Page 1

INSTRUCTION MANUAL

IM245

RGS2012E1

S or E Retrofit Kit

SUBMERSIBLE GRINDER PUMP

INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL

Page 2

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

CAUTION

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the

pump, the controller or in the

manual, look for one of the following signal words and be alert to

the potential for personal injury or

property damage.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

PUMP INSTALLATION

Grinder pumps should be installed in a basin that

is vented per the local plumbing code in your area.

The pump is not to be installed in locations that are

hazardous in accordance with the NEC. All plumbing

should be beneath the frost line for the region station

is installed in to ensure that pipes do not freeze.

Never lift the pump by the cord. Use

the lifting rope provided with the retro-

fit kit for lifting.

OLD PUMP REMOVAL

1. Supply power must be turned off

2. Goulds Water Technology recommendation is to

use a 20 amp circuit breaker. Check the existing

panel for breaker size and replace if necessary.

NOTE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

ALL OPERATING INSTRUCTIONS MUST BE

READ, UNDERSTOOD, AND FOLLOWED BY THE

OPERATING PERSONNEL. GOULDS WATER

TECHNOLOGY ACCEPTS NO LIABILITY FOR

DAMAGES OR OPERATING DISORDERS WHICH

ARE THE RESULT OF NON-COMPLIANCE WITH

THE OPERATING INSTRUCTIONS.

1. This manual is intended to assist in the installation,

operation and repair of the system and must be

kept with the system.

2. Installation and maintenance MUST be performed

by properly trained and qualified personnel.

3. Review all instructions and warnings prior to performing any work on the system.

3. Remove the basin cover from the current station

4. If basin is full of water, pump water out with separate pump or vacuum truck. Discard waste in accordance with local, state and national codes.

5. Disconnect quick disconnect.

2

4. Any safety decals MUST be left on the pump.

5. The system MUST be disconnected from the main

power supply before attempting any operation or

maintenance on the electrical or mechanical part of

the system. Failure to disconnect electrical power

before attempting any operation or maintenance

can result in electrical shock, burns or death.

