Dremel SM20 User Manual

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 1

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

|

|

|

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

SM20

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Call Toll Free for |

Pour obtenir des informations |

|

|

|

Llame gratis para |

|||||||

Consumer Information |

et les adresses de nos centres |

|

|

obtener información |

|||||||||

|

& Service Locations |

de service après-vente, |

|

|

para el consumidor y |

||||||||

|

|

|

appelez ce numéro gratuit |

|

|

ubicaciones de servicio |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-800-4-DREMEL (1-800-437-3635) http://www.dremel.com |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For English Version |

Version française |

|

|

|

Versión en español |

||||||||

|

See page 2 |

Voir page 21 |

|

|

|

Ver la página 40 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 2

|

General Power Tool Safety Warnings |

|

Read all safety warnings and all instructions. Failure to follow the warnings |

! WARNING |

|

|

and instructions may result in electric shock, fire and/or serious injury. |

|

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating the power tool in damp locations is unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and / or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

-2-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 3

Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Power Tool-Specific Safety Warnings

Safety Warnings Common for Grinding, Sanding, and Abrasive Cutting-Off Operations:

This power tool is intended to function as a grinder, sander, or cut-off tool. Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Operations such as polishing or wire brushing are not recommended to be performed with this power tool. Operations for which the power tool was not designed may create a hazard and cause personal injury.

Do not use accessories which are not specifically designed and recommended by the tool manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe operation.

The rated speed of the accessory must be at least equal to the maximum speed marked on the power tool. Accessories running faster than their RATED SPEED can break and fly apart.

The outside diameter and the thickness of your accessory must be within the capacity rating of your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

The arbor size of wheels, flanges, backing pads or any other accessory must properly fit the spindle of the power tool. Accessories with arbor holes that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively and may cause loss of control.

Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels for chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked wires. If power tool or accessory is dropped, inspect for damage or install an undamaged accessory. After inspecting and installing an accessory, position yourself and bystanders away from the plane of the rotating accessory and run the power tool at maximum no-load speed for one minute.

Damaged accessories will normally break apart during this test time.

-3-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 4

Wear personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of stopping flying debris generated by various operations. The dust mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause hearing loss.

Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective equipment.

Fragments of workpiece or of a broken accessory may fly away and cause injury beyond immediate area of operation.

Hold power tool by insulated gripping surfaces only, when performing an operation where the cutting accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire may make exposed metal parts of the power tool “live” and shock the operator.

Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged and your hand or arm may be pulled into the spinning accessory.

Never lay the power tool down until the accessory has come to a complete stop.

The spinning accessory may grab the surface and pull the power tool out of your control.

Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body.

Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Do not operate the power tool near flammable materials. Sparks could ignite these materials.

Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled power

tool to be forced in the direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel to climb out or kickout. The wheel may either jump toward or away from the operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

Maintain a firm grip on the power tool and position your body and arm to allow you to resist kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper precautions are taken.

Never place your hand near the rotating accessory. Accessory may kickback over your hand.

Do not position your body in the area where power tool will move if kickback occurs.

Kickback will propel the tool in direction opposite to the wheel’s movement at the point of snagging.

Use special care when working corners, sharp edges etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent kickback and loss of control.

Safety Warnings Specific for Grinding and Abrasive Cutting-Off Operations:

Use only wheel types that are recommended for your power tool and the specific guard designed for the selected wheel. Wheels for which the power tool was not designed cannot be

adequately guarded and are unsafe.

The guard must be securely attached to the power tool and positioned for maximum safety, so the least amount of wheel is exposed towards the operator. The guard helps to protect operator from broken wheel fragments and accidental contact with wheel.

-4-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 5

Wheels must be used only for recommended applications. For example: do not grind with the side of cut-off wheel.

Abrasive cut-off wheels are intended for peripheral grinding, side forces applied to these wheels may cause them to shatter.

Always use undamaged wheel flanges that are of correct size and shape for your selected wheel. Proper wheel flanges support the wheel thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

Do not use worn down wheels from larger power tools. Wheel intended for larger power tool is not suitable for the higher speed of a smaller tool and may burst.

Additional Safety Warnings Specific for Abrasive Cutting-Off Operations:

Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut. Overstressing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback or wheel breakage.

Do not position your body in line with and behind the rotating wheel. When the wheel, at the point of operation, is moving away from your body, the possible kickback may propel the spinning wheel and the power tool directly at you.

When wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold the power tool motionless until the wheel comes to a complete stop. Never attempt to remove the cut-off wheel from the cut while the wheel is in motion

otherwise kickback may occur. Investigate and take corrective action to eliminate the cause of wheel binding.

Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully reenter the cut. The wheel may bind, walk up or kickback if the power tool is restarted in the workpiece.

Support panels or any oversized workpiece to minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their own weight. Supports must be placed under the workpiece near the line of cut and near the edge of the workpiece on both sides of the wheel.

Use extra caution when making a “pocket cut” into existing walls or other blind areas.

The protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Do not use type 1 abrasive wheels designed for straight grinding.

Do not attempt to cut large stock or sheets of metal as this machine is not designed to be a dedicated cut-off machine.

Safety Warnings Specific for Sanding Operations:

Do not use excessively oversized sanding disc paper. Follow manufacturer’s recommendations, when selecting sanding paper. Larger sanding paper extending beyond the sanding pad presents a laceration hazard and may cause snagging, tearing of the disc or kickback.

-5-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 6

Additional Safety Warnings

GFCI and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the electrical components of the AC rated tool are likely to fail and create a hazard to the operator.

Keep handles dry, clean and free from oil and grease. Slippery hands cannot safely control the power tool.

Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be careful not to disassemble any portion of the tool since internal wires may be misplaced or pinched or safety guard return springs may be improperly mounted.

Certain cleaning agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

Risk of injury to user. The power cord must only be serviced by a Dremel Service Facility.

Do not use type 1A or 27A wheels for face grinding. Side forces applied to these wheels may cause them to shatter or burst.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Do not cut solid metal rod greater than 5/16". Tool may

become damaged.

-6-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 7

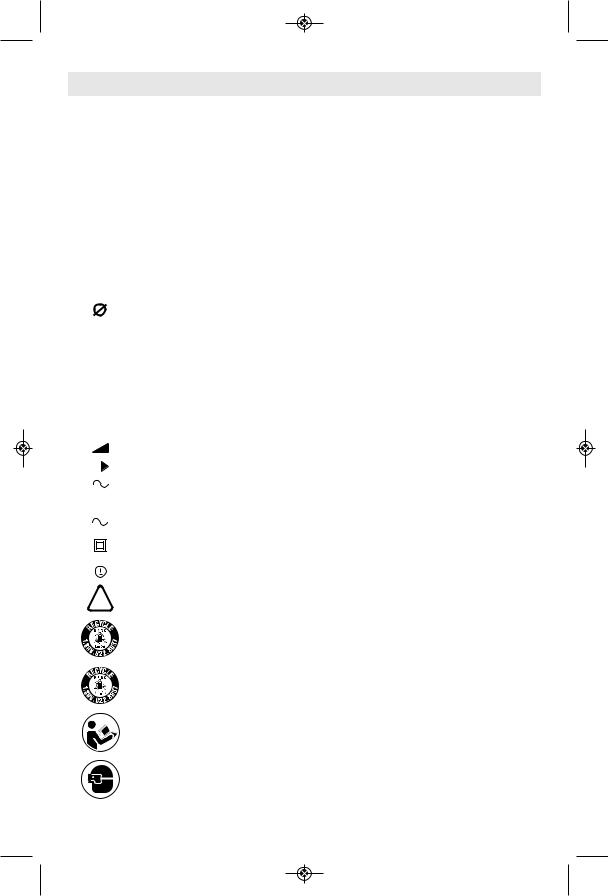

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol |

|

Name |

|

Designation/Explanation |

|||||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

|

Volts |

|

Voltage (potential) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

Amperes |

|

Current |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hz |

|

Hertz |

|

Frequency (cycles per second) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

|

Watt |

|

Power |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

kg |

|

Kilograms |

|

Weight |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

min |

|

Minutes |

|

Time |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s |

|

Seconds |

|

Time |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

Size of drill bits, grinding wheels, etc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n0 |

|

No load speed |

|

Rotational speed, at no load |

||||

|

|

|

|

n |

|

Rated speed |

|

Maximum attainable speed |

|||

|

|

|

|

|

|

|

|

|

|

|

|

.../min |

|

Revolutions or reciprocation |

|

Revolutions, strokes, surface speed, |

|||||||

|

|

|

|

|

|

|

|

|

per minute |

|

orbits etc. per minute |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

Off position |

|

Zero speed, zero torque... |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

1, 2, 3, ... |

|

Selector settings |

|

Speed, torque or position settings. |

|||||||

I, II, III, |

|

|

|

Higher number means greater speed |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

Infinitely variable selector with off |

|

Speed is increasing from 0 setting |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arrow |

|

Action in the direction of arrow |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating or direct current |

|

Type or a characteristic of current |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Class II construction |

|

Designates Double Insulated |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Construction tools. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earthing terminal |

|

Grounding terminal |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Warning symbol |

|

Alerts user to warning messages |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Li-ion RBRC seal |

|

Designates Li-ion battery recycling |

|

|

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ni-Cad RBRC seal |

|

Designates Ni-Cad battery recycling |

|

|

|

|

|

|

|

|

|

|

|

program |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Read manual symbol |

|

Alerts user to read manual |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wear eye protection symbol |

|

Alerts user to wear eye protection |

|

|

|

|

|

|

|

|

|

|

|

|

-7-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 8

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

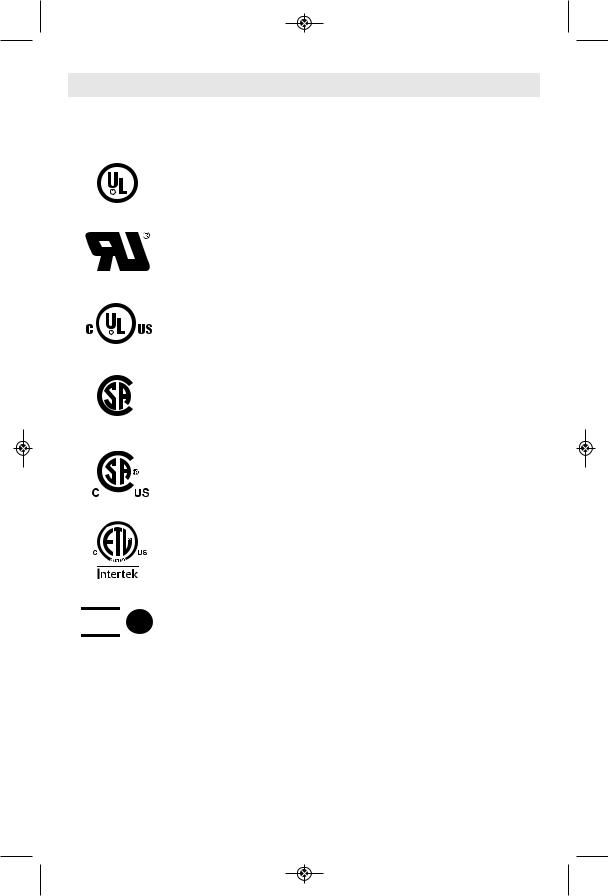

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

-8-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 9

Functional Description and Specifications

Disconnect the plug from the power source before making any assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

