Page 1

FANUC FAST Ethernet

FANUC FAST Data Server

For FANUC Series 0*-MODEL D

OPERATOR’S MANUAL

B-64414EN/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-64414EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC

units, to ensure safe operation of machines fitted with FANUC CNC

units. Read this section carefully before attempting to use any function

described in this manual.

Users should also read the relevant descriptions in the User’s Manual of

the CNC to become fully familiar with the functions to be used.

Contents

DEFINITION OF WARNING, CAUTION, AND NOTE ................s-2

GENERAL WARNINGS AND CAUTIONS....................................s-3

s-1

Page 4

SAFETY PRECAUTIONS B-64414EN/01

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warnings and Cautions according to their bearing on safety. Also,

supplementary information is described as Notes. Read the Warnings,

Cautions, and Notes thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a danger of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

• Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-64414EN/01 SAFETY PRECAUTIONS

GENERAL WARNINGS AND CAUTIONS

WARNING

1 Before operating the machine, thoroughly check the

entered data. Operating the machine with incorrectly

specified data may result in the machine behaving

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

2 Never attempt to machine a workpiece without first

checking the programmed value, compensation value,

current position, and external signal settings. Also,

never attempt to machine a workpiece without first

checking the operation of the machine. Before starting

a production run, ensure that the machine is operating

correctly by performing a trial run using, for example,

the single block, feedrate override, or machine lock

function, or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct

operation of the machine may result in the machine

behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the

user.

3 Ensure that the specified feedrate is appropriate for the

intended operation. Generally, for each machine, there

is a maximum allowable feedrate. The appropriate

feedrate varies with the intended operation. Refer to the

manual provided with the machine to determine the

maximum allowable feedrate. If a machine is run at

other than the correct speed, it may behave

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

4 When using a tool compensation function, thoroughly

check the direction and amount of compensation.

Operating the machine with incorrectly specified data

may result in the machine behaving unexpectedly,

possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

5 The parameters for the CNC and PMC are factory-set.

Usually, there is no need to change them. When,

however, there is no alternative other than to change a

parameter, ensure that you fully Failure to set a

parameter correctly may result in the machine behaving

unexpectedly, possibly causing damage to the

workpiece and/or machine itself, or injury to the user.

s-3

Page 6

SAFETY PRECAUTIONS B-64414EN/01

CAUTION

1 Immediately after switching on the power, do not touch

any of the keys on the MDI panel until the position

display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to

maintenance or other special operations. Pressing any

of these keys may place the CNC unit in other than its

normal state. Starting the machine in this state may

cause it to behave unexpectedly.

2 The operator's manual for FAST Ethernet / FAST Data

Server describes all the basic functions of the CNC,

including the optional functions. The selected optional

functions vary with the machine. Some functions

described in this manual may not, therefore, be

supported by your machine. Check the machine

specifications before using FAST Ethernet / FAST Data

Server.

3 Some machine operations and screen functions are

implemented by the machine tool builder. For an

explanation of their usage and related notes, refer to the

manual provided by the machine tool builder.

For example:

• On some machines, executing a tool function

causes the tool change unit to operate. When

executing a tool function on such a machine, stand

well clear of the tool change unit. Otherwise, there is

a danger of injury to the operator.

• Many auxiliary functions trigger physical

operations, such as rotation of the spindle. Before

attempting to use an auxiliary function, therefore,

ensure that you are fully aware of the operation to be

triggered by that function.

NOTE

Command programs, parameters, and variables are

stored in nonvolatile memory in the CNC. Generally,

the contents of memory are not lost by a power on/off

operation. However, the contents of memory may be

erased by mistake, or important data in nonvolatile

memory may have to be erased upon recovering from a

failure.

To enable the restoration of data as soon as possible if

such a situation arises, always make a backup of the

data in advance.

s-4

Page 7

B-64414EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE .............................................s-2

GENERAL WARNINGS AND CAUTIONS............................................................... s-3

I. GENERAL

1 GENERAL ............................................................................................... 3

1.1 ORGANIZATION ...........................................................................................4

1.2 APPLICABLE MODELS................................................................................. 5

1.3 RELATED MANUALS.................................................................................... 6

II. SPECIFICATION

1 PREFACE................................................................................................ 9

2 DATA SERVER FUNCTIONS ............................................................... 10

2.1 DATA SERVER FILE MANAGEMENT ........................................................ 12

2.1.1 File Names of CNC File Management ...................................................................13

2.1.2 Files which can be Created on a Data Server .........................................................14

2.1.3 Text Files and Binary Files ....................................................................................14

2.2 DATA SERVER MODES ............................................................................. 15

2.3 OPERATION FROM A DATA SERVER ...................................................... 17

2.4 NC PROGRAM FORMAT............................................................................ 19

2.5 LIST FILE FORMAT ....................................................................................21

2.6 ISO CODE INPUT/OUTPUT FUNCTION .................................................... 25

3 FOCAS2/Ethernet FUNCTIONS...........................................................28

4 DNS/DHCP FUNCTIONS ...................................................................... 29

5 MACHINE REMOTE DIAGNOSIS FUNCTIONS...................................30

6 UNSOLICITED MESSAGING FUNCTION ............................................ 31

7 FTP FILE TRANSFER FUNCTION ....................................................... 34

III. SETTING

1 SETTING THE COMMUNICATION FUNCTION ................................... 37

2 SETTING THE DATA SERVER FUNCTIONS....................................... 38

2.1 OPERATING THE DATA SERVER SETTING SCREEN............................. 39

2.2 INPUT OF SPECIAL CHARACTERS .......................................................... 49

c-1

Page 8

TABLE OF CONTENTS B-64414EN/01

2.3 RELATED NC PARAMETERS ....................................................................50

2.4 EXAMPLE OF SETTING THE DATA SERVER FUNCTIONS ..................... 54

3 SETTING THE FOCAS2/Ethernet FUNCTIONS .................................. 55

3.1 OPERATING THE FOCAS2/Ethernet SETTING SCREEN ......................... 56

3.2 RELATED NC PARAMETERS ....................................................................59

3.3 EXAMPLE OF SETTING THE FOCAS2/Ethernet FUNCTIONS.................. 60

4 ERROR MESSAGES DISPLAYED DURING PARAMETER SETTING 61

5 BACKING UP OR RESTORING COMMUNICATION PARAMETERS . 62

IV. OPERATION

1 OPERATING THE DATA SERVER FUNCTIONS.................................67

1.1 DEVICE CHANGE ON THE PROGRAM DIRECTORY SCREEN ............... 68

1.2 OPERATING THE DATA SERVER FILE LIST SCREEN ............................ 69

1.2.1 Displaying and Operating the File List ..................................................................75

1.2.2 File Transfer Operation ..........................................................................................83

1.2.3 Preparations for File Operation and Editing...........................................................85

1.3 OPERATING THE DATA SERVER HOST FILE LIST SCREEN .................87

1.3.1 Displaying and Operating the File List ..................................................................92

1.3.2 File Transfer Operation ..........................................................................................95

1.3.3 Preparations for File Operation ..............................................................................98

1.4 M198-BASED SUBPROGRAM CALL.......................................................... 99

1.5 DNC OPERATION..................................................................................... 100

1.6 NC PROGRAM INPUT .............................................................................. 101

1.7 NC PROGRAM OUTPUT .......................................................................... 103

1.8 FTP SERVER FUNCTIONS ......................................................................105

1.9 INPUT OF SPECIAL CHARACTERS ........................................................ 106

V. CONNECTION

1 SETTING ............................................................................................. 109

1.1 SPECIFICATIONS..................................................................................... 110

1.2 INSTALLATION ......................................................................................... 111

1.2.1 Installation on an Control Unit.............................................................................111

1.2.2 Total Connection Diagram ...................................................................................112

1.2.3 Installing a Memory Card.....................................................................................113

2 CABLE CONNECTION ....................................................................... 115

2.1 CONNECTING TO Ethernet ...................................................................... 116

c-2

Page 9

B-64414EN/01 TABLE OF CONTENTS

2.2 LEADING OUT THE Ethernet CABLE ....................................................... 117

2.3 100BASE-TX CONNECTOR (CD38R) PIN ASSIGNMENTS ....................118

2.4 TWISTED-PAIR CABLE SPECIFICATION................................................ 119

2.4.1 Cable Connection .................................................................................................119

2.4.2 Cable Materials.....................................................................................................120

2.4.3 Connector Specification .......................................................................................122

2.5 ELECTRICAL NOISE COUNTERMEASURES.......................................... 123

2.5.1 Separating Signal Lines........................................................................................123

2.5.2 Clamping and Shielding Cables ...........................................................................123

2.5.3 Grounding the Network........................................................................................126

2.6 CHECK ITEMS AT INSTALLATION .......................................................... 128

VI. MAINTENANCE

1 HARDWARE MAINTENANCE INFORMATION..................................131

1.1 BOARD...................................................................................................... 132

1.1.1 Component Layout...............................................................................................132

1.1.2 LED Indications and Meanings............................................................................133

2 SOFTWARE MAINTENANCE INFORMATION................................... 136

2.1 Ethernet LOG ............................................................................................ 137

2.2 ETHERNET CONNECTION CONFIRMATION..........................................143

2.3 COMMUNICATION STATE CONFIRMATION........................................... 146

2.4 COMMUNICATION SOFTWARE CONFIRMATION.................................. 148

APPENDIX

A TROUBLESHOOTING ........................................................................ 155

A.1 CHECKING COMMUNICATION WITH A HUB..........................................156

A.2 CHECKING CONNECTION WITH THE TRUNK ....................................... 157

A.3 CHECKING SETTINGS............................................................................. 158

A.4 CHECKING COMMUNICATION................................................................159

A.5 TROUBLESHOOTING DATA SERVER FUNCTION PROBLEMS ............ 162

A.5.1 DNC Operation or M198-Based Subprogram Calling .........................................162

A.5.1.1 An alarm occurs when an NC program is performed long time...................... 162

A.5.2 M198-Based Subprogram Calling Fails for an NC Program ...............................164

A.5.3 Operating the DATA SERVER HOST FILE LIST Screen..................................165

A.5.3.1 The list of files cannot be displayed ................................................................165

A.5.3.2 Files cannot be transferred...............................................................................168

c-3

Page 10

TABLE OF CONTENTS B-64414EN/01

A.5.4 Operating the DATA SERVER FILE LIST Screen .............................................170

A.5.4.1 A program cannot be selected as a main program ........................................... 170

B EXAMPLE OF FTP SERVER SETUP ................................................. 172

B.1 SETTING UP FTP SERVER OF Windows 2000 Professional

(FOR INTERNET INFORMATION SERVICE) ........................................... 173

B.2 SETTING UP FTP SERVER OF Windows XP Professional

(FOR INTERNET INFORMATION SERVICE) ........................................... 185

B.3 SETTING UP FTP SERVER OF Windows Vista

(FOR INTERNET INFORMATION SERVICE) ........................................... 209

C FTP CLIENT OPERATION..................................................................228

C.1 OPERATION USING THE FTP COMMAND.............................................. 229

C.2 SECURITY UNBLOCKING IN Windows .................................................... 232

D DNS/DHCP FUNCTION....................................................................... 234

D.1 SETTINGS ON THE COMMUNICATION BOARD SIDE ........................... 235

D.1.1 Setting the DNS Client Function..........................................................................235

D.1.2 Setting the DHCP Client Function .......................................................................237

D.1.3 Related NC Parameters.........................................................................................241

D.2 SETTING UP THE DNS/DHCP SERVER OF Windows 2000 Server........ 242

D.2.1 Example of Setting Up DHCP Server of Windows 2000 Server .........................243

D.2.2 Example of Setting Up DNS Server of Windows 2000 Server ............................250

D.3 EXAMPLE OF SETTING DNS/DHCP........................................................ 256

D.3.1 When DNS/DHCP is Used with the Data Server .................................................256

D.3.2 When DHCP is Used with the FTP Server Function of the Data Server .............258

D.3.3 When DHCP Function is Used with the FOCAS2/Ethernet Function .................260

E MACHINE REMOTE DIAGNOSIS FUNCTIONS................................. 262

E.1 SETTING THE MACHINE REMOTE DIAGNOSIS SETTING SCREEN .... 263

E.1.1 Related NC Parameters.........................................................................................270

E.2 CONTROLLING THE MACHINE REMOTE DIAGNOSIS FUNCTIONS

FROM THE PMC ....................................................................................... 271

E.2.1 Signals ..................................................................................................................271

