Dremel 1800 User Manual [fr]

Owner’s Manual

MODEL 1800 VARIABLE SPEED 18” Scroll Station

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Manual Contents |

|

|

|

|||||||

General Safety Rules . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . .2 |

Making Interior Scroll Cuts . . . . . . . . . . . . . . . . . . . |

. 16. . . |

||||||||

Specific Safety Rules . . . . . . . . . . . . . . . . . . . . . . |

. . . . . .3 - 5 |

Adjusting the Table for Horizontal or Bevel Cutting |

. 16. . . |

||||||||

Additional Safety Rules . . . . . . . . . . . . . . . . . . . . . |

. . . . .5 - 6 |

Operating Adjustments . . . . . . . . . . . . . . . . . . . . . . . . |

. 17. . . |

||||||||

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . .7 |

Aligning the Degree Scale Pointer . . . . . . . . . . . . . |

. 17. . . |

||||||||

General Specifications . . . . . . . . . . . . . . . . . . . . |

. . . . . . . .7 |

Removing and Installing Abrasive Discs . . . . . . . . |

. 17. . . |

||||||||

Motor Specifications . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . .7 |

Power ON/OFF Switch . . . . . . . . . . . . . . . . . . . . . . |

. 17. . . |

||||||||

Connection to a Power Source . . . . . . . . . . . . . |

. . . . . . . .7 |

Adjusting the Lamp . . . . . . . . . . . . . . . . . . . . . . . . . |

. 17. . . |

||||||||

Unpacking & Checking Contents . . . . . . . . . . . . . |

. . . . . . . .8 |

Adjusting the Blower . . . . . . . . . . . . . . . . . . . . . . . . |

. 18. . . |

||||||||

Getting to Know Your Scroll Station . . . . . . . . . . . |

. . . .9 - 10 |

Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . |

. 18. . . |

||||||||

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . .10 |

Adjusting Side Table . . . . . . . . . . . . . . . . . . . . . . . . |

. 18. . . |

||||||||

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . .11 |

Squaring Side Table . . . . . . . . . . . . . . . . . . . . . . . . |

. 18. . . |

||||||||

Installing the Disc Table . . . . . . . . . . . . . . . . . . |

. . . . . . .11 |

Maintaining Your Scroll Station . . . . . . . . . . . . . . . . . . |

. 19. . . |

||||||||

Installing the Flex Shaft (optional accessory) . |

. . . . . . .11 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 19. . . |

||||||||

Mounting the Scroll Station to a Bench . . . . . . |

. . . . . . .12 |

Carbon Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 19. . . |

||||||||

Mounting the Scroll Station to Plywood . . . . . . |

. . . . . . .13 |

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 19. . . |

||||||||

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . .14 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 20. . . |

||||||||

Basic Scroll Station Operations . . . . . . . . . . . . |

. . . . . . .14 |

Recommended Accessories . . . . . . . . . . . . . . . . . . . . |

. 21. . . |

||||||||

Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . .14 |

Dremel Limited Warranty . . . . . . . . . . . . . . . . . . . . . . |

. 22. . . |

||||||||

Removing and Installing Pin-End Blades . . . . . |

. . . . . . .14 |

|

|

|

|

|

|

|

|

|

|

Removing and Installing Plain-End Blades . . . |

. . . . . . .15 |

|

|

|

|

|

|

|

|

|

|

|

Parlez-vous français? Voir page 23 |

|

|

|

|||||||

Blade Tension |

15 |

|

|

|

|

||||||

|

¿Habla español? Ver página 50 |

|

|

|

|||||||

|

|

|

|

|

|

||||||

4915 21st Street

Racine, WI 53406

1-800-437-3635 http://www.dremel.com

Form No. 2610922039 0504

General Safety Rules

|

READ ALL INSTRUCTIONS! Failure to follow the safety rules listed below and other basic safety precautions |

