Denon DN-F300 Service manual

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E2C E1K EUT

DN-F300

33

PROFESSIONAL SOLID STATE PLAYER

X0443 V.01 DE/CDM 0909

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerning important safety

parts

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

DN-F300

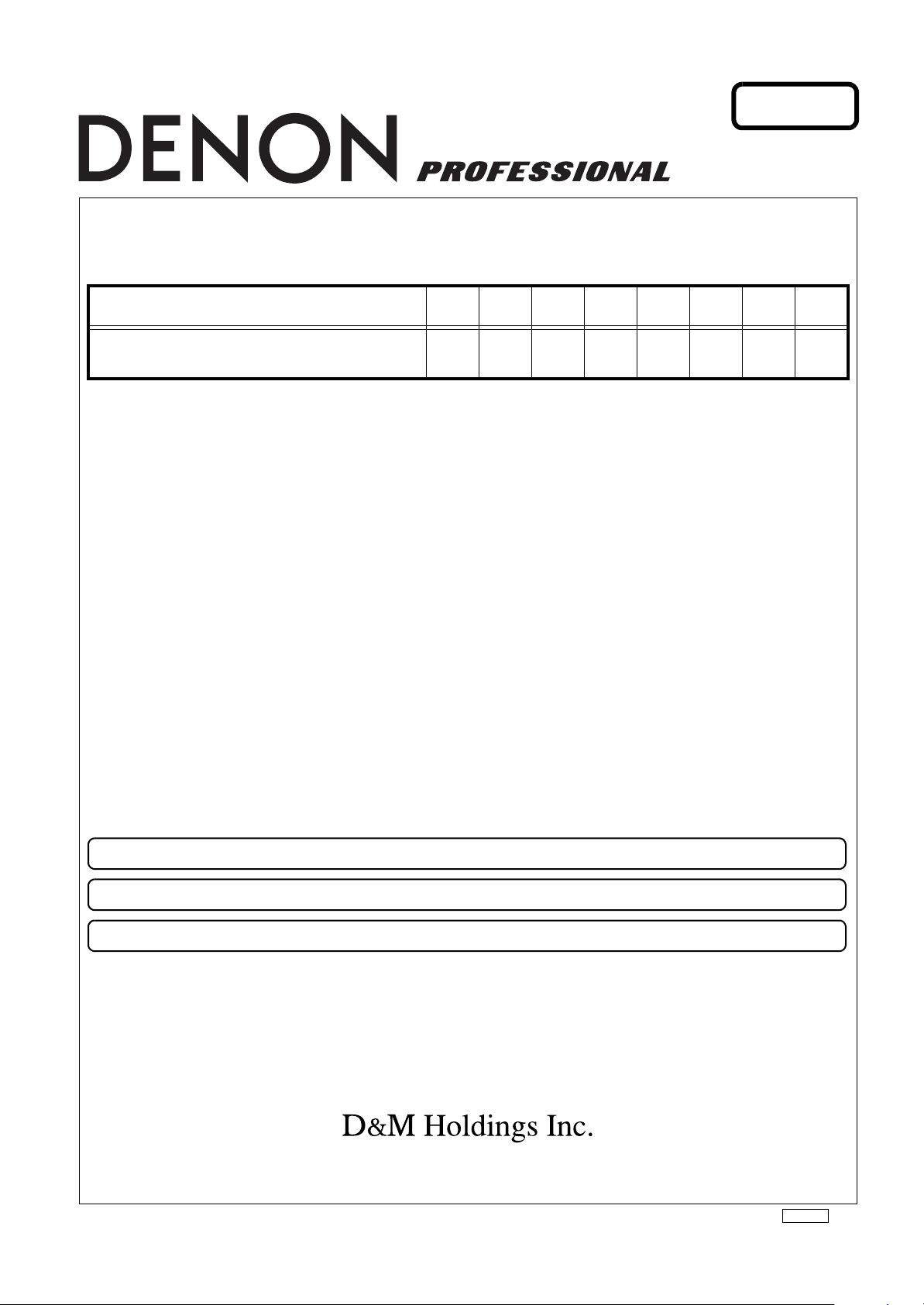

DIMENSION

ዧۃʻሽʼڅڶૻֆ

3

DN-F300

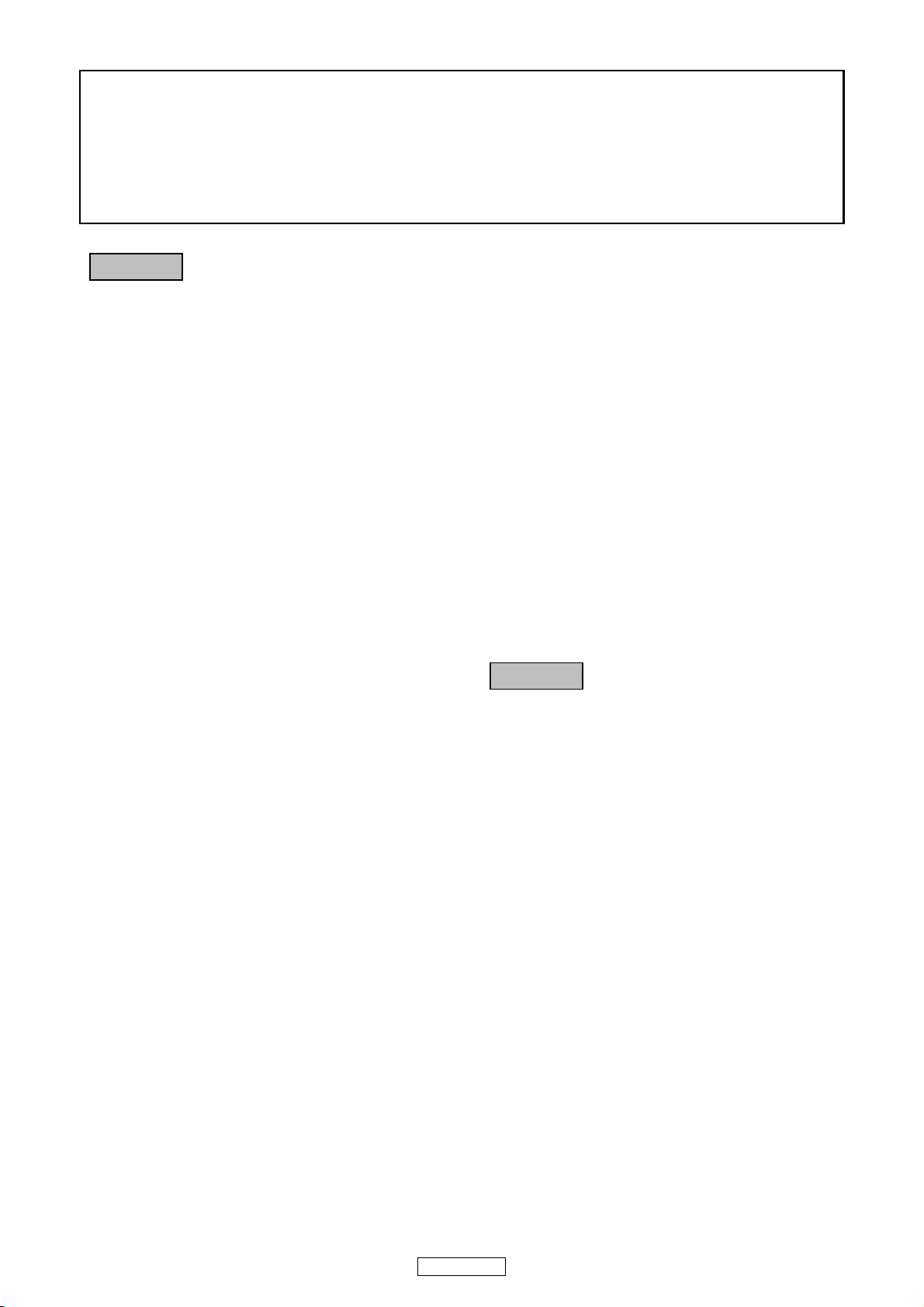

WIRE ARRANGEMENT

Press the coil down to the cable,pls

be noted to avoid the screw hole

(as round marking)

Fix the 5P line of Jack board firmly

with locking cable clip and keep the

distance with black gict cable as far

as possible,but please take attention

that it cant be closed to above

Fix the 9P line in the SD card board

with the 5P line in the USB board

with cable ties,keep the insulation

line under the flat cable

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as they

were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

4

DN-F300

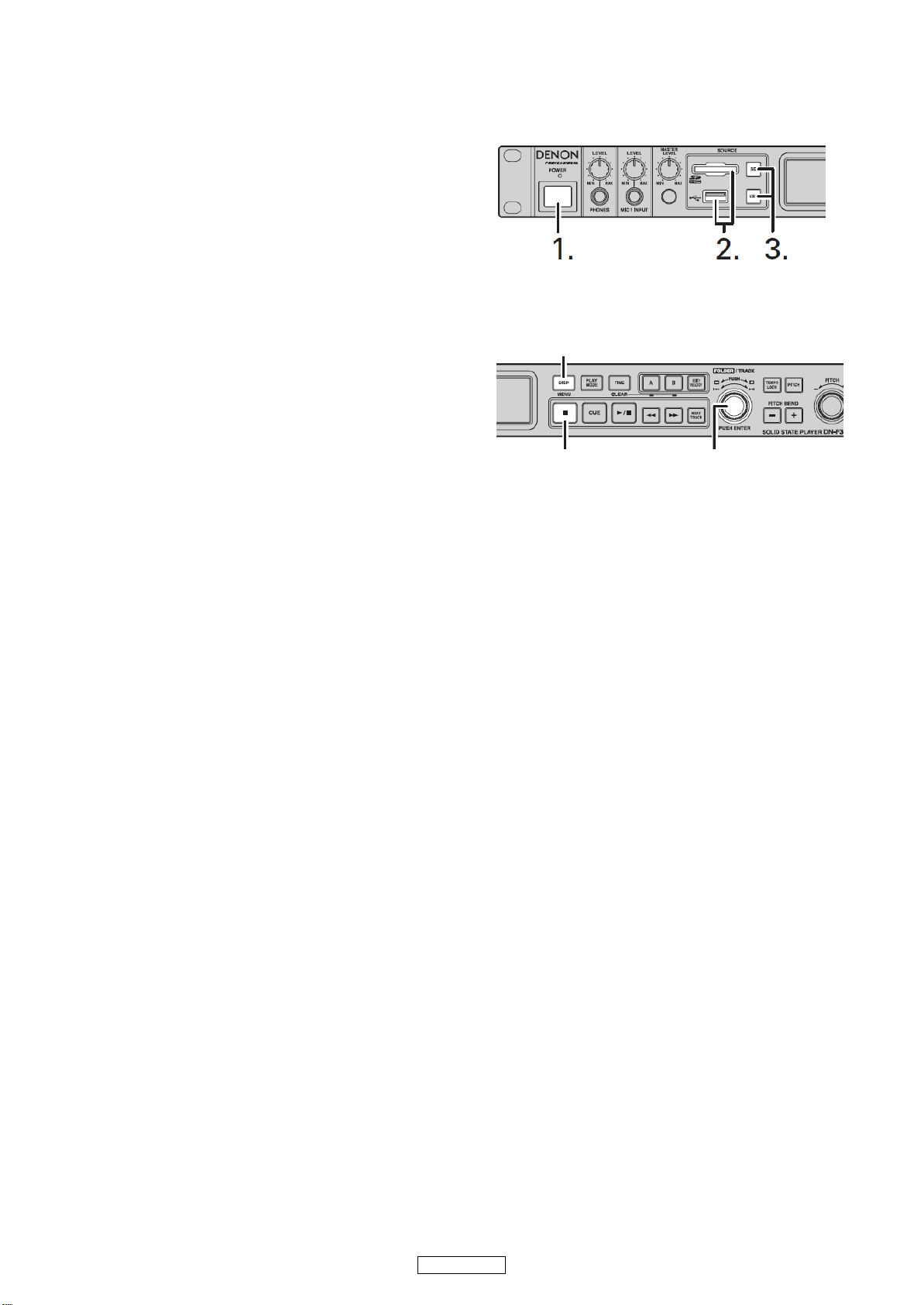

VERSION UPGRADE PROCEDURE OF FIRMWARE

䎘䎑䎃

8. 6. 7.

Use the procedure described below to update the firmware to a newer version.

(1) Press the POWER switch to turn on the power.

(2) Insert a SD card or a USB device that has the update file

'dnf30XXX.bin' on the root. Put both files on the SD card or

the USB device if we provide 2 .bin files.

(3) Press the SD or USB[source] button for the input source to

be updated.

※ At this time, "V-XX.XXOK?" is displayed in the display sec-

tion. If this is not displayed, perform steps (5 )- (8 )and

check the version.

(4) If the FOLDER/TRACK jog is pressed, "Update" flashes in

the display section, and update begins. When update has

completed, the system automatically restarts.

(5) To check the current main unit version, press the MENU/

STORE button for 2 seconds. At this time, the menu list is

displayed in the display section.

(6) Turn the FOLDER/TRACK jog to select "F/W Version".

(7) If the FOLDER/TRACK jog is pressed, the current version is

displayed in the display section.

(8) Press the STOP button to exit the menu mode.

Note:

Please DO NOT touch and DO NOT disconnect power while the unit is being updated.

Before you update the unit, make sure that the power cable is firmly plugged into the DN-F300 and into an AC outlet.

If the power is turned off accidentally while the unit is being updated, the DN-F300 may not start up.

※ Please set the preset menu again after the upgrade.

