Page 1

Service Manual

Fuller Automated Transmissions

TRSM0062

October 2007

FO-6406A-ASW

FO-6406A-ASX

FO-8406A-ASW

FO-8406A-ASX

RT-14910B-AS2

RTLO-14918A-AS2

RTLO-16918A-AS2

RTLO-18918A-AS2

RTLO-20918A-AS2

RTLO-22918A-AS2

RTO-10710B-AS2

RTO-10910B-AS2

RTO-10910B-DM2

RTO-12710B-AS2

RTO-12910B-AS2

RTO-12910B-DM2

RTO-14710B-AS2

RTO-14710C-AS2

RTO-14910B-AS2

RTO-14910B-DM2

RTO-14910C-AS2

RTO-16710C-AS2

RTO-16910B-AS2

RTO-16910B-DM2

RTO-16910C-AS2

RTO-18910B-AS2

Page 2

General Information

General Information

Cautions, and Warnings

WARNING

Follow the specified procedures in the indicated order

to avoid personal injury.

CAUTION

Follow the specified procedures in the indicated order

to avoid equipment malfunction or damage

Note: Additional relevant information not covered in the

service procedure.

IMPORTANT

For additional information and assistance, call the

Roadranger Help Desk at 1-800-826-HELP (4357).

Mexico: 01-800-826-HELP (4357). You may also find

more information at www.Roadranger.com.

Operational Warnings

Before starting a vehicle:

When parking the vehicle or leaving the cab:

8. Place the shift lever in neutral.

9. Set the parking brake.

Do not operate the vehicle if the alternator lamp is lit or if

the gauges indicate low voltage.

Repair Warnings

When disassembling various assemblies, lay all parts on

a clean bench in the same sequence as removed to simplify and reduce the possibility of losing parts.

Disconnect the vehicle’s battery before removing or

installing electronic parts.

Since the cost of a new part is generally a small fraction

of the cost of downtime and labor, avoid reusing a questionable part that could lead to additional repairs and

expense.

Use of other than recommended tools, parts, and instructions listed in this manual may place the safety of the service technician or vehicle driver in jeopardy.

1. Sit in the driver’s seat.

2. Place the Shift Lever in neutral.

3. Set the parking brake.

4. Disengage the clutch.

Before working on the vehicle or leaving the cab with the

engine running:

5. Place the shift lever in neutral.

6. Set the parking brake.

7. Block the wheels.

Do not release the parking brake or attempt to select a

gear until the air pressure is at the correct level.

The location of some components may vary with each

OEM.

The removal and installation procedure described for

each component may vary for your vehicle.

Always use genuine Eaton replacement parts. For a complete list of approved and reputable dealers, write to:

Eaton Corporation

Truck Component Marketing Headquarters

P.O. Box 4013

Kalamazoo, MI 49003

Every effort has been made to ensure the accuracy of the

information contained in this manual. However, Eaton

Corporation makes no warranty, expressed or implied,

based on the information provided.

Page 3

Table of Contents

General Information

Preventive Maintenance

Service Procedures

Cautions, and Warnings ............................................................................................................................................i

How to Use This Manual ......................................................................................................................................... 1

Dry Clutch Models Only .......................................................................................................................................... 3

UltraShift™ HP Models ............................................................................................................................................ 9

Lubricant Filter (UltraShift HP Models Only) – Remove ........................................................................................ 15

Lubricant Filter (UltraShift HP Models Only) – Install ............................................................................................ 17

Rail Select Sensor – Remove ................................................................................................................................ 19

Rail Select Sensor – Install ................................................................................................................................... 21

Gear Select Sensor – Remove ............................................................................................................................... 23

Gear Select Sensor – Install .................................................................................................................................. 25

Input Shaft Speed Sensor – Remove .................................................................................................................... 27

Input Shaft Speed Sensor – Install ........................................................................................................................ 29

Main Shaft Speed Sensor – Remove ..................................................................................................................... 31

Main Shaft Speed Sensor – Install ........................................................................................................................ 33

Output Shaft Speed Sensor – Remove .................................................................................................................. 35

Output Shaft Speed Sensor – Install ..................................................................................................................... 37

Range Valve – Remove ......................................................................................................................................... 39

Range Valve – Install ............................................................................................................................................. 41

Splitter Valve – Remove ........................................................................................................................................ 43

Splitter Valve – Install ........................................................................................................................................... 45

Air Filter/Regulator – Remove ............................................................................................................................... 47

Air Filter/Regulator – Install .................................................................................................................................. 49

Inertia Brake (6-Speed) – Remove ........................................................................................................................ 51

Inertia Brake (6-Speed)– Install ............................................................................................................................ 53

Inertia Brake (7, 10, and 18-Speed) – Remove ..................................................................................................... 55

Inertia Brake (7, 10, and 18 Speed) – Install ......................................................................................................... 57

Inertia Brake Relocation Instructions 8 to 6 Bolt PTO Opening--Remove .............................................................. 59

Inertia Brake Relocation Instructions 8 to 6-Bolt PTO opening--Install ................................................................. 61

Electric Shifter – Remove ...................................................................................................................................... 63

Electric Shifter – Install ......................................................................................................................................... 65

Transmission Controller – Remove ....................................................................................................................... 67

Transmission Controller – Install .......................................................................................................................... 69

Transmission Harness – Remove .......................................................................................................................... 71

Transmission Harness – Install ............................................................................................................................. 73

Gear Display – Remove ......................................................................................................................................... 75

Gear Display – Install ............................................................................................................................................ 77

Shift Control– Remove .......................................................................................................................................... 79

Shift Control – Install ............................................................................................................................................ 81

Transmission – Remove ....................................................................................................................................... 83

Transmission – Install ........................................................................................................................................... 84

Change Control Log .............................................................................................................................................. 85

Table of Contents

ii

Page 4

General Information

How to Use This Manual

This manual is designed to provide detailed information necessary to service and repair the Automation portion of the

following Fuller transmissions:

1. 6-Speed (Fx-x406x-ASX, Fx-x406x-ASW)

2. 7-Speed (TO-xx607x-ASX)

3. 10-Speed (RTO-xxx10x-AS2, RTO-xxx10x-DM2)

4. 18-Speed (RTLO-xx918x-AS2)

The service procedures in this manual are for transmission automation components only. To locate the information you

need, simply locate the procedure in the index, turn to the page specified, and follow the procedure.

To service the mechanical portion of the transmission system, refer to the specific transmission service manual.

Serial Tag Information and Model Nomenclature

Transmission model designation and other transmission identification information are stamped on the serial tag. To

identify the transmission model and serial number, locate the tag on the transmission and then locate the numbers as

shown.

Model

RTO-14710B-AS2

Fuller

Made In

R

Eaton Corporation

Transmission Div.

Kalamazoo, MI. 49003

Serial

Eaton

Transmissions

R

1

Page 5

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 6

General Information

Model Number

The model number gives basic information about the transmission and is explained below. Use this number when calling for service assistance or replacement parts.

6-Speed

Fuller

Overdrive

Torque x 100

Design Level

FO 84 6A0- X-XAS

W-WetClutch

X-Inertia Brake

AutoShift

Gear Ratio

Forward Speeds

General Information

7-Speed

Twin Countershaft

Torque x 100

Design Level

10-Speed

Roadranger

Twin Countershaft

Overdrive

Torque x 100

Design Level

18-Speed

Roadranger

Twin Countershaft

Low Inertia

Overdrive

Torque x 100

Design Level

Overdrive

T O 11 076-B-AS

X - Inertia Brake

AutoShift

Gear Ratio

Forward Speeds

TO-

R

T

14 107B-AS

LO-R

18 189A-AS

2

2 - AutoShift II

(Second Generation)

AutoShift

DM-Data Mechanical Clutch

Gear Ratio

Forward Speeds

2

2 - AutoShift II

(Second Generation)

AutoShift

Gear Ratio

Forward Speeds

PREFIX KEY

F = Fuller

L = Low Inertia

O = Overdrive

R = Roadranger

T = Twin Countershaft

AS = AutoShift

X = Inertia Brake

2 = AutoShift II

(Second Generation)

SUFFIX KEY

W=WetClutch

DM=Data

Mechanical

Clutch

Serial Number

The serial number is the sequential identification number of the transmission. Have the serial number available when

calling for service assistance.

Bill of Material or Customer Number

This number may be located below the model and serial numbers. It is a reference number that is used by Eaton.

2

Page 7

General Information

Dry Clutch Models Only

Preventive Maintenance Overview

To keep the vehicle running properly, it is important to perform preventive maintenance on vehicle components. This

ensures the vehicle and its subassemblies will operate properly throughout their useful life. To cover preventative maintenance completely, you must review the following subjects in detail:

1. Recommended Lubricants

2. Maintenance/Lubricant Change Interval

3. Inspecting the Transmission

4. Changing the Fluid

5. Vehicle System Effects

Recommended Lubricants

Where transmissions are concerned, lubricant is possibly the most important part of keeping a vehicle operating.

Lubricants which meet the Eaton E500 (PS-164) specification are required in the AutoShift transmission. Lubricant

must be approved by Eaton Corporation to qualify for the 5/750,000 warranty. For a list of Eaton Roadranger approved

lubricants, order publication TCMT-0021.

3

Page 8

General Information

Maintenance/Lubricant Change Intervals

IMPORTANT

Transmission filters should be changed durning regular lube intervals. Inspection of the transmission filter should

be conducted during preventative maintenance checks for damage or corrosion. Replace as necessary.

Transmission inspections and lubricant changes depend on the type of lubricant used and whether the vehicle is used

On or Off-highway.

On-highway Lubricant- Vehicles operated on paved roads, interstate highways, and turnpikes are designated as onhighway vehicles. Lubricant change and inspection intervals are the most generous for on-highway vehicles using synthetic lubricants.

Off-highway Lubricant- Vehicles operated in off-highway applications such as coal trucks or mining vehicles, it is more

important to use time rather than mileage to keep the transmission within its proper preventative maintenance schedule. Off-highway applications are divided into two categories, severe and normal. “Severe off-highway” is the designation used when there is excessive dust and dirt. “Normal off-highway” is for applications where dust and dirt are

minimal.

