Drager TI-500 User manual

Transport Incubator

WARNING:

For a full understanding of the performance characteristics of this equipment, the user should carefully read this manual before operating.

Operating Instructions

Model TI500

Table of Contents

Section 1: Symbol Definition and Intended Use

Symbol Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2: Introduction, Features, and Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . 2-7

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Temperature Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Regulations, Standards, and Codes . . . . . . . . . . . . . . . . . . . 2-9

Section 3: Precautions and Safety Tips

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Electrical Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Explosion Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Oxygen Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Electromagnetic Compatibility Precautions. . . . . . . . . . . . . 3-5

Section 4: Installation and Assembly

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Connection to External Power Sources . . . . . . . . . . . . . . . . 4-5

Installation of Oxygen Cylinders . . . . . . . . . . . . . . . . . . . . . 4-6

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page i |

General Operation and Functional Checkout . . . . . . . . . . . .4-7

Section 5: Instructions for Use

Instructions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1 Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . .5-1 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

General Operation and Functional Checkout

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8 Operation During Use . . . . . . . . . . . . . . . . . . . . . . . . 5-16 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-25 Adjustable Stand (Optional) . . . . . . . . . . . . . . . . . . . .5-25 Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-26 Shelf Tie-Down Strap . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Section 6: Cleaning, Maintenance, and Replacement Parts

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1 General Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 Steam Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 Cleaning Hard to Clean Spots. . . . . . . . . . . . . . . . . . . . . . . 6-2 Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2 Sterilizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3 Disassembling for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Access Panel Cuffs . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3 Mattress Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4 Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4 Upper Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4 Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5 Lower Shell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5 Humidity Chamber and Upper Shell . . . . . . . . . . . . . .6-5 Mattress Tray and Deck. . . . . . . . . . . . . . . . . . . . . . . . 6-6 Hood and Accessory Adjustable Stand . . . . . . . . . . . . .6-6 Tubing Access Grommets . . . . . . . . . . . . . . . . . . . . . . .6-7

Page ii |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Air Intake Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Skin Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Assembling After Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Power Failure Alarm Battery . . . . . . . . . . . . . . . . . . . . . . 6-12

Calibration and Preventive Maintenance . . . . . . . . . . . . . 6-13

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Section 7: Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Section 8: Storage and Handling

Storage and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page iii |

Page iv |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Section 1

Symbol Definition

and Intended Use

Symbol Definition

This manual contains different typefaces and icons designed to improve readability and increase understanding of its content. Note the following examples:

•Standard text—used for regular information.

•Boldface text—emphasizes a word or phrase.

•NOTE:—sets apart special information or important instruction clarification.

•The symbol below highlights a WARNING or CAUTION:

Warning and Caution

–A WARNING identifies situations or actions that may affect patient or user safety. Disregarding a warning could result in patient or user injury.

–A CAUTION points out special procedures or precautions that personnel must follow to avoid equipment damage.

•The symbol below highlights a CAUGHT HAZARD WARNING:

Caught Hazard Warning

• The symbol below highlights a CHEMICAL HAZARD WARNING:

Chemical Hazard Warning

•The symbol below highlights an ELECTRICAL SHOCK HAZARD WARNING:

Electrical Shock Hazard Warning

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 1 - 1 |

This product contains different icons designed to increase understanding. Note the following examples:

•The symbol below indicates “Attention! Consult accompanying documents”:

Attention! Consult Accompanying Documents

•The symbol below indicates “Type BF equipment with an F-type isolated (floating) applied part”:

Type BF Equipment

•The symbol below indicates a BATTERY OPERATION INDICATOR:

Battery Operation Indicator

• The symbol below indicates a POWER ON/OFF SWITCH:

Power On/Off Switch

• The symbol below indicates a SET TEMPERATURE DOWN KEY:

Set Temperature Down Key

• The symbol below indicates a SET TEMPERATURE UP KEY:

Set Temperature Up Key

Page 1 - 2 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

• The symbol below indicates a SILENCE/RESET KEY:

Silence/Reset Key

• The symbol below indicates “Electromagnetic interference:”

Electromagnetic Interference

Technical Definitions

•Setpoint—The incubator temperature selected for operation during use.

•Incubator temperature—Air temperature at a point 10 cm (4") above and centered over the mattress surface.