5

DN-F300

TROUBLE SHOOTING

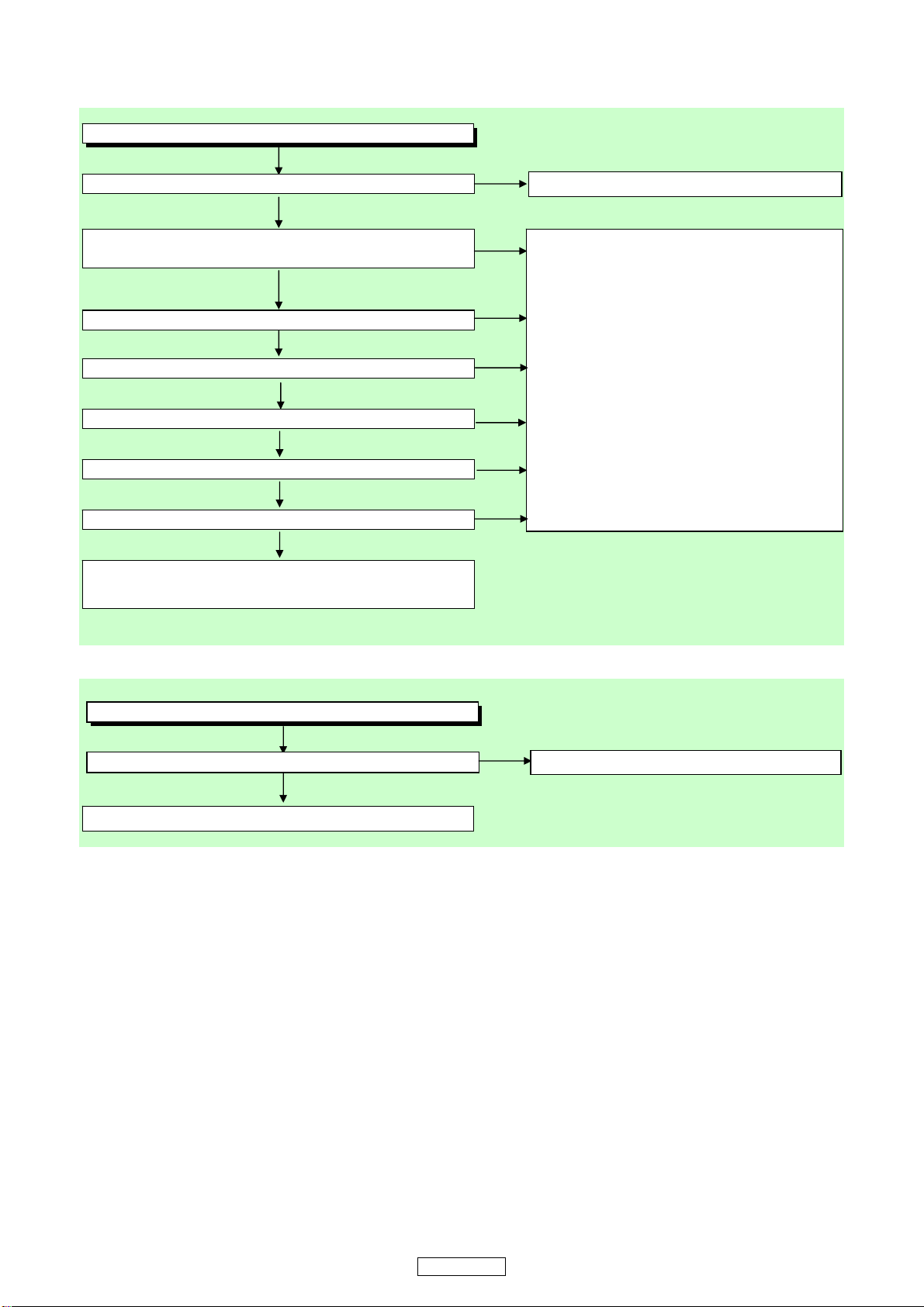

FLOW CHART NO.1䇭(MAIN/POWER UNIT

)

FLOW CHART NO.2 (CONTROL UNIT)

䇭Thepower cannot be turned on.

Is the AC adaptor normal䋿

㪥㫆

㪰㪼㫊

Is normal state restored when once unplugged

power cord is plu

gg

ed again after several seconds?

㪰㪼㫊

㪥㫆

Check if there is any leak or short-circuiting on

the primary or secondly circuit component of

SWITCHING POWER SUPPLY UNIT, and

replace it if defective.

Is the +3.3line voltage normal?

㪰㪼㫊

㪥㫆

Check the the periphery circuit of MAIN and PANEL, and

replace it if defective.

LCD does not display.

Is 5V voltage supplied to 33pins(VCC) of IC203?

㪰㪼㫊

㪥㫆

Check the +5V line and service it if defective.

Is the +5V line voltage normal?

㪥㫆

Is the USB5 line voltage normal?

䇭Is the A5V line voltage normal?

㪰㪼㫊

㪰㪼㫊

㪰㪼㫊

䇭Is the -A5V line voltage normal?

㪰㪼㫊

㪥㫆

㪥㫆

㪥㫆

Replace the AC adaptor.

Replace IC203.

