Page 1

Electromagnetic Flow Meter

Electromagnetic Flow Meter

Installation and User Manual

1EN 3.05 MagFlux Manual 1212

FW: 842018/842009

Page 2

Electromagnetic Flow Meter

Declaration of Conformity

Konformitetserklæring

Vi, MJK Automation A/S,

DK-2850 Nærum, påtager os

det fulde ansvar for at produktet

Declaration of Conformity

We, MJK Automation A/S,

DK-2850 Nærum, declare under

our sole responsibility that the

product

Electromagnetic Flowmeter

som denne erklæring angår,

er i overensstemmelse med

følgende standard(er) eller andre

normdokument(er).

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

efter bestemmelserne i

direktiv

89/336/EEC; 92/31/EEC

Declaration de conformite

Nous, MJK Automation A/S,

DK-2850 Nærum, déclarons

sous notre seule responsabilité

que le produit

to which this declaration relates

is in conformity with the following

standard(s) or other normative

document(s).

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

following the provisions of

Directive

89/336/EEC; 92/31/EEC

Dichiarazione di conformità

Noi, MJK Automation A/S,

DK-2850 Nærum, dichiariamo

sotto la nostra esclusiva responsabilità che l’apparecchio

Konformitätserklärung

Wir, MJK Automation A/S,

DK-2850 Nærum, erklären in

alleiniger Verantwortung, dass

das Produkt

auf das sich diese Erklärung

bezieht mit der/den folgenden

Nor me(en) oder normativen

Dokument(en) übereinstimmt.

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

Gemäss den Bestimmungen der

Richtlinie

89/336/EEC; 92/31/EEC

Declaración de Conformidad

Nosotros, MJK Automation A/S,

DK-2850 Nærum, declaramos

bajo nuestra única responsabilidad que el producto

Electromagnetic Flowmeter

auquel se réfère cette déclaration est conforme á la (aux)

norme(s) ou autre(s) document(s)

normatif(s)

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

conformément aux dispositions

de Directive

89/336/EEC; 92/31/EEC

al quale questa dichiarazione si

riferisce, è conforme alla seguente normativa(e) standard o ad

altri documenti di normativa(e)

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

conformemente alla disposizioni

della Direzione

89/336/EEC; 92/31/EEC

21.11.2006

Jens Kruse

2EN 3.05 MagFlux Manual 1212

al cual se refiere esta declaración, está en conformidad

con la(s) siguente(e) norma(s) u

otros documentos normativos

EN61000-6-3/-4:2001,

EN61000-6-1/-2:1999

según las disposiciones de la(s)

directiva(s)

89/336/EEC; 92/31/EEC

Page 3

Electromagnetic Flow Meter

Table of Contents

1. Introduction 7

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

The MagFlux

®

Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Safety, Repair and Product Identification 13

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Physical Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Flow Sensor 15

Minimum conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Liner selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Electrode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Sizing Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pipe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cabinet Mounted on the Flow Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Potential Equalization and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Type 7100/7200/7600 in Conductive Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Type 7100/7200/7600 in Non-conductive Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Type 7300/7400 in Conductive Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Type 7300/7400 in Non-conductive Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4. Flow Converter 25

Electrical Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Changing the Power Supply Voltage 230/115 V AC . . . . . . . . . . . . . . . . . . . . . . . . .27

Analogue Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Local (compact) Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Remote Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Converter Connection Board - Local . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Converter Connection Board - Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5. System Configuration Examples 33

Compact Converter and Display Unit on Flow Sensor. . . . . . . . . . . . . . . . . . . . . . . .33

Remote Converter with Connection Box on Flow Sensor . . . . . . . . . . . . . . . . . . . . . .34

Wiring Schematic #1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3

FW: 842018/842009

Page 4

Electromagnetic Flow Meter

Remote Display and Multiple Converters Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Wiring Schematic #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6. Startup 39

Initial Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Initial Flow Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flow Direction Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Display Read-out, one connected unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Display Read-out, several connected units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Display Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7. MagFlux Menus 47

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Specify Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Data Logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Graph Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Set Sensor Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Converter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Minimum Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

mA Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Flow Forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Flow Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Forward & Rev. (12mA=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Forward & rev. (4mA=0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Not in use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Settings and Limits for Resettable Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Resettable Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Resettable Forward Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Resettable Reverse Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Resettable Sum Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Non-Resettable Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

NR Forward Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

NR Reverse Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

NR Sum Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Batch Counters 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Settings and Limits for Batch Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

High Flow/Low Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Flow Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Empty Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

4EN 3.05 MagFlux Manual 1212

Page 5

Electromagnetic Flow Meter

24h Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Set Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Display SW Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8. Mechanical Dimensions 101

Standard Flanges - EN-1092-1:2001 - Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Standard Flanges - ANSI B 16.5 - U.S.A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Standard Flanges - AS-4087-2004 - Australia . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Standard Flanges - AS-4087-2004 (cont'd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Standard Flanges - AS-4087-2004 (cont'd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix A. Pop-up and Error Messages 107

Appendix B. MJK-Field Link Software 111

Appendix C. FAQs - Frequently Asked Questions 115

Appendix D. Front Panel Cut-out Drawing 118

Appendix E. Test Certificate 119

Appendix F. Log Files 120

Appendix G. Digital Input/Output Connections 123

Appendix H. Remote Slave Display Unit 124

Connection Board - with a remote "slave" display unit . . . . . . . . . . . . . . . . . . . . . .124

Converter Connection Board - with a "master" display unit . . . . . . . . . . . . . . . . . . . 125

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Configuration for the master unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Configuration for the slave unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

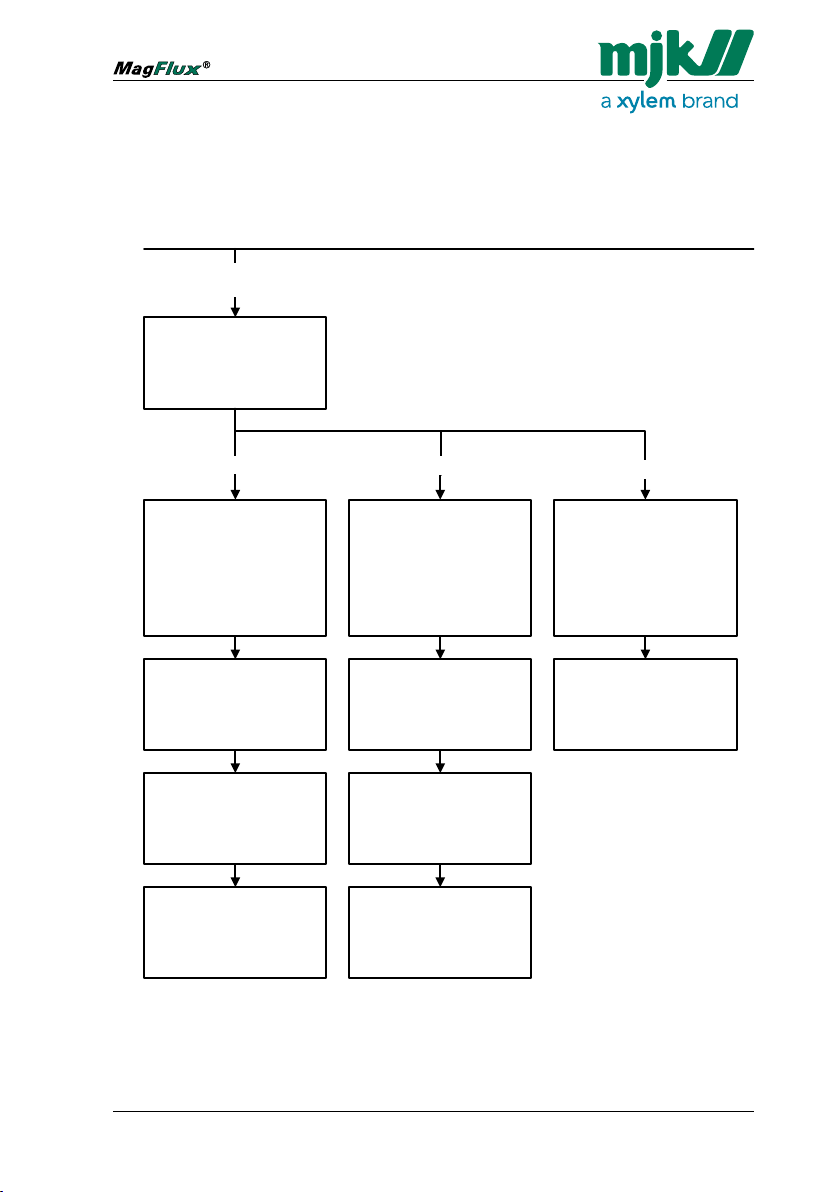

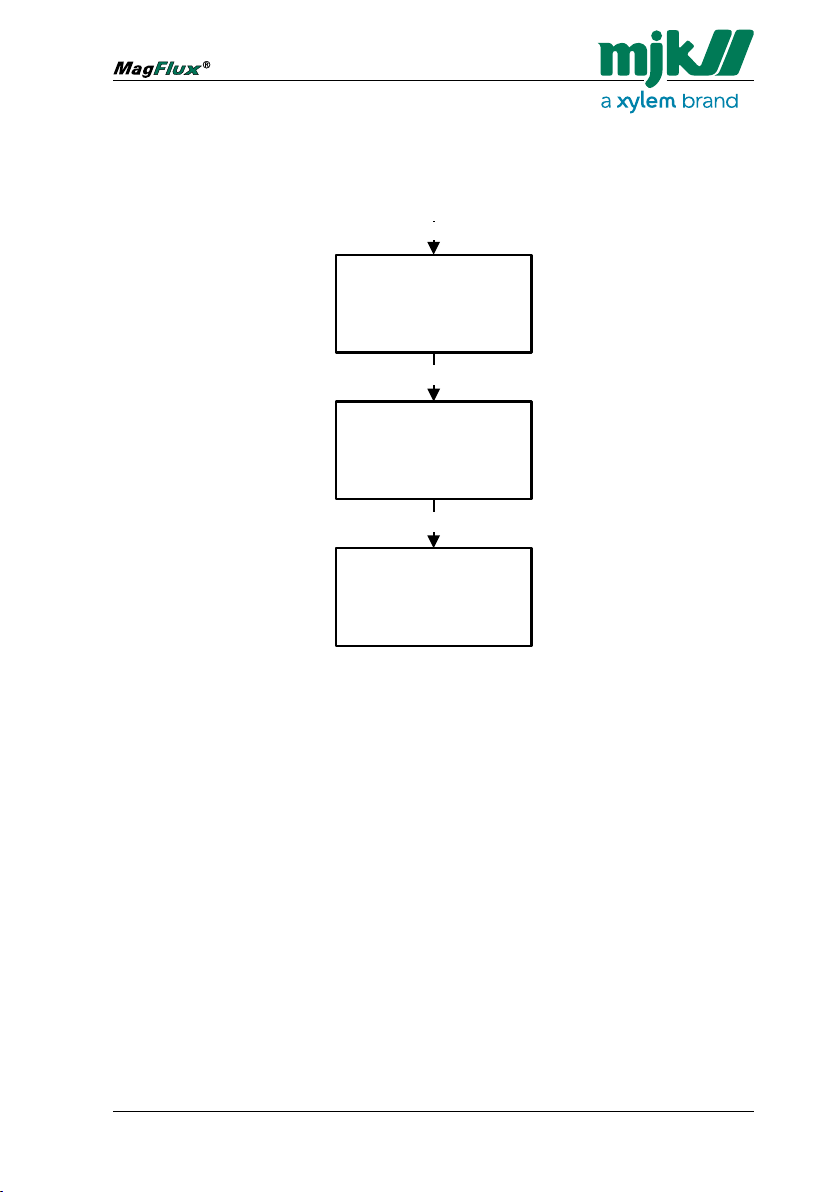

Main Menu Overview 126

Converter Setup Menu Overview 128

Service Menu Overview 138

Display Setup Menu Overview 142

5

FW: 842018/842009

Page 6

Electromagnetic Flow Meter

6EN 3.05 MagFlux Manual 1212

Page 7

Electromagnetic Flow Meter

1. Introduction

Thank you for choosing the MJK MagFlux® electromagnetic flow meter.

We have done our utmost to design and manufacture a flow meter that

satisfies your requirements.

The MagFlux® is suitable for flow measurement in all kinds of conductive fluids, and it is especially suited for flow measurement of water, waste

water, sludge and other fluids containing particles.

The flow meter is easy to install and put into service. However, read this

manual first to learn about the MagFlux® electromagnetic flow meter and

all its features.

You can always contact your local representative or the MJK hot lines for

advice and guidance:

• Europe Tel.: +45 45 56 06 56 E-mail: mjk@mjk.com

• Denmark Tel.: +45 45 56 06 56 E-mail: mjk@mjk.dk

• Norway Tel.: +47 69 20 60 70 E-mail: mjk@mjk.no

• Sweden Tel.: +46 53 31 77 50 E-mail: kontoret@mjk.se

• Holland Tel.: +31 251 672171 E-mail: mjknl@mjk.com

• USA Tel.: +1 847 482 8655 E-mail: mjkusa@mjk.com

• Australia Tel.: +61 3 9758 8533 E-mail: mjkaus@mjk.com

Visit our web sites at www.magflux.dk and www.mjk.com to learn more

about MJK Automation, our other products and the people behind them.

