from JA9 Connector........................................................................124

8.8 SUPPLEMENT ..........................................................................................125

8.8.1 Configuration of Mode A.....................................................................................125

8.8.2 Counter Presetting and Counting .........................................................................126

8.8.3 Setting Data ..........................................................................................................129

8.8.4 Reading Data ........................................................................................................130

8.9 EXAMPLE OF STARTING UP ACT01A ....................................................131

8.9.1 Mode A Startup Flowchart ...................................................................................131

8.9.2 Example of Mode A Ladder.................................................................................132

8.9.3 Mode B Startup Flowchart ...................................................................................136

8.9.4 Example of Mode B Ladder .................................................................................137

9 TEMPERATURE INPUT MODULE .....................................................144

9.1 OVERVIEW ............................................................................................... 145

9.2 TEMPERATURE INPUT MODULE SPECIFICATION ...............................146

9.3 PMC INTERFACE .....................................................................................147

9.3.1 PMC I/O Area ......................................................................................................147

9.3.2 Measurement Mode..............................................................................................148

9.3.3 Details of Output Signals (PMC → Temperature Module)..................................148

c-3

TABLE OF CONTENTS B-61813E/04

9.3.4 Details of Input Signals (Temperature Module → PMC) ....................................151

9.4 COMPLETE CONNECTION OF TEMPERATURE INPUT MODULE ........ 154

9.4.1 Temperature Input Module Connection Diagram ................................................154

9.4.2 Connector Signal Lists .........................................................................................155

9.4.3 Terminal Board Unit Connection Diagram ..........................................................156

9.5 TIMING CHARTS ......................................................................................157

9.6 MEASUREMENT EXAMPLES................................................................... 158

9.7 TERMINAL BOARD UNIT DIMENSIONS.................................................. 165

10 OPTICAL I/O Link ADAPTER.............................................................166

10.1 EXTERNAL DIMENSION OF OPTICAL I/O Link....................................... 167

10.2 WEIGHT OF OPTICAL I/O Link................................................................. 167

10.3 CONNECTION OF OPTICAL I/O Link....................................................... 168

10.4 POWER SOURCE OF OPTICAL I/O Link ADAPTER ...............................169

10.5 INSTALLATION CONDITIONS OF OPTICAL I/O Link ADAPTER ............169

10.6 CAUTIONS FOR USING OPTICAL I/O Link ADAPTERS ......................... 170

10.6.1 Configuring I/O Links Using Optical I/O Link Adapters ....................................170

10.6.2 When Using Series 16i/18i/21i-MODEL B as Master .........................................171

10.6.3 When Using Series 30i/31i/32i-MODEL B as Master .........................................172

10.7 OPTICAL FIBER CABLE ........................................................................... 174

10.7.1 External View of Optical Fiber Cable..................................................................174

10.7.2 Notice of Optical Fiber Cable Handling...............................................................175

10.7.3 Optical Fiber Cable Clamping Method ................................................................176

10.7.4 Relay Using an Optical Fiber Junction Adapter...................................................177

10.7.5 Maximum Transmission Distance by Optical Fiber Junction Cable....................179

11 I/O Link DUMMY UNIT........................................................................ 180

11.1 OVERVIEW ............................................................................................... 181

11.2 EXTERNAL DIMENSIONS ........................................................................ 181

11.3 LED INDICATORS..................................................................................... 182

11.4 WEIGHT ....................................................................................................182

11.5 POWER REQUIREMENTS ....................................................................... 182

11.6 INSTALLATION CONDITIONS.................................................................. 182

11.7 CONNECTION DIAGRAMS....................................................................... 183

11.7.1 When not Connecting FANUC I/O Link Dummy Units in Series.......................183

11.7.2 Connecting FANUC I/O Link Dummy Units in Series........................................184

11.7.3 Grounding.............................................................................................................184

11.7.4 K3X Cable............................................................................................................185

c-4

B-61813E/04 TABLE OF CONTENTS

12 TWO-CHANNEL I/O Link CONNECTOR ADAPTER .........................186

12.1 OVERVIEW ............................................................................................... 187

12.2 CONNECTION FOR USE OF TWO FANUC I/O Link CHANNELS ...........187

12.3 CONNECTING THE CNC WITH TWO-CHANNEL I/O Link CONNECTOR

ADAPTER.................................................................................................. 188

12.4 CABLING................................................................................................... 189

12.5 CONNECTING TWO-CHANNEL I/O Link CONNECTOR ADAPTER TO

I/O Units FOR THE FANUC I/O Link .........................................................189

12.6 CABLE LENGTH .......................................................................................190

12.7 INSTALLING TWO-CHANNEL I/O Link CONNECTOR ADAPTER........... 190

12.8 OUTSIDE DIMENSIONS OF TWO-CHANNEL I/O Link CONNECTOR

ADAPTER.................................................................................................. 191

12.9 MOUNTING TWO-CHANNEL I/O Link CONNECTOR ADAPTER ............192

13 THREE-CHANNEL I/O Link CONNECTOR ADAPTER .....................193

13.1 OVERVIEW ............................................................................................... 194

13.2 CONNECTION FOR USE OF FOUR FANUC I/O Link CHANNELS.......... 194

13.3 CONNECTING THE CNC WITH THREE-CHANNEL I/O Link

CONNECTOR ADAPTER.......................................................................... 195

13.4 CABLING................................................................................................... 195

13.5 ALLOCATING THREE-CHANNEL I/O Link CONNECTOR ADAPTER

SIGNALS ................................................................................................... 196

13.6 CONNECTING THREE-CHANNEL I/O Link CONNECTOR ADAPTER

SIGNAL TO EACH CHANNEL................................................................... 197

13.7 CONNECTING THREE-CHANNEL I/O Link CONNECTOR ADAPTER

TO TWO-CHANNEL I/O Link CONNECTOR ADAPTER........................... 199

13.8 CONNECTING THREE-CHANNEL I/O Link CONNECTOR ADAPTER

TO I/O Units FOR THE FANUC I/O Link ...................................................200

13.9 CABLE LENGTH .......................................................................................200

13.10 INSTALLING THREE-CHANNEL I/O Link CONNECTOR ADAPTER .......200

13.11 OUTSIDE DIMENSIONS OF THREE-CHANNEL I/O Link CONNECTOR

ADAPTER.................................................................................................. 201

13.12 MOUNTING THREE-CHANNEL I/O Link CONNECTOR ADAPTER......... 202

14 SAFETY FOR USING AC....................................................................203

14.1 ENVIRONMENT FOR INSTALLATION .....................................................204

14.1.1 Installation Category (Overvoltage Category) .....................................................204

14.1.2 Pollution Degree...................................................................................................204

c-5

TABLE OF CONTENTS B-61813E/04

II. MAINTENANCE

1 OVERVIEW .........................................................................................207

1.1 SYSTEM CONFIGURATION..................................................................... 208

1.2 I/O Unit-A CONFIGURATION.................................................................... 209

1.3 BLOCK DIAGRAM..................................................................................... 210

1.4 I/O Unit-MODEL A CONFORMING TO UL/C-UL ...................................... 211

1.5 LIST OF UNITS ......................................................................................... 212

1.5.1 Units Conforming to UL/C-UL Standard: Ordering Information

A03B-0819-Jxxx ..................................................................................................212

1.5.2 Other Units (not Conforming to UL/C-UL) .........................................................214

1.5.3 Early Units (Units not Conforming to UL/C-UL: Ordering Information

A03B-0807-Jxxx).................................................................................................214

2 INDICATION........................................................................................ 216

2.1 INTERFACE MODULE (AIF01A, AIF01A2) LED INDICATORS................ 217

2.2 INTERFACE MODULE (AIF01B) LED INDICATORS................................ 220

2.3 INTERFACE MODULE (AIF02C) LED INDICATORS................................ 221

2.3.1 PWR Indicator......................................................................................................221

2.3.2 LNK Indicators.....................................................................................................221

2.3.3 ER Indicators........................................................................................................221

2.3.4 LED Indicators .....................................................................................................221

2.3.5 M/S Indicator........................................................................................................222

2.3.6 No. Indicators .......................................................................................................223

2.4 LED INDICATORS ON THE INPUT/OUTPUT MODULES (HAVING 16

OR FEWER INPUT/OUTPUT POINTS) ....................................................223

3 FUSES................................................................................................. 224

4 REMOVING PC BOARDS...................................................................225

4.1 HOW TO REMOVE TERMINAL BOARD-TYPE I/O MODULE PC

BOARDS ................................................................................................... 226

4.2 HOW TO REMOVE INTERFACE AND CONNECTOR-TYPE I/O

MODULE PC BOARDS .............................................................................228

c-6

I. CONNECTION

B-61813E/04 CONNECTION 1.FANUC I/O Link

1 FANUC I/O Link

I/O Link is a serial interface with a purpose to transfer I/O signals (bit

data) between CNC, cell controller, the I/O Unit-MODEL A, the Power

Mate and so on at high-speed.

- 3 -

1.FANUC I/O Link CONNECTION B-61813E/04

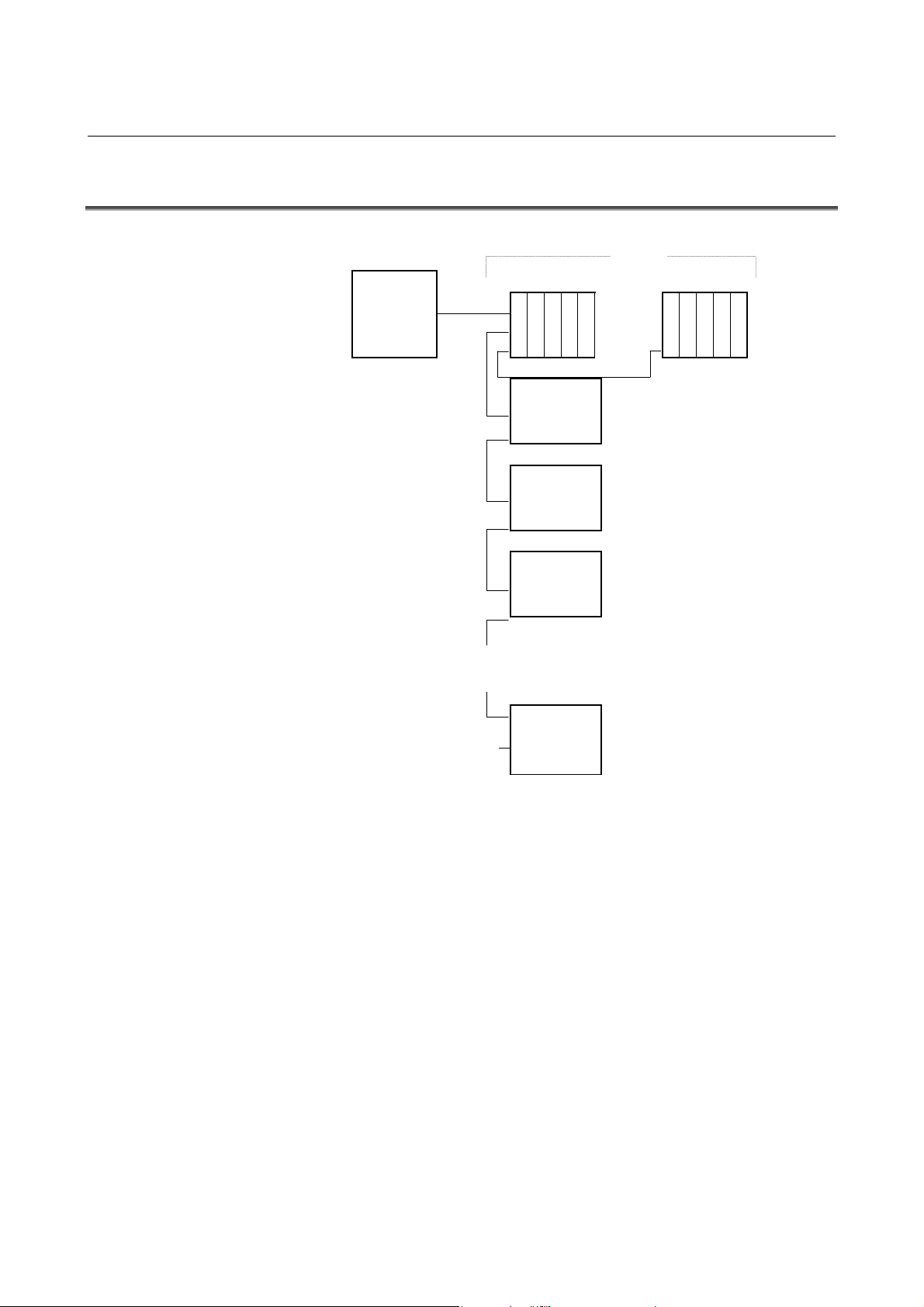

1.1 CONFIGURATION

CNC I/O Unit-A I/O Unit-A

Power Mate

Operator’s

panel

connection

unit

Power Mate

Series

0-C

: : :

: : :

: : :

Operator’s

panel

connection

unit

(1) The FANUC I/O Link is made up of one master and a number of

slaves.

