Delfield 406-MD2-CP2 Installation Manual

Undercounter Refrigerator

The Delfield Company, Model: 406-MD2-CP2, 406-MD2-CP3

Operation Manual

Manufactured exclusively for

McDonald’s® By:

Delfield

980 S. Isabella Rd.

Mt. Pleasant, MI 48858

Tel. (989) 773-7981 Fax (989) 773-2060

406-MD2-CP2 |

406-MD2-CP3 |

115V/60Hz |

220V/50Hz |

Undercounter Refrigerator

Note: Do not install these unit(s) in any area with an ambient temperature in excess of 95˚F/35˚C. Doing so will cause damage to the unit(s).

©2009•McDonald’s Corporation |

Printed in January 2009 |

Printed in |

All Rights Reserved |

|

The United States of America |

Delfield® |

|

|

|

™ |

|

|

|

|

|

|

|

TABLE OF CONTENTS |

|

|

|

Important Warning And Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

|

. 3 |

Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

|

. 4 |

Serial Tag Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 |

|||

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 |

|||

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

5 |

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

5 |

Leveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Stabilizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Electrical Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 |

|||

Undercounter Refrigerator Daily PM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 |

|||

Undercounter Refrigerator Quarterly Clean Condenser Coil PM Card. . . . . . . . . . . . . . |

. |

. |

7 |

Undercounter Refrigerator Quarterly Inspect Door Gasket PM Card. . . . . . . . . . . . . . . |

. |

|

. 8 |

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 |

|||

Replacement Parts Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 |

|||

Standard Labor Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 |

|||

Manufacturers Limited Lifetime Warranty. . . . . . . . . . . . . . . . . . . . . . . . . |

. |

. 12 |

|

Two Year Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

|

13 |

Service Labor Contract. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14-15 |

||

Page For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

Delfield™ ®

Delfield™ ®

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING, OR PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

WARNING DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING UNLESS ALL COVER AND ACCESS PANELS ARE IN PLACE AND PROPERLY SECURED, DO NOT OPERATE THIS EQUIPMENT.

CAUTION Observe the following:

• Minimum clearances must be maintained from all walls and combustible materials.

•Keep the equipment area free and clear of combustible material.

•Adequate clearance for air openings.

•Operate equipment only on the type of electricity indicated on the specification plate.

•Retain this manual for future reference.

For factory assistance, call Page 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

Delfield™ ®

Delfield™ ®

Serial Number

Always have the serial number of your unit available when calling for parts or service.

Serial Tag Location

The Undercounter Refrigerator Serial Tag is located on the right side of the interior back wall.

COVINGTON, TENNESSEE

M O D E L 4 0 6 |

S E R I A L N O . 0 8 0 6 1 5 2 0 0 0 8 2 4 |

R E F R I G . R - 4 0 4 A 7 O Z |

M I N . C I R C U I T A M PA C I T Y 1 5 A |

E L E C . R E Q ( 1 ) 1 1 5 V - 6 0 H Z - 7 A |

|

M A X . O V E R C U R R E N T P R O T. D E V I C E |

1 5 A |

D E S I G N P R E S S U R E S : |

|

H I G H S I D E 4 5 0 P S I G |

L O W S I D E 2 5 0 P S I G |

F O R PA R T S O R S E RV I C E P L E A S E C A L L F O R PA R T S / S E RV I C E 8 0 0 7 3 3 8 8 2 9

Sample Serial Tag

Figure 1.

Undercounter Refrigerator

Specifications

Model |

Number of |

Shelf Area |

Storage |

H.P |

R404 |

V/Hz/Ph |

AMPS |

Ship |

Plug Type |

|

Shelves |

Capacity |

Charge |

Weight |

|||||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

406-MD2-CP2 |

1 |

7.2ft2 |

5.7ft3 |

1/5 |

7oz |

115/60/1 |

7.0 |

176lbs |

NEMA |

|

|

(.67m2) |

(.16m3) |

(79.83kg) |

5-15P |

||||||

|

|

|

|

|

|

|||||

406-MD2-CP3 |

1 |

7.2ft2 |

5.7ft3 |

1/5 |

198g |

220/50/1 |

3.5 |

176lbs |

I |

|

(.67m2) |

(.16m3) |

(79.83kg) |

||||||||

|

|

|

|

|

|

|

Page For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

Installation

Location

Undercounter refrigerators are intended for indoor use only. Be sure the location chosen has a floor strong enough to support the total weight of the cabinet and contents. Reinforce the floor as necessary to provide for maximum loading. Take care when moving the equipment that nothing gets pinched between the unit and stationary objects. Sheet metal edges, although deburred, could cause cuts in certain situations.

For the most efficient refrigeration, be sure to provide good air circulation inside and out.

Inside cabinet: Do not pack refrigerator so full that air cannot circulate.

