Page 1

Computer Numerical Controls

Computer Numerical Controls

Computer Numerical ControlsComputer Numerical Controls

GE Fanuc Automation Europe

GE Fanuc Automation Europe

GE Fanuc Automation EuropeGE Fanuc Automation Europe

Series

Series 15

SeriesSeries

15

1515

- MODEL A

- MODEL A

- MODEL A- MODEL A

/ 150

/ 150

i

/ 150 / 150

i

Connection Manual

Connection Manual

Connection ManualConnection Manual

(Hardware)

(Hardware)

(Hardware)(Hardware)

B-63323EN/03

B-63323EN/03

B-63323EN/03B-63323EN/03

TECHNOLOGY AND MORE

TECHNOLOGY AND MORE

TECHNOLOGY AND MORETECHNOLOGY AND MORE

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by ® or ™ in the main body.

Page 3

B–63323EN/03

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

Page 4

B–63323EN/03

Table of Contents

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . .

1. GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONFIGURATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INSTALLATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CABINET 7. . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Environmental Conditions Around the Cabinet 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Installation Conditions for the CNC and Servo Unit Inside the Cabinet 8. . . . . . . . . . . . . . . . . . . . . . . .

3.2 POWER REQUIREMENTS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL

MAGNETIC CABINET 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 PROTECTION OF PARTS INSIDE A CABINET OR A PENDANT BOX FROM DUST 12. . . . . . .

3.5 THERMAL DESIGN OF THE CABINET 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Temperature Rise within the Cabinet 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Cooling by Heat Exchanger 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Calorific V alue of Each Unit 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 ACTION AGAINST NOISE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 Separating Signal Lines 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Grounding 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 Grounding Units 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 Noise Suppresser 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.5 Cable Clamp and Shield Processing 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 MEASURES AGAINST SURGES DUE TO LIGHTNING 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 Installation Procedure of Surge Protector 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 Notes 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.3 Examples of Surge Protectors 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 CONTROL UNIT 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 Configuration and Installation of the Control Unit 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.2 Replacing the Battery for Memory Backup 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 CABLE–LEAD–IN DIAGRAM 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Control Unit Periphery Connector Layouts 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 LCD Unit Periphery Connector Layout 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TOTAL CONNECTION 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 CONNECTIONS BETWEEN CONTROL UNITS 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 CONNECTIONS BETWEEN SERVO CARD 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CONNECTIONS BETWEEN LCD UNIT 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. POWER SUPPLY UNIT CONNECTION 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 POWER SOURCE UNIT PANEL CONNECTOR LAYOUT 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 POWER SUPPLY CONNECTION 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Connection when an Input Unit is Used 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Power ON/OFF Sequence 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. CONNECTION OF I/O UNITS TO MACHINE INTERFACE 62. . . . . . . . . . . . . . . . . .

6.1 GENERAL 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 5

Table of Contents

B–63323EN/03

6.2 CONNECTION OF THE FANUC I/O LINK 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Connection of FANUC I/O Link by Electric Cable 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Connection of FANUC I/O Link Optical Fiber Cable 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 CONNECTION OF CONNECTOR PANEL I/O MODULE 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Configuration 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Connection Diagram 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 Module Specification 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 DI/DO Connector Pin Assignment 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.5 DI (Input Signal) Connection 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.6 DO (Output Signal) Connection 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.7 DI/DO Signal Ratings 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.8 2A–Output Connector Pin Assignment Diagram 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.9 2A DO (Output Signal) Connection 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.10 2A–Output DO Signal Ratings 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.11 Analog Input Connector Pin Assignment Diagram 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.12 Analog Input Signal Connection 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.13 Analog Input Signal Ratings 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.14 Analog Input Specification 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.15 Manual Pulse Generator Connection 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.16 Cable Length for Manual Pulse Generator 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.17 Connection of Basic and Extension Modules 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.18 Module Installation 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.19 Other Notes 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.20 Distribution I/O Setting 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 CONNECTION OF OPERATOR’S PANEL I/O MODULE (FOR MATRIX INPUT) 107. . . . . . . . . . .

6.4.1 Overall Connection Diagram 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Power Connection 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 DI/DO Connector Pin Arrangement 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.4 DI (General–purpose Input Signal) Connection 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.5 DI (Matrix Input Signal) Connection 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.6 DO (Output Signal) Connection 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.7 Manual Pulse Generator Connection 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.8 External View 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.9 Specifications 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.10 Other Notes 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 CONNECTION OF OPERATOR’S PANEL I/O MODULE (NOT FOR MATRIX INPUT) 124. . . . . .

6.5.1 Overall Connection Diagram 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Power Connection 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 DI/DO Connector Pin Arrangement 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.4 DI (General–Purpose Input Signal) Connection 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.5 DO (Output Signal) Connection 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.6 Manual Pulse Generator Connection 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.7 External View 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.8 Specifications 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.9 Other Notes 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 CONNECTION OF THE FANUC I/O UNIT–MODEL A 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Structure of F ANUC I/O Unit–MODEL A 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Outer Dimensions 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 Mounting and Dismounting Modules 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.4 Connection Diagram 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.5 Connecting Input Power Source 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.6 Grounding 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.7 Connecting Signal Cables 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.8 Connecting with I/O Modules 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.9 Digital Input/Output Module 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.10 Correspondence between I/O Signals and Addresses in a Module 151. . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 6

B–63323EN/03

6.7 CONNECTION OF MACHINE OPERATOR’S PANEL INTERFACE UNIT 153. . . . . . . . . . . . . . . . .

6.8 CONNECTING THE CONNECTION UNIT 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9 CONNECTION OF OPERATOR’S PANEL CONNECTION UNIT 202. . . . . . . . . . . . . . . . . . . . . . . . .

6.10 CONNECTION OF SOURCE OUTPUT OPERATOR’S PANEL CONNECTION UNIT 216. . . . . . . .

6.11 ADDRESS–FIXED SIGNALS 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12 CONNECTION TO THE MACHINE OPERATOR’S PANEL 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

6.6.11 Number of Points for I/O Unit–MODEL A 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.1 Function Overview 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.2 System Configuration 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.3 Signal Assignment 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.4 Interface 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.5 PMC Addresses 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.6 Major Connection Precautions 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.7 State of the LEDs on the Machine Operator’s Panel Interface Unit 169. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.8 Connector (on the Cable Side) Specifications 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7.9 Machine Operator’s Panel Interface Unit Dimension Diagram (Including Connector Locations) 171. . . . .

6.7.10 Machine Operator’s Panel Interface Unit Mounting Dimension Diagram 172. . . . . . . . . . . . . . . . . . . . . . .

6.7.11 Fuse Mounting Position 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.1 Connecting Connection Unit 1 and Connection Unit 2 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.2 Input Signal Regulations for the Connection Unit 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.3 Connector Pin Assignment for the Connection Unit 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8.4 Details of the Connection between the Connection Unit and the Machine 183. . . . . . . . . . . . . . . . . . . . . .

6.8.5 External View of the Connection Unit 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.1 Input Signal Regulations for the Operator’s Panel Connection Unit 203. . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.2 Output Signal Regulations for the Operator’s Panel Connection Unit 204. . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.3 Connector Layout for Sink Output Operator’s Panel Connection Unit 206. . . . . . . . . . . . . . . . . . . . . . . . .

6.9.4 Details of the Connection between the Sink Output Operator’s Panel Connection Unit

and the Machine 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.9.5 External View of Sink Output Operator’s Panel Connection Unit 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.10.1 Source Output Operator’s Panel Connection Unit Input Signal Standard 217. . . . . . . . . . . . . . . . . . . . . . .

6.10.2 Output Signal Standard for Source Output Operator’s Panel Connection Unit 219. . . . . . . . . . . . . . . . . . .

6.10.3 ALARM LEDs on Source Output Operator’s Panel Connection Unit 222. . . . . . . . . . . . . . . . . . . . . . . . .

6.10.4 Connector Pin Assignment Addresses of Source Output Operator’s Panel Connection Unit 224. . . . . . . . .

6.10.5 Details of Machine Side Connections of Source Output Operator’s Panel Connection Unit 226. . . . . . . . .

6.10.6 External Dimensions of Source Output Operator’s Panel Connection Unit 233. . . . . . . . . . . . . . . . . . . . . .

6.12.1 Overview 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.2 T otal Connection Diagram 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3 Each Connections 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.1 Pin assignment 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.2 Power supply connection 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.3 MDI connection 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.4 I/O Link connection 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.5 Emergency stop signal connection 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.6 Power ON/OFF control signal connection 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.7 DI (input signal) connection 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.8 DO (output signal) connection 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.9 Manual pulse generator connection 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.3.10Connector (on the cable side) specifications. 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.4 DI/DO Address 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.4.1 Keyboard of main panel 252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.4.2 Override signals 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.5 DI/DO Mapping 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 7

Table of Contents

6.12.6 Specifications 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.1 Environmental requirement 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.2 Main panel A/B/A1/B1 specification 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.3 Sub panel A/B/B1/C/C1 specification 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.4 Power supply specification 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.5 General–purpose DI signal definition 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.6.6 General–purpose DO signal definition 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.7 Key Symbol Indication on Machine Operator’s Panel 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.7.1 Meaning of key symbols 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.7.2 Detachable key top 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.8 Others 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.9 Connector Locations 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

