Page 1

C

US

INSTRUCTION MANUAL

IM244R04

Models Covered:

SPD Plus

230V 1Ø Input 20-30 HP

230V 3Ø Input 40-60 HP

460V 40-100 HP

575V 40-100 HP

SPD Plus

VARIABLE SPEED PUMP CONTROL

INSTALLATION AND OPERATION MANUAL

U

L

®

Page 2

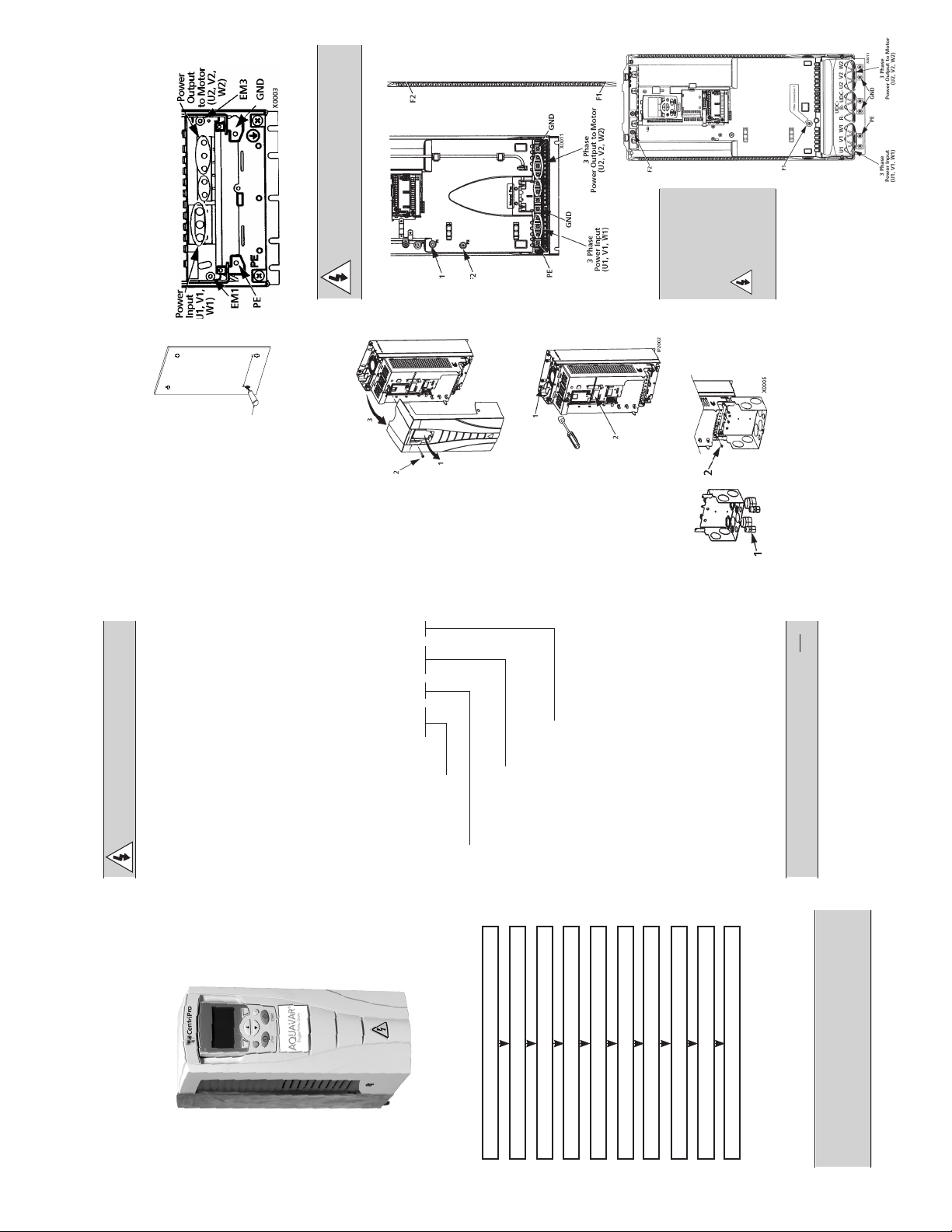

1

3. Strip wires.

3. Check the contents against the order

ground wires to the drive terminals.

See “Power Supply and Wiring”

in the instruction manual.

4. Connect power, motor and

Frame Sizes R1…R4

and the shipping label to verify that all

parts have been received.

The drive requires a smooth,

vertical, solid surface, free from

heat and moisture, with free

Prepare the Mounting Location

WARNING! For oating networks

remove screws at EM1 and EM3 on

Frame Sizes R1…R4.

and PE for wiring.

* Single phase input power must use U1, W1

Frame Size R5

X0002

points.

1. Mark the mounting

2. Drill the mounting holes.

space for air ow – 200 mm (8

in.) above and below, and 25

mm (1 in.) around the sides of

the drive.

1. Remove the control panel

Remove the Front Cover

(display), if attached.

2. Loosen the

captive screw

at

the top.

top to remove

the cover.

3. Pull near the

SPD PLUS and use

1. Position the

screws or bolts to

securely tighten all

four corners.

Mount the Drive

Frame Size R6

WARNING!

sticker in the

appropriate lan-

guage on the inside

plastic shell.

2. Attach a warning

For oating net-

Install the Wiring (copper only)

F1 and F2

on Frame

works remove

screws at

Sizes R5 or R6.

supplied) in the conduit/gland box.

1. Install thin-wall conduit clamps (not

2. Install conduit/gland box.

1. Connect conduit runs to box.

Wiring Power

wiring through conduits.

2. Route input power and motor

_______________

___________________

______________________

_______________________

______________________________

WARNING! The Aquavar should ONLY

be installed by a qualied electrician.

Prepare for Installation

Check

frequency and voltage range must match drive

specifications (3 phase motor only).

• Motor Compatibility – Motor type, nominal current,

indoor controlled environment that is suitable for

• Suitable Environment – Drive requires heated,

the selected enclosure below 122º F (50º C).

requirements. Refer to NEC, Local, State or Munici-

pal codes.

Refer to the Installation Operation Manual and

• Wiring – Follow local codes for wiring and fusing

confirm that all preparations are complete.

Tools Required

Screwdrivers, wire stripper, tape measure, mount-

ing screws or bolts, and drill.

Use the following chart to interpret the type code

found on the drive label.

SPD 4 0600 N1

Single Pump Drive

Voltage

2 – 230 Volt 4 – 460 Volt 5 – 575 Volt

Task

Nominal Horsepower

0400 = 40 HP 0500 = 50 HP 0600 = 60 HP

0750 = 75 HP 1000 = 100 HP

Enclosure and Filter Options

Blank = NEMA 3R, no lter N1 = NEMA 1, no lter

F = NEMA 3R, with lter

NOTE: HP rating is for reference only, and is based on 3Ø input power.

• Voltage

• Nominal Motor Current

• Nominal Frequency

• Nominal Speed

Collect the following data from the motor nameplate

plate for later use in the Aquavar startup:

Collect Motor Data

• Nominal Power

NOTE: Lift the SPD PLUS by its chassis and not

by its cover.

Unpack the Drive

shipper immediately if damaged com-

ponents are found.

1. Unpack the drive.

2. Check for any damage and notify the

SPD PLUS

Quick Start Guide

The installation of the SPD PLUS adjust-able

Centrifugal Pump Controller

2

Overview

PREPARE for installation

UNPACK the drive

PREPARE mounting location

REMOVE the front cover

MOUNT the drive

INSTALL wiring

CHECK installation

REINSTALL the cover

APPLY power

speed drive follows the outline below.

START-UP Assistant

This guide provides a quick reference for

installing SPD PLUS drives having a standard

enclosure (NEMA 1).

NOTE: This guide does not provide detailed

installation, safety or operational instruc-

tions. See the Installation Operation Manual

for complete information.

Application

Page 3

1. Align the cover

Reinstall the Cover

and slide

3

it on.

5

11.1%

40.2 PSI sp

0.0 PSI ac

0.0 HZ

DIR MENU

LOC

REM

WARNING! The SPD PLUS will start

up automatically at power up, if the

external run command is on.

When power is applied to the SPD PLUS,

the captive

screw.

control panel.

2. Tighten

3. Reinstall the

Always reinstall the front cover before turn-

ing power on.

Apply Power

1

the green LED comes on.

1. Apply input power.

NOTE! Before increasing motor speed,

check that the motor is running in the

desired direction.

Run the Start-Up Assistant

to congure the motor and

Start-Up

REM

system parameters. If this is

the rst time the drive has

been powered, the display

will prompt the user if they

would like to run the Start-

Up Assistant. Select Yes to

run the Start-Up Assistant.

If this is not the rst time the drive has been

powered, follow the steps below:

1. From the Main Screen press MENU to

enter the MENU screen.

2. Select QUICKSTART

3. Select Start-Up

4. Follow the menu prompts to congure

the drive.

NOTE! For common parameters and

menu items, use the Help Key to

display descriptions. If you encounter

Alarms or Faults, use the Help Key or

refer to the Diagnostic section of the

instruction manual.

transducer

cable

1. Route the

Wiring the Transducer

through

the conduit.

2. Strip the

transducer

cable

sheathing

and twist

the screen

wire.

wire of the

transducer to

terminal X1-1.

transducer (red or brown) to terminal

X1-10.

transducer (white or black) to X1-5. See

chart in next column.

screw).

3. Connect the screen

4. Connect the power supply wire of the

5. Connect analog output wire from the

6. Install the conduit/gland box cover (1

Digital input impedance 1.5 kΩ. Maximum voltage

1

for digital inputs is 30 V.

Before applying power, perform the follow-

Check Installation

ing checks.

√ Check

Environment conforms to specifications.

The drive is mounted securely.

Proper cooling space around the drive.

Motor and driven equipment are ready for start.

Floating networks: Internal RFI filter disconnected.

Drive is properly grounded, with pump/motor.

Input power (mains) voltage matches the drive

nominal input voltage.

The input power (mains) terminals, U1, V1, W1,

are connected and tightened as specified.

The input power (mains) fuses / mains switch installed.

The motor terminals, U2, V2, W2, are connected

and tightened as specified.

Motor cable is routed away from other cables.

NO power factor compensation capacitors are

connected to the motor cable.

Control terminals are wired and tightened as specified.

NO tools or foreign objects (such as drill shavings) are

inside the drive.

NO alternate power source for the motor is connected

– no input voltage is applied to the output of the drive.

3

Page 4

INDEX

Important Safety Instructions................................................................................................................................................5

System Components .............................................................................................................................................................6

System Design ........................................................................................................................................................................ 8

Piping ....................................................................................................................................................................................10

Mounting the Controller .....................................................................................................................................................10

Power Supply and Wiring ...................................................................................................................................................11

Control Input and Output Functions .................................................................................................................................18

Starting the System ..............................................................................................................................................................19

Troubleshooting ...................................................................................................................................................................22

Appendix A - Input Power Requirements ........................................................................................................................27

Appendix B – Fuse and Wire Sizing ............................................................................................................................. 29-31

Appendix C - Weights and Dimensions ...........................................................................................................................31

Limited Warranty ..................................................................................................................................................................36

NOTE:

• Input and Output power connections require a minimum of 75ºC rated Copper wire only.

• In order to maintain the environmental rating integrity of the enclosure, all openings must be

closed by equipment rated Type 1 for Type 1 enclosures or Type 3R for Type 3R enclosures

• Maximum Ambient temperature range 5º F (-15º C) to 122º F (50º C).

• Maximum Humidity: 95% non-condensing.