||||

! WARNING |

|||||

may result in serious personal injury. |

|

|

|

||

|

Work Area |

REMOVE ADJUSTING KEYS AND WRENCHES |

|||

|

Form the habit of checking to see that keys and adjusting |

||||

|

|

||||

KEEP CHILDREN AWAY |

wrenches are removed from tool before turning it on. |

||||

Do not let visitors contact tool or extension cord. All visitors |

AVOID ACCIDENTAL STARTING |

||||

should be kept away from work area. |

|||||

|

|

Make sure the switch is in the “OFF” position before plugging |

|||

KEEP WORK AREAS CLEAN |

in tool. |

|

|||

Cluttered areas and benches invite accidents. |

|

|

|

||

|

|

GROUND ALL TOOLS |

|||

MAKE WORKSHOP CHILD-PROOF |

This tool is equipped with an approved 3-conductor cord and |

||||

Use padlocks, master switches. |

a 3 prong grounding type plug to fit the proper grounding type |

||||

AVOID DANGEROUS ENVIRONMENTS |

receptacle. The green conductor in the cord is the grounding |

||||

wire. Never connect the green wire to a live terminal. |

|||||

Don’t use power tools in damp or wet locations. Keep work |

|

|

|

||

area well lit. Do not expose power tools to rain. Do not use |

NEVER STAND ON TOOL OR ITS STAND |

||||

the tool in the presence of flammable liquids or gases. |

Serious injury could occur if the tool is tipped or if the cutting |

||||

|

|

tool is accidentally contacted. Do not store materials on or |

|||

|

|

near the tool such that it is necessary to stand on the tool or |

|||

|

Personal Safety |

its stand to reach them. |

|||

|

CHECK DAMAGED PARTS |

||||

KNOW YOUR POWER TOOL |

|||||

Before further use of the tool, a guard or other part that is |

|||||

Read and understand the owner’s manual and labels affixed |

damaged should be carefully checked to ensure that it will |

||||

to the tool. Learn its application and limitations as well as the |

operate properly and perform its intended function. Check for |

||||

specific potential hazards peculiar to this tool. |

alignment of moving parts, mounting, and any other condi- |

||||

DON’T OVERREACH |

tions that may affect its operation. A guard or other part that |

||||

is damaged should be properly replaced. |

|||||

Keep proper footing and balance at all times. |

|||||

|

|

|

|||

|

|

|

|

All repairs, electrical or mechanical, should be |

|

STAY ALERT |

! |

WARNING |

|||

attempted only by trained repairmen. Contact |

|||||

Watch what you are doing. Use common sense. Do not oper- |

the nearest |

Dremel Service Center, Authorized Dremel |

|||

ate tool when you are tired. Do not operate while under med- |

|||||

Service Station. |

|||||

ication or while using alcohol or other drugs. |

|||||

|

|

|

|||

|

|

|

|

Use only Dremel replacement parts; any oth- |

|

DRESS PROPERLY |

! |

WARNING |

|||

ers may create a hazard. |

|||||

Do not wear loose clothing or jewelry. They can be caught in |

|

|

|

||

moving parts. Rubber gloves and non-skid footwear are rec- |

|

|

The use of any other accessories not speci- |

||

|

WARNING |

||||

ommended when working outdoors. Wear protective hair cov- |

! |

||||

fied in the current Dremel catalog, may create |

|||||

ering to contain long hair. |

|||||

a hazard. |

|

||||

|

|

|

|||

USE SAFETY GLASSES |

|

|

Some dust created by power sanding, sawing, |

||

Also wear face or dust mask if cutting operation is dusty, and |

! |

WARNING |

|||

grinding, drilling, and other construction activ- |

|||||

ear plugs during extended periods of operation. |

|||||

ities contains chemicals known to cause cancer, birth defects |

|||||

|

|

||||

Everyday eyeglasses have only impact resistant lenses, they |

or other reproductive harm. Some examples of these chem- |

||||

icals are: |

|

||||

are NOT safety glasses. |

|

||||

GUARD AGAINST ELECTRIC SHOCK |

• Lead from lead-based paints, |

||||

|

|

|

|||

Prevent body contact with grounded surfaces. For example: |

• |

Crystalline silica from bricks and cement and other mason- |

|||

pipes, radiators, ranges, refrigerator enclosures. |

|

ry products, and |

|||

DISCONNECT TOOLS FROM POWER SOURCE |

• Arsenic and chromium from chemically treated lumber. |

||||

Your risk from these exposures varies, depending on how |

|||||

When not in use, before servicing, when changing blades, |

|||||

bits, cutters, etc. |

often you do this type of work. To reduce your exposure to |

||||

|

|

these chemicals: work in a well ventilated area, and work with |

|||

KEEP GUARDS IN PLACE |

approved safety equipment, such as those dust masks that |

||||

In working order, and in proper adjustment and alignment. |

are specially designed to filter out microscopic particles. |

||||

SAVE THESE INSTRUCTIONS

2

|

|

||

Specific Safety Rules |

|

||

Scroll Station Station |

feed the material too quickly. |

Hold the work firmly |

|

|

Observe and follow correct direction of feed and do not |

||

Always disconnect the power cord from the power |

against the table. Feed work into a blade against the teeth |

||

of the blade. Feeding material too forcefully may cause blade |

|||

source before making any adjustments or attaching any |

|||

to snap. |

|

||

accessories. Always turn off saw before disconnecting it |

|

||

|

|

||

to avoid accidental starting when reconnecting to a |

Use caution when cutting materials with an irregular |

||

power source. You may unexpectedly cause the tool to start |

|||

cross-section or rounds like dowel rods. If possible lay |

|||

leading to serious personal injury. |

|||

the material on its "flat" side when cutting. For round |

|||

|

|||

Never leave tool running unattended. Turn power off. |

stock use a "Vee" block to support the material. Wavy |

||

material like molding will tend to rock and may bind while cut- |

|||

Don't leave tool until it comes to a complete stop. |

|||

ting. Rounds will tend to roll while being cut and the blade |

|||

|

|||

Never leave the switches in "ON" position. Before plug- |

may "bite" and grab it from your control. |

||

|

|

||

ging the tool in, check that the switches are "OFF". |

Do not remove jammed cutoff pieces until blade has |

||

Accidental start-ups could cause injury. |

|||

stopped. Never touch blade or other moving parts dur- |

|||

|

|||

Do not use tool if switch does not turn it on and off. Have |

ing use. Contacting the blade or other moving mechanism |

||

may cause inju y. |

|

||

broken switches replaced by an authorized service center. |

|

||

Power Take Off Safety Rules |

|||

Use only Dremel Scroll Station blades. Use the right blade |

|||

size, style and cutting speed for the material and the type of |

The use of attachments and |

accessories not recom- |

|

cut. Sharp blades minimize stalling and kickbacks. Blade |

|||

mended by Dremel may result in risk of injuries. |

|||

teeth should point down toward the table. |

|||

|

|

||

Avoid awkward operations and hand positions and |

Remove the Scroll Station blade and replace it with the |

||

Scroll Station blank in the blade holder before operating |

|||

always make sure you have good balance. A sudden slip |

|||

any attachment from the power take off. Avoid the pos- |

|||

could cause your hand to move into the blade. |

|||

sibility of contacting the reciprocating blade while sand- |

|||

|

|||

Firmly clamp or bolt your saw station to a stable, level |

ing. Inadvertent contact with a blade could cause serious |

||

lacerations. |

|

||

workbench or table. The most comfortable table height is |

|

||

|

|

||

approximately waist height. |

Unplug the tool before changing accessories or attach- |

||

|

|||

Never stand on tool. Serious injury could occur if the tool is |

ments. Accidental start-ups may occur if sander is plugged |

||

in while changing an accessory. |

|

||

tipped or if the blade is unintentionally contacted. |

|

||

|

|

||

Before making a cut, be sure all adjustments are secure. |

Keep the cord to the side away from sanding pad or other |

||

attachments. The cord can be dragged into housing and |

|||

Loose table or guards could shift in use and cause you to |

|||

become entangled with the pad or other moving components. |

|||

loose control of the workpiece. |

|||

Disc Sander Safety Rules |

|||

|

|

||

Always adjust drop foot to just clear the workpiece. |

|

|

|

Proper adjustment of the drop foot will help protect your fin- |

Use only 5" diameter adhesive backed sandpaper discs. |

||

gers and keep blade breakage to a minimum. |

Do not use sandpaper intended for larger sanding pads. |

||

|

Larger sandpaper will extend beyond the sanding pad caus- |

||

Always support large workpieces while cutting to mini- |

ing snagging, tearing of the paper or kickback. |

||

mize risk of blade pinching and kickback. Heavy work- |

|

|

|

piece may cause the table to slip, walk or slide while cutting. |

Make sure the sandpaper disc is not torn or loose before |

||

|

turning tool on. The disc could fly away unexpectedly. |

||

Be sure the blade path is free of nails. Inspect for and |

|

|

|

remove nails from lumber or workpiece before cutting or |

Properly adjust sanding disc to avoid it overhanging the |

||

sanding. |

pad. Spinning sanding disc overhanging its pad can cause |

||

|

severe lacerations. |

|

|

Keep hands away from cutting area. Do not hand hold |

|

|

|

pieces so small that your fingers go under the blade guard. |

Always position your workpiece on the downward side of |

||

Do not reach underneath work or in blade cutting path with |

the direction of rotation arrow while sanding. Hold the |

||

your hands and fingers for any reason. |

work firmly against the table. Sanding on the upward side of |

||

|

the rotation could cause the workpiece to lift up or kickback. |

||

Never start the tool when the blade is in contact with the |

Refer to rotation arrow on your sander guard. |

||

workpiece. Allow the motor to come up to full speed |

|

|

|

before starting a cut. Blade in contact with the workpiece |

Avoid awkward hand positions while sanding. A sudden |

||

on start up will cause it to jump. |

slip could cause a hand to move into abrasive disc. |

||

3

Specific Safety Rules

Keep your fingers and clothing away from the sanding disc. Do not sand pieces that are so small that your fingers touch the sanding disc while sanding. Don't use a rag to hold workpiece while sanding. They could get cut or wedged between the pad and the table.

Do not sand pieces of material that cannot be supported by the table. When sanding larger workpieces provide additional support at the sanding table height. Oversized workpiece may cause the table to shift and you could lose control.

Use miter fence when sanding. Supporting the workpiece prevents it from being ejected from the sander and leaves both hands to control the work.

Do not wet sand with this sander. A liquid entering the motor housing is an electrical shock hazard.

Use special precautions when sanding chemically pressure treated lumber, paint that may be lead based, or any other materials that may contain carcinogens. All persons entering the work area must wear a suitable breathing respirator and protective clothing. Plastic sheeting should seal Work area and persons not protected should be kept out until work Flexarea is thoroughlyShaft Safetycle n d. Rules

Do not operate the flexible shaft with a sharp bend. Over bending the shaft can generate excessive heat on the jacket or hand piece. The recommended minimum is 6" radius.

Be aware of the switch location, when placing the flex shaft down or when picking the tool up. You may accidentally activate the switch.

Always hold the hand piece firmly in your hands during the start-up. The reaction torque of the motor, as it accelerates to full speed, can cause the shaft to twist.

After changing the bits or making any adjustments, make sure the collet nut and any other adjustment devices are securely tightened. Loose adjustment device can unexpectedly shift, causing loss of control; loose rotating components will be violently thrown.

Do not reach in the area of the spinning bit. The proximity of the spinning bit to your hand may not always be obvious.

Allow brushes to run at operating speed for at least one minute before using wheel. During this time no one is to stand in front or in line with the brush. Loose bristles or wires will be discharged during the run-in time.

Wear protective gloves and face shield with wire or bristle brushes. Apply wire or bristle brushes lightly to the work as only the tips of the wire/bristles do the work.

"Heavy" pressure on bristles will cause the wire or bristle to become overstressed, resulting in a wiping action and will cause the bristles/wire to be discharged.

Carefully handle both the tool and individual grinding

wheels to avoid chipping or cracking. Install a new wheel if tool is dropped while grinding. Do not use a wheel that may be damaged. Fragments from a wheel that bursts during operation will fly away at great velocity possibly striking you or bystanders.

Never use dull or damaged bits. Sharp bits must be handled with care. Damaged bits can snap during use. Dull bits require more force to push the tool, possibly causing the bit to break.

Use clamps to support workpiece whenever practical. Never hold a small workpiece in one hand and the tool in the other hand while in use. Allow for sufficient space, at least 6", between your hand and the spinning bit. Round material such as dowel rods, pipes or tubing have a tendency to roll while being cut, and may cause the bit to "bite" or jump toward you. Clamping a small workpiece allows you to use both hands to control the tool.

Inspect your workpiece before cutting. When cutting irregularly shaped workpieces, plan your work so it will not slip and pinch the bit and be torn from your hand. For example, if carving wood, make sure there are no nails or foreign objects in the workpiece. Nails or foreign objects can cause the bit to jump.

Never start the tool when the bit is engaged in the material. Let the bit reach its full set speed before contacting the workpiece. The bit cutting edge may grab the material causing loss of control of the cutter.

Avoid bouncing and snagging the wheel, especially when working corners, sharp edges etc. This can cause loss of control and kickback.

The direction of feed with the bit into the material when carving, routing or cutting is very important. Always feed the bit into the material in the same direction as the cutting edge is exiting from the material (which is the same direction as the chips are thrown). Feeding the tool in the wrong direction causes the cutting edge of the bit to climb out of the work and pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed or bogged down, turn the tool "OFF" by the switch. Wait for all moving parts to stop and unplug the tool, then work to free the jammed material. If the switch to the tool is left "ON" the tool could restart unexpectedly causing serious personal injury.

Do not leave a running tool unattended, turn power off.

Only when tool comes to a complete stop it is safe to put it down.

