Page 1

Computer Numerical Controls

Function Host

Computer Numerical Controls

Computer Numerical ControlsComputer Numerical Controls

GE Fanuc Automation Europe

GE Fanuc Automation Europe

GE Fanuc Automation EuropeGE Fanuc Automation Europe

Series

SeriesSeries

15i / 16i / 18i /21i/

Model A

Remote Diagnosis

Operators Manual

B-63454EN/01

TECHNOLOGY AND MORE

TECHNOLOGY AND MORE

TECHNOLOGY AND MORETECHNOLOGY AND MORE

Page 2

B-63454EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This manual includes safety precautions for protecting the user and preventing

damage to the machine. Precautions are classified into Warnings and Cautions

according to their bearing on safety. Also, supplementary information is described

as Notes. Read the Warnings, Cautions, and Notes thoroughly before attempting to

use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a danger of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

Notes are used to indicate supplementary

information other than Warnings and Cautions.

* Read this manual carefully, and store it in a safe place.

s-1

Page 3

Page 4

B-63454EN/01 PREFACE

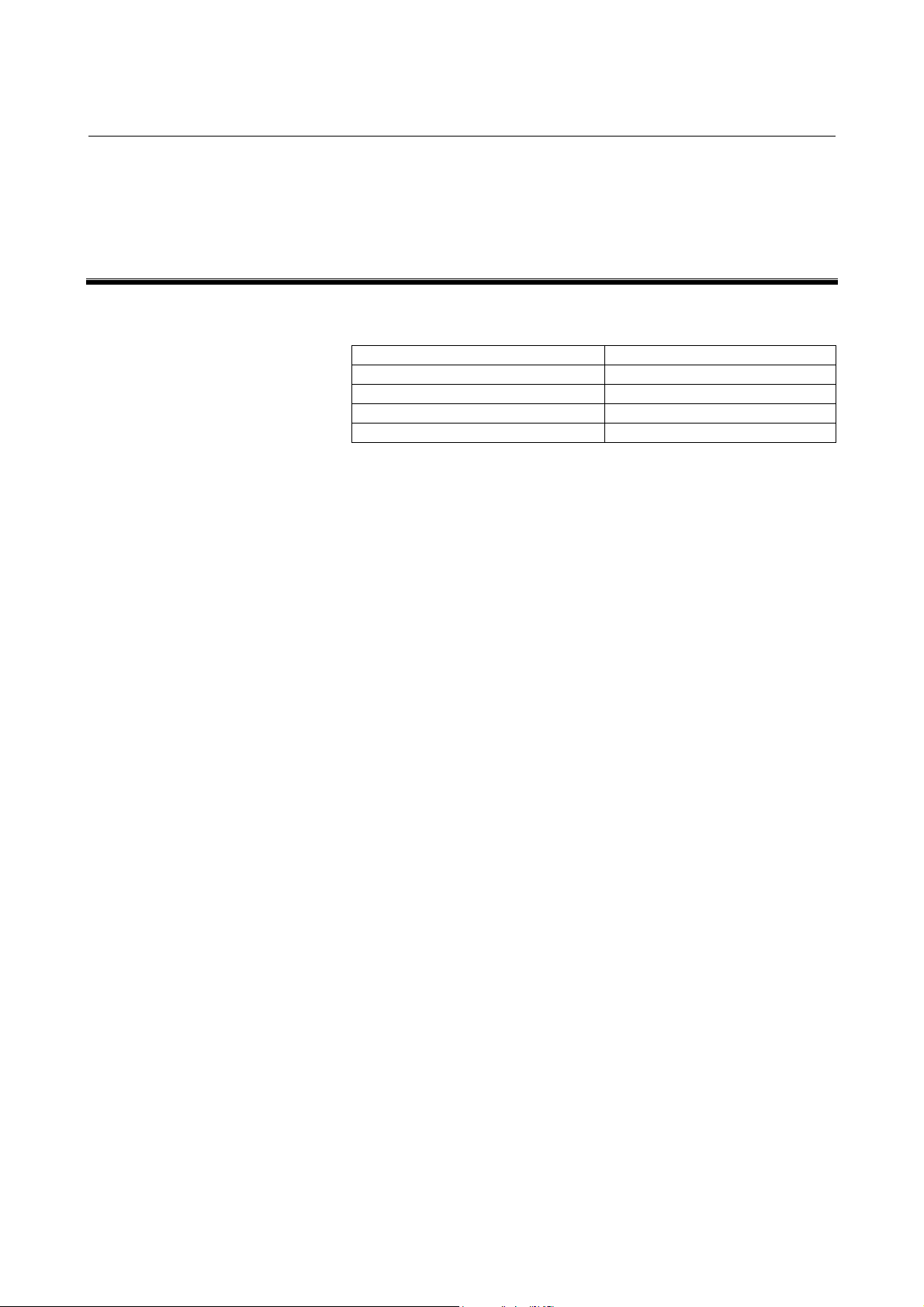

PREFACE

This manual descibes the following products.

Product Name Abbreviation

FANUC Series 15i-MODEL A Series 15i

FANUC Series 16i-MODEL A Series 16i

FANUC Series 18i-MODEL A Series 18i

FANUC Series 21i-MODEL A Series 21i

p-1

Page 5

Page 6

B-63454EN/01

CONTENTS

SAFETY PRECAUTIONS ......................................................................................s-1

PREFACE ................................................................................................................ p-1

1. OVERVIEW..........................................................................................................1

1.1 GENERAL..................................................................................................................................2

1.2 FEATURES ................................................................................................................................ 2

1.3 MODELS SUPPORTED ............................................................................................................ 3

1.3.1 About this Software..........................................................................................................................3

1.4 FUNCTIONS .............................................................................................................................. 4

1.4.1 Download Functions (CNC to Computer)........................................................................................4

1.4.2 Upload Function (Computer to CNC) ..............................................................................................5

1.4.3 Functions related to CNC screen......................................................................................................5

1.5 EXAMPLES OF EXECUTION.................................................................................................. 6

2. INSTALLATION PROCEDURE.....................................................................10

2.1 CAUTIONS ON INSTALLATION.......................................................................................... 11

2.2 INSTALLATION...................................................................................................................... 12

2.3 UNINSTALLATION................................................................................................................ 14

3. CONNECTION...................................................................................................16

3.1 CONNECTION BETWEEN THE CNC AND TELEPHONE LINE........................................... 17

3.1.1 Connecting a Modem Card to the CNC..........................................................................................17

3.1.2 Connecting a Modem Via the RS-232-C Interface.........................................................................18

3.1.3 Making a Direct Connection Via the RS- 232-C In terface.....................................................................20

3.2 CONNECTION BETWEEN THE PERSONAL COMPUTER AND TELEPHONE LINE.... 21

3.3 CNC SETTING......................................................................................................................... 22

3.3.1 Connecting a Modem Card to the CNC..........................................................................................22

3.3.2 Making a Connection Via the RS-232-C Interface:

Using an External Modem or Making a Direct Connection...........................................................22

3.4 SETTING THE PERSONAL COMPUTER............................................................................. 24

3.5 LINE CONNECTION/DISCONNECTION..............................................................................25

3.5.1 Line Connection (when Using a Modem Card)..............................................................................25

3.5.2 Line Disconnection (when Using a Modem Card).........................................................................25

3.5.3 Line Connection/Disconnection

(when Connecting an External Modem Via the RS-232-C Interface).............................................26

3.5.4 Line Connection/Disconnection

(when Making a Direct Connection Via the RS-232-C Interface)...................................................26

3.6 ACCESS RIGHT ...................................................................................................................... 27

3.6.1 About Access Right........................................................................................................................27

3.6.2 Password Setting for the CNC........................................................................................................27

3.6.3 Password Registration on the Host Software Side..........................................................................27

3.6.4 About Passwords............................................................................................................................28

c-1

Page 7

CONTENTS B-63454EN/01

4. OPERATION......................................................................................................29

4.1 FUNCTION OVERVIEW ........................................................................................................ 30

4.1.1 Screen Configuration......................................................................................................................30

4.1.2 Pull-Down Menu............................................................................................................................31

4.1.3 Other Buttons.................................................................................................................................33

4.2 FILE MENU.............................................................................................................................. 34

4.2.1 Print................................................................................................................................................34

4.2.2 US version/Japanese version..........................................................................................................34

4.2.3 eXit.................................................................................................................................................34

4.3 EDIT MENU............................................................................................................................. 35

4.3.1 Copy ...............................................................................................................................................35

4.3.2 Copy to file(I).................................................................................................................................35

4.3.3 select Range ...................................................................................................................................35

4.3.4 Find, Find Next..............................................................................................................................35

4.3.5 Mark, Jump....................................................................................................................................35

4.3.6 Select all................................................................................................................ .........................35

4.3.7 Erase diag data...............................................................................................................................35

4.4 PHONE MENU......................................................................................................................... 36

4.4.1 Dial.................................................................................................................................................36

4.4.2 Hang...............................................................................................................................................36

4.4.3 Phone List, comm List....................................................................................................................36

4.4.4 Phone history..................................................................................................................................38

4.5 SCREEN SWITCHING............................................................................................................ 39

4.5.1 Using the Screen Switching Function.............................................................................................41

4.6 RECEIVE DATA...................................................................................................................... 44

4.6.1 Receive (Display)...........................................................................................................................44

4.6.2 Receive (File).................................................................................................................................46

4.7 SEND DATA............................................................................................................................ 47

4.7.1 Send (Input)....................................................................................................................................47

4.7.2 Send (File)......................................................................................................................................48

4.8 OTHER MENUS ...................................................................................................................... 49

4.8.1 Setting comm..................................................................................................................................49

4.8.2 Folder setting..................................................................................................................................50

4.8.3 Select Path......................................................................................................................................51

4.8.4 AutoGetScreen...............................................................................................................................51

4.8.5 CNC MDI Key(C)..........................................................................................................................51

4.8.6 Keyfree(Q).....................................................................................................................................51

4.8.7 MDIkey..........................................................................................................................................52

4.9 HELP MENU............................................................................................................................ 53

4.9.1 Version info....................................................................................................................................53

c-2

Page 8

B-63454EN/01 CONTENTS

APPENDIX

A. USABLE MODEM CARDS..............................................................................57

B. CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS...................58

c-3

Page 9

Page 10

B-63454EN/01 1. OVERVIEW

1 OVERVIEW

-1-

Page 11

1. OVERVIEW B-63454EN/01

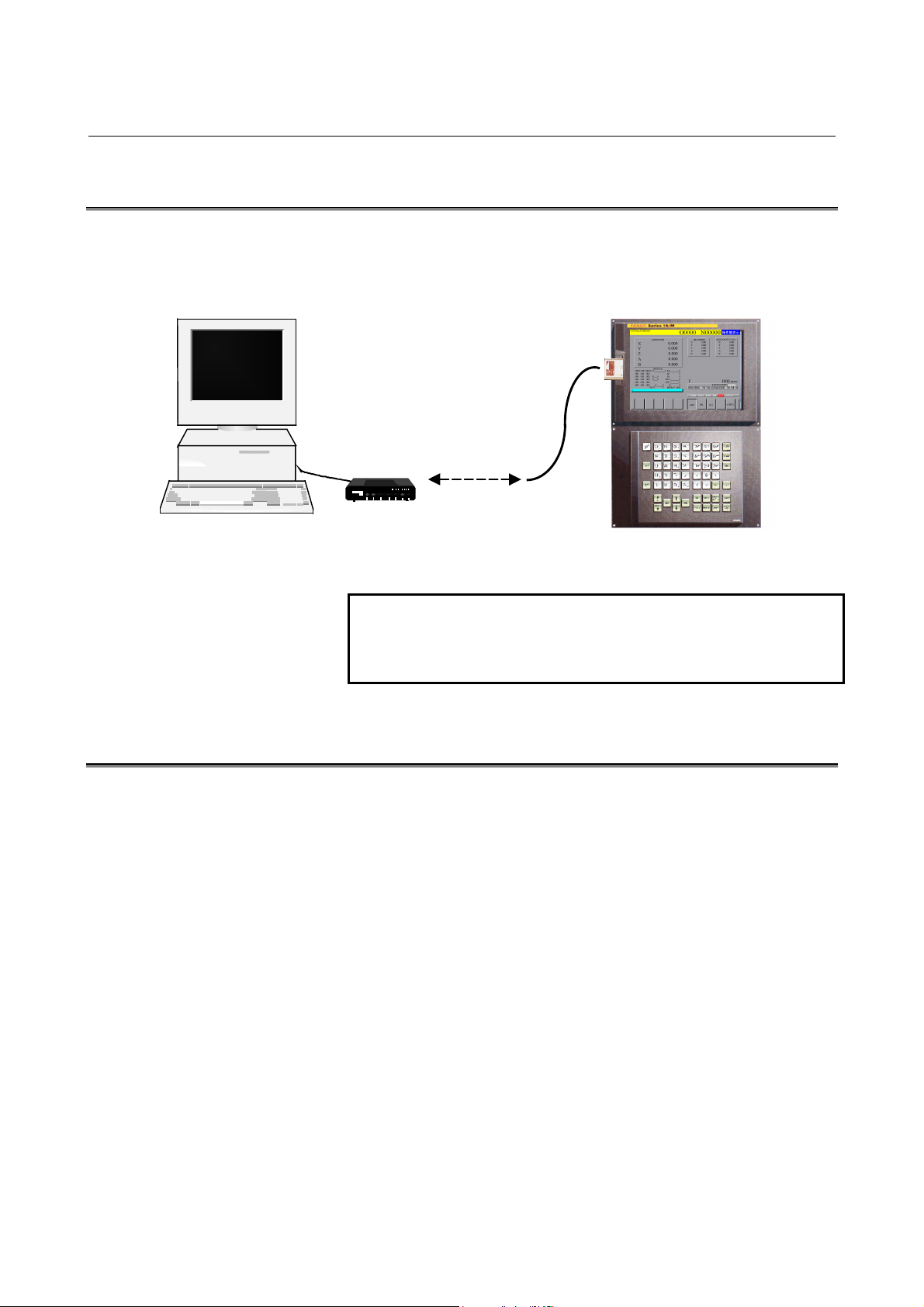

1.1 GENERAL

With the remote diagnosis function, CNC data can be transferred

between the FANUC Serie s 15i/16i/18i/21i and a personal computer,

acting as a service terminal, through a telephone line.