SM20 Dremel® Saw-Max

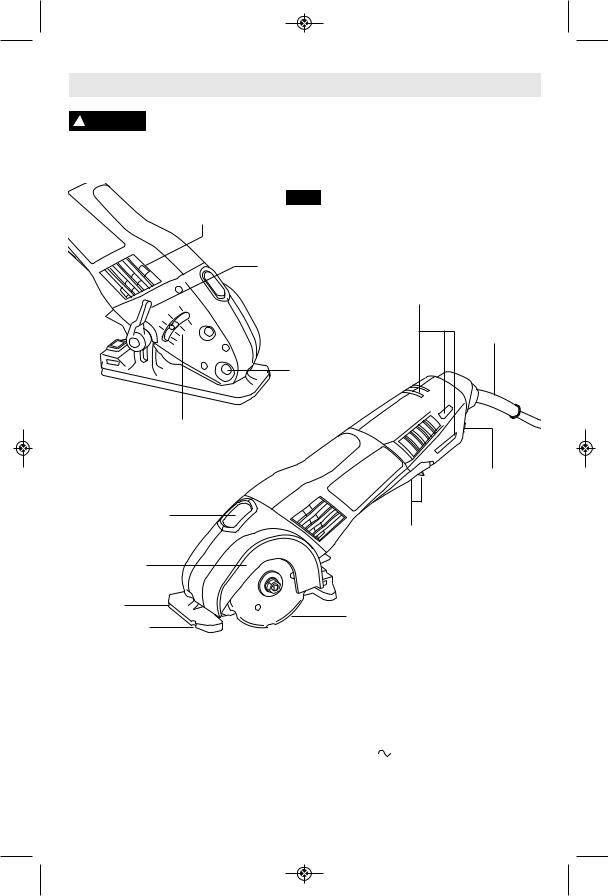

FIG. 1

VENTILATION

OPENINGS

DEPTH

ADJUSTMENT

LEVER

VENTILATION

OPENINGS

CORD

DUST

PORT

DEPTH SCALE

"LOCK-ON" BUTTON

SPINDLE LOCK

|

PADDLE SWITCH WITH |

|

|

"LOCK-OFF" FEATURE |

|

FLUSH CUT |

|

|

FOOT |

|

|

FOOT |

ABRASIVE |

|

|

|

|

LINE GUIDE |

WHEEL |

|

|

|

|

Model number |

SM20 |

|

* Rated speed |

n 17,000/min |

|

* Max. abrasive wheel diameter |

3" (76.2 mm) type 1 |

|

Amperage rating |

6.0 A |

|

Wheel arbor |

.433" (11 mm) |

|

Max. cutting depth |

3/4" (21.5 mm) |

|

Voltage rating |

120V |

60Hz |

* Accessory speed rating must be equal to or greater than the tool’s speed rating. Do not exceed the recommended wheel diameter.

NOTE: For tool specifications refer to the nameplate on your tool.

-9-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 10

Assembly

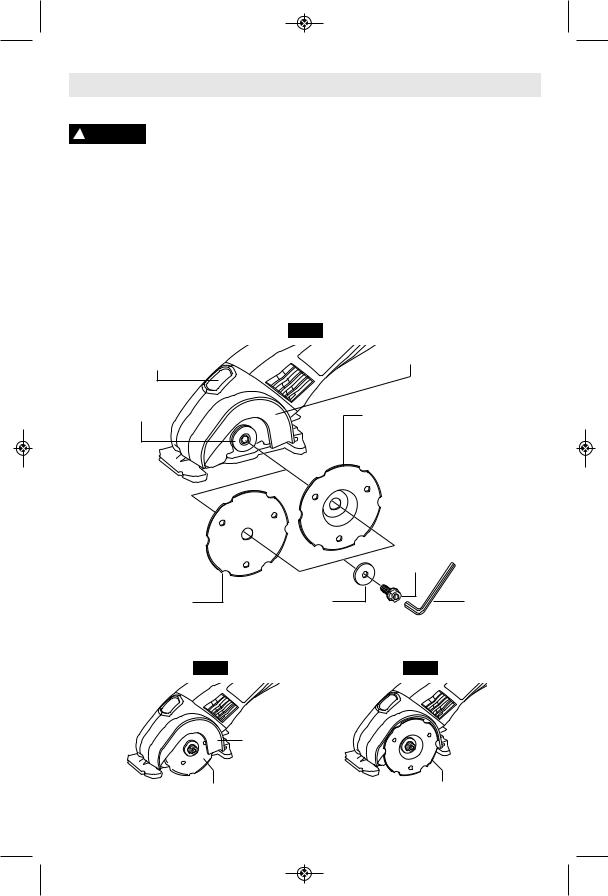

STANDARD FLAT WHEEL ASSEMBLy Disconnect the plug from the power source before

making any assembly, adjustments or changing accessories. Such preventive safety measures reduce the risk of starting the tool accidentally.

1.Turn LOCK BOLT with wrench provided clockwise and remove LOCK BOLT and OUTER WASHER (Fig. 2). If the shaft moves while attempting to loosen the lock bolt press the spindle lock (Fig. 2).

2.Slide wheel behind the guard face and mount it against the INNER WASHER on the shaft (Fig. 2a).

3.Reinstall OUTER WASHER and tighten lock bolt finger tight.