6

DN-F300

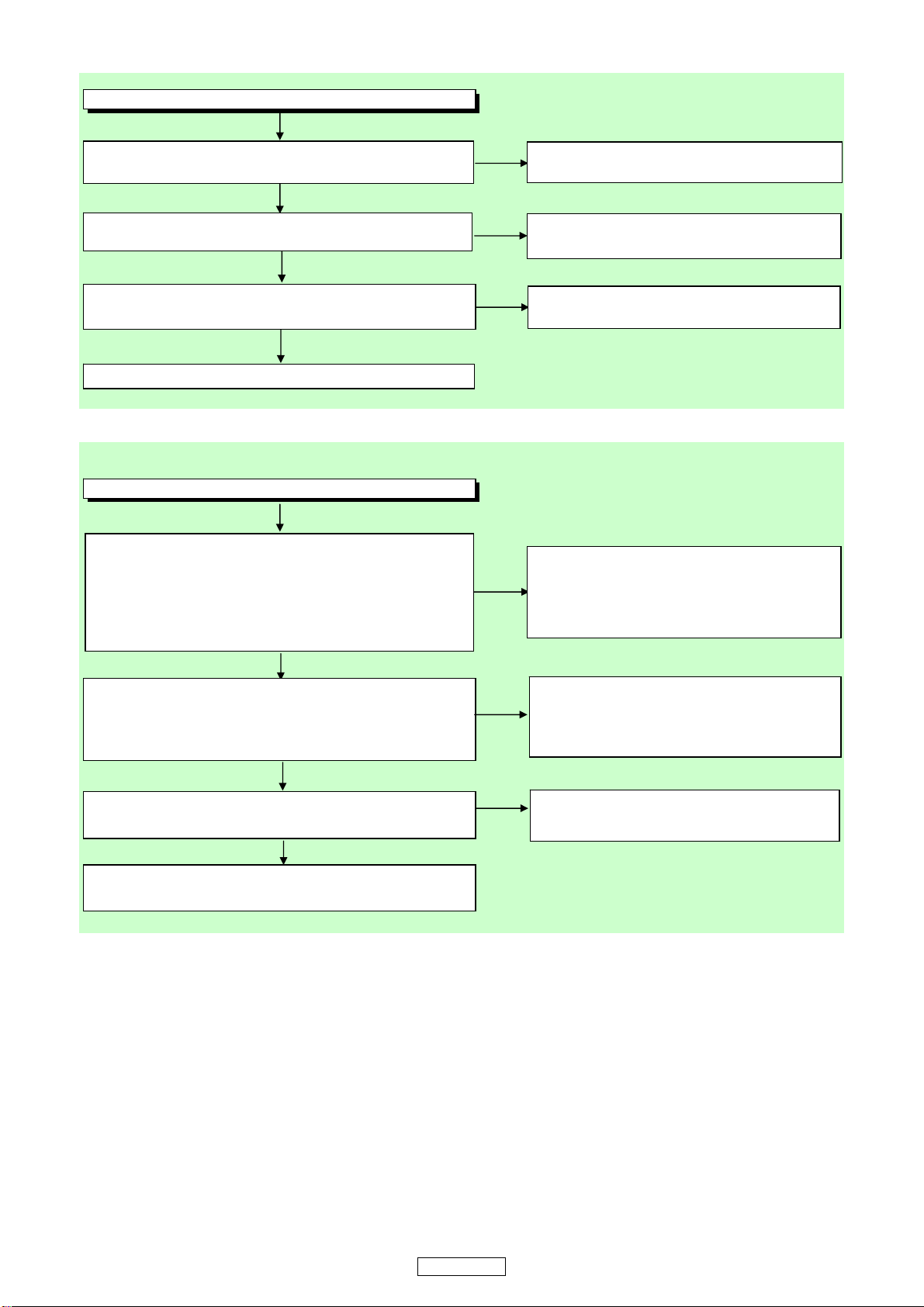

FLOW CHART NO.3䇭(CONTROL UNIT

)

FLOW CHART NO.4䇭(MAIN/POWER UNIT)

䇭The key operation is not functioning.

䇭Both functions of picture and sound do not operate

The WAV file in which test signal of 1kHz/0dB is written is

prepared. With the test signal of 1kHz/0dB it repeats

between B from A and puts in playback state.

Are the audio signals outputted to 26pin(LINE Lch) and

24pin(HP Rch) of IC101, 16pin(LINE Lch) and 13pin(LINE

Rch) of IC103?

㪰㪼㫊

㪥㫆

Check the input signal from IC101, IC103, and

their periphery, and service it if detective.

When the input signal is correct, IC101 or IC103

is replaced.

Are the audio signals outputted to 7pin(HP Lch) and 1pin(HP

Rch) of IC102, 7pin(LINE Lch) and 1pin(LINE Rch) of

IC102?

Check periphery circuit IC102, IC104, and

service it if defective.

When the periphery circuit is correct, IC102 or

IC104 is replaced.

㪰㪼㫊

Is MUTE released, and has been the Q002 base L(0V)?

Check Q002 and the periphery circuit, and

service it if defective.

㪰㪼㫊

Check periphery circuit from 7pin and 1pin to JK104, JK102

of IC102, IC104 and replace it if defective.

㪰㪼㫊

㪥㫆

Are the contact point and the installation state of the tact

switches normal?

Re-install the switches correctly or replace the

㪰㪼㫊

㪥㫆

Does LED light correctly ?

Check the IC201 and their periphery, and

service it if detective.

㪰㪼㫊

㪥㫆

When pressing each switches, do the voltage of each pin

of IC201(shown below) increase?

Check the switches and their periphery, and

service it if detective.

Replace IC201.

㪥㫆

㪥㫆

7

DN-F300

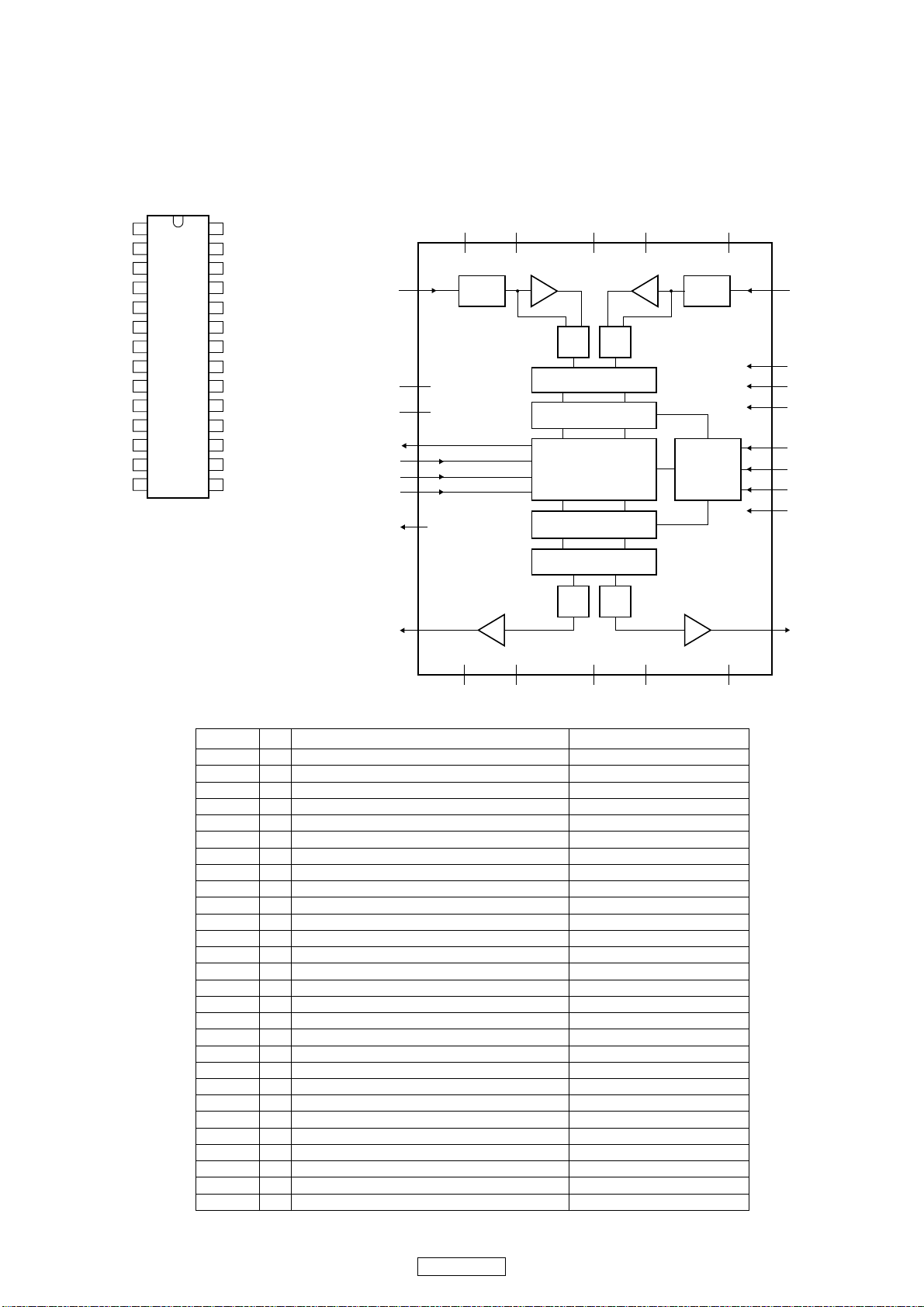

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

UDA1345TS/N2 (IC101)

lfpage

V

SSA(ADC)

