Page 1

OPERATING MANUAL

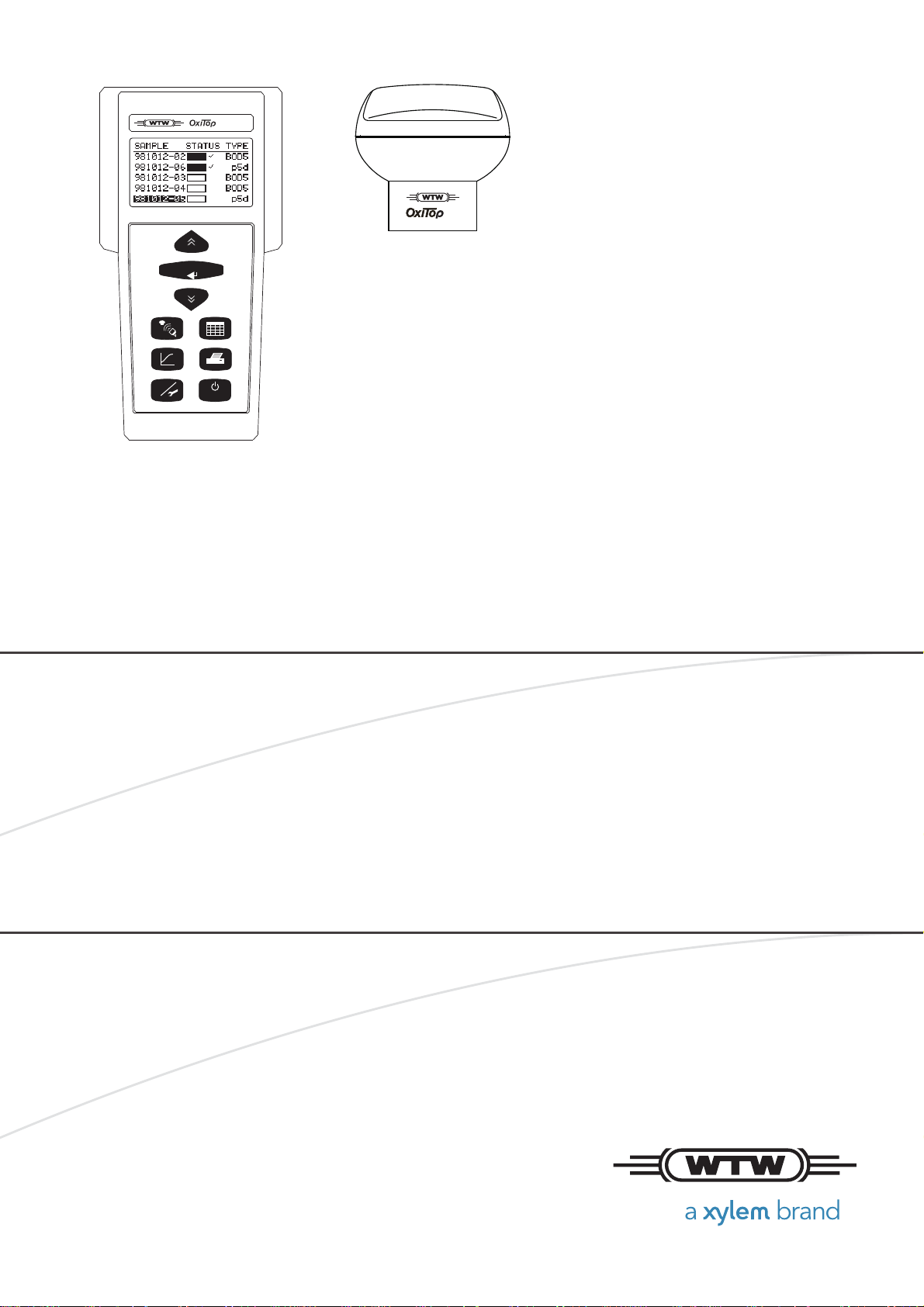

ON/OFF

GLP

RUN/ENTER

OC 1x0

®

®

ba31114e07 08/2014

OxiTop® Control OC 100

®

OxiTop

BOD/OXYGEN CONSUMPTION: BOD, RESPIRATION, BIOGAS DETERMINATION

C or OxiTop® C/B

Page 2

Copyright © 2016 Xylem Analytics Germany GmbH

Printed in Germany.

Page 3

OxiTop® Control OC 100 Contents

OxiTop® Control OC 100 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 The system OxiTop® Control. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 The measurement principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Data management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Literature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.1 Safety information in the operating manual . . . . . . . . . . . 9

2.1.2 Safety signs on the meter. . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Requirements for safe operation . . . . . . . . . . . . . . . . . . . 9

2.2.3 Unauthorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Battery status signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.3 Energy saving feature (automatic switch-off) . . . . . . . . . 12

3.3 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 Inserting the supply battery holder - controller . . . . . . . . 12

4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 General operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.1 Keys - controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Socket field - controller. . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Switching on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.1 Switching on the controller . . . . . . . . . . . . . . . . . . . . . . . 16

4.2.2 Switching on the measuring heads. . . . . . . . . . . . . . . . . 16

4.3 Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3.2 Menus, functions and dialogs. . . . . . . . . . . . . . . . . . . . . 18

4.3.3 The course of the measurement. . . . . . . . . . . . . . . . . . . 19

5 Operating mode: BOD Standard / BOD Routine . . . . . . . . . 21

5.1 Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Starting the measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Calling up all data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 SAMPLE STATUS TYPE list (sample management) . . . . . . . 26

5.4.1 Showing a sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4.2 Erasing data of finished samples . . . . . . . . . . . . . . . . . . 28

5.4.3 Showing the measuring head list . . . . . . . . . . . . . . . . . . 29

ba31114e07 08/2014 3

Page 4

Contents OxiTop® Control OC 100

5.4.4 Calling up data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.4.5 Calling up data - Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5 Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.5.1 Sample statistics (BOD Standard operating mode) . . . . 34

5.5.2 Excluding a curve (BOD Standard operating mode) . . . 35

5.5.3 Cursor interrogation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.5.4 Curves display for cold samples. . . . . . . . . . . . . . . . . . . 37

5.5.5 Measured values outside the measuring range . . . . . . . 37

6 Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 GLP/TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1 GLP/TOOLS main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2 Show free measuring heads . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3 Show settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.4.1 Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.4.2 Operational life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.4.3 Date/time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4.4 GLP (Operating mode BOD Standard ) . . . . . . . . . . . . . 45

7.4.5 GLP - calibration interval (- Calinterval) . . . . . . . . . . . . . 46

7.4.6 Data storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.4.7 AutoTemp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.4.8 Switch-off interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4.9 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.5 Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.5.1 Showing the measuring heads. . . . . . . . . . . . . . . . . . . . 51

7.5.2 Measuring head information. . . . . . . . . . . . . . . . . . . . . . 51

7.5.3 Controller information. . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5.4 cal-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.5.5 Pneumatic test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.6.1 Erasing finished samples . . . . . . . . . . . . . . . . . . . . . . . . 57

7.6.2 Reset/release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.6.3 Reading out data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8 Transmitting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1 Achat OC software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9 Maintenance, cleaning, disposal. . . . . . . . . . . . . . . . . . . . . . 63

9.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.1.1 General maintenance activities . . . . . . . . . . . . . . . . . . . 63

9.1.2 Replacing the supply batteries (controller). . . . . . . . . . . 63

9.1.3 Replacing the data backup battery (controller). . . . . . . . 65

9.1.4 Changing the supply battery (measuring head) . . . . . . . 67

9.2 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.2.1 Cleaning of the sample bottles. . . . . . . . . . . . . . . . . . . . 68

9.2.2 Cleaning of the controller and measuring heads . . . . . . 68

9.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4 ba31114e07 08/2014

Page 5

OxiTop® Control OC 100 Contents

10 What to do if.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.1 Display messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.2 Display messages on the charging status of the batteries . . . 74

10.2.1 Batteries in the controller . . . . . . . . . . . . . . . . . . . . . . . . 74

10.2.2 Battery in the measuring head . . . . . . . . . . . . . . . . . . . . 74

10.3 General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

11 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.1 Controller OxiTop® OC 100. . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.2 Measuring head OxiTop

®

-C or OxiTop®-C/B . . . . . . . . . . . . . 80

ba31114e07 08/2014 5

Page 6

Contents OxiTop® Control OC 100

6 ba31114e07 08/2014

Page 7

OxiTop® Control OC 100 Overview

2

0

m

l

lt

m

2

Op

T

T

V

VV

TR

OM

BOD

M(O2) Molecular weight (32000 mg/mol)

R Gas constant (83.144 lmbar/molK)

T

0

Reference temperature (273.15 K)

T

m

Measuring temperature

V

t

Bottle volume (nominal volume in ml)

V

l

Sample volume in ml

a Bunsen absorption coefficient (0.03103)

p(O

2

) Difference of the D. O. partial pressure (mbar)

1 Overview

1.1 The system OxiTop

®

Control

The classical application field for the OxiTop® measuring heads and controller

is the BODx determination (BODx = Biochemical Oxygen Demand for the time

x). The evaluation of biological degradability (e.g. test according to OECD

301F) is also part of this field.

With different sample vessels, the OxiTop

®

measuring heads and the OxiTop®

Controller 110 can also be used for other applications such as:

Evaluation of respiration and toxicity in earth, sludge, waste and sediment

(e.g. extraction of contaminated earth according to recovery concepts)

Evaluation of the respiration rate of cell cultures

Microbiological growth and stress examinations

Measurement of anaerobic degradation processes (e.g. biogas determina-

tion with the measuring head OxiTop

®

-C/B)

Accessories: see WTW catalog and price list

1.2 The measurement principle

The respirometric measurement is a pressure measurement. If oxygen is

consumed in a closed vessel at a constant temperature, a negative pressure

develops. If a gas is released, an overpressure develops. The OxiTop

measuring head measures and stores this pressure for the whole duration of a

measurement once started.

®

The OxiTop

OC 100 controller collects the pressure values from the

measuring heads and processes them.

The formula shown below is the basis for all calculations for the BOD using the

®

values from the OxiTop

measuring head.

®

ba31114e07 08/2014 7

Page 8

Overview OxiTop® Control OC 100

The interpretation of the pressure differences in the temporal course depends

on the measured material and its preparation and on the sample manipulation

(e. g. intermediate aerations) during the measuring period.

1.3 Data management

The measuring head records the measured values and stores the measuring

data. Using the controller, the collected and stored data are read out from the

measuring head and stored in the “sample management“. Starting at the

OxiTop

®

sample management, it is possible to make the graphical and statis-

tical evaluation of the sample data.

The data can be transferred from the controller to a computer via the RS232

interface. The read-out software Achat OC facilitates to process the stored data

further.

Additionally, the data can be transferred to an IR printer via the IR interface.

1.4 Literature

Further information and application reports on the subject of measuring with the

system OxiTop

CD-ROM Applications for OxiTop

®

Control can be obtained at no cost from WTW:

®

Control

CD-ROM Principles of measuring technique

8 ba31114e07 08/2014

Page 9

OxiTop® Control OC 100 Safety

2 Safety

2.1 Safety information

2.1.1 Safety information in the operating manual

This operating manual provides important information on the safe operation of the instrument. Read this operating manual thoroughly and

make yourself familiar with the instrument before putting it into operation or working with it. The operating manual must b e kept in the vicinity

of the instrument so you can always find the information you need.

Important safety instructions are highlighted in this operating manual.

They are indicated by the warning symbol (triangle) in the left column.

The signal word (e.g. "CAUTION") indicates the danger level:

WARNING

indicates a possibly dangerous situation that can lead to serious (irreversible) injury or death if the safety instruction is not

followed.

CAUTION

indicates a possibly dangerous situation that can lead to slight

(reversible) injury if the safety instruction is not followed.

NOTE

indicates a possibly dangerous situation where goods might be

damaged if the actions mentioned are not taken.

2.1.2 Safety signs on the meter

Note all labels, information signs and safety symbols on the instrument.

A warning symbol (triangle) without text refers to safety information in

this operating manual.

2.2 Safe operation

2.2.1 Authorized use

Only the operation and running of the instrument according to the

instructions and technical specifications given in this operating manual

is authorized (see section 11 T

ECHNICAL DATA, page 79).

Any other use is considered unauthorized.

2.2.2 Requirements for safe operation

Note the following points for safe operation:

• The instrument may only be operated according to the authorized

ba31114e07 08/2014 9

Page 10

Safety OxiTop® Control OC 100

use specified above.

• The instrument may only be supplied with power by the energy

sources mentioned in this operating manual.

• The instrument may only be operated under the environmental

conditions mentioned in this operating manual.

• The instrument may only be opened if this is explicitly described in

this operating manual (example: Changing the batteries).

2.2.3 Unauthorized use

The instrument must not be put into operation if:

• it is visibly damaged (e.g. after being transported)

• it was stored under adverse conditions for a lengthy period of time

(storing conditions, see section 11 T

ECHNICAL DATA, page 79).