Outside cabinet: Be sure that the unit has access to ample air. A minimum space of 3” (7.6cm) at the back of the unit and 1” (2.5cm) at the top and sides is required to conform to

Underwriters Laboratories’ standards. On undercounter units it is imperative that the proper air flow be maintained. The refrigeration system is designed so air will flow under the unit, over the compressor/condenser area, and out at the top rear of the unit. Avoid hot corners and locations near stoves and ovens.

Any restriction of the proper air flow outlined above, total or partial, will void the warranty on

the unit.

Leveling

A level cabinet will perform better because the drain pan will drain properly, the doors will line up with the frames and the cabinet will not be subject to undue strain.

Never stand on the unit! Doing so may result in bodily injury. They are not designed to hold the weight of an

adult and will collapse if misused in this manner.

Stabilizing

These models are supplied on casters for your convenience, for ease of cleaning underneath and mobility.

The unit must be installed in a stable condition with the front wheels locked. Locking the front casters after installation is the owner’s and operator’s responsibility. This will keep the unit from rolling or tipping.

Delfield™ ®

Delfield™ ®

Electrical connection

Refer to the amperage data, the serial tag, your local code or the National Electrical Code to be sure the unit is connected to the proper power source. A protected circuit of the correct voltage and amperage must be run for connection of the line cord, or permanent connection to the unit.

A 7’ (2.1 m) long grounded supply cord and plug are provided with standard units. Simply plug the unit in to begin operation.

The thermostat must be turned to OFF and the unit disconnected from the power source whenever performing service, maintenance functions or cleaning the refrigerated area.

If the supply cord is damaged it must be replaced before operating this equipment. Do not connect a damaged supply cord to a power source. The cord must be replaced by a qualified service personnel.

Operation

Be sure that fan guards are in place before operating. After the unit is connected to power it will automatically begin operating. With the door closed, the temperature of the cabinet should reach 36°F to 40°F (2°C to 4°C) in about one hour. The temperature control, located on the back panel inside the refrigerator, can be adjusted to meet the current conditions.

Temperature control instruction

A thermostat located in the evaporator housing on interior rear of the unit, controls the temperature in the box. The factory setting for the control is “4” and maintains about 38°F (3°C) in the box. Set toward “1” for higher temperatures and toward “7” for lower temperatures.

Continuous opening and closing of the door will hamper the unit’s ability to maintain optimum refrigeration temperature.

Plumbing

Self-contained models are standard with a condensate evaporator. If, for some reason, a unit does not have a condensate evaporator, or the evaporator fails, the unit’s drain must have an outlet to an appropriate drainage area or container.

|

Moisture collecting from improper drainage can |

|

create a slippery surface on the floor and a hazard to |

CAUTION |

employees. It is the owner’s responsibility to provide |

|

a container or outlet for drainage. |

Defrosting

Refrigerators defrost automatically with every cycle of the compressor. The water generated is routed to a pan on the rear of the unit and is evaporated by the heat given off by the compressor.

For factory assistance, call Page 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

|

Delfield® |

|

|

|

|

|

|

|

|

|

|

|

™ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inspect And Clean |

|

|

|

Daily |

|

|

|

RF 2 D1 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||

Why |

Clean the exterior to prevent discoloration or rust. Clean the interior to keep it food safe. |

||||||||||

Time required |

5 minutes to prepare |

15 minutes to complete |

|

|

|

|

|||||

Time of day |

At close |

For 24-hour restaurants: during low-volume periods |

|||||||||

Hazard icons |

|

|

|

|

|

|

|

|

|

|

|

Tools and supplies

Bucket, clean and |

Bucket, soiled towels |

Gloves, rubber |

Goggles |

EXCEED Glass and |

sanitized towels |

|

|

|

Multi Surface Cleaner |

Procedure

1Unplug power cord. Move products from inside unit to walk-in.

2Wear hand and eye protection.

Wear rubber gloves and safety goggles when handling cleaner and sanitizer.

3Clean exterior with EXCEED.

Spray exterior surfaces with EXCEED Glass and Multi Surface Cleaner. Using a clean towel, wipe unit with the “grain” of the stainless steel to avoid marring the finish.

EXCEED Glass and Multi

Surface Cleaner

4Sanitize exterior.

Wipe exterior with a clean, sanitized towel dampened with McD Sanitizer solution.

McD Sanitizer Solution

Page

5Clean interior with EXCEED.

Remove shelves from interior. Spray interior, shelves and gaskets with EXCEED Glass and Multi Surface Cleaner. Using a clean towel, wipe interior, shelves and gaskets.

EXCEED Glass and Multi

Surface Cleaner

6Sanitize interior.

Wipe interior, shelves and gasket with a clean, sanitized towel dampened with McD Sanitizer solution.

