Epson 525, 530, 535, 545, 620 Service Manual

...

SERVICE MANUAL

Color Inkjet Printer

WorkForce 635/Epson StylusOffice TX620FWD/Epson Stylus Office BX625FWD/

Epson ME OFFICE 960FWD

Work Force 633/Work Force 630/Epson Stylus SX620FW

Work Force 645/Epson Stylus Office BX635FWD/

WorkForce 545/Epson Stylus OfficeBX630FW/Epson ME OFFICE 940FW

WorkForce 625/Epson StylusNX625/TX560WD/SX525WD/

Epson Stylus Office BX525WD/Epson ME OFFICE 900WD

Epson Stylus NX530/SX535WD/NX635/Epson Stylus Office BX535WD

WorkForce 60/T42WD/Epson Stylus Office B42WD/Epson ME OFFICE 82WD

Epson ME OFFICE 85ND

CONFIDENTIAL

SEMF09-016

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright 2011 SEIKO EPSON CORPORATION

I & I CS Quality Assurance Department

Confidential

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1.Always disconnect the product from the power source and peripheral devices when servicing the product or performing maintenance.

2.When performing works described in this manual, do not connect to a power source until instructed to do so. Connecting to a power source causes high voltage in the power supply unit and some electronic components even if the product power switch is off. If you need to perform the work with the power cable connected to a power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1.Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2.When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1.Repairs on Epson product should be performed only by an Epson certified repair technician.

2.No work should be performed on this product by persons unfamiliar with basic safety knowledge required for electrician.

3.The power rating of this product is indicated on the serial number/rating plate. Never connect this product to the power source whose voltages is different from the rated voltage.

4.Replace malfunctioning components only with those components provided or approved by Epson; introduction of second-source ICs or other non-approved components may damage the product and void any applicable Epson warranty.

5.In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing internal components.

6.Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads to completely absorb ink wasted due to the ink charge.

7.Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with soap and water immediately. If you have a skin irritation, consult a doctor immediately.

Confidential

8.When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts with sharp edges.

9.Use only recommended tools for disassembling, assembling or adjusting the printer.

10.Observe the specified torque when tightening screws.

11.Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

12.Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may damage the component or give bad influence on the printer function.

13.Apply the specified amount of grease described in this manual.

14.Make the specified adjustments when you disassemble the printer.

15.When cleaning this product, follow the procedure described in this manual.

16.When transporting this product after filling the ink in the printhead, pack the printer without removing the ink cartridges in order to prevent the printhead from drying out.

17.Make sure to install antivirus software in the computers used for the service support activities.

18.Keep the virus pattern file of antivirus software up-to-date.

Confidential

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information necessary for properly performing maintenance and servicing the product.

CHAPTER 1. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the standard operation time for servicing the product.

CHAPTER 2. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 3. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 4. APPENDIX

Provides the following additional information for reference:

Power-On Sequence

Connector Diagram

Troubleshooting

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed, could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed, could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to accomplish a task efficiently. It may also provide additional information that is related to a specific subject, or comment on the results achieved through a previous action.

For Chapter 1 “Disassembly/Reassembly”, symbols other than indicated above are used to show additional information for disassembly/reassembly. For the details on those symbols, see "1.2 Disassembly/Reassembly Procedures (p14)".

Confidential

Revision Status

Revision |

Date of Issue |

Description |

|

|

|

A |

April 28, 2010 |

First Release |

|

|

|

B |

August 6, 2010 |

Revised Contents |

|

|

Chapter 1 |

|

|

"1.1.2 Jigs (p13)" has been added. |

|

|

The Stopper Assy has been added and made change in "Table 1-1 Standard Operation |

|

|

Time (WorkForce 635 series) (p15)" of "1.2.1 Standard Operation Time for servicing |

|

|

the product (p15)". |

|

|

Made change in "Table 1-2 Standard Operation Time (WorkForce 625 series) (p16)" of |

|

|

"1.2.1 Standard Operation Time for servicing the product (p15)". |

|

|

Made change in "1.2.2 Disassembly/Reassembly Flowchart (p19)". |

|

|

Made change in "1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit |

|

|

(p24)". |

|

|

• Made change in " Document Pad (WorkForce 635/625 series) (p24)". |

|

|

• Made change in " Left Housing/Right Housing (WorkForce 635/625 series) (p24)". |

|

|

• Made change in " Panel Unit (WorkForce 635/625 series) (p24)". |

|

|

• Made change in " Lower Panel Housing (WorkForce 635/625 series) (p24)". |

|

|

• Made change in " Panel Board (WorkForce 635/625 series) (p25)". |

|

|

• Made change in " Ink System Assy (p25)". |

|

|

• Made change in " FAX Shield Plate/FAX Connector Cover (WorkForce 635 series) |

|

|

(p25)". |

|

|

• Made change in " Star Wheel Assy (p25)". |

|

|

• Made change in " Main Board Unit (WorkForce 635/625 series) (p26)". |

|

|

• Made change in " Front Frame (p26)". |

|

|

• Made change in " Main Frame (w/ CR Assy) (p26)". |

|

|

• Made change in " Printhead (p26)". |

|

|

• Made change in " ADF Unit (WorkForce 635 series) (1) (p27)". |

|

|

• Made change in " ADF Unit (WorkForce 635 series) (2) (p27)". |

|

|

• " Paper Guide Front Assy (installation using the tools) (p28)" has been added. |