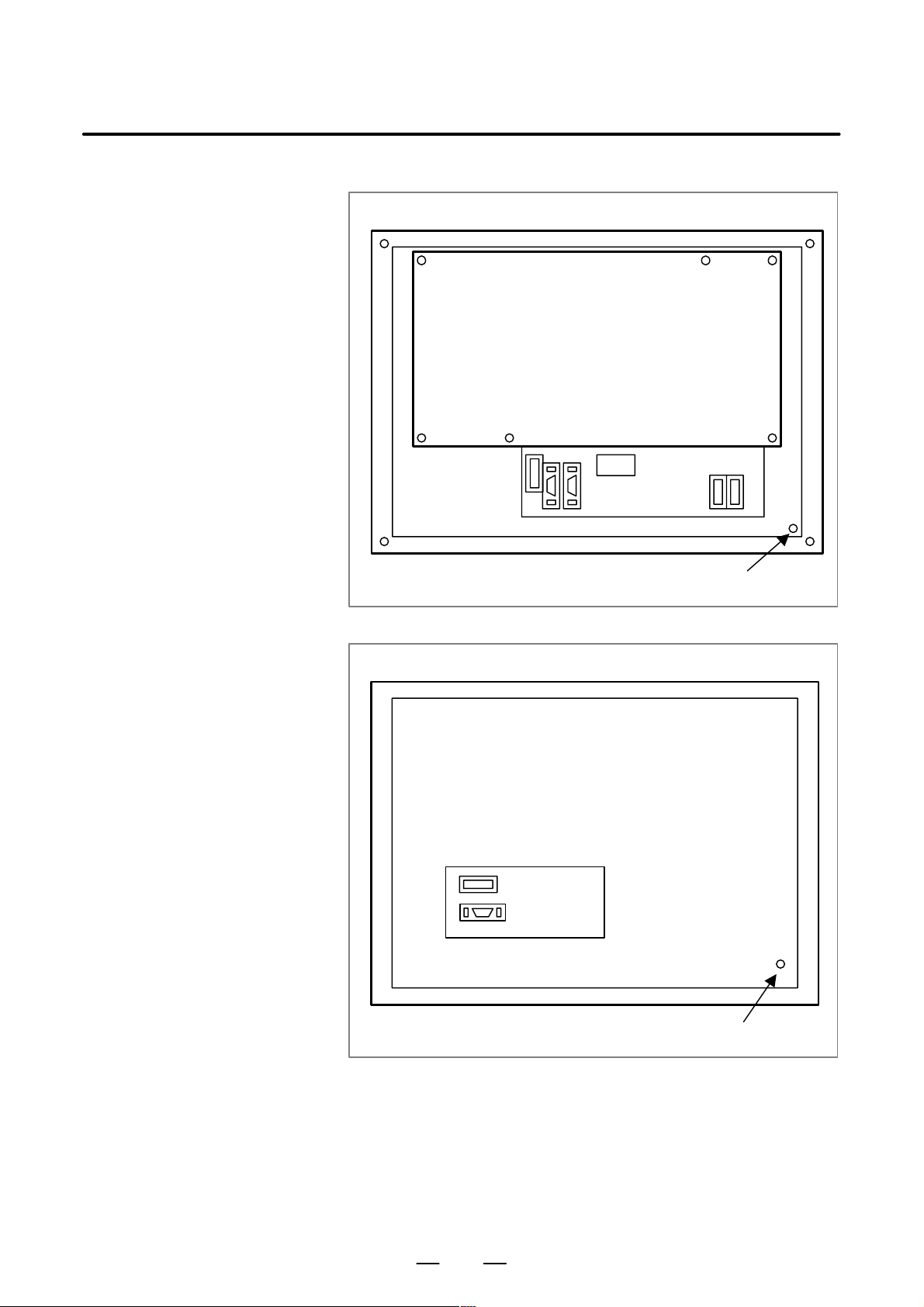

6.12.9.1 Connector locations of main panel A/A1 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.12.9.2 Connector locations of main panel B/B1 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63323EN/03

7. CONNECTION TO CNC PERIPHERALS 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 LCD UNIT (DISPLAYUNIT FOR CNC EXCLUSIVE USE) INTERFACE 266. . . . . . . . . . . . . . . . . .

7.1.1 Connection of 1LCD Unit 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1.1 Conection of LCD unit (for 1LCD connection) 267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1.2 Conection of LCD unit (for 2LCDs connection) 268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Connection of MDI Unit (with CNC–Only Display Used) 269. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 MDI Unit Switch Connection (when LCD Units for Two–LCD Connection are Used) 271. . . . . . . . . . . .

7.1.4 MDI Unit Connection (with No CNC–Only Display Used) 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.5 Mounting the PCMCIA Blind Cover on an LCD Unit for Two–LCD Connection 273. . . . . . . . . . . . . . . .

7.2 I/O UNIT INTERFACE 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 RS–232C Serial Port (JD5A, JD5B, JD5C) 274. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 RS–232C Serial Port (JD36A) 275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 RS422 Serial Port (JD6A, JD6B) 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Connection with FANUC Handy File 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 MANUAL PULSE GENERATOR INTERFACE 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 HIGH–SPEED SKIP (HDI) SIGNAL INTERFACE 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 SPINDLE INTERFACE 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 α Spindle Interface 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Analog Spindle Interface 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Position Coder Interface 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.4 Connection of 1 to 4 Serial Spindles 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 SERVO INTERFACE (FSSB) 296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Connection Example When High–Speed HRV Current Control is not Used 296. . . . . . . . . . . . . . . . . . . .

7.6.2 Connection Example when High–Speed HR V Current Control is Used 298. . . . . . . . . . . . . . . . . . . . . . . .

7.6.3 Requirements for the FSSB Line 299. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4 Separate Detector Interface Unit 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.1 Separate detector interface unit 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.2 Power source connection 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.3 Battery connection for separate absolute detector 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.4 Linear scale interface (parallel interface) 303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.5 Linear scale interface (serial interface) 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.6 Separate pulse coder interface 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.7 Input signal rules 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.8 Connector layout 308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.4.9 Cautions for mounting separate detector interface unit 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 8

B–63323EN/03

Table of Contents

7.7 DATA SERVER INTERFACE 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.1 Data Server Board A1 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.2 Data Server Board A2 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.3 Ethernet Board 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 GENERAL–PURPOSE VOLTAGE INPUT INTERFACE 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 REMOTE BUFFER INTERFACE 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.1 Serial Communication Board A1 (RS–232–C) 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.2 Serial Communication Board A2 (RS–422) 320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10 PROFIBUS 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.1 T otal Connection Diagram of PROFIBUS 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.2 Connectors 323. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11 DEVICENET 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.1 Connection of DeviceNet 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.1.1 Master function 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.1.2 Slave function 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.2 Connector 325. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. HIGH–SPEED SERIAL BUS (HSSB) 326. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 OVERVIEW 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 CAUTIONS 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 CONNECTION DIAGRAM 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 SETTING UP THE HSSB INTERFACE BOARD ON THE CNC 329. . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 PERSONAL COMPUTER SPECIFICATION 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Personal Computer Specifications Required if the ISA Bus Board is Used 331. . . . . . . . . . . . . . . . . . . . . .

8.5.2 Personal Computer Specifications Required if the PCI Bus Board is Used 332. . . . . . . . . . . . . . . . . . . . . .

8.6 INSTALLATION ENVIRONMENT 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 PROCEDURE FOR INSTALLING PERSONAL COMPUTER INTERFACE BOARDS 333. . . . . . . .

8.8 HANDLING PRECAUTIONS 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 RECOMMENDED CABLES 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. FANUC INTELLIGENT TERMINAL 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 OVERVIEW 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 NOTES 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 HARDWARE SPECIFICATIONS 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 COMPLETE CONNECTION DIAGRAMS 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 If Neither the Soft Keys Nor the Touch Panel is Attached 339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 If the Soft Keys are Attached But the Touch Panel is Not Attached 340. . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 If the T ouch Panel is Attached But the Soft Keys are Not Attached 341. . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 SPECIFICATIONS 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 Installation Environment Conditions 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Power Specifications 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 Shutdown 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 INSTALLATION SPACES 345. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 CONNECTION TO PERIPHERAL DEVICES 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.1 Locations of Connectors 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.2 Main Power Input 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.3 Hard Disk Drive 349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.4 Floppy Disk Drive (Signals and Power) 350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.5 Full Keyboard 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 9

Table of Contents

9.7.6 Mouse 353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.7 Parallel Port 354. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.8 Serial Port 2 355. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.9 Serial Port 1 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.10 High–speed Serial Bus (HSSB) 359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.11 Soft Keys (for the Intelligent T erminal with the Soft Keys Attached) 360. . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.12 PCMCIA Card 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63323EN/03

9.8 ISA EXPANSION BOARD 361. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.1 Installation Procedure 361. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.2 Notes on Use 362. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.FANUC PANEL i 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 OVERVIEW 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 ATTENTION 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 HARDWARE SPECIFICATIONS 368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 TOTAL CONNECTION 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 Without Soft–Key & Touch–Panel 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 With Soft–Key , W ithout Touch–Panel 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.3 With Touch–Panel, Without Soft–Key 372. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.4 With Soft–Key and Touch–Panel 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 SPECIFICATION 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.1 Environment 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.2 Power Specification 375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5.3 Shutdown Operation 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 MOUNTING SPACE 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.1 Basic Unit 10.4” LCD Type 377. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.2 Basic Unit 12.1” LCD T ype 378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.3 Basic Unit 15.0” LCD T ype 378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6.4 HDD Unit 379. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 CONNECTION TO PERIPHERAL 380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.1 Connector Location 380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.2 Main Power Input 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.3 Serial Port 1 382. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.4 Serial Port 2+USB 384. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.5 Parallel Port 386. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.6 High Speed Serial Bus (HSSB) 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.7 Mouse 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.8 Full Keyboard 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.9 Hard Disk Drive 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.10 Floppy Disk Drive (Signal & Power) 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.11 Soft–Key (P ANEL i with Soft Key) 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.12 PCMCIA Card 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 METHOD OF MOUNTING PCI EXTENSION BOARD 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.1 Usable Board 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.2 Method of Mounting PCI Extension Board 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.3 Method of Mounting PCI Extension Board 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.EMERGENCY STOP SIGNAL 396. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 10

B–63323EN/03

Table of Contents

APPENDIX

A. UNIT EXTERNAL DIMENSION DIAGRAMS 401. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. EXTERNAL DIMENSIONS OF CONNECTORS 450. . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. 20–PIN INTERFACE CONNECTORS AND CABLES 475. . . . . . . . . . . . . . . . . . . . . . .

C.1 BOARD–MOUNTED CONNECTORS 476. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 CABLE CONNECTOR 477. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 CABLE CONNECTORS 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4 RECOMMENDED CONNECTORS, APPLICABLE HOUSINGS, AND CABLES 480. . . . . . . . . . . .

C.5 CABLE WIRES 481. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. OPTICAL FIBER CABLE 489. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. LIQUID CRYSTAL DISPLAY (LCD) 502. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. MEMORY CARD INTERFACE 504. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. TERMINAL MODULE 509. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.1 OVERVIEW 510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.2 TOTAL CONNECTION 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3 CONNECTION OF EACH PART 512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.1 Pin Assignment 512. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.1.1 Connector Pin Assignment of Connector Panel I/O Module 512. . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.1.2 Connector–terminal Block Pin Assignment of Terminal Module 513. . . . . . . . . . . . . . . . . . . . . . .

G.3.2 Connection of 24VDC Power Supply and Signals 514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.2.1 24VDC Power Supply Connection 514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.2.2 DI (Input Signal) Connection 515. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.3.2.3 DO (Output Signal) Connector 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.4 MOUNTING TERMINAL MODULE 519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5 SPECIFICATIONS 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5.1 Installation Specifications 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5.2 Ordering Specifications 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5.3 Module Specifications 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5.4 Power Voltage 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.5.5 DI/DO (Input/output Signal Specification) 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H. TERMINAL MODULE A 521. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.1 OVERVIEW 522. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.2 TOTAL CONNECTION 523. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3 CONNECTION OF EACH PART 524. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3.1 Pin Assignment 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3.2 Connection of 24VDC Power Supply and Signals 526. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3.2.1 24VDC Power Supply Connection 526. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3.2.2 DI (Input Signal) Connection 527. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.3.2.3 DO (Output Signal) Connector 529. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 11

Table of Contents

H.3.3 Connection of Basic and Extension Modules 531. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63323EN/03

H.4 MOUNTING THE TERMINAL MODULE A 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5 SPECIFICATIONS 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5.1 Installation Specifications 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5.2 Ordering Specifications 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5.3 Module Specifications 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5.4 Power Voltage 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.5.5 DI/DO (Input/output Signal Specification) 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. RELAY MODULE A 534. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.1 OVERVIEW 535. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.2 TOTAL CONNECTION 536. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.3 CONNECTION OF EACH PART 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.3.1 Pin Assignment 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.3.2 Connection of the Relay Module A 538. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.4 OUTLINE OF THE RELAY MODULE A 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.5 SPECIFICATIONS 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.5.1 Installation Specifications 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.5.2 Ordering Specifications 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.5.3 Module Specifications 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 12

B–63323EN/03

1

1. GENERAL

GENERAL

Contents of this manual

How this manual is

organized

This manual describes the electrical and structural specifications required

for connecting the CNC control units, FANUC Series 15i/150i, with a

machine tool, and covers the equipment shown in the configuration

diagram in Chapter 2. When using the CNC control units, be sure to

connect and install them following the instructions in this manual. The

manual outlines the units commonly used for Fanuc CNC control units,

that is, the I/O unit, servo motor, spindle motor , and so on, and describes

additional information on using these units for the Series 15i/150i. Refer

to individual manuals for the detailed specifications of each unit.