10 ba31114e07 08/2014

Page 11

OxiTop® Control OC 100 Commissioning

3 Commissioning

3.1 Scope of delivery

Controller OxiTop® OC 100

Battery holder with batteries (3 x Mignon, AA, AM3, LR6)

Operating manual

Additional scope of delivery: depending on set composition

3.2 Power supply

The controller OxiTop® OC 100 and measuring head OxiTop®-C or OxiTop®C/B are both battery-powered.

Additionally, the controller has a data backup battery. This battery ensures that

your measuring data and instrument settings are stored in the controller

OxiTop

®

OC 100.

3.2.1 Batteries

Controller Power supply 3 alkaline batteries (alkali manganese),

Size: Mignon, AA, AM3, LR6

Runtime: > 100 h

(approx. 1000 start-ups in normal use)

Data backup 1 x lithium battery CR2430 (accessory).

Runtime: typically 4 years

Measuring

head

Power supply Batteries: 2 x lithium battery CR2430 (accessory).

Runtime: typically 2 years

3.2.2 Battery status signals

®

The OxiTop

-OC 100 controller and the OxiTop® measuring heads are powered by batteries. A low battery status of the controller or measuring head is

automatically indicated by a display message and a signal tone after the instrument is switched on (see section 10.2 D

STATUS OF THE BATTERIES, page 74).

ISPLAY MESSAGES ON THE CHARGING

1st level (warning level) Battery LoBat !

2nd level (error level) Battery empty !

The current battery status can also be queried in the menu:

Controller: Menu GLP/TOOLS - Check - Controller Info

Measuring head: Menu GLP/TOOLS -Check - info

ba31114e07 08/2014 11

Page 12

Commissioning OxiTop® Control OC 100

LISTED 8F93

LaboratoryEquipment

E163694

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following conditions: (1)This devise may not

cause harmful interference, and (2) this devise must accept

any interference received, including interference that may

cause undesired operation.

Ser.-Nr.:05150013

OxiTop OC 1x0

WTW 82362 Weilheim

Made in Germany

1x CR 2430 Lithium

3xAlkaline, AA size, 1,5V

1

1

1

1

3.2.3 Energy saving feature (automatic switch-off)

The instrument switches off automatically following the last key actuation after

expiry of the specified switch-off interval.

To specify the switch-off interval: see section 7.4.8 S

WITCH-OFF INTERVAL, page

49.

3.3 Initial commissioning

Perform the following activities:

Insert the supply battery holder in the controller (see section 3 .3.1 I

THE SUPPLY BATTERY HOLDER - CONTROLLER, page 12)

Switch on the instrument

Set the date and time (see section 7.4 S

ETTINGS, page 43)

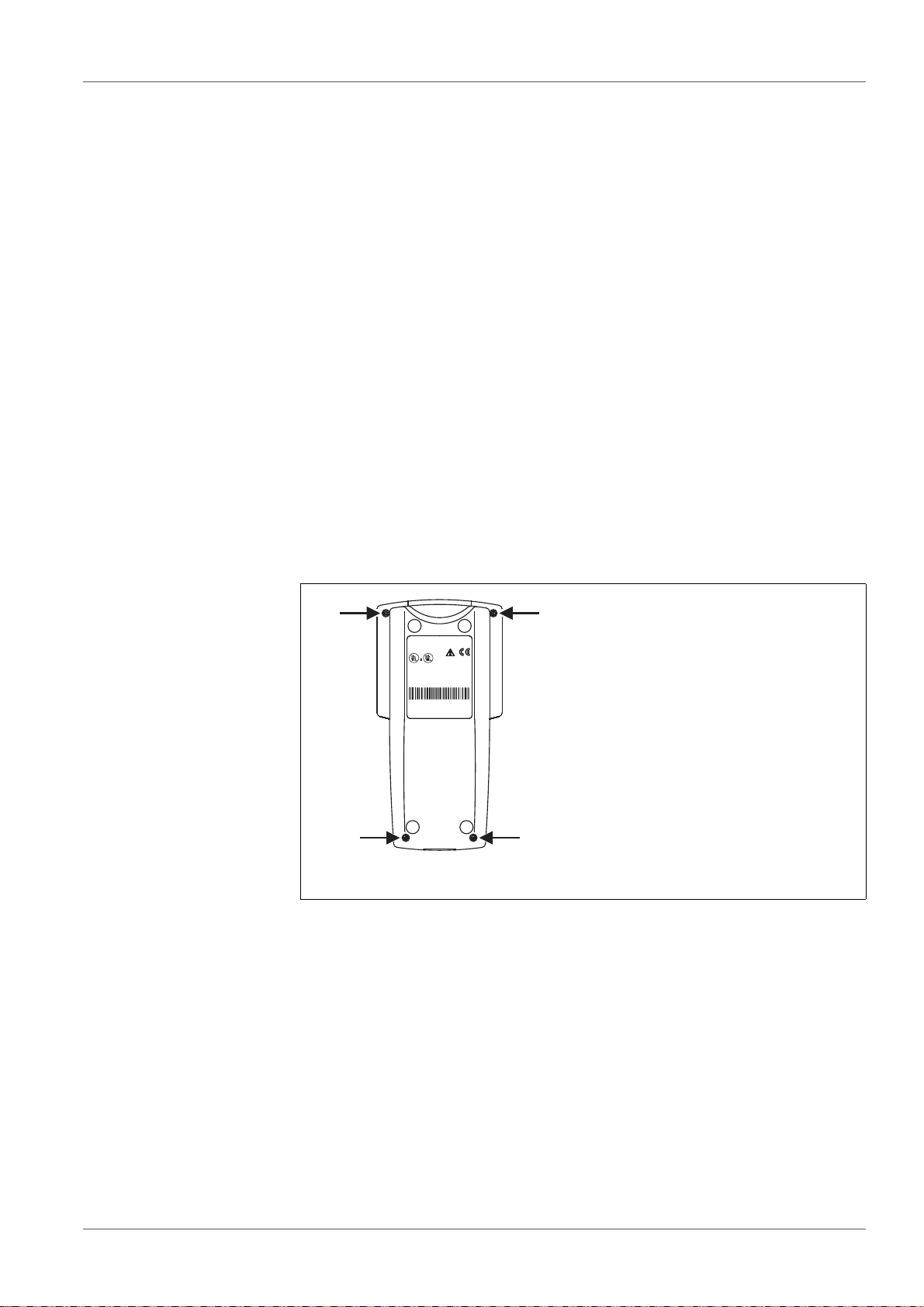

3.3.1 Inserting the supply battery holder - controller

Loosen the 4 screws underneath the housing using a Phillips screwdriver.

NSERTING

1Screws

Place the controller on the lower case.

Remove the upper case and put it down to the right next to the lower case

with the display downwards.

Connect the supply battery holder with the power supply contacts of the

upper case.

Insert the supply battery holder in the lower case with the open side down.

12 ba31114e07 08/2014

Page 13

OxiTop® Control OC 100 Commissioning

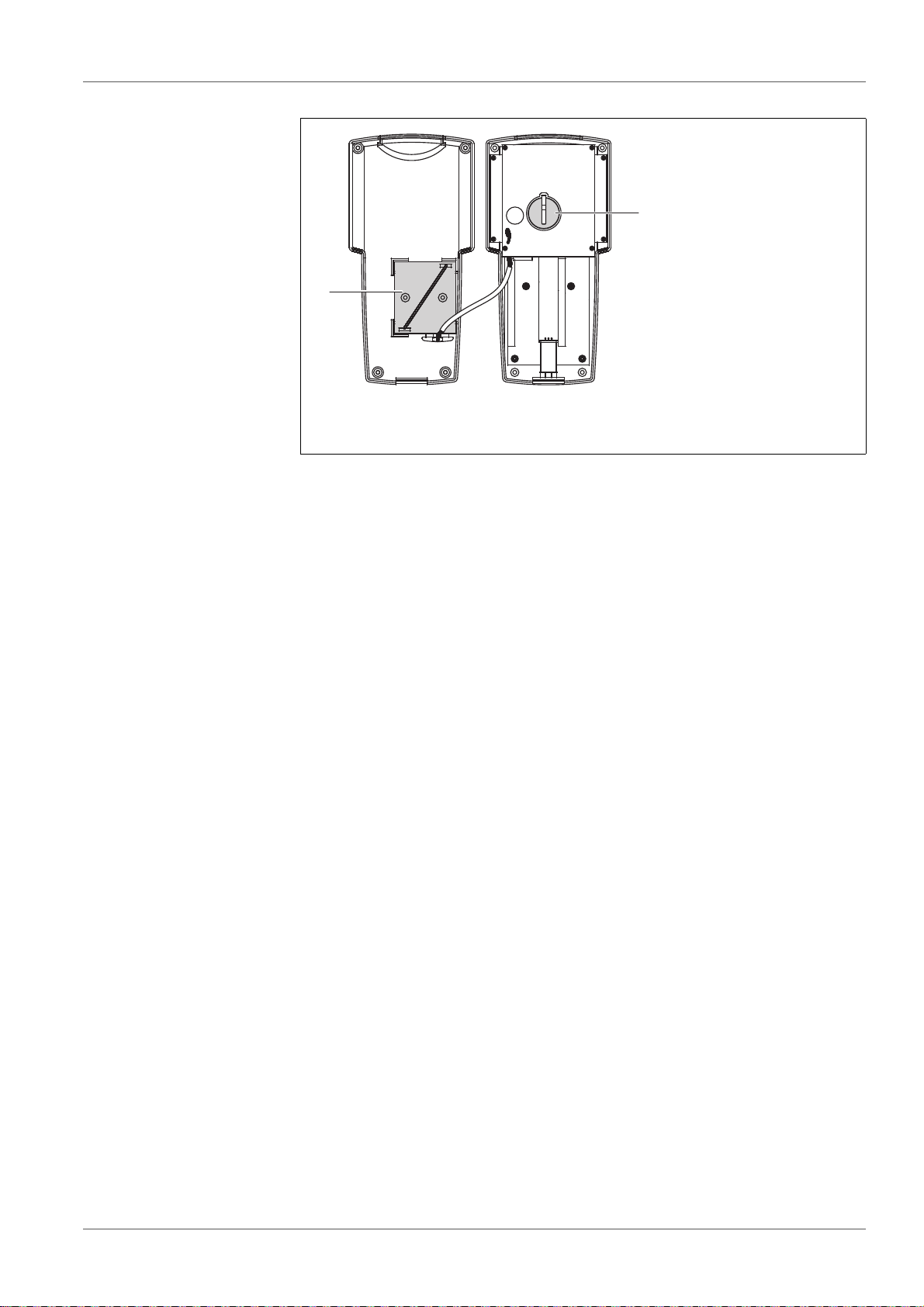

1

2

1 Supply batteries in the battery holder (lower case)

2 Data backup battery (upper case)

Set the upper case on top of the lower case, turn the controller and tighten

the housing screws using the screwdriver.

Switch on the controller. The battery insertion was successful if no error

message appears concerning the supply batteries.

