Page 1

Replacement Switch Assembly

!

5 Burner/Pump Control

5-M Burner/Pump Control – Manual Reset

7B Proportional Control

7B-M Proportional Control – Manual Reset

For Series:

93 94

193 194

Pump Controller/Low Water Cut-Off

INSTRUCTION MANUAL

MM-706B

Replacement Switch

Electrical Ratings

Models with 5 and 5-M Switch

Pump and Burner Switch Contact Ratings

Voltage Pilot Duty Only

120 VAC

240 VAC

CAUTION

WARNING

345 VA

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper

application, installation, and maintenance of plumbing, steam, and electrical

equipment and/or systems in accordance with all applicable codes and ordinances.

• To prevent a fire, do not exceed the switch contact rating.

Models with 7B and 7B-M Switch

Switch Ratings

Burner Valve

120 VAC

345 VA 0 - 135 ohms @ 24 VAC

240 VAC

WARNING

Failure to follow this warning could cause property damage, personal injury or

death.

Page 2

O

FF

O

N

STEP 1 - Removal and Replacement of Contacts and Terminal Panels

T

O

W

E

R

T

UB

E

S

W

I

T

CH

A

S

S

E

MB

LY

TE

R

MI

N

A

L

C

ON

N

E

C

TI

ON

S

S

W

I

TC

H

C

OV

E

R

TER

MIN

AL

PAN

ELS

C

ON

D

U

I

T

C

ON

N

E

C

TOR

N

A

ME

P

LA

TE

FI

TTI

N

G

H

U

B

C

A

!

!

!