MagFlux

®

is a registered trademark of MJK Automation A/S, Denmark.

Trademarks & acknowledgements

Mµ Connect, Connect, MagFlux, Chatter, SuSix, Oxix, pHix and Shuttle

are ® registered trademarks of MJK Automation A/S, Denmark.

Expert and Instrument Link are ™ trademarks of MJK Automation A/S,

Denmark.

VLT® is a registered trademark of Danfoss A/S.

All other trademarks are the property of their respective owners.

MJK Automation A/S is a Xylem Brand.

7

FW: 842018/842009

Page 8

Electromagnetic Flow Meter

About this Manual

The manual is divided into a table of contents, eight chapters, seven appendices and an index.

1. Introduction

Contains a presentation of the MJK MagFlux

meter, the structure of this manual and the operating principles.

2. Safety, Repair and Product Identification

Provide answers to issues regarding safety, mounting, repair,

restrictions and product identification.

3. Flow Sensor

Describes the physical specifications and installation guidelines for the

flow sensor such as liner and electrode selection, example pipe

systems, sizing chart, etc.

4. Flow Converter

Describes the physical specifications and installation rules for the flow

converter such as power supply, in- and outputs, sensor/converter/

display configurations, etc.

5. System Configuration Examples

Illustrates how MagFlux

®

sensors, converters and display units can be

interconnected in real-life scenarios.

®

electromagnetic flow

6. Startup

Describes important checks and basic settings to get started including

the display and keyboard user interface.

7. MagFlux Menus

Contains a comprehensive description of the MagFlux

®

menus,

options and utilities.

8. Mechanical Dimensions

Lists the flange and sensor dimensions and specifications.

* * * * *

8EN 3.05 MagFlux Manual 1212

Page 9

Electromagnetic Flow Meter

Appendix A. Pop-up Events / Error Messages

Lists possible pop-up messages, explains their meaning and offer

solutions to error conditions.

Appendix B. MJK-Field Link Software Upgrade

Describes in detail how to utilise the unique and intuitive MJK-Field Link

software program to upload new display and converter firmware

versions.

Appendix C. FAQs - Frequently Asked Questions

Contains answers to questions that are often asked.

Appendix D. Front Panel Cut-out Drawing

A 1:1 scale drawing of the front panel outline and cut-out area for

installation and mounting purposes.

Appendix E. Test Certificate

Shows an example test certificate which is part of MagFlux

shipments.

Appendix F. Log Files

An example log file illustrates the format and explains the entries.

Appendix G. Digital Input/Output Connections

Illustrates how the digital in- and outputs can be interconnected.

®

* * * * *

Main Menu Overview

Is a continuous presentation of the main menu structure. The size of

this manual does not provide sufficient space for showing the complete

menu structure in one image.

Converter Setup Menu Overview

Is a continuous presentation of the converter setup menu structure.

Service Menu Overview

Is a continuous presentation of the service menu structure.

Display Setup Menu Overview

Is a continuous presentation of the display setup menu structure.

9

FW: 842018/842009

Page 10

Electromagnetic Flow Meter

Operating Principles

The electromagnetic flow meter is an instrument for measuring the flow

of conductive fluid using Faraday's electromagnetic induction law, and

consequently the fluid must be electrically conductive.

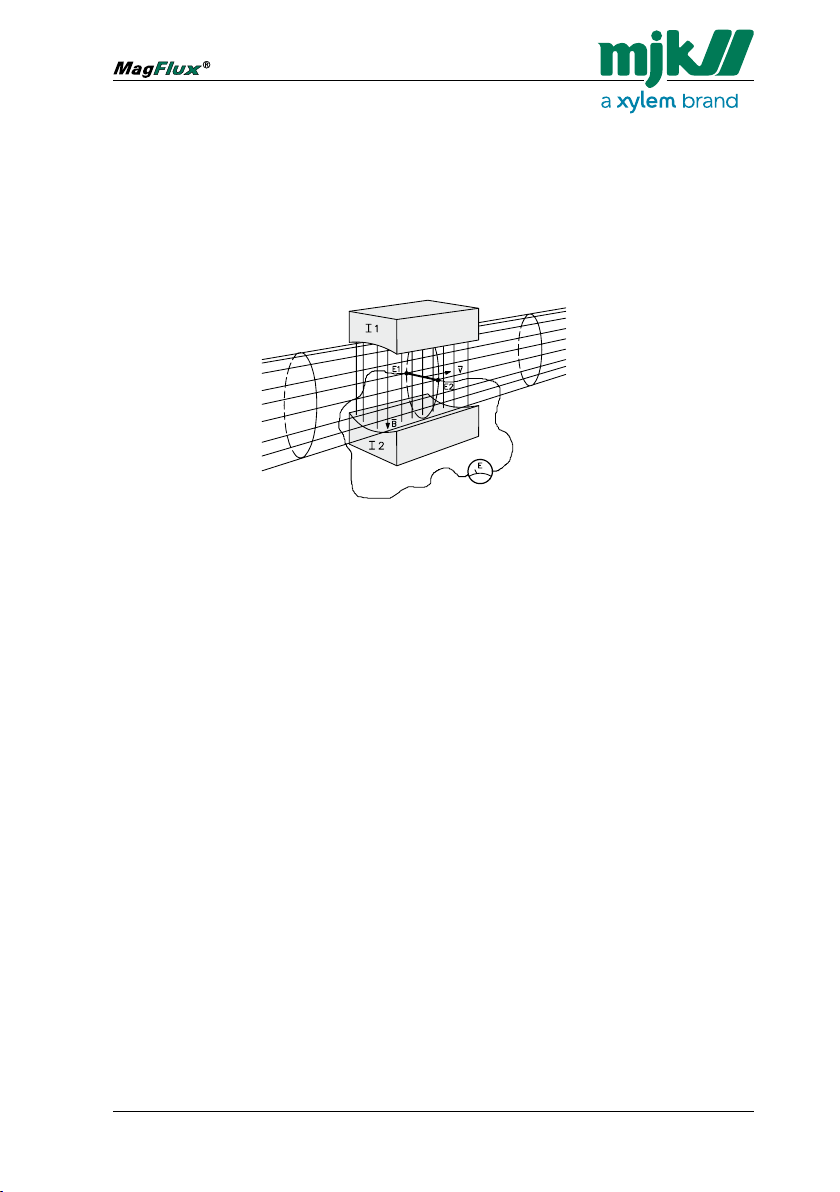

As illustrated below a magnetic field with density B - perpendicular to the

direction of flow - stretches across a fluid flowing within an electrically

isolated pipe.

The magnetic flux will induce a voltage difference (E) that can be measured

between two electrodes arranged perpendicular to the direction of flow

and the magnetic field. The voltage is proportional to the velocity (V) of the

fluid.

➀ E = B x D x V x k [Volt] where

E is the voltage that is induced between the two electrodes

B is the magnetic flux density

D is the distance between the two electrodes

V is the fluid velocity

k is a dimensionless constant

The flow of the fluid Q (m3/s) is given by the following formula:

➁ Q = π x D2 x V / 4 => V = 4 / (π x D2) where

π : is the constant pi (= 22/7)

D: is the internal diameter

V: is the fluid velocity

The combination of above formulas ➀ and ➁ gives the following formula:

E = K x B x D x Q x 4 / (π x D x D) = 4 K x B x Q / (π x D)

Evidently the voltage E is proportional to the actual flow.

10EN 3.05 MagFlux Manual 1212

Page 11

Electromagnetic Flow Meter

The MagFlux® Flow Meter

Measurement

Electromagnetic flow meters may have either direct current (DC) or alternating current (AC) excitation.

When systems are AC excited, electrostatic and/or electromagnetic noise

may influence the measurements. A DC excited system however, is less

sensitive to noise produced by electromagnetic induction, simply because the voltage induced over the electrodes will be a DC voltage. The

drawbacks are measurement errors due to electro-chemical polarization

between the electrodes and the fluid.

The MagFlux® electromagnetic flow meters are excited by a 2.5 Hz

square wave and thereby eliminate the drawbacks of both DC and AC

systems.

A microprocessor receives and measures the amplitude of the pulse with a

16-bit resolution, and converts and displays the result on the display unit.

Electrode Cleaning

Electrode cleaning is always in service to maintain clean and accurate

electrodes. The operating principle is a 55 Hz AC voltage superimposed

on the normal 2.5 Hz square wave. This step effectively reduces the risk

of a dirt layer build-up on the electrodes that eventually will deteriorate and

finally isolate electrical contact to the flow media.

11

FW: 842018/842009

Page 12

Electromagnetic Flow Meter

This page intentionally left blank.

12EN 3.05 MagFlux Manual 1212

Page 13

Electromagnetic Flow Meter

2. Safety, Repair and Product Identification

Safety instructions

1. Read this manual carefully.

2. Pay attention to the environment on the installation site.

3. Wear necessary protective equipment and follow all current safety

regulations.

4. The MagFlux

Always ensure that connected machinery and other equipment are

effectively put out of service (that is to remove the main fuses and lock

main and security switches in off-position) before commencing configuration, fault finding, servicing, maintenance work, etc.

5. WARNING: There is a risk of lethal, electrical shock from "Mains supply" terminals N and L. Be careful not to touch these terminals while

the MagFlux

Physical Mounting

The MagFlux® flow converter/flow meter must not be mounted in

explosion hazardous areas!

Repair

Repair must only be made by MJK or by a service representative approved by MJK.

®

can invoke a start signal for dangerous machinery.

®

is being serviced.

13

FW: 842018/842009

Page 14

Electromagnetic Flow Meter

Product Identification

A delivery will usually consist of a MagFlux® converter and a MagFlux®

flow sensor. Check that the item(s) delivered corresponds to the ordered

item(s). The part number and the calibration code are printed on an identification label sticked onto the flow converter shipping box and on a label

on the flow converter itself. The part number, the serial number, the calibration code and the electrode/lining data for the flow sensor are printed

on a green name plate (see example below).

This calibration code (Cal. code) is unique and provides the MagFlux®

converter with information about flow sensor number, nominal diameter of

the flow sensor and calibration data for the flow sensor.

The current converter firmware requires an 8-character input, but it also

accepts 6 characters plus two "Ok"s. The example above (dw5uq4) would

require that you enter: d w 5 u q 4 "Ok" "Ok", where "Ok" indicates that

you press the "Ok" key without selecting any character. Only small letters

can be entered from the MagFlux® keypad.

If changes are needed to the unique sensor calibration code following

initial setup, this is the calibration code that the "Sensor Calibration Code"

menu must contain (see pages 44 and 86).

14EN 3.05 MagFlux Manual 1212

Page 15

Electromagnetic Flow Meter

3. Flow Sensor

The following conditions must be satisfied to get the full benefit of the

MagFlux® flow sensor.

Minimum conductivity

• The conductivity of the media must be greater than 5 µS/cm.

Liner selection

• Use Teflon® lining for chemicals and food industries

• Use hard rubber lining for drinking water and waste water

• Use soft rubber lining for water with abrasive particles

Electrode selection

• Steel AISI 316TI-1.4571 for general purpose, sewage, water and district

heating systems

• Hastelloy for sea water

• Titanium and platinum for chlorine and other aggressive chemicals

Mounting location

• To obtain a stable and accurate flow measurement, it is very important

that the flow sensor is mounted correctly in the pipe system

• There must be no flow fluctuations

• Avoid locations where vacuum can occur; especially for flow sensors

with Teflon™ linings

• Avoid locations with vibrations from for example pumps

• Avoid locations with extensive temperature changes

• Avoid corrosive environments and locations with a great risk of condensation, or consult factory for special builds for these locations

• Take care that condensate and water cannot enter the connector box

on the flow sensor.

• There must be sufficient free space around the flow sensor.

• IMPORTANT: Observe that the correct flow direction is set in the

MagFlux

flow direction is "A" (flow direction towards left).

®

"Converter Setup" menu and in the "Service Menu". Default

15

FW: 842018/842009

Page 16

Electromagnetic Flow Meter

The flow directions A or B are clearly shown on the name plate. Default

flow direction is "A".