4

Page 5

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

SECTION 1: SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

Hazardous

Pressure

CAUTION

TO AVOID SERIOUS OR FATAL PERSONAL INJURY

OR MAJOR PROPERTY DAMAGE, READ AND

FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL

AND ON EQUIPMENT.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE UNIT.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the

pump, the controller or in the

manual, look for one of the following signal words and be alert to

the potential for personal injury or

property damage. Obey all messages that follow this symbol to avoid

injury or death.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

5. The system MUST be disconnected

from the main power supply before

attempting any operation or main-

tenance on the electrical or mechanical part of

the system. Failure to disconnect electrical power

before attempting any operation or maintenance

can result in electrical shock, burns or death.

6. When in operation, the motor and

pump could start unexpectedly and

cause serious injury.

7. Even when the motor is stopped,

dangerous voltage is present at the

Power Circuit terminals U1, V1, W1

and U2, V2, W2 and, depending on the frame size,

UDC+ and UDC-, or BRK+ and BRK-.

8. WARNING! Dangerous voltage is

present when input power is con-

nected. After disconnecting the supply, wait at least 5 minutes (to let the intermediate

circuit capacitors discharge) before removing the

cover.

9. WARNING! Even when power is

removed from the input terminals of

the SPD Plus, there may be dangerous voltage (from external sources) on the power

disconnect or terminals of the relay outputs R01…R03.

CAUTION

Used without a safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL

INSTRUCTIONS AND WARNINGS

PRIOR TO PERFORMING ANY

WORK ON THIS CONTROLLER.

MAINTAIN ALL SAFETY DECALS.

All operating instructions must be read,

understood, and followed by the operating

personnel. CentriPro accepts no liability for

damages or operating disorders which are the

result of non-compliance with the operating

instructions.

1. This manual is intended to assist in the installation,

operation and repair of the system and must be

kept with the system.

2. Installation and maintenance MUST be performed

by properly trained and qualied personnel.

3. Review all instructions and warnings prior to performing any work on the system.

4. Any safety decals MUST be left on the controller

and/or pump system.

10. WARNING! When the control termi-

nals of two or more drive units are

connected in parallel, the auxiliary

voltage for these control connections must be

taken from a single source which can either be

one of the units or an external supply.

11. WARNING! The SPD Plus is not a

eld repairable unit. Never attempt to

repair a malfunctioning unit; contact

the factory or your local Authorized Service Center

for replacement.

12. WARNING! The SPD Plus will start up

automatically after an input voltage

interruption if the external run command is on.

13. WARNING! The heat sink may reach a high

temperature, in excess of 200º F. Severe

burns are possible.

14. WARNING! If the drive will be used

in a oating network, remove screws

at EM1 and EM3 (Frame size R4) or F1

and F2 (Frame size R5 or R6).

NOTE! For more technical information, contact the

factory or your local SPD Plus representative.

15. WARNING! Always consult your lo-

cal, state, municipal or NEC codes for

proper wiring, electrical installation of

inverter drives and AC motors.

5

Page 6

SECTION 2: SYSTEM COMPONENTS

WARNING

Hazardous

voltage

Hazardous

Pressure

CAUTION

Please review the SPD Plus Variable Speed Pump Controller components and ensure that you have all the parts

and are familiar with their names. Be sure to inspect all components supplies for shipping damage.

SPD Plus Variable Speed Pump Controller Package:

• SPD Plus Variable Speed Controller

• Pressure Transducer with Cable

• Output Reactor (if ordered)

• Installation and Operation Manual

WARNING

DO NOT power the unit or run the pump until all electrical and plumbing connections,

especially the pressure sensor connection, are completed. The pump should not be run dry.

All electrical work must be performed by a qualied technician. Always follow the National

Electrical Code (NEC), or the Canadian Electrical Code (CEC) as well as all local, state and

provincial codes. Code questions should be directed to your local electrical inspector or code

enforcement agency. Failure to follow electrical codes and OSHA safety standards may result in

personal injury or equipment damage. Failure to follow manufacturer's installation instructions

may result in electrical shock, re hazard, personal injury, death, damage to equipment, unsatisfactory

performance and may void manufacturer's warranty.

SPD PLUS TYPE CODE AND PART NUMBER

Type Code:

SPD 4 0600 N1

Enclosure and Filter Options

Blank = NEMA 3R, no lter

F = NEMA 3R, with lter

N1 = NEMA 1, no lter

Nominal Horsepower

0400 = 40 HP

0500 = 50 HP

0600 = 60 HP

0750 = 75 HP

1000 = 100 HP

Voltage

2 = 230V

4 = 460V

5 = 575V

Single Pump Drive

NOTE: HP rating is for reference only, and is based on 3Ø input power.

6

Page 7

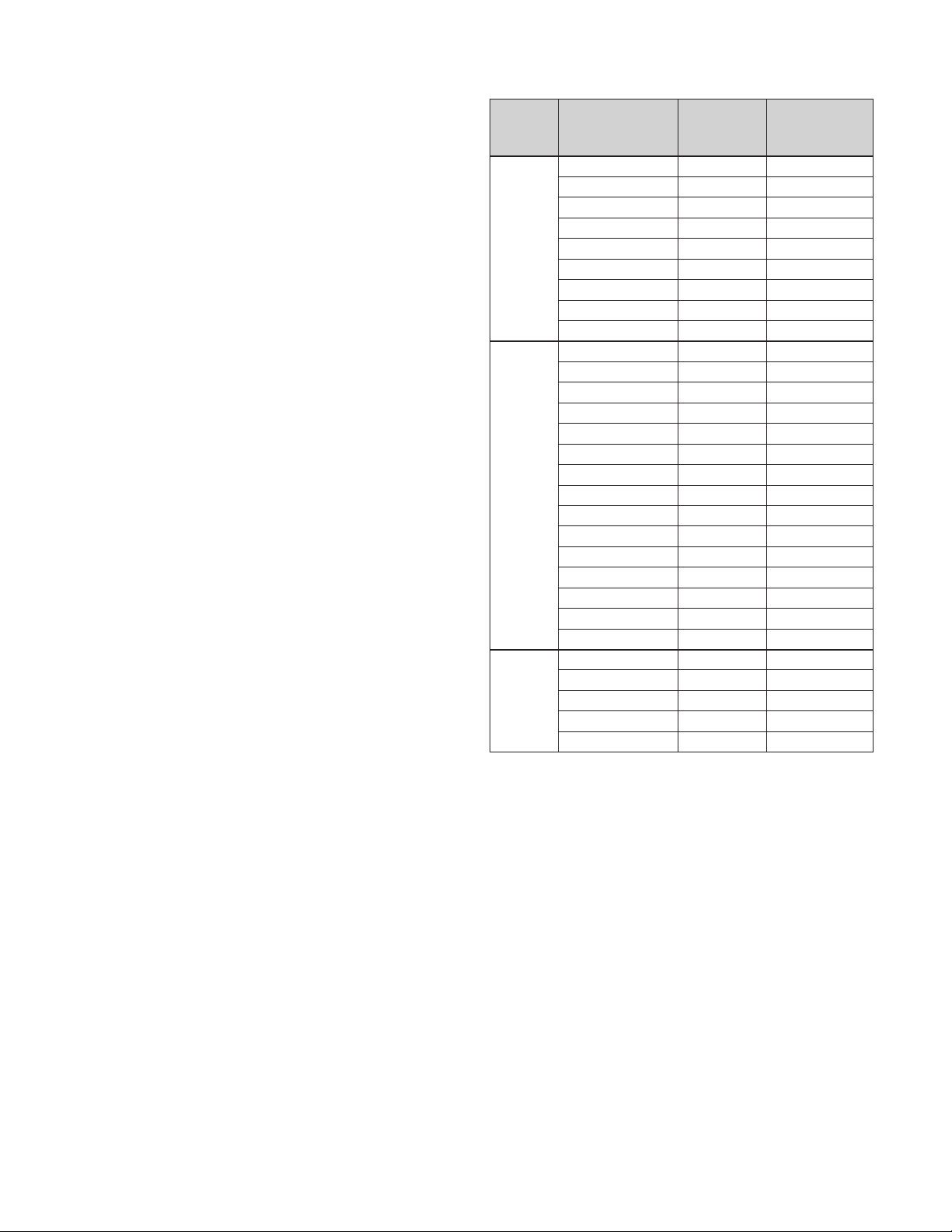

PART NUMBERS

Nominal HP Rating

Supply

Voltage

208/230

460

575

NOTES

1) Refer to Appendix C for frame size details.

2) Drive supplied with pressure transducer and manual.

3) Controllers with an N1 sufx have a NEMA 1 enclosure and are rated for indoor use only.

Model Number

SPD20400 40 20 103 51 114 57 N6

SPD20400F 40 20 129 64 143 72 N6

SPD20400N1 40 20 103 51 114 57 R4

SPD20500 50 25 129 64 143 72 N6

SPD20500F 50 25 160 80 178 89 N6

SPD20500N1 50 25 129 64 143 72 R6

SPD20600 60 30 160 80 178 89 N6

SPD20600F 60 30 199 99 221 111 N6

SPD20600N1 60 30 160 80 178 89 R6

SPD40400 40 — 53 — 59 — N4

SPD40400F 40 — 65 — 72 — N4

SPD40400N1 40 — 53 — 59 — R4

SPD40500 50 — 65 — 72 — N4

SPD40500F 50 — 87 — 97 — N5

SPD40500N1 50 — 65 — 72 — R4

SPD40600 60 — 87 — 97 — N5

SPD40600F 60 — 87 — 97 — N5

SPD40600N1 60 — 87 — 97 — R4

SPD40750 75 — 113 — 125 — N6

SPD40750F 75 — 113 — 125 — N6

SPD40750N1 75 — 113 — 125 — R5

SPD41000 100 — 141 — 157 — N6

SPD41000F 100 — 141 — 157 — N6

SPD41000N1 100 — 141 — 157 — R6

SPD50400N1 40 — 47 — 52 — R4

SPD50500N1 50 — 69 — 77 — R6

SPD50600N1 60 — 69 — 77 — R6

SPD50750N1 75 — 89 — 99 — R6

SPD51000N1 100 — 130 — 144 — R6

3 Phase

Input

1 Phase

Input

Full Load Output

Current (50C)

3 Phase

Input

1 Phase

Input

Full Load Output

Current (40C)

3 Phase

Input

1 Phase

Input

Frame

Size

7

Page 8

SECTION 3: SYSTEM DESIGN

SPD PLUS CENTRIFUGAL PUMP CONTROL SYSTEM

The SPD Plus pump controller is a simple, easy to use

and commission Variable Speed Drive (VSD) designed

specically for use in submersible or above ground

pump systems. The SPD Plus features an integrated

Start-Up Assistant which simplies system commissioning and setup.

NOTE

The SPD Plus is not recommended for the residential

well applications. Consult CentriPro for suitable

Variable Speed Controllers designed for residential

well pumps.