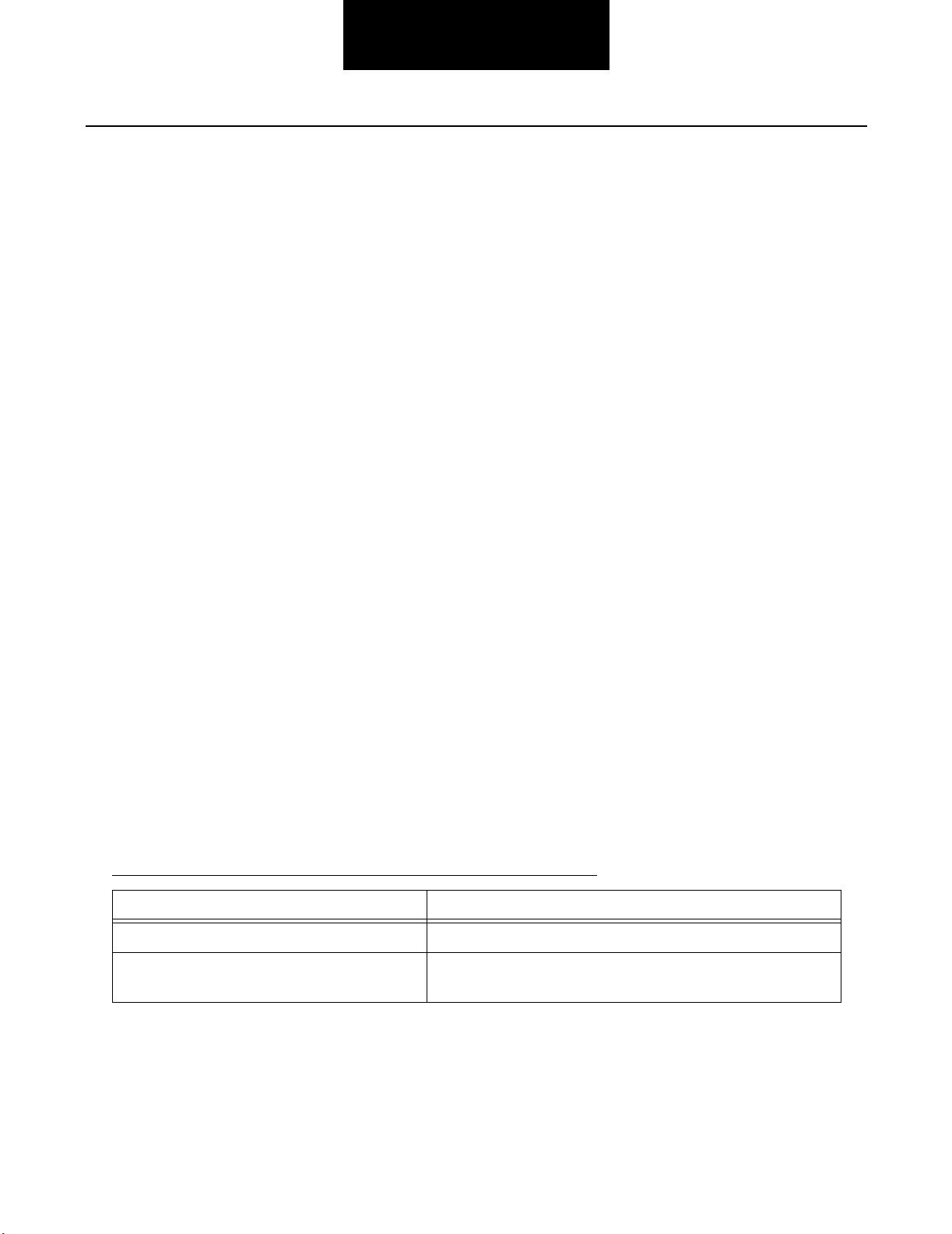

Table 1: Lubricant Change and Inspection (On-highway)

Change Interval Description

Every 2500 miles Inspect lubricant level. Perform Transmission Inspection

Every 250,000 Change transmission lubricant and filter. (if equipped)

*The first lube change may be extended to 500,000 miles (800,000 km) when a transmission has been factory

filled with a lube that is Eaton approved for 500,000 miles (800,000 km) (E-500, PS-164)

General Information

Table 2: Lubricant Change and Inspection (Off-highway)

Change Interval Description

Every 40 hours Inspect lubricant level. Perform Transmission Inspection

Every 1000 hours Change Transmission lubricant and filter (if equipped) where

severe dirt conditions exist

Every 2500 hours Change Transmission lubricant and filter (if equipped) (Normal

off-highway use.)

4

Page 9

General Information

Transmission Inspection

When performing preventive maintenance (PM) inspections, several items must be checked. It is important to perform

every step to ensure the transmission will meet its life expectancy. Proper PM consists of the following steps:

1. Check Lubricant Level

2. Inspect for Loose/Missing Bolts

3. Check for Air Leaks

4. Check for Lubricant Leaks

Check Lubricant Level

When checking the transmission lubricant there are two important points to know: where to check the lubricant and

what the proper lubricant level is. Always be cautious when checking the transmission lubricant as it may be hot.

Checking Location- Checking the lubricant at the lubricant fill plug located on the left side of the main transmission

case.

Proper Lubricant Level- The lubricant is at the proper level when it is even with the bottom of the fill hole. When you

remove the plug to check the lubricant level, lubricant should seep out. Do not use your finger to feel for the lubricant.

Even if you can touch the lubricant, it may not be at the proper level. In a transmission, one inch of lubricant level equals

about one gallon of lubricant.

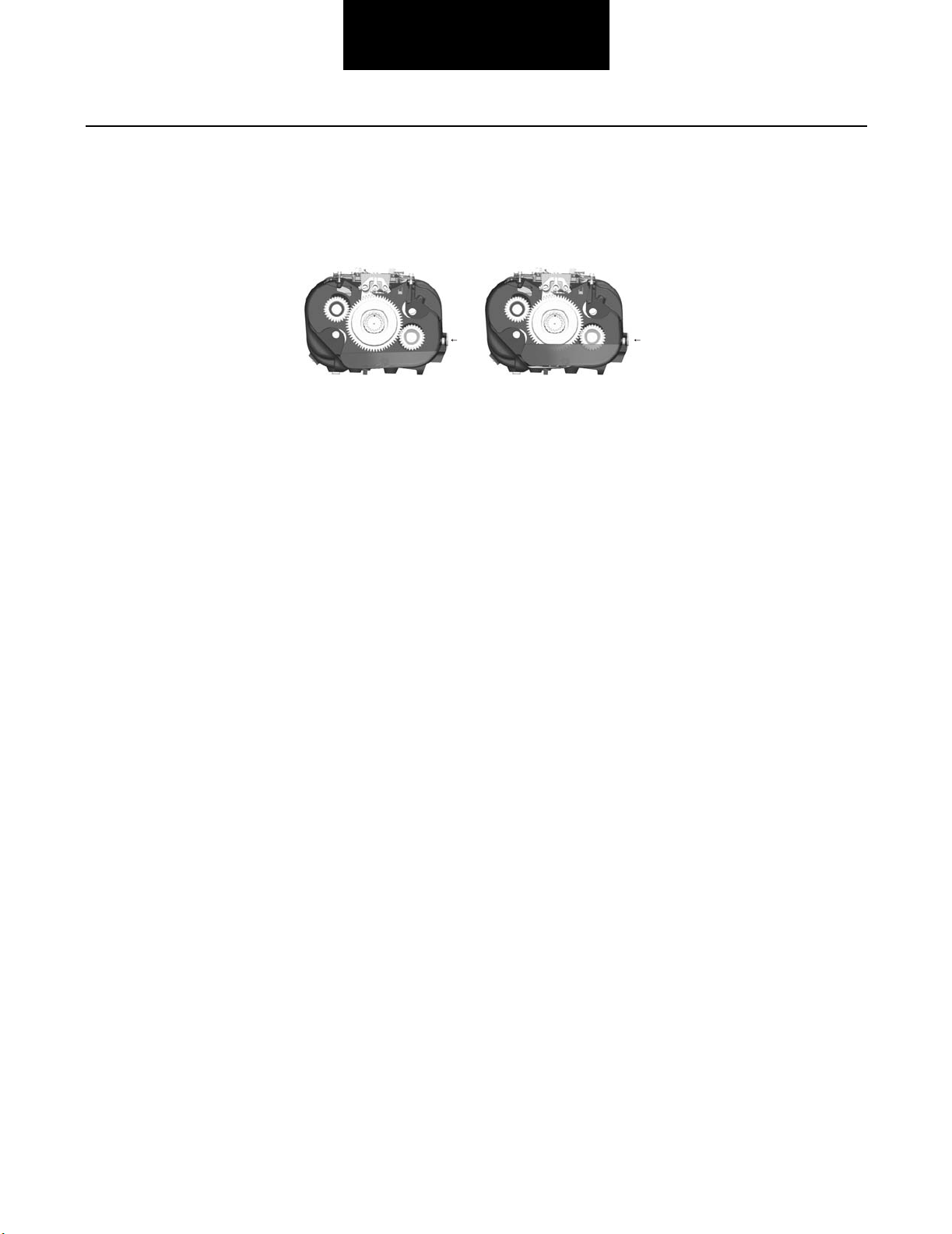

Improper Oil Level

Hole

Proper Oil Level

Hole

Inspect for Loose/Missing Bolts

While you are under the vehicle checking the lubricant, make a quick check for loose or missing bolts. Check all bolts on

the back box, PTO covers, shift bar housing, clutch housing, and transmission controller. Replace any missing or broken bolt with the proper bolt as specified in the Illustrated Parts Listing. Follow the procedure defined in the transmission Service Manual when tightening any bolts.

5

Page 10

General Information

Check for Air Leaks

Two steps are required when checking for an air leak: inspection and repair.

Audible Inspection for Leaks- To find air leaks, make sure the vehicle air system has at least 90 PSI air pressure. Then,

listen for leaks, making sure a vehicle leak is not mistaken for a transmission air leak.

Refer to Troubleshooting Procedures- Once you find an air leak, use the Troubleshooting Guide to isolate the air leak to

the faulty component.

Check for Lubricant Leaks

A lubricant leak could cause a catastrophic transmission failure. Check for leaks first at the gasket surfaces, then the

input shaft, the rear seal, and the transmission cooler.

Gaskets- Visually check each gasket to insure that no leak is present. Typically a moist spot is acceptable; however drips

or larger wet areas are not. Check for leaks at the rear housing, PTO, shift bar housing, shift tower, and clutch housing

gasket surfaces. It is also important to ensure that the leak is indeed coming from the transmission. Make sure the oil is

not being blown back from the engine or another vehicle component.

Input Shaft- Check for leaks around the input shaft. Leaks in this area could be caused by a faulty gasket, input shaft, or

pressurization of the main transmission case by the air system. If you find a leak at the input shaft, make sure the air

system is not leaking into the case before looking for leaking gaskets.

Rear Seal- The rear seal is very important in maintaining lubricant in the transmission. If the seal is improperly installed

or has failed, the transmission may experience a catastrophic failure. Check the rear seal by performing the following

steps:

General Information

Visual Check for Leak- Visually inspect the rear seal for a leak. If a rear seal leak is suspected, proper isolation is necessary.

Verify the Leak Path- Other leaks may give the impression the rear seal is leaking. One possible cause is the vehicle

speed sensor. Any lubricant leak above and in front of the rear seal could cause lubricant to collect around the seal.

Wipe the seal with a clean rag, operate the vehicle, and recheck to verify the leak path. More information can be found in

the Seal Maintenance Guide (TCSM-0912).

Transmission Cooler Leaks- If the vehicle is equipped with a transmission cooler, make sure there are no leaks at the

lubricant cooler, hoses, and fittings of the cooler circuit.

6

Page 11

General Information

Changing Lubricant

When it is time to change the transmission lubricant, there are only a few steps to follow: Draining and filling the transmission, draining and filling the cooler (if equipped), and changing the lubricant filter (if equipped). Remember to be

careful when changing the transmission lubricant, as it may be hot.