|

|

• " Paper Guide Front Assy (Stopper Holder Idle Roller) (p28)" has been added. |

|

|

• " LCD (WorkForce 635/625 series) (p28)" has been added. |

|

|

• Made change in " Front Paper Guide Waste Ink Pad (p28)". |

|

|

• " Stopper Assy (WorkForce 625 series) (p28)" has been added. |

|

|

Made change in "1.4 Routing FFCs/cables (p30)". |

|

|

• Made change in " Inside the USB Cover (WorkForce 635 series) (p30)". |

|

|

• Made change in " Panel Unit (WorkForce 635 series) (p30)". |

|

|

• Made change in " Scanner FFC/Scanner Motor Cable (WorkForce 635/625 series) |

|

|

(p30)". |

|

|

• Made change in " P/S Board Assy (WorkForce 635/625 series) (p30)". |

|

|

• Made change in " FAX Assy (WorkForce 635 series) (p30)". |

|

|

• Made change in " Head FFC (p31)". |

|

|

• Made change in " Main Board (WorkForce 635 series) (p31)". |

|

|

• Made change in " PF Motor (p31)". |

|

|

• Made change in " PE Sensor (p31)". |

|

|

• Made change in " Inside the USB Cover (WorkForce 625 series) (p32)". |

|

|

• Made change in " Main Board (WorkForce 625 series) (p32)". |

|

|

• Made change in " Panel Unit (WorkForce 625 series) (p31)". |

|

|

Chapter 2 |

|

|

Made change in "2.1 Required Adjustments (p34)". |

|

|

"2.2.1 PF Timing Belt Tension Measurement/PF Belt Step Check (p40)" has been |

|

|

added. |

|

|

"2.2.2 Checking the Platen Gap (p43)" has been added. |

|

|

|

Confidential

Revision |

Date of Issue |

Description |

|

|

|

B |

August 6, 2010 |

Chapter 3 |

|

|

Made change in "3.1.2 Lubrication (p46)". |

|

|

Made change in "3.2 Lubrication Points and Instructions (p48)". |

|

|

• Made change in "Fig. 3-1 Lubrication of the Driven Pulley Holder (p48)". |

|

|

• Made change in "Fig. 3-2 Lubrication of the Paper Guide Front Assy (PF Roller) (p48)". |

|

|

• Made change in "Fig. 3-3 Lubrication of the Paper Guide Front Assy (EJ Roller) (p48)". |

|

|

• Made change in "Fig. 3-5 Lubrication of the PF Holder (p48)". |

|

|

• Made change in "Fig. 3-6 Lubrication of the Main Frame (1) (p49)". |

|

|

• Made change in "Fig. 3-8 Lubrication of the EJ Pulley (p49)". |

|

|

• Made change in "Fig. 3-9 Lubrication of the Ink System Assy (1) (p49)". |

|

|

• Made change in "Fig. 3-10 Lubrication of the Ink System Assy (2) (p49)". |

|

|

• Made change in "Fig. 3-11 Lubrication of the CR Assy (p49)". |

|

|

• Made change in "Fig. 3-12 Lubrication of the Scanner Unit (WorkForce 635/625 series) (p50)". |

|

|

• "Fig. 3-15 Lubrication of the Stopper Assy (WorkForce 625 series) (p51)" has been added. |

|

|

Chapter 4 |

|

|

Made change in "4.1 Power-On Sequence (p53)". |

|

|

"4.3 Troubleshooting (p57)" has been added. |

|

|

|

Confidential

Revision |

Date of Issue |

Description |

|

|

|

C |

October 12, 2010 |

Revised Contents |

|

|

All chapters |

|

|

Information of Epson WorkForce 60/T42WD/Epson Stylus Office B42WD/ |

|

|

Epson ME OFFICE 82WD/Epson ME OFFICE 85ND has been added. |

|

|

Chapter 1 |

|

|

Production name has been added in "1.1 Overview (p12)". |

|

|

Made change in "1.1.2 Jigs (p13)". |

|

|

Made change in "1.2 Disassembly/Reassembly Procedures (p14)". |

|

|

Made change in "1.2.1 Standard Operation Time for servicing the product (p15)". |

|

|

• "1-3 Standard Operation Time (WorkForce 60 series) (p17)" has been added. |

|

|

Made change in "1.2.2 Disassembly/Reassembly Flowchart (p19)". |

|

|

• Made change in "1.2.2.1 Housing Part (WorkForce 635 series/WorkForce 625 series) (p19)". |

|

|

• "1.2.2.2 Housing Part (WorkForce 60 series) (p21)" has been added. |

|

|

• Made change in "1.2.2.3 Printer Mechanism Part (p22)". |

|

|

Made change in "1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p24)". |

|

|

• Production name has been added in " USB Cover (WorkForce 635/625 series) (p24)". |

|

|

• Production name has been added in " Decoration Plate (WorkForce 635/625 series) (p24)". |

|

|

• Production name has been added in " Document Pad (WorkForce 635/625 series) (p24)". |

|

|

• Production name has been added in " Left Housing/Right Housing (WorkForce 635/625 |

|

|

series) (p24)". |

|

|

• Production name has been added in " Panel Unit (WorkForce 635/625 series) (p24)". |

|

|

• Production name has been added in " Upper Housing (w/ Panel Unit) (WorkForce 635/ |

|

|

625 series) (p24)". |

|

|

• Production name has been added in " Lower Panel Housing (WorkForce 635/625 series) (p24)". |

|

|

• Production name has been added in " Panel Board (WorkForce 635/625 series) (p25)". |

|

|

• Made change in " CR Scale/Extension Spring (p25)". |

|

|

• Production name has been added in " Shield Plate (w/ Wireless LAN Module) |

|

|

(WorkForce 635/625 series) (p25)". |

|

|

• Production name has been added in " Wireless LAN Module (p25)". |

|

|

• Production name has been added in " Main Board Unit (WorkForce 635/625 series) (p26)". |

|

|

• Production name has been added in " CIS Unit (WorkForce 635/625 series) (p26)". |

|

|

• Made change in " Paper Guide Front Assy (installation using the tools) (p28)". |

|

|

• Made change in " Paper Guide Front Assy (Stopper Holder Idle Roller) (p28)". |

|

|

• Production name has been added in " LCD (WorkForce 635/625 series) (p28)". |

|

|

• " Front Cover (WorkForce 60 series) (p29)" has been added. |

|

|

• " USB Cover (WorkForce 60 series) (p29)" has been added. |

|

|

• " Upper Housing (WorkForce 60 series) (p29)" has been added. |

|

|

• " Stacker Assy (WorkForce 60 series) (p29)" has been added. |

|

|

• " Main Board Unit (WorkForce 60 series) (p29)" has been added. |

|

|

|

Confidential

Revision |

Date of Issue |

|

Description |

|

|

|

|

C |

October 12, 2010 |

Made change in "1.4 Routing FFCs/cables (p30)". |

|

|

|

• Production name has been added in " Cover Open Sensor (WorkForce 635/625 series) (p30)". |

|

|

|

• Production name has been added in " Scanner FFC/Scanner Motor Cable (WorkForce 635/625 |

|

|

|

|

series) (p30)". |

|

|

• Production name has been added in " P/S Board Assy (WorkForce 635/625 series) (p30)". |

|

|

|

• Production name has been added in " PF Encoder Sensor (WorkForce 635/625 series) (p31)". |

|

|

|

• " Main Board (WorkForce 60 series) (p32)" has been added. |

|

|

|

Chapter 2 |

|

|

|

Made change in "2.2.1 PF Timing Belt Tension Measurement/PF Belt Step Check |

|

|

|

|

(p40)". |

|

|

Chapter 3 |

|

|

|

Made change in "3.2 Lubrication Points and Instructions (p48)". |

|

|

|

• Production name has been added in "3-12 Lubrication of the Scanner Unit (WorkForce |