V

DDA(ADC)

V

V

V

SYSCLK

VINL

ref(A)

VINR

ADCN

ADCP

MC1

MP1

V

DDD

V

SSD

MP2

MP3

1

2

3

4

5

6

7

UDA1345TS

8

9

10

11

12

13

28

27

26

25

24

23

22

21

20

19

18

17

16

1514

V

ref(D)

V

SSO

VOUTL

V

DDO

VOUTR

V

DDA(DAC)

V

SSA(DAC)

MC2

MP5

DATAI

DATAO

WS

BCK

MP4

idth

DATAO

VOUTL

VINL

V

DDD

V

SSD

BCK

WS

DATAI

MP1

V

DDA(ADC)VSSA(ADC)

21

3 5

0 dB/6 dB

SWITCH

10

11

18

16

17

19

9

UDA1345TS

26

25 27 23 22

V

DDO

V

SSO

V

ADCPVADCN

76 4

ADC

ADC

DECIMATION FILTER

DC-CANCELLATION FILTER

DIGITAL INTERFACE

INTERPOLATION FILTER

NOISE SHAPER

DAC

DAC

V

DDA(DAC)VSSA(DAC)

V

0 dB/6 dB

SWITCH

L3-BUS

INTERFACE

V

ref(A)

28

ref(D)

VINR

8

MC1

21

MC2

20

MP5

13

MP2

14

MP3

15

MP4

12

SYSCLK

24

VOUTR

MGS875

SYMBOL PIN TYPE DESCRIPTION

V

SSA(ADC)

V

DDA(ADC)

1 analog ground pad ADC analog ground

2 analog supply pad ADC analog supply voltage

VINL 3 analog input pad ADC input left

V

ref(A)

4 analog pad ADC reference voltage

VINR 5 analog input pad ADC input right

V

V

ADCN

ADCP

6 analog pad ADC negative reference voltage

7 analog pad ADC positive reference voltage

MC1 8 5 V tolerant digital input pad with internal pull-down pad mode control 1 (pull-down)

MP1 9 5 V tolerant slew rate controlled digital output pad multi purpose pin 1

V

DDD

V

SSD

10 digital supply pad digital supply voltage

11 digital ground pad digital ground

SYSCLK 12 5 V tolerant digital Schmitt triggered input pad system clock 256, 384 or 512f

MP2 13 3-level input pad multi purpose pin 2

MP3 14 5 V tolerant digital Schmitt triggered input pad multi purpose pin 3

MP4 15 3-level input pad multi purpose pin 4

BCK 16 5 V tolerant digital Schmitt triggered input pad bit clock input

WS 17 5 V tolerant digital Schmitt triggered input pad word select input

DATAO 18 5 V tolerant slew rate controlled digital output pad data output

DATAI 19 5V tolerant digital Schmitt triggered input pad data input

MP5 20 5 V tolerant digital Schmitt triggered input pad multi purpose pin 5 (pull down)

MC2 21 5 V tolerant digital input pad with internal pull-down pad mode control 2 (pull-down)

V

SSA(DAC)

V

DDA(DAC)

22 analog ground pad DAC analog ground

23 analog supply pad DAC analog supply voltage

VOUTR 24 analog output pad DAC output right

V

DDO

25 analog supply pad operational amplifier supply voltage

VOUTL 26 analog output pad DAC output left

V

V

SSO

ref(D)

27 analog ground pad operational amplifier ground

28 analog pad DAC reference voltage

s

8

DN-F300

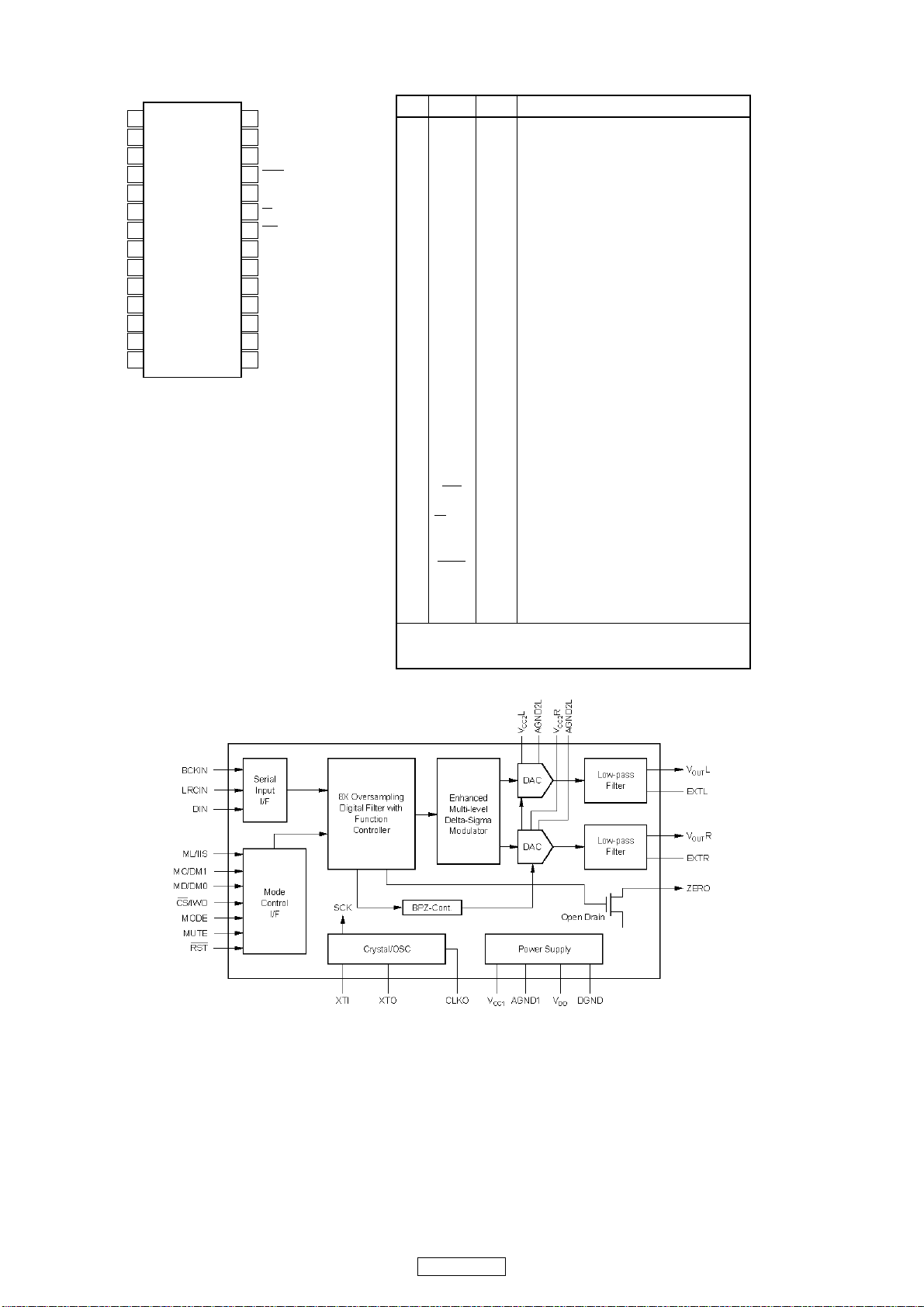

PCM1716E (IC103)

