Page 1

Item

Oxix

Quick Guide for Oxix

Calibration

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

New Calibration Menu..................................................................................................................... 2

Zero Point Calibration ..................................................................................................................... 3

Span Calibration ............................................................................................................................. 4

Salinity Correction Factor................................................................................................................ 5

Restore Factory Calibration ............................................................................................................ 6

Guide to Oxygen-free Solution for Checking Oxix D.O. Sensor Zero Point ..................................... 7

Method........................................................................................................................................ 7

Notes .......................................................................................................................................... 7

How it works................................................................................................................................ 7

Materials ..................................................................................................................................... 7

Safety Precautions...................................................................................................................... 7

EN 5.4 Oxix Quick guide for calibration 1204.doc

1/7

Page 2

Item

Oxix

Quick Guide for Oxix

Calibration

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

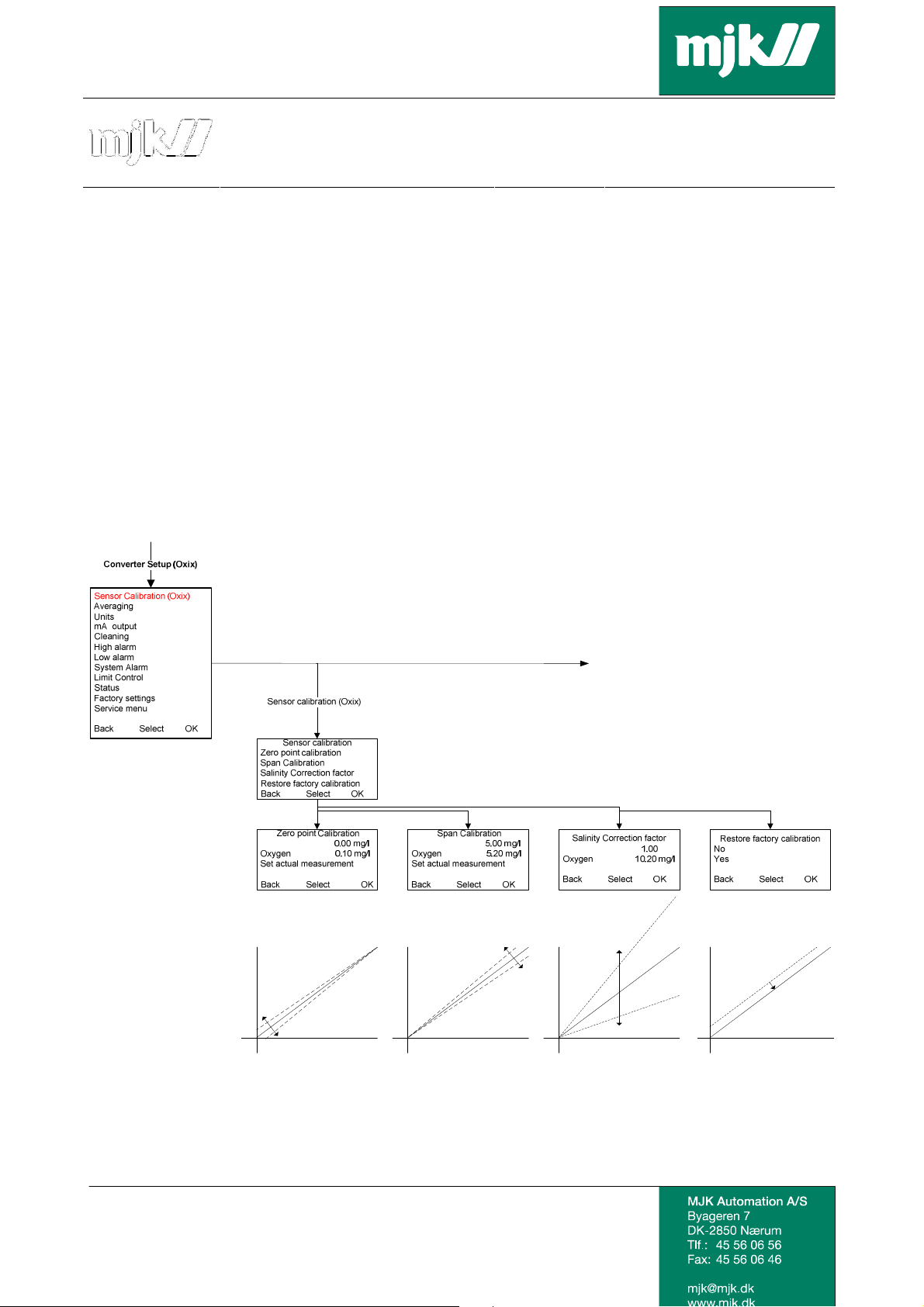

New Calibration Menu

Valid from firmware version 846003-001, a new calibration menu and method have been

introduced in the Oxix converter.

