Dremel 1680 Manual

owner’s manual

MODEL 1680, VARIABLE SPEED

16” SCROLL SAW

Parlez-vous français? Voir page 21 ¿Habla español? Ver página 41

|

|

|

|

|

|

|

|

|

|

|

|

Voltage rating |

120 V |

50 - 60Hz |

|||

Amperage rating |

1.4 A |

|

|||

No load speed |

n0 500-1,600/min |

||||

Throat |

16” |

|

|||

Blade |

5” Plain and pin-end |

||||

Blade stroke |

3/4” |

|

|||

Cutting capacity |

2” at 0º; 1” at 45º |

||||

assembly • operation • safety instructions

P.O. Box 1468

Racine, Wisconsin

1-800-437-3635

http://www.dremel.com

Form No. 2610914195 7/01 |

Printed in Taiwan |

General Safety Rules

! WARNING |

“READ ALL INSTRUCTIONS” Failure to follow the safety rules listed below |

|

and other basic safety precautions may result in serious personal injury. |

||

|

Work Area

KEEP CHILDREN AWAY

Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

KEEP WORK AREAS CLEAN

Cluttered areas and benches invite accidents.

MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches.

AVOID DANGEROUS ENVIRONMENTS

Don’t use power tools in damp or wet locations. Keep work area well lit. Do not expose power tools to rain. Do not use the tool in the presence of flammable liquids or gases.

Personal Safety

KNOW YOUR POWER TOOL

Read and understand the owner’s manual and labels affixed to the tool. Learn its application and limitations as well as the specific potential hazards peculiar to this tool.

DON’T OVERREACH

Keep proper footing and balance at all times.

STAY ALERT

Watch what you are doing. Use common sense. Do not operate tool when you are tired. Do not operate while under medication or while using alcohol or other drugs.

DRESS PROPERLY

Do not wear loose clothing or jewelry. They can be caught in moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protective hair covering to contain long hair.

USE SAFETY GLASSES

Also face or dust mask if cutting operation is dusty, and ear plugs during extended periods of operation.

Everyday eyeglasses have only impact resistant lenses, they are NOT safety glasses.

GUARD AGAINST ELECTRIC SHOCK

Prevent body contact with grounded surfaces. For example: pipes, radiators, ranges, refrigerator enclosures.

DISCONNECT TOOLS FROM POWER SOURCE

When not in use, before servicing, when changing blades, bits, cutters, etc.

KEEP GUARDS IN PLACE

In working order, and in proper adjustment and alignment.

REMOVE ADJUSTING KEYS AND WRENCHES

Form the habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

AVOID ACCIDENTAL STARTING

Make sure the switch is in the “OFF” position before plugging in tool.

GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor cord and a 3 prong grounding type plug to fit the proper grounding type receptacle. The green conductor in the cord is the grounding wire. Never connect the green wire to a live terminal.

NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted. Do not store materials on or near the tool such that it is necessary to stand on the tool or its stand to reach them.

CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part that is damaged should be carefully checked to ensure that it will operate properly and perform its intended function. Check for alignment of moving parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly replaced.

All repairs, electrical or mechanical, should be attempted only by trained repairmen.

Contact the nearest Dremel Service Center, Authorized Dremel Service Station or other competent repair service.

Use only Dremel replacement parts; any ! WARNING others may create a hazard.

The use of any other accessories not spec- ! WARNING ified in the current Dremel catalog, may cre-

ate a hazard.

“SAVE THESE INSTRUCTIONS”

2.

Additional Safety Rules

Tool Use

DON’T FORCE TOOL

It will do the job better and safer at the rate for which it was designed.

USE THE RIGHT TOOL

Don’t force a small tool or attachment to do the job of a heavy duty tool. Don’t used tool for purpose not intend- ed—for example, don’t use a circular saw for cutting tree limbs or logs.

SECURE WORK

Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees both hands to operate the tool.

NEVER LEAVE TOOL RUNNING UNATTENDED

Turn power off. Don’t leave tool until it comes to a complete stop.

Tool Care

DO NOT ALTER OR MISUSE TOOL

These tools are precision built. Any alteration or modification not specified is misuse and may result in dangerous conditions.

AVOID GASEOUS AREAS

Do not operate electric tools in a gaseous or explosive atmosphere. Motors in these tools normally spark, and may result in a dangerous condition.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry, clean and free from oil and grease.