ba31114e07 08/2014 13

Page 14

Commissioning OxiTop® Control OC 100

14 ba31114e07 08/2014

Page 15

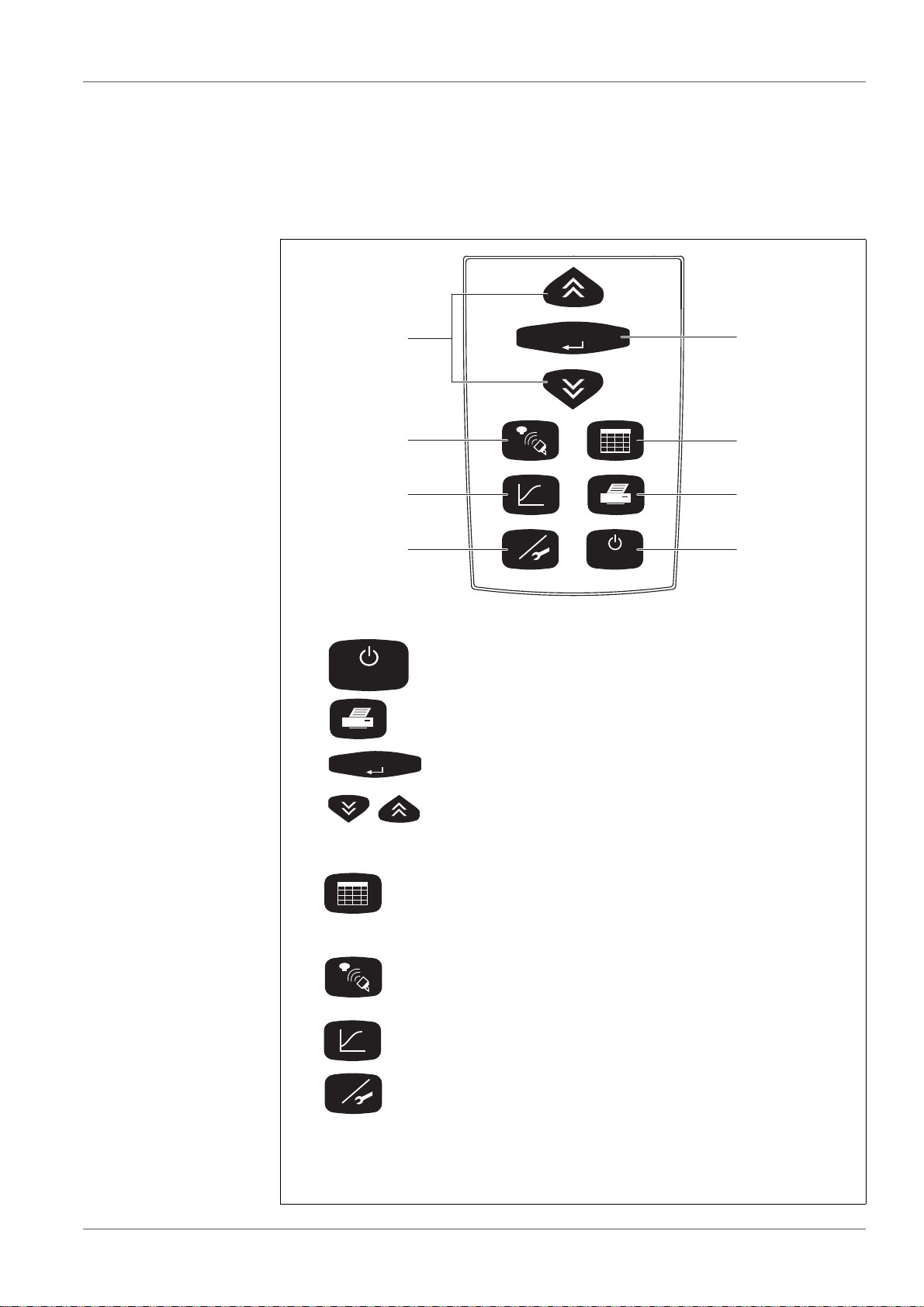

OxiTop® Control OC 100 Operation

ON/OFF

GLP

RUN/ENTER

1

2

5

34

7

8

6

The function keys are used to start a function or to change to another

function. Confirmed data and settings are preserved.

1 <On/Off> Switching on/off

2 <PRINT> Printing of measurement data and set-

tings via IR interface

3 <RUN/

ENTER>

Confirmation of entries

4<><> Select and change settings

Function keys:

5 <ORG> Sample management: List of samples,

reading/calling up/deleting the data of individual measuring heads or samples,

shows measuring heads or samples

6 <COMM> Communication with measuring heads:

Start measuring, change or show settings,

call up data

7 <GRAPH> Evaluation: Graphic and numerical dis-

play of measuring data

8 <GLP> GLP/Tools: Change or display settings,

display free measuring heads, display or

change settings, perform checks or maintenance

ON/OFF

RUN/ENTER

GLP

4Operation

4.1 General operating principles

4.1.1 Keys - controller

ba31114e07 08/2014 15

Page 16

Operation OxiTop® Control OC 100

1

4.1.2 Socket field - controller

1 RS232 interface

The RS232 interface is used for communication with the PC. Usage

of the RS232 interface is exclusively intended with the WTW software

"Achat OC“ (see section 8.1 A

CHAT OC SOFTWARE, page 62).

4.2 Switching on

4.2.1 Switching on the controller

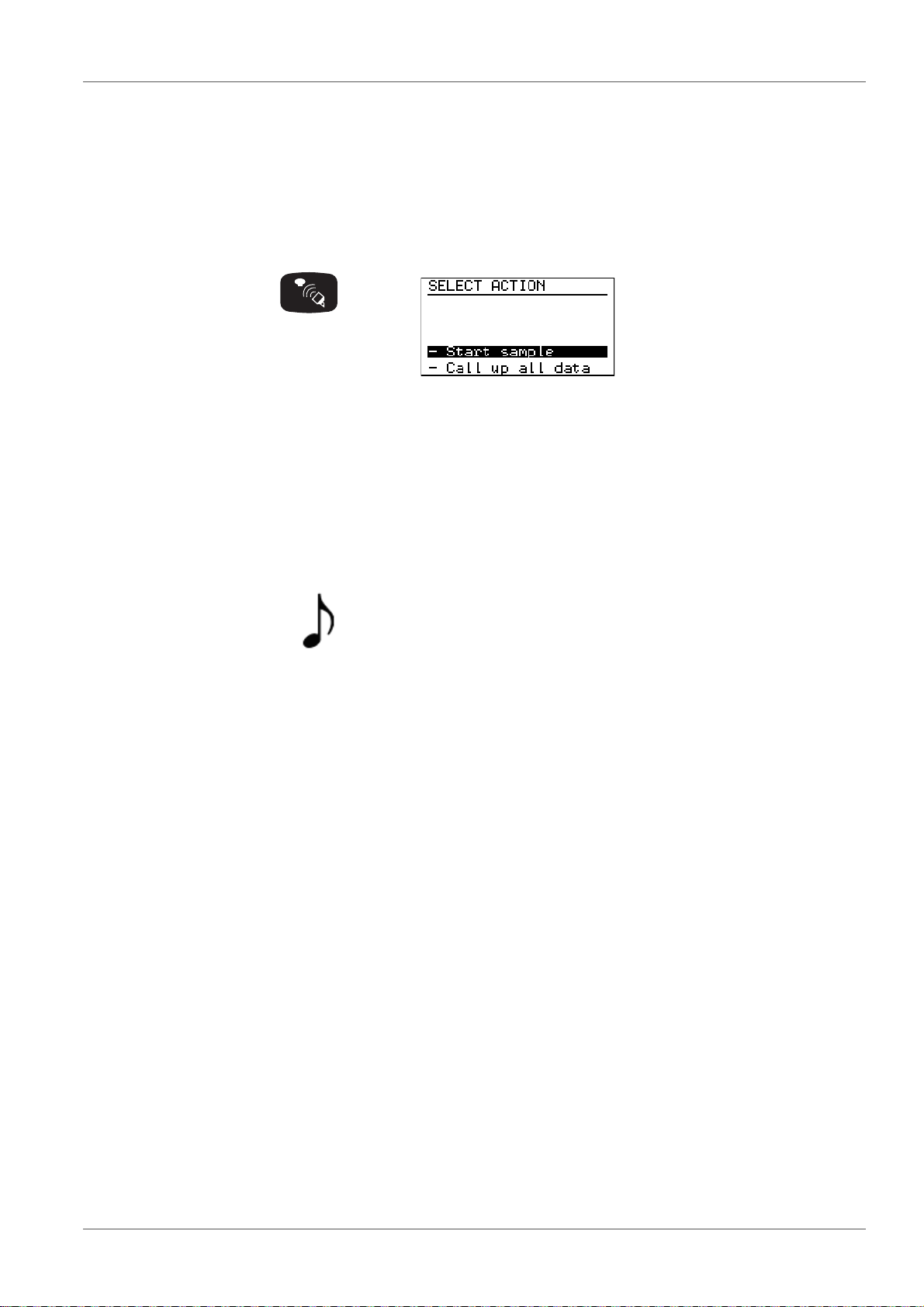

The current date and time appear for approx. 2

seconds (important for the allocation of sample

numbers).

If the date or time is wrong, correct them under

GLP/TOOLS.

The instrument is in the sample management

mode (operating mode BOD Routine , in the

default condition).

4.2.2 Switching on the measuring heads

The measuring heads are immediately ready for operation. The controller

switches the measuring heads on and off during communication.

To avoid malfunctions:

If you use two or more controllers simultaneously make sure that

the distance between the controllers is at least 3 meters!

16 ba31114e07 08/2014

Page 17

OxiTop® Control OC 100 Operation

4.3 Navigation

4.3.1 Operating modes

BOD Routine:

(preselected)

Measurement of single samples for a BOD

(x = 0.5h ... 99d) at 20 °C

x

The measuring range and filling volume can be selected out of seven per-

manent ranges and the corresponding filling volumes.

The function is permanently switched on

BOD Standard: Measurement of up to 12 parallel sample processes per overall sample for

a BOD

(x = 0.5h ... 99d) at 20 °C

x

The measuring range and filling volume can be selected out of seven per-

manent ranges and the corresponding filling volumes.

Automatic sample statistics with averaging

The AutoTemp function and the GLP mode can be switched on

ba31114e07 08/2014 17

Page 18

Operation OxiTop® Control OC 100

4.3.2 Menus, functions and dialogs Example: Pressing the <COMM> button causes the controller to change to the

SELECT ACTION menu (communication with the measuring heads).

Signal tone

Action:

Press button. The instrument displays:

This symbol in the operating manual means:

A signal tone sounds.

Description of what the

action caused and possible

further request:

SELECT ACTION menu

(communication with the measuring heads):

Preselected: - Start sample.

Select a menu item with

<><>.

The selected function or line is

displayed in inverse video.

Confirm the menu item with

<RUN/ENTER>.

The submenu is opened or the

function is carried out.

Measuring head Each measuring head that receives a command from the controller indicates

this by a short flashing signal.

®

The OxiTop

measuring head is indicated by the symbol

18 ba31114e07 08/2014

Page 19

OxiTop® Control OC 100 Operation

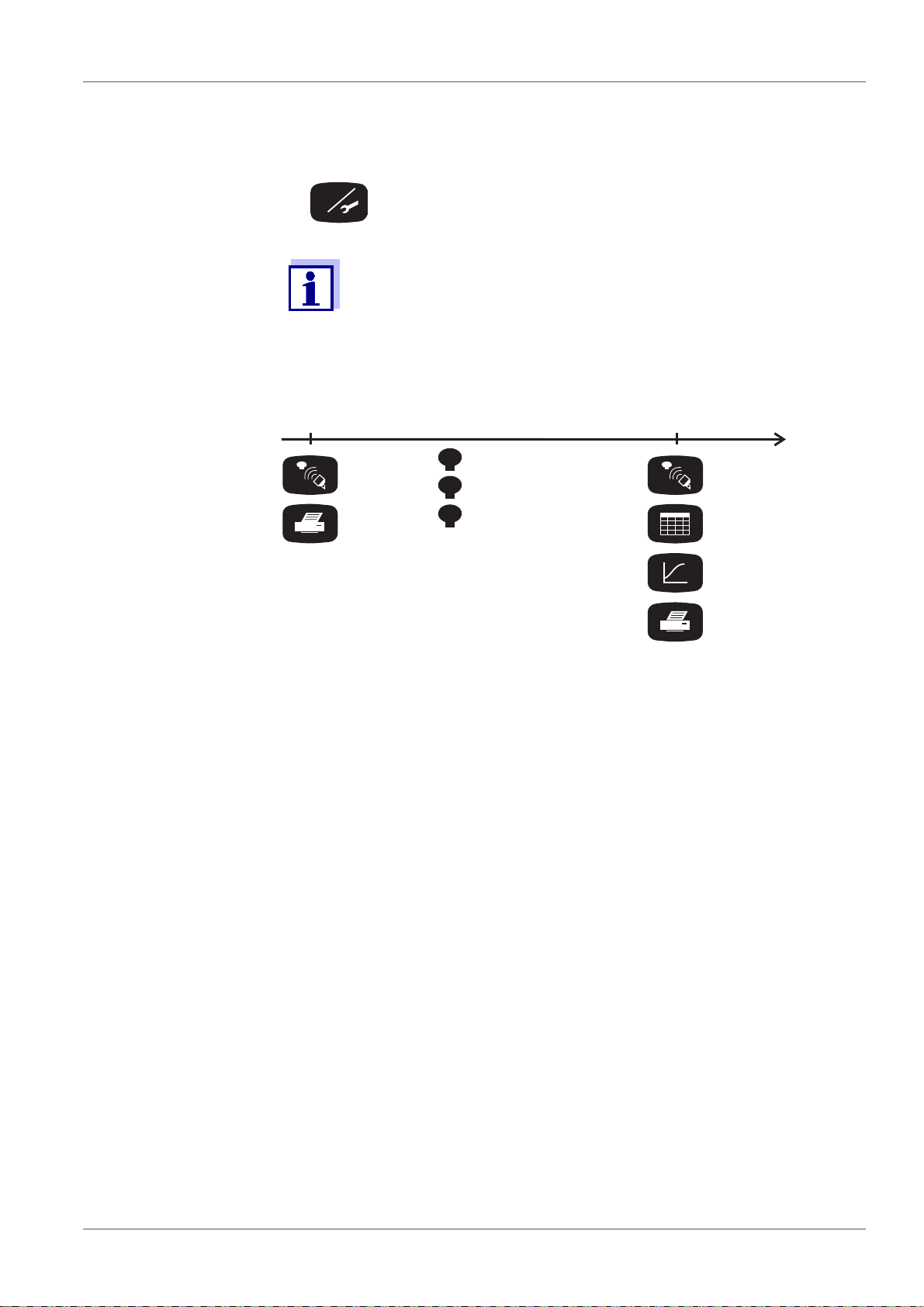

GLP

Time

End of measurement

Start of

measurement

AutoTemp

Measurement

Data transfer

Starting the

measuring

heads

Sample

management

Evaluation

Print

Print

4.3.3 The course of the measurement

Preparation before

starting the mea-

surement

Measuring

Select operating mode

Select settings

Operating mode and settings cannot be changed for a measurement once it is started!

ba31114e07 08/2014 19

Page 20

Operation OxiTop® Control OC 100

20 ba31114e07 08/2014

Page 21

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

RUN/ENTER

5 Operating mode: BOD Standard / BOD Rou-

tine

The BOD Standard mode (parallel sample process for up to 12 measuring

heads per overall sample) is preset in the delivery condition of the controller.