E.2.2 Signal Timing Charts............................................................................................274

E.2.2.1 When the start of machine remote diagnosis is accepted................................. 274

E.2.2.2 When the start of machine remote diagnosis is rejected.................................. 275

E.2.2.3 When machine remote diagnosis is forcibly terminated.................................. 276

E.3 EXAMPLE OF SETTING THE MACHINE REMOTE DIAGNOSIS

FUNCTIONS..............................................................................................277

c-4

Page 11

B-64414EN/01 TABLE OF CONTENTS

E.4 OPERATING THE MACHINE REMOTE DIAGNOSIS SCREEN ............... 278

E.4.1 Selecting an Inquiry Destination ..........................................................................280

E.4.2 Starting Diagnosis ................................................................................................280

E.4.2.1 Diagnosis status ............................................................................................... 280

E.4.2.2 Error numbers and error messages................................................................... 281

E.4.3 Forcibly Terminating Diagnosis...........................................................................281

F UNSOLICITED MESSAGING FUNCTION .......................................... 282

F.1 SETTING OF THE UNSOLICITED MESSAGING FUNCTION .................. 283

F.1.1 Mode Selection.....................................................................................................287

F.1.2 Setting on the CNC Screen...................................................................................290

F.1.3 Setting on the personal computer .........................................................................295

F.2 EXECUTING THE UNSOLICITED MESSAGING FUNCTION...................296

F.2.1 When a PMC Address for control is Used (Response Notification Method).......297

F.2.2 When a PMC Address for Control is Used (Simplified Method).........................300

F.2.3 When a Macro Variable for Control is Used (Simplified Method) ......................302

F.3 RELATED NC PARAMETERS .................................................................. 304

G FTP TRANSFER FUNCTION .............................................................. 305

G.1 SETTING OF THE FTP TRANSFER FUNCTION...................................... 306

G.2 RELATED NC PARAMETERS .................................................................. 311

G.3 Example of setting the FTP file transfer function ....................................... 313

G.4 OPERATING THE FTP FILE TRANSFER FUNCTIONS ........................... 314

G.4.1 Device Change on the Program Directory Screen................................................315

G.4.2 FTP Transfer Host File List..................................................................................316

G.4.2.1 Displaying and operating the file list............................................................... 320

G.4.3 Program Transfer Operation.................................................................................323

G.5 Input of Special Characters ....................................................................... 327

c-5

Page 12

Page 13

I. GENERAL

Page 14

Page 15

B-64414EN/01 GENERAL 1.GENERAL

1 GENERAL

This part explains the organization of this manual.

Chapter 1, "GENERAL", consists of the following sections:

1.1 ORGANIZATION ........................................................................4

1.2 APPLICABLE MODELS .............................................................5

1.3 RELATED MANUALS................................................................6

- 3 -

Page 16

1.GENERAL GENERAL B-64414EN/01

1.1 ORGANIZATION

This manual consists of the following parts:

SAFETY PRECAUTIONS

This section describes the precautions to be observed when

reading this manual.

I. GENERAL

This part describes the chapter organization, applicable models,

and related manuals.

II. SPECIFICATION

This part describes the specifications of the functions that operate

on the FAST Ethernet/FAST Data Server.

III. SETTING

This part describes the method of setting.

IV. OPERATION

This part describes the method of operating the Data Server

functions.

V. CONNECTION

This part describes the method of connection and provides notes.

VI. MAINTENANCE

This part provides an Ethernet board drawing number and

describes the meanings of LED indications.

APPENDIX

These appendixes describe additional information such as that

related to troubleshooting, the operation of the FTP client, and

how to set up the FTP server.

- 4 -

Page 17

B-64414EN/01 GENERAL 1.GENERAL

1.2 APPLICABLE MODELS

This Operator's Manual covers the following models.

The abbreviations in the following table are sometimes used in text

descriptions.

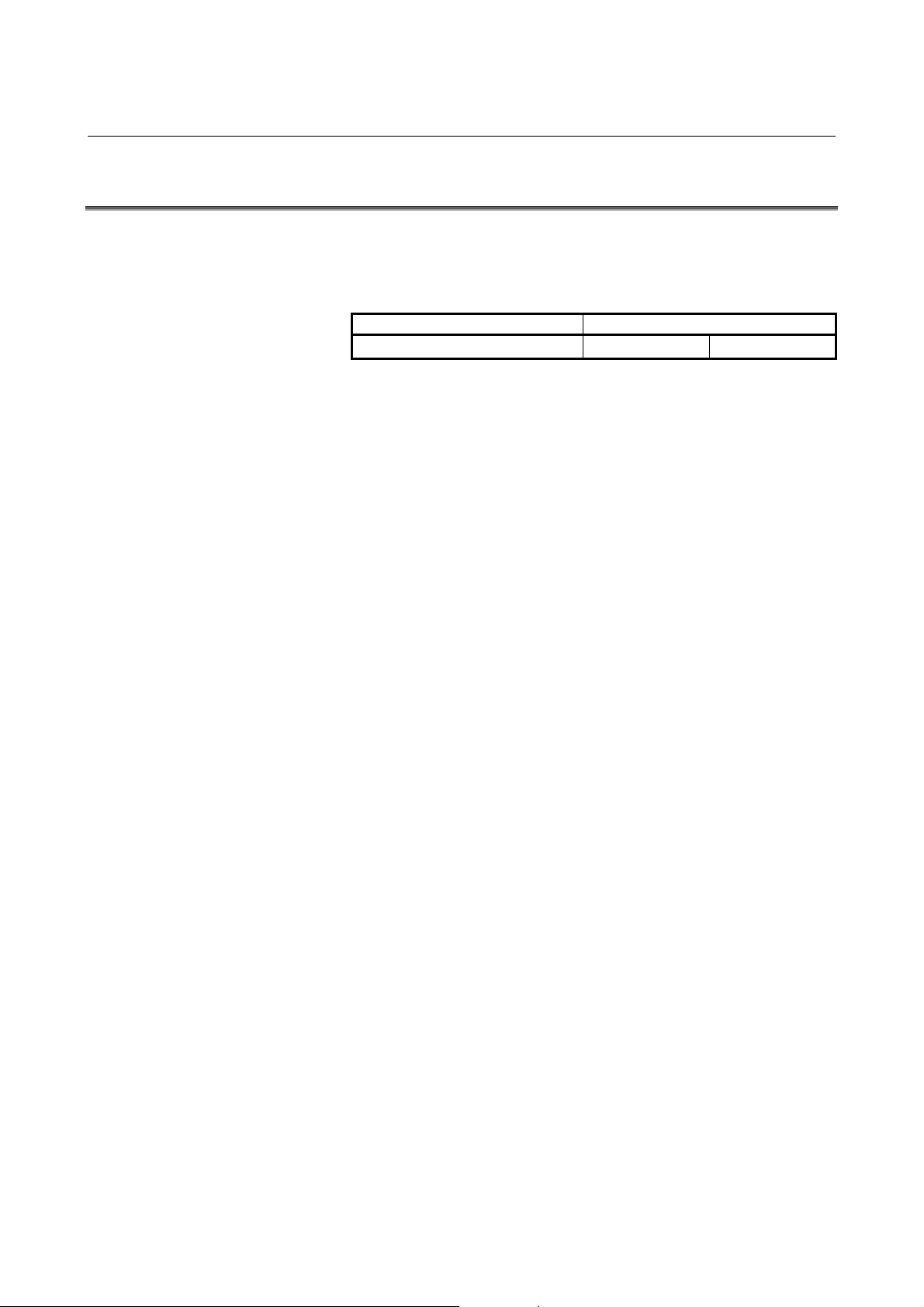

Model name Abbreviation

FANUC Series 0i-MODEL D Series 0i-D 0i-D

- 5 -

Page 18

1.GENERAL GENERAL B-64414EN/01

1.3 RELATED MANUALS

The table below lists manuals related to this Operator's Manual.

Refer to these manuals when you use this Operator's Manual.

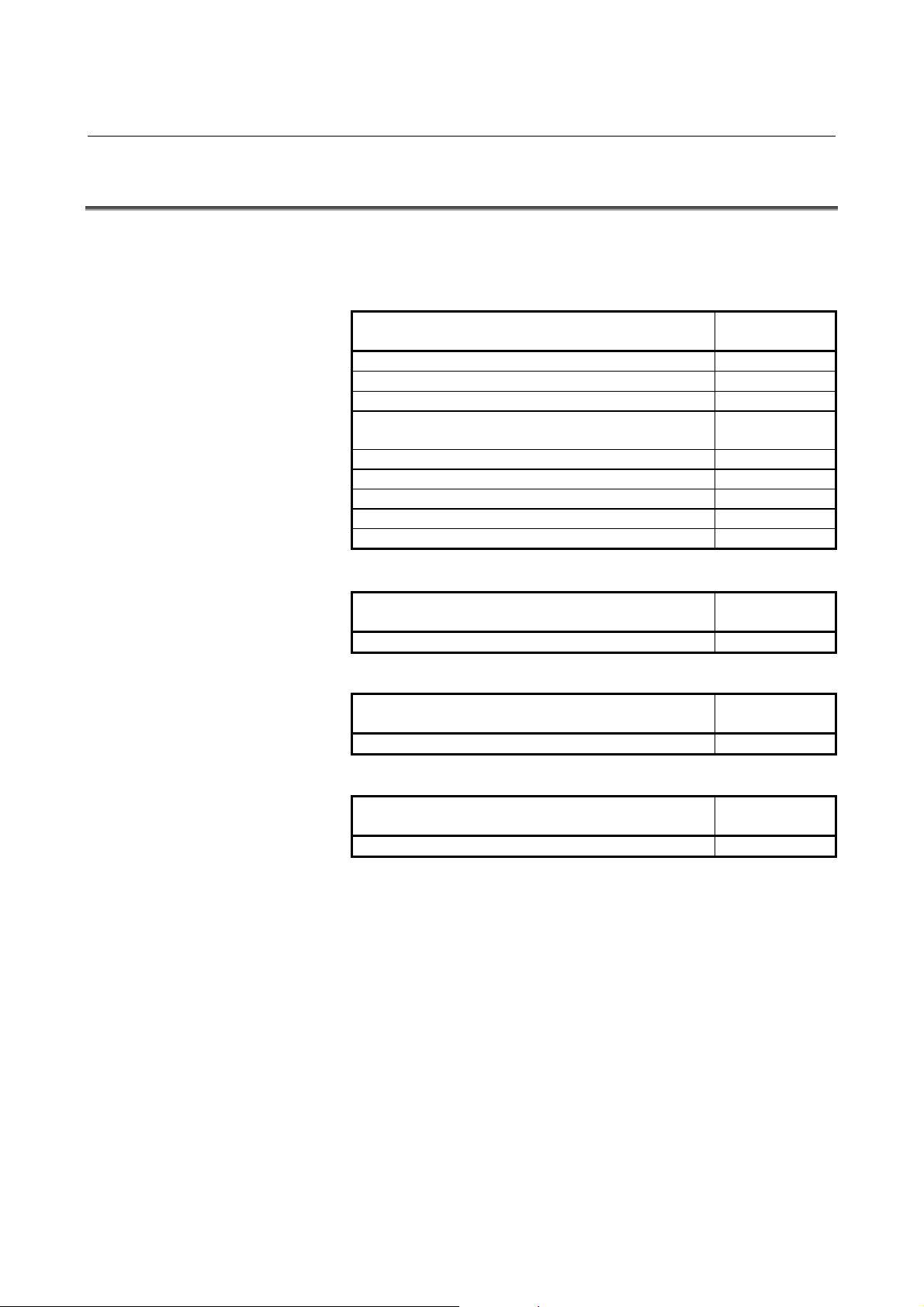

Related manuals of FANUC Series 0i-D

Manual name

DESCRIPTIONS B-64302EN

CONNECTION MANUAL (HARDWARE) B-64303EN

CONNECTION MANUAL (FUNCTION) B-64303EN-1

USER’S MANUAL

(Common to Lathe System/Machining Center System)

USER’S MANUAL (For Lathe System) B-64304EN-1

USER’S MANUAL (For Machining Center System) B-64304EN-2

MAINTENANCE MANUAL B-64305EN

PARAMETER MANUAL B-64310EN

START-UP MANUAL B-64304EN-3

Related manuals of FANUC CIMPLICITY i CELL

Manual name

OPERATOR’S MANUAL B-75074EN

Related manuals of FANUC Machine Remote Diagnosis Package

Manual name

OPERATOR’S MANUAL B-63734EN

Related manuals of FANUC Program Transfer Tool

Manual name

OPERATOR’S MANUAL B-64344EN

Specification

number

B-64304EN

Specification

number

Specification

number

Specification

number

- 6 -

Page 19

II. SPECIFICATION

Page 20

Page 21

B-64414EN/01 SPECIFICATION 1.PREFACE

1 PREFACE

In this manual, a board that has an ATA Flash card or a Compact

Flash Card (collectively called a memory card hereinafter) mounted to

enable the use of the Data Server functions is referred to as a "FAST

Data Server" (or simply as a "Data Server"). On the other hand, a

board that does not have a memory card mounted is referred to as a

"FAST Ethernet".

