Page 1

• Safety Instructions

IM251R01

• Installation

• Operation

• Maintenance

• Warranty

Owner’s Manual

WATER SYSTEM TANK

SAFETY Label Part No. 205817

must be installed. If missing or

destroyed it must be replaced.

Certified to NSF/ANSI 61G

French version begins on page 9.

La version française commence à la page 9.

Thank you for purchasing our product. All Technical and Warranty

Spanish version begins on page 17.

Para la versión en español vaya a la página 17.

PRODUCT DESCRIPTION: Water System Tanks are a precharged diaphragm type vessel which have been manufactured to meet the requirements

of ANSI/NSF Standard-61 (for potable water). This product is specifically designed for ambient temperature water applications “only” where constant

system pressure is desired to minimize pump cycle (preventing frequent stops and starts). It is highly recommended that you enlist the aid of a qualified

service professional to properly size, install, and regularly maintain your Water System Tank to ensure years of safe and troubl

questions should be directed to your local dealer or you may write

us at the address provided on “page 7” of this manual.

e free service.

INSTALLER: PLEASE LEAVE THIS MANUAL FOR OWNER’S USE.

www.completewatersystems.com

For parts, product & service information visit 325116-000

1

Page 2

SAFETY GUIDELINES

Your safety and the safety of others is extremely important in the installation, use and servicing of this product. Many safetyrelated messages and instructions have been provided in this manual and on your own water tank to warn of potential hazards.

CAREFULLY READ AND OBEY ALL SAFETY MESSAGES AND INSTRUCTIONS BEFORE ATTEMPTING TO ASSEMBLE,

INSTALL, OPERATE, OR MAINTAIN THIS PRODUCT. To help recognize this information please observe the following symbols.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message

and how to avoid the risk of injury.

IMPORTANT DEFINITION:

NSF (National Sanitation Foundation) - NSF International is The Public Health and Safety Company™, providing public health and

safety risk management solutions to companies, governments and consumers around the world.

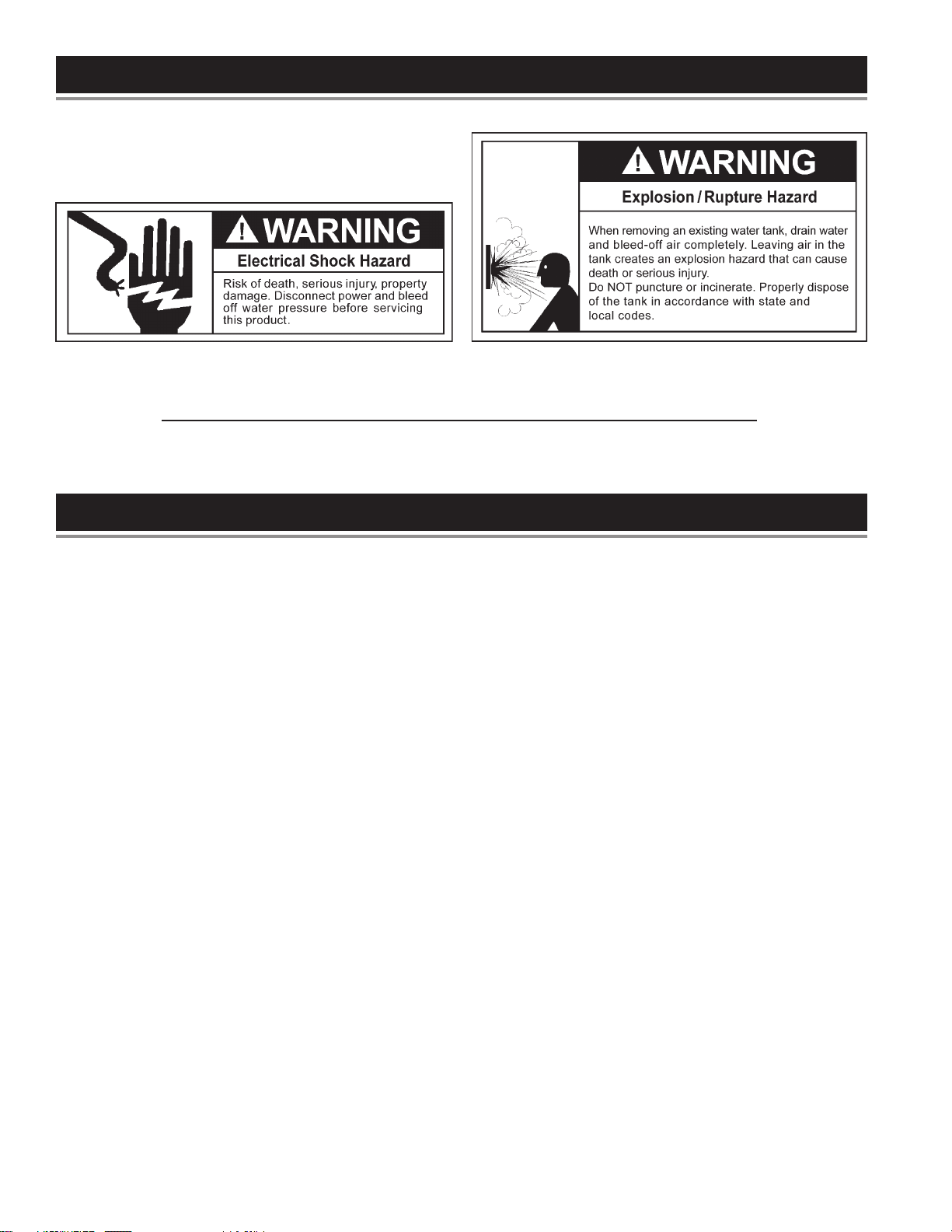

SAFETY WARNINGS AND INSTRUCTIONS

WARNING

Electrical Shock Hazard

Risk of death, serious injur y, property

damage. Disconnect power and bleed

off water pressure before servicing

this product.

2

Page 3

TABLE OF CONTENTS

SAFETY GUIDELINES .............................................................. 2

Important Denition ............................................................ 2