McD Sanitizer Solution

7Put shelves back into the cabinet.

8Plug power cord in. Put product back into unit.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 |

Page 1 of 1 |

#9294285 |

|

For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

407 406, 403, 402, Refrigerator/Freezer Top Work And Counter Under Delfield

Daily

D1 RF2

Delfield™ ®

Delfield™ ®

|

Clean Condenser Coil |

|

|

|

Quarterly |

|

|

|

RF 2 Q1 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Why |

In order to maintain proper refrigeration performance, the condenser must be clean. |

|

|

||||||||

Time required |

5 minutes to prepare |

15 minutes to complete |

|

|

|||||||

Time of day |

At close |

For 24-hour restaurants: during low-volume periods |

|||||||||

Hazard icons |

|

|

|

|

|

|

|

|

|

|

|

Tools and supplies

Vacuum, wet/dry |

Brush, wire |

Procedure

1Unplug unit power cord.

2Locateunit. condenser on back of

3Clean condenser.

Vacuum or wire brush dust and particles from condenser. Remove particles from cabinet.

4Plug the unit power cord in.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 |

Page 1 of 1 |

#9294285 |

|

For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

407 406, 403, 402, Refrigerator/Freezer Top Work And Counter Under Delfield

Quarterly

Q1 2 RF

Page

|

Delfield® |

|

|

|

|

|

|

|

|

|

|

|

™ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

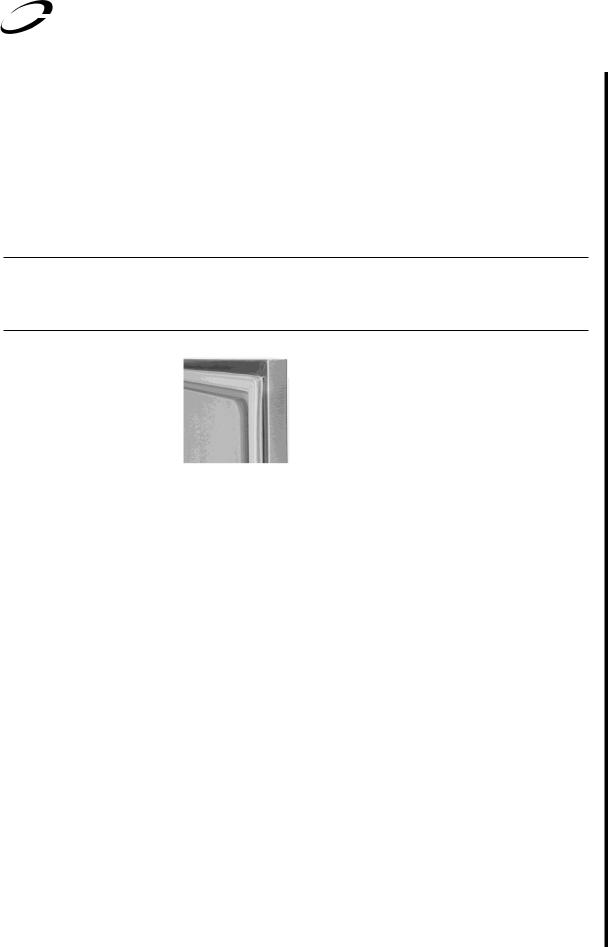

Inspect Door Gaskets |

|

|

|

Quarterly |

|

|

|

RF 2 Q2 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Why |

In order to maintain proper refrigeration performance, the gasket must seal the door to the unit. |

||||||||||

Time required |

0 minutes to prepare |

10 minutes to complete |

|

|

|

|

|||||

Time of day |

At close |

For 24-hour restaurants: during low-volume periods |

|||||||||

Hazard icons |

None |

|

|

|

|

|

|

|

|

|

|

Tools and supplies

None

Procedure

1Inspect door gaskets.

Check that the door gaskets are present.

Check that the door gaskets are present.

Check that there is no space between the unit frame and the gasket.

Check that there is no space between the unit frame and the gasket.

Check that the gasket is tight against the door itself.

Check that the gasket is tight against the door itself.  Check that there are no rips, tears, or cracks on any part of the gasket.

Check that there are no rips, tears, or cracks on any part of the gasket.

2Ifgasket.necessary, order a new

Call 1-800-733-8829 to find a local parts distributor. Have the model and serial number available when calling the distributor.