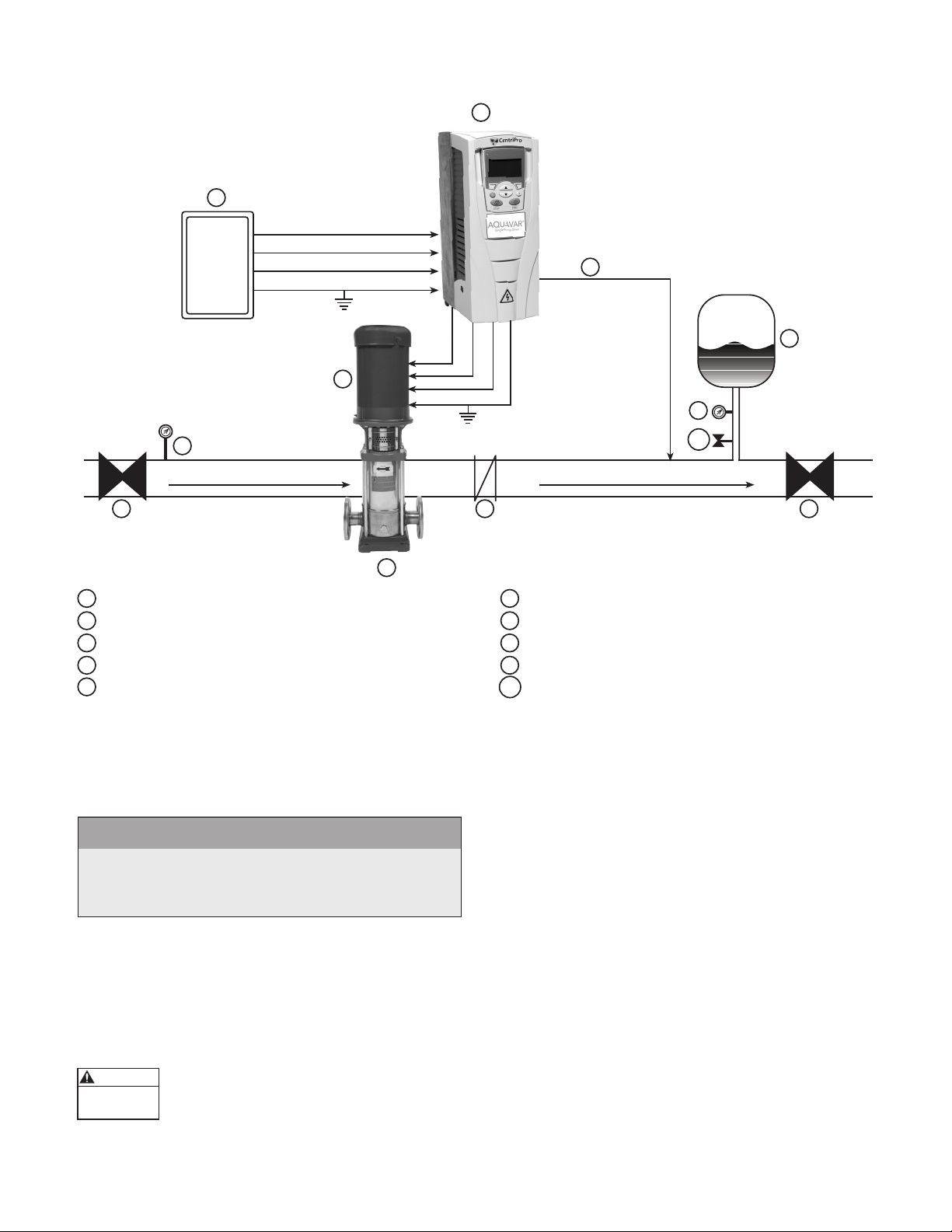

The following diagrams show some typical system

designs using the SPD Plus.

NOTE

Systems MUST be designed by qualied technicians

only and meet all applicable state and local code

requirements.

DIAGRAM #1 shows a typical set up for a submersible pump and control system.

1

2

SUPPLY POWER

U1

V1

W1

GND

6

U2

V2

W2

GND

8

1 DRIVE CONTROLLER

2 FUSIBLE DISCONNECT

3 PRESSURE GAUGE

4 AIR DIAPHRAGM TANK

5 PRESSURE TRANSDUCER

6 3 PHASE OUTPUT (ALWAYS)

7 DISCHARGE CHECK VALVE

8 GATE VALVE (HIGHLY RECOMMENDED

9 SUBMERSIBLE PUMP END

10 SUBMERSIBLE MOTOR (3 PHASE)

11 PRESSURE RELIEF VALVE

3

4

5

7

FLOW

11

9

10

8

Page 9

SECTION 3: SYSTEM DESIGN

1

Hazardous

Pressure

CAUTION

DIAGRAM #2 shows a set-up for an Above Ground booster pump and control system.

2

9

SUCTION

8

SUPPLY POWER

U1

V1

W1

GND

7

U2

V2

W2

3 PHASE OUTPUT

GND

TO MOTOR

4

5

9

10

FLOW

3

1 SPD CONTROLLER 6 AIR DIAPHRAGM TANK

2 FUSIBLE DISCONNECT 7 3 PHASE MOTOR

3 CENTRIFUGAL PUMP 8 GATE VALVE (BALL VALVE)

4 CHECK VALVE 9 PRESSURE GAUGE

5 PRESSURE TRANSDUCER (CABLE ASSEMBLY) 10 PRESSURE RELIEF VALVE

AIR

6

8

SECTION 4: PIPING

GENERAL

NOTE

All plumbing work must be performed by a qualied

technician. Always follow all local, state and provincial

codes.

A proper installation requires a pressure relief valve,

a ¼" female N.P.T. threaded tting for the pressure

sensor, and properly sized pipe. Piping should be

no smaller than the pump discharge and/or suction

connections. Piping should be kept as short as

possible. Avoid the use of unnecessary ttings to

minimize friction losses.

Some pump and motor combinations

controlled by the SPD Plus can create

dangerous pressure. Select pipe

and ttings according to your pipe suppliers’

recommendation. Consult local codes for piping

requirements in your area.

All joints must be airtight. Use PTFE thread seal tape

or another type of pipe sealant to seal threaded

connections. Please be careful when using thread

sealant as any excess that gets inside the pipe may

plug the pressure sensor.

Galvanized ttings or pipe should never be connected

directly to the stainless steel pump discharge or

casing as galvanic corrosion may occur. Barb type

connectors should always be double clamped.

PRESSURE TANK, PRESSURE RELIEF VALVE AND

DISCHARGE PIPING

Use only “pre-charged” tanks on this system. Do not

use galvanized tanks. Select an area that is always

above 34º F (1.1º C) in which to install the tank,

pressure sensor and pressure relief valve. If this is

an area where a water leak or pressure relief valve

blow-off may damage property, connect a drain line

to the pressure relief valve. Run the drain line from the

pressure relief valve to a suitable drain or to an area

where water will not damage property.

9

Page 10

SECTION 4: PIPING (CONTINUED)

Hazardous

Pressure

CAUTION

WARNING

Hazardous

voltage

PRESSURE TANK, SYSTEM PRESSURE

Sizing – A bladder tank (not included) is used to

cushion the pressure system during start-up and shut-

down. It should be sized to at least 20% of the total

capacity of your pump. Example: If your pump is sized

for 100 GPM then size your tank for at least 20 gal.

total volume, not draw down. Pre-charge your bladder

tank to 15-20 PSI below your system pressure. Use the

higher tank pre-charge setting if the system drifts over

5 PSI at a constant ow rate. NOTE: Pre-charge your

tank before lling with water!

CAUTION

Maximum working pressure of HydroPro

bladder tank is 125 psi.

INSTALLING THE PRESSURE SENSOR

The pressure sensor requires a ¼" NPT tting for

installation. Install the pressure sensor with the

electrical connector pointing up to avoid clogging the

pressure port with debris. Install the pressure sensor in

a straight run of pipe away from elbows or turbulence.

For optimum pressure control install the pressure

sensor in the same straight run of pipe as the pressure

tank. Ensure the pressure sensor is within 10 feet of

the pressure tank. Installing the pressure sensor far

away from the pressure tank may result in pressure

oscillations. Do not install the pressure sensor in a

location where freezing can occur. A frozen pipe

can cause damage to the pressure sensor.

The pressure sensor cable must be wired to the

controller control terminals. The pressure sensor

cable wiring diagram is shown in Section 6. The cable

can be shortened for a cleaner installation. Longer

cable lengths are available, consult factory. Maximum

recommended pressure sensor cable length is 300

feet. Avoid leaving a coil of pressure sensor cable as

this can induce unwanted transient voltages and noise

into the system. Do not run the pressure sensor cable

alongside the input or output wiring for more than 1

foot. Maintain a distance of at least 8” between the

pressure sensor cable and input or output wiring.

Ensure the pressure sensor cable is connected as

follows: Brown to terminal 10 (24VDC SUPPLY), White

to terminal 5 (AI2, TRANSDUCER FEEDBACK), Drain to

SCR Terminal 1. Connecting the Drain wire to the SCR

Terminal electrically connects the sensor case to the

chassis of the controller. In some cases this drain wire

must be disconnected from the controller chassis. In

cases where there is grounded metal piping which is

continuous between the transducer and the motor or

the transducer is installed in grounded metal piping,

a ground loop can result so the drain wire must be

disconnected from the chassis. In cases where there

are sections of nonmetallic piping between the

transducer and motor or the transducer is installed

in ungrounded piping this drain wire should be

connected to the controller chassis.

SECTION 5: MOUNTING THE

CONTROLLER

GENERAL

Mount the controller in a ventilated, shaded area.

The controller must be mounted vertically. Be sure

to leave 8 inches of free air space on every side of

the unit. The controller must be in an area with an

ambient between 5 ºF (-15 ºC) and 122 ºF (50 ºC).

If installation is above 3300 feet above sea level,

ambient temperatures are derated 1% per 330 feet

above 3300 feet. The altitude limit for this controller is

6600 ft. Do not install above 6600 ft.

NOTE

Do not block the heat sink (ns) and fans and do not

set anything on the units.

WARNING

The controller access cover should

always be securely fastened to the control box due to the dangerous voltage/

shock hazard inside the unit.

NOTE

Controllers with an N1 sufx have a NEMA 1 enclosure and are rated for indoor use only.