This manual comprises the following chapters and appendix.

1. GENERAL

This chapter. It describes the outline and organization of this manual,

names of models applied and other related manuals.

2. CONFIGURATION

This chapter describes the configuration of the electrical system of the

machine tool with which the CNC is used.

3. INSTALLATION

This chapter describes how to install the CNC.

4. TOTAL CONNECTION

This chapter shows the connection diagrams for the CNC and each

device.

5. POWER SUPPLY UNIT CONNECTION

This chapter describes the connection of the CNC to the power supply

unit and input unit.

6. CONNECTION OF I/O UNITS TO MACHINE INTERFACE

This chapter describes the connection of the CNC to the I/O unit to

machine interface.

7. CONNECTION TO CNC PERIPHERALS

This chapter describes the connection of the CNC to peripherals.

8. HIGH–SPEED SERIAL BUS (HSSB)

This chapter describes the high–speed serial bus (HSSB), which

enables transfer of data between the CNC and the personal computer .

1

Page 13

1. GENERAL

B–63323EN/03

9. FANUC INTELLIGENT TERMINAL

This chapter describes how to connect the CNC to the FANUC

intelligent terminal.

10.FANUC PANEL i (formerly called the FANUC intelligent

terminal for the PCI bus)

This chapter describes how to connect the CNC to the FANUC P ANEL

i.

11.EMERGENCY STOP SIGNAL

This chapter describes the handling of emergency stop signals.

APPENDIX

A. UNIT EXTERNAL DIMENSION DIAGRAMS

B. EXTERNAL DIMENSIONS OF CONNECTORS

C. 20–PIN INTERFACE CONNECTORS AND CABLES

Applicable models

D. OPTICAL FIBER CABLE

E. LIQUID CRYSTAL DISPLAY (LCD)

F. MEMORY CARD INTERFACE

G. TERMINAL MODULE

H. TERMINAL MODULE A

I. RELAY MODULE A

This manual can be used with the following models.

The abbreviated names may be used.

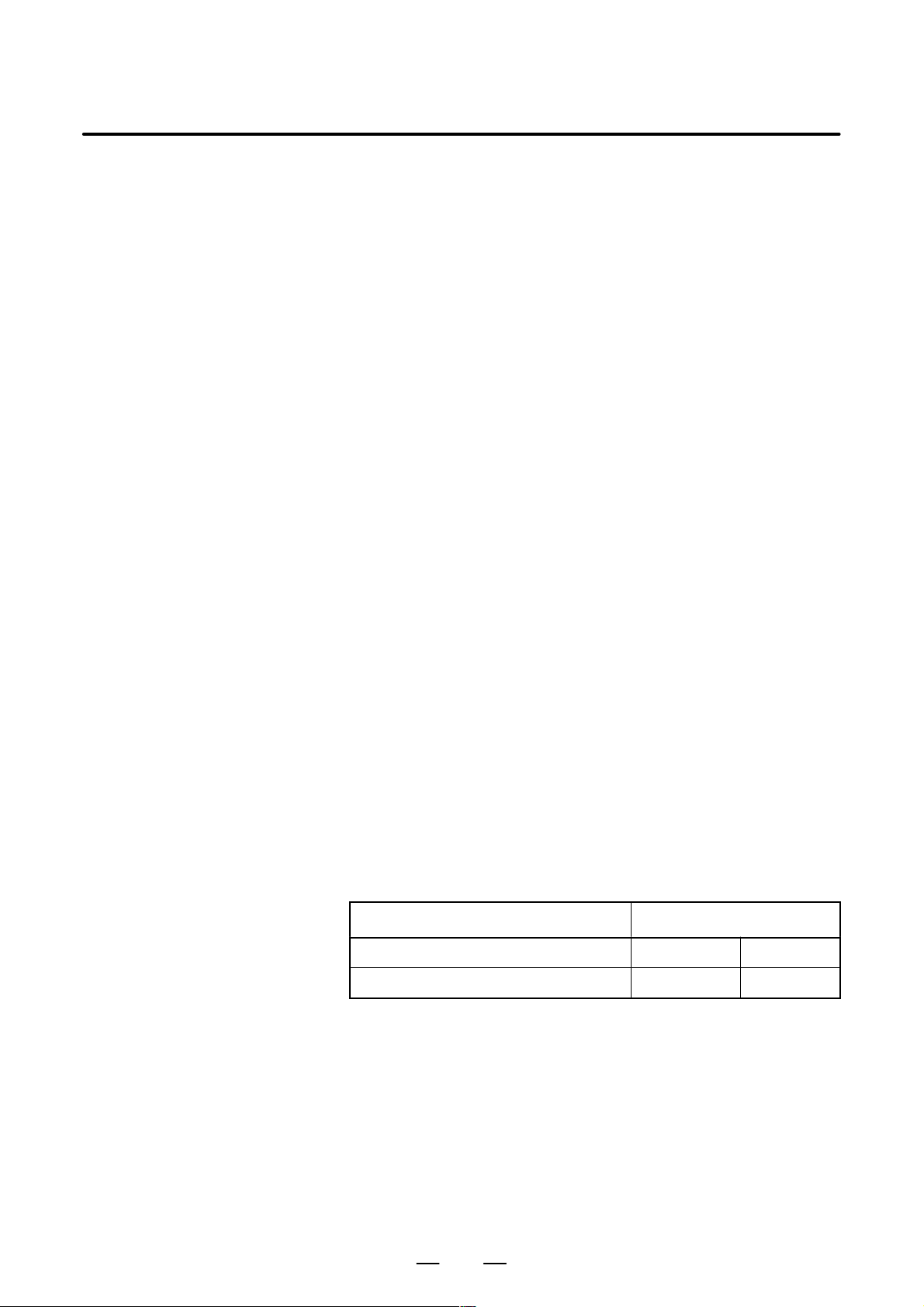

Product Name Abbreviations

FANUC Series 15i–MA 15i–MA Series 15i

FANUC Series 150i–MA 150i–MA Series 150i

2

Page 14

B–63323EN/03

1. GENERAL

Related manuals

The table below lists manuals related to FANUC Series

15i/150i–MODEL A.

In the table, this manual is marked with an asterisk(*).