Page 3

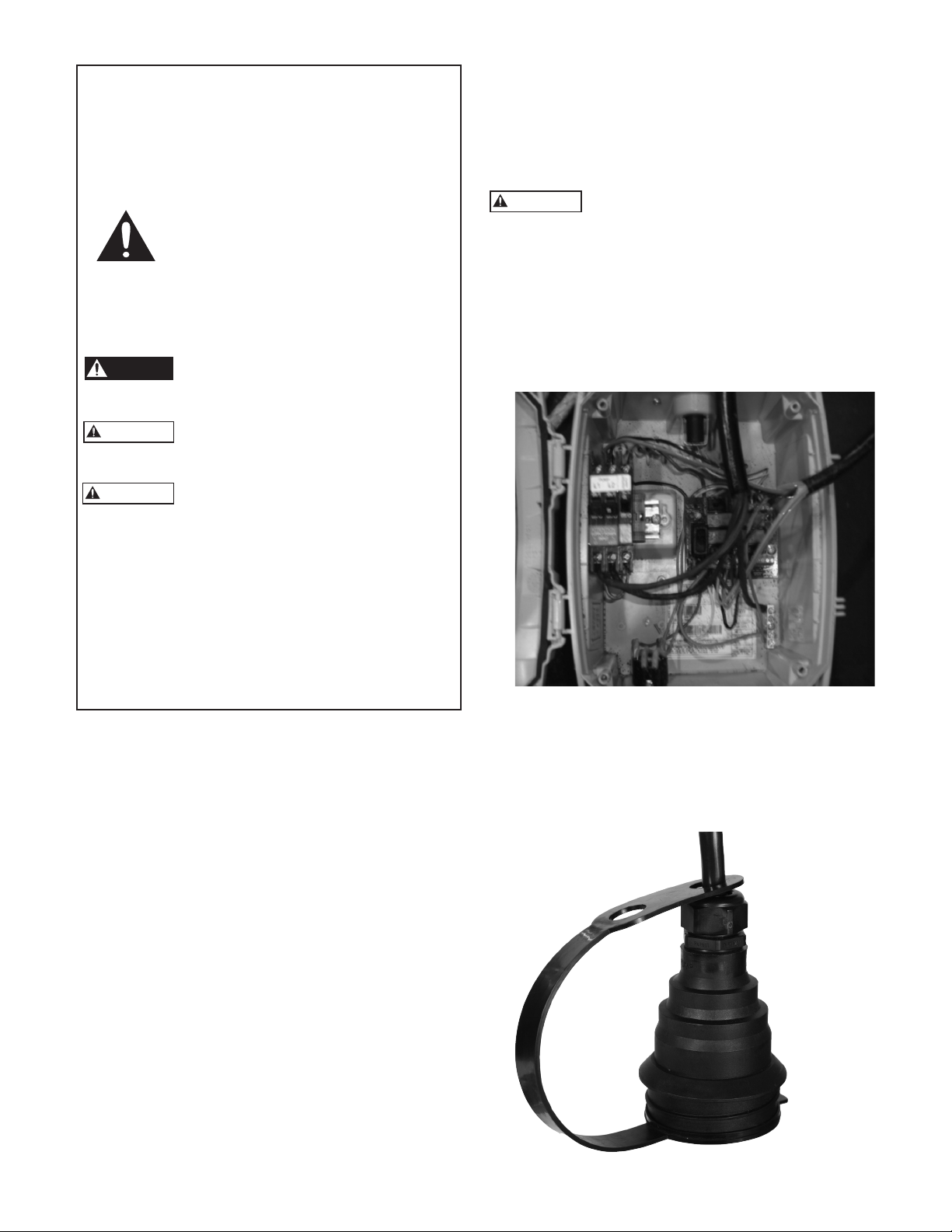

6. Check connections to make sure they are clean

WARNING

and dry.

7. Inspect connection, there are two styles round connectors- shown above and rectangular connectors.

Ensure that the correct Retrofit Kit has been purchased for the style connection being replaced.

8. Remove bolts from cover plate of current unit

3. Retighten all connections, check hardware, and

ensure that no wires or any other obstructions are

in way of pump cutters.

4. Make sure all fittings are tight.

5. Apply gasket tape to the bottom of the cover perimeter, poke holes through the tape at the cover

bolts entries.

9. Close valve of current unit

10. Secure rope to hooks on cover. Lift Unit from

basin.