10

Page 11

SECTION 6: POWER SUPPLY AND WIRING

WARNING

Hazardous

voltage

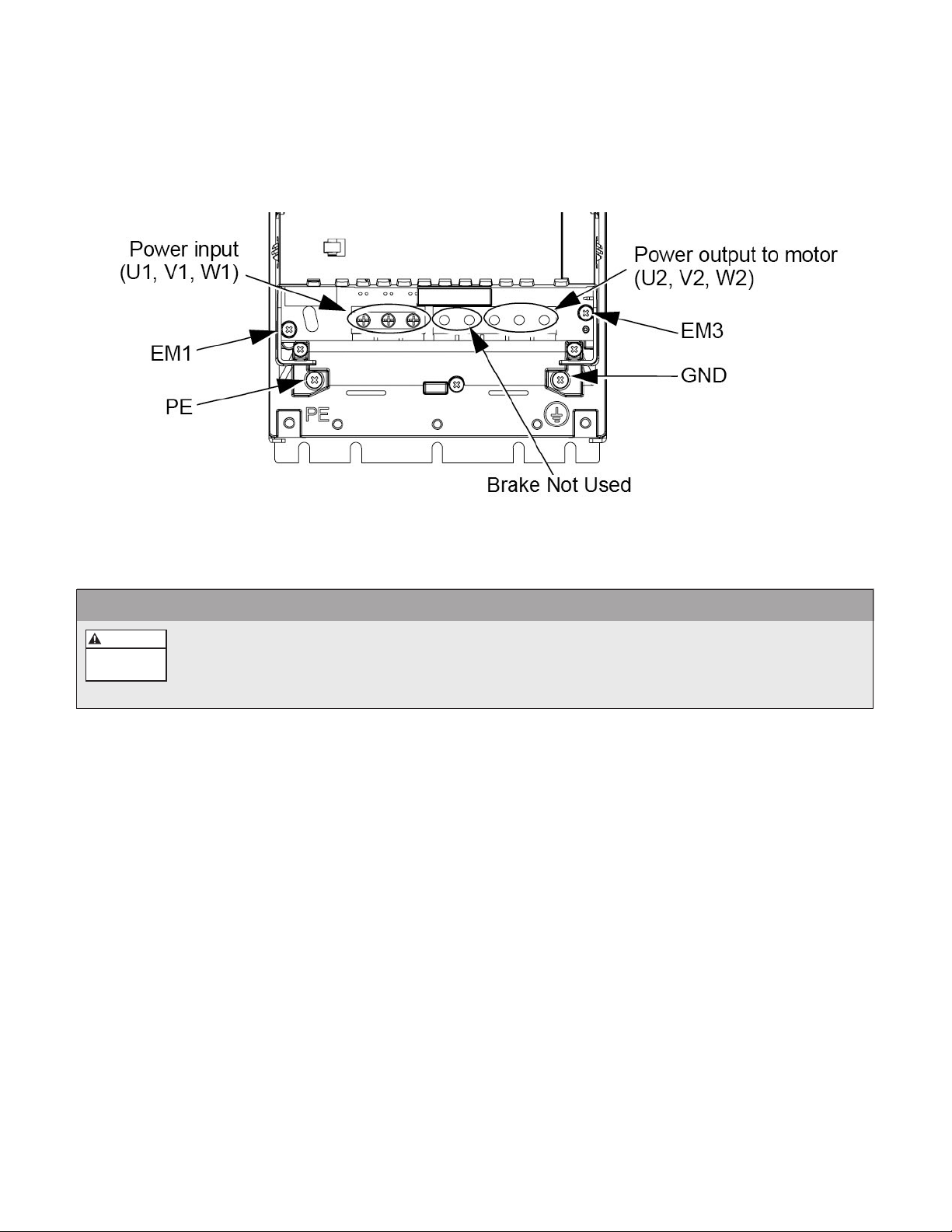

POWER CONNECTION DIAGRAMS

The following diagrams show the power connection layout for each frame size.

• For sizes R4 and N4

WARNING

If the secondary of the transformer is a delta with a grounded leg (corner grounded delta) or

oating network, the line to ground EMC lter components and line to ground MOV protection

must be disconnected or damage to the controller can result. Remove screws EM1 and EM3 for

frame sizes R4/N4 to disable line to ground EMC lter and MOV protection.

FIGURE 1

11

Page 12

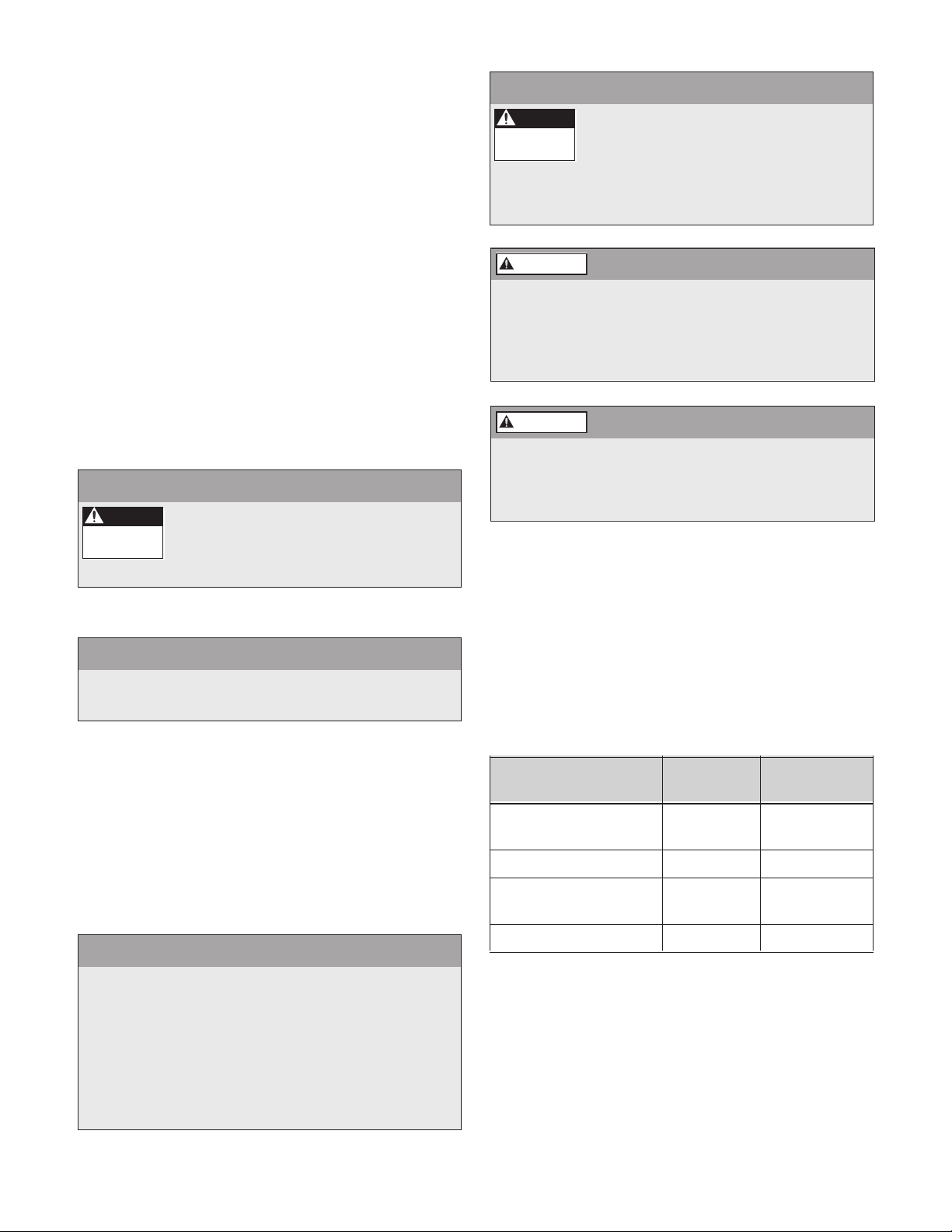

SECTION 6: POWER SUPPLY AND WIRING (CONTINUED)

WARNING

Hazardous

voltage

POWER CONNECTION DIAGRAMS

The following diagrams show the power connection layout for each frame size.

• For sizes R5 and N5 • For sizes R6 and N6

FIGURE 2

FIGURE 3

WARNING

If the secondary of the transformer is a delta with a grounded leg (corner grounded delta) or

oating network, the line to ground EMC lter components and line to ground MOV protection

must be disconnected or damage to the controller can result. Remove screws F1 and F2 for

frame sizes R5/N5 and R6/N6 to disable line to ground EMC lter and MOV protection.

NOTE

For single phase input power, use input power terminals U1, W1 and PE (ground).

12

Page 13

SECTION 6: POWER SUPPLY AND WIRING (CONTINUED)

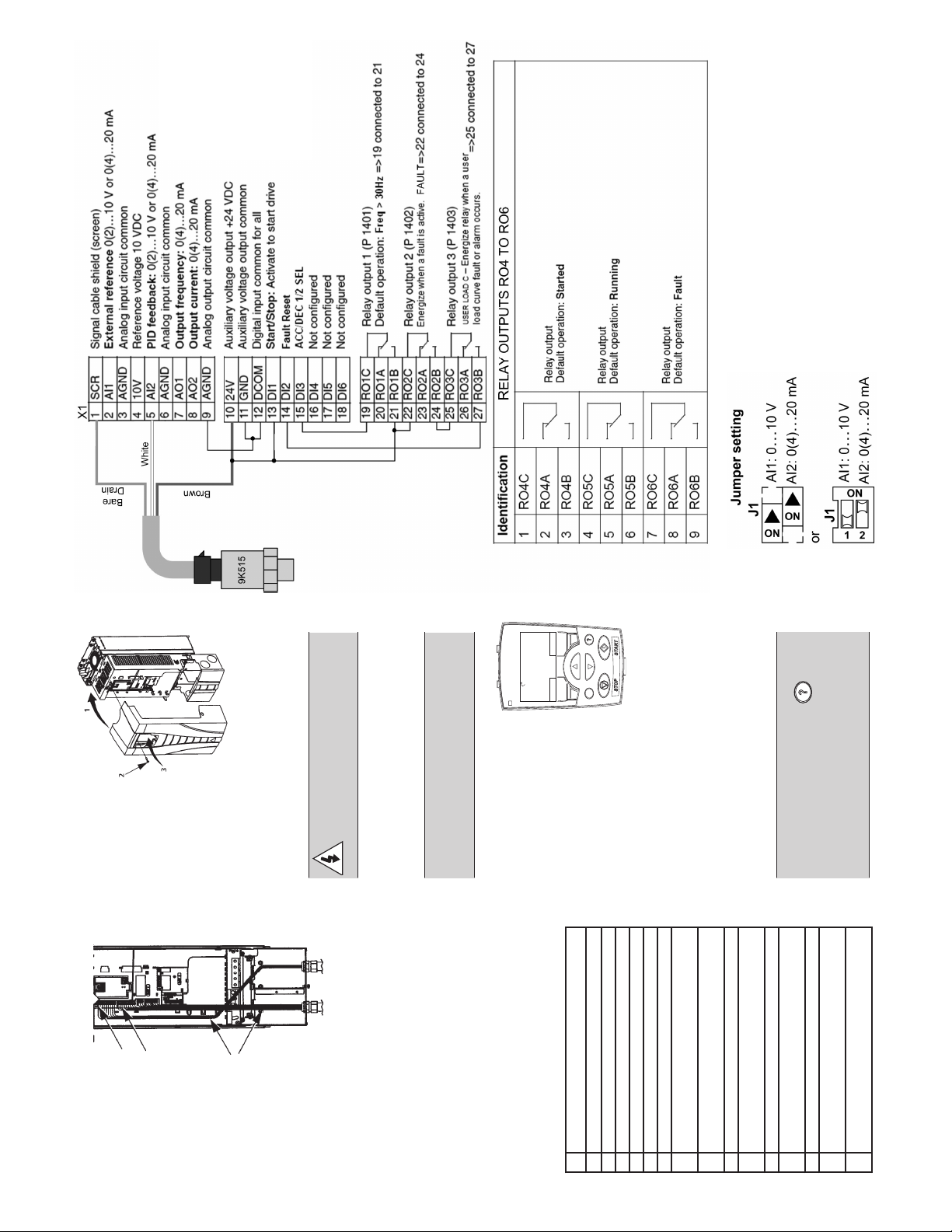

CONTROL TERMINAL CONNECTION DIAGRAM

The diagram below describes the control terminal connections.

NOTE

Pressure sensor cable must be wired during installation. All other connections are wired at the factory.

Identication RELAY OUTPUTS R04 TO R06

1 RO4C

2 RO4A

3 RO4B

4 RO5C

5 RO5A

6 RO5B

7 RO6C

8 RO6A

9 RO6B

NOTE

A jumper wire is installed between DI1 and +24V at the factory. To remotely start and stop the drive while in

REM mode, replace the jumper wire with a non-powered switch.

Relay output

Default operation: Started

Relay output

Default operation: Running

Relay output

Default operation: Fault

FIGURE 4

13

Page 14

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

SECTION 6: POWER SUPPLY AND WIRING

(CONTINUED)

INPUT POWER AND LINE TRANSFORMER

REQUIREMENTS

NOTE

Installation and maintenance MUST be performed

by properly trained and qualied personnel.