Pressure loss

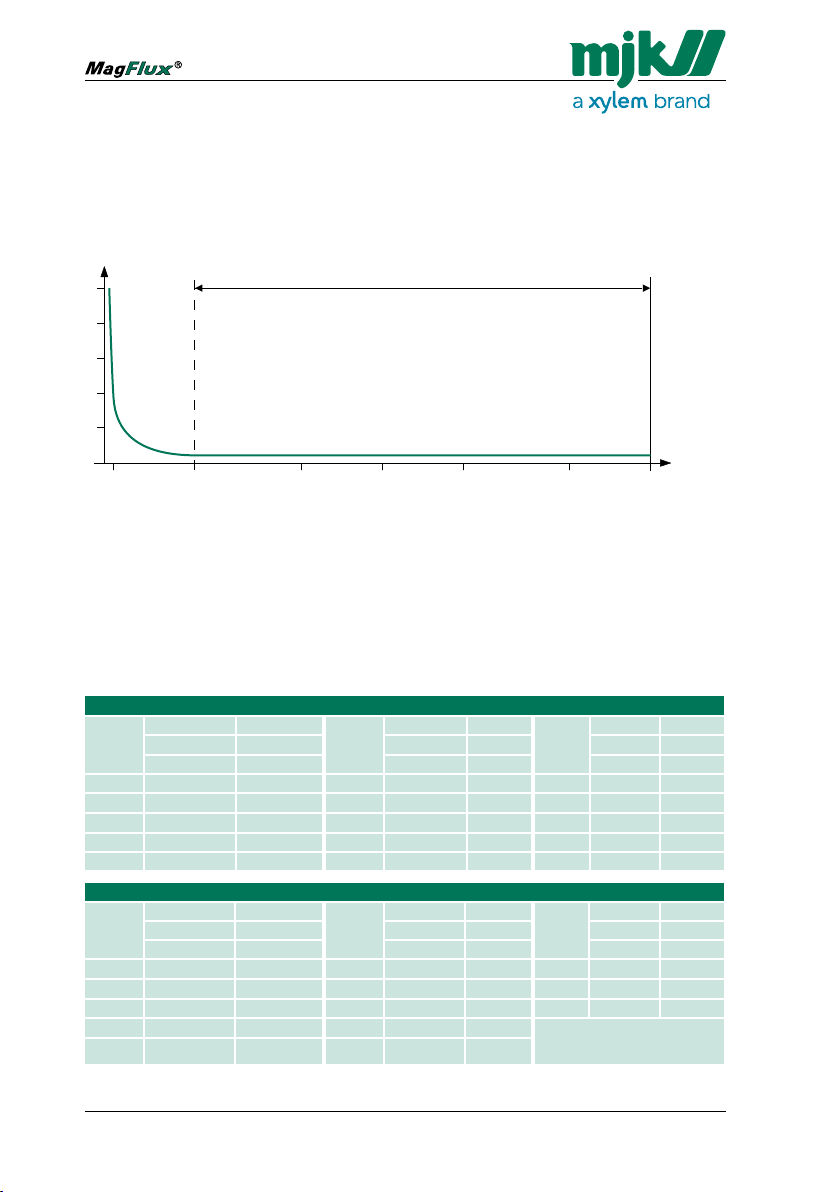

The pressure loss can easily be determined, if the nominal pipe diameter is

greater than the MagFlux® flow sensor. See the diagram below:

Pressure loss graph

0.003

The diagram illustrates that decreasing the internal diameter from 100 mm

(DN) to 80 mm (DO) will cause a pressure loss of 0.003 Bar @3 m/s.

16EN 3.05 MagFlux Manual 1212

Page 17

Electromagnetic Flow Meter

10 m/s

Accuracy

According to the type and size of the flow sensor, the measuring accuracy

will be better than 0.25%, provided that the flow sensor has the correct

dimension.

[%]

5

4

3

2

1

0,20,10 0,5 21 5

Sizing

The flow sensor should be selected so the flow velocity through the sensor

will be between 0.2 - 10 m/s.

MJK recommends that flow velocities in tubes are kept between 1 - 3 m/s

for reliable and safe operation. See also the dimensioning table below and

the dimensioning chart on the following page.

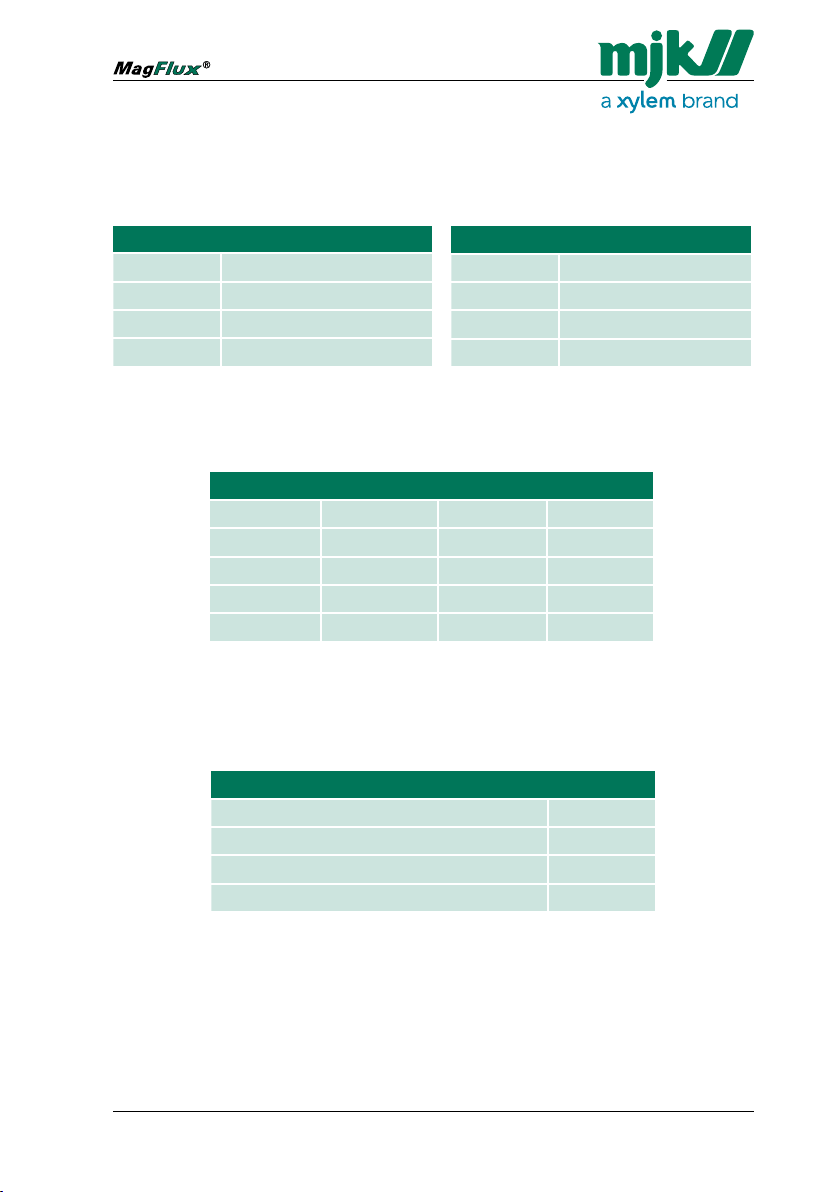

Min and max flow

DN

3 5.09 254 20 226 11304 65 2,39 119

6 20.4 1018 25 353 17676 80 3,62 181

8 36.2 1810 32 579 28944 100 5,65 283

10 56.5 2827 40 905 45360 125 8,84 442

15 127 6362 50 1414 70560 150 12,7 636

Min and max flow

DN

200 22.6 1131 450 115 5726 900 458 22902

250 35.3 1767 500 141 7069 1000 565 28274

300 50.9 2545 600 204 10179 1200 814 40715

350 69.3 3464 700 277 13854 The Qmax. is equal to 20 mA

400 90.5 4524 800 362 18095

Qmin Qmax

0.2 m/s 10 m/s 0.2 m/s 10 m/s 0.2 m/s 10 m/s

[l/h] [l/h] [l/h] [l/h] [m

Qmin Qmax

0.2 m/s 10 m/s 0.2 m/s 10 m/s 0.2 m/s 10 m/s

3

/h] [m3/h] [m3/h] [m3/h] [m3/h] [m3/h]

[m

DN

DN

Qmin Qmax

Qmin Qmax

17

Qmin Qmax

DN

3

Qmin Qmax

DN

factory preset

FW: 842018/842009

/h] [m3/h]

Page 18

Electromagnetic Flow Meter

DN 1000 - 40"

DN 900 - 36"

DN 800 - 32"

DN 700 - 28"

DN 600 - 24"

DN 500 - 20"

DN 450 - 18"

DN 400 - 16"

DN 350 - 14"

DN 300 - 12"

DN 250 - 10"

DN 200 - 8"

DN 150 - 6"

DN 125 - 5"

DN 100 - 4"

DN 80 - 3"

DN 65 - 2 1/2"

DN 50 - 2"

DN 40 - 1 1/2"

DN 32 - 1 1/4"

DN 25 - 1"

DN 20 - 3/4"

DN 15 - 1/2"

DN 10 - 3/8"

DN 8 - 5/16"

DN 6 - 1/4"

DN 3 - 1/8"