Master: Series0-C, Series15/16/18/20/21,

Series15i/16i/18i/20i/21i/30i/31i/32i/0i,

Power Mate-D/H, Power Mate i-D/H, F-D Mate

Slave: I/O Unit-A, I/O Unit-B, Operator's panel connection unit,

Connector panel I/O module, Power Mate,

Series0-C, Servo unit β series (I/O Link option), and so on

(2) Up to 16 groups of slaves can be connected with a single I/O Link.

Number of slaves per one group is as follows.

I/O Unit-A..............................................Up to 2 units (i.e.2 bases)

I/O Unit-B................................................................ Up to 30 units

(Basic unit, basic and extension units).

Operator's panel I/O module ................................................ 1 unit

(1 basic module and extension modules (up to three)

Operator's panel connection unit, connector panel I/O module,

Power Mate, Series0-C, Servo unit β series (I/O Link option)

.............................................................................. 1 unit

(3) Any slave can be connected with any group. However, different

types of slaves cannot be connected with a single group.

Slave

Group

#0

Group

#1

Group

#2

Group

#3

Group

#15

- 4 -

B-61813E/04 CONNECTION 1.FANUC I/O Link

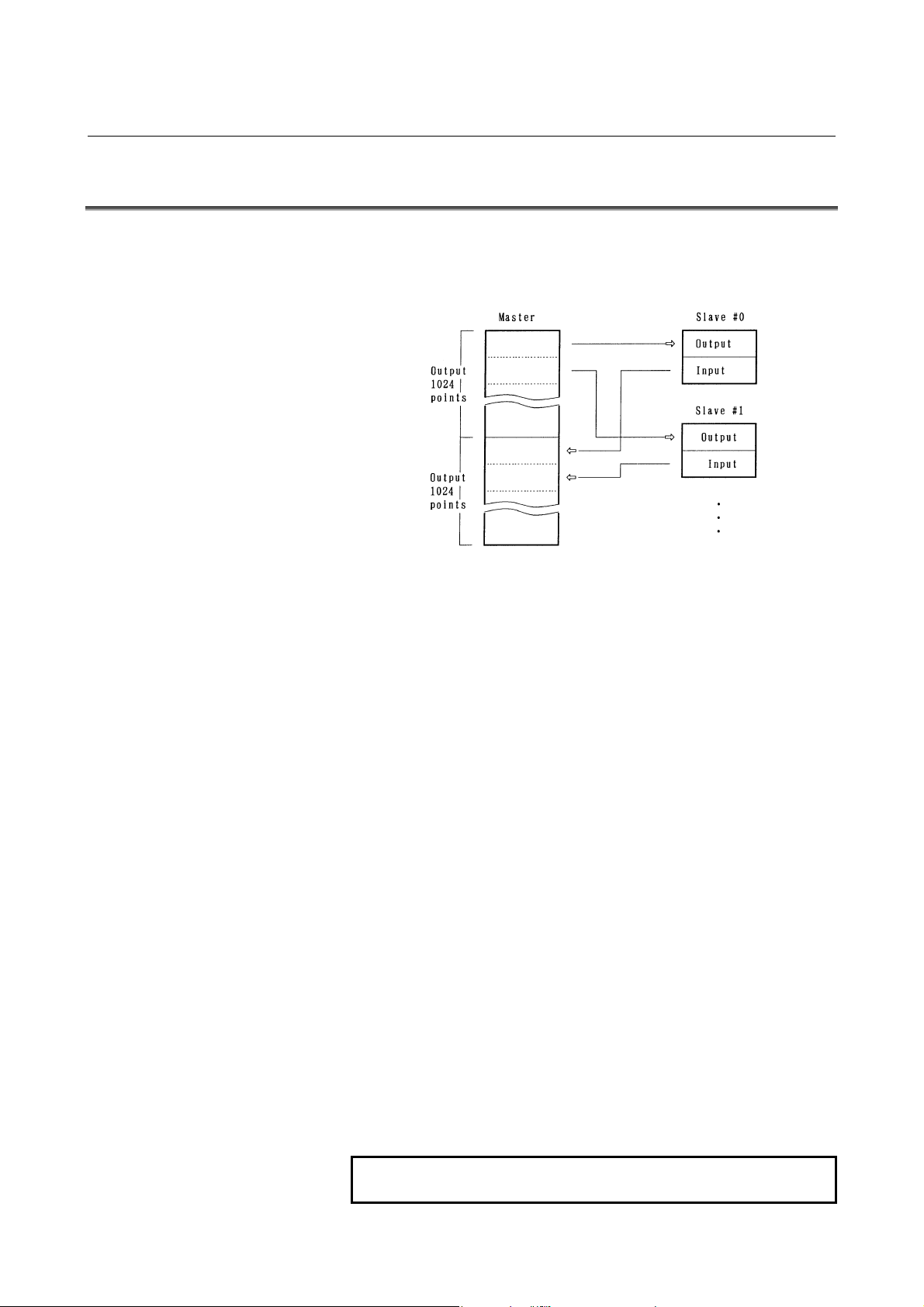

1.2 ALLOCATION OF I/O POINTS

I/O Link has 1024 input points per 1 channel and 1024 output points per

1 channel as viewed from the master.

I/O data is periodically transferred between the master and slaves by

allotting these I/O points to each slave.

Each slave can occupy as many I/O points as determined for it. For the

I/O Link, the total number of I/O points occupied by all slaves per

channel must meet:

Number of input points ≤ 1024

Number of output points ≤ 1024

Number of actual I/O points may differ from that of the occupied ones.

How to determine the number of I/O points to be allotted to each slave

and restrictions for allocation are shown in the followings.

(For the allocation method for I/O points, refer to the PMC

PROGRAMMING MANUAL.)

(1) Sum the numbers of the I/O points for all slaves connected with a

single I/O Link. The sum must satisfy the following restriction :

Number of input points ≤ 1024 (per one I/O Link)

Number of output points ≤ 1024 (per one I/O Link)

(2) Number of the occupied I/O points per one group must satisfy the

following restriction :

Number of input points ≤ 256 (per one group)

Number of output points ≤ 256 (per one group)

(3) Determine the number of I/O points for the I/O Unit-A using the

following.

[Output points]

Sum of the actual output Occupied output

points in a group points

0 to 32 ⇒ 32 points

40 to 64 ⇒ 64 points

72 to 128 ⇒ 128 points

136 to 256 ⇒ 256 points

NOTE

Count AOA05E as 8 points AOA12F as 16 points.

- 5 -

1.FANUC I/O Link CONNECTION B-61813E/04

[Input points]

Sum of the actual output Occupied output

points in a group points

0 to 32 ⇒ 32 points

40 to 64 ⇒ 64 points

72 to 128 ⇒ 128 points

136 to 256 ⇒ 256 points

However, as result of the calculation above, when the number of

input points is not larger than that of the output points in a single

group, the number of input points is assumed to be equal to that of

the output points.

Example 1 : When the following modules are used in the group

No. 0.

AOD32C 3 AID32A 5

AOA12F 2 AIA16G 3

[Output points]

32 × 3 + 16 × 2 = 128 ⇒ 128 points

[Input points]

32 × 5 + 16 × 3 = 208 ⇒ 256 points

Example 2: When the following modules are used in the group

No.2

AOD16C 7 AID16C 4

AOA05E 9 AIA16G 3

[Output points]

16 ×7 + 8 ×9 = 184 ⇒ 256 points

[Input points]

16 ×4 + 16×3 = 112 ⇒ 128 points

In this case, as the number of input points is not

larger than that of the output points, the number of

input points is assumed to be equal to that of the

output points, in other words, 256 points

.

