Page 1

SUPPLEMENT MANUAL

IM250R03

AQUAVAR® CPC

SUPPLEMENT A - Variable Speed Drive

SUPPLEMENT TO THE INSTALLATION AND OPERATION MANUAL (IM167)

Page 2

TABLE OF CONTENTS

SAFETY

Use of Warnings and Notes ...................................................................................................................................................3

INSTALLATION

Application ..............................................................................................................................................................................4

Input Disconnect Features and Functions ...........................................................................................................................4

Installation Flow Chart ............................................................................................................................................................6

Preparing for Installation (Supplement to Aquavar CPC-01/U1 User’s Manual) .............................................................7

Installing the Drive (Supplement to Aquavar CPC-01/U1 User’s Manual) .......................................................................9

Installing the Wiring (Supplement to Aquavar CPC-01/U1 User’s Manual) ................................................................. 10

MAINTENANCE

Maintenance Intervals ......................................................................................................................................................... 14

Drive Module Fan Replacement ........................................................................................................................................ 14

Enclosure Fan Replacement – NEMA 12 Enclosures ....................................................................................................... 15

Enclosure Air Filter Replacement – NEMA 12 Enclosures............................................................................................... 16

TECHNICAL DATA

Cable Sizing / Ratings .......................................................................................................................................................... 19

Fuse Sizing / Ratings ............................................................................................................................................................ 22

Ratings (Supplement to Aquavar CPC-01/U1 User’s Manual) ........................................................................................ 25

Input Power Connections (Supplement to Aquavar CPC-01/U1 User’s Manual) ........................................................ 26

Motor Connections .............................................................................................................................................................. 32

Cooling – R7/R8 .................................................................................................................................................................... 32

Dimensions and Weights (Supplement to Aquavar CPC-01/U1 User’s Manual) ......................................................... 33

Applicable Standards and Markings ................................................................................................................................. 40

INDEX .................................................................................................................................................................................. 42

2

Page 3

SAFETY

WARNING! The AQUAVAR CPC adjustable speed AC drive with Input Disconnect should ONLY be

installed by a qualied electrician.

WARNING! Even when the motor is stopped, dangerous voltage is present at the Power Circuit terminals

U1, V1, W1 and U2, V2, W2 and, depending on the frame size, UDC+ and UDC-, or BRK+ and BRK-.

WARNING! Dangerous voltage is present when input power is connected. After disconnecting the

supply, wait at least 5 minutes (to let the intermediate circuit capacitors discharge) before removing the

cover.

WARNING! Even when power is removed from the input terminals of the AQUAVAR CPC, there may be

dangerous voltage (from external sources) on the terminals of the relay outputs.

WARNING! When the control terminals of two or more drive units are connected in parallel, the auxiliary

voltage for these control connections must be taken from a single source which can either be one of the

units or an external supply.

WARNING! The AQUAVAR CPC will start up automatically after an input voltage interruption if the

external run command is on.

WARNING! When the AQUAVAR CPC with Input Disconnect is connected to the line power, the Motor

Terminals T1, T2 and T3 are live even if the motor is not running. Do not make any connections when the

AQUAVAR CPC with Input Disconnect is connected to the line. Disconnect and lock out power to the

drive before servicing the drive. Failure to disconnect power may cause serious injury or death.

NOTE! For more technical information, contact the factory or your local AQUAVAR representative.

WARNING! Do not attempt to install or remove EM1, EM3, F1 or F2 screws while power is applied to

the drive’s input terminals.

WARNING! Do not control the motor with disconnecting device (disconnecting means); instead, use

the control panel start and stop keys, or commands via the I/O board of the drive. The maximum allowed

number of charging cycles of the DC capacitors (i.e. power-ups by applying power) is ve in ten minutes.

WARNING! The opening of a branch-circuit protective device may be an indication that a fault has been

interrupted. To reduce the risk of re or electric shock, current-carrying parts and other components of

the controller should be examined and replaced if damaged or equivalent.

USE OF WARNINGS AND NOTES

There are two types of safety instructions throughout this manual:

• Notes draw attention to a particular condition or fact, or give information on a subject.

• Warnings caution you about conditions which can result in serious injury or death and/or damage to the

equipment. They also tell you how to avoid the danger. The warning symbols are used as follows:

DANGEROUS VOLTAGE WARNING warns of high voltage which can cause physical injury and/or

damage to the equipment.

GENERAL WARNING warns about conditions, other than those caused by electricity, which can result

in physical injury and/or damage to the equipment.

3

Page 4

INSTALLATION

Study these installation instructions carefully before proceeding. Failure to observe the warnings and instructions may cause a malfunction or personal hazard.

WARNING! Before you begin read “Safety” on page 3.

WARNING! When the Aquavar CPC with Input Disconnect is connected to the line

power, the Motor Terminals T1, T2, and T3 are live even if the motor is not running. Do

not make any connections when the Aquavar CPC with Input Disconnect is connected

to the line. Disconnect and lock out power to the drive before servicing the drive. Failure to disconnect power may cause serious injury or death.

Application

This manual contains supplemental information that is unique to Aquavar CPC input dis-

connect congurations (“FD” sufx). Refer to the base manual, Aquavar CPC User’s Manual

(IM167), for all other information.

Input Disconnect Features and Functions

The Aquavar CPC with Input Disconnect is an Aquavar CPC AC adjustable frequency drive

packaged with an input disconnect switch, and with a door mounted, external operating

handle. The operating handle can be padlocked in the OFF position (padlock not supplied).

Enclosure options are NEMA 1, NEMA 12 and NEMA 3R (UL Type 1, UL Type 12 and UL Type

3R).

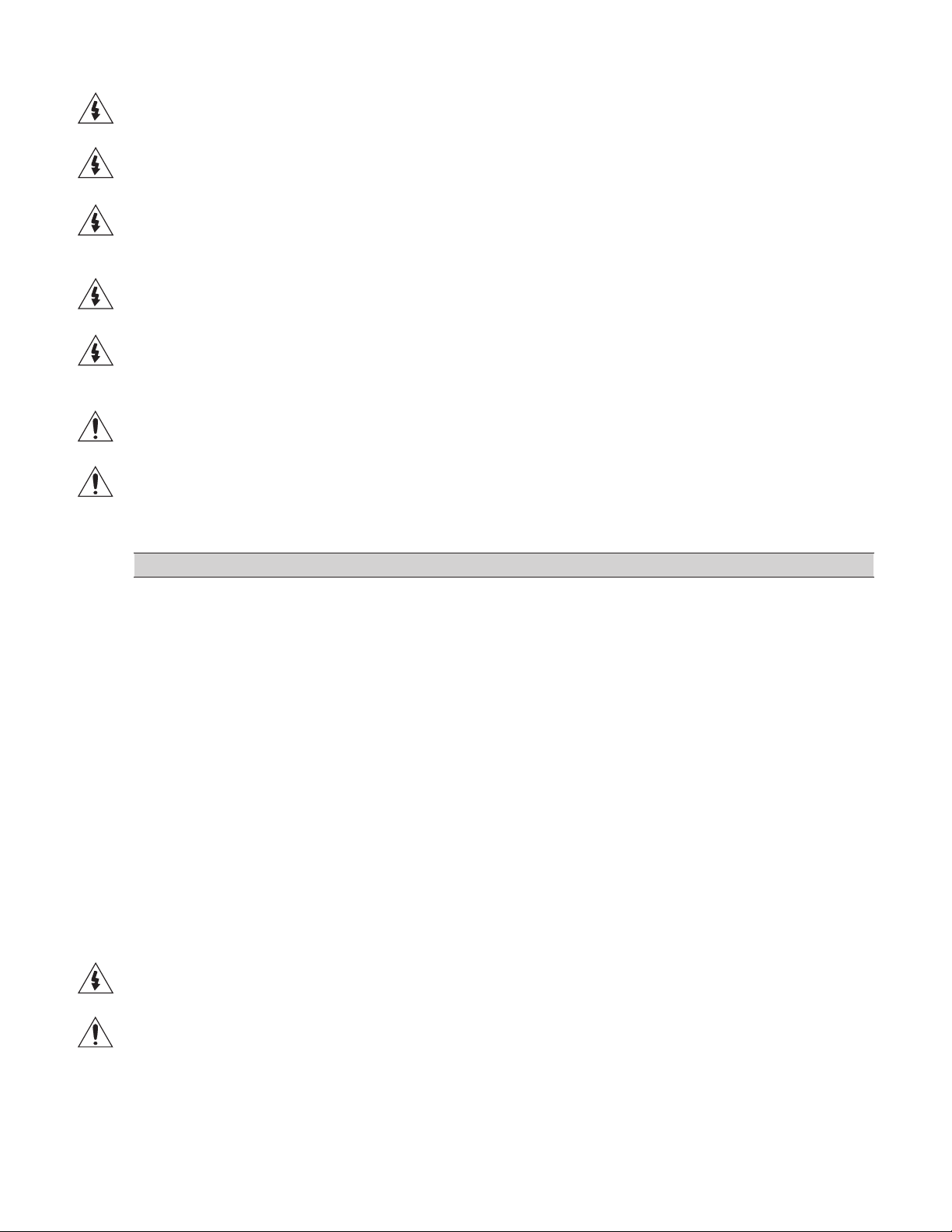

The following is a typical power diagram:

Disconnect Switch

or Circuit Breaker

3 Phase

Input Power

or

1 Phase

Input Power

3

Drive with Input Disconnect

Aquavar

CPC

Drive

3Ø

3

Motor

4

Page 5

INSTALLATION

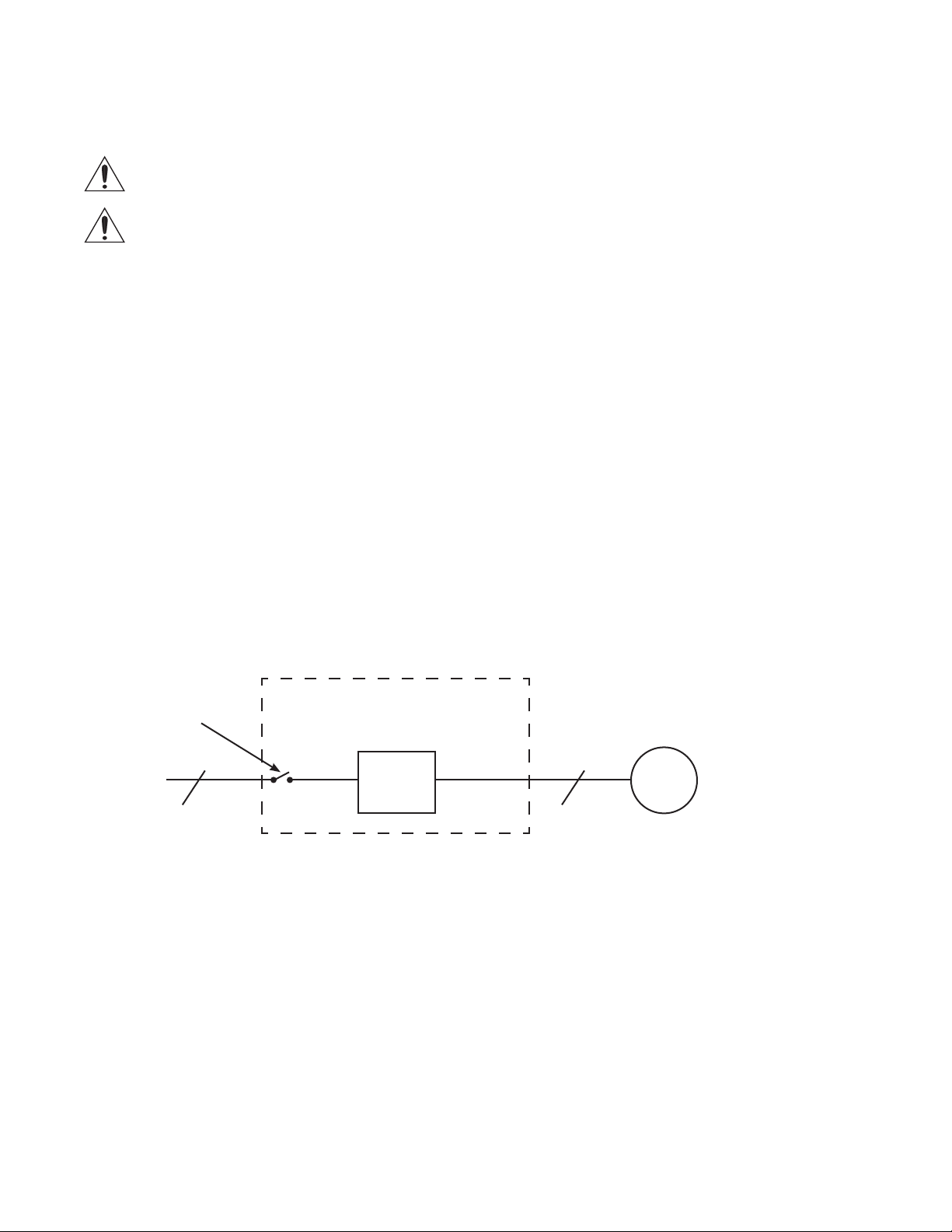

The following gures show the front view of the Aquavar CPC Input Disconnect standard

congurations and identify the major components.