SAFETY WARNINGS AND INSTRUCTIONS ............................ 2

FEATURES AND OPERATING CYCLES .................................. 3

The Water Systems Tank Concept ............................................ 3

INSTALLATION PROCEDURES ............................................... 4

Typical Submersible Pump Installation ...................................... 4

Typical Jet Pump Installation .............................................. 4

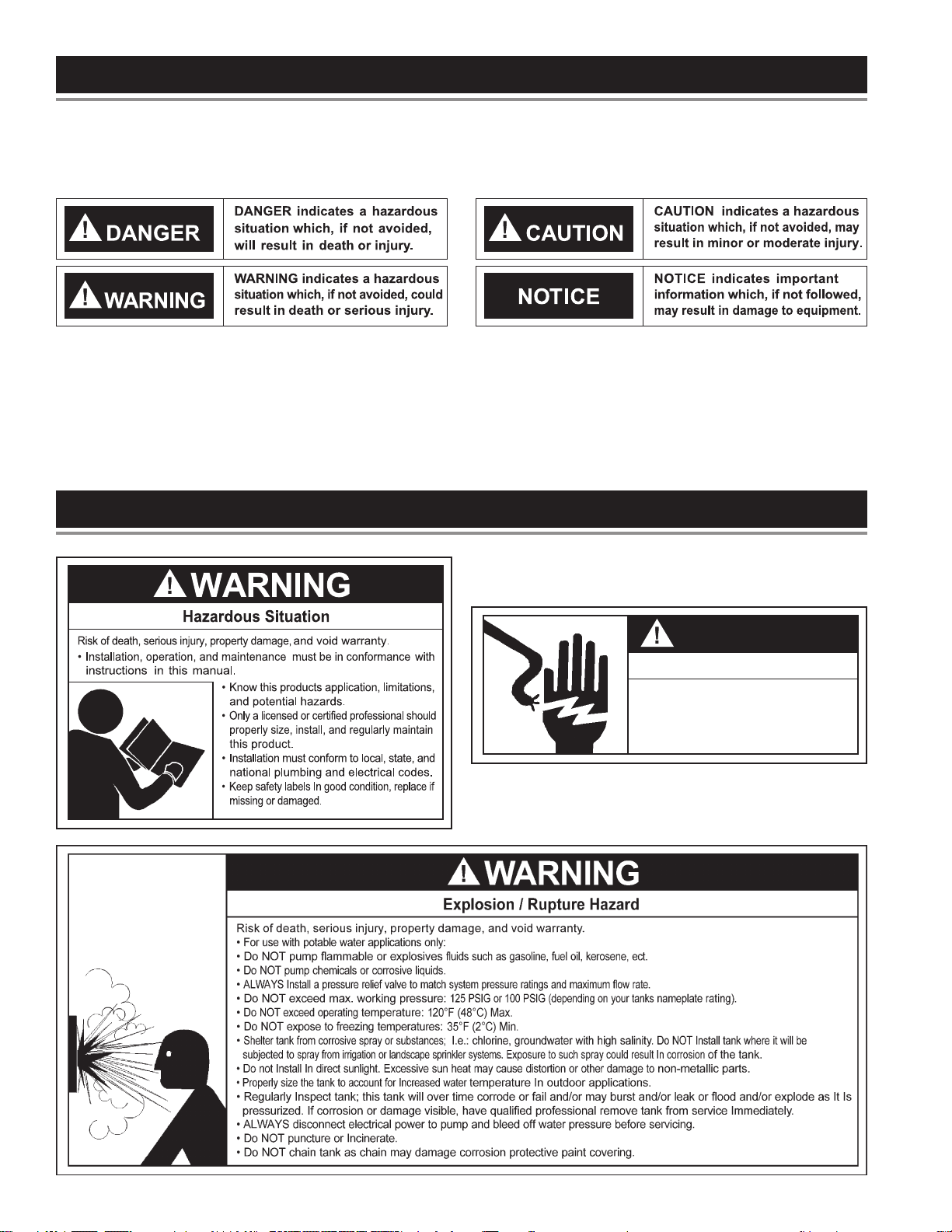

FEATURES AND OPERATING CYCLES

The Water Systems Tank Concept

The water system tank does more than simply store water. It

helps to protect the system components. A properly sized tank

will provide adequate ow even when the pump is not running. It

saves energy by reducing the number of pump starts. In addition,

the water system tank provides increased system component life

due to fewer pump cycles.

The water system tank consists of a steel tank (A) containing a

sealed-in-place heavy duty diaphragm (B) which separates air

from the water. The portion of the tank where water is stored (C)

is lined to isolate water from the metal tank. This protects the tank

from internal corrosion.

MULTIPLE TANK INSTALLATION PROCEDURE ..................... 4

OPERATION .............................................................................. 5

TROUBLE SHOOTING ............................................................. 5

Air Charge in Tank and Pressure Switch Setting ................ 5

Tank Decommision and Disoposal ..................................... 6

NOTES ...................................................................................... 6

WARRANTY .............................................................................. 7

1. Prior to shipping, the tank

is pressurized to a standard

precharge as defined in

the “OPERATION” part of

this manual.

2. A s water enters the

ta nk, the air above th e

diaphragm is compressed

and its volume is reduced

by the volume of water

that enters.

3. The pressure in the tank

rises. Water continues to

enter until the pump cut-out

pressure is reached. The

pump shuts off and the tank

is now lled.

AIR WATER

3

4. The pressure in the air

chamber forces water into

the system when a demand

occurs without causing the

pump to operate immediately.

Pressure in the chamber

finally drops to the pump

cut-in pressure, the pump

switch activates the pump and

repeats the lling cycle.

Page 4

INSTALLATION PROCEDURES

Typical Submersible Pump Installation

FIGURE 1.

1. When replacing an existing water tank, drain-off water and

bleed-off air completely from tank before discarding.

2. Set and position new tank on a rm, level surface with adequate

drainage. Typical installation shown in gures 1 & 2.

3. For best results use new piping; i.e.: Iron, copper, or rigid PVC.

Typical Jet Pump Installation

FIGURE 2.

4. If your system is capable of exceeding a working pressure of

125/100 psig (typically submersible pumps), install a pressure

relief valve (rated at 125/100 psig or less, but greater than

turn off pressure) in the system no more than 10 feet from the

tank. The valve should be the same pipe size as the tank outlet.

This is not necessary on tank-mounted jet pump units.

MULTIPLE TANK INSTALLATION PROCEDURE

Water system tanks can be connected together to increase supply

of usable water (drawdown). Two tanks of same size will double

the supply and three tanks will triple the supply. When using a high

capacity pump, the manifold and pressure switch assembly must

be installed in the pipe line as close to center of tanks as possible.

Manifold and main should be 2 times the size of feederline.

5. Connect tank to the pump discharge line using the same

size pipe as the pump tap, or larger.

6. The tank should be flushed 5 times prior to household

use, see Operation section.

4

Page 5

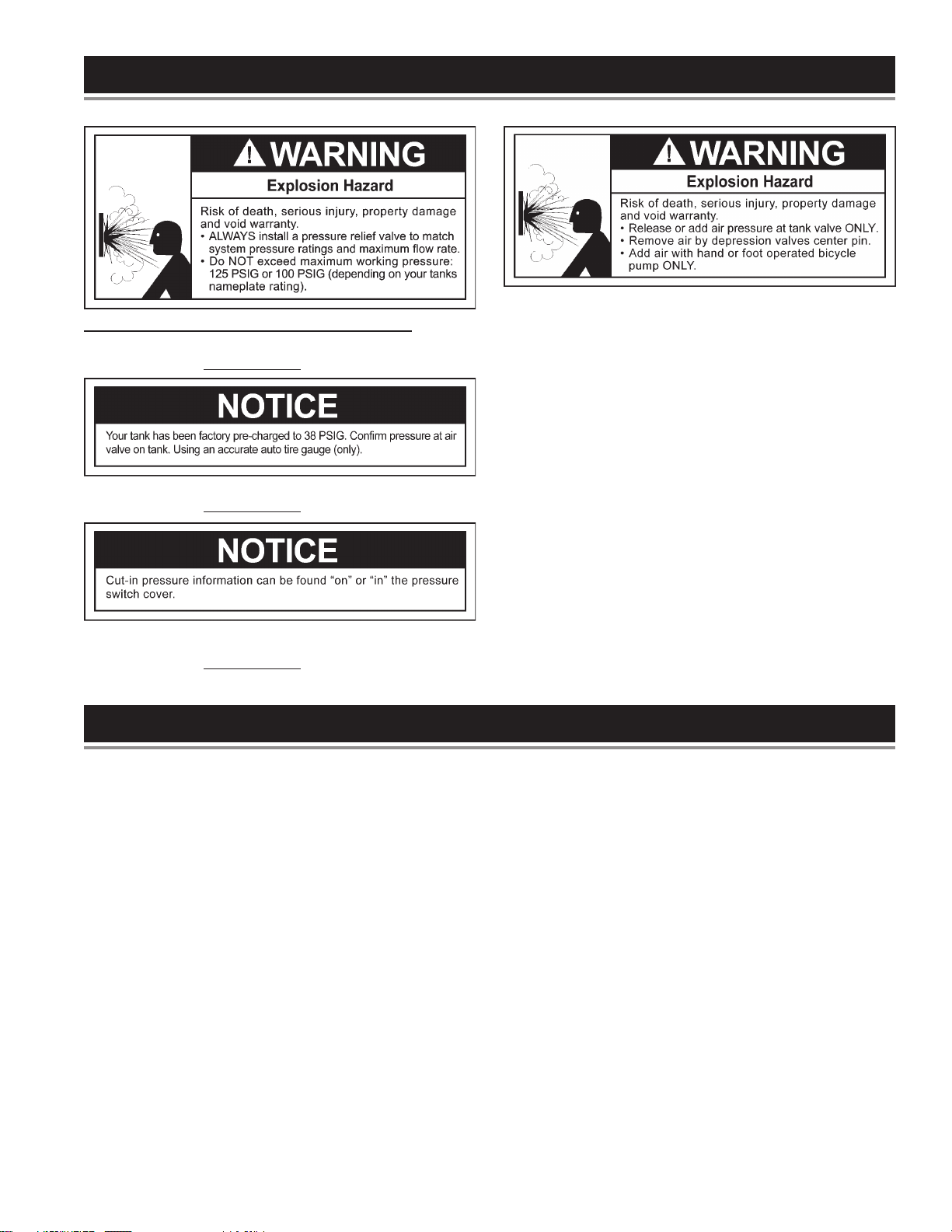

OPERATION

BEFORE PUMPING WATER INTO YOUR SYSTEM:

1. Verify your tanks standing air pressure:

• record here: PSIG (as received new)

2. Determine the pumps cut-in pressure setting:

• record here: PSIG (switch)

3. Adjust tanks pre-charge air pressure:

• 2-3 PSIG (below) cut-in pressure setting of pump.