4.Press spindle lock to lock shaft and tighten LOCK BOLT counter-clockwise until tight with the wrench provided.

FLUSH CUTTING WHEEL ASSEMBLy

1.Repeat step 1 of above.

2.Place flush cutting wheel against the INNER WASHER on the spindle shaft. (Fig. 2b).

3.Reinstall OUTER WASHER and tighten LOCK BOLT finger tight.

4.Press spindle lock to lock shaft and tighten LOCK BOLT counter-clockwise until tight with the wrench provided.

SPINDLE LOCK

INNER

WASHER

STANDARD

FLAT WHEEL

FIG. 2a

FIG. 2

GUARD FACE

FLUSH CUTTING WHEEL (OPTIONAL)

LOCK

BOLT

OUTER WASHER |

WRENCH |

FIG. 2b

GUARD

FACE

STANDARD |

FLUSH |

WHEEL |

CUTTING WHEEL |

-10-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 11

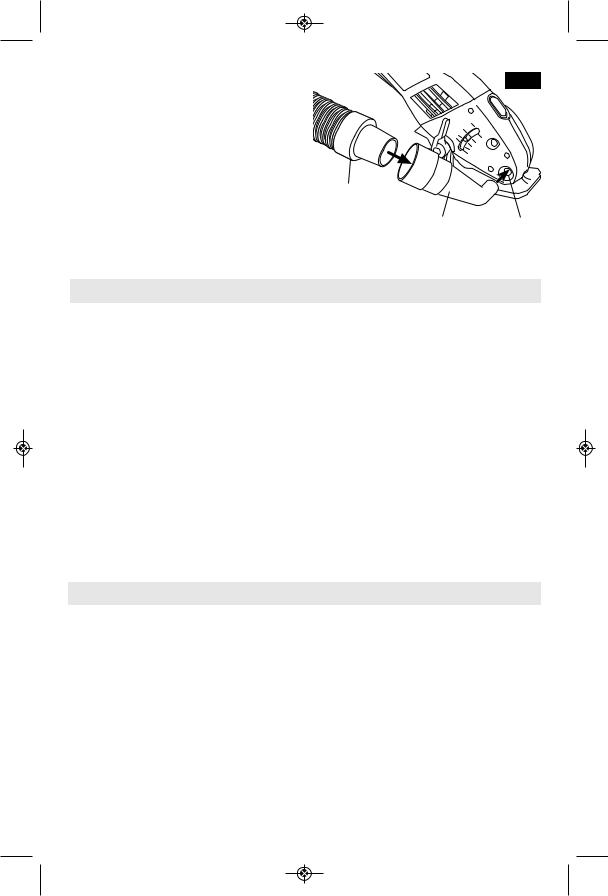

DUST ExTRACTION (Optional accessory)

Your tool is equipped with a dust port for dust extraction. To use this feature, insert dust port adapter (optional accessory) into dust port, attach vacuum hose into the adapter, then connect the opposite end of the hose to a shop vacuum cleaner (Fig. 3).

FIG. 3

VACUUM HOSE (Not included)

DUST PORT ADAPTER |

DUST |

(Optional accessory) |

PORT |

Introduction

Thank you for purchasing the Dremel SM20.

This tool was designed to tackle a wide variety of projects in and around the home. The Dremel SM20 completes tasks quicker and more efficiently than a series of other tools that would be needed to complete a job or project. This tool is also compact, ergonomic, and cuts virtually all common materials.

After using your new Dremel SM20 you’ll find that it is the right size tool to get projects done at just a fraction of the size of a traditional circular saw. With a full line of accessories the tool cuts through virtually any common material in the homewood, plastic, metal, drywall and tile. The tool also features two cutting wheel positions, one position using a standard flat

wheel for all your typical straight cuts and a second position for making flush cuts along flooring or against a wall.

In addition to versatility, the Dremel SM20 provides excellent line of sight for confident, precise cuts so you will get accurate cuts the first attempt and avoid wasting time or material.

Visit www.dremel.com to learn more about what you can do with your new Dremel tool.

INTENDED USE

This Dremel SM20 tool is intended for straight cuts in wood, plastic, metal, drywall, fiberboard, and tile using the applicable accessories recommended by Dremel.

Operating Instructions

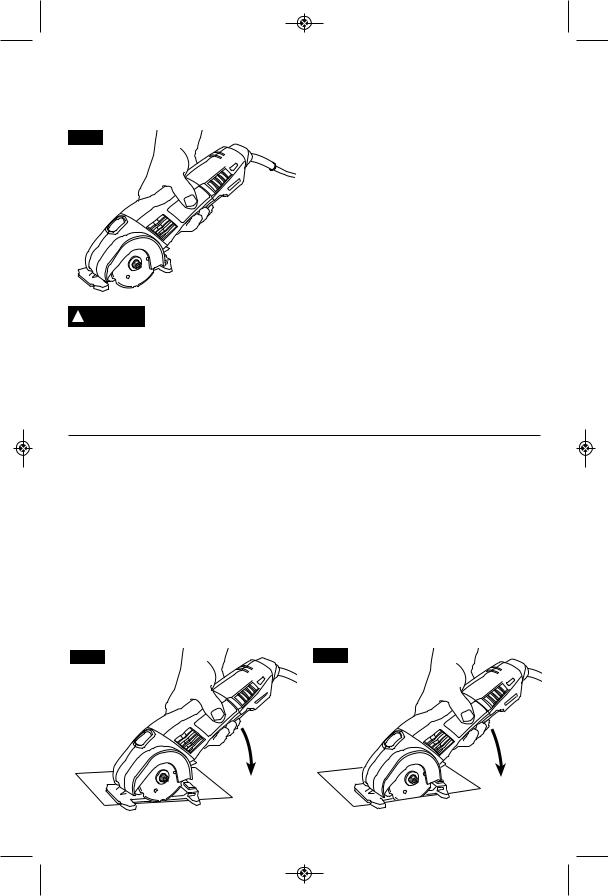

! WARNING |

Hold the tool with both hands |

|

while starting the tool, since |

|

torque from the motor can cause the tool to twist.