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

1

2

3

4

5

6

7

8

9

10

0, 2

0, 3

0, 4

0, 5

0, 6

0, 7

0, 8

0, 9

1

2

3

4

5

6

7

8

9

10

20

30

40

50

60

70

80

90

0, 02

0, 01

0, 03

0, 04

0, 05

0, 06

0, 07

0, 08

0, 09

0, 1

20 000

30 000

10 0

20 0

30 0

40 0

50 0

60 0

70 0

80 0

90 0

10 00

20 00

30 00

40 00

50 00

60 00

70 00

80 00

90 00

10 000

1,5

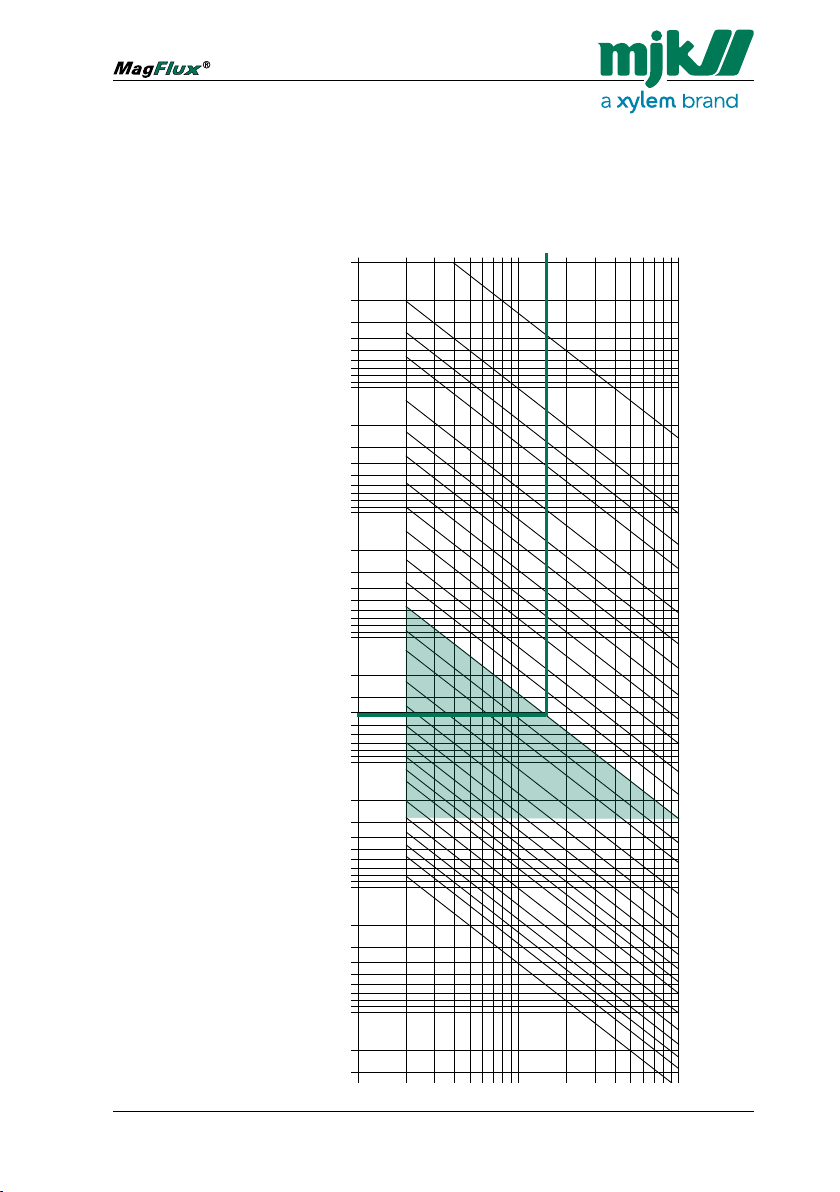

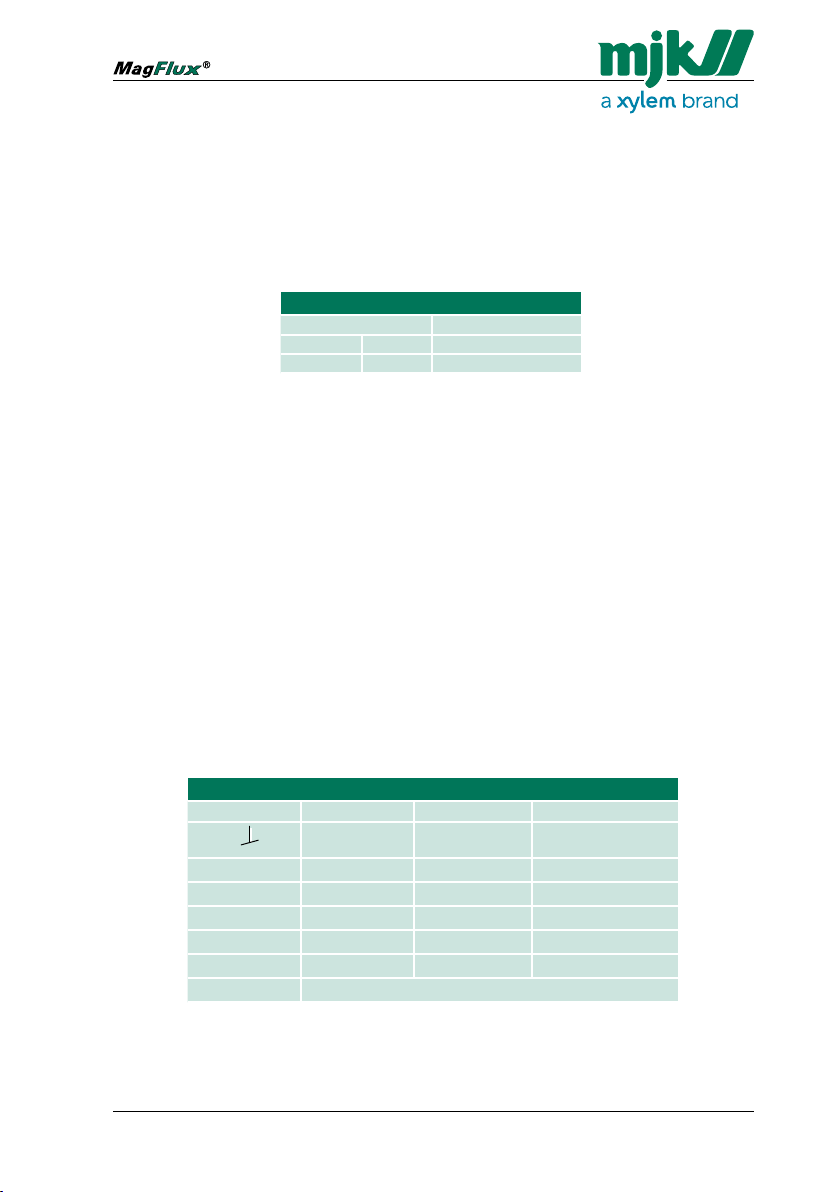

Sizing Chart

Example: A MagFlux with an internal diameter of 100 mm can measure

flow rates between approx. 290m3/h and 5.6 m3/h, and the fluid velocity is

1.5 m/s at a flow rate of approx. 42 m3/h.

Fluid velocity [m/s]

Size

3

/h]

Flow [m

18EN 3.05 MagFlux Manual 1212

Page 19

Electromagnetic Flow Meter

3

2

3

2

3

2

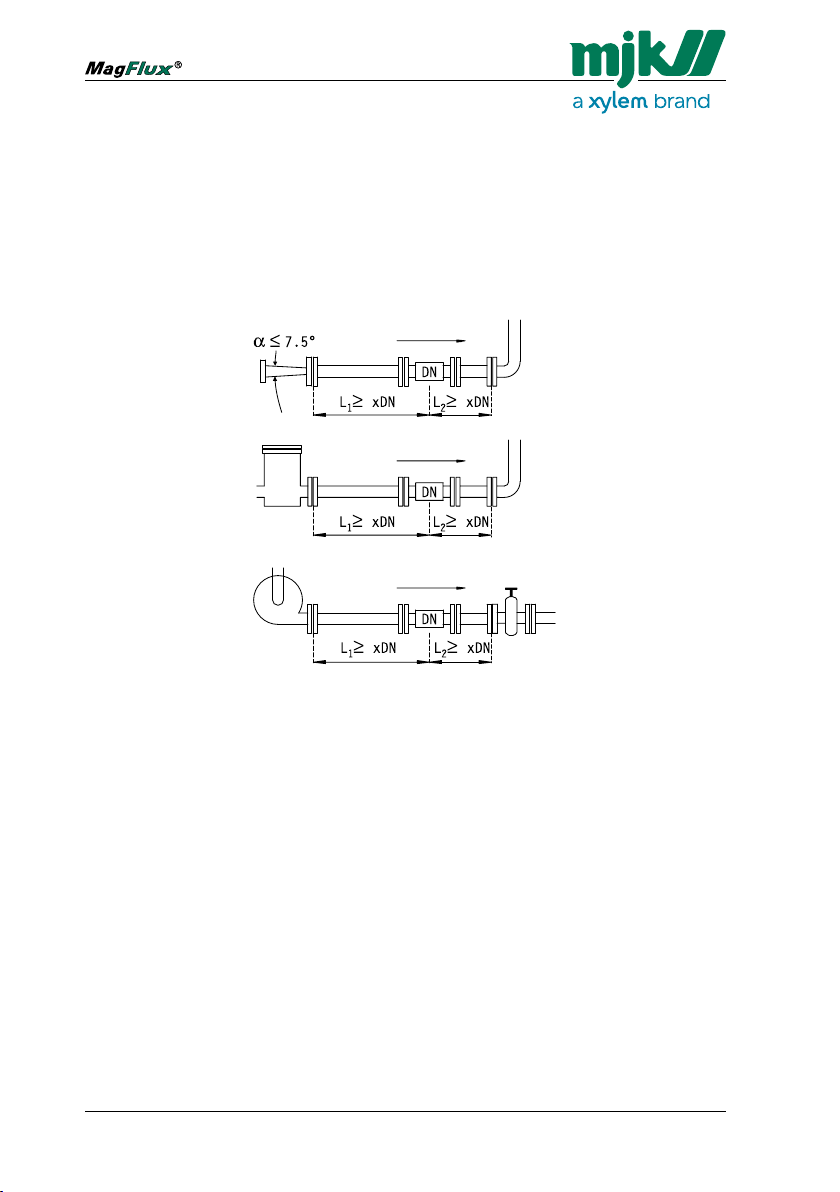

Pipe System

1. The flow sensor must be mounted in a location which is free from interfering elements like valves, Ts, bends, pumps, etc. to ensure a laminar

flow without turbulence upstream of the flow sensor. For that reason

the flow sensor must be mounted in a straight pipe at a distance from

interfering elements of minimum 3 x DN upstream and minimum 2 x

DN downstream.

Flow direction

Flow direction

Flow direction

Important: Valves should always be mounted on the downstream side

of the flow sensor!

19

FW: 842018/842009

Page 20

Electromagnetic Flow Meter

2. If it becomes necessary to use reducers, the inner angle must not

exceed 7.5°.

The minimum length to keep the angle below 7.5° can be checked by

means of the formula below:

L = (D - d) x 7.63

where "D" is the large diameter and "d" the small diameter of the re-

ducer.

Example: If a flow sensor in dimension DN 80 is mounted downstream

of a 100 mm pipe, the reducer must then have a length of minimum

152,6 mm in order to keep the inner angle below 7,5 °.

3. Flange connections must be assembled concentrically on both the up-

stream and the downstream side. Measuring accuracy will be affected

by turbulence in the liquid from poorly made connections.

Important: Gaskets and grounding rings must also be mounted con-

centrically!

4. The flow sensor should always be filled with liquid. For that reason the

flow sensor must not be mounted at the highest point of the pipe system or in free outlets, where gravity could empty or partially empty the

pipe.

20EN 3.05 MagFlux Manual 1212

Page 21

Electromagnetic Flow Meter

5. The flow sensor can be mounted vertically or horizontally.

If the flow sensor is mounted vertically, the flow direction should always

be upwards. In that way the effect from possible bubbles in the liquid

will be significantly reduced, just as it will ensure that the flow sensor is

always filled with liquid.

In case the liquid is carrying particles, for example when measuring

sludge, sewage, etc., the flow sensor must be mounted vertically.

6. When mounting horizontally in pipes with free downstream outlet, the

flow sensor should be mounted such that it will always be filled with liquid, for example in a bend situated lower than the height of the outlet.

In case the liquid is carrying particles, e.g. when measuring sludge,

sewage etc. the flow sensor must be mounted vertically.

21

FW: 842018/842009

Page 22

Electromagnetic Flow Meter

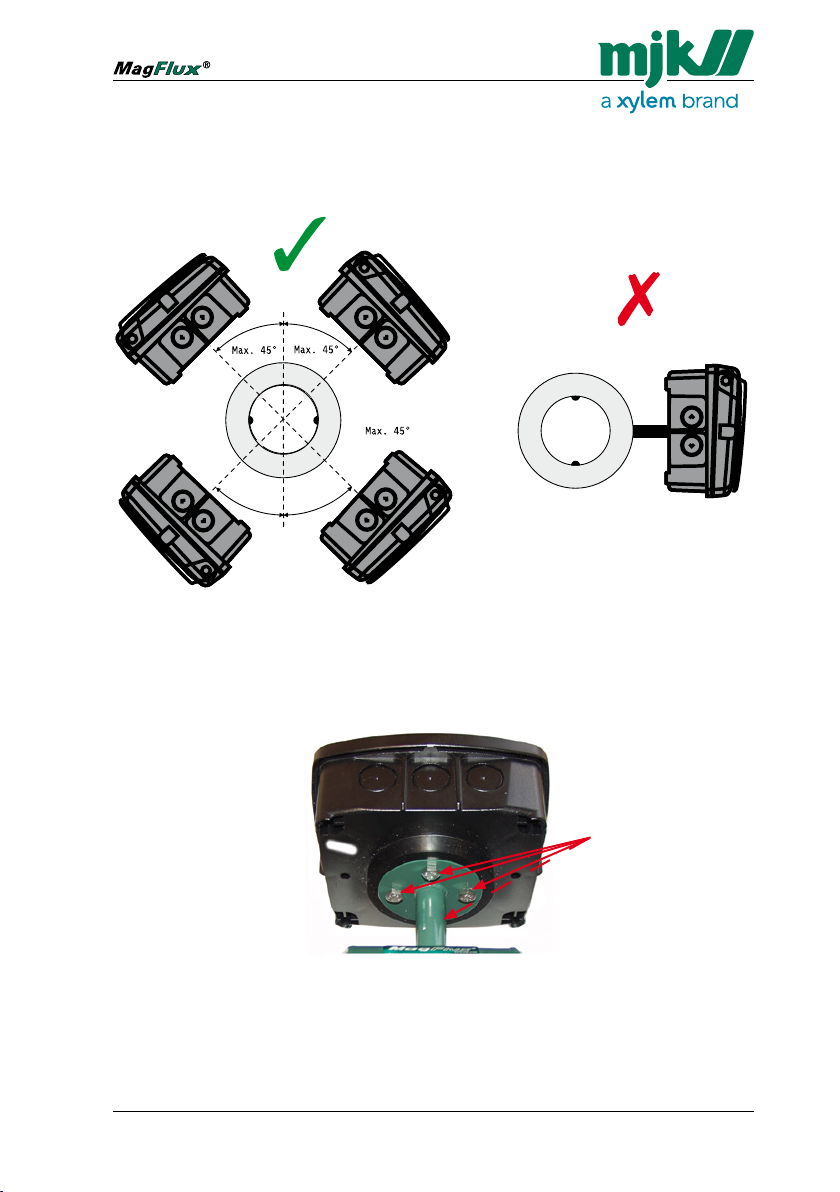

7. When mounting horizontally the flow sensor can be rotated max. +/- 45°

seen from the connection end. If the flow sensor is rotated more than

45°, one of the electrodes may not be in full contact with the liquid.

Cabinet Mounted on the Flow Sensor

The cabinet is mounted on the flow sensor with four pcs. 6x12 hex cap

screws.