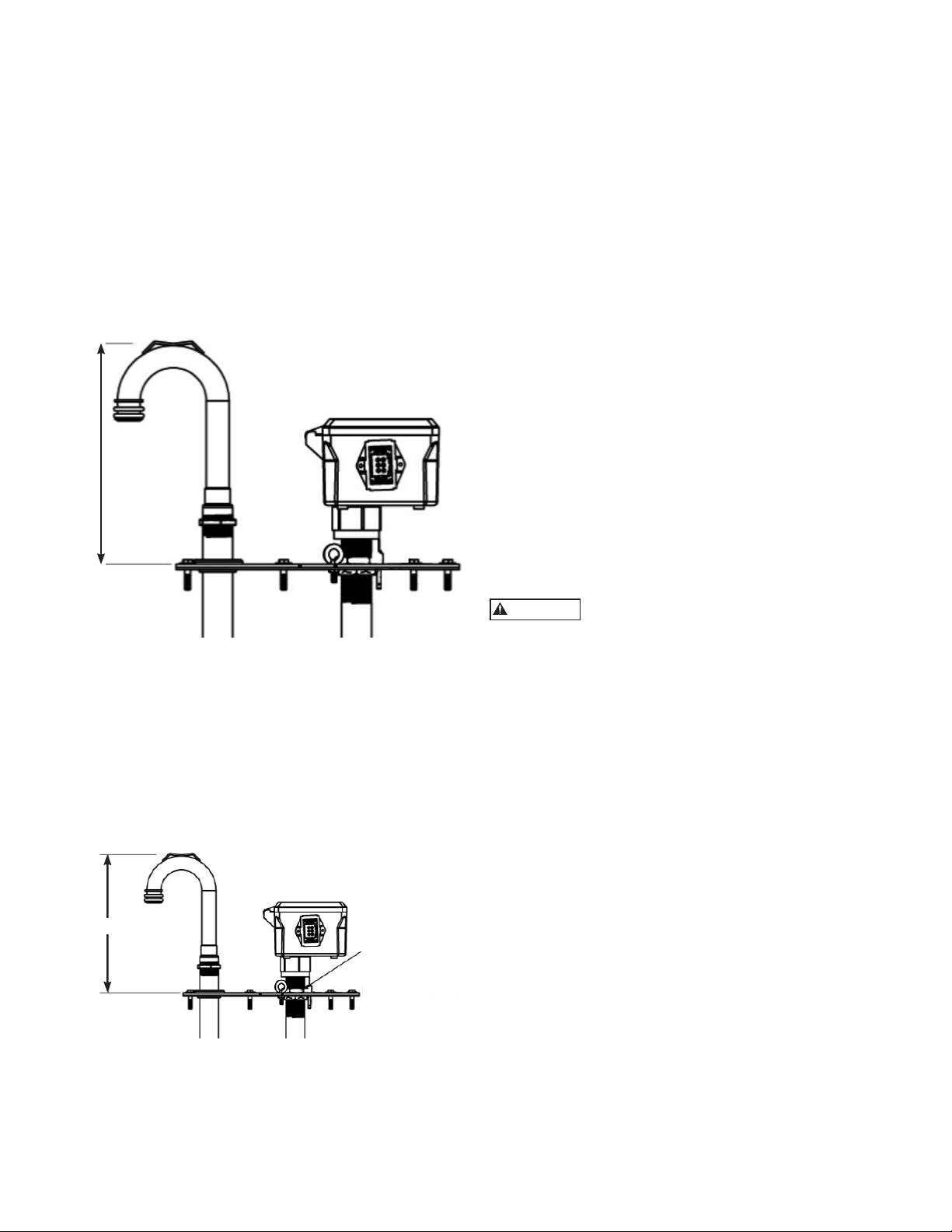

11. Measure distance on Candy cane for setting up

new retrofit – see below.

INSTALLING THE GOULDS WATER

TECHNOLOGY RETROFIT KIT

1. Adjust the center nut until the candy cane elbow

distance measured above matches the old unit.

(This is pre-set at factory to 12.38”.) Secure adjustable nuts with Loctite so that vibration does not

loosen the nut.

6. Lubricate O-rings on the discharge elbow to ease

installing into the receiver.

7. Using rope lower the grinder assembly in the basin. Align cover tabs to tank slots.

8. Align discharge elbow to Receiver. Unit will rest

on the tank flange with the elbow fully inserted in

receiver.

9. Open valve to latch with the discharge elbow.

Adjustment to nut may need to be made to alter

height at this point.

10. Once in place and latched install the 6 bolts back

into the cover plate.

11. Reconnect the power adapter from the power to

the new retrofit kit adapter.

12. Check electrical resistance to make sure that the

panel is free of shorts and ground faults.

13. Check grounding connections is made properly

Licensed electricians should be present

for panel or breaker energizing. If faults

caused by damage or poor installation have not

been detected, serious damage can result when

power is applied.

14. Turn on power to breakers.

15. Fill tank to test if pump and floats operate properly. See troubleshooting chart for problems

encountered.

16. Once tested and operating properly replace the

basin cover.

12.375

ADJUSTABLE NUTS

2. Check floats so that they have an unobstructed

free area in the tank. (These are pre-set at the

factory.)