|

|

|

|

635/625 series) (p50)". |

|

|

• Production name has been added in "3-13 Lubrication of the Duplex Unit (p50)". |

|

|

|

• Production name has been added in "3-15 Lubrication of the Stopper Assy (WorkForce |

|

|

|

|

625 series) (p51)". |

|

|

Chapter 4 |

|

|

|

Made change in "4.2 Connector Diagram (p56)". |

|

|

|

Made change in "4.3.1 Troubleshooting Workflow (p57)". |

|

|

|

Made change in "4.3.2 Fatal Error Code (p59)". |

|

|

|

|

|

C |

November 24, |

Chapter 1 |

|

|

2010 |

1.2.1Standard Operation Time for servicing the product Table 1-1 on page 13-14 |

|

|

|

|

Standard Operation Time(WorkForce 635 series) is added. |

|

|

1.2.1Standard Operation Time for servicing the product Table 1-2 on page 14-15 |

|

|

|

|

Standard Operation Time(WorkForce 620 series) is added. |

|

|

1.2.1Standard Operation Time for servicing the product Table 1-3 on page 15 |

|

|

|

|

Standard Operation Time(WorkForce 60 series) is added. |

|

|

|

|

D |

December 17, |

|

Add product name(WorkForce630/WorkForce633/StylusNX625/SX620FW). |

|

2010 |

|

Delete product name(WorkForce620). |

|

|

|

|

E |

June 21,2011 |

Revised Contents |

|

|

|

Chapter 1 |

|

|

|

1.2.1Standard Operation Time for servicing the product Table 1-1 on page 15-18 |

|

|

|

|

Standard Operation Time(Adjustment & Total time) is added. |

|

|

Made change in “Paper guide front supporting tools (A) size for WorkForce625 |

|

|

|

|

series(A)”(p28). |

|

|

About the directions for a tools (Comment postscript p28). |

|

|

|

All Chapters |

|

|

|

The model name “WorkForce 645/545/Epson Stylus office BX630FW/BX635FWD/ |

|

|

|

|

Epson Stylus NX530/SX535WD/BX535WD/NX635/Epson ME OFFICE 940FW” are |

|

|

|

added, and revision is changed. |

|

|

|

|

Confidential

Epson WorkForce 635/620/60 series |

Revision E |

Contents

Chapter 1 Disassembly/Reassembly

1.1 |

Overview |

.................................................................................................................... ............................................. |

12 |

|

|

1.1.1 |

Tools ............................................................................................................................................................... |

12 |

|

|

1.1.2 |

Jigs .................................................................................................................................................................. |

|

13 |

1.2 |

Disassembly/Reassembly .....................................................................................................................Procedures |

14 |

||

|

1.2.1 |

Standard .......................................................................................Operation Time for servicing the product |

15 |

|

|

1.2.2 Disassembly/Reassembly ..............................................................................................................Flowchart |

19 |

||

|

1.2.2.1 ............................................................... |

Housing Part (WorkForce 635 series/WorkForce 625 series) |

19 |

|

|

1.2.2.2 ..................................................................................................... |

Housing Part (WorkForce 60 series) |

21 |

|

|

1.2.2.3 ......................................................................................................................... |

Printer Mechanism Part |

22 |

|

1.3 |

Detailed Disassembly/Reassembly ...........................................................................Procedure for each Part/Unit |

24 |

||

1.4 |

Routing FFCs/cables ............................................................................................................................................... |

30 |

||

Chapter 2 Adjustment |

|

|||

2.1 |

Required Adjustments ............................................................................................................................................. |

34 |

||

2.2 |

Details of ............................................................................................................................................Adjustments |

40 |

||

|

2.2.1 PF Timing ..........................................................................Belt Tension Measurement/PF Belt Step Check |

40 |

||

|

2.2.2 Checking ................................................................................................................................the Platen Gap |

43 |

||

|

2.2.3 MAC .....................................................................................................................................Address Setting |

44 |

||

Chapter 3 Maintenance |

|

|||

3.1 |

Overview ................................................................................................................................................................. |

|

46 |

|

|

3.1.1 |

Cleaning.......................................................................................................................................................... |

46 |

|

|

3.1.2 |

Lubrication...................................................................................................................................................... |

46 |

|

3.2 |

Lubrication .........................................................................................................................Points and Instructions |

48 |

||

Chapter 4 Appendix |

|

|||

4.1 |

Power-On Sequence ................................................................................................................................................ |

53 |

||

4.2 |

Connector .................................................................................................................................................Diagram |

56 |

||

4.3 |

Troubleshooting....................................................................................................................................................... |

57 |

||

|

4.3.1 Troubleshooting ............................................................................................................................Workflow |

57 |

||

|

4.3.2 |

Fatal .............................................................................................................................................Error Code |

59 |

|

10

Confidential

CHAPTER 1

DISASSEMBLY/REASSEMBLY

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

1.1 Overview

This chapter describes procedures for disassembling the main parts/units of WorkForce 635 series, WorkForce 625 series and WorkForce 60 series. Unless otherwise specified, disassembled parts/units can be reassembled by reversing the disassembly procedure. See the cautions or tips for disassembly/reassembly described in "1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p24)".

Read the " Safety Precautions (p3)" before disassembling and reassembling.

When you have to remove units or parts that are not described in this chapter, see the exploded diagrams of SPI (Service Parts Information).

In this chapter, the product names are called as follows:

WorkForce 635 series:WorkForce 635/Epson Stylus Office TX620FWD/Epson Stylus

Office BX625FWD/Epson ME OFFICE 960FWD

Work Force 633/Work Force 630/Epson Stylus SX620FW Work Force 645/Epson Stylus Office BX635FWD/ WorkForce 545/Epson Stylus Office BX630FW/Epson ME OFFICE 940FW

WorkForce 625 series:WorkForce 625/Epson Stylus NX625/TX560WD/SX525WD/

Epson Stylus Office BX525WD/Epson ME OFFICE 900WD

Epson Stylus NX530/SX535WD/NX635/Epson Stylus Office BX535WD

WorkForce 60 series: WorkForce 60/T42WD/Epson Stylus Office B42WD/

Epson ME OFFICE 82WD/Epson ME OFFICE 85ND

1.1.1 Tools

Use only specified tools to avoid damaging the printer.