Do not grind or sand near flammable materials. Sparks from the wheel could ignite these materials.

Do not touch the bit or collet after use. After use the bit and collet are too hot to be touched by bare hands.

Do not allow familiarity gained from frequent use of your rotary tool to become commonplace. Always remember

4

that a careless fraction of a second is sufficient to inflict |

with one hand while using any of these accessories. The |

||||||||

severe injury. |

|

reason is that these wheels will grab if they become slightly |

|||||||

|

|

canted in the groove, and can kickback, causing loss of con- |

|||||||

Do not alter or misuse tool. Any alteration or modification is |

trol resulting in serious injury. Your second hand should be |

||||||||

a misuse and may result in serious personal injury. |

used to steady and guide the hand holding the tool. When a |

||||||||

|

|

cutoff wheel grabs, the wheel itself usually breaks. When the |

|||||||

When using the steel saws, cutoff wheels, high-speed |

steel saw, high-speed cutters or tungsten carbide cutter grab, |

||||||||

cutters or tungsten carbide cutters, always have the |

it may jump from the groove and you could lose control of the |

||||||||

work securely clamped. Never attempt to hold the work |

tool. |

|

|

|

|

|

|||

|

Additional Safety Rules |

|

|

|

|||||

|

Tool Use |

For your own safety, do not operate your Scroll Station until |

|||||||

|

it is completely assembled and installed according to the |

||||||||

|

|

||||||||

DON’T FORCE TOOL |

instructions...and until you have read and understood the fol- |

||||||||

It will do the job better and safer at the rate for which it was |

lowing: |

|

|

|

|

|

|||

designed. |

|

1. General Safety Rules ........................................................2 |

|||||||

|

|

||||||||

USE THE RIGHT TOOL |

2. |

Motor Specifications and |

|

|

|

||||

|

Electrical Requirements ..................................................7 |

||||||||

Don’t force a small tool or attachment to do the job of a heavy |

|

||||||||

3. Getting to Know Your Scroll Station ......................9 - 10 |

|||||||||

duty tool. Don’t use tool for purpose not intended—for exam- |

|||||||||

4. |

Operation ..................................................................14 - 16 |

||||||||

ple, don’t use a circular saw for cutting tree limbs or logs. |

|||||||||

5. Maintaining Your Scroll Station ....................................19 |

|||||||||

|

|

||||||||

SECURE WORK |

|

STABILITY OF SAW |

|

|

|

||||

Use clamps or a vise to hold work when practical. It’s safer |

|

|

|

||||||

Your Scroll Station must be bolted securely to a stand or |

|||||||||

than using your hand and it frees both hands to operate the |

|||||||||

workbench. In addition, if there is any tendency for the Scroll |

|||||||||

tool. |

|

||||||||

|

Station to tip over or move during certain operations, such as |

||||||||

|

|

||||||||

NEVER LEAVE TOOL RUNNING UNATTENDED |

cutting long, heavy boards, bolt your Scroll Station stand or |

||||||||

workbench to the floor. |

|

|

|

||||||

Turn power off. Don’t leave tool until it comes to a complete |

|

|

|

||||||

|

|

|

|

|

|

|

|||

stop. |

|

LOCATION |

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

|

Tool Care |

This Scroll Station is intended for indoor use only. |

|

||||||

|

PROTECTION: Eyes, hands, face, ears and body. |

|

|||||||

DO NOT ALTER OR MISUSE TOOL |

|

||||||||

|

|

|

|

|

|

|

|||

These tools are precision built. Any alteration or modification |

|

|

TO |

AVOID BEING |

PULLED |

INTO |

THE |

||

! WARNING |

|||||||||

not specified is misuse and may result in dangerous condi- |

|||||||||

BLADE— |

|

|

|

||||||

tions. |

|

DO NOT WEAR: |

|

|

|

|

|||

AVOID GASEOUS AREAS |

|

|

|

|

|||||

• |

Loose Fitting Gloves |

|

|

|

|||||

Do not operate electric tools in a gaseous or explosive atmo- |

|

|

|

||||||

• |

Necktie |

|

|

|

|

|

|||

sphere. Motors in these tools normally spark, and may result |

|

|

|

|

|

||||

• |

Loose Clothing |

|

|

|

|

||||

in a dangerous condition. |

|

|

|

|

|||||

• |

Jewelry |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

MAINTAIN TOOLS WITH CARE |

DO: |

|

|

|

|

|

|||

Keep tools sharp and clean for better and safer performance. |

|

|

|

|

|

||||

• |

Tie Back Long Hair |

|

|

|

|||||

Follow instructions for lubricating and changing accessories. |

|

|

|

||||||

• |

Roll Long Sleeves Above Elbow |

|

|

|

|||||

Inspect tool cords periodically and if damaged, have repaired |

|

|

|

||||||

|

|

|

|

|

|

|

|||

by authorized service facility. Inspect extension cords period- |

a. |

If any part of your saw is missing, malfunctioning, has |

|||||||

ically and replace if damaged. Keep handles dry, clean and |

|||||||||

|

been damaged or broken . . . such as the motor switch, or |

||||||||

free from oil and grease. |

|

||||||||

|

other operating control, a safety device or the power |

||||||||

|

|

|

|||||||

Before connecting the tool to a power source (receptacle, out- |

|

cord...cease operating immediately until the particular part |

|||||||

|

is properly repaired or replaced. |

|

|

|

|||||

let, etc.), be sure voltage supplied is the same as that speci- |

|

|

|

|

|||||

|

|

|

|

|

|

|

|||

fied on the nameplate of the tool. A power source with a volt- |

b. Do not |

cut |

piece too small |

to hold |

by |

hand. |

|||

age greater than that specified for the tool can result in serious |

|||||||||

|

HINT: When making a very small cut out, always secure |

||||||||

injury to the user, as well as damage to the tool. If in doubt, DO |

the workpiece to a scrap piece of plywood with double- |

|

NOT PLUG IN THE TOOL. Using a power source with a volt- |

||

faced tape. This way, the work is supported and your fin- |

||

age less than the nameplate rating is harmful to the motor. |

||

gers are away from the blade. |

||

|

c. Never turn your Scroll Station on before clearing the table of all objects (tools, scraps of wood, etc.) except for the workpiece and related feed or support devices for the operation planned.

5

Additional Safety Rules

d. Avoid awkward hand positions where a sudden slip could |

i. Quick Release Tension Lever should be in down position |

|||||||||

|

cause a hand to move into the blade. |

|

|

before operating. |

|

|

|

|||

• |

ALWAYS adjust the drop foot to just clear the workpiece to |

THINK SAFETY |

|

|

|

|||||

|

protect the operator, keep blade breakage to a minimum |

SAFETY IS A COMBINATION OF OPERATOR COMMON |

||||||||

|

and provide maximum support for blade. |

SENSE AND ALERTNESS AT ALL TIMES WHEN THE Scroll |

||||||||

• Always adjust blade tension correctly. |

Station IS BEING USED. |

|

|

|

||||||

• |

The Scroll Station should cut on the down stroke. Always |

|

|

|

Do not allow familiarity (gained from frequent |

|||||

|

make sure blade teeth are oriented downward toward |

! |

WARNING |

|||||||

|

use of your Scroll Station) to become com- |

|||||||||

|

|

|

|

|

|

|

|

|

||

|

table. |

|

|

|

|

|

|

|

|

|

|

monplace. Always remember that a careless fraction of a |

|||||||||

• When cutting a large piece of material, make sure it is sup- |

||||||||||

second is sufficient to inflict severe injury. |

|

|

||||||||

|

ported at table height. |

|

|

|

|

|

|

|

|

|

• Hold the work firmly against the table. |

|

|

|

|

The operation of any power tool |

|||||

|

|

|

|

|||||||

|

|

|

|

can result in foreign objects being |

||||||

• Do not feed the material too fast while cutting. Only feed |

|

|

|

|

||||||

|

|

|

|

|||||||

|

|

|

|

thrown |

into the eyes, |

which can |

||||

|

the material fast enough so that the blade will cut. Keep |

|

|

|

|

|||||

|

|

|

|

|

result |

in severe eye |

damage. |

|||

|

fingers away from the blade. |

|

|

|

|

|||||

|

|

|

|

|

Always wear safety goggles that |

|||||

|

|

|

|

|

|

|||||

• Use caution when cutting off material which is irregular in |

|

|

|

|

comply |

with ANSI Z87.1 |

before |

|||

|

|

|

|

|||||||

|

cross section‚ it could pinch the blade before the cut is |

|

|

|

|

commencing power tool operation. |

||||

|

completed. A piece of molding, for example, must lay flat |

|

|

|

|

|

|

|

|

|

|

on the table and not be permitted to rock while being cut. |

|

|

|

Some dust created by power sanding, sawing, |

|||||

|

! |

WARNING |

||||||||

• Use caution when cutting off round material such as dowel |

grinding, drilling,and other construction activi- |

|||||||||

ties contains chemicals known to cause cancer, birth defects |

||||||||||

|

rods or tubing. They have a tendency to roll while being |

|||||||||

|

or other reproductive harm. Some examples of these chem- |

|||||||||

|

cut, causing the blade to “bite”. |

|||||||||

|

icals are: |

|

|

|

||||||

e. Never leave the Scroll Station running unattended. Turn |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||