PIN ASSIGNMENTS

LRCIN

DIN

BCKIN

CLKO

XTI

XTO

DGND

V

VCC2R

AGND2R

EXTR

NC

V

OUT

AGND1

1

2

3

4

5

6

7

PCM1716E

8

DD

9

10

11

12

13

R

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/IIS

MC/DM1

MD/DM0

MUTE

MODE

CS/IWO

RST

ZERO

V

2L

CC

AGND2L

EXTL

NC

V

L

OUT

V

1

CC

PIN NAME I/O DESCRIPTION

1 LRCIN IN Left and Right Clock Input. This clock is equal to

the sampling rate - f

2 DIN IN Serial Audio Data Input

3 BCKIN IN Bit Clock Input for Serial Audio Data.

(1)

.

S

(1)

(1)

4 CLKO OUT Buffered Output of Oscillator. Equivalent to

System Clock.

5 XTI IN Oscillator Input (External Clock Input)

6 XTO OUT Oscillator Output

7 DGND — Digital Ground

8V

9V

— Digital Power +5V

DD

2R — Analog Power +5V

CC

10 AGND2R — Analog Ground

11 EXTR OUT Rch, Common Pin of Analog Output Amp

12 NC — No Connection

13 V

R OUT Rch, Analog Voltage Output of Audio Signal

OUT

14 AGND1 — Analog Ground

15 V

16 V

1 — Analog Power +5V

CC

L OUT Lch, Analog Voltage Output of Audio Signal

OUT

17 NC — No Connection

18 EXTL OUT Lch, Common Pin of Analog Output Amp

19 AGND2L — Analog Ground

20 V

2L — Analog Power +5V

CC

21 ZERO OUT Zero Data Flag

22 RST IN Reset. When this pin is low, the DF and

modulators are held in reset.

23 CS/IWO IN Chip Select/Input Format Selection. When this

pin is low, the Mode Control is effective.

24 MODE IN

Mode Control Select. (H: Software, L: Hardware)

(2)

(3)

(2)

25 MUTE IN Mute Control

26 MD/DM0 IN Mode Control, DATA/De-emphasis Selection 1

27 MC/DM1 IN Mode Control, BCK/De-emphasis Selection 2

28 ML/I2S IN Mode Control, WDCK/Input Format Selection

(2)

(2)

(2)

NOTES: (1) Pins 1, 2, 3; Schmitt Trigger input. (2) Pins 22, 24, 25, 26, 27,

28; Schmitt Trigger input with pull-up resister. (3) Pin 23; Schmitt Trigger

input with pull-down resister.

9

DN-F300

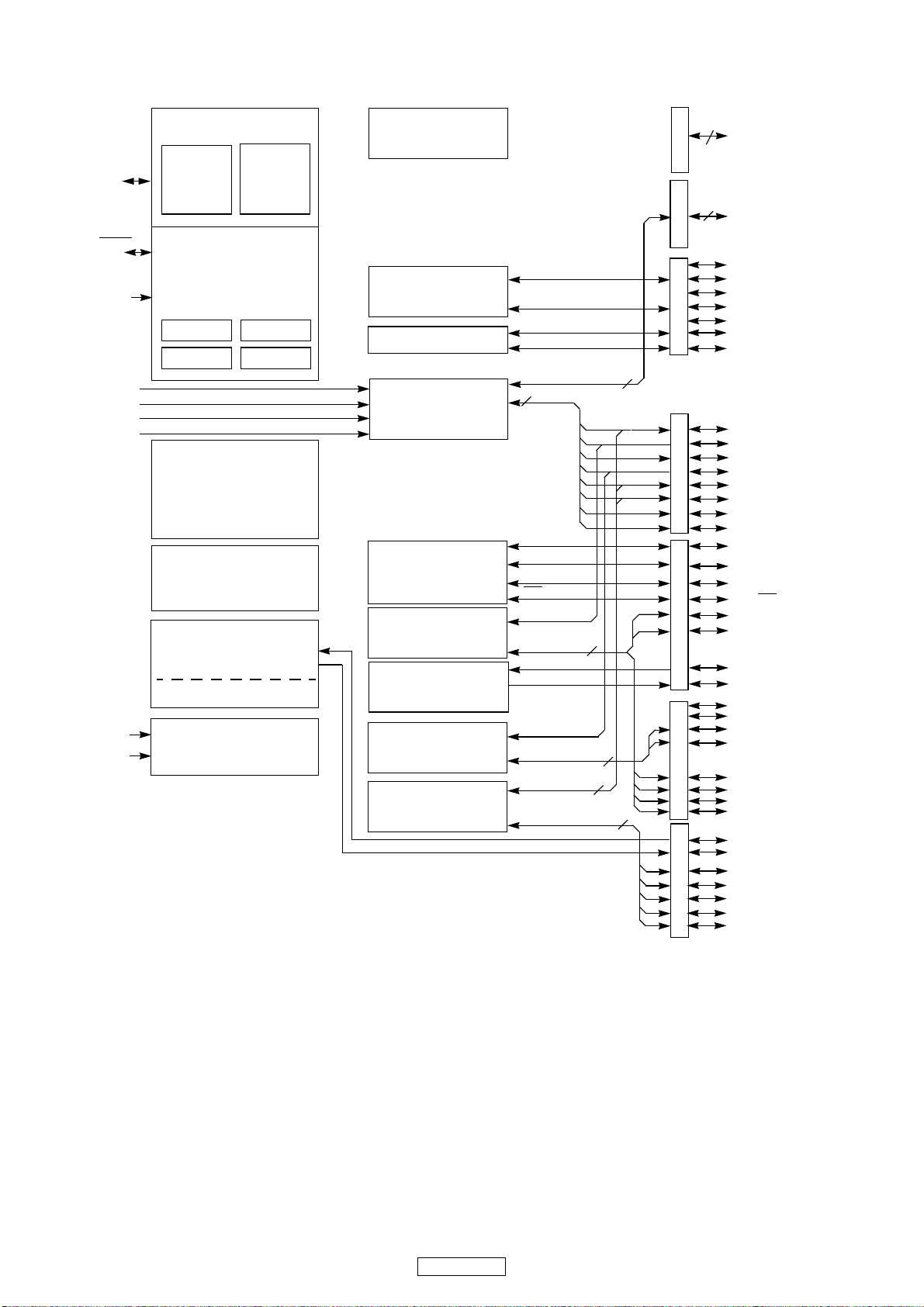

MC9508AW60 (IC201)