• record here: PSIG (active tank).

4. Release air or add air to the tank to make the pressure in the

tank 2-3 psig LESS than the pump cut-in pressure setting.

5. It will be necessary to expel air from the piping system

on new installations. To do this open all faucets and turn on

the pump. Observe that a mixture of water and air will sputter

from the faucet. Run the system until a steady flow of

water exists. Open and close the faucets several times to

assure that all air has been removed. If streams do not

become steady, an air leak may exist. Check for leaks on

suction side piping.

6. It may be necessary to make nal adjustments on the system

pressure switch setting because at times the actual pressure

switch setting will vary from what is stated on the cover. Such

variation, though not harmful, could cause a momentary lag of

water delivery. To make this adjustment follow these steps:

a. Fill the system until the pump shuts off.

b. Open a faucet and drain water system tank until

c. If there is a pause in water ow from time water system tank is

emptied and pump starts up again, decrease air pressure in tank

until it is 2 to 3 psig below cut-in pressure setting. See Trouble

Shooting section 3(a-b) for procedure.

d. Close the faucets and rell the watersystem tank. Repeat

steps (b) and (c) if necessary until there is no longer a

pause in water ow.

pump starts.

TROUBLE SHOOTING

IF YOU THINK YOU HAVE A PROBLEM WITH YOUR WATER

SYSTEM TANK, YOU SHOULD MAKE THE FOLLOWING

TESTS AND OBSERVATIONS BEFORE YOU CALL YOUR

PROFESSIONAL DEALER.

1. Observe water system operation and note any unusual

occurrence such as water spurting from a faucet rather than

a steady ow (indicates air in the system) or short cycling of

the pump (rapid starts and stops).

2. In the event that evidence of a small leak near the water tting

appears, check at elbow. The introduction of cold water to

a warm tank may form condensation especially in warmer

climates. It is important to provide adequate drainage.

3. The tank drawndown is governed by the air pressure in the tank

and the cut-in and cut-out pressure settings on the pressure

switch. If you have concerns about the drawndown, you should

check those settings as follows:

a. Air charge in Tank. Turn off electric power to the pump.

Open a nearby faucet and drain the tank completely. Check

the pressure in the water system tank using a standard,

high quality tire gauge. If the air pressure in the tank is

not approximately 2-3 psi below the pump cut-in setting,

tank pressure must be adjusted by a qualified professional.

Replace the valve stem cap. For suspected air leakage

soapy water can be used to check the air valve and tank

seams for leaks. If a tank leak appears replacement by a

qualified professional is required.

b. Pressure Switch Setting. Start the pump allowing system

pressure to build until cut-off setting is reached (note gauge

pressure once pump stops). Then open faucet draining tank

down until cut-in setting is reached (note gauge pressure

once pump starts). The proper pressure differential would

be 20 psi (not exceeding 25 psi). If your system pressure

is not maintaining a proper differential you should contact

a qualified professional for service.

5

Page 6

TANK DECOMMISSION AND DISPOSAL

Your water system tank has a limited life expectancy and will undoubtedly

need to be replaced at some point. When decommissioning your old

pressurized tank it is necessary to follow these important procedures

to ensure safe disposal:

NOTES

6

Page 7

LIMITED WARRANTY

Xylem Inc , the warrantor, extends the following LIMITED WARRANTY to the owner of this water system tank.

1. TANK

If within five years after in stal lation the tank or, a pa r t thereof shall prove upon examination by the warrantor

to be defective in material or workmanship, the warrantor, at his option, shall exchange or repair such part or portion. The warranty on

the replacement tank will be limited to the unexpired term of the original warranty.

2. CONDITIONS AND EXPECTATIONS

This warranty shall apply only when the tank is installed in accordance with local plumbing and building codes, ordinances, regulations,

and good industry practices, and only when the tank is installed, operated and maintained in accordance with this manual and Seller’s

instructions. In addition, a high pressure electrical cut-off switch and/or a pressure relief valve must be installed when the tank is installed

on an ambient temperature water system whose maximum working pressure has the ability to exceed 100 pounds per square inch gauge (psig).

a. This warranty shall apply only when the water system is used:

(1) on ambient temperature water systems at pressures not exceeding the working pressure for the water system;

(2) in the United States, its territories or possessions, and Canada,

b. The following shall void this warranty: any accident, any misuse, physical damage, abuse (including freezing) to the water

system tank; any alteration of the tank; any operation of the tank in a modified form; any repair of the tank other than by

Seller or without Seller’s written approval; any damage from ordinary wear and tear, corrosion, or chemical attack; and

any damage due to a defective power supply or improper electrical protection,

c. Seller’s obligations to repair and/or replace hereunder are conditioned upon written notice of any alleged defect within

then (10) calendar days of its discovery.

3. SERVICE AND REPAIR EXPENSE

Under this limited warranty the warrantor will provide only a replacement tank or part thereof. The owner is responsible for all

other costs. Such costs may include but are not limited to:

a. Labor charges for service, removal, repai

b. Shipping and delivery charges for forwarding the new tank or replacement part from the nearest distributor and returning

the claimed defective tank or part to such distributor except in the state of California where such charges are the

manufacturer’s responsibility.

4. LIMITATION ON IMPLIED WARRANTIES

Implied warranties, including any warranty of merchantability imposed on the sale of this tank under state law are limited to five (5) year

duration for the tank or any of its parts. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you.

5. CLAIM PROCEDURES

Any claim under this warranty should be initiated with the dealer who sold the tank, or with any other dealer handling the warrantor’s

products. If this is not practicable, the owner should contact:

U.S. Customers Canadian Customers

Xylem Inc. Xylem Inc.

2881 East Bayard St. 55 Royal Road

Seneca Falls, NY 13148 Guelph, ON N1H1T1

a. The warrantor will only honor replacement with identical or similar tank or parts thereof which are manufactured or

distributed by the warrantor,

b. Dealer replacements are made subject to in-warranty validation by warrantor,

6. LIMITATIONS/DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE ON BEHALF OF THE WARRANTOR WITH RESPECT TO THE

TANK OR THE INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE TANK.

IN NO EVENT IS SELLER LIABLE FOR ANY OTHER FORM OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED,

INCIDENTAL, CONSEQUENTIAL, PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BU T NOT LIMITED TO

LOSS OF USE OF THE UNIT, INCONVENIENCE, LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS OF PROFIT,

LOSS OF PRODUCTION, LOSS OF ANTICIPATED SAVINGS OR REVENUE, OR LOSS OF OPPORTUNITY.

THE WARRANTOR SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE

TO ANY PERSONS OR PROPERTY, WHETHER DIRECT OR IND

a. Some states do not allow the exclusion or limitation of the incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

b. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state,

c. The terms of this agreement and all rights and obligations hereunder shall be governed by the laws of the jurisdiction of

seller’s office to which this order has been submitted.

Fill in the following for your own reference. Keep it. Registration is not a condition of warranty. The model and serial number are found on

the water system tank.

r, or reinstallation of the water system or any component part,

IRECT, AND WHETHER ARISING IN CONTRACT OR IN TORT.

Model No.________Serial No._____________________________Date Installed________ Dealer’s Name_______________________

__________________________________ Dealer’s Address________________________’._______________Phone No.___________

City & State (Provincial)______________________________________Zip (Postal Code)_______

KEEP THIS WARRANTY POSTED ADJACENT TO THE TANK FOR FUTURE REFERENCE.

7

Page 8

IM251R01

8

Page 9

Manuel d’instructions

IM251R01

RÉSERVOIR POUR SYSTÈME D’ALIMENTATION EN EAU

L’ÉTIQUETTE DE SÉCURITÉ

(pièce no 205817) doit être

fixée sur l’appareil. Dans le

ca s contraire ou si elle est

• Consignes de sécurité

• Installation

• Utilisation

• Entretien

• Garantie

endommagée, la remplacer.

Conforme à la norme

NSF/ANSI 61G

Nous vous remercions d’avoir acheté un de nos produits. Pour

toute question technique ou relative à la garantie, s’adresser

au détaillant local ou écrire à l’adresse indiquée à la page 7 du

présent manuel.