18. Affix nameplate provided to the control panel so

the new unit can be identified as a RGS2012E1S or

E1E Retrofit Kit by Goulds Water Technology.

Pump specifics can be found under the standard

Goulds Water Technology product RGS2012 on the

website www.completewatersystems.com, Goulds

Water Technology Wastewater tab.

3

Page 4

TROUBLESHOOTING CHART

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE ATTEMPTING ANY

SERVICE CAN CAUSE SHOCK, BURNS OR DEATH.

SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION

MOTOR NOT

RUNNING

NOTE: If circuit breaker

“OPENS” repeatedly,

DO NOT reset. Call

qualified electrician.

Motor thermal protector tripped. Allow motor to cool. Insure minimum pump

submergence. Clear debris from casing and

impeller.

Open circuit breaker or blown fuse. Determine cause, call a qualified electrician.

a) Manual operation Pump impeller binding or jammed.

Power cable is damaged.

Inadequate electrical connection in

control panel.

b) Automatic

operation

No neutral wire connected to control

panel.

Inadequate electrical connection in

control panel.

NOTE: Check the pump

in manual mode first

to confirm operation.

If pump operates, the

automatic control or

wiring is at fault. If pump

does not operate, see

above.

PUMP WILL NOT

Defective liquid level switch. With switch disconnected, check continuity

Insufficient liquid level to activate

controls.

Liquid level cords tangled. Untangle cords and insure free operation.

Liquid level cords tangled. Untangle cords and insure free operation.

TURN OFF

Pump is air locked. Shut off pump for approximately one minute,

Influent flow is matching pump’s

discharge capacity.

LITTLE OR NO

LIQUID DELIVERED

Check valve installed backwards,

plugged or stuck closed.

BY PUMP

Excessive system head. Consult with dealer.

Pump inlet plugged. Inspect and clear as required.

Improper voltage or wired incorrectly. Check pump rotation, voltage and wiring.

Pump is air locked. See recommended action, above.

Impeller is worn or damaged. Inspect impeller, replace as required.

Liquid level controls defective or

improperly positioned.

Check motor amp draw. If two or more times

higher than listed on pump nameplate,

impeller is locked, motor bearings or shaft

is damaged. Clear Inadequate electrical

connection debris from cutter, casing and

impeller, consult with dealer.

Resistance between power leads and ground

should read infinity. If any reading is incorrect,

call a qualified electrician.

Inspect control panel wiring. Call a qualified

electrician.

while activating liquid level switch. Replace

switch, as required.

Allow liquid level to rise 3” to 4” (76 mm - 101

mm) above turn-on level.

then restart. Repeat until air lock clears. If

air locking persists in a system with a check

valve, a 3⁄16” (4.8 mm) hole may be drilled in

the discharge pipe approximately 2” (51 mm)

above the discharge connection.

Larger pump may be required.

Check flow arrow on valve and check valve

operation.

Consult with qualified electrician.

Inspect, readjust or replace as required.

4

Page 5

TROUBLESHOOTING CHART

SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION

PUMP CYCLES

CONSTANTLY

JUNCTION BOX WIRING DIAGRAM

Discharge check valve inoperative. Inspect, repair or replace as required.

Sewage containment area too small. Consult with dealer.

Liquid level controls defective or

improperly positioned.

Influent excessive for this size pump. Consult with dealer.

Inspect, readjust or replace as required.