Block Diagram

BKGD/MS

RESET

IRQ

V

DDAD

V

SSAD

V

REFL

V

REFH

V

DD

V

SS

HCS08 CORE

BDC

HCS08 SYSTEM CONTROL

RESETS AND INTERRUPTS

MODES OF OPERATION

POWER MANAGEMENT

RTI COP

IRQ LVD

USER FLASH

(AW60 = 63,280 BYTES)

(AW48 = 49,152 BYTES)

(AW32 = 32,768 BYTES)

(AW16 = 16,384 BYTES)

USER RAM

AW60/48/32 = 2048 BYTES

AW16 = 1024 BYTES

INTERNAL CLOCK

GENERATOR (ICG)

LOW-POWER OSCILLATOR

VOLTAGE

REGULATOR

CPU

DEBUG

MODULE (DBG)

SERIAL COMMUNICATIONS

INTERFACE MODULE (SCI2)

IIC MODULE (IIC1)

10-BIT

ANALOG-TO-DIGITAL

CONVERTER (ADC1)

SERIAL PERIPHERAL

INTERFACE MODULE (SPI1)

6-CHANNEL TIMER/PWM

MODULE (TPM1)

SERIAL COMMUNICATIONS

INTERFACE MODULE (SCI1)

2-CHANNEL TIMER/PWM

MODULE (TPM2)

8-BIT KEYBOARD

INTERRUPT MODULE (KBI1)

NOTES:

1. Port pins are software configurable with pullup device if input port.

2. Pin contains software-configurable pullup/pulldown device if IRQ is enabled

(IRQPE = 1). Pulldown is enabled if rising edge detect is selected (IRQEDG = 1)

3. IRQ does not have a clamp diode to V

DD. IRQ should not be driven above VDD.

4. Pin contains integrated pullup device.

5. Pins PTD7, PTD3, PTD2, and PTG4 contain both pullup and pulldown devices.

Pulldown enabled when KBI is enabled (KBIPEn = 1) and rising edge is selected

(KBEDGn = 1).

RxD2

TxD2

SDA1

SCL1

AD1P7–AD1P0

8

AD1P15–AD1P8

SPSCK1

MOSI1

MISO1

SS1

TPM1CLK

TPM1CH5–

TPM1CH0

RxD1

TxD1

TPM2CLK

TPM2CH1–TPM2CH0

KBI1P7–KBI1P5

KBI1P4–KBI1P0

EXTAL

XTAL

8

PTA7– PTA0

PORT A

8

PTB7/AD1P7–

PTB0/AD1P0

PORT B

PTC6

PTC5/RxD2

PTC4

PTC3/TxD2

PORT C

PTC2/MCLK

PTC1/SDA1

PTC0/SCL1

8

PTD7/AD1P15/KBI1P7

PTD6/AD1P14/TPM1CLK

PTD5/AD1P13

PTD4/AD1P12/TPM2CLK

PORT D

6

2

3

5

PORT E

PORT F

PORT G

PTD3/AD1P11/KBI1P6

PTD2/AD1P10/KBI1P5

PTD1/AD1P9

PTD0/AD1P8

PTE7/SPSCK1

PTE6/MOSI1

PTE5/MISO1

PTE4/

SS1

PTE3/TPM1CH1

PTE2/TPM1CH0

PTE1/RxD1

PTE0/TxD1

PTF7

PTF6

PTF5/TPM2CH1

PTF4/TPM2CH0

PTF3/TPM1CH5

PTF2/TPM1CH4

PTF1/TPM1CH3

PTF0/TPM1CH2

PTG6/EXTAL

PTG5/XTAL

PTG4/KBI1P4

PTG3/KBI1P3

PTG2/KBI1P2

PTG1/KBI1P1

PTG0/KBI1P0

10

DN-F300

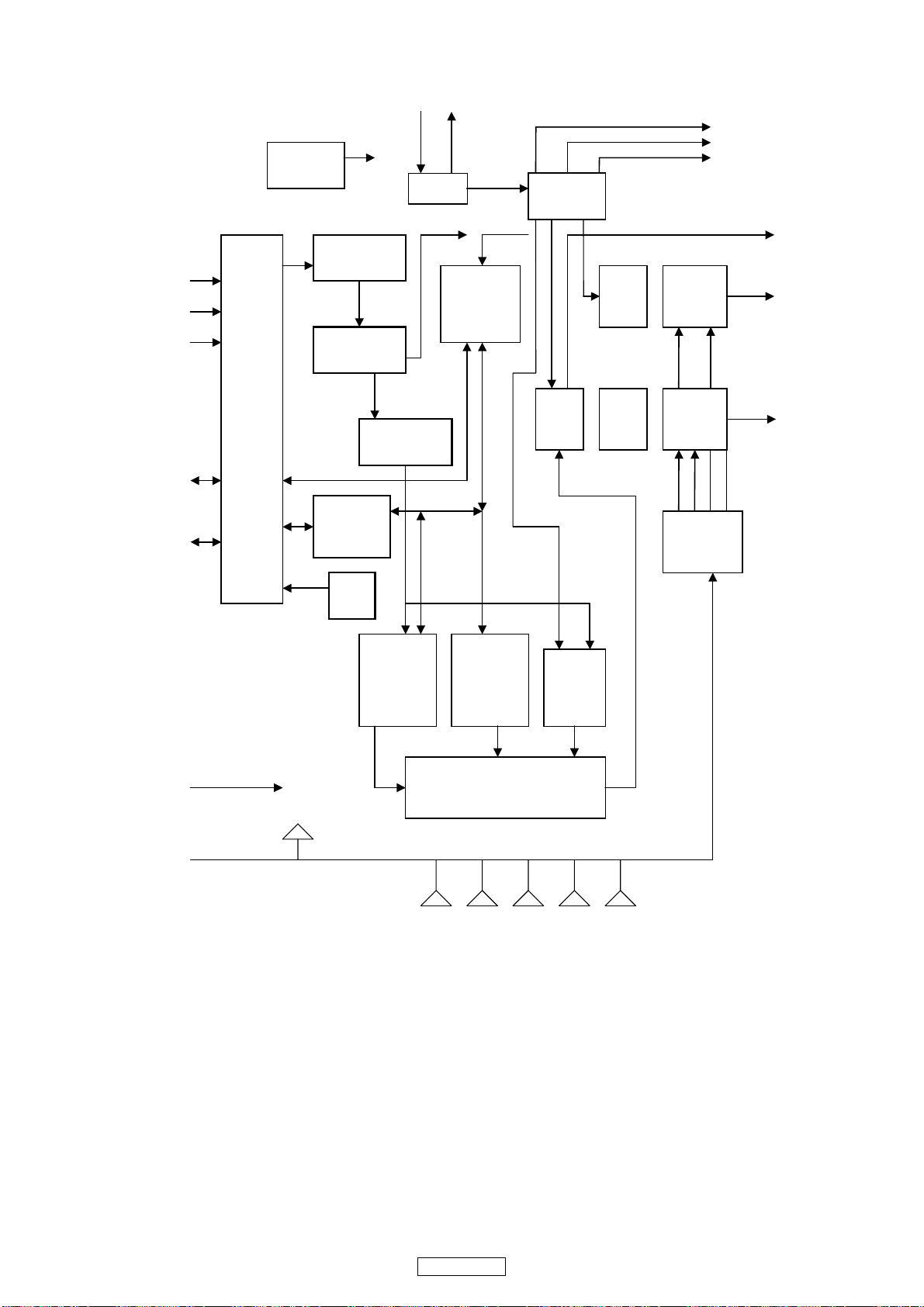

ST7066-0B (IC203)