Name |

Availability |

EPSON Part Code |

|

|

|

(+) Phillips screwdriver #1 |

O |

1080530 |

|

|

|

(+) Phillips screwdriver #2 |

O |

--- |

|

|

|

Flathead screwdriver |

O |

--- |

|

|

|

Flathead Precision screwdriver #1 |

O |

--- |

|

|

|

Tweezers |

O |

--- |

|

|

|

Longnose pliers |

O |

--- |

|

|

|

Acetate tape |

--- |

1003963 |

|

|

|

Nippers |

O |

--- |

|

|

|

Note 1: Some of the tools listed above are commercially available. 2: EPSON provides the tools listed with EPSON part code.

Disassembly/Reassembly |

Overview |

12 |

Confidential

Epson WorkForce 635/625/60 series Revision E

1.1.2 Jigs

Name |

Q’ty |

EPSON Part Code |

|

|

|

|

|

Paper guide front supporting tool (A)* |

1 |

WorkForce 635 series: |

1543170 |

|

|

WorkForce 625 series: |

1543171 |

|

|

WorkForce 60 series: |

1543170 |

|

|

|

|

Paper guide front supporting tool (B)* |

1 |

WorkForce 635 series: |

1543539 |

|

|

WorkForce 625 series: |

1543544 |

|

|

WorkForce 60 series: |

1543539 |

|

|

|

|

Paper guide front supporting tool (C)* |

3 |

WorkForce 635 series: |

1543541 |

|

|

WorkForce 625 series: |

1543547 |

|

|

WorkForce 60 series: |

1543541 |

|

|

|

|

Printhead supporting tool |

2 |

1543169 |

|

|

|

|

|

Note *: The required tools differ between WorkForce 635 series, WorkForce 625 series and WorkForce 60 series. Be careful not to mix up the tools.

Disassembly/Reassembly |

Overview |

13 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

1.2 Disassembly/Reassembly Procedures

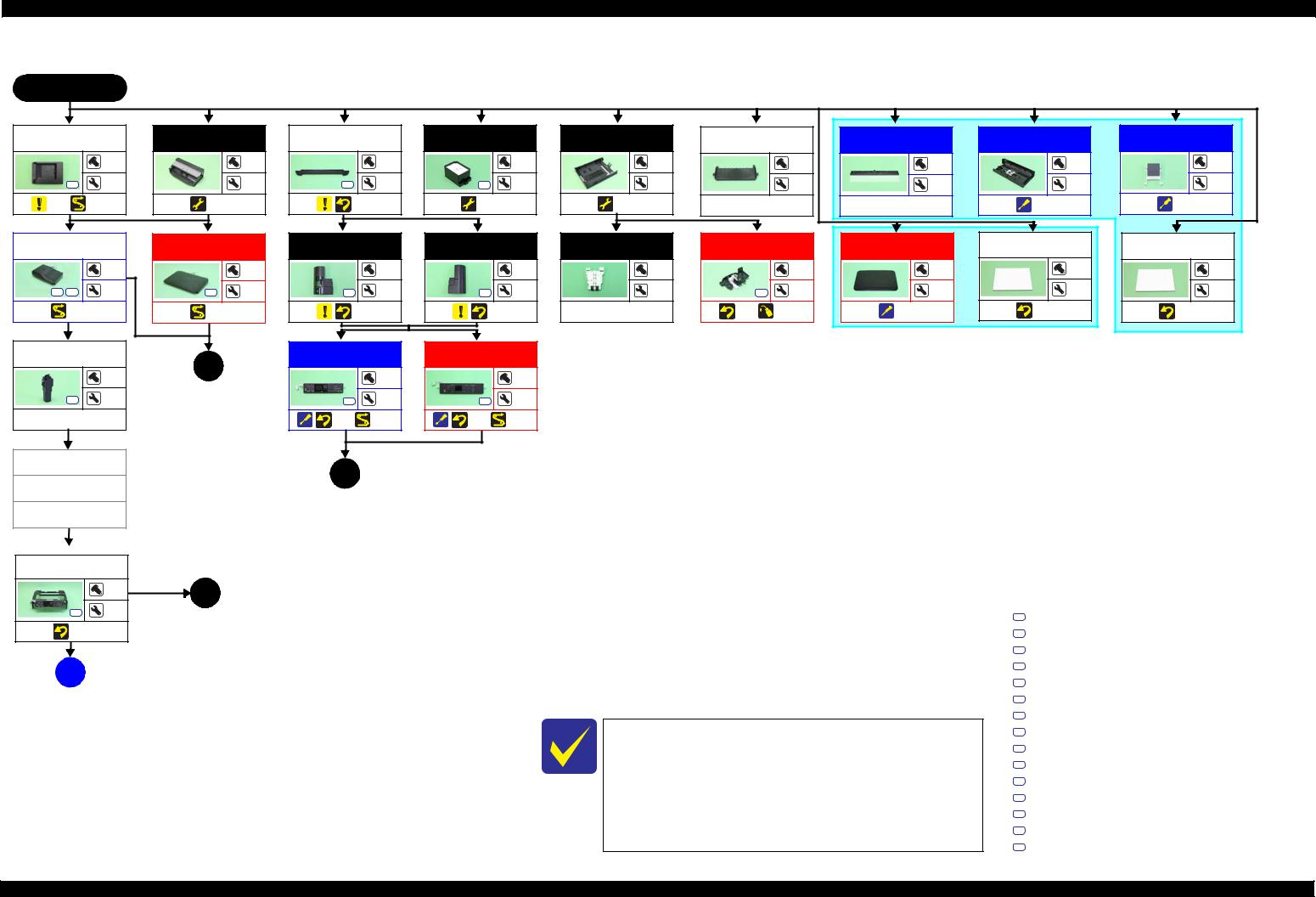

This section describes procedures for disassembling the parts/units in a flowchart format. For some parts/units, detailed procedures or precautions are provided (accordingly indicated by icons and cell's color). Refer to the explanations in the example chart below and perform an appropriate disassembling and assembling procedure. (See "1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p24)".)

For routing cables, see "1.4 Routing FFCs/cables (p30)".

The example below shows how to see the charts on the following pages.

Explanation available in the Reference Guide

Black letters indicate a part/ unit not supplied as an ASP.