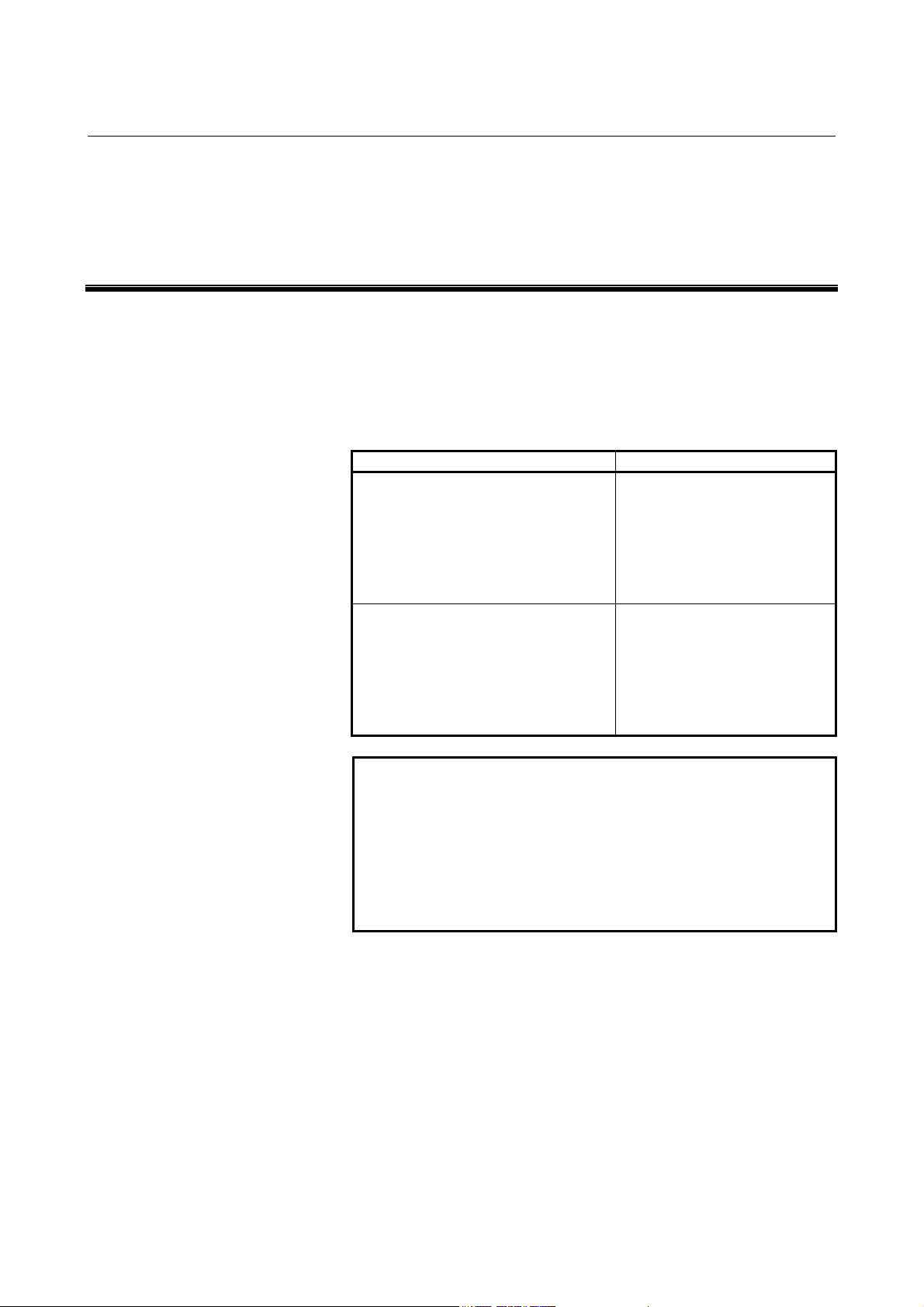

Board name Usable function

- Data Server functions

- FOCAS2/Ethernet functions

FAST Data Server

(or simply referred to as "Data Server")

FAST Ethernet

NOTE

To use the Data Server functions, the Data Server

function option is required.

To use the FOCAS2/Ethernet functions, CNC

screen display functions, machine remote

diagnosis functions, unsolicited messaging

function, and FTP file transfer function, the

Ethernet function option is required.

- CNC screen display functions

- Machine remote diagnosis

functions

- Unsolicited messaging

function (FOCAS2/Ethernet)

- FOCAS2/Ethernet functions

- CNC screen display functions

- Machine remote diagnosis

functions

- Unsolicited messaging

function (FOCAS2/Ethernet)

- FTP file transfer function

- 9 -

Page 22

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

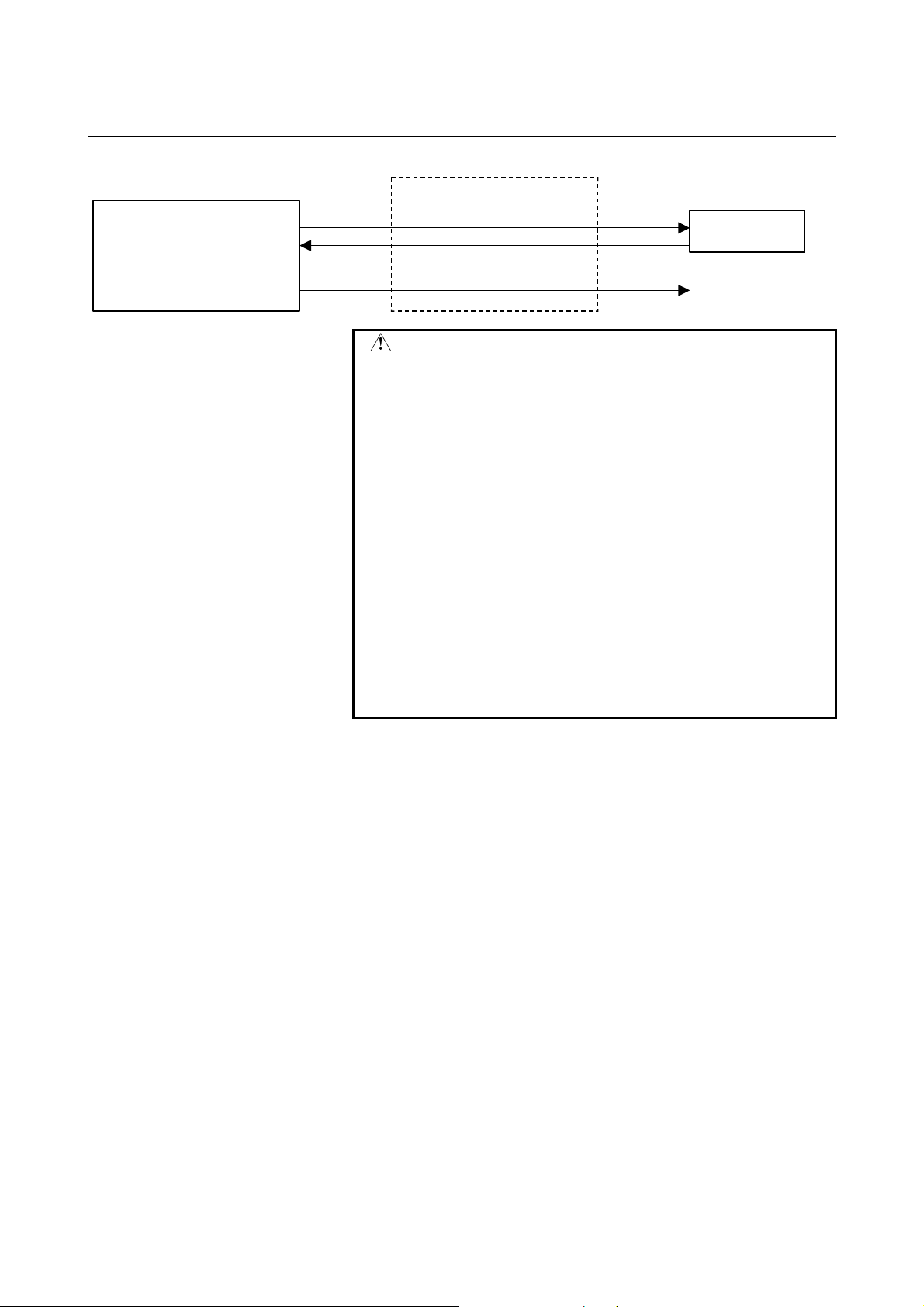

2 DATA SERVER FUNCTIONS

The Data Server functions use a memory card built into a board for

storing files and can transfer files and perform DNC operation using

FTP.

A Data Server can operate on both FTP client and FTP server.

When you use a Data Server to transfer files, the Data Server operates

as an FTP client and communicates with the FTP server on the host

computer.

When you use the host computer to transfer files, the Data Server

operates as an FTP server and communicates with the FTP client on

the host computer.

NOTE

1 When the host computer operates as an FTP

server, FTP server software must be run on the

host computer. When the host computer operates

as an FTP client, FTP client software must be run

on the host computer.

2 The Program Transfer Tool (drawing number:

A08B-9510-J513 [Version 3 or later]) is available

as a PC tool for transferring NC programs between

the CNC and personal computer. This tool allows

NC programs to be transferred between a personal

computer and CNC memory or Data Server

memory card through a simple operation on the

personal computer side. The transfer of NC

programs between a personal computer and CNC

memory requires the FOCAS2/Ethernet functions,

and that between a PC and Data Server memory

card requires the Data Server functions.

Chapter 2, "DATA SERVER FUNCTIONS", consists of the following

sections:

2.1 DATA SERVER FILE MANAGEMENT ..................................11

2.2 DATA SERVER MODES ..........................................................15

2.3 OPERATION FROM A DATA SERVER..................................17

2.4 NC PROGRAM FORMAT.........................................................19

2.5 LIST FILE FORMAT .................................................................21

2.6 ISO CODE INPUT/OUTPUT FUNCTION................................25

- 10 -

Page 23

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

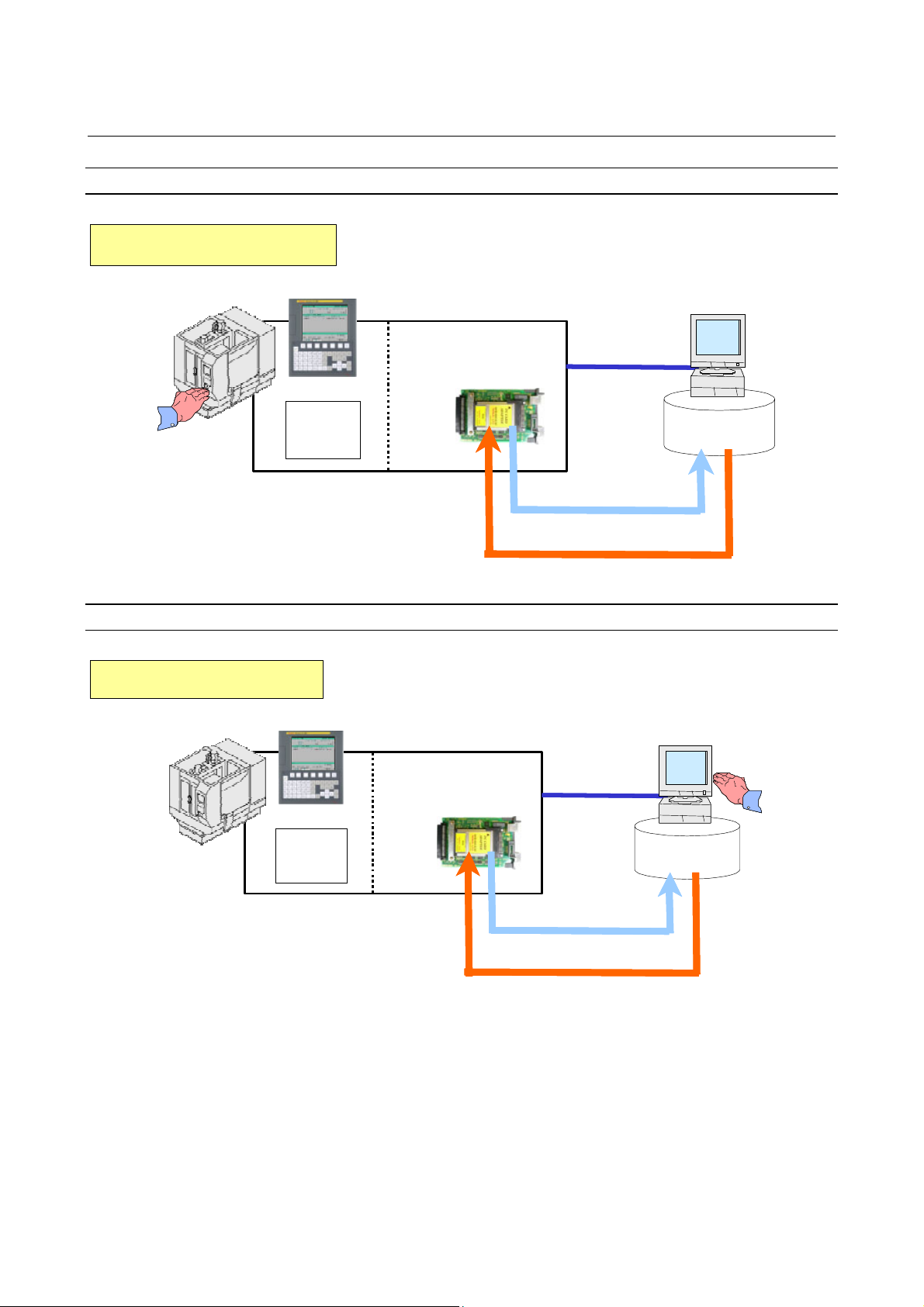

FTP client

FTP client

Operation

FTP server

FTP server

CNC

CNC

memory

CNC

FTP sever

FAST Data Server

Ethernet

Hard disk

PUT

GET

FTP client

CNC

memory

FAST Data Server

Ethernet

GET

PUT

Operation

Hard disk

- 11 -

Page 24

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

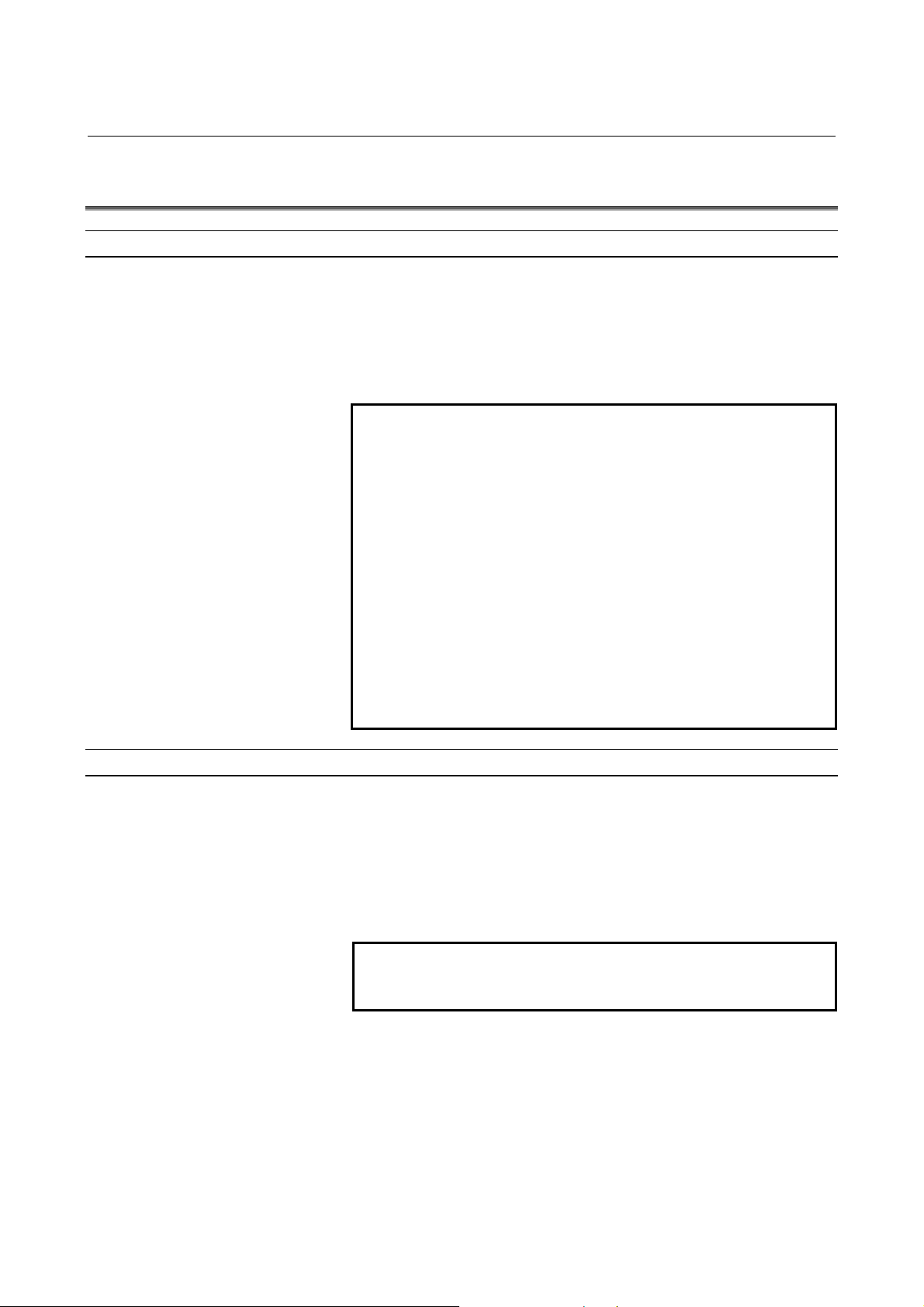

2.1 DATA SERVER FILE MANAGEMENT

With the Data Server functions, you can format the built-in memory

card in the CNC file management mode to manage NC programs.

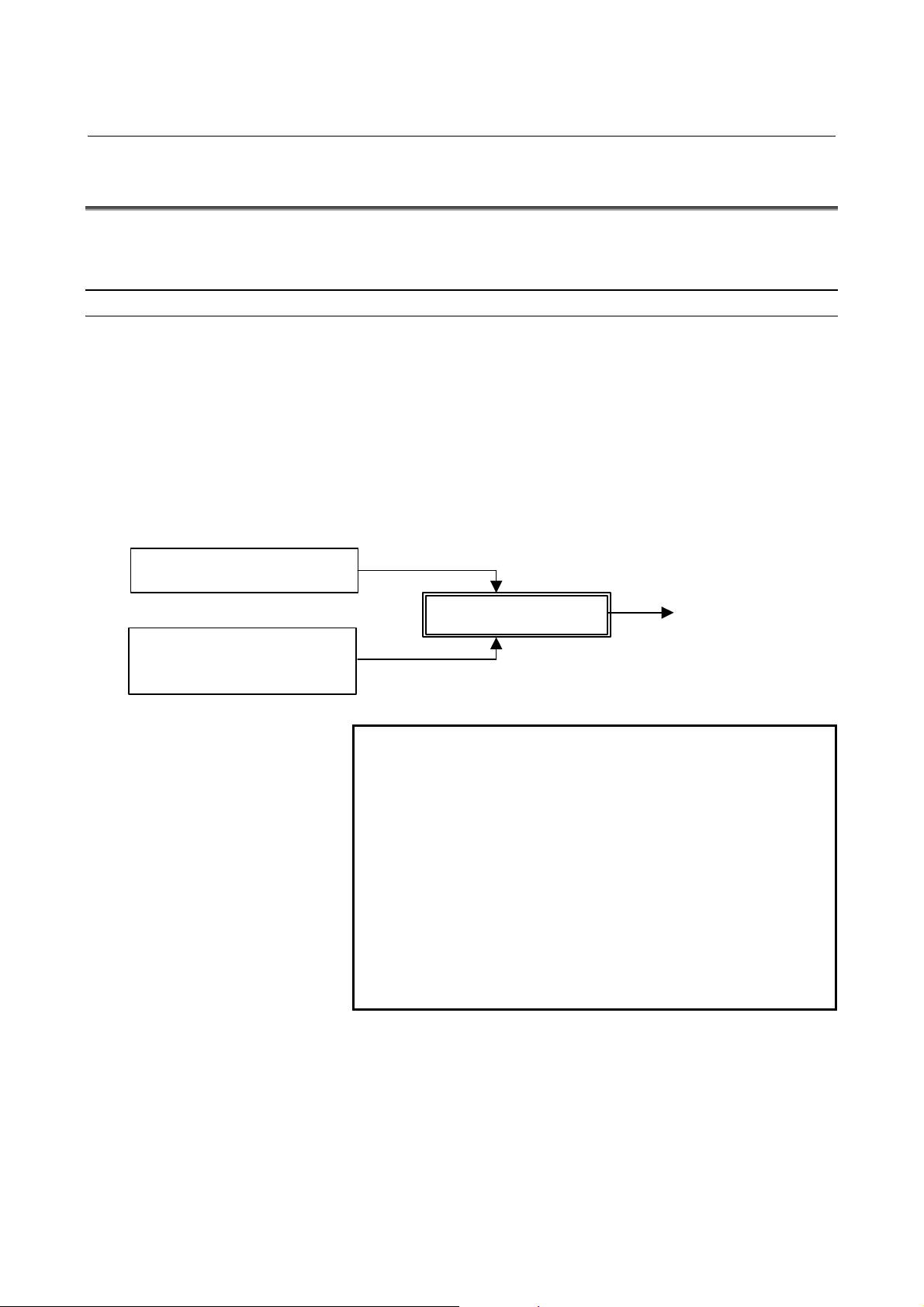

CNC file management

For NC programs managed in the CNC file management mode,

memory operation such as custom macro commands and M98-based

subprogram calling are available. Operate the NC programs using the

PROGRAM FOLDER screen in the same way as for NC programs in

the CNC memory.

As a CNC external input/output device, DNC operation and

M198-based subprogram calling are available. In this case, operate

NC programs using the DATA SERVER FILE LIST screen.

PROGRAM FOLDER screen

Edit operation

DATA SERVER FILE LIST

screen

CNC file management

(DNC operation is also available.)

File transfer operation

Memory operation

NOTE

1 The Data Server for the Series 0i-D allows editing

and memory operation of NC programs stored on

the memory card, so the method of managing files

on the memory card differs from the file

management method of conventional Data

Servers. Note that, therefore, the memory card of

the Series 0i-D is not compatible with the memory

cards of Data Server models for the Series 0i-C .

2 For operation and details of the DATA SERVER

FILE LIST screen, refer to Chapter 1,

"OPERATING THE DATA SERVER FUNCTIONS,"

in Part IV, "OPERATION."

- 12 -

Page 25

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.1.1 File Names of CNC File Management

A file name of CNC file management may be an arbitrary file name of

up to 32 characters.

• Up to 32 characters

• Alphabetic characters (in upper and lower cases), numeric

characters, and four symbols (+, -, _, and .)

NOTE

1 File names are case-sensitive.

2 Any file name or folder name cannot begin with a

period (.).

3 It is impossible to assign the same name to a file

and a folder.

File names and program numbers

When a file name assigned to a file consists of uppercase O and a

numeric value, the file name is treated as a program number.

Values ranging from 1 to 9999 can be used.

A value beyond this range cannot be used for a file name in the

program number format.

Example)

File names that can be used as program numbers

“O0123” Program number 123

“O0001” Program number 1

“O3000” Program number 3000

“O9999” Program number 9999

File names that cannot be used as program numbers

“ABC” (Does not have the format "O plus a numeric value")

“o123” (Does not begin with uppercase letter "O")

“O123.4” (Uses a character other than numeric characters)

NOTE

1 When files on a Data Server are managed by

program number, their program numbers always

consist of "O" plus a 4-digit number. So, even if

there are files managed with different file names

such as "O1" and "O01" on a personal computer,

their program numbers are regarded as the same

when these files are transferred to the Data Server.

