INSTRUCTION MANUAL

IMCPFIBRGLR01

Fiberglass Basin

INSTALLATION REFERENCE GUIDE

Owner’s Information

Owner’s Information

Table of Contents

Table of Contents

Controller Model Number:

Controller Serial Number:

Pump Model Number:

Pump Serial Number:

Motor Model Number:

Motor SFA:

Tank Serial Number:

Installer:

Installer Telephone Number:

Installation Date:

NOTICE: RECORD THE MODEL NUMBERS

AND SERIAL NUMBERS FROM THE

PUMP AND CONTROLLER IN THIS

INSTRUCTION MANUAL FOR FUTURE

REFERENCE. GIVE IT TO THE OWNER

OR AFFIX IT TO THE CONTROLLER

WHEN FINISHED WITH THE

INSTALLATION.

SUBJECT PAGE

1. Safety Instructions ..................................................... 3

2. Purpose ..................................................................... 3

3. Disclaimer ................................................................. 3

4. Material Handling ..................................................... 3

General Handling ...................................................... 3

Unloading, Lifting and Lowering ............................... 3

Storage ................................................................... 3-4

Pre-Installation Inspection ......................................... 4

5. Excavating ................................................................. 4

Location of Excavating .............................................. 4

Maximum Burial Depth ............................................. 4

Handling of Excavated Materials ............................... 4

Work Area Safety ....................................................... 4

6. Backfilling ................................................................. 4

General ...................................................................... 4

Placement of Basin ..................................................... 4

Backfill Material ........................................................ 4

Placement and Compaction of Backfill ....................... 5

Supporting Piping, Equipment and Accessories .......... 5

7. Anchorage ................................................................. 5

General ...................................................................... 5

Methods of Anchorage............................................... 5

Anchorage Requirements ........................................... 5

Fiberglass Basin Installation Reference Guide ................ 6

Limited Warranty .......................................................... 8

2

WARNING

DANGER

WARNING

CAUTION

1: SAFETY INSTRUCTIONS

1: SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump,

the controller or in the manual, look for

one of the following signal words and

be alert to the potential for personal

injury or property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause

personal injury or property damage.

NOTICE: INDICATES SPECIAL

INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE

FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

In addition to proper system engineering and competent

manufacturing, the use of basin installers who have both

practical experience and integrity to assist that the basin

be installed properly constitutes the greatest protection

from catastrophic basin failure and liability exposure.

3: DISCLAIMER

3: DISCLAIMER

Every reasonable effort has been put forth by CentriPro

and its agents to ensure the accuracy and reliability

on the information contained in this reference guide.

However, neither CentriPro, its agents, nor its consultant

make any representation, warranty, or guarantee in

connection with the publication of these recommended

methods and procedures. CentriPro hereby disclaims any

liability for loss or damage resulting from their use; for

the violation of any federal, state, county, or municipal

regulations with which these recommended methods and

procedures may conflict; or for the infringement of any

patent resulting from the use of recommended methods

and procedures.

4: MATERIAL HANDLING

4: MATERIAL HANDLING

GENERAL HANDLING

Although the exterior surfaces of our fiberglass reinforced

plastic (FRP) sump and sewage basins are designed,

to withstand normal handling, they can be damaged

during transportation and installation. Basins must not

be dropped, dragged, or handled with sharp objects and

with the exception of the minimal movement involved in

a visual inspection, should not be rolled.

2: PURPOSE

2: PURPOSE

The purpose of this guide is to provide a brief reference

to the recommended methods and procedures for

installing CentriPro underground sump and sewage

basins to ensure that damage or premature failure of the

basin do not occur.

Studies conducted by both environmental regulatory

agencies and trade organizations demonstrate that

the most significant source of leaks and failures in

underground storage systems is improper handling and

installation. Proper handling and installation requires

practical experience combined with strict adherence to

proven methods and procedures.

This guide is not intended to serve as a basic instructional

manual. The installation of our sump and sewage basins

is a specialized skill, and is assumed that the individuals

who install our products and refer to this guide will have

basic understanding of such procedures as excavating,

backfilling, pipe fitting, and electrical work. No amount

of written instruction by a manufacture or a regulatory

agency will convert an inexperienced, under-supervised

laborer into a skilled, experienced mechanic. The

ability to recognize and correctly respond to abnormal

conditions during a basin installation requires field

experience as well as mechanical aptitude.