Before connecting the tool to a power source (receptacle, outlet, etc.), be sure voltage supplied is the same as that specified on the name-

plate of the tool. A power source with a voltage greater than that specified for the tool can result in serious injury to the user, as well as damage to the tool. If in doubt, DO NOT PLUG IN THE TOOL. Using a power source with a voltage less than the nameplate rating is harmful to the motor.

! WARNING For your own safety, do not operate your Scroll Saw until it is completely assembled

and installed according to the instructions...and until you have read and understood the following:

1. |

General Safety Rules.............................................. |

2-4 |

2. |

Motor Specifications and Electrical .......................... |

|

|

Requirements ............................................................ |

5 |

3. |

Getting to Know Your Scroll Saw ........................ |

8-9 |

4. |

Operating Adjustments .......................................... |

10 |

5. |

Basic Scroll Saw Operations ............................ |

11-14 |

6. |

Mounting the Scroll Saw.................................... |

15-16 |

7. |

Maintaining Your Scroll Saw .................................. |

17 |

8. STABILITY OF SAW

Your Scroll Saw must be bolted securely to a stand or workbench. In addition, if there is any tendency for the Scroll Saw to tip over or move during certain operations, such as cutting long, heavy boards, bolt your Scroll Saw stand or workbench to the floor.

9. LOCATION

This Scroll Saw is intended for indoor use only.

10. PROTECTION: Eyes, hands, face, ears and body.

TO AVOID BEING PULLED INTO THE

! WARNING BLADE—

DO NOT WEAR: |

Loose Fitting Gloves |

|

Necktie |

|

Loose Clothing |

|

Jewelry |

DO: TIE BACK LONG HAIR

ROLL LONG SLEEVES ABOVE ELBOWS

a. If any part of your saw is missing, malfunctioning, has been damaged or broken . . . such as the motor switch, or other operating control, a safety device or the power cord...cease operating immediately until the particular part is properly repaired or replaced.

b.Do not cut piece too small to hold by hand. HINT: When making a very small cut out, always secure the workpiece to a scrap piece of plywood with doublefaced tape. This way, the work is supported and your fingers are away from the blade.

c.Never turn your Scroll Saw on before clearing the table of all objects (tools, scraps of wood, etc.) except for the workpiece and related feed or support devices for the operation planned.

3.

Additional Safety Rules

d. Avoid awkward hand positions where a sudden slip could cause a hand to move into the blade.

•ALWAYS adjust the drop foot to just clear the workpiece to protect the operator, keep blade breakage to a minimum and provide maximum support for blade.

•Always adjust blade tension correctly.

•The Scroll Saw should cut on the down stroke. Always make sure blade teeth are oriented downward toward table.

•When cutting a large piece of material, make sure it is supported at table height.

•Hold the work firmly against the table.

•Do not feed the material too fast while cutting. Only feed the material fast enough so that the blade will cut. Keep fingers away from the blade.

•Use caution when cutting off material which is irregular in cross section‚ it could pinch the blade before the cut is completed. A piece of molding, for example, must lay flat on the table and not be permitted to rock while being cut.

•Use caution when cutting off round material such as dowel rods or tubing. They have a tendency to roll while being cut, causing the blade to “bite”.

e.Never leave the Scroll Saw running unattended. Turn the saw OFF, make sure the saw has come to a complete stop, and then remove plug from power supply before leaving the work area.

f.Do not perform layout, assembly or setup work on the table while the cutting tool is operating.

g.Turn saw off and remove plug from power supply outlet before installing or removing an accessory attachment.

h. Access Door must be closed before operation.

i. Quick Release Tension Lever should be in down position before operating.

11. THINK SAFETY

SAFETY IS A COMBINATION OF OPERATOR COMMON SENSE AND ALERTNESS AT ALL TIMES WHEN THE SCROLL SAW IS BEING USED.

Do not allow familiarity (gained from fre- ! WARNING quent use of your Scroll Saw) to become

commonplace. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

WARNING

WARNING

Wear Eye Protection

The operation of any power tool can result in foreign objects being thrown into the eyes, which can result in severe eye damage. Always wear safety goggles that comply with ANSI Z87.1 before commencing power tool operation.