Drain the Transmission

1. Locate the drain plug on the bottom of the transmission case.

2. Place a drain pan under the drain plug.

3. Remove the drain plug and allow the lubricant to drain completely.

4. Once drained, reinstall the drain plug and tighten to 45-55 lbs.ft. (61.0-74.6 N•m). Sealant is not required on

the drain plug threads.

Drain the Cooler (if equipped)

1. Remove both cooler lines at the transmission.

2. Pressurize one line with 30 PSI of air pressure to force the lubricant out of the cooler.

3. Once drained, reconnect the coolant lines to the transmission. Make sure the lines are not crossed.

Fill the Transmission

1. Remove the transmission fill plug and fill the transmission with approved lubricant.

2. The transmission is full when the lubricant starts to flow out of the fill hole.

3. Replace the fill plug and tighten to 60-70 lbs.ft. (81.3-94.9 N•m).

Fill the Cooler (if equipped)

1. Place the transmission in neutral and start the vehicle.

2. Release the clutch to rotate the input shaft of the transmission, allowing the pump to fill the cooler.

3. Run the vehicle for one minute.

4. Shut off the vehicle, recheck the transmission lubricant level and add lubricant as required.

Change the “Spin-on” Filter (if equipped)

1. Remove the filter from the “spin-on” casting.

2. Catch any lubricant that seeps from the filter.

3. Clean the casting surface.

4. Install a new filter and hand tighten.

7

Page 12

General Information

Vehicle System Effects

Some vehicle systems can affect the transmission operation and possibly cause a failure. The air system is a major system that can affect the transmission components.

Air System- If the air system is not given recommended preventive maintenance, it can cause problems for the transmission system. Although the transmission has an Air Filter/Regulator, it can only protect the transmission from contaminants for so long. This is why it is important to follow OEM recommendations for air system preventive

maintenance. It is important to regularly drain air tanks and ensure lubricant is not being pumped into the system. It can

cause corrosion or, in cold climates, it could freeze and prevent the shift mechanisms from operating. If lubricant is

allowed into the system, it could fill the air system components and cause them to lose valuable air volume, slowing or

preventing movement.

General Information

8

Page 13

General Information

UltraShift™ HP Models

Preventive Maintenance Overview

To keep a vehicle running properly, it is very important to perform preventive maintenance on the vehicle components.

This ensures the vehicle and its subassemblies will operate properly. To cover preventive maintenance completely, you

must review the following subjects in detail.

1. Specified Lubricants

2. Maintenance/Lubricant Change Intervals

3. Inspecting the Transmission

4. Changing the Fluid

5. Clutch Calibration

Specified Lubricants

Where transmissions are concerned, lubrication is possibly the most important part of keeping a vehicle operating.

Synthetic Dexron III

Synthetic Dexron III must be used in the WetClutch portion of the transmission.

CD-50

CD-50 must be used in the gearbox portion of the transmission.

Maintenance/Lubricant Change Intervals

Transmission inspections and lubricant changes are outlined below.

For a list of Eaton Roadranger approved lubricants, order publication TCMT-0020.

Table 1: Lubricant Inspection and Change Interval (On-highway)

Interval Description

Every 2,500 miles Inspect lubricant level. Perform Transmission Inspection.

Every 5 years or 500,000 miles, whichever

occurs first

Change transmission lubricants and filters.

For additional lubricant information, see TCMT-0021.

9

Page 14

General Information

Transmission Inspections

When performing preventive maintenance, several items must be checked. It is important to perform every step to

ensure the transmission will meet its life expectancy. Proper preventative maintenance consists of the following steps:

1. Check WetClutch Lubricant Level

2. Check Gearbox Lubricant Level

3. Inspect for Loose/Missing Bolts

4. Check for Lubricant Leaks

Check Lubricant Level

When checking the WetClutch model, there are three important things to know: where to check the lubricants, what is

the proper lubricant level, and what is the proper lubricant type. Always be cautious when checking the transmission

fluid since it may be hot.

General Information

Checking WetClutch Lubricant

The WetClutch portion is checked using a dipstick located in the engine compartment.

Proper WetClutch Lubricant Level

WetClutch lubricant level should be checked when idling in neutral, with the transmission temperature between 60° F

and 120° F (15.5° C and 48.8° C) and when the vehicle has been idling in neutral for at least two (2) minutes. Proper

lubricant level is obtained when the lubricant is between the cold ADD mark and the cold FULL marks on the dipstick.

Due to thermal expansion of the lubricant, it is not recommended to check the level when the transmission is above

120° F (48.8° C).

ADD COLD FULL

(COLD 60-120

F) SYNTHETIC DEXRON III

Checking Gearbox Lubricant

The gearbox portion is checked at the lubricant fill plug located on the right side of the gear case.

10

Page 15

General Information

Proper Gearbox Lubricant Level

The gearbox lubricant is at the proper level when it is even with bottom of the fill hole. When you remove the plug to

check the lubricant level, lubricant should seep out. Do not use your finger to feel for the lubricant. Even if you can

touch the lubricant, it may not be at the proper level. In a transmission, one inch of lubricant level equals about one gallon of lubricant.

Improper Oil Level

Hole

Proper Oil Level

Hole

Inspect for Loose/Missing Bolts

While you are under the vehicle checking the lubricant, make a quick check for loose or missing bolts. Check all bolts on

the PTO cover, inertia brake, shift bar housing, clutch housing oil pan, output flange, and transmission controller.

Replace any missing or broken bolt with the proper bolts as called out in the illustrated parts listing. Follow the procedure defined in the transmission service manual when tightening any bolts.

Check for Lubricant Leaks

A lubricant leak could cause a catastrophic transmission failure. Check for leaks at the gasket surfaces, lubricant lines,

flywheel housing, rear seal, and the cooler.

Gaskets

Visually check each gasket to ensure that no leak is present. Typically, a moist spot is acceptable, however, drips or

larger wet areas are not. Check for leaks at the rear housing, PTO cover, shift bar housing, clutch housing to main case,

inertia brake, and clutch oil pan. It is also important to ensure that the leak indeed is coming from the transmission.

Make sure the lubricant is not being blown back from the engine or another vehicle component.

Lubricant Lines

There are three external lines for lubricant on the UltraShift HP transmission. One lubricates the inertia brake and the

other two are for the oil cooler. Check the lines to ensure they are not leaking.

Flywheel Housing/Clutch Housing

Check for leaks around the flywheel housing/clutch housing mating surface. A faulty seal or loose fittings could cause

leaks in the area. The UltraShift HP transmission has what is called a “wet housing” which means that the clutch housing is used as a sump for the WetClutch lubricant. Any leaks here could cause a transmission failure.

Transmission Cooler Leaks

11

Page 16

General Information

Ensure there are no leaks at the lubricant cooler, hoses, and fittings of the cooler circuit.

Changing the Lubricant

When it is time to change the transmission lubricant, there are only a few steps to follow:

• Draining and Filling the WetClutch portion

• Draining and Filling the Gearbox portion,

• Draining and Filling the Cooler,

• Changing the Lubricant Filters

WARNING

Remember to be careful when changing the transmission lubricant, as it may be hot.

Drain the Transmission Gearbox and WetClutch Housing

1. Locate the drain plugs at the bottom of the transmission gear case and on the clutch housing oil pan.

2. Place a drain pan under each drain plug.

3. Remove both drain plugs and allow the lubricants to drain completely.

4. Disconnect both cooler lines at the WetClutch housing.

5. Pressurize one line with 20 PSI until all lubricant is forced out of the cooler.

General Information

6. Reconnect both cooler lines.

12

Page 17

General Information

Change WetClutch Filters

Change the lubricant filters when the transmission lubricant is changed. Detailed information can be found on removal

and replacement of the oil filters in this service manual.

Fill the Transmission

1. Install the transmission gearbox drain plug and tighten to 45-55 lbs.ft. (61.0-74 N•m). Sealant is not required

on the drain plug threads.

2. Install the clutch housing oil pan drain plug and torque to 34-48 lbs.ft. (46-65N•m). Sealant is not required on

the drain plug thread.

3. Fill the transmission gearbox with the recommended lubricant until the lubricant seeps out of the fill hole.

4. Install the fill plug and torque to 25-35 lbs.ft. (34-47 N•m).

5. Slowly fill the clutch through the dipstick tube with a maximum of 18 pints (8.5 liters) of the recommended

lubricant.

6. Place the transmission in neutral position and apply the parking brakes. Start the engine and let idle for five (5)

minutes, (this allows oil to fill the WetClutch system and cooling system), add oil as needed to obtain a level at

the proper temperature range. Total oil quantity should be approximately 24 pints: this varies depending on the

cooling system capacity.

7. Increase the engine idle slowly to 1500 RPM for two (2) minutes. Next, recheck the oil level at normal idle

speed in neutral, again adding oil to obtain a level at the proper temperature range.

8. Replace the dipstick and tighten securely.

Clutch Calibration

The UltraShift HP system automatically provides for clutch wear. The system will initiate a clutch calibration once per

vehicle power up, when certain vehicle conditions are right. Of these conditions, the most important ones include: when

the engine is running at idle speed, during normal operating temperature, when the vehicle is stopped, and when neutral

is selected on the Shift Control. During the calibration, the clutch is partially engaged until the engine begins to slightly

lug down. It will then disengage the clutch and repeat this process several times. The calibration process usually takes

as little as thirty seconds but can take as long as two (2) minutes. The calibration will be aborted when any position

other than neutral is selected on the Shift Control.

If it appears that the vehicle is not engaging smoothly from a stop, it is possible that the clutch needs to be re-calibrated. If it has not been previously calibrated during the current power up, stop the vehicle with the engine idling at its

normal operating temperature and place the Shift Control in neutral and wait two (2) minutes. If the calibration is being

performed you should hear the engine slightly lug down and then return to its no load condition several times.

If calibration does not occur a Power Down/Power Up will initiate a calibration.

13

Page 18

Oil Leak Inspection Process

General Information

Inspect for Oil Leak

General Information

Determine if it is a Weep or a Leak

Weep: Stained, damp, no drips, light oil film,

dirt adhered to the contaminated area.

Gasket Rear Seal Leak

Leak: Extremely wet or dripping of oil in the

contaminated area.

Step 1

1. Clean suspected oil weep

area with a clean dry cloth

or mild soluble degreaser.

2. Ensure lube is to proper

level.

3. Notify the customer that it

is only a weep and it is not

considered to be detrimental

to the life of the transmission.

4. Repair is complete.

1. Do not repair: Rear seal is

designed to allow min

seepage (refer to Roadranger

TCSM-0912 Seal Maintance

Guide).

2. Ensure lube is to proper

level.

imal

Step 2

Step 3

1. Determine the origin of the leak path.

2. If origin of leak is obvious skip to Step 3.

3. If the origin of the oil leak is not obvious then

use either of the two following steps to determine

the oil leak:

Note: Do not use a high pressure spray washer to

clean the ar

force contamination into the area of concern and

temporarily disrupt the leak path.

i. Clean area with a clean dry cloth or mild

soluble degreaser and fill the transmission to

the proper lube level.

OR

ii. Clean the area as noted above and insert tracer

dye into the tr

transmission to proper lube level.