Modem Card (Note)

Telephone line

Personal computer

on the host side

1.2 FEATURES

Modem

Series 15i/16i/18i/21i

NOTE

In this manual, modem cards and digital

communication cards are collectively referred to as

modem cards.

(1) By inserting a modem card into the slot on the front of the LCD

unit, a connection can be made to a mobile telephone or

conventional telephone line.

(2) By using a telephone line, the state of a CNC machine tool

installed for from the service center can be m onitored, and its data

can be modified.

(3) Information such as alarm information, parameters, and programs

can be transferred to the service center, so that speedy and timely

maintenance and service are possible.

-2-

Page 12

B-63454EN/01 1. OVERVIEW

1.3 MODELS SUPPORTED

This software runs under Windows95, Windows98, or Windows

NT4.0(*1) on an IBM-PC/AT compatible machine.

*1 This software runs under Windows NT4.0 including

Microsoft Windows NT4.0 Service Pack 3 or above.

1.3.1 About this Software

This software incorporates the following product, the copyright of

which is possessed by Microsoft Corporation of the U.S.A.:

- Microsoft Windows Visual Basic

This software incorporates the following product:

- PDQ COMM

Copyright(c) 1997 Crescent Div. of Progress Software &

Bunka Orient

NOTE

IBM is a registered trademark of International

Business Machines Corporation of the U.S.A..

Windows is a registered trademark of Microsoft

Corporation of the U.S.A..

Visual Basic is a trademark of the Microsoft

Corporation of the U.S.A..

-3-

Page 13

1. OVERVIEW B-63454EN/01

1.4 FUNCTIONS

The software provides the functions listed below.

1.4.1 Download Functions (CNC to Computer)

(See also: Section 4.6)

a. Display

(0) CNC series and edition (21) Number of tool groups

(1) Maintenance information (22) Number of tools

(23) Tool life(2) Printed circuit board

information(*1) (24) Tool life counter

(3) Parameter

(4) Program

(5) Offset

(6) Macro variable

(7) Diagnostic information

(8) Signal state

(9) Machine position

(10) Actual feedrate

(11) Program number (29) Tool information 1

(12) Tool group number (30) Tool information 2

edition (32) Alarm state

(14) Absolute position (33) Ladder title

(15) Skip position (34) Program directory

(16) Servo delay (35) Memory contents

delay (36) Modal data

(18) A/D conversion data (37) Status information

(19) Spindle motor load (38) Alarm history(*2)

(20) Sequence number being

executed

(2 5) Tool length compensation

number 1

(2 6) Tool length compensation

number 2

(27) Cutter compensation

number 1

(28) Cutter compensation

number 2

(31) Tool number(13) Ladder/PMC series and

(dedicated to FANUC)(17) Acceleration/deceleration

(39) Signal state (continuous)

*1, *2 Only for the Series 16i/18i/21i

b. File

For the Series 16i/18i/21i

(0) Maintenance information (4) Operation history

(1) All parameters (5) Alarm history

(2) All programs

(3) One program

-4-

(6) Reception of signals in a

batch

Page 14

B-63454EN/01 1. OVERVIEW

For the Series 15i

(0) Maintenance information

(1) All parameters

(2) All programs (6) System alarm

(3) One program

(4) Operation history/alarm

history

(5) Printed circuit board

information

(7) Reception of signals in a

batch

1.4.2 Upload Function (Computer to CNC)

(See also: Section 4.7)

a. File

(1) All parameters

(2) Program transmission

(3) Program check

b. Input

(1) Parameter

(2) Offset

(3) Macro variable

(4) Signal (PMC/D, K, and others)

(5) Message

1.4.3 Functions related to CNC screen

(See also: Section 4.5.1)

(1) Acquisition of CNC screen data

(2) CNC screen switching

(3) Soft key operation

(4) Page UP/Page DOWN key operation

-5-

Page 15

1. OVERVIEW B-63454EN/01

1.5 EXAMPLES OF EXECUTION

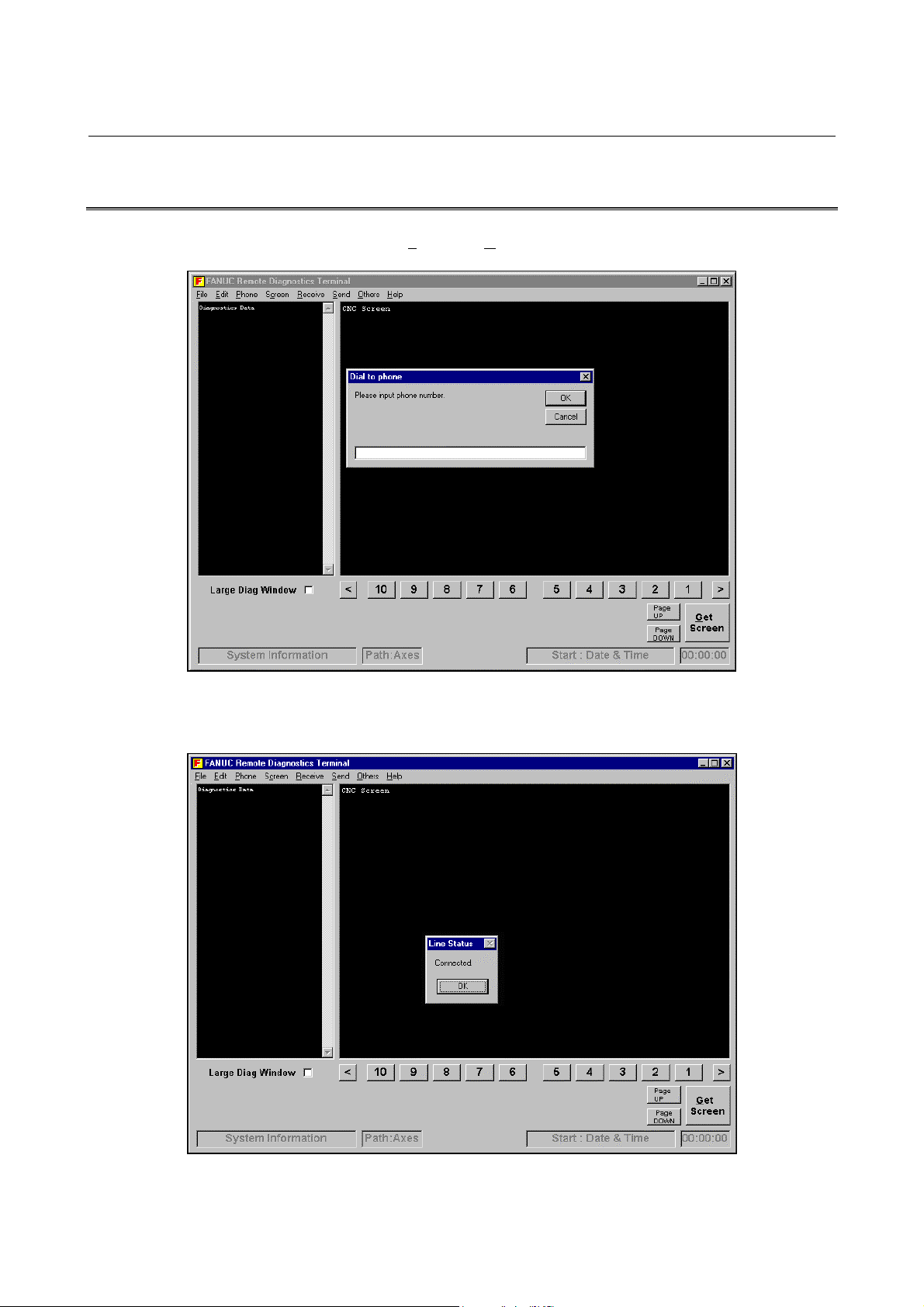

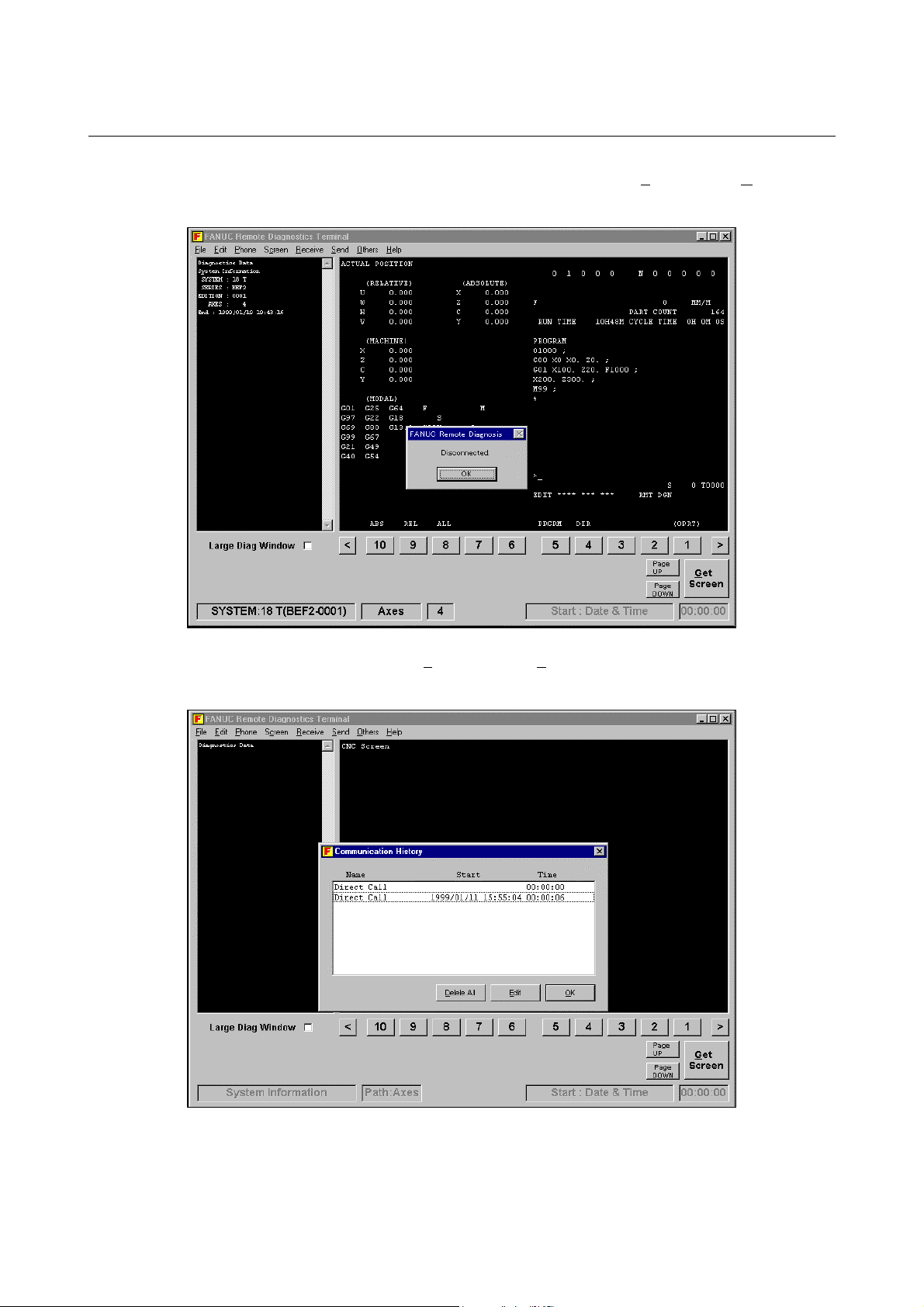

Choose Phone and Dial, then enter the desired telephone number.

