yaskawa MX1 Maintenance Manual

%

YASKAWA

ELECTRIC

'UW

tjr

'.y

,

0E-C843-7-350

INSTRUCTIONS

ft.

MYASNACmm:;

./'K’Tiy

’

/

•

/}•*•**’•«

CNC

/

*ÿ<ÿÿÿ'

•'

’

•*•••«

f

SYSTEM

••

•

'

?

•'

•

••

.~«V-'

rV-f-v-y

FOR

-Ic/T

•

MAINTENANCE

MACHINING

•

*'

MANUAL

CENTERS

'

•

f

A

*k'l\

y

1

•*.*.

•ÿ'

•

'

-v

i

*.

'

I

>'

......

•

v.

:

}

A

•:

/

thoroughly,

tor

Before

read

luture

initial

these

and

relerence.

operation

instructions

retain

'

t

fix

-**

~

This

so.;

:

A

manual

instructions

and

tion

This

features

are

marked

of

your

builder's

<>•-•ÿÿ

L;:?-.

a.

is

primarily

for

maintenance.

manual

YASNAC

of

with

YASNAC

manual.

;-..A;

<

>tl

L

YASNAC

applies

MX1.

a

dagger.

MX1,

v.vrV.

.';

g

lu.'.

<:

intended

MX1

to

refer

'•»

AU

-W

»

programming,

the

basic

The

optional

For

the

to

the

to

give

and

optional

features

specifications

machine

?>:

operators

opera¬

tool

«.

••.••••-ÿ

:<

-

:

....

•

-

V

u.

.w.«.

TV

O:

i

-

f,.'

r

.

i«.

POUES

04

TMlt

St

crox

5*0001.

TM2

OJTTIK)

PVB

TM3:

ExnSNRL

TM4:.'

0007.42.38

0001,

0000.

00002

HDIP

10.25

03.48

00.

JLS*

noose

S£

00

1

BBSS

BBBB

DQD

BBS

C

IP!

YASNAC

OPERATOR'S

MX1

STATION

TABLE

OF

CONTENTS

CENERAL

1.

COMPONENT

1.1

YASNAC

1.2

CONTROL

1.3

1.4

1.4.1

1.4.2

1.4.3

1.4.4

2.

2.1

2.1.1

2.1.2

2.1.3

2.2

2.2.1

2.2.2

2.3

CODES

2.4

2.4.1

CONTROL

BLOCK

DIAGRAM

SYSTEM

MAINTENANCE

ROUTINE

Tape

Reader

Control

Servomotor

Battery

TROUBLESHOOTING

TROUBLE

Nature

Operations

NC

Unit

TROUBLESHOOTING

List

of

Counteracting

TROUBLESHOOTING

42

SUPPLY

Input

Power

3

ARRANGEMENT

SYSTEM

6

INSTRUMENTS

INSPECTION

8

Panel

and

9

ISOLATION

and

Circumstances

and

Check

Alarm

Codes

Alarms

VOLTAGE

Supply

3

OF

YASNAC

SCHEDULE

8

DC

Motor

JO

10

Programming

12

BY

ALARM

13

24

WITHOUT

CHECK

Voltage

44

OF

for

of

7

Spindle

Trouble

Checks

CODES

ALARM

Check

2.4.2

2.5

STICS

2.5,1

2.5.2

Input/Output

7

2.5.3

3.

8

3.1

3.2

3.2.1

3.3

3.3.1

JO

JO

12

3.3.2

3.3.3

3.3.4

Parameter

3.3.5

Parameter

3.3.6

44

APPENDIX

PENSATION

DC

Power

STATUS

DISPLAY

FUNCTION

Outline

Displays

Operating

Signals

of

List

ADJUSTMENTS

Standard

ADJUSTMENT

POWER

TRANSFORMER

Tape

Changing

DISPLAYING

Parameter

Parameter

Parameter

Input

Tape

Data

Punching-Out

Data

Parameter

STORED

76

Supply

BY

(DCN)

Procedure

46

Input/Output

UPON

PROCEDURES

on

AND

WRITING

Types

Display

Data

Data

Writing

Setting

of

59

Setting

of

59

Numbers

LEADSCREW

Voltage

Check

ON-LINE

46

46

to

Display

INSTALLATION

55

CONNECTIONS

Control

5

8

Transformer

PARAMETERS

58

58

and

Data

Data

and

Their

ERROR

45

DIAGNO¬

Signals

55

and

Contents

COM¬

57

47

(IT)

57

58

3

60

Subject

Adjustment

A

ADJUSTMENTS

Alarm

APPENDIX

COMPENSATION

B

Battery

Block

C

Component

Codes,

Diagram

System

Control

Counteracting,

D

DC

Power

C

GENERAL

Input

Power

M

Maintenance

N

Nature

NC

Unit

O

Operating

Signals

Procedures

STORED

9

Arrangement

3

Panel

Supply

3

Supply

Circumstances

and

Check

Procedure

46

UPON

of

List

76

Yasnac

of

8

Alarms

Voltage

Instruments

10

55

INSTALLATION

13

LEADSCREW

Control

of

Yasnac

24

Check

Voltage

Check

7

of

Trouble

Display

to

55

ERROR

System

Control

45

44

Input/Output

INDEX

6

O

Operations

Outline

Parameter

P

Parameter

Parameter

Parameter

PARAMETERS,

Power

R

Routine

S

Servomotor

Setting

Punching-Out

Setting

Input

Standard

Status

Function

Supply

T

Tap

Tape

Trouble

Changing

and

of

Displays

Data

Data

Numbers

Types

Transformer

Inspection

and

Data

Data

59

of

Input/Output

Display

(DCN)

Voltage

Reader

Isolation

TROUBLESHOOTING

troubleshooting

Troubleshooting

Programming

Display

Writing

and

58

DISPLAYING

Connections

Schedule

DC

Motor

Parameter

and

and

of

Parameter

by

59

On-Line

46

Check

Control

on

8

10

by

alarm

without

46

56

58

Their

Signals,

44

code

Alarm

Checks

Contents

WRITING

AND

57

7

for

Spindle

Data,

Data,

Diagnostics

Transformer

Tape

List

JO

Codes

JO

60

58

0

8

of

47

(IT)

57

42

2

YASNAC

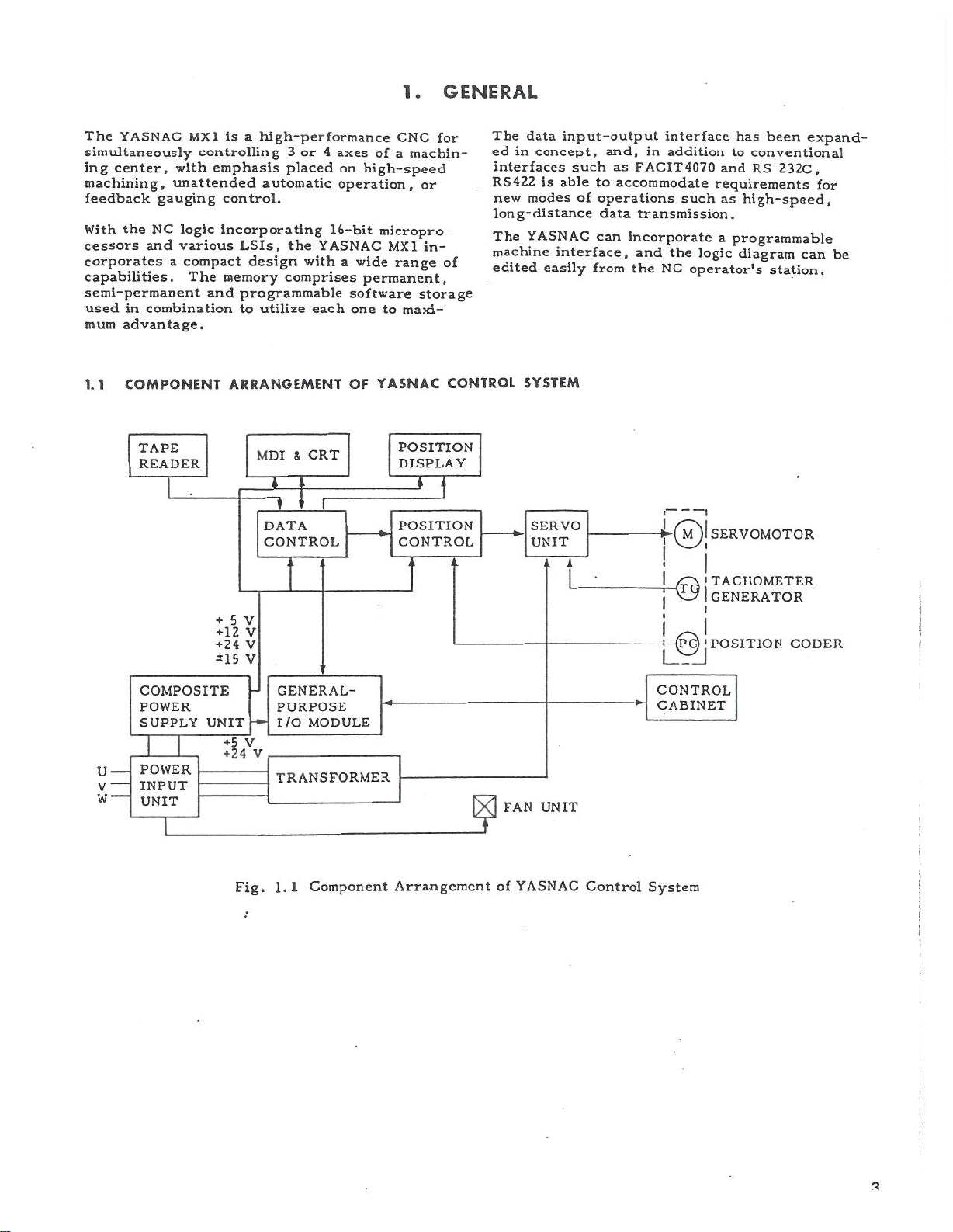

The

simultaneously

center,

ing

machining,

feedback

With

cessors

the

gauging

NC

and

corporates

capabilities.

semi-permanent

used

mum

combination

in

advantage.

MX1

controlling

with

emphasis

unattended

logic

various

compact

a

The

and

high-performance

is

a

3

placed

automatic

control.

incorporating

LSIs,

memory

the

design

comprises

programmable

utilize

to

or

4

16-bit

YASNAC

with

each

axes

of

on

high-speed

operation,

a

wide

permanent,

software

one

1.

CNC

a

machin¬

or

micropro¬

MX1

in¬

range

storage

to

maxi¬

GENERAL

for

of

The

ed

interfaces

RS422

new

long-distance

The

machine

edited

data

concept,

in

is

modes

YASNAC

easily

input-output

and,

such

able

to

of

operations

data

can

interface,

from

interface

in

as

accommodate

addition

FACIT4070

such

transmission.

incorporate

and

the

NC

the

to

and

requirements

as

a

programmable

logic

operator's

has

been

conventional

232C,

RS

high-speed,

diagram

station.

expand¬

for

can

be

1.1

U

—

V

—

w

—

COMPONENT

TAPE

READER

COMPOSITE

POWER

SUPPLY

POWER

INPUT

UNIT

UNIT

ARRANGEMENT

*.

MDI

I

1

DATA

CONTROL

+

V

5

V

+12

+

V

24

V

*15

GENERAL-

PURPOSE

I/O

V

+5

+

V

24

TRANSFORMER

OF

CRT

MODULE

YASNAC

POSITION

DISPLAY

o

POSITION

CONTROL

CONTROL

.

i

FAN

SYSTEM

SERVO

UNIT

UNIT

I

1

---

I©!

<

r@i

i

L_S_I

CONTROL

CABINET

SERVOMOTOR

'TACHOMETER

GENERATOR

i

(PG):

POSITION

CODER

i

Fig.

.•

1.1

Component

Arrangement

YASNAC

of

Control

System

!

!

;

!

1.1

COMPONENT

ARRANGEMENT

OF

YASNAC

CONTROL

SYSTEM

(Cont'd)

GENERAL-PURPOSE

MODULE

1/0

(2)

N

Px

I

I

l

I

"k

i

k

X

COMPOSITE

SUPPLY

POWER

(CPS-25N)

UNIT

CPU

RACK

(SEE

NEXT

PAGE)

GENERAL-

PURPOSE

MODULE

Fig.

(1)

1.2

I/O

si

I

i

J

Built-in

P0W&R

r

INPU

*VÿIT

Type

z_z

1,

KEYBOARD

/

7

/

/

*

with

MDI

TAPE

Door

UNIT

MODULE

CRT

.

/

r

*ÿ

OUTLET

Open

UNIT

COVER

DATA

TAPE

TAPE

MODULE

I/O

READER

REELS

/

\

POWER

JZNC-TU05

Tk

!

1

----

k

X

X

INPUT

POWER

JZNC-TU06

Fig.

1.3

(1)

SSKS'Hil

L

(CPS-25N)

>v

GENERAL-

PURPOSE

MODULE

GENERAL-

PURPOSE

MODULE

I/O

(1)

I/O

(2)

UNIT

(2)

Unbundled

UNIT

INPUT

OVER

Type,

with

Fig.

CPU

(SEE

1.1.4.)

o

RACK

FIG.

Door

1.4

o

Open

CPU

DATA

I/O

MODULE

0

Rack

III

Ill

III

1

1

ll

5

l

\

1

5

MEMORY

DATA

CPU

SERVO

CPU

ADDITIONAL

MODULE

MODULE

MODULE

AXIS

SERVO

\

JAMCD-Ki02-

(

(1)

JANCD-MJCU

JANCD-CPOlB

JANCD-CP02

MODULE

RY

MODULE

JANCD-IW05

OR

(-MM31C)

JANCD-SROI

-MM

CD

06

r-

i

(2)

)