©McDonald’s Corporation · Planned Maintenance Manual · Revised January 2009 |

Page 1 of 1 |

#9294285 |

|

Page For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

407 406, 403, 402, Refrigerator/Freezer Top Work And Counter Under Delfield

Quarterly

Q2 2 RF

Delfield™ ®

Delfield™ ®

406-MD2-CP2 Wiring Diagram

115V/60Hz/1Ø |

L1 G N |

NEMA 5-15P |

|||||

|

|

|

|

|

|

|

Supply Cord & |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Plug Furnished |

|

|

|

|

|

|

|

|

Black White

Evaporator Fan

|

|

|

|

|

|

|

Temperature |

|

|

|

|

Condensing |

|

|

|

|

|

|||

|

|

|||||

Control |

|

|

|

|

Unit |

|

|

|

|||||

406-MD2-CP3 Wiring Diagram

230V/50Hz/1Ø |

L1 G N |

Supply Cord & |

||||||

|

|

|

|

|

|

|

|

Plug Furnished |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Brown Blue

Evaporator Fan

|

|

|

|

|

|

|

Temperature |

|

|

|

|

Condensing |

|

|

|

|

|

|||

|

|

|||||

Control |

|

|

|

|

Unit |

|

|

|

|||||

For factory assistance, call Page 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

|

Delfield® |

|

|

|

|

|

|

™ |

|

|

|

|

|

|

|

|

|

|

||

Replacement Parts |

|

|

|

|

||

|

406-MD2-CP2 |

|

|

406-MD2-CP3 |

|

|

|

Part # |

Description |

|

Part # |

Description |

|

0074057 |

Capillary tube, .042” id x 144” |

|

120-CB6-0030 |

Bracket, coffee machine |

|

|

3234160 |

Caster, 5” |

9321079 |

Bumper |

|

||

3234161 |

Caster, 5” with brake |

|

129-C15-0103 |

Bumper bracket |

|

|

3526997 |

Compressor |

0074057 |

Capillary tube, .042” id x 144” |

|

||

3516446 |

Compressor relay |

3235515 |

Caster 4” |

|

||

2194787 |

Compressor start capacitor |

3235516 |

Caster 4”, with brake |

|

||

0053452 |

Condensate heater only |

3526940 |

Compressor (220V) |

|

||

0330154 |

Condensate pan assembly |

0053452 |

Condensate heater only |

|

||

|

|

(includes condensate heater) |

0330154 |

Condensate pan assy |

|

|

3516275 |

Condenser coil |

|

|

(includes condensate heater) |

|

|

3516172 |

Condenser fan blade |

3516275 |

Condenser coil |

|

||

3516173 |

Condenser fan guard |

3516172 |

Condenser fan blade |

|

||

2162691 |

Condenser fan motor |

3516173 |

Condenser fan guard |

|

||

|

000-B3I-003E |

Door assembly, hinged right |

2162692 |

Condenser motor (220V) |

|

|

1702623 |

Door gasket |

|

000-B3I-003H |

Door assembly, right hinged |

|

|

3516116 |

Evaporator coil |

1702623 |

Door gasket |

|

||

3516172 |

Evaporator fan blade |

3516172 |

Evaporator fan blade |

|

||

3516173 |

Evaporator fan guard |

3516173 |

Evaporator fan guard |

|

||

2162691 |

Evaporator motor |

2162692 |

Evaporator motor (220V) |

|

||

3516321 |

Filter drier |

3516116 |

Evaporator coil |

|

||

3237569 |

Hinge bracket, bottom left |

3516321 |

Filter drier |

|

||

3237563 |

Hinge bracket, bottom right |

3237569 |

Hinge bracket, bottom left |

|

||

3237568 |

Hinge bracket, top left |

3237563 |

Hinge bracket, bottom right |

|

||

3237562 |

Hinge bracket, top right |

3237568 |

Hinge bracket, top left |

|

||

3237516 |

Hinge cartridge (spring loaded) |

3237562 |

Hinge bracket, top right |

|

||

|

3234225A |

Pivot cap, nylon, 1” square |

3237516 |

Hinge cartridge (spring loaded) |

|

|

|

117-CB5-0030 |

Pump bracket |

|

3234225A |

Pivot cap, nylon, 1” square |

|

3978030 |

Shelf |

3978030 |

Shelf |

|

||

5189779 |

shelf clip |

5189779 |

shelf clip |

|

||

|

MCP00207 |

Shoulder screw |

|

MCP00207 |

Shoulder screw |

|

|

000-CB1-0030 |

Speed rail assembly |

|

2194759KT |

Temperature control |

|

|

2194759KT |

Temperature control |

|

|

(includes control, knob and dial plate) |

|

|

|

(includes control, knob and dial plate) |

2194761 |

Temperature control knob only |

|

|

2194761 |

Temperature control knob only |

3516135 |

Thermometer, hanging |

|

||

3516135 |

Thermometer, hanging |

3516059 |

Thermometer, solar digital |

|

||

|

120-C85-0030 |

Whipped cream box |

|

000-CB1-0030 |

Speed rail assembly |

|

Page 10 For factory assistance, call 888-436-5442

or 989-773-7981 Fax 888-779-2040 www.delfield.com

Loading...

Loading...