Start the tool before applying to work and let the tool come to full speed before contacting the workpiece. Lift the tool from the work before releasing the switch. DO NOT turn the switch “ON” and “OFF” while the tool is under load; this will greatly decrease the switch life.

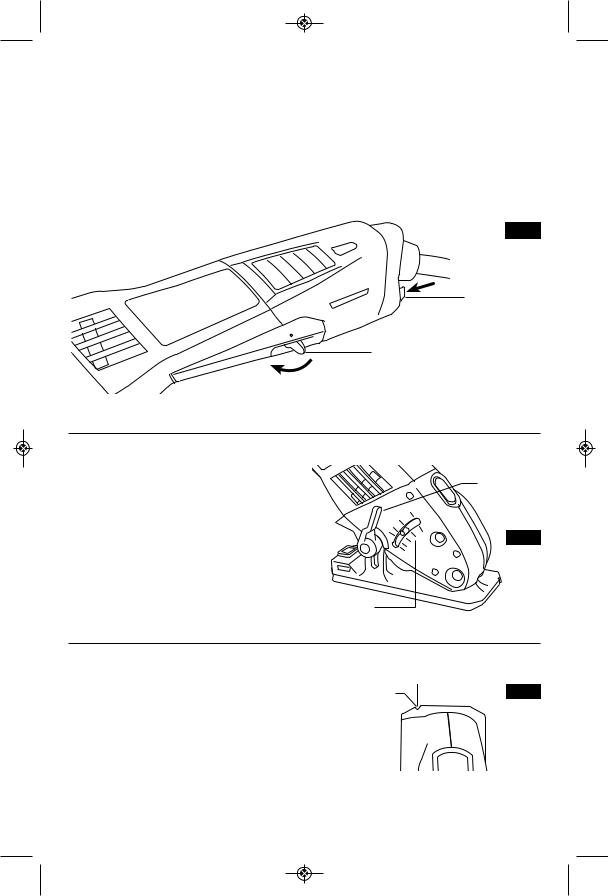

PADDLE SWITCH WITH

"LOCK-OFF" FEATURE

The Paddle switch enables the operator to control the switch functions of "Lock-OFF", and "ON/OFF".

TO UNLOCK SWITCH AND TURN TOOL "ON": Push "Lock-OFF" switch release lever forward to unlock paddle switch, then squeeze paddle switch (Fig. 4).

TO SWITCH TOOL "OFF": Release pressure on paddle lever. The switch is spring loaded and will return to "OFF" position automatically (Fig. 4).

-11-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 12

"LOCK-ON" BUTTON |

In order to try to avoid recoil (a situation where |

||

The "Lock-ON" feature, incorporated into the |

the wheel wants to skip out of the material) it |

||

paddle switch, is a convenience for long |

is recommended to make cuts in the same |

||

operations. |

direction as the rotation of the wheel. |

||

TO LOCK SWITCH "ON": After paddle switch |

|

|

It is important to read and |

|

! WARNING |

||

has been activated push "Lock-ON" button at |

|

|

understand the section in |

|

|

||

rear of tool completely in and release paddle |

this manual called “Kickback and Related |

||

switch (Fig. 4). |

Warnings”. |

|

|

TO SWITCH TOOL "OFF": Squeeze and release paddle switch (Fig. 4).

FIG. 4

"LOCK-ON" BUTTON

"LOCK-OFF" SWITCH

RELEASE LEVER

PADDLE SWITCH

PADDLE SWITCH

DEPTH ADJUSTMENT

Disconnect plug from power source. Loosen the depth adjustment lever located on the right side of the tool. The foot is spring loaded and will lower automatically (Fig. 5).

Tighten lever counter clockwise at the depth setting desired. Check desired depth (Fig. 5).

DEPTH

ADJUSTMENT

LEVER

FIG. 5

DEPTH SCALE

LINE GUIDE |

LINE GUIDE |

FIG. 6 |

The cutting guide notch will give an |

|

|

approximate line of cut (Fig. 6). Make sample |

|

|

cuts in scrap lumber to verify actual line of cut. |

|

|

-12-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 13

GENERAL CUT OFFS

Maintain a firm grip and operate the switch with a decisive action. Never force the tool. Use a light and continuous pressure (Fig. 7).

FIG. 9

After completing a cut and the switch has been released, be aware of the necessary time it takes for the

wheel to come to a complete stop during coast down. Do NOT set the tool down until the accessory has come to a complete stop.

1.Make sure material being cut is secured in a vise or fixture before attempting to cut

2.Keep your body positioned to either side of the wheel, but not in line with the wheel. It is important to support the tool properly and to position your body such as to minimize body exposure from possible wheel binding and recoil.

3.Grip the tool firmly while cutting and always be ready and able to manage the cut.

4.Avoid jamming, twisting or pinching the wheel with the workpiece of otherwise applying excessive side pressure to the wheel.

CUTTING TILE

Make sure material being cut is secured in a vise or fixture before attempting to cut.

Turn the tool on and wait for the wheel to reach full speed. For cuts that extend to the edge of a tile, cut all the way through edge(s) along your cut line.