|

the saw OFF, make sure the saw has come to a complete |

• Lead from lead-based paints, |

|

|

|

|||||

|

stop, and then remove plug from power supply before |

• |

Crystalline silica from bricks and cement |

and |

other |

|||||

|

leaving the work area. |

|||||||||

|

|

|

masonry products, and |

|

|

|

||||

|

|

|

|

|

|

|

||||

f. |

Do not perform layout, assembly or setup work on the |

• Arsenic and chromium from chemically treated lumber. |

||||||||

|

table while the cutting tool is operating. |

Your risk from these exposures varies, depending on how |

||||||||

g. Turn saw off and remove plug from power supply outlet |

often you do this type of work. To reduce your exposure to |

|

these chemicals: work in a well ventilated area, and work |

||

before installing or removing an accessory attachment. |

||

with approved safety equipment, such as those dust |

||

|

||

h. Access Door must be closed before operation. |

masks that are specially designed to filter out microscopic |

|

particles. |

||

|

NOTE AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS

THAT APPEAR ON THE PANEL ON SCROLL STATION HOUSING:

6

|

|

|

|

Specifications |

|

General Specifications |

|

|

Voltage Rating . . . . . . . . . . . . . . . |

. . . . . . . . . .120 V, 60 Hz |

|

Amperage Rating . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . .1.6 A |

|

No Load Speed . . . . . . . . . . . . . . . |

No 500-1,700/min (SPM) |

|

Throat . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . .18" |

|

Blade . . . . . . . . . . . . . . . . . . . . . . |

. . . .5” plain and pin-end |

|

Blade Stroke . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . .3/4" |

|

Cutting Capacity |

1fl" at 0°, 1" at 45° |

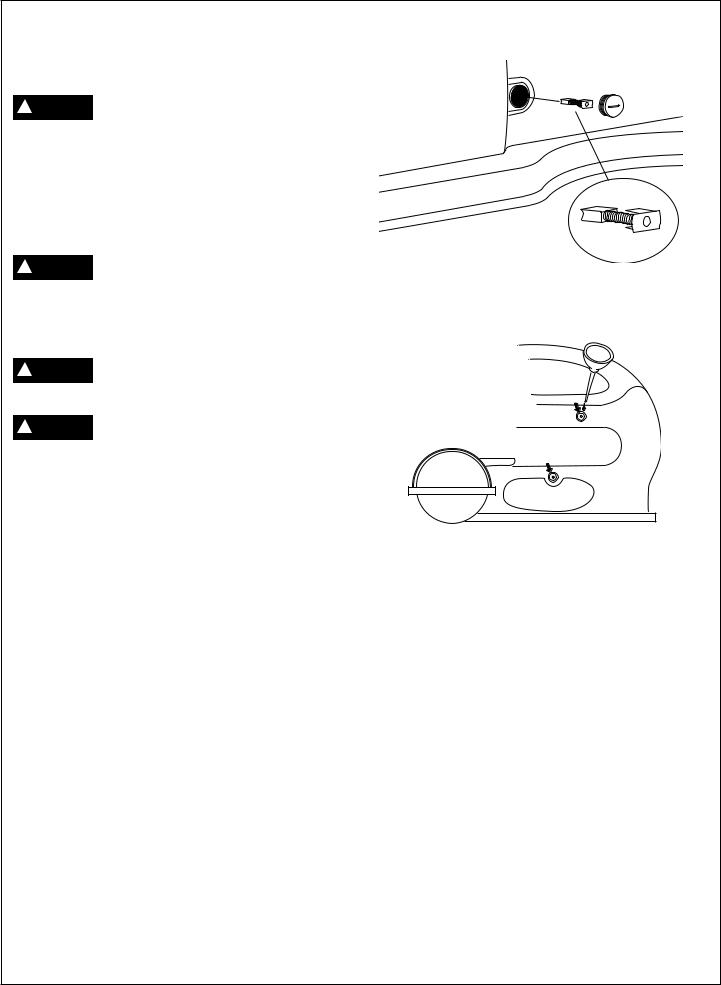

Figure 1. Grounded Wall Outlet |

|

||

Motor Specifications

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock.

This Scroll Station is designed to use a variable speed RPM motor. It is wired for operation on 110-120 volts, 60 Hz. alternating current. Before connecting the motor cord to wall outlet, make certain the power switch is in the OFF position and be sure the electric current is of the same characteristics as stamped on the Scroll Station nameplate.

Connection To A Power Source

This machine must be grounded while in use to protect the operator from electric shock.

Plug power cord into a 110-120V properly grounded type outlet protected by a 15-amp dual element time delay fuse or circuit breaker.

Not all outlets are properly grounded. If you are not sure that your outlet, as pictured on this page, is properly grounded; have it checked by a qualified electrician.

! DANGER To avoid electric shock, do not touch the metal prongs on the plug when installing or

removing the plug to or from the outlet.

! DANGER Failure to properly ground this power tool can cause electrocution or serious shock, particularly when used near metal plumbing or other metal objects.

If shocked, your reaction could cause your hands to hit the tool.

! DANGER |

If power cord is worn, cut or damaged in any |

way, have it replaced immediately to avoid |

shock or fire hazard.

Your unit is for use on 120 volts; it has a plug that looks like the one in Figure 1.

This power tool is equipped with a 3-conductor cord and this plug requires a mating 3-conductor grounded type outlet as shown. It must be grounded in accordance with all local codes and ordinances.

If the outlet you are planning to use for this power tool is of the two-prong type, DO NOT REMOVE OR ALTER THE GROUNDING PRONG IN ANY MANNER. Have a qualified electrician replace the TWO-prong outlet with a properly grounded THREE-prong outlet.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. If repair or replacement of the electric cord or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded.

Always use proper extension cord. The use of any extension cord will cause some loss of power. To keep this to a minimum and to prevent overheating and motor burn-out, use the table below to determine the minimum wire size (A.W.G.) extension cord. Use only 3-wire extension cords which have 3-prong grounding type plugs and 3-pole receptacles which accept the tool’s plug. Make sure your extension cord is in good condition. Extension Cord Length Wire Size A.W.G. 0-25 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 26-50 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 51-100 feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

SAVE THESE INSTRUCTIONS

7

Unpacking & Checking Contents

! WARNING To avoid injury from unexpected starting or electrical shock, always remove plug from

wall outlet when tool is not in use.

Model 1800 Scroll Station is shipped complete in one carton. Separate all “loose parts” from packing materials and check each item with the “Packing List” to make sure all items are accounted for before discarding any packing material.

! WARNING If any parts are missing, do not attempt to operate Scroll Station, plug in the power cord or turn the switch on until the missing parts are obtained and

are installed correctly.

Item |

Description Packing List |

Qty. |

|

A |

18” Scroll Station ...................................................... |

1 |

|

B |

Owner’s Manual ........................................................ |

1 |

|

C |

Parts Bag (containing) .............................................. |

1 |

|

D |

|

Side Table with Side Miter ...................................... |

1 |

E |

|

Flat Head Screws.................................................... |

2 |

F |

|

Wing Knobs ............................................................ |

2 |

G. |

|

Flip-up Guard .......................................................... |

1 |

|

|

Allen Wrench (2 mm, 2.5 mm & 4 mm) .................. |

1 |

|

|

Drive Screw for Flex Shaft Attachment .................. |

1 |

|

|

Adaptor for future additions .................................... |

1 |

|

|

Spacer .................................................................... |

2 |

|

|

O Ring .................................................................... |

2 |

|

|

Drive Nut ................................................................ |

1 |

Blades ............................................................................ |

12 |

||

To remove protective coating from the table surface, moisten a soft cloth with kerosene or WD-40 and wipe off coating. Do not use acetone, gasoline or lacquer thinner for this purpose. After removing protective coating, If you wish, you may apply a coat of paste wax to the table to allow the workpiece to slide easily across the table surface and deter rust. Wipe the table thoroughly with a clean dry cloth.

NOTE: Hardware to mount this Scroll Station to a bench or leg set is NOT supplied. See ASSEMBLY-MOUNTING THE SCROLL STATION, Page 8, for recommended hardware size.