Ref. Ink System Assy |

White letters indicate a part/ |

||

unit supplied as an ASP. |

|||

|

|

||

|

|

1 |

|

|

|

Shows the screw types and |

|

S4 |

|

the specified torque in the |

|

|

“Screw type/torque list”. |

||

|

|

||

(p 25) |

(p 49) |

|

|

|

|

Reference page |

|

USB Cover |

|

||

|

|

1 |

|

S3 |

|

2 |

|

(p 24) |

(p 30) |

Shows removal/installation |

|

|

|

as a unit/assy. is available. |

|

Item |

|

Description |

Reference |

|

Parts/unit name |

|

White-letter |

Part/unit supplied as an ASP |

--- |

|

Black-letter |

Part/unit not supplied as an ASP |

--- |

|

|

|

|||

|

|

|

|

|

|

|

|

Indicates a practice or condition that could result in |

Indicates the reference |

|

|

|

injury or loss of life if not strictly observed. |

page in blue-letter |

|

|

|

|

|

|

|

|

Indicates a practice or condition that could result in |

Indicates the reference |

|

|

|

damage to, or destruction of equipment if not strictly |

|

|

|

|

page in blue-letter |

|

|

|

|

observed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates the parts that are inevitably broken in the |

|

|

|

|

disassembling procedure, and should be replaced with |

--- |

|

|

|

a new one for reassembly. |

|

|

|

|

|

|

|

|

|

Indicates necessary check items in the disassembling/ |

Indicates the reference |

|

|

|

assembling procedure. |

page in blue-letter |

|

|

|

Indicates supplementary explanation for disassembly |

Indicates the reference |

Icon |

|

|

is given. |

page in blue-letter |

|

|

|

|

|

|

|

Indicates particular tasks to keep quality of the units |

Indicates the reference |

|

|

|

|

||

|

|

|

are required. |

page in blue-letter |

|

|

|

|

|

|

|

|

Indicates particular routing of cables is required. |

Indicates the reference |

|

|

|

page in blue-letter |

|

|

|

|

|

|

|

|

|

Indicates particular adjustment(s) is/are required. |

Chapter 2 " Adjustment |

|

|

|

(p33)" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates lubrication is required. |

Chapter 3 " Maintenance |

|

|

|

(p45)" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicates the number of screws securing the parts/ |

--- |

|

|

|

units. |

|

|

|

|

|

|

|

|

|

Indicates the points secured with other than a screw |

--- |

|

|

|

such as a hook, rib, dowel or the like. |

|

|

|

|

|

|

|

|

|

|

|

Disassembly/Reassembly |

Disassembly/Reassembly Procedures |

14 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

1.2.1 Standard Operation Time for servicing the product

The following are the standard operation time for servicing the product. Those are based on the MTTR result measured using a prototype.

The underlined parts/units are supplied as After Service Parts.

Standard Operation Time for servicing WorkForce 635 series: See Table 1-1

Standard Operation Time for servicing WorkForce 625 series: See Table 1-2

Standard Operation Time for servicing WorkForce 60 series: See Table 1-3

Table 1-1. Standard Operation Time (WorkForce 635 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