- 6 -

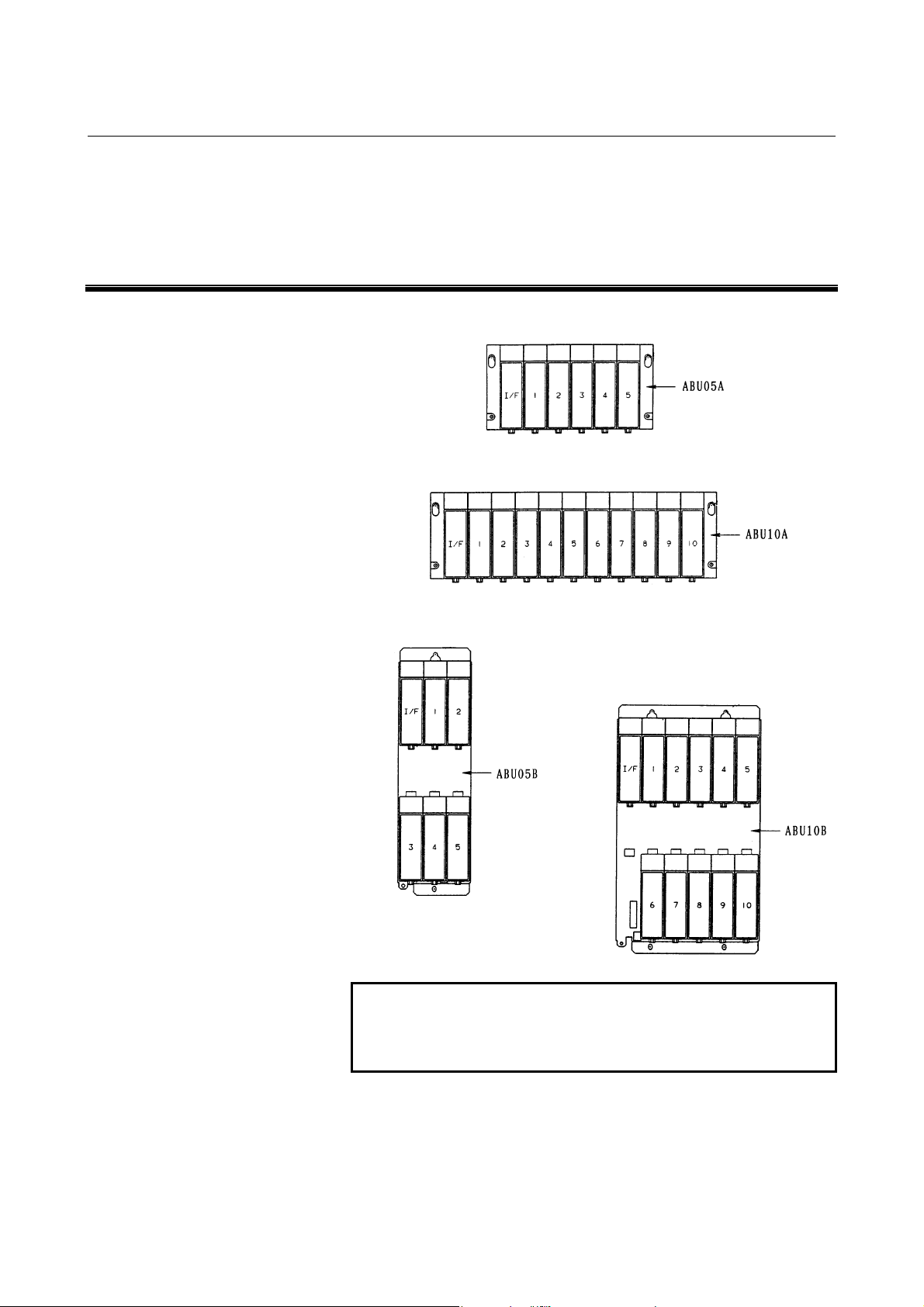

B-61813E/04 CONNECTION 2.I/O Unit CONFIGURATION

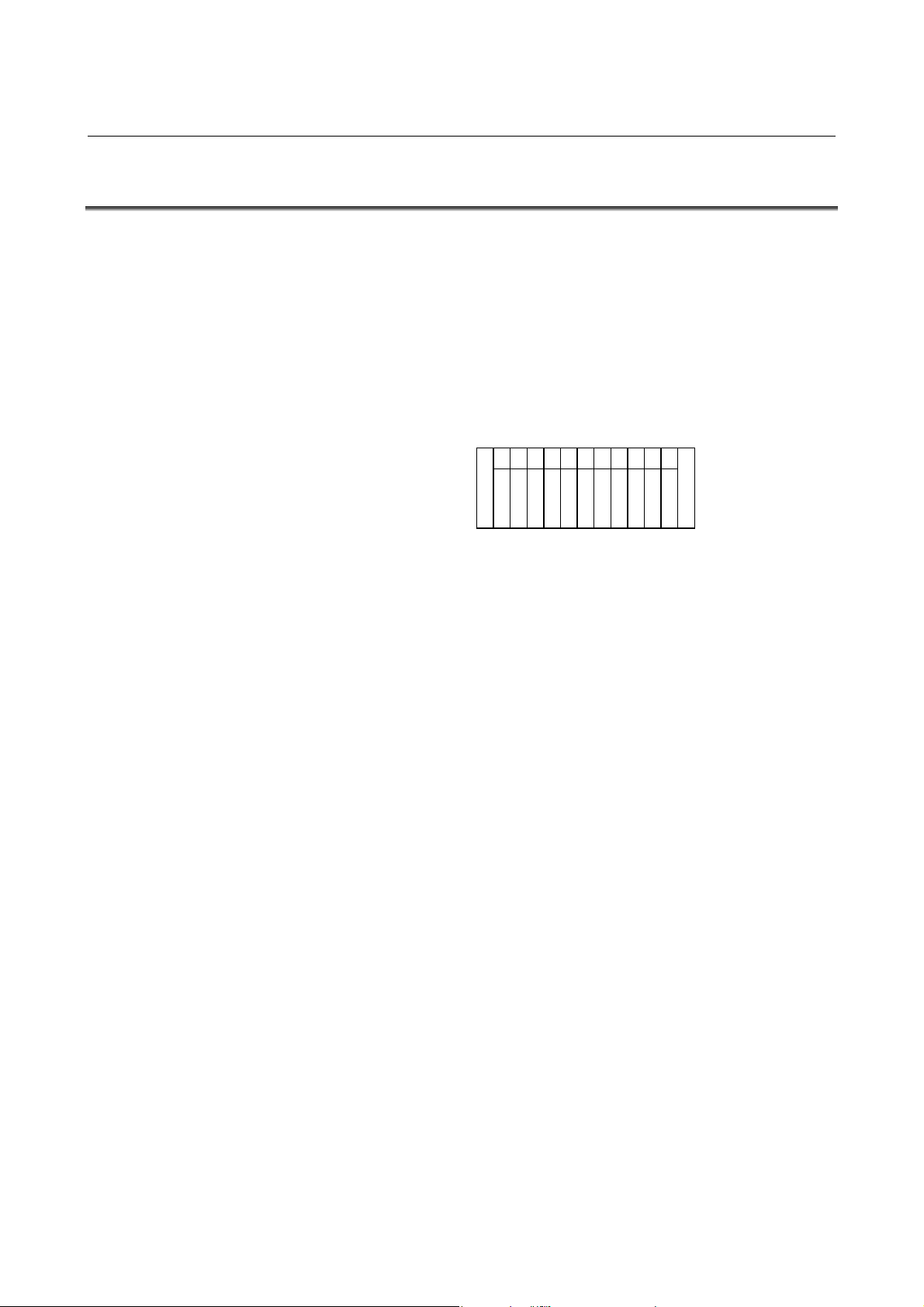

2 I/O Unit CONFIGURATION

5-slot horizontal base unit (ABU05A)

10-slot horizontal base unit (ABU10A)

5-slot vertical base unit (ABU05B)

10-slot vertical base unit (ABU10B)

NOTE

I/F : Interface module (AIF01A, AIF01A2,

AIF01B, or AIF02C)

1 to 10 : I/O modules

- 7 -

3.INSTALLATION CONNECTION B-61813E/04

3 INSTALLATION

- 8 -

B-61813E/04 CONNECTION 3.INSTALLATION

3.1 ENVIRONMENT FOR INSTALLATION

3.1.1 Environmental Conditions outside the Cabinet

The peripheral units and the control unit have been designed on the

assumption that they are housed in closed cabinets. In this manual

"cabinet" refers to the following:

• Cabinet manufactured by the machine tool builder for housing the

control unit or peripheral units;

• Operation pendant, manufactured by the machine tool builder, for

housing the LCD/MDI unit or operator's panel.

• Equivalent to the above.

The environmental conditions when installing these cabinets shall

conform to the following table. Section 3.2 describes the installation

and design conditions of a cabinet satisfying these conditions.

Ambient

temperature

of the cabinet

Humidity

Vibration

Meters above

sea level

Environment

NOTE

If the CNC is installed 1000 m or higher above sea level,

the allowable upper ambient temperature of the CNC in

the cabinet is changed as follows.

Assume that the allowable upper ambient temperature

of the CNC in the cabinet installed 1000 m or higher

above sea level decreases by 1.0°C for every 100 m rise

in altitude.

Example)

55°C - 1750/100 × 1.0°C = 47.5°C

Therefore, the allowable ambient temperature range is

from 0°C to 47.5°C.

Operating

Storage, Transport

Temperature change

Normal

Short period

(less than 1 month)

Operating

Non-operating

Operating

Non-operating

75%RH or less, no condensation

95%RH or less, no condensation

Normal machine shop environment

(The environment must be considered if the

cabinets are in a location where the density

of dust, coolant, organic solvent, and/or

corrosive gas is relatively high.)

0°C to 45°C

-20°C to 60°C

0.3°C/minute or less

0.5G or less

1.0G or less

Up to 1000 m

Up to 12000 m

(Note)

The upper allowable ambient temperature of the CNC

in the cabinet installed 1750 m above sea level is:

- 9 -

3.INSTALLATION CONNECTION B-61813E/04

3.2 DESIGNING CONDITION FOR A CABINET

When designing a cabinet to contain the I/O Unit-A, take the same care

as taken for the cabinet containing the CNC control unit and other units.

For details, refer to the CNC CONNECTION MANUAL.

In addition, when mounting the I/O Unit, conform to the followings in

view of maintenance, environmental durability, noise resistance and the

like.

(1) In order to ventilate inside the module well, mount the I/O Unit in

the direction shown in the figure below.

Upside

Downside

(2) Separate each I/O Unit at least 100 mm vertically from the other

units so as to ensure effective ventilation and make it easy to

attach/detach wires and modules.

(3) Do not put equipments which generate a large amount of heat

under the I/O Unit.

(4) Low-level signals are transferred through the signal cables K1X

and K2X. (For these cables, see the general connection diagram.)

Lay out these cables apart from the wires for AC power source and

the I/O wires of the I/O module by 100 mm or more.

(5) Make sure that there is no protruding portion such as a screw on

the mounting surface of the I/O Unit.

(6) Heat values of I/O Unit are listed in Table 3.3

- 10 -

B-61813E/04 CONNECTION 3.INSTALLATION

)