4

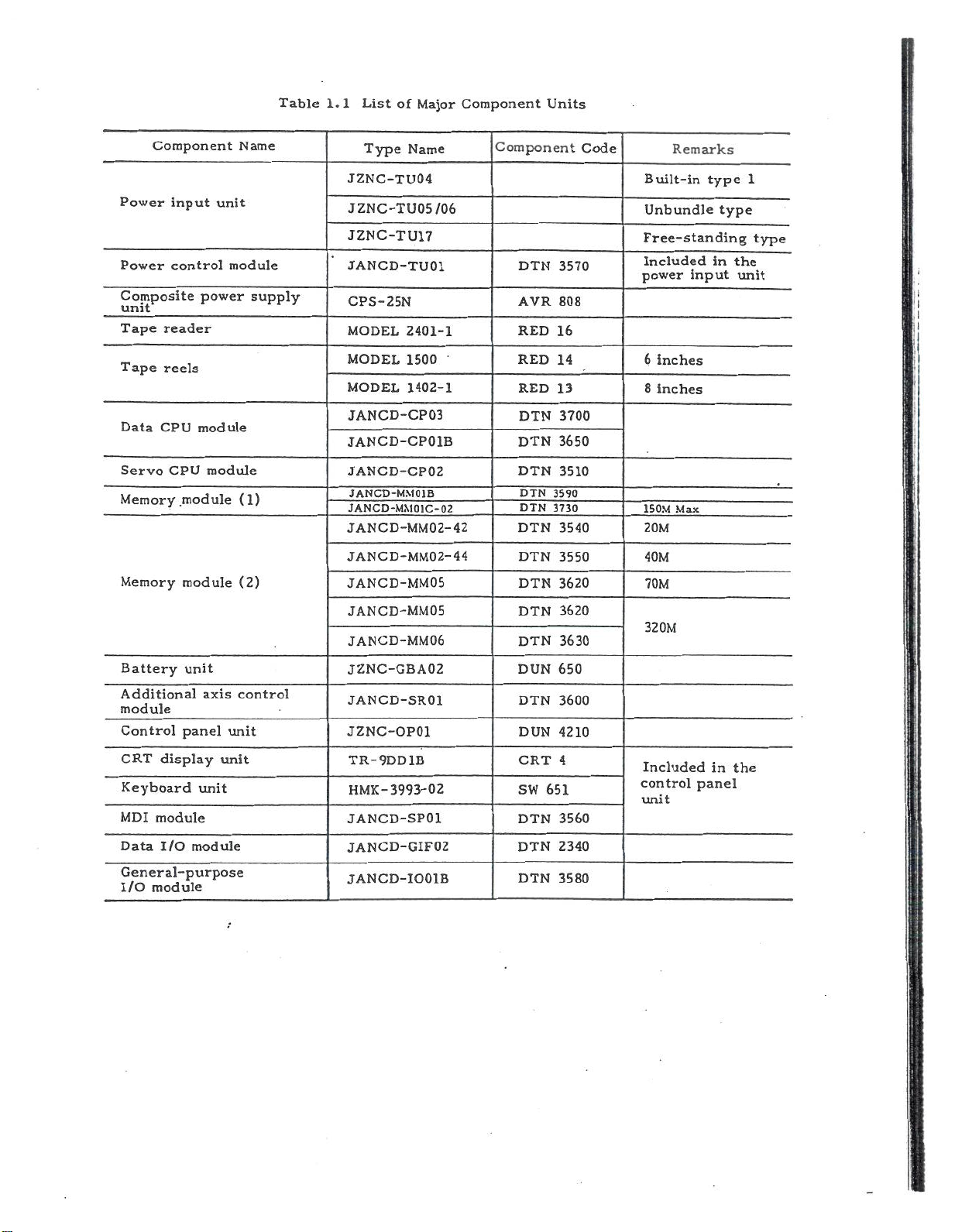

Table

1.1

List

of

Major

Component

Units

Component

Power

Power

Composite

unit

Tape

reader

Tape

reels

CPU

Data

Servo

CPU

Memory

Memory

input

control

power

module

module

module

unit

module

module

Name

supply

(1)

(2)

Type

Name

JZNC-TU04

JZNC-TU05/06

JZNC-TU17

JANCD-TU01

CPS-25N

MODEL

MODEL

MODEL

JANCD-CP03

JANCD-CP01B

JANCD-CP02

JANCD-M.M01B

JANCD-MMO

JANCD-MM02-42

JANCD-MM02-44

JANCD-MM05

2401-1

1500

1402-1

1C-0Z

Component

DTN

AVR

RED

RED

RED

DTN

DTN

DTN

DTN

DTN

DTN

DTN

DTN

3570

808

16

14

13

3700

3650

3510

3590

3730

3540

3550

3620

Code

Remarks

Built-in

Unbundle

type

Free-standing

Included

power

6

8

150.M

20M

70M

input

inches

inches

Max

40M

in

1

type

type

the

unit

Battery

Additional

unit

axis

module

Control

CRT

Keyboard

MDI

Data

panel

display

module

I/O

unit

module

General-purpose

module

I/O

unit

unit

;

control

JANCD-MM05

JANCD-MM06

JZNC-GBA02

JANCD-SR01

JZNC-OP01

TR-9DD1B

HMK-3993-02

JANCD-SP01

JANCD-GIF02

JANCD-IO01B

DTN

DTN

DUN

DTN

DUN

CRT

SW

DTN

DTN

DTN

651

3620

3630

650

3600

4210

4

3560

2340

3580

320M

Included

control

unit

in

panel

the

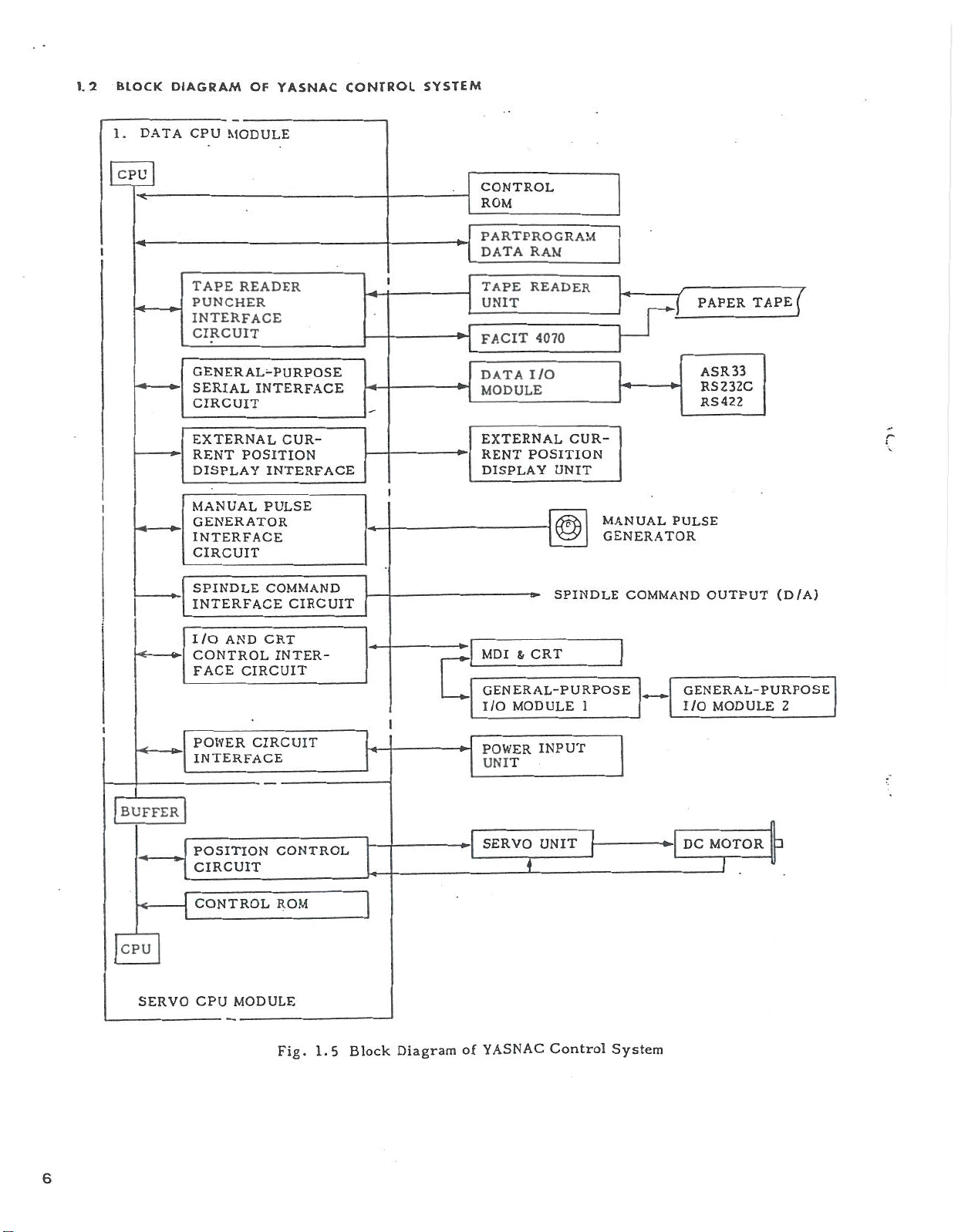

1.2

BLOCK

DIAGRAM

OF

YASNAC

CONTROL

SYSTEM

1.

CPU

DATA

-*ÿ

CPU

MODULE

TAPE

PUNCHER

INTERFACE

CIRCUIT

READER

GENERAL-PURPOSE

SERIAL

CIRCUIT

EXTERNAL

RENT

DISPLAY

MANUAL

GENERATOR

INTERFACE

CIRCUIT

INTERFACE

CUR¬

POSITION

INTERFACE

PULSE

CONTROL

ROM

PARTPROGRAM

DATA

-*

TAPE

UNIT

FACIT

DATA

**

MODULE

EXTERNAL

RENT

DISPLAY

I

RAM

READER

4070

I/O

CUR¬

POSITION

UNIT

®

MANUAL

GENERATOR

PULSE

PAPER

ASR33

RS232C

RS422

TAPE

7

p

•*-

BUFFER

CPU

SERVO

SPINDLE

INTERFACE

I/O

AND

CONTROL

CPU

CIRCUIT

CIRCUIT

MODULE

FACE

POWER

INTERFACE

POSITION

CIRCUIT

CONTROL

COMMAND

CIRCUIT

CRT

INTER¬

CONTROL

ROM

SPINDLE

CRT

&

MDI

GENERAL-PURPOSE

I/O

MODULE

POWER

UNIT

SERVO

1

INPUT

UNIT

1

COMMAND

GENERAL-PURPOSE

I/O

DC

OUTPUT

MODULE

MOTOR

J

(D/A)

2

3

Fig.

1.5

Block

Diagram

YASNAC

of

Control

System

6

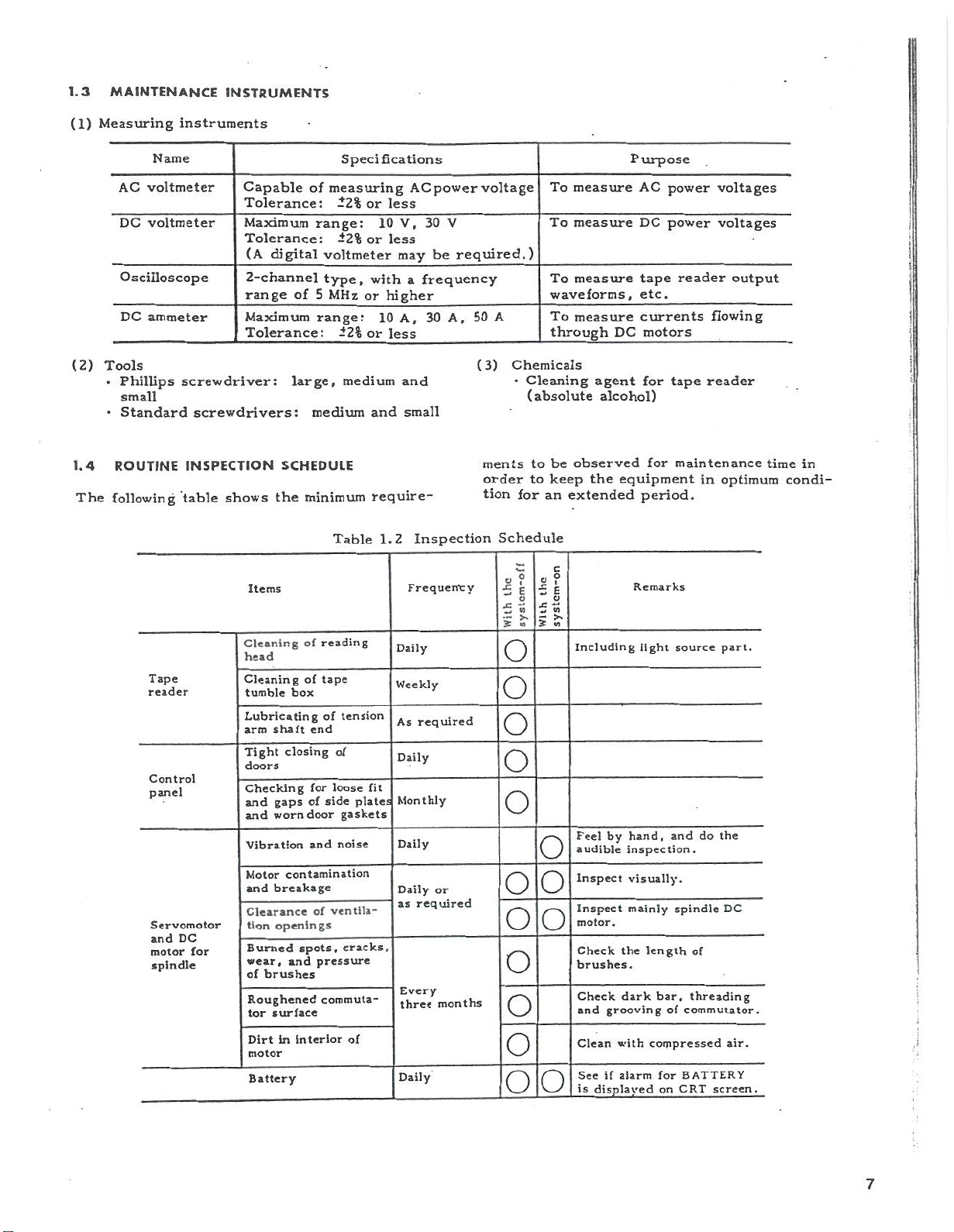

1.3

MAINTENANCE

(1)

Measuring

INSTRUMENTS

instruments

(2)

1.4

The

Name

AC

voltmeter

DC

voltmeter

Oscilloscope

DC

ammeter

Tools

Phillips

•

small

•

Standard

ROUTINE

following

Tape

reader

Control

panel

Servomotor

and

motor

spindle

Capable

Tolerance:

Maximum

Tolerance:

(A

2-channe]

range

Maximum

Tolerance:

screwdriver:

screwdrivers:

INSPECTION

table

shows

Cleaning

head

Cleaning

tumble

Lubricating

arm

Tight

doors

Checking

and

and

Vibration

Motor

and

Clearance

DC

for

digital

of

large,

SCHEDULE

the

Items

box

shaft

closing

gaps

worn

contamination

breakage

openings

tion

Burned

wear,

and

of

brushes

Roughened

surface

tor

Dirt

in

motor

Battery

of

range:

voltmeter

type,

5

MHz

range:

medium

minimum

reading

of

tape

of

of

end

for

of

side

door

and

of

spots,

pressure

commuta¬

interior

Specifications

measuring

±2%

or

less

10

i

or

less

2%

with

or

higher

10

i2%

or

less

medium

and

require-

1.2

Table

tension

of

fit

loose

plates

gaskets

noise

ventila¬

cracks,

of

AC

V,

30

may

a

frequency

A,

30

and

small

Inspection

Frequerrcy

Daily

Weekly

required

As

Daily

Monthly

Daily

Daily

required

as

Every

three

Daily

power

V

required.)

be

A,

or

months

voltage

A

50

(3)

ments

order

tion

Chemicals

•

Cleaning

(absolute

to

to

for

Schedule

«

?

E

fi

5

a

£«

£S

«*«

*

o

o

o

o

o

o

o

o

o

o

o

o

o

o

To

measure

To

measure

measure

To

waveforms,

measure

To

through

observed

be

keep

an

extended

i

«

?

E

o

Including

Feel

audible

Inspect

Inspect

motor.

o

Check

brushes.

Check

and

Clean

See

is

DC

agent

alcohol)

the

equipment

by

the

dark

grooving

with

alarm

if

displayed

Purpose

AC

power

DC

power

tape

etc.

currents

motors

for

for

period.

Remarks

light

hand,

inspection.

visually.

mainly

length

bar.

of

compressed

for

on

voltages

voltages

reader

flowing

reader

tape

maintenance

in

optimum

source

and

spindle

part.

the

do

of

threading

commutator.

BATTERY

CRT

screen.

output

DC

air.

time

i

i

in

condi¬

]

i

7

1.4.1

(1)

A.

B.

(2)

A.

B.

Cleaning

or

Cleaning

READER

TAPE

the

Remove

withablower

with

clean

Remove

source)

Clean

clean,

Remove

1.1.2)

and

box

soft

oil

the

the

soft

clean

with

tape

or

cloth

tape

the

on

of

the

by

cloth

braided

loosening

the

tape

rubbish

oily

with

dust,

top

tape

cloth.

tape

reader

brush.

dust,

absolute

guide

if

with

tumble

outlet

bottom

or

brush.

and

any,

a

nylon

two

of

and

If

wipe

blower

box

cover

the

(Daily)

head

dust

the

glass

using

it

alcohol.

the

tape

LED

on

brush.