To change to the BOD Routine operating mode (single samples): see section

7.4.1 O

The handling of controller and measuring heads is basically the same in both

operating modes. Where there are differences for the BOD Routine operating

mode they are described.

5.1 Sample preparation

See application reports.

Screw the OxiTop

close them tightly.

PERATING MODE, page 43.

®

measuring heads onto the measuring vessels and

NOTE

Never use joint grease or other lubricants for your OxiTop

®

measuring

heads. Some of these products contain solvents that can cause severe

damage to the plastic housing of the measuring head.

The sealing of the measuring vessels is perfectly adequate without

grease. However, you should always wipe off heavy contamination and

®

particles on the sealing surfaces of the rubber sleeves and OxiTop

measuring heads. WTW accepts no liability for damage due to the use of

joint grease.

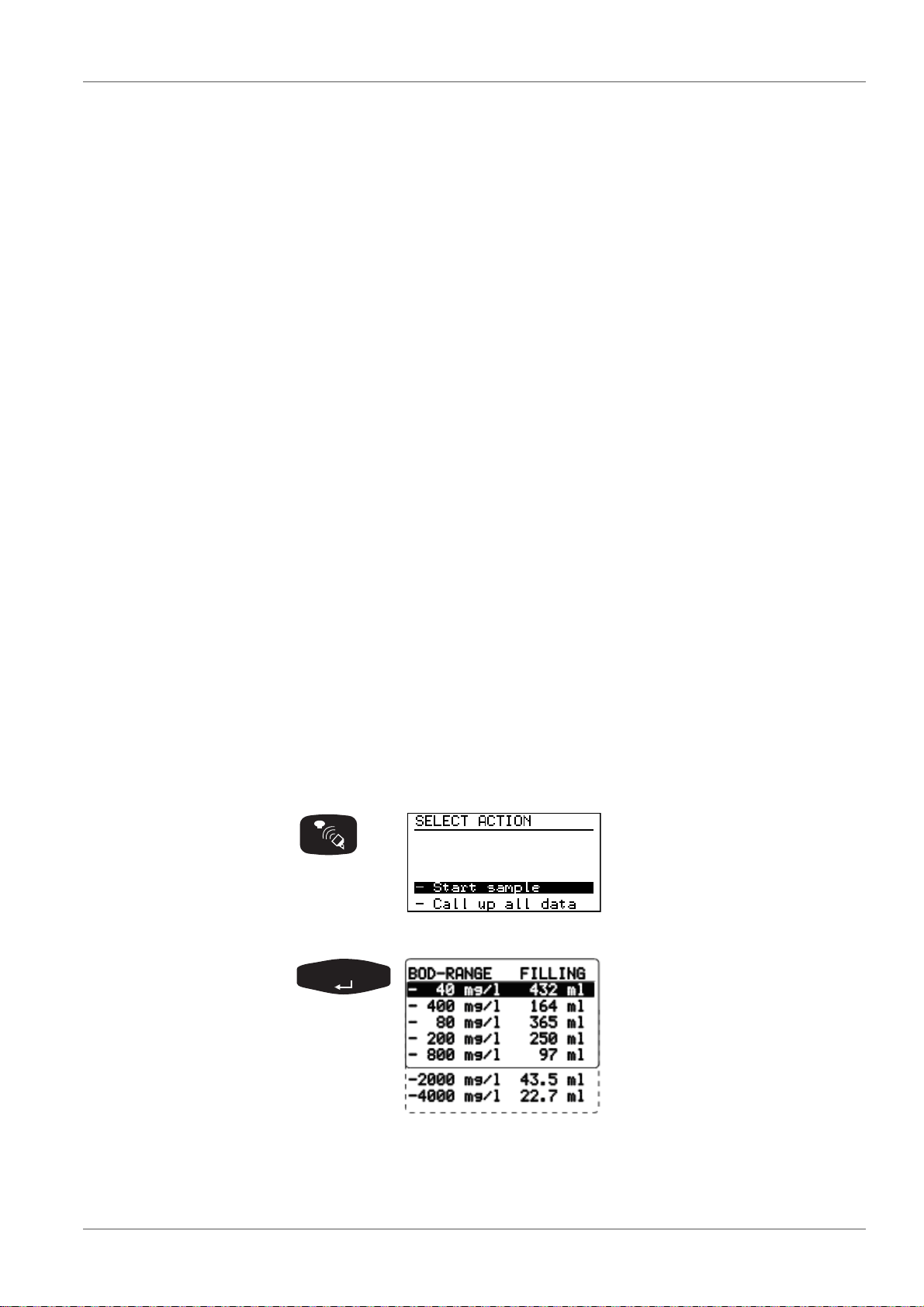

5.2 Starting the measurement

SELECT ACTION menu (communication with the measuring

heads):

Preselected: - Start sample.

(In BOD Routine mode appears:

START).

Select the measuring range with

<><>.

The filling volume required is

given in the right hand column.

The controller stores the setting

(memory function: the last

selected measurement range is

set).

ba31114e07 08/2014 21

Page 22

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

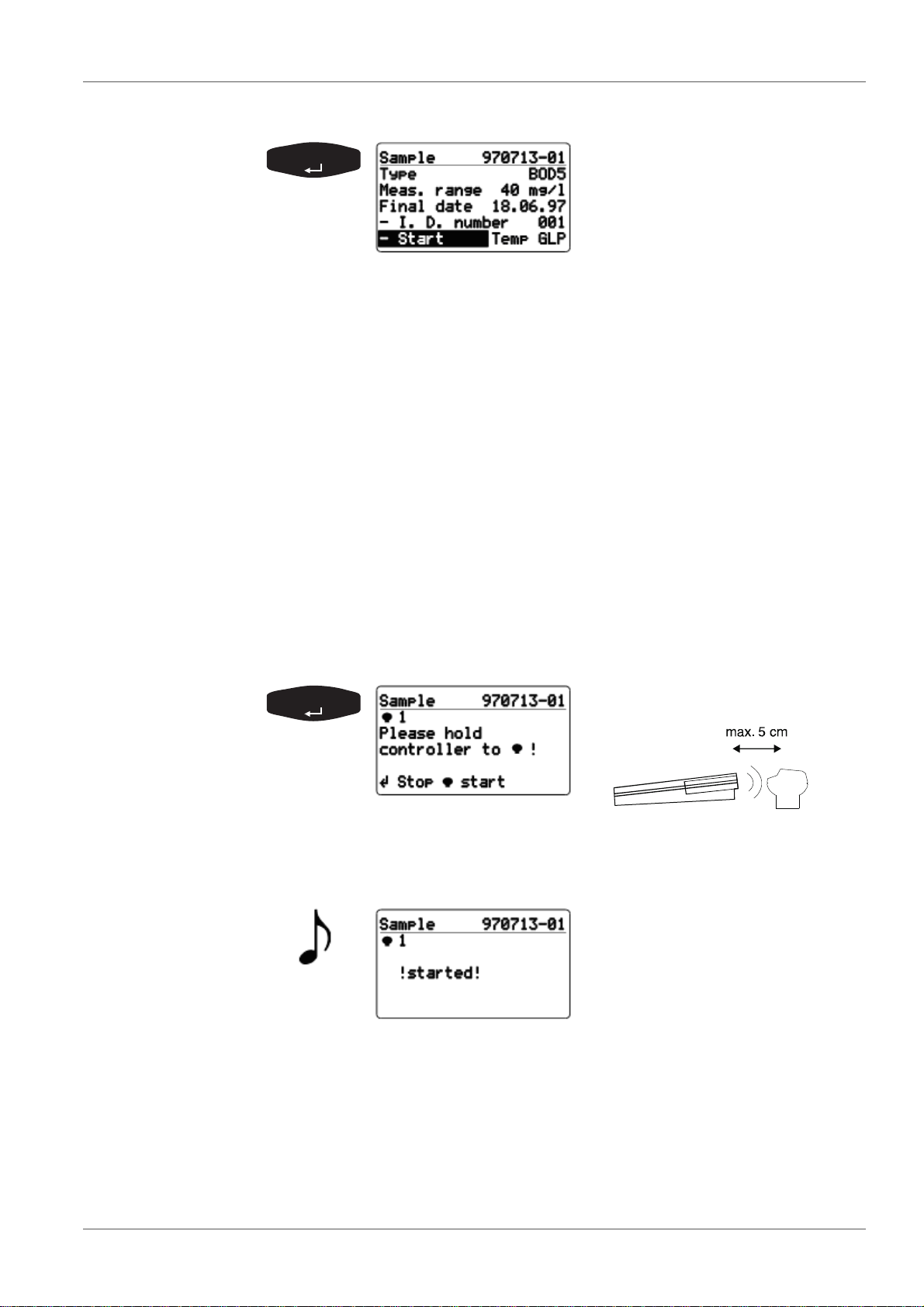

Confirm the selected measurement range for the sample. The

automatically assigned sample

number (YY/MM/DD and

sequential number) is given in

the header line.

Additional information:

Type of measurement, run duration, measurement range,

final date, ID number.

Temp display => the AutoTemp function (see section 7.1

GLP/TOOLS

MAIN MENU, page 41) is switched on.

GLP display => the GLP function (see section 7 GLP/

TOOLS, page 41) is switched on.

Change the ID number for the additional identification of the

sample (e.g. sampling location) as follows:

Select the - I.D. number menu item with <><>

Confirm with <RUN/ENTER>.

Set the required Id number (setting range 001 ... 255) with

<><>.

Confirm with <RUN/ENTER>.

Use <PRINT>

(in BOD Routine mode only), see section 6 P

to print out the entire sample information

RINTING, page

39).

Confirm the start of measure-

ment. Contact selection:

The controller repeatedly sends the start information in the

scanner mode until feedback is successfully received from the

OxiTop

®

measuring head. After the successful start message

from the measuring head:

Displays ! started !

From this

point in time, the sample exists

within the SAMPLE STATUS

TYPE list (sample manage-

ment).

Subsequently, the request to

start the next measuring head is

made automatically.

In BOD Routine operating mode there is no 1... identifier in

the display, and the

controller automatically returns to the entry menu after starting

the measuring head.

22 ba31114e07 08/2014

Page 23

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

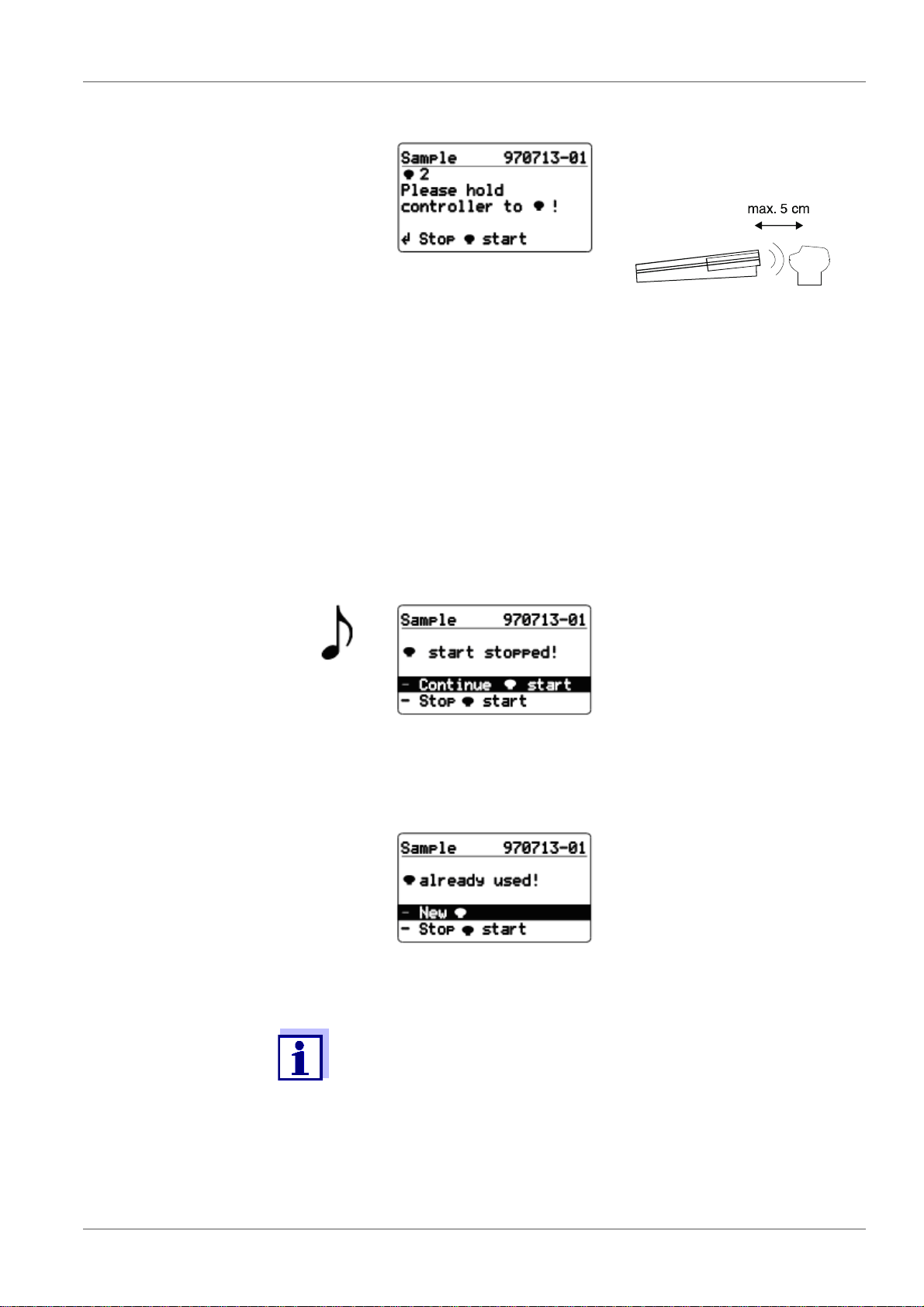

Start the next measuring head

(2).