•Temperature equilibrium—The condition reached when the average incubator temperature does not vary more than 0.2°C (0.36°F) over a period of one hour.

•Temperature overshoot—The amount by which the incubator temperature exceeds the average incubator temperature at temperature equilibrium when the setpoint is changed from 30°C (86°F) to 34°C (93.2°F).

•Temperature rise time—The time required for the incubator temperature to rise to 34°C (93°F) from an ambient temperature of 23°C (73.4°F) with a 36°C (96.8°F) setpoint.

•Temperature uniformity—The amount by which the average temperature at each of five points 10 cm (4") above the mattress surface differs from the average incubator temperature at temperature equilibrium. (The five points are the centers of five areas created by lines that divide the width and length of the mattress surface.)

•Temperature variability—During steady temperature conditions, the incubator temperature (measured 10cm above center mattress) is within 1°C of the average incubator temperature.

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 1 - 3 |

Intended Use

This manual provides instructions for installation, use, operator maintenance, and troubleshooting of the transport incubator (Model TI500).

Dräger Medical cannot be responsible for the performance and safety of the incubator if the user does not operate the unit in accordance with the instructions, fails to follow the maintenance recommendations, or makes any repairs with unauthorized components. Only qualified service personnel should perform calibration and repair. Additional technical information is available from the manufacturer upon request through your local distributor.

All personnel who will be working with the unit should read, thoroughly understand, and have ready access to this manual. Store the manual with the incubator when not in use. If there is anything you do not understand, please contact your local representative for further information.

Page 1 - 4 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Section 2

Introduction, Features,

and Specifications

Introduction

The transport incubator provides transport of high-risk, premature, low birth-weight, or critically ill newborns. It provides a means to control air temperature, oxygen concentrations, and relative humidity. A doublewalled hood permits full visibility and provides an effective thermal and sound barrier from the environment. Arm ports and door panels provide front and head access, and the mattress tray slides out of the head end for additional access to the newborn. Tubing access grommets are on both sides of the front access panel and at the head end (left) panel. An observation lamp is also included.

The incubator is designed to operate from either a sine or square wave AC power source. In addition, the incubator can operate from an external 12V DC or 28V DC source or integral 12V DC batteries. Whenever the unit is connected to an AC voltage source and the main Power switch is set to the ON-1 position, the batteries automatically charge.

A comprehensive visual and audible fault alarm system, with a test function to verify proper alarm operation, is included along with a

Battery Status indicator.

System Overview

A forced air circulating system controls temperature, humidity, and oxygen concentration. A motor-driven impeller draws a controlled amount of room air through the air/oxygen intake filter. Supplemental oxygen, introduced through the oxygen inlet connector on the left side of the unit (when viewed from the front of the unit), displaces a portion of room air to maintain the total gas intake (including oxygen) at the same level. Since the impeller/filter controls the amount of room air and the flow meter setting controls the amount of oxygen, a predictable oxygen concentration within the incubator can be attained.

In addition to drawing fresh, filtered air into the incubator, the impeller recirculates at a much greater flow than that of the fresh gas inflow. The air is directed over the humidity sponge for humidification, when used. When the access panel of the hood is closed, the air enters the infant

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 1 |

compartment up through the slots at the right end of the housing. After circulating within the infant compartment, the air is then circulated down the left end of the housing, past the temperature sensing probe, and back to the impeller.

The transport incubator is designed to operate from one of three power sources. The three sources are used in the following order: If external AC is not available, the incubator switches to external DC. If that is not available, it switches to its internal batteries.

The batteries can be charged only when the unit is operating from an AC source.

Temperature Control

A temperature sensor, located in the recirculation air path, and a proportional control circuit, which determines the heater output required to maintain the desired incubator temperature, regulate the incubator temperature. The number of Heater indicators lit on the control panel indicate the relative amount of heat provided.

The incubator temperature can be maintained from 21.5°C (70.7°F) to 38°C (100.4°F), as selected with the temperature controls on the control panel. The temperature, as sensed by a sensor located within the housing, is compared to the setpoint. Control circuitry, which proportions the heater output to maintain the setpoint, supplies the information from this sensor. The temperature is displayed on the front panel. The setpoint is preset to 36°C (96.8°F) ± 0.15°C, and, unless the setting is changed, the incubator heats to this temperature. The Set Temp controls on the control panel can change the setpoint to a prescribed temperature (see “Operation During Use” on page 5-16). An additional sensor within the housing serves as a backup to limit the incubator maximum air temperature to 39°C (102.2°F) ± 0.5°C. At this limit, the High Temperature alarm activates, and the heater shuts off.

