Global Water

800-876-1172 • globalw.com

Global Water

Instrumentation, Inc.

11390 Amalgam Way

Gold River, CA 95670

T: 800-876-1172

Int’l: (916) 638-3429, F: (916) 638-3270

6” Tipping Bucket: RG200

02/05/10

01-343

- 1 -

Global Water

800-876-1172 • globalw.com

Congratulations on your purchase of the Global Water RG200

6” Tipping Bucket. This instrument has been quality tested and

approved for providing accurate and reliable measurements. We

are confident that you will find the RG200 to be a valuable asset

for your application. Should you require assistance, our technical

staff will be happy to help.

Table of Contents

I. Checklist • • • • • • • Page 3

II. Inspection

III. Tipping Bucket Installation

IV. Tipping Bucket Calibration Information

V. Adjusting the Rain Gauge Tipping Bucket

VI. Tipping Bucket Calibration Check

VII. Tipping Bucket Specifications

VIII. Maintenance

IX. Troubleshooting

X. Warranty

* Copyright © Global Water Instr umentation, Inc. 2005

• • • • • • • 10

• • • • • • 3

• • • • 4

• • 5

• • 7

• • • 8

• • • • 8

• • • • • • 9

• • • • • • 9

- 2 -

I. RG200 Checklist

a. 6” Tipping Bucket

b. RG200 Manual

c. Mounting Screws, strainer, metric conversion weight

II. Inspection

a. Your RG200 unit was carefully inspected and certified by our Quality

Assurance Team before shipping. If any damage has occurred during

shipping, please notify Global Water Instrumentation, Inc. and file a

claim with the carrier involved.

Use the checklist to ensure that you have received everything needed

to operate the RG200.

