Delfield 549-CH, 561-CD, 573-CH, 573-CR, 573-CRR User Manual

...

April 2010

500 Series

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier of damage! Inspect all

components immediately. See page 2.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

500 Series Display Cases Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

2

©2010 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademark of The

Delfield Company.

RECEIVING & INSPECTING EQUIPMENT ..............................2

SPECIFICATIONS ..................................................................3

PRESSURE CONTROL SETTINGS .........................................5

INSTALLATION ................................................................. 5, 6

OPERATION ..................................................................... 5, 6

CARE & CLEANING ..............................................................6

WIRING DIAGRAMS

500-CR self-contained refrigerated units .......................

7

500-OR open refrigerated units .....................................

7

500-CD dry storage units ..............................................

8

500-CH curved heated units ..........................................

8

EXPLODED VIEWS & PARTS LISTS

537-CD ..........................................................................

9

549-CD ..........................................................................

9

561-CD ........................................................................

10

573-CD ........................................................................

10

537-CR, CRR ...............................................................

11

549-CR, CRR ...............................................................

11

561-CR, CRR ...............................................................

12

573-CR, CRR ...............................................................

12

549-CH ........................................................................

13

561-CH ........................................................................

13

573-CH ........................................................................14

549-OR ........................................................................

14

FLUORESCENT LIGHT ASSEMBLY .....................................15

DOOR ASSEMBLY ...............................................................16

REFRIGERATION ASSEMBLES............................................17

FOOD WELL ASSEMBLY .....................................................18

REPLACEMENT PARTS LIST ..............................................19

STANDARD LABOR GUIDELINES ........................................20

STANDARD WARRANTIES ............................................ 21-22

NOTES ................................................................................23

The Serial number on all 500 Series units is located on the

rear of the unit, near the ON/OFF switch.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots can be found at www.delfield.com.

CONTENTS SERIAL NUMBER LOCATION

RECEIVING AND INSPECTING THE EQUIPMENT

Even though most equipment is shipped crated, care should

be taken during unloading so the equipment is not damaged

while being moved into the building.

1. Visually inspect the exterior of the package and skid or

container. Any damage should be noted and reported

to the delivering carrier immediately.

2. If damaged, open and inspect the contents with the

carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment

notify the carrier. Notification should be made verbally

as well as in written form.

4. Request an inspection by the shipping company of the

damaged equipment. This should be done within 10

days from receipt of the equipment.

5. Check the lower portion of the unit to be sure adjustable

feet are not bent.

6. Also open the compressor compartment housing and

visually inspect the refrigeration package. Be sure lines

are secure and base is still intact.

7. Freight carriers can supply the necessary damage forms

upon request.

8. Retain all crating material until an inspection has been

made or waived.

Uncrating the Equipment

First cut and remove the banding from around the crate.

Remove the front of the crate material, use of some tools will

be required. If the unit is on legs remove the top of the crate

as well and lift the unit off the skid.

500 Series Display Cases Service and Installation Manual

3

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

500 SERIES SPECIFICATIONS

MODEL DELFIELD VOLTS/HERTZ AMPS

NUMBER PART # PHASE (includes lights & fan)