Score the tile first along your cut line, making multiple passes to progressively cut through the tile.

This tool does not use wheels designed for face-grinding. If your cut requires a smooth, finished edge, use an appropriate tile finishing tool to refine the tile edge.

PLUNGE OR INTERIOR CUTS

The size and versatility of the Dremel SM20 make it an excellent option for making plunge or interior cuts into a workpiece such as flooring, paneling, or siding.

1.Mark the surface to be cut with the desired cut lines

2.Loosen the Depth Adjustment Lever so that the spring loaded foot releases and goes to the zero depth setting. Leave the Depth Adjustment Lever loose during this cut.

3.Rest the Foot of the tool on the workpieces and Align the tool’s wheel with the cut line (Fig. 8).

FIG. 10

4.While holding the tool firmly, Press the Paddle Switch and allow the tool’s wheel to come up to full speed.

5.Slowly plunge/lower the tool and wheel into the workpiece (Fig. 9).

6.Guide the tool forward and complete the cut

7.Release the Paddle Switch and allow the tool to come to a complete stop.

8.Remove the tool from the workpiece.

9.Repeat steps 3-8 as required to complete your cuts.

FIG. 11

-13-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 14

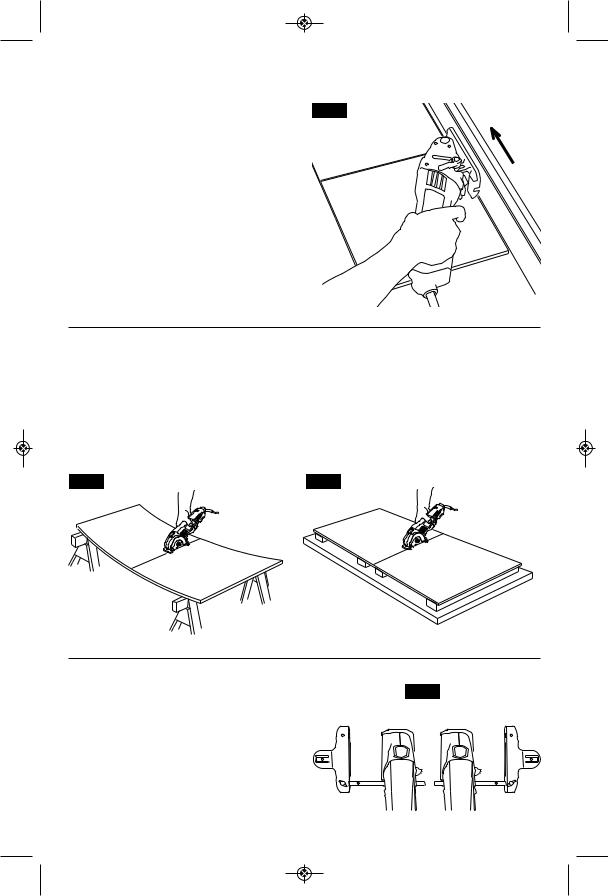

FLUSH CUTTING

First, consider the desired height of the flush cut. For flooring installation, add up the thickness of your flooring adhesive, the flooring itself, and any underlayments or other material that will add to the thickness of the finished floor.

1.Install the flush cutting wheel on the tool as described in “Flush Cutting Wheel Assembly”, page 10.

2.Adjust the depth of the wheel to the desired depth setting.

3.Turn the tool on it’s side so that the flush cut foot rests against the flooring.

4.Firmly grip the tool. Turn tool on and allow it to come to full speed before entering workpiece.

5.Complete your cut and remove the tool from the workpiece before turning the tool off.

FIG. 10

CUTTING LARGE SHEETS

Large sheets and long boards sag or bend, depending on support. If you attempt to cut without leveling and properly supporting the piece, the wheel will tend to bind, causing KICKBACK and extra load on the motor (Fig. 11).

Support the panel or board close to the cut, as shown in (Fig. 12). Be sure to set the depth of the cut so that you cut through the sheet or

FIG. 11

board only and not the table or work bench. The two-by-fours used to raise and support the work should be positioned so that the broadest sides support the work and rest on the table or bench. Do not support the work with the narrow sides as this is an unsteady arrangement. If the sheet or board to be cut is too large for a table or work bench, use the supporting two-by-fours on the floor and secure.

FIG. 12

RIGHT

WRONG

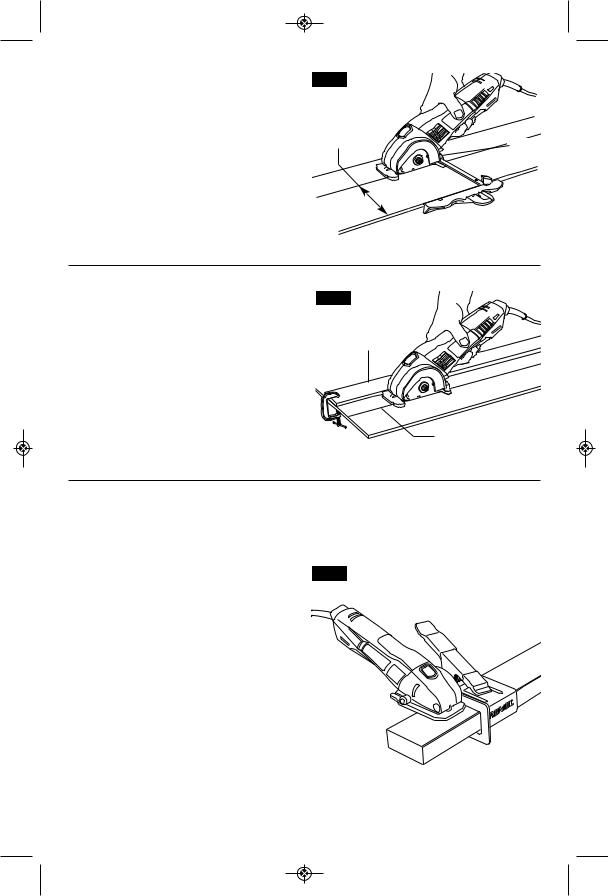

STRAIGHT EDGE GUIDE |

FIG. 13 |

The straight edge guide (optional attachment) is used for cuts parallel to the edge of the work, and can be used from either side of the foot plate for cutting on the left or right side of the material.