Global Water

800-876-1172 • globalw.com

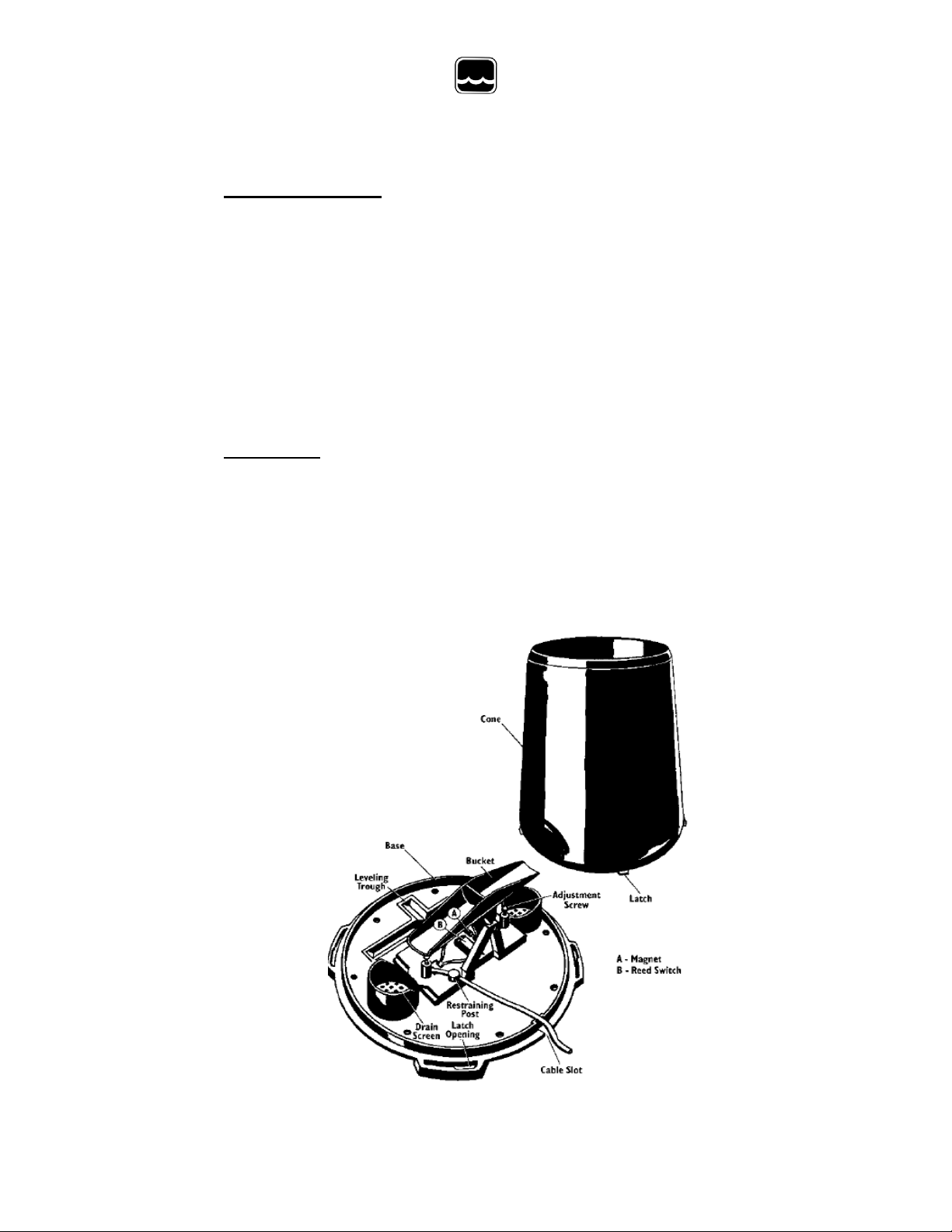

Rain Gauge Internal Components

- 3 -

800-876-1172 • globalw.com

III. Tipping Bucket Installation

Tools and Materials Needed

You may need some of the following tools and materials to install the

RG200 Rain Gauge Tipping Bucket:

1. Drill with 3/32" (2 mm) drill bit

2. Medium Phillips Screwdriver

3. 3/16" (or 5 mm) Wrench

4. Cable Clips or Weather-Resistant Cable Ties with screw holes or other

means for mounting

5. Bubble Level

Precautions

Global Water

a. The tipping bucket requires a clear an unobstructed mounting location

to obtain accurate rainfall readings. It must also be mounted on a level

surface that is free of vibration. Once the tipping bucket is mounted

remove the housing cover by rotating it counter clockwise. Verify that

the tipping bucket is not held in the center position. If held in upright

gently press either end down against the stop to ensure proper

operation.

b. To ensure that the surface is level, use a bubble level or pour water

into the T-shaped leveling trough in the base and observe the surface

of the water.

c. Be sure there is an unobstructed path for water runoff from the drain

screens.

d. Choose a location that is easily accessible for normal cleaning and is

distant from trees or other sources of heavy pollen or debris.

- 4 -

Global Water

800-876-1172 • globalw.com

Installation of Tipping Bucket with the GL500 Data Logger

e. Pass the Tipping Bucket cable through an unused strain relief. Attach

the two wires to the pulse channel of the GL500.

Installation of Tipping Bucket with other Global Water products

f. The Tipping Bucket comes with an attached RCA jack. Review the

literature for the other product to determine where the Tipping Bucket

RCA jack should be plugged into.

IV. Tipping Bucket Calibration Information

a. Accurate calibration can be obtained only with laboratory equipment,

but an approximate field check can be easily made. The tipping

bucket mechanism is a simple and highly reliable device. Any

accumulation of foreign material, dust, etc. will alter the calibration of

the unit. The tipping bucket must be calibrated with the rate of flow of

water through the tipping bucket mechanism. At least 36 seconds

should be allowed to fill one side of the tipping bucket. This

represents a maximum flow rate of one inch of rain per hour. If the

flow rate is increased, the unit will read low (if properly calibrated).

Decreasing the rate of flow will not affect the calibration. Some time is

required for the bucket to tip (a few milliseconds). During the first 50%

of this tipping time, water continues to flow into the filled bucket; the

last 50% of this tipping time, water flows into the empty bucket. The

amount of water flowing during the first 50% of time is the error, the

faster the flow rate the greater the error. At flow rates of one inch per

hour or less, the water actually drips into the bucket rather than

flowing. Under these conditions, the bucket tips between drips and

there is no error in the readings.

- 5 -

Global Water

800-876-1172 • globalw.com

Optional Metric Measurement Adapter

The rain gauge collector tipping bucket mechanism contains a standard

measurement weight magnet that takes measurements in .01” for every

tip of the bucket. The tipping bucket assembly contains a metric

measurement that adjusts the tipping bucket mechanism so that it takes

0.2 mm metric measurements. To change the weight magnet:

1. Find the metric measurement adapter included in the hardware.

2. Locate the standard measurement weight magnet between the arms of

the tipping mechanism.

3. Open the arms slightly with one hand while pulling the magnet out with

the other hand.

4. Separate an end cap from one side of the magnet.

5. Slide the magnet, with the exposed end of the magnet first, into the

open slot of the metric measurement adapter.