A factory calibration of both zero point and span has been made at delivery; these calibrations can

be done independently of each other. It is not usually necessary to calibrate. We recommend

checking the zero position every 6 to 12 months.

The calibration is saved in the converter and you will need to conduct a new calibration if the

sensor is moved to another converter.

We recommend conducting a factory reset of the sensor before conducting a new calibration, since

you avoid that any errors in an existing calibration affect the new calibration.

We have also added a menu with the possibility of adjusting salinity levels in the measurement.

EN 5.4 Oxix Quick guide for calibration 1204.doc

2/7

Page 3

Item

Oxix

Quick Guide for Oxix

Calibration

Zero Point Calibration

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

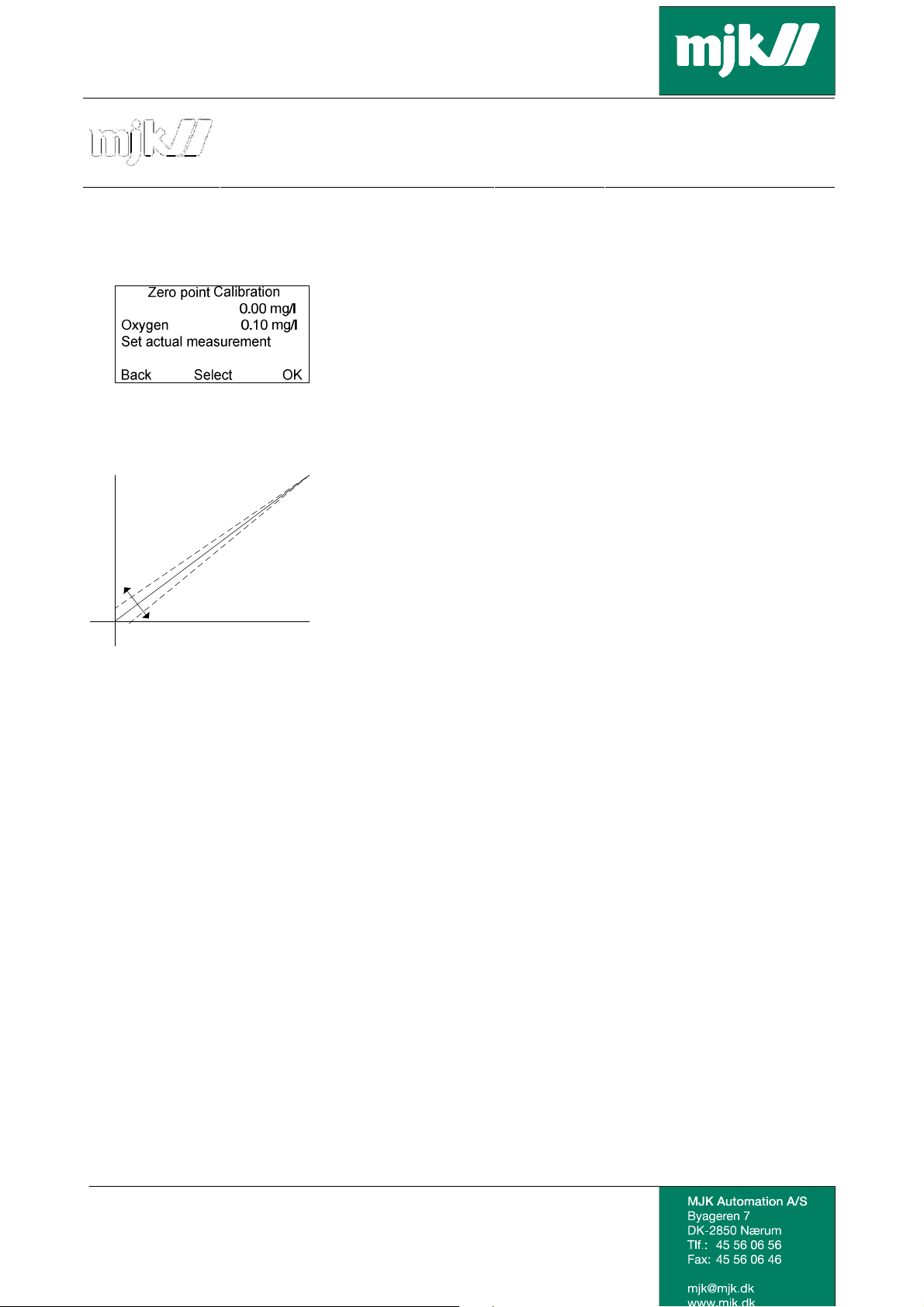

A zero point check or calibration is conducted as follows:

• The sensor is set for a zero point solution. The current measurement is shown in line 2

(0.10mg/l in this example).