If the basin or its shell is damaged, installation should

be suspended until CentriPro or its agent can make a

determination of the extent of damage. Any repairs must

be first authorized in writing by CentriPro and than be

done in accordance with CentriPro instructions.

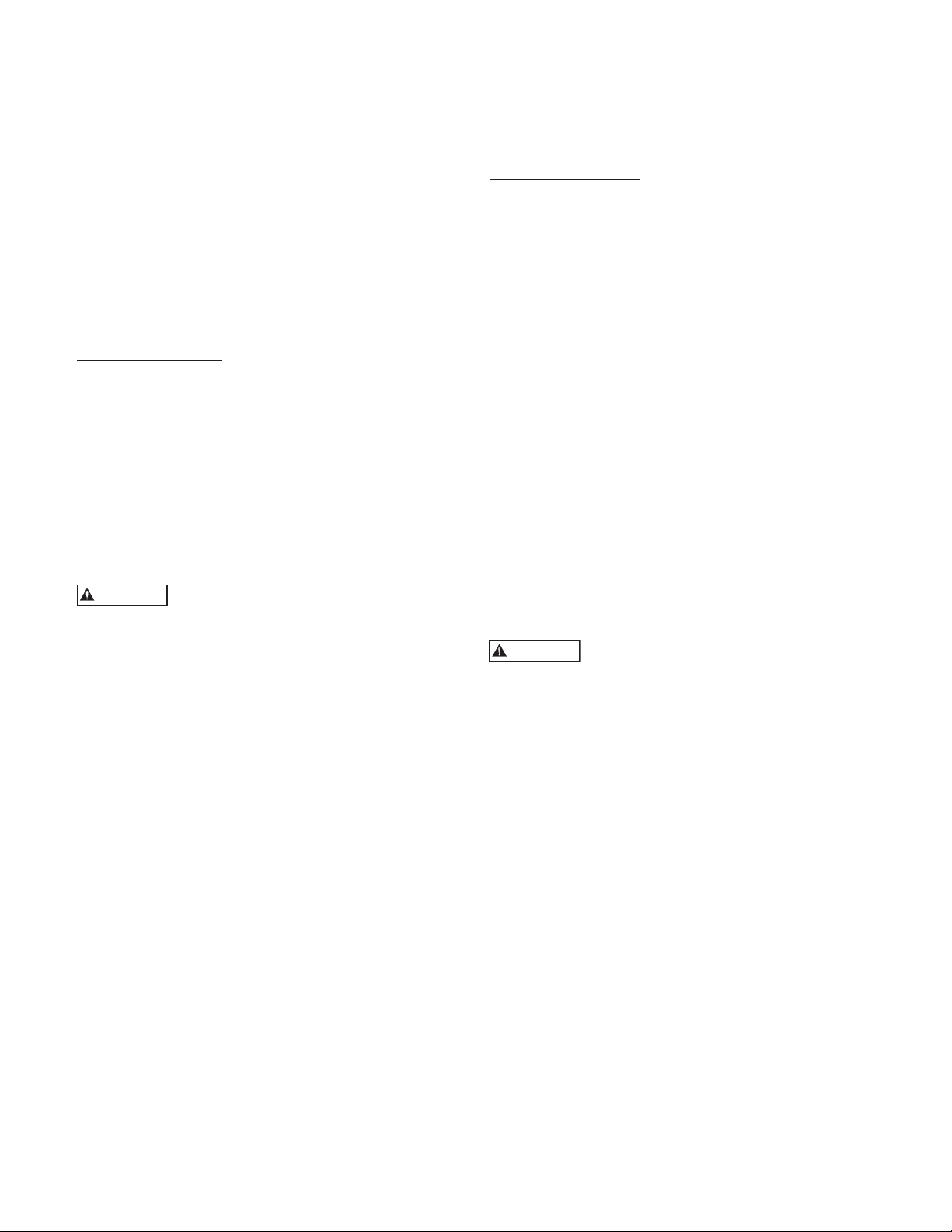

UNLOADING, LIFTING AND LOWERING

The proper way of moving a basin is by lifting it, using

chains or cables with the optional lifting lugs (not more

than 30* included angle) or by using a non-marring sling

around the basin. Before any attempt is made to move a

basin, it should be established that all of the equipment

and accessories have sufficient capacity and reach to lift

and lower the basins without dragging and/or dropping.