22EN 3.05 MagFlux Manual 1212

Page 23

Electromagnetic Flow Meter

Potential Equalization and Grounding

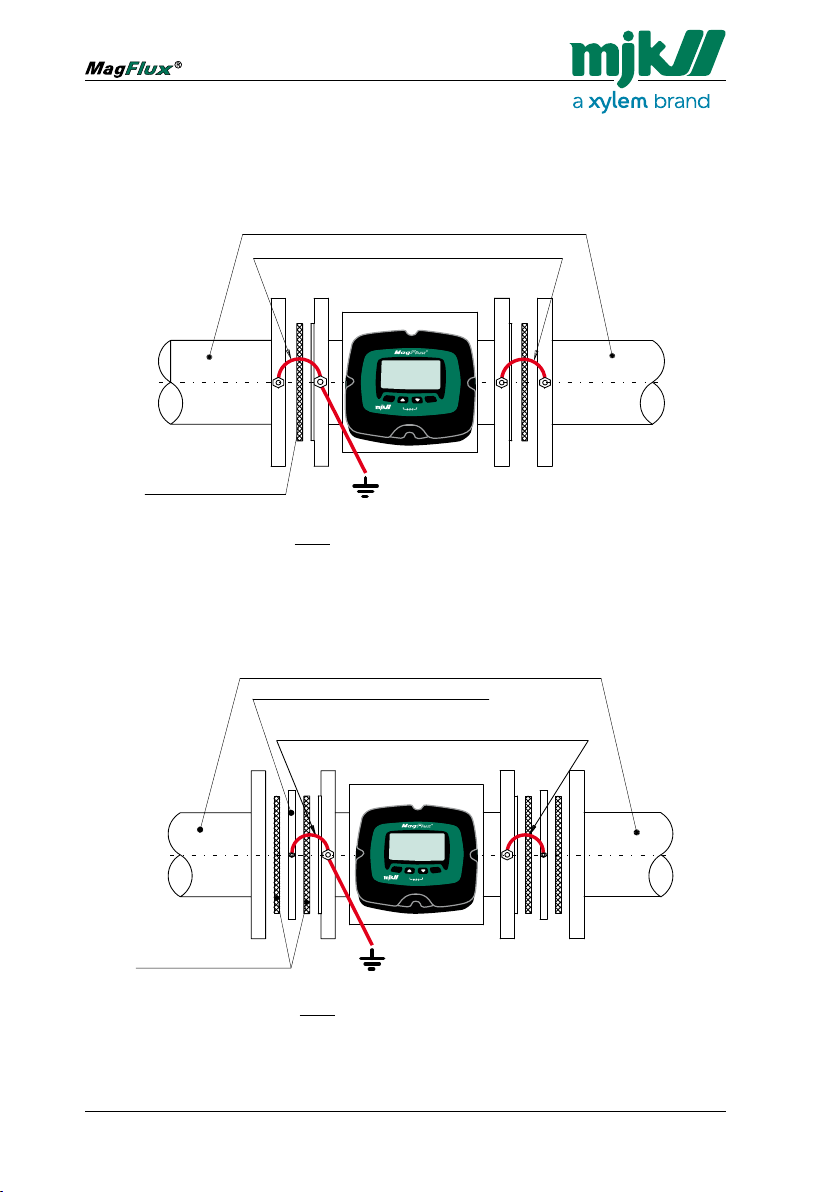

Type 7100/7200/7600 in Conductive Pipes

Conductive pipes

Equalization connection

Soft gasket

Ground connection.

NB! The flow sensor must be connected to an effective ground

connection, and the wire dimension must be at least 1.5 mm

Type 7100/7200/7600 in Non-conductive Pipes

2

.

Non-conductive pipes

Grounding ring (Min. thickness = 5 mm.)

Potential equalization connection

Soft gasket

Ground connection.

NB! The flow sensor must be connected to an effective ground

connection, and the wire dimension must be at least 1.5 mm

23

2

FW: 842018/842009

.

Page 24

Electromagnetic Flow Meter

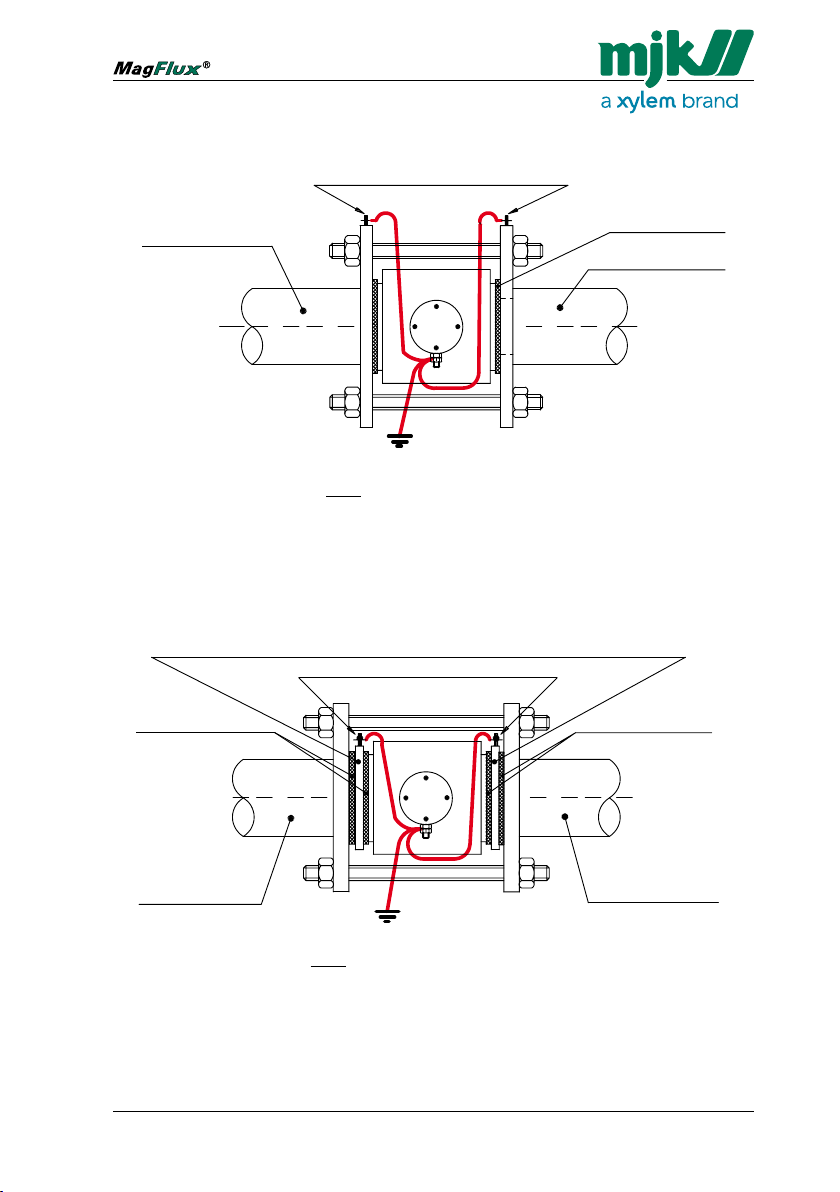

Type 7300/7400 in Conductive Pipes

Potential equalization connection

Conductive pipe

Ground connection.

NB! The flow sensor must be connected to an effective ground

connection, and the wire dimension must be at least 1.5 mm

Type 7300/7400 in Non-conductive Pipes

Grounding ring (Min. thickness = 5 mm.)

Potential equalization connection

Soft gasket

Soft gasket

Conductive pipe

2

.

Soft gasket

Non-conductive pipe

Ground connection.

NB! The flow sensor must be connected to an effective ground

connection, and the wire dimension must be at least 1.5 mm

24EN 3.05 MagFlux Manual 1212

Non-conductive pipe

2

.

Page 25

Electromagnetic Flow Meter

521255

Ground from

flow pipe

Red

White

White

Black

Green

White

L2E2E1

L1GND

Mains

supply

-mA--RE2--RE1--DI1--Display-

+ +A B DI COM CNO NO PE N L

- -

FUSE

www.mjk.com

Fuse rating: 100 mAT @ 115 V AC

63 mAT @ 230 V AC

521254

Connection for top

mounted operator panel

Live

Neutral

Protective earth

PE N L

Terminals

for remote

operator panel

+ A B

-

Up to four MagFlux® flow sensors can

be connected to one operator panel:

4 wire cable.2 wire cable.

A, B

+, A, B,

-

4-20 mA (Active.)

Max. 500 Ω

Electronic relay

Max. 50 V 120 mA resistive load

Mechanical relay

Max. 50 V 1A resistive load

< 5 VDC = O ; > 10 VDC = I

Max. 30 VDC

+DI COM COMNO NO

-

DO1DI DO2 AO

FUSE

MAINS SUPPLY

Sensor #1

Sensor #4

Operator

panel

4. Flow Converter

Electrical Mounting

Warning: The MagFlux® flow converter / flow sensor must not be

mounted in explosion hazardous areas!

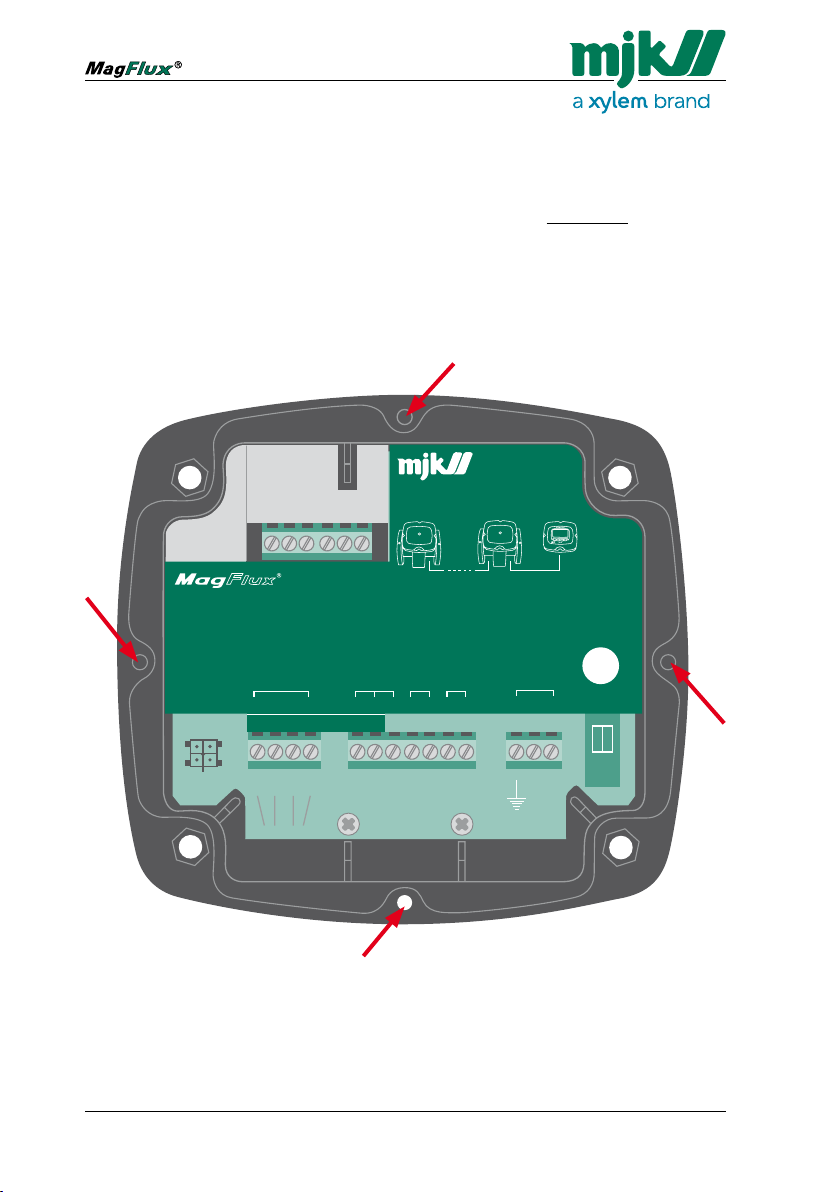

Loosen the four screws (position indicated by arrows) and remove the

display unit to gain access to the terminals.

25

FW: 842018/842009

Page 26

Electromagnetic Flow Meter

Power Supply

The flow converter must be supplied from a properly fused mains outlet, a

24 volt AC outlet, or a 10 - 30 V DC power supply/battery.

Power Supply 230 V AC, 115 V AC or 24 V AC

Terminal Designation

PE Protective ground

N 230 / 115 / 24 V AC neutral

L 230 / 115 / 24 V AC live

Power Supply 10 - 30 V DC

Terminal Designation

PE Protective ground

— DC neutral

+ DC live

The internal fuse ratings are:

Internal Fuse Ratings

Voltage Rating Order no. Dimension

230 V AC 0.063 mA T 550030 5 x 20 mm

115 V AC 0.125 mA T 550035 5 x 20 mm

24 V AC 0.5 mAT 550049 5 x 20 mm

10 - 30 V DC 1.0 AT 550051 5 x 20 mm

The technical specifications/requirements for a 10 - 30 V DC power

supply/battery are:

Technical Specifications for 10 - 30 V DC Power Supply

Power consumption without display < 5 W

Power consumption with display < 8 W

Peak start current @12 V DC,1 second Approx. 1,5 A

Peak start current @24 V DC,1 second Approx. 1 A

26EN 3.05 MagFlux Manual 1212

Page 27

Electromagnetic Flow Meter

Changing the Power Supply Voltage 230/115 V AC

To change the input mains voltage from 230 VAC to 115 VAC (or vice

versa) proceed as follows:

1. Loosen the four screws on the front and lift out the display (see also

page 25).

2. Note down the color and position of the wires in the terminal blocks,

and then loosen the terminal screws.

3. Unscrew the two screws that hold the metal cover and then remove it.

4. Unscrew the four screws that hold the mother PCB (the printed circuit

board with all the electrical components).

5. Remove the mother PCB and look at the back side. This is what you

should see (230 V AC configuration):

6. Unsolder and remove the jumper indicated by the arrow.

27

FW: 842018/842009

Page 28

Electromagnetic Flow Meter

7. Look at the following picture to see where two new jumpers must be

inserted (115 V AC configuration):

8. Insert and solder 2 jumpers (wires) in the positions indicated by the ar-

rows.