Always follow the National Electrical Code (NEC) or

Canadian Electric Code (CEC), as well as all state,

local and provincial codes when wiring the system.

The type of transformer and the connection

conguration feeding a drive plays an important

role in its performance and safety. The following is

a brief description of some of the more common

congurations and a discussion of their virtues and

shortcomings. Always ask what type of power system

the site has before sizing the drive.

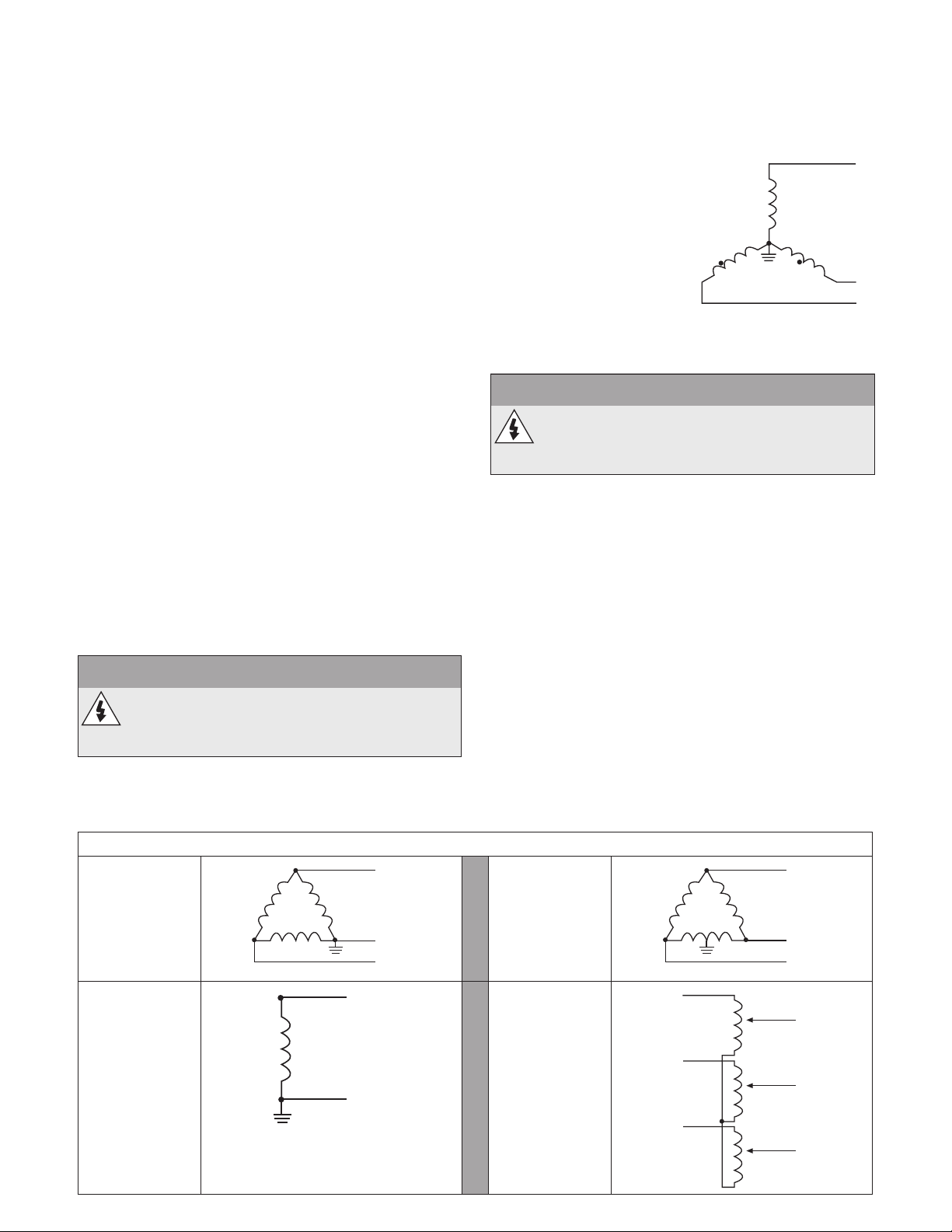

DELTA/WYE WITH GROUNDED WYE NEUTRAL:

This conguration is one of if not the most common.

It provides rebalancing of unbalanced voltage with

a 30 degree phase shift. Depending on the output

connections from the drive to motor, the grounded

neutral may be a path for common mode current

caused by the drive output.

DELTA/DELTA WITH GROUNDED LEG

UNGROUNDED SECONDARY

Grounding of the transformer secondary is essential

to the safety of personnel as well as the safe operation

of the drive. Leaving the secondary oating can

permit dangerously high voltages between the

chassis of the drive and the internal power structure

components. In many cases this voltage could exceed

the rating of the input MOV protection devices of

the drive causing a catastrophic failure. In all cases,

the input power to the drive should be referenced to

ground. If the transformer can not be grounded, then

an isolation transformer must be installed with the

secondary of the transformer grounded.

WARNING

If the secondary of the transformer is

a delta with a grounded leg (corner

grounded delta) or oating network,

the line to ground EMC lter components and line

to ground MOV protection must be disconnected or

damage to the controller can result. Remove screws

EM1 and EM3 for frame sizes R4/N4 or F1 and F2

for frame sizes R5/N5 and R6/N6 to disable line to

ground EMC lter and MOV protection. Refer to

Figures 1, 2 and 3 for screw locations.

RESISTANCE GROUNDING AND GROUND FAULT

PROTECTION

Another common conguration providing voltage

rebalancing with no phase shift between input and

output. Again, depending on the output connections

from the drive to motor, the grounded neutral may be

a path for common mode current caused by the drive

output.

WARNING

If the secondary of the transformer is

a delta with a grounded leg (corner

grounded delta) or oating network,

the line to ground EMC lter components and line

to ground MOV protection must be disconnected or

damage to the controller can result. Remove screws

EM1 and EM3 for frame sizes R4/N4 or F1 and F2

for frame sizes R5/N5 and R6/N6 to disable line to

ground EMC lter and MOV protection. Refer to

Figures 1, 2 and 3 for screw locations.

14

Connecting the Wye secondary neutral to ground

through a resistor is an acceptable method of

grounding. Under a short circuit secondary condition,

any of the output phases to ground will not exceed

the normal line to line voltage. This is within the rating

of the MOV input protection devices on the drive.

The resistor is often used to detect ground current

by monitoring the associated voltage drop. Since

high frequency ground current can ow through this

resistor, care should be taken to properly connect the

drive motor leads using the recommended cables

and methods. In some cases, multiple drives on one

transformer can produce a cumulative ground current

that can trigger the ground fault interrupt circuit.

Page 15

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

OPEN DELTA (CONSULT FACTORY)

This type of conguration is common on 230 volt

systems. From time to time it may be encountered

where only single phase power is available and

three-phase power is required. The technique uses

two single phase transformers to derive a third phase.

When used to power a drive this conguration must

be derated to about 70% of the single phase rating of

one transformer. This system provides poor regulation

and it is possible that only the two line connected

phases will provide power. In this case the drive must

be derated to 50 % of its rating. (Ex. A 20 HP 230 volt

drive now becomes a 10 HP 230 volt drive.)

WARNING

“Open Delta” power systems should

be sized using the 50% derate factor.

Consult factory.

SINGLE PHASE CONNECTION

For drives with a diode rectier front end it is possible

to run a three phase output with a single phase input.

Only part of the three phase input bridge is used.

Ripple current becomes 120 Hz rather than 360. This

places a greater demand on the DC lter components

(capacitor bank and DC choke). The result is that the

drive must be derated to 50% current. Single phase

will not work with an SCR front end drive.

LINE TRANSFORMER

The line input voltage and transformer power must

meet certain phase and balance requirements. If

you or your installing electrical contractor is in

doubt of the requirements, the following provide

guidelines for the SPD Plus installation. When in

doubt contact the local power utility or the factory.

If an isolation transformer is used, the best choice is

ONE three phase, six winding transformer. A delta

primary is best for third harmonic cancellation. A wye

secondary avoids circulating current problems and

provides the very desirable option of grounding the

secondary neutral for minimum voltage stress and

ripple to ground. The transformer should have a KVA

rating at least 1.1 times the maximum connected HP.

A K factor of 6 is sufcient if transformer impedance

is greater than 2%. A K Factor of 5 is sufcient if

transformer impedance is greater than 3%. The

transformer manufacturer may provide derating for

non K Factor rated transformers to operate at the

drive produced K Factor levels.

Other transformer congurations are acceptable.

Three single phase transformers can be used if

they are identical for phase to phase symmetry and

balance. A wye connected primary neutral should

never be grounded. Great care should be taken with

delta primary delta secondary congurations. Any lack

of phase to phase symmetry could result in circulating

currents and unacceptable transformer heating.

WARNING

Never use phase converters with drives

as nuisance tripping and possible

damage may occur. Instead, use single

phase input power and 50% derate factor.

INPUT POWER SPECIFICATIONS

InputPower(mains)ConnectionSpecications

208/220/230/240 VAC 3-phase or 1-phase – 15% …+10% for SPD2XXXX

Voltage (U1) 380/400/415/440/460/480 VAC 3-phase -15%...+10% for SPD4XXXX

500/525/575/600 VAC 3-phase -15%....+10% for SPD5XXXX

Prospective Short- Maximum allowed prospective short-circuit current in the supply is 100 kA

Circuit Current providing that the input power cable of the drive is protected with

(IEC 629) appropriate fuses. US: 100 000 AIC.

Frequency 48…63 Hz

Imbalance Maximum ±3% of nominal phase to phase input voltage

Fundamental Power

0.98 (at nominal load)

Factor (cos phi1)

15

Page 16

SECTION 6: POWER SUPPLY AND WIRING

Hazardous

voltage

DANGER

(CONTINUED)

CONDUIT, WIRE AND FUSE SIZING

When selecting the input power cable follow the rules

below:

• Do not use aluminum wires

• The cable must be able to carry the drive load

current

• The cable must be rated for at least 75ºC

• A four conductor cable (three phases and ground)

or four insulated conductors routed through

conduit may be used. Shielding is not required.

The use of metal conduit with metal conduit

connectors is recommended for all electrical

connections. Use the NEC or CEC to determine

the required conduit size for the application.

Refer to the wire sizing tables in Appendix B to

determine the maximum length for the input and

output cables. The maximum recommended total

voltage drop on both input and output cable

combined is 5%. Standard wire sizing table provides

maximum cable lengths for input or output cables.

Because of this the lengths given in the table must be

adjusted so the total voltage drop does not exceed

5%. For example, if the input wire sizing chart in the

appendix gives the maximum length of 400' and

only 100' is used then only 25% of the total voltage

drop (1.25% drop) is used. The maximum output

cable length must then be adjusted to 75% of its

value so that the maximum voltage drop of 5% is not

exceeded.

Provide a dedicated fused disconnect rated for drives

input current rating. (Fused disconnect included for

NEMA3R enclosures.) No other equipment should be

used for this disconnect. Use fast acting class T fuses.

The recommended fuse sizes for each model are

listed below.