Alarms

Each time the unit turns on, it automatically activates a test sequence to verify that the visual display and audible alarms are functional.

•High Temperature—A sensor located below the deck sounds this alarm when the incubator temperature is equal to or greater than 39°C (102.2°F) ± 0.5°C. A flashing High Temp indicator and a tone

Page 2 - 2 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

indicate a High Temperature alarm. Internally, the heater turns off. To silence this alarm for 5 min, press the Silence/Reset key.

•Sensor—Circuitry is provided to monitor the High Temperature alarm sensor for shorts or open condition. A flashing sensor indicator and an intermittent tone indicate a Sensor alarm. This alarm resets itself.

•High Heater Temperature—The Heater Temperature indicator flashes along with an intermittent alarm to indicate that the heater temperature has exceeded 77°C (170.6°F). When this condition occurs, the heater and heater indicators turn off. To silence this alarm for

5 min, press the Silence/Reset key.

•Airflow—The Airflow indicator flashes along with an intermittent alarm to indicate that the fan impeller has stopped rotating or is missing. When this condition occurs, the heater and heater indicators turn off. To silence this alarm for 5 min, press the Silence/Reset key.

•Low DC—The Low DC indicator flashes, and an intermittent alarm sounds, to indicate that the incubator DC power source has fallen below a predetermined value.

•Power failure—An internal battery that is separate from the battery powers the Power Failure alarm circuit. The alarm lights and a continuous tone sounds if AC power is lost and no external DC or internal battery is present. To silence this alarm for 5 min, press the Silence/Reset key. If the power source switches from AC to battery or external DC to battery, the Power Failure alarm lights, and an intermittent tone sounds. To reset the alarm, press the Silence/Reset key.

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 3 |

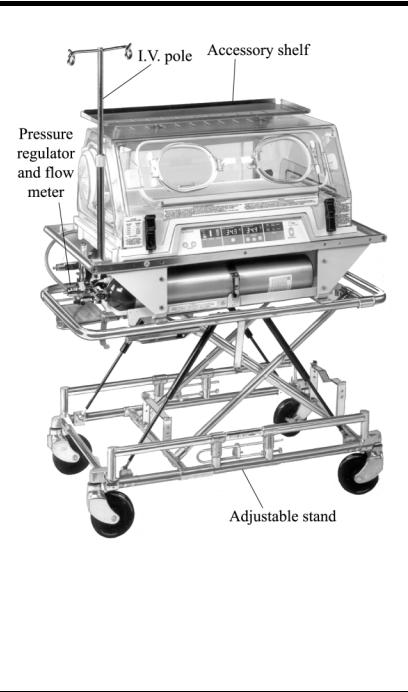

Optional Equipment

Page 2 - 4 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Optional equipment available for use with the transport incubator is listed below. For part numbers for the accessories, refer to “Replacement Parts” on page 6-13.

•IV pole

•Accessory shelf

•Pressure regulator and flow meter

•DC power cord adapter

•Adjustable stand

•Second battery option

The adjustable stands are designed to provide a convenient means of moving the transport incubator. Each stand is adjustable to different heights. They are designed to lock into the litter bar of an ambulance with a fastener such as a FERNO®1 Model 175 Series Cot Fastener System.

NOTE:

The locking mechanisms vary with the ambulance or helicopter used.

1. Ferno® is a registered trademark of Ferno-Washington, Inc.

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 5 |

Specifications

Specifications for the transport incubator are provided below. The use of infant seats, head hoods, or other accessories within the incubator can alter the air flow pattern and affect the following:

•temperature uniformity

•temperature variability

•correlation of the incubator temperature reading to center mattress temperature

•infant skin temperature

All specifications are subject to change without notice.