- 6 -

Global Water

800-876-1172 • globalw.com

6. Insert the metric measurement adapter between the arms of the tipping

bucket, with solid side of the metric measurement facing up.

V. Adjusting the Rain Gauge Tipping Bucket

Our Rain Gauge is calibrated at the factory so the bucket tips (and records

rainfall) for each 0.01" (or 0.2 mm if the metric adapter has been fitted) of

rain. To adjust the calibration slightly, use a 3/16" (or 5 mm) wrench to

rotate the adjustment screws that are located underneath the bucket.

The adjustment guide embossed in the platform shows how far you must

rotate both screws in turn to effect a 1% and a 2% change.

Moving the screws in the positive (+) direction causes the bucket to tip

more times (i.e. give a larger count) for a given amount of water.

- 7 -

Global Water

800-876-1172 • globalw.com

VI. Tipping Bucket Calibration Check

a. Obtain a plastic or metal container of at least one-quart capacity.

Place a very small hole in the bottom of the container.

b. Place the can in the tipping bucket funnel.

c. Pour exactly 27.9 ounces of water into the can.

d. If it takes less than 45 minutes for the water to run out, then the hole in

the container is too large.

e. Rough field calibration of this sort should result in one hundred tips, +

three.

f. Adjusting screws are located under the tipping bucket mechanism on

the base plate. Adjust both screws equally, i.e. if you turn one a half

turn then turn the other a half turn. Turning the screws clockwise will

increase the number of tips per 27.9 ounces of water. Turning the

screws counter-clockwise decreases number of tips per 27.9 ounces

of water. One half turns of both screws normally results in a change of

2-3%.

VII. Tipping Bucket Specifications

Resolution: 0.01 inches

Accuracy: 3% up to 4”/hr

Average Switch Closure Time: 135 ms

Maximum Bounce Settling Time: 0.75 ms

Maximum Switch Rating: 30 VDC @ 0.2 amps

Operating Temperature: 0° to +51°C

Size of Gauge: 6”x15”

Weight: 2.0 lb.

- 8 -

VIII. Maintenance

The funnel and tipping bucket mechanism should be cleaned periodically.

An accumulation of dirt, bugs, etc. on the tipping bucket will adversely

affect the readings.

1. Separate the cone from the base.

2. Use warm soapy water and a soft cloth to clean pollen, dirt, and other

debris from the cone, cone screens, and bucket.

3. Use a pipe cleaner to clear the funnel hole in the cone and the drain

screens in the base.

4. When all parts are clean, rinse with clear water.

5. Reattach the cone and replace the screen.

6. Reconnect the rain collector cable to the junction box.

Global Water

800-876-1172 • globalw.com

IX. Trouble Shooting

Issue: 6” Tipping Bucket not reading correctly

a. Clean Tipping Bucket.

b. Recalibrate Tipping Bucket.

Other issues

c. Call us for tech support: 800-876-1172 or 916-638-3429 (many

problems can be solved over the phone). Fax: 916-638-3270 or Email:

globalw@globalw.com.

Be prepared to describe the problem you are experiencing including

specific details of the application and installation and any additional

pertinent information.

d. In the event that the equipment needs to be returned to the factory for

any reason, please call to obtain an RMA# (Return Material

Authorization). Do not return items without an RMA# 6” Tipping

Bucketed on the outside of the package.

Include a written statement describing the problems.

- 9 -

Send the package with shipping prepaid to our factory address. Insure

your shipment, as the warranty does not cover damage incurred during

transit.

e. When calling for tech support, please have the following information

ready;

X. Warranty

a. Global Water Instrumentation, Inc. warrants that its products are free

from defects in material and workmanship under normal use and

service for a period of one year from date of shipment from factory.

Global Water’s obligations under this warranty are limited to, at Global

Water’s option: (I) replacing or (II) repairing; any products determined

to be defective. In no case shall Global Water’s liability exceed the

products original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by Global Water

Instrumentation, Inc., or which has been subject to misuse, negligence

or accident. It is expressly agreed that this warranty will be in lieu of

all warranties of fitness and in lieu of the warranty of merchantability.

b. The warranty begins on the date of your invoice.

Global Water

800-876-1172 • globalw.com

1. Model #.

2. Unit serial number.

3. P.O.# the equipment was purchased on.

4. Our sales number or the invoice number.

5. Repair instructions and/or specific problems relating to the

product.

- 10 -

Loading...

Loading...