9. Turn around the PCB and replace the 63 mAT fuse on the right side

with a 125 mAT fuse ( or vice versa going from 115 VAC to 230 VAC).

10. Re-insert the PCB and re-assemble the flow meter (see also steps 4, 3,

2 and 1).

28EN 3.05 MagFlux Manual 1212

Page 29

Electromagnetic Flow Meter

Analogue Output

The analogue output is an active output with a max. load of 800Ω.

Analogue Output

Terminal Designation

AO + 4-20 mA

AO

-

4-20 mA

The analogue output can be programmed for indication of:

- direct flow

- inverse flow

- bidirectional flow

- absolute flow

See details on pages 63 - 66 incl.

Digital Outputs

MagFlux® has two digital outputs - DO 1 with an opto (light triggered)

relay and DO 2 with a mechanical relay.

They can both be programmed for the following functions:

- high and low flow alarms

- pulse output for counters R Totalizer Forward and Reverse

- batch 1 and batch 2 counters

- system error alarm

- empty pipe alarm

- flow direction indication

Opto Relay (DO1)

Terminal Designation

DO 1 Com Max. 50 V DC /120 mA

DO 1 NO

Mechanical Relay (DO2)

Terminal Designation

DO 2 Com Max. 50 V DC /1 A

DO 2 NO

DO 1 shares the common terminal (Com) with DI.

29

FW: 842018/842009

Page 30

Electromagnetic Flow Meter

See also application examples in Appendix G. Digital Input/Output Connections on page 123.

Digital Input

MagFlux® has one digital input which is activated with a voltage higher

than 10 V DC and de-activated with a voltage lower than 5 V DC.

Digital Input

Terminal Designation

DI Com

DI Max. 30 V DC

The digital input (DI) can be programmed for the following functions:

- start and pause batch 1 and batch 2 counters

- reset counters R Totalizer Forward and Reverse

- reset counter R Totalizer Sum

DI shares the common terminal (Com) with DO 1.

See also application examples in Appendix G. Digital Input/Output Con-

nections on page 123.

Local (compact) Flow Sensor

Connect the compact (local) flow sensor to the flow converter with the

wires coming from the flow sensor as shown below.

Compact Flow Sensor

Terminal Signal Designation Colour from sensor

1

2 E1 Electrode Red

3 E2 Electrode White

4 GND Ground Black

5 L1 Coil Blue

6 L2 Coil Brown

7, 8 and 9 not used

Liquid GND

Built-in liquid

ground electrode

30EN 3.05 MagFlux Manual 1212

Black/shield

Page 31

Electromagnetic Flow Meter

Remote Flow Sensor

Connect the remote flow sensor to the flow converter with the included

cable (part number 691080).

Important: Do not use other cable types!

Important: Terminals 1 and 4 must be shunted!

The extension cable length between converter and sensor must under

normal circumstances not exceed 50 meters. Power lines running in parallel and noisy environments may reduce the max. length to less than 50

meters. Consult MJK personnel for advice and guidance.

Remote Flow Sensor 691080

Terminal Signal Designation Colour

1

Liquid GND Shield

before March 2011

- -

2 E1 Wire pair no. 1 Red Red

3 E2 Wire pair no. 1 White White

4 GND Wire pair no. 3 Black Black

5 L1 Wire pair no. 2 Green Blue

6 L2 Wire pair no. 2 White Brown

7, 8 and 9 not used

Colour

from March 2011

Converter Connection Board - Local

Red

White

Black

Blue

Brown

Electronic relay

max. 50 V DC 120 mA

Electromechanical relay

max. 50 V AC / 1 A

Conn ection for

Flow Senso r

For attached

Display Unit

For remote

Display Unit

DI 1

Digital output 1 DO 1

Digital input

10-30 V DC

4-20 mA max. 800 Ω

DO 2Digital output 2

4-20 mA output

31

63 mAT @ 230 V AC

Fuse rating: 125 mAT @ 115 V AC

Power supply

FW: 842018/842009

Page 32

Electromagnetic Flow Meter

Converter Connection Board - Remote

691080 cable

before March 2011

Connection for

local sensor

A

1 2 3 4 5 6 7 8 9

Connection for

remote converter

B

1 2 3 4 5 6 7 8 9

Connection for

local sensor

A

1 2 3 4 5 6 7 8 9

Plug for local

display unit

Connection for

remote display unit

Plug for local

display unit

691080 cable

from March 2011

Connection for

remote converter

B

1 2 3 4 5 6 7 8 9

32EN 3.05 MagFlux Manual 1212

Connection for

remote display unit

Page 33

Electromagnetic Flow Meter

5. System Configuration Examples

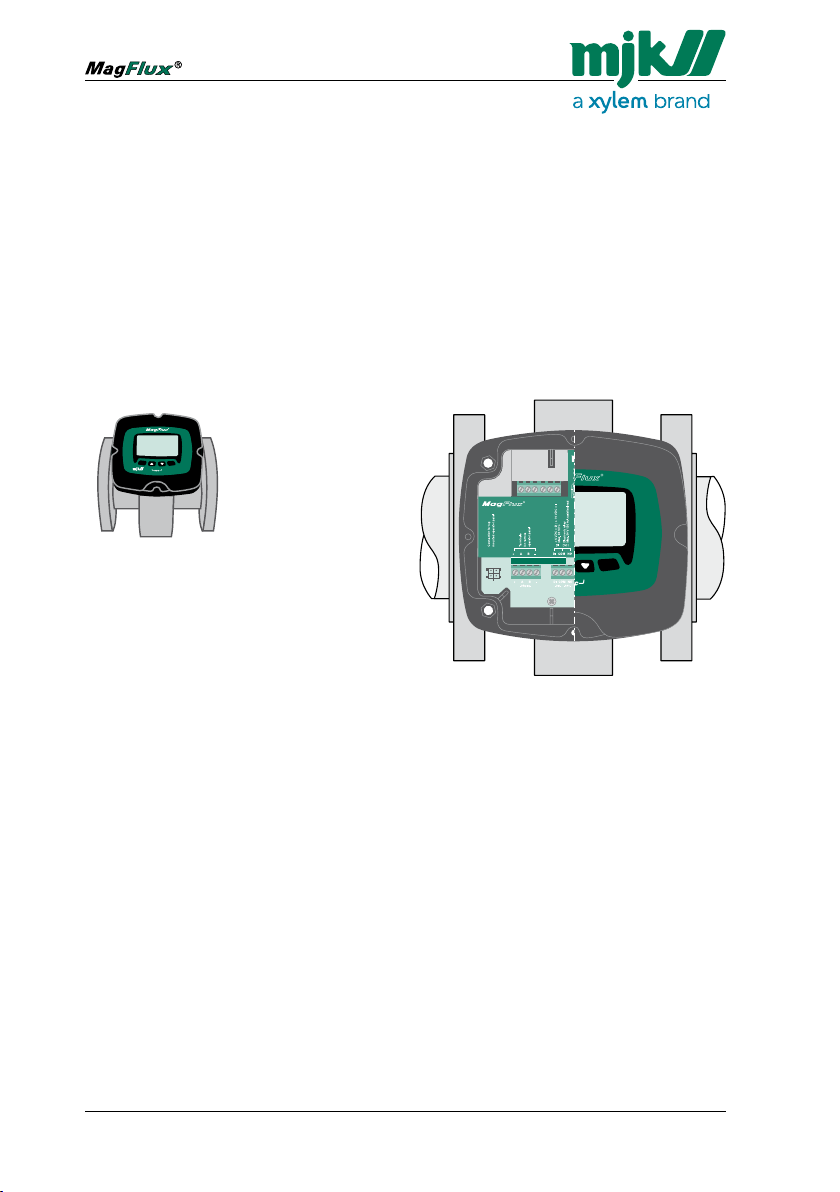

Compact Converter and Display Unit on Flow Sensor

Configuration: The MagFlux® Converter and Display Unit is mounted

directly on the MagFlux® Flow Sensor.

Order numbers for this configuration:

207xxx MagFlux® Flow Sensor

207920 MagFlux® Converter with Display Unit for sensor mounting

207920 consists of:

207940 Display Unit

807000 Converter PCB

800070 Field Cabinet

bottom part for sensor

mounting

33

FW: 842018/842009

Page 34

Electromagnetic Flow Meter

Remote Converter with Connection Box on Flow Sensor

Configuration: The MagFlux® Converter and Display Unit is remote

mounted for example when the sensor is to be buried or submerged.

Order numbers for this configuration:

207xxx MagFlux® Flow Sensor

207925 MagFlux® Converter with Display Unit for wall mounting

691080 MagFlux® Sensor cable

579035 MagFlux® Gel Potting Kit IP68

207920

A

1 2 3 4 5 6

207925 consists of:

207940 Display Unit

207020 MagFlux connection

PCB (see picture below)

820050 Blind Lid

800070 Cabinet bottom part

for sensor mounting

800075 Cabinet bottom part

for wall mounting

B

1 2 3 4 5 6

Converter connection PCB

34EN 3.05 MagFlux Manual 1212

Page 35

Electromagnetic Flow Meter

A

207920

1 2 3 4 5 6 7 8 9

Wiring Schematic #1

for "Remote Converter with Connection Box on Flow Sensor" on the opposite page (page 34).

Flow Sensor

Connect one end of

the MJK cable to the

flow sensor as described in the table

below. All 3 shields are

twisted and connected

in slot 1. The white

lead in pair no. 3 is not

used.

B Connection for remote converter

Terminal Signal Wire Colour before

1

GND Shield

2 E1 Pair no. 1 Red Red

3 E2 Pair no. 1 White White

4 GND Pair no. 3 Black Black

- - Pair no. 3 White -

5 L1 Pair no. 2 Green Blue

6 L2 Pair no. 2 White Brown

7, 8, 9 not used

March 2001

- -

Colour from

March 2011

B

1 2 3 4 5 6 7 8 9

Blue

Brown

Remote Converter

(and Display Unit)

Connect the other end

of the MJK cable to

the remote converter

as shown to the right.

The "1 Shield" lead

goes into "Ground

from flow pipe", the

"2 Red" lead goes

into "E1 Red", the "3

White" lead into "E2

White", and so on.

Blue

Brown

35

FW: 842018/842009

Page 36

Electromagnetic Flow Meter

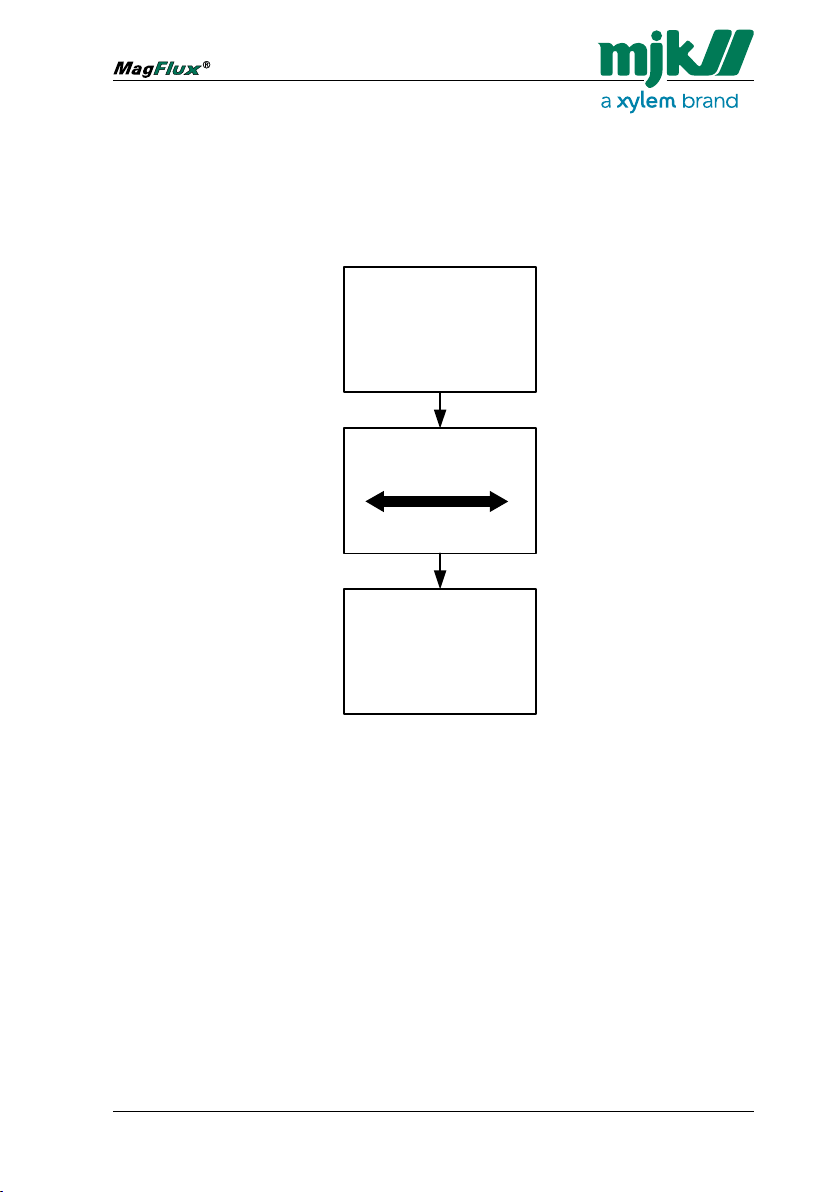

Remote Display and Multiple Converters Wiring

Configuration: Two locally mounted MagFlux® Flow Sensors and converters with blind lid and one remote mounted Display Unit.

