Drager Medical Air Compressor Operation manual

Drager

“MEDICAL AIR COMPRESSOR

OPERATION AND SERVICE MANUAL

SPECIFICATIONS:

Minimum Continuous Output: 60 Ipm © 37 psi

Outlet |

Pressure: |

37-49 |

psi |

|

|

|

|||

Dew |

Point Depression: |

3° |

C |

below |

room ambient |

||||

Power |

Requirement: |

115V, |

60Hz, 10 |

Amps |

|||||

Current |

Leakage: |

|

|

normal |

polarity open ground |

||||

|

|

|

|

|

|

less |

than 85 |

microamps |

|

Circuit |

Breaker: |

15 |

Amps |

|

|

|

|||

Weight: |

126 |

Ibs. |

|

|

|

|

|

|

|

Noise |

Level: |

52 |

dBa |

+ |

2 dBa |

|

|

||

Compressor |

Safety |

Valve: |

85 |

psig t |

5 psig |

||||

*PRECAUTIONS

Before |

operating |

or |

servicing |

the |

air |

compressor, |

read |

and |

understand |

all |

the accompanying |

manuals. |

Be |

familiar |

|||

with |

all |

the precautions, notes |

and |

warnings. Drager is |

not |

responsible |

for |

damages |

caused |

by |

misuse. |

Do |

not |

||||

use |

the |

compressor |

if repair is needed. Replace broken |

or |

worn parts |

immediately. |

Follow |

the |

instructions |

in this |

|||||||

service |

manual to |

perform scheduled |

maintenance |

and |

repairs. |

|

|

|

|

|

|

|

|||||

WARNING: |

To avoid shock hazard, refer all servicing to qualified |

|

|

|

||||||||||||||

- |

personnel. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

WARNING: |

Do |

not use the compressor in the |

presence |

of flammable |

|

|

||||||||||||

- |

anesthetics. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

WARNING: |

The |

compressor |

is |

grounded. |

DO |

NOT |

plug |

it into an |

ungrounded |

|

||||||||

|

outlet |

or |

an adaptor. |

|

|

|

|

|

|

|

|

|

|

|

|

|||

WARNING: |

Never |

put oxygen |

|

into the |

compressor. |

The |

electrical |

components |

|

|||||||||

- |

are |

not |

approved |

for oxygen |

use. |

|

|

|

|

|

|

|

|

|

||||

CAUTION: |

It is |

recommended |

that |

you |

install |

a |

transparent |

water |

trap |

at |

|

|||||||

|

the |

inlet |

of all blenders, |

respirators, |

etc. |

to |

|

protect them from |

|

|||||||||

|

moisture in case the drying system |

|

of the |

compressed |

air |

source |

|

|||||||||||

|

(portable |

or piped) |

fails. |

The |

water |

|

trap |

should |

be checked |

and |

|

|||||||

| |

emptied |

daily. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

CAUTION: |

The |

compressor |

is |

of the oil-less type and |

MUST |

NOT |

be |

|

|

|||||||||

|

lubricated. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0-18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ОКАСЕК |

ОЛ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

JUNE |

199! |

| TABLE OF CONTENTS

ROUTINE MAINTENANCE

WEEKLY QUARTERLY YEARLY

BETWEEN 8000-9000 HOURS TROUBLE SHOOTING

A. PRESSURE GAUGE NEEDLE STICKS OR VIBRATES

B.OVERHEATING

C.NOISE/EXCESSIVE VIBRATION

D.WATER PROBLEMS

E.HIGH PRESSURE

F.LOW PRESSURE

|

If |

the |

compressor |

is |

not running |

- |

If |

the |

compressor |

is |

running |

SERVICE

A. TO CHECK FOR A FAULTY SOLENOID

B. ADJUSTING THE PRESSURE SWITCH

EXTERNAL AIR RESERVOIR KIT

A.AIR OUTLET MODIFICATIONS

B. INSTALLING OPTIONAL EXTERNAL AIR RESERVOIR KIT

REPLACEMENT PARTS LIST

WIRING SCHEMATIC

PNEUMATIC SCHEMATIC

ROUTINE MAINTENANCE

O © © © © © 00 “Y Y Y“ Y“ OO Mn NN

Note: After performing any maintenance procedure, verify the performance of the unit to the specifications on page 1, use an RT-200 or equivalent measuring device.

WEEKLY

Remove the |

foam inlet filter |

on |

the front |

of the compressor. Wash it in warm soapy water, rinse well, allow to dry |

and reinstall. |

Replacement |

part |

#13989. |

|

QUARTERLY

Wash/replace the air pump intake filter elements:

|

“FILTER, |

COMPLETE INTAKE |

1. |

_Unthread the 8 screws from the rear door and remove |

968-402 |

|

door. |

|

2.Locate the muffler in the left side of the compartment.

Unscrew intake filter assy. from the muffler.