IMPORTANT! If you require any assistance with these instructions, please contact the Dremel Service Department

at: 1-800-437-3635

Tools Needed

Phillips Screwdriver (not included)

Combination Square (not included)

A

G E

E

F

D

E

F

Figure 2. Packing List Parts

1

2

3

Combination Square Must be True

1. Use the straight edge of a 3/4" thick board (this edge must be perfectly straight).

2. Draw a line on the board along this edge.

3. There should be no gap or overlap when the square is flipped over in dotted position.

8

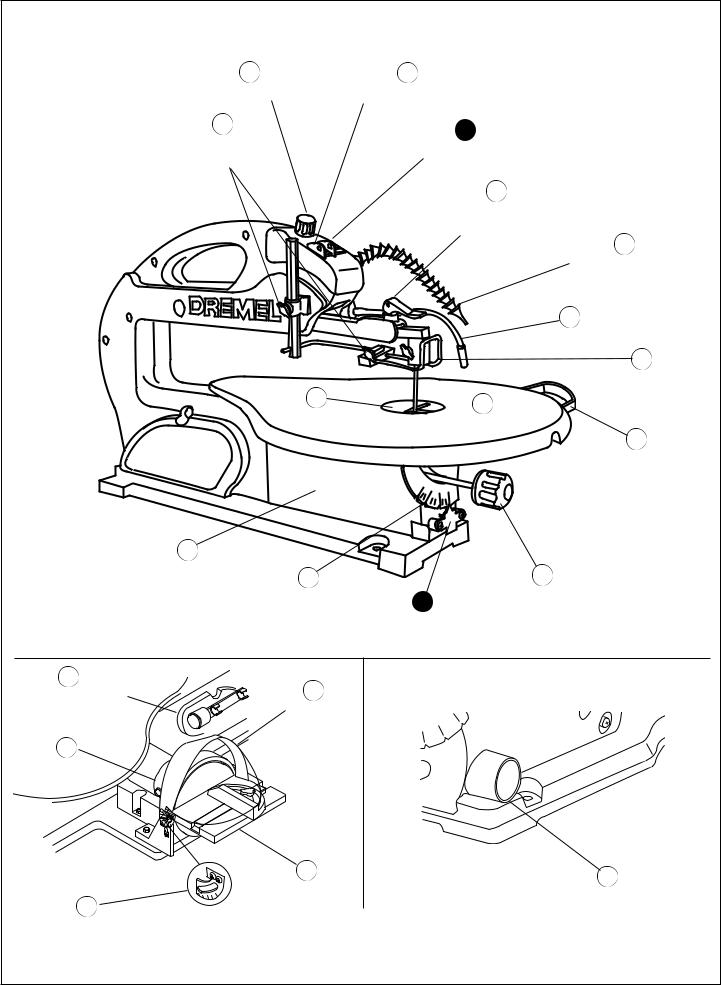

Getting to Know Your Scroll Station |

|||||||

|

|

8 |

|

|

9 |

|

|

|

|

Variable Speed Dial |

Power ON/OFF Switch |

|

|||

|

|

4 |

|

|

|

10 |

|

|

|

Drop Foot |

|

|

|

|

|

|

|

|

|

Light ON/OFF Switch |

|

||

|

|

Wing Knob (2) |

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

Quick Release |

|

|

|

|

|

|

|

Tension Lever |

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

Sawdust Blower |

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

Light |

|

|

|

|

|

|

|

Drop3Foot |

|

|

|

12 |

|

|

11 |

|

|

|

|

Table Insert |

|

|

||

|

|

|

|

Table |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

Blade Storage |

|

|

|

|

|

|

|

Drawer |

|

|

14 |

|

|

|

|

|

|

Easy Access Door |

15 |

|

|

6 |

|

|

|

|

|

|

|

|

||

|

|

Table Tilt Detents |

7 |

Table Lock Knob |

|||

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Degree Scale |

|

|

20 |

|

|

19 |

|

|

|

|

Flex Shaft Holder |

|

|

|

|

|

|

|

|

|

Flip-up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guard |

|

|

|

|

18 |

|

|

|

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

|

16 |

|

|

|

21 |

|

|

|

Side Table & |

|

|

||

|

|

|

|

|

Vacuum Hook-up |

||

17 |

|

|

Disc Sander |

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Side Table Scale |

|

|

|

|

|

|

|

|

|

|

Figure 3. Scroll Station Components |

|

|||

|

|

|

|

9 |

|

|

|

Getting to Know Your Scroll Station

This versatile Scroll Station is great for making toys, puzzles, games, fretwork, and jewelry. Because of its cutting capacity, it is a handy do-it-yourself tool. It cuts wood up to 1fl" thick as well as plastics and non-ferrous metals.

1. BLADE STORAGE DRAWER

Your Scroll Station is equipped with a blade storage area located under the right side of the saw table (when facing table). The blade storage area conveniently stores both Pinand Plain-end blades.

2. SAWDUST BLOWER

Keeps workpiece clean for better visibility. For best results, always direct air flow from blower tube at blade and workpiece. To adjust, simply bend to desired position.

3. DROP FOOT

The drop foot should always be lowered until it just rests on top of the workpiece to prevent workpiece from lifting, but not so much that the workpiece drags.

4. DROP FOOT WING KNOBS

Allows you to adjust the height and rotation of the drop foot and lock it into the desired position.

5. QUICK RELEASE TENSION LEVER

Allows you to quickly loosen, or tighten the blade to its proper tension with lever action.

6. TABLE LOCK KNOB

Allows you to tilt the table and lock it at desired angle up to 45° to the left or 5° to the right.

7. DEGREE SCALE

Shows the degree the table is tilted.

8. VARIABLE SPEED DIAL

Your Scroll Station is equipped with a variable speed dial for greater versatility.

9. POWER ON/OFF SWITCH

Has holes provided by the switch for a lock (not included). THIS FEATURE IS INTENDED TO PREVENT UNAUTHOURIZED AND POSSIBLY HAZARDOUS USE BY CHILDREN AND OTHERS. To turn saw on, push power switch to the ON (I) position; to turn saw off, push power switch to the OFF (O) position.

10. LIGHT SWITCH

To turn light on, push light switch to the ON (I) position; to turn light off, push light switch to the OFF (O) position.

11. TABLE

Provide working surface to support workpiece.

12. TABLE INSERT

Insert may be removed for ease of changing blades. Insert should always be in place and flush with table during cutting operation.

13. LIGHT

Illuminates the workpiece.

14. EASY ACCESS DOOR

Allows easy access to lower blade holder when changing blades.

15. TABLE TILT DETENTS

Automatically stops the table to the left at 0°, 15°, 30°, and 45° increments, and to the right up to 5°.

16. SIDE TABLE & DISC SANDER

Allows multiple positIons for sanding work piece.

17. SIDE TABLE TILT SCALE

Displays adjustments at 0°, 15°, 30°, and 45° increments.

18. MOTOR

Provides power to the disc sander and optional flex shaft tool.

19. FLIP-UP GUARD

Protects disc sander when saw is in operation.

20. FLEX SHAFT HOLDER

Protects flex shaft (if attached) when saw is in operation. Flex shaft should be disconnected before sawing is performed.

21. VACUUM HOOK-UP

Your Scroll Station is equipped with a vacuum hook-up. This feature will allow you to attach any 1-1/4" vacuum hose into the hole provided for convenient sawdust removal.

KERF The slot cut by the blade.

LEADING EDGE

The edge of the workpiece which is pushed into the blade first.

SAWBLADE PATH

The area of the workpiece directly in line with and moving toward the sawblade edge.

BLADE TOOTH SET

The distance that the edge of the sawblade tooth is bent (onset) outward from the side of the blade.

TRAILING EDGE

The workpiece edge last cut by the sawblade.

WORKPIECE

The item on which the cutting operation is being performed.

10

Assembly

Installing the Disc Table & Guard

Refer to Figure 4.

Assemble the side table and guard, using two wing knobs, large spacers, flat head screws, and o-rings. Put spacers on wing knobs, then insert through sliding scales on sides of table and screw into bottom holes in base. Next, insert flat head screws through clear plastic guard, then though o-rings and tighten into top holes on table and base. Adjust table to desired angle and tighten wing knobs.

Installing the Flex Shaft

(Optional Accessory - Model 225)

The optional flex shaft is used mainly for drilling pilot holes when making interior scroll cuts (see OPERATION) or for sanding. Also refer to the manual supplied with the Flex Shaft.

Refer to Figure 5.

1.Remove the two Phillips head mounting screws and wing knobs securing the side table to the guard.

2.Remove the Phillips head screw securing the disc to the motor and remove the disc.

3.Insert the drive screw (supplied with the Scroll Station) into the end of the motor shaft and tighten securely.

4.Insert square cable through the square hole in the drive screw and fully into the motor shaft.

5.Secure the flex shaft to the motor shaft and tighten securely.

6.Flex shaft should be disconnected from the motor shaft before sawing is performed.

Flex shaft must be stored in holder when attached and not in use.

Do not engage shaft lock on handpiece while motor is running.