NOTE: When using the straight edge guide on the left side or right side of the tool, position guide as shown (Fig. 13).

-14-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 15

RIP CUTS

Rip cuts are easy to do with a straight edge guide (Fig. 14). Straight edge guide is available as an accessory (optional attachment). To attach, insert straight edge guide, insert fence through slots in foot to desired width as shown and secure with the set screw.

FIG. 14

DESIRED WIDTH OF CUT

SET

SCREW

STRAIGHT

STRAIGHT

EDGE GUIDE

RIP BOARD GUIDE

When rip cutting large sheets, the straight edge guide may not allow the desired width of cut. Clamp or nail a straight piece of 1" (25 mm) lumber to the sheet as a guide (Fig. 15). Use the right side of the foot against the board guide.

FIG. 15

RIP BOARD

GUIDE

DESIRED WIDTH

OF CUT

2”x4” CUTTING GUIDE

The Dremel SM20 and the 2”x4” Cutting Guide (Optional Attachment) can be used to quickly and accurately make cuts in 2”x4” lumber. Since the depth of cut is less than the thickness of a 2”x4” one cut on each side of the wood will be required to complete a cut through the work piece.

1.Measure and mark the desired cut line on the piece of wood.

2.Slide the 2”x4” Cutting Guide over the wood in the designated location of the cut.

Note: When using the standard wheel measure a 1” offset to properly align the guide to the offset indicator in the cutting guide. While using the flush cut wheel, line the fence of the tool up with the cut line.

3.Clamp the cutting guide to the work piece in the desired location to make the cut.

4.Firmly hold the tool and use the edge of the guide as a fence and make the first cut, (Fig. 16)

5.Flip the work piece over while leaving the cutting guide clamped in place and make a second cut to complete the cut through the 2”x4”.

FIG. 16

-15-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 16

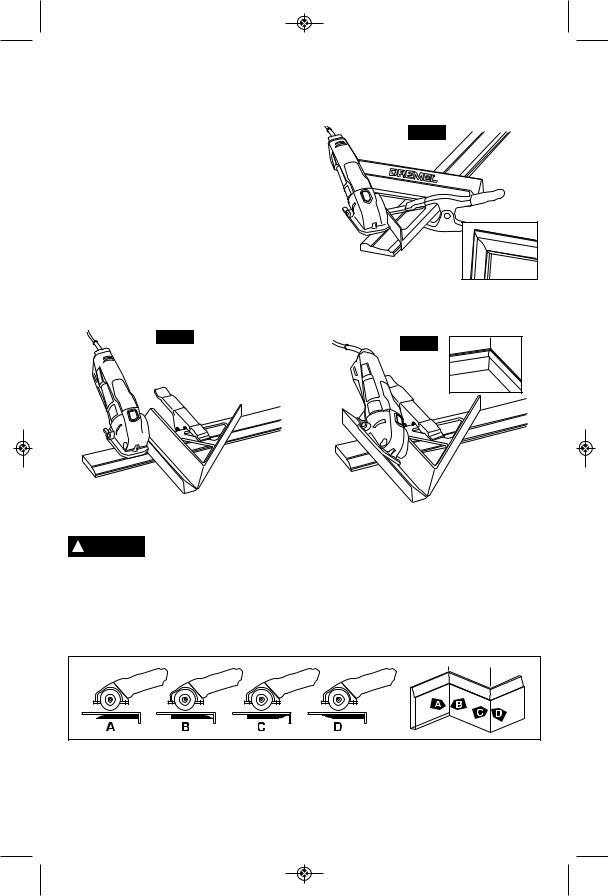

MITER/TRIM CUTTING GUIDE

The Dremel SM20, Miter/Trim Cutting Guide (Optional Attachment) and Flush Cutting Wheel is a perfect combination to make miter, bevel, and straight cuts in baseboard, trim, and molding. Angle indicators also aid in making accurate cuts for other common angles like 15°, 22.5° or 30°.

1.Measure and mark the desired cut line on the piece of wood.

2.Position the Miter/Trim Cutting Guide over the wood in the designated location of the cut.

3.Clamp the cutting guide to the workpiece in the desired location to make the cut.

4.Firmly hold the tool and make the cut.

Straight Cutsuse the outside edge of the cutting guide as the fence, (Fig. 17)

FIG. 17

45° Miter Cutsuse the angled edge of the cutting guide as the fence, (Fig. 18).

Ensure the tool is properly seated in the guide before starting the tool and use caution when

stopping the tool within the cutting rail to ensure that the cutting wheel does not come into contact with the cutting guide.

Miter Cuts (15°, 22.5° or 30°)- Pivot the cutting guide at the designated corner to the desired

angle using the angle indicator marking on the cutting guide, complete the cut using the outside edge of the cutting guide as the fence, (Fig. 17).

FIG. 18

45° Bevel CutsWhile using the flush cutting wheel only, place the saw in the cutting rail to complete the cut, (Fig. 19).