Basins should be maneuvered with guide ropes attached

to the sides.

Under NO, circumstances are the use of

chains or cables around the basin shell

permitted.

STORAGE

Basins should be stored in a secure, controlled area

where the potential for accidental damage or vandalism

will be minimized. The storage area should be free from

sharp objects, rocks and any other foreign solutions or

materials that could cause damage to the basins. Chock

3

WARNING

the basins until they are needed for installation and if

WARNING

windy conditions are possible, secure the basins with

non-marring restraints of a size and number adequate for

securing the basin.

PRE-INSTALLATION INSPECTION

Basins, vales, equipment, and piping materials should

be physically and visually inspected before installation.

Adherence to the project’s specifications should also be

confirmed before installation. If the basin or any of its

internal components are damaged, installation should be

suspended until a determination of the extent of damage

can be made by CentriPro or its agent. Any repairs must

be first authorized in writing by CentriPro and then be

done in accordance with CentriPro instructions.

WORK AREA SAFETY

Safe installation procedures shall be the sole responsibility of the basin installer. Work safety requirements are

defined in U.S. Department of Labor 29 CFR part 1926,

subpart P, Excavations.

6: BACKFILLING

6: BACKFILLING

GENERAL

Careful selection, placement, and compaction of

approved backfill material is critical to a successful basin

installation. Among the common problems associated

with basin leaks and premature failures are:

• Use of incorrect backll material

5: EXCAVATING

5: EXCAVATING

EXCAVATING

The excavation should provide adequate space for

the basin, piping, and other buried equipment and for

the replacement and compaction of backfill materials

particularly around the basin walls. The size, shape and

wall slope of the excavation should be determined by soil

conditions, depth of excavation, shoring requirements,

and if workers are required to enter the excavation,

safety considerations and federal, sate, county, and

municipal regulations.

Locate all overhead and underground

utilities before excavating.

LOCATION OF EXCAVATING

Excavation for an underground basin should be made

with due care to avoid undermining foundations of

existing structures and contact with underground

utilities. In the absence of building codes or regulations,

maintain a minimum distance of five feet plus a slope or

45* from the bottom of the compacted sub-base to the

bottom of the adjacent structures, foundations, footings,

and property lines (as shown in the attached illustration).

Additional distances may be required to assure that

any loading carried or created by the foundations and

supports cannot be transferred to the basins.

MAXIMUM BURIAL DEPTH

If burial depth is greater than the basin height, contact

CentriPro to determine if additional wall reinforcement

is required and secure written authorization.

HANDLING OF EXCAVATED MATERIALS

Excavated materials, which cannot be removed from the

job site, should be carefully stored as far from the edge of

the basin excavation as possible. Unless approved for use

as backfill, excavation materials should be securely stored

separate from the approved backfill materials.

• Inadequate or improper placement or compaction

• Rocks, clods, or debris left in the excavation or basin

• Voids under or around the perimeter of the basin

• Failure to prevent the migration of backll materials

PLACEMENT OF BASIN

The bottom of the basin excavation should be covered

with suitably with graded, leveled, and compacted

backfill material to a depth of at least 12 inches

(compacted sub-base). If a concrete hold-down/antiflotation pad is required, this bedding can be reduced

to a depth of at least 6 inches. The carefully lower the

basin into the excavation and centered on the compacted

backfill or concrete pad (see attached).

Placement of a basin on a concrete pad or

compacted sub-base smaller than the total

basin bottom area or on intermediate supports (saddles)

will cause uneven distribution of loads. This may

contribute to structural failure, and is never permitted.

BACKFILL MATERIAL

Back fill material should be clean, well granulated, free

flowing, non-corrosive, and inert. It should be free of ice,

snow, debris, rock, or organic material, all of which could

damage the tank and interfere with the compaction of

the backfill material. The largest particles should not be

larger than 3/4”. Not more than 3% (by weight) should

pass through a # 8 sieve, and the backfill material should

conform to ASTM C-33, Paragraph 9.1 requirements.

Approved backfill materials include:

• Pea Gravel, naturally rounded particles with a

minimum diameter of 1/8” and a maximum diameter

of 3/4”.

