Page 1

Manual

MJK 713

Open Channel Flowmeter

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

1

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 2

Manual

Declaration of Conformity

Konformitetserklæring

Vi, MJK Automation A/S,

DK-2850 Nærum, påtager os

det fulde ansvar for at produktet

Declaration of Conformity

We, MJK Automation A/S,

DK-2850 Nærum, declare under

our sole responsibility that the

product

Konformitätserklärung

Wir, MJK Automation A/S,

DK-2850 Nærum, erklären in

alleiniger Verantwortung, dass

das Produkt

MJK Expert Series 1400 / 3400 Pressure Level Transmitter

som denne erklæring angår,

er i overensstemmelse med

følgende standard(er) eller andre

normdokument(er).

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

efter bestemmelserne i

direktiv

2004/108/EC

Declaration de conformite

Nous, MJK Automation A/S,

DK-2850 Nærum, déclarons

sous notre seule responsabilité

que le produit

to which this declaration relates

is in conformity with the following

standard(s) or other normative

document(s).

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

following the provisions of

Directive

2004/108/EC

Dichiarazione di conformità

Noi, MJK Automation A/S,

DK-2850 Nærum, dichiariamo

sotto la nostra esclusiva responsabilità che l’apparecchio

auf das sich diese Erklärung

bezieht mit der/den folgenden

Nor me(en) oder normativen

Dokument(en) übereinstimmt.

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

Gemäss den Bestimmungen der

Richtlinie

2004/108/EC

Declaración de Conformidad

Nosotros, MJK Automation A/S,

DK-2850 Nærum, declaramos

bajo nuestra única responsabilidad que el producto

MJK Expert Series 1400 / 3400 Pressure Level Transmitter

auquel se réfère cette déclaration est conforme á la (aux)

norme(s) ou autre(s) document(s)

normatif(s)

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

conformément aux dispositions

de Directive

2004/108/EC

al quale questa dichiarazione si

riferisce, è conforme alla seguente normativa(e) standard o ad

altri documenti di normativa(e)

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

conformemente alla disposizioni

della Direzione

2004/108/EC

06.07.2011

Jens Kruse

UL Approvals

UL-CUL listed, File # E 194021 UL 508/c22: 2 No. 142-M1987.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

2

al cual se refiere esta declaración, está en conformidad

con la(s) siguente(e) norma(s) u

otros documentos normativos

EN60079.0:2006, EN60079.11:2007

EN61000-6-1:2007

EN61000-6-3:2007

según las disposiciones de la(s)

directiva(s)

2004/108/EC

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 3

Manual

Contents

Introduction 5

Safety instructions 5

Repair 5

Hazardous areas 5

Product identification 6

Mounting 6

General 6

Explosion hazardous areas 6

Mechanical mounting 7

MJK 713 Flowmeter 7

®

Shuttle

Ultrasonic Sensor 7

Measuring distances for Parshall flumes 9

Measuring distances for Palmer & Bowlus flumes 9

Measuring distances for rectangular weirs 9

Measuring distances for V-notch weirs 9

Measuring along a wall or other plane 10

Flow measurement with smaller flumes / weirs 10

The spread of the ultrasonic signal 10

Measuring through a concrete deck 11

Measurement through a pipe for foam protection. 11

Model 3100 Hydrostatic Transmitter 12

Measuring distances for Parshall flumes 12

Measuring distances for Palmer & Bowlus flumes 12

Measuring distances for rectangular weirs 13

Measuring distances for V-notch weirs 13

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

Electrical mounting 14

MJK 713 System Package 1 14

MJK 713 System Package 2 14

MJK 713 System Package 3 14

Cable extension 15

Ultrasonic sensor 15

Cutting the cable 15

Hydrostatic transmitter 16

Cutting the cable 16

Display and keyboard 17

Quick start 17

Initial startup 18

3

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 4

Manual

Indications 19

Function keys 20

Flow key Q(t) 20

Totalizer key SQ(t) 20

Alarm key 21

Power loss alarm 21

Sample key 21

Menu key 22

System Configuration 23

1.0 Set basic parameters 23

1.1 Set date and time 23

1.2 Access code enabled/disabled 23

1.3 Enter new access code 23

1.4 Select unit measurement 23

1.5 Select unit volume 23

1.6 Select unit flow rate 23

2.0 Set sensor parameters 23

2.1.1 Distance from zero to bottom of sensor 23

2.1.2 Hydrostatic sensor range 23

2.2 Level averaging 23

3.0 Choose primary device 24

3.1 Parshall flumes 24

3.2 Palmer & Bowlus flumes 24

3.3 V-notch weir 24

3.4 Rectangular weir 24

3.4.1 With or without contraction 24

3.4.2 Rectangular weir crest width 24

3.5 Q(h) linearization 24

3.5.1 Number of Q(h) points 24

3.5.2 Select decimal point for the flow values 24

3.5.3 Linearization height value 24

3.5.4 Linearization flow value 24

3.6 Optional formula 24

3.6.1 Optional formula - enter exponent 24

3.6.2 Select decimal point for coefficient 24

3.6.3 Optional formula - enter coefficient 24

3.7 Flow range / level range 25

4.0 Set digital output parameters 25

4.1 Select digital outputs (1-5) 25

4.2 Select function for DO 25

4.3 Alarm flow rate low 25

4.4 Alarm flow rate high 25

4.5 Set volume between pulses 25

4.6 Digital output ON-time 25

4.7 Choose delay on signal 26

4.8 Digital output NC/NO 26

5.0 Analog output 0-20 / 4-20 mA 26

Menu chart 27

Indication menus 27

Configuration menus 27

Appendix 30

A Factory settings 30

B Trouble shooting 31

C Technical specifications 32

D Hardware adjustments 33

E System Package 2 Shuttle

®

used as signal amplifier 34

F Max. head to max. nominal flow 37

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

4

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 5

Manual

Introduction

Thank you for choosing an MJK 713 Open Channel Flowmeter.

The MJK 713 Open Channel Flowmeter is a high quality

flow measurement instrument, in which the relation

between functions, userfriendliness and precision is

optimum.

The MJK 713 Open Channel Flowmeter use either an

ultrasonic transmitter or a hydrostatic pressure

transmitter. This must be specified at time of ordering.

The MJK 713 Open Channel Flowmeter measures the

flow rate of water or wastewater in all types of open weirs

and flumes and provides a display of both current flow

rate and totalized flow.

Yet MJK 713 is simple to set up and use in almost all applications, we recommend that you read this manual thoroughly in order to gain full use from the equipment.

You can always contact your representative or the MJK

Service Hotline for advice and guidance. Also, take a look

at www.mjk.com for additional product and application

information.

MJK Automation A/S is a Xylem brand.

Safety instructions

1: Read this manual carefully.

2: Be aware of the environment on the installation site.

Wear necessary protective equipment and follow all

current safety regulations.

3: MJK 713 can provide a start signal for dangerous

machinery. Always ensure that

connected machinery and other equipment are ef-

fectively being put out of service (i.e. removal of main

fuses, lock main and/or security switches in off position) before commencing installation, fault finding,

service and maintenance work etc.

4A: MJK 713 model 2500: There is a risk of lethal

electrical chock from terminal 1 to 5 and L-0.

Be careful not to touch these while the unit is in service.

4B: MJK 713 model 3000: There is a risk of lethal

electrical chock from terminal L-0. Be careful not to

touch these while the unit is in service.

Repair

1: Repair of Ex approved equipment (ultrasonic trans-

mitter) must only be made by MJK or by a service

representative approved by MJK.

Hazardous areas

1: All current local and national standards, regulations

regarding installation and use of Ex or hazardous

zone approved equipment, certifications and safety

instructions for Ex equipment, that have been used

together with the installation of the Shuttle

®

ultra-

sonic transmitter must be strictly observed.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

5

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 6

Manual

Product identification

General

A standard MJK 713 is delivered for two different measuring ranges (0 - 1 ft and 0 - 3 ft).

It is very important that the measuring range is correct

for the flume in question in order to obtain maximum

measuring accuracy.

Check that the item(s) delivered corresponds to the ordered item(s). The item number is printed on a label that

is sticked onto the packing. Shown below is the label for

a MJK 713 System Package 1 delivery including a MJK

713 flowmeter and a Shuttle

®

ultrasonic sensor:

Mounting

General

MJK 713 measures the flow in an open flume or weir

based on the level of the head in the flume. The method

of measurement are based on the following mathematical

function:

x

Flow Q = f(head

× constant)

where the exponent x and the constant depends on the

type of weir or flume.

The flow converter has 3 different linearization

systems depending on how the volume of water is measured:

- preprogrammed formulas for different dimensions of

the most common flumes and weirs, Parshall flumes,

Palmer & Bowlus flumes, V-notch weirs, and rectangular weirs.

- for other flumes and weirs with a known calculation

formula the exponent and the factor of the calculation formula can be set.

- for flumes where no calculation formula exists, a

number of known flow values can be entered,

on which a point linearization and curve extrapolation

is calculated.

➀

➁

➁

➃

➀ Item number

➁ Item description

An identical marking can

be found on the right

hand side of the level

transmitter cabinet:

➂

➂

➂ Serial number

➃ Software version

It is obvious that the flow calculation is highly dependant

on the accuracy of the level measurement. It is therefore

important to follow the mounting instructions carefully for

the Shuttle

®

Ultrasonic Sensor (MJK 713 System Package 1 or 2) or MJK model 3100 Pressure Transmitter

(MJK 713 System Package 3).

Explosion hazardous areas

The Shuttle

®

ultrasonic sensor is Ex approved and can be

mounted in Zone 2 without the need of a

zener barrier. It is not approved for Class I Division I

zones.