Some dust created by power sanding, ! WARNING sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

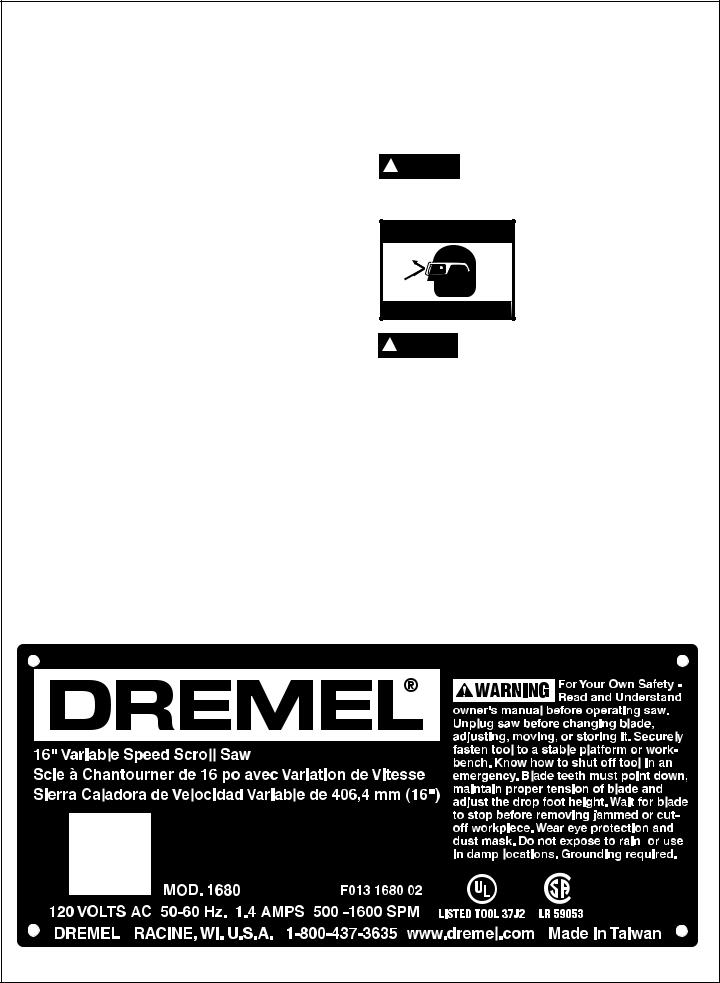

NOTE AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS THAT APPEAR ON THE PANEL ON SCROLL SAW HOUSING:

4.

Motor Specifications and

Electrical Requirements

Motor Specifications

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

This Scroll Saw is designed to use a Variable Speed RPM motor. It is wired for operation on 110-120 volts, 60 Hz. alternating current. Before connecting the motor cord to power source, make certain the switch is in the “OFF” position and be sure the electric current is of the same characteristics as stamped on the nameplate.

Connection To A Power

Source

This machine must be grounded while in use to protect the operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet protected by a 15-amp dual element time delay fuse or circuit breaker.

Not all outlets are properly grounded. If you are not sure that your outlet, as pictured below, is properly grounded; have it checked by a qualified electrician.