(Weekly)

leading

(See

mounting

tape

from

tape

the

is

a

Also

retainer.

(light

Fig.

screws

tumble

glass

stained

gauze

with

B.

After

inspecting

close

the

door

When

the

it

or

closed

the

on

of

(Left-hand

and

clicks

The

H

OPEN

right

the

Door)

door)

securely

YE001).

the

key

turn

ter-turn).

an

CLOSED

POSITION

a

all

until

open

CLOSED

With

lock

side

door

Hinged

control

the

fasten

using

the

opening

into

way

(approximately

can

key

position.

POSITION

door

or

the

be

door

key

closing,

OPEN

door

with

locks

provided

keyhole

removed

POSITION

&

m

the

With

on

lock

of

side

door

Hinged

open,

(2

per

(No.

insert

and

a

quar¬

from

CLOSED

_

_

CLOSED

POSITION

door

left

the

(Right-hand

Door)

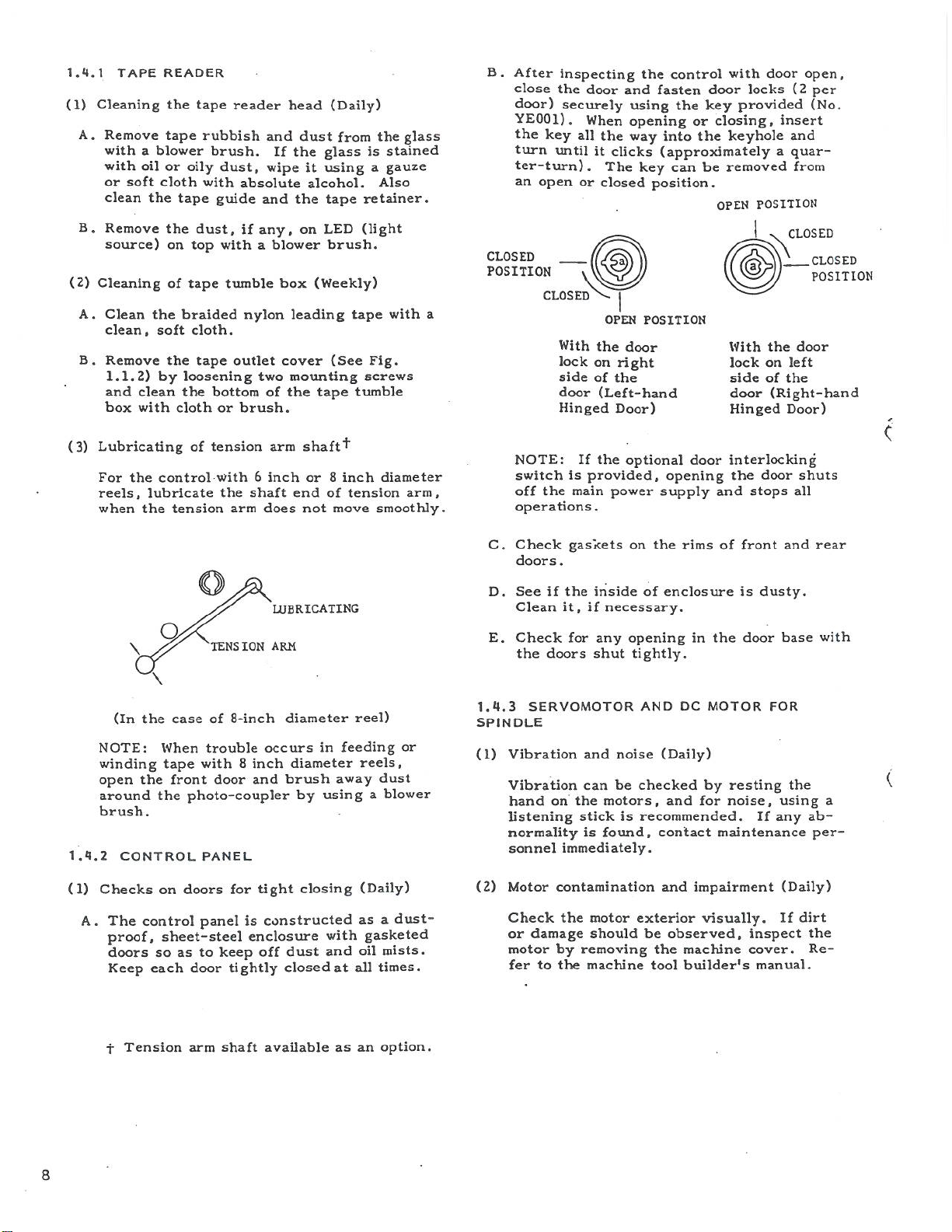

(3)

1.4.2

(1)

Lubricating

For

the

reels,

when

control

lubricate

the

\

\

(In

the

NOTE:

winding

the

open

around

brush.

Checks

the

CONTROL

of

tension

Q

case

When

with

tape

front

photo-coupler

PANEL

doors

on

tension

with

the

shaft

arm

TENSION

8-inch

of

trouble

8

door

for

arm

shaft

6

inch

or

end

not

does

LUBRICATING

ARM

diameter

occurs

inch

and

tight

in

diameter

brush

by

closing

8

inch

of

move

feeding

away

using

tension

smoothly.

reel)

reels,

a

(Daily)

diameter

arm,

or

dust

blower

NOTE:

switch

off

operations.

Check

C.

doors

See

D.

Clean

Check

E.

the

1.4.3

SPINDLE

(1)

Vibration

Vibration

hand

listening

normality

sonnel

(2)

Motor

the

If

is

provided,

the

main

gaskets

.

the

if

doors

SERVOMOTOR

inside

it,

if

any

for

shut

and

can

motors,

the

on

stick

found,

is

immediately.

contamination

optional

power

the

on

of

necessary.

opening

tightly.

AND

noise

checked

be

is

recommended.

door

opening

supply

rims

enclosure

in

DC

(Daily)

and

contact

and

impairment

interlocking

the

and

front

of

is

the

MOTOR

resting

by

noise,

for

maintenance

stops

door

door

dusty.

FOR

If

any

shuts

all

and

base

the

using

ab¬

(Daily)

c

rear

with

a

per¬

A.

The

proof,

doors

Keep

Tension

f

control

sheet-steel

so

each

as

panel

to

door

arm

keep

tightly

shaft

constructed

is

enclosure

dust

off

closed

available

with

and

at

as

a

as

gasketed

mists.

oil

times.

all

option.

an

dust-

Check

damage

or

motor

fer

to

the

by

the

motor

should

removing

machine

exterior

be

the

tool

visually.

observed

machine

builder's

,

inspect

cover.

If

manual.

dirt

the

Re¬

8

i

(3)

Clearance

(Daily)

Check

spindle

dirt,

inspect

machine

builder's

Inspection

for

tial

the

described

maintaining

control.

Quarterly

Brushes

The

carbon

around

cause

armature

the

avoid

commutators

months.

Double

off

inspecting

worst

both

the

motor

and

this,

check

control

(Disconnecting

power

or

Carbon

Under

wears

If

contaminated

normal

circuit.

When

B.

those

a

unit

serious

wear

new

supply

off

fatal

(4)

A.

Minertia

DC

motor

Minertia

either

If

C.

brush

unit.

of

ventilation

the

ventilation

motor.

the

cover.

manual.

commutators

of

Inspection

the

in

Inspection

case,

following

dust

from

commutator,

troubles

the

flashover

it

and

for

sure

to

may

brushes

be

power

the

servo

be

brushes

completely)

injury.

brushes

normal

2

to

by

excessive,

is

armature

overcurrent

brush

shown

one.

motor

for

motor

the

length

below,

brush,

assembly

is

it

If

spindle

Refer

excellent

the

work

Commutators

of

brushes,

inside

such

lead

have

to

sure

and

servomotor

and

circuit

control

.

Failure

operating

mm

4

junior

spindle:

J

series:

must

window

window

clogged

motor

to

the

and

three

as

the

of

to

an

least

at

power

servo

breaker

unit

conditions,

1000

per

check

surface,

flows

becomes

replace

series:

17

or

pigtail

be

replaced

blockage

DC

of

with

removing

machine

brushes

performance

to

be

executed

items.

and

accumulated

motor,

the

layer

commutator.

damage.

fatal

inspection

every

OFF

is

power

inside.

of

the

cannot

so

to

do

operating

see

to

or

through

shorter

brush

the

6

mm

below

or

mm

7

or

mm

broken,

is

(or

dust

is

short

three

by

before

may

brush

if

if

motor

than

or

below

as

AC)

or

the

tool

essen¬

is

may

of

In

To

the

on

turning

power

shut

cause

hours.

oil

has

ab¬

with

below

whole

a

1

of

the

5)

(

A.

B.

(6)

A

.

.

B

(7)

1.4.4

Make

position

displayed,

battery

month.

Commutator

Visually

commutator

After

100

mutator

brown

developed

no

attention

See

if

is

ing)

above

trouble.

Threading

surface

load.

carbon

dentally

is

dust

commutator

the

surface.

the

maintenance

Motor

inside

Visually

inspection

The

dried

running,

inner

parts

holders

compressed

28.5-56.5

oily

If

to

due

contact

Servomotor

the

As

is

5000

the

by

hours.

less

than

BATTERY

sure

that

CRT

of

contact

must

surface

check

through

to

should

or

chocolate

an

a

blackened

on

the

is

observed,

or

may

A

blackened

dust

produced

a

cause

withaclean

(dirty)

check

window

carbon

but

such

and

brushes

air

ps)

carbon

poor

oil

YASNAC

with

life

expectancy

hours,

company

possible,

If

8

hours

"BAT"

screen

be

replaced

surface

200

operating

take

color.

ideal

other

commutator

than

bar,

commutator.

investigate

grooving

be

due

bar

in

commutator

sparkings.

blackened

of

If

sparking

representative.

motor

the

.

dust

it

is

recommended

as

(air

pressure:

dust

exists

or

seal

service

oil

seal

the

inspection

should

yearly

recommended.

is

or

is

maintenance

roughness

inspection

hours,

on

a

polished

The

to

be

threading

If

on

the

to

too

small

is

the

slots,

dry

occurs,

interior

not

will

commutator,

be

cleaned

inside

defective

personnel.

oil

seals

of

done

be

inspection

"A/B"

not

on

displayed.

personnel.

with

new

a

of

window.

the

light

motor

film

and

kept

clean.

(or

any

of

the

cause

commutator

of

a

result

or

the

If

bar,

wipe

to

cloth

contact

through

affect

that

brush-

with

2-4

kg/cm4,

the

enclosure,

and

and

maintenance

every

the

right-low

one

the

com-

has

needs

groov¬

the

motor

of

acci¬

carbon

smooth

motor

the

a

dry

motor

brushes

5000

taking

it

If

The

within

the

of

f

i

rl

h

i

:

i;

i

!

!

is

a

NOTE:

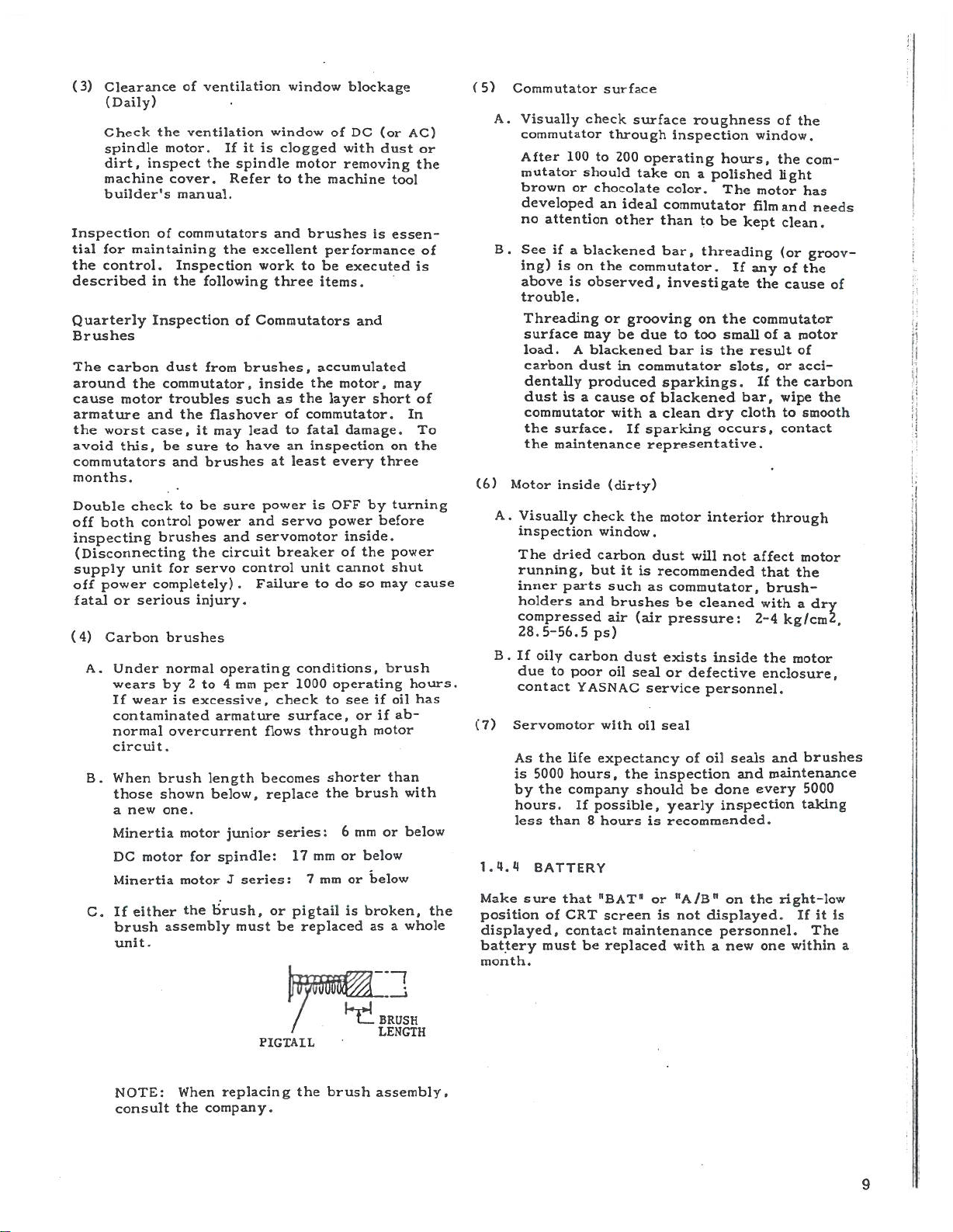

consult

When

the

replacing

company.

PIGTAIL

the

---

BRUSH

LENGTH

brush

assembly,

9

TROUBLE

2.1

to

Try

trouble

the

lating

the

serviceman

•

*

Type

In

In

the

of

NATURE

fying

time

2.1.1

(1)

operate?

What

trouble

•

Was

positioning

•

Was

Was

-

•

Was

•

What

•

In

What

•

Does

•

Is

the

•

Is

the

(2)

Frequency

•

When

when

•

How

(3)

Recurrence

Run

•

trouble

the

being

able

Verify

-

tributed

*

Increase

Ask

under

fully

occurred.

trouble

called

following

your

of

what

what

was

occurred?

the

the

the

an

auxiliary

was

which

was

the

trouble

trouble

did

other

often

the

several

NC

unit

programmed.

to

external

the

the

which

ISOLATION

analyze

and/or

in

points

system:

AND

trouble

mode

did

mode(s)

the

display

positioning

error,

tool

path

feedrate

the

alarm

program

sequence

the

trouble

related

associated

trouble

of

the

trouble

machines

did

it

of

trouble

program

and

offset

values

or

decrease

operator

the

circumstances

the

This

is

necessary

for

will

having

the

minimize

to

correct

CIRCUMSTANCES

the

trouble

does

the

of

incorrect

displayed

erroneous

system

MDI

occur?

b

(error

position

(by

correct?

function

used?

number?

did

the

trouble

number?

a

to

in

tool

with

particular

changing?

recur

develop?

operation?)

in

were

occur?

experienced

that

tape

times.

compare

Check

them

the

trouble

Is

disturbances?

remaining

stored.

the

explain

and

override

the

occurred.

values

being

to

trouble

TROUBLESHOOTING

2.

in

YASNAC

the

trouble.

the

OF

normally

CRT

when

axis,

how

occur?

feedrate?