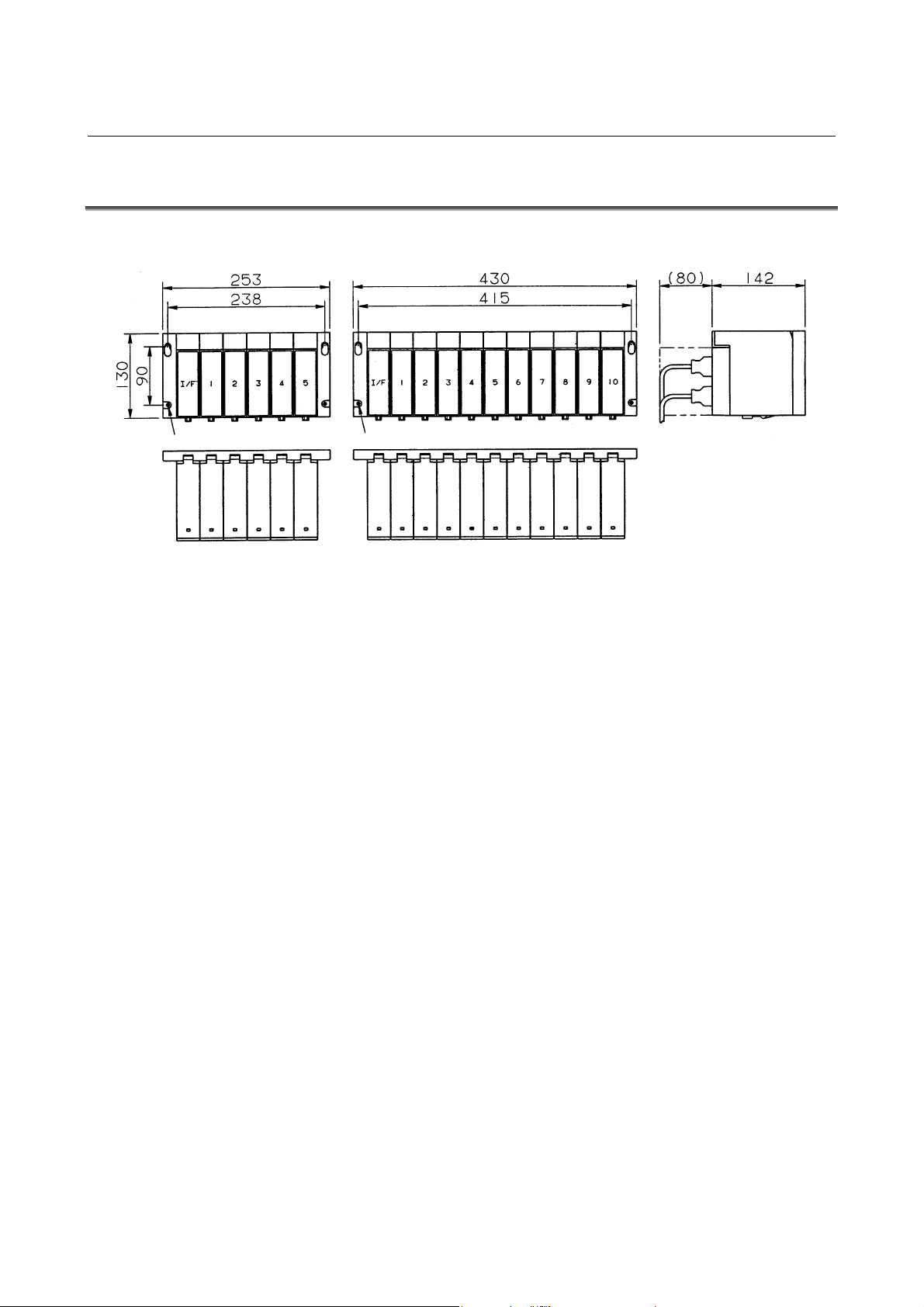

3.3 OUTER DIMENSION OF I/O Unit

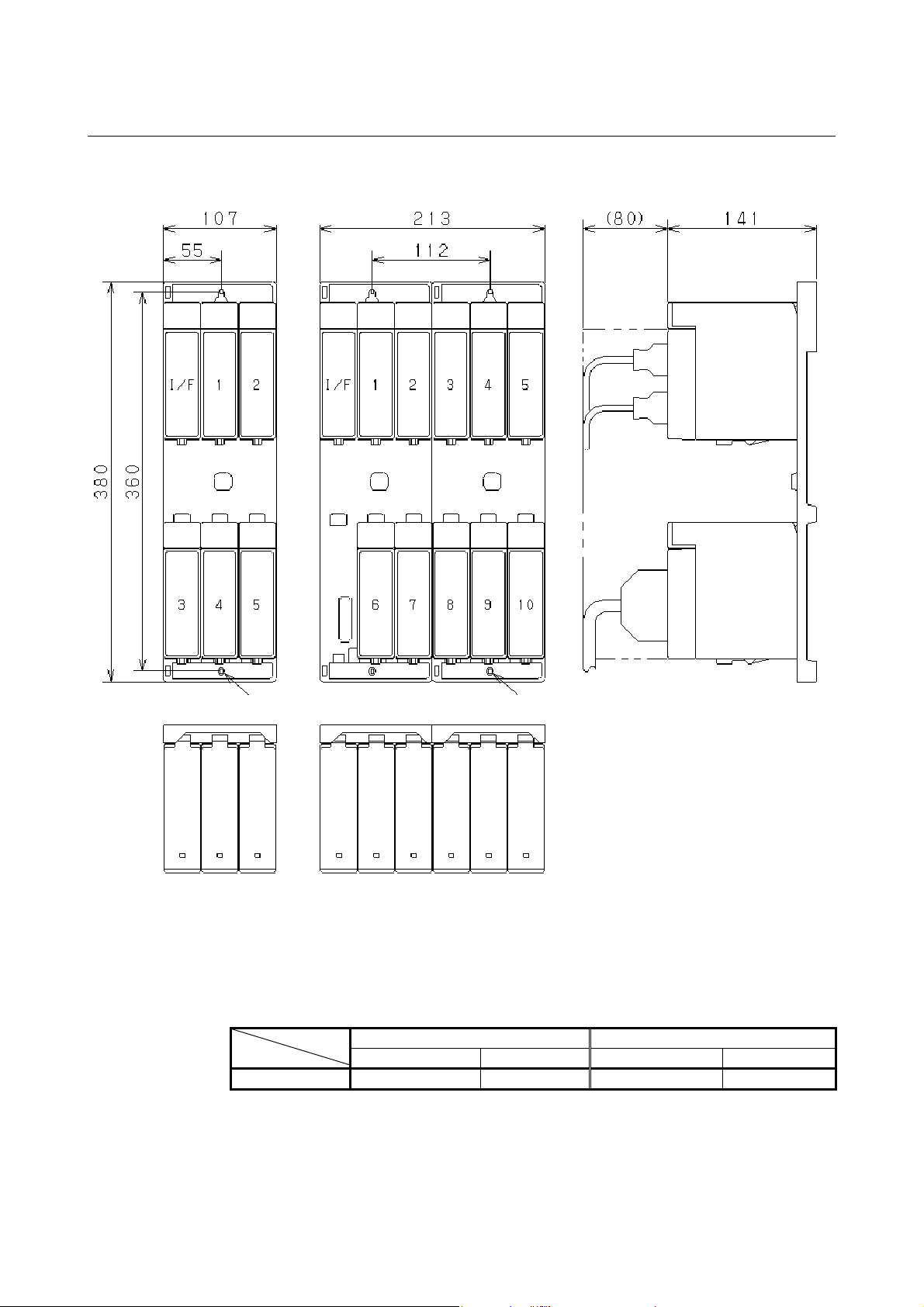

Horizontal base units (ABU05A and ABU10A)

Hole for an M4 screw (4 places) Hole for an M4 screw (4 places

- 11 -

3.INSTALLATION CONNECTION B-61813E/04

Vertical base units (ABU05B and ABU10B)

Hole for an M4 screw (2 places) Hole for an M4 screw (4 places)

* The ABU05B and ABU10B units that were shipped early on are

housed in a metal case.

The distances between mounting holes for the metal case and their

size are the same as for the plastic case used for the current units.

However, the width of the metal case differs from that of the

plastic case as listed below.

Width

Plastic case Metal case Plastic case Metal case

107mm 110mm 213mm 217mm

ABU05B ABU10B

- 12 -

B-61813E/04 CONNECTION 3.INSTALLATION

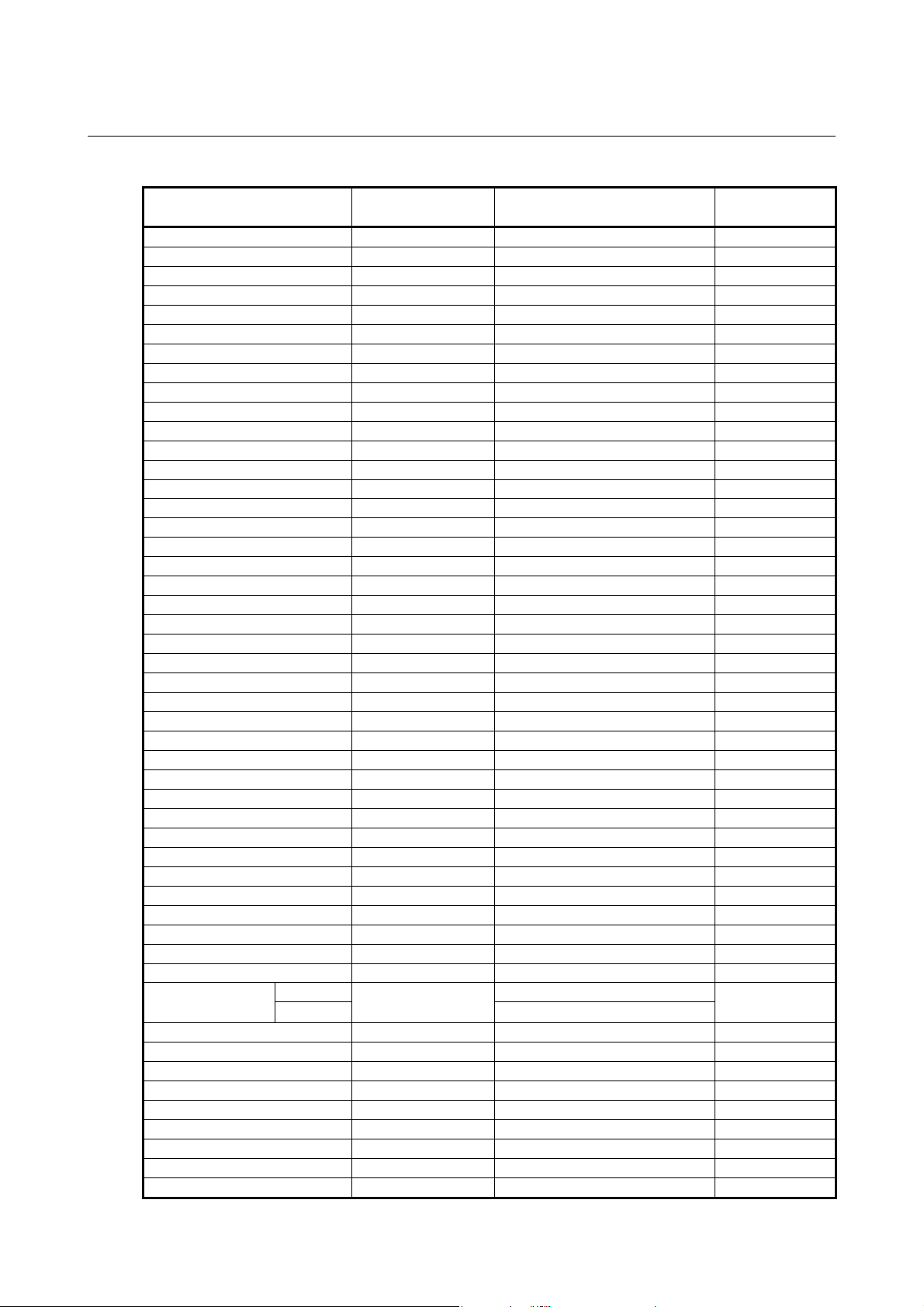

Table 3.3 Heat value and weight of each module

Module name

ABU10A - - 600

ABU10B - - 740

ABU05A - - 350

ABU05B - - 380

AIF01A 1.2 - 300

AIF01A2 1.2 - 300

AIF01B 1.2 - 270

AIF02C 1.2 - 300

Basic heat value

(W)

*1 AID32A1 1.2 0.23 250

*2 AID32B1 1.2 0.23 250

AID32H1 1.2 0.23 250

AID16C 0.1 0.21 300

AID16K 0.1 0.21 300

AID16D 0.1 0.21 300

AID16L 0.1 0.21 300

*3 AID32E1 0.1 0.23 220

AID32E2 0.1 0.23 220

*4 AID32F1 0.1 0.23 220

AID32F2 0.1 0.23 220

AIA16G 0.1 0.21 300

*5 AOD32A1 0.3 - 220

AOD08C 0.1 0.04+0.4×IL2 380

AOD08D 0.1 0.04+0.6×IL2 380

AOD08DP 0.1 0.04+0.1×IL2 310

AOD16C 0.1 0.04+1.4×IL2 300

AOD16D 0.1 0.04+1.4×IL2 320

AOD16D2 0.1 0.04+0.1×IL2 320

AOD16D3 0.1 0.04+0.1×IL2 320

AOD16DP 0.1 0.04+1.8×IL2 310

*6 AOD32C1 0.1 0.01+0.8×IL2 220

AOD32C2 0.1 0.01+0.8×IL2 220

*7 AOD32D1 0.1 0.01+0.8×IL2 200

AOD32D2 0.1 0.01+0.8×IL2 200

AOA05E 0.1 0.13+1.5×IL 370

AOA08E 0.1 0.13+1.5×IL 370

AOA12F 0.1 0.11+1.5×IL 320

AOR08G 0.1 0.3+0.1×IL2 300

AOR16G 0.1 0.3+0.1×IL2 350

AOR16H2 0.1 0.3+0.1×IL2 250

AIO40A

Input 0.23

Output

0.2

AAD04A 3.1 - 350

AAD04B 3.1 - 370

ADA02A 3.1 - 350

ADA02B 3.1 - 350

ACT01A 4.1 - 220

ATI04A 4.0 - 260

ATI04B 4.0 - 260

ATB01A - - 100

ATB01B - - 120

Heat value per one I/O point

(W)

0.01+1.3×IL

Weight (g)

350

- 13 -

3.INSTALLATION CONNECTION B-61813E/04

Module name

Optical I/O Link adapter - - 100

I/O Link dummy unit - - 120

Basic heat value

(W)

• Total ‘Heat value per 1 I/O point’ for simultaneous ON points plus

‘Basic heat value’ is the heat value of the module.

• IL : Load current of output

• *1 to *7 : "AxD32x" produced to the old specification is

equivalent to "AxD32x1" (with additional "1" at the

end) produced to the current specification.

