Page 1

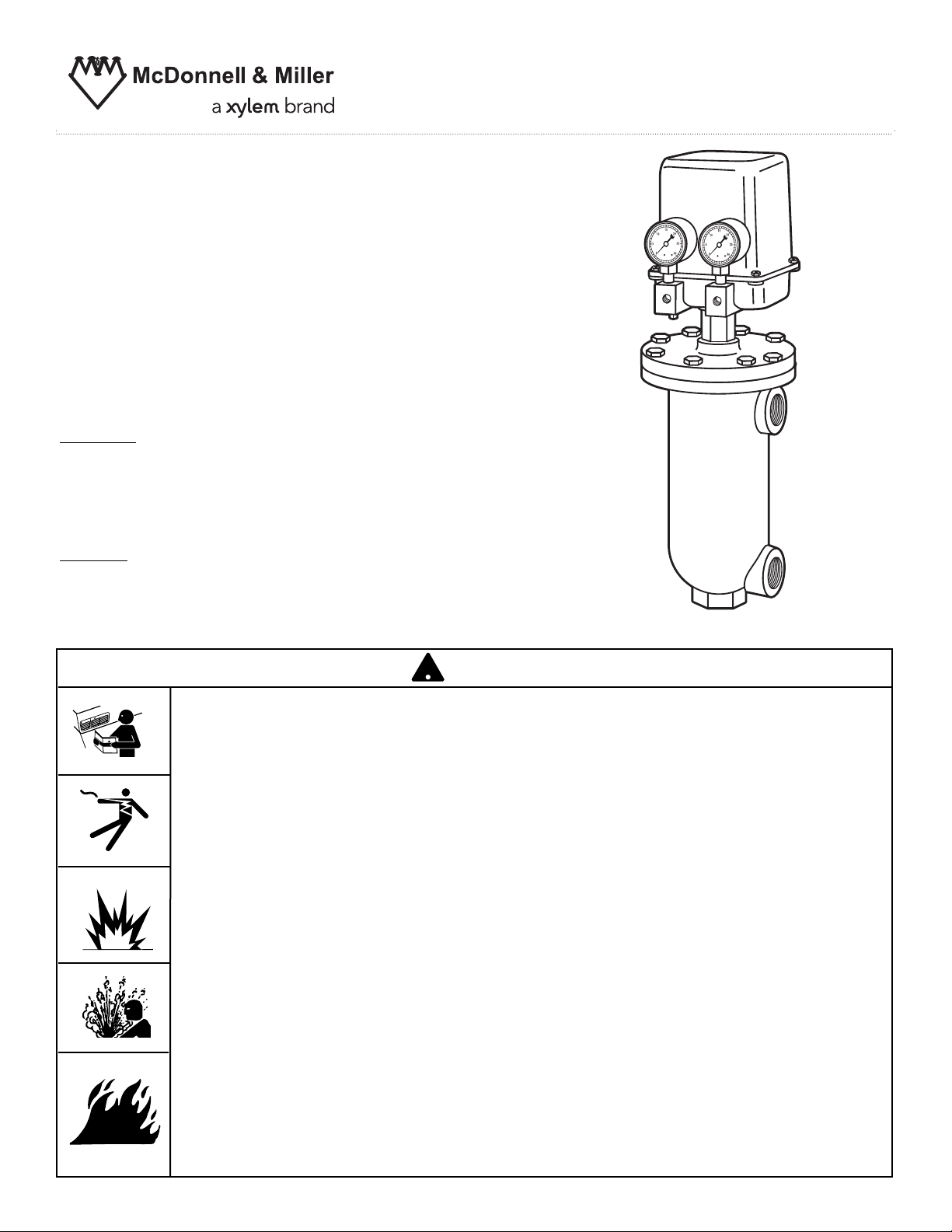

Model PFC-1-G (direct acting)

PFC-1-GR (reverse acting)

Modulating Pneumatic

Liquid Level Controls

APPLICATIONS:

– Use with other pneumatic devices, for liquid level

sensing in tank or pressure vessel where electrical

processes are not suitable, such as certain hazardous

locations.