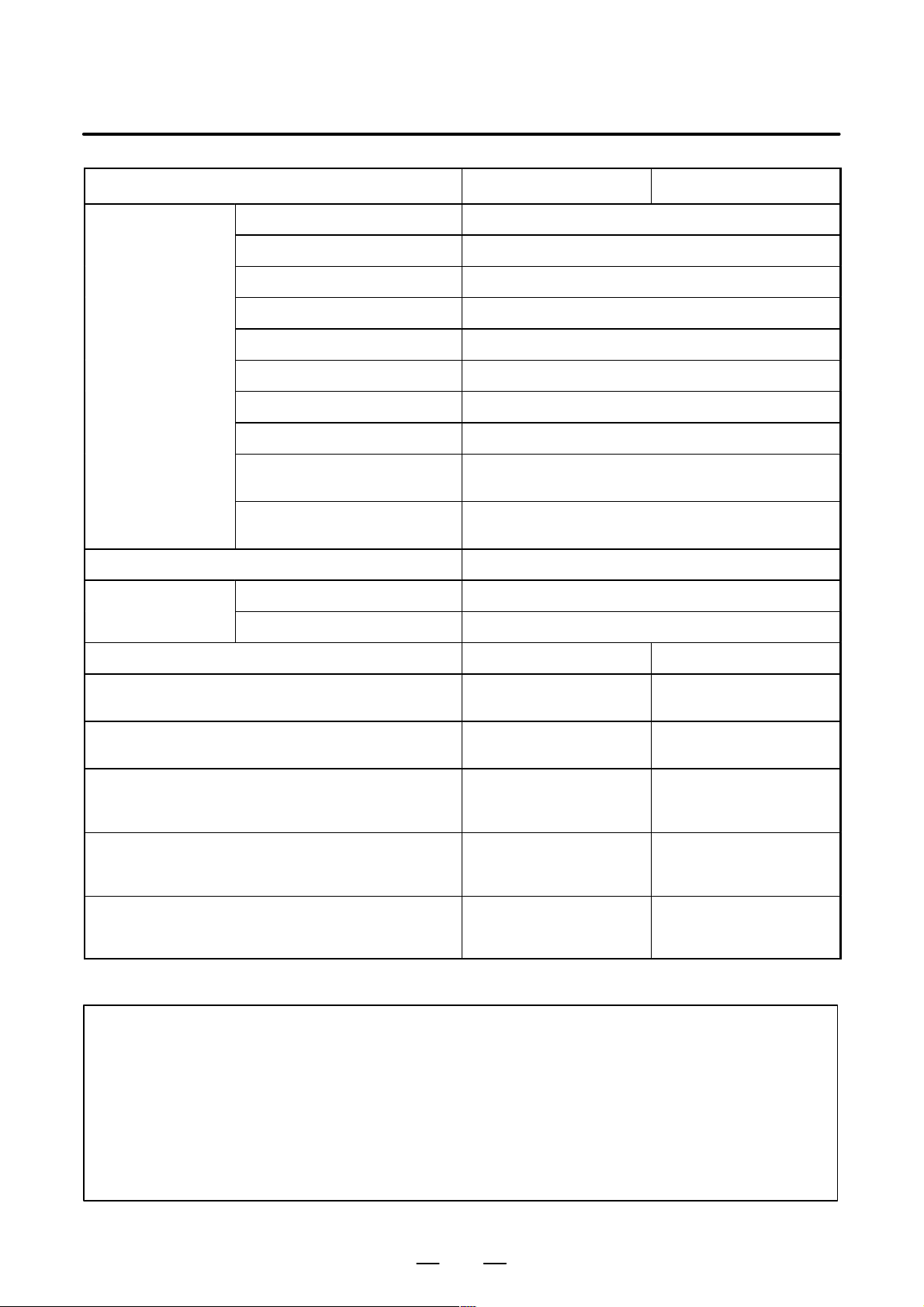

Table 1 Related manuals

Manual name

DESCRIPTIONS B–63322EN

CONNECTION MANUAL (Hardware) B–63323EN *

CONNECTION MANUAL (Function) B–63323EN–1

OPERATOR’S MANUAL (PROGRAMMING) B–63324EN

OPERATOR’S MANUAL (OPERATION) B–63324EN–1

MAINTENANCE MANUAL B–63325EN

PARAMETER MANUAL B–63330EN

DESCRIPTIONS (Supplement for Remote Buffer) B–63322EN–1

PROGRAMMING MANUAL (Macro Compiler/Macro Executor) B–63323EN–2

Specification

number

3

Page 15

2. CONFIGURATION

CONFIGURATION

2

B–63323EN/03

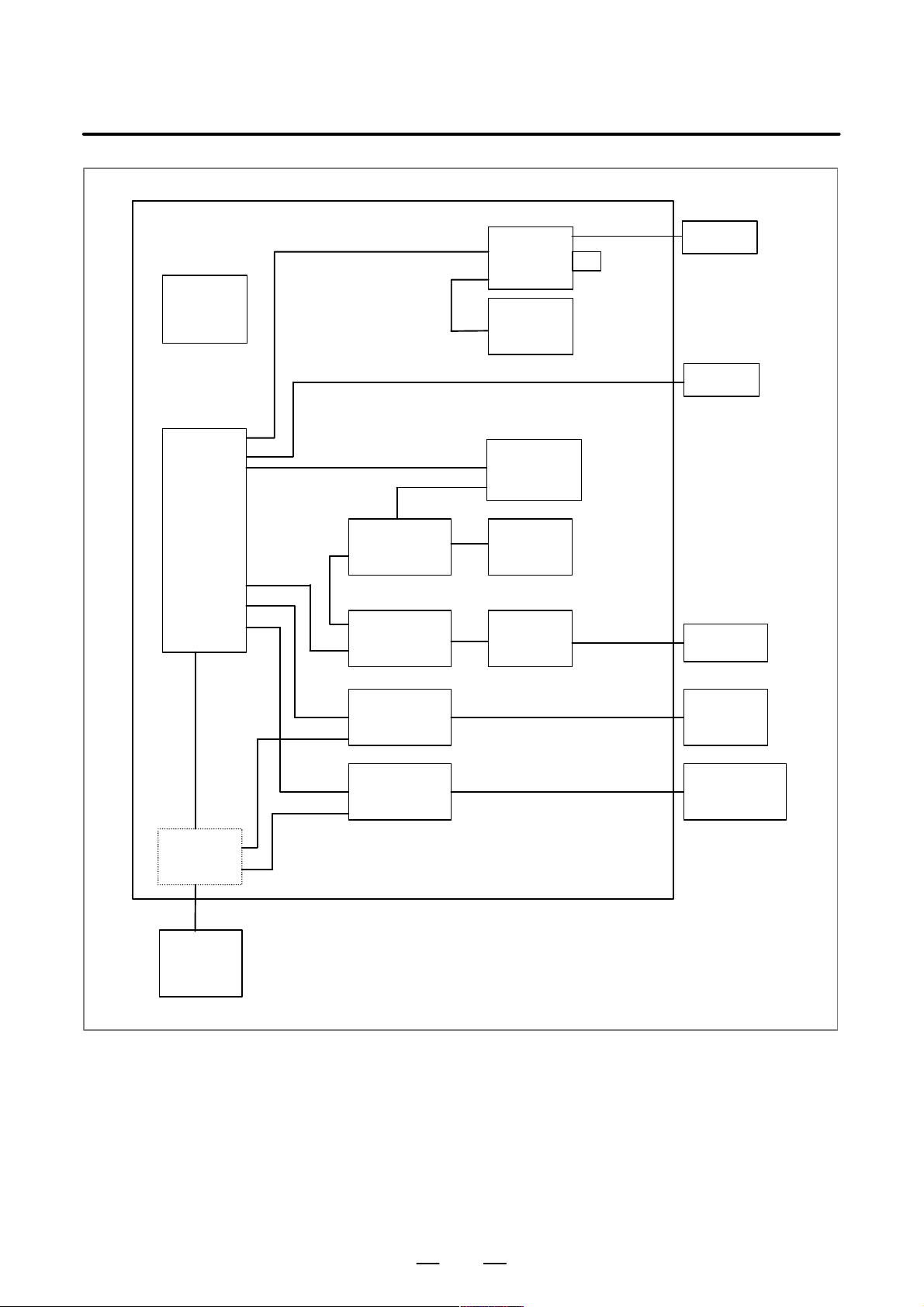

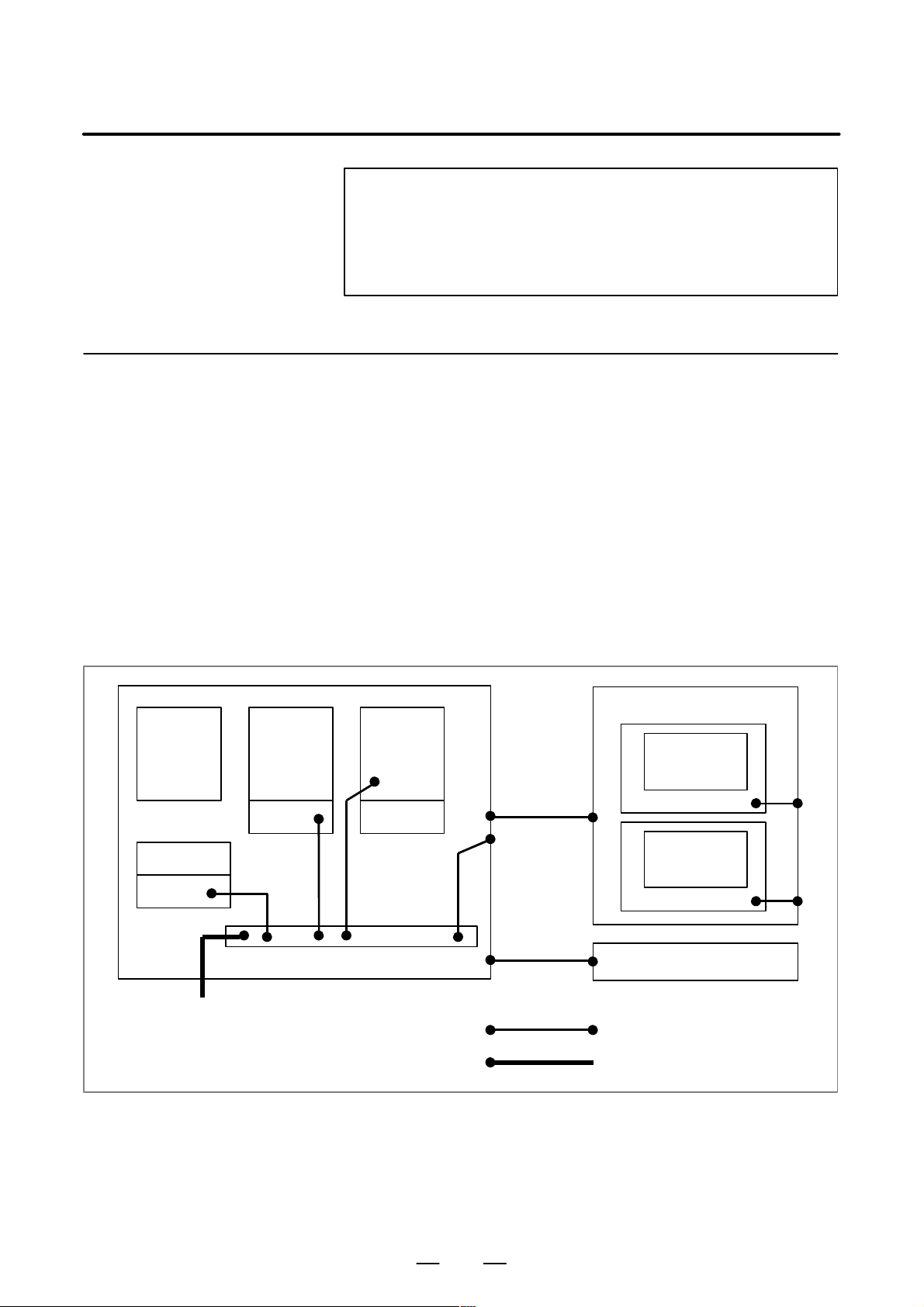

The following figure shows the configuration of the electrical system of

the machine tool with which this control is used.

This manual describes how to connect the units illustrated in this diagram.

The machine tool body, machine operator’s panel, power magnetic

circuit, and sensor/actuator are specific to the machine tool and are the

builder’s responsibility. This manual does not cover the internal

connection of these units to the machine tool.

4

Page 16

B–63323EN/03

Machine tool magnetics cabinet

Heat

exchanger

LCD unit

MDI unit

2. CONFIGURATION

I/O unit

Memory card

I/O unit

CNC

Export

transformer

Operator’s

panel I/O unit

Wiring panel

I/O unit

Servo

amplifier

Spindle

amplifier

Manual pulse

generator

Machine

operator’s

panel

Power magnetics cabinet

control circuit

Sensors

Servo

motor

Spindle motor

Distribution

board

5

Page 17

3. INSTALLATION

INSTALLATION

3

B–63323EN/03

6

Page 18

B–63323EN/03

3.1

ENVIRONMENTAL REQUIREMENTS OUTSIDE THE CABINET

3. INSTALLATION

3.1.1

Environmental Conditions Around the Cabinet

The peripheral units and the control unit have been designed on the

assumption that they are housed in closed cabinets. In this manual

“cabinet” refers to the following:

D Cabinet manufactured by the machine tool builder for housing the

control unit or peripheral units;

D Operation pendant, manufactured by the machine tool builder, for

housing the control unit or operator ’s panel.

D Equivalent to the above.

The environmental conditions when installing these cabinets shall

conform to the following table. Section 3.3 describes the installation and

design conditions of a cabinet satisfying these conditions.

Ambient

Temperature

Temperature

Change

Humidity

Condition

Operating 0°C to 45°C 5°C to 40°C

Storage,

Transport

Normal

Short period (less

than 1 month)

Case of not using

hard disk

–20°C to 60°C

Max. 0.3°C/min. Max. 0.3°C/min.

75%RH or less, no

condensation

95%RH or less, no

condensation

Case of using

hard disk

10% to 75%RH, no

condensation

10% to 90%RH, no

condensation

Vibration Operating 0.5 G or less

Vibration Non–operating 1.0 G or less

Altitude 1000 m or less

Normal machine shop environment

Environment

(The environment must be considered if the cabinets are in a

location where the density of dust, coolant, and/or organic

solvent is relatively high.)