The communication between the sensors and the Display Unit is executed

on shielded twisted 2- and 4-wire cables using the Modbus

tion protocol on RS-485.

Order numbers for this configuration:

207xxx MagFlux® Flow Sensor (2 pcs.)

207925 MagFlux® Converter with

Display Unit for wall mounting

®

communica-

207925 consists of:

207940 Display Unit

207020 MagFlux connection

PCB

820050 Blind lid

800070 Cabinet bottom part

for sensor mounting

800075 Cabinet bottom part

for wall mounting

Note: The total maximum cable length for

the 2- and 4-wire shielded twisted cables

is 1000 meters.

36EN 3.05 MagFlux Manual 1212

Page 37

Electromagnetic Flow Meter

Wiring Schematic #2

for the "Remote Display and Multiple Converters Wiring" example on the

opposite page (page 36).

Local flow sensor 1

2-wire twisted shield cable:

Connect lead "1" to slot "A",

lead "2" to slot "B" and the

twisted shield to slot "-".

1 2

Shield

Local flow sensor 2

2-wire twisted shield cable:

Connect lead "1" to slot "A",

lead "2" to slot "B" and

twisted shield to slot "-".

4-wire twisted shield cable:

Connect lead "1" to slot "A",

lead "2" to slot "B",

lead "3" to slot "+" and

lead "4" and twisted shield to slot "-".

213

4 and

shield

Remote display unit

4-wire twisted shield cable:

Connect lead "1" to slot "A",

lead "2" to slot "B",

lead "3" to slot "+" and

lead "4" and twisted shield to slot "-".

37

FW: 842018/842009

Page 38

Electromagnetic Flow Meter

This page intentionally left blank.

38EN 3.05 MagFlux Manual 1212

Page 39

Electromagnetic Flow Meter

6. Startup

Initial Checks

Before switching on power the following steps must be checked.

1. The local mains power supply voltage corresponds to the voltage

printed on the identification label of the flow converter.

2. All electrical connections are made in accordance with the electrical

connection diagram shown on page 32.

3. All terminal screws are tightened.

4. All cable glands are tightly secured.

5. All grounding connections are made in accordance with the instructions in this manual (see page 23).

Initial Flow Measurement

1. Make sure that the flow sensor is completely filled with liquid.

2. Turn on power to the flow converter and wait one minute.

3. Verify or enter the calibration code of the flow sensor in the

"Converter Setup/Service Menu/Sensor Calibration Code" menu (see

also page 86).

If the entered calibration code is incorrect, and for example indicates a

wrong internal diameter, read the correct calibration code on the converter as explained on page 14.

Flow Direction Check

1. Allow free flow through the sensor.

2. Check on the display unit screen that the flow value increases. If the

value goes negative, check that the "Flow direction" option is set correctly and/or check the electrical connections on the flow sensor.

Language Selection

1. The default display language is English. If another language is required,

proceed with step 2.

2. Select "Display Setup" from the Main Menu.

3. Select "Language" from the Display Setup menu and chose the required language (see page 96).

39

FW: 842018/842009

Page 40

Electromagnetic Flow Meter

Display Read-out, one connected unit

All MagFlux® display read-outs are illustrated and described in this manual.

Chapter 6. MagFlux Menus (on page 47) gives a detailed description of the

displays shown during setup, configuration and normal operation.

A 5-line LCD screen displays symbols and the actual status during setup,

configuration, servicing and normal operation (see also page 48).

Keyboard for reading and programming the MagFlux

The display shown above will in the remaining part of this manual be stylized

to appear like this:

MagFlux

Flow

FTot 18.77 m

Select

4.1 m

40EN 3.05 MagFlux Manual 1212

3

/h

3

Setup

Page 41

Electromagnetic Flow Meter

Oxix1

Oxygen sat.

91.9 %

Select

Setup

Display Read-out, several connected units

When several MJK units are interconnected, for example an Oxix® dissolved oxygen transmitter and MagFlux® flow meter with different names

and Modbus ID numbers, a "Display Overview Menu" is available at top

level (press "Back" repeatedly):

4.1 m3/h

MagFlux

Oxix1 91.9 %

All connected units are displayed and sorted by their ID numbers, and

consequently each unit can be selected and set up as required:

Important:

More connected units can only by managed as described above, if

each unit have been assigned a unique name and Modbus ID number. See page 98 for details.

Display Keys

The keys and the soft keys (variable key functions determined by the

display firmware) are used for initial programming and normal operation of

the flow meter.

The function(s) of the four available keys is displayed at the bottom of the

display. The symbols and actual functions are described in detail in the

sections that describe the individual menus.

MagFlux

Flow

FTot 18.77 m

Select

4.1 m

Back Select

3

/h

3

Setup

or

Setup

Oxix1

Oxygen sat.

Select

91.9 %

Setup

41

FW: 842018/842009

Page 42

Electromagnetic Flow Meter

Contrast Adjustment

Adjust the display contrast by pressing the two outmost keys simultaneously (indicated by the keys) and press the up/down keys as required.

Save the new setting by pressing the two outmost keys simultaneously.

System Reset

You can reset and refresh all system displays and key combinations by

pressing all four keys simultaneously.

This feature is especially useful during for example a service call, where

the display language (Dutch, Danish, etc.) cannot be understood by the

service person. A system reset immediately sets the display language to

(GB) English.

The system reset must not be confused with the ultimate "Recover factory

settings" (see page 100) which deletes all local configurations/settings and

replaces them with default factory settings.

42EN 3.05 MagFlux Manual 1212

Page 43

Electromagnetic Flow Meter

Main Menu

Initial Setup

Initial setup is normally performed by MJK personnel and is required to get

started with the MagFlux® flow meter.

A unique sensor calibration code provides the MagFlux® flow converter

with information about flow sensor number, nominal diameter and calibration data.

If changes to the unique sensor calibration code are needed following

physical installation and initial setup, the "Sensor Calibration Code" menu

must be addressed.

A password is not required to enter or change the sensor calibration code.

Toggle through the displayed digits with the right-arrow key when prompted for a password and press OK.

1. Press the "Setup" key on the LCD display (see below) to enter the

MagFlux

®

Main Menu.

MagFlux

Flow

FTot 18.77 m

Select

4.1 m

Setup

3

/h

3

2. Press the up/down keys to highlight the required menu line (here:

"Converter Setup") and then press OK to select it.

Specify Main Screen

Factory Settings

Data Logger

Password

Set Sensor Name

Converter Setup

Converter Setup

Display Setup

Back Select OK

43

FW: 842018/842009

Page 44

Electromagnetic Flow Meter

Sensor Calibration Code

|

Back Select >

S/N not entered

Set Flow Direction

Follow Arrow A

Follow Arrow B

Back Select OK

MagFlux1

Flow 0.00 m

3

/h

FTot 00.000 m

3

Select Setup

A B

3. Then select "Service Menu" and "Sensor Calibration Code".

Converter Setup

Service Menu

Converter Setup

Minimum Flow

Averaging

Units

mA Output

R Totalizer Forward

R Totalizer Reverse

R Totalizer Sum

NR Totalizer Forward

NR Totalizer Reverse

NR Totalizer Sum

Batch Counter 1

Batch Counter 2

High Flow

Low Flow

Flow Direction

Empty Pipe

24h Flow

Status

Service Menu

Service Menu

Back Select OK

Sensor Calibration Code

Sensor Calibration Code

Converter SW Ver.

Product Data

Reset Counter Time

Internal Meas. & Cal.

Minimum Velocity

Calibrate Flow now

Calibrate Volume

Calibrate mA

Test Velocity

Freeze Coil

Read Event Log

Back on Stock

Back Select OK

Sensor Calibration Code

Sensor Calibration Code

dw5uq4

Back Select OK

Set Flow Direction

Follow Arrow A

Follow Arrow B

A B

Back Select OK

4. Enter the calibration code read from the converter label (or pass

through or change the displayed calibration code) and then press OK.

See also details regarding the calibration code on page 14.

5. Select the correct flow direction in the "Set Flow Direction" menu and

press OK.

44EN 3.05 MagFlux Manual 1212

Page 45

Electromagnetic Flow Meter

Type Password

0000

Back Select >

Service Menu

Sensor Calibration Code

Converter SW Ver.

Product Data

Reset Counter Time

Internal Meas. & Cal.

Minimum Velocity

Calibrate Flow now

Calibrate Volume

Calibrate mA

Test Velocity

Freeze Coil

Read Event Log

Back On Stock

Back Select OK

OK

Converter SW Ver.

Product Data

Back

Product ID

56136

Back Select >

Product type No.

0000207910

Back Select >

Track No.

00000

Back Select >

HW type No.

00000510250

OK

OK

OK

Reset Counter Time

Reset Counter 11

Systen Runtime 1632838

Since reset 426838

Runtime (days) 18

Back Select OK

Converter 842009-005

Build 7659

Build 719

Bootload 840020-002

6. Pass through the "DN" menu and press OK.

Sensor Calibration Code

Sensor Calibration Code

7V3RI0

The MagFlux® is now configured with default settings and is ready for use.

Note: If the sensor has not been pre-configured from the factory with

a sensor calibration code, the calibration code procedure is

somewhat different form the just mentioned.

Back Select >

Set Flow Direction

Follow Arrow A

Follow Arrow B

<A ----------------------------- B>

Back Select OK

DN

00025

Back Select >

OK

OK

See the steps on the following page to configure a non-configured sensor

with a calibration code.

45

FW: 842018/842009

Page 46

Electromagnetic Flow Meter

1. Apply power to the sensor.

2. When the "Sensor Calibration Code" menu appears (see below), enter

the calibration code read from the converter label and press OK.

S/N not entered

Sensor Calibration Code

|

Back Select >

Set Flow Direction

Follow Arrow A

Follow Arrow B

A B

Back Select OK

MagFlux1

Flow 0.00 m

FTot 00.000 m

Select Setup

3

/h

3

3. Select the correct flow direction from the "Set Flow Direction" menu

and press OK.

4. Sensor calibration code configuration is now finished, and you are

returned to the Main Menu.

46EN 3.05 MagFlux Manual 1212

Page 47

Electromagnetic Flow Meter

Main Menu

7. MagFlux Menus

All the MagFlux® menus and sub menus are shown and described in the

following sections.

Continous overviews of the menu and sub-menu structures are presented

on the gatefolds at the end of this manual:

• Main Menu Overview (page Gf-1)

• Converter Setup Menu Overview (page Gf-2)

• Service Menu Overview (page Gf-3)

• Display Setup Menu Overview (page Gf-4)

Main Menu

1. Press the "Setup" key on the MagFlux® display (see below) to enter the

MagFlux® Main Menu.

MagFlux

Flow

FTot 18.77 m

Select

4.1 m

3

/h

3

Setup

The MagFlux® Main Menu contains a number of sub menus (see figure

below).

Specify Main Screen

Specify Main Screen

Factory Settings

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required menu line (here:

Specify Main Menu) and then press OK to select it.

47

FW: 842018/842009

Page 48

Electromagnetic Flow Meter

Select Line

Line 1 - Sensor Name

Line 2 - Flow

Line 3 - FTot

Line 4

Line 5

Back Select OK

Specify Main Screen

Select Line Content

Not in use

Flow

RFTot

RRTot

RTTot

FTot

RTot

Cnt

Flow Direction

Batch 1

Batch 2

Batch 1 Dn

Batch 2 Dn

Batch 1 Cnt

Batch 2 Cnt

Batch 1 Vol

Batch 2 Vol

Clock

Back Select OK

Specify Main Screen

The "Specify Main Screen" menu allows you to customize the MagFlux®

display to suit your requirements. You can add and remove the five available display lines and configure them individually.

1. Press the up/down keys to highlight the required menu line and then

press OK to select it.

2. Press the up/down keys to highlight the required option and press OK.

48EN 3.05 MagFlux Manual 1212

Page 49

Electromagnetic Flow Meter

The available options are:

Not in use

The line will not be used. The set free space will be used by the other

lines.

Sensor Name

The actual sensor name like a number, a location, a name or a function

will be displayed

Note: The actual sensor name is defined later on in the "Set Sensor

Name" menu on page 59.

Flow

Actual flow rate (in units chosen in the menu for primary units).