The Flowmeter (= the electronic box with

display) must not be mounted in explosive

hazardous areas.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

6

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 7

Manual

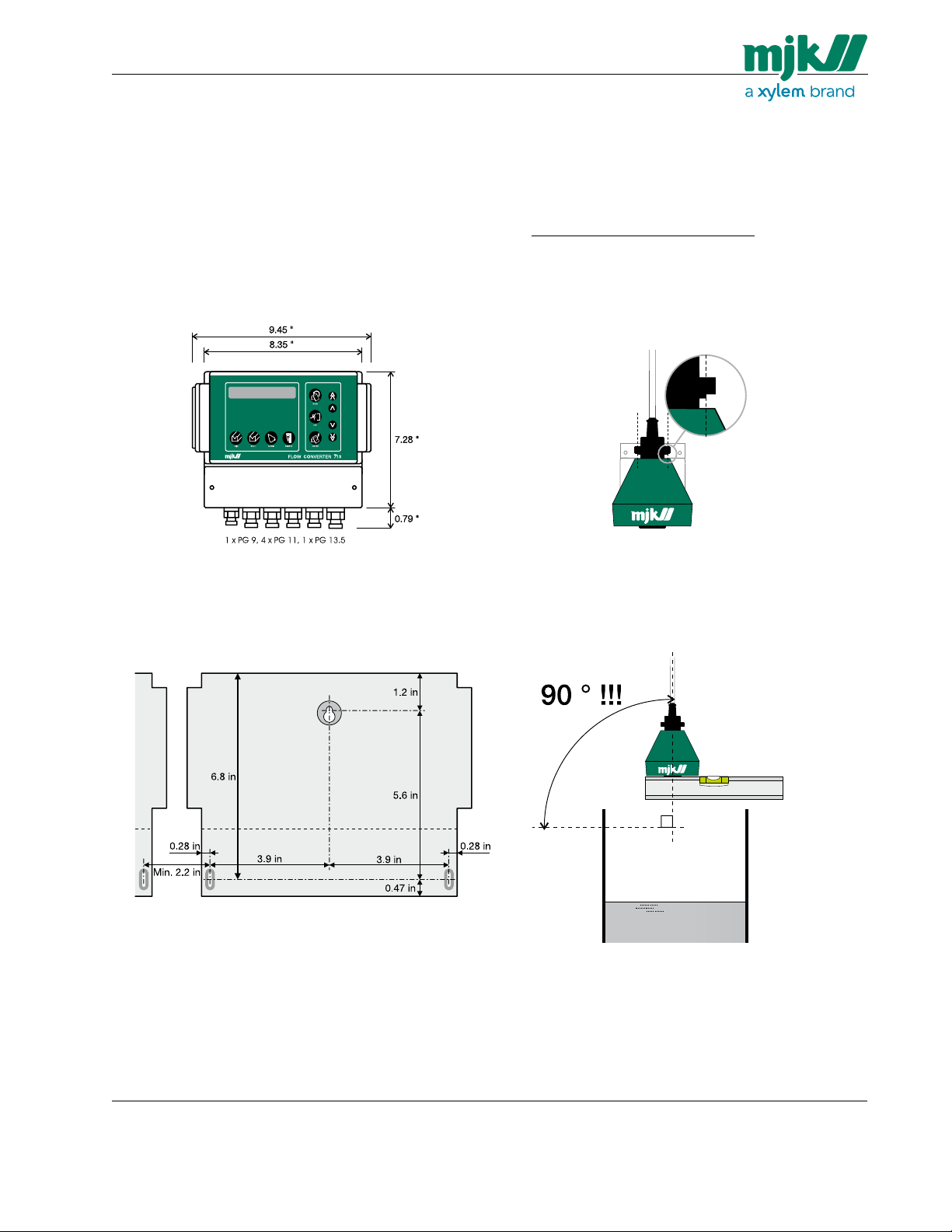

Mechanical mounting

MJK 713 Flowmeter

The MJK 713 Flowmeter is in NEMA 4X enclosure and

can be mounted outdoors directly on a wall or in a panel

using a panel mounting kit (order no. 200105). A sun

shield (order no. 200115) is recommended in very sunny

locations.

The MJK 713 Flowmeter must be

mounted vertically in order to observe the

NEMA4X standard.

Shuttle® Ultrasonic Sensor

The following are extremely important when

mounting the ultrasonic transmitter:

1: It should be mounted securely.

2: It should be mounted absolutely vertical.

Use a spirit level in TWO directions.

3: It should be mounted in the correct distance from

the bottom of the flume / weir.

Observe the blocking distance!

4: It should be mounted in the correct distance from

the inlet.

Mechanical dimensions for the MJK 713 Flowmeter.

The drawing below shows the drilling distances for

mounting the cabinet on a wall:

A full scale print of above drawing can be found at the

end of this manual.

1: The ultrasonic sensor is equipped with a nut for bracket

mounting. Note the recess on the nut - it must be fitted

safely in the bracket for firm fixing to the bracket:

2a: To ensure a reliable and precise level measurement it is

of vital importance that the ultrasonic sensor points down

absolutely vertical against the liquid surface.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

7

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 8

Manual

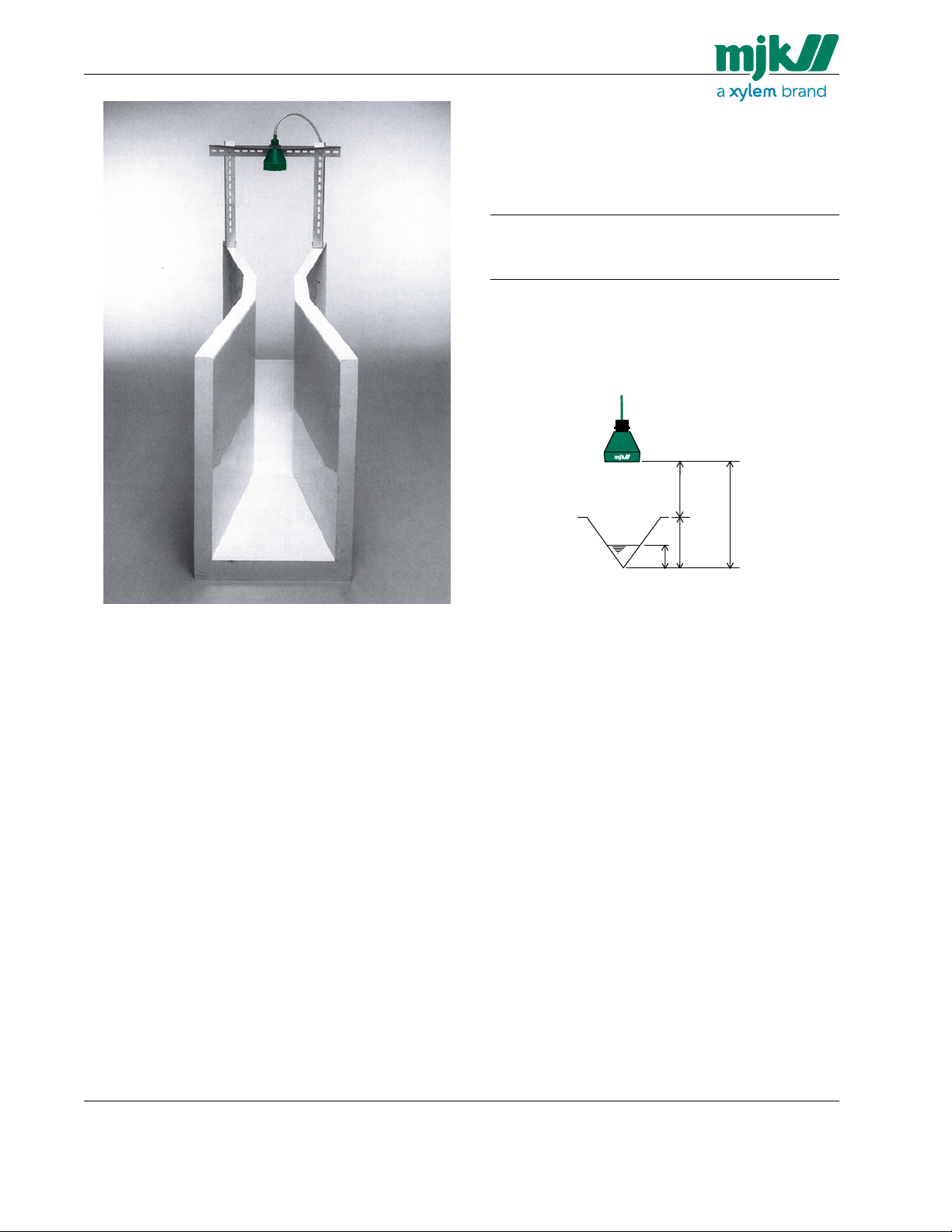

3: The ultrasonic sensor should be installed so that

the bottom of the sensor is as close as possible to

the max. height of the head but not closer than the

blocking distance.

Measuring range: 0 - 1’ 0 - 3’

Blocking distance: )* 16” 16”

Min. measuring range: 4” 12”

Max. measuring range: 12” 36”

Max. sensor height

)* 14” for System Package 2.

(w. Shuttle

➁: 30" 54"

®

Level Transmitter as signal amplifier.)

Maximum sensor height ➁ = Blocking distance ➀

+ measuring range ➃

➀

➁

2b: We deliver two types of sensor brackets that can be used

in almost any installation. The bracket shown is a flume

mounting bracket (order no. 200230 / 200235).