Operate vehicle to normal transmission operating

temperature and inspect the area for oil leak(s)

visually or if tracer dye was introduced use an UVL

(Ultraviolet Light) to detect the tracer dye’s point

of origin.

Note: When i

make sure the assumed leak area is not being

contaminated by a source either forward or above

the identified area such as the engine, shift tower,

shift bar housing, top mounted oil cooler, etc...

ea. Use of a high pressure spray may

ansmission lube and fill

nspecting for the origin of the leak(s)

Once the origin of the leak is identified, repair the

oil leak using proper repair proced

designated model service manual.

ures from the

Step 4

After the repair is completed, verify the leak is

repaired and operate the vehicle to normal

transmission operating temperature.

Inspect repaired area to ensure oil leak has been

eliminated. If the leak(s) still occurs, repeat steps

or contact the Roadranger Call Cen

1-800-826-4357.

ter at

14

Page 19

Service Procedures

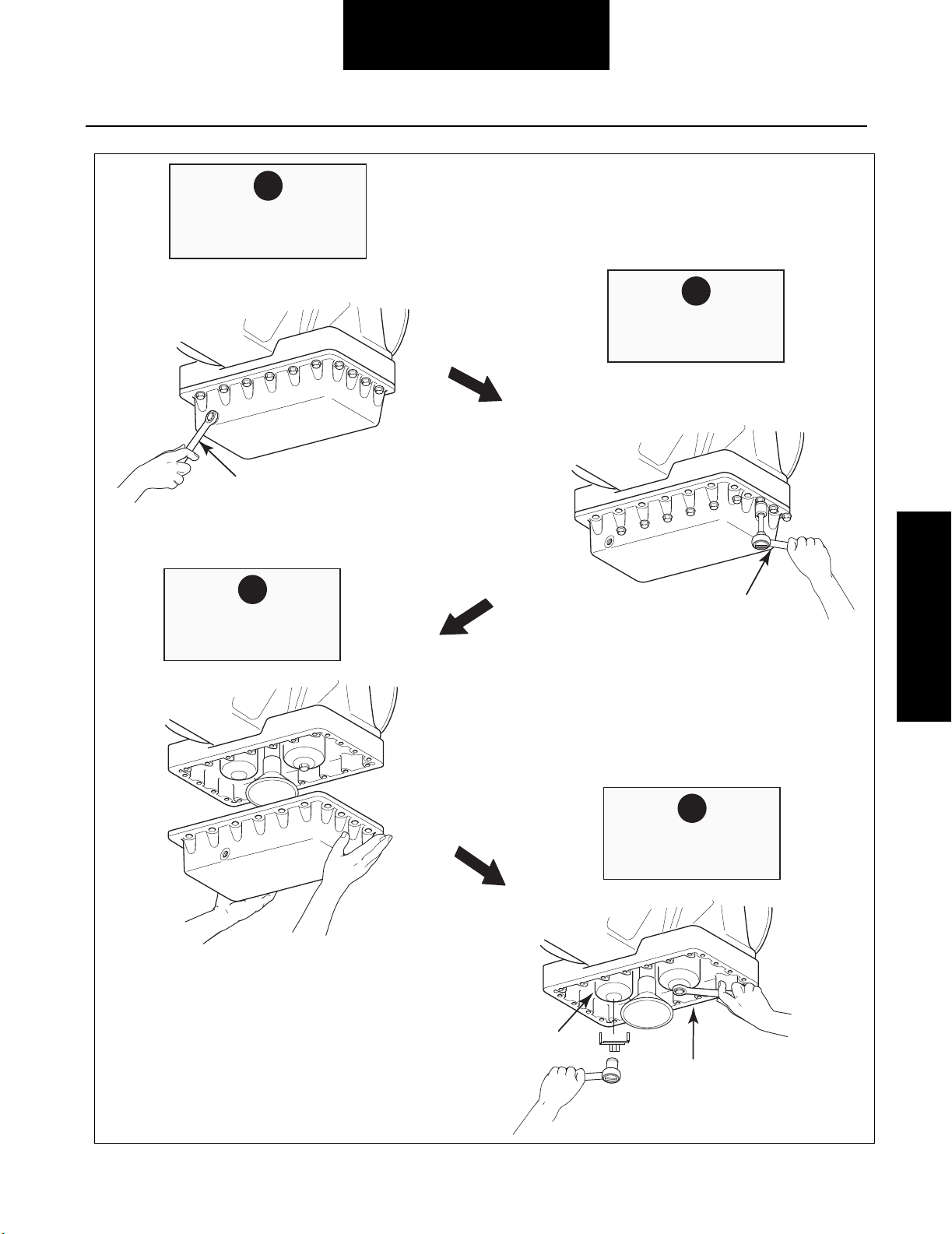

Lubricant Filter (UltraShift HP Models Only) – Remove

Special Instructions

None

Required Tools

2. Using a 15mm wrench, remove the oil pan mounting

bolts. Record location of the long and short bolts.

3. Remove the WetClutch oil pan and gasket.

4. Remove the two (2) WetClutch filters. Make sure filter seals are removed.

• Basic Hand Tools

Removal

1. Remove the drain plug and drain the fluid from the

WetClutch portion of the transmission.

CAUTION

Fluid may be hot.

Note: The filters will contain fluid when they are

removed.

IMPORTANT

Transmission filters should be changed during regular lube intervals. Inspection of the transmission

filter should be conducted during preventative

maintenance checks for damage or corrosion.

Replace as necessary.

Filter Location

15

Low Pressure Filter

High Pressure Filter

Page 20

1

Remove Drain Plug

Drain Fluid

Service Procedures

2

Remove Oil Pan

Mounting Bolts

Wrench

3

Remove Oil Pan

and Gasket

Service Procedures

15 mm Wrench

4

Remove Filters

Lubricant Filter Removal

Low Pressure Filter

High Pressure Filter

16

Page 21

Service Procedures

Lubricant Filter (UltraShift HP Models Only) – Install

Special Instructions

5. Using a 15mm wrench install the mounting bolts and

tighten to 30-35 lbs.ft. (41-47 N•m) using a cross

pattern.

Install each filter in its correct location.

Clean filter seal mating surfaces on the transmission.

Clean and remove all old gasket material from the mating

surfaces of the clutch housing and the oil pan.

Required Tools

Basic Hand Tools

Installation

1. Lubricate each filter seal ring with synthetic Dexron

III prior to installation.

2. Install the low-pressure filter and turn until seal

touches. Then tighten 3/4 to 1 full turn.

3. Install the high-pressure filter and tighten to 25-30

lbs.ft. (34-41 N•m).

4. Install a new gasket and the WetClutch oil pan.

Note: Put the long and short bolts back in their

proper location.

6. Install the oil pan drain plug and tighten to 34-48

lbs.ft. (46-65 N•m).

Note: Fill the WetClutch portion with the proper fluid.

Final Check

Make sure the bolts are properly tightened.

Make sure the WetClutch portion is properly filled with

the specified fluid.

Check for fluid leaks during and after operating the vehicle.

IMPORTANT

Transmission filters should be changed during regular

lube intervals. Inspection of the transmission filter

should be conducted during preventative maintenance

checks for damage or corrosion. Replace as necessary.

17

Page 22

Service Procedures

1

Lubricate Seal

Rings

Seal Ring

3

Install and Torque

High Pressure Filter

2

Install and Tighten

Low Pressure Filter

Low Pressure Filter

4

Install Oil Pan

and Gasket

Service Procedures

High Pressure Filter

Install and Torque

Mounting Bolts

Mouting Bolts

Pan Gasket

5

Oil Pan

Torque Wrench

6

Install and Torque

Drain Plug

Drain Plug

Torque Wrench

Lubricant Filter Installation

18

Page 23

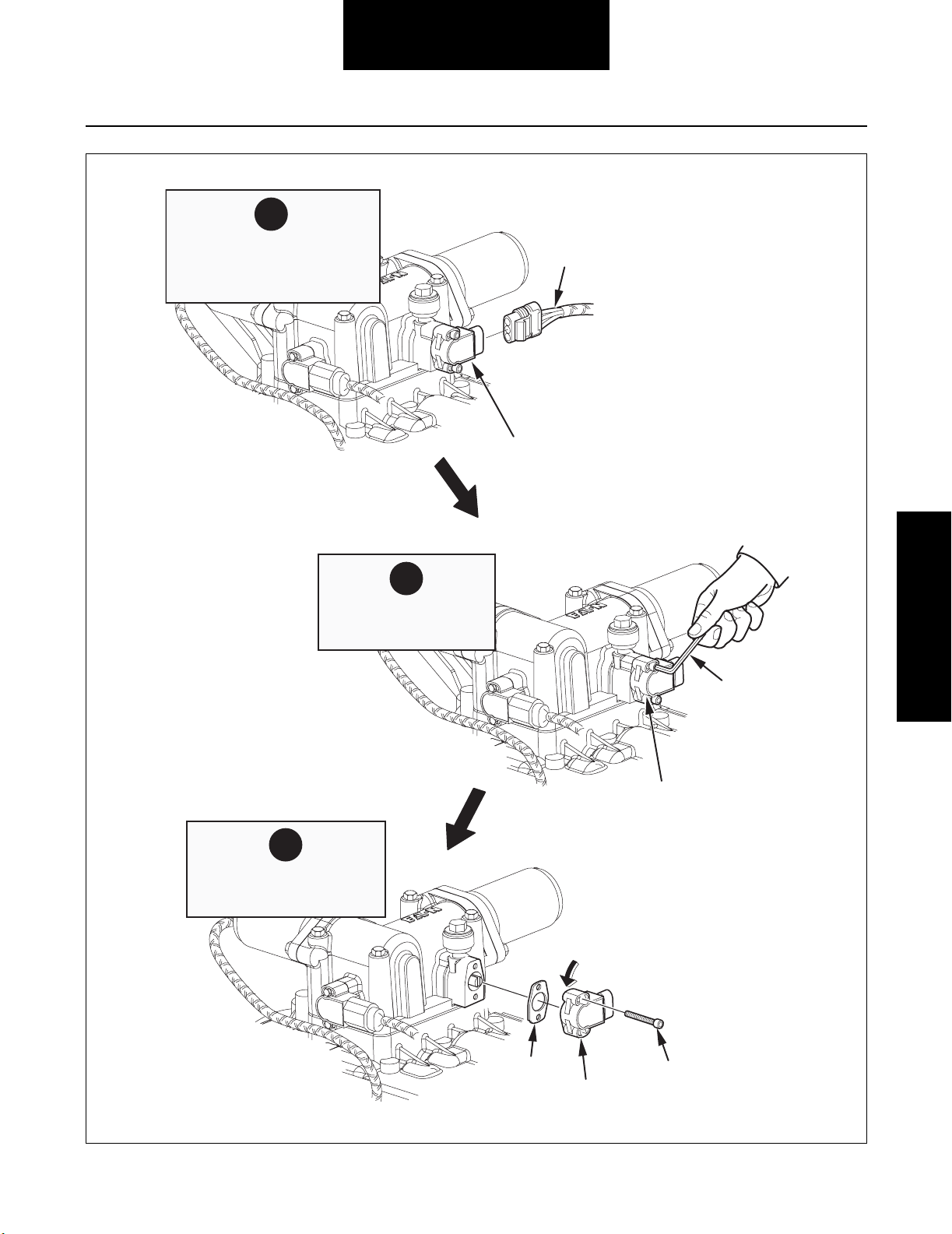

Rail Select Sensor – Remove

Service Procedures

Special Instructions

While removing the hex key mounting screws, hold the

sensor in place. Do not allow it to snap out of position.