R1 … R4 R5, R6 R7, R8

NEMA 1 & 12 NEMA 1 & 12 NEMA 1 & 12

Enclosures Enclosures Enclosures

Aquavar CPC Drive

Control Panel

BP0096

BP0094

Operating Handle

for Disconnect Switch

BP0093

5

Page 6

INSTALLATION

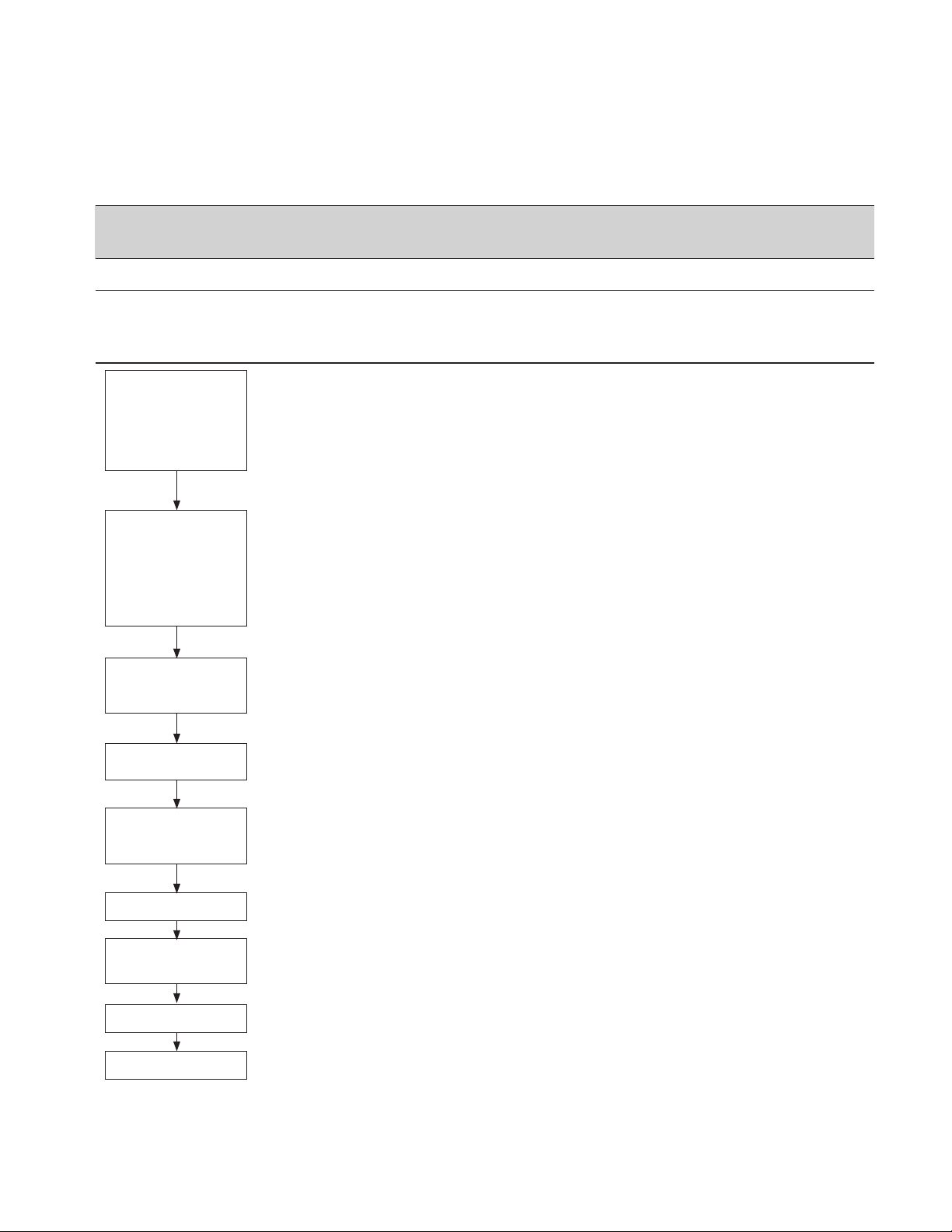

Installation Flow Chart

The installation of Input Disconnect congurations for Aquavar CPC drives follows the outline

below. The steps must be carried out in the order shown. At the right of each step are references to the detailed information needed for the correct installation of the unit.

NOTE! References in the middle column below are to the Aquavar CPC User’s Manual

(IM167). References in the third column below are to this manual.

Refer to the

Task Aquavar CPC User’s Manual

Additional Reference

in this Manual

“Installation” Section

PREPARE for “Preparing for Installation” • R7/R8: “Lifting the Drive”

installation on page 7.

• “Drive Identication” on page 8.

• “Suitable Mounting Location”

on page 9.

PREPARE the “Prepare the Mounting Location” • R7/R8: “Prepare the Mounting

Mounting Location – R7 and R8” on

Location page 9.

• “Dimensions and Weights

(Supplement to Aquavar CPC

User’s Manual)” on page 27.

REMOVE the “Remove Front Cover” R7/R8: “Remove Side Panel- R7 and

front cover R8 NEMA 1 and 12 Enclosures” on

page 9.

MOUNT the drive “Mount the Drive” R7/R8: “Mount the Drive” on

page 10.

INSTALL wiring “Wiring Overview” and “Installing the Wiring (Supplement

“Install the Wiring” to Aquavar CPC User’s Manual)”

starting on page 10.

CHECK installation “Check Installation” —

REINSTALL the “Reinstall Cover” —

cover

APPLY power “Apply Power” —

START-UP “Start-Up” —

6

Page 7

INSTALLATION

Preparing for Installation (Supplement to Aquavar CPC User’s Manual)

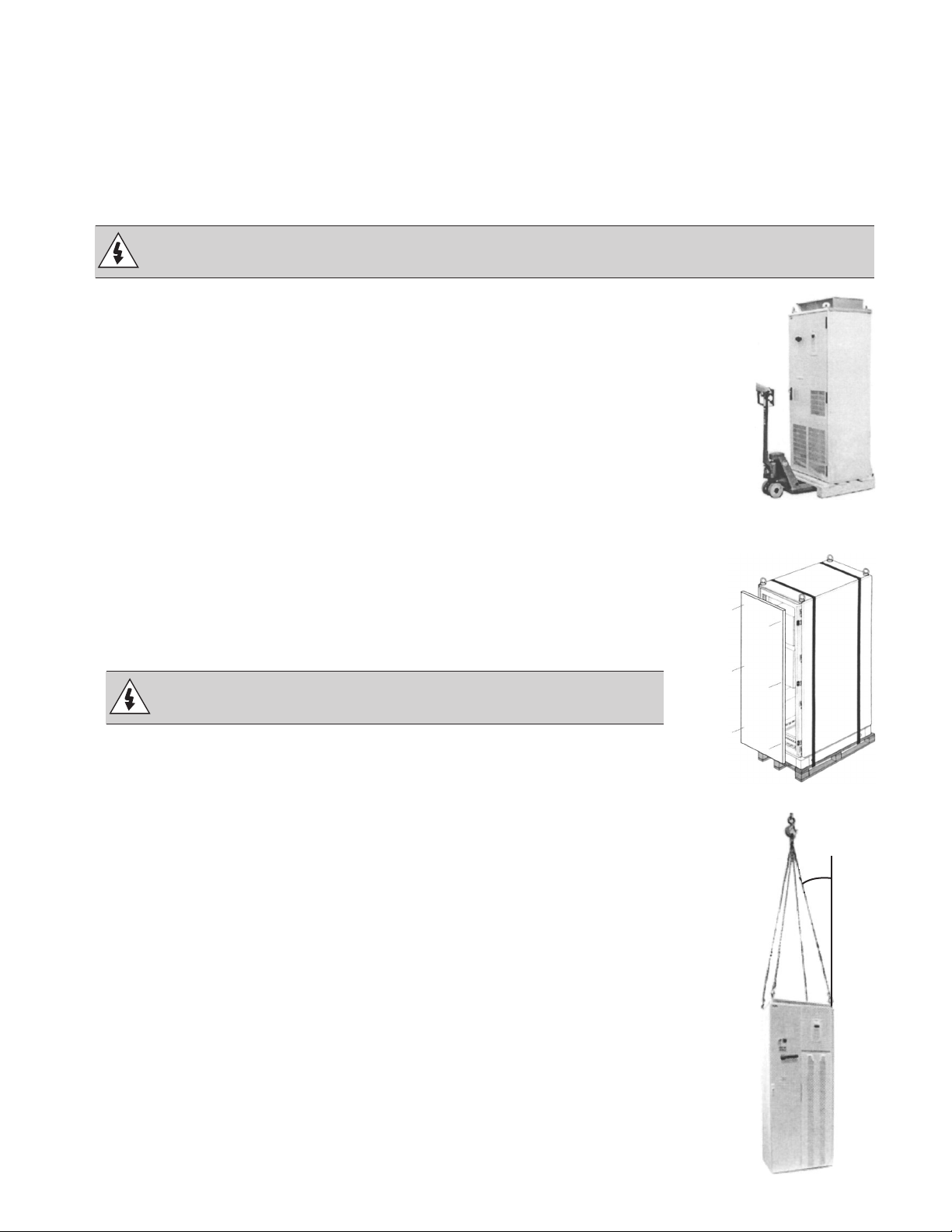

Lifting the Drive

R7…R8 Frames

WARNING! Handle and ship oor mounted enclosures only in

the upright position. These units are not designed to be laid on their backs.

1. Use a pallet truck to move the package/enclosure to the installation site.

2. Remove the cabinet side panels from NEMA 1 and 12 enclosures for

access to the cabinet/pallet mounting bolts. (Six (6) torx screws hold

each cabinet side panel in place. Leave the side panels off until later.)

PC00005

3. Remove the 4 bolts that secure the cabinet to the shipping pallet.

WARNING! Use the lifting lugs/bars at the top of the unit

to lift R7/R8 drives.

4. Use a hoist to lift the drive. (Do not place drive in nal position until

mounting site is prepared.

2

R70010

30º

PC00003

7

Page 8

INSTALLATION

Preparing for Installation (Supplement to Aquavar CPC User’s Manual)

Drive Identication

To identify the type of device you are installing, refer to the type code number on the device

identication label.

• Wall mounting base drives – label attached on the side surface of the heat sink.

• Packaged drive with screw cover – label attached to outside surface on the left ide of the

enclosure.

• Enclosure with hinged cover/door – label on inside surface of the cover/door.

Type Code Number

Use the following to interpret the type code found on the identication label.

CPC 4 370 1 FD

AQUAVAR® (Series)

Voltage

2 – 208-240 Volt

4 – 480 Volt

5 – 575 Volt

Amps

370 Amps

*See Technical Section

NEMA Enclosure Rating

1 – NEMA 1

2 – NEMA 12

Disconnect with Drive Fuses

NOTE: Standard equipment on 200 HP and above models, R7-R8 Frames.

Options

* Consult factory for other options, if available. Not all combinations may be available.

Ratings and Frame Size

Charts in the “Ratings” sections of the Aquavar CPC User’s Manual and this manual list

technical specications, and identify the drive’s frame size.

NOTE! Some instructions in this document vary, depending on the drive’s frame size. To

read the Ratings table, you need the “Output current rating” entry from the type code (see

above).

8

Page 9

INSTALLATION

Suitable Mounting Location

For selecting a suitable mounting location for FD congurations, refer to:

• Preparing for installation in the Aquavar CPC User’s Manual, and

• The Technical Data section of this manual for information on dimensions and weights.

Installing the Drive (Supplement to Aquavar CPC User’s Manual - IM167)

WARNING! Metal shavings or debris in the enclosure can damage electrical

equipment and create a hazardous condition. Where parts, such as conduit plates

require cutting or drilling, rst remove the part. If that is not practical, cover nearby

electrical components to protect them from all shavings or debris.

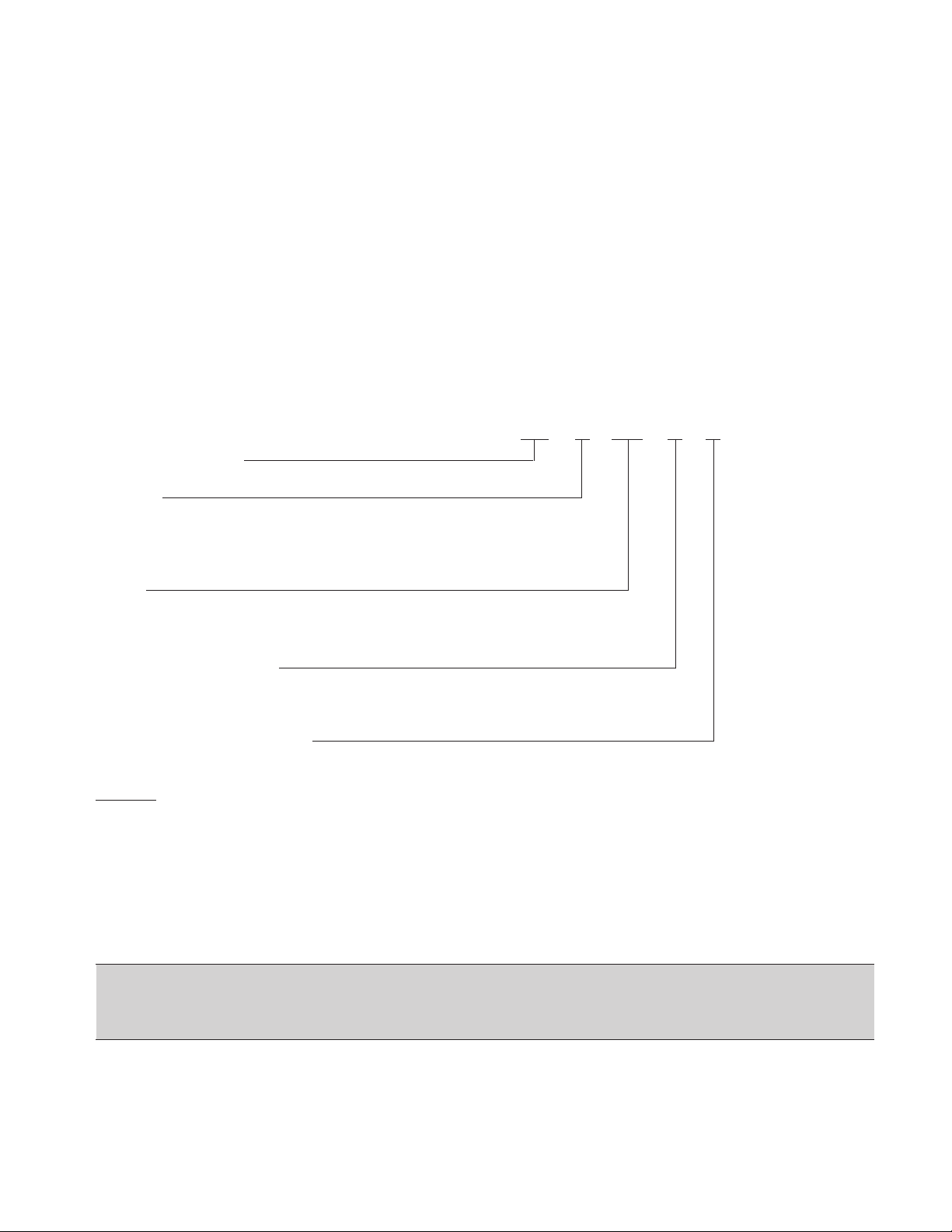

Prepare the Mounting Location – R7 and R8

The Aquavar CPC should only be mounted where all of

the requirements dened in “Preparing for Installation”

are met.