(Did

it

values

the

those

with

attribut¬

value.

circumstances

which

iso¬

for

Veri¬

down

TROUBLE

the

values?

much)?

mode?

occur

the

in

dis¬

2.1.2

(1)

Operations

•

Was

•

Was

Was

gram?

•

Was

tion?

•

Was

or

•

Was

•

Can

•

Was

ly

•

Was

•

Was

•

Were

operations?

(2)

Punched

•

Was

•

Was

•

Were

•

Was

this

•

Was

•

Was

•

Was

(3)

Programming

•

Is

Was

•

instruction

Did

•

•

Did

•

Was

verification?

(4)

Settings

•

Were

made

•

Was

Operations

the

operator

there

the

operator

the

program

the

program

absolute

the

tool

other

the

optional

used?

the

tape

the

program

there

the

tape

the

tape

tapes

the

program

operation?

the

tape

the

tape

a

black

the

program

the

program

the

trouble

trouble

the

a

check

there

prior

fuse

a

and

a

recent

command?

compensation

operating

correctly

any

tape

contaminated?

bent

properly

correctly

puncher

tape

manual?

list

any

to

starting

blown?

Programming

properly

change

well

familiar

interrupted

placed

modes

skip

block

set?

properly

inadvertent

or

crimpled?

spliced?

successfully

punched?

operating

used?

new?

formulated

occur

in

occur

in

made

and

corrections

the

trained?

operators?

of

with

before

under

properly

selected?

be

function

coded?

or

run

according

a

particular

a

subprogram?

used

or

adjustments

operation?

Checks

the

pro¬

comple¬

incremental

set?

proper¬

erroneous

prior

normally?

to

block?

tape

for

(

to

<

the

10

(5)

.

(6)

2.1.3

(1)

Was

•

•

Was

Was

•

What

•

Was

•

board)

•

Was

•

Was

Was

•

•

Was

External

Was

•

justed?

•

Was

adjusted?

•

Was

•

Is

there

frequency

machine,,

range?

•

Was

nearby?

•

Is

ed

•

Has

inside

Has

’

this

Ambient

•

What

•

Was

•

Was

Was

•

in

•

Were

•

Was

NC

Control

Was

•

Was

•

*

Was

Was

•

an

the

an

was

the

the

the

the

the

the

the

the

there

there

similar

the

the

unit?

was

there

the

there

the

there

the

the

the

the

the

emergency

machine

alarm

the

alarm

?

MODE

override

machine

feed

factors

machine

control

NC

unit

any

sewing

welding

any

any

failures

user

NC

the

same

conditions

the

any

tape

any

immediate

any

system

CHECK

UNIT

unit

MDI

tape

tape

unit

stop

ready

tool

state

alarm

lamp

effect?

in

number?

lit

switch

set

to

set?

lock

set?

hold

tool

recently

cabinet

recently

source

noise

machine,

machine)

new

machine

made

in

NC

your

an

other

unit?

trouble

temperature?

abrupt

oil

or

contaminated?

cutting

reader

area?

vibrations?

exposed

exterior

CRT

&

reader

reader

unit

kept

door

operated

maintained?

on

a

in

normal

"0"?

recently

repaired

(e.g.,

unit

factory?

attempt

occured

change

to

normal?

clean?

closed?

with

to

operate?

module

position?

repaired

electrical

within

recently

that

at

previously

in

fluid

direct

the

its

door

(on

print

or

repaired

or

adjusted?

crane,

high

discharge

interference

installed

has

develop¬

adjustments

with

temperature?

splashed,

sunlight?

open?

ad¬

or

(2)

(

(4)

(5)

(6)

•

•

•

3)

•

•

•

•

•

•

•

Did

any

interior?

Tape

Was

the

What

forms

Control

Was

the

the

Was

(Was

port

Was

the

Composite

Was

the

Were

+24

V.

•

Was

each

Was

a

•

Was

the

Was

the

•

the

Was

cabinet?

•

How

Was

voltage?

•

Was

interlock

•

there

Is

amount

machine,

ing

Grounding

Was

•

•

Was

Cables

•

Were

•

Was

any

•

Was

any

•

Was

any

machining

reader

tape

were

the

from

unit

control

fan

the

air

normal?)

interior

power

input

the

output

il5

voltage

fuse

circuit

shield

wiring

much

did

there

any

the

front

in

any

current

of

grounding

the

shield

cable

internal

external

cable

chips

reader

characteristics

the

tape

interior

unit

motor

operating

from

flow

damaged

supply

voltage

voltages

V)?

within

blown?

breaker

properly

properly

the

input

significant

rear

or

effect)

connectors

?

machine

in

electrical

properly

grounding

cable

cable

broken

enter

contaminated?

reader?

interior

normal?

the

cooling

by

unit

normal

tolerance?

contaminated?

normally?

corrosive

tripped?

grounded?

inside

voltage

drop

door

open

that

consumes

the

factory

discharge

connected?

proper?

securely

damaged?

damaged?

or

contaminated?

the

of

the

(+5

the

fluctuate?

in

input

(with

(e.g.

machine)?

inserted?

cabinet

wave-

air

exhaust

V,

control

a

large

gas?

+12

door

,

weld¬

V,

i

2.1.3

NC

UNIT

CHECK

(Cont'd)

1.

Depress

the

(ALM)

key

(7)

Modules

*

Were

all

*

Were

plug

What

•

•

Were

was

connections

modules

(8)

•

*

•

(9)

&

MDI

Were

Was

Was

CRT

push

the

the

Parameters

Did

the

parameter

(10)

Interface

•

Were

the

installed?

ly

•

Was

the

•

Were

the

equipped

•

Were

the

DGN

the

2.2

TROUBLESHOOTING

an

alarm

If

"A/B"

line

function.

the

lowing

(for

the

of

alarm

operations:

CRT

In

condition

(on

printed

modules

connectors

the

correct?

unit

buttons

flat

keyboard

flat

cable

actual

table

power

cable

relay,

with

I/O

(diagnostic)

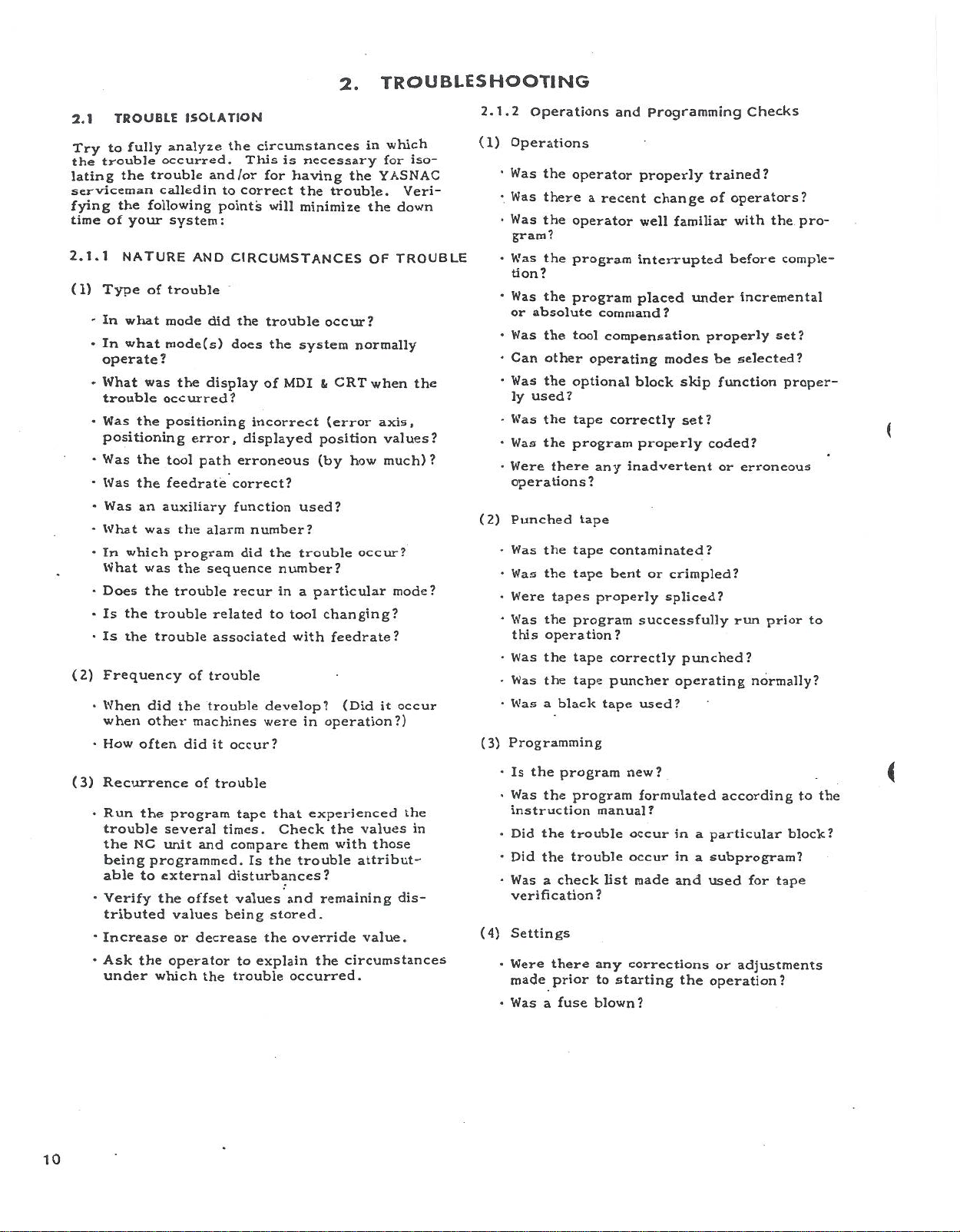

condition

battery

screen

this

securely

revision

(on

freely

free

parameters

attached

cable

positively

solenoid,

a

noise

signals

occurs,

alarm)

regardless

case,

be

will

circuit

properly

letter?

flat

operable?

of

defects?

to

and

shielded?

suppressor?

normally

function?

ALARM

BY

a

blinks

detailed

displayed

board)

installed?

secured?

cable)

operable?

match

the

NC

cable

motor,

generated

display

on

of

information

between

those

NC

unit?

separate¬

etc.

CODE

"ALM"

the

the

by

in

each

bottom

mode

the

the

by

of

fol¬

This

will

and

alarm

importance,

cause

messages

with

up

the

to

to

most

4

pairs

appear

of

in

serious

alarm

order

one

codes

of

at

the

top.

NOTE:

appears

There

Eliminate

the

the

the

or

and

selected

In

is

-ÿT<

IL

.

Tj

TTl

*.]

Alarm

(RESET)

alarm

alarm

"840"

an

taking

no

need

M

fM*

i*.i

the

cause

key,

display

codes

are

function

state,

alarm

priority

to

operate

r

Codes

of

and

will

"800,"

displayed

key.

over

and

the

the

be

"810,

regardless

the

any

the

*

•)

rv

I

i

•

r*3

Messages

alarm

alarm

reset.

[i

ri

or

2.

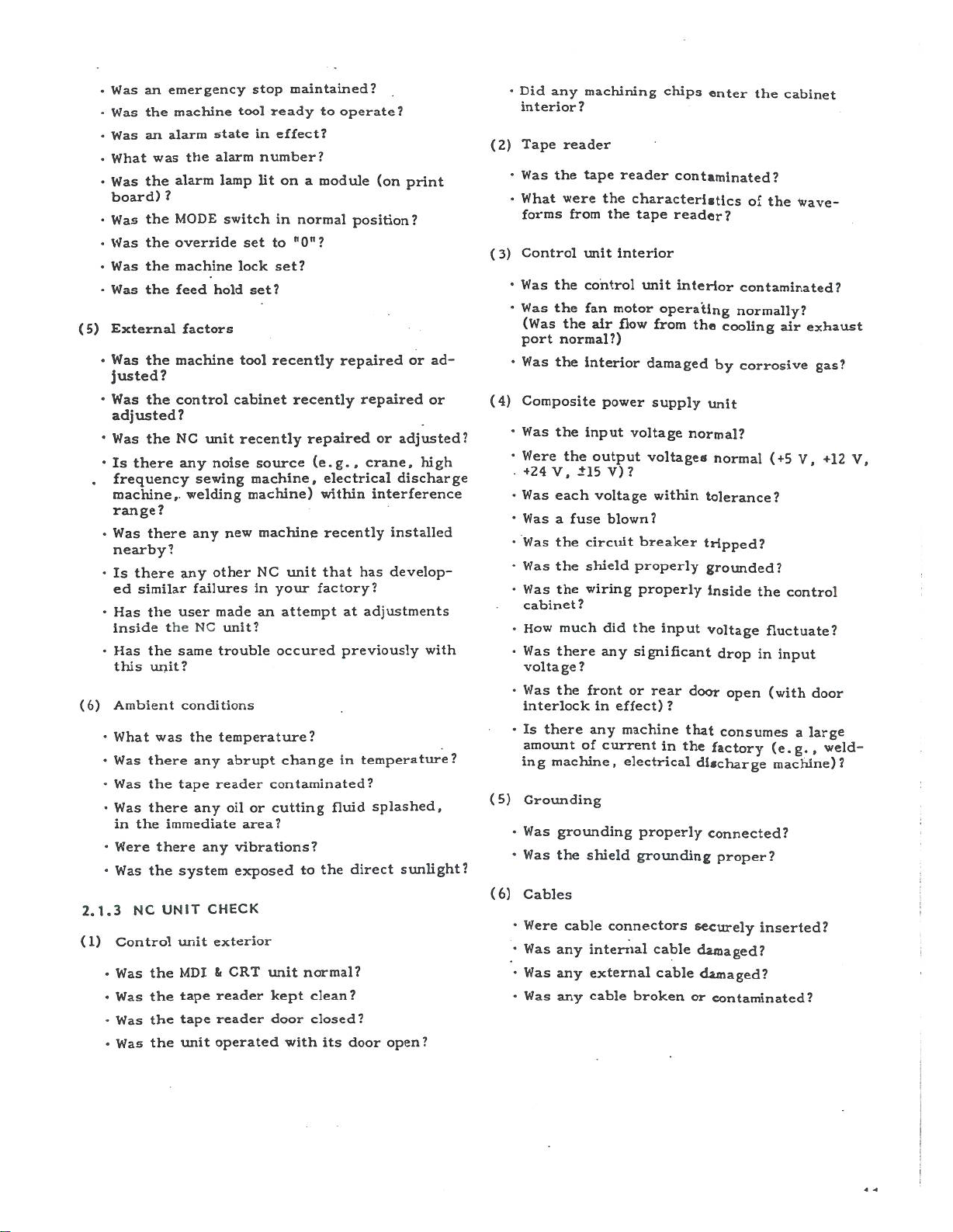

The

alarm

codes

are

categorized

alarm

other

(PAGE)

*.

and

state

Notice

820,"

as

screen

IV*.

depress

and

"830"

the

of

follows:

display.

key.

that

12

Alarm

000

100

200

300

400

500

600

700

800

900

Table

No.