DESCRIPTION DU PRODUIT : Les réservoirs à diaphragme pour les systèmes d’alimentation en eau potable ont été fabriqués conformément aux normes

ANSI/NSF 61. Ils sont conçus uniquement pour l’eau à température ambiante et pour maintenir une pression d’eau constante, minimisant ainsi les cycles

de pompage (moins de départs et d’arrêts de la pompe). Afin que le réservoir pour système d’alimentation en eau soit sécuritaire et fonctionne correctement

pendant des années, il est fortement conseillé d’engager un technicien agréé pour le dimensionner, l’installer et l’entretenir régulièrement.

INSTALLATEUR : REMETTRE LE PRÉSENT MANUEL AU PROPRIÉTAIRE DE L’APPAREIL

www.completewatersystems.com

Pour en savoir plus sur les pièces, les produits et le service, consulter 325116-000

9

Page 10

DIRECTIVES DE SÉCURITÉ

Il est très important de veiller à sa sécurité et à celle des autres durant l’installation, l’utilisation et l’entretien de l’appareil. De

nombreux messages et consignes de sécurité sont indiqués dans le présent manuel et sur le réservoir d’eau pour mettre en

garde contre les risques potentiels. AVANT D’ASSEMBLER, D’INSTALLER, DE FAIRE FONCTIONNER OU D’ENTREPRENDRE

DES TRAVAUX D’ENTRETIEN, LIRE ATTENTIVEMENT TOUS LES MESSAGES DE SÉCURITÉ ET TOUTES LES INSTRUCTIONS

CONCERNANT CET APPAREIL. Les symboles ci-dessous indiquent les directives de sécurité.

ATTENTION indique un danger

qui, s’il n’est pas évité, risque

d’entraîner des blessures

mineures ou modérées.

AVIS indique une directive

importante qui, si elle n’est pas

suivie, risque d’entraîner des

dommages matériels.

DANGER

AVERTISSEMENT

DANGER indique un danger qui,

s’il n’est pas évité, causera des

blessures graves ou mortelles.

AVERTISSEMENT indique un

danger qui, s’il n’est pas évité,

risque de causer des blessures

graves ou mortelles.

ATTENTION

AVIS

En général, les messages de sécurité indiquent le type de danger encouru si les consignes ne sont pas respectées et les

moyens d’éviter les accidents.

DÉFINITION IMPORTANTE

NSF (National Sanitation Foundation) – NSF International, dont le slogan est The Public Health and Safety Company™, propose

aux entreprises, aux administrations publiques et aux consommateurs à l’échelle mondiale des solutions de gestion des risques en

matière de santé et de sécurité.

AVERTISSEMENTS ET INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT

Situation dangereuse

Risque de dommages, de blessures graves ou mortelles ou

d’annulation de la garantie.

• Installer, utiliser et entretenir l’appareil conformément aux

instructions du présent manuel.

• Connaître le cadre d’utilisation, les limitations et les dangers

potentiels de l’appareil.

• Faire dimensionner, installer et

régulièrement entretenir l’appareil par un

technicien agréé uniquement.

• Installer l’appareil conformément aux

codes locaux, provinciaux et nationaux

s’appliquant à la plomberie et à l’électricité.

• Garder les étiquettes de sécurité en

bon état. Les remplacer si elles ne sont

pas xées sur l’appareil ou si elles sont

endommagées.

10

Page 11

TABLE DES MATIÈRES

DIRECTIVES DE SÉCURITÉ .................................................... 2

Dénition importante .......................................................... 2

AVERTISSEMENTS ET INSTRUCTIONS DE SÉCURITÉ ....... 2

CARACTÉRISTIQUES ET CYCLES DE

FONCTIONNEMENT ................................................................. 3

Concept du réservoir pour système d’alimentation en eau 3

DIRECTIVES D’INSTALLATION ............................................... 4

Installation type avec pompe submersible ......................... 4

Installation type avec pompe à jet ...................................... 4

DIRECTIVES D’INSTALLATION DE

PLUSIEURS RÉSERVOIRS ...................................................... 4

UTILISATION ............................................................................. 5

DÉPANNAGE ............................................................................ 5

Pression d’air dans le réservoir et réglage du manostat .... 5

Mise hors service du réservoir et élimination ..................... 6

REMARQUES ........................................................................... 6

GARANTIE ................................................................................ 7

CARACTÉRISTIQUES ET CYCLES DE FONCTIONNEMENT

Concept du réservoir pour système d’alimentation en eau

Le réservoir pour système d’alimentation en eau ne sert pas

seulement à stocker de l’eau. Il aide à protéger les composants

du système. Un réservoir de capacité appropriée assure un bon

débit d’eau même lorsque la pompe ne fonctionne pas. Il permet

d’économiser l’énergie en réduisant le nombre de démarrages de

la pompe. Enn, il augmente la durée de vie des composants du

système en réduisant le nombre de cycles de la pompe.

Le réservoir pour système d’alimentation en eau est constitué d’un

réservoir en acier (A) comprenant une membrane (B) hermétique

très résistante qui sépare l’air de l’eau. La partie du réservoir où

se trouve l’eau (C) est dotée d’un revêtement servant à isoler l’eau

de la paroi métallique et ainsi à protéger l’intérieur du réservoir

contre la corrosion.

1. Ava n t l’e xp éd it i o n ,

le réservoir reçoit une

pressi o n de précha r g e

standard, précisée à la

rubrique « Utilisation » du

présent manuel.

2. À mesure que de l’eau est

admise dans le réservoir,

l’air situé au-dessus de la

membrane se comprime

et son volume diminue en

fonction de celui de l’eau.

3. La pression du réservoir

augmente. L’admission

d’eau se poursuit jusqu’à ce

que la pression de coupure

de la pompe soit atteinte.

La pompe s’arrête, et le

réservoir est maintenant

plein.

AIR EAU

4. En raison de la pression

d’air dans la chambre étanche,

l’eau s’engage dans le système

lorsqu’une demande se produit

sans entraîner la mise en

marche immédiate de la pompe.

La pression dans la chambre

diminue jusqu’à atteindre la

pression d’enclenchement de

la pompe. Le manostat active

alors la pompe, qui exécute le

cycle de remplissage.

11

Page 12

DIRECTIVES D’INSTALLATION

Installation type avec pompe submersible

FIGURE 1.

1. Avant de remplacer un réservoir d’eau, le vider complètement

et relâcher la pression interne.

2. Placer le nouveau réservoir sur une surface plane, solide et bien

drainée. Deux installations types sont illustrées aux gures 1 et 2.

3. Pour obtenir de meilleurs résultats, utiliser de nouvelles conduites

(cuivre, acier, PVC rigide, etc.).

Installation type avec pompe à jet

FIGURE 2.

AVIS

AVIS

Pour un rendement optimal, il faut réduire les pertes de charge

causées par le frottement et la dénivellation : installer le réservoir le

plus près possible du manostat (24 po/61 cm ou moins).

4. Si le système risque de produire une pression de service

supérieure à 125 ou à 100 lb/po

généralement le cas des systèmes avec pompe submersible,

intégrer au système, à moins de 10 pi (3 m) du réservoir, une

soupape de décharge avec une pression nominale de 125 ou

de 100 lb/po2 (861,8 ou 689,4 kPa) ou moins, mais supérieure à

la pression d’arrêt de la pompe. La soupape doit avoir le même

diamètre que la sortie du réservoir. Cette opération n’est pas

nécessaire pour les réservoirs avec une pompe à jet.

2

(862 ou 689 kPa), ce qui est

Risque de dommages. Des efforts trop élevés appliqués sur le raccord

durant l’installation peuvent endommager le réservoir ou le raccord.

Toujours soutenir le raccord du réservoir avec une clé pendant le

letage ou le serrage de la conduite de raccordement.

5. Raccorder le réservoir à la conduite d’évacuation de la pompe

au moyen d’un tuyau d’un diamètre égal ou supérieur à celui

de la prise de la pompe.

6. Le réservoir doit être vidangé cinq fois avant que l’eau puisse

servir à un usage domestique (voir la rubrique « Utilisation »).

DIRECTIVES D’INSTALLATION DE PLUSIEURS RÉSERVOIRS

Il est possible de relier plusieurs réservoirs pour augmenter le volume

d’eau disponible entre l’arrêt et le départ de la pompe (tirage) : deux ou

trois réservoirs de même capacité permettent de doubler ou de tripler

la quantité d’eau disponible. Avec une pompe de grande capacité,

installer le collecteur et le manostat sur la conduite le plus près

possible du centre du groupe de réservoirs. Le collecteur et la

conduite principale doivent être deux fois plus gros que la conduite

d’alimentation.