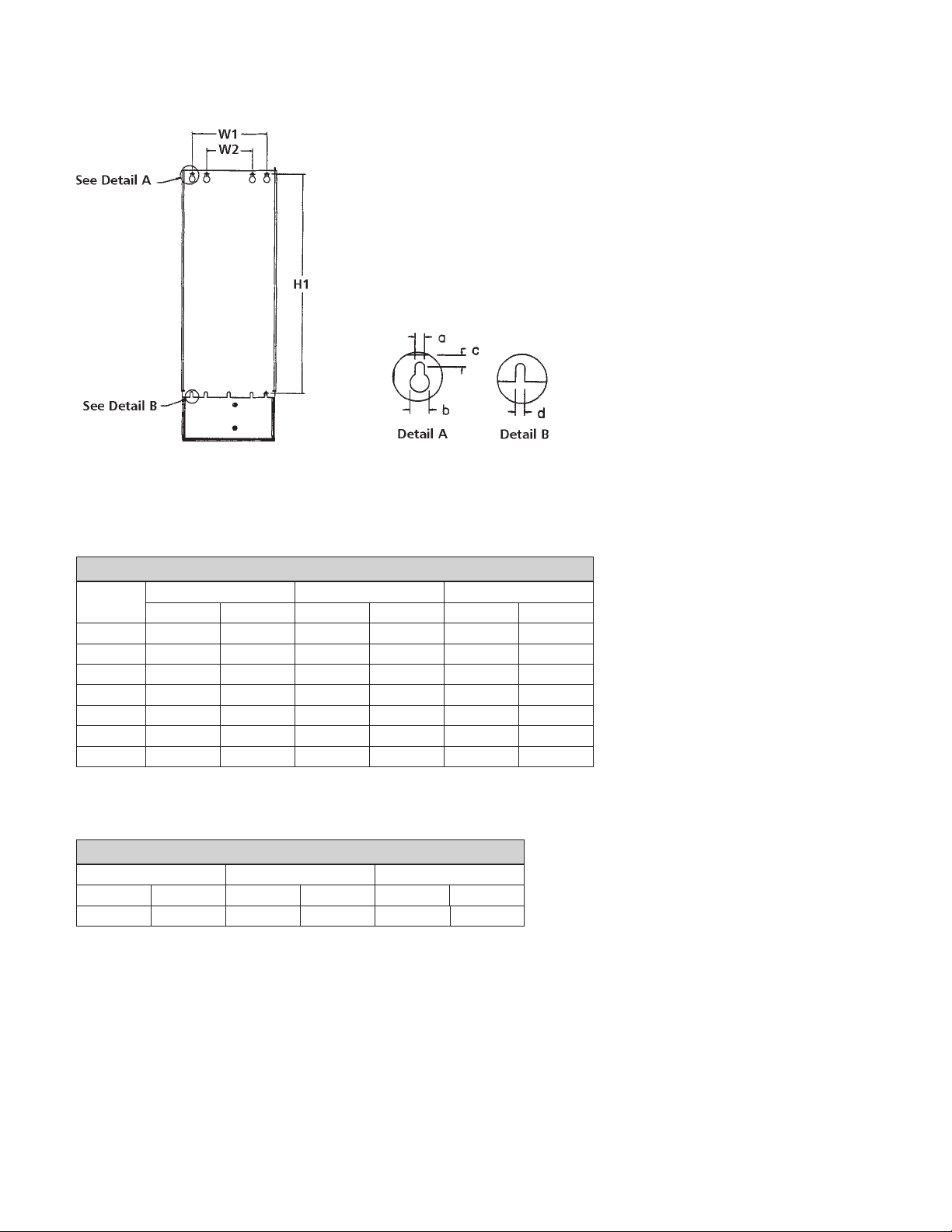

INPUT POWER CONNECTIONS

Before making this connection, measure and verify

the site voltage phase to phase and phase to ground.

In the case of high line to ground voltage it may be

necessary to disconnect the line to ground EMC and

MOV protection. See Figures 1, 2 and 3 for details.

Ensure the ground wire is connected back to the

service entrance ground and that the service entrance

ground is bonded to a proper ground rod.

Input

Voltage

230V

460V

575V

16

Model Number

SPD20400 114 150

SPD20400F 143 200

SPD20400N1 114 150

SPD20500 143 200

SPD20500F 178 250

SPD20500N1 143 200

SPD20600 178 250

SPD20600F 221 300

SPD20600N1 178 250

SPD40400 59 80

SPD40400F 72 90

SPD40400N1 59 80

SPD40500 72 90

SPD40500F 96 125

SPD40500N1 72 90

SPD40600 96 125

SPD40600F 96 125

SPD40600N1 96 125

SPD40750 124 175

SPD40750F 124 175

SPD40750N1 124 175

SPD41000 157 200

SPD41000F 157 200

SPD41000N1 157 200

SPD50400N1 52 60

SPD50500N1 77 100

SPD50600N1 77 100

SPD50750N1 99 150

SPD51000N1 144 200

Input Current

(Arms)

Mains Fuse Size

(UL Class T)

Ensure disconnect switches

are locked in the OFF

position before making this

connection. For models with an N1 (NEMA

1) sufx, connect conduit to the conduit

box supplied with the controller. For all

other models (NEMA 3R), drill a hole that

is properly sized for the conduit used in

the bottom of the enclosure.

NOTE: Drilling in to the side or top of the

enclosure will violate the NEMA 3R rating.

Use metal conduit and metal conduit

connectors. Size the conduits according to

the NEC, CEC or local codes. Use the wire

sizing chart in Appendix B to determine

the size of the input power wires.

Connect the conduit and insert the wires

into the controller or enclosure. Connect

wires to the “INPUT” terminal block. For

N1 models, this terminal block is on the

controller and the terminal locations are

as shown in Figures 1, 2 and 3. For all

other models, this connection is made

to the input side of the fused disconnect

that is included in the enclosure. The

connections from the output side of the

disconnect to the controller are made at

the factory. Connect the ground wire to

the terminal labeled GND. For three phase

input, connect the input phase wires to

U1, V1 and W1. For single phase input,

connect the input wires to U1 and W1.

Page 17

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

WARNING

Hazardous

voltage

DANGER

Measure and verify site voltage phase to phase and

phase to ground prior to connected power to the

controller.

Consult motor manual to determine the wire size for

the application. Ensure the ground connection to

the motor is continuous. Connect wires to the output

terminal block on the controller labeled U2, V2, W2,

and GND. Connect the ground wire to the terminal

labeled GND.

NOTE

Verify that there is at least 8” between input and

output connections or input connections and control

wiring.

DANGER

The controller has a high leakage

current to ground. The input terminals

marked “GND” must be directly

connected to the service entrance ground. Failure to

properly ground the controller or motor will create

an electrical shock hazard.

NOTE

Do not use GFCI protection with this controller.

Nuisance tripping will result.

NOTE

A single phase power input is designated only on

230 V specically, and the corresponding SPD Plus

pump controllers are derated to 50%.

DANGER

Status Code Indicator Light and Control

Panel Display are not voltage indicators!

Always turn off disconnect switch and

wait 5 minutes before servicing.

If a reactor is used for a submersible motor, connect

drive output terminal block U2, V2, W2 and GND to

the corresponding input terminals of the load reactor.

Connect the output terminals of the reactor to the

motor leads and GND. When wiring the load reactor

ensure all input connections from the controller are on

the same side of the reactor terminal block.

NOTE

A load reactor or load lter is required in installations

where the output motor leads exceed 50 ft.

NOTE

It is recommended to use a load reactor with all 575V

installations.

NOTE

Models with ‘F’ sufx include a load reactor prewired

to the controller.

NOTE

Ensure you have a three phase motor and verify

the motor voltage matches input power supply

voltage. Verify that the motor service factor amps

do not exceed the drive output at rated ambient

temperature. Ensure the ground is continuous

between the controller and the motor. Ensure there

is at least 8" between the output wires and any other

wires.

DANGER

The controller will remain electrically

charged for 5 minutes after power

is turned off. Wait 5 minutes after

disconnecting power before opening controller

access cover as there is a severe shock hazard.

OUTPUT POWER CONNECTIONS

Ensure input power disconnect is locked

in the off position before making the

output power connections. Run the motor

lead wire from the motor or conduit box through

metal conduit to the bottom of the controller. Use

metal conduit and metal conduit connectors. Size

the conduits according to the NEC, CEC or local

codes. Connect conduit and insert the wires through

the bottom of the enclosure or controller conduit

box extension. For frames N4, N5 and N6, it may be

necessary to drill a hole in the bottom of the enclosure

for conduit and wire entry.

For CentriPro motors, connecting U2 to Red, V2 to

Black and W2 to Yellow will give the correct rotation.

To change rotation, swap any two motor leads U2, V2

or W2.

Motor power and type are to be specied in Start-Up

Menu on drive keypad before running pump system.

DANGER

The controller has high leakage current

to ground. The output terminals

marked “GND” or “ ” must be directly

connected to the motor ground. Failure to properly

ground the controller or motor will create

an electrical shock hazard.

17

Page 18

SECTION 7: CONTROL INPUT AND

WARNING

WARNING

OUTPUT FUNCTIONS

The control terminals allow for a variety of control

functions. Some of the terminals are prewired by the

factory. Removing prewired connections can disable

some controller functions. Refer to the information

below before removing prewired connections.

Turn off all power to the controller

before wiring devices to the control

terminals.

All the DI inputs are switch inputs. Do

not connect external power to these

inputs or damage to the controller will result. Only

connect non-powered switch contacts to these inputs.

START/STOP (DI1,13): The DI1 input allows the pump/

motor to be turned on and off by an external switch

while in REM mode. The input is pre-wired to +24V

terminal 10.

For external control of this input, use only a nonpowered external switch. Connect the contacts of the

switch to terminals 10 (+24VDC Supply) and 13 (DI1-

START/STOP). When the switch is closed the controller

is in START mode (output to motor is enabled). When

the switch is open the controller is in STOP mode

(output to motor is disabled).

TRANSDUCER INPUT (AI2, 5) and +24VDC (10):

These terminals are the transducer feedback and

transducer power supply. The controller is congured

with a 300 PSI 4-20mA output pressure transducer.

Connect the 3-wire pressure transducer cable with

white wire of signal to terminal AI2/5, brown wire

of +24 VDC transducer power supply to the drive

terminal 10, and shield/drain wire to terminal 1/SCR.

Refer to Section 4 for pressure transducer installation

details.

RELAY OUTPUTS (RO1-R03, 19-27): Relay outputs

RO1 through RO3 (terminals 19 to 27) are used to

perform motor control and fault functions inside the

controller. These functions are described below.

Start Ramp: Submersible motors require a start

ramp function that ramps from 0Hz (stopped)

to 30Hz in 1 second. DI3/15 ACC/DEC SEL and

RO1/19-21 Ramp Select are used to implement this

function.

No Water Restart Time: The No Water Restart Time

is used to automatically restart the controller after a

No Water/Loss of Prime (dry well) Fault is detected.

This function is implemented using DI2/14 Fault

Reset, RO2/22-24 Fault Output and RO3/25-27

Under Load Output.

WARNING

Disabling the No Water Restart Time function by

removing the prewired connections will prevent

the controller from automatically restarting after a

No Water/Loss of Prime Fault is detected.

ANALOG OUTPUTS (AO1, 7 and AO2, 8): These

terminals provide 0-20mA output signals that can be

used to control auxiliary equipment. These outputs

are congured in the application software. Analog

Output 1 (AO1/7) is precongured to output a

0-20mA signal based on the output frequency of the

controller. Where 0Hz corresponds to 0mA and 60Hz

corresponds to 20mA. Analog Output 2 (AO2/8)

is precongured to output a 0-20mA signal based

on the output current of the controller. Where 0A

corresponds to 0mA and 100% of controller rated

output current corresponds to 20mA. The external

device used with the Analog Outputs must have an

impedance less than 500Ω.