099

to

199

to

299

to

to

399

to

499

599

to

to

699

to

799

899

to

to

999

Spindle

Stop

Stop

Immediate

Immediate

Immediate

NC

at

at

system

Operation

block

block

stop

stop

stop

stop

end

end

2.1

Tape

Macro,

output

Overtravel,

positioning,

Servo,

FG,

Sequence

Sequencer

CPU

Off-line

format

operation

error,

emergency

RPG

error,

error

Type

error

reference

error

message

RAM

of

,

sequence

machine

(2)

error.

Alarm

alarm

external

ready

stop,

error

point

overload

ROM

Input/

(1)

return,

error

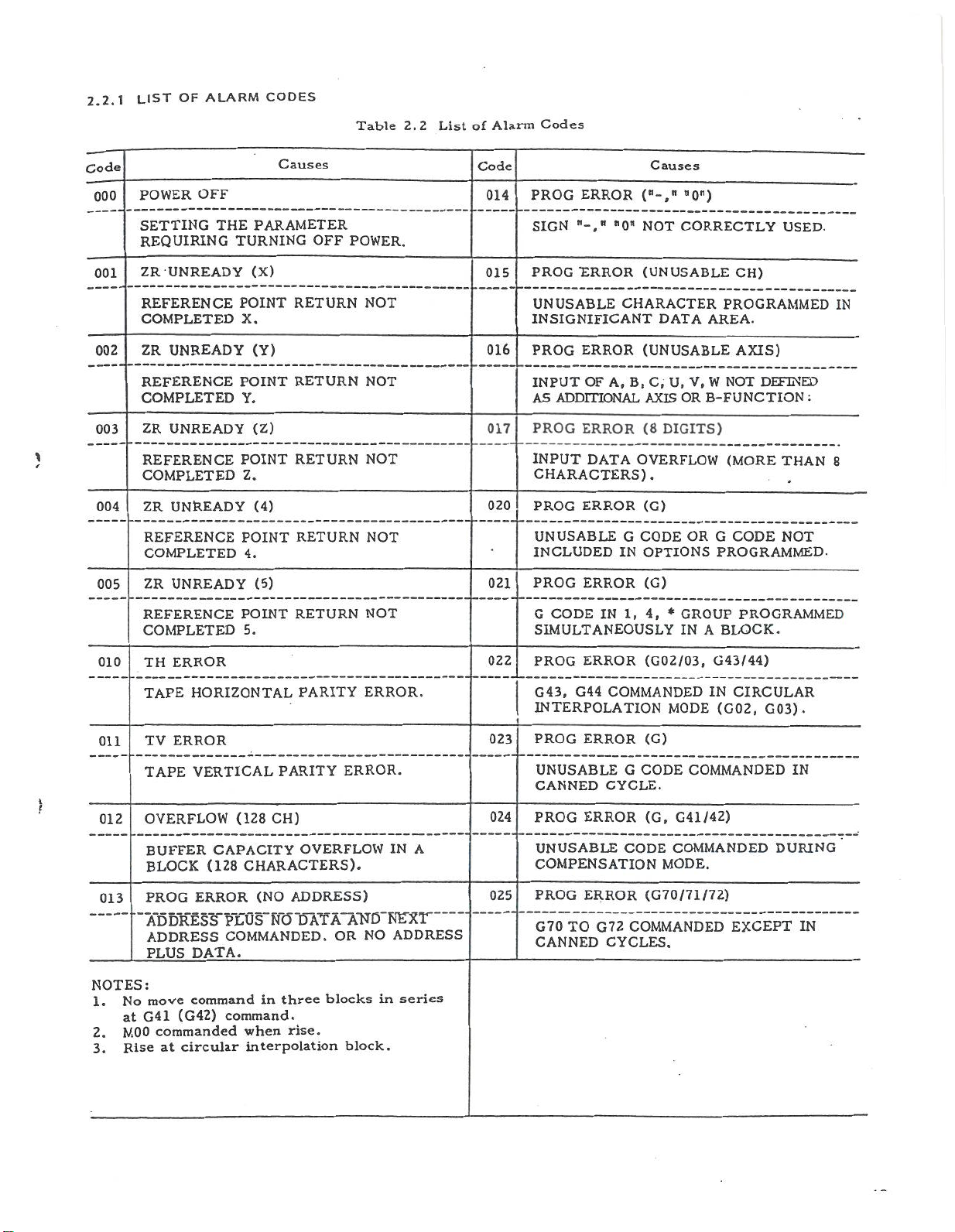

2.2.1

LIST

OF

ALARM

CODES

Table

2.2

List

of

Alarm

Codes

Code

000

001

002

POWER

SETTING

REQUIRING

ZR

REFERENCE

COMPLETED

ZR

REFERENCE

OFF

THE

UNREADY

UNREADY

COMPLETED

ZR

003

1

004

005

UNREADY

REFERENCE

COMPLETED

UNREADY

ZR

REFERENCE

COMPLETED

UNREADY

ZR

Causes

PARAMETER

TURNING

(X)

POINT

RETURN

X.

(Y)

POINT

RETURN

Y.

(Z)

POINT

RETURN

Z.

(4)

POINT

4.

(5)

OFF

RETURN

POWER.

NOT

NOT

NOT

NOT

Code

014

015

016

017

020

021

PROG

SIGN

ERROR

PROCERROR

UNUSABLE

INSIGNIFICANT

PROG

INPUT

AS

PROG

INPUT

CHARACTERS).

PROG

ERROR

OF

ADDITIONAL

ERROR

DATA

ERROR

UNUSABLE

INCLUDED

PROG

ERROR

Causes

n

"0"

NOT

(UNUSABLE

CHARACTER

DATA

(UNUSABLE

C,

A,

B.

U.

AXIS

DIGITS)

(8

OVERFLOW

(G)

CODE

G

IN

OPTIONS

(G)

n

0")

CORRECTLY

CH)

PROGRAMMED

AREA.

AXIS)

V,

W

NOT

B-FUNCTION

OR

(MORE

OR

G

CODE

PROGRAMMED.

USED.

DEFINED

:

THAN

NOT

IN

8

010

011

012

013

NOTES:

No

1.

at

MOO

2.

Rise

3.

REFERENCE

COMPLETED

ERROR

TH

TV

TAPE

ERROR

HORIZONTAL

VERTICAL

TAPE

OVERFLOW

BUFFER

DR

(128

ERROR

E

S

BLOCK

PROG

”

AD

ADDRESS

move

DATA.

command

(G42)

PLUS

G41

commanded

circular

at

POINT

5.

PARITY

CH)

(128

CAPACITY

CHARACTERS).

(NO

0

S~

S~

PL

NO

COMMANDED.

_

three

in

command.

rise.

when

interpolation

RETURN

PARITY

ERROR.

OVERFLOW

ADDRESS)

AN

A~

"DAT

OR

blocks

block.

NOT

ERROR.

IN

N£7

B~

ADDRESS

NO

series

in

A

XT

_

CODE

G

SIMULTANEOUSLY

022

PROG

G43,

INTERPOLATION

PROG

023

UNUSABLE

CANNED

PROG

024

UNUSABLE

COMPENSATION

025

PROG

G70

CANNED

IN

ERROR

G44

COMMANDED

ERROR

CYCLE.

ERROR

ERROR

TO

G72

CYCLES.

1,

4,

GROUP

IN

A

(G02/03,

MODE

(G)

CODE

G

CODE

COMMANDED

G41/42)

(G.

COMMANDED

MODE.

(G70/71/72)

COMMANDED

PROGRAMMED

BLOCK.

G43/44)

IN

CIRCULAR

(G02,

G03).

DURING

EXCEPT

IN

IN

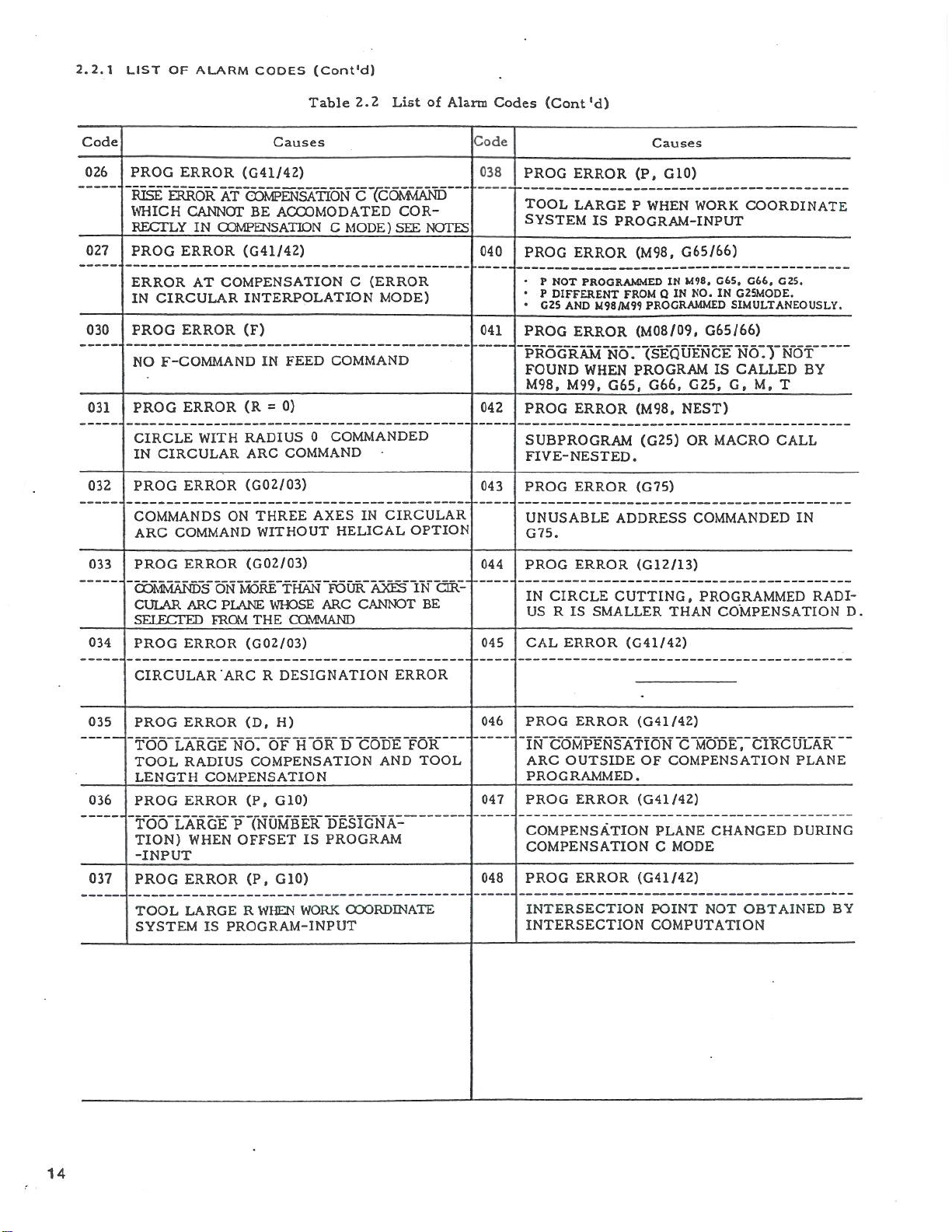

2.2.1

LIST

OF

ALARM

CODES

(Cont'd)

Code

PROG

026

~RlSE~E3lR6R"

WHICH

RECTLY

027

030

031

032

PROG

ERROR

CIRCULAR

IN

PROG

F-COMMAND

NO

PROG

CIRCLE

CIRCULAR

IN

PROG

COMMANDS

ARC

Table

2.2

Causes

ERROR

(G41/42)

ODÿENfÿTlON

AT

C

CANNOTBEACOOMODATED

IN

COMPENSATION

ERROR

AT

(G41/42)

COMPENSATION

C

MODE)

C

INTERPOLATION

WITH

(F)

(R

RADIUS

ARC

(G02/03)

ON

THREE

FEED

IN

0)

=

0

COMMAND

AXES

WITHOUT

COMMAND

COMMANDED

HELICAL

ERROR

ERROR

ERROR

COMMAND

of

List

“(COMMAND

COR-

SEE

NOTES

(ERROR

MODE)

•

CIRCULAR

IN

OPTION

Alarm

Code

038

040

041

042

043

Codes

(Cont'd)

PROG

TOOL

SYSTEM

PROG

NOT

•

P

•

P

DIFFERENT

C25

•

PROG

PROGRAM

FOUND

M98,

PROG

SUBPROGRAM

FIVE-

PROG

UNUSABLE

G75.

ERROR

LARGE

IS

PROGRAM-INPUT

ERROR

PROGRAMMED

AND

M98/M99

ERROR

NO.

WHEN

M99,

G65,

ERROR

NESTED.

ERROR

ADDRESS

Causes

G10)

(P,

P

WHEN

G65/66)

(M98,

M98,

IN

Q

FROM

IN

PROGRAMMED

(M08/09,

(SEQUENCE

PROGRAM

G66,

(G25)

NEST)

OR

(M98,

(G75)

WORK

NO.ING25MODE.

COORDINATE

G6S,

G66.

SIMULTANEOUSLY.

G65/66)

NO/J

IS

CALLED

G25,

COMMANDED

M,

G,

MACRO

G25.

NOT

BY

T

CALL

IN

PROG

033

COMMANDS”

CULAR

SELECTED

034

PROG

CIRCULAR

035

PROG

“

TOO"

TOOL

LENGTH

036

PROG

TOO-

TION)

-INPUT

037

PROG

TOOL

SYSTEM

ERROR

ARC

ERROR

(G02/03)

MORE'fHAN

ON

PLANE

FROM

(G02/03)

ARC

ERROR

LARGE

RADIUS

(D,

“NO”

COMPENSATION

ERROR

LXR

WHEN

ERROR

LARGE

(P,

G“E

"P

TN

OFFSET

(P,

R

IS

PROGRAM-INPUT

"FOUR

WHOSE

THE

R

OF

COMPENSATION

UMB

WHEN

ARC

COMMAND

DESIGNATION

H)

“6

D“

R-

“H

G10)

“DESIGN

ER”

PROGRAM

IS

G10)

COORDINATE

WORK

AXES

CANNOT

ERROR

“FOR

CODE

AND

A“““

T

N“

BE

TOOL

OR-

044

045

046

PROG

IN

US

CAL

PROG

ERROR

CIRCLE

IS

R

ERROR

ERROR

'ÿ“COMPENSATION

ARC

OUTSIDE

PROGRAMMED.

PROG

047

COMPENSATION

COMPENSATION

048

PROG

INTERSECTION

INTERSECTION

ERROR

CUTTING.

SMALLER

ERROR

(G12/13)

PROGRAMMED

THAN

(G41/42)

(G41/42)

“MODE-,-

”C

COMPENSATION

OF

(G41/42)

PLANE

MODE

C

(G41/42)

POINT

NOT

COMPUTATION

COMPENSATION

ULAR”

CIRC

PLANE

CHANGED

DURING

OBTAINED

RADI¬

D.