7

Page 19

3. INSTALLATION

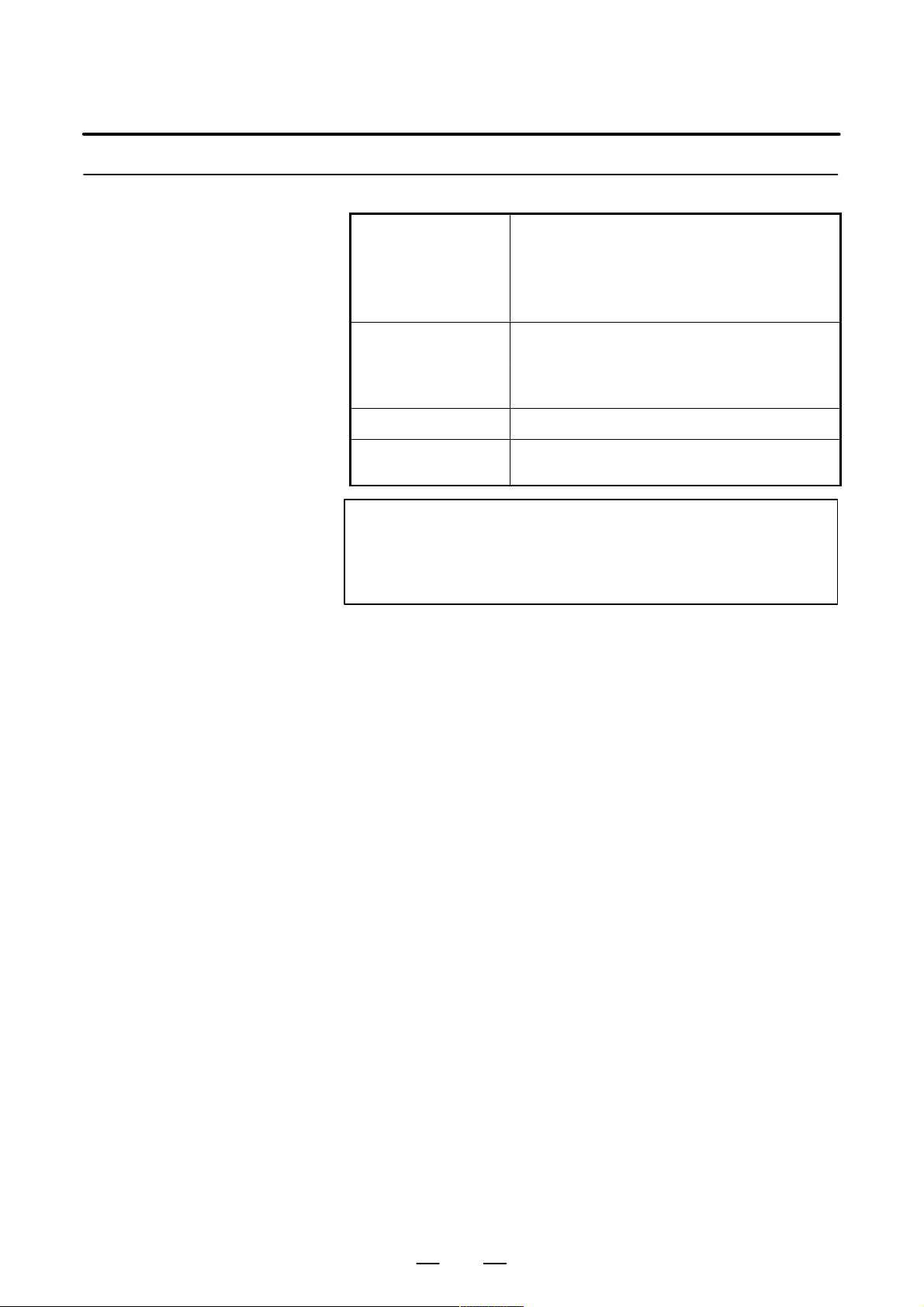

3.1.2

Installation Conditions for the CNC and Servo Unit Inside the Cabinet

Operating: 0°C to 55°C

(no hard disk drive used)

Ambient temperature

Humidity

Vibration 0.5 G or less

Operating: 5°C to 50°C

(hard disk drive used)

Storage and transportation: –20°C to 60°C

95% or less (relative) with no condensation

(no hard disk drive used)

75% or less (relative) with no condensation

(hard disk drive used)

B–63323EN/03

Environment

The unit shall not be exposed direct to cutting oil,

lubricant or cutting chips.

NOTE

1 When using the FANUC PANEL i, also see Subsection

10.5.1.

2 If using the intelligent terminal, see Section 9.5.1.

8

Page 20

B–63323EN/03

3. INSTALLATION

3.2

POWER REQUIREMENTS

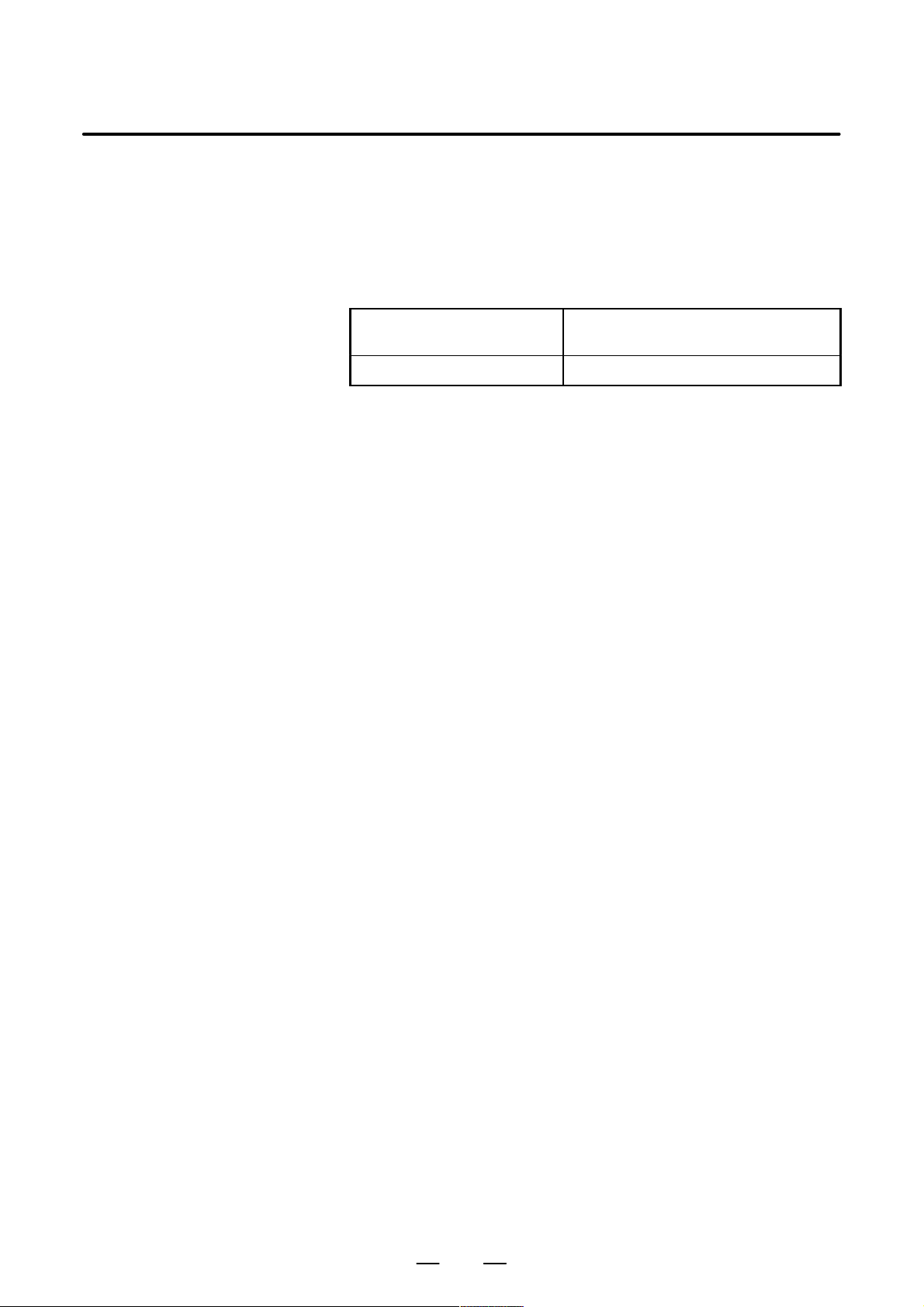

The power requirement of the CNC control unit is calculated as the sum

of the power required by the control and servo sections.

The control section power requirement includes the power required for

control, the LCD, I/O units, the operator panel interface, and the

on/off–controlled 200 V AC service outlet (2.5 A maximum) for the power

supply unit.

Control section power

requirement

Servo section power requirement Varies with the type of related servo motor

1.2 KV A

9

Page 21

3. INSTALLATION

B–63323EN/03

3.3

DESIGN AND INSTALLATION CONDITIONS OF THE MACHINE TOOL MAGNETIC CABINET

When a cabinet is designed, it must satisfy the environmental conditions

described in Section 3.1. In addition, the magnetic interference on the

screen, noise resistance, and maintenance requirements must be

considered. The cabinet design must meet the following conditions :

D The cabinet must be fully closed.

The cabinet must be designed to prevent the entry of airborne

dust,coolant,and organic solvent.

D The cabinet to hold the control unit must be designed to maintain a

difference in temperature of up to 10°C between the air in the cabinet

and the outside air when the temperature in the cabinet rises.

For details of the thermal design, see 3.4.

D A closed cabinet must be equipped with a fan to circulate the air

within. (This is not necessary for a unit with fan.)

The fan must be adjusted so that the air moves at 0.5 m/sec along the

surface of each installed unit.

CAUTION : If the air blows directly from the fan to the unit, dust

easily adheres to the unit. This may cause the unit to fail.

D For the air to move easily, a clearance of 100 mm is required between

each unit and the wall of the cabinet. (This is not necessary for a unit

with fan.)

D Packing materials must be used for the cable port and the door in order

to seal the cabinet.

D The LCD unit and MDI unit must not be installed in such a place that

coolant would directly fall onto the unit.

The front panels of the LCD unit and the MDI unit are dustproof.

However, avoid installing the units in locations where their front

panels directly receive coolant. For an explanation of the dust

protection measures for the power magnetics cabinets and pendant

boxes of machine tools, see Section 3.4.

D Noise must be minimized.

As the machine and the CNC unit are reduced in size, the parts that

generate noise may be placed near noise–sensitive parts in the

magnetics cabinet.

The CNC unit is built to protect it from external noise. Cabinet design

to minimize noise generation and to prevent it from being transmitted

to the CNC unit is necessary. See section 3.6 for details of noise

elimination/management.

D When determining the layout of units in the cabinet, consider

maintainability; arrange the units in such a way that they can be easily

replaced during maintenance and inspection.

D The hard disk drive and floppy disk drive must not be installed near

the source of a strong magnetic field.