RELAY OUTPUTS (RO4-RO6, 1-9): The relay outputs

RO4-RO6 have been congured for Ready, Running

and Fault functions respectively. The operation of

relay outputs RO4-RO6 is described below.

Controller Ready Relay (RO4, 1-3): This relay output

is congured to energize when the controller is

ready to function. The controller is ready when no

faults exist and the input supply voltage is within

range.

Run Relay (RO5, 4-6): This relay output is

congured to energize when the controller is

running the motor. The relay is de-energized when

the controller stops the motor.

Fault Relay (RO6, 7-9): This relay output is

congured to energize when the controller is

faulted. The relay is de-energized when there is no

system fault or after a fault clears.

WARNING

Disabling the Start Ramp function by removing the

prewired connections can result in damage to the

submersible motor and will void the motor and

controller warranty.

18

Page 19

SECTION 8: STARTING THE SYSTEM

APPLY POWER

When power is applied to the SPD Plus Controller, the status LED turns green.

SPD Plus Drive keypad functionality and Main Screen display is described below:

Status LED Motor State Reference Value

Control Mode

Motor Speed

Soft Key 1

LOC/REM

Stop

REM

40.2 PSI sp

0.0 PSI ac

0.0 HZ

DIRMENU

LOC

REM

11.1%

Pressure Setpoint

Actual System Pressure

Soft Key 2

Up/Down Buttons

Help Function

Start

Name Function

Displays Drive Status:

Green Constant = Not Faulted/No Alarm

Status LED

Motor State

Control Mode

Reference Value

Pressure Setpoint Displays the system pressure setpoint in PSI.

Actual System

Pressure

Motor Speed Actual motor speed in Hz.

Soft Key 1 Function of this button changes according to the state of the display panel.

Soft Key 2 Function of this button changes according to the state of the display panel.

LOC/REM Toggles the drive control mode between local (LOC) and remote (REM). See Control Mode above.

Up/Down Buttons

Help Button Displays information about the parameter or screen shown on the display.

Start

Stop

Green Flashing = Alarm

Red Constant = Faulted (Auto-restart fault)

Red Flashing = Faulted (Locked Out)

Rotating = Drive is Running the Motor

Stationary = Drive has Stopped the Motor

Displays the current control mode of the drive. In local mode (LOC) the drive ignores the pressure

sensor feedback and speed is set with the up and down buttons. In remote mode (REM) the drive

uses the pressure sensor feedback signal to control the system pressure.

In REM: Displays the pressure setting in %.

In LOC: Displays the speed reference in Hz.

Displays the actual system pressure in PSI as indicated by the pressure transducer.

In REM: Changes the pressure setting.

In LOC: Changes the speed reference.

In sub menus: changes parameters

In REM: Button is disabled

In LOC: Initiates operation of the drive.

In REM: Button is disabled

In LOC: Stops operation of the drive.

19

Page 20

SECTION 8: STARTING THE SYSTEM

(CONTINUED)

START-UP ASSISTANT

Do you want to

use the start-up

assistant?

YES

NO

EXIT

NOTE

If this is the rst time

that the drive has been

powered or the StartUp Assistant has not

been run, the display

will prompt the user if

they would like to run

the Start-Up Assistant.

Select Yes using the up

and down arrows then

press OK to run the

Start-Up Assistant.

The Start-Up Assistant will prompt the user for

information about the application, motor information

and fault response. The prompt screens are shown

below:

MOTOR TYPE

SETTING: Select the

motor type used in the

application using the

up and down arrows

and press OK.

The minimum

frequency is set

to 30Hz for the

Submersible setting

and 15Hz for the

Above Ground setting.

The next prompt will

be for either to enter

the motor horsepower

rating or the motor nominal current rating. The

prompt displayed will depend on the controller size.

The Start-Up Assistant can be entered at any time by

following the procedure below:

QUICKSTART: From

the Main Screen press

MENU key to enter

MENU as shown

below and choose

QUICKSTART.

MOTOR

HORSEPOWER

SETTING: Select the

motor HP used in

the application. The

controller lists only

the valid HP selections

based on the

controller size. If there

is only 1 valid selection

based on the drive

size and motor type,

this screen is skipped.

Note that the prompt

will also change based

on the controller

voltage rating.

20

START-UP: Select StartUp with the up and

down arrows and press

SEL.

MOTOR NOMINAL

CURRENT SETTING:

The display will initially

show a default current

based on the previous

selections. Enter the

nominal motor current

rating using the up

and down arrows on

the keypad. This is the

full load current rating

for the motor.

Page 21

RAMP SPEED

WARNING

SETTING: Select

the ramp speed

based on the system

requirements. The

ramp speed sets the

acceleration and

deceleration time

for the motor. The

acceleration time

is the time for the

motor to transition

from 0Hz (stopped)

to 60Hz (full speed).

The deceleration time

is the time for the

motor to transition

from 60Hz (full speed) to 0Hz (full stopped). The

FAST ramp selection sets the acceleration ramp to 5

seconds and the deceleration ramp to 8 seconds. The

MEDIUM ramp selection sets both the acceleration

and the deceleration ramp to 25 seconds. The SLOW

ramp selection sets both the acceleration and the

deceleration ramp to 60 seconds.

RESTART PRESSURE

DROP SETTING: The

Restart Pressure Drop

Setting allows the user

to select the amount of

pressure drop allowed

in the system before

the pump restarts after

a No Water Demand

condition is detected.

A No Water Demand

condition exists

when the pump has

satised the desired

system pressure and

reached the minimum

frequency. If the

Restart Pressure Drop is set to 5 PSI and the pump has

satised the desired system pressure and turned off

on no demand, the controller will turn the pump back

on after the system pressure has dropped 5 PSI below

the system pressure setting.

Setting the Ramp Speed too fast can result in

unstable operation and can damage pump, motor

and piping.

NO WATER RESTART

TIME SETTING: The

No Water Restart

Setting sets the time

between detection

of a No Water/Loss

of Prime fault and the

restart of the system.

For example, if the No

Water Restart Time

is set to 10 MIN, the

system will restart 10

minutes after a Water/

Loss of Prime fault has

been detected. This

parameter is typically

set according to the

recovery rate of the water source. The restart time can

be set to 10 minutes, 30 minutes or 1 hour using the

Start-Up Assistant.

START REMINDER

SCREEN: This is a

reminder screen.

This screen is shown

only if the controller

is set to local mode

(LOC). To change to

remote mode (REM)

and enable pressure

control, press the LOC/

REM button.

CAUTION

The controller ignores the pressure sensor feedback

signal and Start Signal on DI1 when operated in local

(LOC) mode. Hazardous pressure can result.

The controller is now set up and is ready to be started.

SETTING THE CONTROL MODE

The Control Mode can be set to either local (LOC)

or remote (REM). The Control Mode is indicated in

the upper left hand corner of the display screen. Use

REM for pressure control mode. This mode uses the

pressure transducer feedback on AI2 to control the

system pressure. Note that the start and stop buttons

on the display are disabled in REM mode. The start

enable on DI1 can be used to remotely start and stop

the motor. Use LOC for xed speed mode. The speed

can be set with the up and down buttons on the

keypad. The motor can be started and stopped using

the start and stop buttons on the keypad. The in LOC

mode the start enable on DI1 is disabled.

21

Page 22

WARNING

WARNING

SETTING PRESSURE SETPOINT

Hazardous

voltage

DANGER

Hazardous

voltage

DANGER

When in REM mode, set the desired pressure setpoint

by pressing the Up or Down arrow keys on keypad.

Push and hold the Up or Down arrow keys until the

desired pressure setting is obtained. The pressure

setpoint is displayed on the rst row of the Main

Screen display with units of ‘PSI SP’. The actual

system pressure reported by the pressure transducer

is displayed on the second row of the Main Screen

display with units of ‘PSI AC’.

DRIVE STATUS LED

The status code indicator light or LED displays the

status of the controller. The status indicator is located

in the upper left hand corner of the display keypad.

A constant green status indicates that the pump is

in normal operation. A blinking green status code

indicates the unit has an alarm. A constant red status

code indicates the unit is faulted and will attempt

to automatically restart. A blinking red status code

indicates the unit is faulted and will not attempt to

restart. See Section 9 for Troubleshooting.

DANGER

The status code indicator light is not

a voltage indicator! Always turn off

disconnect switch and wait 5 minutes

before servicing.

MOTOR ROTATION DIRECTION

NOTE

Before increasing motor speed, check that the motor

is running in the desired direction.

If the pressure/ow seems low or the system is

indicating Motor Overload error check the motor

rotation direction. Turn the disconnect switch to

the off position and wait 5 minutes. Switch any two

output leads on the controller, U2, V2 or W2. Turn

the disconnect switch to the on position. Observe

pressure and ow. If the pressure or ow still seems

low check plumbing. For CentriPro Motors, connecting

U2 to Red, V2 to Black and W2 to Yellow will give the

correct rotation.

NOTE

SECTION 9: TROUBLESHOOTING

DANGER

Disconnect power, lock-out all switch

disconnects then wait 5 minutes before

attempting to service the unit. Use

caution as there may still be hazardous voltage on

the input side of the switch disconnect powering

the unit.

Do not attempt any measurement, parts replacement

or other service procedure not described in this

manual. Such action will void the warranty, may

endanger correct operation and increase downtime

and expense.

All electrical installation and maintenance work

described in this chapter should only be undertaken

by qualied service personnel. The Safety instructions

on the rst pages of this manual must be followed.

GENERAL

The SPD Plus is a self-diagnosing controller. If a problem occurs, observe the Fault or Alarm messages on

the control panel display as well as the Status LED on

the keypad.

STATUS INDICATOR

The Status Indicator is located in the upper left hand

corner of the keypad display. The chart below describes the possible states of the Status Indicator.

Drive State LED Color

Flashing

Not Faulted/

No Alarm

Green Constant

Alarm Green Flashing

Faulted

(Auto-restart fault)

Red Constant

Faulted (Locked Out) Red Flashing

Constant/

It is possible for the pump to maintain constant

pressure with a low ow or a high suction head even

if the pump is rotating backwards. While the pump

is running use an amp probe on one of the output

power leads connected to the motor and compare

the current draw between the two rotation directions.

The lowest current reading typically indicates the

pump is running in the correct direction.

22

RED – FAULTS:

The drive signals that it has detected a severe error, or

fault, by:

• Enabling the red LED on the drive according to

the table above.

• Overriding the control panel display with the

display of a fault code.

• Stopping the motor (if it was on).

Page 23

SECTION 9: TROUBLESHOOTING

(CONTINUED)

The fault code on the control panel display is temporary. Pressing any of the following buttons removes

the fault message: MENU, ENTER, UP button, or

DOWN button. The message reappears after a few

seconds if the control panel is not touched and the

fault is still active.

FLASHING GREEN – ALARMS:

For less severe errors, called alarms, the diagnostic

display is advisory. For these situations, the drive

is simply reporting that it had detected something

“unusual.” In these situations, the drive:

• Flashes the green LED on the drive (does not

apply to alarms that arise from control panel

operation errors).

• Overrides the control panel display with the

display of an alarm code and/or name.

FAULT LISTING

Fault

Code

1 OVERCURRENT

2 DC OVERVOLT

3 DEV OVERTEMP

4 SHORT CIRC

6 DC UNDERVOLT

7 AI1 LOSS Fault not enabled

Fault Name In Panel Description and Recommended Corrective Action

Output current is excessive. Check for and correct:

• Excessive motor load, pump overload

• Insufcient acceleration time

• Faulty motor, motor cables or connections

• Bound pump or locked rotor

Intermediate circuit DC voltage is excessive. Check for and correct:

• Static or transient overvoltages in the power supply.