Features:

– A float-operated, modulating, pneumatic level controller

– Side-mounting pipe connections

– Direct or reverse action convertible

– Field adjustable operating range & proportioning band

INSTRUCTION MANUAL

MM-110C

Ratings:

Maximum Vessel Pressure: 250 psig (17.6 kg/cm2)

Maximum Fluid Temperature: 406° F (208°C)

Maximum Supply Air Pressure: 20 psig (1.4 kg/cm

CAUTION

WARNING

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation,

and maintenance of plumbing, steam, and electrical equipment and/or systems in accordance

with all applicable codes and ordinances.

• If tank or receiver is pressurized relieve pressure to 0 psi (0 Bar) before servicing.

Drain water level down and let cool to 80°F (27°C).

• Boiler manufacturer schematics should always be followed. In the event that the boiler

manufacturer's schematic does not exist, or is not available from the boiler manufacturer,

refer to the schematics provided in this document.

• To prevent water damage check to make sure there is adequate floor drainage capacity.

Check all components in the system to insure they will not leak in the event of an

overfeed condition.

• After installation, check for proper operation of all of the limit and operating controls before

leaving the site.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

2

WARNING

!

!

)

&

'

Page 2

2

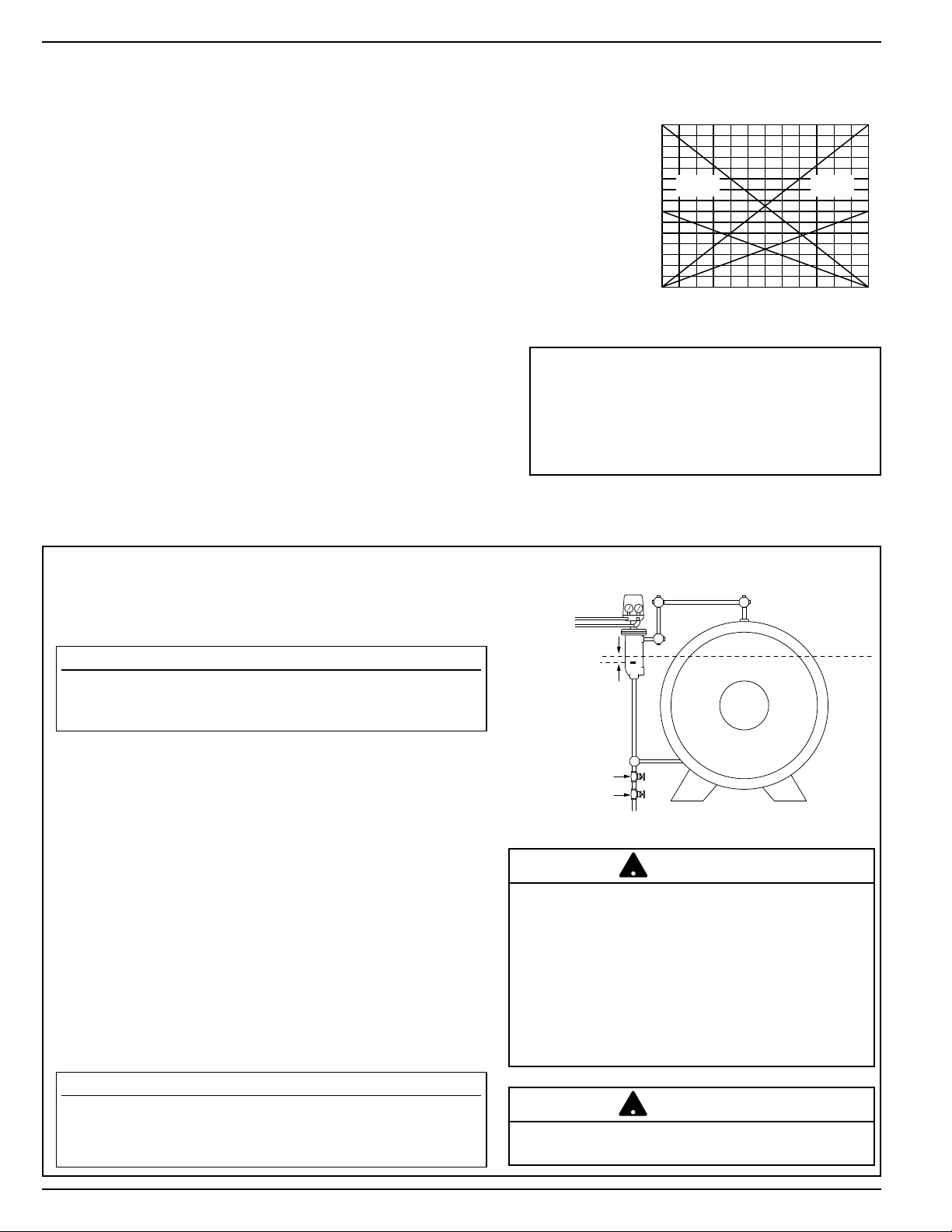

The model PFC should be installed vertically on the side

of the tank or vessel and connected with 1” equalizing

pipes. Plug all unused body connections. Control must be

plumb, with no more than a 2°-3° slant in any direction.

Control should be set with mark on casting 1” below the

desired operating level in tank. Keep equalizing lines as

short as possible and avoid creating any pockets. Crosses

with plugs should be used at any right angle connections

to facilitate cleaning. A blow-off valve should be installed

to permit blowdown operation and draining the float

chamber. All connections must be securely tightened in

leak-tight arrangement.

Gauges should be positioned for convenient reading.

Head assembly can be reoriented by removing 8 bolts in

the top of the head assembly and repositioning the entire

head as desired so gauges can be read conveniently.

Piping Hook-up

INSTALLATION –

Boiler / Hydronic Installation

TOOLS NEEDED:

Two (2) pipe wrenches, one (1) flathead screw driver

and pipe thread dope.