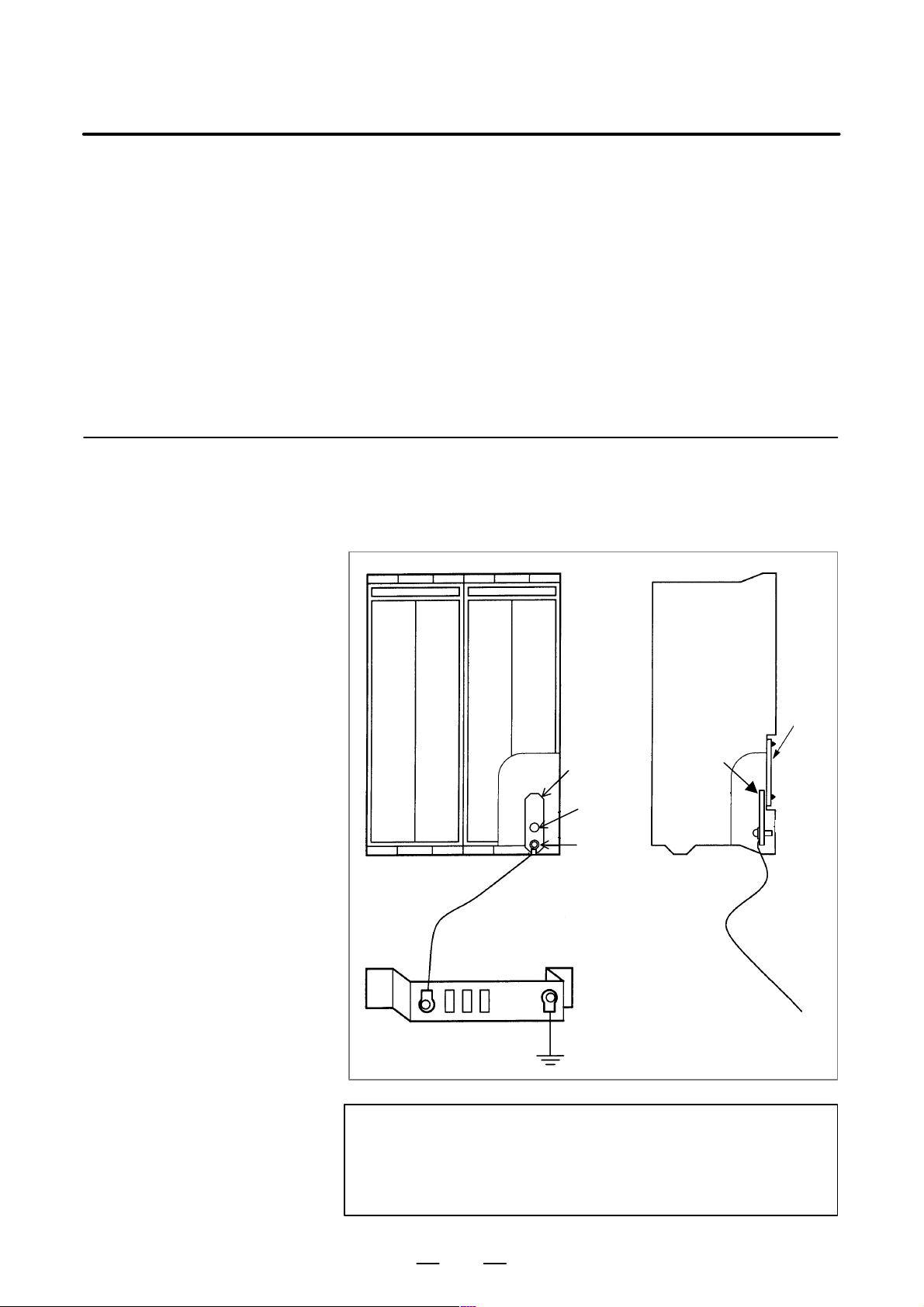

D The installation conditions of the I/O unit and connector panel I/O

module must be satisfied.

To obtain good ventilation in the module, the I/O unit and connector

panel I/O module must be installed in the direction shown in the

following figure. Clearances of 100 mm or more both above and

below the I/O unit are required for wiring and ventilation.

Equipment radiating too much heat must not be put below the I/O unit

and connector panel I/O module.

10

Page 22

B–63323EN/03

3. INSTALLATION

Top

Bottom

Connector panel I/O module or

I/O base unit

(No screws or protrusions shall

extend from the bottom of this

unit.)

D If the CNC unit is installed at an altitude of over 1,000 m, an upper

limit is placed on the ambient temperature (one of the environmental

conditions described in Section 3.1) for the CNC within the cabinet.

Each increment of 100 m over 1,000 m requires that 1.0°C be

subtracted from the maximum allowable ambient temperature for the

CNC in the cabinet.

Example) If a cabinet containing the CNC is installed at an altitude

of 1,750 m, the maximum allowable ambient temperature

for the CNC is: 55°C – 750/100 × 1.0°C = 47.5°C

The allowable ambient temperature range for the CNC is therefore

from 0°C to 47.5°C.

If the hard disk drive in the CNC is used, the CNC can be installed only

at an altitude ranging from:

–60 to 3,000 m when in operation

–60 to 12,000 when not in operation

D Unspecified frequencies may cause the CNC control unit and hard disk

drive to vibrate at their resonance frequency, possibly subjecting unit

components to an acceleration higher than allowable. After mounting

the CNC control unit on your machine, carefully check for any

abnormal conditions.

CAUTION

For a control unit with a hard disk, data stored on the hard

disk may be destroyed due to operator errors or accidents

even when the environmental conditions above are

satisfied. To guard against such data loss, back up the

important hard disk data regularly. In particular, never turn

off the power, even momentarily , while the hard disk is being

accessed or the operating system is running, as doing so is

highly likely to destroy part of the contents of the disk. End

users should be made fully aware of this, to ensure that they

do not inadvertently lose important data.

11

Page 23

3. INSTALLATION

B–63323EN/03

3.4

PROTECTION OF PARTS INSIDE A CABINET OR A PENDANT BOX FROM DUST

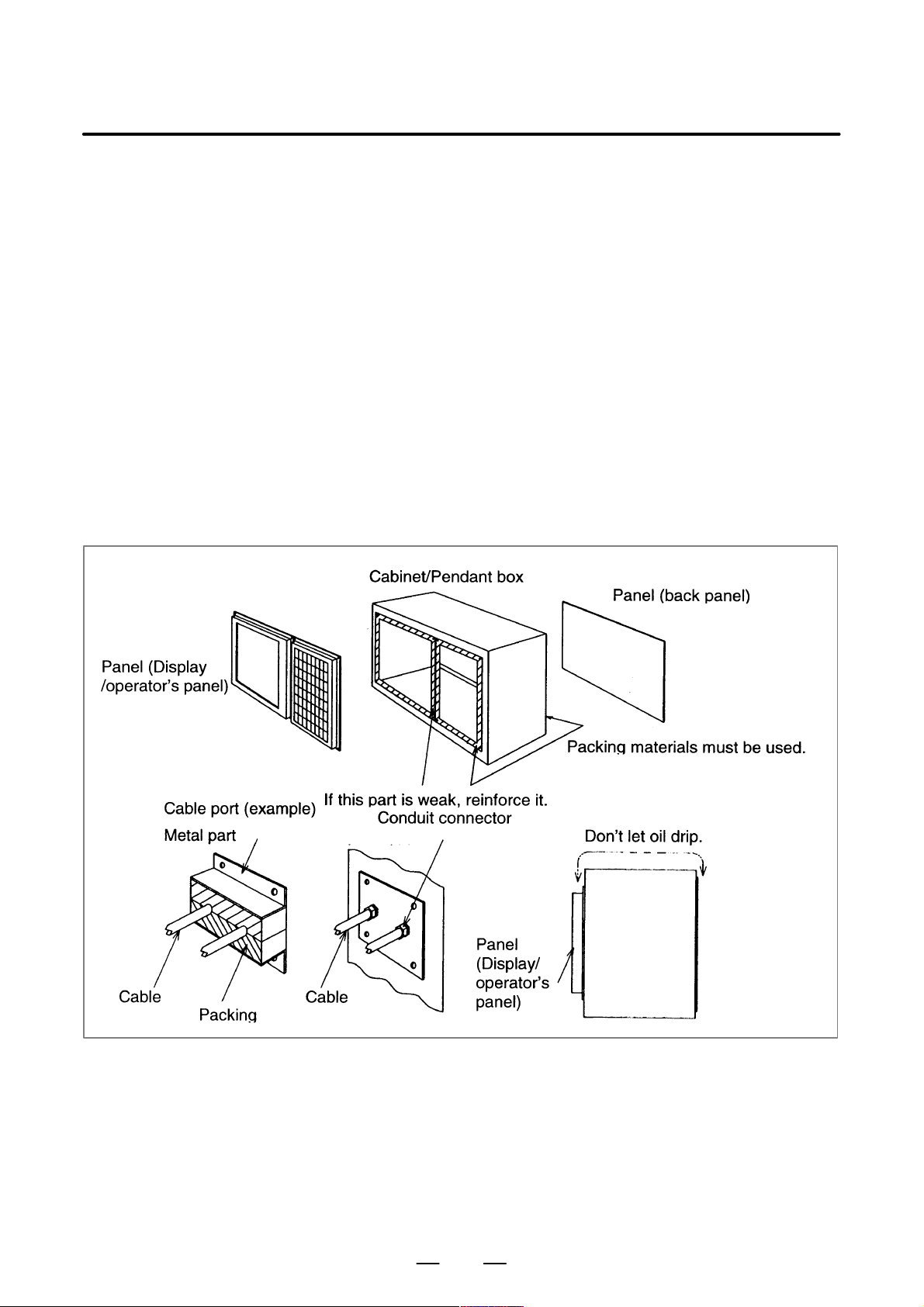

When a cabinet or a pendant box, which houses a display and an operator’s

panel, is designed, it must satisfy following conditions to prevent from

the entry of airborne dust, coolant, and organic solvent.

(1) A cabinet or a pendant box must be fully closed.

(2) Packing materials must be used for the fixed side of a display and an

operator’s panel in order to seal a cabinet or a pendant box.

(3) Packing materials must be used for the door of a cabinet or a pendant

box in order to seal a cabinet or a pendant box.

(4) Packing materials must be used for a back panel in order to seal a

cabinet or a pendant box.

(5) Packing materials and conduit connector and so on must be used for

the cable port in order to seal a cabinet or a pendant box.

(6) ALL holes must be filled.

(7) A display and an operator ’s panel must not be placed in a location

where coolant and cutting chips would directly fall onto them.

(8) Don’t let oil drip from the top of a cabinet or a pendant to panel sides.

12

Page 24

B–63323EN/03

3. INSTALLATION

3.5

THERMAL DESIGN OF THE CABINET

3.5.1

Temperature Rise within the Cabinet

The purpose of the thermal design of the cabinet is to limit the difference

in temperature between the air in the cabinet and the outside air to 10°C

or less when the temperature in the cabinet increases.

The internal air temperature of the cabinet increases when the units and

parts installed in the cabinet generate heat. Since the generated heat is

radiated from the surface of the cabinet, the temperature of the air in the

cabinet and the outside air balance at certain heat levels. If the amount

of heat generated is constant, the larger the surface area of the cabinet, the

less the internal temperature rises. The thermal design of the cabinet

refers to calculating the heat generated in the cabinet, evaluating the

surface area of the cabinet, and enlarging that surface area by installing

heat exchangers in the cabinet, if necessary. Such a design method is

described in the following subsections.

The cooling capacity of a cabinet made of sheet metal is generally 6 W/°C

per 1m

cabinet having a surface area of 1 m

cabinet rises by 1°C. In this case the surface area of the cabinet refers to

the area useful in cooling , that is, the area obtained by subtracting the area

of the cabinet touching the floor from the total surface area of the cabinet.

There are two preconditions : The air in the cabinet must be circuited by

the fun, and the temperature of the air in the cabinet must be almost

constant.The following expression must then be satisfied to limit the

difference in temperature between the air in the cabinet and the outside air

to 10°C or less when the temperature in the cabinet rises:

Internal heat loss P [W] x

6[W/m

For example, a cabinet having a surface area of 4m

of 24W/°C. T o limit the internal temperature increase to 10°C under these

conditions, the internal heat must not exceed 240W. If the actual internal

heat is 320W, however, the temperature in the cabinet rises by 13°C or

more. When this happens, the cooling capacity of the cabinet must be

improved using the heat exchanger described next.

2

surface area, that is, when the 6W heat source is contained in a

2

⋅°C] × surface area S[m2]×10[°C] of rise in temperature

2

, the temperature of the air in the

2

has a cooling capacity

3.5.2

Cooling by Heat Exchanger

If the temperature rise cannot be limited to 10°C by the cooling capacity

of the cabinet, a heat exchanger must be added. The heat exchanger

forcibly applies the air from both the inside and outside of the cabinet to

the cooling fin to obtain effective cooling. The heat exchanger enlar ges

the surface area.