• Deceleration time is too fast

• Power wires routed too close to each other. Ensure at least 8" between

power wires and all other wiring.

Controller heatsink is overheated. Temperature is at or above 115ºC (239ºF).

Check for and correct:

• Fan failure

• Obstructions in the air ow

• Dirt or dust coating on the heatsink

• Excessive ambient temperature

• Excessive motor load

• Ambient temperature

• Altitude

Fault current. Check for and correct:

• A short-circuit in the motor cable(s) or motor.

• Supply disturbances

Intermediate circuit DC voltage is not sufcient. Check for and correct:

• Missing phase in the input power supply.

• Blown fuse

• Undervoltage on mains

The alarm messages disappear from the control panel

display if/when any of the following are pressed on

the control panel: MENU, ENTER, UP button or DOWN

button. The message returns periodically as long as

the alarm condition exists.

CORRECTING FAULTS

The recommended corrective action for faults is:

• Use the "Fault Listing" table below to nd and

address the root cause of the problem.

• Reset the drive by pressing RESET on keypad.

•NOTE:Itmaybenecessarytoremoveand

reapply the Start Signal on DI1 to start the

drive after a fault is reset by pressing RESET

on the keypad.

• Turn the power off for 5 minutes then turn on.

23

Page 24

SECTION 9: TROUBLESHOOTING (CONTINUED)

FAULT LISTING

Fault

Code

Fault Name In Panel Description and Recommended Corrective Action

8 TRANSDUCER LOSS

Signal from the pressure transducer is out of range. Check for and correct:

• Source and connection for analog input.

• Vacuum in the system. Remove sensor from piping to release vacuum.

• Failed pressure transducer. To diagnose this failure a meter capable of

reading milliamperes (mA) and DC voltage (VDC) is required.

- Set the meter to read DC voltage (VDC)

- Place the black lead on terminal 11 (GND) and the red lead on terminal

10 (+24VDC SUPPLY)

- If functioning properly, the DC voltage will be 24VDC +/- 10%. If this

voltage is not present, disconnect all control terminals and repeat the

measurement. If voltage does not recover, replace controller.

- Disconnect the White wire in the sensor cable from terminal 5.

- Set the meter to read DC current (mA)

- Connect the black lead from the meter to terminal 5

(AI2, TRANSDUCER INPUT)

- Connect the red lead from the meter to the White wire in the sensor

cable.

- The meter will display the output of the sensor. If functioning properly,

the output of the sensor will be between 4mA and 20mA depending

on the pressure in the system. Refer to the chart below to determine

the sensor feedback at various pressures.

Pressure Transducer Output vs. Applied Pressure

for a 300 PSI, 4-20mA Output Transducer

24

20

16

12

8

4

Transducer Output (mA)

0

050 100 150 200 250 300

Pressure (PSI)

9 MOT OVERTEMP

10 PANEL LOSS

12 MOTOR STALL

24

NOTE: The controller is programmed to automatically reset the Transducer

Loss Fault every 10 seconds for 1 minute. If the fault is not corrected in this

time the fault must be reset by pressing reset on the keypad or by cycling

power to the controller.

Motor is too hot, based on the controller's estimate.

• Check for overloaded motor.

• Enter the Start-Up Assistant and ensure motor parameters are set

correctly.

Panel communication is lost drive is in local control mode (LOC). Check for

and correct:

• Communication lines and connections

Motor stall. Motor is operating in stall region. Check for and correct:

• Excessive motor load.

• Insufcient motor power.

• Bound pump.

Page 25

SECTION 9: TROUBLESHOOTING (CONTINUED)

FAULT LISTING

Fault

Code

16 EARTH FAULT

18 THERM FAIL

19 OPEX LINK

20

21

22 SUPPLY PHASE

26 DRIVE ID Internal fault. Conguration Block Drive ID is not valid. Contact factory.

27 CONFIG FILE Internal conguration le has an error. Contact factory.

34 MOTOR PHASE

35 OUTP WIRING

36 INCOMPATIBLE SW The drive cannot use the software. Internal fault. Contact factory.

37 CB OVERTEMP

38

Fault Name In Panel Description and Recommended Corrective Action

Possible ground fault detected in the motor or motor cables. The drive

monitors for ground faults while the drive is running the motor and while the

motor is stopped. Detection is motor sensitive when the drive is not running

and can produce false positives. Possible corrections:

• Check for/correct faults in the input and output wiring.

• Verify the controller uses a recommended load reactor for long output

cable runs.

• A delta grounded input power supply and motor cables with high

capacitance may result in erroneous error reports during non-running.

Internal fault. The thermistor measuring the internal temperature of the drive

is open or shorted. Contact factory.

Internal fault. A communication related problem has been detected on the

ber optic link between the control and OINT boards. Contact factory.

OPEX PWR

CURR MEAS

NO WATER/LOSS OF

PRIME

Internal fault. Exceptionally low voltage detected on the OINT power supply.

Contact factory.

Internal fault. Current measurement is out of range. Contact factory.

Ripple voltage in the DC link is too high. Check for and correct:

• Missing mains phase

• Blown fuse

• Input wiring/connections

• High voltage unbalance on the input power supply

Fault in the motor circuit. One of the motor phases is lost.

Check for and correct:

• Motor fault

• Motor cable fault

• Internal fault

Possible power wiring error detected. When drive is not running it monitors

for an improper connection between the drive input power and the drive

output. Check for and correct:

• Proper input wiring - line voltage is NOT connected to drive output.

• The fault can be erroneously declared if the input power is a delta

grounded system and motor cable capacitance is large.

Drive control board is overheated. The fault trip limit is 88ºC. Check for and

correct:

• Excessive ambient temperature

• Fan failure

• Obstructions in the air ow.

This fault is detected when the pump load on the motor is lower than expected. Check for and correct:

• Adequate well level or water supply

• Plugged suction screen

• Restriction in piping.

• Air bound pump.

• Deadheaded pump, pump running against a closed valve.

• Incorrect setting of motor parameters. Run the Start-Up Assistant and

verify motor settings.

NOTE: The controller will automatically restart after this fault is detected

when the No Water Restart Time set in the Start-Up Assistant expires.

25

Page 26

WARNING

SECTION 9: TROUBLESHOOTING (CONTINUED)

FAULT RESETTING

CONSTANT RED LED

To reset the drive for faults indicated by a constant

(not ashing) LED, correct the problem and do one of

If an external source for start command is selected

and it is active, the SPD Plus may start immediately

after fault reset.

the following:

• Press RESET from the control panel.

• Turn the power off and wait 5 minutes. Turn the

power back on.

FLASHING RED LED

To reset the drive for faults indicated by a ashing red

LED:

• Turn the power off and wait 5 minutes. Turn the

power back on

CORRECTING ALARMS

The recommended corrective action for alarms is:

• Determine if the Alarm requires any corrective

action (action is not always required).

• Use "Alarm Listing" below to nd and address the

root cause of the problem.

ALARM LISTING

Fault

Code

Fault Name In Panel Description and Recommended Corrective Action

Current limiting controller is active. Check for and correct:

• Excessive motor load, pump overload.

2001 OVERCURRENT

• Insufcient acceleration time

• Faulty motor, motor cables or connections.

• Bound pump or locked rotor.

Overvoltage controller is active. Check for and correct:

• Static or transient overvoltages in the power supply.

2002 OVERVOLTAGE

• Deceleration time is too fast.

• Power wires routed too close to each other. Ensure at least 8" between

power wires and all other wiring.

Panel communication is lost and the drive is in local control mode (LOC).

2008 PANEL LOSS

Check for and correct:

• Communication lines and connections

Drive heatsink is hot. This alarm warns that a DEVICE OVERTEMP fault may

be near. Check for and correct:

• Fan failure

2009 DEVICE OVERTEMP

• Obstructions in the air ow

• Dirt or dust coating on heatsink

• Excessive ambient temperature

• Excessive motor load

Motor is too hot, based on the controller's estimate. This alarm warns that a

2010

MOTOR OPERATING

IN SERVICE FACTOR

RANGE

MOT OVERTEMP fault trip may be near.

• Check for overloaded motor

• Enter the Start-Up Assistant and ensure motor parameters are set cor-

rectly.

2013 AUTORESET

2018 NO WATER DEMAND

This alarm warns that the drive is about to perform an automatic fault reset

which may start the motor.

This alarm warns that the controller has turned off the pump due to lack of

demand. The speed of the pump has dropped below the minimum speed.

Signals that the drive is performing a First Start evaluation of motor charac-

2025 FIRST START

teristics. This is normal the rst time the motor is run after the motor parameters are entered or changed.

2027

NO WATER/LOSS OF

PRIME

This alarm is issued to warn that a No Water/Loss of Prime fault may be near.

See Fault Code 38, No Water Loss of Prime for details.

2028 START DELAY Shown during the Start Delay. The start delay time is set to 1 second.

26

Page 27

WARNING

SECTION 9: TROUBLESHOOTING (CONTINUED)

TROUBLESHOOTING FAULTS, ALARMS AND

PERFORMANCE PROBLEMS

In Troubleshooting, always consider the following

possibilities:

• Faults — Press Reset key rst, enter Start Up

Assistant and verify the settings are appropriate.

• Electrical supply/ motor/ wiring/grounding

— check your supply voltage, motor wiring,

transducer wiring, and grounding.

• Mechanical/Pump/ Rotation — check pump

rotation, rubbing or other mechanical problems;

pump “run out”.

APPENDIX A: INPUT POWER SPECIFICATIONS

Do not operate the drive outside the nominal

input line voltage range. Over-voltage can result in

permanent damage to the drive.

SOMETIMES DRIVE INPUT ISOLATION

TRANSFORMERS ARE SPECIFIED TO DEAL WITH

ONE OR MORE OF THE FOLLOWING ISSUES:

1) Short Circuit Protection: Input transformers are

sometimes used to provide impedance to reduce

the available short circuit current to levels that the

input clearing devices, such as fuses or circuit

breakers, are rated to handle. Line reactors can

perform this impedance function much more cost

effectively.

• Hydraulic System/ Piping — check to ensure

proper suction and discharge piping layout,

proper NPSHa, air entrainment, vortex, friction

loss, system curve compensation etc.

• Environment — protect from high temperatures,

direct sun, freezing temperatures, high altitude,

dust, vibration, lack of air ow.

to ground transient protection. Isolation

transformers are not required for this protection

within those energy levels. Additional distribution

transformer primary transient surge arrestors

may be required if the potential transient energy

reected to the drive exceed those levels. MOV's

are rated to handle high levels of one shot

transient energy. MOV's are not meant to handle

continuously recurring transients. A problem

of continuously recurring transients should be

corrected before connecting a drive.

3) Harmonic Mitigation: Input transformers are

sometimes used to provide impedance to reduce

the harmonic currents generated in the drive. Line

reactors can perform this function much more

cost effectively.

2) Transient Protection: Input transformers are

sometimes used to provide transient surge

impedance. All the SPD Plus drives have

capacitors and MOV's (Metal Oxide Varistor transient

protectors) providing 120 to 360 joules, line to line

INPUT POWER SPECIFICATIONS

InputPower(mains)ConnectionSpecications

208/220/230/240 VAC 3-phase or 1-phase – 15% …+10% for SPD2XXXX

Voltage (U1) 380/400/415/440/460/480 VAC 3-phase -15%...+10% for SPD4XXXX

500/525/575/600 VAC 3-phase -15%....+10% for SPD5XXXX