0123-45-6789

Clicking the OK button establishes a connection. Once a connection is

established, the following screen appears:

-6-

Page 16

B-63454EN/01 1. OVERVIEW

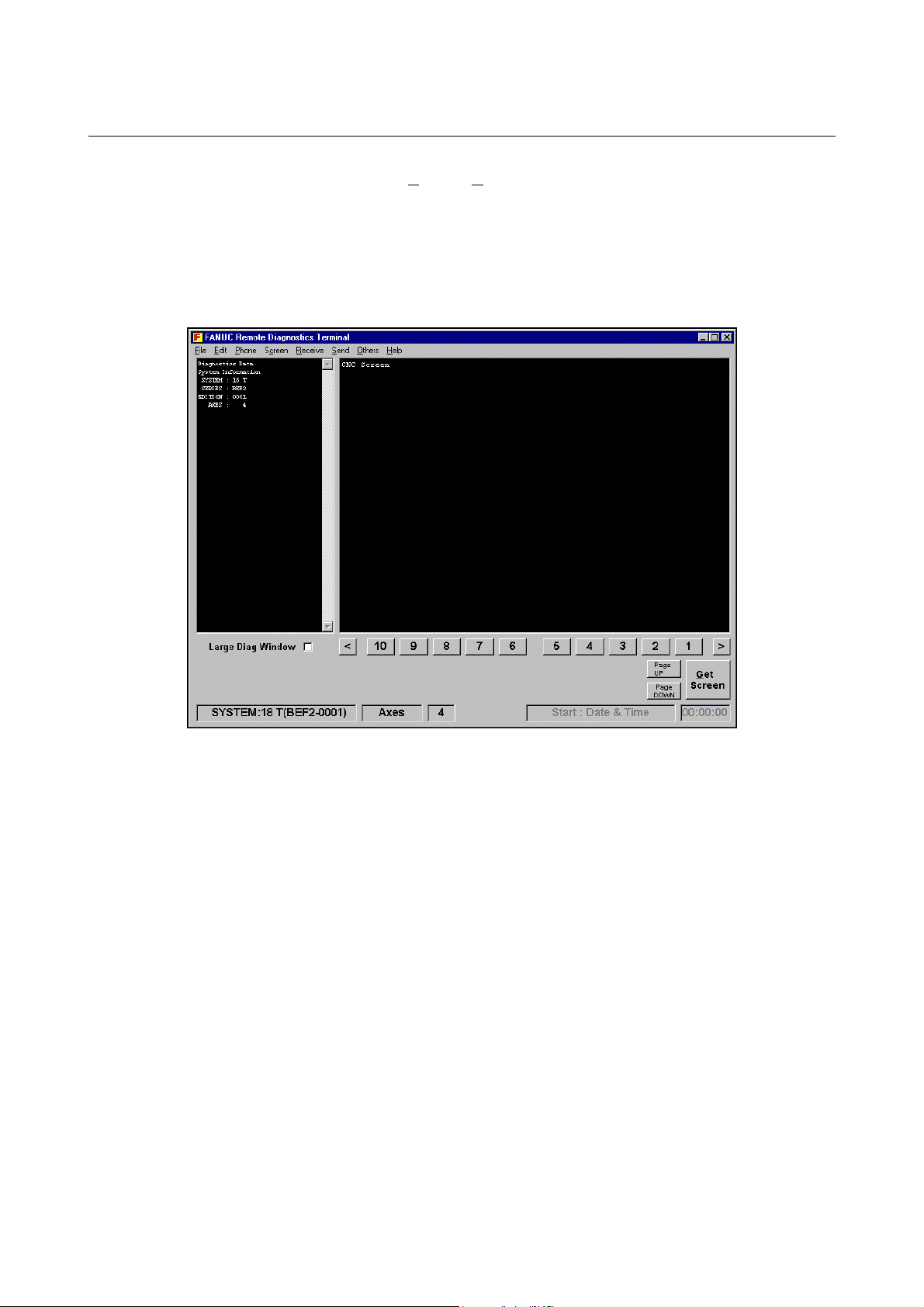

Choose Receive, Display, then (0) CNC Series and Edition. T hen, the

selected data is transferred to the host (in the upper-left part of the

screen). CNC series and edition data is also displayed in the lower-left

part of the screen. With the Series 16i/18i/21i, this information is

received automatically if a telephone line connection is made using a

modem. With the Series 15i, this information is received automa tically

at all times.

-7-

Page 17

1. OVERVIEW B-63454EN/01

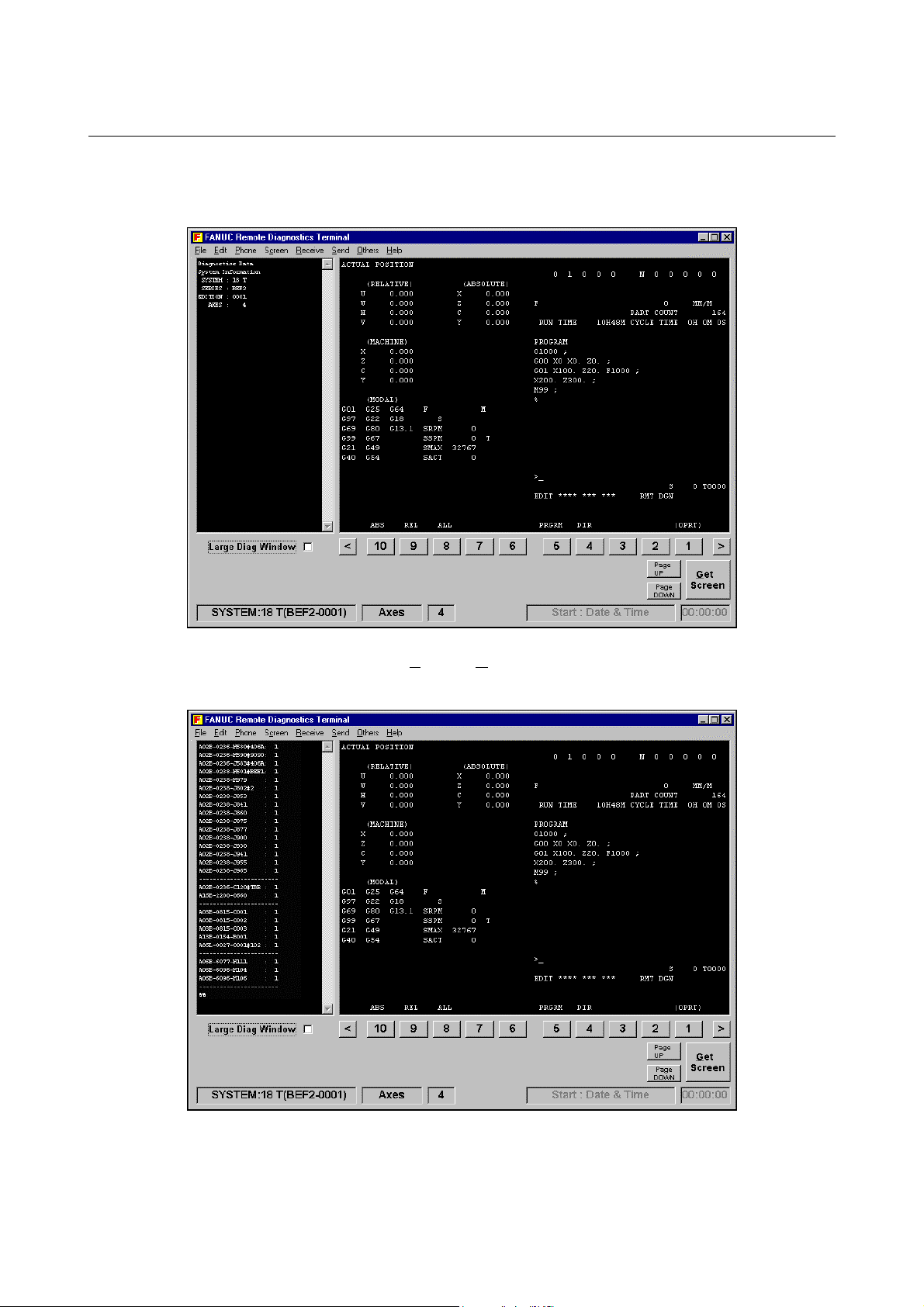

Clicking the GET Screen button transfers the display data for the

current CNC screen.

Choose Receive, D

isplay, then (0) Mainte Info. Then, maintenance

information is received (on the left side of the screen).

-8-

Page 18

B-63454EN/01 1. OVERVIEW

Upon the completion of diagnosis, choose Phone and the Hang to break

the connection.

Choosing Phone and then Phone history allows the user to check the

telephone call history.

-9-

Page 19

2. INSTALLATION PROCEDURE B-63454EN/01

2 INSTALLATION PROCEDURE

-10-

Page 20

B-63454EN/01 2. INSTALLATION PROCEDURE

2.1 CAUTIONS ON INSTALLATION

- At least 6.5MB of free hard disk space is required to install the

host software.

- To upgrade the host software, delete the existing "FANUC

Remote Diagnosis," then install the new version. If a new version

is installed without first deleting the existing version, the new

version may not operate normally.

- When deleting the host software from the personal computer,

select and delete "FANUC Remote Diagnosis" with Add/Remove

Programs on the Control Panel. If the directory and files are

deleted directly, the host software cannot be deleted completely,

leaving the DLL file, OCX file, registry information, and so forth.

- When installing/uninstalling the host software, term inate all other

applications.

- When installing the host software under Windows NT4.0, log on

as the administrator.