2 When a text file assigned an arbitrary file name

other than a program number is input to the CNC

memory, it is necessary to specify the program

number set in the CNC memory.

- 13 -

Page 26

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

2.1.2 Files which can be Created on a Data Server

In the initial status, the maximum number of files which can be

created on a memory card on a Data Server is 2047 and the maximum

file size is 512 MB. Each folder is counted as one file.

The maximum number of files and the maximum file size can be

changed using NC parameter No. 930.

For details, see Section 2.3, "RELATED NC PARAMETERS," in Part

III, "SETTING."

2.1.3 Text Files and Binary Files

You can store the following two types of files on a memory card on a

Data Server: text files and binary files.

For a text file, memory operation and edit operation as well as DNC

operation can be performed by selecting it as a main program.

On the other hand, memory and edit operations cannot be performed

for a binary file.

If NC data other than an NC program is not handled as a binary file, it

may not be able to be input or output correctly. NC data punched and

stored on a memory card on a Data Server from the CNC is

automatically handled as a binary file. A file to be transferred from a

personal computer to a memory card on a Data Server must be

specified explicitly as a binary file.

More specifically, for GET operation on a Data Server operation

screen, you can use soft key [GET] or [BGET] to specify whether to

handle the file as a text file or a binary file.

When the Data Server is used as an FTP server, you can execute an

ASCII (text file) command or a BIN (binary file) command on your

personal computer (FTP client) to specify whether to handle the file as

a text file or a binary file.

NOTE

1 An NC program stored as a text file is converted to

an editable file format so that the file can be edited

on the CNC. For this reason, when a text file is

read from the host computer to the memory card

on the Data Server, then the file is transferred to

the host computer, binary compatibility can no

longer be maintained.

2 In the case of a text file, the file name and program

name are identical. If a file having a program name

different from the file name on the personal

computer side is transferred as a text file, the

program name is replaced by the file name.

Note, however, that only when the file is transferred

through an operation on the CNC side, precedence

can be given to the program name by setting bit 3

(DSF) of NC parameter No. 905.

- 14 -

Page 27

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.2 DATA SERVER MODES

Each Data Server mode determines the input or output destination

when a Data Server is operated as a CNC external input/output device.

You can select one of the following two modes.

NOTE

Data Server modes are valid only when the Data

Server is operated as an external storage device of

the CNC. In case of main program operation for

editing and a memory operation and an M98-based

subprogram call, programs on the memory card of

the Data Server are selected regardless of the

Data Server mode.

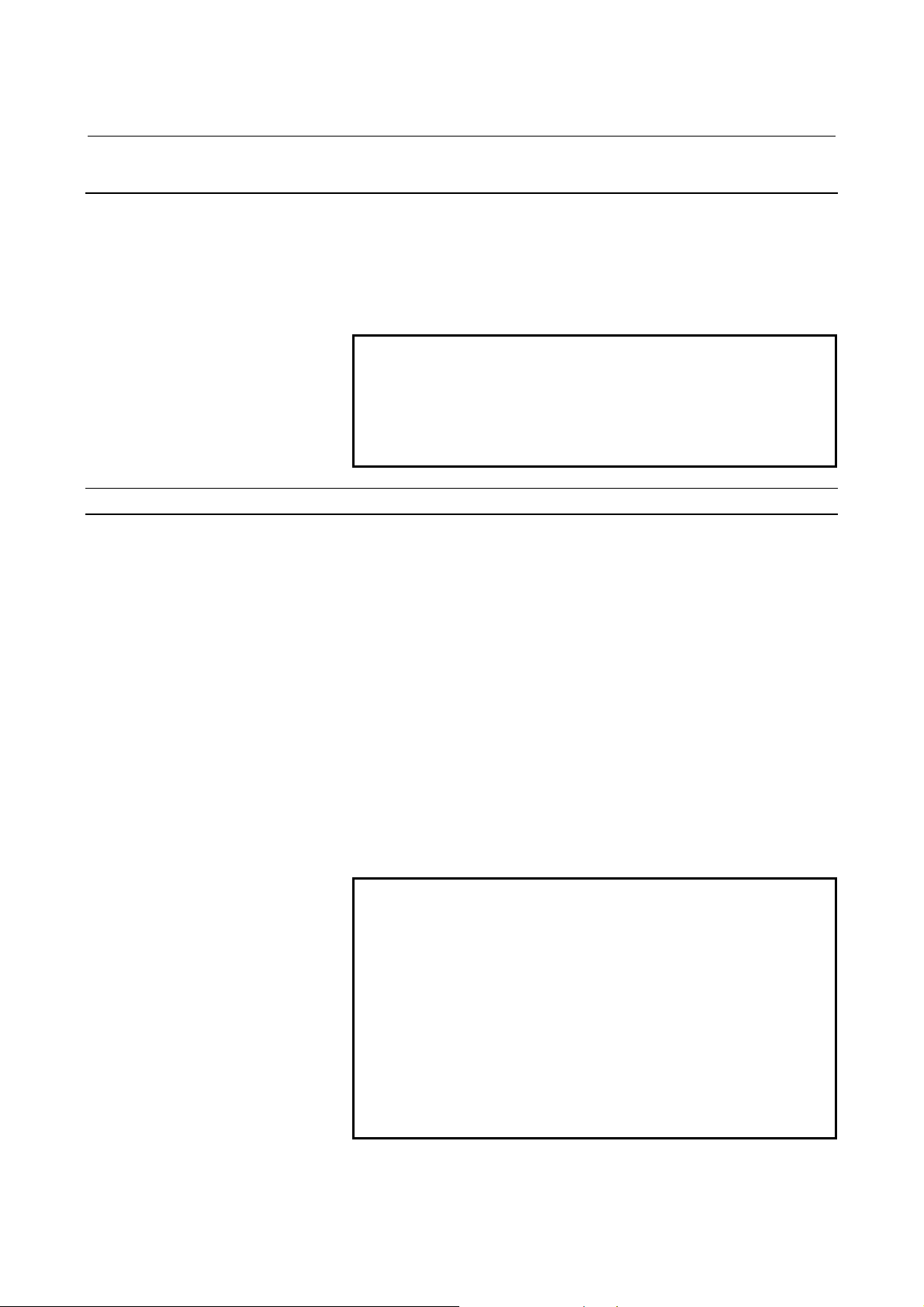

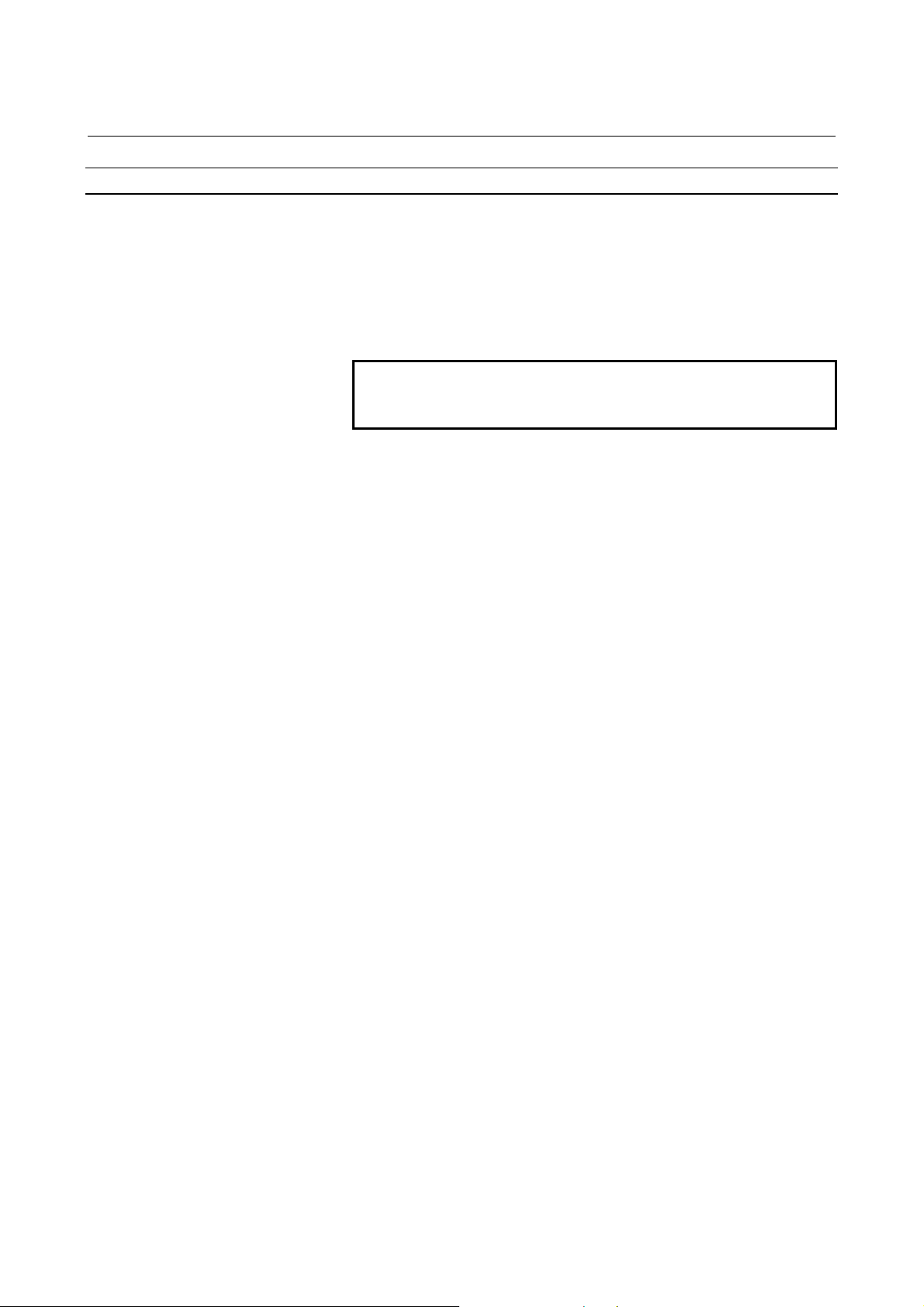

Storage mode

The memory card built into the Data Server is selected as the external

input/output device.

For example, when DNC operation or M198-based subprogram

calling is executed, the relevant NC program is called from the

memory card built into the Data Server.

When input operation is executed for the Data Server, the relevant NC

program is read from the memory card built into the Data Server.

Conversely, when NC program output operation is executed for the

Data Server, the output NC program is written on the memory card

built into the Data Server.