PC00023

Frame sizes R7 and R8 have mounting holes inside

the enclosure base. See “NEMA 1 and 12, R7…R8

Mounting Dimensions” on page 28.

Where it is not possible to use either mounting hole

at the back of the base, use an L-bracket at the top of

the enclosure to secure the cabinet to a wall or to the

back of another enclosure. Bolt the L-bracket to the

enclosure using the lifting lug bolt hole on the top of

the enclosure.

Remove Side Panels – R7 and R8 NEMA 1 and 12 Enclosures

Cabinet Door

Fastening points when installed

back against a wall (top view)

Fastening points when installed

back against back

Fastening the cabinet at the top

using L-brackets (side view)

L-bracket

M12 bolt (1/2 to 9/16 in)

Cabinet top

2

1. To open the cabinet door, loosen the quarter-turn screws

that hold the cabinet door closed.

2. Installation access is easier if these panels are kept off

throughout the installation.

R70020

9

Page 10

INSTALLATION

Mount the Drive

R7…R8

1. Use a hoist to move the cabinet into position.

NOTE! If the cabinet location does not provide access to the cabinet

sides, be sure to re-mount side panels before positioning cabinet.

2. Install and tighten mounting bolts.

Installing the Wiring (Supplement to Aquavar CPC User’s Manual)

WARNING!

• Metal shavings or debris in the enclosure can damage electrical equipment and create a

hazardous condition. Where parts, such as conduit plates require cutting or drilling, rst

remove the part. If that is not practical, cover nearby electrical components to protect

them from all shavings or debris.

• Do not connect or disconnect input or output power wiring, or control wires, when power

is applied.

30º

PC00003

• Never connect line voltage to drive output Terminals T1, T2 and T3.

• Do not make any voltage tolerance tests (Hi Pot or Megger) on any part of the unit.

Disconnect motor wires before taking any measurements in the motor or motor wires.

• Make sure that power factor correction capacitors are not connected between the drive

and the motor.

Wiring Requirements

Refer to the “Wiring Requirements” Section in the Aquavar CPC User’s Manual. The

requirements apply to all Aquavar CPC drives. In particular:

• Use separate, metal conduit runs for the following different classes of wiring:

– Input power wiring

– Motor wiring

– Control/communications wiring

• Properly and individually ground the drive, the motor and cable shields.

• Ground the pressure transducer or piping back to the Aquavar chassis or common

grounding point.

10

Page 11

INSTALLATION

Wiring Overview

Power Connection – Standard Input Disconnect (R1…R6, Wall Mounted)

The following gures show the Standard Input Disconnect (wall mounted) wiring connection

points. Refer to the Aquavar CPC User’s Manual for control connections to the drive.

R1…R4

NEMA 1 & 12

Enclosures

BP0058

Ground

Motor

Terminals

Gnd

Input Power

Terminals

Disconnect Switch

or Circuit Breaker

Input Power

Terminals

I/O Conduit

(Bottom)

Aquavar

CPC

Lug(s)

R5, R6

NEMA 1 & 12

Enclosures

I/O Conduit

(Top)

Motor

Terminals

BP0057

11

Page 12

INSTALLATION

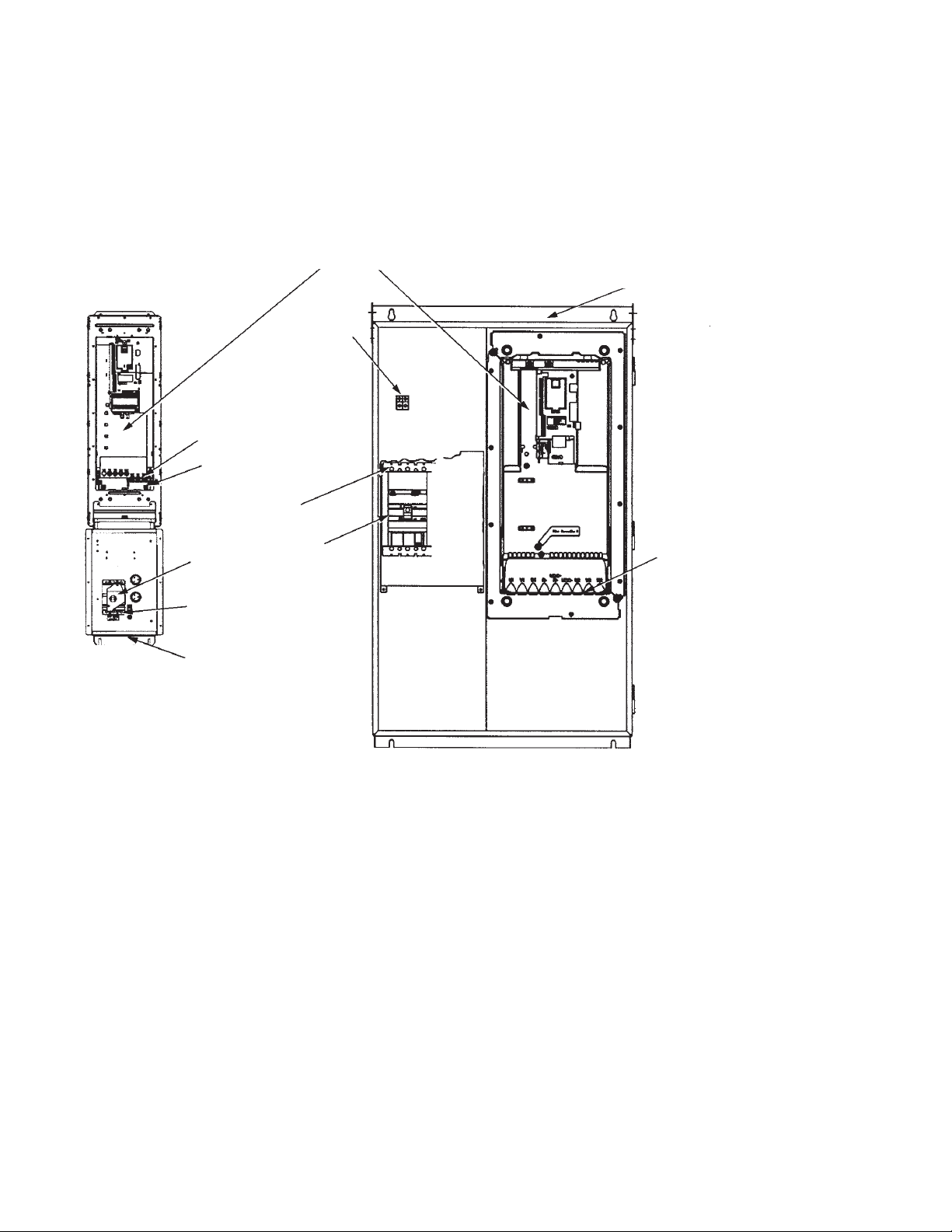

Power Connection – Standard Input Disconnect (R7…R8, Floor Mounted)

The R7 and R8 Aquavar CPC Standard Input Disconnect units are congured for wiring access

from the top and include a removable conduit mounting plate. The following gure shows the

Standard Input Disconnect (oor mounted) wiring connection points. Refer to the Aquavar

CPC User’s Manual for control connections to the drive.

Motor

Terminals

Input Power

Terminals

Disconnect Switch

or Circuit Breaker

R7

NEMA 1 & 12

Ground Lug

Bar

CPC

Terminals

Input Power

Terminals

Disconnect Switch

or Circuit Breaker

Motor

CPC

R8

NEMA 1 & 12

Ground Lug

Bar

12

BP0054 BP0055

Page 13

INSTALLATION

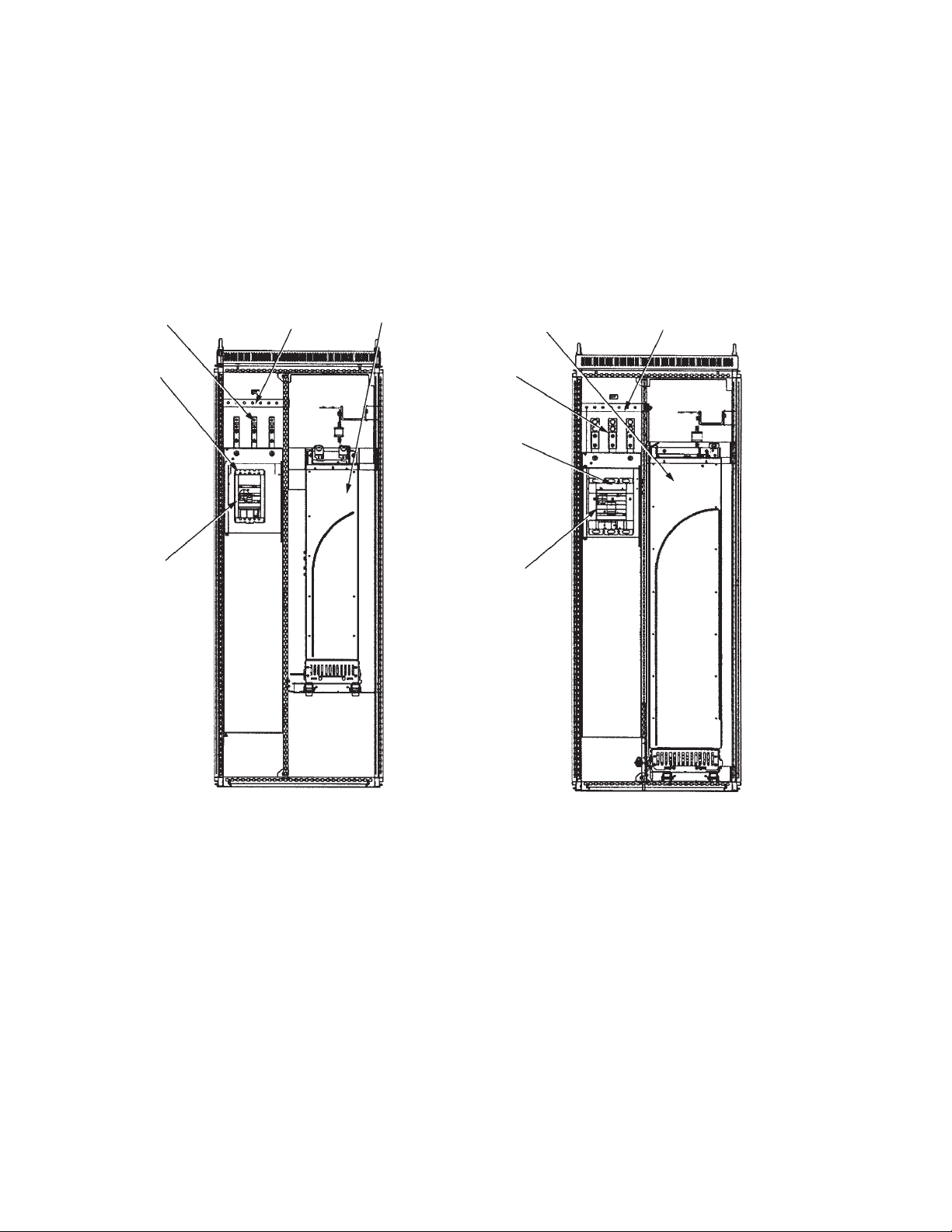

Install the Line Input Wiring

Line Input Connections – Standard Input Disconnect Congurations

Connect input power to the terminals of the disconnect switch or circuit breaker. Connect the

equipment grounding conductor to the ground lug. The gure below shows the connection

points for Standard Input Disconnect congurations.

R1…R4

NEMA 1 & 12

Enclosures

BP0058

Input

Power

Dashed line is ground run.

R5, R6

NEMA 1 & 12

Enclosures

BP0057

Input

Power

R7, R8

NEMA 1 & 12

Enclosures

BP0054

R7 shown.

R8 similar to R7.

WARNING! Check the motor and motor wiring insulation before connecting the

Aquavar CPC to line power. Follow the procedure in the Aquavar CPC User’s Manual.

Before proceeding with the insulation resistance measurements, check that the Aquavar

CPC is disconnected from incoming line power. Failure to disconnect line power could

result in death or serious injury.

NOTE! For the remainder of the installation and start-up (motor and control wiring) refer to

the Aquavar CPC User’s Manual.