-11-

Page 21

2. INSTALLATION PROCEDURE B-63454EN/01

2.2 INSTALLATION

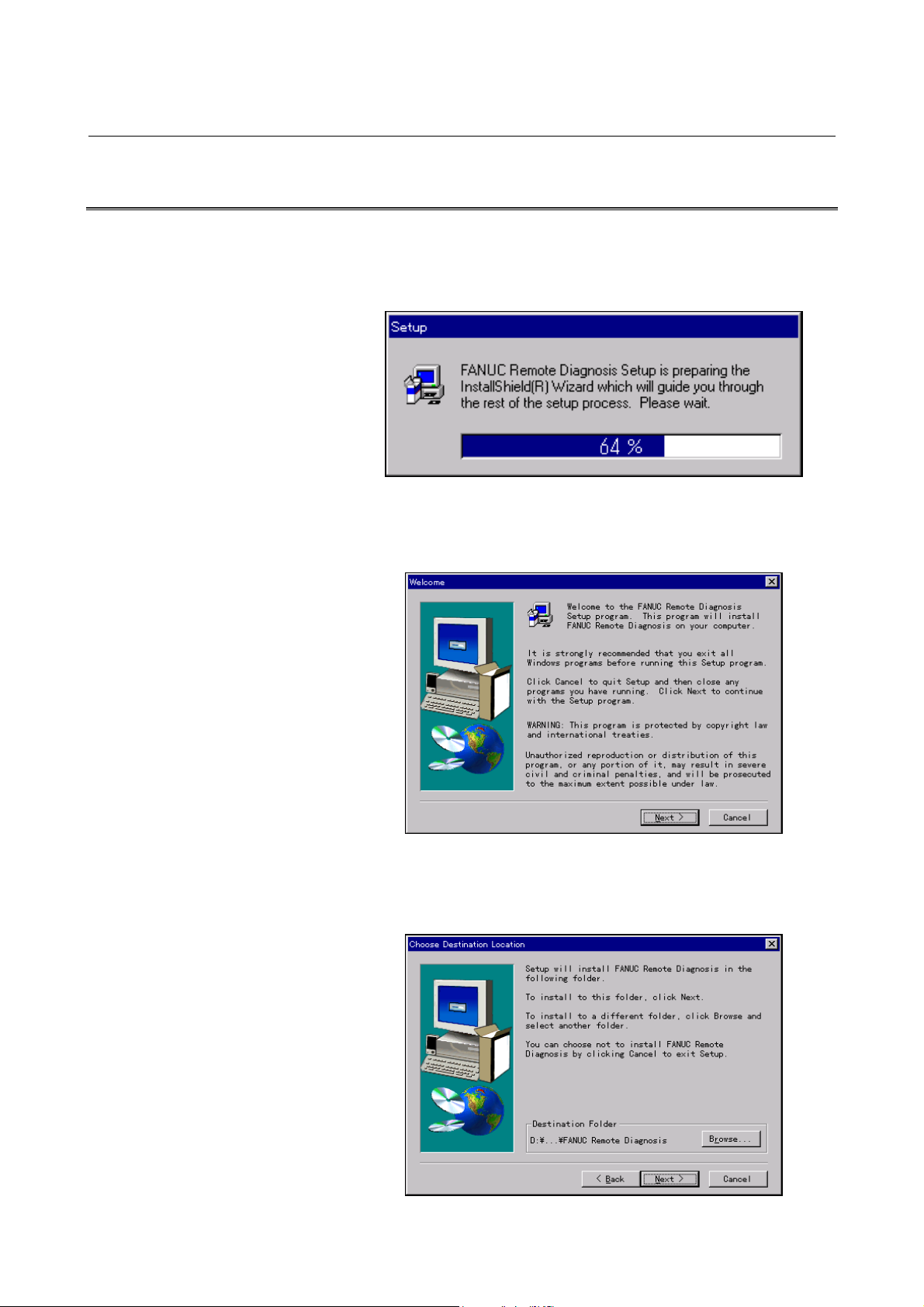

(1) Insert the first floppy disk into the floppy disk drive, and then

execute "Setup.exe" from the floppy disk. Then, the message

shown below appears.

(2) After a short while, the message below appears. Click the Next

button to proceed to the next step.

(3) Click the Next button.

The installation directory can be changed by clicking the Browse

button.

-12-

Page 22

B-63454EN/01 2. INSTALLATION PROCEDURE

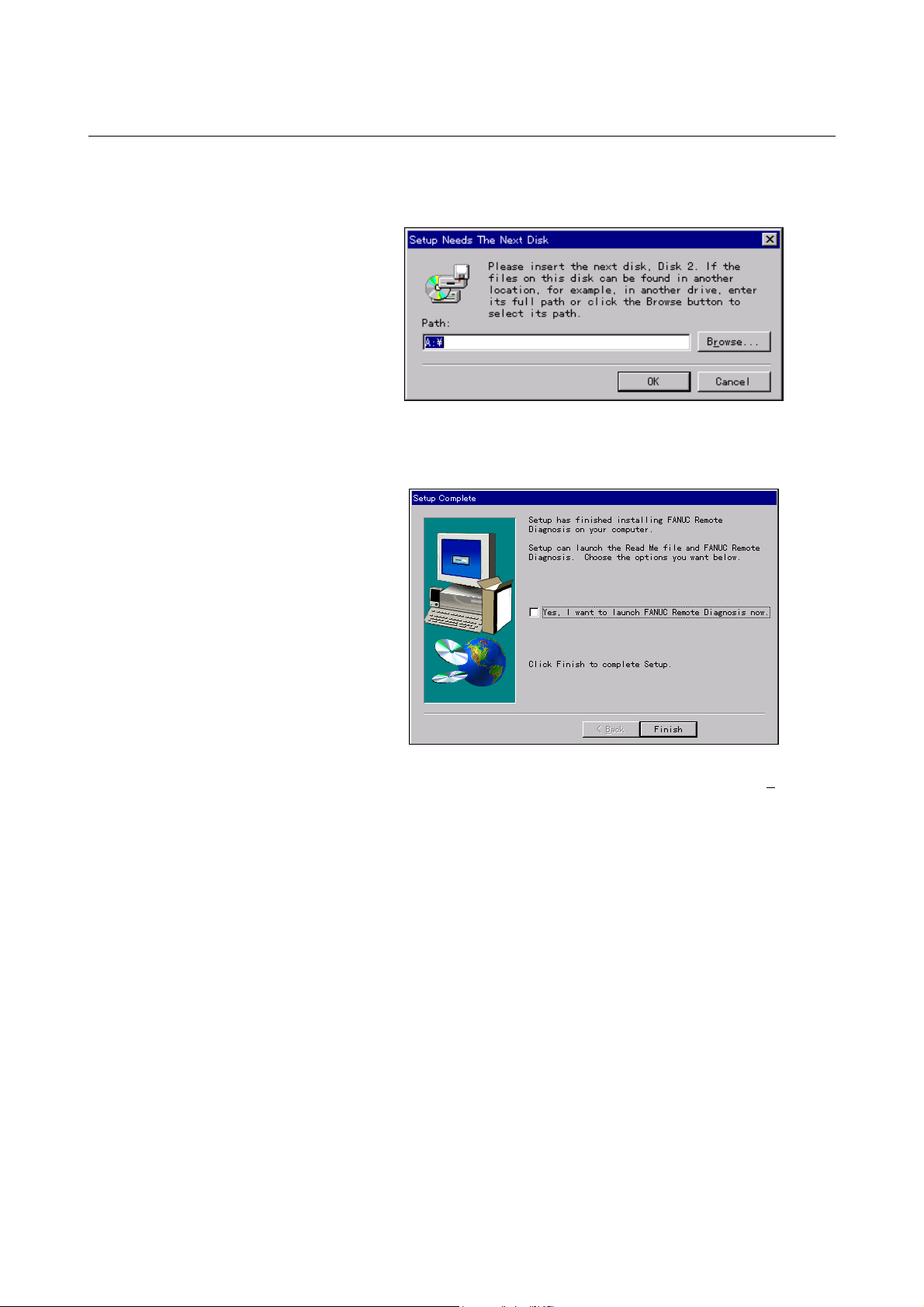

(4) After a short while, the message below appears. I nsert the second

floppy disk into the drive, and then click the OK button.

(5) Upon the normal completion of installation, the message below

appears. Clicking the Finish button terminates the installation.

(6) The host program can be activated by choosing Start, Programs,

and then FANUC Remote Diagnosis from the menu.

-13-

Page 23

2. INSTALLATION PROCEDURE B-63454EN/01

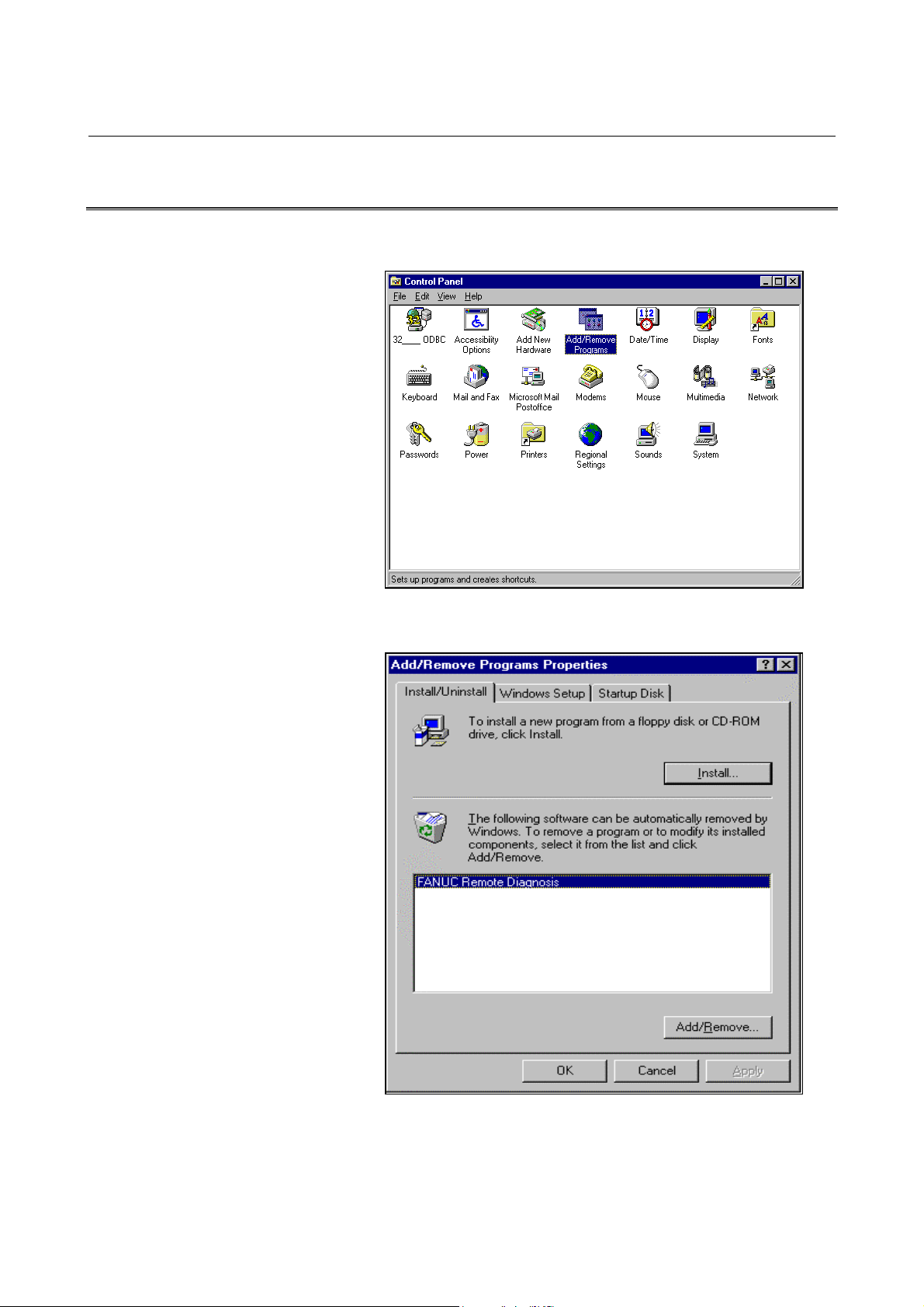

2.3 UNINSTALLATION

(1) Start Add/Remote Programs in the Control Panel.

(2) Specify deletion of the application "FANUC Remote Diagnosis."

-14-

Page 24

B-63454EN/01 2. INSTALLATION PROCEDURE

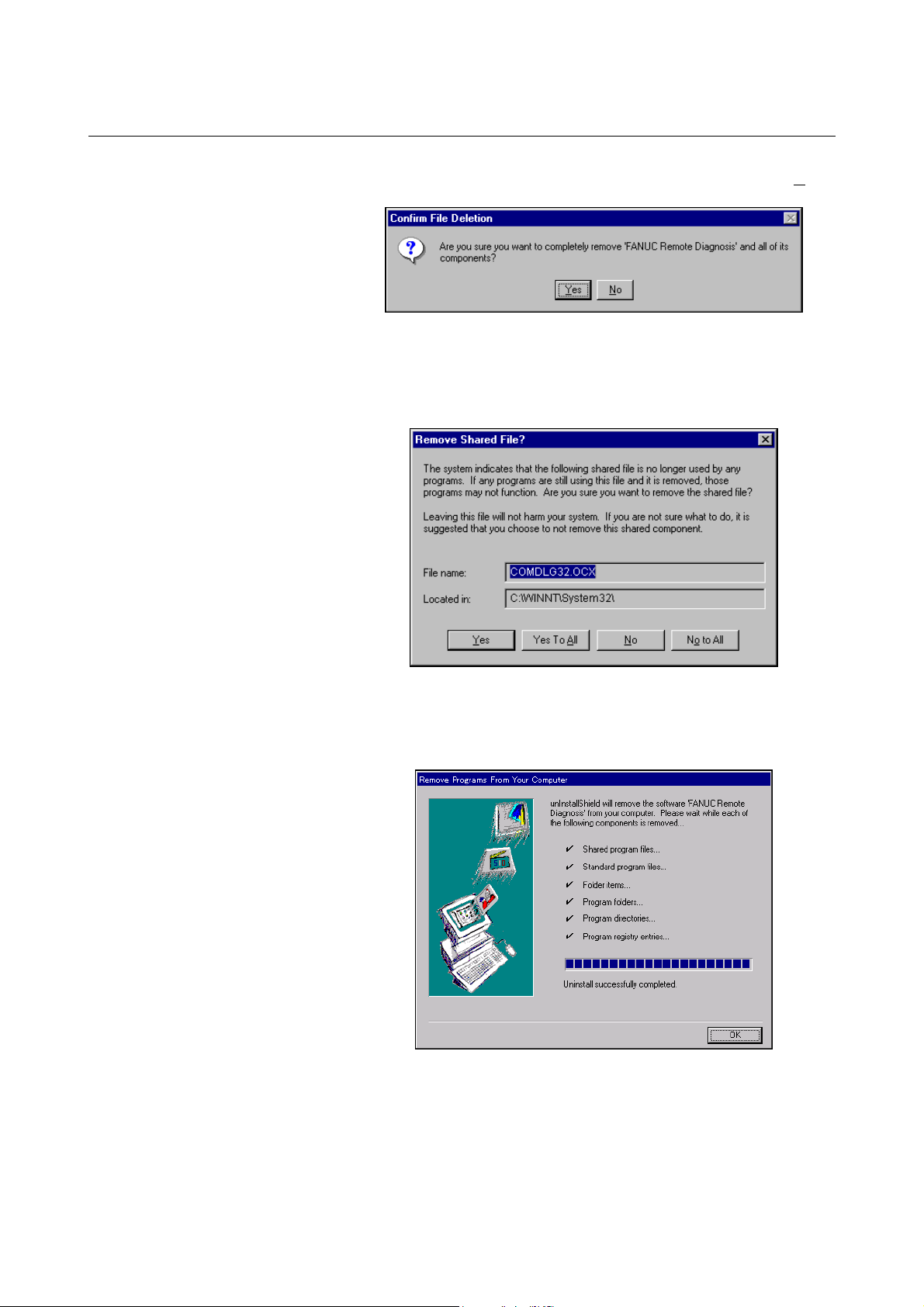

(3) The dialog box for deletion confirmation appears. Choose Yes.