Input

FTP mode

Data Server

Memory card

Output

CNC memory

DNC operation

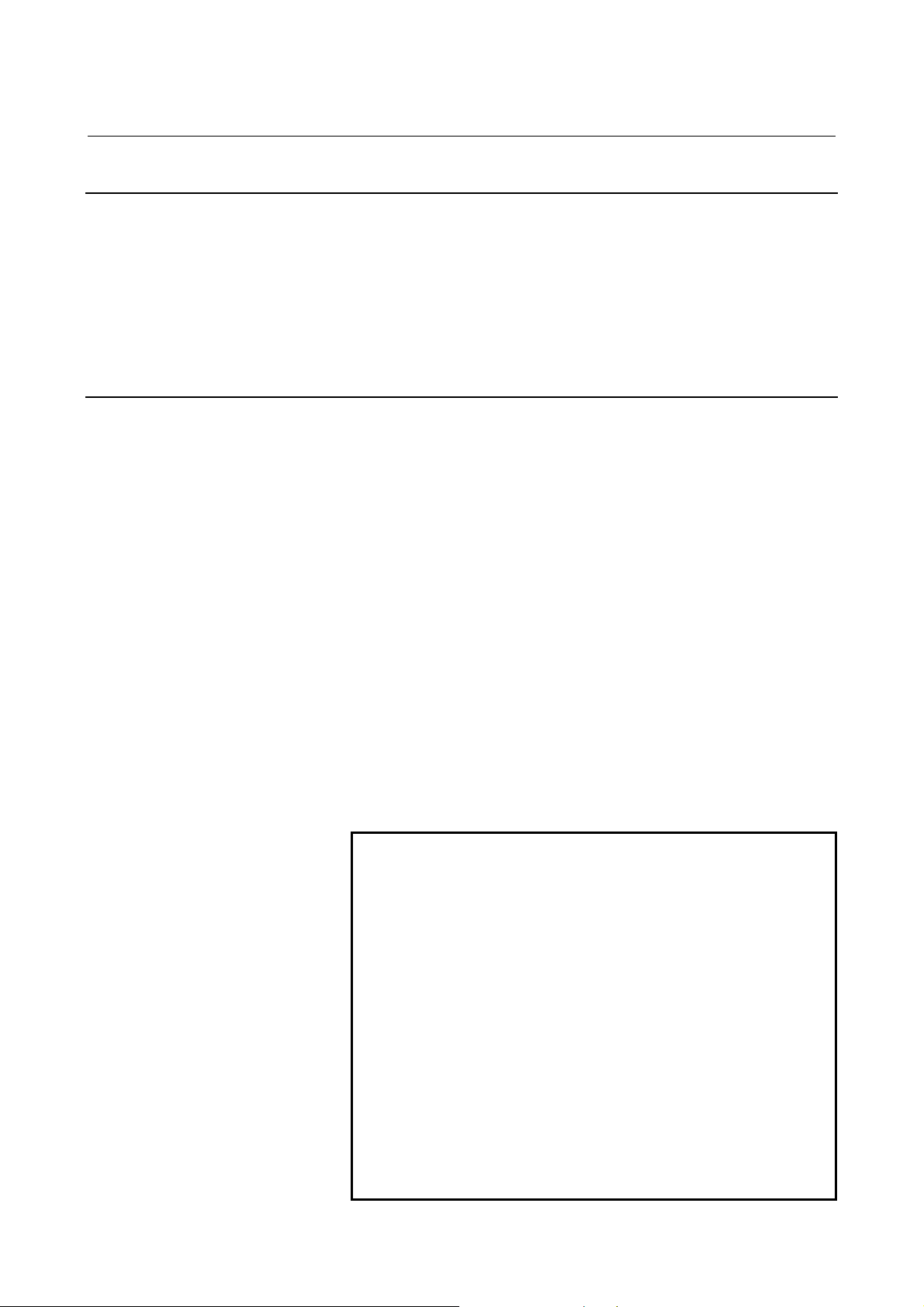

The host computer connected to the Data Server is selected as the

external input/output device.

For example, when DNC operation or M198-based subprogram

calling is executed, the relevant NC program is called from the host

computer.

When input operation is executed for the Data Server, the relevant NC

program is read from the host computer connected to the Data Server.

Conversely, when NC program output operation is executed for the

Data Server, the output NC program is directly written on the host

computer.

- 15 -

Page 28

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

Host computer

Data Server

Input

Output

CNC memory

DNC operation

CAUTION

1 In the FTP mode, an NC program is transferred

from the host computer to the CNC. For this

reason, if the line is disconnected during

communication for some reason such as noise on

the network, the disconnection directly affects the

CNC operation as compared with the storage

mode. Before DNC operation in the FTP mode,

surely take measures to prevent noise and make

sure that good communication conditions are

present.

2 When feed hold is performed during DNC

operation in the FTP mode, communication with

the host computer may be stopped. In this case,

the host computer may disconnect the

communication. Perform feed hold during a trial

run and completely confirm that the communication

with the host computer is not disconnected.

- 16 -

Page 29

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.3 OPERATION FROM A DATA SERVER

Memory operation

You can perform memory operation for an NC program on the

memory card built into a Data Server in the same way as for an NC

program in the CNC memory.

You can also supply an NC program simultaneously for a multipath

CNC system.

NOTE

1 When memory operation is performed, a selected

program on the Data Server must be a text file. It is

impossible to use a binary file for memory

operation.

2 Memory and edit operations for the Data Server

can be performed only for NC programs stored in

the memory card built in the Data Server. Memory

and edit operations cannot be performed directly

for files on the host computer.

3 When memory operation is performed using a

program in the Data Server memory card as the

main program, a subprogram in the same folder as

the main program can be called by the M98

subprogram call.

M198 subprogram operation

In the storage mode, you can perform M198 calling from the memory

card built into a Data Server. In the FTP mode, you can perform M198

calling form the host computer.

On the DATA SERVER FILE LIST screen, set an M198 folder in

advance. When M198 calling is specified, the set M198 folder is

searched for the target subprogram.

NOTE

M198 subprogram operation cannot be performed

simultaneously for two paths.

- 17 -

Page 30

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

DNC operation

In the storage mode, you can perform DNC operation from the

memory card built into a Data Server. In the FTP, you can perform

DNC operation from the host computer.

On the DATA SERVER FILE LIST screen, set the file name for DNC

operation in advance. When DNC operation starts, the set DNC

operation file is called.

NOTE

DNC operation cannot be performed for the

second path.

- 18 -

Page 31

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.4 NC PROGRAM FORMAT

NC programs prepared on the host computer must have the following

format:

% TITLE ;

O0001(COMMENT) ;

⋅

⋅

⋅

M30 ;

%

An NC program starts with a tape start (%). In the subsequent part

(leader section) until EOB (;, program start) is encountered, a

comment such as a title can be inserted as necessary.

At the beginning of the program part, be sure to specify a program

name, which must be either an O number (program number) or an

arbitrary file name of not more than 32 characters enclosed by "<" and

">". This O number or file name must be used for management on the

personal computer.

If the O number in the NC program or the program name in the

arbitrary file name does not match the file name on the personal

computer, the file name on the personal computer is used as the

program name by default when the file is transferred from the personal

computer to the Data Server.

The semicolon ";" used at the end of each block means EOB (end of

block) and actually functions as LF (LF: 0A in hexadecimal), CR-LF

(CR: 0D in hexadecimal), or LF-CR-CR.

The NC program must end with "M code ; tape end (%)".

For information about the NC program structure, refer to the user's

manual (B-64304EN).

WARNING

If an NC program prepared on the host computer

does not use the program format specified by the

CNC, executing the NC program can cause an

unpredictable operation. So, special care should be

taken when an NC program is prepared on the host

computer.

- 19 -

Page 32

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

NOTE

1 Put "%" (tape end) at the end of the file. Do not

allow the program to continue beyond the tape

end.

2 Do not use any characters other than the usable

characters, including in comment sections. If any

unusable characters - Japanese characters in

particular - are used, they may be interpreted as

unexpected control characters.

3 EIA codes cannot be used for a Data Server.

4 When two or more NC programs are managed with

a single file on the host computer, transferring that

file to the Data Server memory card as a text file

results in those programs being registered as a

single NC program; the transferred file is not

automatically divided into separate NC programs.

- 20 -

Page 33

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.5 LIST FILE FORMAT

In the LIST-GET, LIST-PUT, and LIST-DELETE functions described

later, one of the following list file formats must be used:

Format 1

% ;

O0001(COMMENT) ;

N111 ;

N222 ;

N333 ;

:

:

N999 ;

%

Format 2

% ;

O0001(COMMENT) ;

N111 (PC-File) ;

N222 (PC-File) ;

N333 (PC-File) ;

:

:

N999 (PC-File) ;

%

Format 3

% ;

O0001(COMMENT) ;

(Dtsvr-File) ;

(Dtsvr-File) ;

(Dtsvr-File) ;

:

:

(Dtsvr-File) ;

%

Format 4

% ;

O0001(COMMENT) ;

(Dtsvr-File, PC-File) ;

(Dtsvr-File, PC-File) ;

(Dtsvr-File, PC-File) ;

:

:

(Dtsvr-File, PC-File) ;

%

- 21 -

Page 34

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

Specifications common to all formats

<1> A list file begins with a tape start "%".

<2> In the next block, be sure to specify an O number. Assign this O

number as the file name.

A comment enclosed in parentheses "(" and ")" can be inserted

between the O number and EOB.

<3> In the subsequent blocks, specify files to be processed.

<4> The list file must end with "%".

Specifications of format 1

The following describes the specifications of list file format 1:

<1> This specification method applies when the file names of files to

be processed have the format "Oxxxx" (where "xxxx" denotes a

4-digit number). In this case, change "O" in file name "Oxxxx" to

"N" when specifying the file name. The 4-digit number can be

zero-suppressed. The example shows that files O0111, O0222,

O0333, and so on up to O0999 are processed sequentially.

<2> The LIST-GET service transfers "Oxxxx" files stored on the

built-in hard disk of the host computer to the built-in memory

card of the FAST Data Server without modifying file names

"Oxxxx". The LIST-PUT service transfers "Oxxxx" files stored

on the built-in memory card of the FAST Data Server to the

built-in hard disk of the host computer without modifying file

names "Oxxxx". The LIST-DELETE service deletes "Oxxxx"

files stored on the built-in memory card of the FAST Data

Server.

Specifications of format 2

The following describes the specifications of list file format 2:

<1> This specification method applies when files to be processed are

named "Oxxxx" (where "xxxx" denotes a 4-digit number) on the

built-in memory card of the FAST Data Server and are named

arbitrary file names on the built-in hard disk of the host computer.

In this case, change "O" in file name "Oxxxx" to "N" when

specifying the file name on the FAST Data Server. The 4-digit

number can be zero-suppressed. The example shows that files

O0111, O0222, O0333, and so on up to O0999 are processed

sequentially.

A file name on the built-in hard disk of the host computer can be

specified by enclosing it with parentheses "(" and ")" following

the corresponding "Nxxxx". The characters that can be used in

file names depend on the OS of the host computer.

<2> The LIST-GET service transfers files with arbitrary file names

"PC-File" stored on the built-in hard disk of the host computer to

the built-in memory card of the FAST Data Server as "Oxxxx"

files. The LIST-PUT service transfers "Oxxxx" files stored on

the built-in memory card of the FAST Data Server to the built-in

hard disk of the host computer as files with arbitrary file names

"PC-File". The LIST-DELETE service deletes "Oxxxx" files

stored on the built-in memory card of the FAST Data Server.

- 22 -

Page 35

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

Specifications of format 3

The following describes the specifications of list file format 3:

<1> This specification method applies when the file names of files to

be processed are arbitrary file names. In this case, file names on

the built-in memory card of the FAST Data Server and on the

built-in hard disk of the host computer are assumed to be the

same. Specify an arbitrary file name enclosed with parentheses

"(" and ")". Arbitrary file names are those that can be used on the

Data Server side.

<2> The LIST-GET service transfers files with arbitrary file names

"Dtsvr-File" stored on the built-in hard disk of the host computer

to the built-in memory card of the FAST Data Server with the

file names kept unchanged.

The LIST-PUT service transfers "Dtsvr-File" files stored on the

built-in memory card of the FAST Data Server to the built-in

hard disk of the host computer with the file names "Dtsvr-File"

kept unchanged. The LIST-DELETE service deletes "Dtsvr-File"

files stored on the built-in memory card of the FAST Data

Server.

Specifications of format 4

The following describes the specifications of list file format 4:

<1> This specification method applies when files to be processed

have arbitrary file names. In this case, file names on the built-in

memory card of the FAST Data Server and file names on the

built-in hard disk of the host computer are assumed to be

different. Specify a file name on the built-in memory card of the

FAST Data Server and a file name on the built-in hard disk of the

host computer in parentheses, separated by a comma ",".

<2> The LIST-GET service transfers files with arbitrary file names

"PC-File" stored on the built-in hard disk of the host computer to

the built-in memory card of the FAST Data Server as

"Dtsvr-File" files.

The LIST-PUT service transfers "Dtsvr-File" files stored on the

built-in memory card of the FAST Data Server to files with file

name "PC-File" on the built-in hard disk of the host computer.

The LIST-DELETE service deletes "Dtsvr-File" files stored on

the built-in memory card of the FAST Data Server.

Limitations on file names in a list file

The following limitations apply when file names are specified in a list

file:

<1> As arbitrary file names on the built-in memory card of the FAST

Data Server, only the following 66 types of ASCII characters can

be used and the maximum length is 32 characters:

Numeric characters 0 to 9

Lowercase letters a to z

Uppercase letters A to Z

Four symbols (+, -, _, .)

- 23 -

Page 36

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

<2> The characters that can be used in arbitrary file names on the

built-in hard disk of the host computer depend on the OS of the

host computer.

Arbitrary file names may consist of up to 255 characters.

However, the number of characters that can actually be used

depends on the OS of the host computer.

Storage locations of list files

The LIST-GET, LIST-PUT, and LIST-DELETE services are useful

functions for managing NC programs in groups.

The places where list files are prepared vary depending on the service

to be executed.