USB Cover |

32 |

|

0 |

|

32 |

ADF Unit/Scanner Unit |

272 |

|

0 |

|

272 |

Scanner Unit |

392 |

|

0 |

|

392 |

CIS Unit |

505 |

|

0 |

|

505 |

ADF Unit |

392 |

|

0 |

|

392 |

Front ADF Cover |

466 |

|

0 |

|

466 |

Top ADF Cover |

470 |

|

0 |

|

470 |

|

|

|

|

|

|

Right ADF Cover |

505 |

|

0 |

|

505 |

Rear ADF Cover |

425 |

|

0 |

|

425 |

|

|

|

|

|

|

ADF Document |

402 |

|

|

|

402 |

Support |

|

|

|

||

|

|

|

|

|

|

ADF Cover Assy |

12 |

|

0 |

|

12 |

ADF Pad Assy |

17 |

|

0 |

|

17 |

Document Pad |

23 |

|

0 |

|

23 |

|

|

|

|

|

|

Decoration Plate |

34 |

|

0 |

|

34 |

Left Housing |

61 |

|

0 |

|

61 |

Hinge |

287 |

|

0 |

|

287 |

Upper Housing |

484 |

|

0 |

|

484 |

(w/ Panel Unit) |

|

|

|||

|

|

|

|

|

|

Upper Housing |

518 |

|

0 |

|

518 |

Cover Open Sensor |

518 |

|

0 |

|

518 |

|

|

|

|

|

|

Duplex Unit |

8 |

|

411 |

|

419 |

Right Housing |

52 |

|

0 |

|

52 |

Panel Unit |

183 |

|

0 |

|

183 |

|

|

|

|

|

|

Panel Gear |

200 |

|

0 |

|

200 |

Panel Lever |

200 |

|

0 |

|

200 |

Lower Panel Housing |

299 |

|

0 |

|

299 |

|

|

|

|

|

|

Panel Board |

318 |

|

0 |

|

318 |

LCD |

366 |

|

0 |

|

366 |

Button |

464 |

|

0 |

|

464 |

Upper Panel Housing |

512 |

|

0 |

|

512 |

|

|

|

|

|

|

Cassette Assy |

8 |

|

135 |

|

143 |

Pickup Assy |

24 |

|

0 |

|

24 |

|

|

|

|

|

|

Waste Ink Tray Assy |

35 |

|

14 |

|

49 |

Paper Sheet Assy |

13 |

|

114 |

|

127 |

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Main Frame (w/ CR Assy) |

1140 |

|

937 |

|

2077 |

Upper Paper Guide |

1181 |

|

657 |

|

1838 |

PE Holder Assy |

1230 |

|

302 |

|

1532 |

CR Motor |

1255 |

|

70 |

|

1325 |

CR Scale Holder |

1164 |

|

0 |

|

1164 |

CR Assy |

1190 |

|

570 |

|

1760 |

Hinge Cover |

|

|

|

|

|

Cartridge/Cartridge |

517 |

|

0 |

|

517 |

Cover |

|

|

|

|

|

I/C Guide |

523 |

|

0 |

|

523 |

Inner Head Cable |

556 |

|

0 |

|

556 |

Cover |

|

|

|||

|

|

|

|

|

|

Printhead |

646 |

|

1152 |

|

1798 |

|

|

|

|

|

|

Holder Board Assy |

508 |

|

0 |

|

508 |

CSIC Terminal |

535 |

|

0 |

|

535 |

CR Contact |

524 |

|

0 |

|

524 |

Module |

|

|

|||

|

|

|

|

|

|

Holder Board |

551 |

|

0 |

|

551 |

Head FFC |

1267 |

|

0 |

|

1267 |

Front Frame |

1167 |

|

570 |

|

1737 |

Star Wheel Assy |

1192 |

|

249 |

|

1441 |

|

|

|

|

|

|

Paper Guide Front Assy |

1304 |

|

735 |

|

2039 |

Front Paper Guide |

1308 |

|

0 |

|

1308 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

EJ Pulley |

1208 |

|

43 |

|

1251 |

EJ Roller |

1229 |

|

454 |

|

1683 |

PF Holder/PF Timing |

1387 |

|

43 |

|

1430 |

Belt |

|

|

|||

|

|

|

|

|

|

PF Motor |

1429 |

|

87 |

|

1516 |

Frame Base Assy |

1359 |

|

859 |

|

2218 |

Lower Paper Guide |

1363 |

|

14 |

|

1377 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

PE Sensor |

1332 |

|

53 |

|

1385 |

Stacker Assy |

1327 |

|

0 |

|

1327 |

Frame Base |

1304 |

|

0 |

|

1304 |

Extension Spring |

529 |

|

0 |

|

529 |

(Upper Paper Guide) |

|

|

|||

|

|

|

|

|

|

CR Scale |

565 |

|

0 |

|

565 |

Driven Pulley/Extension |

641 |

|

0 |

|

641 |

Spring |

|

|

|||

|

|

|

|

|

|

Cam Holder Assy |

503 |

|

0 |

|

503 |

Extension Spring |

566 |

|

0 |

|

566 |

Disassembly/Reassembly |

Disassembly/Reassembly Procedures |

15 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

Table 1-1. Standard Operation Time (WorkForce 635 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

FAX Grounding Plate |

521 |

|

0 |

|

521 |

PF Encoder Sensor |

829 |

|

0 |

|

829 |

|

|

|

|

|

|

Main Board Unit |

800 |

|

1144 |

|

1944 |

Shield Plate |

949 |

|

0 |

|

949 |

(w/ Wireless LAN Module) |

|

|

|||

|

|

|

|

|

|

Wireless LAN Module |

838 |

|

0 |

|

838 |

Main Board |

987 |

|

0 |

|

987 |

|

|

|

|

|

|

P/S Board Assy |

529 |

|

0 |

|

529 |

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

FAX Assy |

560 |

|

0 |

|

560 |

FAX Shield Plate/ |

625 |

|

0 |

|

625 |

FAX Connector Cover |

|

|

|||

|

|

|

|

|

|

Fax Board |

625 |

|

0 |

|

625 |

Right Frame |

496 |

|

0 |

|

496 |

|

|

|

|

|

|

Ink System Assy |

540 |

|

0 |

|

540 |

Waste Ink Pad |

575 |

|

0 |

|

575 |

(Bottom of Ink System Assy) |

|

|

|||

|

|

|

|

|

|

Table 1-2. Standard Operation Time (WorkForce 625 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

USB Cover |

32 |

|

0 |

|

32 |

|

|

|

|

|

|

Scanner Unit |

147 |

|

0 |

|

147 |

CIS Unit |

236 |

|

0 |

|

236 |

Document Cover |

21 |

|

0 |

|

21 |

Document Pad |

23 |

|

0 |

|

23 |

|

|

|

|

|

|

Decoration Plate |

40 |

|

0 |

|

40 |

|

|

|

|

|

|

Left Housing |

67 |

|

0 |

|

67 |

|

|

|

|

|

|

Hinge |

162 |

|

0 |

|

162 |

|

|

|

|

|

|

Upper Housing |

365 |

|

0 |

|

365 |

(w/ Panel Unit) |

|

|

|||

|

|

|

|

|

|

Upper Housing |

503 |

|

0 |

|

503 |

Cover Open Sensor |

399 |

|

0 |

|

399 |

|

|

|

|

|

|

Duplex Unit |

8 |

|

316 |

|

324 |

|

|

|

|

|

|

Right Housing |

58 |

|

0 |

|

58 |

|

|

|

|

|

|

Panel Unit |

189 |

|

0 |

|

189 |

Panel Gear/Panel Lever |

216 |

|

0 |

|

216 |

Lower Panel Housing |

286 |

|

0 |

|

286 |

Panel Board |

383 |

|

0 |

|

383 |

LCD |

431 |

|

0 |

|

431 |

LCD Cover |

433 |

|

0 |

|

433 |

|

|

|

|

|

|

Button |

447 |

|

0 |

|

447 |

Upper Panel Housing |

497 |

|

0 |

|

497 |

|

|

|

|

|

|

Cassette Assy |

8 |

|

115 |

|

123 |

|

|

|

|

|

|

Pickup Assy |

24 |

|

0 |

|

24 |

|

|

|

|

|

|

Waste Ink Tray Assy |

35 |

|

7 |

|

42 |

|

|

|

|

|

|

Main Board Unit |

644 |

|

774 |

|

1418 |

|

|

|

|

|

|

Shield Plate |

|

|

|

|

|

(w/ Wireless LAN |

739 |

|

0 |

|

739 |

Module) |

|

|

|

|

|

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Main Frame (w/ CR Assy) |

984 |

|

957 |

|

1941 |

Upper Paper Guide |

1025 |

|

527 |

|

1552 |

PE Holder Assy |

1074 |

|

402 |

|

1476 |

CR Motor |

1099 |

|

62 |

|

1161 |

CR Scale Holder |

1006 |

|

0 |

|

1006 |

CR Assy |

1032 |

|

441 |

|

1473 |

Hinge Cover |

|

|

|

|

|

Cartridge/Cartridge |

396 |

|

0 |

|

396 |

Cover |

|

|

|

|

|

I/C Guide |

402 |

|

0 |

|

402 |

Inner Head Cable |

435 |

|

0 |

|

435 |

Cover |

|

|

|||

|

|

|

|

|

|

Printhead |

525 |

|

1023 |

|

1548 |

Holder Board Assy |

389 |

|

0 |

|

389 |

CSIC Terminal |

440 |

|

0 |

|

440 |

CR Contact |

401 |

|

0 |

|

401 |

Module |

|

|

|||

|

|

|

|

|

|

Holder Board |

428 |

|

0 |

|

428 |

Head FFC |

1109 |

|

0 |

|

1109 |

|

|

|

|

|

|

Front Frame |

1011 |

|

441 |

|

1452 |

|

|

|

|

|

|

Star Wheel Assy |

1036 |

|

201 |

|

1237 |

|

|

|

|

|

|

Paper Guide Front Assy |

1036 |

|

634 |

|

1670 |

Front Paper Guide |

1148 |

|

0 |

|

1148 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

EJ Pulley |

1207 |

|

43 |

|

1250 |

EJ Roller |

1052 |

|

359 |

|

1411 |

PF Holder/PF Timing |

1273 |

|

78 |

|

1351 |

Belt |

|

|

|||

|

|

|

|

|

|

PF Motor |

1273 |

|

78 |

|

1351 |

|

|

|

|

|

|

Frame Base Assy |

1148 |

|

892 |

|

2040 |

Lower Paper Guide |

1152 |

|

7 |

|

1159 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

PE Sensor |

1176 |

|

201 |

|

1377 |

|

|

|

|

|

|

Disassembly/Reassembly |

Disassembly/Reassembly Procedures |

16 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

Table 1-2. Standard Operation Time (WorkForce 625 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Wireless LAN Module |