(4) The dialog box for confirming that files such as the OCX and DLL

files may be deleted appears. Choose whether to delete these

files.

(5) Upon the completion of application deletion, the message below

appears.

Clicking the OK button terminates the uninstallation work.

-15-

Page 25

3. CONNECTION B-63454EN/01

3 CONNECTION

-16-

Page 26

B-63454EN/01 3. CONNECTION

3.1 CONNECTION BETWEEN T HE CNC AND TELEPHONE LINE

3.1.1 Connecting a Modem Card to the CNC

For the Series 16i/18i/21i

- After turning off the power to the CNC, insert the modem card

into the slot on the front of the CNC’s LCD unit.

- Turn on the power to the CNC. The m odem card is automatically

initialized.

- Whether the modem card has been initialized normally can be

checked using the screen displayed by the following key

operations:

For the Series 15i

Press function key [OFFSET],

If the modem card is initialized normally, "OK" is displayed at the end

of the screen. If the modem card fails to initialize norm ally, the m odem

card itself or a component such as a connector may be faulty.

, and then soft key <MODEM>.

WARNING

It is dangerous to insert a modem card when the

power to the CNC is on. An expected operation may

occur as a result.

NOTE

For an explanation of how to use the modem card,

see the operator’s manuals prov ided wi th the modem

card and mobile telephone. When a mobile

telephone line is used, normal communication may

be impeded by the signal reception status even if the

modem card and its connection are normal.

- After turning off the power to the CNC, insert the modem card

into the slot on the front of the CNC’s LCD unit.

- Turn on the power to the CNC, then set the CNC parameters to

initialize the modem card.

- Whether the modem card has been initialized normally can be

checked on the screen displayed by the following key operations:

Press function key [OFFSET SETTING], soft key <CHAPTER>, and

the soft key <MODEM SETTING>.

If the modem card is initialized normally , the modem type is displayed.

If the modem card is not initialized norm ally, the m odem card itself or a

component such as a connector may be faulty.

For details of the modem setting screen, refer to the relevant section in

"FANUC Series 15i Operator’s Manual (Operation) (B-63324EN)".

-17-

Page 27

3. CONNECTION B-63454EN/01

WARNING

It is dangerous to insert a modem card when the

power to the CNC is on. An expected operation can

occur.

NOTE

For an explanation of how to use the modem card,

see the operator’s manuals prov ided wi th the modem

card and mobile telephone. When a mobile

telephone line is used, normal communication may

be impeded by the signal reception status even if the

modem card and its connection are normal.

3.1.2 Connecting a Modem Via the RS-232-C Interface

Connect an external modem to the reader/punch interface of the CNC.

As the connection cable, a cable used for modem connection (straight

type) is used. For details, refer to the manual for the modem.

For making a connection, CNC parameter setting is required. The

parameter numbers for setting vary between the Series 15i and the

Series 16i/18i/21i.

(See also: Section 3.3.2)

NOTE

1 T he RS-232-C serial port of the CNC has +5 V and

+24 V outputs. Pin 25 of the reader/punch interface

relay connector outputs +24 V. Usually, modems do

not require these power supplies. Ensur e that these

power supplies are not connected to the modem by

the connection cable. Ensure also that even if these

power supplies are connected to the modem, modem

operation is not adversely affected. If these power

supplies are connected to a modem without sufficient

care, the modem may be damaged.

2 An external modem connected to the CNC must be

set as described in the examples below when the

power is turned on. By referring to the specifications

of the modem being used, set the modem, for

example, with a personal computer as described

below.

Setting example 1 (for the Series 16i/18i/21i)

An external modem, when turned on, must be set as following:

- Automatic termination enabled

-18-

Page 28

B-63454EN/01 3. CONNECTION

- CD signal turned on at all times

- ER signal turned on at all times

- Data flow control XON/XOFF

- Automatic transmission speed adjustment enabled (to allow

automatic adjustment for connection at a maximum allowable

speed)

- Command echo not used

- Result code not used

Example of external modem setting

In this example, the use of the following modem is assumed for

command settings:

Panasonic: TO-BXF56K

Connect the modem to the personal computer, then start the terminal

software.

→ For connection between the personal computer and modem, refer

to the manuals provided with the personal computer and modem.

→ Windows is delivered with terminal software named Hyper

Terminal.

Using the terminal software, send the following commands, in the

listed order, to the modem:

Command Description

AT&F : Returns the settings to their initial values.

ATS0=3 : Sets the S register (to ring three times for automatic

AT&C0 : Turns on the CD signal at all times.

AT&D0 : Turns on the ER signal at all times.

AT&K4 : Applies XON/XOFF flow control.

AT&Y0 : Reads the settings of profile 0 when the power is on.

ATN1 : Enables automatic mode (for automatic transmission

ATE0 : Does not use command echo.

ATQ1 : Does not use result code.

AT&W0 : Saves the settings as profile 0.

In addition to the above, CNC parameter setting is required. See

Appendix B.

Setting example 2 (for the Series 15i)

- Automatic termination enabled

- Error correction connection display not provided

- Fixed terminal speed mode enabled

- CD signal turned on at all times

- ER signal turned on at all times

- Send data flow control XON/XOFF

- Receive data software flow XON/XOFF

- Receive data hardware flow not used

- Transmission speed specification (for setting of a transmission

speed on the CNC)

termination).

speed determination).

-19-

Page 29

3. CONNECTION B-63454EN/01

- Command echo not used

- Local echo not used

- Result code not used

Example of external modem setting

In this example, the use of the following modem is assumed for

command settings:

Omron: ME3314B

Connect the modem to the personal computer, then start the terminal

software. (For details of the connection between the personal computer

and modem, refer to the manuals provided with the personal computer

and modem.)

Send the commands below, in the listed order, to the modem. It is

assumed that the transmission speed on the CNC side is 9600 bps.

Command Description

AT&F : Returns the settings to the initial setting values.

ATS0=3 : Sets the S register (to ring three times for automatic

termination).

AT&A0 : Provides no error correction connection display.

AT&B1 : Enables fixed terminal speed mode.

AT&C0 : Turns on the CD signal at all times.

AT&D0 : Turns on the ER signal at all times.

AT&H2 : Send data flow control XON/XOFF.

AT&I1 : Receive data software flow XON/XOFF

AT&R1 : Provides no receive data software flow.

AT&N6 : Transmission speed specification (9600 bps)

AT&Y0 : Reads the settings of profile 0 when the power is on

ATE0 : Does not use command echo.

ATF1 : Does not use local echo.

ATQ1 : Does not use result code.

AT&W0 : Saves the settings as profile 0.

3.1.3 Making a Direct Connection Via the RS-232-C Interface

Remote diagnosis can be performed without using a telephone line.

Connect the reader/punch interface of the CNC directly to the personal

computer. As the connection cable, a cable for I/O device connection

(cross-type) is used.

For making a connection, CNC parameter setting is required. The

parameter numbers for setting vary between the Series 15i and the

Series 16i/18i/21i.

(See also: Section 3.3.2)

-20-

Page 30

B-63454EN/01 3. CONNECTION

3.2 CONNECTION BETWEEN THE PERSONAL COMPUTER

AND TELEPHONE LINE

Make a connection as explained in the manuals provided with the

personal computer and modem.

-21-

Page 31

3. CONNECTION B-63454EN/01

3.3 CNC SETTING

3.3.1 Connecting a Modem Card to the CNC

For the Series 16i/18i/21i

Basically, no parameters need to be set. For transm ission at a baud rate

other than 9600 bps, make the following settings:

- Bit 6 (MCB) of No. 0201 = 1

- No. 0203 = 1 to 12

(For details, see Appendix B.)

The optional reader/punch interface is not required.

NOTE

When a mobile telephone is used, the

communication baud rate is 9600 bps.

For the Series 15i

Make the following parameter settings:

- Bit 2 (ISP) of No. 0000 = 1

- Bit 3 (NCR) of No. 0000 = 1

- Bit 4 (EIA) of No. 0000 = 0

- No. 0020 through No. 0023 = 12

- No. 0040 = 17

- No. 5004 = 1 to 6

Set parameter No. 5110 through No. 5162 according to the setting of

parameter No. 5004. Set 3 as the I/O device specification number in

parameters No. 5110 through No. 5162.

Upon the completion of communication parameter setting, set the

parameter below. When the parameter below is set to 1, the CNC

acquires the communication parameters, and initializes and opens the

port. Set the parameter to 0 once remote diagnosis ends.

- Bit 6 (RDN) of No. 0000 = 1

The optional reader/punch interface is not required.

3.3.2 Making a Connection Via the RS-232-C Interface:

Using an External Modem or Making a Direct Connection

For the Series 16i/18i/21i

Make the following parameter settings:

- Bit 0 (SB2) of No. 0201 = 0

- Bit 1 (ASC) of No. 0201 = 1

- Bit 2 (NCR) of No. 0201 = 1

- No. 0203 = 1 to 12

(For details, see Appendix B.)

-22-

Page 32

B-63454EN/01 3. CONNECTION

When starting remote diagnosis, set bit 0 (RDG) of param eter No. 0002

to 1. Upon the completion of remote diagnosis, set bit 0 of parameter

No. 0002 to 0.

When bit 0 of No. 0002 = 1, the line status can be check ed on the CNC

screen by pressing the following keys in this order:

Function key [MESSAGE], Soft key

<RMTDGN>

When the CNC is normal, the following message appears, indicating

that the CNC is awaiting data:

LINE STATUS : DATA WAITING

If the CNC experiences a fault, the following message appears:

LINE STATUS : LINE ERROR

Set bit 0 of parameter No. 0002 to 0 once, then set the same bit to 1. I f

the error message still appears, turn off the power to the CNC and

personal computer, then back on again, or check the connections.

, and Soft key

For the Series 15i

NOTE

The optional reader/punch interface is required.

Make the following parameter settings:

- Bit 2 (ISP) of No. 0000 = 1

- Bit 3 (NCR) of No. 0000 = 1

- Bit 4 (EIA) of No. 0000 = 0

- No. 0020 through 0023 = 12

- No. 0040 = 1, 2, or 3

Set parameter No. 5001 through No. 5003 and No. 5110 through No.

5162 according to the setting of parameter No. 0040.

Set 3 as the I/O device specification number in parameter No. 5110

through No. 5162.

Upon the completion of communication parameter setting, set the

parameter below. When the parameter below is set to 1, the CNC

acquires the communication parameters, and initializes and opens the

port. Set the parameter to 0 upon the completion of remote diagnosis.

- Bit 6 (RDN) of No. 0000 = 1

NOTE

The optional reader/punch interface is not required.

-23-

Page 33

3. CONNECTION B-63454EN/01

3.4 SETTING THE PERSONAL COMPUTER

The user must choose Others and Setting comm for communicationrelated setting.