FACTORY SETTINGS

DIRECT ACTING—MODEL PFC-1-G - The higher the liquid

level, the higher the output pressure. Control can be changed

to Reverse Acting.

REVERSE ACTING—MODEL PFC-1-GR - The higher the liquid

level, the lower the output pressure. Control can also be changed

to Direct Acting.

NOTE: Pneumatic operated valves are also available as either

Direct Acting or Reverse Acting.When control and valve are the

same –both Direct Acting or Reverse Acting– the valve opens

as liquid level falls. When they are not the same, valve opens

as level rises.

MAXIMUM PROPORTIONAL BAND—Control goes through

its full operating range—from 3 to 15 psi output— with 2” of

level change inside the float chamber. The proportional band

can be adjusted to as little as 1” of level change.

SET POINT—The mark cast on float housing indicates the

low point of the control operating range. The operating level to

be maintained in the tank should be 1” above this mark. This

set point can be field adjusted about 3/4”.

OPERATION

The model PFC is float operated, and

mounts on the side of the tank or pressure

vessel. Its design allows field adjustment of

operational level, adjustment of proportional

band and conversion to either direct acting

or reverse acting operation.

Remove float blocking plug and dowel pin, located

in the bottom tapping of the control, before installation. Remove cardboard stop inside the top housing

before putting control in operation.

When using tape sealants on pipe or fittings external

threads follow the manufacturer's instructions—do

not place tape on first thread. When using thread

joint compound on pipe or fittings external threads

follow manufacturer's instructions—use sparingly

do not place compound on first thread.

!

CAUTION

Operating

Range

Proportional

Band

Output Air

2" (51mm)100%

1" (25mm)50%

3691215

(.2) (.4) (.6) (.8) (1)

Reverse

Acting

Direct

Acting

psi

(kg/cm

2

)

NOTE

The control is factory set to the mark on the float housing and

to maximum proportional band. If the proportional band is

adjusted, the point of minimum output may be as much as 1/2”

above the mark.

Be sure to release pressure from float chamber

before removing the 8 bolts.

!

CAUTION

IMPORTANT

Follow the boiler manufacturer’s instructions along with all

applicable codes and ordinances for piping, blow-down valve,

water gauge glass, tri-cock and electrical requirements.