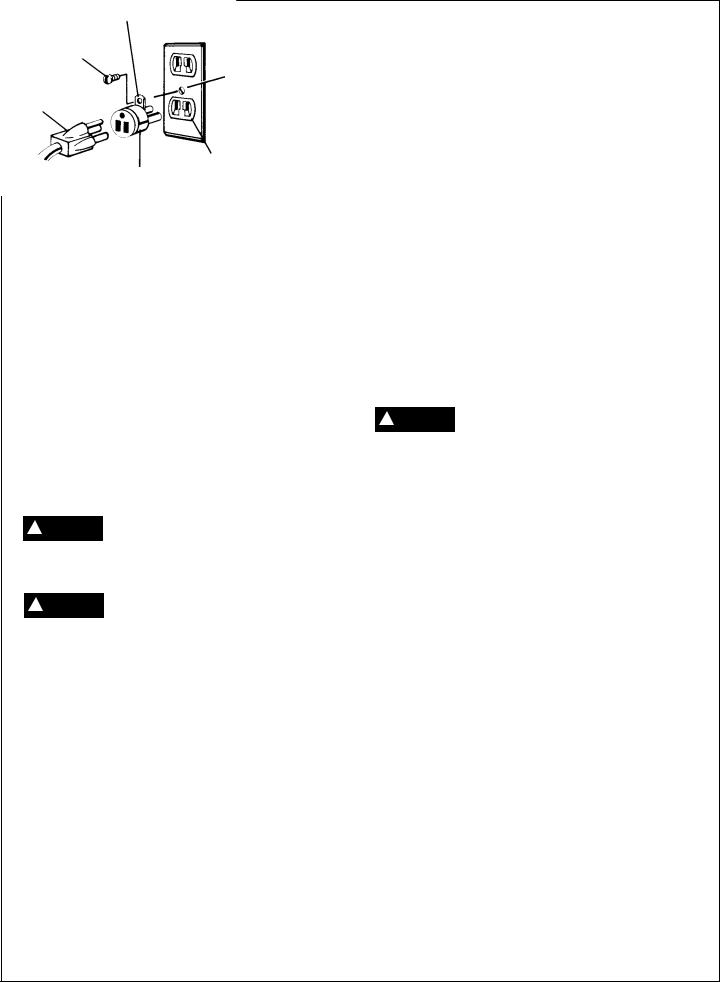

! |

DANGER |

To avoid electric shock, do not touch the |

|

metal prongs on the plug when installing or |

|||

|

|

||

removing the plug to or from the outlet. |

|||

! |

DANGER |

Failure to properly ground this power tool can |

|

|

|||

cause electrocution or serious shock, particularly when used near metal plumbing or other metal objects. If shocked, your reaction could cause your hands to hit the tool.

If power cord is worn, cut or damaged in any way, have it replaced immediately to avoid

shock or fire hazard.

Your unit is for use on 120 volts; it has a plug that looks like the one below.

3-PRONG PLUG

GROUNDING PRONG

ALWAYS USE A

GROUNDED

OUTLET

This power tool is equipped with a 3-conductor cord and grounding type plug, approved by Underwriters Laboratories and the Canadian Standards Association. The ground conductor has a green jacket with or without yellow stripes and is attached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type outlet as shown. It must be grounded in accordance with all local codes and ordinances.

If the outlet you are planning to use for this power tool is of the two-prong type, DO NOT REMOVE OR ALTER THE GROUNDING PRONG IN ANY MANNER. Have a qualified electrician replace the TWO-prong outlet with a properly grounded THREE prong outlet.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician.

The green grounding lug extending from the adapter must be connected to a permanent

ground such as a properly grounded outlet box.

GROUNDING LUG

SCREW |

MAKE SURE THIS |

|

IS CONNECTED TO |

|

A KNOWN |

3-PRONG |

GROUND |

|

|

PLUG |

|

|

2-PRONG |

ADAPTER |

RECEPTACLE |

NOTE: The adapter illustrated is for use only if you already have a properly grounded 2-prong receptacle. Adapter is not allowed in Canada by the Canadian Electrical Code. Always use proper extension cord.

The use of any extension cord will cause some loss of power. To keep this to a minimum and to prevent overheating and motor burn-out, use the table below to determine the minimum wire size (A.W.G.) extension cord. Use only 3-wire extension cords which have 3-prong grounding type plugs and 3- pole receptacles which accept the tool’s plug. Make sure your extension cord is in good condition.

Extension Cord Length |

Wire Size A.W.G. |

|

0-25 |

Feet |

18 |

26-50 |

Feet |

16 |

51-100 |

Feet |

16 |

“SAVE THESE INSTRUCTIONS”

5.

Table of Contents

General Safety Rules...................................................... |

2 |

Additional Safety Rules ................................................ |

3-4 |

Motor Specifications and Electrical |

|

Requirements .................................................................. |

5 |

Connection to a Power Source.......................................... |

5 |

Unpacking and Checking Contents .............................. |

7 |

Table of Loose Parts.......................................................... |

7 |

Glossary of Terms............................................................ |

8 |

Getting to Know Your Scroll Saw .............................. |

8-9 |

Operating Adjustments ................................................ |

10 |

Setting the Table for Horizontal or Bevel Cutting............ |

10 |

Aligning the Degree Scale Pointer .................................. |

10 |

Basic Scroll Saw Operations .................................. |

11-14 |

Removing and Installing Pin-End Blades ........................ |

12 |

Removing and Installing Plain-End Blades .................... |

12 |

Adjusting the Lamp.......................................................... |

13 |

Replacing the Bulb .......................................................... |

13 |

On/Off Switch .................................................................. |

13 |

Variable Speed Switch .................................................... |

13 |

Reset Button .................................................................... |

13 |

Making Interior Scroll Cuts Pin-End Blades and |

|

Plain-End Blades.............................................................. |

14 |

Mounting the Scroll Saw.......................................... |

15-16 |

Mounting the Scroll Saw to a Bench .............................. |

15 |

Mounting the Scroll Saw to Plywood .............................. |

16 |

Attaching Scroll Saw to Leg Set...................................... |

16 |

Maintaining Your Scroll Saw ........................................ |

17 |

Lubrication ...................................................................... |

17 |

Recommended Accessories ........................................ |

18 |

Trouble Shooting............................................................ |

19 |

Dremel Limited Warranty .............................................. |

22 |

Service Parts List...................................................... |

61-64 |

6.