12

Page 13

UTILISATION

AVANT DE POMPER DE L’EAU DANS LE SYSTÈME

1. Vérier la pression d’air du réservoir vide d’eau.

• Pression à la réception du réservoir =

lb/po

2

(ou kPa)

AVIS

Le réservoir est prérempli d’air à une pression de 38 lb/po2 (262 kPa).

Cette pression doit être conrmée au niveau de la soupape du réservoir

uniquement à l’aide d’un manomètre pour pneus sufsamment précis.

2. Indiquer la pression d’enclenchement de la pompe.

• Pression au manostat = lb/po

2

(ou kPa)

AVIS

Des renseignements sur la pression d’enclenchement sont indiqués à

l’extérieur ou à l’intérieur du couvercle du manostat.

3. Ajustement de la pression de précharge.

• Régler la pression du réservoir à 2-3 lb/po

de moins que la pression d’enclenchement de la pompe.

• Pression du réservoir en service =

lb/po2 (ou kPa)

2

(13,8-20,7 kPa)

4. Faire sortir ou entrer de l’air pour que la pression dans le

réservoir soit de 2 ou 3 lb/po

2

(13,8 ou 20,7 kPa) INFÉRIEURE

à la pression d’enclenchement de la pompe.

5. Il faut purger l’air des canalisations pour toute nouvelle

installation. Pour ce faire, ouvrir tous les robinets et mettre

la pompe en marche. Les robinets devraient projeter un

mélange d’eau et d’air. Faire fonctionner le système jusqu’à

ce que l’eau coule librement. Ouvrir et fermer plusieurs fois

les robinets pour s’assurer que l’air a été entièrement purgé

des canalisations. Si l’écoulement d’eau est variable, vérier

s’il n’y a pas une fuite d’air dans les conduites d’aspiration.

6. Il peut être nécessaire d’ajuster le réglage du manostat, car le

réglage réel diffère parfois de ce qui est indiqué sur le couvercle

du manostat. Un tel écart n’est pas dangereux, mais pourrait

retarder momentanément l’acheminement de l’eau. Voici les

étapes à suivre pour faire cet ajustement :

a) Remplir le système jusqu’à ce que la pompe s’arrête.

b) Ouvrir un robinet et vider le réservoir jusqu’à la mise en

marche de la pompe.

c) Si l’écoulement de l’eau est momentanément interrompu

entre la n de la vidange du réservoir et le démarrage

de la pompe, réduire la pression d’air dans le réservoir

jusqu’à ce qu’elle soit de 2 ou 3 lb/po

2

(13,8 ou 20,7 kPa)

inférieure à la pression d’enclenchement de la pompe.

Pour en savoir plus, consulter les sections 3a) et 3b)

de la rubrique « Dépannage ».

d) Fermer les robinets et remplir d’eau le réservoir. Au

besoin, répéter les étapes b) et c) jusqu’à ce que

l’écoulement de l’eau soit continu.

DÉPANNAGE

SI UN PROBLÈME SEMBLE TOUCHER LE RÉSERVOIR,

FAIRE LES ESSAIS ET VÉRIFIER LES ÉLÉMENTS

CI-DESSOUS AVANT D’APPELER LE DÉTAILLANT.

1. Observer le fonctionnement du système d’alimentation en

eau et noter tout signe inhabituel, comme de l’air projeté d’un

robinet au lieu de l’écoulement normal de l’eau ou un bref

cycle de fonctionnement de la pompe (démarrages et arrêts

fréquents).

2. S’il semble y avoir une petite fuite près du tuyau d’eau, vérier

le coude. L’admission d’eau froide dans un réservoir ayant

une température plus élevée peut causer de la condensation,

surtout sous des climats chauds. Il est important d’assurer un

bon drainage.

3. Le tirage du réservoir est régi par la pression d’air à l’intérieur

de celui-ci et les réglages du manostat pour l’arrêt et le

redémarrage de la pompe. En cas de problème avec le tirage,

vérier les éléments suivants :

a. Pression d’air dans le réservoir. Mettre la pompe hors

tension. Ouvrir un robinet à proximité et vider complètement

le réservoir. Vérier la pression de l’air dans le réservoir au

moyen d’un manomètre standard précis. Si la pression dans

le réservoir n’est pas de 2 à 3 lb/po

2

(de 13,8 à 20,7 kPa)

inférieure à la pression d’enclenchement de la pompe,

elle doit être ajustée par un technicien agréé. Remettre en

place le capuchon de tige de soupape. Si une fuite d’air est

soupçonnée, appliquer de l’eau savonneuse sur la soupape et

les joints du réservoir. Dans le cas où une fuite est présente,

faire remplacer le réservoir par un technicien agréé.

b. Réglage du manostat. Démarrer la pompe pour mettre le

système sous pression jusqu’à ce que la pression d’arrêt

de la pompe soit atteinte. Prendre note de la pression au

manomètre lorsque la pompe s’arrête. Ensuite, ouvrir le

robinet de vidange du réservoir jusqu’à ce que la pression

d’enclenchement de la pompe soit atteinte. Prendre note

de la pression au manomètre lorsque la pompe démarre.

Le différentiel de pression devrait idéalement être 20 lb/po

(138 kPa), mais jamais supérieure à 25 lb/po

2

(172 kPa). Si le

système ne peut maintenir un différentiel de pression adéquat,

demander à un technicien agréé de vérier le système.

13

2

Page 14

MISE HORS SERVICE ET ÉLIMINATION DU RÉSERVOIR

Le réservoir ayant une durée de vie limitée, il faudra certainement

le remplacer tôt ou tard. Pour mettre hors service un réservoir sous

pression en toute sécurité, suivre les directives ci-dessous.

REMARQUES

14

Page 15

GARANTIE LIMITÉE

Xylem, Inc., le garant, offre la GARANTIE LIMITÉE ci-dessous au propriétaire du réservoir pour système d’alimentation en eau.

1. RÉSERVOIR

Si, au cours des cinq années qui suivent l’installation initiale, le réservoir ou un de ses éléments présente, après inspection par le garant,

des défauts de matériau ou des vices de fabrication, le garant s’engage, à sa discrétion, à le réparer ou à le remplacer. La garantie

s’appliquant au réservoir de remplacement se limitera alors à la période restante de la garantie d’origine.

2. CONDITIONS ET ATTENTES

La présente garantie ne s’applique que si le réservoir est installé conformément aux codes locaux de la plomberie et du

bâtiment, aux ordonnances et règlements en vigueur, aux instructions fournies avec l’appareil et aux normes sectorielles

et que s’il est installé, utilisé et entretenu conformément au présent manuel et aux instructions du fournisseur. De

plus, si le réservoir est relié à un systè

maximale peut dépasser 100 lb/po

a) La présente garantie ne s’applique que si le réservoir pour système d’alimentation en eau est :

1) utilisé avec un système d’alimentation en eau à température ambiante à une pression ne dépassant pas la pression de service

2) est utilisé au Canada, aux États-Unis, dans leurs territoires et possessions.

b) L’endommagement accidentel du chauffe-eau, l’usage abusif ou inapproprié (notamment en cas de dommages causés par le gel),

c) Le fournisseur n’est tenu de réparer ou de remplacer l’appareil décrit ci-dessous que si les prétendus défauts lui sont signalés par

3. FRAIS D’ENTRETIEN ET DE RÉPARATION

Conformément à la présente garantie, la responsabilité du garant se limite à fournir un réservoir de remplacement ou une pièce de

a) Les frais de main-d’œuvre pour l’entretien, la réparation, la désinstallation ou la réinstallation du réservoir ou de la pièce;

b) Les frais d’expédition et de livraison du nouveau réservoir ou des pièces de rechange à partir du distributeur le plus proche de même que

4. LIMITES DES GARANTIES IMPLICITES

Les garanties implicites, y compris toute garantie de qualité marchande que les lois locales (province ou État) imposent à la vente du

5. DEMANDE DE RÉPARATION OU DE REMPLACEMENT

Toute demande de réparation ou de remplacement en vertu de la présente garantie doit être adressée au fournisseur du réservoir ou à

Aux États-Unis Au Canada

Xylem, Inc. Xylem, Inc.