OUTPUT AIR TO

CONTROL DEVICE

SUPPLY AIR

BALL VALVE

GATE VALVE

1”

DUAL

VALVE S

FOR

BLOW

DOWN

NORMAL

OPERATING

LEVEL

Page 3

3

TANK INSTALLATION

START-UP AND ADJUSTMENT PROCEDURE

AIR SUPPLY CONNECTIONS

It is good practice to install an air filter in the air supply

line. Control must be supplied with clean, dry instrument

air at 20 psi. (Supply pressure in excess of 20 psi will

cause a slight downward shift of the set point. Supply

pressure less than 20 psi may not give sufficient output pressure to achieve control valve close-off.)

Connect air supply to either of the two 1/8” NPT ports

directly below the gauge marked SUPPLY. Connect

either of the two ports below gauge marked OUTPUT

to valve or other control device. (Alternate ports are

provided for convenience; be sure to plug the two

ports not used with plugs provided.)

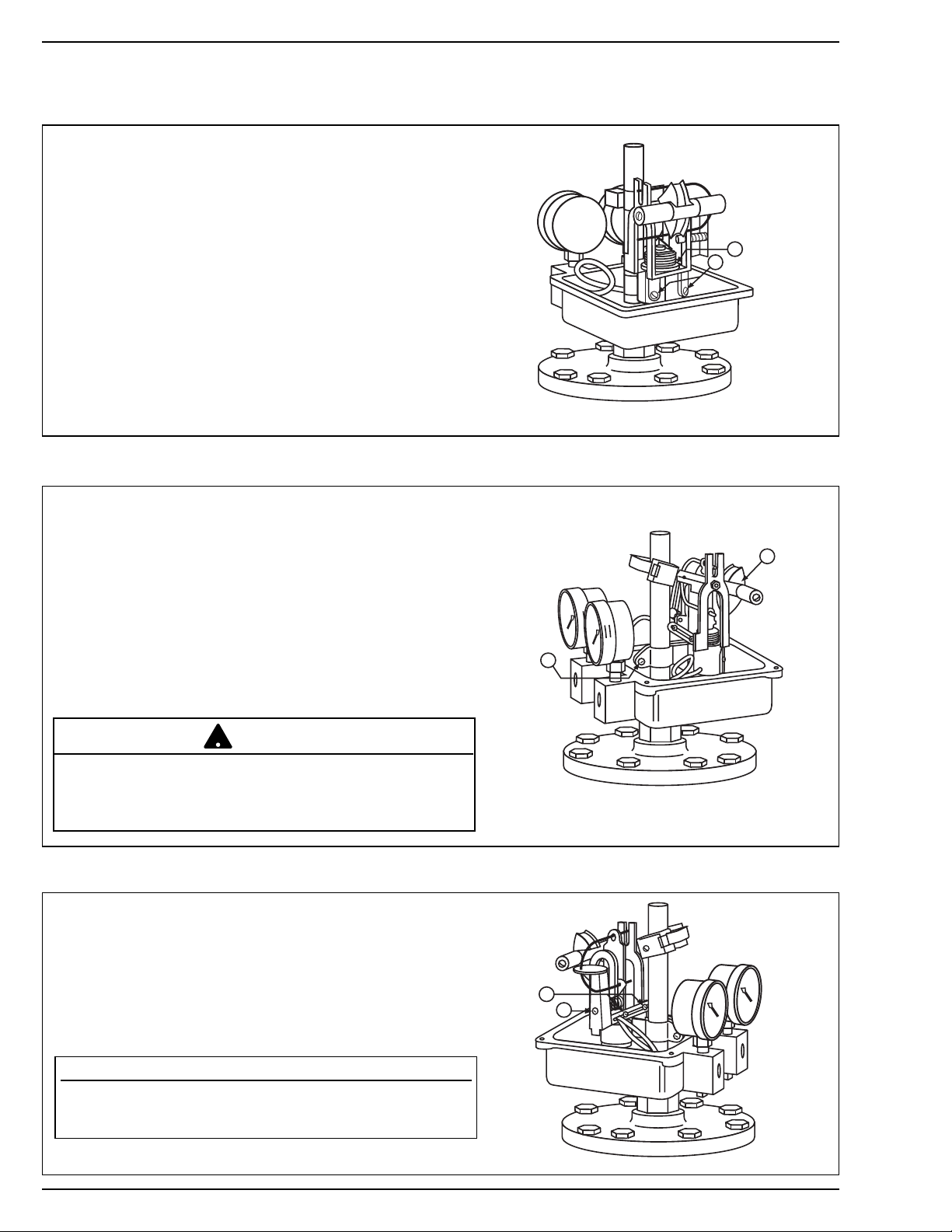

Remove cover from head of control. Carefully remove

cardboard shipping stop under the yoke, by straightening

the tabs on the sides and folding it lengthwise. Turn on

air supply.