➃

➂

➀ Blocking distance ➁ Sensor height

➂ Actual measurement ➃ Measuring range

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

8

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 9

Manual

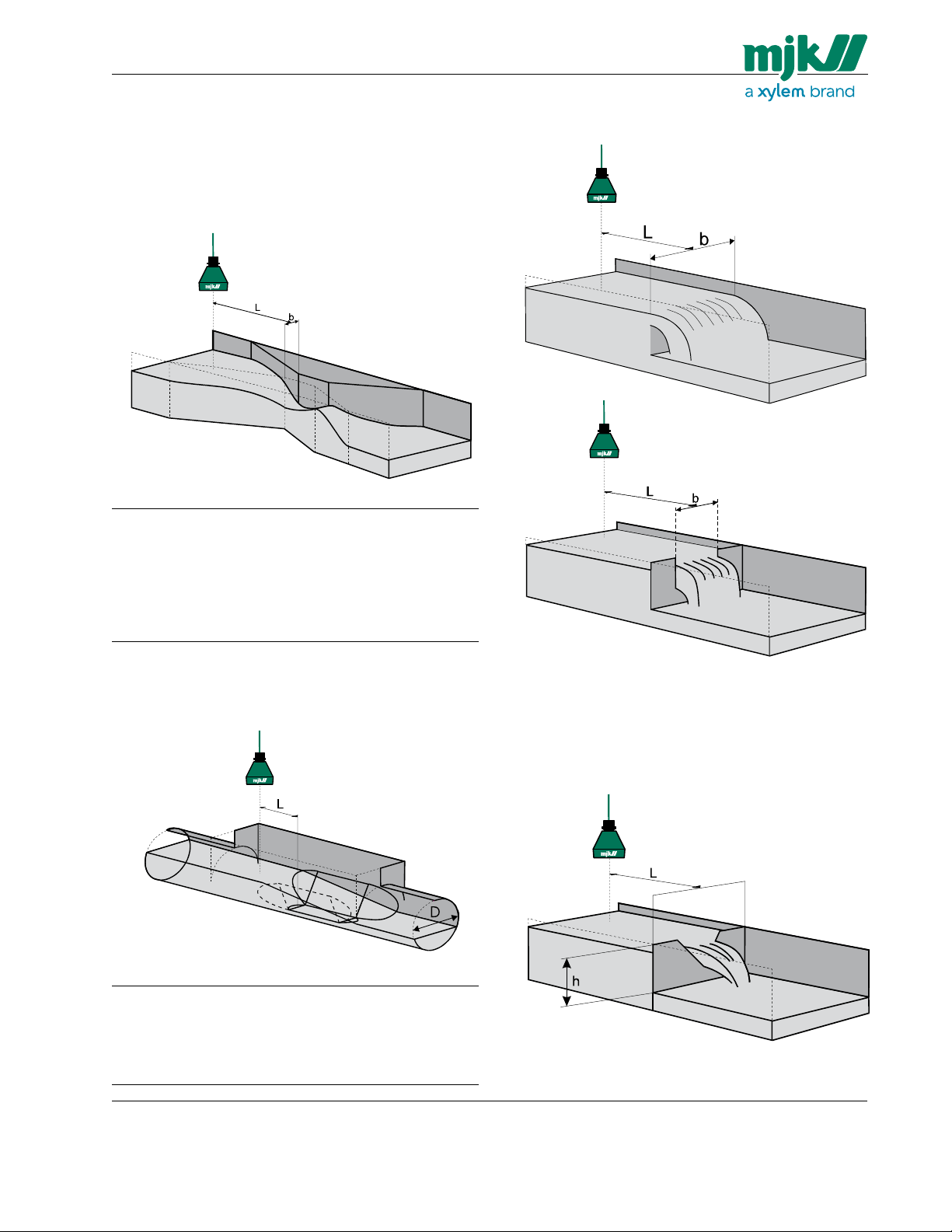

4: Mount the sensor in the correct upstream distance

from the head in the flume / weir.

The distance depends on the dimension and type

of flume / weir.

Measuring distances for Parshall flumes

Throat width b: Distance L: Throat width b: Distance L:

1” 10” 36” 43”

2” 11” 48” 47”

3” 12” 60” 51”

6” 16” 72” 56”

9” 23” 84” 59”

12” 36” 96” 63”

18” 37.5” 120” 72”

24” 39” 144” 80”

Measuring distances for rectangular weirs

- with and without side contraction

Measuring distances for Palmer & Bowlus flumes

Diameter D: Distance L: Diameter D: Distance L:

4” 2” 18” 9”

6” 3” 21” 10.5”

8” 4” 24” 12”

10” 5” 27” 13.5”

12” 6” 30” 15”

15” 7”

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

(L = D/2)

The distance L should be between 4 to 5 times the nominal width b.

Measuring distances for V-notch weirs

The distance L should be between 3 to 4 times the

height h of the notch.

9

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 10

Manual

Measuring along a wall or other plane

The values in table 1 assume the ultrasonic signal is sent

along a smooth surface like a wall or plane without any

projections, joints, butts etc.

If the surface is not smooth or has projections (i.e. joints

on prefab elements), the ultrasonic signal will be impedeaded too much, and for that reason

the values for minimum distance to wall in table 1 should

be increased with 50 - 100 % !

Flow measurement with smaller flumes / weirs

Smaller flumes may cause problems if the ultrasonic signal reflects on the edges of the flume as shown below

(fig. 2a).

The edges should be cut off (fig. 2c) or the ultrasonic

sensor should be mounted in a pipe (fig. 2b) with smooth

inner surface.

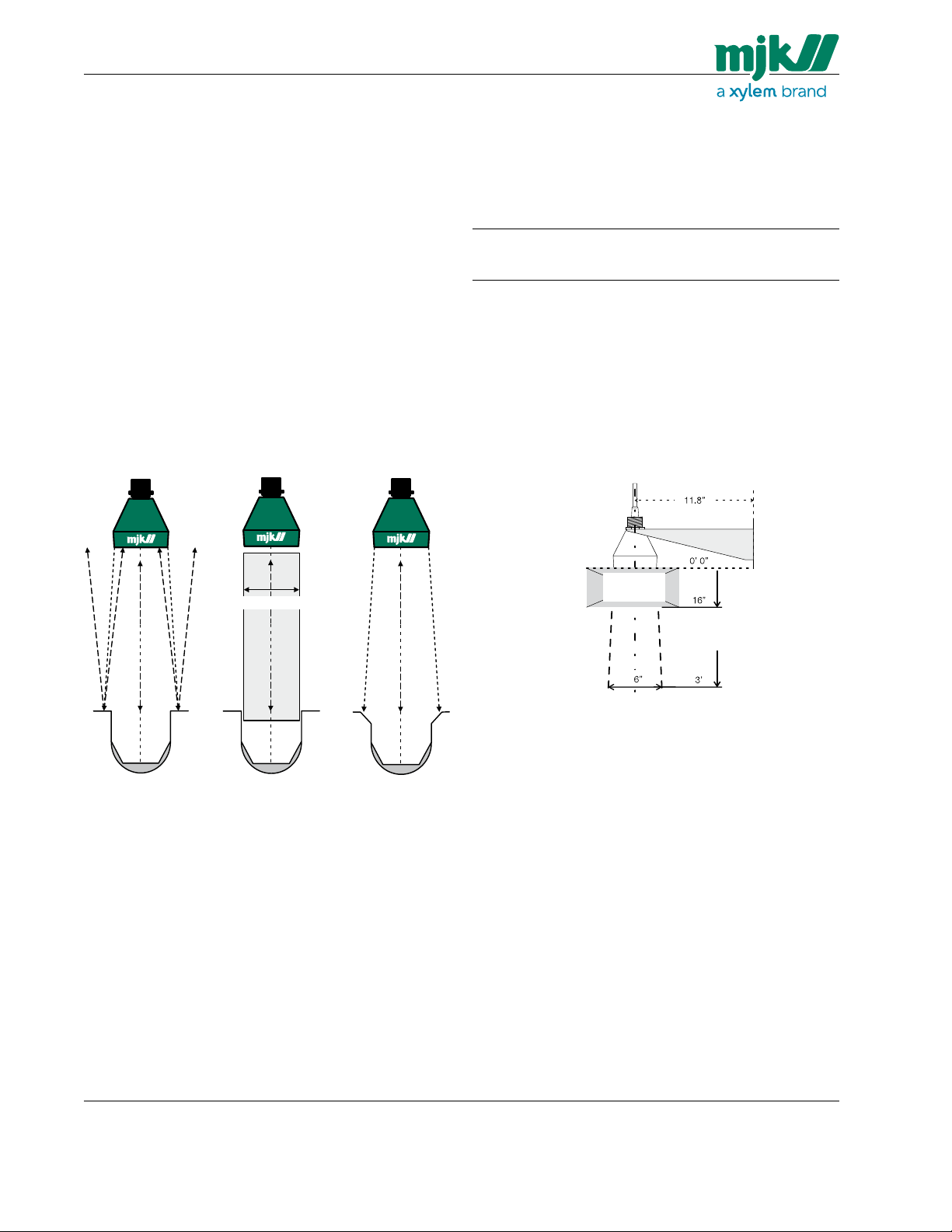

The spread of the ultrasonic signal

The table and illustration below show the spread of the

ultrasonic signal in conjunction to the measuring distance:

Measuring Beam Minimum distance to

SMOOTH

distance: spread: wall (from center line):

1’ 5” 2.3”

2’ 5” 2.6”

3’ 6” 2.9”

Table 1: The ultrasonic signal spread along a smooth wall and minimum

distance to center line in conjunction to the measuring distance.

Accordingly, as the measuring distance increases, the

distance from the center line to a smooth wall should also

be increased.

To avoid false echoes from e.g. edges, a minimum distance as shown on the drawing must be kept. The sensor

can be mounted in a smooth pipe if the distance cannot

be obtained. (See figure 1.)

(min. dia. 5 in)

A B C

Figure 2: Use a pipe (B) or cut off the edges (C) on small weirs to prevent

disturbing reflections from the flume edges.

Blocking

distance!

Figure 1: The signal spread in conjunction with the measurement distance. The

signal spread should be increased by 50 - 100 % if the surface is not

smooth!