• Set the desired measuring value on the first line using the up and down arrow keys.

• Save the current measurement setup by pressing OK.

The value is saved in the converter and will correct the measurement value of the sensor.

See section Guide to Oxygen-free Solution for Checking Oxix D.O. Sensor Zero Point.

EN 5.4 Oxix Quick guide for calibration 1204.doc

3/7

Page 4

Item

Oxix

Quick Guide for Oxix

Calibration

Span Calibration

Span Calibration

5.00 mg/l

Oxygen 5.20 mg/l

Set actual measurement

Back Select OK

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

A span check or calibration is conducted as follows:

• The sensor is measuring. The current measurement is shown in line 2 (5.20 mg/l in this

example).

• Set the desired measuring value on the first line using the up and down arrow keys.

• Save the current measurement setup by pressing OK.

It is generally difficult to conduct a span calibration. Usually, a reference sensor is used to verify

the measurement. For non-oxygen solutions, a variation of 1 to 5% between two sensors can occur

(even when the sensors are placed right next to each other). Air bubbles on the optical window will

create measurement variations.

Theory on making oxygen saturated solution

An oxygen saturated solution can be made from demineralised water being oxygenated for a

minimum of 30 minutes with atmospheric air. This saturation can then be calculated into an oxygen

concentration.

The temperature of the solution is measured with decimal and the atmospheric pressure is

measured with mm Hg.

The ppm or mg/l value of the saturated solution at the given temperature can then be decided by

using a matrix.