• Crushed rock, washed and free-owing angular

particles between 1/8” and 1/2” in size.

4

WARNING

WARNING

PLACEMENT AND COMPACTION OF

BACKFILL

Compaction of backfill materials should be adequate to

ensure the support of the tank, and to prevent movement

or settlement. Backfill materials should be placed in 12”

lifts and compacted to a minimum soil modulus of 700

pounds per square inch (psi).

SUPPORTING PIPING, EQUIPMENT AND

ACCESSORIES

Support for piping, equipment and other accessories

must be provided during backfilling. Using the basin to

support piping, equipment, cribbing, bracing, or blocking

is never permitted. During backfilling, temporary

supporting materials must be carefully installed and

removed to prevent damage to the basin, piping, or

equipment.

Using the basin to support any loading

carried or created by piping, equipment,

cribbing, bracing, or blocking is never permitted.

7: ANCHORAGE

7: ANCHORAGE

GENERAL

When basin installations are located in areas subject

to high water tables or flooding, provisions should be

made to prevent the basins, either empty or filled, from

floating. The buoyancy force to be offset is determined

primarily by the volume of the basin.

METHODS OF ANCHORAGE

All methods of anchoring basins use the weight of the

backfill materials to offset the buoyancy forces. The

use of supplemental mechanical anchoring methods (a

concrete hold-down pad) increases the amount of backfill

ballast, which is mechanically attached to the basin. The

recommended method of attachment is to pour concrete

grout over the basin’s anti-floatation flange and concrete

grout over the basin’s anti-floatation flange and concrete

hold-down pad (see attached illustration).

ANCHORAGE REQUIREMENTS

Requirements of anchorage, thickness of concrete

hold-down pads, as well as the size of anchors and

reinforcement must be calculated for each installation

based on the environmental conditions of that specific

installation.

Use “submerged” material weights when

calculating anchorage requirements.

Example: weight of concrete (150 ponds per cubic foot)

minus the weight of the water (62.4 pounds per cubic

foot) equals a “submerged” weight of 87.6 pounds per

cubic foot.

The principle offsetting factors include:

• Backll materials

• Concrete hold-down pad

• Friction between the tank, backll materials and the

surrounding soil

5

FIBERGLASS BASIN INSTALLATION REFERENCE GUIDE

30º Maximum

Lifting cable or chain

Spreader bar

Finish grade

Optional lifting lugs

CAUTION:

HANDLE WITH CARE

DO NOT DROP

DO NOT IMPACT

DO NOT ROLL

DO NOT WRAP

Cable or chain

around basin

Compacted sub-base

minimum 12” or 8”

when used with concrete

hold-down pad

Adjacent structure, foundation,

footing or property line

5”–0”

minimum

45”

minimum

Slope and size of excavation as

pipe area and engineer’s

specification. In the absence of

these, consider continuation of

soil, depth of excavation and

safety considerations.

Basin anti-flotation flange

Compacted sub-base and/or

concrete slab as per engineer’s

specification.

18” minimum backfill

compacted to a minimum

soil modules of 700 PSI

Finish grade

Fiberglass Basin as

required per

engineer’s

specification

In the absence of building codes, or regulations,

maintain a minimum distance of 5 feet plus a slope

of 40” from the bottom of the compacted sub-base

to the bottom of the adjacent structure’s foundation,

footing or property line.

1”

3/4”

1/2”

1/4”

Pea Gravel Crushed Brick

BACKFILL MATERIAL REQUIREMENTS

NOTE: The intent of these installation instructions and illustrations is to ensure that

damage or premature failure to the basin will not occur. These installation instructions

and illustrations are NOT intended to preclude normal safety procedures which should

be followed to prevent injury to personnel. SAFE INSTALLATION PROCEDURES SHALL

BE ENTIRELY THE RESPONSIBILTY OF THE INSTALLER.

6

Backfill material

Concrete grout as

required per

engineer’s

specification

NOTES

7

CENTRIPRO LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by CentriPro.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty

period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is

shorter.

A dealer who believes that a warranty claim exists must contact the authorized CentriPro distributor from whom the pump was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the CentriPro Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between CentriPro and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation,

limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/centripro

CentriPro is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. IMCPFIBRGL Rev 1 February 2013

Loading...

Loading...