Required Tools

• Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Rail

Select Sensor.

2. Using a 5/32” hex key wrench, remove the two (2)

sensor hex key mounting screws.

Note: Carefully allow the sensor to rotate (not snap)

to a relaxed position or the sensor can snap

when the hex key mounting screws are

removed.

3. Remove the sensor and gasket from the housing.

Rail Select

Sensor

Rail Select Sensor Location

19

Page 24

1

Disconnect

Transmission Harness

from Sensor

Service Procedures

Transmission

Harness

Rail Select Sensor

3

Remove

Sensor and Gasket

Service Procedures

2

Remove Hex Key

Mounting Screws

5/32"

Hex Key

Wrench

Rail Select Sensor

Rotate to

Relaxed Position

Rail Select Sensor Removal

Gasket

Rail Select

Sensor

Hex Key

Mounting

Screw

120RMVRS

20

Page 25

Rail Select Sensor – Install

Service Procedures

Special Instructions

While installing the hex key mounting screws, hold the

Rail Select Sensor in place. Do not allow it to snap out of

position.

Torques given below are in pound-inches. Use care not to

overtighten.

Required Tools

Basic Hand Tools

Installation

1. Align the sensor’s tab with the slot in the shifter

housing. Then insert the Rail Select Sensor, with

gasket, into its mounting location.

Note: Install the sensor so the connector opening

faces the right side of the transmission.

2. Using a 5/32" hex key wrench, install the hex key

mounting screws and tighten to 21-27 lbs.in. (2.4-

3.1 N•m).

Note: Carefully hold the sensor in position while

installing the hex key mounting screws or the

sensor can snap.

3. Reconnect the Transmission Harness to the Rail

Select Sensor.

Final Check

Make sure the gasket is installed between the sensor and

the shifter housing.

Make sure the screws are tightened to specification.

Make sure all connections are tight.

Make sure the Transmission Harness is properly connected to the Gear Select Sensor.

Be sure to perform the Electric Shifter calibration procedure before operating the transmission.

21

Page 26

1

Insert Sensor

and Gasket

Service Procedures

Rotate to

Align Mounting

Holes

3

Reconnect

Transmission Harness

to Sensor

Gasket

2

Install Hex Key

Mounting Screws

Hex Key

Mounting Screw

Rail Select

Sensor

Service Procedures

5/32"

Hex Key

Wrench

Rail Select Sensor

Transmission Harness

Rail Select Sensor Installation

Rail Select Sensor

120INSRS

22

Page 27

Gear Select Sensor – Remove

Service Procedures

Special Instructions

While removing the hex key mounting screws, hold the

sensor in place. Do not allow it to snap out of position.

Required Tools

Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Gear

Select Sensor.

2. Using a 5/32” hex key wrench, remove the two (2)

sensor hex key mounting screws.

Note: Carefully allow the sensor to rotate to a relaxed

position, or the sensor can snap when the

hex key mounting screws are removed.

3. Remove the sensor and gasket from the housing.

Gear Select

Sensor

Gear Select Sensor Location

23

Page 28

1

Disconnect

Transmission Harness

from Sensor

Gear Select

Sensor

Service Procedures

Transmission

Harness

2

Remove Hex Key

Mounting Screws

Service Procedures

Rotate to

Relaxed Position

Hex Key

Mounting

Screw

Gear Select

Sensor

Gasket

5/32"

Hex Key

Wrench

3

Remove

Sensor

and Gasket

Gear Select

Sensor

120RMVGS

Gear Select Sensor Removal

24

Page 29

Gear Select Sensor – Install

Service Procedures

Special Instructions

While installing the hex key mounting screws, hold the

Gear Select Sensor in place. Do not allow it to snap out of

position.

Torques given below are in pound-inches. Use care not to

overtighten.

Install the sensor, so the connector opening faces the

back of the transmission.

Required Tools

Basic Hand Tools

Installation

1. Align the sensor’s tab with the slot in the shifter

housing. Then insert the Gear Select Sensor with

gasket into its mounting location.

2. Using a 5/32" hex key wrench, install the two (2) hex

key mounting screws and tighten to 21-27 lbs.in.

(2.4-3.1 N•m).

Note: Carefully hold the sensor in position while

installing the hex key mounting screws, or

the sensor can snap.

3. Reconnect the Transmission Harness to the Gear

Select Sensor.

Final Check

Make sure the gasket is installed between the sensor and

the shifter housing.

Make sure the screws are tightened to specification.

Make sure all connections are tight.

Make sure the Transmission Harness is properly connected to the Gear Select Sensor.

Be sure to perform the Electric Shifter calibration procedure before operating the transmission.

25

Page 30

1

Insert Sensor

and Gasket

Rotate to Align

Mounting Holes

Service Procedures

Hex Key

Mounting

Screw

Gear Select

Gasket

Sensor

3

Reconnect

Transmission Harness

to Sensor

5/32"

Hex Key Wrench

Gear

Select

Sensor

2

Install Hex Key

Mounting Screws

Service Procedures

Gear

Select

Sensor

Gear Select Sensor Installation

Transmission

Harness

120INSGS

26

Page 31

Service Procedures

Input Shaft Speed Sensor – Remove

Special Instructions

Drain the transmission lubricant on 6-Speed transmissions before removing the Input Shaft Speed Sensor.

Input Shaft Speed Sensor location varies as follows:

• 6-Speed- Top or side of Inertia Brake

• 7, 10 and 18-Speed- Right front of Shift Bar

Housing.

Required Tools

• Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Input

Shaft Speed Sensor.

2. Using a 3/8" wrench, remove the sensor retaining

bolt.

Note: On 6-Speed transmissions, drain the lubricant

before removing the sensor.

3. Remove the Input Shaft Speed Sensor, with O-ring,

from the transmission housing.

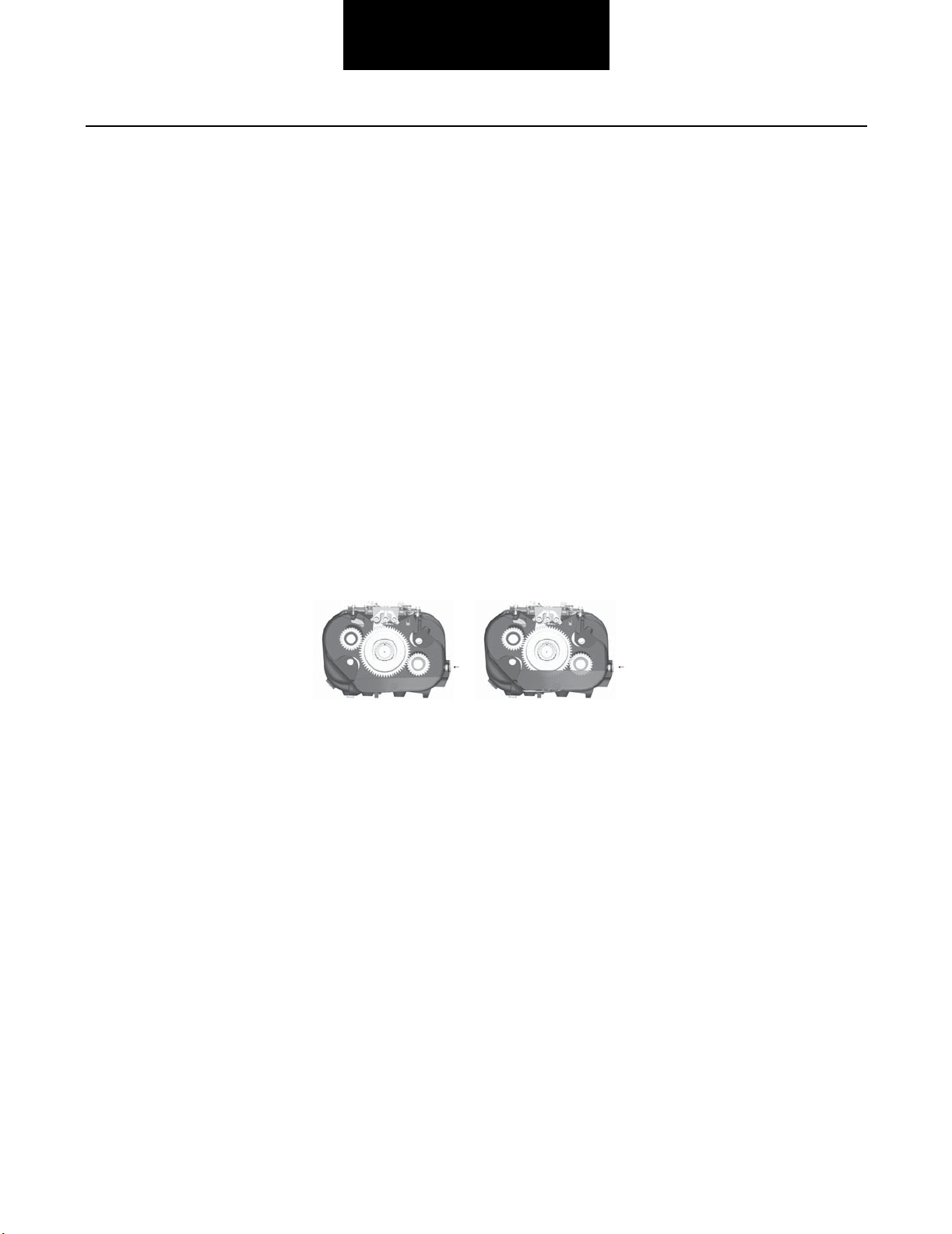

6-Speed 7-Speed 10 and 18-Speed

Input Shaft

Speed Sensor

Input Shaft

Speed Sensor

Input Shaft Speed Sensor Location

27

Input Shaft

Speed Sensor

Page 32

6-Speed

1

Disconnect

Transmission Harness

Service Procedures

2

Remove

Retaining Bolt

Retaining

Bolt

Input Shaft Speed Sensor

3

Remove

Speed Sensor

Transmission

Harness

7, 10 and 18-Speed

1

Disconnect

Transmission Harness

Transmission

Harness

3/8" Wrench

3/8" Wrench

2

Remove

Retaining Bolt

Input

Shaft

Speed

Sensor

120RMVIS

Service Procedures

Retaining Bolt

3

Remove

Speed Sensor

Input Shaft Speed Sensor Removal

28

Page 33

Input Shaft Speed Sensor – Install

Service Procedures

Special Instructions

Clean the mounting surface on the housing and remove

any burrs or sharp edges.

Lubricate the O-ring with Eaton Fuller silicone #71214 or

equivalent.

Input Shaft Speed Sensor location varies as follows:

• 6-Speed- Top or side of Inertia Brake

• 7, 10 and 18-Speed- Right front of Shift Bar

Housing.