Example

2

For a cabinet with a surface area of 4 m

radiation capacity of 9 W/°C is used, the total heat radiation capacity

increases to

6W/m

This means that even if the internal heat generation is 320 W, the

temperature rise is held below 10 °C.

2

⋅°C × 4m2⋅+⋅9W/°C = 33W/°C

13

, if a heat exchanger with a heat

Page 25

3. INSTALLATION

3.5.3

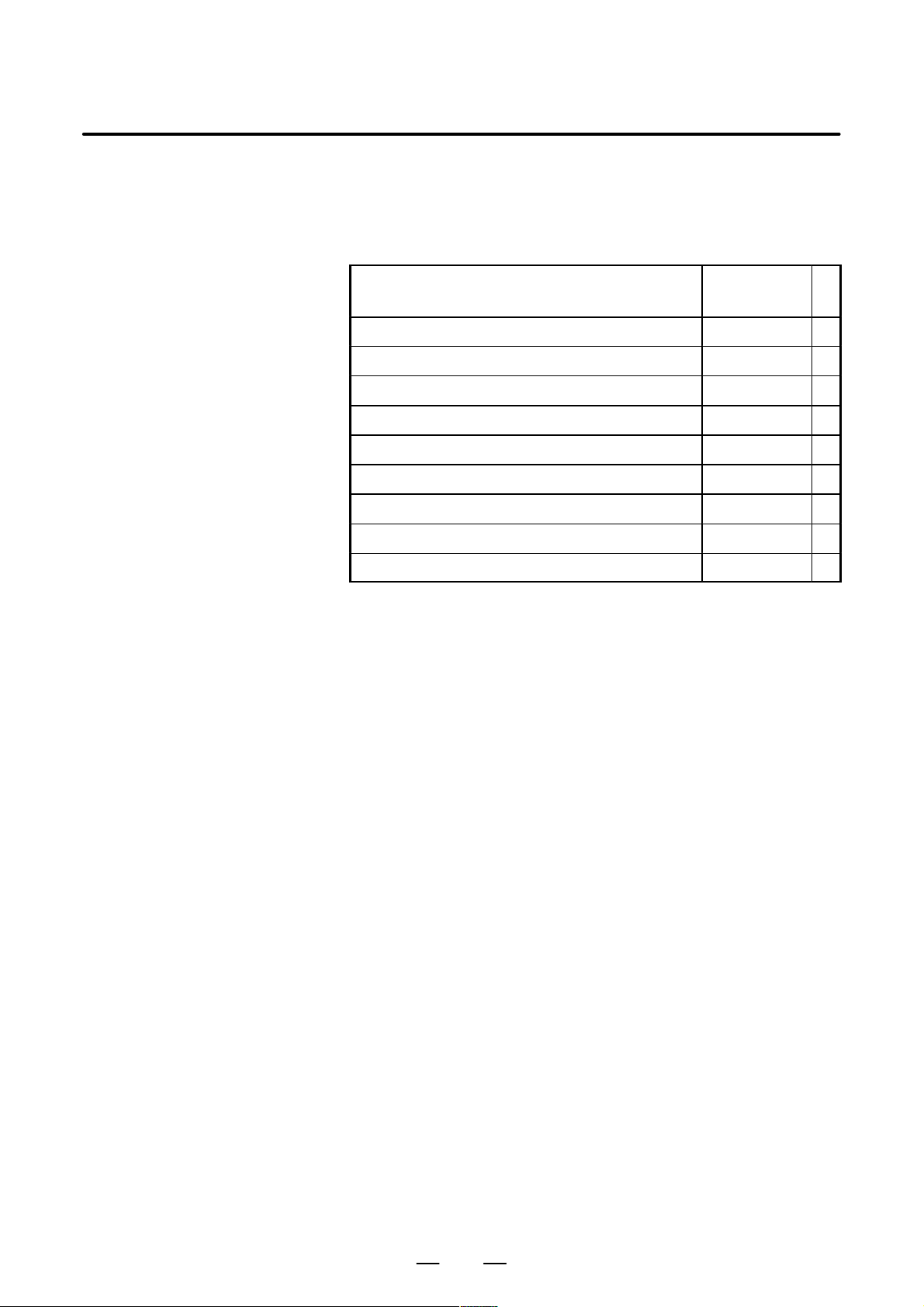

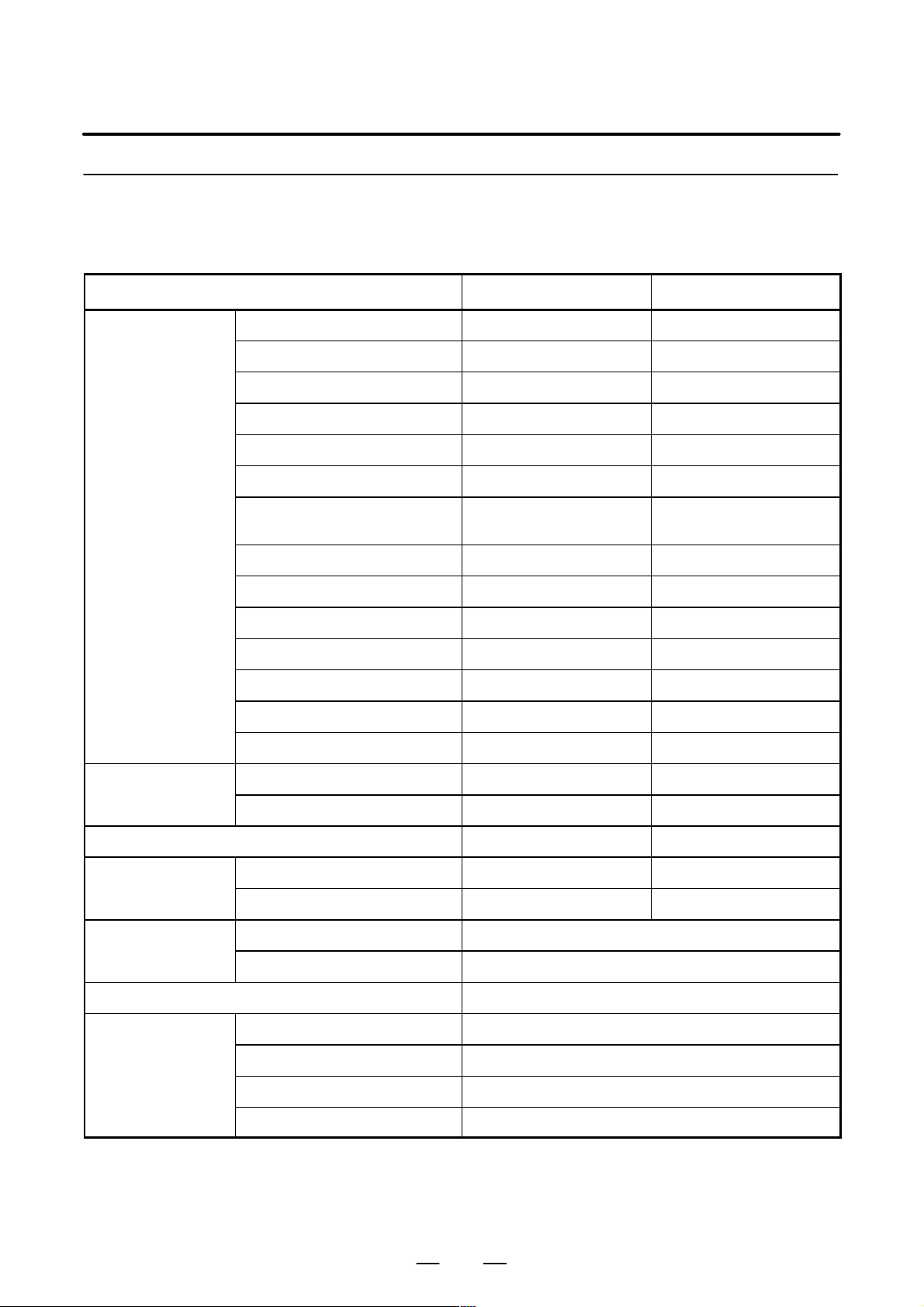

Calorific Value of Each Unit

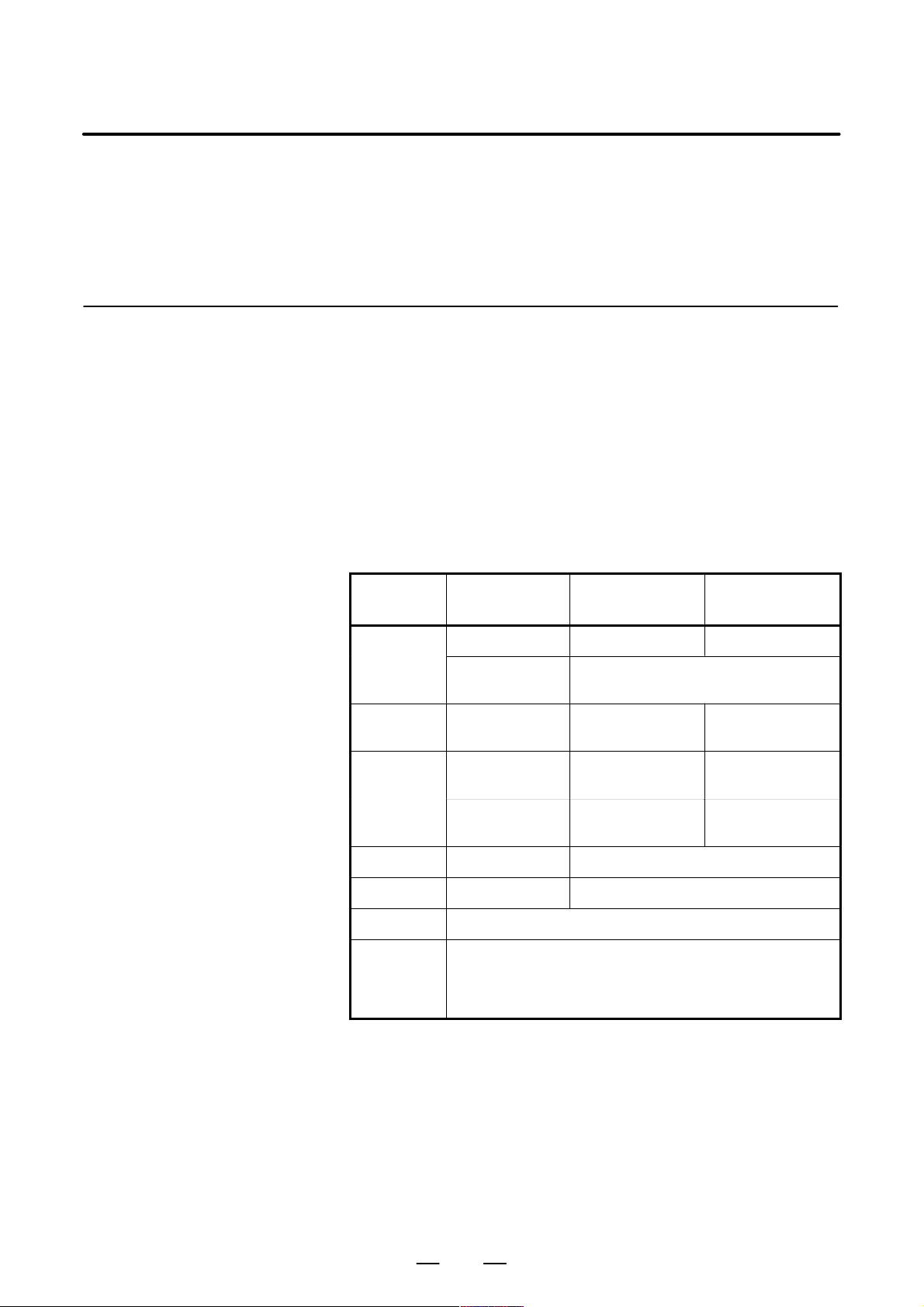

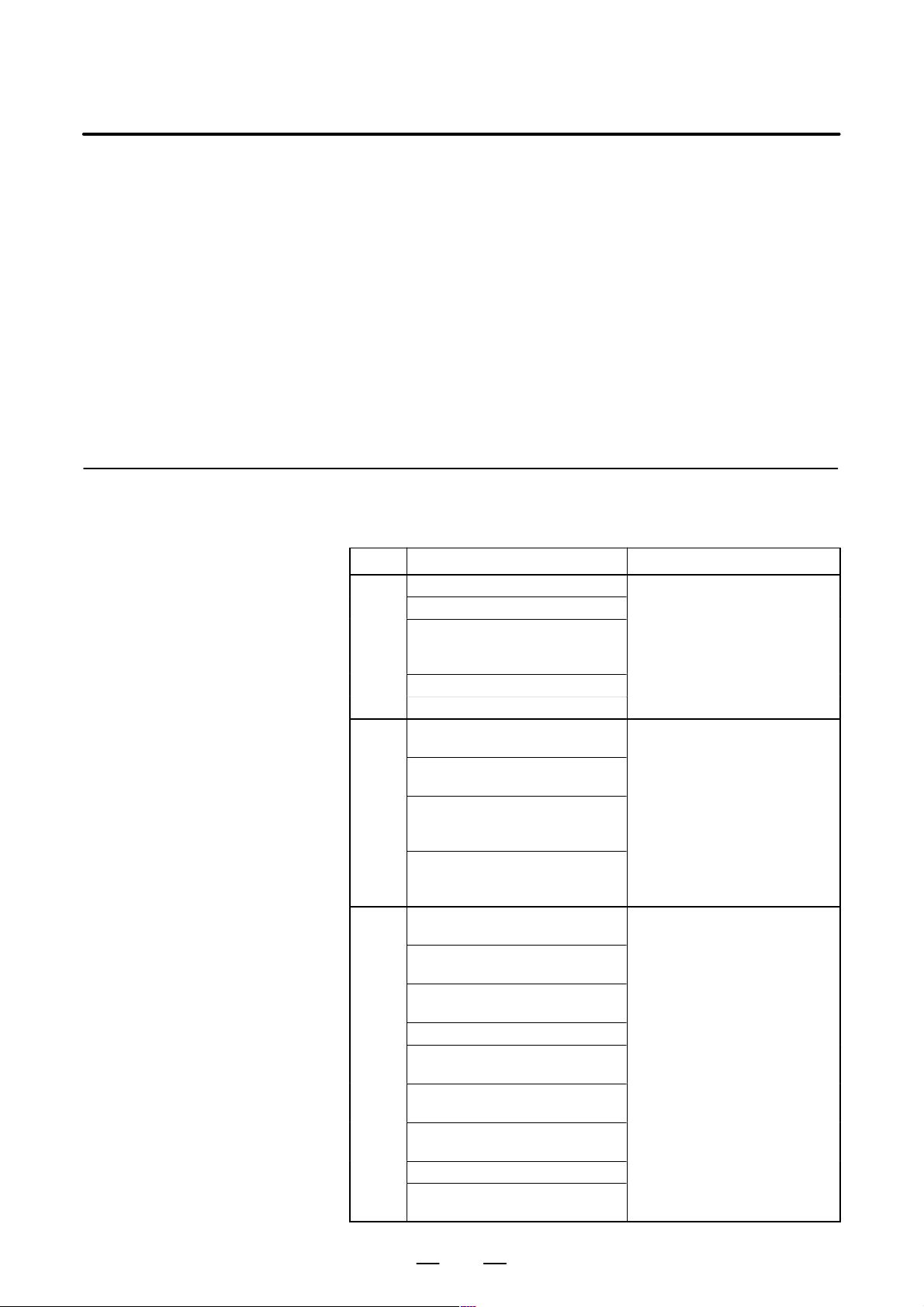

Product name Calorific value Remarks

B–63323EN/03

Control unit

Basic unit (2 slots) 64W

Basic unit (4 slots) 68W

Main CPU board 38W

Additional axis board 10W

HSSB board 4W

Data server board A1 6W

Data server board A2 6.3W Including the 0.3 W of the

A T A card(*1)

PMC C–language board 7W

Serial communication board 7W

DeviceNet board B 5W

DeviceNet board C 4W

Profibus board (master) 4W

Profibus board (slave) 6W

Etehrnet board 6W

LCD unit

Hard disk unit for data server 13W

Separate detector

interface unit

Connection unit

Operator’s panel connection unit 3.6W + 0.18 W × Number of ONs

I/O unit model A

10.4″ color LCD unit 20W

9.5″ monochrome LCD unit 18W

Basic unit 9W (*2)

Basic unit + Additional unit 14W (*2)

Connection unit 1 16W + 0.18W × Number of ON inputs

Connection units 1 and 2 25W + 0.18W × Number of ON inputs

AIF01A, AIF01B 1.2W

AID32A, AID32B 1.2W + 0.23W × Number of ON inputs

AID16A, AID16B 0.1W + 0.21W × Number of ON inputs

AID32E, AID32F 0.1W + 0.23W × Number of ON inputs

14

Page 26

B–63323EN/03

3. INSTALLATION

Product name RemarksCalorific value

I/O unit model B

I/O module for operator’s panel 3.6W + 0.18W × Number of ON inputs

I/O module for con-

nector panel

Exported transformer for control unit 51W

BIF04A1 1.6W

AIF02C 1.2W

BID16A1, BID16B1 1.5W + 0.23 × Number of ON inputs

BID16P1, BID16Q1 0.6W + 0.23 × Number of ON inputs

BOA12A1 0.9W + (0.09 + 1.1 × IL2) x Number of ON outputs

BOD16A1 1.0W + (0.13 + 0.3 × IL2) Number of ON outputs

BOD16P1 0.3W + (0.13 + 0.3 × IL2) x Number of ON outputs

BIA16P1 0.1W + 0.21 × Number of ON inputs

BMD88A1, BMD88B1 1.3W + 0.23 × Number of ON input points +

(0.13 + 0.3 × IL

BMD88P1, BMD88Q1 0.4W + 0.23 × Number of ON input points +

(0.13 + 0.3 × IL

Basic unit 3.6W + 0.18W × Number of ON inputs

Extension unit 3.6W + 0.18W × Number of ON inputs

2

) × Number of ON output points

2

) × Number of ON output points

Intelligent terminal, 10.4”

(A13B–0178–B025 to –B032)

Intelligent terminal, 12.1”

(A13B–0082–B040 to –B042)

PANEL i (formerly called the intelligent terminal for the PCI

bus) 10.4”

(A08B–0082–B001 to –B004)

PANEL i (formerly called the intelligent terminal for the PCI

bus) 12.1”

(A08B–0082–B011 to –B014)

PANEL i (formerly called the intelligent terminal for the PCI

bus) 15.0”

(A08B–0082–B021 to –B023)

30W During normal operation(*3)

36W During normal operation(*3)

40W During normal operation (*3)

52W During normal operation (*3)

52W During normal operation (*3)

NOTE

1 The calorific value of the ATA flash card is subject to change because of the adoption of a

large–capacity card, changes in the card specifications, and so on.

2 Does not include the calorific value of the heat generated inside the separate detector.

3 Units assumed to be active during normal operation: Intelligent terminal, PANEL i HDD unit,

HDD fan, FDD unit, full keyboard, and mouse. Units assumed to be inactive during normal