13

Page 14

MAINTENANCE

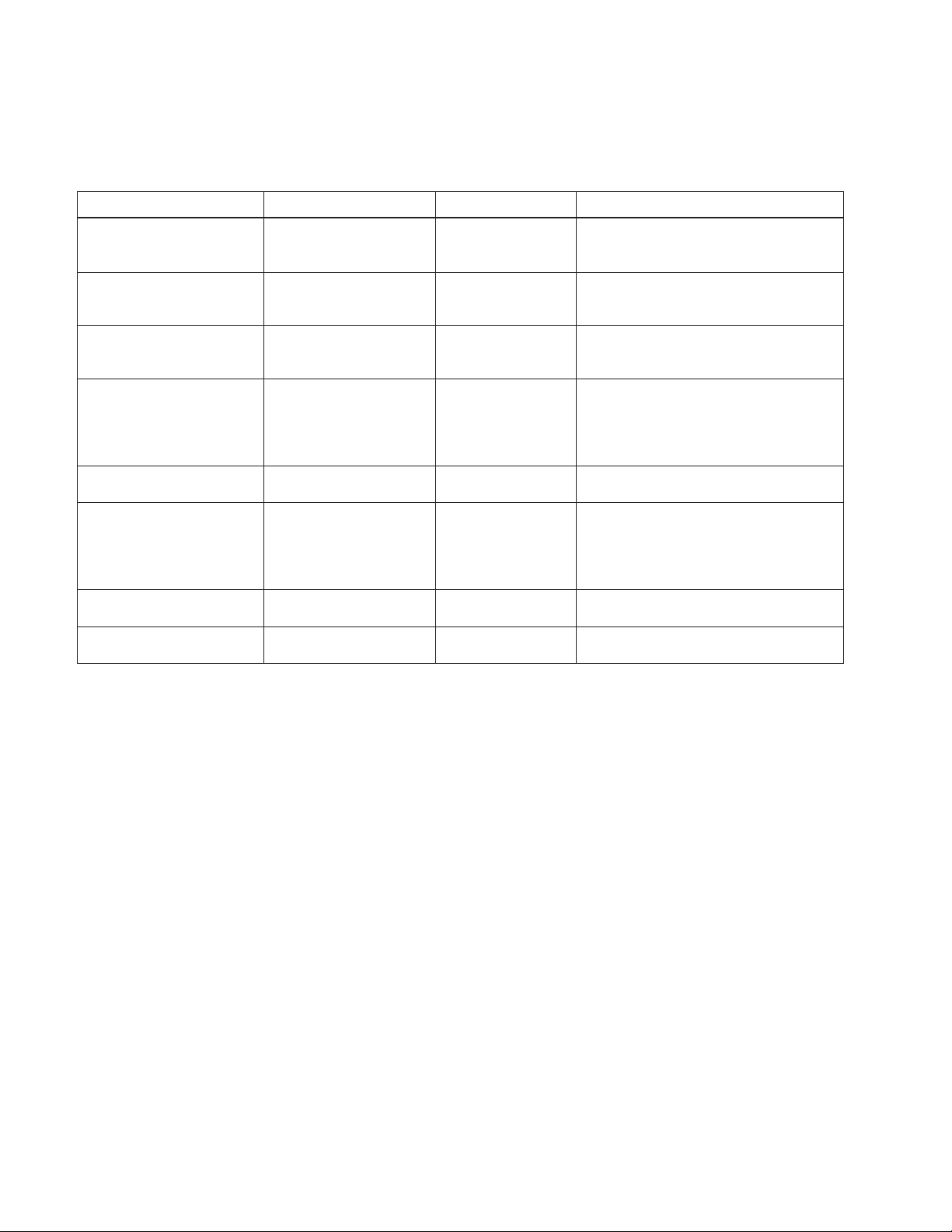

Maintenance Intervals

If installed in an appropriate environment, the drive requires very little maintenance. This table

lists the routine maintenance intervals recommended by CentriPro.

Maintenance Conguration Interval Instruction

Check/replace R5/R6 R5/R6 NEMA 12 Check every 3 “Frame Sizes R5/R6 – Enclosure

enclosure inlet air lter enclosures months. Replace Inlet Air Filter” on page 16.

as needed.

Check/replace R7/R8 R7/R8 NEMA 12 Check every 3 “Frame Sizes R7/R8 – NEMA 12

enclosure inlet air lter enclosures months. Replace Enclosure Inlet Air Filter” on

as needed. page 16.

Check/replace R7/R8 R7/R8 NEMA 12 Check every 6 “Frame Sizes R7/R8 – NEMA 12

enclosure exhaust air enclosures months. Replace Enclosure Exhaust Filters” on

lter as needed. page 18.

Check and clean All Depends on the See “Maintenance” in Aquavar

heatsink dustiness of the CPC User’s Manual.

environment

(every 6…12

months)

Replace drive All Every 6 years See “Maintenance” in Aquavar

module fan CPC User’s Manual.

Replace enclosure NEMA 12 Every 3 years See “Frame Sizes R7/R8 – NEMA

fan(s) 12 Enclosures” on page 15. For

other frame sizes, see

“Maintenance” in Aquavar CPC

User’s Manual.

Change capacitor Frame sizes R5 and Every 10 years See “Maintenance” in Aquavar

R6 CPC User’s Manual.

Replace battery in the All Every 10 years See “Maintenance” in Aquavar

Assistant control panel CPC User’s Manual.

Drive Module Fan Replacement

The drive module fan cools the heatsink. Fan failure can be predicted by the increasing

noise from fan bearings and the gradual rise in the heatsink temperature in spite of

heatsink cleaning. If the drive is operated in a critical part of a process, fan replacement is

recommended once these symptoms start appearing. Replacement fans are available from

the factory. Do not use other than CentriPro specied spare parts.

To monitor the running time of the cooling fan, see “Group 29: Maintenance Trig” in the

Aquavar CPC Users’s Manual.

Frame Sizes R7 and R8

Refer to the installation instructions supplied with the fan kit.

14

Page 15

MAINTENANCE

Enclosure Fan Replacement – NEMA 12 Enclosures

NEMA 12 enclosures include an additional fan (or fans) to move air through the enclosure.

Frame Sizes R7/R8 – NEMA 12 Enclosures

The enclosure fan is located in the exhaust box on top of the NEMA 12

enclosure.

1. Remove the left and right lter frames of the exhaust fan box by lifting

them upwards.

2. Disconnect the fan’s electrical connector from the cabinet roof (top

right Inside the cabinet).

3. Undo the four fastening screws at the corners of the fan frame. The

screws are through bolts with nuts on the inside of the cabinet.

(Do not drop the hardware into the drive).

PC00014

PC00017

PC00021

PC00018

PC00018

4. Remove the fan and fan frame as one unit.

5. Disconnect the fan wiring and capacitor from the fan frame.

Then remove the four screws attaching the fan to the fan frame.

Remove the old fan.

6. Install the new fan and capacitor with the

replacement part for CentriPro in the reverse

order of the above. Ensure the fan is centered

on the velocity stack and rotates freely.

Velocity

Stack

Capacitor

PC00014

PC00014

PC00020

15

Page 16

MAINTENANCE

Enclosure Air Filter Replacement – NEMA 12 Enclosures

Frame Sizes R5/R6 – Enclosure Inlet Air Filter

This procedure applies to disconnect congurations in R5 and R6 frame sizes with NEMA 12

enclosures. This lter is located at the bottom of the enclosure. Use the following procedure to

check and replace lters.

1. On the enclosure, remove the screw holding the lter bracket in place.

2. Slide the lter bracket forward until the hooks on the bracket clear the slots on the

enclosure base. This step allows the lter and bracket to drop free from the enclosure.

Back of Enclosure

Enclosure

Slot

Hook

Mounting

Screw

Filter Bracket

3. Lift the lter out of the lter bracket and replace as appropriate.

4. With the lter in the lter bracket, align the hooks on the bracket with the slots in the

enclosure base, and press the hooks up into the slots.

5. Slide the lter bracket back, making sure that the hooks catch on the enclosure.

6. Replace the mounting screw. Tighten until the gasket on the bracket is about 50%

compressed.

Frame Sizes R7/R8 – Nema 12 Enclosure Inlet Air Filter

The inlet air lter for the R7/R8 NEMA 12 enclosure is

located in the enclosure front door.

1. While holding the top of the lter frame, pull up on

the bottom of the frame. The lter frame will slide up

approximately ¾ inch and can then safely removed

by tilting away from the cabinet and lifting up.

16

PC00010PC00015

Page 17

MAINTENANCE

2. Lay the lter frame on a at work surface. Remove

the 3 retaining brackets by squeezing the tabbed

corners in towards the middle of each bracket

until the bracket clears the lter frame. Save these

brackets for replacement. Remove and inspect the

lter.

3. Install the replacement lter. Be sure to tuck the lter

into the grove around the entire lter frame. This is very

important for proper installation.

4. Reinstall the 3 lter restraining brackets. These will

prevent the lter from being pulled out of the lter

frame.

PC00009 PC00007

PC00013

• Install the center bracket rst.

• Install the 2nd bracket overlapping the center

bracket by ½ to the left.

PC00007 PC00009

• Install the 3rd bracket overlapping the center bracket by ½ to the right.

1st lter retaining bracket

1st and 2nd lter retaining brackets

All 3 lter retaining brackets

5. Install the lter frame back to the cabinet door. Carefully

align the mounting hooks to the slots in the cabinet

door. The hooks should be pointing down. Press in at the

center of the lter frame with your knee and gently press

down with your hands at the top of the frame. The lter

frame will slide down approximately ¾ inch and should

be sealed securely to the door around the entire lter

frame.

PC00008PC00006

17

Page 18

MAINTENANCE

Frame Sizes R7/R8 – NEMA 12 Enclosure Exhaust Filters

The exhaust lters in the R7/R8 NEMA 12 enclosure are located in the exhaust box at the top

of the enclosure.

There are 2 lter frames attached to the exhaust box.

1. Remove each lter frame:

• Lift up on the lter frame until it slides approximately ¾ inch.

• Pull away from the exhaust box to remove.

2. For each lter frame, remove the wire retainers

that hold the lters in place:

• Lay the lter frames on a at work surface.

• The wire retainers have a square “U” shape.

Remove by squeezing the open end of the“U”

towards the middle of the “square” until the

retainer top (open end of “U”) clears the lter

frame.

PC00001 PC00019

• Save the retainers for reinstallation.

3. Remove and inspect the lter.

4. Install clean lters.

NOTE! When installing DUSTLOK® lter media, the white side must face

to outside of the cabinet, and the orange side faces in. Be sure to tuck

the lter edges into the groove around the entire lter frame. This detail

is very important for proper operation.

PC00021

5. Reinstall the lter restrainers.

• Insert the base of a retainer (bottom of “U”

shape) into a lter frame channel.

• Squeeze the open end of the “U” until it

clears the lter frame.

• Seat the open end of the “U” in the lter

frame channel.

• Release the retainer to its relaxed, square

shape.

6. Install each lter frame to the bonnet on top of the

cabinet.

• Carefully align the frame’s mounting hooks with the

slots in the bonnet. (The hooks should be pointing

down.)

• Press down at the top of the lter frame. (The lter

frame slides down approximately ¾ inch).

• Check all around the lter frame for a secure seal to

the exhaust box.

18

PC00022

PC00001PC00019

PC00011PC00012

Page 19

TECHNICAL DATA

The following tables provide current, horsepower, frame size and recommended cable sizes for the Aquavar CPC.

NOTE: THIS MANUAL SUPERCEDES PAGES 131-135 OF IM167R08.

CABLE SIZING/ RATINGS

208…240 Volt Drives

GWT AQUAVAR CPC

NEMA 1

Voltage Phase

Base

Model

CPC20171 8.5 2 R1 14 14

CPC20241 12 3 R2 14 10

CPC20311 15.5 5 R2 14 8

CPC20461 23 7.5 R3 12 6

CPC20591 29.5 10 R3 10 4

1

CPC20881 44.0 15 R4 8 2

CPC21141 57.0 20 R4 6 1/0

CPC21431 71.5 25 R6 4 3/0

CPC21781 89.0 30 R6 3 4/0

CPC22211 110.5 40 R6 2

CPC22481 124.0 50 R6 1

CPC20121 11.8 3 R1 14 14

230

CPC20171 16.7 5 R1 14 14

CPC20241 24.2 7.5 R2 12 10

CPC20311 30.8 10 R2 10 8

CPC20461 46.2 15 R3 8 6

CPC20591 59.4 20 R3 6 4

3

CPC20751 74.8 25 R4 4 3

CPC20881 88.0 30 R4 3 2

CPC21141 114.0 40 R4 2 1/0

CPC21431 143.0 50 R6 1/0 3/0

CPC21781 178.0 60 R6 2/0 4/0

CPC22211 221.0 75 R6 4/0

CPC22481 248.0 100 R6

NOTE 1: Recommended AWG Size based on NEC table 310.16 , 40º C ambient, 90º C, UL type copper wire. For other wire

sizes or types, consult local, state or NEC codes.

NOTE 2: Frame sizes R7 and R8, the Aquavar CPC will have multiple conductor terminals for each phase. Consult technical

section ( CABLE TERMINALS)

Cont.

Output

Amps

Normal Duty

Horsepower

Frame

Size²

Output

Cable

Min. AWG¹

250MCM

or 2 X 1

Input

Cable

Min. AWG¹

300 MCM

or 2 x 1/0

350MCM

or 2 x 2/0

300 MCM

or 2 x 1/0

350MCM

or 2 x 2/0

Vendor

Part Number

ACS550-U1-017A-

2+N2000+P918+X1555

ACS550-U1-024A-

2+N2000+X1555

ACS550-U1-031A-

2+N2000+X1555

ACS550-U1-046A-

2+N2000+X1555

ACS550-U1-059A-

2+N2000+X1555

ACS550-U1-088A-

2+N2000+X1555

ACS550-U1-114A-

2+N2000+X1555

ACS550-U1-143A-

2+N2000+X1555

ACS550-U1-178A-

2+N2000+X1555

ACS550-U1-221A-

2+N2000+X1555

ACS550-U1-248A-

2+N2000+X1555

ACS550-U1-012A-

2+N2000+P918+X1555

ACS550-U1-017A-

2+N2000+P918+X1555

ACS550-U1-024A-

2+N2000+X1555

ACS550-U1-031A-

2+N2000+X1555

ACS550-U1-046A-

2+N2000+X1555

ACS550-U1-059A-

2+N2000+X1555

ACS550-U1-075A-

2+N2000+X1555

ACS550-U1-088A-

2+N2000+X1555

ACS550-U1-114A-

2+N2000+X1555

ACS550-U1-143A-

2+N2000+X1555

ACS550-U1-178A-

2+N2000+X1555

ACS550-U1-221A-

2+N2000+X1555

ACS550-U1-248A-

2+N2000+X1555

19

Page 20

TECHNICAL DATA

The following table provides Aquavar CPC rating information, and recommended wire sizing for the input and output cables.