Block Diagram

RS

RW

E

DB4 to

DB7

DB0 to

DB3

MPU

Interface

Input/

Output

Buffer

Reset

Circuit

Instruction

Register (IR)

Instruction

Decoder

Data

Register

(DR)

OSC1 OSC2

CPG

Display

data RAM

(DDRAM)

80x8 bits

Address

Counter

Timing

Generator

40-bit

shift

registe

16-bit

shift

registe

40-bit

latch

circuit

Common

Signal

Driver

Segment

Signal

Driver

LCD Drive

Voltage

Selector

CL1

CL2

M

D

COM1 to

COM16

SEG1 to

SEG40

GND

Vcc

Busy

Flag

Character

generator

RAM

(CGRAM)

64 bits

Character

generator

ROM

(CGROM)

9,920 bits

Parallel/Serial converter

and

Attribute Circuit

V1 V2 V3 V4 V5

Cursor

and

Blink

controller

11

DN-F300

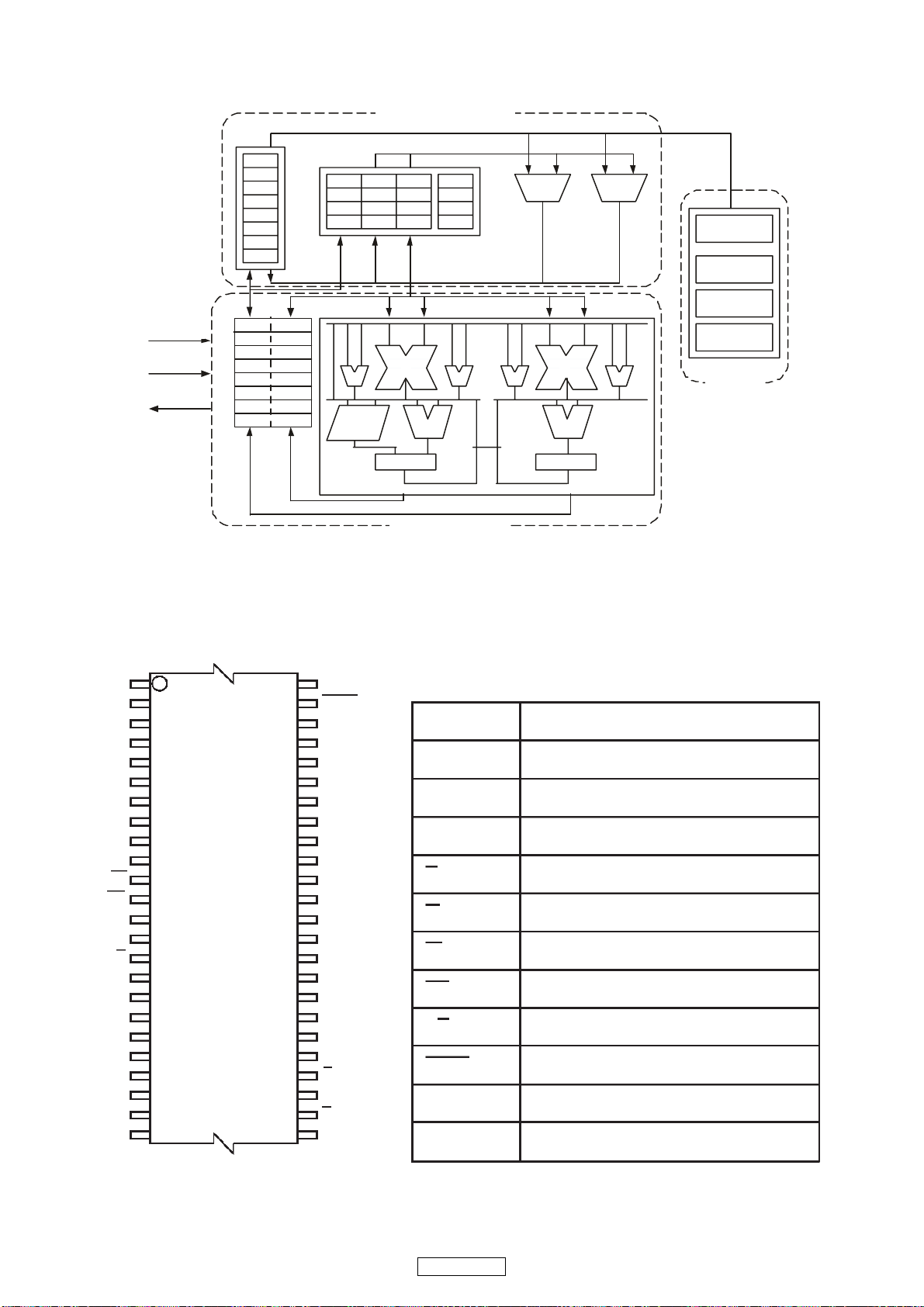

ADSP-BF532 (U1)

Block Diagram

LD032BITS

LD132BITS

SD 3 2 BI TS

R7

R6

R5

R4

R3

R2

R1

R0

R7 .H

R6 .H

R5 .H

R4 .H

R3 .H

R2 .H

R1 .H

R0 .H

ADDRESS ARITHMETIC UNIT

SP

FP

P5

P4

P3

P2

P1

P0

R7.L

R6.L

R5.L

R4.L

R3.L

R2.L

R1.L

R0.L

I3

I2

I1

I0

BARREL

SHIF TER

L3

B3

L2

L1

L0

16

A0 A1

M3

B2

M2

B1

M1

B0

M0

88 8 8

40 40

DAG0 DAG 1

16

SEQUENCER

ALIGN

DECODE

LOOP B UFFER

CONTROL

UN IT

M29W800B70N6 (U4)

A15

1

A14

A13

A12

A11

A10 DQ14

A9

A8

NC

NC

W

M29W800T

RP

NC

NC

12

13

M29W800B

(Normal)

RB

A18

A17

A7

A6

A5

A4

A3

A2

24 25

A1

48

37

36

AI02179

A16

BYTE

V

SS

DQ15A–1

DQ7

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

E

A0

DATA AR ITHMETIC UNIT

A0-A18 Address Inputs

DQ0-DQ7 Data Input/Outputs, Command Inputs

DQ8-DQ14 Data Input/Outputs

DQ15A–1 Data Input/Output or AddressInput

E Chip Enable

G Output Enable

W Write Enable

RP Reset / Block TemporaryUnprotect

RB Ready/Busy Output

BYTE Byte/Word Organisation

V

CC

V

SS

Supply Voltage

Ground

12

DN-F300

Loading...

Loading...