Figure 4. Installing the Side Table

Flex Shaft Holder

Drive Nut

Figure 5. Installing the Flex Shaft

(optional accessory)

11

Assembly

Mounting the Scroll Station

to a Bench

The Scroll Station should be fastened securely to a firm supporting surface such as a stand or workbench, using the three mounting holes.

NOTE: When mounting this saw to a workbench, a solid bench is preferable to a plywood bench where noise and vibration will be more noticeable.

We recommend to reduce noise and vibration, that a soft foam pad be placed between your Scroll Station and workbench (not included).

Quantity Description

1 Soft foam pad, such as carpet padding, 24”x12”x1/2”

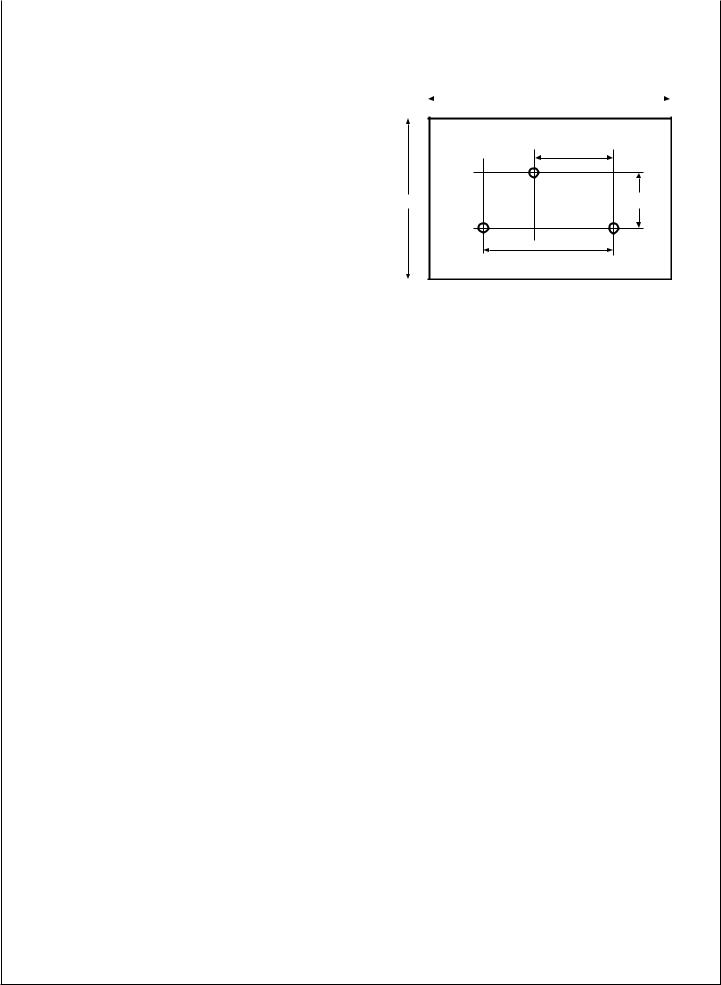

When mounting the Scroll Station to a workbench, holes should be drilled through the foam pad or carpet and mounting surface of the workbench using the dimensions illustrated in Figure 6.

Each of the three mounting holes should be bolted securely using no less than 1/4" hex bolts, flat washers, lockwashers, and nuts (not included). We recommend:

Quantity Description

4 Hex Head Bolts,

1/4"-20 x 1/4"-20 x Length Required 4 Flat Washers, 9/32" I.D.

4 Lockwasher, 9/32" I.D.

8 Hex Nuts, 1/4"-20

(Hardware not included)

Refer to Figures 6 and 7.

1.Locate and mark where the Scroll Station is to be mounted.

2.Drill the three (3) 5/16" holes through the workbench.

3.Place the Scroll Station on the workbench aligning holes in the base with the holes drilled in the workbench. Insert all three (3) bolts and secure using washers, lockwashers and nuts.

NOTE: Do NOT overtighten mounting bolts. If using recommended foam pad, leave some cushion in the foam pad for absorbing noise and vibration.

11-7/8"

7-7/8"

19-13/16""

Figure 6. Bench Mounting Template

Figure 7. Table Mounting Hardware (not included)