Contact selection:

The number of the measuring

head is automatically incremented.

The controller continues to work with the contact selection, i.e.

you can now start a sequence of measuring heads (parallel

sample process) without having to press any further keys by

holding the controller to the next measuring head to be

started.

When all the measuring heads provided for this sample have

been started:

Confirm Stop start with <RUN/ENTER>.

The controller returns to the entry menu.

If no measuring head is started (e.g. because the controller

was not held to - or not close enough to - a measuring head):

The start was stopped.

Use <RUN/ENTER> - Continue

start to confirm “Continue

start” and hold the controller to a

measuring head (see above).

Return to entry level menu with

-Stop start

If an attempt is made to start a measuring head that was

already started:

Displays already used!

Use <RUN/ENTER> to confirm -

New and hold the controller

to a free measuring head (see

above).

Return to entry level menu with

-Stop start

In the delivery state, the controller automatically makes space when

Start is selected if the measured value memory is full.

To do this, it deletes the oldest finished sample (if a finished sample

is available). You can change this setting to “manual erase” (see

section 7.4.6 D

ATA STORAGE, page 47).

ba31114e07 08/2014 23

Page 24

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

40 cm to 1 m

RUN/ENTER

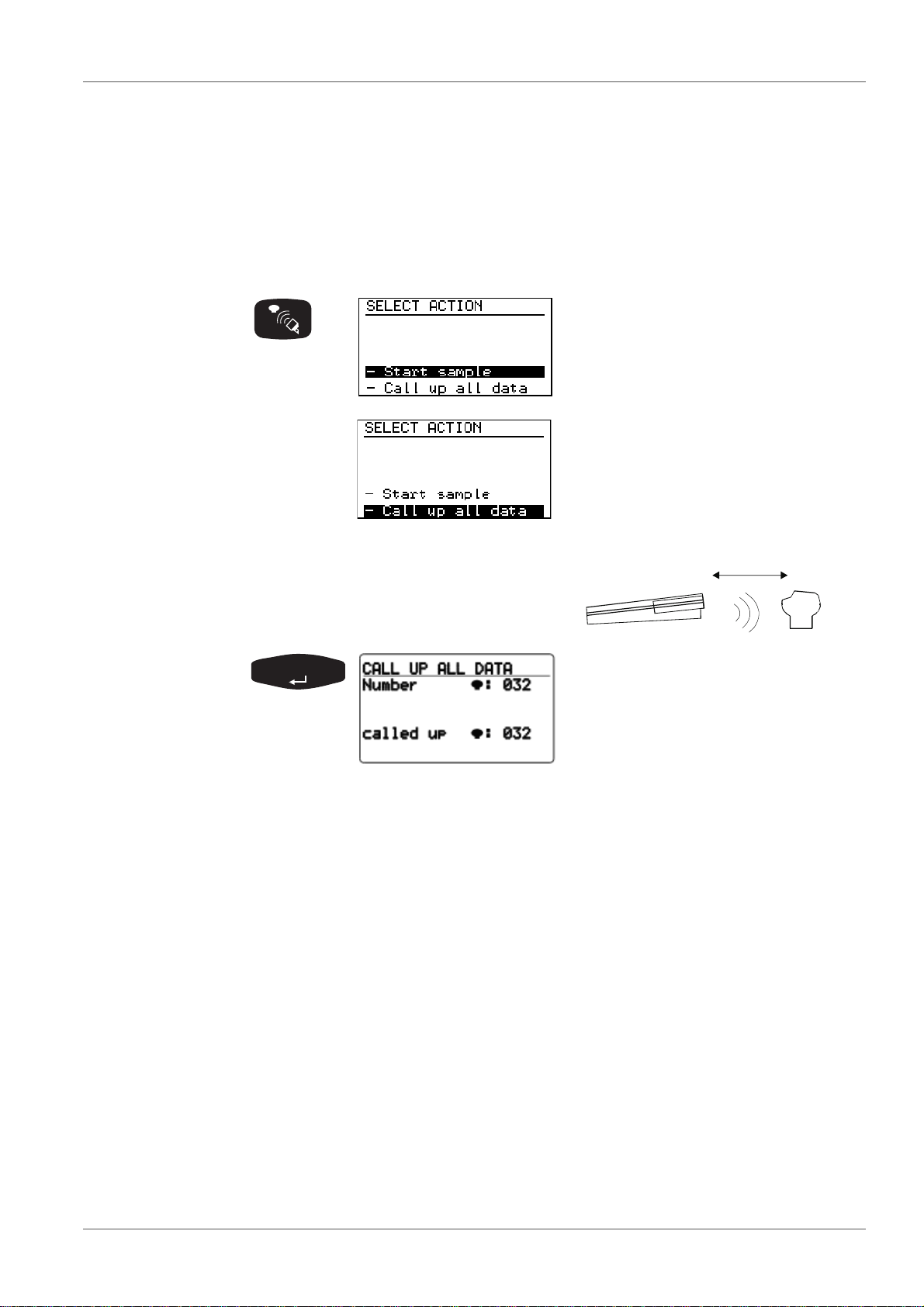

5.3 Calling up all data

This function is used to call up the data of all measuring heads, no

matter in which operating mode they were started.

To call up the data of individual measuring heads: see section 5.4

SAMPLE STATUS TYPE

LIST (SAMPLE MANAGEMENT), page 26.

SELECT ACTION menu (communication with the measuring

heads):

Preselected: - Start sample.

Select the - Call up all data menu

item with <><>

Point the controller at the measuring

heads:

Queries the data of all active

measuring heads in the scanner

mode.

The controller stores the data

obtained and updates the

SAMPLE STATUS TYPE list

(sample management).

Duration of a pass: approx. 3

seconds for 12 measuring heads

in a stirring system.

If the measuring heads do not all respond in the 1st pass of the data query,

the controller searches for the missing measuring heads in the scanner mode

for approximately a further 7 seconds. Without having to press another key,

you can continue the data queries at other locations (e.g. other stirring platforms or other thermal cabinets).

Approximately 7 seconds after the last call up was performed, the scanner

mode breaks off automatically and the following display appears:

24 ba31114e07 08/2014

Page 25

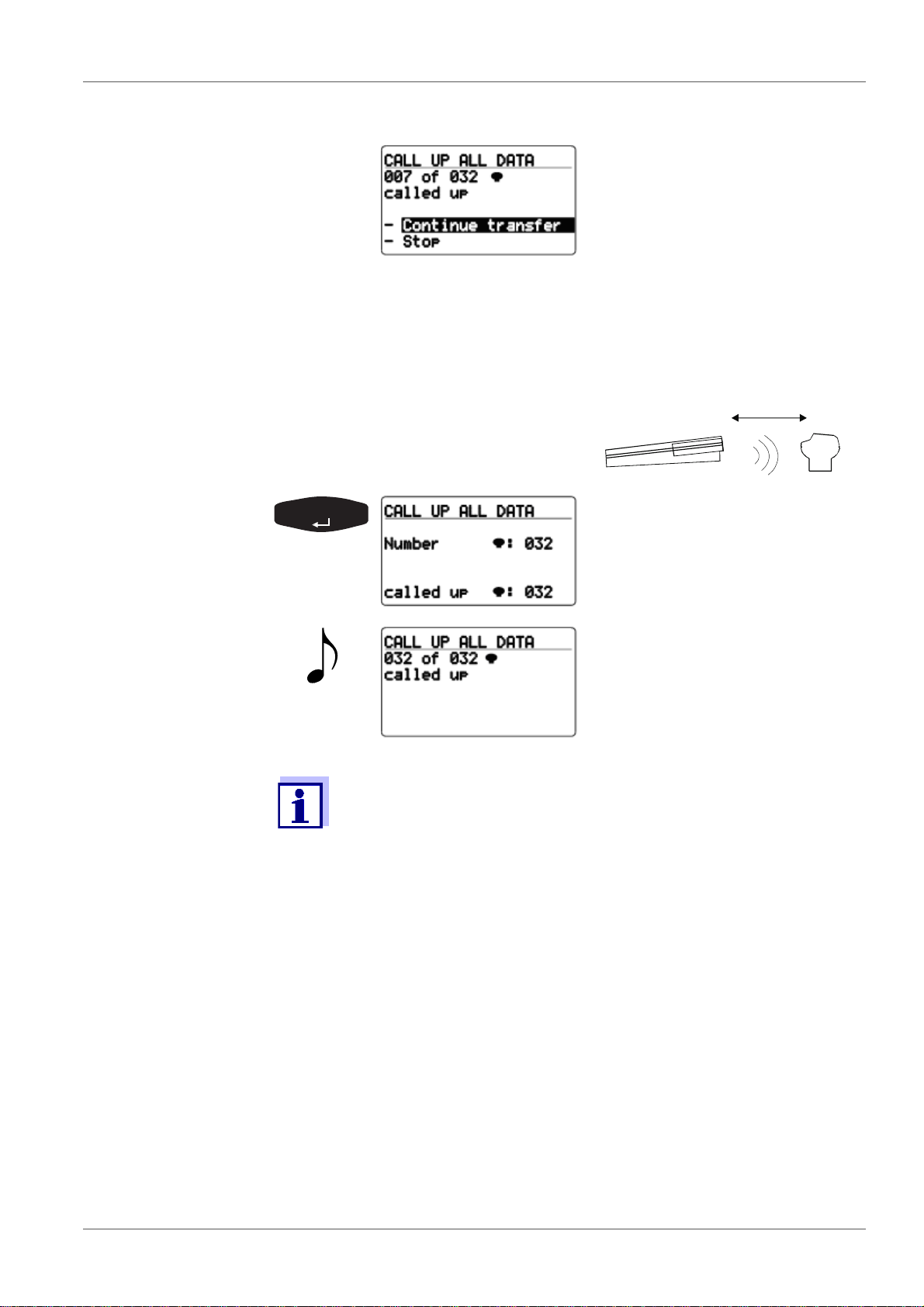

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

40 cm to 1 m

RUN/ENTER

Preselected:

- Continue transfer:

A new pass is made only for

measuring heads that have not

yet responded.

Return to the entry menu with -

Stop

For information on searching for

missing measuring heads, see

section 10 W

HAT TO DO IF..., page

69

Point the controller at the measuring

heads:

The call up of further measuring

heads is performed in the scanner mode.

Message that all the data of all

the measuring heads has been

called up. The instrument then

returns to the entry menu.