Physical Specifications

Feature |

Dimension |

|

|

Transport incubator and |

|

standard stand |

|

(Ferno-Washington stand, model 147A) |

|

Nominal length |

102 cm (40") |

Nominal width |

56.5 cm (22.25") |

Nominal height (low hood) |

111.8 cm (44") maximum, 81.3 cm |

|

(32") minimum |

Nominal height (high hood) |

116.2 cm (45.75") maximum, 85.7 cm |

|

(33.75") minimum |

Nominal weight (including |

72.1 kg (159 lb) |

the incubator, adjustable |

|

stand, and one battery) |

|

Nominal weight (including |

82.5 kg (181.9 lb) |

the incubator, adjustable |

|

stand, and two batteries) |

|

Transport incubator |

|

Nominal length |

95.9 cm (37.75") |

Nominal width |

52.7 cm (20.75") |

Nominal height (low hood) |

50.8 cm (20.00") |

Nominal height (high hood) |

55.2 cm (21.75") |

Stands |

|

Nominal length |

102 cm (40.25") |

Page 2 - 6 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Feature |

Dimension |

|

|

Nominal width |

56.5 cm (22.25") |

Nominal height |

61.0 cm (24.00") - maximum, 30.5 cm |

|

(12.00") - minimum |

Environmental Specifications

Feature |

Dimension |

|

|

Operating temperature range |

10°C (50°F) to 30°C (86°F) (incubator |

(ambient) |

must be at least 3°C higher than the |

|

ambient.) |

Storage temperature |

-40°C (-40°F) to +70°C (158°F) ambi- |

|

ent |

Relative Humidity Range |

0% to 95% RH, non-condensing |

Altitude |

Operating range: sea level to 3 km |

|

(10000 ft); non-pressurized ambient or |

|

sea level to 12 km (40000 ft); pressur- |

|

ized ambient |

|

Shipment range: sea level to 12km |

|

(40000 ft) |

Performance Specifications

Feature |

Dimension |

|

|

Mattress air velocity (aver- |

<20 cm/sec (39 ft/min) |

age air and oxygen-flow rate |

|

circulated within the mattress |

|

area defined by five points up |

|

to a height of 4" above the |

|

mattress) |

|

Carbon dioxide (CO2) level |

Less than 0.5% when a 4% mixture of |

within the hood |

CO2 in the air is delivered at 750 ml |

|

(25 oz) per min at a point 10 cm (4") |

|

above the center of the mattress. |

Oxygen concentration |

Adjustable from a range of 21% to at |

|

least 58% with oxygen flow rates |

|

≥ 6 LPM (1.6 gal/min). |

|

(Concentrations are achieved in less |

|

than 40 minutes at the corresponding |

|

oxygen flow.) |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 7 |

Feature |

Dimension |

|

|

Noise level within the hood |

Less than 60 dBa with ambient levels |

|

to ≤ 50 dBa |

Observation light |

376.7 lx (35.0 fc) at 10 cm (4") above |

|

the center of the mattress |

Correlation of the displayed |

≤ 1°C |

incubator temperature to the |

|

actual incubator temperature |

|

at temperature equilibrium |

|

(see “Technical Definitions” |

|

on page 1-3). |

|

Electrical Specifications

Feature |

Dimension |

|

|

External power requirements |

110V/120V AC, 50/60/400 Hz, 270W |

|

maximum sine or square wave or |

|

220V/240V AC, 50/60/400 Hz, 270W |

|

maximum sine or square wave, |

|

11V DC to 13V DC, 200W maximum, |

|

26V DC to 30V DC, 200W maximum |

Internal battery type |

Lead acid, vented, rechargeable |

Internal battery voltage |

12V DC nominal |

Internal battery quantity |

1 (2 optional) |

Internal battery capacity |

24 Amp hours per battery |

Internal battery charge time |

10 hours per battery |

(from full discharge) |

|

Internal battery life expect- |

200 complete charge/discharge cycles |

ancy |

|

Chassis leakage current |

300µA or less (110V/120V AC units) |

|

500µA or less (220V/240V AC units) |

Page 2 - 8 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Temperature Specifications