NOTE: THIS MANUAL SUPERCEDES PAGES 131-135 OF IM167R08.

CABLE SIZING/ RATINGS

380…480 Volt Drives

GWT AQUAVAR CPC

Volt-

age

Phase

NEMA 1

Base

Model

CPC40061

CPC40081

CPC40121

CPC40151

CPC40231

CPC40311

CPC40381

CPC40441

CPC40591

CPC40721

CPC40771

460 3

CPC40961

CPC41241

CPC41571

CPC41801

CPC42451

CPC43161

CPC43681

CPC44141

CPC44861

CPC45261

CPC46021

CPC46451

NOTE 1: Recommended AWG Size based on NEC table 310.16 , 40º C ambient, 90º C, UL type copper wire. For other wire

sizes or types, consult local, state or NEC codes.

NOTE 2: Frame sizes R7 and R8, the Aquavar CPC will have multiple conductor terminals for each phase. Consult technical

section ( CABLE TERMINALS) for max. wire diameter and torque values. For submersible motors consult motor manufacturer

on recommended wire type and size based on lead length and amperage.

20

Cont.

Output

Amps

Normal

Duty

Horsepower

Frame

Size²

Output Cable

Min. AWG¹

Input Cable

Min. AWG¹

6.9 3 R1 14 14

8.8 5 R1 14 14

11.9 7.5 R1 14 14

15.4 10 R2 12 14

23 15 R2 12 10

31 20 R3 10 8

38 25 R3 8 8

44 30 R4 8 6

59 40 R4 6 4

72 50 R4 4 3

77 60 R5 4 3

96 75 R5 3 1

124 100 R6 1 1/0

157 125 R6 2/0 3/0

180 150 R6 3/0 4/0

245 200 R7

316 250 R7

368 300 R8

414 350 R8

486 400 R8

526 450 R8

602 500 R8

645 550 R8

300MCM or

2 X 1/0

500MCM or

2 X 3/0

600MCM or 2 X

4/0 or 3 X 1/0

2 X 250MCM

or 3 X 2/0

2 X 300MCM

or 3 X 3/0

2 X 350MCM

or 3 X 4/0

2 X 500MCM or

3 X 250MCM

2 X 500MCM or

3 X 250MCM

350MCM or

2 X 300MCM

2 X 350MCM

2 X 500MCM

2 X 500MCM or

3 X 250MCM

2 X 500MCM or

3 X 250MCM

2 X 2/0

2 X 3/0

2 X 4/0

Vendor

Part Number

ACS550-U1-06A9-

4+N2000+P918+X1555

ACS550-U1-08A8-

4+N2000+X1555

ACS550-U1-012A-

4+N2000+P918+X1555

ACS550-U1-015A-

4+N2000+X1555

ACS550-U1-023A-

4+N2000+X1555

ACS550-U1-031A-

4+N2000+X1555

ACS550-U1-038A-

4+N2000+X1555

ACS550-U1-045A-

4+N2000+X1555

ACS550-U1-059A-

4+N2000+X1555

ACS550-U1-072A-

4+N2000+X1555

ACS550-U1-078A-

4+N2000+X1555

ACS550-U1-097A-

4+N2000+X1555

ACS550-U1-125A-

4+N2000+X1555

ACS550-U1-157A-

4+N2000+X1555

ACS550-U1-180A-

4+N2000+X1555

ACS550-U1-246A-

4+N2000+X1555

ACS550-PC-316A-

4+N2000+X1555

ACS550-PC-368A-

4+N2000+X1555

ACS550-PC-414A-

4+N2000+X1555

ACS550-PC-486A-

4+N2000+X1555

ACS550-U2-526A-

4+N2000+X1555

ACS550-U2-602A-

4+N2000+X1555

ACS550-U2-645A-

4+N2000+X1555

Page 21

TECHNICAL DATA

The following tables provide current, horsepower, frame size and recommended cable sizes for the Aquavar CPC.

NOTE: THIS MANUAL SUPERCEDES PAGES 131-135 OF IM167R08.

CABLE SIZING/ RATINGS

600 Volt Drives

GWT AQUAVAR CPC

NEMA 1

Voltage Phase

Base

Model

CPC50031 2.7 2 R2 14 14

CPC50041 3.9 3 R2 14 14

CPC50061 6.1 5 R2 14 14

CPC50091 9 7.5 R2 14 14

CPC50111 11 10 R2 14 14

CPC50171 17 15 R2 14 14

CPC50221 22 20 R3 12 10

CPC50271 27 25 R3 10 10

460 3

CPC50321 32 30 R4 10 8

CPC50411 41 40 R4 8 6

CPC50521 52 50 R4 6 6

CPC50621 62 60 R4 6 4

CPC50771 77 75 R6 4 3

CPC50991 99 100 R6 3 1

CPC51251 125 125 R6 2 2/0

CPC51441 144 150 R6 1 3/0

NOTE 1: Recommended AWG Size based on NEC table 310.16 , 40º C ambient, 90º C, UL type copper wire. For other wire

sizes or types, consult local or Provincial codes.

NOTE 2: Terminal block for input voltage and output motor voltage have diameter limits. Consult technical section ( CABLE

TERMINALS) for max. wire diameter and torque values.

Cont.

Output

Amps

Normal Duty

Horsepower

Frame

Size²

Output

Cable

Min. AWG¹

Input

Cable

Min. AWG¹

Vendor

Part Number

ACS550-U1-02A7-

6+N2000+X1555

ACS550-U1-03A9-

6+N2000+X1555

ACS550-U1-06A1-

6+N2000+X1555

ACS550-U1-09A0-6

+N2000+X1555

ACS550-U1-011A-

6+N2000+X1555

ACS550-U1-017A-

6+N2000+X1555

ACS550-U1-022A-

6+N2000+X1555

ACS550-U1-027A-

6+N2000+X1555

ACS550-U1-032A-

6+N2000+X1555

ACS550-U1-041A-

6+N2000+X1555

ACS550-U1-052A-

6+N2000+X1555

ACS550-U1-062A-

6+N2000+X1555

ACS550-U1-077A-

6+N2000+X1555

ACS550-U1-099A-

6+N2000+X1555

ACS550-U1-125A-

6+N2000+X1555

ACS550-U1-144A-

6+N2000+X1555

For submersible motor applications refer to motor manufacturers recommendations based on lead length and voltage drop.

21

Page 22

TECHNICAL DATA

The following table provides Aquavar CPC rating information, and recommended fuse sizing for the input short

circuit protection. Branch circuit protection must be provided by the end user, contractor or distributor. Sized

according to local or applicable NEC codes.

FUSE SIZING/ RATINGS

208…240 Volt Drives

GWT AQUAVAR CPC

NEMA 1

Voltage Phase

Base

Model

CPC20171 8.5 2 R1 21.3 25

CPC20241 12 3 R2 30.0 30

CPC20311 15.5 5 R2 38.8 40

CPC20461 23 7.5 R3 57.5 60

CPC20591 29.5 10 R3 73.8 80

1

CPC20881 44.0 15 R4 110.0 110

CPC21141 57.0 20 R4 142.5 150

CPC21431 71.5 25 R6 178.8 200

CPC21781 89.0 30 R6 222.5 225

CPC22211 110.5 40 R6 276.3 300

CPC22481 124.0 50 R6 310.0 350

CPC20121 11.8 3 R1 13.6 15

230

CPC20171 16.7 5 R1 19.2 25

CPC20241 24.2 7.5 R2 27.8 30

CPC20311 30.8 10 R2 35.4 40

CPC20461 46.2 15 R3 53.1 60

CPC20591 59.4 20 R3 68.3 80

3

CPC20751 74.8 25 R4 86.0 100

CPC20881 88.0 30 R4 101.2 110

CPC21141 114.0 40 R4 131.1 150

CPC21431 143.0 50 R6 164.5 200

CPC21781 178.0 60 R6 204.7 250

CPC22211 221.0 75 R6 254.2 300

CPC22481 248.0 100 R6 285.2 350

NOTE 3: UL Class T fuses are recommended for short circuit protection. Very fast acting Bussmann* T-tron type JJN and JJS

are shown in the Aquavar CPC tables. Other manufacturers are acceptable if they meet fuse requirements.

Cont.

Output

Amps

Normal Duty

Horsepower

Frame

Size

Input

Current

Amps

Fuse Type³

JJN

Vendor

Part Number

ACS550-U1-017A-

2+N2000+P918+X1555

ACS550-U1-024A-

2+N2000+X1555

ACS550-U1-031A-

2+N2000+X1555

ACS550-U1-046A-

2+N2000+X1555

ACS550-U1-059A-

2+N2000+X1555

ACS550-U1-088A-

2+N2000+X1555

ACS550-U1-114A-

2+N2000+X1555

ACS550-U1-143A-

2+N2000+X1555

ACS550-U1-178A-

2+N2000+X1555

ACS550-U1-221A-

2+N2000+X1555

ACS550-U1-248A-

2+N2000+X1555

ACS550-U1-012A-

2+N2000+P918+X1555

ACS550-U1-017A-

2+N2000+P918+X1555

ACS550-U1-024A-

2+N2000+X1555

ACS550-U1-031A-

2+N2000+X1555

ACS550-U1-046A-

2+N2000+X1555

ACS550-U1-059A-

2+N2000+X1555

ACS550-U1-075A-

2+N2000+X1555

ACS550-U1-088A-

2+N2000+X1555

ACS550-U1-114A-

2+N2000+X1555

ACS550-U1-143A-

2+N2000+X1555

ACS550-U1-178A-

2+N2000+X1555

ACS550-U1-221A-

2+N2000+X1555

ACS550-U1-248A-

2+N2000+X1555

22

Page 23

TECHNICAL DATA

The following table provides Aquavar CPC rating information, and recommended fuse sizing for the input short

circuit protection. Branch circuit protection must be provided by the end user, contractor or distributor. Sized

according to local or applicable NEC codes. NOTE: THIS MANUAL SUPERCEDES PAGES 131-135 OF IM167R08.

FUSE SIZING/ RATINGS

380…480 Volt Drives

GWT AQUAVAR CPC

NEMA 1

Voltage Phase

Base

Model

CPC40061 6.9 3 R1 7.9 10

CPC40081 8.8 5 R1 10.1 15

CPC40121 11.9 7.5 R1 13.7 15

CPC40151 15.4 10 R2 17.7 20

CPC40231 23 15 R2 26.5 30

CPC40311 31 20 R3 35.7 40

CPC40381 38 25 R3 43.7 50

CPC40441 44 30 R4 50.6 60

CPC40591 59 40 R4 67.9 80

CPC40721 72 50 R4 82.8 90

CPC40771 77 60 R5 88.6 100

460 3

CPC40961 96 75 R5 110.4 125

CPC41241 124 100 R6 142.6 175

CPC41571 157 125 R6 180.6 200

CPC41801 180 150 R6 207.0 250

CPC42451 245 200 R7 281.8 300

CPC43161 316 250 R7 363.4 400

CPC43681 368 300 R8 423.2 450

CPC44141 414 350 R8 476.1 500

CPC44861 486 400 R8 558.9 600

CPC45261 526 450 R8 604.9 600

CPC46021 602 500 R8 692.3 800

CPC46451 645 550 R8 741.8 800

NOTE 3: UL Class T fuses are recommended for short circuit protection. Very fast acting Bussmann* T-tron type and JJS are

shown in the Aquavar CPC tables. Other manufacturers are acceptable if they meet fuse requirements.

Cont.

Output

Amps

Normal Duty

Horsepower

Frame

Size

Input

Current

Amps

Fuse Type³

JJS

Vendor

Part Number

ACS550-U1-06A9-

4+N2000+P918+X1555

ACS550-U1-08A8-

4+N2000+X1555

ACS550-U1-012A-

4+N2000+P918+X1555

ACS550-U1-015A-

4+N2000+X1555

ACS550-U1-023A-

4+N2000+X1555

ACS550-U1-031A-

4+N2000+X1555

ACS550-U1-038A-

4+N2000+X1555

ACS550-U1-045A-

4+N2000+X1555

ACS550-U1-059A-

4+N2000+X1555

ACS550-U1-072A-

4+N2000+X1555

ACS550-U1-078A-

4+N2000+X1555

ACS550-U1-097A-

4+N2000+X1555

ACS550-U1-125A-

4+N2000+X1555

ACS550-U1-157A-

4+N2000+X1555

ACS550-U1-180A-

4+N2000+X1555

ACS550-U1-246A-

4+N2000+X1555

ACS550-PC-316A-

4+N2000+X1555

ACS550-PC-368A-

4+N2000+X1555

ACS550-PC-414A-

4+N2000+X1555

ACS550-PC-486A-

4+N2000+X1555

ACS550-U2-526A-

4+N2000+X1555

ACS550-U2-602A-

4+N2000+X1555

ACS550-U2-645A-

4+N2000+X1555

23

Page 24

TECHNICAL DATA

The following table provides Aquavar CPC rating information, and recommended fuse sizing for the input short

circuit protection. Branch circuit protection must be provided by the end user, contractor or distributor. Sized

according to local or applicable NEC codes. NOTE: THIS MANUAL SUPERCEDES PAGES 131-135 OF IM167R08.

FUSE SIZING/ RATINGS

600 Volt Drives

GWT AQUAVAR CPC

NEMA 1

Voltage Phase

Base

Model

CPC50031 2.7 2 R2 2.7 10

CPC50041 3.9 3 R2 3.9 10

CPC50061 6.1 5 R2 6.1 10

CPC50091 9 7.5 R2 9 15

CPC50111 11 10 R2 11 15

CPC50171 17 15 R2 17 25

CPC50221 22 20 R3 22 25

CPC50271 27 25 R3 27 40

575 3

CPC50321 32 30 R4 32 40

CPC50411 41 40 R4 41 50

CPC50521 52 50 R4 52 60

CPC50621 62 60 R4 62 80

CPC50771 77 75 R6 77 100

CPC50991 99 100 R6 99 150

CPC51251 125 125 R6 125 175

CPC51441 144 150 R6 144 200

NOTE 3: UL Class T fuses are recommended for short circuit protection. Very fast acting Bussmann* T-tron type JJS are

shown in the Aquavar CPC tables. Other manufacturers are acceptable if they meet fuse requirements.