Required Tools

• Basic Hand Tools

Installation

1. Using a smooth, twisting motion, fully insert the

sensor in the transmission housing opening.

2. Using a 3/8" wrench, install the retaining bolt and

tighten to 8-10 lbs.ft. (10.8-13.6 N•m).

3. Reconnect the Transmission Harness to the Input

Shaft Speed Sensor.

Note: Fill the transmission with lubricant.

Final Check

Make sure the transmission is properly filled with lubricant.

Make sure the retaining bolt is properly tightened.

Make sure the Transmission Harness is properly connected to the Input Shaft Speed Sensor.

29

Page 34

6-Speed

Service Procedures

Input Shaft

Speed Sensor

Retaining

1

Insert

Speed Sensor

7, 10 and 18-Speed

Input Shaft

Speed Sensor

Retaining

Bolt

Bolt

3/8" Wrench

2

Install

Retaining Bolt

3/8" Wrench

Transmission Harness

3

Reconnect

Transmission Harness

Service Procedures

Transmission Harness

1

Insert

Speed Sensor

Input Shaft Speed Sensor Installation

2

Install

Retaining Bolt

3

Reconnect

Transmission Harness

30

Page 35

Service Procedures

Main Shaft Speed Sensor – Remove

Special Instructions

None

Required Tools

Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Main

Shaft Speed Sensor.

2. Using a 3/8” wrench, remove the sensor retaining

bolt.

3. Remove the sensor, with O-ring, from the transmission housing.

Main Shaft

Speed Sensor

Main Shaft Speed Sensor Location

31

120LOC13

Page 36

Service Procedures

Transmission

Harness

1

Disconnect

Transmission Harness

3/8" Wrench

Service Procedures

2

Retaining Bolt

Remove

Retaining Bolt

Main Shaft

Speed Sensor

3

Remove

Speed Sensor

Main Shaft

Speed Sensor

120RMVMI

Main Shaft Speed Sensor Location

32

Page 37

Main Shaft Speed Sensor – Install

Service Procedures

Special Instructions

Clean the mounting surface on the housing and remove

any burrs or sharp edges.

Lubricate the O-ring with Eaton Fuller silicone #71214 or

equivalent.

Required Tools

Basic Hand Tools

Installation

1. Using a smooth, twisting motion, fully insert the

Main Shift Speed Sensor in the transmission housing opening.

2. Using a 3/8” wrench, install the retaining bolt and

tighten to 8-10 lbs.ft. (10.8-13.6 N•m).

3. Reconnect the Transmission Harness to the Sensor.

Final Check

Make sure the retaining bolts are properly tightened.

Make sure the Transmission Harness is properly connected to the Main Shaft Speed Sensor.

33

Page 38

Service Procedures

Retaining Bolt

Main Shaft

Speed Sensor

1

Insert

Speed Sensor

Transmission

Harness

2

Install

Retaining Bolt

Service Procedures

3/8" Wrench

120RMVMI

Main Shaft

Speed Sensor

3

Reconnect

Transmission Harness

Main Shaft Speed Sensor Installation

34

Page 39

Service Procedures

Output Shaft Speed Sensor – Remove

Special Instructions

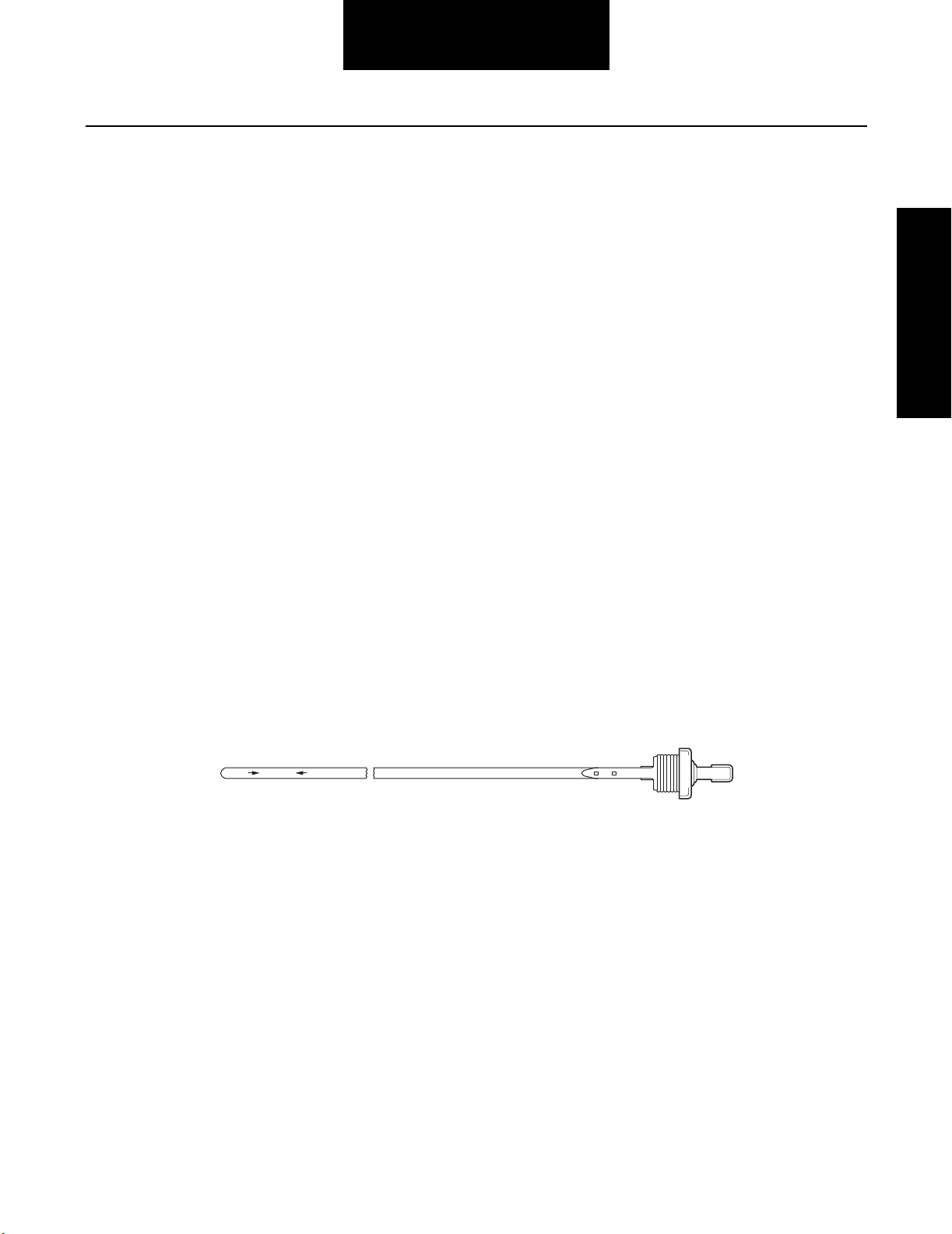

The Output Shaft Speed Sensor location may vary

depending on OEM design specifications. The sensor

may be located at the 12 o’clock (shown in Figure 13), 10

o’clock, or 6 o’clock position on the Output Shaft Housing.

The 10 and 18-Speed transmissions have an exposed

tone ring on the output shaft. However, the service procedure for the Output Shaft Speed Sensor is the same for

all models.

Required Tools

Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Output Shaft Speed Sensor.

2. Using a wrench, remove the sensor retaining bolt.

Retaining bolt size varies as follows:

a. 6 and 7-Speed - Use a 3/8” wrench

b. 10 and 18-Speed - Use a 13mm wrench.

3. Remove the sensor, with O-ring, from the transmission housing.

Output Shaft

6 and 7-Speed

Speed Sensor

Output Shaft Speed Sensor Location

35

Output Shaft

Speed Sensor

10 &18-Speed

Page 40

Service Procedures

1

Disconnect

Transmission Harness

from Speed Sensor

Transmission Harness

Transmission

Harness

1

Disconnect

Transmission Harness

Transmission Harness

from Speed Sensor

Ouptut Shaft

Speed Sensor

Output Shaft

Speed Sensor

Output Shaft

Speed Sensor

6 & 7-Speed

3/8" Wrench

10 & 18-Speed

Retaining Bolt

10 & 18-Speed

13mm Wrench

2

Remove

Output Shaft

Speed Sensor

Retaining

3

Remove

Speed Sensor

Retaining

Bolt

Retaining Bolt

Output Shaft

Bolt

Speed Sensor

Speed Sensor

Output Shaft

Speed Sensor

3

Remove

Service Procedures

120RMVMI

1

Disconnect

Transmission Harness

from Speed Sensor

Output Shaft Speed Sensor Removal

2

Remove

Retaining Bolt

2

Remove

Retaining Bolt

3

Remove

Speed Sensor

120RMVMI

13mm Wrench

120RMVMI

36

Page 41

Service Procedures

Output Shaft Speed Sensor – Install

Special Instructions

Clean the mounting surface on the housing and remove

any burs or sharp edges.

Required Tools

Basic Hand Tools

Installation

1. Using a smooth, twisting motion, fully insert the

Output Shaft Speed Sensor in the transmission

housing opening.

Note: Lubricate the O-ring with Eaton Fuller silicon

#71214 or equivalent.

2. Using a wrench, install the retaining bolt and tighten

as follows:

a. 6 and 7-Speed- Use a 3/8” wrench and tighten

to 8-10 lbs.ft. (10.8-13.6 N•m).

b. 10 and18-Speed- Use a 13mm wrench and

tighten to 15-19 lbs.ft. (20.3-25.8 N•m).

3. Reconnect the Transmission Harness to the Output

Shaft Speed Sensor.

Final Check

Make sure the retaining bolts are properly tightened.

Make sure the Transmission Harness is properly connected to the Main Shaft Speed Sensor.

37

Page 42

Output Shaft

Speed Sensor

Retaining Bolt

Service Procedures

6 & 7-Speed

3

Reconnect

Transmission Harness

Output Shaft

Speed Sensor

Speed Sensor

Retaining Bolt

1

Insert

Speed Sensor

1

Insert

Output Shaft

Speed Sensor

3/8" Wrench

2

Install

Retaining Bolt

10 &18-Speed

3

Reconnect

Transmission Harness

Transmission

Harness

Service Procedures

120RMVMI

Output Shaft

Speed Sensor

Output Shaft Speed Sensor Installation

2

Install

Retaining Bolt

13mm Wrench

Transmission

Harness

120INS18

38

Page 43

Range Valve – Remove

Service Procedures

Special Instructions

The Range Valve may be difficult to remove from the

housing because of the O-rings.

Do not use a hammer to loosen the Range Valve in the

housing.

Required Tools

Basic Hand Tools

Removal

1. Relieve system air pressure by draining the air tanks

on the vehicle. When air pressure is relieved disconnect the Transmission Harness from the Range

Valve assembly.

2. Using a 5/16” wrench, remove the four (4) mounting

capscrews.

3. Lift and remove the Range Valve from the housing.

Note: The Range Valve may be difficult to remove

from the housing.