12

|

|

|

|

|

Assembly |

|

|

|

|

Mounting the Scroll Station |

|

|

|

|

to Plywood |

|

24" |

|

|

|

|

|

||

An alternative method of securing your Scroll Station is to |

|

|

fasten the Scroll Station base to a mounting board 18" x 24". |

|

11-7/8" |

Any good grade of plywood with a 3/4" minimum thickness is |

|

|

|

|

|

recommended. Follow the instructions for MOUNTING THE |

|

|

SCROLL STATION TO A BENCH, substituting the 18" x 24" |

15" |

7-7/8" |

board for the workbench and using 1/4"-20 flat head screws |

||

for the hex head bolts (Figure 7). Screws must be mounted |

|

|

from underneath the plywood with washers and nuts on top. |

|

|

NOTE: For proper stability, holes must be countersunk so |

|

19-13/16" |

|

|

|

screw heads are flush with the bottom surface of the sup- |

|

|

porting board. |

|

|

Securely clamp board to workbench using two or more “C” |

|

Figure 8. Plywood Mounting Template |

|

|

|

clamps. |

|

|

13

Operation

|

|

Basic Scroll Station Operations |

• To cut thicker wood, use wider blades with fewer teeth per inch. |

||||

|

|

• Most blade packages state the size or thickness of wood |

|||||

Follow these instructions for operating your Scroll Station to |

|||||||

|

which that blade is intended to cut, and the radius (size of |

||||||

get the best results and to minimize the likelihood of person- |

|

curve) which can be cut with that blade. |

|||||

al injury. |

• Wider blades can’t cut curves as tight or small as thinner |

||||||

|

|

|

|

||||

|

|

|

Always observe the safety precautions here |

|

blades. |

||

|

! |

WARNING |

|

||||

|

|

|

|

||||

|

|

|

and on pages 2 - 6. |

• This saw uses 5" long, Pinor Plain-End type blades only |

|||

|

|

|

|||||

Protection: Eyes, Hands, Face, Ears and Body |

|

(See RECOMMENDED ACCESSORIES on page 21). |

|||||

• |

Blades wear faster when (1) cutting plywood, which is very |

||||||

|

|

|

To avoid being pulled into the saw blade – |

||||

|

! |

WARNING |

|

abrasive, (2) when sawing wood which is thicker than the |

|||

|

|

|

|

|

3/4" blade stroke, (3) when sawing hardwood or (4) when |

||

|

|

|

|

|

|||

DO NOT WEAR: |

|

side pressure is placed on the blade. |

|||||

|

|

Blades |

|||||

• Loose Fitting Gloves |

|

|

|||||

• |

Necktie |

|

|

||||

|

|

|

|||||

• Loose Clothing |

Your new Scroll Station accepts 5" Pin-End blades or 5" |

||||||

• Jewelry |

Plain-End blades (See RECOMMENDED ACCESSORIES on |

||||||

DO: |

page 21). |

||||||

|

|

|

|||||

• |

Tie Back Long Hair |

The blades can be used in either 0° (forward facing) or 90° (to |

|||||

• |

Roll Long Sleeves Above Elbows |

||||||

• The saw does not cut wood by itself. You allow the saw to |

the left) position. |

||||||

|

|

|

|||||

|

|

cut wood by guiding the wood into the blade as it moves. |

1. |

Remove hex bolt from upper and lower blade holders. |

|||

• The blade teeth cut ONLY on the down stroke. |

2. Remove blade holders and rotate 90° so the blade slot |

||||||

• The drop foot should always be lowered until it just rests |

|||||||

|

faces the left side of the saw. |

||||||

|

|

on top of the workpiece. |

|

||||

|

|

|

|

|

|||

• You must feed the wood into the blade slowly because the |

3. |

Re-install hex bolts and tighten securely. |

|||||

|

|

teeth of the blade are very small and they can only remove |

|

|

|

||

|

|

wood when they are on the down stroke. The blade will flex |

|

|

To prevent personal injury always disconnect |

||

|

|

! |

WARNING |

||||

|

|

backwards when applying feed pressure. Too much feed |

the plug from power source before changing |

||||

|

|

pressure will cause blade breakage. Let the blade do the |

blades or making adjustments. |

||||

|

|

work. |

|

Removing and Installing |

|||

• |

|

There is a learning curve for each person who wants to |

|

||||

|

|

use this saw. During that period of time it is expected that |

|

|

Pin-End Blades |

||

|

|

some blades will break until you learn how to use the saw |

|

|

|||

|

|

and receive the greatest benefit from the blades. |

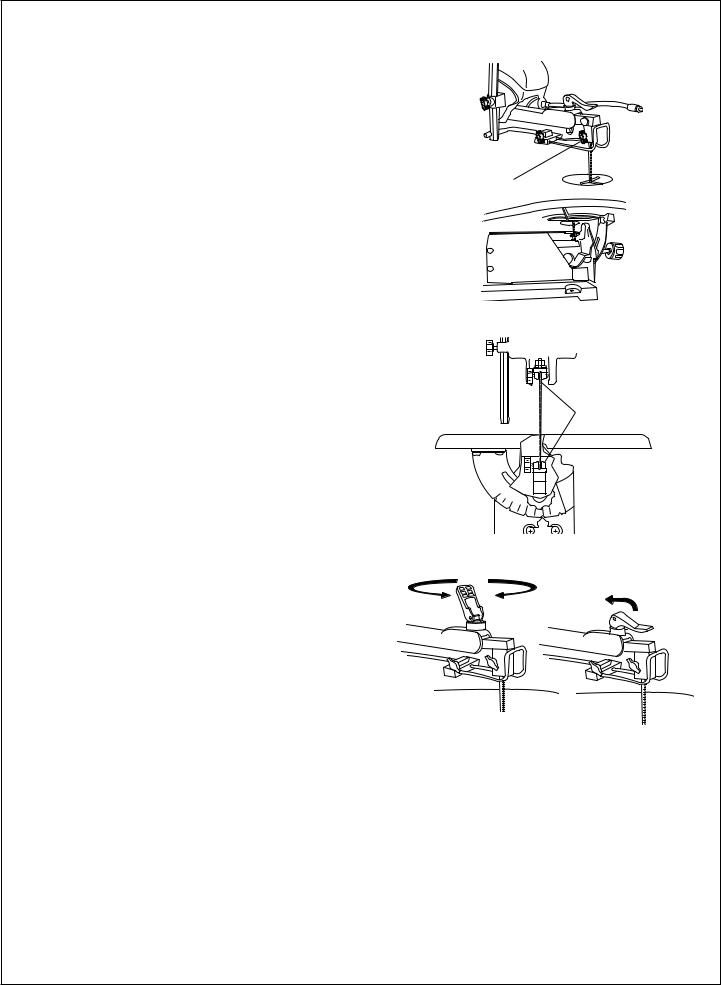

1. |

Release blade tension by lifting up the Quick Release |

|||

|

|

|

|

||||

• |

|

Best results are achieved when cutting wood less than |

|

Tension Lever and turning counterclockwise (Figure 11). |

|||

|

|

1" thick. |

|

|

|

||

• When cutting wood thicker than 1", the user must feed the |

2. Open easy access door and loosen the blade clamping |

||||||

|

knobs on the upper and lower blade holders. Remove |

||||||

|

|

wood very slowly into the blade, increase blade tension |

|

||||

|

|

|

blade from the upper and lower blade holders by pulling |

||||

|

|

and take extra care not to bend or twist the blade while cut- |

|

||||

|

|

|

forward on blade and then lifting the blade through the |

||||

|

|

ting in order to maximize blade life. |

|

||||

|

|

|

access hole in the table. Slight downward pressure |

||||

|

|

|

|

|

|||

• |

|

Teeth on Scroll Station blades wear out and blades must |

|

against the upper holder may be helpful when removing |

|||

|

|

be replaced frequently for best cutting results. Scroll |

|

blade from upper holder. |

|||

|

|

Station blades generally stay sharp for 1/2 hour to 2 hours |

|

|

|

||

|

|

of cutting. |

NOTE: Table insert may be removed for better access. Table |

||||

• To get accurate cuts, be prepared to compensate for the |

insert must be replaced before operating the saw. |

||||||

|

|

|

|||||

|

|

blade’s tendency to follow the wood grain as you are cut- |

3. |

Look at the blade holders closely and notice the blade |

|||

|

|

ting. |

|||||

|

|

|

slots and pin recesses in the blade holders. |

||||

|

|

|

|

|

|||

When choosing a blade to use with your Scroll Station |

|

|

|

||||

consider the following carefully: |

NOTE: In order to cut, and avoid uncontrollable lifting of the |

||||||

• Choose a blade that allows at least three (3) teeth to be in |

workpiece, the teeth of the blade used on the Scroll Station |

||||||

contact with the workpiece at all times. |

should always point downward as shown in (Figure 11) when |

|

installed. |

||

• Very fine, narrow blades should be used to scroll cut in thin |

||

|

||

wood (1/4" thick or less). |

|

14

Operation

4. Install the blade by inserting one end of the blade through the access hole in the table and hook the blade pin in the pin recess in the lower blade holder. Slide the top blade pin into the pin recess of the upper blade holder. You may need to press down lightly on the upper blade holder to install the blade.

5. Check to see that the pins are properly located in the blade holders.

6. To properly secure the blade securely tighten the wing knob on the upper and lower holders.

7. Tension blade (see BLADE TENSION below).

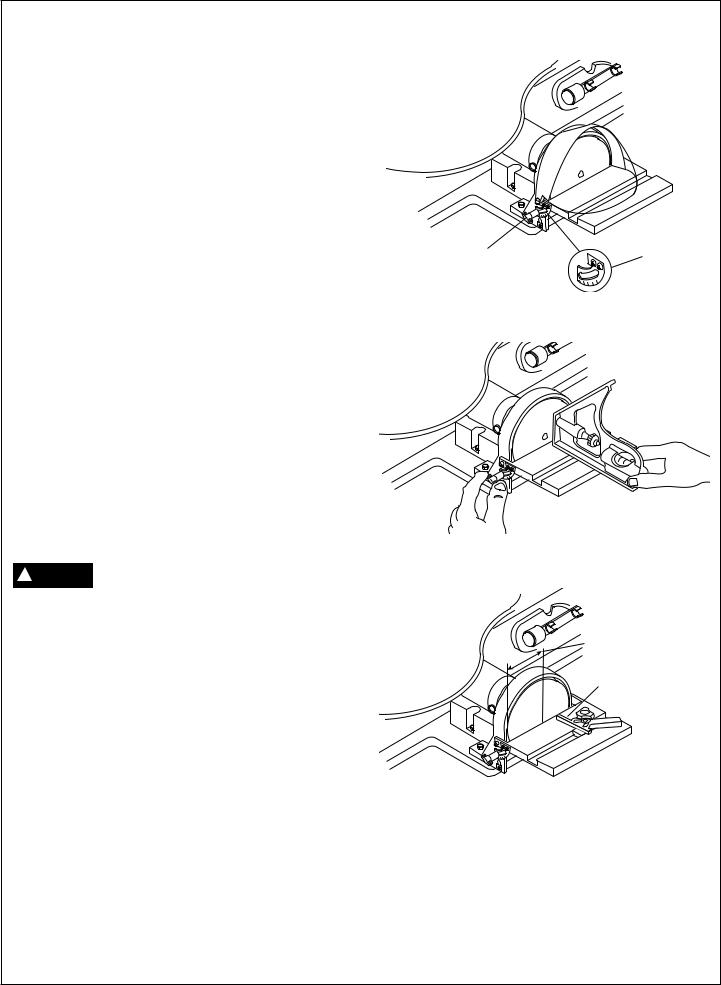

Removing and Installing

Plain-End Blades

1.Release blade tension by lifting up the Quick Release Tension Lever (Figure 11) and turn counterclockwise.

2.Open easy access door and loosen the blade wing knob on the upper and lower blade holders (Figure 9). Remove blade from the upper and lower blade holders by pulling forward on blade and then lifting the blade through the access hole in the table. Slight downward pressure may be necessary on the upper arm.

NOTE: Table insert may be removed for better access. Table insert must be replaced before operating the saw.

3.Install the blade by inserting one end of the blade through the access hole in the table and centering the blade in the blade slot in the upper and lower blade holders (Figure 10).

4.To properly secure the blade securely tighten the wing knob on the upper and lower holders.

5.Tension blade (see BLADE TENSION below).

NOTE: In order to cut, and avoid uncontrollable lifting of the workpiece, the teeth of the blade used on the Scroll Station should always point downward as shown in (Figure 9) when installed.

To tension blade, move Quick Release Tension Lever to “down” position. As the lever is lowered, tension will be applied to the blade (Figure 11).

ATTENTION: Moving the lever downward should require moderate, steady pressure only. If heavy pressure is needed, the blade is too tight. Loosen tension by rotating the Quick Release Tension Lever counterclockwise 1-2 turns, then reset the tension lever to the “down” position. If the tension lever is in the “down” position and the blade is too loose, you can increase tension by leaving the tension lever “down” and rotating it clockwise just until you feel the slack in the blade

Wing

Knobs

Figure 9. Changing Blades

Blades Properly Seated

in Holders

Figure 10. Installing Blades

Figure 11. Quick Release Tension Lever removed. Then turn the tension lever ONE full turn clockwise. This amount of blade pressure should do well for most cutting operations and blades.

When the blade tension has been properly adjusted, you should be able to lift up the Quick Release Tension Lever, remove and install the blade, lower the lever and return the original blade tension. The life of the tension lever will be extended if you back the tension off one-half turn before lifting the lever.