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

10

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 11

Manual

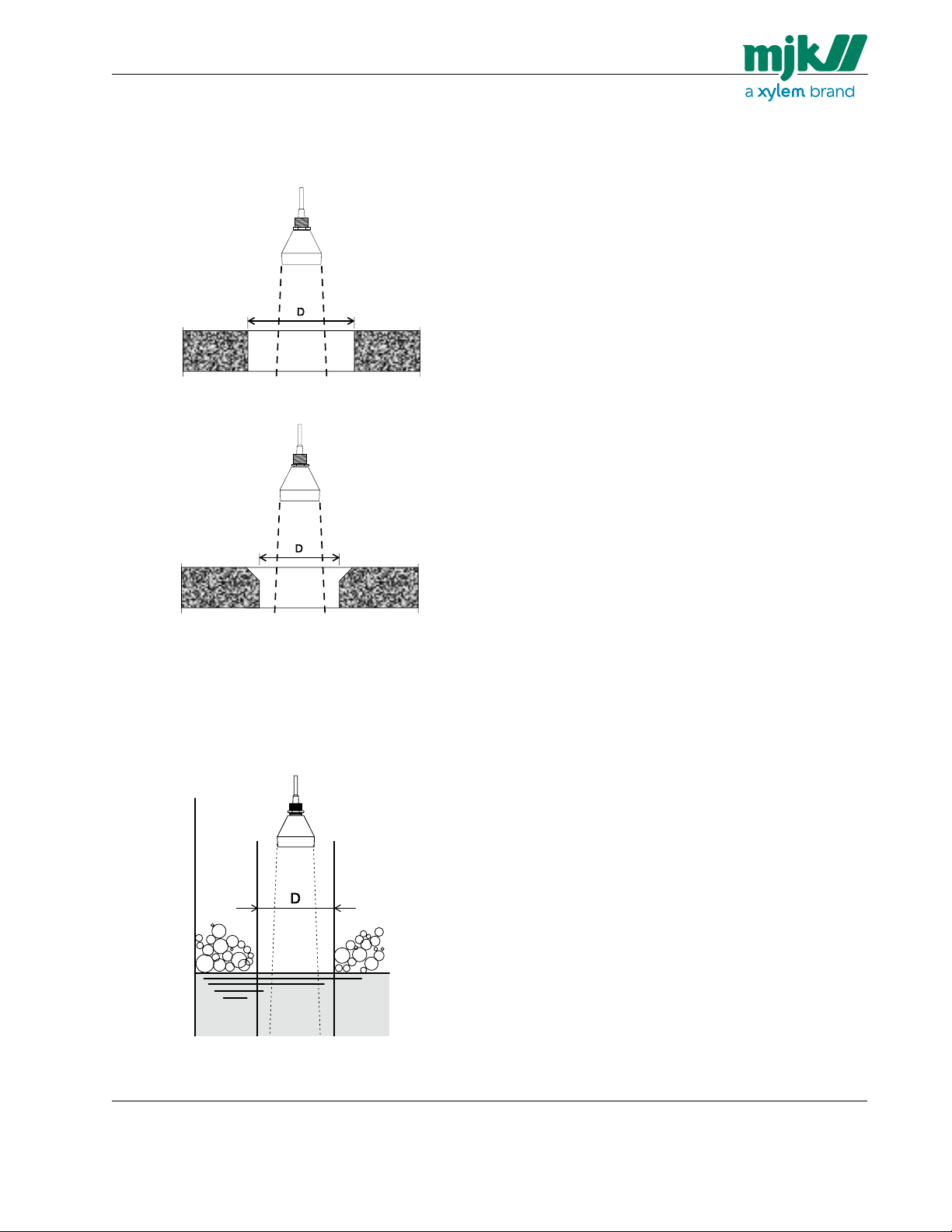

Measuring through a concrete deck

When the ultrasonic sensor is measuring through a concrete deck, the dimension of the opening should be made

as shown below: (See table 1 for the sensor spread.)

Min. diameter (D)

= sensor spread +

100 %

Measurement through a concrete deck with

Measurement through a concrete deck with

sharp edge.

Min. diameter (D) =

45 - 60 ° edge cutoff.

sensor spread

+ 50 %

Measurement through a pipe for foam protection.

When measuring on liquids prone to build up foam on the

surface, it can become necessary to measure through a

pipe, since the build up of foam rarely will occur inside the

pipe.

Measurement through a pipe for foam protection.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

Min. diameter (D)

= sensor spread +

100 %

11

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 12

Manual

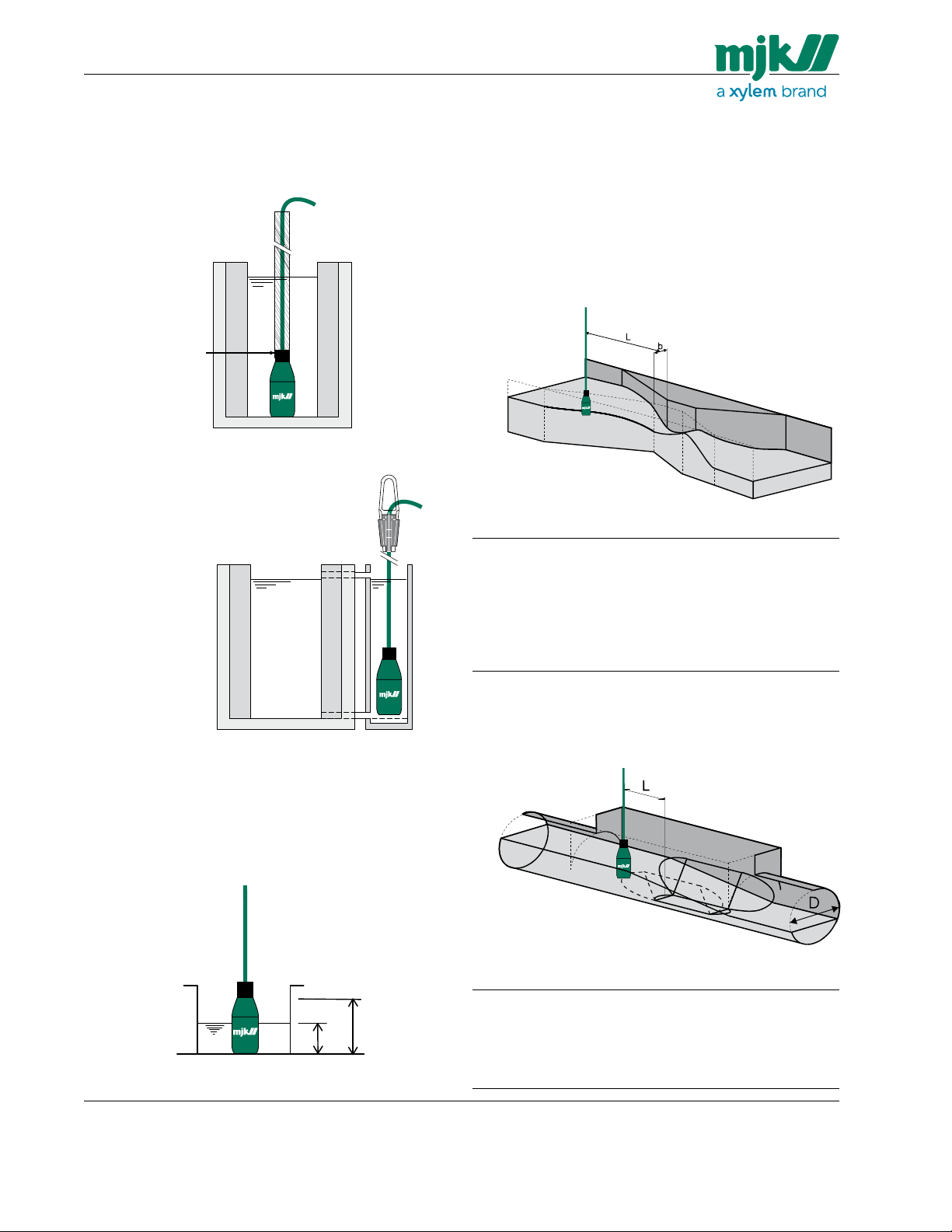

Model 3100 Hydrostatic Transmitter

The following directions should be followed when mounting the pressure transmitter:

1: It should be mounted securely - preferably on

a pipe.

1 in NPT thread

pressure transmitter from hurling around in a Parshall flume.

The use of a

stilling well is the

best option!

A 1 in pipe is used to prevent the

3: Mount the transmitter in the correct upstream

distance from the contraction in the flume / weir.

The distance depends on the dimension and type

of flume / weir.

4: Mount the transmitter at a location with no or very

little turbulence - preferably in a stilling well placed

in the correct distance from the contraction.

Measuring distances for Parshall flumes

Throat width b: Distance L: Throat width b: Distance L:

1” 10” 36” 43”

2” 11” 48” 47”

3” 12” 60” 51”

6” 16” 72” 56”

9” 23” 84” 59”

12” 36” 96” 63”

18” 37.5” 120” 72”

24” 39” 144” 80”

In case the water stream is so intense that the turbulence will affect the measuring

accuracy, the pressure transmitter must be placed in a stilling well. Note, that the

transmitter should be positioned in the stilling well at the same height as the

zero flow level!

2: It should be placed in the correct height over the

bottom of the flume / weir.

➁

➀

➀ Actual measurement

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

➁ Measuring range

Measuring distances for Palmer & Bowlus flumes

A stilling well should always

be used together with a

pressure transmitter!

Diameter D: Distance L: Diameter D: Distance L:

4” 2” 18” 9”

6” 3” 21” 10.5”

8” 4” 24” 12”

10” 5” 27” 13.5”

12” 6” 30” 15”

15” 7”

12

(L = D/2)

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 13

Manual

Measuring distances for rectangular weirs

- with and without side contraction

The distance L should be between 4 to 5 times the nominal width b.

Measuring distances for V-notch weirs

The distance L should be between 3 to 4 times the

height h of the notch.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

13

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 14

Manual

Electrical mounting

MJK 713 must not be connected to the power supply

before the ultrasonic sensor / pressure transmitter is

mounted and connected correctly.

MJK 713 is supplied from the mains on terminal

“0” and “P”.

Current regulations for conductor and fuse dimensions

should always be observed.

MJK 713 System Package 1

MJK 713 2500 with ultrasonic sensor

Standard cable length 40 ft.

(Can be extended to max.150 ft. using

MJK no. 690010 cable.

No. 1 = brown

No. 2 = red

Ultrasonic Sensor

No. 3 = orange

No. 4 = yellow

No. 5 = black

Power

supply

Remove the lid to gain access to the terminals.

MJK 713 2500 Flowmeter

Relay out 1

Relay out 2

Relay out 3

Relay out 4

Current output

(0 / 4 - 20 mA)

Totalizer output

MJK 713 System Package 2

MJK 713 3000 with ultrasonic sensor using Shuttle® Level Transmitter as signal amplifier

®

Level Transmitter

Shuttle

MJK 713 3000 Flowmeter

Power

Ultrasonic Sensor

supply

By looping the 4-20 mA signal through one of the relay

outputs on the Shuttle

failure on the Shuttle® Level Transmitter will trig a

system failure message on the MJK 713. Note that

the Shuttle® must be programmed as described in

appendix E in order to achieve this function.