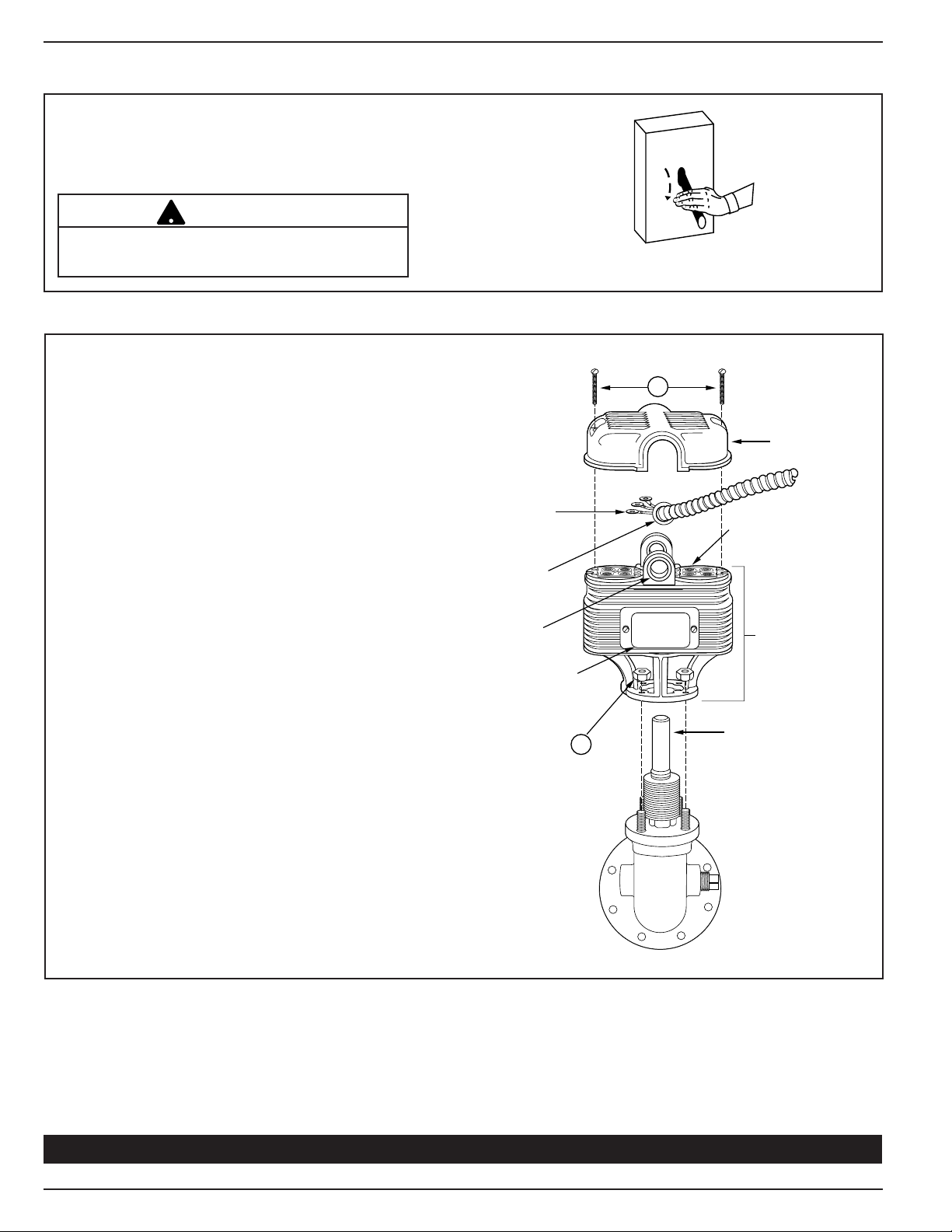

a. Turn power off to boiler and all controls.

Allow boiler to cool to 80˚F (27˚C) and

educe the pressure to 0 psi (0 bar).

r

CAUTION

There may be more than one source of power to

the boiler.

b. Remove and Replace Switch Assembly

• Remove two screws (A) and lift off

switch cover.

• Identify terminal connections for

rewiring and then disconnect all wires

from terminal panels.

• Remove conduit connector and wires

from the integral fitting hub.

• Remove four hex nuts (B) and carefully

lift switch assembly up and off

tower tube.

• Carefully slide new switch assembly

over tower tube and secure with four

hex nuts (B). Make sure nameplate is

in same position as old unit.

• Remove two screws (A) and lift switch

cover off new unit.

• Install conduit fitting from old unit

with attached wires on switch assembly.

• Reconnect wiring to terminal panel in

exactly the same position as removed.

• Replace switch cover and fasten with

two screws (A).

Proceed to Step 2 to Test Control

2

Page 3

STEP 2 - Testing

!

!

– Dimensions shown are typical.

– The following testing procedure is only meant to serve as a verification of proper

operating sequence.

a. Turn on power to boiler and pump circuits.

With the boiler empty, the pump should turn on (5 or 5-M switch models) or the valve open

(7B or 7B-M switch models). The burner should remain off and boiler should begin to fill with water.

CAUTION

Immediately turn off all power if the burner turns on with no water in the gauge glass.

nvestigate further before continuing procedure.

I

b. For Automatic Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

the burner should turn on.

For Manual Reset Models

When water level in the gauge glass is approximately 1 3/8” (35mm) above the horizontal cast line,

press the manual reset button and the burner should turn on.

c. For 5 or 5-M Switch Models

When water level in the gauge glass is approximately 2 1/8” (54mm) above the horizontal cast line,

the pump should turn off.

For 7B or 7B-M Switch Models

When water level in the gauge glass is approximately 2 11/16” (68mm) above the horizontal cast

line, the valve should be closed.

CAUTION

If pump does not turn off or valve close, turn off water supply to boiler. Investigate

further before continuing procedure.

d. With the water in the boiler at its normal level and burner on, SLOWLY open the blow-down valve

until it is fully open. As the water level in the gauge glass begins to drop, verify that the following

occurs.

For 5 or 5-M Switch Models

When water level drops to approximately 1 1/8” (29mm) above the horizontal cast line, the pump

should turn on.

When water level drops to the horizontal cast line, the burner should turn off.

For 7B or 7B-M Switch Models

As the water level drops, the valve should begin to open.

When the water level drops to approximately 7/8” (22mm) above the horizontal cast line, the valve

should be full open.

When the water level drops to the horizontal cast line, the burner should turn off.

e. Close the blow-down valve after burner turns off and restore water level to normal operating level.

f. Repeat testing procedure several times to ensure proper operation of control.

g. After testing and verification of control operation, the boiler can be returned to service.

3

Page 4

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-706B November 2012 Part No. 210418

Loading...

Loading...