Dry Storage Display Cases

537-CD 078-5371 115/60/1 5.0

549-CD 078-5491 115/60/1 5.0

561-CD 078-5611 115/60/1 5.0

573-CD 078-5731 115/60/1 5.0

MODEL DELFIELD NUMBER OF VOLTS/HERTZ

NUMBER PART # 12 X 20 WELLS PHASE AMPS

Heated Display Cases

549-CH 078-5494 3 120, 208-240V/60/1 19.0/21.0

561-CH 078-5614 4 120, 208-240V/60/1 24.0/27.0

573-CH 078-5734 5 120, 208-240V/60/1 30.0/34.0

MODEL DELFIELD VOLTS/HERTZ EVAPORATOR CAPACITY CABINET LOAD

NUMBER PART # H.P.* PHASE AMPS BTU/°TD BTU/HOUR

Remote Refrigerated Display Cases

537-CRR CONSULT FACTORY 1/2* 115/60/1 5.0 180 1730

549-CRR 078-5493 1/2* 115/60/1 5.0 190 2250

561-CRR 078-5613 3/4* 115/60/1 6.0 190 2770

573-CRR 078-5733 3/4* 115/60/1 6.0 290 3290

*Recommended horsepower

MODEL DELFIELD VOLTS/HERTZ CABINET LOAD SYSTEM CAPACITY REFRIGERATION

NUMBER PART # H.P. PHASE AMPS BTU/HOUR BTU/HOUR CHARGE 404A

Self-Contained Refrigerated Display Cases

537-CR 078-5372 1/2 115/60/1 12.0 1730 3258 32 oz.

549-CR 078-5492 1/2 115/60/1 12.0 2250 3316 32 oz.

561-CR 078-5612 3/4 115/60/1 16.0 2770 4919 48 oz.

573-CR 078-5732 3/4 115/60/1 16.0 3290 5387 48 oz.

MODEL DELFIELD VOLTS/HERTZ CABINET LOAD SYSTEM CAPACITY REFRIGERATION

NUMBER PART# H.P. PHASE AMPS BTU/HOUR BTU/HOUR CHARGE 404A

Open Front Refrigerated Display Cases

549-OR 078-5495 1/2 115/60/1 12.0 2030 3354 32 oz.

500 Series Display Cases Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

4

Location

To meet NSF standards, all units must be sealed

to the floor.

Be sure the location chosen has a floor strong enough

to support the total weight of the cabinet and contents.

Contents fully loaded in this product line can weigh as much

as 1500 lbs. Reinforce the floor as necessary to provide for

maximum loading.

For the most efficient refrigeration, be sure to provide good

air circulation inside and out. Do not pack the refrigerator so

full that air cannot circulate. Be sure that the exterior of the

unit has access to ample air. Avoid hot corners and locations

near stoves and ovens.

Leveling

To level unit, simply lower the four adjustable rubber feet

located under the unit to the floor and adjust until unit is

level. A level cabinet will perform better because the drain

will empty properly, the doors will line up with the frames

correctly and the cabinet will not be subject to undue strain.

Plumbing

Self-contained models are standard with a condensate

evaporator. If the evaporator fails, the unit’s drain must have

an outlet to an appropriate drainage area or container.

Moisture collecting from improper drainage

can create a slippery surface on the floor and

a hazard to employees. It is the owner’s and

operator’s responsibility to provide a container or

outlet for drainage.

Electrical connection

Refer to the amperage data on page 3, the serial tag, your

local code or the National Electrical Code to be sure the

unit is connected to the proper power source. A protected

circuit of the correct voltage and amperage must be run for

connection of the line cord, or permanent connection to the

unit.

Self-contained units have an ON/OFF switch located on

the operators side. Simply turn the switch to ON to begin

operation.

The power switch should be turned to OFF and the

unit disconnected from the power source whenever

performing service or maintenance functions.

CAUTION

On self-contained models, after turning the ON/OFF switch

to ON, the unit’s compressor will begin operating. Delfield

display cases are designed to maintain an operational

temperature of 36°F to 40°F.

Do not load the storage area in a way that restricts the air

flow. Overloading will result in the loss of temperature. Do

not throw items into the storage area. The interior of the

cabinet and the blower coil may be damaged by this type of

neglect, which is not covered under your warranty.

These units use HFC-404A refrigerant, and

have a lock-out high pressure limiting device.

Under severe overloading conditions, in the

event of a condenser fan failure or a plugged or

blocked condenser, this device may shut down

the refrigeration system. See page 17 for part number

information if a replacement is required.

INSTALLATION: 500 CD, CR, CRR & OR

OPERATION: 500 CD, CR, CRR & OR

500 Series Display Cases Service and Installation Manual

5

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

Pressure Control

The temperature is controlled by an adjustable pressure

control located in the machine compartment. An adjustable

control has the word COLDER near the knob, with an arrow

to indicate the adjustment direction. These controls are

field adjustable and do not require a service agent. If you

have any questions, feel free to contact the Delfield Service

Department.