Range Valve Location

39

Range

Valve

120LOC15

Page 44

Transmission

Harness

1

Disconnect

Transmission Harness

from Range Valve

Service Procedures

Range Valve

5/16" Wrench

Mounting Capscrew

Service Procedures

O-Ring

2

Remove Mounting

Capscrews

Range Valve

3

Remove

Range Valve from

Transmission Housing

Range Valve Removal

40

Page 45

Range Valve – Install

Service Procedures

Special Instructions

Torques given below are in pound-inches. Use care not to

overtighten.

Use care when installing O-rings

Required Tools

Basic Hand Tools

Installation

1. Install and push the Range Valve down into the

housing.

Note: Lubricate O-ring with Eaton Fuller silicone

#71214 or equivalent.

Note: The valve is keyed to fit its mounting location.

Take care to align the key in the valve with the

notch in the housing.

2. Using a 5/16” wrench, install the four (4) mounting

capscrews and tighten to 21-27 lbs.in. (2.4-3.1 N•m)

using a cross pattern.

3. Reconnect the Transmission Harness to the Range

Valve and close all air tank drains.

Final Check

Make sure the mounting bolts are properly tightened.

Make sure the Transmission Harness is connected and

locked.

Make sure all air tank drains are closed.

41

Page 46

Service Procedures

Key

Range Valve

O-Ring

Transmission Harness

1

Install

Range Valve

Notch

5/16" Wrench

Mounting Capscrew

Service Procedures

2

Install Mounting

Capscrews

3

Reconnect

Transmission Harness

to Range Valve

Range Valve Installation

Range Valve

42

Page 47

Splitter Valve – Remove

Service Procedures

Special Instructions

The Splitter Valve may be difficult to remove from the

transmission housing because of the O-ring seals.

Do not use a hammer to loosen the Splitter Valve in the

housing.

Required Tools

Basic Hand Tools

Removal

1. Relieve system air pressure by draining air tanks on

the vehicle. When air pressure has been relieved,

disconnect the Transmission Harness from the Splitter Valve.

2. Using a 5/16” wrench, remove the four (4) mounting

capscrews.

3. Lift and remove the Splitter Valve from the housing.

Note: The Splitter Valve may be difficult to remove

from the housing.

Splitter Valve Location

43

Splitter

Valve

120LOC14

Page 48

Service Procedures

1

Disconnect

Transmission Harness

from Splitter Valve

Transmission

Harness

O-Ring

Splitter Valve

5/16" Wrench

Service Procedures

Mounting Capscrew

2

Remove Mounting

Capscrews

3

Remove

Splitter Valve

from Housing

Splitter Valve Removal

Splitter Valve

44

Page 49

Splitter Valve – Install

Service Procedures

Special Instructions

Torques given below are in pound-inches. Use care not to

overtighten.

Required Tools

Basic Hand Tools

Installation

1. Install and push the Splitter valve down into the

housing.

Note: Lubricate O-rings with Eaton Fuller silicone

#71214 or equivalent.

Note: The valve is keyed to fit its mounting location.

Take care to align the key in the valve with the

notch in the housing.

2. Using a 5/16” wrench, install the (4) mounting capscrews and tighten to 21-27 lbs.in. (2.4-3.1 N•m)

using a cross pattern.

3. Reconnect the Transmission Harness to the Splitter

Valve and close all air tank drains.

Final Check

Make sure the mounting capscrews are properly tightened.

Make sure the Transmission Harness is connected and

locked.

Make sure all air tank drains are closed.

45

Page 50

O-Ring

Notch

Service Procedures

Key

Splitter Valve

1

Install

Splitter Valve

5/16" Wrench

Mounting Capscrew

Service Procedures

2

Install Mounting

Capscrews

3

Reconnect

Transmission Harness

to Splitter Valve

Splitter Valve Installation

Transmission

Harness

46

Page 51

Air Filter/Regulator – Remove

r

Service Procedures

Special Instructions

The Air Filter/Regulator has two (2) O-rings located

between the Air Filter/Regulator and the Range Cylinder

Cover.

Required Tools

Basic Hand Tools

Removal

1. Relieve system air pressure by draining all air tanks

on the vehicle. Then, using a 7/16” wrench, remove

the two (2) mounting capscrews.

2. Remove the Air Filter/Regulator assembly and two

(2) O-rings located in the recesses of the Range Cylinder Cover.

Air Filter/Regulator Location

47

Air

Filter/Regulato

120LOC16

Page 52

Air Filter/Regulator

Service Procedures

1

Remove

Mounting Capscrews

7/16" Wrench

Service Procedures

Mounting

Capscrews

2

Remove

Air Filter/Regulator

and O-Rings

O-Rings

Air Filter/Regulator Removal

48

Page 53

Air Filter/Regulator – Install

Service Procedures

Special Instructions

The Air Filter/Regulator has (2) O-rings located between

the Air Filter/Regulator and the Range Cylinder Cover.

Required Tools

Basic Hand Tools

Installation

1. Press the O-rings into the recesses in the Range Cylinder Cover.

Note: Lubricate O-rings with Eaton Fuller silicone

#71214 or Equivalent.

2. Install the Air Filter/Regulator:

a. Apply Eaton Fuller sealant #71205 or equivalent

to the two (2) mounting capscrews.

b. Position the Air Filter/Regulator over the O-

rings.

c. Insert the capscrews into the Air Filter/Regulator

mounting holes.

d. Using a 7/16” wrench, install the two (2) mount-

ing capscrews and tighten to 8-12 lbs.ft. (10.8-

16.3 N•m).

Final Check

Make sure the mounting capscrews are properly tightened.

Make sure all air supply fittings are tight.

Make sure all air tank drains are closed.

49

Page 54

1

Install O-Rings in

Range Cylinder Cover

Service Procedures

O-Rings

Service Procedures

Air Filter/Regulator

2

Install

Air Filter/Regulator

7/16" Wrench

Air Filter/Regulator Installation

Mounting

Capscrews

50

Page 55

Inertia Brake (6-Speed) – Remove

Service Procedures

Special Instructions

None

Required Tools

Basic Hand Tools

Removal

1. Drain the lubrication from the transmission and disconnect the Transmission Harness from the Input

Shaft Speed Sensor and the Inertia Brake coil.

2. Using a 3/8” wrench, remove the Input Shaft Speed

Sensor.

3. Using a 7/8” wrench, remove the lubricant supply

line from the Inertia Brake.

CAUTION

The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake when the mounting

bolts are removed.

4. Using a 9/16” wrench, remove the (6) mounting

bolts from the Inertia Brake.

5. Remove the Inertia Brake, spacer, and gaskets from

the transmission.

Note: The Inertia Brake will contain some lubricant.

Inertia Brake

6-Speed Inertia Brake Location

51

Page 56

Service Procedures

Transmission

Harness

Input Shaft

Speed Sensor

Inertia

Brake

Coil

1

Disconnect

Transmission Harness from

Input Shaft Speed Sensor,

and Inertia Brake Coil

2

Remove

Speed Sensor

3/8" Wrench

Service Procedures

3

7/8" Wrench

Lubricant

Supply

Line

4

Remove

Mounting Bolts

Use a

9/16" Wrench

Disconnect

Line

Inertia Brake

Gasket

Gasket

Spacer

5

Remove Inertia Brake,

Spacer, and Gaskets

6-Speed Inertia Brake Removal

52

Page 57

Inertia Brake (6-Speed)– Install

Service Procedures

Special Instructions

Clean and remove all old gasket material from the mating

surfaces of the Inertia Brake spacer and transmission.

CAUTION

The Inertia Brake is heavy. Be prepared to handle the

weight of the Inertia Brake until the mounting bolts are

installed.

Required Tools

Basic Hand Tools

Installation

1. Install the Inertia Brake, spacer, and gasket being

careful to align the Inertia Brake gear with the drive

gear.

2. Using a 9/16” wrench, install the (6) mounting bolts.

Tighten mounting bolts to 35-45 lbs.ft. (47.5-61.0

N•m) using a cross pattern.

3. Using a 7/8” wrench, reconnect the lubricant supply

line to the Inertia Brake and tighten to 20-22 lbs.ft.

(27-30 N•m).

4. Using a 3/8” wrench, install the Input Shaft Speed

Sensor and tighten to 8-12 lbs.ft. (11-16 N•m).

5. Reconnect the Transmission Harness to the Input

Shaft Speed Sensor and the Inertia Brake Coil.

Note: Fill the transmission with lubricant.

Final Check

Make sure the mounting bolts are properly tightened.

Make sure the lubricant supply line fitting is properly

tightened.

Make sure the transmission is properly filled with lubricant.

Make sure the Transmission Harness is connected and

locked.

Check for lubricant leaks after operating the vehicle.

53

Page 58

1

Install Inertia Brake,

Spacer, and Gaskets

Service Procedures

2

Install

Mounting Bolts

Use a

9/16" Wrench

3/8" Wrench

Inertia Brake

4

Install

Speed Sensor

Gasket

Spacer

7/8" Wrench

Lubricant

Supply Line

Gasket

Service Procedures

3

Reconnect

Line

Input Shaft

Speed Sensor

Transmission

Harness

Inertia Brake Installation

5

Reconnect

Transmission Harness

to Input Shaft Speed

Sensor and Inertia

Brake Coil

Inertia Brake Coil

54

Page 59

Service Procedures

Inertia Brake (7, 10, and 18-Speed) – Remove

Removal

Special Instructions

Drain the lubricant from the transmission. The Inertia

Brake will still contain some lubricant.

Required Tools

Basic Hand Tools

1. Disconnect the Transmission Harness from the Inertia Brake Coil.

2. Using a 7/8” wrench, disconnect the lubricant supply

line from the Inertia Brake.

CAUTION

The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake when the mounting

bolts are removed.

3. Using a 9/16” wrench, remove the six (6) mounting

bolts from the Inertia Brake.

4. Remove the Inertia Brake and gasket from the transmission.

Inertia Brake

7, 10, and 18-Speed Inertia Brake Location

55

Page 60

Inertia

Brake

Coil

Service Procedures

Transmission

Harness

1

Disconnect

Transmission Harness

from the

Inertia Brake Coil

Inertia

Brake

2

Disconnect

Line

Lubricant

Supply Line

7/8"

Wrench

Gasket

Inertia Brake

Service Procedures

Inertia

Brake

3

Remove

Mounting Bolts

7, 10, and 18-Speed Inertia Brake Remove

4

Remove

Inertia Brake

and Gasket

Use a 9/16" Wrench

56

Page 61

Service Procedures

Inertia Brake (7, 10, and 18 Speed) – Install

Special Instructions

2. Using a 9/16” wrench, install the six (6) mounting

bolts. Tighten mounting bolts to 35-45 lbs.ft. (47.530 N•m) using a cross pattern.

None

Required Tools

Basic Hand Tools

Installation

1. Install the Inertia Brake and gasket, being careful to

align the Inertia Brake gear with the drive gear.

Note: Clean and remove all old gasket material from

the mating surfaces of the Inertia Brake and

transmission.

CAUTION

The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake until the mounting

bolts are installed.

3. Using a 7/8” wrench, reconnect the lubricant supply

line to the Inertia Brake and tighten to 20-22 lbs.ft.

(27-30 N•m).

4. Reconnect the Transmission Harness to the Inertia

Brake Coil.

Note: Fill the transmission with lubricant.