Feature |

Dimension |

|

|

Operating temperature |

Maintains a differential of up to 25°C |

|

(45°F) between the ambient |

|

temperature and setpoint for 90 min |

|

per battery. Example: With a setpoint |

|

of 36°C (96.8°F) and ambient |

|

temperature of 11°C (51.8°F), the |

|

operating time (full heater, all heater |

|

lights on) is 90 min for one battery, or |

|

3 hours for two batteries. |

Operating range (normal) |

10°C (50°F) to 30°C (86°F) |

|

The incubator setpoint must be at least |

|

3.0°C (5.4°F) higher than the ambient |

|

temperature. |

Operating range (limited) |

0°C (32°F) to 30°C (86°F) |

|

At more extreme ambient |

|

temperatures, the incubator |

|

temperature may not be maintained |

|

due to extreme ambient temperatures. |

Relative humidity (RH) |

0% to 95% RH non-condensing, IEC |

operating range |

class I equipment, internally-powered |

|

equipment. |

Temperature setpoint range |

21.5°C (70.7°F) ± 1.5°C to 38.0°C |

|

(100.4°F) in 0.1°C increments |

Temperature rise time |

30 min. (nominal) |

Temperature variability |

1.0°C (1.8°F) |

Temperature overshoot |

2.0°C (3.6°F) |

Temperature uniformity |

1.0°C (1.8°F) |

Regulations, Standards, and Codes

The Transport Incubator, Model TI500 complies with the following safety and performance standards:

•EN 60601-1—1990, Medical Electrical Equipment, Part 1: General Requirements for Safety, including Amendments 1 and 2

•EN 60601-1-2—2002, Collateral Standard: Electromagnetic Compatibility—Requirements and Tests

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 9 |

•EN 60601-2-20—1996, Particular Requirements for the Safety of Transport Incubators, including Amendment 1

Guidance and Manufacturer’s Declaration— Emissions

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the unit should ensure that the unit is used in such an environment.

|

|

Electromagnetic |

Emissions Test |

Compliance |

Environment— |

|

|

Guidance |

|

|

|

Radio frequency |

Group 1 |

The TI500 Transport |

(RF) emissions— |

|

Incubator uses RF |

CISPR 11 |

|

energy only for its |

|

|

internal function. |

|

|

Therefore, its RF |

|

|

emissions are very |

|

|

low and are not |

|

|

likely to cause inter- |

|

|

ference with nearby |

|

|

electronic equip- |

|

|

ment. |

RF emissions |

Class B |

Although the TI500 |

CISPR 11 |

|

Transport Incubator |

|

|

is not intended for |

|

|

operation from the |

|

|

public low-voltage |

|

|

power supply net- |

|

|

work, the product |

|

|

does comply with the |

|

|

more restrictive RF |

|

|

Emission levels of |

|

|

Class B. |

|

|

|

Page 2 - 10 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Guidance and Manufacturer’s Declaration— Emissions

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the unit should ensure that the unit is used in such an environment.

|

|

Electromagnetic |

Emissions Test |

Compliance |

Environment— |

|

|

Guidance |

|

|

|

Harmonics |

Not Applicable |

The TI500 Transport |

IEC 61000-3-2 |

|

Incubator is suitable |

|

|

for use in all estab- |

Voltage fluctua- |

Not Applicable |

|

tions/flicker emis- |

|

lishments other than |

sions |

|

domestic and those |

IEC 61000-3-3 |

|

directly connected to |

|

|

the public low-volt- |

|

|

age power supply |

|

|

network that supplies |

|

|

buildings used for |

|

|

domestic purposes. |

|

|

|

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 11 |

Guidance and Manufacturer’s Declaration—Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Environment— |

||||

Level |

Level |

|||

|

Guidance |

|||

|

|

|

||

|

|

|

|

|

Electrostatic |

± 6 kV contact |

± 6 kV contact |

The floors |

|

Discharge ESD |

|

|

should be |

|

IEC 61000-4-2 |

± 8 kV air |

± 8 kV air |

wood, con- |

|

|

|

|

crete, or |

|

|

|

|

ceramic tile. If |

|

|

|

|

floors are cov- |

|

|

|

|

ered with syn- |

|

|

|

|

thetic, the |

|

|

|

|

relative humid- |

|

|

|

|

ity should be at |

|

|

|

|

least 30%. |

|

Electrical fast |

± 2 kV for |

± 2 kV for |

Mains power |

|

transient/burst |

power supply |

power supply |

quality should |

|

IEC 61000-4-4 |

lines |

lines |

be that of a typ- |

|

|

|

|

ical commer- |

|

|

|

|

cial or hospital |

|

|

|

|

environment. |

|

|

± 1 kV for |

N/A for |

There are no |

|

|

input/output |

input/output |

I/O cables for |

|

|

lines |

lines |

this product. |

|

|

|

|

|

|

Surge |

± 1 kV Differ- |

± 1 kV Differ- |

Mains power |

|

IEC 61000-4-5 |

ential |

ential |

quality should |

|

|

|

|

be that of a typ- |

|

|

± 2 kV Com- |

± 2 kV Com- |

ical commer- |

|

|

mon |

mon |

cial or hospital |

|

|

|

|

environment. |

Page 2 - 12 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Guidance and Manufacturer’s Declaration—Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Environment— |