operation: PCMCIA card, ISA expansion board, serial interface expansion device,

parallel–interface–connected device. Note that the generated heat will increase if peripheral

devices and ISA expansion boards are connected.

15

Page 27

3. INSTALLATION

B–63323EN/03

3.6

ACTION AGAINST NOISE

3.6.1

Separating Signal Lines

The CNC has been steadily reduced in size using surface–mount and

custom LSI technologies for electronic components. The CNC also is

designed to be protected from external noise. However, it is difficult to

measure the level and frequency of noise quantitatively, and noise has

many uncertain factors. It is important to prevent both noise from being

generated and generated noise from being introduced into the CNC. This

precaution improves the stability of the CNC machine tool system.

The CNC component units are often installed close to the parts generating

noise in the power magnetics cabinet. Possible noise sources into the

CNC are capacitive coupling, electromagnetic induction, and ground

loops.

When designing the power magnetics cabinet, guard against noise in the

machine as described in the following section.

The cables used for the CNC machine tool are classified as listed in the

following table:

Process the cables in each group as described in the action column.

Group Signal line Action

Primary AC power line

Secondary AC power line

AC/DC power lines (containing

the power lines for the servo and

A

spindle motors)

AC/DC solenoid

AC/DC relay

DC solenoid (24VDC)

DC relay (24VDC)

DI/DO cable between the I/O unit

B

and power magnetics cabinet

DI/DO cable between the I/O unit

and machine

Cable between the CNC and I/O

unit

Cable for position and velocity

feedback

Cable between the CNC and

spindle amplifier

Cable for the position coder

Cable for the manual pulse gen-

C

erator

Cable between the LCD and the

MDI

RS–232C and RS–422 interface

cable

Cable for the battery

Other cables to be covered with

the shield

Bind the cables in group A separately (Note 1) from groups B

and C, or cover group A with an

electromagnetic shield (Note 2).

See Section 3.6.4 and connect

spark killers or diodes with the

solenoid and relay.

solenoid and relay.

Connect diodes with DC solenoid and relay .

Bind the cables in group B separately from group A, or cover

group B with an electromagnetic

shield.

Separate group B as far from

Group C as possible.

It is more desirable to cover

group B with the shield.

Bind the cables in group C separately from group A, or cover

group C with an electromagnetic

shield.

Separate group C as far from

Group B as possible.

Be sure to perform shield processing in Section 3.6.5.

16

Page 28

B–63323EN/03

3. INSTALLATION

NOTE

1 The groups must be 10 cm or more apart from one another

when binding the cables in each group.

2 The electromagnetic shield refers to shielding between

groups with grounded steel plates.

3.6.2

Grounding

Distributed

I/O

α Tamplifier

AC power

The CNC machine tool has three grounding systems:

D Grounding system for signals

The grounding system for signals provides the reference potential (0

V) for the electric signal system.

D Protective grounding system

The protective grounding system is intended to ensure safety and

shield any external noise and internally–generated noise. It consists

of device frames, unit cases, panels, as well as the shields of the

interface cables connecting devices.

D Protective earth (PE) system

The protective earth (PE) system connects the protective grounding