For the Series 16i/18i/21i

For the Series 15i

Set each item according to the parameters for the personal computer,

telephone line, and CNC.

(See also: Section 4.9.1)

Set Data Bit, Parity Bit, and Flow Control as follows:

Data Bit = 8, Parity Bit = None, Flow Control = Xon/Xoff

Set the other items according to the parameters for the personal

computer, telephone line, and CNC.

(See also: Section 4.9.1)

-24-

Page 34

B-63454EN/01 3. CONNECTION

3.5 LINE CONNECTION/DISCONNECTION

3.5.1 Line Connection (when Usi ng a Modem Card)

a) Making a connection for the first time

Choose Phone and then D

appears:

Enter the desired telephone number, then click the OK button to

establish the connection.

ial. Then, the following window

b) Making a connection to the same destination more than once

The user can make a connection to a destination by other means

very easily provided that destination is registered in the list of

destinations.

(See also: Section 4.4)

NOTE

The type of telephone line needs to be entered in the

communication settings.

(See also: Section 4.9.1)

3.5.2 Line Disconnection (w hen Usi ng a Modem Card)

Choose Phone and then Hang. The connection is broken.

-25-

Page 35

3. CONNECTION B-63454EN/01

3.5.3 Line Connection/Disconnection (when Connecting an

External Modem Via the RS-232-C Interface)

For the Series 16i/18i/21i

A connection can be made/broken in the same way as when a modem

card is used.

(See also: Section 3.5.1)

(See also: Section 3.5.2)

Before making a connection, set bit 0 of CNC parameter No. 0002 to 1.

After line disconnection, set bit 0 of parameter No. 0002 to 0.

(See also: Section 3.3.2)

For the Series 15i

A connection can be made/broken in the same way as when a line is

connected using a modem card.

(See also: Section 3.5.1)

(See also: Section 3.5.2)

3.5.4 Line Connection/Disconnection (when Making a Direct

Connection Via the RS-232-C Interface)

For the Series 16i/18i/21i

Operation from the host software is not required. To make a

connection, set bit 0 of CNC parameter No. 0002 to 1. To break the

connection, set bit 0 of parameter No. 0002 to 0.

(See also: Section 3.3.2)

For the Series 15i

In communication setting, set RS-232-C for Device, then choose Phone

and the Dial. The line is connected.

-26-

Page 36

B-63454EN/01 3. CONNECTION

3.6 ACCESS RIGHT

3.6.1 About Access Right

To access a CNC for which a password is set to protect the CNC

machine tool information, the access right must be acquired using the

password. Otherwise, the CNC information cannot be acquired.

3.6.2 Password Setting for the CNC

For an explanation of how to set a CNC password, see Appendix B.

For the Series 16i/18i/21i

Parameter No. 211 through No. 213, and No. 221 through No. 223

For the Series 15i

Parameter No. 0042 through No. 0047

3.6.3 Password Registration on the Host Software Side

Before making a connection, register a password by using the setting

dialog box (Communication List Properties) for the communication

destination. Enter an eight-digit password. For an explanation of

dialog box display operation and connection-related operation after

password input, see Section 4.4.3.

Enter passwords.

When a communication destination is registered, passwords are

registered together with the name and telephone number of the

communication destination.

Subsequently, when choosing, and connecting to, a communication

destination displayed on the Phone menu, acquire the access right by

using the password registered here.

-27-

Page 37

3. CONNECTION B-63454EN/01

3.6.4 About Passwords

Password 1 : Password 1: Enter a password for all remote diagnosis

function services.

If an entered password is unacceptable, the following

dialog box is displayed when an attem pt is m ade to m ak e

a connection, and the attempt to connect to the CNC is

rejected:

Password 2 : Enter a password for acquiring the right to access

programs.

If an entered password is unacceptable, the following

dialog box appears when an attempt is made to access a

program, and the attempt to access the program is

rejected:

Password 3 : Enter a password for acquiring the right to access

parameter information.

If an entered password is unacceptable, the following

dialog box appears when an attempt is made to access a

parameter, and the attempt to access the parameter is

rejected:

-28-

Page 38

B-63454EN/01 4. OPERATION

4 OPERATION

-29-

Page 39

4. OPERATION B-63454EN/01

4.1 FUNCTION OVERVIEW

4.1.1 Screen Configuration

When the remote diagnosis host software is started, the following

screen appears:

C

AB

E

F

H

G

A. Diagnosis data display screen : This area displays diagnosis data received from the CNC.

B. CNC screen data display : This area displays screen data received from the C NC. On ly character

data is displayed. Graphics are not displayed. Attributes such as color,

reverse video, and blinking are not transferred.

C. Pull-down menu : Various operation menus are provided.

D. Get Screen button : This button is used to acquire CNC screen data (character data).

E. S oft keys : Sele cti ng a s oft key ha s th e sa me ef fec t as pre ssi ng a s oft key o n th e

CNC.

F. Page UP/Page DOWN : Selecting Page UP/Page DOWN has the same effect as pressing the

MDI key PAGE UP/PAGE DOWN on the CNC.

G. Large Diag Window : Checking the check box enlarges the display of area A.

H. Start:Date&Time : Choosing this item displays the start date and time of communication

and the duration of communication when a modem is used.

D

−30−

Page 40

B-63454EN/01 4. OPERATION

4.1.2 Pull-Down Menu

The menus on the screen are configured as described below.

For the Series 16i/18i/21i

File Edit Phone Screen Receive Send Others Help

File Print

US version >

Japanese version >

eXit

Edit Copy

Copy to file(I)

select Range

Find

Find Next

Mark

Jump

Select all

Erase diag data

Phone Phone List

Dial

Hang

comm List

Phone history

Screen ( 0) POSITION >

( 1) PROGRAM >

( 2) OFFSET >

( 3) SYSTEM >

( 4) MESSAGE >

( 5) CUSTOM >

Prints the currently displayed host software screen data.

Switches the menu language and screen format.

Quits the host software.

Performs operations on the diagnosis data display screen.

Performs operations associated with the connection with the CNC.

Switches the screen display from one CNC screen to another

according to the menu selection.

Receive Display

File > ( 0) Mainte Info

Send Input > Selects the data to be sent to the CNC.

File >

Selects the data to be received from the CNC.

( 1) All Parameters

( 2) All Program

( 3) One Program

( 4) Operation History

( 5) Alarm History

( 6) Receive Signals

-31-

Page 41

4. OPERATION B-63454EN/01

Others Setting comm

Folder setting

Select Path >

AutoGetScreen >

MDIkey >

Keyfree(Q)

CNC MDI Key(C) >

Help Version info

For the Series 15i

File Edit Phone Screen Receive Send Others Help

File Print

US version >

Japanese version >

eXit

Edit Copy

Copy to file(I)

select Range

Find

Find Next

Mark

Jump

Select all

Erase diag data

Makes settings related to the serial port.

Makes directory settings such as file input/output.

Chooses a CNC system.

Chooses whether to transfer screen data automatically.

To be chosen when MDI key input is performed from the personal computer

To be chosen when soft key operation is disabled during operation

Chooses whether to disable MDI operation on the CNC.

Displays the version of the host software.

Prints the currently displayed host software screen data.

Switches the menu language and screen format.

Quits the host software.

Performs operations on the diagnosis data display screen.

Phone Phone List

Dial

Hang

comm List

Phone history

Screen ( 0) POSITION >

( 1) PROGRAM >

( 2) OFFSET >

( 3) SYSTEM >

( 4) MESSAGE >

Receive Display

File > ( 0) Mainte Info

Performs operations associated with the connection with the CNC.

Switches the screen display from one CNC screen to another

according to the menu selection.

Selects the data to be received from the CNC.

( 1) All Parameters

( 2) All Program

( 3) One Program

( 4) Operation / Alarm History

( 5) Circuit Info

( 6) System Alarm

( 7) Receive Signals

−32−

Page 42

B-63454EN/01 4. OPERATION

Send Input >

File >

Others Setting comm

Folder setting

Select Path >

AutoGetScreen >

MDIkey >

Keyfree(Q)

CNC MDI Key(C)>

Help Version info

4.1.3 Other Buttons

Selects the data to be sent to the CNC.

Makes settings related to the serial port.

Makes directory settings such as file input/output.

Not used

Chooses whether to transfer screen data automatically.

Not used

To be chosen when soft key operation is disabled during operation

Not used

Displays the version of the host software.

(a) Get Screen button

This button is used to acquire CNC screen data (character data).

(b) Soft keys

Choosing a soft key has the same effect as pressing a soft key on

the CNC.

(c) Page UP and Page DOWN keys

Choosing these keys has the same effect as pressing the MDI key s

PAGE UP and PAGE DOWN on the CNC.

These buttons are used in combination with each other.

(See also: Section 4.5)

-33-

Page 43

4. OPERATION B-63454EN/01

4.2 FILE MENU

4.2.1 Print

The user can print the data currently displayed on the host software.

NOTE

The printer to be used needs to be set in W indows

beforehand.

4.2.2 US version/Japanese version

The user can select the language used, for example, for the host

software menus.

For the Series 16i/18i/21i

At the same time, the user must choose the type of CNC screen data

display and the number of soft keys.

For the Series 15i

4.2.3 Exit

US version →

80 characters wide : Display in English/80 characters wide/10

soft keys

40 characters wide : Display in English/40 characters wide/5 soft

keys

Japanese version →

80 characters wide : Display in Japanese/80 characters wide/10

soft keys

40 characters wide : Display in Japanese/40 characters wide/5

soft keys

US version : Display in English

Japanese version : Display in Japanese

This menu item quits this software (remote diagnosis host software).

−34−

Page 44

B-63454EN/01 4. OPERATION

4.3 EDIT MENU

4.3.1 Copy

This menu item copies the selected data to the Windows clipboard.

Right-clicking a selected range of data has the same effect.

4.3.2 Copy to file(I)

Selected data can be output to a file. When this menu item is chosen,

the file name selection dialog box appears. When a file name is chosen

in the dialog box, the selected data is output as text data to that file.

4.3.3 select Range

This menu item moves the cursor to the diagnosis data display screen.

4.3.4 Find, Find Next

4.3.5 Mark, Jump

4.3.6 Select all

4.3.7 Erase diag data

The user can search for data displayed on the diagnosis data display

screen.

The jump function enables the user to move the cursor to a desired

position on the diagnosis data display screen. The mark function is

used to set a jump destination. When the m ark function is executed, the

point where the cursor is currently positioned is memorized as a mark

position, and the last specified position becomes a jump destination.

This menu item selects all data on the diagnosis data display screen.

This menu item deletes the data on the diagnosis data display screen.

-35-

Page 45

4. OPERATION B-63454EN/01

4.4 PHONE MENU

4.4.1 Dial

When this menu item is chosen, the following window appears:

Enter the desired telephone number, then click the OK button to start

the connection of the telephone line.

NOTE

The type of telephone line must be entered in the

communication settings.

(See also: Section 4.9.1)

4.4.2 Hang

When this menu item is chosen after the end of remote diagnosis, the

connection is broken.

4.4.3 Phone List, comm List

This function enables a connection to easily be made to a

communication destination registered in the list of communication

destinations. First, a desired communication destination must be

registered in the phone list by using comm List.

(1) When comm List is chosen, the following dialog box appears:

−36−

Page 46

B-63454EN/01 4. OPERATION

(2) To set a new communication destination, choose the New button

with the mouse. To modify an existing communication

destination, choose the communication destination with the

mouse, and the click the Properties button. Then, the following

communication destination setting dialog box appears.

(3) Enter desired information. If a password has been set for the CNC,

enter the password in the password field. Then, click the OK

button.

The screen display returns to the communication destination

setting menu of (1) above. Then, click the Save button to save the

setting, and then click the Exit button.

(4) The communication destination names registered in the list of

communication destinations are displayed in Phone List of Phone.

By choosing from the list, a connection can be made easily.

-37-

Page 47

4. OPERATION B-63454EN/01

Phone list

4.4.4 Phone history

NOTE

Up to ten communication destinations are displayed

on the menu. The order of communication

destinations can be changed by clicking the

UP/DOWN button in co mm List. An item for which

Add Menu List is not checked in the communication

destination setting dialog box is not added to Phone

List.

The history of communication can be checked.

The Name field displays the name of a communication destination if a

connection is made using the list of communication destinations. If a

connection is made using Dial, "Direct Call" is indicated.

−38−

Page 48

B-63454EN/01 4. OPERATION

4.5 SCREEN SWITCHING

The user can switch from one CNC screen to another. The Get Screen

button is used to transfer the information of a switched screen. (See

also: Section 4.1.3)

For the Series 16i/18i/21i

The items indicated below are displayed. Symbols [i], [M], and [T] on

the menu represent those functions dedicated to the i series, M series,

and T series, respectively.