682 |

|

0 |

|

682 |

Main Board |

739 |

|

0 |

|

739 |

|

|

|

|

|

|

PF Encoder Sensor |

673 |

|

0 |

|

673 |

|

|

|

|

|

|

Right Frame |

377 |

|

0 |

|

377 |

|

|

|

|

|

|

Ink System Assy. |

421 |

|

0 |

|

421 |

|

|

|

|

|

|

Waste Ink Pad |

437 |

|

0 |

|

437 |

(Bottom of Ink System Assy) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

P/S Board Assy |

410 |

|

97 |

|

507 |

|

|

|

|

|

|

Stopper Assy |

|

|

0 |

|

|

|

|

|

|

|

|

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Stacker Assy |

1171 |

|

0 |

|

1171 |

Frame Base |

1203 |

|

709 |

|

1912 |

|

|

|

|

|

|

Extension Spring |

410 |

|

0 |

|

410 |

(Upper Paper Guide) |

|

|

|||

|

|

|

|

|

|

CR Scale |

446 |

|

0 |

|

446 |

|

|

|

|

|

|

Driven Pulley/Extension |

406 |

|

0 |

|

406 |

Spring |

|

|

|||

|

|

|

|

|

|

Cam Holder Assy |

384 |

|

0 |

|

384 |

|

|

|

|

|

|

Extension Spring |

379 |

|

0 |

|

379 |

|

|

|

|

|

|

Table 1-3. Standard Operation Time (WorkForce 60 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

USB Cover |

34 |

|

0 |

|

34 |

|

|

|

|

|

|

Printer Cover |

9 |

|

0 |

|

9 |

|

|

|

|

|

|

Upper Housing |

162 |

|

0 |

|

162 |

(w/ Printer Cover) |

|

|

|||

|

|

|

|

|

|

Upper Housing |

171 |

|

0 |

|

171 |

|

|

|

|

|

|

Duplex Unit |

4 |

|

411 |

|

415 |

|

|

|

|

|

|

Cassette Assy |

4 |

|

135 |

|

139 |

|

|

|

|

|

|

Pickup Assy |

25 |

|

0 |

|

25 |

|

|

|

|

|

|

Waste Ink Tray Assy |

24 |

|

14 |

|

38 |

|

|

|

|

|

|

Stacker Assy |

128 |

|

0 |

|

128 |

|

|

|

|

|

|

Front Cover |

13 |

|

0 |

|

13 |

|

|

|

|

|

|

Panel Unit |

44 |

|

0 |

|

44 |

Panel Board |

101 |

|

0 |

|

101 |

LED Lens |

94 |

|

0 |

|

94 |

|

|

|

|

|

|

Button |

126 |

|

0 |

|

126 |

Front Panel Cover |

126 |

|

0 |

|

126 |

|

|

|

|

|

|

Stacker Open Sensor |

56 |

|

0 |

|

56 |

|

|

|

|

|

|

Main Board Unit |

348 |

|

1144 |

|

1492 |

|

|

|

|

|

|

Wireless LAN Module |

392 |

|

0 |

|

392 |

Shield Plate |

581 |

|

0 |

|

581 |

(w/ Cover Open Sensor) |

|

|

|||

|

|

|

|

|

|

Main Board |

581 |

|

0 |

|

581 |

|

|

|

|

|

|

Cover Open Sensor |

354 |

|

0 |

|

354 |

|

|

|

|

|

|

PF Encoder Sensor |

361 |

|

0 |

|

361 |

|

|

|

|

|

|

Front Frame |

583 |

|

570 |

|

1153 |

|

|

|

|

|

|

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Main Frame (w/ CR Assy) |

550 |

|

937 |

|

1482 |

Upper Paper Guide |

566 |

|

657 |

|

1223 |

PE Holder Assy |

592 |

|

302 |

|

894 |

|

|

|

|

|

|

CR Motor |

627 |

|

70 |

|

697 |

CR Scale Holder |

570 |

|

0 |

|

570 |

CR Assy |

601 |

|

570 |

|

1171 |

Hinge Cover |

|

|

|

|

|

Cartridge/Cartridge |

193 |

|

0 |

|

193 |

Cover |

|

|

|

|

|

I/C Guide |

199 |

|

0 |

|

199 |

Inner Head Cable |

208 |

|

0 |

|

208 |

Cover |

|

|

|||

|

|

|

|

|

|

Printhead |

279 |

|

1152 |

|

1431 |

Holder Board Assy |

179 |

|

0 |

|

179 |

CSIC Terminal |

230 |

|

0 |

|

230 |

CR Contact |

191 |

|

0 |

|

191 |

Module |

|

|

|||

|

|

|

|

|

|

Holder Board |

242 |

|

0 |

|

242 |

Head FFC |

632 |

|

0 |

|

632 |

|

|

|

|

|

|

Paper Guide Front Assy |

716 |

|

735 |

|

1451 |

Front Paper Guide |

847 |

|

0 |

|

847 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

EJ Pulley |

616 |

|

43 |

|

659 |

EJ Roller |

624 |

|

454 |

|

1078 |

|

|

|

|

|

|

PF Holder/PF Timing |

750 |

|

43 |

|

793 |

Belt |

|

|

|||

|

|

|

|

|

|

PF Motor |

822 |

|

87 |

|

909 |

|

|

|

|

|

|

Frame Base Assy |

716 |

|

859 |

|

1575 |

Lower Paper Guide |

721 |

|

14 |

|

735 |

Waste Ink Pad |

|

|

|||

|

|

|

|

|

|

Disassembly/Reassembly |

Disassembly/Reassembly Procedures |

17 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

Table 1-3. Standard Operation Time (WorkForce 60 series)