||||

Level |

Level |

|||

|

Guidance |

|||

|

|

|

||

|

|

|

|

|

Voltage dips, |

<5% UT |

<5% UT |

Mains power |

|

short interrup- |

(> 95% dip in |

(> 95% dip in |

quality should |

|

tions and volt- |

UT ) for 0.5 |

UT ) for 0.5 |

be that of a typi- |

|

age variations |

cycles |

cycles |

cal commercial |

|

on power sup- |

or hospital |

|||

|

|

|||

ply input lines |

40% UT |

40% UT |

environment. If |

|

IEC 61000-4- |

the user of the |

|||

(60% dip in |

(60% dip in |

|||

11 |

TI500 Transport |

|||

UT ) for 5 |

UT ) for 5 |

Incubator |

||

|

||||

|

cycles |

cycles |

requires contin- |

|

|

|

|

ued operation |

|

|

70% UT |

70% UT |

during power |

|

|

(30% dip in |

(30% dip in |

mains interrup- |

|

|

UT ) for 25 |

UT ) for 25 |

tions, it is rec- |

|

|

ommended that |

|||

|

cycles |

cycles |

||

|

the TI500 Trans- |

|||

|

|

|

||

|

<5% UT |

<5% UT |

port Incubator |

|

|

be powered from |

|||

|

(> 95% dip in |

(> 95% dip in |

an |

|

|

UT ) for 5 s |

UT ) for 5 s |

uninterruptible |

|

|

|

|

power supply or |

|

|

|

|

a battery. |

|

|

|

|

Note: The TI500 |

|

|

|

|

Transport Incu- |

|

|

|

|

bator, with its |

|

|

|

|

internal bat- |

|

|

|

|

tery(s), provides |

|

|

|

|

continued opera- |

|

|

|

|

tion during |

|

|

|

|

power mains |

|

|

|

|

interruptions. |

|

|

|

|

|

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 13 |

Guidance and Manufacturer’s Declaration—Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Environment— |

||||

Level |

Level |

|||

|

Guidance |

|||

|

|

|

||

|

|

|

|

|

Power fre- |

3 A/m |

3 A/m |

Power fre- |

|

quency |

|

|

quency mag- |

|

(50/60 Hz) |

|

|

netic fields |

|

magnetic field |

|

|

should be at |

|

IEC 61000-4-8 |

|

|

levels charac- |

|

|

|

|

teristic of a typ- |

|

|

|

|

ical location in |

|

|

|

|

a typical com- |

|

|

|

|

mercial or hos- |

|

|

|

|

pital |

|

|

|

|

environment. |

Note UT is the a.c. mains voltage prior to application of the test level.

Page 2 - 14 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Guidance and Manufacturer’s Declaration— Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Level |

Level |

Environment— |

|

|

|

Guidance |

|

|

|

Recommended |

|

|

|

Separation |

|

|

|

Distance |

|

|

|

|

Conducted RF |

|

|

Portable and |

IEC 61000-4-6 |

|

|

mobile RF |

|

|

|

communica- |

|

|

|

tions equip- |

|

|

|

ment should be |

|

|

|

used no closer |

|

|

|

to any part of |

|

|

|

the TI500 |

|

|

|

Transport Incu- |

|

|

|

bator, includ- |

|

|

|

ing cables, than |

|

|

|

the recom- |

|

|

|

mended separa- |

|

|

|

tion distance |

|

|

|

calculated from |

|

|

|

the equation |

|

|

|

applicable to |

|

|

|

the frequency |

|

|

|

of the transmit- |

|

|

|

ter. |

|

|

|

Recommended |

|

|

|

separation |

|

|

|

distance |

|

|

|

|

|

3 Vrms |

3 Vrms |

d = 1.2 P |

|

|

|

|

|

150 kHz to 80 |

|

|

|

MHz outside |

|

|

|

ISM bandsa |

|

|

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 15 |

Guidance and Manufacturer’s Declaration— Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test IEC 60601 Test |