POSITION

- ABSOLUTE - HANDLE INTERRUPT

- RELATIVE - OPERATING MONITOR

- ALL - [i] C Executor

PROGRAM

- MDI PROGRAM - C.A.P.

- PROGRAM - SCHEDULE

- LIBRARY - CYCLE TIME

- CURRENT BLOCK

-NEXT BLOCK

- PROGRAM CHECK - [i] JOG

- PROGRAM RESTART - [i] C Executor

- FLOPPY DIRECTORY

OFFSET

- OFFSET (GEOM,WEAR) -

- SETTING PARAMETER [T] Y-AXIS OFFSET

- WORK COORDINATE -

- MACRO VARIABLE [T] TOOL FORM

- MENU - [iM] C Executor

- OPERATOR’S PANEL [T] BARRIER

- TOOL LIFE - [T] B-AXIS OFFSET

-

[M] CHOPPING PARAMETER - [iT] 2ND OFFSET GEOMETRY

[T] WORK SHIFT

-[i] DATA SERVER

DIRECTORY

[M] TOOL LENGTH MES.-B

[iM] INTERFERENCE CHECK

- [iT] C Executor

-39-

Page 49

4. OPERATION B-63454EN/01

SYSTEM

- PARAMETER

- DIAGNOSE

-PMC

- [I] DATA SERVER

MAINTENANCE

- [I] DATA SERVER MODE

STORAGE

- SYSTEM - [I] VGA COLOR SETTING

-MEMORY

- PITCH ERROR

- SERVO SETTING

- SPINDLE SETTING

-

[I] PERIODICAL

MAINTENANCE DISP

- [I] MAINTENANCE

INFORMATION DISP

- [i] C-SERV - [I] PMM

- M-CODE GRP SETTING

- OPERATION HISTORY

-

[I] PROGRAM TAPE

MEMORY CHECK DISP

- ALL I/O - [I] FSSB SETTING DISPLAY

- [I] C-OPER - [I] C Executor

- [I] DATA S ERVER SETTING

MESSAGE

-ALARM -NETWORK MESSAGE

- EXTERNAL MESSAGE

- ALARM HISTORY

-

OPERATOR’S MESSAGE - [I] FACTOLINK

-

REMOTE DIAGNOSTICS - [I] C Executor

-

EXTERNAL/OPERATOR’S

MESSAGE HISTORY

- [I] DATA SERVER

MESSAGE

CUSTOM

- LANGUAGE - CUSTOM 2

- CUSTOM 1 - CUSTOM 3

For the Series 15i

NOTE

If a screen that cannot be displayed while the CNC is

being diagnosed is chosen, the screen cannot be

switched correctly.

The items below are displayed.

POSITION

- OVER ALL - ABSOLUTE

- RELATIVE - MACHINE

PROGRAM

- PROGRAM TEXT - ACTUAL BLOCK

-

PROGRAM DIRECTORY - OPERATING MONITOR

- PROGRAM CHECK - POSITION DATA

- LAST BLOCK

OFFSET

- TOOL OFFSET - FLOPPY DIRECTORY

- WORK ZERO OFFSET - MEMORY CARD

-

SETTING PARAMETER

-TIMER

COM. SETTING (RS232C,

-

RS422)

SERVICE

-40-

Page 50

B-63454EN/01 4. OPERATION

- PARAMETER - SYSTEM CONFIGURATION

-PMC- PITCH ERROR

COMPENSATION

- SERVO SETTING

- DIAGNOSIS - HPCC

-

DI/DO SIGNAL MONITOR - FSSB SETTING

-

PERIODICAL MAINTENANCE - CONTENTS OF MEMORY

-

MAINTENANCE

INFORMATION

MESSAGE

-ALARM

NOTE

If a screen that cannot be displayed while the CNC is

being diagnosed is chosen, the screen cannot be

switched correctly.

4.5.1 Using the Screen Swit ching Function

The screen of the CNC under remote diagnosis can be switched by

using the screen switching menu, the soft keys on the host software,

and the Page UP/Page DOWN keys. Note that switching switches only,

the CNC screen. Clicking the Get Screen button can transfer the CNC

screen information currently being displayed to the host software.

Thus, the user can view a switched screen on the host software as in the

case of direct CNC operation.

NOTE

1 Information such as coordinates and signal states

cannot be displayed on a real-time basis.

2 Only character data is displayed on the host software.

3 Character attributes (such as color, reverse video,

and the blinking state) cannot be displayed.

(1) A command based on screen selection/page key/soft key

operation is issued with the host software.

Screen selection

Page keys

Soft keys

Personal computer on

the host side

Series 15i/16i/18i/21i

-41-

Page 51

4. OPERATION B-63454EN/01

(2) When the command is received, the CNC screen is switched.

(3) CNC screen information is transferred to the host software by

using the Get Screen button.

GET SCREEN button

Example of screen switching

Display before screen switching

Supplement : By choosing Others and AutoGetScreen, screen

information can also be transferred automatically after

screen switching.

-42-

Page 52

B-63454EN/01 4. OPERATION

Choose Screen, (3) SYSTEM, and then (4) SYSTEM, and then click

the Get Screen button. The screen display changes to the following:

-43-

Page 53

4. OPERATION B-63454EN/01

4.6 RECEIVE DATA

4.6.1 Receive (Display)

The following data can be displayed by choosing Receive and then

Display from the menu.

(0) CNC series and edition (14) Absolute position (27) Cutter compensation number 1

(1) Maintenance information (15) Skip position (28) Cutter com pensation nu mber 2

(16) Servo delay (29) Tool information 1(2) Printed circuit board

information(*1) (17) Acceleration/deceleration delay (30) Tool information 2

(3) Parameter (18) A/D conversion data(*2) (31) Tool number

(4) Program (19) Spindle motor load (32) Alarm state

(5) Offset (33) Ladder title

(6) Macro variable

(7) Diagnostic information (21) Number of tool groups

(8) Signal state (22) Number of tools

(9) Machine position (23) Tool life (36) Modal data

(10) Actual feedrate (24) Tool life counter (37) Status information

(11) Program number (38) Alarm history(*3)

(12) Tool group number

(13) Ladder/PMC series and

edition

(20) Sequence number being

executed (34) Program directory

(35) Memory contents (dedicated to

FANUC)

(25) Tool length compensation

number 1 (39) Signal state (continuous)

(26) Tool length compensation

number 2

*1 Only for the Series 16i/18i/21i

*2 Not usable with the Series 16i/18i/21i

*3 Only for the Series 16i/18i/21i

WARNING

The function for receiving (35) memory contents is

dedicated to FANUC. Using this function incorrectly

can result in an unexpected operation.

NOTE

1 The function f or receiving (18) A/D conversion data

cannot be used with the Series 16i/18i/21i.

2 Data such as actual feedrate and the signal state

cannot be taken in on a real-time basis.

-44-

Page 54

B-63454EN/01 4. OPERATION

Supplement:

(5) Offset

In addition to an offset number, an offset ty pe must be set. Set an

offset type as described below

M series (machining center)

Tool radius Tool length

Wear 0 2

Figure 1 3

(Supplement) Set 0 when there is no tool radius/tool length

distinction and no wear/figure distinction.

T series (lathe)

X-axis Z-axis Tool nose

radius

Wear 0 2 4 6 8

Figure 1 3 5 7 9

Virtual

tool nose

Y-axis

(34) Program directory

For the Series 16i/18i/21i

After a program number, a comm ent and the num ber of characters

used are displayed. If no comment is added to a program, control

in/control out codes are displayed.

As the number of characters used, and the number of characters

indicated in a CNC program directory display is displayed.

<Example of display>

O2114(MAIN PROGRAM)360

O2119(SUB1)120

O2147()60

For the Series 15i

In a program directory, only the program numbers are displayed.

(39) Signal state (continuous)

The state of a specified one-byte PMC signal is automatically and

continuously read and displayed. So, the user can use this

function to check whether a signal is changing. Because of

transmission speed limitations, however, the state of a signal

cannot be displayed completely on a real-time basis.

-45-

Page 55

4. OPERATION B-63454EN/01

4.6.2 Receive (File)

The data files listed below can be received by choosing Receive and

File from the menu.

(See also: Section 4.8.2)

For the Series 16i/18i/21i

(0) Maintenance information

(1) All parameters

(2) All programs

(3) One program

(4) Operation history

(5) Alarm history

(6) Reception of signals in a batch

Supplement:

The function for receiving (4) Operation history receives a CNC

operation history recorded on the CNC, as a data file. (The same data

as that output to the CNC can be acquired.) For details of the operation

history, including the format of operation history data, refer to

"FANUC Series 16i/18i/21i Maintenance Manual (B-63005EN)".

For the Series 15i

(0) Maintenance information

(1) All parameters

(2) All programs

(3) One program

(4) Operation history/alarm history

(5) Printed circuit board information

(6) System alarm

(7) Reception of signals in a batch

NOTE

Before maintenance information can be received, the

CNC must be placed in edit mode (with the Series 15i

only).

-46-

Page 56

B-63454EN/01 4. OPERATION

4.7 SEND DATA

4.7.1 Send (Input)

The following data can be entered by choosing Send and Input.

(1) Parameter (4) Signal

(2) Offset (5) Message

(3) Macro variable

Supplement:

(2) Offset

In addition to an offset number, an offset type needs to be set. Set

an offset type as described below.

M series (machining center)

Tool radius Tool length

Wear 0 2

Figure 1 3

(Supplement) Set 0 when there is no tool radius/tool length

distinction and no wear/figure distinction.

T series (lathe)

X-axis Z-axis Tool nose

radius

Wear 0 2 4 6 8

Figure 1 3 5 7 9

Virtual

tool nose

Y-axis

(5) Message

With this function, a message entered through the host computer

can be displayed on the CNC screen. When a message is sent, the

CNC screen is automatically switched to the remote diagnosis

screen to display the sent message. Only alphanum eric characters

can be used.

-47-

Page 57

4. OPERATION B-63454EN/01

4.7.2 Send (File)

The data described below can be sent by choosing Send and then File.

(See also: Section 4.8.2)

(1) All parameters

(2) Program transmission

(3) Program check

NOTE

1 Bef ore parameters can be entered or all parameters

can be sent, the CNC must be placed in the

emergency stop state.

2 Bef ore programs can be sent or checked, the CNC

must be placed in edit mode.

3 For the Series 16i/18i/21i

If the file size of data to be sent or checked exceeds a

limit described below, the data cannot be sent or

checked. If a file exceeding a size described bel ow is

sent, the remote diagnosis software and CNC will

hang.

Parameter: 1500 bytes

Program: 400 bytes

-48-

Page 58

B-63454EN/01 4. OPERATION

4.8 OTHER MENUS

4.8.1 Setting comm

The following dialog box appears.

For the Series 16i/18i/21i

For the Series 15i

Set each item as described below.

Port : Set a serial port number of the personal computer.

BPS : Set the same transmission speed as that set on the

CNC.

DATA Bit : Set 8.

Stop Bit : Set 1.

Parity Bit : Set None when using a modem line.

Flow Control : Set Xon/Xoff when making a direct connection to the

CNC without using a modem.

Tone/Pulse : Specify the type of telephone line to be connected to

the host.

Device : Set Modem when using a modem line.

Set RS-232-C when making a direct connection to the

CNC without using a modem.

Note, however, that even if RS-232-C is set, the value

is not held. Instead, the setting in the dialog box

returns to Modem.

Port : Set a serial port number of the personal computer.

BPS : Set the same transmission speed as that set on the

CNC.

DATA Bit : Set 8.

Stop Bit : Set the same number of stop bits as that set on the

CNC.

Parity Bit : Set None.

-49-

Page 59

4. OPERATION B-63454EN/01

Flow Control : Set Xon/Xoff.

Tone/Pulse : Specify the type of a telephone line to be connected to

the host.

Device : Set Modem when using a modem line.

Set RS-232-C when making a direct connection to the

CNC without using a modem.

Note, however, that even if RS-232-C is set, the value

is not held. Instead, the setting in the dialog box

returns to Modem.

4.8.2 Folder setting

This menu item is used to make settings related to those directories

used for host software operation.

Set each item as described below.

Home directory : Directory in which the remote diagnosis host

software is installed

Upload file directory : Default directory used for data transfer from

the host to the CNC.

See also: Section 4.7.2

Download file directory : Default directory used for data transmission

from the CNC to the host.