BY

14

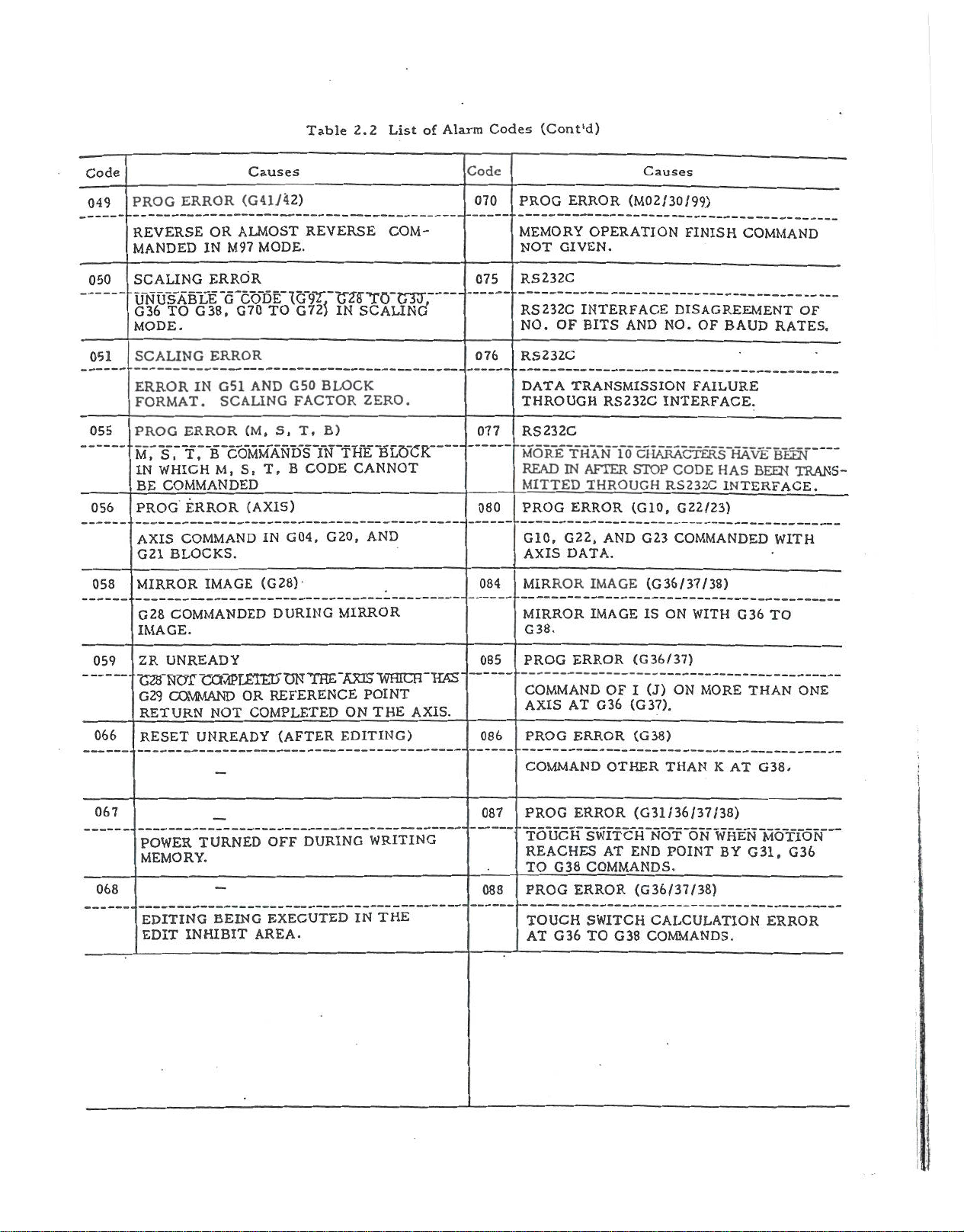

Table

2.2

List

of

Alarm

Codes

(Corvt'd)

Code

PROG

049

REVERSE

MANDED

SCALING

050

"UNOSABEE

G36

MODE.

SCALING

051

ERROR

FORMAT.

055

PROG

M

IN

BE

056

PROG

AXIS

G21

058

MIRROR

G28

IMAGE.

OR

IN

M97

ERROR

(G41742)

ALMOST

ERROR

G"CODE"TG"ÿ.'U7FFT0*TRRR;

G38,

ERROR

IN

G70

G51

TO

SCALING

ERROR

'COMM

T

S'

r'B

S,

WHICH

COMMANDED

M,

ERROR

COMMAND

BLOCKS.

IMAGE

COMMANDED

Causes

MODE.

TO

AND

(M.

S.

ANMTN

T,

_

(AXIS)

IN

(G28)

DURING

REVERSE

G72)

G50

BLOCK

FACTOR

T,

CODE

B

G04,

IN

B)

'THE

CANNOT

G20,

MIRROR

COM¬

SCALING

ZERO.

‘BL£rCR.~

AND

Code

070

075

076

077

080

084

PROG

MEMORY

NOT

ERROR

GIVEN.

RS232C

RS232C

OF

NO.

RS232C

DATA

THROUGH

RS232C

'

MO

RE

"THAN

READ

IN

MITTED

PROG

G22,

G10r

DATA.

AXIS

MIRROR

MIRROR

G38.

Causes

(M02/30/99)

OPERATION

INTERFACE

BITS

TRANSMISSION

RS232C

TO

AFTER

THROUGH

ERROR

AND

IMAGE

IMAGE

NO.

AND

INTERFACE.

CHAÿCTORS“HA‘

STOP

RS232C

(G10,

G23

(G36/37/38)

IS

ON

FINISH

COMMAND

DISAGREEMENT

OF

FAILURE

CODE

BAUD

HAS

VE

BEEN

BEEN

RATES.

INTERFACE

G22/23)

COMMANDED

WITH

G36

WITH

TO

OF

TRANS-

.

059

066

067

068

UNREADY

ZR

~C2r

NOT

COMMAND

G29

RETURN

RESET

POWER

MEMORY.

EDITING

INHIBIT

EDIT

"CQt/PLErmJ

OR

COMPLETED

NOT

UNREADY

TURNED

BEING

AREA.

THE

"AXIS

ON

REFERENCE

ON

(AFTER

OFF

EDITING)

DURING

EXECUTED

WCCR

POINT

THE

WRITING

THE

IN

“

HAS

AXIS.

G36

TO

(G36/37)

(J)

OF

I

(G37).

(G38)

OTHER

(G31/36/37/38)

'NOT

CH

IT

END

AT

(G36/37/38)

G38

COMMANDS.

ON

MORE

THAN

POINT

K

"ON"

W

BY

AT

HEN

CALCULATION

THAN

G38.

”M6~T

G31,

ERROR

ONE

fo

G36

FT

:

“

AT

ERROR

AT

ERROR

ERROR

SW

G38

COMMANDS.

ERROR

SWITCH

G36

PROG

085

'

COMMAND

AXIS

086

PROG

COMMAND

PROG

087

’TOUCH”

REACHES

TO

PROG

088

TOUCH

2.2.1

LIST

OF

ALARM

CODES

(Cont'd)

Code

100

101

102

103

104

CAL

ERROR

MAGNITUDE

EXCEEDING

CAL

ERROR

EXPONENT

EXCEEDING

CAL

ERROR

CALCULATION

OVERFLOW

CAL

ERROR

ROOT

PROG

SAME

TWICE

VALUE

ERROR

ADDRESS

UPPER

OF

ALLOWABLE

ERROR.

BLOCK.

IN

A

Causes

(FIXED

OF

(FLOATING)

(DIVISION)

(SQUARE

IS

(DOUBLE

POINT)

FIXED

LIMIT.

FLOATING

DIVISOR

NEGATIVE(-).

A

REPEATED

Table

POINT

RANGE.

ZERO

ROOT)

ADD)

2.2

DATA

POINT

MORE

OR

List

DATA

THAN

of

Alarm

Code

111

114

115

116

117

Codes

MACRO

MOVE

MAND

MACRO

NO.

MACRO

NO.

BRACKETS

MACRO

CONDITION

NOT

(Cont'd)

ERROR

COMMAND

OF

MACRO

ERROR

OF

DOs

ERROR

OF

LEFT

ERROR

ESTABLISHED

Causes

(MOVE

IN

CALLED

(DO-FORMAT)

ENDs

AND

((

BRACKETS

NOT

THE

(DO-END

lÿnÿ3

G66-M99)

FINISHING

M99

NOT

UNMACH)

]

SAME.

IN

DOn.

BY

AND

NO.)

G66.

THE

COM¬

SAME.

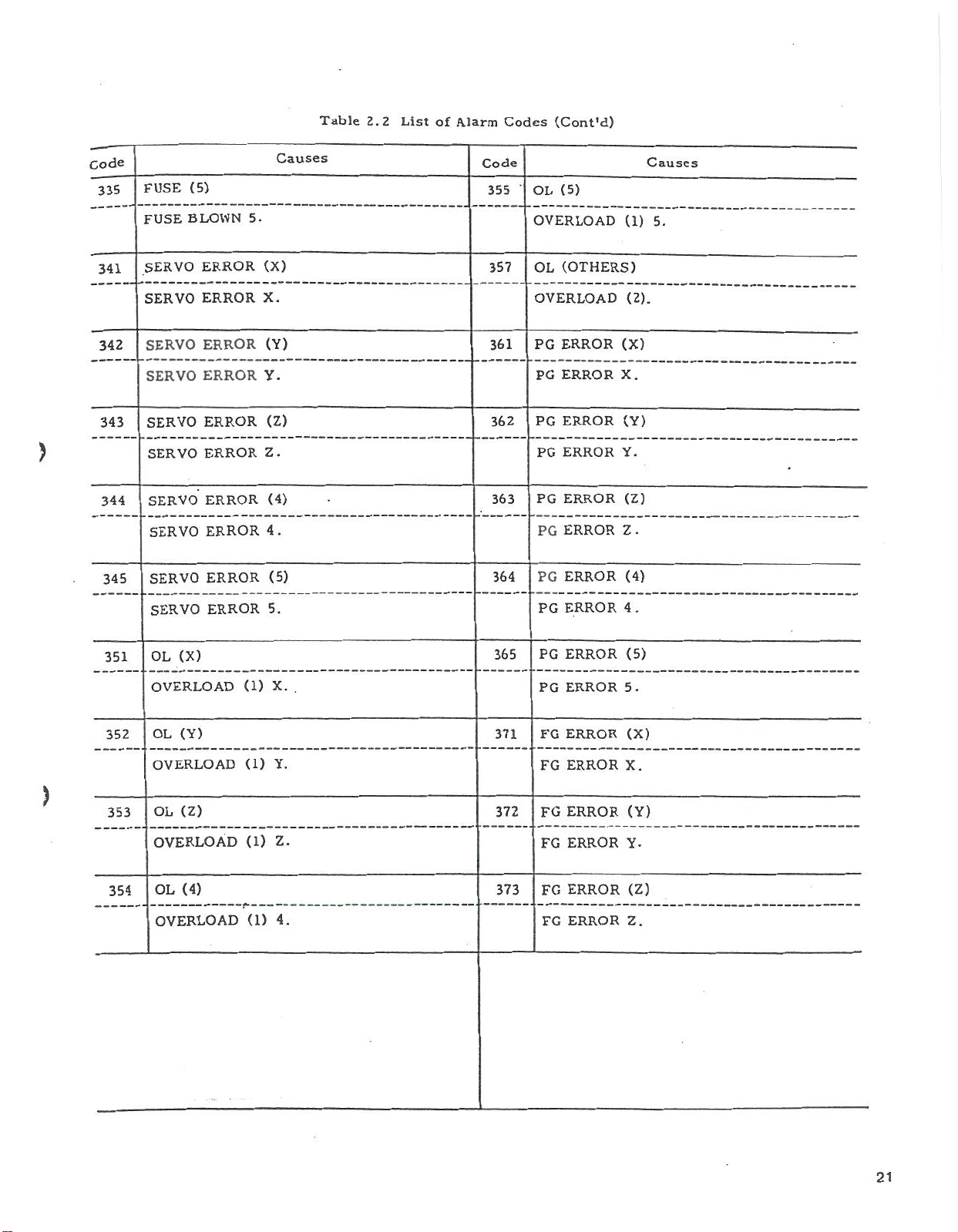

RIGHT

105

107

108

MACRO

CONSTANTS

EXCEEDING

MACRO

ERROR

EQUATION.

MACRO

UNDEFINED

DESIGNATED.

ERROR

ERROR

IN

ERROR

__

109

110

MACRO

COMM

AS

SIDE

MACRO

MULTIPLE

EXCEEDING

ERROR

AND

SUBSTITUTION

OF

THE

ERROR.

(CONSTANT)

USABLE

LIMIT.

THE

(FORMAT)

FORMAT

THE

(UNDEFIN

VARIABLE

(#NO

PROHIBITED

ED

LAYERS

THE

IN

EQUATION.

((

]

5

OF

UPPER

USER

NO)

#

LEFT)

"V

ARIA

__

MACRO

(5).

IN

AND

NO.

NOT

LEFT-HAND

LIMIT)

PARENTHESES

LIMIT

BLE

118

120

121

122

123

MACRO

CONDITION

OR

PRTN

SEQUENCE

PROGRAM.

PRTN

G92

ATION

PRTN

G54

OPERATION

PRTN

"CO

DEPRESSING

PROGRAM

ERROR

SEQUENCE

NO

ERROR

ERROR

COMMANDED

DURING

ERROR

TO

G59

ERROR

OR

DTNATI

(GOTO

0

<n£

9999

NO.

(NOT

FOUND)

NO.

NOT

(G92)

THROUGH

PROGRAM

(G54-G59)

COMMANDED

DURING

(ORG)

2

S"Y

S

YEM*

THE

RESTART

ORG

.

N)

NOT

ESTABLISHED

IN

GO

FOUND

PROGRAM

IN

MDI

RESTART.

THROUGH

CHANG

BUTTON

TO

n.

PART

OPER¬

RESTART.

_B

ED

Y

DURING

MDI

16

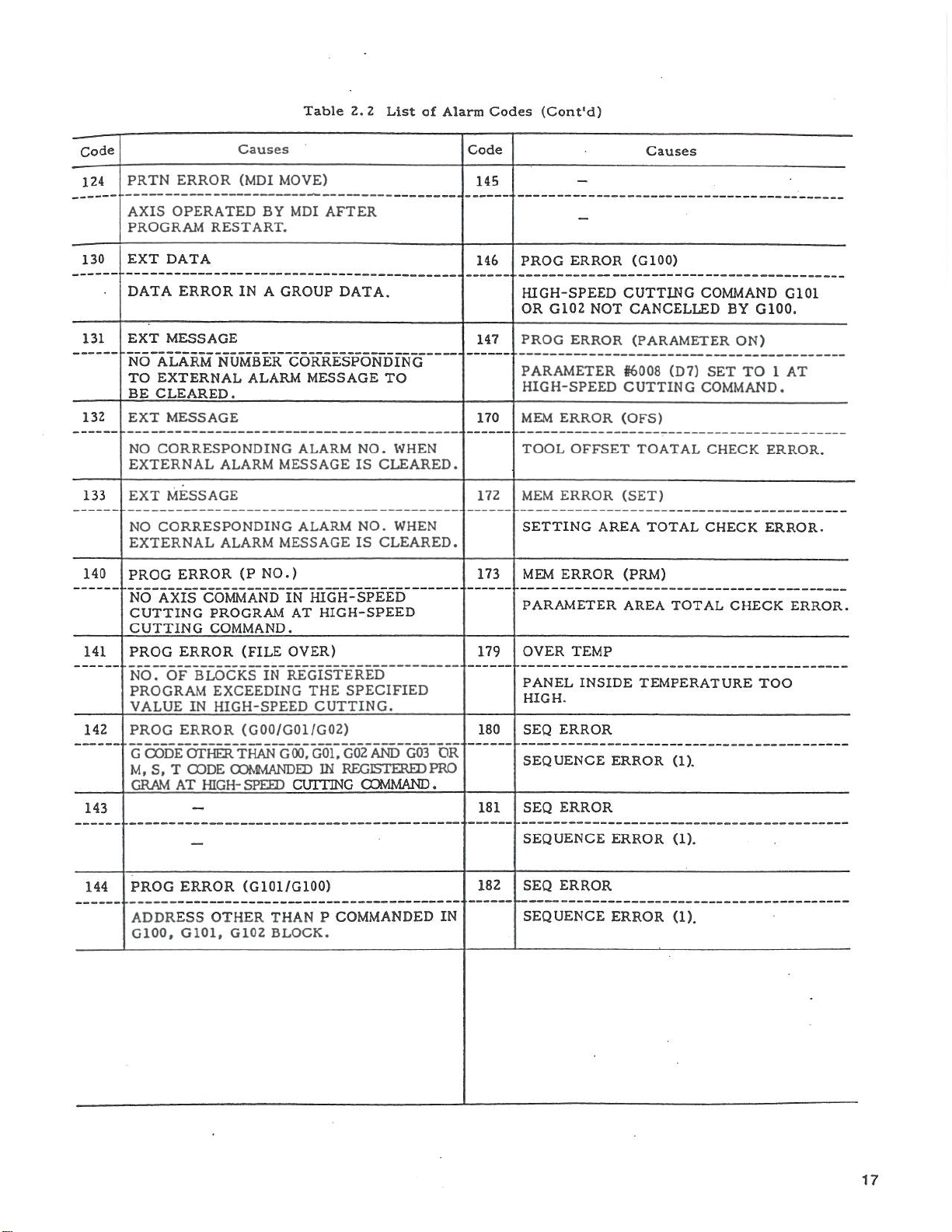

Table

2.2

List

of

Alarm

Codes

(Cont'd)

Code

124

130

131

132

133

140

141

142

143

Causes

(MDI

PRTN

AXIS

PROGRAM

EXT

DATA

EXT

F6~AL~ARM

TO

BE

EXT

NO

EXTERNAL

EXT

EXTERNAL

PROG

CUTTING

CUTTING

PROG

PROG

ERROR

OPERATED

RESTART.