Check the supply gauge for proper air pressure—20 psi

maximum. Gently swing the yoke through its full arc of

travel to make sure the magnets do not rub against the

tower tube (A).

Check the output gauge for proper output. Move the

yoke through its full arc; output should range from 3 to

15 psi. With the yoke in a horizontal position, the output should be approximately 9 psi.

To Start Operation (After all piping installation has been completed)

5” Min. Clearance Required

to Remove Cover

1/8” NPT

Output

OUTPUT AIR TO

CONTROL DEVICE

SUPPLY AIR

1”

1/8” NPT

Supply

NORMAL

OPERATING

LEVEL

7” O.D.

BALL VALVE

GATE VALVE

DUAL

VALVE S

FOR

BLOW

DOWN

A

Page 4

4

When the control is placed in service, and after any

adjustment, make sure of proper air output. With

cover removed, and air supply turned on, check that

the output gauge shows a range from 3 to 15 psi

when the yoke is moved manually through a full arc of

travel. With the yoke in horizontal position, the output

should be approximately 9 psi.

If necessary to adjust: Loosen the two relay lock

screws (C). Turn knurled adjusting collar (D) until output is 9 psi with yoke held in horizontal position.

(Rotate the collar clockwise, when viewed from the

top, to increase the output pressure or counter clockwise to decrease.) Tighten two lock screws securely.

To Adjust Air Output

For later reference, note proper orientation of control

mechanism with base. Slightly loosen clamp screw

(E), and slide control mechanism up or down on the

tower tube. If practical, adjust the level of the liquid to

desired control point, approximately 1” above the low

level mark on the float housing.

Make sure mechanism is in proper orientation with

base: the (M) yoke counterbalance weights should be

parallel to the back side of the base. Then tighten

clamp screw securely.

To Adjust Operating Level (Set Point)

START-UP AND ADJUSTMENT PROCEDURE (continued)

The position of the clamp screw must not be higher

than the top surface of the mechanism housing.

Positioning the mechanism too high may cause the magnets

to disengage, resulting in loss of output control.

!

CAUTION

Loosen two locking screws at bottom of the proportional

band spring bracket (F). Turn the proportional band

adjusting screw (G) until the desired proportional band

is attained. (Screw is full out for factory-set maximum

band.) Tighten two locking screws in spring bracket

securely.

To Adjust Proportional Band

NOTE

This adjustment may require several small incremental

changes followed by operational checks before final setting

is achieved.

D

C

M

E

F

G

Page 5

When the control is placed in service, and after any adjustment,

make sure that magnets clear the tower tube. With cover

removed, move the yoke manually through a full arc of travel.

If necessary to adjust: Loosen pivot screw lock nut (B), using a

11/32” wrench. Adjust pivot screw (not shown) in a direction to

free the rubbing. When magnets clear tube properly, tighten

lock nut securely, and make sure the yoke is engaged with

internal armature.

After installation, test the control for operating levels and reposition

the mechanism, if necessary. Make sure the magnets are

engaged with the internal armature. Engagement is indicated

by resisting movement. Replace cover.

5

Remove two locking screws at bottom of proportional band

spring bracket (F). Remove proportional band adjusting screw

and coil spring (G). Remove proportional band spring bracket

and U-shaped proportional band spring (H). It may be necessary

to compress U-shaped spring slightly to withdraw it from the

upper spring follower (J) and lower guide (K).

Loosen two inner pivots (L), using a 5/16” open end wrench

on the hex-shaped base of the pivots. Rotate counterweight

(M) 180° until it rests on the stop. The eccentric will display DA

when in the proper position for direct acting, and RA for reverse

acting operation.Tighten the two inner pivots (L) securely against

the yoke.