FIG. 19

The guide positions the saw to make bevel cuts in workpieces up to 9/16" thick. To make a cut, first position the tool into the rail so the back of the tool’s foot fits into the keying feature. Switch on the tool and proceed to make the cut. Stop the tool before removing from guide.

Determine if a Inside Left, Outside Left, Inside Right, or Outside Right cut is required and orient the workpiece. Positions A, B, C, or D.

-16-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 17

Maintenance Information

Service

NO USER SERVICEABLE

PARTS INSIDE. Preventive maintenance performed by unauthorized personnel may result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Dremel Service Facility.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service.To maintain peak efficiency of the motor, the may brushes be serviced by a Dremel Service Facility.

Cleaning

To avoid accidents always disconnect the tool from the power supply before cleaning or

performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

Certain cleaning agents ! CAUTION and solvents damage

plastic parts. Some of these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

Extension Cords

If an extension cord is necessary, a cord with adequate size conductors that is capable

of carrying the current necessary for your tool must be used. This will prevent excessive voltage drop, loss of power or overheating. Grounded tools must use 3- wire extension cords that have 3-prong plugs and receptacles.

NOTE: The smaller the gauge number, the heavier the cord.

RECOMMENDED SIZES OF ExTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s |

Cord Size in A.W.G. |

Wire Sizes in mm2 |

|||||||

|

|

|

|

|

|

|

|

||

Ampere |

|

|

|

|

|

|

|

|

|

Cord Length in Feet |

Cord Length in Meters |

||||||||

Rating |

|||||||||

25 |

50 |

100 |

150 |

15 |

30 |

60 |

120 |

||

|

|||||||||

3-6 |

|

|

|

|

|

|

|

|

|

18 |

16 |

16 |

14 |

0.75 |

0.75 |

1.5 |

2.5 |

||

6-8 |

18 |

16 |

14 |

12 |

0.75 |

1.0 |

2.5 |

4.0 |

|

8-10 |

18 |

16 |

14 |

12 |

0.75 |

1.0 |

2.5 |

4.0 |

|

10-12 |

16 |

16 |

14 |

12 |

1.0 |

2.5 |

4.0 |

— |

|

12-16 |

14 |

12 |

— |

— |

— |

— |

— |

— |

|

|

|

|

|

|

|

|

|

|

|

-17-

DM 2610013190 06-11:DM 2610013190 06-11.qxp 6/6/11 10:43 AM Page 18

|

Dremel SM20 Accessories |

|

Use only Dremel SM20, high-performance accessories. Other accessories are |

! WARNING |

|

|

not designed for this tool and may lead to personal injury or property damage. |

|

Multi-Purpose Carbide Wheel

SM500

SM500

Abrasive cutting wheel with carbide grit which is intended to cut wood and other soft materials.

Abrasive cutting wheel with carbide grit which is intended to cut wood and other soft materials.

Multi-Purpose Cut-off Wheel SM510

Reinforced Type 1 Abrasive cut-off wheel which is intended to cut a variety of materials such as metal and plastic.

Masonry Cut-off Wheel SM520

Reinforced Type 1 Abrasive cut-off

wheel which is intended to make sore cuts in masonry and stone.

Diamond Wheel SM540

Diamond abrasive wheel which is intended to make cuts in hard materials such as marble, concrete, brick, porcelain, and tile.

Flush Cut Carbide Wheel

SM600

SM600

Offset abrasive cutting wheel with carbide grit which is intended to cut wood and other soft materials.

Offset abrasive cutting wheel with carbide grit which is intended to cut wood and other soft materials.

|

|

|

SM500 |

SM510 |

SM520 |

SM540 |

SM600 |

|

|

|

Carbide |

Multi- |

Masonry |

Diamond |

Flush Cut |

|

|

|

Wheel |

Purpose |

Cut-off |

Wheel |

Wheel |

|

|

|

|

Cut-off |

Wheel |

|

|

Material |

|

|

|

Wheel |

|

|

|

Wood |

|

Plywood |

X |

|

|

|

X |

|

|

|

|

||||

|

|

Pine |

X |

|

|

|

X |

|

|

Popula |

X |

|

|

|

X |

|

|

Oak |

X |

|

|

|

X |

|

|

Composite (OSB, |

|

X |

|

|

X |

|

|

fiberboard) |

|

|

|

|

|

|

|

Laminate flooring |

X |

|

|

|

X |

Drywall |

|

Drywall |

X |

|

|

|

X |

Metal |

|

Copper Pipe |

|

X |

|

|

|

|

|

Conduit |

|

X |

|

|

|

|

|

Coated Wire |

|

X |

|

|

|

|

|

shelving |

|

|

|

|

|

|

|

HVAC |

|

X |

|

|

|

|

|

AL sheet, gutter, |

|

X |

|

|

|

|

|

fascia |

|

|

|

|

|

|

|

Gal. sheet metal |

|

X |

|

|

|

|

|

Threaded rod |

|

X |

|

|

|

Plastic |

|

Plexiglass |

X |

X |

|

|

|

|

|

(sheet plastic) |

|

|

|

|

|

|

|

Vinyl siding, gutter |

X |

X |

|

|

|

|

|

PVC pipe |

X |

X |

|

|

|

Tile |

|

Wall Tile |

|

|

|

X |

|

|

|

Floor Tile |

|

|

|

X |

|

Masonry |

|

Brick Fascia |

|

|

X |

X |

|

|

|

Cement board |

|

|

X |

X |

|

|

|

Pavers |

|

|

X |

X |

|

Other |

|

Fiberglass |

|

X |

|

|

|

|

|

|

|

|

|

|

|

-18-

Loading...

Loading...