(Example: Old specification AID32E → AID32E1)

Heat value per one I/O point

(W)

Weight (g)

- 14 -

B-61813E/04 CONNECTION 3.INSTALLATION

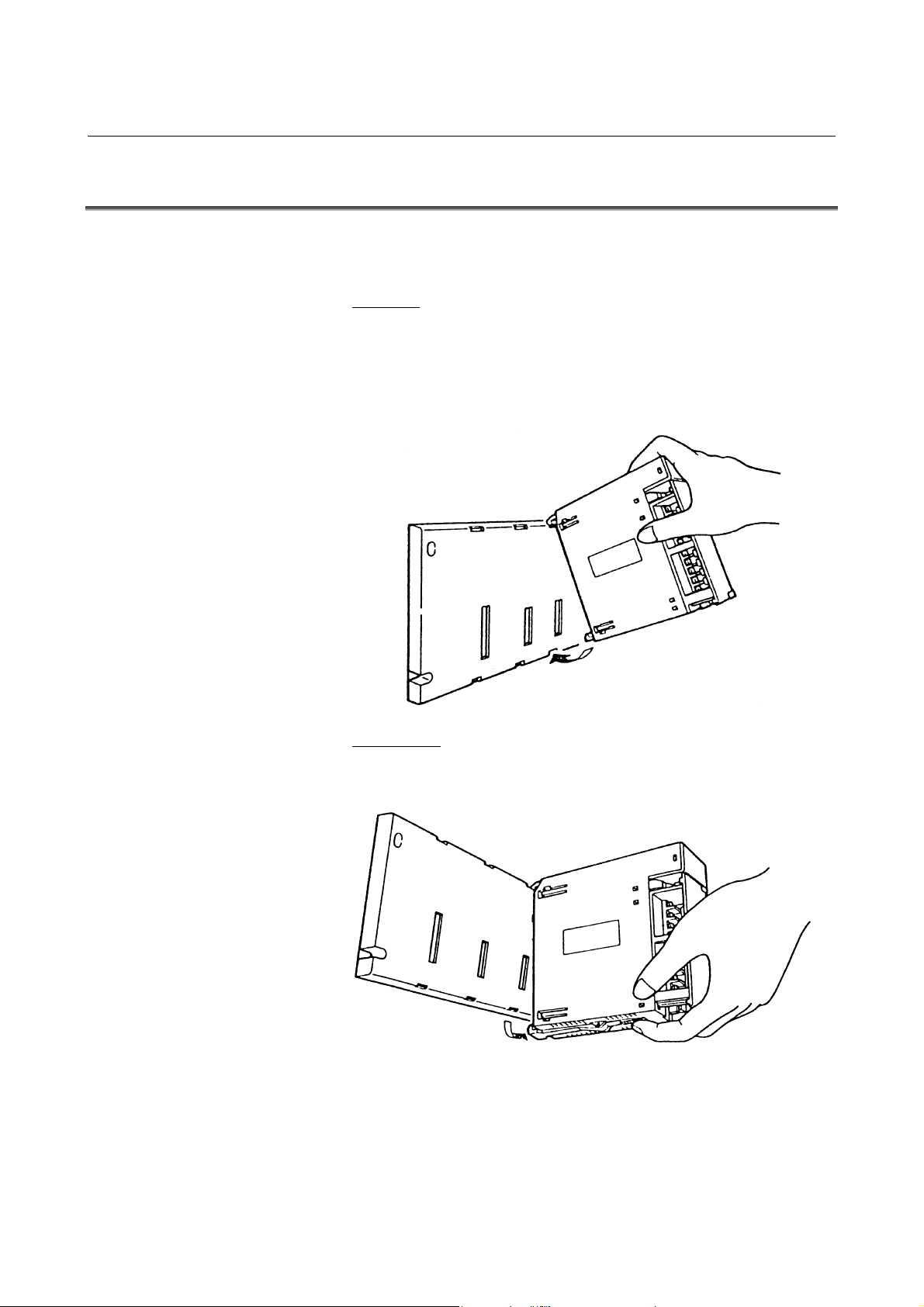

3.4 MOUNTING AND DISMOUNTING MODULES

Interface modules and various types of I/O modules can be mounted to

and dismounted from the base unit easily as shown below.

Mounting

Hang the hook at the top of the module on the groove in the upper

side of the base unit, and make the connector of the module

engage with that of the base unit. Push the module in the lower

groove of the base unit till the stopper in the lower side of the

module stops.

Dismounting

Release the stopper by pushing the lever at the bottom of the

module, and then push the module upwards.

- 15 -

4.CONNECTION CONNECTION B-61813E/04

4 CONNECTION

- 16 -

B-61813E/04 CONNECTION 4.CONNECTION

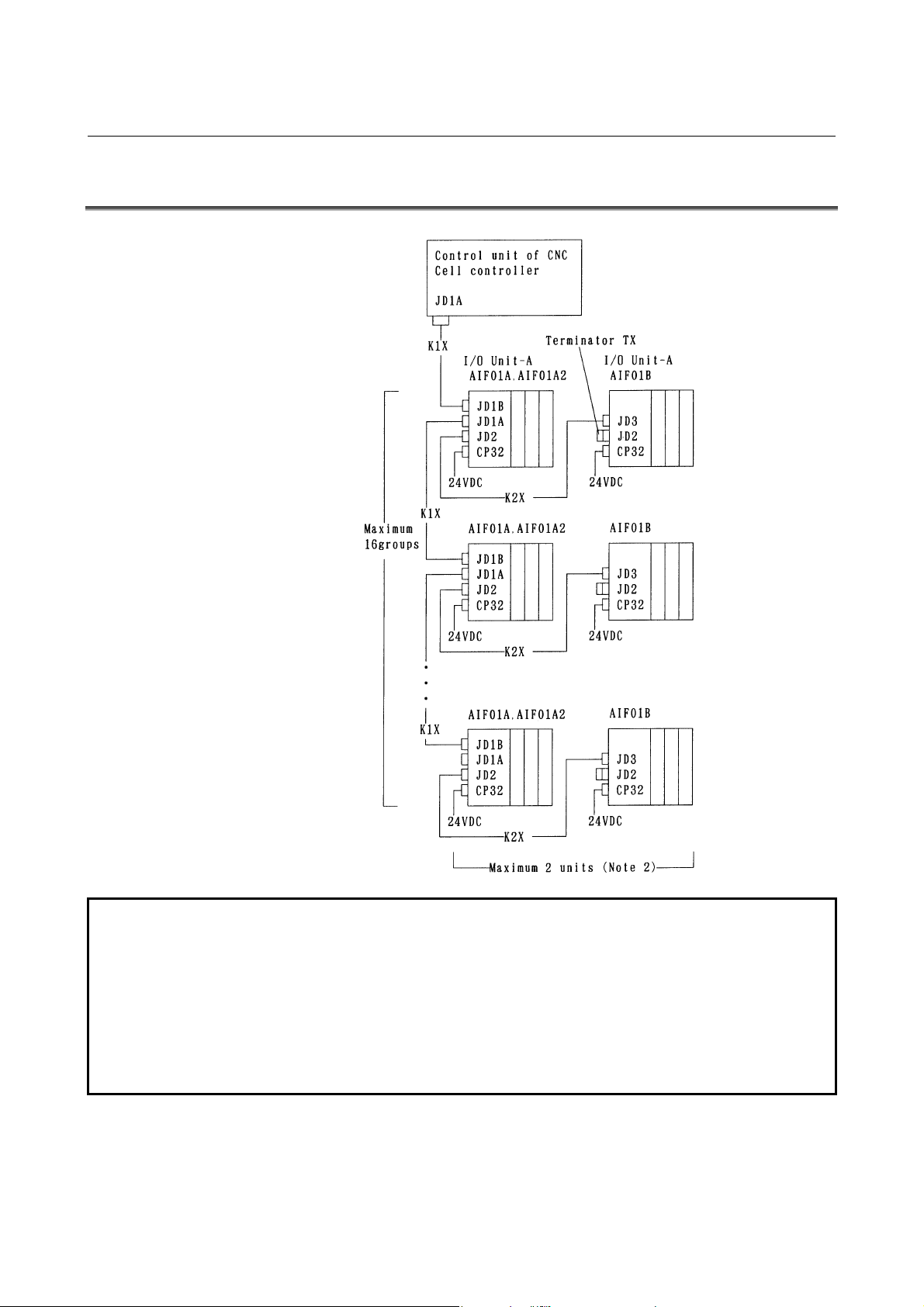

4.1 GENERAL CONNECTION DIAGRAM

NOTE

1 Number of I/O Units and connecting method are restricted depending on the

allocation of the I/O points. Refer to the section 1.2,"Allocation of I/O points."

2 If the master unit is the F-D Mate, one group can consist of up to four I/O Units.

3 Cable K1X can be an optical fiber cable by using the optical I/O link adapter.

See chapter 10.

4 Terminator TX is required for connector JD2 of the AIF01B that is the last unit to be

connected in the group. If no AIF01B is in use, no terminator has to be attached to the

JD2 connector of the AIF01A or AIF01A2.

- 17 -

4.CONNECTION CONNECTION B-61813E/04

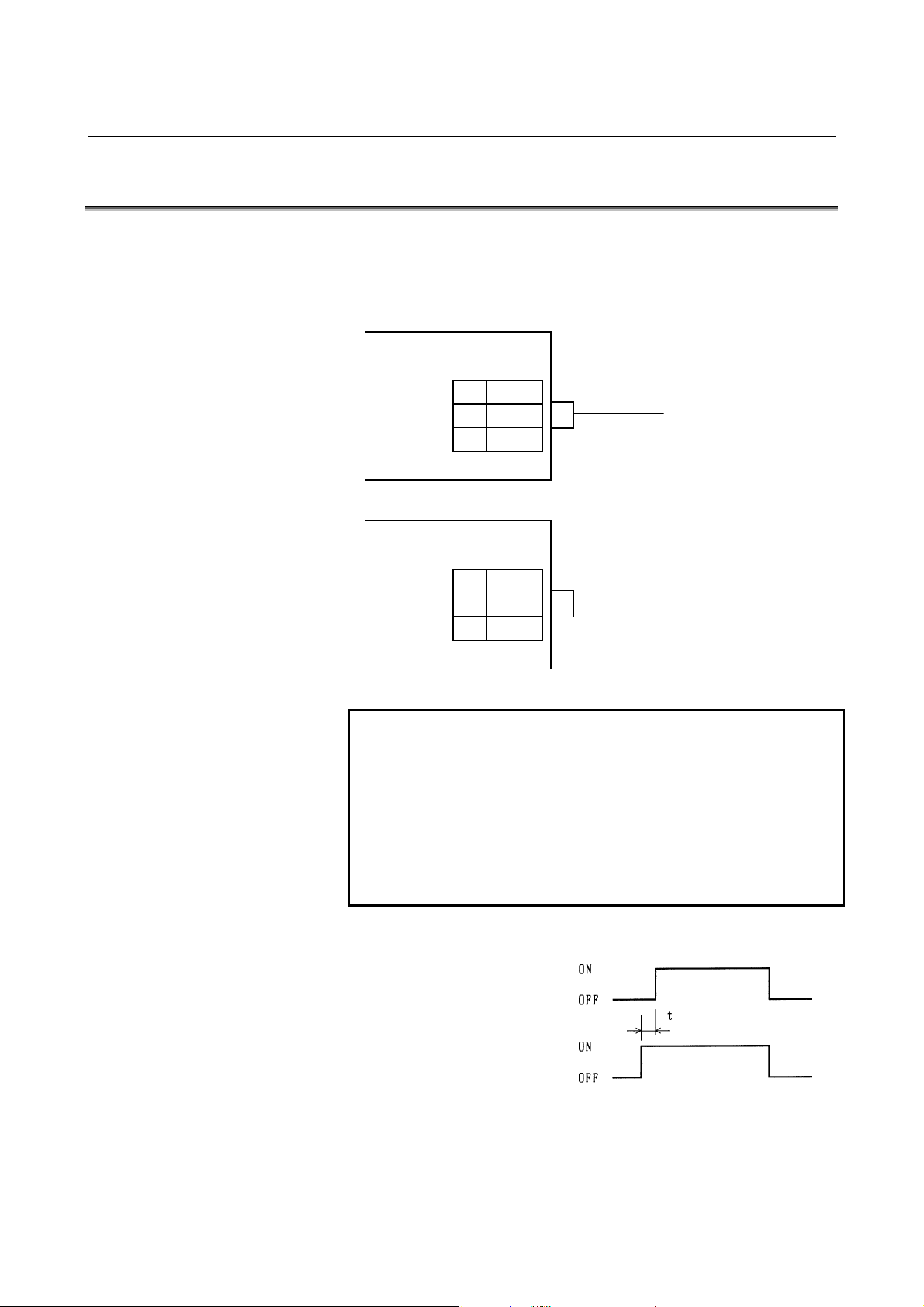

4.2 CONNECTING INPUT POWER SOURCE

Connect the following power source with the connector CP32 or CP1 of

the interface module (AIF01A, AIF01A2, AIF01B, or AIF02C).