123 45678

RED

ALARM

FLOAT

BLACK

ORANGE

PUMP ON/OFF

FLOAT

PUMP

WHITE

GREEN

N/C

5

Page 6

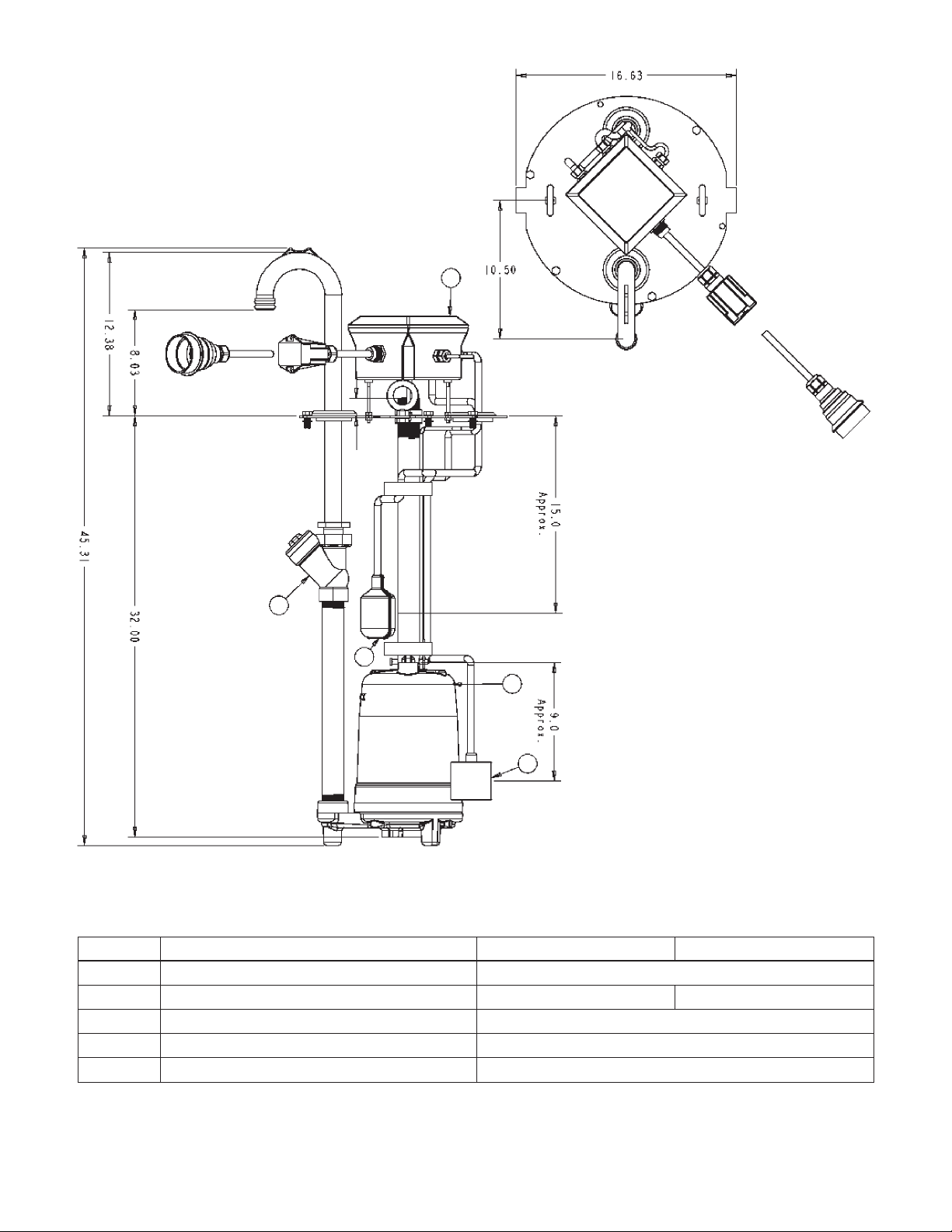

REPAIR PARTS

2

3

4

1

5

Item No. Major Components Standard Extreme

1 RGS2010 Grinder E1 RGS2012E1

2 Junction Box with Electrical Adaptor 9K600 9K601

3 Check / Anti-Siphon Valve A9-12BAS

4 Signal Master FS A2N03

5 Pump Master Plus FS A2E03

All dimensions ± 1/8 tolerance unless noted.

6

Page 7

NOTES

7

Page 8

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for

a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (888) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM245 Rev. 0 June 2012

Loading...

Loading...