Immediately after the complete measurement data records of a finished measurement have been called up, the corresponding measuring head is given the free status. The measuring head can be

used for a new measurement. The relevant sample in the

SAMPLE STATUS TYPE list (sample management) is marked as

finished (see section 5.4 SAMPLE STATUS TYPE

MANAGEMENT), page 26), as soon as the measurement time has

LIST (SAMPLE

expired and the data of all measuring heads of this sample have

been called up.

ba31114e07 08/2014 25

Page 26

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

3

2

1

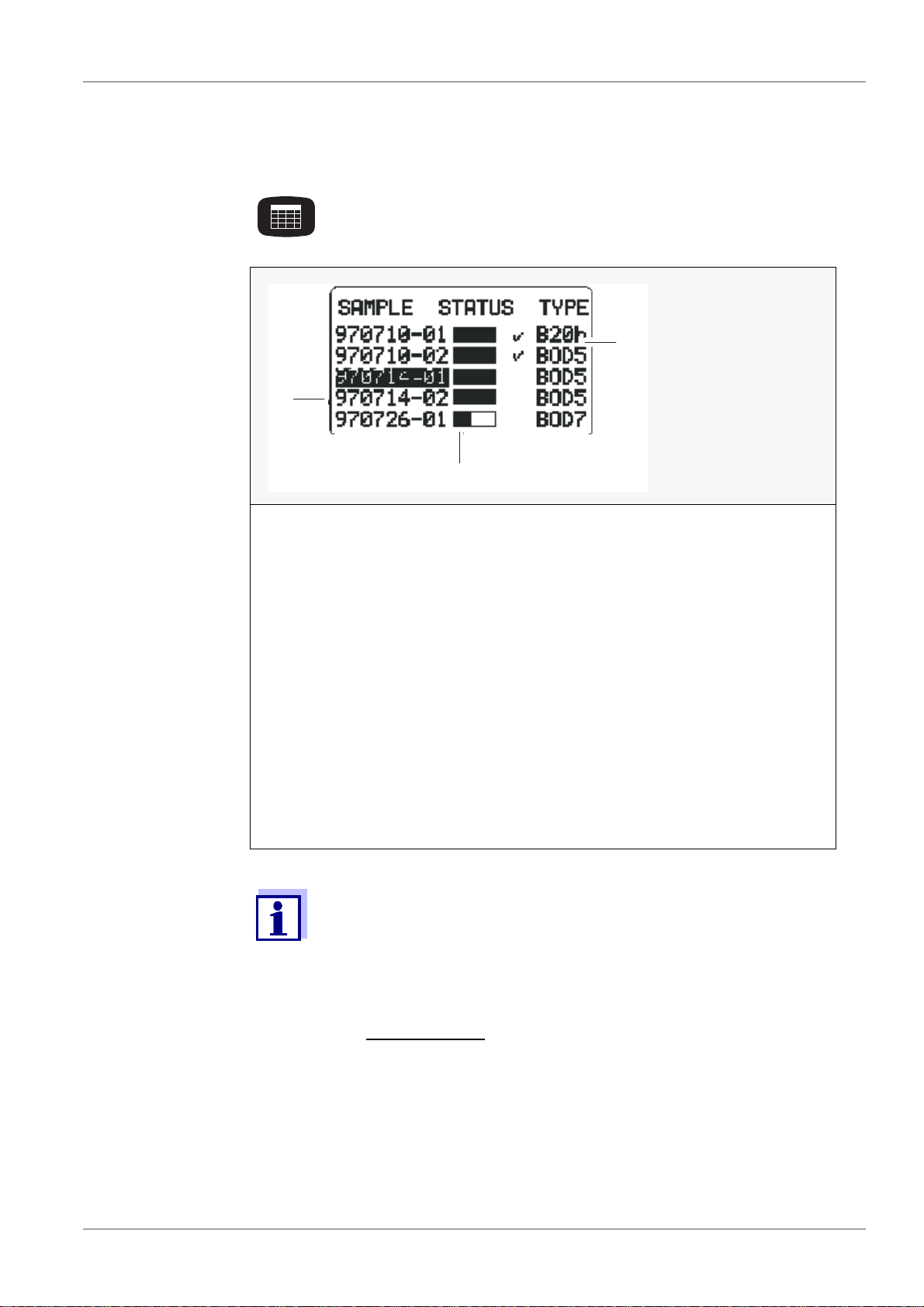

5.4 SAMPLE STATUS TYPE list (sample management)

Entry into the sample management.

A list of samples appears in the display (if samples are available):

1 Sample number:

Date (JJ/MM/TT) and consecutive number

2 Temporal process of the sample:

– Status bar partly filled:

The sample is not yet ready.

– Status bar filled:

The ready and complete data set of the sample can be called up

from the measuring head.

– Status bar filled plus checkmark:

The sample is ready. The complete data set is given in the controller for evaluation.

3 BOD type and run duration.

– B20h: BOD with 20 hours run duration

– BOD5: BOD with 5 days run duration

The samples started in the BOD Routine operating mode also

appear in the SAMPLE STATUS TYPE lists (sample management)

of all other modes. Data of samples that have been started in other

operating modes do not appear in the sample management of the

BOD Routine operating mode.

Reporting order:

At the upper end of the list: finished samples (if available)

Under this: current samples

Sorting of the samples:

according to date and sequential number 01 ... 99,

from the oldest to the newest sample.

26 ba31114e07 08/2014

Page 27

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

RUN/ENTER

40 cm to 1 m

RUN/ENTER

Select a sample.

According to the sample selected, one of the two following

menus appears.

Finished sample Current sample

The header line contains the following data of the selected

sample:

Sample number

ID number (e.g. I001)

BOD type and run duration.

5.4.1 Showing a sample

This function is used to find the measuring heads or samples. Sample

labeling is not necessary.

Point the controller at the measuring

heads:

SAMPLE STATUS TYPE list

(sample management)

Use <><> to select a sample.

Select the -Show sample menu

item with <><>

The controller transmits the call

up of the selected sample. The

allocated measuring heads flash

for approx. 5 seconds.

After the message, the controller automatically returns to the

previous menu.

ba31114e07 08/2014 27

Page 28

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

RUN/ENTER

5.4.2 Erasing data of finished samples

This function erases the data of finished samples from the

SAMPLE STATUS TYPE list ( sample management) of the controller.

You can only erase a sample if it is finished; in non-finished samples,

the menu item -Erase sample does not appear.

SAMPLE STATUS TYPE list

(sample management)

Use <><> to select a finished sample.

Select the - Erase sample menu

item with <><>.

Safety prompt with possibility to

return.

The sample was erased.

After the message, the controller automatically returns to the

SAMPLE STATUS TYPE list (sample management).

28 ba31114e07 08/2014

Page 29

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

RUN/ENTER

40 cm to 1 m

5.4.3 Showing the measuring head list

This function is used to allocate individual measuring heads to the relevant sample in the SAMPLE STATUS TYPE list (sample management)

and to find individual measuring heads.

Select the - list menu item

with <><>

The list of measuring heads of

the selected sample is displayed

together with the serial numbers

of the measuring heads.

(In the BOD Routine operating

mode, this list always contains

only one measuring head.)

Point the controller at the measuring

heads:

Use <><> to select a measuring head and confirm with

<RUN/ENTER>.

The controller repeatedly transmits the call up of the selected

measuring head. The measuring head flashes for approx. 5

seconds.

Use <ORG> to return to the SAMPLE STATUS TYPE list

(sample management).

5.4.4 Calling up data

This function is used to call up the data of individual samples.

To call up the data of all samples, see section 5.3 C

ALLING UP ALL DATA,

page 24.

ba31114e07 08/2014 29

Page 30

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

40 cm to 1 m

RUN/ENTER

SAMPLE STATUS TYPE list

(sample management)

Use <><> to select a sam-

ple whose

run duration is not yet com-

pleted (bar not yet full)

data after complete mea-

surement that have not yet

been called up (bar full, no

checkmark)

Jumps to submenu of the

selected sample.

Preselected: - Call up data

Point the controller at the measuring heads:

Sequential call up of the measuring heads allocated to the

sample (in this example: 7) in

the scanner mode:

The controller

stores the data obtained

updates the

SAMPLE STATUS TYPE

list (sample management)

Duration of a pass:

approx. 3 seconds for 12 measuring heads in a stirring system.

The controller confirms the call

up performed.

The controller then returns

automatically to the submenu.

30 ba31114e07 08/2014

Page 31

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

RUN/ENTER

If the measuring heads do not all respond, the following display appears:

Renewed start of the data call

up.

The controller continues to search for missing measuring

heads in the scanner mode. Without having to press another

key, you can continue the data queries at other locations

(e.g. other stirring platforms or other thermal cabinets).

Approximately 7 seconds after the last call up was performed, the scanner mode breaks off and the following display appears:

Use <RUN/ENTER> to restart

the data transfer (see above).

Return to the

SAMPLE STATUS TYPE list

(sample management).

Transferred and completed

samples appear with a checkmark next to them.

(The complete measurement

data records of all finished

measuring heads of the sample have been procured.)

Immediately after the successful data transfer of a sample, the allocated measuring heads are given the free status. The measuring

heads can be used for a new measurement.

The user administration function is not active in the delivery condition.

5.4.5 Calling up data - Stop

If a measuring head is missing

or defective and the controller

cannot call up the sample as a

result, you can stop the data

transfer with the -Stop menu

item.

ba31114e07 08/2014 31

Page 32

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

RUN/ENTER

After confirmation, the display

message shown here appears.

Three displays are then possible:

Case 1 The sample is still running and

individual measuring heads of

the sample are not attainable.

Case 2 The run duration of the sample

has ended and the finished, all

data of the attainable measuring

heads have been transferred.

-Erase:

Removes missing measuring

then

heads from the data stock. The

completed sample is given the

“finished” status.

-Back:

Jumps back to the previous

menu.

Abort using a function key: The

stopped sample is not declared

as “finished”.

Case 3: No measuring head of a sample

is attainable.

(In the BOD Routine operating

mode: The relevant measuring

head is not attainable).

-Erase:

Removes a sample from the

data stock.

then

-Back:

Jumps back to the previous

menu.

- Show

:

As in - Show sample, but selectively for missing measuring

heads (identification option if only the sender of the measuring

head is defective. Otherwise, see the section 10 W

IF..., page 69)

HAT TO DO

32 ba31114e07 08/2014

Page 33

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

1

2

- Missing

:

5.5 Evaluation

Only appears when the run duration of the sample has

expired. Here you can remove the data of a missing or defective measuring head from the SAMPLE STATUS TYPE list

(sample management) of the controller. In the BOD Standard

operating mode, you can set a sample to the "finished" status

(checkmark ) if all the other measuring heads are already “finished”: Erases the missing measuring heads from the

SAMPLE STATUS TYPE list (sample management).

SAMPLE STATUS TYPE list

(sample management)

Use <><> to select a sam-

ple.

Use <PRINT> to print out the

results with curves.

Evaluation of the sample:

Display of all the curves together

with mean value data.

Check the display for outliers.

Use <PRINT> to print the results

with curves (according to printing format - see

1 End of measuring range

the section 6 P

RINTING, page 39)

2 Mean value

Example: Overall sample with

outlier.

In the BOD Routine operating mode, the evaluation shows the

selected sample as a single curve with the measured value

data.

Use <RUN/ENTER> to switch between the cursor interrogation (see section 5.5.3 C

URSOR INTERROGATION, page 36) dis-

play of the curve with measured value data.

Scroll through the parallel samples: Display of individual curves

(cyclical pass) with data of the

BOD final value.

Use <PRINT> to print out a single result with a single curve.

ba31114e07 08/2014 33

Page 34

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

5.5.1 Sample statistics (BOD Standard operating mode)

Starting point:

Display of a single curve.

Changes to sample statistics.

The menu selection shown here

only appears if the number of

measuring heads (n) is at least

2.

If n = 1 pressing of <RUN/

ENTER>

changes directly to the

cursor

interrogation.

When jumping to the selection menu from “Show all curves“, the

menu item - Exclude curve is not displayed.

Results of the finished sam-

Data of the current sample:

ple:

Mean value

SD: standard deviation

(from n = 3)

n: number of measuring

end date

current mean value

n: number of measuring

heads

heads

<PRINT>

Printout of the results with

curves

<PRINT>

Printout of the data (current

mean value, n, sample information) with curve paths to

date

34 ba31114e07 08/2014

Page 35

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

RUN/ENTER

RUN/ENTER

RUN/ENTER

5.5.2 Excluding a curve (BOD Standard operating mode) This function is used to temporarily exclude a single curve (e.g. an

outlier) from the evaluation and averaging of an overall sample.

The curve is only excluded temporarily! The data stock of the

SAMPLE STATUS TYPE list (sample management) does not

change. The excluded curve is present again when the call is

repeated.

The function "List of measuring heads“ (see section 5.4

SAMPLE STATUS TYPE

LIST (SAMPLE MANAGEMENT), page 26) is used

to find leaky or defective single samples.

Display of single curves:

Select curve.

Use <><> to select -

Exclude curve.

- Exclude curve is preselected.

-Back: Returns to the previous

menu.

Message

Curve excluded!.

Updated display (curve

excluded, mean value recalculated).

Use <PRINT> to print the

updated results with curves

(without the excluded curve).

ba31114e07 08/2014 35

Page 36

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

1

2

3

RUN/ENTER

5.5.3 Cursor interrogation

Starting point:

Display of a single curve with

measured value data.

Use <><> to select -Cursor

query (this menu is not dis-

played in the BOD Routine operating mode).

Use <><> to run through the

curve values.

Use <PRINT> to print out the

current display.