|

|

Time (second) |

|

||

Parts/Unit |

Replace- |

|

Adjust- |

Total |

|

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

Star Wheel Assy |

609 |

|

249 |

|

858 |

|

|

|

|

|

|

CR Scale |

195 |

|

0 |

|

195 |

|

|

|

|

|

|

Driven Pulley/Extension |

252 |

|

0 |

|

252 |

Spring |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Right Frame |

170 |

|

0 |

|

170 |

|

|

|

|

|

|

Ink System Assy |

223 |

|

0 |

|

223 |

|

|

|

|

|

|

Waste Ink Pad |

|

|

|

|

|

(Bottom of Ink System |

228 |

|

0 |

|

228 |

Assy) |

|

|

|

|

|

|

|

Time (second) |

|

||

Parts/Unit |

|

|

|

|

|

Replace- |

|

Adjust- |

Total |

||

|

ment |

|

ment |

||

|

|

|

|||

|

|

|

|

|

|

PE Sensor |

768 |

|

53 |

|

821 |

Frame Base |

773 |

|

0 |

|

773 |

|

|

|

|

|

|

Extension Spring |

201 |

|

0 |

|

201 |

(Upper Paper Guide) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

Cam Holder Assy |

200 |

|

0 |

|

200 |

|

|

|

|

|

|

Extension Spring |

219 |

|

0 |

|

219 |

|

|

|

|

|

|

Power Supply Unit |

83 |

|

0 |

|

83 |

|

|

|

|

|

|

Disassembly/Reassembly |

Disassembly/Reassembly Procedures |

18 |

Confidential

Epson WorkForce 635/625/60 series |

Revision E |

1.2.2 Disassembly/Reassembly Flowchart

1.2.2.1 Housing Part (WorkForce 635 series/WorkForce 625 series)

START |

|

|

|

|

|

|

|

|

|

|

|

USB Cover |

Duplex Unit |

Decoration Plate |

|

Waste Ink Tray |

|

Cassette Assy |

Stacker Assy |

Paper Sheet Assy |

ADF Cover Assy |

ADF Pad Assy |

|

|

Assy |

|

|||||||||

|

1 |

--- |

|

3 |

|

1 |

--- |

--- |

--- |

--- |

--- |

S3 |

2 |

--- |

S4 |

6 |

S3 |

4 |

--- |

4 |

1 |

2 |

4 |

(p 24) |

(p 30) |

(p 35) |

(p 24) |

|

(p 35) |

|

(p 35) |

--- |

--- |

(p 27) |

(p 27) |

ADF Unit/ |

Scanner Unit |

Left Housing |

Right Housing |

Pickup Assy |

Stopper Assy |

Document Cover |

Document Pad |

Document Pad |

Scanner Unit |

|

|

2 |

|

1 |

|

1 |

|

1 |

--- |

|

2 |

--- |

--- |

--- |

S3 |

S8 |

--- |

S3 |

--- |

S4 |

2 |

S4 |

2 |

1 |

S4 |

2 |

4 |

--- |

--- |

(p 30) |

(p 32) |

(p 24) |

(p 24) |

--- |

(p 28) |

(p 51) |

(p 24) |

(p 24) |

(p 24) |

Hinge |

|

1 |

Panel Unit |

|

Panel Unit |

|

|

1 |

|

3 |

|

3 |

|

|

(p 20) |

|

|

|||

|

|

|

|

|

|

|

S4 |

--- |

|

S4 |

6 |

S4 |

6 |

--- |

(p 24) |

(p 30) |

(p 24) |

(p 31) |

Decoration Plate |

|

|

2 |

Left Housing |

|

|

|

|

|

(p 20) |

|

|

|

|

|

Right Housing |

|

|

|

Upper Housing |

|

|

|

(w/ Panel Unit) |

|

|

|

|

4 |

3 |

(p 20) |

S4 |

--- |

|

|

(p 24) |

|

|

|

A

A

(p 22)

See "1.2.2.2Housing Part (WorkForce 60 series) (p21)" for removing the housing part of WorkForce 60 series.

When replacing the Printer Mechanism supplied as an ASP, make sure to adjust the Stopper Holder Idle Roller in the proper attachment position, and then perform the PF Timing Belt tension measurement. See " Paper Guide Front Assy (Stopper Holder Idle Roller) (p28)" and "2.2.1PF Timing Belt Tension Measurement/ PF Belt Step Check (p40)" for the details.

Flowchart 1-1. Disassembly Flowchart of Housing Part (1)

Disassembly/Reassembly |

Disassembly/Reassembly Flowchart |

|

|

|

|

|

|

|

WorkForce 635 series specific parts/unit |

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

WorkForce 625 series specific parts/unit |

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

WorkForce 635 series/ |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

WorkForce 625 series common parts/unit |

|

||

Screw type/torque |

|

|

|

|

|

|

||||

list |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

|

|

Screw type |

|

Torque |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

C.B.P-TITE SCREW,2.5X8,F/ZN-3C |

4 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S2 |

C.B.P-TITE SCREW,2X8,F/ZN-3C |

2 |

0.5 kgf·cm |

|

||||

|

|

S3 |

C.B.P-TITE SCREW,3X10,F/ZB-3C |

6 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S4 |

C.B.P-TITE SCREW,3X10,F/ZN-3C |

6 |

1 kgf·cm |

|

||||

|

|

S5 |

C.B.S-TITE SCREW,3X10,F/ZN-3C |

6 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S6 |

C.B.S-TITE SCREW,3X6,F/ZN-3C |

4 |

0.5 kgf·cm |

|

||||

|

|

S7 |

C.B.S-TITE SCREW,3X6,F/ZN-3C |

6 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S8 |

C.B.S-TITE SCREW,3X6,F/ZN-3C |

8 |

1 kgf·cm |

|

||||

|

|

S9 |

C.P.SCREW,2.5X6,F/ZN-3C |

2 |

0.5 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S10 |

C.P.SCREW,3X4,F/ZN-3C |

2 |

0.5 kgf·cm |

|

||||

|

|

S11 |

C.P.SCREW,3X4,F/ZN-3C |

4 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S12 |

C.P.SCREW,2.6X3,F/ZN-3C |

4 |

1 kgf·cm |

|

||||

|

|

S13 |

C.B.P-TITE SCREW(S-P1),3X12,F/ZN-3C |

5 - 6 kgf·cm |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

S14 |

|

C.B.P-TITE SCREW,2.5X8,F/ZN-3C |

2 |

0.5 kgf·cm |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

S15 |

C.B.P-TITE SCREW,3X4,F/ZN-3C |

6 |

1 kgf·cm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

19

Confidential

Loading...

Loading...