• Voltage: 24VDC ±10%

• Current: Determine from Table 4.4

AIF01A / AIF01B / AIF02C

CP32

1 +24V

2 GND

3

AIF01A2

CP1

1 +24V

2 GND

3

NOTE

Turn ON the power for the I/O Unit just when or

before the power for the CNC or the cell controller is

turned ON. When the CNC or cell controller power is

turned OFF, make sure to turn the power to the I/O

Unit OFF as well. If the power is not turned on and off

according to the above procedure, an error occurs in

the CNC or the controller, or the I/O Unit is not

normally connected to the power.

Power for the master device

Power for the I/O Unit

t ≥ 500 ms (Turn ON of the power for I/O Unit can be late 500 ms or less.)

SORIAU JAPAN (manufactured by former Nippon

Burndy) Tri-pole connector (Brown)

Housing : SMS3PNS-5 A63L-0001-0202#3LN

Contact : RC16M-SCT3 A63L-0001-0226

24VDC

Tyco Electronics

Housing : 1-178288-3

Contact : 1-175218-5

Housing and contact set

A02B-0120-K324

24VDC

- 18 -

B-61813E/04 CONNECTION 4.CONNECTION

4.3 GROUNDING

Connect the grounding terminal of the base unit (ABU05A, ABU05B,

ABU10A, or ABU10B) to ground.

(1) Horizontal type base unit

Use a wire of 2 mm

(2) Vertical type base unit

(a) For metal case (early shipment)

Grounding terminal

(M3 screw terminal)

M4 hole for grounding

NOTE

Connect the grounding terminal to the grounding hole

portion.

(b) For plastic case

(2) When the cable K1X (See overall connection figure in section 4.1)

runs between different cabinets, make sure to connect the cabinets

with a wire more than 5.5 mm

Grounding terminal

(M3 screw terminal)

2

or more for grounding.

2

.

- 19 -

4.CONNECTION CONNECTION B-61813E/04

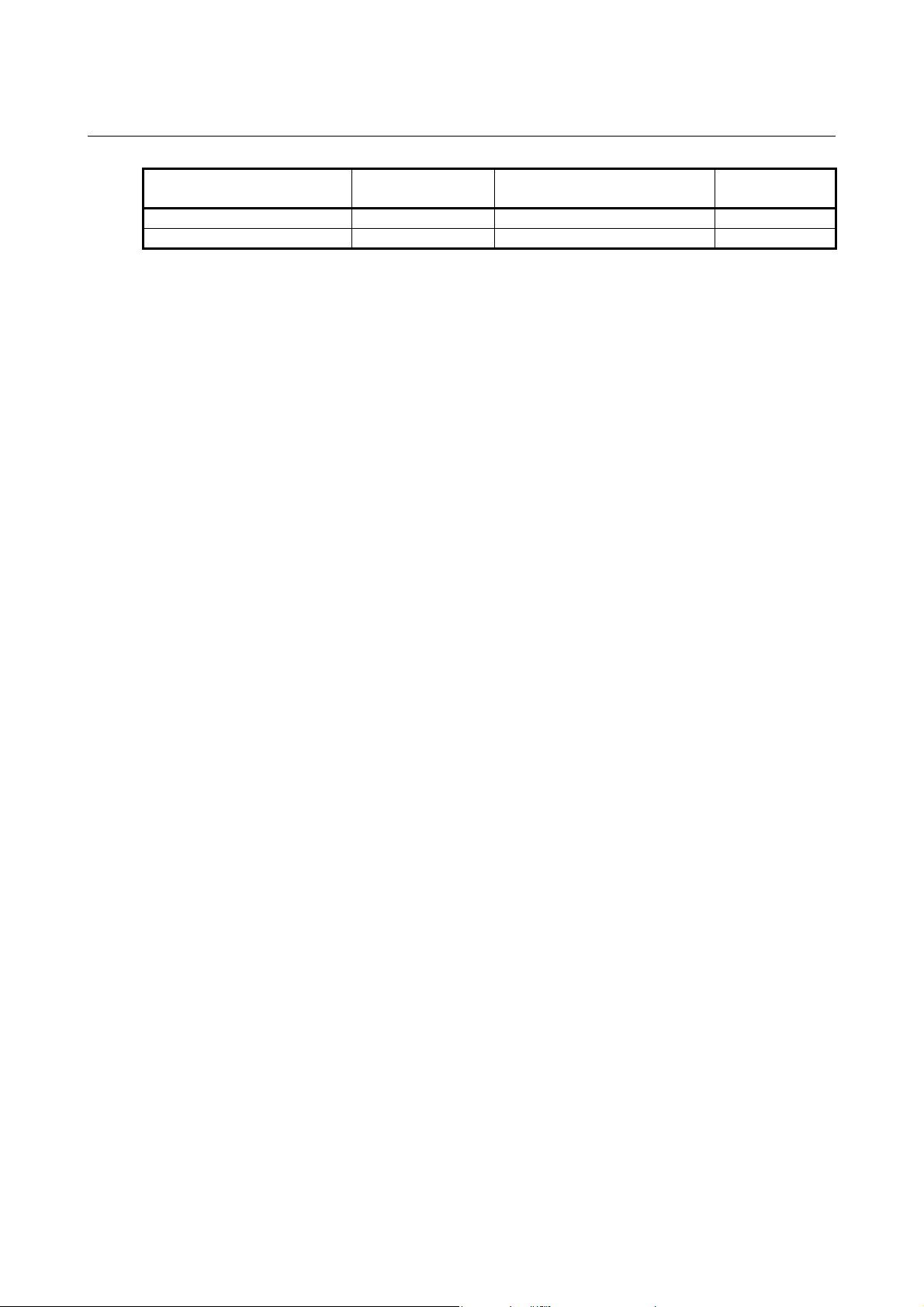

4.4 REQUIRED CURRENT

Table 4.4 Required current of each module

Module name

AIF01A 50

AIF01A2 50

AIF01B 50

AIF02C 50

AID32A1 20+0.5×n 30+7.5×n

AID32B1 20+0.5×n 30+7.5×n

AID32H1 20+0.5×n 30+7.5×n

AID16C 5

AID16K 5

AID16D 5

AID16L 5

AID32E1 5

AID32E2 5

AID32F1 5

AID32F2 5

AIA16G 5+1.5×n

AOD32A1 14

AOD08C 5+2×n

AOD08D 5+2×n

AOD08DP 5+2×n

AOD16C 5+2×n

AOD16D 5+2×n

AOD16D2 5+2×n

AOD16D3 5+2×n

AOD16DP 5+2×n

AOD32C1 5+0.5×n

AOD32C2 5+0.5×n

AOD32D1 5+0.5×n

AOD32D2 5+0.5×n

AOA05E 5+5.5×n

AOA08E 5+5.5×n

AOA12F 5+4.5×n

AOR08G 5 10×n

AOR16G 5 10×n

AOR16H2 5 10×n

AIO40A

AAD04A 5 130

AAD04B 5 130

ADA02A 6 120

ADA02B 6 130

ACT01A 170+0.3×α

ATI04A 62.5 100

ATI04B 62.5 100

Input 20+0.5×n 30+7.5×n

Output 5+0.5×n

n: Number of the input and output points (for each module)

which turn ON simultaneously

α: +5-V current (mA) output to the outside

• Add the sums of the columns A and B for the modules to be used.

The sum is the required current.(Unit: mA)

• For each base unit, keep the sum of column A and the sum of

column B to within 500 mA and 1,500 mA, respectively.

Required current (mA) of+24V

A B

- 20 -

B-61813E/04 CONNECTION 4.CONNECTION

A

4.5 INTERFACE MODULE (AIF01A, AIF01A2, AIF01B)

Details of the cables K1X, K2X and the terminator shown in the general

connection diagram are as follows.

(1) Cable K1X

CNC, Cell controller

or

IF01A, AIF01A2

JD1A

0V

11

SIN

12

13

14

15

16

17

18

19

20

0V

0V

0V

0V

0V

*SIN

SOUT

*SOUT

JD1A JD1B

10

1

2

3

4

5

6

7

8

9

Connector HONDA TSUSHIN

PCR-E20FS

AIF01A, AIF01A2

JD1B

SIN

*SIN

SOUT

*SOUT

14

11

12

13

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

0V

0V

0V

0V

0V

0V

SIN (1)

*SIN (2)

SOUT (3)

*SOUT (4)

0V (11)

0V (12)

0V (13)

0V (14)

0V (15)

0V (16)

(3) SOUT

(4) *SOUT

(1) SIN

(2) *SIN

(11) 0V

(12) 0V

(13) 0V

(14) 0V

(15) 0V

(16) 0V

(a) Make sure to use twisted pair wires for signal SIN and *SIN,

and signals SOUT and *SOUT.

(i) Recommended cable material: A66L-0001-0284#10P

(twisted pair/shielded)

(ii) Shielding wires should be connected with the grounding

plate of the cabinet at the JD1A side using a cable clamp.

(Refer to the CONNECTION MANUAL for the CNC

and the cell controller.)

(iii) Maximum cable length: 10 m (15 m if used to connect

I/O devices within the same cabinet)

(iv) Make sure not to connect to the connector spare pins.

(v) In the following cases, make sure to use an optical I/O

link adapter and an optical fiber cable.(See Chapter 10)

• When the cable is more than 10 meters long.

• When the cable runs between different cabinets

and there is no appropriate ground wire between

the cabinets.

• When there is concern that the cable is influenced

by strong noise.

- 21 -

4.CONNECTION CONNECTION B-61813E/04

(vi) When an optical I/O link adapter is used: Cable to be

used between the interface module (AIF01A) and the

optical I/O link adapter is dissimilar to this cable. (See

Chapter 10.)

(2) Cable K2X

AIF01A, AIF01A2, or

AIF01B

• Connect the signals with a same name.

• Make sure to use twisted pair wires for the following signals:

S1 and * S1, S2 and *S2, S3 and *S3

S4 and * S4, S5 and *S5, S6 and *S6

• Do not connect the pins No.10, No.19 and No.20 as they are

used internally.

• Recommended cable material: A66L-0001-0284#10P

(twisted pair/shielded)

• Maximum cable length: 2m

AIF01B

- 22 -

B-61813E/04 CONNECTION 4.CONNECTION

(3) Terminator TX

Ordering information : A03B-0807-K806

Short-circuit

• If no AIF01B is in use, the TX terminator does not have to be

attached to the JD2 connector of the AIF01A or AIF01A2.

• If at least one AIF01B is in use, attach the terminator to the

JD2 connector of the last AIF01B in the same group.

• Short-circuit the TRM1s, the TRM2s and the TRM3s one

another respectively in a manner that a TRM1 is with another

TRM1 and so on.

- 23 -

4.CONNECTION CONNECTION B-61813E/04

A

A

4.6 INTERFACE MODULE (AIF02C) CONNECTION

4.6.1 Overview

One interface module (AIF02C) can control communication with both

I/O Unit-A and Unit-B, when it is connected to the FANUC I/O Link.

The following examples show a configuration in which two

conventional separate interface modules, I/O Unit-A and I/O Unit-B,

are used and a configuration in which the AIF02C is used.