DATA

ERROR

MESSAGE

“NUMB

EXTERNAL

CLEARED.

MESSAGE

CORRESPONDING

ALARM

MESSAGE

CORRESPONDING

NO

ALARM

ERROR

NO”

AXISCOMM

PROGRAM

COMMAND.

ERROR

NO7~6

PROGRAM

VALUE

G

M,

GRAM

F"

BLOCKS-

EXCEEDING

IN

HIGH-SPEED

ERROR

OTDE-OTHE31THXNG6O;

S,

CODE

T

AT

COMMANDED

HIGH-SPEED

MOVE)

BY

MDI

IN

A

GROUP

EIl"c6¥RE¥p6iTDiNG

ALARM

_

(P

N

A

(FILE

(G00/G01/G02)

MESSAGE

ALARM

MESSAGE

ALARM

MESSAGE

NO.)

HIGH

I

D~

if

HIGH-SPEED

AT

_

OVER)

N_REGIST1J

I

THE

CUTTING.

GOl"

CUTTING

AFTER

DATA.

NO.

IS

NO.

IS

1

PE

S

RED"

SPECIFIED

AND

G02~

REGISTERED

IN

COMMAND.

TO

WHEN

CLEARED.

WHEN

CLEARED.

"

E

D~

G03_

OR

PRO

__

Code

145

146

147

170

172

173

179

180

181

PROG

HIGH-SPEED

OR

PROG

PARAMETER

HIGH-SPEED

MEM

TOOL

MEM

SETTING

MEM

ERROR

G102

ERROR

ERROR

OFFSET

ERROR

ERROR

NOT

AREA

PARAMETER

OVER

PANEL

HIGH.

SEQ

SEQUENCE

SEQ

TEMP

INSIDE

ERROR

ERROR

Causes

(G100)

CUTTING

CANCELLED

(PARAMETER

(D7)

16008

CUTTING

(OFS)

TOATAL

(SET)

TOTAL

(PRM)

AREA

ERROR

TOTAL

TEMPERATURE

(1).

COMMAND

BY

G100.

ON)

SET

TO

1

COMMAND.

CHECK

CHECK

ERROR.

ERROR.

CHECK

TOO

G101

AT

ERROR.

144

PROG

ADDRESS

G100,

ERROR

G101,

(G101/G100)

OTHER

G102

THAN

BLOCK.

COMMANDED

P

IN

182

SEQUENCE

SEQ

ERROR

SEQUENCE

ERROR

ERROR

(1).

(1).

17

2.2.1

LIST

OF

ALARM

CODES

(Cont'd)

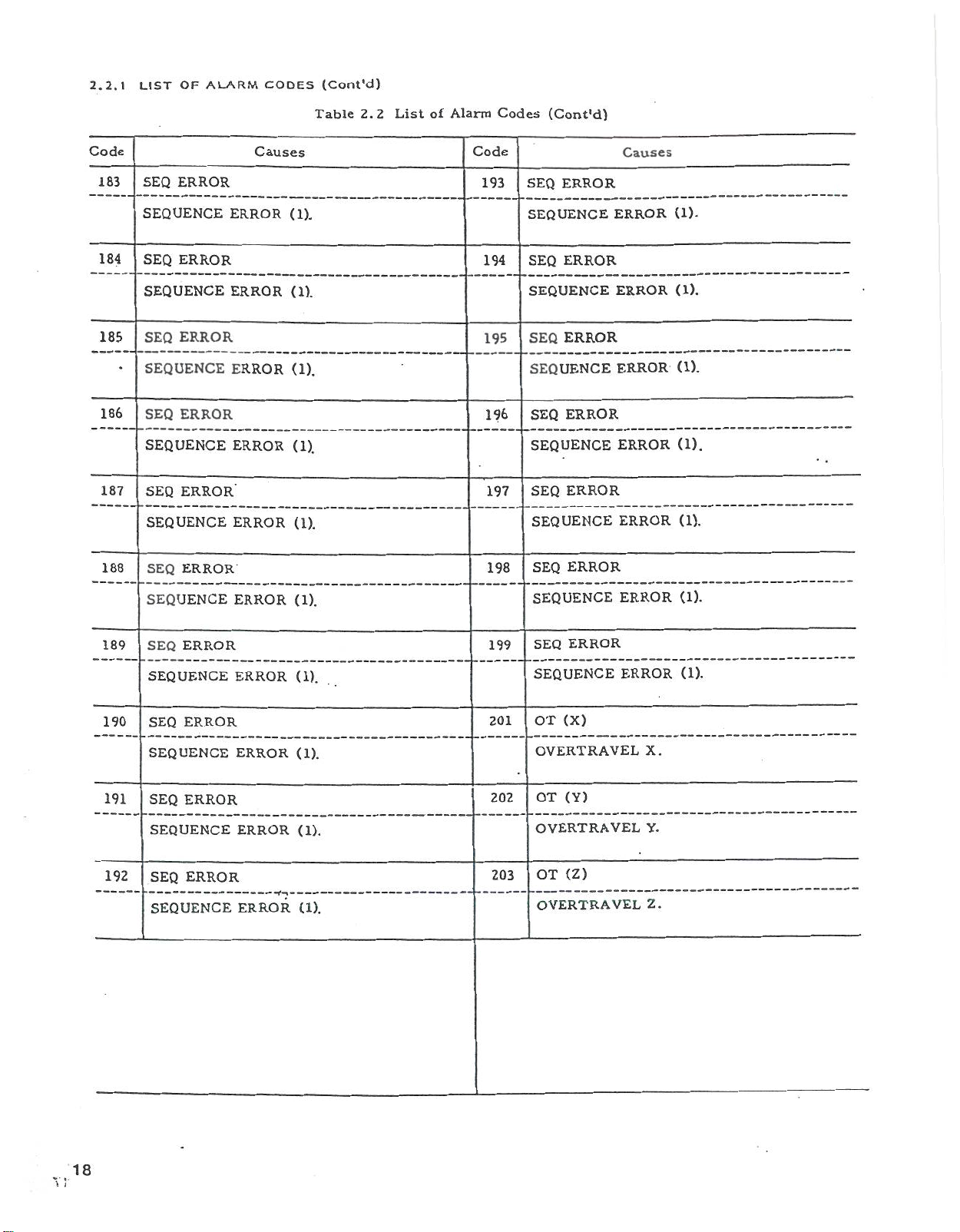

Code

183

184

185

186

187

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

Causes

ERROR

ERROR

ERROR

ERROR

ERROR

(1).

(1).

(1).

(1).

(1).

Table

2.2

List

of

Alarm

Code

193

194

195

196

197

Codes

(Cont'd)

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

Causes

ERROR

ERROR

ERROR

ERROR

ERROR

(1).

(1).

(1).

(1).

(1).

188

189

190

191

192

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

ERROR

ERROR

ERROR

ERROR

ERROR

(1).

(1).

(1).

(1).

(1).

198

199

201

202

203

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

(X)

OT

ERROR

ERROR

OVERTRAVEL

(Y)

OT

OVERTRAVEL

(Z)

OT

OVERTRAVEL

(1).

(1).

X.

Y.

Z.

18

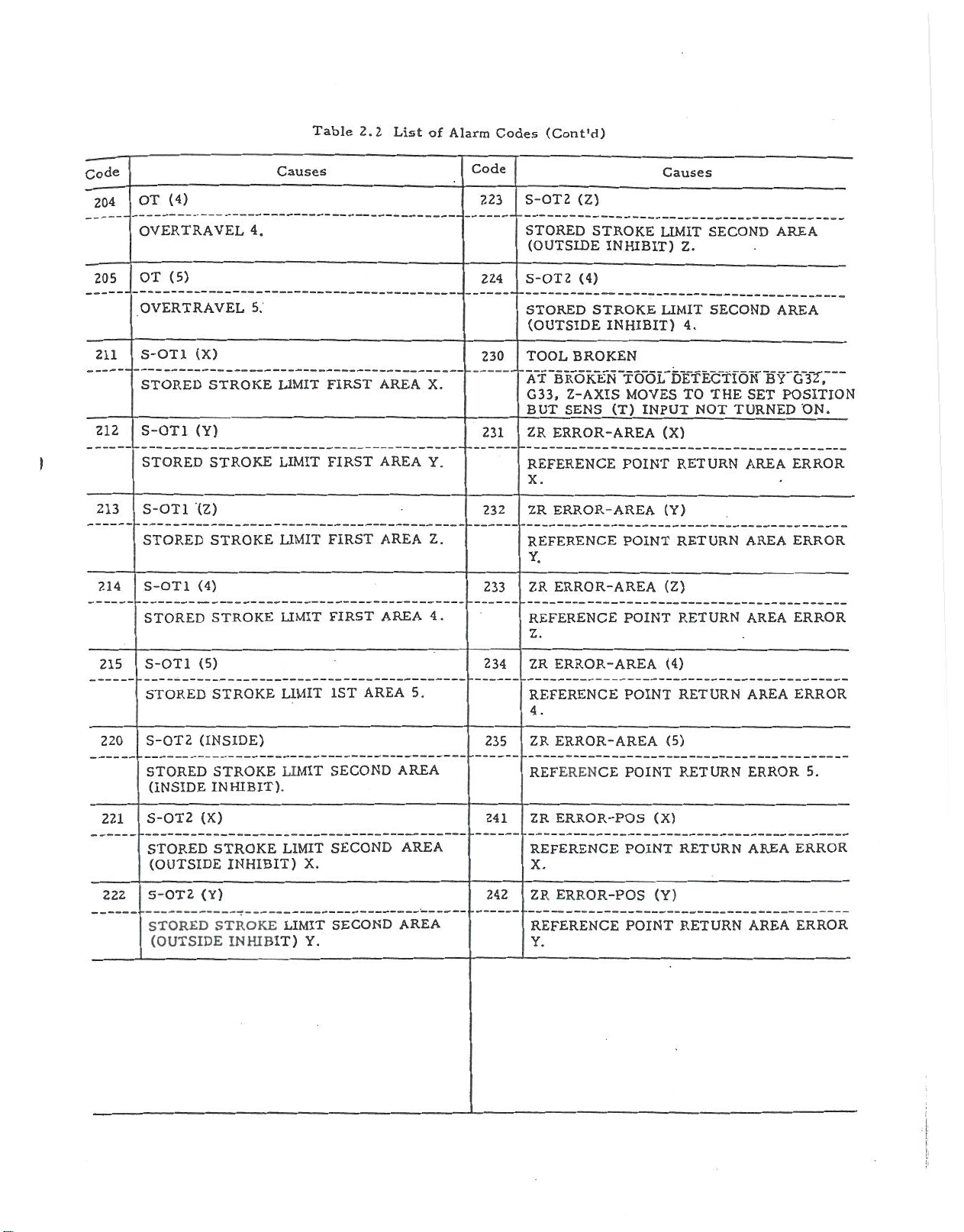

Table

2.2

List

of

Alarm

Codes

(Cont'd)

X.

Y.

Z.

Code

223

224

230

231

232

S-OT2

STORED

(OUTSIDE

S-OT2

STORED

(OUTSIDE

TOOL

AT

G33,

BUT

ZR

REFERENCE

X.

ZR

(Z)

STROKE

(4)

STROKE

BROKEN

"BROKEN

Z-AXIS

SENS

ERROR-AREA

ERROR-AREA

REFERENCE

INHIBIT)

INHIBIT)

"TOOL-

MOVES

(T)

INPUT

POINT

POINT

Causes

Z.

LIMIT

4.

SECOND

SECOND

LIMIT

DETECTION'

TO

THE

NOT

(X)

RETURN

(Y)

RETURN

SET

TURNED

AREA

AREA

AREA

AREA

¥

Y‘G3T.

POSITION

ERROR

ERROR

ON.

4.

5.

Causes

LIMIT

LIMIT

LIMIT

FIRST

FIRST

FIRST

AREA

AREA

AREA

Code

(4)

OT

204

OVERTRAVEL

(5)

OT

205

OVERTRAVEL

S-OT1

211

STORED

S-OT1

212

213

STORED

S-OT1

STORED

I

(X)

STROKE

(Y)

STROKE

(Z)

STROKE

Y.

214

S-OT1

(4)

233

ERROR-AREA

ZR

(Z)

215

220

221

222

STORED

S-OT1

STORED

S-OT2

STORED

(INSIDE

S-OT2

STORED

(OUTSIDE

S-OT2

STORED

(OUTSIDE

STROKE

(5)

STROKE

(INSIDE)

STROKE

INHIBIT).

(X)

STROKE

INHIBIT)

(Y)

STROKE

INHIBIT)

LIMIT

LIMIT

LIMIT

LIMIT

X.

LIMIT

Y.

FIRST

AREA

1ST

SECOND

SECOND

SECOND

AREA

AREA

AREA

AREA

4.

234

5.

235

241

REFERENCE

Z.

ZR

ERROR-AREA

REFERENCE

4.

ZR

ERROR-AREA

REFERENCE

ZR

ERROR-POS

REFERENCE

POINT

POINT

POINT

POINT

(4)

(5)

(X)

RETURN

RETURN

RETURN

RETURN

AREA

AREA

ERROR

AREA

ERROR

ERROR

5.

ERROR

X.

242

ZR

ERROR-POS

REFERENCE

Y.