Final Check

Make sure the mounting bolts are properly tightened.

Make sure the lubricant supply line is properly tightened.

Make sure the transmission is properly filled with lubricant.

Make sure the Transmission Harness is connected and

locked.

Check for lubricant leaks after operating the vehicle.

57

Page 62

1

Install

Inertia Brake

and Gasket

Gasket

Inertia Brake

Service Procedures

2

Install

Mounting Bolts

Use a 9/16" Wrench

Inertia

Brake Coil

Lubricant

Supply

Line

Transmission

Harness

7/8" Wrench

Service Procedures

Inertia Brake

3

Reconnect

Line

4

Reconnect

Transmission Harness

to Inertia Brake Coil

Input Shaft

Speed Sensor

7, 10,18-Speed Inertia Brake Installation

Inertia Brake

58

Page 63

Service Procedures

Inertia Brake Relocation Instructions 8 to 6 Bolt PTO Opening--Remove

Special Instructions

None

Required Tools

• Basic Hand Tools

Removal

1. Disconnect the Transmission Harness from the Inertia Brake Coil and remove the tie straps restraining

this harness branch.

CAUTION

Oil may be hot.

Note: Drain the lubricate front he transmission.

Drain the lubricant from the Inertia Brake. On

older product the Inertia Brake will still

remain full of lubricant (no drain plug).

CAUTION

The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake when the mounting

bolts are removed.

3. Remove the six (6) mounting bolts from the Inertia

Brake.

4. Remove the Inertia Brake and gasket from the

adapter plate.

5. Remove the eight (8) mounting bolts from the

adapter plate.

6. Remove and discard the adapter plate and gasket

from the transmission.

7. Remove the six (6) mounting bolts from the 6-bolt

PTO cover.

8. Remove and discard the 6-bolt PTO cover and gasket from the transmission.

Note: Use care not to damage the harness.

2. Disconnect the lubricant supply line from the Inertia

Brake.

59

Note: Clean and remove all old gasket material from

the mating surfaces of the Inertia Brake and

transmission PTO coverings. Locate the harness push-in anchor point for reference during re-installation to 6-bolt opening.

Page 64

Service Procedures

Inertia Brake

Service Procedures

60

Page 65

Service Procedures

Inertia Brake Relocation Instructions 8 to 6-Bolt PTO opening--Install

Special Instructions

None

CAUTION

The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake until the mounting

bolts are installed.

Required Tools

Basic Hand Tools

Installation

1. Clean and thoroughly dry all mating surfaces

(including the gasket) prior to assembly.

Note: The transmission Inertia Brake may be

mounted to the 6-bolt PTO opening directly,

or mounted utilizing a 6-bolt PTO Angle

Adapter to assist in aiding chassis clearance.

2. If a 6-bolt PTO Angle Adapter is required, install the

Angle Adapter to the 6-bolt PTO opening following

the manufacturer’s instructions.

3. Inertia Brakes installed with the Angle Adapter

require a new lubrication hose.

4. Using the six (6) 3/8 mounting bolts, install the Inertia Brake and gasket, being careful to align the Inertia

Brake gear with the drive gear. Tighten mounting

bolts to 40-45 lbs. ft. (54-61 N•m) using a cross pattern.

Note: When mounted directly, orient the Inertia

Brake housing with hose connection forward/

electrical connection rearward, same orientation as 8-bolt. When mounted to a 6-bolt PTO

Angle Adapter, orient the Inertia Brake housing with hose connection rearward / electrical

connection forward. Ensure gasket, Inertia

Brake, and mating mounting faces are

assembled dry (no lubricant or grease).

5. Reconnect the lubricant supply line to the Inertia

Brake and tighten to 20-22 lbs. ft. (27-30 N•m).

6. Reroute and reconnect the transmission harness to

the Inertia Brake Coil. Dress the harness along the

transmission case from the Inertia Brake up to the

top of the transmission. Install the harness push-in

anchor to the threaded-hole anchor point in the Inertia Brake housing. Install tie wraps every 6-10

inches. The harness should not have sharp bends or

be under tension.

7. Install the PTO to the 8-bolt PTO opening following

the manufacture’s instructions.

Note: Fill the transmission with lubricant.

Final Check

• Make sure the mounting bolts are properly

tightened.

• Make sure the lubricant supply line is properly

tightened.

• Make sure the transmission is properly filled

with lubricant.

• Make sure the transmission harness is con-

nected and locked.

• Check for lubricant leaks after operating the

vehicle.

• Check that the Inertia Brake has sufficient clear-

ance to prevent contacting tanks, brackets,

frame rails, exhaust, or any other part of the

vehicle. Contacting anything when stationary or

moving will cause damage to Inertia Brake,

Angle Adapter, or other vehicle equipment.

61

Page 66

Service Procedures

-

Service Procedures

-

62

Page 67

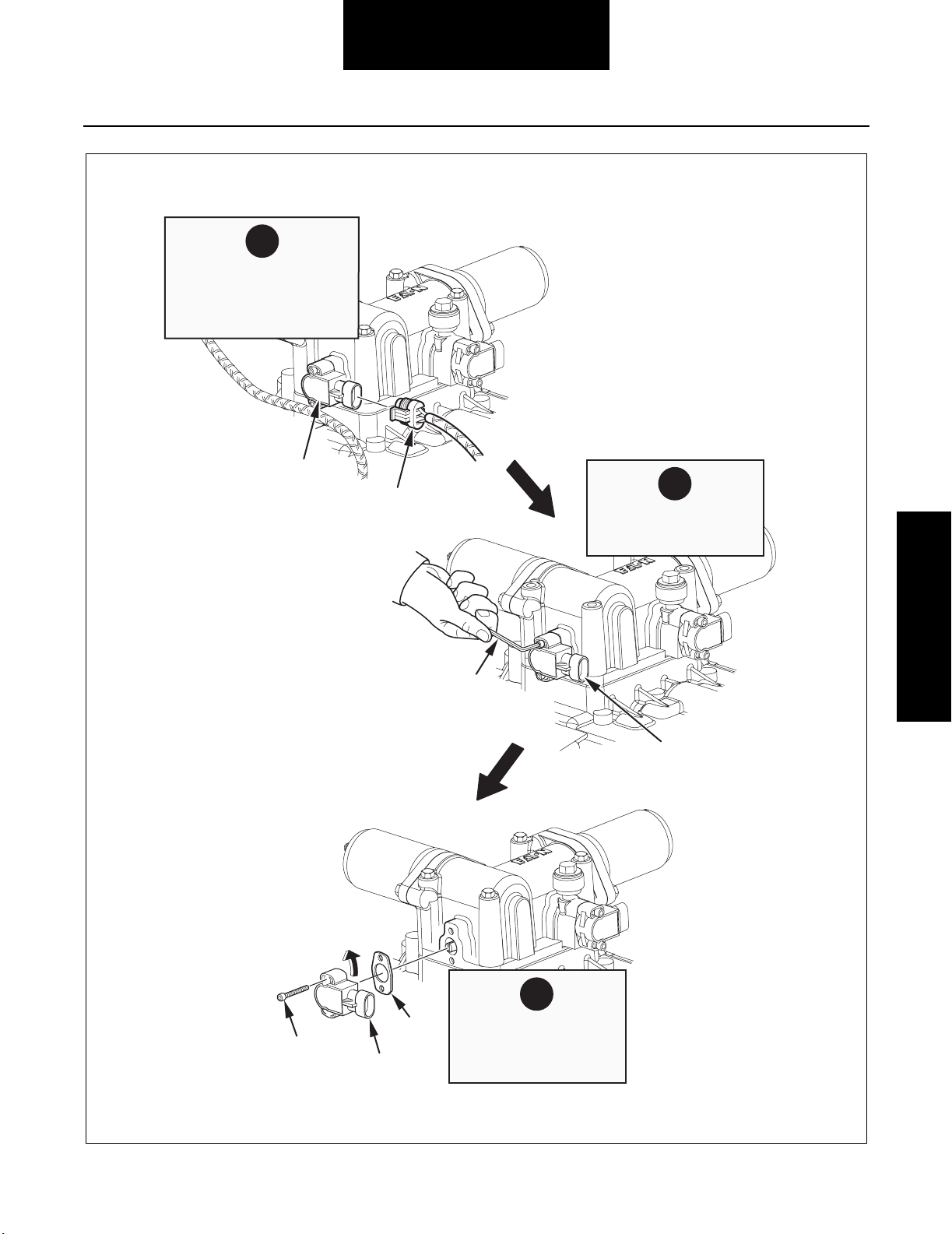

Electric Shifter – Remove

Service Procedures

Special Instructions

None

Required Tools

Basic Hand Tools

Removal

1. Remove nylon cable ties from the motor wires. Disconnect the Transmission Harness from the Rail

Select Sensor and the Gear Select Sensor.

2. Disconnect the Rail Select and Gear Select Motors

from the Transmission Controller.

3. Using a 9/16” wrench, remove the four (4) mounting

capscrews.

4. Remove the Electric Shifter and gasket.

Electric

Shifter

Electric Shifter Location

63

120LOC19

Page 68

Service Procedures

1

Disconnect

Transmission Harness

from Rail and Gear

Select Sensors

Gear Select

Sensor

Transmission

Harness

9/16" Wrench

Transmission

Rail Select Sensor

2

Disconnect Rail and

Gear Motors from

Transmission Controller

Controller

Rail Select

Motor Connector

Service Procedures

Gear Select

Motor Connector

3

Remove Mounting

Capscrews

Electric Shifter

Shift Finger

Gasket

Shift Blocks

4

Remove Electric

Shifter and Gasket

Electric Shifter Removal

64

Page 69

Electric Shifter – Install

Service Procedures

Special Instructions

Make sure the three (3) sets of detent balls and springs

are installed properly in the Shift Bar Housing.

Required Tools

Basic Hand Tools

Installation

1. Clean and remove old gasket material from the Shift

Bar Housing. Position a new gasket at the Electric

Shifter location.

WARNING

Possible Pinch Point - Make sure battery is disconnected before removal of XY shifter.

2. Check to ensure the shift blocks are in the neutral

position, then move the shift finger to the center

(neutral) location.

Note: If the shift finger is not properly aligned, the

Electric Shifter will not fit properly at its

mounting location.

4. Reconnect the Rail Select and Gear Select Motors to

the Transmission Controller.

5. Reconnect the Transmission Harness to the Rail

Select and Gear Select Sensors. Using nylon ties,

secure the motor wires to the transmission in their

previous position.

Calibration

To operate properly, the system must be calibrated as

follows:

1. Turn the ignition switch on and allow the trans-

mission to power up.

2. Turn the ignition switch to off and wait two min-

utes.

IMPORTANT

The Electric Shifter must be calibrated before the vehicle is placed into operation.

Final Check

Make sure the mounting capscrews are tightened to the

correct specification.

Note: Apply Eaton sealant #71205 or equivalent to

the mounting capscrews before installing.

3. Position the Electric Shifter on the Shift Bar Housing.

Then using a 9/16” wrench, install the mounting

capscrews and tighten in a cross pattern as follows:

a. 6-Speed (Aluminum Housing)- Tighten to 20-25

lbs.ft.(28-35 N•m).