(1) Configuration example in which separate interface modules

CNC cell controller

are used

(Note 2)

To the next group

CNC cell controller

To the next group

IF01A

IF01A2

(Note 2)

DI/DO unit

DI/DO unit

Group #0

Base expansion

Group #1

DI/DO unit

DI/DO unit

DI/DO unit

(2) Configuration example in which AIF02C is used

Group #0

(NOTE 1)

Group #1

Base expansion

DI/DO unit DI/DO unit

DI/DO unit

- 24 -

B-61813E/04 CONNECTION 4.CONNECTION

In this way, using the AIF02C eliminates the necessity for the interface

unit (BIF04A1) for I/O Unit-B, which has conventionally been used

separately; this configuration is suitable for a small I/O Unit-B system.

Note the following points.

NOTE

1 The AIF02C cannot be used for base expansion.

2 The BIF04A1 can branch to a maximum of eight

communication lines.

The AIF02C can branch only to a maximum of two

distributed link cables.

4.6.2 Connection

(1) Connection diagram

[a] Configuration with two distributed link cables (note the

(From group n-1)

setting of the terminating resistor.)

Groups n

and n+1

Distributed link

DI/DO unit DI/DO unit

DI/DO unit

(To group n+2)

DI/DO unit DI/DO unit

NOTE

*1 Set the terminating resistor DIP switch to ON.

*2 Set the terminating resistor DIP switch to OFF.

[b] Connection with one distributed link cable (note the setting

of the terminating resistor.)

(From group n-1)

Groups n

and n+1

Distributed link

DI/DO unit

DI/DO unit

DI/DO unit

DI/DO unit

(To group n+2)

NOTE

*1 Set the terminating resistor DIP switch to ON.

*2 Set the terminating resistor DIP switch to OFF.

- 25 -

4.CONNECTION CONNECTION B-61813E/04

(2) Connection with the I/O Link

The AIF02C occupies two groups on the I/O Link.

When groups #n and #n+1 are used, for example, the

smaller-numbered group, #n, is assigned to the I/O Unit-A, and the

larger-numbered group, #n+1, is assigned to the I/O Unit-B.

[a] Connection of the I/O link cable

Connect the I/O link cable from the previous group to JD1B.

Connect JD1A to the I/O link cable leading to the next group.

Use the K1X I/O link signal cable, the same I/O link signal

cable type as that for the AIF01A.

[b] Number of occupied I/O points on the I/O link

The nominal number of occupied I/O points may differ from

the actual number of I/O points.

For the details of the number of I/O points occupied by the I/O

Unit-B, refer to Section 4.3.1, "Number of points occupied on the

interface unit I/O link," of the FANUC I/O Unit-B MODEL

Connection Manual (B-62163E).

(3) Connection with the distributed link (I/O Unit-B)

[a] Number of distributed communication lines

"T1" can connect to two communication lines (twisted-pair

wires).

So, it is possible to branch to up to two lines.

To branch to more lines, you should use the I/O Unit-B

interface unit (BIF04A1), which enables branching to up to

eight communication lines.

[b] Terminal board "T1," used for connection with the

distributed link cable

The distributed link cable is connected to "T1."

AIF02C

T1

1S+

2S-

3FG

<1> Use twisted-pair wires as the distributed link cable.

<2> The distributed link cable is polarity-sensitive. Match

the signal polarity of the AIF02C with that of the basic

unit.

<3> The terminal board has M3 screws with a terminal

cover.

Refer to Section 4.4, "Connecting a Distributed Link," and Section

4.6.2.2, "Connecting the communications cable," of the FANUC I/O

Unit-MODEL B Connection Manual (B-62163E) for details.

- 26 -

B-61813E/04 CONNECTION 4.CONNECTION

4.6.3 Setting with the DIP Switch

In the AIF02C, distributed link settings can be made with the DIP

switch on the back of the module.

The settings and corresponding signals are shown below.

1

2

3

4 EDSP

5 Q

6 H

7 URDY

8 R

(1) EDSP (error display method selection)

Normally, set EDSP to the ON position.

(2) Q and H (communication speed setting)

Normally, set both Q and H to the OFF positions.

(3) URDY (setting of the power on/off information for the unit)

Normally, set URDY to the OFF position.

(4) R (terminating resistor setting)

The ON position means that a terminating resistor must be

installed. The OFF position means that no terminating resistor

need be installed.

When only one communication cable is connected to the AIF02C,

terminate it and the basic unit at the end of the communication

cable with a resistor.

When two communication cables are connected to the AIF02C,

terminate the basic unit connected to the end of each

communication cable with a resistor. Do not connect a terminating

resistor to the AIF02C. (Refer to Section 4.6.2, "Connection.")

Refer to Section 5.1.1, "DIP switch setting," of the FANUC I/O

Unit-MODEL B CONNECTION MANUAL (B-62163E).

Unused

- 27 -

4.CONNECTION CONNECTION B-61813E/04

play

4.7 CONNECTING WITH I/O MODULES

From the point of view of an external connecting method, there are two

types of I/O modules such as one with a terminal block and one with a

connector.

Terminal block manufactured by

Weidmüller (used in the AOD16D3)

Input/output

LED

A 0 . . . 7

B 0 . . . 7

dis

Specification of the terminal

block on the module

BL3.5//24/90F

The following three different connectors can be used on the

connector-type module.

Specification of the connector on the

module

Manufactured by HONDA TSUSHIN

MR-50RMA

Manufactured by HIROSE ELECTRIC

HIF3BB-50PA-2.54DS

Manufactured by HIROSE ELECTRIC

HIF4-40P-3.18DS

Module name

AID32A1

AID32B1

AID32H1

AID32E1

AID32F1

AOD32A1

AOD32C1

AOD32D1

AIO40A

AID32E2

AID32F2

AOD32C2

AOD32D2

AOR16H2

AOD16D2

- 28 -

B-61813E/04 CONNECTION 4.CONNECTION

(1) Connect with each module following the connection diagrams of

Sections 4.2 and 5.3.

(2) The terminal block is a removable type.

[Dismounting the terminal block]

<1> Open the cover of the terminal

block.

<2> Push up the latch at the top of the

terminal block.

<3> Drag out the tab at the top of the

terminal block and pull it out.

The terminal block will be

removed from the module.

[Mounting the terminal block]

<1> Insert the protruding portion at

the bottom of the terminal block

in the groove of the module

side.

<2> Push the terminal block using

the engaging point of the protruding portion and the groove

as an axis and mount it in the module firmly.

<3> Open the cover of the terminal block and check to make

sure the latch at the top of the terminal block is firmly set.

(3) Cautionary points when wiring terminal block type

2

• Wiring material : AWG22 to 18 (0.3 to 0.75 mm

)

A wire as this as possible is recommended.

• Crimp style terminal : M3.5

Crimp style terminal with no

insulation sleeve and a short distance

"A", as illustrated in the drawing

below, is recommended.

DAIDO SOLDERLESS TERMINAL 1.25-S3.5

NICHIFU 1.25-3.5S etc.

• Mark tube : Use a short mark tube as possible and cover

crimped part with the mark tube.

• Recommended tightening torque : 1 to 1.4 N⋅m

(4) Wiring to the terminal block manufactured by Weidmüller

2

• Wire with a cross section of 0.08 to 1.5 mm

(VDE)/AWG28

to AWG14 (UL/CSA)

• Recommended tightening torque: 0.8 N⋅m

• Size conformable when a ferrule (rod terminal) is used: 0.5 to

1.5 mm

2

Peeling length: 6 mm

- 29 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

5 DIGITAL INPUT/OUTPUT MODULES

- 30 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

5.1 LIST OF MODULES

(1) Digital input modules

Input

type

Non-

insulation

type DC

input

Insulation

type DC

input

AC input AIA16G

Module

name

AID32A1 24VDC

AID32B1 24VDC

AID32H1 24VDC

AID16C 24VDC

AID16K 24VDC

AID16D 24VDC

AID16L 24VDC

AID32E1 24VDC

AID32E2 24VDC

AID32F1 24VDC

AID32F2 24VDC

Rated

voltage

100 to

120VAC

Rated

current

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

7.5mA

10.5mA

(120VAC)

Polarity

*1

Both Maximum 20msec 32 Connector A Not provided

Both Maximum 2msec 32 Connector A Not provided

Both

NEG Maximum 20msec 16 Terminal block Provided

NEG Maximum 2msec 16 Terminal block Provided

POS Maximum 20msec 16 Terminal block Provided

POS Maximum 2msec 16 Terminal block Provided

Both Maximum 20msec 32 Connector A Not provided

Both Maximum 20msec 32 Connector B Not provided

Both Maximum 2msec 32 Connector A Not provided

Both Maximum 2msec 32 Connector B Not provided

-

Response time Points

Maximum 2msec

Maximum 20msec

ON: Maximum 35msec

OFF: Maximum 45msec

8

24

16 Terminal block Provided

NEG circuit example

POS circuit example

External

connection

*2

Connector A Not provided

LED display

Input pin

Current

+

-

Common pin

Input module

Common pin

+

-

Current

Input pin

Input module

NOTE

1 Polarity

NEGative : (Current source type, source type, or Nch)

Regard to be ON when input is at Low level.

POSitive : (Current sink type, sink type, or Pch)

Regard to be ON when input is High level.

2 Connectors (Section 5.4 shows a connector signal arrangement diagram as viewed

from the front of the module.)

Connector A : HONDA TSUSHIN MR-50RMA connector

It is recommended that the MR-50LW (housing) and MR50-FH

(soldering-type connector) or MRP-50F01 (crimp connector) +

MRP-F112 (contact) be used on the cable.

Connector B : HIROSE ELECTRIC HIF3BB-50PA-2.54DS

It is recommended that the HIF3BB-50D-2.54R (press-mount

connector) be used on the cable.

3 For the details of the specifications for each module, refer to the section 5.3.

- 31 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(2) Digital output modules

External

connection

*2

Terminal block

B

LED

display

Not

provided

Provided Fuse

Not

provided

Not

provided

Not

provided

Not

provided

Output

protection

Not provided

Output

protection

device

Output

protection

device

Not provided

Not provided

Not provided

Not provided

Output type Module name

Non-insulation

type DC output

Insulation type

DC output

AC output

RELAY output

AOD32A1 5 to 24VDC 0.3A NEG 32 8 Connector A

AOD08C 2A NEG 8 8 Terminal block Provided Fuse

AOD08D 2A POS 8 8 Terminal block Provided Fuse

AOD08DP 2A POS 8 8 Terminal block Provided

AOD16C 0.5A NEG 16 8 Terminal block Provided Not provided

AOD16D 0.5A POS 16 8 Terminal block Provided Not provided

AOD16D2 2A POS 16 4 Connector C Provided Not provided

AOD16D3 2A POS 16 4

AOD16DP 0.3A POS 16 8 Terminal block Provided

AOD32C1 0.3A NEG 32 8 Connector A

AOD32C2 0.3A NEG 32 8 Connector B

AOD32D1 0.3A POS 32 8 Connector A

AOD32D2

AOA05E

AOA08E

AOA12F

AOR08G 4A - 8 1 Terminal block Provided Not provided

AOR16G

AOR16H2 30VDC 2A - 16 4 Connector B Provided Not provided

Rated

voltage

12 to 4VDC

100 to

240VAC

100 to

120VAC

Maximum

250VAC /

30VDC

Maximum

current

0.3A POS 32 8 Connector B

2A - 5 1 Terminal block Provided Fuse

1A - 8 4 Terminal block Provided Fuse

0.5A - 12 6 Terminal block Provided Fuse

2A - 16 4 Terminal block Provided Not provided

Polarity

*1

Points

Points/

common

(3) Digital input/output hybrid module

Input/output

type

Non-insulation

type DC input

Non-insulation

type DC output

Module name

AIO40A

Rated

voltage

24VDC

24VDC

Specification

Current rating:

7.5 mA

Response

time: 20 ms

(maximum)

Maximum

current:

0.2 A/point and

2A for common

Polarity

Points

*1

Both 24 24

NEG 16 16

Points/

common

External

connection

*2

Connector A

(shared by input

and output signals)

LED

display

Not

provided

Output

protection

Not provided

- 32 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

NEG circuit example

Common pin

POS circuit example

Output pin

Output module

+24V

Load

Current

0V

Current

+

-

Output pin

Output module

+24V

+

Load

0V

Common pin

NOTE

1 Polarity

NEGative : (Current sink type) Output is at Low level when ON.