Swing spring follower (J) back to upright position. Carefully

replace proportional band spring bracket and U-shaped proportional band spring (H), making sure that top leg of spring passes

inside the spring follower and between the two upright arms,

and the bottom leg passes inside the guide (K).

Replace proportional band adjusting screw and coil spring (G).

Tighten adjusting screw until the lock screws (F) can be replaced

through the slots in the proportional band spring bracket.

Adjust proportional band as desired (see above) and tighten

lock screws (F).

To Change Direct Acting Operation to Reverse Acting Operation

START-UP AND ADJUSTMENT PROCEDURE (continued)

If Magnets Rub on Tower Tube

One of the pivots on the yoke arm is spring loaded; any lateral force

on the yoke may give a false picture of actual clearances.

!

CAUTION

Overtightening could loosen the eccentric from the lead

counterweight.

!

CAUTION

Perform the air output adjustment procedure after any other changes

to the mechanism.

!

IMPORTANT

M

H

F

G

L

J

K

B

Page 6

Troubleshooting

McDonnell & Miller

Shipment may cause the control to lose calibration. If

erratic operation is observed:

a. Check position of yoke movement relative to tube

tower magnet movement.

b. Position the clamp screw even with the rib of the

mechanism housing.

c. Perform ADJUST AIR OUTPUT procedure after

any changes to mechanism.

Too much vibration of the control or float or rapid level

changes may cause the magnets to disengage,

resulting in a loss of output control. Manually reengage the magnets by slowly moving the yoke

through its entire range of motion until the magnets reengage. If re-engagement does not occur, the float

and internal magnet assembly may be damaged.

Removal of the head from the chamber would then be

required to correct the condition.

MAINTENANCE

SCHEDULE:

• Blow down control weekly to verify operation.

When this control is used as a boiler control,

blow down control as follows when boiler is in

operation

-Daily if operating pressure is above 15 psi.

-Weekly if operating pressure is below 15 psi.

NOTE

More frequent blow-down may be necessary

due to dirty boiler water and/or local codes.

• Disassemble and inspect annually.

Replace the controller if it is worn, corroded,

or if components no longer operate properly.

• Inspect the float, chamber and equalizing piping

annually. Remove all sediment and debris.

• Replace control every 15 years.

More frequent replacement may be required when

severe conditions exist.

Internal (Wetted) Parts Dirty

The internal parts can operate improperly if dirt, scale

or rust is allowed to build. This condition can be a

result of not blowing down the control as recommended and/or improper boiler water chemical treatment.

Float is Crushed

Crushed floats are typically caused by improper blowdown. Drain piping from blow-down valve to drain

should be checked for proper pitch and the blow-down

procedure followed when blowing down the control.

Purchase and install a new float ball after investigating and correcting the problem.

Float is Filled with Water

The seam weld on the float can sometimes deteriorate. This can be caused by the type of chemical treatment used in the boiler. While this is a rare occurrence, the chemical treatment supplier should be consulted to determine if a reaction could occur.

Purchase and install a new float after investigating

and correcting the problem.

PROCEDURE

CAUTION

!

To prevent serious personal injury from steam pipe

blow down, connect a drain pipe to the control

opening to avoid exposure to steam discharge.

Failure to follow this caution could cause

personal injury

When blowing down a control at pressure, the blowdown valve should be opened slowly. The piping needs

to be warmed up and stagnant water in the drain piping

needs to be pushed out. Suddenly opening a blow-down

valve causes steam to condense, which creates water

hammer. Damage to components can occur when water

hammer occurs due to improper blow-down piping.

For these reasons, McDonnell & Miller recommends

a dual valve blow-down system for each control.

1. With water in the boiler at its normal level, open

“Positive Shut-off Ball Valve”.

2. Open “Throttling Gate Valve” slowly until drain piping heats up and then open fully. Observe that the

water level starts falling in the gauge glass.

3. Close “Throttling Gate Valve” after verifying that

controlled air valve opens fully.

If this does not happen, immediately close all

valves, turn off burner and correct the problem.

4. Close “Positive Shut-off Ball Valve”.

5. Observe that the water level returns to its normal

level before leaving site.

.

NOTE

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-110C July 2013 Part No. 210552

Loading...

Loading...