RFTot

Resettable Forward Totalizer counter

32bit (unit L) 4 294 967 295 L

RRTot

Resettable Reverse Totalizer counter

32bit (unit L) 4 294 967 295 L

RTTot

Resettable Total Totalizer counter

32bit (unit L) 2 147 483 647 L (+/- half of Tot)

FTot

Forward Totalizer counter

64bit (unit mm

3

) 18 446 744 073 709 551 615 mm

RTot

Reverse Totalizer counter

64bit (unit mm

3

) 18 446 744 073 709 551 615 mm

Cnt

Totalizer sum Counter

64bit (unit mm

3

) 9 223 372 036 854 775 807 mm3 (+/- half of Tot)

Flow Direction

Flow direction "A" or "B" will be displayed.

3

3

49

FW: 842018/842009

Page 50

Electromagnetic Flow Meter

Batch 1

Timer for batch volume 1

Batch 2

Timer for batch volume 2

Batch 1 DN

Displays the missing amount of Batch volume 1 (DN = down)

Batch 2 DN

Displays the missing amount of Batch volume 2 (DN = down)

Batch 1Cnt

Batch 1 Counts (number of batches)

Batch 2 Cnt

Batch 2 Counts (number of batches)

Batch 1 Vol

Batch 1 Volume

Batch 2 Vol

Batch 2 Volume

Clock

Time and date

The size of the display lines will automatically increase or decrease as the

number of display lines is removed or added to maximize the field of view

for the measured values

50EN 3.05 MagFlux Manual 1212

Page 51

Electromagnetic Flow Meter

Main Menu

Factory Settings

The "Factory Settings" menu resets the display to default settings, to metric settings or to US settings.

Note: The converter settings are not changed from this menu. Converter

settings are covered in "Converter Setup" on page 61.

1. Press the up/down keys to highlight the required menu line (here: Fac-

tory Settings) and then press OK to select it.

Specify Main Screen

Factory Settings

Factory Settings

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required option and then press

OK to select it.

Factory Settings

Recover Factory Settings

Cancel

Default

Set to Metric

Set to US

Back Select OK

The available options are:

Cancel

Exit the menu without changes.

51

FW: 842018/842009

Page 52

Electromagnetic Flow Meter

Default

When "Default" is selected, the following settings are not affected and

remain as chosen by the user:

• Sensor Name

• Device ID

• Flow Direction

• DN, size

• Calibration

• Calibration Code

The in- and outputs are not activated from the factory. Activate the in- and

outputs by configuring the functions with for example the default values

shown in the following tables:

• MagFlux Default DI/DO Settings

• MagFlux Default 20 mA Settings

MagFlux Default DI/DO Settings

Digital Output 1 (opto) - DO1 Digital Output 2 (mech.) - DO2 Digital Input - DI

Counter R Totalizer Forward Counter R Totalizer Forward RESET R Totalizer Forward

Counter R Totalizer Reverse Counter R Totalizer Reverse RESET R Totalizer Reverse

Batch Counter 1 Batch Counter 1 RESET R Totalizer Sum

Batch Counter 2 Batch Counter 2 Start / Pause Batch counter 1

Low Flow Low Flow Start / Pause Batch counter 2

High Flow High Flow

Flow Direction Flow Direction

Empty Pipe Empty Pipe

Note: The same function can not be on assigned to both relays.

52EN 3.05 MagFlux Manual 1212

Page 53

Electromagnetic Flow Meter

MagFlux Default 20 mA Settings

Metric US

DN [mm] Flow [m3/h] Size Flow [GPM]

3 0,25

6 1 1/4¼" 10

8 2

10 5 3/8" 10

15 5 ½" 30

20 10 3/4" 50

25 20 1" 75

32 30 1¼" 100

40 50 1½" 200

50 75 2" 300

65 100 2½" 500

80 200 3" 800

100 300 4" 1000

125 400 5" 2000

150 600 6" 3000

200 1000 8" 5000

250 2000 10" 7700

300 2500 12" 10000

350 3000 14" 10000

400 4500 16" 20000

450 6000 18” 25000

500 7000 20” 30000

600 10000 24” 40000

700 15000 28” 60000

800 20000 32” 80000

900 25000 36” 100000

1000 30000 40” 100000

1200 40000 48” 200000

53

FW: 842018/842009

Page 54

Electromagnetic Flow Meter

Set to metric

All converter-related units can be set to the following units (default

values in bold italics)

:

Flow Unit

m3/sec

l/sec

l/min

l/h

m3/h

RFTot RRTot RSTot FTot RTot Cnt

l l l

hl hl hl hl hl hl

kl kl kl kl kl kl

3

m

m

Totalizers

l l l

3

3

m

3

m

3

m

Set to US

All converter-related units can be set to the following units (default

values in bold italics)

Totalizers

3

3

ft

3

ft

3

ft

gal gal gal

Flow Unit

ft3/h

MGD

GPM

RFTot RRTot RSTot FTot RTot Cnt

3

ft

ft

gal gal gal

MG MG MG MG MG MG

3

m

3

ft

54EN 3.05 MagFlux Manual 1212

Page 55

Electromagnetic Flow Meter

Main Menu

Data Logger

Magflux® provides a data logger with a capacity of approx. 20,000 entry

points. See Appendix E on page 120 for examples and descriptions of log

files.

The data logger operates after the FIFO principle (First In, First Out). If the

data logger is full and new data are coming in, the oldest data are discarded.

1. Press the up/down keys to highlight the required menu line (here: Data

Logger) and then press OK to select it.

Specify Main Screen

Factory Settings

Data Logger

Data Logger

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to change the highlighted digit, and then press

the right-key (>) to proceed to the next digit.

Data Logger

Set Log Interval

Back Select >

0010 sec

3. Continue until all digits have been set and press OK.

The log interval can be set in intervals from 10 sec. up to 9999 sec.

55

FW: 842018/842009

Page 56

Electromagnetic Flow Meter

The data log contains:

• Date

• Time

• Flow values

In case of a power failure, the data logger continues when power returns.

If more converters are connected to one Display Unit, each converter has

its own individual log interval and can be sorted.

All converters share the same memory of 160.000 entry points.

The log data can be shown on the Display Unit or be stored in an external

CSV file. MJK-Field Link software is needed for transfer of data into CSV

file format via the USB port in the display unit. The format can be read in

for example Microsoft

An example of the log capacity of one sensor versus the time interval is

shown in the following table.

Seconds Minutes Hours Days

10 - 444,45 18,51

30 - 1333,34 55,55

- 1 2667 111

- 5 13333 555

- 10 26667 1111

- 30 80000 3333

- 60 160000 6667

®

Excel® (see Appendix B on page 120 for details).

Log interval Log capacity

56EN 3.05 MagFlux Manual 1212

Page 57

Electromagnetic Flow Meter

10.000M3/H

2006-08-21

16:09:42 3.039M3/H

<< >>< >

Innlet flow

flow

32,5

m3/h

cnt 1 312535 m3

Select Graph

Graph Display

The content of the Data Logger can displayed on the Display Unit by

pressing the up/down keys simultaneously (esc), highlighting "Flow" and

selecting "Graph"

Inlet flow

flow

32,5 m3/h

cnt 1 312535 m3

Select Graph

The Display Unit then shows the Graph screen. To return to the Main

Menu display screen, select "esc" by pressing the up/down keys simultaneously.

The Y axis is automatically scaled according to the Qmax of the mA output.

Double-arrow keys jump forward and backward one screen frame at a

time. Single-arrow keys move the cursor forward and backward on the

screen.

The actual values at the cursor position is shown at the bottom of the

screen.

57

FW: 842018/842009

Page 58

Electromagnetic Flow Meter

Main Menu

Password

A password provides (and prevents) access to all the settings in the

Display and Converter unit. The code consists of a numeric 5-digit code

between 0 and 65535. If your current password is lost or forgotten, the

password protection can be overruled with the code "01750".

1. Press the up/down keys to highlight the required menu line (here: Pass-

word) and then press OK to select it.

Specify Main Screen

Factory Settings

Data Logger

Password

Password

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required option and then press

OK to select it.

Password

Type Password

00000

Back Select >

Login

Login

Activate/Deactivate

Change Password

Back Select OK

Activate/

Deactivate

Activate

Deactivate

Back Select OK

58EN 3.05 MagFlux Manual 1212

Change Password

Set New Password

00000

Back Select >

Page 59

Electromagnetic Flow Meter

Main Menu

The available options are:

Login

Use the up/down keys to set the digits one by one. Continue with >

until all digits have been set and then press OK.

Activate/Deactivate

Write protection. Selecting "Activate" means that a password must

be entered to change vital settings. "Deactivate" disables password

protection.If your current password is lost or forgotten, the password

protection can be overruled with the code "01750".

Change Password

The present 5-digit password can be changed as required.

Set Sensor Name

A unique name and/or number, a function or a location can be assigned

for a sensor (here: "MagFlux1"). It is consequently shown on the main

display with up to 4 display lines.

MagFlux1

Flow

32,5

Cnt 1 312535 m3

Back Select Setup

m3/h

1. Press the up/down keys to highlight the required menu line (here: Set

Sensor Name) and then press OK to select it.

Specify Main Screen

Factory Settings

Data Logger

Password

Set Sensor Name

Set Sensor Name

Converter Setup

Display Setup

Back Select OK

59

FW: 842018/842009

Page 60

Electromagnetic Flow Meter

Set Sensor Name

MagFlux1

Back Select >

Set Sensor Name

2. To change the default sensor name (MagFlux1), press the left/right keys

to highlight the wanted character.

3. Press the up/down keys to change the highlighted character and then

press > to proceed to the next character.

4. Continue with > until all numeric and alphabetical characters have been

set to for example "Inlet flow" (see below).

5. Press OK.

The available characters depend on the chosen language. English, for

example, provides the following character set:

a b c d e f g h i j k l m n o p q r s t u v w x y z A B C D E F G H I J K L M N

O P Q R S T U V W X Y Z <space> 1 2 3 4 5 6 7 8 9 and 0.

Inlet flow

Flow

32,5

Cnt 1 312535 m3

Back Select Setup

m3/h

60EN 3.05 MagFlux Manual 1212

Page 61

Electromagnetic Flow Meter

Main Menu

Converter Setup

Converter Setup

Minimum Flow

Averaging

Units

mA Output

R Totalizer Forward

R Totalizer Reverse

R Totalizer Sum

NR Totalizer Forward

NR Totalizer Reverse

NR Totalizer Sum

Batch Counter 1

Batch Counter 2

High Flow

Low Flow

Flow Direction

Empty Pipe

Status

Service Menu

Minimum Flow

24h Flow

Converter Setup

"Converter Setup" provides configuration options for volumes, batches,

units, etc. See detailed descriptions in the following sections and in the

overview pages at the end of this manual.

1. Press the up/down keys to highlight the required menu line (here: Converter Setup) and then press OK to select it.

Specify Main Screen

Factory Settings

Data Logger

Password

Set Sensor Name

Converter Setup

Converter Setup

Display Setup

Back Select OK

2. Press the up/down keys to highlight the required option and then press

OK to select it.

The available options are described in detail in the following sections.

61

FW: 842018/842009

Page 62

Electromagnetic Flow Meter

Averaging

Units

Averaging

0010 sec

Back Select >

Flow Forward

Flow Reverse

Forward & rev. (12mA=0)

Forward & rev. (4 mA=0)

Not in use

Back Select OK

Flow

m

3

/sec

l/sec

l/min

l/h

m

3

/h

3

Units

mA Output

Flow Forward

Flow Reverse

Forward & rev. (12mA=0)

Forward & rev. (4 mA=0)

Not in use

Back Select OK

Flow

m

3

/sec

l/sec

l/min

l/h

m

3

/h

3

Minimum Flow

The "Minimum Flow" option sets the minimum flow rate.

Magflux® flow meters are default set to the values shown on page 17.

The unit for the flow rate can be set from the "Units" option (see page 64).

Minimum Flow

Minimum Flow

0.177 m

Back Select >

3

/h

1. Select the digits one by one with the left/right keys and set the value

with the up/down keys.

2. Press OK to save the final setting.

Averaging

The "Averaging" option sets the time period within which the measurements are smoothed and averaged.

Averaging

Averaging

Back Select >

1. Select the digits one by one with the left/right keys and set the value

with the up/down keys.

2. Press OK to save the final setting.

0010 sec

62EN 3.05 MagFlux Manual 1212

Page 63

Electromagnetic Flow Meter

mA Output

Flow Forward

Flow Reverse

Forward & rev. (12mA=0)

Forward & rev. (4 mA=0)

Not in use

Back Select OK

(4mA = 0 Flow)

(12mA = 0 Flow, +4mA = - 20mA)

Units

The "Units" option sets the unit for the flow rate. The available units are

shown below.

Units

3

m

/sec

l/sec

l/min

l/h

3

m

/h

3

ft

/h

MGD

GPM

Back Select OK

Flow

1. Press the up/down keys to highlight the required unit and then press

OK to select it.

mA Output

When a MagFlux® is connected to a power supply for the first time, the

mA output is automatically set to provide 4 mA at zero flow and 20 mA at

a flow corresponding to the theoretical Qmax of the flow sensor.