1 The scaling of the Y-axis

is automatically adapted

to the measured value

2 Measuring time at the

cursor position

3 Measured value at the

cursor position

Or from the display of all the single curves:

Use <><> to run through the

curve mean values.

Use <PRINT> to print out the

current display.

Return to the previous menu using <RUN/ENTER>.

Return to the display of all the single curves using <GRAPH>.

36 ba31114e07 08/2014

Page 37

OxiTop® Control OC 100 Operating mode: BOD Standard / BOD Routine

5.5.4 Curves display for cold samples

Display of a single curve.

Display of all curves.

When samples are inserted that are too cold the maximum AutoTemp time is

not sufficient for the sample temperature to reach the incubation temperature:

Warming the sample can cause excess pressure.

Display: Negative values of the curve will be truncated and the curve

originates from the time axis but not the origin.

5.5.5 Measured values outside the measuring range

In the following cases, undef. (undefined) is displayed instead of the

measured value or mean value during evaluation:

A measured curve exceeding the measuring range at any point of its

path.

A measured curve undercutting the measuring range at its end

point.

Sample displays:

A measured value exceeds the measuring

range (Overflow).

A measured value undercuts the measuring

range (Underflow).

ba31114e07 08/2014 37

Page 38

Operating mode: BOD Standard / BOD Routine OxiTop® Control OC 100

A measured value temporarily leaves the measuring range.

After the exclusion of the defective curve (see section 5.5.2 EXCLUDING

A CURVE (BOD STANDARD OPERATING MODE), page 35), the controller

displays the mean value again.

38 ba31114e07 08/2014

Page 39

OxiTop® Control OC 100 Printing

6Printing

Switch on the IR printer.

Point the controller at the printer:

When printing from the SAMPLE STATUS TYPE list (sample management) or from the evaluation:

The controller transfers the report data of the selected sample to the IR interface.

Print date and print time

Sample number

Measured value: mean value, SD, n (with parallel samples)

or end value (with single samples)

Type and run duration, measurement range

Start date and start time, end date, ID number

If GLP is switched on: Note, GLP On

If the AutoTemp function is switched on:

Note, AutoTemp On

Curve(s) + BOD mean value or end value

With GLP On: List of the serial numbers of the measuring

heads allocated to the sample (only for samples started in

the BOD Standard measuring modes)

ba31114e07 08/2014 39

Page 40

Printing OxiTop® Control OC 100

Printing from the evaluation:

If the controller is

in the display of all curves with cursor display

in the display of the single curves with or with-

out cursor interrogation

the printout is a copy of the display indication.

40 ba31114e07 08/2014

Page 41

OxiTop® Control OC 100 GLP/TOOLS

GLP

7 GLP/TOOLS

7.1 GLP/TOOLS main menu

GLP/TOOLS menu:

Select a menu item with <><>.

Confirm with <RUN/ENTER>.

The selected menu opens up or the function is

carried out.

GLP/TOOLS menu:

- Show free

- Show Settings The current settings are displayed here.

- Settings Here you can undertake or change the following settings:

- Check - Show (finished/all)

- Maintenance - Erase sample

This function is used to identify free measuring heads. Thus an additional

sample labeling is not required. Free measuring heads can be used to start

new samples.

- Operation mode

- Measuring time

- date/time

-GLP; calibration interval (not in the BOD Routine operating mode)

- Memory erase!

- AutoTemp (BOD Standard

- Switch-off interv.(not in the BOD Routine operating mode)

- Temperature- Height- Air pressure- Limit pressure- Language

- info (with report printout)

- Controller Info (with report printout)

- Cal Test

- Pneumatic test

(in the controller - SAMPLE STATUS TYPE list (sample management))

- Reset/release

- Restore data

ba31114e07 08/2014 41

Page 42

GLP/TOOLS OxiTop® Control OC 100

GLP

40 cm to 1 m

GLP

RUN/ENTER

7.2 Show free measuring heads

This function is used to identify free measuring heads. Free measuring

heads can be used to start new samples.

GLP/TOOLS menu:

Preselected: - Show free

.

Press <RUN/ENTER>.

Point the controller at the measuring

heads:

All free measuring heads flash

for approx. 5 seconds.

7.3 Show settings

The current settings are displayed here.

GLP/TOOLS menu:

Select the - Show Settings menu

item with <><>

The following example illustrates the presettings in the

BOD Standard operating mode:

SHOW SETTINGS menu:

A list containing the current settings is displayed.

Use <><> to scroll.

(Automatic stop at the beginning

and end of the list)

In the "Show settings“ menu:

Print out the whole list of current settings (as in the display).

42 ba31114e07 08/2014

Page 43

OxiTop® Control OC 100 GLP/TOOLS

GLP

RUN/ENTER

7.4 Settings

With this function you can undertake or change settings. The table

below shows the settings in the delivery state.

GLP/TOOLS menu.

Select the - Settings menu item with

<><>

Default setting (bold)

Setting

Operating mode BOD Routine BOD Standard

Operational life 5 days

Date current current

and setting range

(0.5 h to 99 days)

5 days

(0.5 h to 99 days)

Time current current

GLP Off

(permanently set)

On

Off

Calibration interval --- 12 months

to 36 months

Clearing the memory automatic

or manual

AutoTemp On

(permanently set)

Switch-off interval 5 minutes

(permanently set)

automatic

or manual

On

Off

5 minutes

to 15 minutes

Language German German

7.4.1 Operating mode

You can select the following operating modes:

BOD Standard

BOD Routine

SETTINGS menu:

Select the - Operation mode

menu item with <><>.

ba31114e07 08/2014 43

Page 44

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

Confirm with <RUN/ENTER>.

Select the required operating

mode <><>.

Confirm with <RUN/ENTER>.

-Back:: Return to the main

menu SETTINGS:

7.4.2 Operational life

Here you determine the run duration of the measurement.

SETTINGS menu:

Use <><> to select the -

Measuring time menu item.

Set the days (1 to 99) or hours

(0.5 to 23) with <><>.

Confirm with <RUN/ENTER>.

Display:

Adjusted meas. time.

Delivery condition: 5 days.

44 ba31114e07 08/2014

Page 45

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

7.4.3 Date/time

Here you set the date and time for the controller (important for the

assignment of sample numbers).

SETTINGS menu:

Use <><> to select the -

date/time menu item.

Use <><> to set each number block on a black background.

Confirm with <RUN/ENTER>.

Set the day, month, year, minutes, seconds one after the

other.

The run duration of samples already started is not affected by

changing the date or time.

7.4.4 GLP (Operating mode BOD Standard )

The GLP (Good Laboratory Practice) set of rules requires a detailed

description of all equippings and procedures in a laboratory.

These descriptions include the room equipment of the laboratory, the

instruments used, and the measuring procedures laid down, and

require the complete documentation of the samples tested. The type

and frequency of the use of test resources is to be described and documented as well.

To make the documentation of the test resource monitoring easier an d

simpler the OxiTop

®

Control system has a GLP mode.

When this mode is switched on, the following data are documented:

the calibration intervals that have been set

the calibrations that have been performed

The reports contain the series numbers of the measuring head and

controller and the date of the calibration.

The GLP mode monitors the calibration intervals and blocks the start of

a new measurement if a calibration will be due within the measuring

time.

ba31114e07 08/2014 45

Page 46

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

Switching the GLP func-

tion on or off

SETTINGS menu:

Use <><> to select the -

GLP menu item.

GLP menu:

Preselected: -GLP

Confirm with <RUN/ENTER>.

Use <><> to select either

GLP On or Off.

Confirm with <RUN/ENTER>.

7.4.5 GLP - calibration interval (- Calinterval)

Set the time period (1 to 36 months) here. When it expires, the instrument registers that the next test resource monitoring of the measuring

heads is due. After the calibrating interval expires, measuring is

blocked until the calibration is performed or the Off setting is selected.

If the end of the calibrating interval set up lies within the measuring

time of a measurement to be started, this measurement cannot be

started.

GLP menu:

Use <><> to select the -

Calinterval menu item.

Confirm with <RUN/ENTER>.

Use <><> to set the time

period for the calibrating interval

(1 - 36 months).

Default setting:

12 months.

Confirm with <RUN/ENTER>.

46 ba31114e07 08/2014

Page 47

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

7.4.6 Data storage

Here, you can set whether the controller should automatically erase the

oldest finished samples if the memory is full to create space for new

measurement data (setting auto).

With the manual setting, the message "Memory lack! Erase finished

sample/s! is displayed if the memory is full (see section 10 W

IF..., page 69).

HAT TO DO

Back up your data regularly!

SETTINGS menu:

Use <><> to select the -

Memory menu item.

Preselected: MEMORY -Erase

auto

To change it:

Confirm with <RUN/ENTER>.

Use <><> to select either

auto or manual.

Confirm with <RUN/ENTER>.

-Back (return to the SETTINGS

menu)

7.4.7 AutoTemp

The AutoTemp function controls the automatic start of the measurement after checking the temperature adaptation.

The pretemperature regulation to the precise incubator temperature is

recommended but not essential. Recommendation: e.g. regulate the

temperature of the sample for BOD5 measurements from 15 °C up to

20 °C.

You can tightly close the sample bottle with the measuring head immediately and start the measurement. The AutoTemp function then automatically triggers the start of the actual measuring after checking the

temperature adaptation. The measuring time of the AutoTemp phase

(adaptation phase plus the test phase) is added to the sample

measuring time selected in the settings.

Pretemperature regula-

tion of the sample

With the AutoTemp function switched on and, adhering to the recommendation according to the table, the error quota that results from the

temperature adaptation of the sample to the incubator temperature,

ba31114e07 08/2014 47

Page 48

GLP/TOOLS OxiTop® Control OC 100

T

Incubator

, is smaller than 1% of the selected measurement range final

value.

Measuring time

of the measurement

1 day

2 days T

3 days T

4 days T

5 ... 99 days T

Recommended sample temperature at the start of the measurement

T

Incubator-0.5K ... TIncubator

Incubator-1K ... TIncubator

Incubator-2K ... TIncubator

Incubator-3K ... TIncubator

Incubator-5K ... TIncubator

BOD5 15°C ... 20°C

The AutoTemp function The AutoTemp function is made up of the adaptation phase and the

test phase.

Adaptation phase

The phase without evaluation of the pressure process. The duration of

the adaptation phase is defined for the various measuring times

according to the table. The adaptation of the microbiology to the characteristics of the sample is made in this phase and small temperature

deviations, too high and too low temperatures of the sample, can be

compensated for. The measuring system is zeroed after the adaptation

phase has expired.

Sequence of the test

phase:

Test phase

The phase in which the further pressure process direction in the sample

bottle is checked. The test phase is defined for the various measuring

times according to the table.

In this phase, the continuing temperature deviation can be compensated if the temperature of the sample is too low.

With a further drop in pressure (consumption) or constant pressure

after the adaptation phase, the pressure value at the end of the adaptation phase is the starting point of the measurement.

On a further increase of pressure following the adaptation phase (the

sample is still too cold), the turning point of the pressure process at

which the pressure increase changes into a pressure drop, is the

starting point of the measurement. If the sample is too warm the test

phase is dropped (temper the sample according to the table on the last

page).

If no starting point is found (according to the procedure given in points

1 and 2) after the termination of the AutoTemp phase (time limit

exceeded), the last measuring point of the AutoTemp phase forms the

starting point.

This means that the BOD curve in the graphical evaluation does not

emerge from the coordinate origin at the zero time point. A sample that

was too cold was started.

48 ba31114e07 08/2014

Page 49

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

BOD measuring

time

Duration of the adaptation phase

Duration of the test phase

0.5 to 23 hours Since the measurement times are very short, the system always suppresses the AutoTemp phase here

even if the AutoTemp function is switched on in the settings.

1, 2, 3, 4, 5 days 14, 28, 42, 56, 70 minutes Max. 28, 56, 84, 112, 140

minutes

6 to 99 days

70 minutes Max. 140 minutes

in a 1 day pattern

Switch the AutoTemp function on or off (only in operating modes

BOD Standard):

SETTINGS menu

Use <><> to select the -

AutoTemp menu item.

Preselected: - AutoTemp On

To change it:

Confirm with <RUN/ENTER>.

Use <><> to select either -

AutoTemp On or Off.

Confirm with <RUN/ENTER>.

-Back (to the AutoTemp menu)

7.4.8 Switch-off interval

The time interval after the last time a key is pressed can be set here.

After this time interval expires, the controller switches itself of f to save

energy. Possible settings: 5 to 15 minutes. Default setting: 5 minutes.

In BOD Routine mode the switch-off interval is permanently set to

5 min and cannot be changed.

SETTINGS menu:

Use <><> to select the -

Switch-off interv. menu item.

ba31114e07 08/2014 49

Page 50

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

Preset:

-Interval: 5 minutes

To change it:

Confirm with <RUN/ENTER>.

Set the required number of minutes with <><>.

Confirm with <RUN/ENTER>.