Compliance |

Electromagnetic |

Level |

Level |

Environment— |

|

|

Guidance |

|

|

Recommended |

|

|

Separation |

|

|

Distance |

|

10 Vrms |

10 Vrms |

|

|

|

|

|

d = |

1.2 |

P |

|

|

150 KHz to 80 |

|

|

|

|

|

MHza |

|

|

|

|

Radiated RF |

10 V/m |

10 V/m |

|

|

|

IEC 61000-4-3 |

|

d = |

1.2 |

P |

80 |

|

|

MHz to 800 |

|||

|

|

|

|||

|

|

MHz |

|

|

|

|

80 MHz to 2.5 |

d = |

2.3 |

P |

|

|

GHz |

800 MHz to 2.5 |

|||

|

|

||||

|

|

GHz |

|

|

|

Page 2 - 16 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Guidance and Manufacturer’s Declaration— Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Level |

Level |

Environment— |

|

|

|

Guidance |

|

|

|

Recommended |

|

|

|

Separation |

|

|

|

Distance |

|

|

|

|

|

|

|

where P is the |

|

|

|

maximum out- |

|

|

|

put power rat- |

|

|

|

ing of the |

|

|

|

transmitter in |

|

|

|

watts (W) |

|

|

|

according to the |

|

|

|

transmitter |

|

|

|

manufacturer |

|

|

|

and d is the rec- |

|

|

|

ommended sep- |

|

|

|

aration distance |

|

|

|

in meters (m).b |

|

|

|

in watts and D |

|

|

|

is the recom- |

|

|

|

mended |

|

|

|

separation dis- |

|

|

|

tance in meters. |

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 17 |

Guidance and Manufacturer’s Declaration— Immunity

The TI500 Transport Incubator is intended for use in the electromagnetic environment specified below. The customer or user of the TI500 Transport Incubator should assure that the unit is used in such an environment.

Immunity Test |

IEC 60601 Test |

Compliance |

Electromagnetic |

|

Level |

Level |

Environment— |

|

|

|

Guidance |

|

|

|

Recommended |

|

|

|

Separation |

|

|

|

Distance |

|

|

|

|

|

|

|

Fields strengths |

|

|

|

from fixed RF |

|

|

|

transmitters, as |

|

|

|

determined by |

|

|

|

an electromag- |

|

|

|

netic site sur- |

|

|

|

vey c, should be |

|

|

|

less than the |

|

|

|

compliance |

|

|

|

level in each |

|

|

|

frequency |

|

|

|

range.d |

|

|

|

Interference |

|

|

|

may occur in |

|

|

|

the vicinity of |

|

|

|

equipment |

|

|

|

marked with |

|

|

|

the following |

|

|

|

symbol: |

|

|

|

|

a.The ISM (industrial, scientific and medical) bands between 150 kHz and 80 MHz are 6.765 MHz to 6.795 MHz; 13.553 MHz to 13.567 MHz; 26.957 MHz to 27.283 MHz; and 40.66 MHz to 40.70 MHz.

Page 2 - 18 |

Transport Incubator (Model TI500) User Manual (67 990 70) |

b.The compliance levels in the ISM frequency bands between 150 kHz and 80 MHz and in the frequency range 80 MHz to 2.5 GHz are intended to decrease the likelihood that mobile/portable communications equipment could cause interference if it is inadvertently brought into patient areas. For this reason, an additional factor of 10/3 is used in calculating the recommended separation distance for transmitters in these frequency ranges.

c.Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To access the electromagnetic environment due to fixed RF transmitters, an electromagnetic sit survey should be considered. If the measured field strength in the location in which the TI500 Transport Incubator is used exceeds the applicable RF compliance level above, the TI500 Transport Incubator should be observed to verify normal operation. IF abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the TI500 Transport Incubator.

d.Over the Frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

NOTE:

At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE:

These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from structures, objects and people

Transport Incubator (Model TI500) User Manual (67 990 70) |

Page 2 - 19 |

Loading...

Loading...