The refrigeration systems on self-contained CR & OR models

were adjusted at the factory to maintain between 36°F and

40°F. No adjustment should be necessary. If adjustment

does become needed however, the factory recommended

settings are:

Low-pressure settings (CR models): 82 psi cut-in,

47 psi cut-out, 35 psi differential.

Low-pressure settings (OR models): 82 psi cut-in,

40 psi cut-out, 42 psi differential.

Operating pressures: High, 170 to 200 psi. Low, 30 to 37

psi.

In attempting to adjust the pressure control, you can

do damage to your unit by accidentally adjusting the

differential. Please make small incremental adjustments

if a temperature adjustment is necessary, please contact

the service department at Delfield (800) 733-8829 #1,

or your local service agent. Delfield is not responsible

for charges incurred while having the pressure control

adjusted.

CONTROL SETTINGS: 500 CR & OR

500 Series Display Cases Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

6

Installation should be done by personnel

certified and licensed to install and maintain

electrical appliances.

Location

Be sure the location chosen has a floor strong enough

to support the total weight of the cabinet and contents.

Contents fully loaded into this product line can weigh as

much as 1500 lbs. Reinforce the floor as necessary to

provide for maximum loading.

Leveling

A level cabinet looks better and will perform better because

the drain pan will drain properly, the doors will line up with

the frames properly, and the cabinet will not be subject to

undue strain.

Electrical connection

Connections must be made in accordance with

all applicable local codes and/or the National

Electrical Code. Refer to the wiring diagrams on

pages 6 and 7.

INSTALLATION: 500 CH

OPERATION: 500 CH

For most efficient operation, keep covered insets empty in

each well during preheating and when the well is not in use.

Dry operation

1) Pre-heat the well on “HIGH” for approximately

15 minutes.

2) After pre-heating, set the control to your

desired serving temperature.

Only 6” (15.2cm) deep insets should be used with a dry

food well. When operated dry, the bottom of the food well

will discolor. Refer to cleaning instructions to remove

discoloration.

Temperature

Product in pans . . . . . . . . . . . . . . . . . . . . . . 140°F to 160°F

S

T PE

S

NOTE: Intended for DRY OPERATION ONLY.

CLEANING: ALL MODELS

Clean the food wells daily. Wash with non-abrasive cleanser

and non-abrasive pad. If necessary, a mild abrasive may be

used. Do not use steel wool.

For all stainless steel parts, use mild, non-abrasive soap

or detergent and warm water. This may be followed by an

application of stainless steel cleaner or polish which will

eliminate water spotting and fingerprints and will bring out

the finish of the stainless steel.

Do not use a hose or pressure wash on these

units. The water will damage the electrical

components.

Cleaning the condenser (refrigerated units)

In order to maintain proper refrigeration, the condenser

fins must be cleaned of dust, dirt and grease every three

months. If condenser is totally blocked after three months

increase cleaning frequency. Clean the condenser with a

vacuum cleaner or stiff brush. If extremely dirty, use a

commercially available condenser cleaner.

Cleaning the sliding door assembly

All Delfield 500 Series display cases feature a Pike sliding

door assembly. Regular cleaning of door tracks with mild

soap and water will keep them free of foreign matter

insuring many years of use. The glass may be cleaned with

a glass cleaner.

Before the unit is used the first time for serving, turn the

temperature knob to “10” and heat the well for 20 minutes.

Do not be alarmed if smoke appears; this preheat should

burn off any residue or dust on the heating element.

Hot surfaces can cause serious burns. Always

wear some type of protective covering on your

hands and arms when removing lids or pans

from the unit.

Never place food directly into the well. Always use pans.

Always place covers on pans when not serving to prevent

food from drying out and to reduce your operating cost.