-Back (to the SETTINGS menu)

7.4.9 Language

®

Select the language here in which the displays of the OxiTop

controller appear. The

controller has the following 5 languages stored in it (default German):

German - English - French - Italian - Spanish.

SETTINGS menu:

Use <><> to select the -

Language menu item.

Preset:

-Mode German

To change it:

Confirm with <RUN/ENTER>.

Set the required language with

<><>.

Confirm with <RUN/ENTER>.

From now on the displays

appear in the selected language.

-Back (return to the SETTINGS

menu)

SETTINGS menu.

-Back (to the GLP/TOOLS

menu )

or

with <GLP>.

50 ba31114e07 08/2014

Page 51

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

RUN/ENTER

40 cm to 1 m

RUN/ENTER

7.5 Check

Main menu GLP/TOOLS.

Use <><> to select the -

Check menu item.

7.5.1 Showing the measuring heads

CHECK menu:

Preselected:

-Show

Point the controller at the measuring

heads:

All the measuring heads that are addressed flash for 5 seconds.

7.5.2 Measuring head information

SHOW menu:

Preselected:

- Show free

Use <><> to select either

- Free or

-All

.

CHECK menu:

Select the - info menu item

with <><>.

ba31114e07 08/2014 51

Page 52

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

The measuring head flashes.

A display appears on the con-

troller giving the following information:

Series number of the measur-

ing head,

Battery status

(OK/LOBAT/EMPTY!!),

the next calibration date (only

in operating

modeBOD Standard)

Status of the measuring head

(free/used/defective).

If the measuring head is "used":

Use <><> to scroll

through the display of further

information:

– Start date

– Final date

– Sample number

– Type and

– Measuring range of the

measurement

Use <RUN/ENTER> to return

to the CHECK menu.

Repeat the procedure for each

measuring head.

If the measuring head does not respond, the following display

appears after approximately 7 seconds:

Query stopped!

You can select between

- Continue query (see above)

and

-Stop (return to the CHECK

menu)

52 ba31114e07 08/2014

Page 53

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

7.5.3 Controller information

CHECK menu.

Use <><> to select the -

Controller Info menu item.

The display shows the following

information:

Number of measuring heads

for which there is still memory

capacity

Status of the supply batteries

Status of the data backup

batteries (OK/LOBAT).

Use <><>

to scroll to the

specification of the

Software version

Series number

(can differ from the example

shown here)

Return to the CHECK menu:

With <RUN/ENTER>.

7.5.4 cal-test

The cal-test function is used to test the sealing of the system measur ing

head - rubber sleeve - sample bottle and the operability of the system

®

OxiTop

Control.

In the BOD Standard mode with the GLP On setting, the con troller indicates when the next cal test is due, depending on the set calibration

interval (see section 7.4.4 GLP (O

PERATING MODE BOD STANDARD ),

page 45).

®

To perform the test, you need the WTW test resource, OxiTop

PM,

order number 209 333.

Sample preparation: see operating manual of the OxiTop

®

PM test

resource.

CHECK menu.

Use <><> to select the -Cal

Test menu item.

ba31114e07 08/2014 53

Page 54

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

The instrument automatically

allocates the sample number (in

the header line).

The filling volume (164 ml) and

the type together with the run

time of 5 days are preset.

For information on the further handling of the sample up to the

“finished” status: See section 5.2 S

TARTING THE MEASUREMENT,

page 21.

The Cal sample appears together with the other samples in the

SAMPLE STATUS TYPE list (sample management). The BOD

type is CAL:

SAMPLE STATUS TYPE list

(sample management)

Evaluation of the Cal

test

Use <><> to select the test

sample.

Entry into the evaluation.

Display of the selected sample

as a curve with measurement

value data.

Compare measurement value

with lot test value (according to

operating manual of OxiTop

®

PM) .

Now you can set a new calibra-

tion date for the measuring head

with the controller.

- Show (to find the relevant

measuring head):

Function and messages as

described (see section 5.4

SAMPLE STATUS TYPE

SAMPLE MANAGEMENT), page 26.

(

54 ba31114e07 08/2014

LIST

Page 55

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

40 cm to 1 m

- Set Cal date

This menu item only appears if

the controller is in the

BOD Standard operating mode,

GLP is switched on and the test

is finished.

-Stop:

Return to the curve display. The

Cal test is considered as not

performed.

The controller sets a new test

date in the measuring head. The

controller calculates the new

test date from the current date +

the specified check interval (see

section 7.4.5 GLP -

INTERVAL (- CALINTERVAL), page

CALIBRATION

46).

The controller displays the set-

ting of the calibration date.

If the date was not set successfully (e.g. because the controller was not held to - or not held close enough to - the measuring head):

Repeat the procedure using

<RUN/ENTER>.

Then continue as described

above.

7.5.5 Pneumatic test

The pneumatic test tests the measurement precision of the measuring

head.

It says nothing about the long-term impermeability of the system.

To perform the pneumatic test, you require the test resource, OxiTop

®

PT (WTW order number 209 334).

ba31114e07 08/2014 55

Page 56

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

RUN/ENTER

The user interface of the controller guides you through the test:

CHECK menu.

Use <><> to select the -

Pneumatic test menu item.

Set the plunger of the syringe on

®

the OxiTop

PT test resource to

5 scale parts.

Tightly screw the measuring

head to be tested onto the Oxi-

®

Top

PT test resource.

(Exceeding the time causes a

return to the CHECK menu).

(Exceeding the time causes a

return to the CHECK menu).

The controller display shows the

result of the pneumatic test.

Use <RUN/ENTER> to return to

the CHECK menu.

7.6 Maintenance

GLP/TOOLS menu.

Use <><> to select the -

Maintenance menu item.

56 ba31114e07 08/2014

Page 57

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

RUN/ENTER

RUN/ENTER

RUN/ENTER

RUN/ENTER

RUN/ENTER

7.6.1 Erasing finished samples

Here you can erase the data of finished samples that are already evaluated or no longer required in order to free memory in the controller.

MAINTENANCE menu:

-Erase sample preselected

ERASE FINISHED SAMP.

menu:

Preselected: - From sample no.

-all

-Back (to the MAINTENANCE

submenu)

The controller displays the list of

the finished samples.

The oldest finished sample is

marked.

With <>, you can mark further

samples.

With <>, you can remove the

marking again.

The controller asks if you really

want to erase the marked samples from the memory.

After confirmation, the display

message shown here appears

for 2 seconds and then the controller returns to the menu

ERASE FINISHED SAMP..

In the selection of erase “All“ samples, the following display

appears:

The controller asks if you really

want to erase the samples from

the memory.

Continue: see above.

ba31114e07 08/2014 57

Page 58

GLP/TOOLS OxiTop® Control OC 100

If no finished samples are available in the memory, the following display appears:

58 ba31114e07 08/2014

Page 59

OxiTop® Control OC 100 GLP/TOOLS

RUN/ENTER

RUN/ENTER

7.6.2 Reset/release

This function can be used to release measuring heads again that were

unintentionally started.

After carrying out the - Reset/release function the data of the

measuring head are erased!

MAINTENANCE menu:

Use <><> to select the -

Reset/release menu item.

The serial number of the measuring head and the sample

number appear on the display.

- Reset/release

Confirm with <RUN/ENTER>.

The release for the measuring

head has been performed..

-Back:

(measuring head not released)

Display message:

Reset performed!

Repeat the procedure for each

measuring head to be released.

Display message when the last measuring head of a sample

has been released:

Use <RUN/ENTER> to return to

the RESET/RELEASE menu.

ba31114e07 08/2014 59

Page 60

GLP/TOOLS OxiTop® Control OC 100

RUN/ENTER

RUN/ENTER

RUN/ENTER

7.6.3 Reading out data

In case you lost your controller or your controller is defective, the

"Restore data" function facilitates to restore the data of running

measurements using a new or other controller. This means the data are

not lost!

To perform this function the memory of the controller mu st be absolutely empty! The data of each single measuring head are restored

one after the other in a sequence. It is not possible to leave this

function and to continue it afterwards because then the memory

would no longer be empty.

Select the - Restore data menu

item.

Select the -Restore data

menu item.

Confirm the restoration for one

measuring head and hold the

controller to the measuring

head. Contact selection:

The controller displays the

serial number of the selected

measuring head.

After confirming again the data

of the measuring head are read

out and stored in the controller.

The Id number of the sample is not restored, it is always I999.

60 ba31114e07 08/2014

Page 61

OxiTop® Control OC 100 GLP/TOOLS

The controller returns to the

RESTORE DATA menu.

Perform this procedure for every

measuring head with a measurement running, without leaving the RESTORE DATA

function.

If the data of a measuring head were already restored the following is displayed for approx. 3 seconds:

Then the controller returns to

the RESTORE DATA menu.

Perform the restoration with

another measuring head.

If the memory of the controller is not empty the following is displayed for

approx. 3 seconds:

After this, the RESTORE DATA

menu is displayed again.

It is not possible to restore the

data with the controller. Contact

the WTW service department.

It is possible to restore the data of all running measurements if the

controller is in the BOD Routine operating mode. In the

SAMPLE STATUS TYPE list (sample management), however, only

the samples that were started in the BOD Routine operat ing mode

are displayed in this case. To have all samples shown, switch over

to another operating mode (see section 7 GLP/TOOLS, page 41).

ba31114e07 08/2014 61

Page 62

Transmitting data OxiTop® Control OC 100

8 Transmitting data

The RS232 interface is used to transmit data to a PC (see section 4.1.2

S

OCKET FIELD - CONTROLLER, page 16).

For details, see operating manual of the Achat OC software.

8.1 Achat OC software

With the Achat OC software, you can

Execute the sample management of the controller on the PC (back

up the data regularly!)

Comfortably display the sample management together with addi-

tional information on the screen

Select samples in the PC and transfer the measurement data of the

selected samples from the controller to the PC

Export the measurement data for processing with spreadsheet pro-

grams

For details, see operating manual of the Achat OC software.

62 ba31114e07 08/2014

Page 63

OxiTop® Control OC 100 Maintenance, cleaning, disposal

LISTED 8F93

LaboratoryEquipment

E163694

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following conditions: (1)This devise may not

cause harmful interference, and (2) this devise must accept

any interference received, including interference that may

cause undesired operation.

Ser.-Nr.:05150013

OxiTop OC 1x0

WTW 82362 Weilheim

Made in Germany

1x CR 2430 Lithium

3xAlkaline, AA size, 1,5V

1

1

1

1

1

2

9 Maintenance, cleaning, disposal

9.1 Maintenance

9.1.1 General maintenance activities

The only maintenance activity required is replacing the batteries.

9.1.2 Replacing the supply batteries (controller)

®

Switch off the controller OxiTop

Loosen the 4 screws underneath the housing using a Phillips screw-

driver.

-OC 100.

1Screws

Place the controller on the lower case.

Remove the upper case and put it down to the right next to the lower

case with the display downwards.

1 Supply batteries in the battery holder (lower case)

2 Data backup battery (upper case)

ba31114e07 08/2014 63

Page 64

Maintenance, cleaning, disposal OxiTop® Control OC 100

Remove the supply battery holder from the fixing in the lower case

and turn it around.

Remove the empty supply batteries.

Insert the new supply batteries - 3 pieces, alkaline (alkali manga-

nese), Size: Mignon, AA, AM3, LR6).

NOTE

Ensure that they are inserted in the correct position!

(The poles are marked in the supply battery holder.)

Always replace the complete set of batteries.

Turn the supply battery holder around again and place it in the fixing

in the lower case.

Set the upper case on top of the lower case, turn the controller and

tighten the housing screws using the screwdriver.

Switch on the controller. The battery change was successful if no

error message appears concerning the supply batteries.

It is recommended to use only brand name batteries of the type

specified as “Alkaline“. Using other types of battery can adversely

affect the reliable functioning.

The supply batteries have no influence on data integrity.

Dispose of used batteries according to the local regulations of your

country.

End users within the European Union are obligated to return used

batteries (even ecologically compatible ones) to a collection point

set up for recycling purposes.

Batteries are marked with the crossed-out waste container symbol.

Therefore, they may not be disposed with the domestic waste.

64 ba31114e07 08/2014

Page 65

OxiTop® Control OC 100 Maintenance, cleaning, disposal

LISTED 8F93

LaboratoryEquipment

E163694

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following conditions: (1)This devise may not

cause harmful interference, and (2) this devise must accept

any interference received, including interference that may

cause undesired operation.

Ser.-Nr.:05150013

OxiTop OC 1x0

WTW 82362 Weilheim

Made in Germany

1x CR 2430 Lithium

3xAlkaline, AA size, 1,5V

1

1

1

1

1

2

9.1.3 Replacing the data backup battery (controller)

Evaluate and back up all the measurement data.

Options available:

– print out the results (see section 6 P

RINTING, page 39)

– save the data in the PC using the software “Achat OC“, see sec-

tion 8.1 A

CHAT OC SOFTWARE, page 62