POSitive : (Current source type) Output is at High level when ON.

2 Connector and terminal block B

(Section 5.4 shows a connector signal arrangement diagram as viewed from the front

of the module.)

Connector A : HONDA TSUSHIN MR-50RMA connector

It is recommended that the MR-50LW (housing) and MR50-FH

(soldering-type connector) or MRP-50F01 (crimp connector) +

MRP-F112 (contact) be used on the cable.

Connector B : HIROSE ELECTRIC HIF3BB-50PA-2.54DS

It is recommended that the HIF3BB-50D-2.54R (press-mount

connector) be used on the cable.

Connector C : HIROSE ELECTRIC HIF4-40P-3.18DS

It is recommended that the HIF4-40D-3.18R (press-mount

connector) be used on the cable.

Terminal block B : Weidmüller BL3.5/24/90F

The terminal block for the cable comes with the module.

3 For the details of the specifications for each module, refer to the section 5.3.

4 The maximum current of the DC output module includes the permissible rush current.

-

- 33 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

5.2 CORRESPONDENCE BETWEEN I/O SIGNALS AND

ADDRESSES IN A MODULE

The term "address in a module" refers to an address allocated within

each DI/DO module and relative to the start address (Xm, Yn) of the

module.

5.2.1 Module with 16/32 Digital Inputs (DI)

Input bits

Address in the

module

Xm A7 A6 A5 A4 A3 A2 A1 A0

Xm+1 B7 B6 B5 B4 B3 B2 B1 B0

Xm+2 C7 C6 C5 C4 C3 C2 C1 C0

Xm+3 D7 D6 D5 D4 D3 D2 D1 D0

5.2.2 Module with 5/8/12/16/32 Digital Outputs (DO)

Address in the

module

Yn A7 A6 A5 A4 A3 A2 A1 A0

Yn+1 B7 B6 B5 B4 B3 B2 B1 B0

Yn+2 C7 C6 C5 C4 C3 C2 C1 C0

Yn+3 D7 D6 D5 D4 D3 D2 D1 D0

7 6 5 4 3 2 1 0

When a contact connected to an input of an input module is closed, the

corresponding input signal becomes "1".

Output bits

7 6 5 4 3 2 1 0

When the output signal from an output module is "1", the corresponding

output contact (or transistor) is closed.

DI module of

16 points

DI module of

32 points

DO module of 5

and 8 points

DO module of 12

and 16 points

DO module of

32 points

- 34 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

5.2.3 AIO40A Module (Hybrid Module with 24 Input and 16 Output

Points)

The allotment of this module requires 4 input and 2 output bytes.

Input byte 4 (Xm + 3) is invalid.

Input section

Address in the

module

Xm A7 A6 A5 A4 A3 A2 A1 A0

Xm+1 B7 B6 B5 B4 B3 B2 B1 B0

Xm+2 C7 C6 C5 C4 C3 C2 C1 C0

7 6 5 4 3 2 1 0

Input bits

Xm+3

Output section

Address in the

module

Yn D7 D6 D5 D4 D3 D2 D1 D0

Yn+1 E7 E6 E5 E4 E3 E2 E1 E0

- - - - - - - -

Output bits

7 6 5 4 3 2 1 0

- 35 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

5.3 SPECIFICATION FOR EACH MODULE

Specifications for the module are shown in the following pages.

(1) Input module AID32A1

(2) Input module AID32B1

(3) Input module AID32H1

(4) Input module AID16C

(5) Input module AID16K

(6) Input module AID16D

(7) Input module AID16L

(8) Input module AID32E1

(9) Input module AID32E2

(10) Input module AID32F1

(11) Input module AID32F2

(12) Input module AIA16G

(13) Output module AOD32A1

(14) Output module AOD08C

(15) Output module AOD08D

(16) Output module AOD08DP

(17) Output module AOD16C

(18) Output module AOD16D

(19) Output module AOD16D2

(20) Output module AOD16D3

(21) Output module AOD16DP

(22) Output module AOD32C1

(23) Output module AOD32C2

(24) Output module AOD32D1

(25) Output module AOD32D2

(26) Output module AOA05E

(27) Output module AOA08E

(28) Output module AOA12F

(29) Output module AOR08G

(30) Output module AOR16G

(31) Output module AOR16H2

(32) Input/output module AIO40A

- 36 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(1) Input module AID32A1 (Non-insulation type)

Item Specifications

Points/module 32 points

Points/common 16 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 18VDC, min. 6mA

OFF voltage, current Max. 6VDC, max. 1.5mA

OFF→ON Max.20ms Response time

ON→OFF Max.20ms

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and

circuitry

+24V or GND can be selected for input common as above fig.

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each

system.

NOTE

1 Make sure to connect all common (CMA, CMC) pins.

2 This module outputs +24 V on pins 13, 17, 04, and 08.

- 37 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(2) Input module AID32B1 (Non-insulation type)

Item Specifications

Points/module 32 points

Points/common 16 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 18VDC, min. 6mA

OFF voltage, current Max. 6VDC, max. 1.5mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and

circuitry

+24V or GND can be selected for input common as above fig.

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each

system.

NOTE

1 Make sure to connect all common (CMA, CMC) pins.

2 This module outputs +24 V on pins 13, 17, 04, and 08.

- 38 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(3) Input module AID32H1

Item Specifications

Points/module 32 points

Points/common 16 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 18VDC, min. 6mA

OFF voltage, current Max. 6VDC, max. 1.5mA

Response time

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and

circuitry

OFF→ON Max.2ms (A0 to A7)

Max.20ms (B0 to D7)

ON→OFF Max.2ms (A0 to A7)

Max.20ms (B0 to D7)

+24V or GND can be selected for input common as above fig.

NOTE

1 Make sure to connect all common (CMA, CMC) pins.

2 This module outputs +24 V on pins 13, 17, 04, and 08.

This is the value from input to output in the module. The actual

value is determined by adding it to the scanning time depending

on each system.

- 39 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(4) Input module AID16C

Item Specifications

Points/module 16 points

Points/common 16 points/common

Sink/source current Source current type

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4mA

OFF voltage, current Max. 5VDC, max. 1.5mA

OFF→ON Max.20ms Response time

ON→OFF Max.20ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each

system.

(Note)

NOTE

Pins 18 and 19 are for factory use only.

Do not connect any wire to them

- 40 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(5) Input module AID16K

Item Specifications

Points/module 16 points

Points/common 16 points/common

Sink/source current Source current type

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4mA

OFF voltage, current Max. 5VDC, max. 1.5mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

(Note)

NOTE

Pins 18 and 19 are for factory use only.

Do not connect any wire to them

- 41 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(6) Input module AID16D

Item Specifications

Points/module 16 points

Points/common 16 points/common

Sink/source current Sink current type

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4mA

OFF voltage, current Max. 5VDC, max. 1.5mA

OFF→ON Max.20ms Response time

ON→OFF Max.20ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

(Note)

NOTE

Pins 18 and 19 are for factory use only.

Do not connect any wire to them

- 42 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(7) Input module AID16L

Item Specifications

Points/module 16 points

Points/common 16 points/common

Sink/source current Sink current type

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4mA

OFF voltage, current Max. 5VDC, max. 1.5mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

(Note)

NOTE

Pins 18 and 19 are for factory use only.

Do not connect any wire to them

- 43 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(8) Input module AID32E1

Item Specifications

Points/module 32 points

Points/common 8 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4.5mA

OFF voltage, current Max. 6VDC, max. 2mA

OFF→ON Max.20ms Response time

ON→OFF Max.20ms

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 44 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(9) Input module AID32E2

Item Specifications

Points/module 32 points

Points/common 8 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4.5mA

OFF voltage, current Max. 6VDC, max. 2mA

OFF→ON Max.20ms Response time

ON→OFF Max.20ms

Input display Not provided

External connection Connector (HIROSE ELECTRIC HIF3BB-50PA-2.54DS in accordance with MIL

standard)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 45 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(10) Input module AID32F1

Item Specifications

Points/module 32 points

Points/common 8 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4.5mA

OFF voltage, current Max. 6VDC, max. 2mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 46 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(11) Input module AID32F2

Item Specifications

Points/module 32 points

Points/common 8 points/common

Sink/source current Both directions

Input voltage 24VDC +10%, −20%

Input current 7.5mA (average)

ON voltage, current Min. 15VDC, min. 4.5mA

OFF voltage, current Max. 6VDC, max. 2mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display Not provided

External connection Connector (HIROSE ELECTRIC HIF3BB-50PA-2.54DS in accordance with MIL

standard)

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 47 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(12) Input module AIA16G

Item Specifications

Points/module 16 points

Points/common 16 points/common

Sink/source current 100 to 115VAC ±15%

Input voltage 132Vrms, 50/60 Hz

Input current 10.55mArms (120VAC, 50Hz)

ON voltage, current Min. 74Vrms, min. 6mArms

OFF voltage, current Max. 20Vrms, max. 2.2mArms

OFF→ON Max.35ms Response time

ON→OFF Max.45ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Common 16 points/common

Terminal connection and

circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 48 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(13) Output module AOD32A1 (Non-insulation type)

Item Specifications

Points/module 32 points

Points/common 8 points/common

Sink/source current Sink current type

Rated load voltage 5 to 24VDC +20%, −15%

Maximum load current 0.3A (however 2A/common)

Maximum voltage drop when ON 0.24V (load current ×0.8Ω)

Maximum leak current when OFF 0.1mA

OFF→ON Max.1ms Response time

ON→OFF Max.1ms

Input display Not provided

External connection Connector (HONDA TSUSHIN MR-50RMA)

Terminal connection and circuitry

NOTE

For the common (CMA, CMB, CMC, CMD) , make

sure to use both of them.

- 49 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(14) Output module AOD08C

Item Specifications

Points/module 8 points

Points/common 8 points/common

Sink/source current Sink current type

Rated load voltage 12 to 24VDC +20%, −15%

Maximum load current 2A (however 4A/fuse)

Maximum voltage drop when ON 0.8V (load current ×0.4Ω)

Maximum leak current when OFF 0.1mA

OFF→ON Max.2ms Response time

ON→OFF Max.2ms

Input display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Fuse 5A, 1 piece for each output A0-A3 and A4-A7.

Terminal connection and circuitry

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 50 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

(15) Output module AOD08D

Item Specifications

Points/module 8 points

Points/common 8 points/common

Sink/source current Source current type

Rated load voltage 12 to 24VDC +20%, −15%

Maximum load current 2A (however 4A/fuse)

Limit of load Refer to load derating curve (Fig. 5.3(a))

Maximum voltage drop when ON 1.2V (load current ×0.6Ω)

Maximum leak current when OFF 0.1mA

OFF→ON Max.2ms Response

Time

Output display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Fuse 5A, 1 piece for each output A0-A3 and A4-A7.

Terminal connection and circuitry

ON→OFF Max.2ms

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

- 51 -

5.DIGITAL INPUT/OUTPUT MODULESCONNECTION B-61813E/04

(16) Output module AOD08DP

Item Specifications

Points/module 8 points

Points/common 8 points/common

Sink/source current Source current type

Rated load voltage 12 to 24VDC +20%, −15%

Maximum load current 2A (however 8A/common)

Output current limit

Maximum voltage drop when ON 0.18V (load current ×0.09Ω)

Maximum leak current when OFF 0.1mA

OFF→ON Max.2ms Response

Time

Output display LED display

External connection Terminal block connector (20 terminals, M3.5 screw terminal)

Terminal connection and circuitry

ON→OFF Max.2ms

2.8A (Min.)

Output

circuit

This is the value from input to output in the module. The actual value is

determined by adding it to the scanning time depending on each system.

Load

Internal

circuit

- 52 -

B-61813E/04 CONNECTION5.DIGITAL INPUT/OUTPUT MODULES

t

• AOD08DP output protection