For the LIST-GET service, NC programs to be operated on are present

on the built-in hard disk of the host computer, so list files are placed

also on the built-in hard disk of the host computer.

For the LIST-PUT and LIST-DELETE services, NC programs to be

operated on are present on the built-in memory card of the FAST Data

Server, so list files are also prepared on the built-in memory card of

the FAST Data Server.

- 24 -

Page 37

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

2.6 ISO CODE INPUT/OUTPUT FUNCTION

This function is intended to accomplish NC data input and output

between the CNC and Data Server, as well as between a personal

computer and Data Server, using the ISO code. Unlike the traditional

ASCII code characters, each ISO code character has parity data

appended to it. The function checks this parity data, which improves

the reliability of data input and output operations.

While the most significant bit of an ASCII code character is in an OFF

state, the ISO code uses the most significant bit to store parity data so

that each character has an even number of ON bits.

NOTE

1 NC data may not be transferred properly between

a personal computer and Data Server, depending

on the FTP communication software used on the

personal computer.

2 If a parity error is found in the ISO code in the

comment section, it is not regarded as an error and

the character in question is converted to a space.

3 If the ASCII code is selected as the input/output

code, the parity check is not performed. Even if the

data to be transferred is ISO code data, it is

transferred as ASCII code data with the parity data

in the most significant bit removed.

4 To input data to or output data from the CNC

requires that a Data Server be selected as the

input/output device. For information about

input/output device and input/output code

selection, see SETTING, Section 2.3, "RELATED

NC PARAMETERS".

5 A tool (FANUC ISO Converter) is available that

allows you to create and check ISO code NC data

on a personal computer. For details of this tool,

refer to the appendix of the "User’s Manual

(Common to Lathe System/Machining Center

System) (B-64304EN)".

- 25 -

Page 38

2.DATA SERVER FUNCTIONS SPECIFICATION B-64414EN/01

Input from the Data Server to CNC

If the ISO code is selected as the input/output code, an ISO code

check is performed to verify the validity of data when the CNC

receives the data from the Data Server.

If any character with invalid parity data is found, the input/output

operation ends abnormally.

Target functions

<1> Program input

<2> M198 subprogram call

<3> DNC operation

NOTE

1 The CNC checks the ISO code in the received

data, regardless of whether the Data Server file is

a text file or binary file.

For information about text files and binary files, see

Subsection 2.1.3, "Text Files and Binary Files".

2 The CNC checks the ISO code in the received

data, regardless of the Data Server mode.

In the FTP mode, therefore, ISO code NC data

needs to be prepared on the personal computer

side.

For information about the Data Server mode, see

Section 2.2, "DATA SERVER MODES".

Output from the CNC to Data Server

If the ISO code is selected as the input/output code, an ISO code

check is performed to verify the validity of data when the data is

stored in the Data Server memory card.

If any character with invalid parity data is found, the input/output

operation ends abnormally.

Target function

<1> Program output

NOTE

1 When the Data Server is in the FTP mode, data is

output directly to the personal computer and the

Data Server does not perform the ISO code check.

In this case, perform the check on the personal

computer side.

2 When more than one NC program is output

simultaneously or NC parameters are output, the

data is output to the Data Server as a binary file.

In the case of a binary file, the Data Server does

not perform the ISO code check.

- 26 -

Page 39

B-64414EN/01 SPECIFICATION 2.DATA SERVER FUNCTIONS

File transfer from a personal computer to Data Server

If the ISO code is selected as the input/output code, an ISO code

check is performed to verify the validity of data when the data

received from the personal computer is stored in the Data Server

memory card.

If any character with invalid parity data is found, the input/output

operation ends abnormally.

Target functions

<1> GET (Data Server = FTP client)

<2> PUT (Data Server = FTP server)

NOTE

1 It is necessary to prepare ISO code NC data on the

personal computer side.

2 In the case of binary file transfer, the ISO code

check is not performed when the data is stored in

the Data Server memory card.

File transfer from the Data Server to personal computer

If the ISO code is selected as the input/output code, data is output as

ISO code data from the Data Server memory card.

Target functions

<1> PUT (Data Server = FTP client)

<2> GET (Data Server = FTP server)

NOTE

1 Perform the ISO code check on the personal

computer side, as needed.

2 In the case of binary file transfer, the Data Server

does not perform ISO code conversion.

- 27 -

Page 40

3.FOCAS2/Ethernet FUNCTIONS SPECIFICATION B-64414EN/01

3 FOCAS2/Ethernet FUNCTIONS

The FOCAS2/Ethernet functions can remotely control and monitor the

CNC by using a personal computer. For details, refer to the manual

delivered with the FOCAS2 library software.

NOTE

1 In the FOCAS2/Ethernet functions, the CNC

operates as a server and waits for a

communication start request from a personal

computer that operates as a client.

As communication with the personal computer

starts, two sockets are used for control and

monitoring from the personal computer and for file

transfer.

2 The Program Transfer Tool (drawing number:

A08B-9510-J513 [Version 3 or later]) is available

as a PC tool for transferring NC programs between

the CNC and personal computer. This tool allows

NC programs to be transferred between a personal

computer and CNC memory or Data Server

memory card through a simple operation on the

personal computer side. The transfer of NC

programs between a personal computer and CNC

memory requires the FOCAS2/Ethernet functions,

and that between a PC and Data Server memory

card requires the Data Server functions.

- 28 -

Page 41

B-64414EN/01 SPECIFICATION 4.DNS/DHCP FUNCTIONS

4 DNS/DHCP FUNCTIONS

If DNS/DHCP functions are used for communication setting of the

Data Server functions and FOCAS2/Ethernet functions, Ethernet

addresses (IP address and subnet mask) can be set at a time on the host

computer to facilitate Ethernet address control.

DNS

With the DNS function, a fully qualified domain name (e.g.,

www.fanuc.co.jp

address just consisting of numbers (e.g., 192.168.0.10) when a TCP/IP

communication destination is to be specified.

NOTE

To use the DNS function, a personal computer

having the DNS server function is additionally

required. See APPENDIX D, "DNS/DHCP

FUNCTION."

DHCP

) can be specified instead of a hard-to-remember IP

With the DHCP function, Ethernet addresses (IP address and subnet

mask) that need to be set on the CNC can be set on the host computer.

NOTE

To use the DHCP function, a personal computer

having the DHCP server function is additionally

required. See APPENDIX D, "DNS/DHCP

FUNCTION."

- 29 -

Page 42

5. MACHINE REMOTE

DIAGNOSIS FUNCTIONS

SPECIFICATION B-64414EN/01

5 MACHINE REMOTE DIAGNOSIS

FUNCTIONS

With the machine remote diagnosis functions, checking of the internal

CNC status, ladder program editing, and other operations can be

performed as necessary by using a personal computer through a LAN.

For details, refer to “Machine Remote Diagnosis Package

OPERATOR’S MANUAL (B-63734EN).”

- 30 -

Page 43

6.UNSOLICITED MESSAGING

B-64414EN/01 SPECIFICATION

FUNCTION

6 UNSOLICITED MESSAGING FUNCTION

This chapter describes the unsolicited messaging function.

- 31 -

Page 44

6. UNSOLICITED MESSAGING

A

A

A

A

FUNCTION

SPECIFICATION B-64414EN/01

Overview of the unsolicited messaging function

An overview of the unsolicited messaging function is provided below.

With the unsolicited messaging function, the CNC transmits messages

(CNC/PMC data) in an unsolicited manner to application software on

the personal computer according to a command from an NC program

or ladder program. By using this function, the need for application

processing on the personal computer to periodically inquire about the

state of the CNC can be eliminated.

When the conventional function is used

Inquiry

Response

pplication software

When the unsolicited messaging function is used

NC program or ladder

program checks for

CNC/PMC data

changes.

NC program or ladder

program

NOTE

The unsolicited messaging function is a part of the

pplication software

アプリケーションソフトウェア

Notification

FOCAS2/Ethernet function.

pplication checks for

CNC/PMC data changes.

pplication receives

notification from CNC.

- 32 -

Page 45

6.UNSOLICITED MESSAGING

B-64414EN/01 SPECIFICATION

FUNCTION

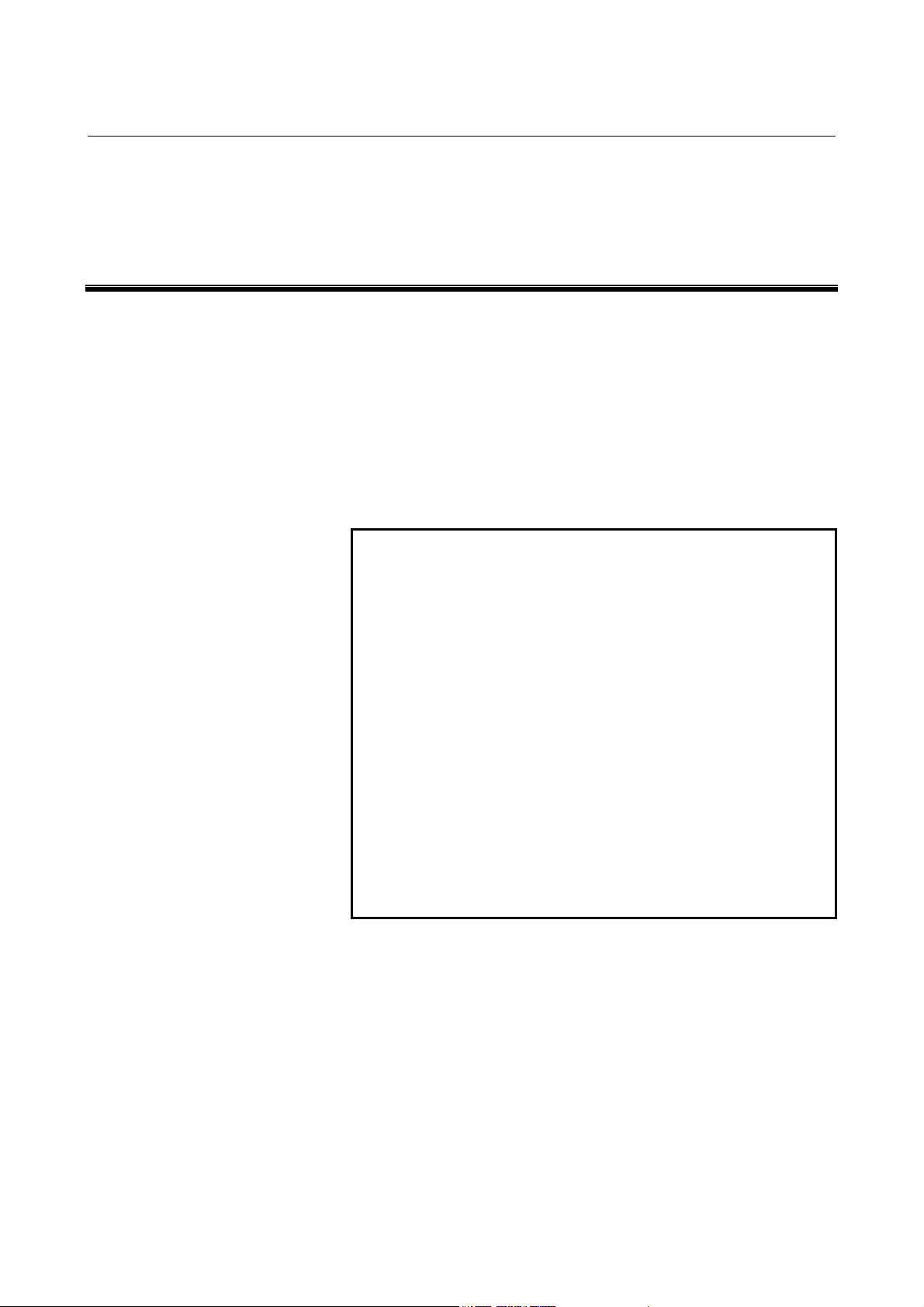

Unsolicited messaging function execution procedure

The execution procedure for the unsolicited messaging function is

described below.

1 Preparation on the personal compute

Create an application using the FOCAS2 function for the

unsolicited messaging function and install the unsolicited

message server on a personal computer. For the method of

creating an application using the FOCAS2 function for the

unsolicited messaging function and the method of installing the

unsolicited message server, refer to

MESSAGING FUNCTION", in "FANUC Open CNC

FOCAS1/FOCAS2 CNC/PMC Data Window Library Operator's

Manual".