See also: Section 4.6.2

The methods described below are available to modify the settings of

the Folder Setting dialog box.

a) Using the keyboard

(1) Using the [tab] key, position the cursor to an item to be set.

(2) Enter data through the keyboard.

b) Method using the mouse

(1) With the mouse, move the cursor to an item to be set.

(2) Click the [Browse] button to display the folder selection

dialog box. Select a desired folder.

c) Methods a) and b) can be combined for folder selection.

-50-

Page 60

B-63454EN/01 4. OPERATION

4.8.3 Select Path

For the Series 16i/18i/21i

When diagnosing a multi-path CNC, select a path to be diagnosed.

NOTE

The loader cannot be diagnosed.

This function can be used only with the Series

16i/18i/21i.

4.8.4 AutoGetScreen

When On displayed on the pull-down menu is chosen, screen data can

be transferred simply by choosing a page key or soft key on the screen.

4.8.5 CNC MDI Key(C)

4.8.6 Keyfree(Q)

By choosing Disable displayed on the pull-down menu, MDI operation

from the CNC can be disabled. The status RMT DGN, indicated during

remote diagnosis on the CNC stops blinking, and is turned on.

NOTE

This function can be used only with the Series

16i/18i/21i.

When each soft key is locked (with the color changed to gray) to

disable key operation, choosing Keyfree(Q) cancels key locking to

enable soft key operation.

-51-

Page 61

4. OPERATION B-63454EN/01

4.8.7 MDIkey

When On displayed on the pull-down menu is chosen, the input

operation of the MDI keys other than the function key s and soft keys on

the CNC can be performed through the full keyboard on the personal

computer.

(1) Select On. Then, the MDI button (A) appears.

(2) Click the MDI button. The MDI key operation dialog box (B)

appears.

(3) Key in data, then click the OK button. Then, the keyed data is

transferred to the CNC.

(4) When performing a search operation, press the soft key SEARCH.

(5) When making a setting, press the INPUT key.

NOTE

This function can be used only with the Series

16i/18i/21i.

-52-

Page 62

B-63454EN/01 4. OPERATION

4.9 HELP MENU

4.9.1 Version info

This menu item displays the version of the host software.

Example of display

-53-

Page 63

Page 64

APPENDIX

Page 65

Page 66

B-63454EN/01 APPENDIX A. USABLE MODEM CARDS

A USABLE MODEM CARDS

The operation of the cards listed below has been confirmed.

(1) Cards manufactured by TDK Corp.

Type Product name Remarks

Modem card (analog) DF2814B

DF3314ES

DF3314EX

DF5600

DF5660

For analog lines

Digital communication card DVP3314S

DP9600

(2) Cards manufactured by NTT DOCOMO

Type Product name Remarks

Digital communication card 9600MarkII For digital mobile telephone

* The product names are generally trademarks or registered

trademarks of each manufacturer.

* Digital mobile telephone (digital communication cards) can be

used only in Japan.

* Even in Japan, digital mobile telephone may not be usable,

depending on the reception conditions.

For digital mobile telephone

-57-

Page 67

B.

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

APPENDIX B-63454EN/01

B CNC PARAMETERS RELATED TO

REMOTE DIAGNOSIS

Parameters for the Series 16i/18i/21i

#7 #6 #5 #4 #3 #2 #1 #0

0002 RDG

[Data type] Bit

# 0 RDG Remote diagnosis is:

0: Not performed.

1: Performed.

When performing remote diagnosis using an RS-232-C serial port, set

this parameter to 1 after modem and cable connection and preparation.

When a modem card is used, this parameter need not be set.

#7 #6 #5 #4 #3 #2 #1 #0

0201 MCB NCR ASC SB2

[Data type] Bit

# 0 SB2 The number of stop bits is:

0: 1

1: 2

When performing remote diagnosis, set this parameter to 0.

# 1 ASC As code used for data output:

0: ISO code is used.

1: ASCII code is used.

When performing remote diagnosis, set this parameter to 1.

# 2 NCR When an EOB (End of Block) is output:

0: "LF" "CR" "CR" are output.

1: "LF" only is output.

When performing remote diagnosis, set this parameter to 1.

# 6 MCB Data is transferred between the modem card and CNC:

0: At a baud rate of 9600 bps.

1: At a baud rate set in parameter No. 203.

For details of the settings when MCB = 1, see parameter No. 203.

-58-

Page 68

B-63454EN/01 APPENDIX B.

0203 Baud rate (for remote diagnosis)

[Data type] Byte

Set a baud rate to be used for data transfer in remote diagnosis

according to the tables below.

When an RS-232-C serial port is used

Setting Baud rate (bps) Setting Baud rate (bps)

1 50 7 600

2 100 8 1200

3 110 9 2400

4 150 10 4800

5 200 11 9600

6 300 12 19200

When a modem card is used

(when bit 6 (MCB) of parameter No. 201 = 1)

Setting Baud rate (bps) Setting Baud rate (bps)

1 28800 7 600

2 38400 8 1200

3 57600 9 2400

4 - 10 4800

5 - 11 9600

6 300 12 19200

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

NOTE

The baud rates above are applicable to data transfer

between the CNC and modem.

The communication baud rate may fall below the

setting, depending on the modem and

communication line.

0204 Channel for remote diagnosis

[Data type] Byte

[Valid data range] 0, 1, 2

The interface used for remote diagnosis is:

0, 1: RS-232-C serial port 1 (channel 1)

2: RS-232-C serial port 2 (channel 2)

For remote diagnosis using the RS-232-C interface, the optional

reader/punch interface is required.

0211 Password 1 for remote diagnosis

0212 Password 2 for remote diagnosis

0213 Password 3 for remote diagnosis

[Valid data range] 1 to 99999999

Set passwords for using the remote diagnosis function. With the

remote diagnosis function, the passwords described below are used to

prevent unauthorized persons from accessing system parameters and

machining programs without permission.

-59-

Page 69

B.

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

Password 1:

Password 2:

Password 3:

APPENDIX B-63454EN/01

Set a password for all remote diagnosis serv ices. (If this password

is not entered on the host (personal computer, for example), none

of the remote diagnosis function services are available.)

Set a password for part programs. (If this password is not entered

on the host (personal computer, for example), operations such as

program input/output and checking cannot be performed.)

Set a password for parameters. (If this password is not entered on

the host (personal computer, for example), operations such as

parameter input/output cannot be performed.)

NOTE

Once a value other than 0 is set as a password, the

password can be changed only if the same value is

set as the corresponding keyword (parameter No.

221 to No. 223). If a value other than 0 is set as a

password, the setting of the password is not

displayed on the parameter screen (a blank

appears). Care is necessary when setting the

password.

0221 Keyword 1 for remote diagnosi s

0222 Keyword 2 for remote diagnosi s

0223 Keyword 3 for remote diagnosi s

[Valid data range] 1 to 99999999

Set the keyword corresponding to each password for the remote

diagnosis function.

Keyword 1: Keyword for password 1 (parameter No. 211)

Keyword 2: Keyword for password 2 (parameter No. 212)

Keyword 3: Keyword for password 3 (parameter No. 213)

When a value other than 0 is set as a password (parameter No. 211 to

No.213), the password can be changed only if the same value is set as

the corresponding keyword.

NOTE

The values of the keywords are set to 0 when the

power is turned on. The parameter screen does not

display the setting of each keyword (a blank

appears).

Parameters for the Series 15i

#7 #6 #5 #4 #3 #2 #1 #0

-60-

Page 70

B-63454EN/01 APPENDIX B.

0000 RDN EIA NCR ISP

[Input type] Setting input

[Data type] Bit

# 2 ISP 0: ISO codes includes a parity bit.

1: ISO code does not includes a parity bit.

The parity bit of ISO code is channel 8 of punched tape. When

performing remote diagnosis, set this parameter to 1.

# 3 NCR When an EOB is punched with ISO code:

0: "LF" "CR" "CR" are punched.

1: "LF" only is punched.

When performing remote diagnosis, set this parameter to 1.

# 4 EIA The punch code is:

0: ISO code

1: EIA code

When performing remote diagnosis, set this parameter to 0.

# 6 RDN The remote diagnosis function is:

0: Disabled.

1: Enabled.

When this parameter is set to 1, remote diagnosis is performed using a

set communication device. Before setting this param eter to 1, m ake all

necessary communication settings. Before modifying the

communication settings, set this parameter to 0. Upon the completion

of remote diagnosis, set this parameter to 0.

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

NOTE

0020 I n terface num ber of an input device for foreground

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 to 16

Set the interface number of an input device for foreground.

When performing remote diagnosis, set this bit to 12.

0021 Interface number of an output device for foreground

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 to 16

Set the interface number of an output device for foreground.

When performing remote diagnosis, set this bit to 12.

When this parameter is set to 1, the set

communication device is used exclusively. So, while

this parameter is 1, input/output operations such as

program read and punch operations must not be

performed from the NC.

0022 Interface num ber of an i nput device for background

[Input type] Setting input

-61-

Page 71

B.

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

[Data type] Integer

[Valid data range] 0 to 16

Set the interface number of an input device for background.

When performing remote diagnosis, set this bit to 12.

0023 Interface number of output device for background

[Input type] Setting input

[Data type] Integer

[Valid data range] 0 to 16

Set the interface number of output device for background.

When performing remote diagnosis, set this bit to 12.

0040 Channel for remote diagnosis

[Input type] Setting input

[Data type] Integer

[Valid data range] 1 to 3

The interface used for remote diagnosis is:

1: RS-232-C serial port 1 (JD5A)

2: RS-232-C serial port 2 (JD5B)

3: RS-232-C serial port 3 (JD36A)

17: Modem card (PCMCIA card slot on the LCD unit)

APPENDIX B-63454EN/01

0042 Password 1 for remote diagnosis

[Input type] Lock parameter

[Data type] Integer

[Valid data range] 0 to 99999999

0043 Keyword 1 for remote diagnosi s

[Input type] Lock parameter

[Data type] Integer

[Valid data range] 0 to 99999999

0044 Password 2 for remote diagnosis

[Input type] Lock parameter

[Data type] Integer

[Valid data range] 0 to 99999999

0045 Keyword 2 for remote diagnosi s

[Input type] Lock parameter

[Data type] Integer

[Valid data range] 0 to 99999999

0046 Password 3 for remote diagnosis

[Input type] Lock parameter

[Data type] Integer

[Valid data range] 0 to 99999999

0047 Keyword 3 for remote diagnosi s

[Input type] Lock parameter

-62-

Page 72

B-63454EN/01 APPENDIX B.

[Data type] Integer

[Valid data range] 0 to 99999999

Parameter No. 0042, No. 0044, and No. 0046 above are used to set

passwords for using the remote diagnosis function.

With the remote diagnosis function, the passwords described below are

used to prevent unauthorized persons from accessing system

parameters and machining programs without permission.

Password 1:

Set a password for all remote diagnosis serv ices. (If this password

is not entered on the host (personal computer, for example), none

of the remote diagnosis function services are available.)

Password 2:

Set a password for part programs. (If this password is not entered

on the host (personal computer, for example), operations such as

program input/output and checking cannot be performed.)

Password 3:

Set a password for parameters. (If this password is not entered on

the host (personal computer, for example), operations such as

parameter input/output cannot be performed.)

Parameter No. 0043, No. 0045, and No. 0047 above are used to set the

keywords corresponding to the passwords for the remote diagnosis

function.

Keyword 1: Keyword for password 1 (parameter No. 0042)

Keyword 2: Keyword for password 2 (parameter No. 0044)

Keyword 3: Keyword for password 3 (parameter No. 0046)

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

When a value other than 0 is set as a password (parameter No. 0042, No.

0044, or No. 0046), the password can be changed only if the same value

is set as the corresponding keyword.

NOTE

5001 Device number of a reader/punch connected to JD5A of the main unit

[Input type] Setting input

[Data type] Integer

[Valid data range] 1 to 6

Once a value other than 0 is set as a password, the

password can be changed only if the same value as

the corresponding keyw ord (parameter No. 0043, No.

0045, or No. 0047) is set. If a value other than 0 is set

as a password, the setting of the password is not

displayed on the parameter screen (a blank

appears). Care is necessary when setting

passwords.

The values of the keywords are set to 0 when the

power is turned on. The parameter screen does not

display the setting of each keyword (a blank

appears).

-63-

Page 73

B.

CNC PARAMETERS RELATED TO REMOTE DIAGNOSIS

Set the device number of a reader/punch connected to the JD5A

connector. In parameters No. 5100 through No. 5162, set the