Cont.

Output

Amps

Normal Duty

Horsepower

Frame

Size

Input

Current

Amps

Fuse Type³

JJS

Vendor

Part Number

ACS550-U1-02A7-

6+N2000+X1555

ACS550-U1-03A9-

6+N2000+X1555

ACS550-U1-06A1-

6+N2000+X1555

ACS550-U1-09A0-6

+N2000+X1555

ACS550-U1-011A-

6+N2000+X1555

ACS550-U1-017A-

6+N2000+X1555

ACS550-U1-022A-

6+N2000+X1555

ACS550-U1-027A-

6+N2000+X1555

ACS550-U1-032A-

6+N2000+X1555

ACS550-U1-041A-

6+N2000+X1555

ACS550-U1-052A-

6+N2000+X1555

ACS550-U1-062A-

6+N2000+X1555

ACS550-U1-077A-

6+N2000+X1555

ACS550-U1-099A-

6+N2000+X1555

ACS550-U1-125A-

6+N2000+X1555

ACS550-U1-144A-

6+N2000+X1555

24

Page 25

TECHNICAL DATA

Ratings (Supplement to Aquavar CPC User’s Manual - IM167)

NOTE! The ratings listed below are exceptions to the ratings listed in the Aquavar CPC

User’s Manual.

Ratings, 380…480 Volt Drives

Type Code

Valid up to 40°C (104 °F)

Normal Use Heavy-Duty Use

AQUAVAR CPC-FD -

see below

CPC4245xFD 245 200 192 150 R7

CPC4316xFD 316 250 240 200 R8

CPC4368xFD 368 300 302 250 R8

CPC4414xFD 414 350 368 300 R8

CPC4486xFD 486 400 414 350 R8

CPC45261FD 526 450 477 400 R8

CPC46021FD 602 500 515 450 R8

CPC46451FD 645 550 590 500 R8

I

2N

A

P

HP

N

I

2hd

A

P

hd

HP

Frame

Size

Vendor

Part Number

ACS550-PD-246A-

4+N2000+X1555

ACS550-PD-316A-

4+N2000+X1555

ACS550-PD-368A-

4+N2000+X1555

ACS550-PD-414A-

4+N2000+X1555

ACS550-PD-486A-

4+N2000+X1555

ACS550-PD-526A-

4+N2000+X1555

ACS550-PD-602A-

4+N2000+X1555

ACS550-U2-645A-

4+N2000+X1555

NOTE: I2N = Motor current draw normal

PN = Normal rated power

I

Phd = Heavy-duty NEMA power rating

= Heavy-duty current rating

2hd

25

Page 26

TECHNICAL DATA

Input Power Connections (Supplement to Aquavar CPC User’s Manual)

Fuses

NOTE! Although fuses listed are similar in functional characteristics to fuses listed in

the Aquavar CPC User’s Manual, physical characteristics may differ. Fuses from other

manufacturers can be used if they meet the functional characteristics of those in these

tables.

Drive input fuses are provided to disconnect the drive from power in the event that a

component fails in the drive’s power circuitry.

208…240 Volt Fuses

208 … 240 Volt

Base

Drive Input Fuse Ratings

Drive

HP Identication

Frame

Size

1 CPC2004xFD R1 15 KTK-R-15

2 CPC2007xFD R1 15 KTK-R-15

3 CPC2012xFD R1 15 KTK-R-15

5 CPC2017xFD R1 30 KTK-R-30

7.5 CPC2024xFD R2 30 KTK-R-30

10 CPC2031xFD R2 50 JJS-50

15 CPC2046xFD R3 80 JJS-80

20 CPC2059xFD R3 80 JJS-80

25 CPC2075xFD R4 100 JJS-100

30 CPC2088xFD R4 125 170M1368

40 CPC2114xFD R4 160 170M1369

50 CPC2143xFD R6 200 170M1370

60 CPC2178xFD R6 250 170M1371

75 CPC2221xFD R6 315 170M1372

100 CPC2248xFD R6 315 170M1372

Amps

(600V)

Bussmann

Type

Vendor

Part Number

ACS550-PD-04A6-

2+N2000+P918+X1555

ACS550-PD-07A5-2

+N2000+X1555

ACS550-PD-012A-2

+N2000+X1555

ACS550-PD-017A-2

+N2000+X1555

ACS550-PD-024A-2

+N2000+X1555

ACS550-PD-031A-2

+N2000+X1555

ACS550-PD-046A-2

+N2000+X1555

ACS550-PD-059A-2

+N2000+X1555

ACS550-PD-075A-2

+N2000+X1555

ACS550-PD-088A-

2+N2000+X1555

ACS550-PD-114A-

2+N2000+X1555

ACS550-PD-143A-

2+N2000+X1555

ACS550-PD-178A-

2+N2000+X1555

ACS550-PD-222A-

2+N2000+X1555

ACS550-PD-248A-

2+N2000+X1555

NOTE: “x” represents both NEMA 1 and NEMA 12 enclosures.

26

Page 27

TECHNICAL DATA

380…480 Volt Fuses

380 … 480 Volt

Base

Drive Input Fuse Ratings

Drive

HP Identication

Frame

Size

3 CPC4006xFD R1 15 KTK-R-15

5 CPC4008xFD R1 15 KTK-R-15

7.5 CPC4012xFD R1 15 KTK-R-15

10 CPC4015xFD R2 30 KTK-R-30

15 CPC4023xFD R2 30 KTK-R-30

20 CPC4031xFD R3 50 JJS-50

25 CPC4038xFD R3 50 JJS-50

30 CPC4044xFD R3 100 JJS-100

40 CPC4059xFD R4 100 JJS-100

50 CPC4072xFD R4 100 JJS-100

60 CPC4077xFD R5 125 170M1368

75 CPC4096xFD R5 125 170M1368

100 CPC4124xFD R6 160 170M1369

125 CPC4157xFD R6 200 170M1370

150 CPC4180xFD R6 250 170M1371

200 CPC4245xFD R7 400 JJS-400

250 CPC4316xFD R8 400 JJS-400

300 CPC4368xFD R8 400 JJS-400

350 CPC4414xFD R8 600 JJS-600

400 CPC4486xFD R8 600 JJS-600

450 CPC4526xFD R8 800 JJS-800

500 CPC4602xFD R8 800 JJS-800

550 CPC4645xFD R8 800 JJS-800

Amps

(600V)

Bussmann

Type

Vendor

Part Number

ACS550-PD-06A9-4

+N2000+X1555

ACS550-PD-08A8-

4+N2000+X1555

ACS550-PD-012A-4

+N2000+X1555

ACS550-PD-015A-4

+N2000+X1555

ACS550-PD-023A-4

+N2000+X1555

ACS550-PD-031A-4

+N2000+X1555

ACS550-PD-038A-4

+N2000+X1555

ACS550-PD-045A-

4+N2000+X1555

ACS550-PD-059A-4

+N2000+X1555

ACS550-PD-072A-4

+N2000+X1555

ACS550-PD-078A-4

+N2000+X1555

ACS550-PD-097A-4

+N2000+X1555

ACS550-U1-125A-

4+B055+N2000+X1555

ACS550-PD-157A-

4+N2000+X1555

ACS550-PD-180A-

4+N2000+X1555

ACS550-PD-246A-

4+N2000+X1555

ACS550-PD-316A-

4+N2000+X1555

ACS550-PD-368A-

4+N2000+X1555

ACS550-PD-414A-

4+N2000+X1555

ACS550-PD-486A-

4+N2000+X1555

ACS550-U2-526A-

4+N2000+X1555

ACS550-U2-602A-

4+N2000+X1555

ACS550-U2-645A-

4+N2000+X1555

NOTE: “x” represents both NEMA 1 and NEMA 12 enclosures.

27

Page 28

TECHNICAL DATA

500…600 Volt Fuses

500 … 600 Volt

Base

Drive Input Fuse Ratings

Drive

HP Identication

Frame

Size

Amps

(600V)

Bussmann

Type

2 CPC5002xFD R2 15 KTK-R-15

3 CPC5004xFD R2 15 KTK-R-15

5 CPC5006xFD R2 15 KTK-R-15

7.5 CPC5009xFD R2 15 KTK-R-15

10 CPC5011xFD R2 30 KTK-R-30

15 CPC5017xFD R2 30 KTK-R-30

20 CPC5022xFD R3 50 JJS-50

25 CPC5027xFD R3 50 JJS-50

30 CPC5032xFD R4 100 JJS-100

40 CPC5041xFD R4 100 JJS-100

50 CPC5052xFD R4 100 JJS-100

60 CPC5062xFD R4 100 JJS-100

75 CPC5077xFD R6 125 170M1368

100 CPC5099xFD R6 125 170M1368

125 CPC5125xFD R6 160 170M1369

150 CPC5144xFD R6 200 170M1370

Vendor

Part Number

ACS550-PD-02A1-

6+N2000+X1555

ACS550-PD-04A1-

6+N2000+X1555

ACS550-PD-06A1-

6+N2000+X1555

ACS550-PD-09A1-

6+N2000+X1555

ACS550-PD-11A1-

6+N2000+X1555

ACS550-PD-17A1-

6+N2000+X1555

ACS550-PD-22A1-

6+N2000+X1555

ACS550-PD-27A1-

6+N2000+X1555

ACS550-PD-32A1-

6+N2000+X1555

ACS550-PD-41A1-

6+N2000+X1555

ACS550-PD-52A1-

6+N2000+X1555

ACS550-PD-62A1-

6+N2000+X1555

ACS550-PD-77A1-

6+N2000+X1555

ACS550-PD-99A1-

6+N2000+X1555

ACS550-PD-125A1-

6+N2000+X1555

ACS550-PD-144A1-

6+N2000+X1555

NOTE: “x” represents both NEMA 1 and NEMA 12 enclosures.

Input Power Cables / Wiring – R7/R8

NEC

Based on:

• NEC Table 310-16 for copper wires • 40 °C (104 °F) ambient temperature

• 90 °C (194 °F) wire insulation • Copper cables with concentric copper shield

• Not more than three current-carrying conductors in raceway or cable, or earth (directly buried).

Max Load Current (A) Cu Wire Size (AWG/kcmil) Max Load Current (A) Cu Wire Size (AWG/kcmil)

345 400 MCM or 2 x 2/0 474 2 x 250

391 500 MCM or 2 x 3/0 534 2 x 300

410 2 x 3/0 615 2 x 350

465 2 x 4/0 711 2 x 500

28

Page 29

TECHNICAL DATA

Drive’s Power Connection Terminals (Supplement to Aquavar CPC User’s Manual)

The following tables show maximum wire size and required tightening torque for incomming

power and motor terminals, and grounding terminal lug information.

208…240 Volt, Terminals

208 … 240 Volt

Frame

HP Type Code

1 CPC2004xFD R1

2 CPC2007xFD R1

3 CPC2012xFD R1

5 CPC2017xFD R1

7.5 CPC2024xFD R2

10 CPC2031xFD R2

15 CPC2046xFD R3

20 CPC2059xFD R3

25 CPC2075xFD R4

30 CPC2088xFD R4

40 CPC2114xFD R4

50 CPC2143xFD R6

60 CPC2178xFD R6

75 CPC2221xFD R6

100 CPC2248xFD R6

Size

Circuit

Breaker

#10

35 in-lbs

#6

45 in-lbs

#3

50 in-lbs

#1

50 in-lbs

350 MCM

274 in-lbs

2 x 250

MCM

274 in-lbs

Power Wiring Data

Disconnect

Switch

#10

7 in-lbs

#8

7 in-lbs

#4

18 in-lbs

#1

55 in-lbs

#1/0 70 in-lbs

300 MCM

275 in-lbs

2 x 250 MCM

275 in-lbs

Motor

Terminals

#10

12 in-lbs

12 in-lbs

24 in-lbs

48 in-lbs

#1/0

48 in-lbs

350 MCM

360 in-lbs

#6

#3

#1

Ground

Lugs

NEMA

1 & 12

#10

35 in-lbs

#3

50 in-lbs

#2

50 in-lbs

3 x #3/0

250 in-lbs

Vendor

Part Number

ACS550-PD-04A6-

2+N2000+P918+X1555

ACS550-PD-07A5-2

+N2000+X1555

ACS550-PD-012A-2

+N2000+X1555

ACS550-PD-017A-2

+N2000+X1555

ACS550-PD-024A-2

+N2000+X1555

ACS550-PD-031A-2

+N2000+X1555

ACS550-PD-046A-2

+N2000+X1555

ACS550-PD-059A-2

+N2000+X1555

ACS550-PD-075A-2

+N2000+X1555

ACS550-PD-088A-

2+N2000+X1555

ACS550-PD-114A-

2+N2000+X1555

ACS550-PD-143A-

2+N2000+X1555

ACS550-PD-178A-

2+N2000+X1555

ACS550-PD-222A-

2+N2000+X1555

ACS550-PD-248A-

2+N2000+X1555

NOTE: “x” represents both NEMA 1 and NEMA 12.

29

Page 30

TECHNICAL DATA

380…480 Volt, Terminals

380 … 480 Volt

Power Wiring Data

Frame

HP Type Code

3 CPC4006xFD R1

5 CPC4008xFD R1

7.5 CPC4012xFD R1

10 CPC4015xFD R2

15 CPC4023xFD R2

20 CPC4031xFD R3

25 CPC4038xFD R3

30 CPC4044xFD R4

40 CPC4059xFD R4

50 CPC4072xFD R4

60 CPC4077xFD R4

75 CPC4096xFD R5

100 CPC4124xFD R6

125 CPC4157xFD R6

150 CPC4180xFD R6

200 CPC4245xFD R7

250 CPC4316xFD R8

300 CPC4368xFD R8

350 CPC4414xFD R8

400 CPC4486xFD R8

450 CPC4526xFD R8

500 CPC4602xFD R8

550 CPC4645xFD R8

NOTE: “x” represents both NEMA 1 and NEMA 12.