500 Series Display Cases Service and Installation Manual

7

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

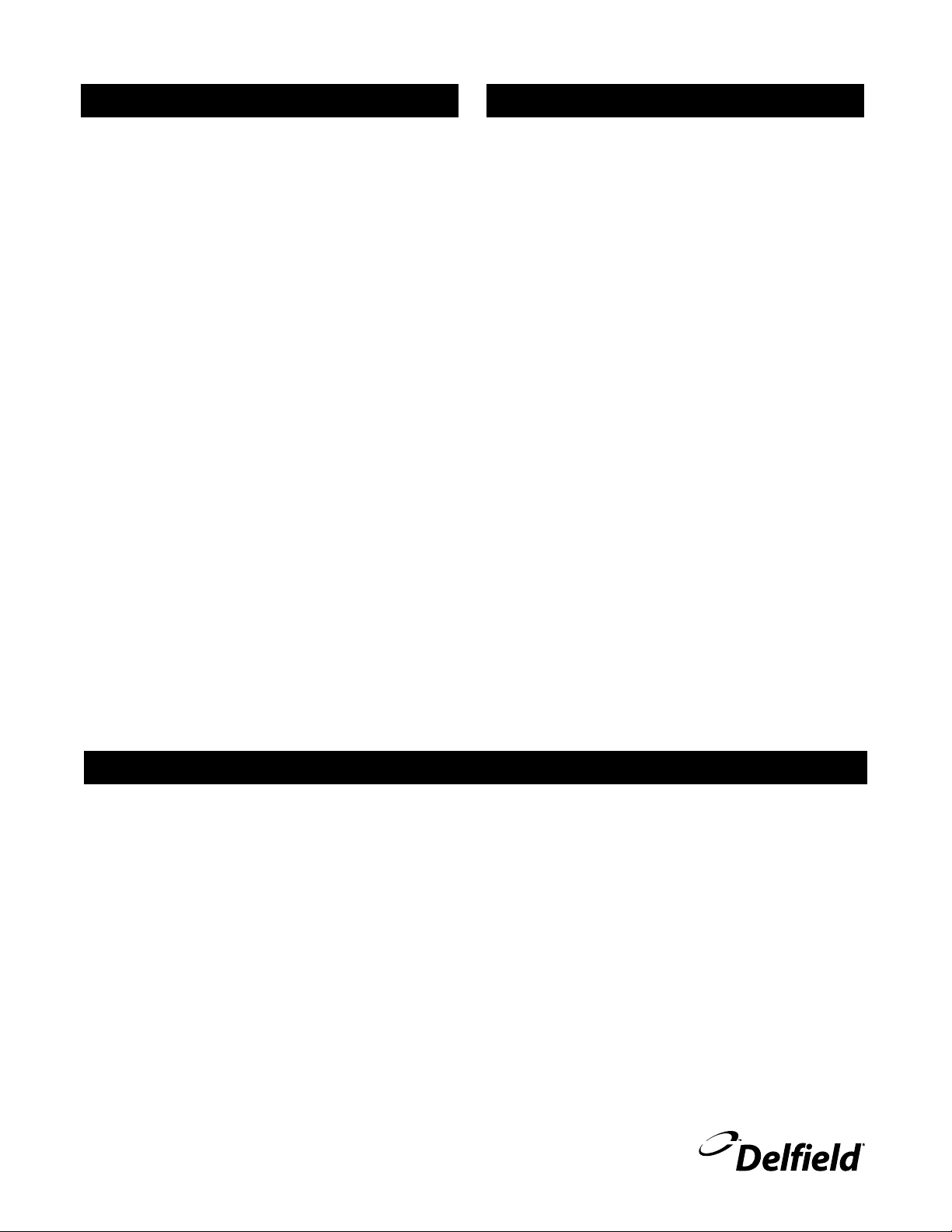

WIRING: 500 CR

WIRING: 500 OR

NEUTRAL

NEUTRAL

500 Series Display Cases Service and Installation Manual

For customer service, call (800) 733-8829, (800) 773-8821, Fax (989) 773-3210, www.delfield.com