3.Snap the cap off of the intake filter and pull the filter

|

elements out. Wash them in warm soapy |

water. |

Rinse |

|

|

||||||

|

well, allow to dry and |

reinstall. |

While |

the |

cap is |

off, wipe it |

|

|

|||

|

and the inside |

of the |

filter |

with |

a |

clean |

dry |

cloth. |

|

“ |

FILTER, FELT |

4. |

Reassemble by |

reversing |

steps |

1 |

through |

3. |

|

||||

|

|

901-425 |

|||||||||

|

|

|

|

|

|

|

|

|

|

— FILTER, |

FOAM |

|

|

|

|

|

|

|

|

|

FIGURE i |

901-426 |

|

|

|

|

|

|

|

|

|

|

|

|

|

YEARLY

A |

Preventive Maintenance Kit should |

be installed, part #14003. |

It |

includes: |

|. |

Inlet Filters |

|

(6) |

#13989 |

|

.. |

Water |

Jar |

Filter |

#924-401 |

|

3. |

Water Jar O-ring |

#13530 |

|||

4. |

Regulator |

Diaphragm |

#923-402 |

||

5. |

Relief |

Valve |

Diaphragm |

#923-401 |

|

6. |

Intake |

Filter |

Element |

#901-425 |

|

7. |

Intake |

Filter |

Element |

#901-426 |

|

A. To install the intake filter element see 'QUARTERLY' page 2.

B.To install the water trap jar o-ring and water trap filter:

‘Remove the inlet filter from the front of the unit.

=No

FIGURE 2

2. |

‘Loosen |

the 2 |

screws |

that |

hold |

the |

inlet |

grille |

in place and remove |

|

grille. |

|

|

|

|

|

|

|

|

3 |

Pull the |

tubing |

off of |

the |

bottom |

of |

the |

water |

jar. |

À,

4. 'Unthread the bowl and remove.

5 ‘Unthread the retainer cap and remove the filter.

6 Install the new filter and reinstall the retainer cap.

7Carefully position the new O-ring on top of the water jar and rethread. !t is important to make this seal tight.

L = mues que)

© “To install the relief valve and regulator diaphragms:

1 |

‘Unthread |

the |

8 |

screws |

from the |

rear |

door and |

remove |

the |

door. |

2. |

Relief valve |

has |

a white |

locking |

ring, |

regulator |

has a |

red |

locking |

|

| |

ring. |

|

|

|

|

|

|

|

|

|

3. |

Unthread and remove the bonnet portion of the relief valve. |

|||||||||

4. |

Remove the worm diaphragm, install the replacement and |

|

||||||||

. |

reassemble |

relief valve. |

|

|

|

|

|

|

||

5. |

Unthread |

the |

bonnet from the regulator. |

|

|

|

||||

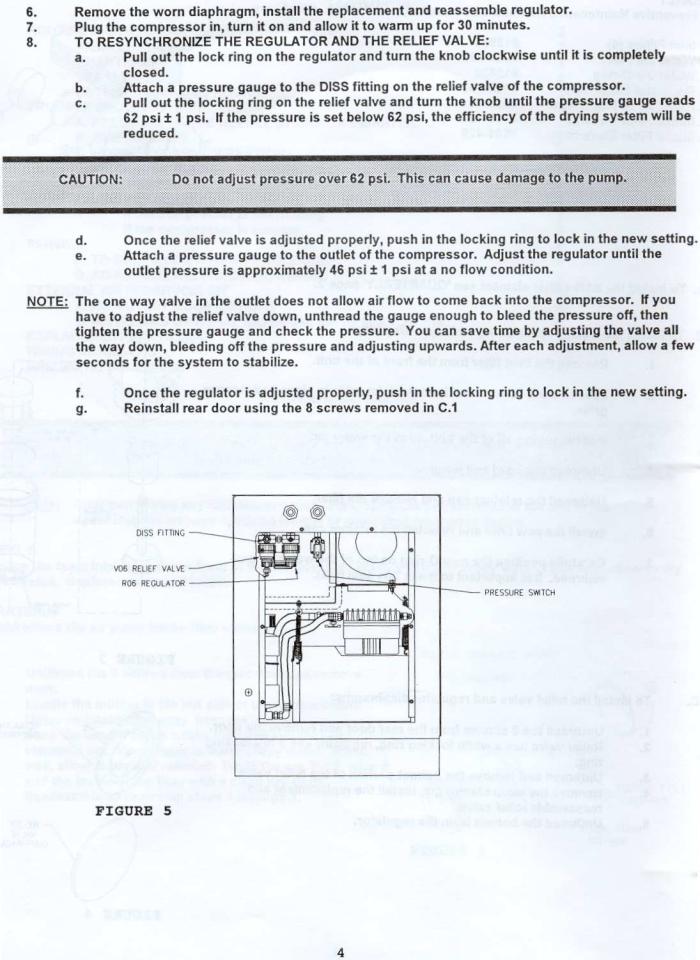

FIGURE 3

REGULATOR O A Y DIAPHRAGM

- |

RELIEF |

|

VALVE |

/ |

DIAPHRAGM |

|

FIGURE 4

Loading...

Loading...