30

Size

Circuit

Breaker

#10

35 in-lbs

#6

45 in-lbs

#3

50 in-lbs

#1

50 in-lbs

350 MCM

274 in-lbs

2 x 250 MCM

274 in-lbs

2 x 500

MCM

274 in-lbs

3 x 400

MCM

375 in-lbs

Disconnect

Switch

18 in-lbs

55 in-lbs

62 in-lbs

70 in-lbs

300 MCM

275 in-lbs

2 x 250 MCM

274 in-lbs

2 x 500 MCM

274 in-lbs

3 x 400 MCM

375 in-lbs

#10

7 in-lbs

#8

7 in-lbs

#4

#1

#1

#1/0

Motor

Terminals

#10

12 in-lbs

#6

12 in-lbs

#3

24 in-lbs

#1

48 in-lbs

#1/0

48 in-lbs

#2/0

132 in-lbs

350 MCM

360 in-lbs

2 x 250 MCM

2 x 500

MCM

500 in-lbs

2 x 600

MCM

500 in-lbs

3 x 400 MCM

Ground

Lugs

NEMA

1 & 12

#10

35 in-lbs

#6

35 in-lbs

#3

50 in-lbs

#1

50 in-lbs

3 x #3/0

250 in-lbs

5 Bus Bar

Holes

(13/32”

Bolts)

Vendor

Part Number

ACS550-PD-06A9-4

+N2000+X1555

ACS550-PD-08A8-

4+N2000+X1555

ACS550-PD-012A-4

+N2000+X1555

ACS550-PD-015A-4

+N2000+X1555

ACS550-PD-023A-4

+N2000+X1555

ACS550-PD-031A-4

+N2000+X1555

ACS550-PD-038A-4

+N2000+X1555

ACS550-PD-045A-

4+N2000+X1555

ACS550-PD-059A-4

+N2000+X1555

ACS550-PD-072A-4

+N2000+X1555

ACS550-PD-078A-4

+N2000+X1555

ACS550-PD-097A-4

+N2000+X1555

ACS550-U1-125A-

4+B055+N2000+X1555

ACS550-PD-157A-

4+N2000+X1555

ACS550-PD-180A-

4+N2000+X1555

ACS550-PD-246A-

4+N2000+X1555

ACS550-PD-316A-

4+N2000+X1555

ACS550-PD-368A-

4+N2000+X1555

ACS550-PD-414A-

4+N2000+X1555

ACS550-PD-486A-

4+N2000+X1555

ACS550-U2-526A-

4+N2000+X1555

ACS550-U2-602A-

4+N2000+X1555

ACS550-U2-645A-

4+N2000+X1555

Page 31

TECHNICAL DATA

500…600 Volt, Terminals

500 … 600 Volt

Frame

HP Type Code

2 CPC5002xFD R2

3 CPC5004xFD R2

5 CPC5006xFD R2

7.5 CPC5009xFD R2

10 CPC5011xFD R2

15 CPC5017xFD R2

20 CPC5022xFD R3

25 CPC5027xFD R3

30 CPC5032xFD R4

40 CPC5041xFD R4

50 CPC5052xFD R4

60 CPC5062xFD R4

75 CPC5077xFD R6

100 CPC5099xFD R6

125 CPC5125xFD R6

150 CPC5144xFD R6

Size

Circuit

Breaker

#6

62 in-lbs

#3

62 in-lbs

#1

62 in-lbs

350 MCM

274 in-lbs

Power Wiring Data

Disconnect

Switch

#8

7 in-lbs

#4

18 in-lbs

#1

55 in-lbs

#1

62 in-lbs

#1/0

70 in-lbs

300 MCM

275 in-lbs

Motor

Terminals

12 in-lbs

24 in-lbs

48 in-lbs

350 MCM

360 in-lbs

#6

#3

#1

Ground

Lugs

NEMA

1 & 12

#6

35 in-lbs

#3

50 in-lbs

#2

50 in-lbs

3 x #3/0

250 in-lbs

Vendor

Part Number

ACS550-PD-02A1-

6+N2000+X1555

ACS550-PD-04A1-

6+N2000+X1555

ACS550-PD-06A1-

6+N2000+X1555

ACS550-PD-09A1-

6+N2000+X1555

ACS550-PD-11A1-

6+N2000+X1555

ACS550-PD-17A1-

6+N2000+X1555

ACS550-PD-22A1-

6+N2000+X1555

ACS550-PD-27A1-

6+N2000+X1555

ACS550-PD-32A1-

6+N2000+X1555

ACS550-PD-41A1-

6+N2000+X1555

ACS550-PD-52A1-

6+N2000+X1555

ACS550-PD-62A1-

6+N2000+X1555

ACS550-PD-77A1-

6+N2000+X1555

ACS550-PD-99A1-

6+N2000+X1555

ACS550-PD-125A1-

6+N2000+X1555

ACS550-PD-144A1-

6+N2000+X1555

NOTE: “x” represents both NEMA 1 and NEMA 12.

31

Page 32

TECHNICAL DATA

Cable Terminals (Frames R1-R6)

U1, V1, W1

U2, V2, W2

Frame

Size

1

R1

1

R2

1

R3

1

R4

1

R5

Minimum

Wire Size

2

mm

0.75 18 10 8 1.4 1 10 8 1.4 1

0.75 18 10 8 1.4 1 10 8 1.4 1

2.5 14 25 3 2.5 1.8 16 6 1.8 1.3

6 10 50 1/0 5.6 4 25 3 2 1.5

6 10 70 2/0 15 11 70 2/0 15 11

BRK±, UDC± Terminals

Maximum

Wire Size

AWG mm

2

Tightening

Torque

AWG N•m lb•ft mm

R6 95 3/0 240 350 MCM 40 30 95 3/0 8 6

1 Aluminum cable cannot be used with frame sizes R1…R6 because of its lower capacity.

Note: See the recommended cable sizes for different load currents in section Cable Sizing/Ratings.

Motor Connections

Motor Connection Specications – R7/R8

Earthing PE Terminal

Maximum

Wire Size

2

AWG N•m lb•ft

Tightening

Torque

Motor Connection Specications

Maximum Motor

Cable Length

R7…R8 300 m 980 ft Does not apply

Frame

Maximum Motor Cable Length*

Size

fsw = 1 or 4 kHz fsw = 8 kHz or 12 kHz

WARNING! Using a motor cable longer than specied in the chart above may cause permanent

damage to the drive.

Cooling – R7/R8

Cooling Specications

Method Internal fan, ow direction from bottom to top.

• R7/R8: Free space in front of enclosure: 152 mm (6 in).

Requirement

• R7/R8: Free space at sides of enclosure: None required for cooling.

• R7/R8: Also see “Additional Free Space Recommendations” on page 33.

Air Flow, 380…480 Volt Drives – R7/R8

The following table lists heat loss and air ow data for 380…480 Volt drives.

Drive Heat Loss Air Flow

CPC-xx- Frame Size W BTU/Hr m3/h ft3/min

-245A-4 R7 3850 13000 300 540

-316A-4 R8 5300 18000 700 1220

-368A-4 R8 6850 23000 700 1220

-414A-4 R8 7000 24000 700 1220

-486A-4 R8 7600 26000 700 1220

-526A-4 R8 7800 27000 700 1220

-602A-4 R8 8100 28000 700 1220

-645A-4 R8 9100 31000 700 1220

• R7/R8: Free space above enclosure: None required for cooling.

32

Page 33

TECHNICAL DATA

Dimensions and Weights (Supplement to Aquavar CPC User’s Manual)

Mounting Dimensions

NEMA 1 & 12, R1…R6 Mounting Dimensions

See Detail A

See Detail B

a

c

R1…R4

W1

W2

R5/R6

W1

H

H

DS0301

b d

Detail BDetail A

W2

BP0057

NEMA 1 and NEMA 12 – Mounting Dimensions for each Frame Size

R1 R2 R3 R4 R5 R6

Ref.

mm in mm in mm in mm in mm in mm in

W1* 98 3.9 98 3.9 160 6.3 160 6.3 600 23.6 600 23.6

W2* 98 3.9 98 3.9 160 6.3 160 6.3 600 23.6 600 23.6

H* 712 28.0 812 32.0 983 38.7 1117 44.0 1175 46.3 1175 463

a 5.5 0.2 5.5 0.2 6.5 0.25 6.5 0.25 6.5 0.25 9.0 0.35

b 10.0 0.4 10.0 0.4 13.0 0.5 13.0 0.5 14.0 0.55 14.0 0.55

c 5.5 0.2 5.5 0.2 8.0 0.3 8.0 0.3 8.5 0.3 8.5 0.3

d 5.5 0.2 5.5 0.2 6.5 0.25 6.5 0.25 6.5 0.25 9.0 0.35

Mounting Hardware

M6 1/4 M6 1/4 M6 1/4 M6 1/4 M8 5/16 M8 5/16

* Measurements are center to center.