2881 East Bayard St. 55 Royal Road

Seneca Falls, NY 13148 Guelph ON N1H 1T1

a) Pour le remplacement, le garant s’engage à fournir un réservoir ou des pièces de rechange identiques ou semblables, qu’il fabrique

b) Les remplacements effectués par le détaillant doivent être autorisés par le garant pendant la période de validité de la garantie.

6. LIMITATIONS ET EXONÉRATION DE RESPONSABILITÉ

AUCUNE GARANTIE EXPRESSE

a) Les restrictions ou exclusions ci-dessus ne s’appliquent pas dans les provinces ou États qui n’autorisent pas l’exclusion ou la restriction

b) La présente garantie confère au propriétaire des droits particuliers auxquels peuvent s’ajouter d’autres droits établis par l’État ou la

c) Les modalités de la présente entente ainsi que tous les droits et toutes les obligations s’y rattachant sont assujettis aux lois auxquelles

Entrer les renseignements demandés ci-dessous et conserver le document à des fins de consultation. Les conserver. L’inscription auprès du fabricant

n’est pas une condition de la garantie. Le

du système;

la modification non autorisée, l’utilisation après modification ou la tentative de réparer des fuites du réservoir par un agent autre que

le fournisseur ou sans le consentement écrit de celui-ci et l’endommagement causé par l’usure normale, la corrosion, les produits

chimiques, une alimentation électrique défectueuse ou une protection électrique inadéquate entraînent l’annulation de la garantie.

écrit dans les dix jours de leur constatation.

rechange. Tous les autres frais sont à la charge du propriétaire. Ceux-ci peuvent comprendre ce qui suit, mais sans s’y limiter :

les frais de retour du réservoir ou des éléments défectueux à ce distributeur, sauf en Californie où ces frais incombent au fabricant.

réservoir, se limitent à une période de cinq ans pour le réservoir et ses pièces. Comme certaines provinces ou certains États interdisent

de limiter la durée d’une garantie implicite, les présentes limites peuvent ne pas s’appliquer.

tout autre détaillant chargé de la vente ou de l’entretien des produits du garant. Si cela n’est pas possible, le propriétaire doit transmettre

sa demande à l’une des adresses suivantes :

ou distribue lui-même.

RELATIVE AU RÉSERVOIR OU À L’INSTALLATION, AU FONCTIONNEMENT, À LA RÉPARATION

OU AU REMPLACEMENT DU RÉSERVOIR N’EST OU NE SERA ACCORDÉE AU NOM DU GARANT. LE FOURNISSEUR NE PEUT

ÊTRE TENU RESPONSABLE DES DOMMAGES SOUS TOUTES LEURS FORMES, QU’ILS SOIENT, DIRECTS, INDIRECTS,

EXTRAJUDICIAIRES, ACCESSOIRES, PUNITIFS OU SPÉCIAUX, Y COMPRIS NOTAMMENT DES PERTES OU DES DOMMAGES

MATÉRIELS, D’UN MANQUE À GAGNER OU DE LA PERTE D’UTILISATION, DE JOUISSANCE DE L’APPAREIL, DE PRODUCTION,

D’ÉCONOMIES OU DE REVENUS PRÉVUS OU D’OCCASIONS D’AFFAIRES. LE GARANT NE PE

EN VERTU DE LA PRÉSENTE GARANTIE OU AUTREMENT, DES DOMMAGES DIRECTS OU INDIRECTS TOUCHANT LES PERSONNES

OU LES BIENS, PEU IMPORTE QUE CES DOMMAGES SOIENT INHÉRENTS AU CONTRAT OU DE NATURE DÉLICTUELLE.

des dommages consécutifs ou indirects. Par conséquent, elles peuvent ne pas s’appliquer dans le cas présent.

province de résidence.

est soumis le fournisseur de l’appareil concerné.

numéro de modèle et le numéro de série sont inscrits sur la plaque signalétique du réservoir.

me d’alimentation en eau à température ambiante dont la pression de service

2

(689,5 kPa), il faut installer un manostat électrique ou une soupape de décharge.

UT ÊTRE TENU RESPONSABLE,

Modèle : ____________ N° de série : ________________________________ Date d’installation : __________________________

Nom du détaillant : _____________________________________ Adresse du détaillant : _______________________________________

Tél. : ____________________ Ville et province ou État : _________________________________________ Code postal : ____________

GARDER CETTE GARANTIE À PROXIMITÉ DU RÉSERVOIR POUR CONSULTATION ULTÉRIEURE.

15

Page 16

IM251R01

16

Page 17

• Medidas de seguridad

IM251R01

• Instalación

• Funcionamiento

• Mantenimiento

• Garantía

Manual del usuario

TANQUE DE SISTEMA DE AGUA

Debe instalarse la etiqueta de

SEGURIDAD con el no. de pieza

205817. Debe reemplazarse si

falta o presenta daños.

Este producto cumple con los

requisitos de la norma NSF/ANSI 61G

Gracias por haber comprado nuestro producto. Para aclarar

cualquier duda técnica o sobre la garantía, comuníquese

directamente con su distribuidor local o escríbanos a la dirección

que se indica en la “página 7” de este manual.

DESCRIPCIÓN DEL PRODUCTO: Los tanques de sistema de agua son tanques de diafragma precargados, fabricados de conformidad con la norma

ANSI/NSF 61 (para agua potable). Este producto está diseñado específicamente para usarse “únicamente” con aplicaciones de agua a temperatura

ambiente cuando se requiere una presión constante para minimizar el ciclo de la bomba (con lo que se previenen arranques y paradas frecuentes). Es

muy importante que un técnico de servicio calificado verifique que su tanque de sistema de agua sea del tamaño adecuado, se instale correctamente

y reciba mantenimiento regularmente a fin de que funcione de forma segura y sin problemas por mucho tiempo.

INSTALADOR: ESTE MANUAL DEBE CONSERVARLO EL PROPIETARIO.

www.completewatersystems.com

Si requiere información sobre piezas, productos y servicios, visite 325116-000

17

Page 18

INDICACIONES DE SEGURIDAD

La seguridad de usted y de cualquier otra persona es absolutamente importante durante la instalación, uso y mantenimiento

de esta unidad. La información incluida en este manual y en su tanque de agua proporciona una gran cantidad de mensajes

e instrucciones sobre seguridad que tienen el propósito de advertirle sobre peligros potenciales. ANTES DE PROCEDER

A LA INSTALACIÓN, OPERACIÓN O MANTENIMIENTO DE ESTE PRODUCTO, LEA CON ATENCIÓN Y SIGA TODAS LAS

INSTRUCCIONES Y MEDIDAS DE SEGURIDAD. Los siguientes símbolos pueden ayudarle a identicar este tipo de información.

PELIGRO

ADVERTENCIA

PELIGRO indica una situación

de peligro probable que, si se

ignora, originará lesiones graves

o mortales.

ADVERTENCIA indica una

situación de peligro probable

que, si se ignora, podría originar

lesiones graves o mortales.

CUIDADO

ATENCIÓN

CUIDADO indica una situación

de peligro probable que, si se

ignora, puede originar lesiones

menores o moderadas.

ATENCIÓN indica información

importante que, si se ignora,

puede ocasionar daños

materiales.

En general todos los mensajes de seguridad indicarán el tipo de peligro, los riesgos que se corren si no se siguen las

medidas de seguridad, y la forma en que pueden evitarse los riesgos de sufrir lesiones.

DEFINICIONES IMPORTANTES:

NSF (National Sanitation Foundation) - NSF International es The Public Health and Safety CompanyMR, que provee soluciones de

gestión de riesgos de salud y seguridad pública a compañías, gobiernos y consumidores de todo el mundo.

INSTRUCCIONES Y ADVERTENCIAS DE SEGURIDAD

ADVERTENCIA

Situación de peligro

Riesgo de muerte, lesiones graves, daños materiales e invalidación

de garantía.

• Para la instalación, operación y mantenimiento deben seguirse las

instrucciones contenidas en este manual.

• Usted debe familiarizarse con la aplicación, las limitaciones y los

riesgos potenciales de este producto.

• Únicamente un profesional certicado y

autorizado debe encargarse de medir,

instalar y dar mantenimiento regularmente

a este producto.

• La instalación debe hacerse de

conformidad con los códigos de plomería y

electricidad locales, estatales y nacionales.