MJK 713 System Package 3

MJK 713 3000 with hydrostatic level transmitter

No. 1 = red

No. 2 = brown

No. 3 = black

Pressure Transmitter

Power

supply

Note: 1: Conduit hubs are to beconnected to the

conduit prior to the connection to the enclosure.

2: Terminal tightening torque = 0.5 Nm.

®

Level Transmitter, a system

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

14

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 15

Manual

Cable extension

One of the most common faults on a MJK 713

installation is bad or faulty cable connections.

It is recommended to use a MJK connection box if the

sensor cable must be extended.

Ultrasonic sensor

The Shuttle

®

ultrasonic sensor are standard de-livered

with 40 ft of cable. The ultrasonic sensor can be delivered with up to 150 ft of cable on order, or the standard

40 ft cable can be extended to max. 150 ft.

The cable is a special low capacity cable,

so extensions should always be made with

the same type of cable.

MJK Connection

Box (NEMA 4X),

order no. 200590.

To Shuttle®

ultrasonic

sensor

Max.

150 ft !

To MJK 713

flow meter

The cable is delivered with the wires stripped as shown

with the black wire (no. 5) soldered to the shield:

When the cable is cut, only 4 wires will appear:

The ultrasonic sensor cable has 5 wires with both color

code and number:

Number: Color: Designation:

1 Brown Ultrasonic pulse

2 Red

3 Orange Temperature compensation

4 Yellow

5 Black Shield )*

)* This wire is connected to the cable shield.

The wires are mounted according to the terminal markings on the connection box PCB and on the MJK 713

respectively.

Cutting the cable

When the cable has been cut, the shield

should be mounted in terminal 5 instead of

the black wire !

When the ultrasonic sensor is mounted and connected

correctly, the MJK 713 can be connected to the power

supply.

See section ‘Quick start’ on page 18.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

15

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 16

Manual

Hydrostatic transmitter

The pressure transmitter are delivered with 40 ft of cable

as standard.

The cable can be lengthened with any type of cable using

MJK connection box 202922. Although the measuring

signal is not sensitive to electrical noise, we recommend

the use of a screened cable.

Ensure that no moisture can enter the pressure

compensation tube inside the cable.

MJK Connection

Box (NEMA 4X)

with vent plug,

order no 202922.

To MJK 713

flow meter

Max. loop resistance

600 Ω !

To pressure

transmitter

The factory delivered cable has three wires marked with

the numbers 1 - 2 - 3.

Number: Color: Designation:

1 Black Positive (+) wire

2 Black Negative (-) wire

3 Black Shield )*

4 - Air pressure compensation tube

)* This wire is connected to the cable shield.

The wires are mounted according to the terminal markings on the connection box PCB and on the MJK 713

respectively.

Take care not to block or squeeze the air pressure

compensation tube ➃.

When the cable is cut, 7 wires will appear:

➂

When the cable has been cut, the shield

should be mounted in terminal 3 instead of

the black wire !

The small-gauged colored wires MUST NOT be used or

short circuited as it may damage the pressure transmitter.

The colored wires should be cut off in different lengths

to prevent them from short circuit.

See also separate instruction manual for the MJK pressure transmitter.

When the pressure transmitter is mounted and connected

correctly, the MJK 713 can be connected to the power

supply.

See section ‘Quick start’ on page 18.

Cutting the cable

The cable is delivered with the wires stripped as shown

with wire no. 3 soldered to the shield:

➃

➂

➁

➀

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

16

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 17

Manual

Display and keyboard

Display

2 x 24 character backlit display for indication

of menus and values.

ESCape

This key allows you to change back to the main

menu or to undo a new choice. By pressing

the ESCape button two or three times, you will

return to the function indications. If you think

you are lost, or you think you made a mistake,

simply press this button a few times to start over.

However, the escape function is disabled when

choosing primary device.

MENU

By pressing the MENU key,

the display will change to

the next main menu.

Arrow keys

The arrow keys are used

for changing a current

setting.

Pressing the arrow keys

change the values up

or down. By pressing

the ”up” arrow keys, the

number in the display will

increase.

Pressing the ”down”

arrow keys will decrease

the value.

ENTER

This key allows you to

change between the main

menu to a sub-menu, as

well as between submenus.

The key also allows you

to confirm the choice

from a sub-menu.

Q(t)

Registers for flow rate:

- instantaneous value

- average flow rate for

the last 1 hour

- average flow rate today

- average flow rate for

the last 24 hours

Σ Q(t)

Registers for:

- total flow

- total flow 1 hour

- total flow today

- total flow 24 hours

- 99 days log

Quick start

When MJK 713 is powered up for the first time, a quick

setup sequence will be initiated that will guide you

through the following basic settings needed for most

installations:

1: selection of primary device / flow calculation

formula

2: max. flow range

3a: ultrasonic transmitter distance

(applies to MJK 713 2500 /

System Package 1 only)

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

ALARM

Alarm record with the previous nine alarms incl. date

and time of occurrence.

SAMPLE

Registration of:

- total number of samples

- number of samples today

- number of samples within the

last 24 hours

3b: hydrostatic sensor range

(applies to MJK 713 3000 /

System Package 2 & 3 only)

After these initial settings has been made, MJK 713 will

automatically begin to measure flow. If you wish to take

advantage of the flow converter’s many other advanced

functions, such as flow proportion sampling, the remaining sections of this manual will help you to configure the

unit.

17

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 18

Manual

Initial startup

MJK 713 will show the following display at power-up:

MJK 713 initiates the quick setup sequence after app. 30

sec:

The following menus is only shown the first time MJK 713

is powered up and will not appear again after the initial

quick setup sequence unless the quick start sequence is

initiated again by holding ALARM + SAMPLE simultaneously and pressing

ENTER while in level readout menu.

This is shown when ENTER is pressed the first time.

1:

Select flume/weir or flow calculation formula with arrow

keys and confirm with ENTER. Choose between Parshall

flume, Palmer & Bowlus flume, V-notch weir, rectangular

weir or optional formula.

The max. flow range determines the range of the mA output. MJK 713 will calculate the max. level based on the

desired max. flow for the selected primary device, and

set the analog output to give out 20 mA at the max. flow.

(The setting is also used internally to monitor the functions of the flow meter.)

This menu will appear for a MJK 713 2500 /

System Package 1:

3a:

Set the distance from the zero point (= zero flow level in

flume/weir) to the bottom of the ultrasonic sensor with the

arrow keys and confirm with ENTER.

Distance from zero

point to bottom of

sensor

This menu will appear for a MJK 713 3000 /

System Package 2 & 3:

Depending on the selection of flume/weir type or calculation method, a number of menus for setting some specific

information may appear.

No matter which primary device being selected, the following will be displayed as the last:

2:

In this menu the maximum flow for the selected primary

device should be set in accordance with the value stated

in the tables in Appendix E.

It is very important to set the correct maximum

flow value, since it will dramatically reduce

measuring errors!

Set the desired max. flow range for the installation with

the arrow keys and confirm with ENTER.

MJK 713 will now calculate the max. level related to the

selected primary device and display the result in in the

second line.

3b:

Set the measuring range for the hydrostatic pressure

transmitter with the arrow keys and confirm with ENTER.

The basic data entries is now finished and MJK 713

starts

to measure the flow.

To take advantage of MJK 713’s many advanced functions, please see the system configuration section starting on page 23.

Note: For System Package 2 (MJK 713 3000 with

®

Shuttle

Level Transmitter as signal amplifier:

See appendix E for the necessary settings for

the Shuttle

®

Level Transmitter

Note: “Quick Start” sequence can be initiated again

by holding ALARM + SAMPLE simultaneously

and pressing ENTER while in level readout

menu.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

18

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 19

Manual

Indications

At the front of the flow converter, there are 4 function

keys: the flow rate key Q(t), the totalizer key Σ Q(t), the

alarm key ALARM and the sample key SAMPLE.

When one of these keys is pressed one or more times,

the different function menus appear. The menus available

depend on how you configure the flow converter.

Configuring the flow converter is accomplished in the

configuration menus, which in turn are divided into several sub-menus. You gain access to the configuration

menus by pressing the MENU key. In each menu the different settings are obtained by pressing the arrow keys.

Note: A complete diagram of the menus can be

found in the back of this manual. This diagram

will be very helpful to you if you choose to

configure the flow converter!

Flow Key.

See also page 20.

Totalizer Key.

See also page 20.

99 x 24

hours log

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

Alarm Key.

See also page 21.

Last 9 alarm log.

19

Sample Key.

See also page 21.

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 20

Manual

Function keys

Flow key Q(t)

This key shows the values of the relevant flow, as well as

various average values.

F1 Flow

Press once for:

Here the instantaneous actual flow is shown. The flow is

calculated from the chosen Q(h)-formula. Measuring value

with time and date is indicated.

F2 Average flow 1 HR

Press twice for:

Here the average flow for the last full hour is indicated.

F3 Average flow today

Press three times for:

Totalizer key SQ(t)

This key will give access to indication of summed quantities.

F5 Totalizer

Press once for:

Here the total quantity is indicated, from when the value

was last reset. The quantity is updated every second

and is indicated with time and date. The value is reset by

pressing ENTER.

F6 Totalizer 1 hour

Press twice for:

Here the summed quantity for the previous full hour is indicated (e.g. 11:00AM -12:00PM).

F7 Totalizer today

Press three times for:

Here the average flow from 12:00:00AM to the current

time is indicated. The display is updated every second.

F4 Average flow 24 HR

Press four times for:

Here the average flow for the last full 24 hours is indicated

(12:00:00AM to 11:59:59PM).

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

Here the summed quantity for today is indicated. The result along with the time interval is updated every second.

The value is reset by pressing ENTER.

F8 Totalizer 24 hour 99 days log

Press four times for :

Here the 24 hours summed quantity log is indicated. The

quantity and the date for the previous day are logged every 24 hours (12:00:00AM). The log goes back 99 days.

The arrow keys are used for accessing the log.

Note, that the MJK 713 must have been in service for

at least 24 hrs before the last 24 hr log will contain valid

data, and at least 99 days before the full 99 days log will

contain valid data.