Unpacking and Checking Contents

To avoid injury from unexpected starting or electrical shock, always remove plug from

power source when tool is not in use.

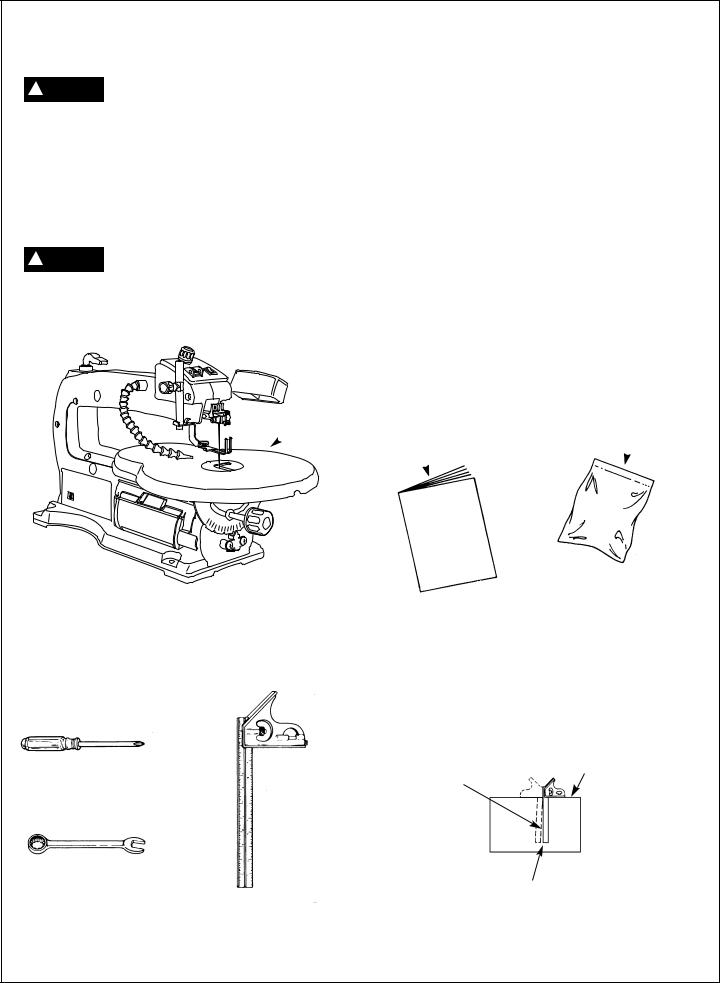

Model 1680 Motorized Scroll Saw is shipped complete in one carton.

1. Unpacking and Checking Contents. Separate all “loose parts” from packing materials and check each item with the “Table of Loose Parts” to make sure all items are accounted for before discarding any packing material.

If any parts are missing, do not attempt to ! WARNING operate Scroll Saw, plug in the power

cord or turn the switch on until the missing parts are obtained and are installed correctly.

A

|

|

Table of Loose Parts |

|

Item |

Description |

Qty. |

|

A |

16” Scroll Saw .......................................................... |

1 |

|

B |

Owner’s Manual ........................................................ |

1 |

|

C |

Loose Parts Bag (containing).................................... |

1 |

|

|

Allen Wrench (3 mm) ................................................ |

1 |

|

|

Allen Wrench (5 mm) ................................................ |

1 |

|

|

Blades .................................................................... |

11 |

|

NOTE: Hardware to mount this Scroll Saw to a bench or leg set is NOT supplied. See mounting instructions on Page 15-16 for recommended hardware size.

To remove protective coating from the table surface, moisten a soft cloth with kerosene and wipe off coating. Do not use acetone, gasoline or lacquer thinner for this purpose.

After removing protective coating, If you wish, you may apply a coat of paste wax to the table to allow the workpiece to slide easily across the table surface and deter rust. Wipe the table thoroughly with a clean dry cloth.

C

B

PHILLIPS SCREWDRIVER

WRENCHES 7/16 in.

Tools Needed

COMBINATION SQUARE MUST BE TRUE

Check its accuracy as illustrated below.

|

|

|

STRAIGHT EDGE OF |

|

|

|

|

BOARD 3/4” THICK- |

|

|

|

THIS EDGE MUST BE |

||

DRAW LIGHT LINE |

||||

ON BOARD ALONG |

|

|

PERFECTLY STRAIGHT |

|

|

|

|

|

|

THIS EDGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SHOULD BE NO GAP OR OVERLAP WHEN COMBINATION SQUARE IS FLIPPED OVER IN DOTTED POSITION

SQUARE

7.

Loading...

Loading...