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

33

Page 34

TECHNICAL DATA

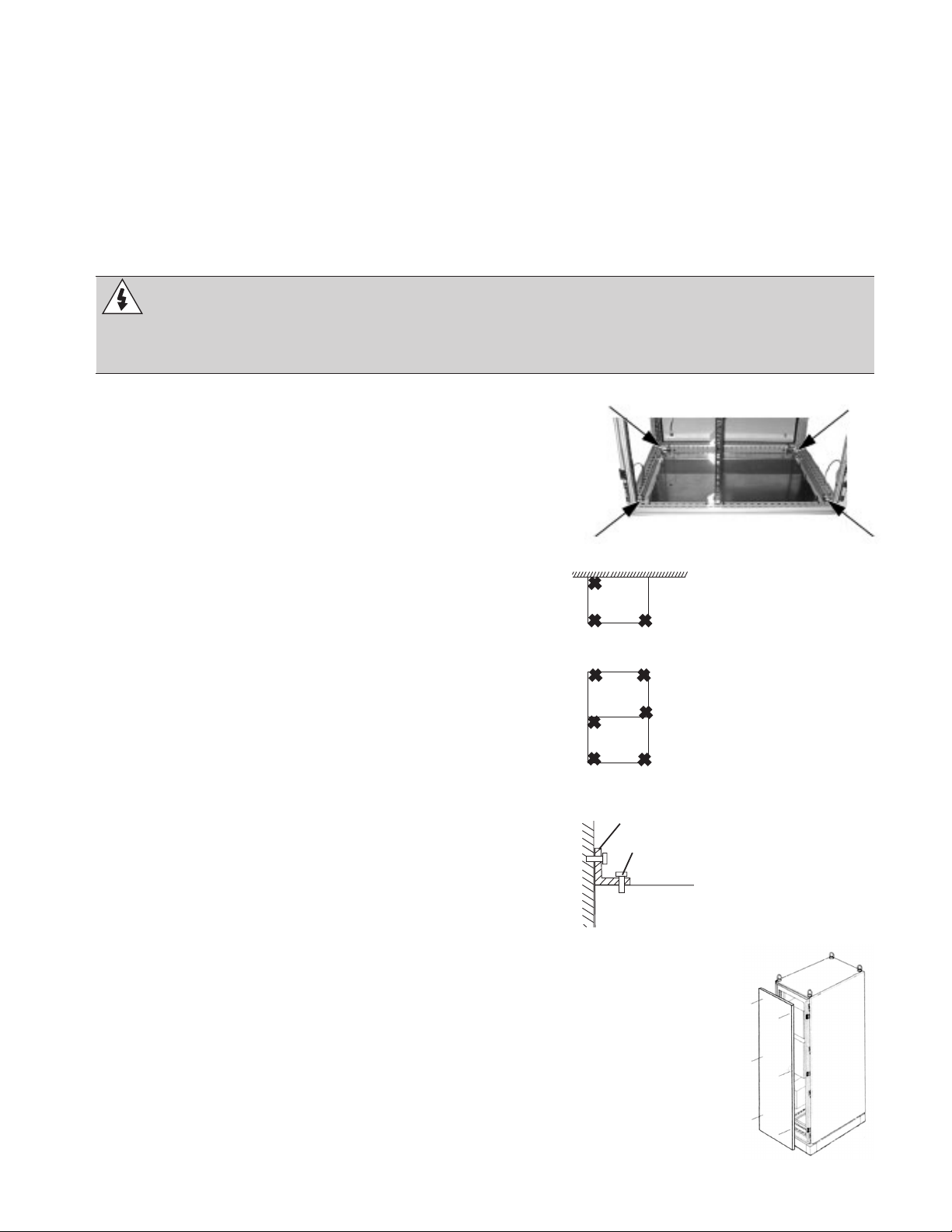

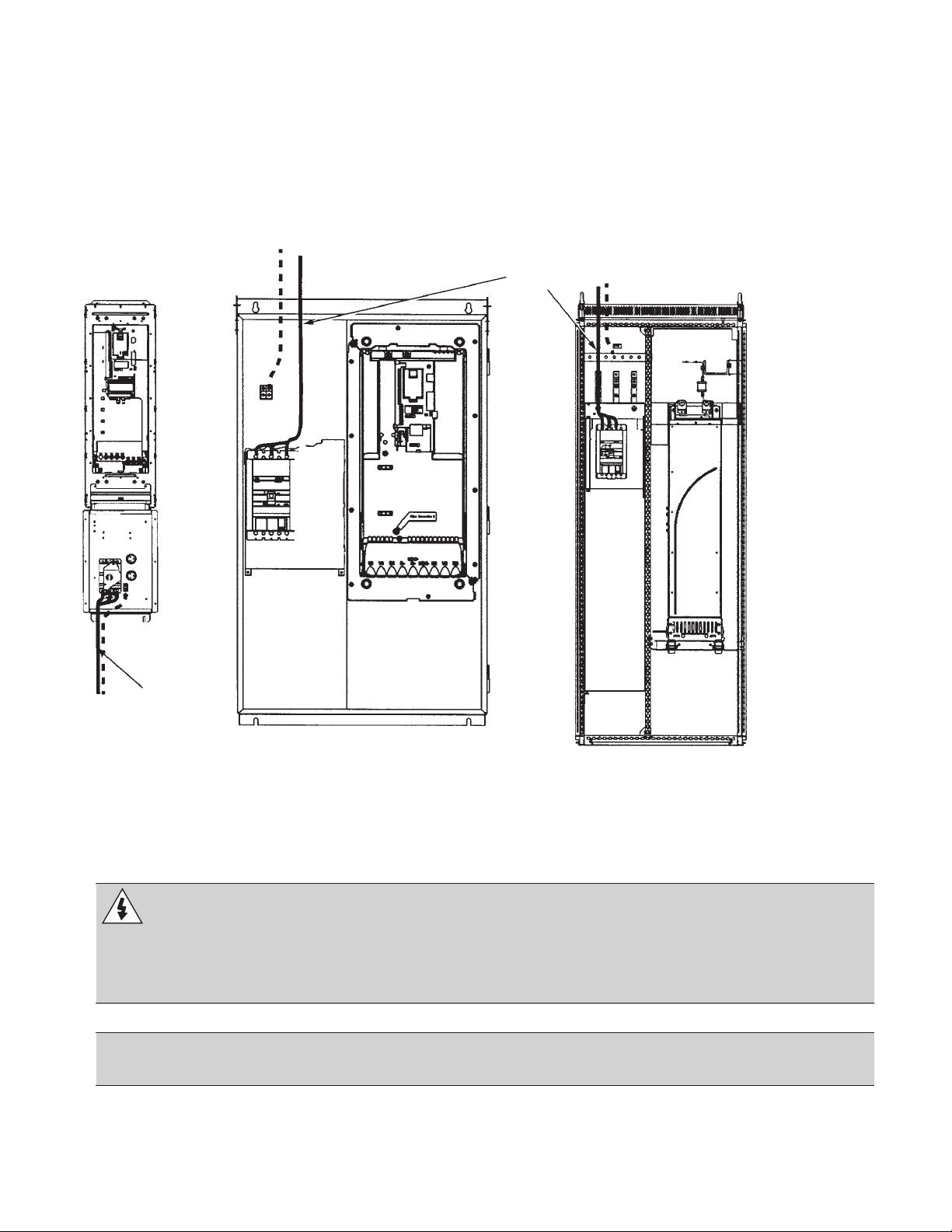

NEMA 1 & 12, R7…R8 Mounting Dimensions

NEMA 1 and NEMA 12 – Dimensions for each Frame Size

R7 & R8

Ref.

Top View

mm in

W 806 31.7

D 659 25.9

a 675 26.6

b 474.5 18.7

c 61 2.4

d 65.5 2.6

Mounting Hardware

11 mm 13/32

* Measurements are center to center.

b

a

d

D

c

W

Weights

The following table lists typical maximum weights for each frame size. Variations within each

frame size (due to components associated with voltage/current ratings and options) are minor.

Weight

En-

closure

R1 R2 R3 R4 R5 R6 R7 R8

kg lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg lb. kg lb.

NEMA 1 13 28 17 37 45 100 55 121 121 266 163 360 230 506 360 793

NEMA 12 15 33 19 42 47 103 57 125 123 271 166 375 250 551 380 837

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

34

Page 35

TECHNICAL DATA

Outside Dimensions

Outside Dimensions

NEMA 1, R1…R4 Outside Dimensions

H

W

DS0301

D

DS0302

Input Disconnect, NEMA 1, R1…R4

Dimensions

W 198 7.8 198 7.8 260 10.2 260 10.2

H 729 28.7 829 32.6 1013 39.9 1147 45.2

D 283 11.2 295 11.6 304 11.9 332 13.1

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

Ref.

R1 R2 R3 R4

mm in mm in mm in mm in

35

Page 36

TECHNICAL DATA

NEMA 12, R1…R4 Outside Dimensions

H

W

DS0303

D

DS0304

Input Disconnect, NEMA 12, R1…R4

Dimensions

W 222 8.7 222 8.7 267 10.5 267 10.5

H 744 29.3 844 33.2 1030 40.6 1163 45.8

D 283 11.2 295 11.6 304 11.9 332 13.1

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

Ref.

R1 R2 R3 R4

mm in mm in mm in mm in

36

Page 37

TECHNICAL DATA

NEMA 1, R5/R6 Outside Dimensions

H

D

W

BP0063

Input Disconnect, NEMA 1, R5/R6

W 713 28.1 713 28.1

H 212 47.7 1212 47.7

D 484 19.1 484 19.1

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

Dimensions

Ref.

R5 R6

mm in mm in

37

Page 38

TECHNICAL DATA

NEMA 12, R5/R6 Outside Dimensions

W

H

BP0062

D

Input Disconnect, NEMA 12, R5/R6

W 734 28.9 734 28.9

H 1371 54.0 1371 54.0

D 484 19.1 484 19.1

NOTE: -088A-2, -114A-2 and -097A-4 NEMA 1 & 12 units are R4 frame base drives in R5 enclosures.

R5 enclosure information applies.

Dimensions

Ref.

R5 R6

mm in mm in

38

Page 39

TECHNICAL DATA

NEMA 1 & 12, R7…R8 Outside Dimensions

W

H

BP0017

D

Outside Dimensions by Frame Size

R7 R8

Enclosure Ref.

mm in mm in

W 806 31.7 806 31.7

NEMA 1 H 2125 83.7 2125 83.7

D 659 25.9 659 25.9

W 806 31.7 806 31.7

NEMA 12 H 2377 93.6 2377 93.6

D 659 25.9 659 25.9

Additional Free Space Recommendations

In addition to the free space requirements for cooling (“Cooling - R7/R8”), allow:

• 800 mm (31.5 in) in front of R7/R8 enclosures – room for the cabinet door to swing open.

• 305 mm (12 in) above R7/R8, IP54 / UL Type 12 enclosures – room for fan replacement.

39

Page 40

CU

CU

U

C

TECHNICAL DATA

Applicable Standards

Drive compliance with the following standards is identied by the standards “marks” on the type code label.

Mark Applicable Standards

UL 508C and UL Standard for Safety, Power Conversion Equipment, second

U

L

®

C22.2 No. 14 edition and CSA Standard for Industrial Control Equipment

UL 508A UL Standard for Safety, Industrial Control Panels

C22.2 No. 14 CSA Standard for Industrial Control Equipment

Compliance is valid with the following provisions:

• The motor and control cables are chosen as specied in this manual.

• The installation rules of this manual are followed.

The AQUAVAR is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical

amperes, 600 V maximum.

For open type enclosures, that is units without the conduit box and/or cover for enclosures, that is units without

the conduit box and/or cover for IP21/UL type 1 units or without the conduit place and/or top cover for IP54

units, the unit must be mounted inside an enclosure per National Electrical Code and local electrical codes.

LISTED

L

®

U

L

®

S

UL/CSA Markings

U

LISTED

A UL mark is attached to ACS550 drives to verify that the drive follows the provisions of UL 508C.

L

®

S

A CSA mark is attached to ACS550-U1 type drives to verify that the drive follows the provisions of C22.2

NO. 14.

®

The ACS550 is suitable for use in a circuit capable of delivering not more than 100 kA RMS symmetrical

amperes, 600 V maximum. The ampere rating is based on tests done according to UL 508.

Branch circuit protection must be provided in accordance with local codes.

The ACS550 has an electronic motor protection feature that compiles with the requirements of UL 508C

and, for ACS550-U1, C22.2 No. 14. When this feature is selected and properly adjusted, additional

overload protection is not required unless more than one motor is connected to the drive or unless

additional protection is required by applicable safety regulations. See parameters 3005 (MOT THERM

PROT) and 3006 (MOT THERM RATE).

The drives are to be used in a controlled environment.

Note: For open type enclosures, i.e. drives without the conduit box and/or cover for IP21 / UL type 1

drives, or without the conduit plate and/or hood for IP54 / UL type 12 drives, the drive must be mounted

inside an enclosure in accordance with National Electric Code and local electrical codes.

Brake choppers, when applied with appropriately sized brake resistors, will allow the drive to dissipate

regenerative energy (normally associated with quickly decelerating a motor). Frame sizes R1 and

R2 have a built-in brake chopper as standard equipment. For frame sizes R3…R6, contact your ABB

representative for appropriate parts.

WARNING! Do not attempt to install or remove EM1, EM3, F1 or F2 screws while power is

applied to the drive’s input terminals.

WARNING! Do not control the motor with the disconnecting device (disconnecting means);

instead, use the control panel start and stop keys and , or commands via the I/O

board of the drive. The maximum allowed number of charging cycles of the DC capacitors

(i.e. power-ups by applying power) is ve in ten minutes.

40

Page 41

TECHNICAL DATA

CE Marking

A CE mark is attached to the drive to verify that the drive follows the provisions of the European Low

Voltage and EMC Directives.

Note: The 600 V ACS550-U1 drives are not CE approved.

Compliance with the EMC Directive

The Directive denes the requirements for immunity and emissions of electrical equipment used

within the European Union. The EMC product standard (IEC/EN 61800-3 [2004]) covers requirements

stated for drives.

Compliance with IEC/EN 61800-3 (2004)

C-Tick Marking

The drive carries C-Tick marking.

✔

C-Tick marking is required in Australia and New Zealand. A C-Tick mark is attached to the drive to

verify compliance with the relevant standard (IEC 61800-3 (2004) — Adjustable speed electrical power

drive systems — Part 3: EMC product standard including specic test methods), mandated by the Trans-

Tasman Electromagnetic Compatibility Scheme.

The Trans-Tasman Electromagnetic Compatibility Scheme (EMCS) was introduced by the Australian

Communication Authority (ACA) and the Radio Spectrum Management Group (RSM) of the New

Zealand Ministry of Economic Development (NZMED) in November 2001. The aim of the scheme is

to protect the radio frequency spectrum by introducing technical limits for emission from electrical/

electronic products.

Compliance with IEC/EN 61800-3 (2004)

41

Page 42

INDEX

Refer to the Aquavar CPC User’s Manual (IM167) index for topics not listed here.

A

air ow........................................32

C

cable requirements

input power ................................28

capacitor

change, maintenance interval.................14

connection points

oor mounted enclosures ....................12

wall mounted enclosures.....................11

model code ....................................8

control panel

maintenance interval, battery . . . . . . . . . . . . . . . . .14

cooling .......................................32

cover

remove .....................................6

current

rating code..................................8

D

dimensions

mounting, R1...R6 ...........................33

mounting, R7...R8 ...........................34

outside, NEMA 12, R1...R4....................36

outside, NEMA 12, R5...R6....................38

outside, NEMA 1, R1...R4 .....................35

outside, NEMA 1, R5...R6 .....................37

outside, NEMA 1/NEMA 12, R7...R8............39

disconnect

diagram ....................................4

features, functions

drive

fan replacement ............................14

identication ................................8

proper lifting ................................7

weight .....................................34

E

enclosure protection class code...................8

enclosure, NEMA 12

air lter maintenance ........................16

fan replacement ............................15

F

fan, drive module

maintenance interval ........................14

replacement procedure......................14

fan, enclosure

maintenance interval ........................14

replacement procedure......................14

lter, enclosure

R5/R6 inlet, maintenance interval..............14

R5/R6 inlet, maintenance procedure...........16

R7/R8, exhaust, maintenance interval ..........14

R7/R8, exhaust, maintenance procedure .......18

R7/R8, inlet, maintenance interval .............14

R7/R8, inlet, maintenance procedure ..........16

free space

for access, R7/R8............................39

for cooling ....................................32

fuses .........................................26

208...240 volt drives .........................26

380...480 volt drives .........................27

500...600 volt drives .........................28

G

grounding

requirements ...............................10

H

heat loss .....................................232

heatsink

maintenance interval ........................14

I

input disconnect

see disconnect

input power

cable/wire requirements .....................28

fuses ......................................26

installation

ow chart ...................................6

preparation .................................7

L

label

type code ...................................8

location, mounting ..............................9

42

Page 43

INDEX

M

maintenance

drive module fan replacement ................14

enclosure fan replacement ...................14

intervals ...................................14

R5/R6 enclosure inlet lter ...................16

R7/R8 enclosure exhaust lter ................18

R7/R8 enclosure inlet lter ...................16

manuals, listing .................................ii

motor

connection specications ....................32

motor cable

maximum length ............................32

N

NEMA 1

code .......................................8

NEMA 12

code .......................................8

R

ratings ........................................25

remove cover...................................6

S

safety ..........................................3

specications

cooling ....................................32

motor connections ..........................32

standards .....................................40

C22.2 No. 14 ...............................40

UL 508C ...................................40

T

terminals

power, wire sizes ............................29

type code ......................................8

V

voltage

rating code..................................8

W

warning

automatic start up ............................3

dangerous voltages ..........................3

listing.......................................3

parallel control connections ...................3

qualied installer.............................3

weight

drive ......................................34

wiring

connection diagrams, oor mounted ..........12

connection diagrams, wall mounted ...........11

line input installation ........................13

overview ...................................11

requirements ...............................10

43

Page 44

CENTRIPRO LIMITED WARRANTY

This warranty applies to all Aquavar CPC controllers manufactured by Xylem, Inc.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist

for a period of twenty-four (24) months from date of installation or thirty (30) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized CentriPro distributor from whom the controller was purchased and furnish complete details

regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the CentriPro Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between CentriPro and the dealer in purchases,

consignments or contracts for sale of the subject controllers.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing controllers to

customers.

(3) “Customer” means any entity who buys or leases the subject controllers from a dealer. The “customer” may mean an individual, partnership, corporation, limited

liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.centripro.com