(Y)

POINT

RETURN

AREA

ERROR

I

i

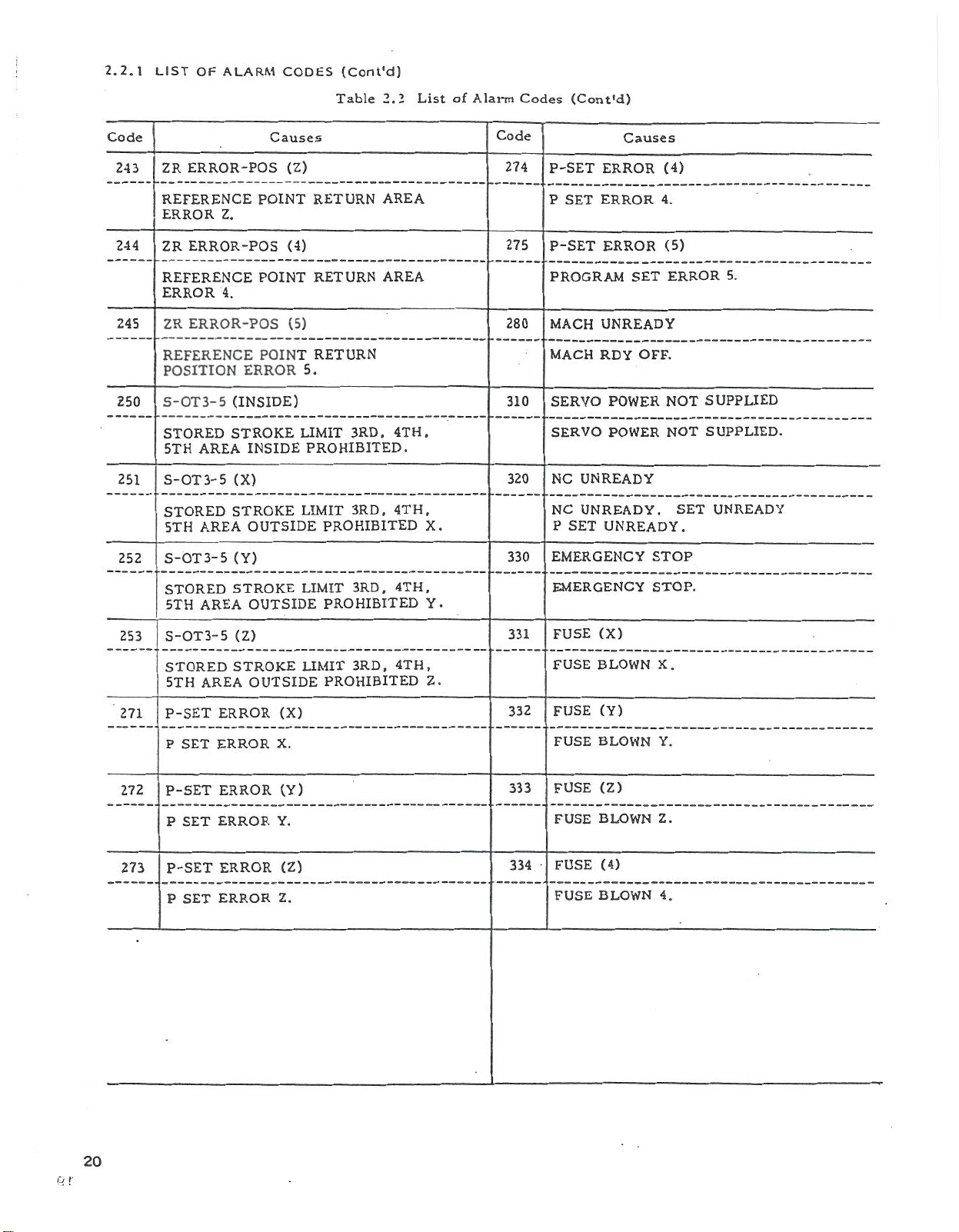

2.2.1

LIST

OF

ALARM

CODES

(Cont'd)

Code

243

244

245

250

251

ERROR-POS

ZR

REFERENCE

ERROR

ZR

Z.

ERROR-POS

REFERENCE

ERROR

ZR

4.

ERROR-POS

REFERENCE

POSITION

S-OT3-5

STORED

5TH

S-OT3-5

STORED

5TH

(INSIDE)

STROKE

AREA

(X)

STROKE

AREA

Causes

(Z)

POINT

(4)

POINT

(5)

POINT

ERROR

INSIDE

OUTSIDE

Table

RETURN

RETURN

RETURN

5.

LIMIT

3RD,

PROHIBITED.

LIMIT

3RD.

PROHIBITED

2.2

AREA

AREA

4TH

4TH,

List

,

X.

of

Alarm

Code

Codes

274

275

280

310

320

(Cont'd)

P-SET

P

P-SET

SET

ERROR

ERROR

ERROR

PROGRAM

MACH

MACH

SERVO

SERVO

NC

NC

P

UNREADY

RDY

POWER

POWER

UNREADY

UNREADY.

SET

UNREADY.

Causes

SET

OFF.

(4)

4.

(5)

ERROR

NOT

NOT

SET

5.

SUPPLIED

SUPPLIED.

UNREADY

252

253

271

272

273

S-OT3-5

STORED

5TH

AREA

S-OT3-5

STORED

AREA

5TH

P-SET

P

SET

P-SET

SET

P

P-SET

SET

P

(Y)

STROKE

OUTSIDE

(Z)

STROKE

OUTSIDE

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

(X)

X.

(Y)

Y.

(Z)

Z.

LIMIT

3RD,

PROHIBITED

LIMIT

3RD,

PROHIBITED

4TH,

4TH

Y.

,

Z.

330

331

332

333

334

EMERGENCY

EMERGENCY

FUSE

FUSE

FUSE

(X)

BLOWN

(Y)

BLOWN

(Z)

BLOWN

(4)

BLOWN

FUSE

FUSE

FUSE

FUSE

FUSE

STOP

STOP.

X.

Y.

Z.

4.

20

!

H

Table

2.2

List

of

Alarm

Codes

(Cont'd)

Code

FUSE

SERVO

SERVO

SERVO

SERVO

SERVO

SERVO

SERVO

SERVO

(5)

BLOWN

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

FUSE

335

SERVO

341

342

343

)

344

345

Causes

5.

(X)

X.

(Y)

Y.

(Z)

Z.

(4)

4.

(5)

Code

355

357

361

362

363

364

'

(5)

OL

OVERLOAD

(OTHERS)

OL

OVERLOAD

ERROR

PG

ERROR

PG

ERROR

PG

ERROR

PG

ERROR

PG

ERROR

PG

ERROR

PG

(X)

X.

(Y)

Y.

Z.

(1)

(2).

(Z)

(4)

Causes

5.

.

4

(5)

5.

(X)

X.

351

352

SERVO

OL

ERROR

(X)

OVERLOAD

(Y)

OL

OVERLOAD

(1)

(1)

5.

X.

Y.

365

371

PG

PG

PG

FG

FG

ERROR

ERROR

ERROR

ERROR

ERROR

)

353

354

(Z)

OL

OVERLOAD

(4)

OL

OVERLOAD

ERROR

373

FG

FG

FG

FG

ERROR

ERROR

ERROR

372

(1)

Z.

•f'

(1)

4.

(Y)

Y-

(Z)

Z.

21

•V!

i

ft-

2.2.1

LIST

OF

ALARM

CODES

(Cont'd)

Table

2.2

List

of

Alarm

Codes

(Cont'd)

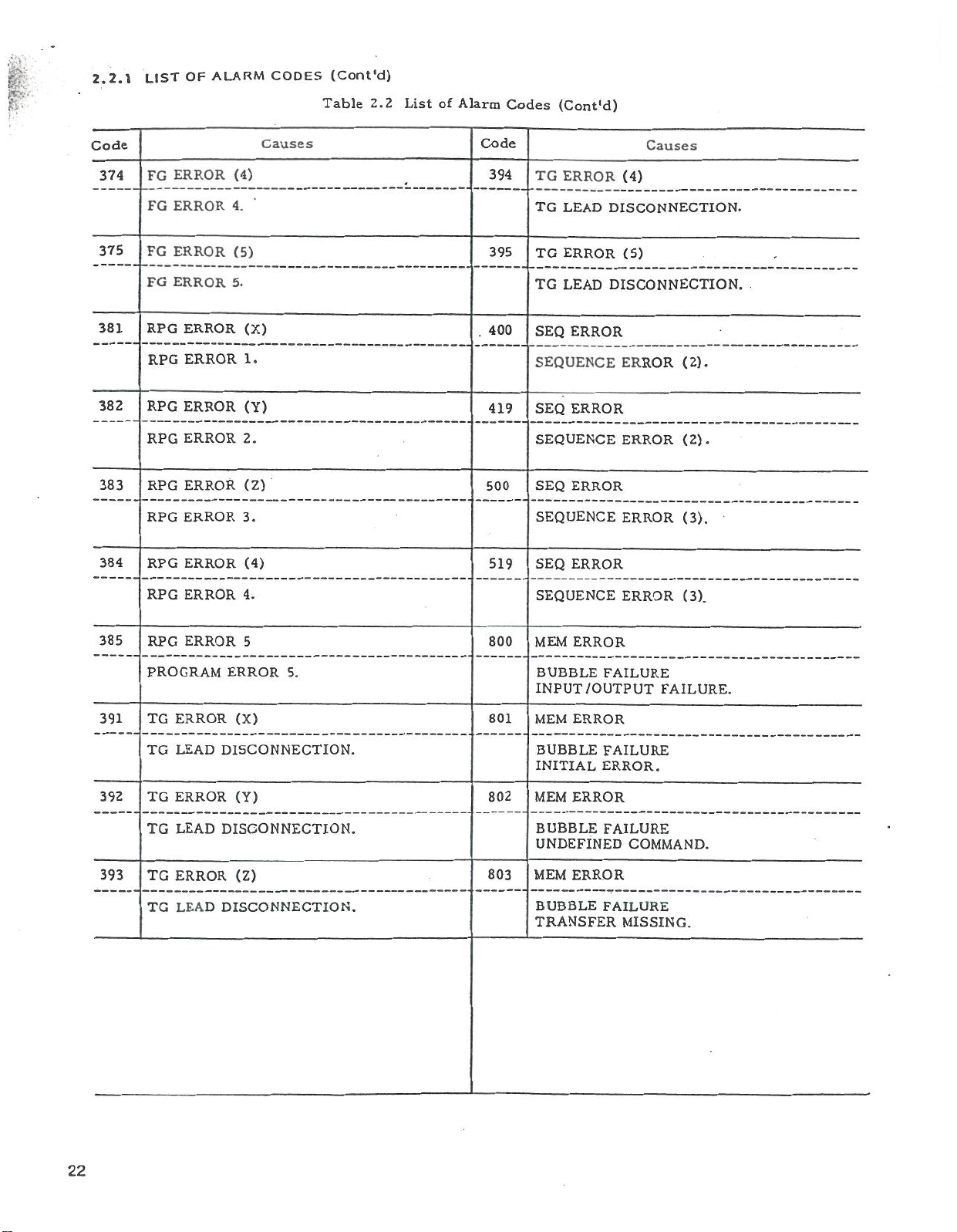

Code

374

375

381

382

383

384

FG

FG

FG

FG

RPG

RPG

RPG

RPG

RPG

RPG

RPG

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

(4)

4.

(5)

5.

(X)

1.

(Y)

2.

(Z)

3.

(4)

Causes

Code

394

395

400

.

419

500

519

TG

ERROR

TG

LEAD

TG

ERROR

TG

LEAD

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

SEQUENCE

SEQ

ERROR

Causes

(4)

DISCONNECTION.

(5)

DISCONNECTION.

ERROR

ERROR

ERROR

(2).

(2).

(3).

385

391

392

393

RPG

ERROR

RPG

ERROR

PROGRAM

TG

ERROR

TG

LEAD

TG

ERROR

TG

LEAD

TG

ERROR

TG

LEAD

4.

5

ERROR

(X)

5.

DISCONNECTION.

(Y)

DISCONNECTION.

(Z)

DISCONNECTION.

800

801

802

803

SEQUENCE

ERROR

MEM

BUBBLE

INPUT

MEM

BUBBLE

INITIAL

MEM

BUBBLE

FAILURE

/OUTPUT

ERROR

FAILURE

ERROR.

ERROR

FAILURE

UNDEFINED

MEM

ERROR

BUBBLE

FAILURE

TRANSFER

ERROR

(3).

FAILURE.

COMMAND.

MISSING.

22

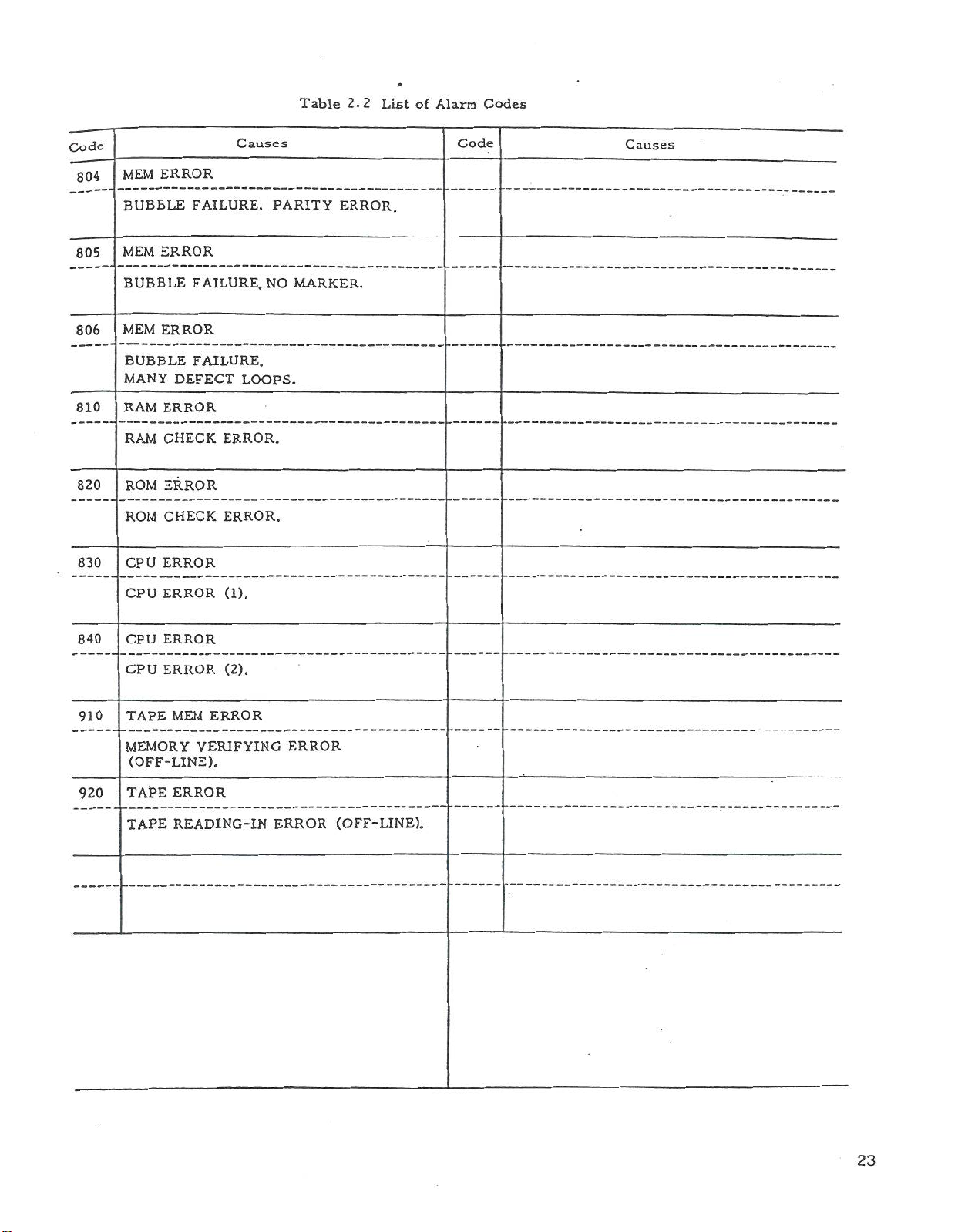

Table

2.2

List

of

Alarm

Codes

Code

804

805

806

810

820

830

ERROR

MEM

BUBBLE

ERROR

MEM

BUBBLE

MEM

ERROR

BUBBLE

MANY

ERROR

RAM

CHECK

RAM

ROM