• Las etiquetas de seguridad deben

mantenerse en buen estado y ser

reemplazadas cuando se pierdan o dañen.

18

Page 19

CONTENIDO

INDICACIONES DE SEGURIDAD ............................................ 2

Deniciones importantes .................................................... 2

INSTRUCCIONES Y ADVERTENCIAS DE SEGURIDAD ........ 2

CARACTERÍSTICAS Y CICLOS DE FUNCIONAMIENTO ....... 3

El concepto del tanque de sistema de agua.............................. 3

PROCEDIMIENTOS DE INSTALACIÓN ................................... 4

Instalación típica de una bomba sumergible ............................. 4

Instalación típica de una bomba eyectora .......................... 4

PROCEDIMIENTO DE INSTALACIÓN MÚLTIPLE

DE TANQUES ........................................................................... 4

FUNCIONAMIENTO .................................................................. 5

IDENTIFICACIÓN DE FALLAS ................................................. 5

Carga de aire en el tanque y ajuste del presostato ............ 5

Desarmado y eliminación del tanque ................................. 6

NOTAS ...................................................................................... 6

GARANTÍA ................................................................................ 7

CARACTERÍSTICAS Y CICLOS DE FUNCIONAMIENTO

Concepto del tanque de sistema de agua

La función del tanque va más allá del simple almacenamiento de

agua, ya que ayuda a proteger los componentes del sistema y, si

es del tamaño apropiado, suministra un ujo adecuado aunque

la bomba no esté funcionando. Además, debido a que reduce

el número de arranques y ciclos de la bomba, ahorra energía y

prolonga la vida de los componentes del sistema.

Los componentes del tanque de sistema de agua son: un tanque

de acero (A) que contiene un diafragma de uso rudo sellado en

su lugar (B), que separa el aire del agua. La porción del tanque

donde se almacena el agua (C) está recubierta para aislar el agua

del metal del tanque y así se protege contra la corrosión.

1. Antes de su envío, el

tanque se presuriza a la

precarga es t á n d ar que

se indica en la sección

“FUNCIONAMIENTO” de

este manual.

2. El volumen de aire que

se encuentra arriba del

diafragma se comprime

pr o p o rc i o n a l m e nt e a l

volumen de agua que entra

en el tanque.

3. La presión del tanque

se eleva. El agua continúa

entrando hasta que alcanza

la presión de corte de la

bomba y ésta se desactiva,

lo cual indica que el tanque

está lleno.

AIRE AGUA

19

4. La presión en la cámara

de aire fuerza la entrada

de agua al sistema

cuando se demanda, sin

que la bomba funcione de

inmediato. Cuando la presión

nalmente disminuye al nivel

de activación de la bomba,

el interruptor la pone en

funcionamiento para que se

repita el ciclo de llenado.

Page 20

PROCEDIMIENTOS DE INSTALACIÓN

Instalación típica de una bomba sumergible

FIGURE 1.

1. Antes de retirar el tanque existente para su reemplazo, drene

el agua y purgue el aire completamente.

2. Ubique y coloque el tanque nuevo sobre una supercie rme y

nivelada con un drenaje adecuado. Las Figuras 1 y 2 muestran

la instalación típica.

3. Para mejores resultados utilice tubería nueva, por ejemplo de

hierro, cobre o PVC rígido.

Instalación típica de una bomba eyectora

FIGURE 2.

ATENCIÓN

Para optimizar el funcionamiento, evite el efecto de pérdida por

fricción y las diferencias de elevación. Instale el tanque cerca del

presostato: a no más de 24 pulgadas (61 cm).

4. Si la presión de trabajo de su sistema puede rebasar los

125/100 PSIG (como es el caso de la mayoría de las bombas

sumergibles), instale una válvula de alivio de presión (con una

capacidad nominal de 125/100 PSIG o menos, pero mayor que

la presión de apagado) a no más de 10 pies (3 m) del tanque.

La válvula debe ser del mismo diámetro que la tubería de salida

del tanque. Esto no es necesario en las unidades de bombas

eyectoras montadas en tanques.

Peligro de daños materiales. Aplicar una fuerza excesiva en la junta

durante la instalación puede provocar suras en el tanque, en el

empalme, o en ambos. Siempre refuerce los empalmes con una llave

al enroscar o apretar el tubo de conexión

5. Conecte el tanque al conducto de evacuación de la bomba

con tubería del mismo diámetro, o mayor, que la salida de la

bomba.

6. Antes de usar el tanque, debe llenar el tanque con agua y

drenarlo completamente 5 veces para enjuagarlo. Consulte la

sección “Funcionamiento”.

ATENCIÓN

PROCEDIMIENTO DE INSTALACIÓN MÚLTIPLE DE TANQUES

Los tanques de sistema de agua pueden conectarse juntos para

aumentar el suministro de agua utilizable (cantidad extraíble).

Dos tanques del mismo tamaño duplicarán el suministro, y tres lo

triplicarán. Cuando se usa una bomba de alta capacidad, el conjunto

del colector y presostato debe instalarse en la tubería lo más cerca

posible de los tanques. La medida del colector y del conducto

principal debe ser del doble del conducto de alimentación.

20

Page 21

FUNCIONAMIENTO

BEFORE PUMPING WATER INTO YOUR SYSTEM:

1. Verique la presión estática de aire de su tanque:

• anótela aquí: PSIG (recién recibida)

ATENCIÓN

Su tanque ha sido precargado a 38 PSIG de fábrica. Verique la

presión en la válvula de aire del tanque. Utilice un manómetro preciso

para neumáticos de auto (únicamente).

2.Vea cu á l es la presión de ac t i v a c i ó n de la bomba

preestablecida:

• anótela aquí: PSIG (presostato)

ATENCIÓN

La información relativa a la presión de activación la puede encontrar

en el anverso o el reverso de la tapa del presostato.

3. Ajuste la presión del aire precargado del tanque:

• Presión de activación de la bomba a 2-3 PSIG (por debajo).

• anótela aquí: PSIG (tanque activo).

4. Libere o agregue aire hasta que la presión en el tanque quede

entre 2 y 3 PSIG POR DEBAJO de la presión de activación

preestablecida de la bomba.

5. Si la instalación es nueva, tendrá que purgar el aire del

sistema de tubería. Para hacer esto, abra todas las llaves

y encienda la bomba. Una mezcla de agua y aire saldrá

a presión. Deje que el agua corra hasta formar un flujo

constante. Para asegurar que salga todo el aire, abra y

cierre las llaves varias veces. Si el flujo no se estabiliza,

es posible que exista una fuga de aire. Revise que no haya

fugas en la tubería de aspiración.

6. A veces es necesario hacer algunos ajustes nales cuando la

presión real diere de la indicada en la tapa del presostato, lo

cual no es peligroso pero puede causar que el ujo de agua se

demore momentáneamente. Para ajustarla, siga estos pasos:

a. Llene el sistema hasta que la bomba se apague.

b. Abra una llave y drene el tanque de sistema de agua

hasta que la bomba se encienda.

c. Si hay una pausa en el ujo de agua entre el momento en

que se vacíe el tanque y la bomba se vuelva a poner en

marcha, reduzca la presión del aire en el tanque hasta

que quede de 2 a 3 PSIG por debajo de la presión de

activación indicada. Vea el procedimiento en el apartado

3 (a-b) de la sección “Identicación de fallas”.

d. Cierre las llaves y vuelva a llenar el tanque de sistema

de agua. Repita los pasos (b) y (c) hasta que el ujo de

agua sea constante.

IDENTIFICACIÓN DE FALLAS

SI CREE QUE EL TANQUE DE SISTEMA DE AGUA TIENE

PROBLEMAS, ANTES DE LLAMAR A SU DISTRIBUIDOR

LOCAL DEBE HACER LAS SIGUIENTES PRUEBAS Y

OBSERVACIONES.

1. Observe cómo funciona el sistema de agua para vericar que

no ocurra ninguna anomalía –por ej., que el ujo de agua de

una llave sea inestable (lo cual indica la presencia de aire en

el sistema) o que el ciclo de la bomba sea demasiado corto

(arranque y parada rápidos).

2. Si hay algún indicio de una pequeña fuga cerca del empalme

de tubería, revise el codo. La introducción de agua fría en

un tanque caliente puede generar condensación, sobre todo

en un clima cálido, por lo que es importante proporcionar un

drenaje adecuado.