20

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 21

Manual

Alarm key

The digital outputs can be configured as alarms of one of

the following alarm types: high flow, low flow and sensor

error. In addition a Power Loss alarm is generated if the

power supply to the flow converter is interrupted. Press

the alarm key to see the previous nine alarms. A new

alarm is registered as alarm no 1, the other alarms are

moved one place, and the alarm which was previously

registered as alarm no 9 is erased.

F9 Alarm display

After pressing the key once alarm no. 1 is shown, which

is the latest alarm; press again and alarms 2-9 come up.

By using the arrow keys it is possible to move backwards

and forwards between the alarms.

The instant an alarm is registered, the alarm type, the

digital output and the time is shown on the display:

When the alarm is no longer active, the time of switch

off is registered. Beware that different alarms could have

been activated in the meantime, meaning the alarm is no

longer no. 1:

Sample key

If one or more of the digital outputs are configured for

controlling a sampler, pressing this key will give following

indications:

F10 Number of samples

Press once for:

This display indicates how many samples have been

taken since last reset or system start up. Press ENTER

for reset, see menu F13.

F11 Number of samples today

Press twice for:

This display indicates how many samples have been

taken today (12:00 AM - now). Press ENTER for reset,

see menu F13.

F12 Number of samples 24 HR

Press three times for :

Power loss alarm

Start of power loss is registred with a precision of 5 min.

End of power loss is registred when the flowmeter is

powered up.

The upper line in the display shows the time for starting

the alarm. The bottom line shows the time for stop. When

an alarm is detected only the time for start is shown in the

upperline of the display, signaling that the alarm has not

disappeared.

When a new alarm appears the display will change from

the previous chosen main menu to F9 - alarm indication,

alarm.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

This menu indicates how many samples were taken

yesterday. Value and date for the previous 24 hours are

indicated.

F13 Reset

Some counter values can be set at 0-level by using the

enter key. One of the following menus will appear:

When a counter has reached its max. value a negative

number is shown. Then reset the counter as described in

F13.

21

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 22

Manual

Menu key

This key gives access to the configuration menus with

readout and programming of the submenus.

A selection is made with the arrow keys (up or down) and

confirmed with the “ENTER” key. Non-confirmed selections will flash in the display, whereas a current/confirmed

selection in shown non-flashing.

Level

Press MENU once for:

Here the measured level (LEVEL) and the value for the

analogue output (I) is indicated. The digital

outputs are indicated as D1-D5. “0” indicates nonactivated output, whereas “1” indicates activated

outputs.

Access denied

What happens when the wrong access code is keyed in:

It will not be possible to make changes in the setup. Return to the previous chosen menu by pressing the ESC

key once.

Language

Press MENU twice for:

Change the language with the arrow keys and confirm

with ENTER.

Enter access code

Press MENU three times for:

The remaining configuration menus can be protected with

a 4-digit access code. Enter the access code with the arrow keys and press “ENTER”. Double

arrows changes the first two digits, single arrows changes the last two digits.

When the access code is keyed in, access to the remaining configuation menus will be given for 5 min. since last

key pressed.

The access code 1111 can always be used.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

22

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 23

Manual

System Configuration

1.0 Set basic parameters

Access to the configuration menus are obtained by

pressing ENTER twice.

1.1 Set date and time

Time and date is adjusted with the arrow keys, followed

by ENTER.

1.2 Access code enabled/disabled

The remaining configuration menus can be protected by

an access code to prevent unauthorized access to the

configuration menus. It will still be possible to

operate MJK 713’s normal functions and readouts. Select

function with the arrow keys and confirm with ENTER.

1.3 Enter new access code

If access code is enabled this menu displays a

chosen access code (4 digits) for access to the configuration menus. Double arrows changes the first two digits,

single arrows changes the last two digits. Change the

code and confirm with ENTER.

1.4 Select unit measurement

Level indication and unit of elevation can be chosen as:

m, cm, mm, ft, in

Select with the arrow keys and confirm with ENTER.

2.0 Set sensor parameters

Access is obtained by pressing ENTER. Press MENU

once to enter the main menu.

2.1.1 Distance from zero to bottom of sensor

(MJK 713 2500 only.)

Enter the distance from the bottom of the ultrasonic sensor to the actual zero point. Double arrows changes the

first two digits, single arrows changes the last two digits.

Set the distance and confirm with

ENTER.

2.1.2 Hydrostatic sensor range

(MJK 713 3000 only.)

Select the measuring range for the hydrostatic

sensor with the arrow keys and confirm with ENTER.

Zero level for Palmer & Bowlus flume.

1.5 Select unit volume

The unit for volume can be chosen between:

m

3

, Gal, CF

Select with the arrow keys and confirm with ENTER.

1.6 Select unit flow rate

The unit for flow can be chosen between:

l/s, m

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

3

/h, GPM, CFS, MGD

Zero level for Parshall flume.

2.2 Level averaging

This menu sets the interval for averaging the level measurement. The interval can be set between 1 and 60 seconds. Select the interval with the arrow keys and confirm

with ENTER.

23

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 24

Manual

3.0 Choose primary device

Select the type of flume/weir or flow calculation formula.

6 options are available: Parshall flume, Palmer & Bowlus

flume, V-notch weir, rectangular weir, linearization and optional flow formula. Select the desired flume/weir or flow

calculation formula with the arrow keys and confirm the

selection with ENTER.

Note that entering this menu will force you to go through

all submenus concerning the selected flume / flow calculation formula.

3.1 Parshall flumes

For Parshall flumes there is a choice between the

following standard sizes: 1”, 2”, 3”, 6”, 9”, 12”, 18”, 24”,

36”, 48”, 60”, 72”, 96”, 120”, and 144”.

Select the size with the arrow keys and confirm with ENTER.

3.2 Palmer & Bowlus flumes

For Palmer & Bowlus flumes there is a choice between

the following standard sizes: 4”, 6”, 8”, 10”, 12”, 15”, 18”,

21’’, 24”, 27” and 30”. Select the size with the arrow keys

and confirm with ENTER.

3.3 V-notch weir

Set the notch angle

with the arrow keys and confirm with ENTER.

3.4 Rectangular weir

Select this menu for rectangular weirs with and without

side contraction.

3.4.1 With or without contraction

Select if the weir has a contraction or not.

See also page 9.

α between 22,5 and 120 degrees

3.5.2 Select decimal point for the flow values

Select the decimal point and 10/100/1000 multiplier for

the flow points between

X.XXXX and XXXXX000

with the arrow keys and confirm with ENTER.

3.5.3 Linearization height value

Set the level [h] for a Q(h) point with the arrow keys and

confirm with ENTER. The level unit will be the unit selected in menu 1.4.

Note: Always start with the lowest value, then the next

and so on until the largest value is reached. The height 0

has a default flow of 0. The highest Q(h)-point automatically gives the measuring range.

The level value can be set within the level span.

3.5.4 Linearization flow value

Set the volume [Q] for the corresponding Q(h)-point with

the arrow keys and confirm with ENTER. The volume

MUST be greater than the value previously entered. The

volume unit will be the unit selected in menu 1.6.

3.6 Optional formula

This menu is used for entering the coefficient K and expo-

X

nent

in the basic flow formula Q(h) = K x hX.

Q is the flow in the chosen flow unit, h presents the level

in the chosen measurement unit, K is a factor between

0.000,01 and 6,500,000 and x is the exponent between

1 and 3.

3.6.1 Optional formula - enter exponent

Set the exponent

x

for the flow calculation formula with

the arrow keys and confirm with ENTER. Double arrow

changes the value fast and single arrow changes the

value slowly.

3.4.2 Rectangular weir crest width

Set the width b (see page 9) of the weir and confirm with

ENTER.

3.5 Q(h) linearization

This menu is used for entering a customized Q(h) linearization based on up to 10 linearizatioin points.

3.5.1 Number of Q(h) points

Enter the number (from 1 to 10) of Q(h)-points for the linearization with the arrow keys and confirm with ENTER.

The selected number of Q(h) points decides how many

times the menus 3.5.3 to 3.5.4 will appear.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

3.6.2 Select decimal point for coefficient

Select the decimal point / leading zero for the coeficient

for the flow formula. Select between

0.XXXXX and XXXXX

with the arrow keys and confirm with ENTER.

3.6.3 Optional formula - enter coefficient

Set the factor K with the arrow keys an confirm with ENTER. The factor can be set within 0.00001 to 6,500,000.

24

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 25

Manual

3.7 Flow range / level range

This menu is mainly used to set the span of the mA output in relation to the calculated flow, but can also be used

to check the flow calculation in relation to the measured

level based on the formula for the

selected primary device / flow calculation.

Simply enter the flow with the arrow keys and press ENTER, and MJK 713 calculates the corres-ponding level.

The mA output span is set by entering the flow value

where the mA output should give out 20 mA.

An example: If a 12” Palmer & Bowlus flume is

selected as primary device, the nominal maximum flow

will be 881 GPM at a level of 9.1 in.

If the flow range value is set to 881 in this menu, MJK

713 calculates the level, the mA output will give out 20

mA at max. nominal flow and 4 / 0 mA at zero flow.

If the flow range value is changed to 400 GPM, the mA

output will give out 20 mA at 400 GPM and upwards and

4 / 0 mA at zero flow.

4.0 Set digital output parameters

Press ENTER for configuring digital outputs or press

MENU for MAIN MENU

4.1 Select digital outputs (1-5)

Configuring of the five digital outputs. Select with the arrow keys which digital output to program, confirm with

ENTER.

Digital output 5 (DO5) is output for an external counter.

4.2 Select function for DO

For digital output 1-4 select with arrow keys between

various functions: counter output, sampler, flow > 0%,

flow high, flow low and alarm sensor error. The choice is

confirmed with ENTER.

Counter output: After a preset quantity the output is

activated to trig an external counter.

Sampler: After a preset quantity the output is

activated to trig a sampling device or a

chemical dosing device.

Flow > 0%: Signal to indicate that the flow is greater

than 0 is applied, i.e. when measuring

emergency stormflow.

Flow rate high: Activated if flow exceeds a given flow

rate.