EN 5.4 Oxix Quick guide for calibration 1204.doc

4/7

Page 5

Item

Oxix

Quick Guide for Oxix

Calibration

Salinity Correction Factor

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

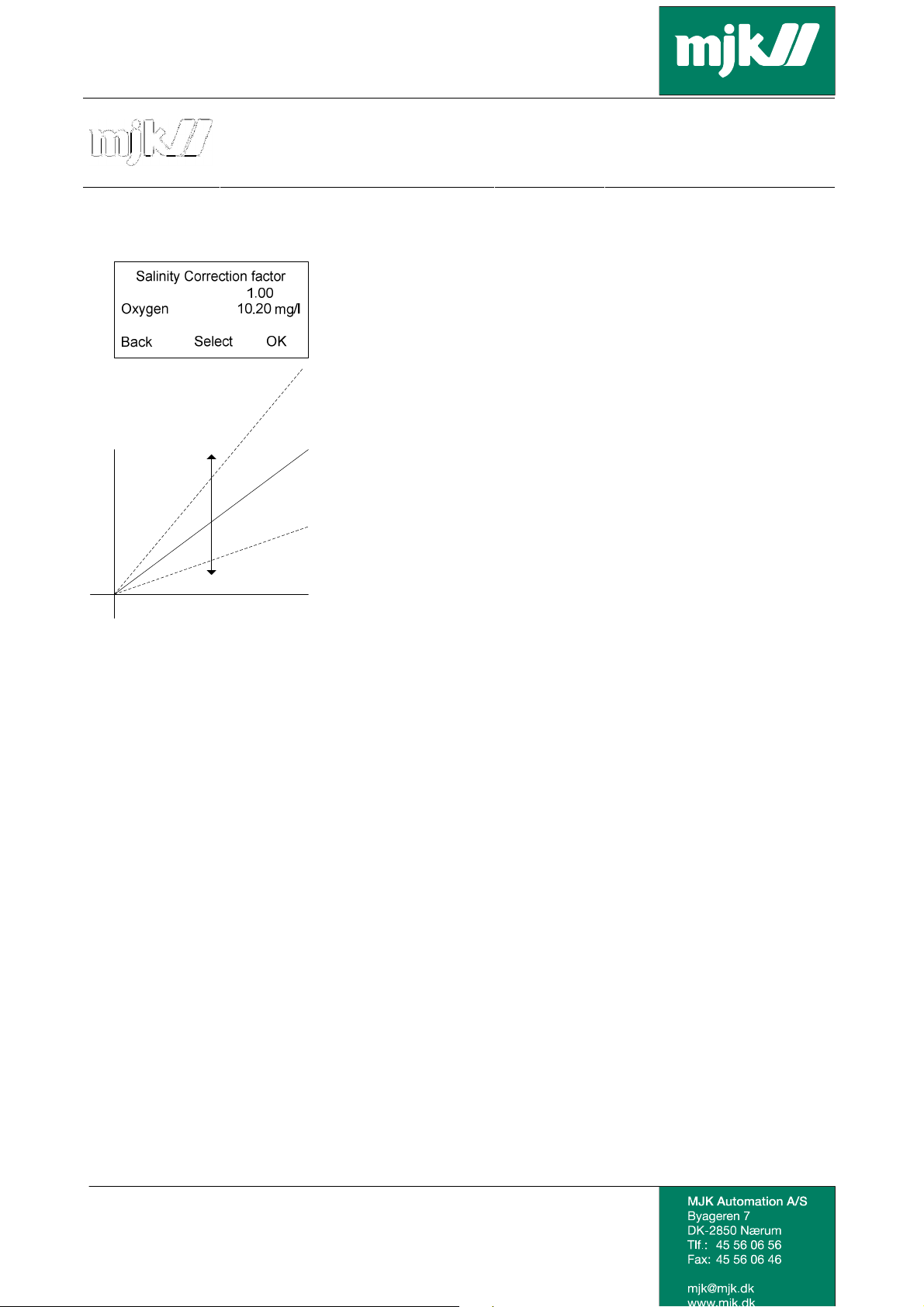

Oxix in salinity applications

A salinity correction factor is entered as follows:

• The sensor is measuring. The current measurement is shown in line 2 (10.20 mg/l in this

example).

• Set the desired salinity correction factor on the first line using the up and down arrow keys.

The interval is from 0.500 to 1.500.

• Save the current correction factor setup by pressing OK.

When measurement is done in the ppm or mg/litre units, a salinity correction is required (not when

measuring in % SAT!).

The correction factor for the current application is found in a matrix with factors for different salinity

levels, where the salinity level is shown by electrical conductivity.

It is assumed that the salinity level in the application is stable, as the factor can only be entered

manually. Alternatively, Oxix can be used without correction factor and in itself correct the DO

measuring based on the measured conductivity by third-party equipment.

EN 5.4 Oxix Quick guide for calibration 1204.doc

5/7

Page 6

Item

Oxix

Quick Guide for Oxix

Calibration

Restore Factory Calibration

Restore factory calibration

No

Yes

Back Select OK

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

The sensor should be reset before calibrating zero point or span by using Reset Factory

Calibration.

This helps avoiding any errors in an existing calibration affecting the new calibration.

EN 5.4 Oxix Quick guide for calibration 1204.doc

6/7

Page 7

Item

Oxix

Quick Guide for Oxix

Calibration

Name:

Version: 04-2012 KJ

FW 846003-001

Release date: 12/07 2011

S/N at release date: 97060

Guide to Oxygen-free Solution for Checking Oxix D.O. Sensor

Zero Point

Method

• Clean Oxix® and its optical window thoroughly.

• Dissolve 3 tablespoons Na2SO3 in 4 litres of tap water in an open container (bucket).

• Stir for about 1 minute.

• Immerse the sensor and let it rest in the solution for at least 30 minutes. (Towards the

bottom with the window down; check that there are no air bubbles on the lens.

Notes

This solution actually contains a concentration of approximately 0.10 ppm dissolved oxygen.

In time, if the solution is left alone, stratification will occur so that the concentration will be higher

towards to the surface.

If you need a reference sample with a dissolved oxygen concentration close to zero (approx. 0.02

ppm), the reference sample must be made with demineralised water and the solution must rest for

12-24 hours before measuring it.

It is important that the sensor and the optical window are completely clean when zero-point or

calibration is conducted.

How it works

Na2SO3 (sodium sulphite) removes oxygen from the solution since Na2SO3 is oxidized by O2

(oxygen) into Na2SO4 (sodium sulphate) following the reaction:

2Na2SO3+O2 → 2 Na2SO

Materials

Bucket

Measuring jug

Tablespoon

Chemicals/Reagents

Sodium sulphite, Na2SO3, CAS-Nr. 7757-83-7 (Supplier VWR, Bie & Berntsen)

Tap water (alternatively, demineralised water)

Safety Precautions

Safety instructions for Na2SO3: None. There are no R- or S-phrases for the product.

4

EN 5.4 Oxix Quick guide for calibration 1204.doc

7/7

Loading...

Loading...