3. La cantidad de agua extraíble depende de la presión del aire

en el tanque y de los ajustes de la presión de activación y de

corte en el presostato. En caso de dudas sobre la cantidad

de agua extraíble, revise dichos ajustes como se indica a

continuación:

a. Carga de aire en el tanque. Desconecte el suministro

de energía eléctrica a la bomba. Abra una llave cercana

y drene el tanque completamente. Revise la presión en

el tanque de sistema de agua usando un manómetro

estándar para neumáticos de alta calidad. Si la presión

del aire no es de aproximadamente 2 ó 3 PSI por debajo

del valor de activación preestablecido de la bomba, ésta

debe ser ajustada por un técnico calificado. Reemplace la

tapa del vástago de la válvula. Revise que no haya fugas

aplicando una solución de agua con jabón en la válvula

de aire y uniones del tanque. Si detecta una fuga, pida a

un técnico calificado que reemplace el tanque.

b. Ajuste del presostato. Encienda la bomba y deje que la

presión del sistema la apague (observe la presión que

indique el manómetro una vez que la bomba se detenga).

Después abra la llave y drene el tanque hasta alcanzar la

presión de activación preestablecida (observe la presión

indicada en el manómetro una vez que la bomba se ponga

en marcha). El diferencial de presión adecuado deberá ser

de 20 PSI (sin exceder de 25 PSI). Si el diferencial en la

presión del sistema no es el adecuado, comuníquese con

un técnico calificado para que atienda el problema.

21

Page 22

DESARMADO Y ELIMINACIÓN DEL TANQUE

Su tanque de sistema de agua tiene una expectativa de vida limitada

y en algún momento será necesario reemplazarlo. Al momento

de desarmar su tanque presurizado viejo es importante seguir los

siguientes procedimientos para eliminarlo de una forma segura:

NOTAS

22

Page 23

GARANTÍA LIMITADA

Xylem Inc, el garante, extiende la siguiente GARANTÍA LIMITADA al propietario de este calentador de agua.

1. TANQUE

Si dentro de los cinco años siguientes a la instalación el tanque o una de sus piezas presentan un defecto comprobado de fabricación o

en cualquiera de sus materiales, el garante reemplazará o reparará la pieza o parte defectuosa. La garantía de reemplazo del calentador

de agua se limita al plazo vigente de la garantía original.

2. CONDICIONES Y EXPECTATIVAS

Esta garantía es válida únicamente cuando la instalación del tanque se realiza de conformidad con los ordenamientos, leyes y

códigos locales aplicables de plomería y de construcción, y las buenas prácticas de la industria, y sólo cuando la instalación,

operación y mantenimiento se realizan de acuerdo con las instrucciones de este manual y del fabricante. Y en la inteligencia de que

cuando el tanque se encuentre instalado en un sistema de agua a la temperatura ambiente cuya presión de trabajo máxima pueda

ser superior a 100 libras por pulgada cuadrada manométrica (PSIG), cuente con un interruptor de corte eléctrico de alta presión y/o

una válvula de alivio de presión.

a. Esta garantía se aplica únicamente cuando el calentador se usa:

(1) con agua a la temperatura ambiente y a presiones que no excedan la presión de trabajo del sistema;

b. La presente garantía quedará invalidada por cualquiera de las siguientes causas: un accidente, mal uso, daño material o

c. Las obligaciones del vendedor de reparar y/o reemplazar el tanque en virtud de lo anterior están condicionadas a la notificación

3. GASTOS DE REPARACIÓN Y SERVICIO

La obligación que asume el garante conforme a esta garantía se limita al reemplazo del calentador de agua o las piezas mencionadas

a. Mano de obra por servicio de desinstalación, reparación o reinstalación del calentador de agua o de cualquier pieza.

b. Los cargos de envío y entrega del tanque nuevo o la pieza de repuesto del distribuidor más cercano y la devolución de la pieza o

4. LIMITACIONES DE GARANTÍAS IMPLÍCITAS

Las garantías implícitas, incluida la de comerciabilidad, establecidas en relación con la venta de este calentador de conformidad con

5. PROCEDIMIENTO DE RECLAMACIÓN

Cualquier reclamación relacionada con esta garantía debe iniciarse con el distribuidor que vendió esta unidad o con cualquier otro

Clientes en Estados Unidos Clientes en Canadá

Xylem Inc. Xylem Inc.

Seneca Falls, NY 13148 Guelph, ON N1H1T1

a. La obligación del garante bajo esta garantía se limita al reemplazo de piezas o calentadores por piezas o calentadores idénticos o

b. Los reemplazos del distribuidor están sujetos a la aprobación de la garantía por el garante.

6. LIMITACIONES/DESCARGO DE RESPONSABILIDADES

EL GARANTE NO RECONOCE NINGUNA OTRA GARANTÍA EXPRESA EXISTENTE O FUTURA HECHA EN NOMBRE DEL GARANTE

a. Algunos estados prohíben la exclusión o limitación de daños incidentales o consecuenciales, de manera que las limitaciones o

b. Esta garantía le da derechos legales específicos. Otros Estados le otorgan derechos adicionales que pueden variar de un estado

c. Los términos de este contrato y todos los derechos y obligaciones aquí estipulados se regirán por las leyes de la jurisdicción de la

Escriba a continuación la información correspondiente y consérvela como referencia. El registro no es una condición de la garantía. El modelo

y número de serie se encuentran en el tanque de sistema de agua.

(2) en los Estados Unidos, sus territorios o posesiones, y Canadá;

abuso (incluido el congelamiento) que afecte el tanque de sistema de agua; cualquier alteración de éste; modificación en su

funcionamiento; reparación no hecha ni autorizada por escrito por el vendedor; daño por uso y desgaste comunes, corrosión o

ataque químico; y daño causado por un suministro defectuoso de energía eléctrica o por falta de protección eléctrica adecuada,

previa de cualquier defecto supuesto dentro de los diez (10) días calendario posteriores a su detección.

en la misma. El propietario es responsable de cualesquiera costos adicionales. Dichos costos pueden incluir, entre otros:

el tanque defectuoso a dicho distribuidor, salvo en el Estado de California, donde deben ser cubiertos por el fabricante.

las leyes del estado, tienen una vigencia de cinco (5) años para el calentador y cualquiera de sus piezas. Algunos estados prohíben

poner límites a la vigencia de una garantía implícita de manera que esta limitación podría no aplicarse en su área.

distribuidor que maneje los productos del garante. En caso de que esto no sea factible, el propietario deberá dirigirse a:

2881 East Bayard St. 55 Royal Road

similares, fabricados o distribuidos por el garante.

EN RELACIÓN CON EL CALENTADOR O LA INSTALACIÓN, FUNCIONAMIENTO, REPARACIÓN O REEMPLAZO DE CALENTADOR.

EN NINGÚN CASO EL VENDEDOR SE HARÁ RESPONSABLE DE OTROS DAÑOS, YA SEAN DIRECTOS O INDIRECTOS,

CONVENCIONALES, INCIDENTALES, EMERGENTES, PUNITIVOS O ESPECIALES, INCLUYENDO SIN LIMITACIÓN ALGUNA

LA INTERRUPCIÓN DEL USO DE LA UNIDAD, INCONVENIENTES, PÉRDIDA DE BIENES MUEBLES O DAÑOS A LOS MISMOS,

PÉRDIDA DE GANANCIAS, PÉRDIDAS DE PRODUCCIÓN, PÉRDIDAS DE AHORROS O INGRESOS PREVISTOS, O PÉRDIDA

DE OPORTUNIDADES.

DIRECTOS O INDIRECTOS, O QUE SE DERIVEN O NO DE UN CONTRATO.

exclusiones anteriores podrían no aplicarse en su área.

a otro.

oficina del vendedor a la cual se haya remitido esta orden.

EL GARANTE NO ASUME NINGUNA RESPONSABILIDAD POR DAÑOS PERSONALES O MATERIALES,

No. de modelo.__________No. de serie___________________Fecha de instalación___________ Nombre del distribuidor_____________

______________________________Dirección del distribuidor________________________’.______________No. telefónico__________

Ciudad y Estado (localidad)______________________________________Código postal_______

GUARDE ESTA GARANTÍA CERCA DEL TANQUE PARA SU CONSULTA EN EL FUTURO.

23

Page 24

IM251R01

24

Loading...

Loading...