Flow rate low: Activated if flow drops below a given flow

rate.

Sensor error: Activated at sensor error. Factory default

is 5 minutes without an approved sensor

signal.

Output disabled: Output not used.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

4.3 Alarm flow rate low

The limit for flow low is keyed in using the arrow keys.

The span is 0 - 90 % of max. flow.

4.4 Alarm flow rate high

The limit for high flow is keyed in using the arrow keys.

The span is 10 - 100 % of max. flow.

4.5 Set volume between pulses

The volume that passes between each time a pulse is

sent to a DO is keyed in. The interval between the pulses

is limited to min. 1 sec.

4.6 Digital output ON-time

The ON time for the DO is keyed inusing the arrow keys.

Double arrow changes the value fast with 1 sec. jumps.

Single arrow changes the value slowly with 0.1 sec.

jumps. The range is 0.1 - 30 sec.

25

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 26

Manual

4.7 Choose delay on signal

The time limit for an alarm must be exceeded before a

DO is activated.

The format is as follows - min:ss The maximum delay is

99 minutes and 59 seconds.

4.8 Digital output NC/NO

The relay function for digital output is keyed in, as Normally Open (NO) or Normally Closed (NC). Select with arrow keys, confirm with ENTER.

5.0 Analog output 0-20 / 4-20 mA

Select between 0-20 or 4-20 mA output. Select with arrow keys, confirm with ENTER.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

26

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 27

Manual

Menu chart

Indication menus Configuration menus

Flow rate key

Press 1 X: Average flow rate 1 hr

Press 2 X: Average flow rate today

Press 3 X: Average flow rate 24 hr

Totalizer key

Press 1 X: Totalizer 1 hr

Press 2 X: Totalizer today

Press 3 X: Totalizer last 24 hr

In the last selection the

totalizer values for the last 99

days can be displayed using

the arrow keys.

Alarm key

Press 1 X for alarm list with

last 9 alarm log.

Toggle alarms

with arrow keys.

Sampler key

Press 1 X: Total number of samples

Press 2 X: Number of samples today

Press 3 X: Number of samples last 24 hr

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

27

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 28

Manual

Configuration menus

1.0

1.1

1.2

1.3

1.4

1.5

1.6

2.0 3.0

2.1.1

2.1.2

2.2

3.1 3.2 3.3

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

28

3.7

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 29

Manual

Configuration menus

4.0 5.0

4.1

4.2

4.5

4.6

3.4 3.5 3.6

4.3

4.4

4.7

4.8

3.4.1 3.5.1 3.6.1

3.4.2 3.5.2 3.6.2

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

3.5.3 3.6.3

3.5.4

29

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 30

Manual

Appendix A

Factory settings

Basic parameters: Factory setting: Current settings:

Access Code: Disabled (Code: 1111)

Measurement Level: Inches

Measurement Volume: Gallons

Measurement Flow: MGD

Sensor distance: 30 in / 54 in*

Averaging of Level: 1 sec.

Range for flow: 1,000 MGD / 10.00 MGD*

Flow Calculations

Parshall Flume: 6’’ range (10 in):

Palmer & Bowlus Flume: 10’’ range (10 in):

V-notch: 90 °

Rectangular Crest width = 10.00 in

Optional Formula: Exponent = 1.000,

Factor= 0.100

Digital output

DO1: Disabled

(On-time = 0.5 sec)

DO2: Disabled

(On-time = 0.5 sec)

DO3: Disabled

(On-time = 0.5 sec)

DO4: Disabled

(On-time = 0.5 sec)

DO5: Counter 10.000/100.000 GAL*

On-time = 0.5 sec

Analog output

AO: 4 - 20 mA

* Depending on measuring range.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

30

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 31

NOITACIDNI KCEHC YDEMER/ESUAC

siyalpsidehT

tilton

ylppusrewoP gnitnuomeriW ylmrifdaelehtdnadevomernoitalusniehtfoni¼muminimerA

?detnuom

ylppusrewoP '0'dekramslanimretneewtebtneserpegatloveviltcerrocehtsI

?'P'dna

?tcatni)CAV511@Am002(esufyramirpUSPehtsI

dnalenaptnorfehtmorfswercsgniniaterruofehtevomeR

edisdnahtfelehtnodetacolsiesufehT.lenaptnorfehtevomer

.yrassecenfiegnahcxE.BCPrewolehtnoremrofsnartehtwoleb

317 setacid

ni

rorremetsys

ecafrusdiuqiL htgnertslangiS ?ymaofecafrusdiuqilehtsI

ehtgninrutyblangiscinosartluehtfohtgnertsehtgnisaercniyrT

.esiwkcolcretemoitnetop'niaG'

dnalenaptnorfehtmorfswercsgniniaterruofehtevomeR

rewolehtnodetacolsiretemoitnetopehT.lenaptnorfehtevomer

.Dxidneppaees-BCP

gnigarevaleveL ?ydaetsnuecafrusdiuqilehtsI

.2.2noitcesees-gnigarevalevelrofgnittesehtgnisaercniyrT

elttuhS

®

cinosartlU

-rosneS

erusserP

rett

imsnarT

gnitnuomeriW noitcennoceeS?slanimrettcerrocehtotdetcennocseriwehterA

.margaid

snoisnetxeelbaC ?snoitcennocehtniretawerehtsI

.htgneldnaepytelbackcehC?yltcerrocedamsnoisnetxeehterA

nehwxobnoitcennocssofnaDaesuotdednemoccersitI

.selbacgnidnetxe

elttuhS

®

cinosartlU

rosneS

noitidnoC ?dekcarcroderuolocsimrosnesehtfotrapkcalbehtsI

ehtrofdetiustonsirosnesehttahtsetacidnigniruolocsiM

.etisnoitallatsniehtnotnemnori

vne

noitcnuF sirosneseht,tonfI?sdnuosgnikcilcgnittimsnartrosnesehtsI

.ytluaf

gnitnuomrosneS ?LACITREVYLETULOSBAdetnuomrosnesehtsI

anidetnuomylmrifsirosnesehttahttnatropmiylemertxesitI

elttuhSfognitnuomlacinahceM'noitceseeS.noitisoplacitrev

®

.'rosneScinosartlU

ecnatsidgnirusaeM 61nahteromsiecnatsidgnirusaemehtosdetnuomrosnesehtsI

?tf3/tf1nahtsseldnani

ebtontsumegnargnirusaemmuminim/mumixamehT

.dedeecxe

tuo-daerle

veL

tonsi

gnignahc

elttuhS

®

cinosartlU

rosneS

gnitnuomrosneS ?LACITREVYLETULOSBAdetnuomrosnesehtsI

anidetnuomylmrifsirosnesehttahttnatropmiylemertxesitI

elttuhSfognitnuomlacinahceM'noitceseeS.noitisoplacitrev

®

.'rosneScinosartlU

etisnoitallatsnI rehtorosnoitalumuccayttafgib.ge(noitcurtsbonaerehtsI

?langiscinosartluehtgnibrutsid)stcejbo

tuo-daerleveL

gnorwsi

elttuhS

®

cinosartlU

rosneS

gnitnuomrosneS ?LACITREVYLETULOSBAd

etnuomrosnesehtsI

anidetnuomylmrifsirosnesehttahttnatropmiylemertxesitI

fognitnuomlacinahceM'noitceseeS.noitisoplacitrev

elttuhS

®

.'rosneScinosartlU

elbaC epytelbacdevorppa-nonahtiwdednetxeelbacrosnesehtsI

?tf051dnoyebdednetxero/dna

Manual

Appendix B

Trouble shooting

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

31

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 32

Manual

5.31

1.26

Dia.1.97

MNPT

Appendix C

Technical specifications

Ultrasonic Sensor - one year warranty

Measuring range: 0 - 1 ft., 0 - 3 ft., 0 - 10 ft.

Frequency: 30 / 75 kHz

Beam angle: 3 / 7 °

Temperature range: - 5 to + 150 °F

Accuracy: ± 0.04 "

Deadband: 14 "

Dimensions: Dia. 4.06 ", height 4.17 "

Materials: VALOX (reg. tm of General Electric Co.)

Cable: Shielded, oil resistant PUR insulation, length 39 ft.

Can be extended to 150 ft. using MJK 690010 cable.

Enclosure: NEMA 6P, waterproof, withstands submersion up to 30 ft.

Approvals: FM Class 1 Division 1 Groups A-G

CE EN50081-1, EN50082-1

Model 3400 Hydrostatic Level Transmitter - 1 year warranty

Temperature range: 15 … 160 °F

Temp. deviation, zero point: Better than ± 0.01 % / °F

Temp. deviation, full range: Better than ± 0.005 % / °F

Linearity / Stability: Better than ± 0.5 % FS

Measurement accuracy: Better than ± 0.1 % FS @ 50 to 85 °F

Better than ± 0.2 % FS @ full temperature range.

Long time stability: Better than ± 0.1% FS per year

Material:

Diaphragm: 99.9 % Al2O3

Measurement cell packing: Viton

Supply voltage: 10 - 30 V DC (12 - 30 V DC for cable lengths above 315 ft.)

Output: Two-wire 4 - 20 mA (passive transmitter)

Cable: 2 × AWG 20, shielded, oil resistant PUR insulation

Cable length: 39 ft. Longer cable lengths available, consult the factory.

Enclosure: NEMA 6P,

withstands a static pressure equal to max. measuring range.

Approvals: UL

CE EN50081-1, EN50082-1

Can be delivered with other cable lengths on request.

Housing: PPS

®

®

Class 1 Division 1 Groups A-D and ATEX Ex ia IIC T6

713 Series Open Channel Flowmeter

Measuring ranges: 0 - 1 ft., 0 - 3 ft., 0 - 10 ft. or custom ranges

Dimensions: Height 7.28 “, width 9.45 “, depth 4.53 “

Power supply: 110 - 120 V AC, power consumption max. 10 W

Temperature range: - 5 to + 150 °F

Accuracy: 0.2 % of adjusted range

Materials: Polystyrene (housing and cover)

Enclosure: NEMA 4X

Input signal: Either from ultrasonic sensor or from hydrostatic level

transmitter

or other (0)4 - 20 mA signal.