8

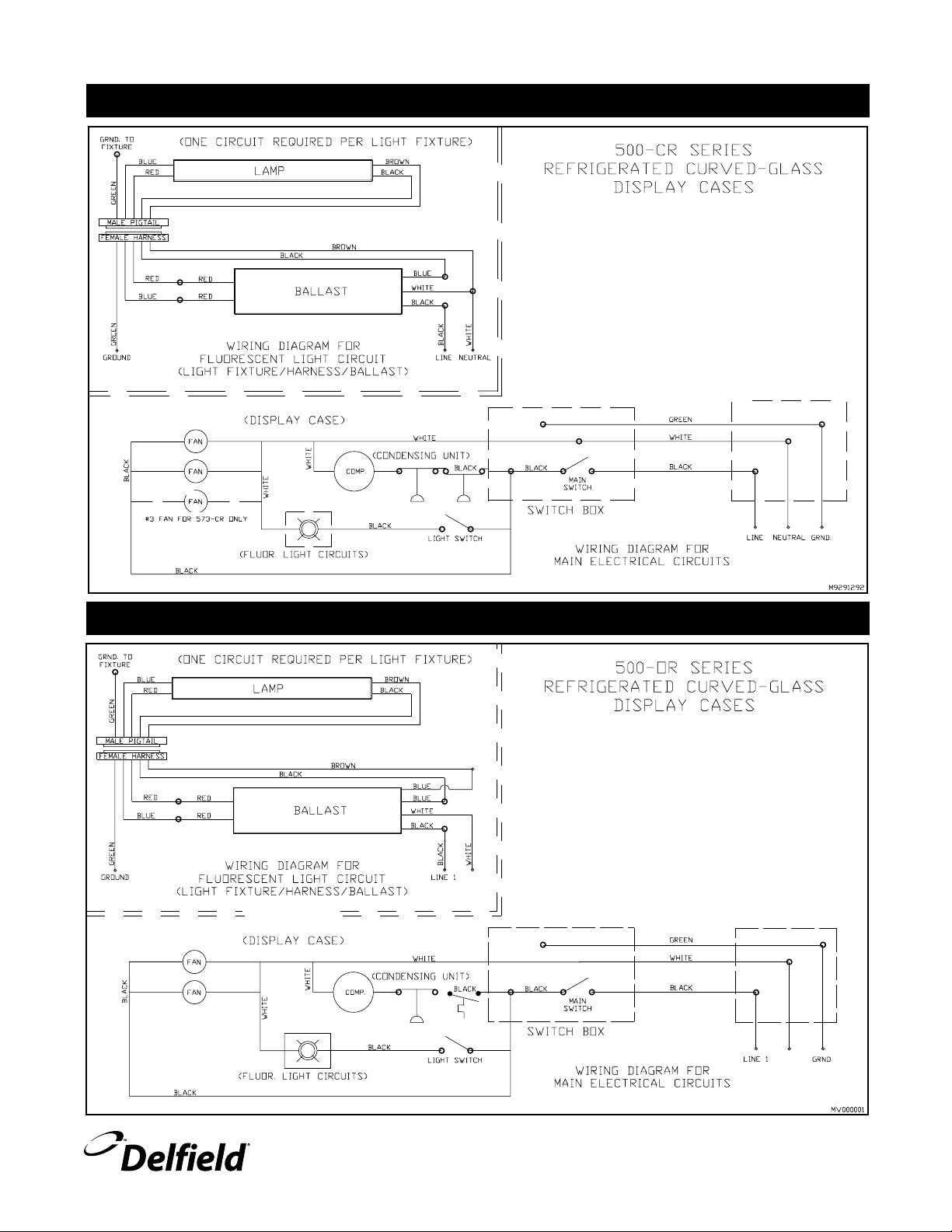

WIRING: 500 CD

WIRING: 500 CH

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

J

P P P P

RED

RED

RED

RED

RED

RED

RED

HEATED SHELF

120V

P LL

2

1

H

H

1 2

208V208V208V

21

P L L

2

H

H

1

21

LLP

2

H

H

1

2

LL

1

P

H

2

1

H

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

Loading...

Loading...