2 Preparation on the CNC

Create an NC program or ladder program for controlling

unsolicited messaging.

For the method of creating an NC program or ladder program,

see Appendix F.2, "EXECUTING THE UNSOLICITED

MESSAGING FUNCTION."

3 Setting of the communication parameters for the

unsolicited messaging function

To use the unsolicited messaging function, the following

communication parameter settings are needed:

(1) Setting for using the FOCAS2/Ethernet function

(2) Setting of the parameters for the unsolicited messaging

function

For (2), a choice can be made from two modes of setting: CNC

mode for setting on the CNC screen and the PC mode for setting

on the personal computer.

For the setting method of (1) and (2), see Appendix F.1,

"SETTING OF THE UNSOLICITED MESSAGING

FUNCTION."

4 Starting the NC program or ladder program

Start the NC program or ladder program created in step 2,

"Preparation on the CNC". At this time, no unsolicited message

is transmitted to the personal computer until step 5, "Starting the

unsolicited messaging function", is executed.

5 Starting the unsolicited messaging function

Execute the FOCAS2 function cnc_unsolicstart on the personal

computer. This execution places the CNC in the state (named

"Ready") where a transmission request from the NC program or

ladder program is awaited. Each time a transmission request is

made from the NC program or ladder program, an unsolicited

message is automatically transmitted to the personal computer.

6 Ending the unsolicited messaging function

To end unsolicited message transmission, execute the FOCAS2

function cnc_unsolicstop on the personal computer. This

execution places the CNC in the state (named "Not Ready")

where no unsolicited message is transmitted even when a request

for transmission is made from the NC program or ladder

program.

Chapter 5, "UNSOLICITED

- 33 -

Page 46

7.FTP FILE TRANSFER FUNCTION SPECIFICATION B-64414EN/01

7 FTP FILE TRANSFER FUNCTION

The FTP file transfer function is operated from the CNC to transfer a

file. It works as an FTP client and communicates with the FTP server

on the host computer.

NOTE

1 The FTP server software needs to be running on

the host computer.

2 The FTP file transfer function cannot perform M198

subprogram calling or DNC operation.

- 34 -

Page 47

III. SETTING

Page 48

Page 49

1. SETTING THE COMMUNICATION

B-64414EN/01 SETTING

FUNCTION

1 SETTING THE COMMUNICATION

FUNCTION

This part describes the settings required to operate the following

FAST Ethernet/FAST Data Server functions:

• Data Server functions

• FOCAS2/Ethernet functions

• CNC screen display functions

NOTE

For details of the machine remote diagnosis

functions, unsolicited messaging function, and FTP

file transfer function, see the relevant appendixes.

Notes on using the Data Server functions

CAUTION

When setting the FAST Ethernet/FAST Data

Server for the first time, carefully set data such as

an IP address and conduct a sufficient

communication test, consulting with your network

administrator.

If data such as an IP address is not set correctly, a

communication failure can affect the entire

network. Take sufficient care.

- 37 -

Page 50

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

2 SETTING THE DATA SERVER

FUNCTIONS

This chapter describes the communication setting for the Data Server

functions.

Notes on using the functions for the first time

CAUTION

1 When using the FAST Data Server for the first time, be sure to

initialize the memory card, set parameters, then turn the power off

then back on. If an attempt is made to use the Data Server functions

without following these steps, normal operation is not guaranteed.

2 Before performing FTP communication using the FAST Data Server

for the first time, consult with your network administrator, carefully

set a network address and other items, and conduct communication

tests thoroughly. Any error in settings such as a network address

setting can lead to an adverse influence such as a communication

failure on the entire network.

In particular, IP address duplication causes an intermittent

communication failure in the Data Server, which can result in a

system error in the CNC. So, be very careful when making settings.

3 When the power to the CNC is turned off during access to the

memory card, files stored on the memory card may be destroyed.

So, be careful not to turn off the power to the CNC during access to

the memory card.

4 In preparation for damage to the memory card, always take backup

copies of the files stored on the memory card to the host computer.

NOTE

1 With the Data Server functions (FTP client), a single CNC can

connect only one FTP server.

2 With the Data Server functions (FTP server), a single CNC can

connect up to five FTP clients. However, some FTP client software

programs may each internally use two or more FTP clients. Note,

therefore, that the number of FTP clients is not always equal to the

number of applications.

3 The Data Server functions do not support passive mode (PASV

command).

- 38 -

Page 51

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

2.1 OPERATING THE DATA SERVER SETTING SCREEN

This section describes the setting screen for operating the Data Server

functions.

Procedure

1 Press the function key .

2 Soft key [ETHBRD] appear. (When there is no soft keys, press

the continue key.)

3 Press soft key [ETHBRD] to display the Ethernet Setting screen.

4 Press soft keys [COMMON] and [DTSVR] and then enter

parameters for the items that appear.

- 39 -

Page 52

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

COMMON screen (BASIC)

Press soft key [COMMON] to display the COMMON screen

(BASIC).

Setting item

Display item

COMMON screen (BASIC)

Item Description

IP ADDRESS Specify the IP address of the FAST Data Server.

(Example of specification format: "192.168.0.100")

SUBNET MASK Specify a mask address for the IP addresses of the

network.

(Example of specification format: "255.255.255.0")

ROUTER IP

ADDRESS

Specify the IP address of the router.

Specify this item when the network contains a router.

(Example of specification format: "192.168.0.253")

Item Description

MAC ADDRESS FAST Data Server MAC address

NOTE

The second page (detail screen) of the COMMON

screen is to be set when the DNS/DHCP function is

used. For details, see Appendix D, "DNS/DHCP

FUNCTION."

- 40 -

Page 53

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

Data Server screens (CONNECT 1, CONNECT 2, CONNECT 3)

Press soft key [DTSVR] to display the Data Server screen.

By using page keys

, the three host computers at

connection destinations 1, 2, and 3 can be set.

Data Server screen 1 (for connection destination 1)

Data Server screen 2 (for connection destination 1)

- 41 -

Page 54

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

Setting item

Item Description

HOST NAME

PORT NUMBER Specify the port number. Usually, set 21 because the

USER NAME Specify the name of the user to log on to the host

PASSWORD Specify the password for the above user name.

LOGIN FOLDER Specify a work folder to be used when the user logs in

Specify the IP address of the host computer.

(Example of specification format: "192.168.0.200")

FTP communication is used.

computer using FTP. (A user name of up to 31

characters can be specified.)

The password must always be specified.

to the host computer. (Up to 127 characters can be

specified.)

If no data is set, the home folder set on the host

computer is used as a login folder.

Operation

Select a connection destination.

1 Press soft key [(OPRT)] to display soft key [HOST]. Then, press

soft key [HOST] to display soft keys [CONECT1], [CONECT2],

and [CONECT3].

2 Press one of soft keys [CONECT1], [CONECT2], and

[CONECT3] according to the host computer to which you want

to make a connection. The screen title of connection destination

1, 2 or 3 is displayed in reverse video. The screen title displayed

in reverse video indicates the connection destination host

computer.

When connection destination 1 is selected

- 42 -

Page 55

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

Data Server screens (FTP SERVER)

Press soft key [DTSVR] to display the Data Server screen.

By using page keys

, the FTP server setting screen is

displayed after the connection destination 1, 2, or 3 screen.

Data Server screen 1 (FTP SERVER)

Data Server screen 2 (FTP SERVER)

- 43 -

Page 56

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

Setting item

Item Description

USER NAME Specify a user name to be used when the host

computer logs in to the Data Server. (A user name of

up to 31 characters can be specified.)

PASSWORD Specify the password for the above user name.

The password must always be specified.

LOGIN FOLDER Specify a work folder to be used when the host

computer logs in to the Data Server. (Up to 127

characters can be specified.)

If no data is set, the home folder (home directory) is

used as a login folder.

- 44 -

Page 57

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

Data Server MODE screen (SETTING)

Press soft key [DS MODE] to display the Data Server MODE screen

(SETTING). The current mode can be checked and changed.

Display item

Operation

Data Server screen (SETTING)

Item Description

CHANNELS Displays the number of channels currently being used.

MODE Displays the currently set Data Server mode.

STORAGE MODE

FTP MODE

The Data Server mode can be changed.

1 Press soft key [(OPRT)] to display soft keys [STORAGE] and

[FTP].

2 To change the mode to a desired mode, press the soft key of the

desired mode.

- 45 -

Page 58

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

Data Server MODE screen (MAINTENANCE)

Display item

Press soft key [DS MODE] and press page keys

display maintenance information for each channel.

Data Server MODE screen (MAINTENANCE)

Item Description

CHANNEL Interface number of the buffer used for transferring NC

programs between the CNC and Data Server.

For example, a channel is assigned to each path.

EMPTY

COUNTER

TOTAL SIZE Used for maintenance.

WRITE POINTER

READ POINTER

Used for maintenance.

This item indicates the number of cases where the

buffer becomes empty while NC programs are being

transferred from the Data Server to the CNC.

This item indicates the total number of bytes

transferred when an NC program is transferred from

the Data Server.

Used for maintenance.

This item indicates the buffer use status when NC

programs are transferred from the Data Server to the

CNC.

to

- 46 -

Page 59

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

Data Server FORMAT screen

Press soft key [DS FMT] to display the format screen of the memory

card built into the Data Server.

Display item

Data Server FORMAT screen

Item Description

DEVICE NAME Indicates the storage media currently being used by

the Data Server.

"ATA" or "NONE" is indicated.

FORMAT TYPE Indicates the format type of the memory card.

"CNC FILE" or "---" is displayed.

When "---" is displayed, check whether the memory

card is mounted properly and is formatted correctly.

CHECK DISK

Indicates the check result.

When no check is made : “-----“

When the check result is normal : “OK”

When the check result is abnormal : “NG”

- 47 -

Page 60

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

Procedure (CHECK DISK)

1 Press soft key [(OPRT)] then soft key [CHKDSK].

2 Press soft key [EXEC] to check the format of the memory card

and display the check result.

CAUTION

If the check result is abnormal, determine the

cause of trouble from an error message displayed

on the ETHERNET LOG screen and back up the

files stored on the memory card immediately.

Then, try to reformat the memory card.

NOTE

1 An error occurs if other Data Server functions are

operated when a check disk is made.

2 Also when a program on the memory card of the

Data Server is selected as a main program, the

check disk operation cannot be performed.

Procedure (CNC FORMAT)

1 Press soft key [(OPRT)] then soft key [CNC FMT].

2 Press soft key [EXEC] to format the memory card built into the

FAST Data Server.

CAUTION

1 Do not turn off the power to the CNC when the

memory card is being formatted. Otherwise, the

memory card can be damaged.

2 When the memory card is formatted, all files held

on the memory card are erased.

NOTE

1 An error occurs if other Data Server functions are

operated when the memory card is formatted.

2 Also when a program on the memory card of the

Data Server is selected as a main program, the

memory card cannot be formatted.

- 48 -

Page 61

2. SETTING THE DAT

A

B-64414EN/01 SETTING

SERVER FUNCTIONS

2.2 INPUT OF SPECIAL CHARACTERS

By setting bits 4 and 5 (SI1 and SI2) of NC parameter No. 13115, it is

possible to input special characters and lowercase characters that are

not available on the MDI keys.

Setting this NC parameter displays soft key [CHA-EXT], and pressing

this soft key displays the following set of soft keys.

Each time you press soft key [ABC/abc], you switch from uppercase

input to lowercase input or vice versa. The uppercase/lowercase input

state can be checked in the key input field.

Uppercase input Lowercase input

- 49 -

Page 62

2. SETTING THE DATA

SERVER FUNCTIONS

SETTING B-64414EN/01

2.3 RELATED NC PARAMETERS

The NC parameters related to the Data Server functions are described

below.

#7 #6 #5 #4 #3 #2 #1 #0

0000 TVC

[Input type] Setting input

[Data type] Bit path

# 0 TVC When a file is transferred from the personal computer to the Data

Server, a TV check is:

0: Not performed.

1: Performed.

NOTE

This parameter is valid only for text files.

For text files, see Subsection 2.1.3, "Text Files and

Binary Files" in Part II, "SPECIFICATION."

0020 I/O CHANNEL : Input/output device selection

[Input type] Setting input

[Data type] Byte

[Valid data range] 5 : Selects the Data Server as the input/output device.

#7 #6 #5 #4 #3 #2 #1 #0

0100 NCR CRF CTV