Digital outputs: Terminal 6 - 17: relay no. 1-4, max. 250 V, max. 4

Terminal 19 - 20: Totalizer output (optocoupler),

Analog output: Terminal 21 - 22: (0)4-20 mA, max. 500 ohm loop

Calculation: Standard formulas according to ASTM standards and

US Department of the Interior.

Optional formula Q = C × h

10 point level to flow curve linearization.

Indication 2 × 24 character backlit LCD display for reading and

calibration.

Approvals: UL-cUL listed*,

file # 194021 UL 508/c22: 2 No. 142-M1987

Warranty: 1-year limited warranty

A resistive / max. 100 W inductive

load. Selectable as alarm, counter,

flow > 0 or sampler output.

max. 36 V AC/DC, 50 mA, one

shot,

programmable from 100 ms to

10 s.

resistance, galvanically isolated.

x

or

Dimensions and accessories

MJK 713

Flowmeter

Universal bracket

(order no. 200205)

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

Sensor bracket, short

(order no. 200219)

Sensor bracket, standard

(order no. 200220)

32

®

Shuttle

Ultrasonic Sensor

3.78 “

MJK 3400

Level Transmitter

Flume mounting bracket

(Max. width 21.7 in: order no. 202020 /

max. width 37.4 in: order no. 202021).

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 33

Manual

Appendix D

Hardware adjustments

Pressure measuring circuit

MJK 713 is factory adjusted to general applications. If

parts are replaced or at special applications a secondary

adjustment might be necessary. Below is shown which

adjustments might be necessary to carry out ”in field”.

Ultrasonic measuring circuit

GAIN

MAX

MIN

RANGE

RESP.

FAST SLOW

Gain:

With this potentiometer the signal strength of the received

signal can be adjusted. The potentiometer is normally set

in center position. At applications where there are disturbances close to the spread range of the sensor it might

be necessary to reduce the signal strength. E.g. small

Palmer & Bowlus flumes or when measuring is carried out

through a pipe.

In other cases where e.g. the surface is unsteady or

there are occurrences of foam, it might be necessary to

increase the signal strength. To reduce turn counterclockwise and to increase turn clockwise.

Resp. (Response):

If the surface is very unsteady the level measuring itself

can be dampened with the potentiometer.

Range:

The range of the potentiometer adjusts the level measuring itself. To carry out an adjustment, measure the distance between the 0-point and the bottom of the sensor

and check the setting in menu no. 0.1.

Adjust then the current level and the range of the potentiometer is adjusted to correct display in menu no. 0.1.

The rest of the potentiometers requires special measuring

equipment and should therefore only be adjusted by an

authorized workshop.

SLOW

RESP.

FAST

SPAN

ZERO

Resp. (Response):

If the surface is very unsteady the level measuring itself

can be dampened with the potentiometer.

Span:

The span potentiometer is adjusted to correct level measuring at high level.

Zero:

The span potentiometer is adjusted to correct measuring

at low level.

Control circuit

MINMAX

CONTRAST

ICI5

The control circuit is placed behind the front plate. The

display can be adjusted satisfying display here. The contrast will automatically be adjusted according to the surrounding temperature.

Changing the EPROM:

If the MJK 713 program should be replaced you must follow these instructions:

1: Turn off the power.

2: Remove the top lid.

3: Remove the EPROM (ICI5).

4: Insert the new EPROM. The notch must face

upwards as shown on the PC board. Be careful not

to damage the EPROM.

5: Replace the top lid again and turn on the power.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

33

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 34

Manual

Appendix E

System Package 2 - Shuttle

®

used as

signal amplifier

To ensure a correct flow measurement when using

a Shuttle

Shuttle

®

as signal amplifier, the mA signal from the

®

must correspond to the selected level range on

the MJK 713. Four parameters must therefore be set on

the Shuttle

®

: the measuring unit, the zero point, the level

range and the mA output zero/span.

The keyboard is used for the initial programming of the

®

Shuttle

and is therefore hidden behind the front lid. The

keys are marked with symbols indicating their function.

Display

LCD-display with

symbols for indication

during programming

and normal service.

Setting of measuring unit

The measuring unit should be set to the same unit as

used on the MJK 713.

Press

(UNIT) once.

Select the measuring unit with the UP/DOWN keys and

confirm with ENTER.

Setting of level readout

The level readout should be set to the actual level in the

flume / weir.

Keyboard

Keyboard with a

brief instruction for

programming the

SONOLEV™.

The lower part can be

tipped up to show the

terminal designations.

When Shuttle® is connected to the power supply for the

first time, the following display will appear:

Press (ENTER) once.

At the same moment Shuttle

®

registers an echo, the

zero point is automatically adjusted to the level that is

present in the flume or weir.

Furthermore, the mA output is set to 4 mA at the current

zero point and 20 mA at a level corresponding to a distance of 14 in from the ultrasonic sensor.

Bottom of sensor

e.g. 4 ft.

Actual level (0.5 ft)

Press again.

Use the UP/DOWN keys and confirm with ENTER.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

34

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 35

Manual

Setting of zero and span for the mA output

The mA output must be set to 4 mA at zero level (0.00 ft)

and 20 mA at max. level (= the max.

measuring range for MJK 713 - either 1 or 3 ft).

Max. flow level

20 mA out

Press once.

Zero flow level

4 mA out

Setting of relay output #1

If the mA output is looped through relay 1 as shown on

the connection diagram on page 14 (System Package 2),

MJK 713 will indicate a system error in case of a power

failure or a a system error on the Shuttle

Press

once.

®

:

Use the UP/DOWN keys to select SYSTEM ERROR function and confirm with ENTER:

Use the UP/DOWN keys to set the zero point and confirm

with ENTER.

The mA output must be set to 20 mA at max. level

(1 or 3 ft).

Press

again.

Use the UP/DOWN keys to set the span and confirm with

ENTER.

Set the desired time delay for the relay:

Use the arrow keys and comfirm with ENTER.

Set the relay mode to ‘n.c’ - NORMALLY CLOSED (‘n.c =

normally closed):

Use the arrow keys and comfirm with ENTER.

®

Shuttle

will now revert to normal read-out:

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

35

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 36

Manual

When the level starts to rise, Shuttle® will also

indicate the level of the mA output with the bar graph.

One segment is roughly 1 mA.

Mount the lid when all settings are made.

See also separate SONOLEV™ 3000 manual.

Note: The MJK 713 analog input must be set to 4-20

mA (factory default).

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

36

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 37

Manual

Appendix F

Max. head to max. nominal flow

Parshall flumes, 1 to 144 in

Dimension: Max. head: (Max. nominal flow)

[ft] [CFS]

1” Parshall 0,70 0,195

2” Parshall 0,80 0,478

3” Parshall 1,10 1,15

6” Parshall 1,50 3,91

9” Parshall 2,00 8,87

12” Parshall 2,50 16,13

18” Parshall 2,50 24,56

24” Parshall 2,50 33,11

36” Parshall 2,50 50,39

48” Parshall 2,50 67,93

60” Parshall 2,50 85,62

72” Parshall 2,50 103,5

96” Parshall 2,50 139,5

120” Parshall 2,75 198,7

144” Parshall 3,50 347,0

Rectangular weirs with side contractions

Dimension: Max. head: (Max. nominal flow)

[ft] [CFS]

1 ft w. contraction 0,50 1,060

1½ ft w. contraction 0,75 2,920

2 ft ft w. contraction 1,00 5,994

2½ ft w. contraction 1,25 10,47

3 ft w. contraction 1,50 16,52

4 ft w. contraction 2,00 33,91

5 ft w. contraction 2,50 59,23

6 ft w. contraction 3,00 93,44

8 ft w. contraction 4,00 191,8

10 ft w. contraction 5,00 335,1

Palmer & Bowlus flumes, 4 to 30 in

Dimension: Max. head: (Max. nominal flow)

[ft] [CFS]

4” P&B 0,25 0,121

6” P&B 0,35 0,295

8” P&B 0,50 0,690

10” P&B 0,60 1,119

12” P&B 0,70 1,676

15” P&B 0,90 3,086

18” P&B 1,05 4,614

21” P&B 1,25 7,042

24” P&B 1,40 9,464

27” P&B 1,60 13,09

30” P&B 1,75 16,52

The values stated are valid only for contractions constructed

with the minimum dimensions as shown in above figure.

Rectangular weirs without side contractions

Dimension: Max. head: (Max. nominal flow)

[ft] [CFS]

1 ft wo. contraction 0,50 1,177

1½ ft wo. contraction 0,75 3,244

2 ft wo. contraction 1,00 6,660

2½ ft wo. contraction 1,25 11,63

3 ft wo. contraction 1,50 18,35

4 ft wo. contraction 2,00 37,67

5 ft wo. contraction 2,50 65,81

6 ft wo. contraction 3,00 103,8

8 ft wo. contraction 4,00 213,1

10 ft wo. contraction 5,00 372,3

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

The values stated are valid only for contractions constructed

with the minimum dimensions as shown in above figure.

37

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 38

Manual

V-notch weirs

Dimension: Max. head: (Max. nominal flow)

[ft] [CFS]

22,5° V-notch 2,00 2,811

30° V-notch 2,00 3,824

45° V-notch 2,00 5,855

60° V-notch 2,00 8,163

90° V-notch 2,00 14,14

120° V-notch 2,00 24,49

The values stated are valid only for contractions constructed

with the minimum dimensions as shown in above figure.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

38

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 39

Manual

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

39

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Page 40

Manual

Liability

MJK Automation A/S are liable to the common rules of Danish

law on product liability, however, the liability is reduced to

coverage of our public liability insurance of products. To the

extent where nothing else follows in lines of invariable rules of

law, we are not liable for loss of profits and working deficits or

other indirect losses.

Changes

As our products are developed continuously, we reserve the

right to make any alterations without prior notice.

US 3.10 713 FLOW CONVERTER 1210 - SW 833062

40

MJK North America, Inc.

37 Sherwood Terrace, #126

Lake Bluff, Il 60044

Tel.: 847-482-8655

Fax: 847-482-8654

mjkusa@mjk.com

www.mjk.com

Loading...

Loading...