NOTE: It may be necessary to re-adjust the tension lever 15 when using different types of blades.

|

|

Operation |

|

|||

|

Making Interior Scroll Cuts |

|

|

|

|

|

|

(Pin-End Blades & Plain-End Blades) |

|

|

|

|

|

! |

WARNING TO AVOID ACCIDENTAL STARTING, |

|

|

|

||

|

ALWAYS TURN SWITCH TO OFF (O) AND |

|

|

|

||

REMOVE PLUG FROM POWER SOURCE BEFORE |

|

|

|

|||

REMOVING OR REPLACING THE BLADE. |

|

|

|

|

||

A main benefit of this saw is the ability to perform intricate |

|

|

|

|||

interior cuts quickly and easily. This is best accomplished |

|

|

|

|||

using the Quick Release Tension Lever. Simply follow these |

|

|

|

|||

steps (Figure 12): |

|

|

|

|

|

|

1. Drill appropriate sized pilot hole in work piece. |

|

|

|

|

||

2. Release Quick Release Tension Lever. |

|

|

Figure 12. Making Interior Scroll Cuts |

|||

|

|

|

|

|

||

3. Remove the blade from the upper blade holder |

as |

|

|

|

||

|

explained on page |

14 or 15, REMOVING AND |

|

|

|

|

|

INSTALLING BLADES. |

|

|

|

|

|

4. Thread blade through pilot hole from underneath |

the |

|

|

Drop Foot |

||

|

|

Table |

||||

|

workpiece. If needed, remove the table insert. This will |

|

|

|||

|

allow the blade to angle forward for more clearance |

|

Drop Foot |

|

||

|

between the workpiece and the upper arm housing. |

|

Wing Knob |

|

||

|

Reinstall the blade in the upper blade holder. Replace |

|

(Height |

|

||

|

|

Adjustment) |

|

|||

|

table insert. |

|

|

|

|

|

|

|

|

|

|

|

|

5. |

Re-tension blade by pulling tension lever down. |

|

|

Drop Foot |

|

|

|

|

|

|

|

Wing Knob |

|

6. |

Lower drop foot until it just rests on top of the workpiece |

|

(Angle |

|

||

|

and you’re ready to begin cutting. |

|

|

Adjustment) |

|

|

|

|

|

|

|

||

7. When finished making the interior scroll cuts simply remove |

|

|

|

|||

|

the blade from the upper blade holder, as described on page |

|

|

|

||

|

14 & 15, REMOVING AND INSTALLING BLADES, then |

|

|

|

||

|

remove the board from the table. |

|

|

Degree Scale |

|

|

|

Adjusting the Table for |

|

|

|

||

|

|

Table Lock Knob |

|

|||

|

|

|

|

|

||

|

Horizontal or Bevel Cutting |

|

|

Figure 13. Adjusting Table for Horizontal |

||

1. |

Loosen the table lock knob, and the saw table can be tilt- |

|

||||

|

|

or Bevel Cutting |

||||

|

ed to the left and locked at any angle from 0° horizontal |

|

|

|||

|

|

|

|

|||

|

cutting position up to 45° for bevel cutting (Figure 15). |

4. |

When cutting with the table angled, adjust drop foot so |

|||

|

Your tool also features table tilt detents which audibly |

|||||

|

|

it’s parallel to the table. To adjust, loosen the wing knob, |

||||

|

click into place to the left every 15°. The table may be |

|

||||

|

|

turn drop foot to correct angle, tighten wing knob (Figure |

||||

|

tilted to the right up to 5°. |

|

|

|||

|

|

|

13). |

|

||

|

|

|

|

|

|

|

2. |

A degree scale is provided under the work table as a |

Always make sure the blade does not contact either side of |

||||

|

convenient reference for setting the approximate table |

|||||

angle for bevel cutting. When greater precision is |

the drop foot, table opening or insert. |

|

|

||

required, make practice cuts and adjust the table as nec- |

NOTE: When cutting at extreme angles, the drop foot should |

|

essary for your requirements. |

||

be lifted off the workpiece, as it will impede cutting. Hold the |

||

|

||

3. Loosen the drop foot wing knob and lower by hand until |

workpiece against the table. |

|

|

||

it just rests above the workpiece surface, then securely |

|

|

tighten the drop foot wing knob. The drop foot should |

|

|

always rest just above the workpiece to help prevent the |

|

|

workpiece from lifting off the table. |

|

16

|

Operating Adjustments |

|

||

|

Aligning the |

|

|

Drop Foot Wing Knob |

|

Degree Scale Pointer |

|

|

|

|

|

|

|

|

|

|

|

|

(Height Adjustment) |

The table is factory set to 0º. If further adjustments are nec- |

|

|

|

|

essary, please follow the instructions below: |

|

|

|

|

1. Loosen the table lock knob and move the table until it is |

Drop Foot |

|

Square |

|

|

|

|||

Wing Knob |

|

|

||

|

90° to the blade. |

Blade |

|

|

|

(Angle |

|

||

2. Remove the blade, remove the drop foot assembly, then |

Adjustment) |

|

|

|

|

reinstall the blade (see REMOVING AND INSTALLING |

|

|

|

|

BLADES, page 14 or 15). Place a small square on the |

|

|

|

|

table next to the blade as shown in (Figure 14) to check |

|

|

|

|

if the table is 90º to the blade. If no adjustment is |

Degree Scale |

|

|

|

required, re-install the drop foot assembly. |

Pointer |

|

|

|

If adjustment is necessary. Loosen, but don’t remove the |

|

||

|

|

|

|

|

|

two screws holding the pointer. With the steel ball cen- |

Pointer |

|

Steel Ball |

|

tered in the 0º detent, slide the pointer left or right until |

Adjustment Screw |

||

|

|

|||

|

the blade is parallel to the square. |

|

|

|

3. Tighten the table lock knob, both screws, and reinstall |

Figure 14. Aligning the Degree Scale Pointer |

|||

|

the drop foot. Remember, the degree scale is a conve- |

|||

|

|

|

|

|

|

nient guide but should not be relied upon for precision. |

|

|

|

|

Make practice cuts in scrap wood to determine if your |

|

|

|

|

angle setting is correct. |

|

|

|

|

Removing and Installing |

|

|

|

|

Abrasive Discs |

|

|

|

The disc furnished with the sander is self-adhesive type. |

|

|

|

|

Refer to Figure 15. |

|

|

|

|

1. Remove the the disc table adjustment wing knobs and |

|

|

|

|

|

Phillips hd. screws, then remove the disc table. |

|

|

|

2. To remove the abrasive disc, work the edge of disc back |

|

|

|

|

|

then peel it away from the backing plate. |

|

|

|

3. |

Rotate the disc and continue peeling until it is removed. |

|

|

|

4. Remove the protective backing from the new disc. |

|

|

|

|

|

Carefully center disc on backing plate and apply pres- |

Figure 15. Removing and Installing Abrasive Discs |

||

|

sure to disc. |

|||

|

|

|

|

|

5. |

Install disc table using Phillips hd. screws and lock |

|

|

|

|

knobs. |

|

|

|

|

Power ON/OFF Switch |

|

|

Power ON/OFF Switch |

|

Variable Speed Control |

|

||

|

|

|

||

|

|

|

|

Light ON/OFF Switch |

Turn the power on or off using the Power ON (I) / OFF (O) switch |

|

|

Blower |

|

(Figure 16). |

|

|

||

|

|

|

||

Your saw features an overload switch that protects the motor |

|

|

Light |

|

from overheating and damage. If the switch is tripped, the motor |

|

|

||

|

|

|

||

will automatically stop. When this occurs, turn the ON/OFF |

|

|

|

|

switch to the OFF (O) position. The tool will automatically reset. |

|

|

|

|

Turn the power switch to the ON (I) position. |

|

|

|

|

|

Adjusting the Lamp |

Figure 16. Adjusting the Lamp or Blower |

||

|

|

|||

Turn the lamp switch to ON (I). Position the lamp as needed to |

|

|

|

|

illuminate the workpiece (Figure 16). |

|

|

|

|

17

Operating Adjustments |

|

|

Adjusting the Blower |

|

|

Position the blower as needed to blow-off sawdust from the |

|

|

workpiece (Figure 16). |

|

|

Variable Speed Control |

|

|

Turn the control to vary the speed of the saw, disc sander and |

|

|

other optional attachments (Figure 16). |

|

|

Adjusting Side Table |

|

|

1. Loosen the side table lock knobs and move the side |

Wing Knob |

Scale |

table to the desired angle. A scale is located under the |

||

left side lock knob (Figure 17). |

(1 each side) |

|

|

2. Tighten the wing knobs. |

Figure 17. Adjusting the Side Table Angle |

|

|

Squaring Side Table |

|

For most projects, the table should be square with the sanding disc. Check using a combination square (Figure 18).