Page 1

INSTRUCTION MANUAL

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE.

Models BCF, HCF & SSCF

Fixed Tube Sheet Heat Exchangers

Page 2

Table of Contents

Introduction and Safety………………………….……………………………………………2

Introduction...…………………………………………………………………..……………….2

Safety………………………………………………………………………….………………..2

Safety terminology and symbols……………………………………………..……………...2

User Safety ………………………………………………………………….……………….3

General safety rules ……………………………………………………… ………………..3

Safety equipment …………………………………..……………………… ……………….4

Product Warranty ……….………………………………………………….………………...4

Product Description…………………………………………………………………….……..5

General description………...……………………………………………………….………...5

Installation…………………………………………………………………………….………...6

Installation ………………..………….……………………………………...........................6

Operation……………………………………………………………………………………….6

Startup ………………………………… .……………………………….............................6

Maintenance…………………………………………………………………........................ 7

Maintenance and cleaning Procedures………………………………………………..…..7

Storage

Storage ……………………………………………………………………………………... 9

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual

1

Page 3

Introduction and Safety

INTRODUCTION

Th

e purpose of this manual is to provide necessary information for:

-Installation

-Operation

-Maintenance

CAUTION:

Read this manual carefully before installing and using the product.

Improper use of the product can cause personal injury and damages to

property and may void the warranty.

NOTICE:

Save this manual for future reference, and keep it readily available at the

location of the unit.

SAFETY

WARNING:

-The operator must be aware of safety precautions to prevent physical injury.

-Operating, installing, or maintaining the unit in any way that is not covered in

this manual could cause death, serious injury, or damage to the equipment.

This includes any modification to the equipment or use of parts not provided

by Xylem. If there is a question regarding the intended use of the equipment,

please contact a Xylem representative before proceeding.

-Do not change the service application without the approval of an authorized

Xylem representative.

CAUTION:

You must observe the instructions contained in this manual. Failure to do so

could result in physical injury, damage, or delays.

Terminology and symbols

It is extremely important that you read, understand, and follow the safety

messages and regulations carefully before handling the product. They are

published to help prevent these hazards:

-Personal accidents and health problems

-Damage to the product

-Product malfunction

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual

2

Page 4

Hazard levels

Hazard categories

DANGER:

A

hazardous situation which, if not, avoided, will result in death or serious injury

WARNING:

A hazardous situation which, if not, avoided, could result in death or serious injury

CAUTION:

A hazardous situation which, if not, avoided, could result in minor or moderate

injury

NOTICE:

-A potential situation which, if not avoided, could result in undesirable conditions

-A practice not related to personal injury

Hazard categories can either fall under hazard levels or let specific symbols

replace the ordinary hazard level symbols.

These are examples of other categories that can occur. They fall under the

ordinary hazard levels and may use complementing symbols:

-Crush hazard

-Cutting hazard

-Arc flash hazard

USER SAFETY

General safety rules

Applicable general safety rules:

-Always keep the work area clean.

-Pay attention to the risks presented by gas and vapors in work area.

-Avoid all electrical dangers and pay attention to the risks of electric shock or arc

flash hazards.

-Always bear in mind the risk of drowning, electrical accidents, and burn injuries.

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual

3

Page 5

Safety equipment

Use safety equipment according to the company regulations. Use this safety

equipment within the work area:

-Hard hat

-Safety goggles, preferably with side shields

-Protective shoes

-Protective gloves

-Gas mask

-Hearing protection

-First-aid kit

-Safety devices

NOTICE:

Never operate a unit unless safety devices are installed. Also see specific

information about safety devices in other chapters of this manual.

PRODUCT WARRANTY

Coverage

Xylem undertakes to remedy defects in products from Xylem under these

conditions:

-The faults are due to defects in design, materials, or workmanship.

-The faults are reported to a local sales and service representative within the

warranty period.

-The product is used only under the conditions that are described in this manual.

-All service and repair work that is done by Xylem authorized personnel.

-Genuine Xylem parts are used.

Limitations

Warranty does not cover defects caused by:

-Deficient maintenance

-Improper installation

-Modifications or changes to the product and installation that are made without

consulting a Xylem authorized representative

-Incorrectly executed repair work

-Normal wear and tear

Xylem assumes no liability for the following situations:

-Bodily injury

-Material damages

-Economic losses

Warranty claim

Xylem products are high quality products with expected reliable operation and long

life. However, should the need for a warranty claim arise, contact your local sales

representative or the manufacturer.

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual

4

Page 6

Product Description

GENERAL DESCRIPTION

BCF, HCF & SSCF heat exchangers are fixed tube heat exchangers using 1/4", 3/8"

and 5/8" diameter tubes. BCF units use copper tubes, brass shells and CI bonnets.

SSCF units are made of all 316 S/S materials. Material options exist for both

products. Tubes are roller expanded into the tube shells.

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual

5

Page 7

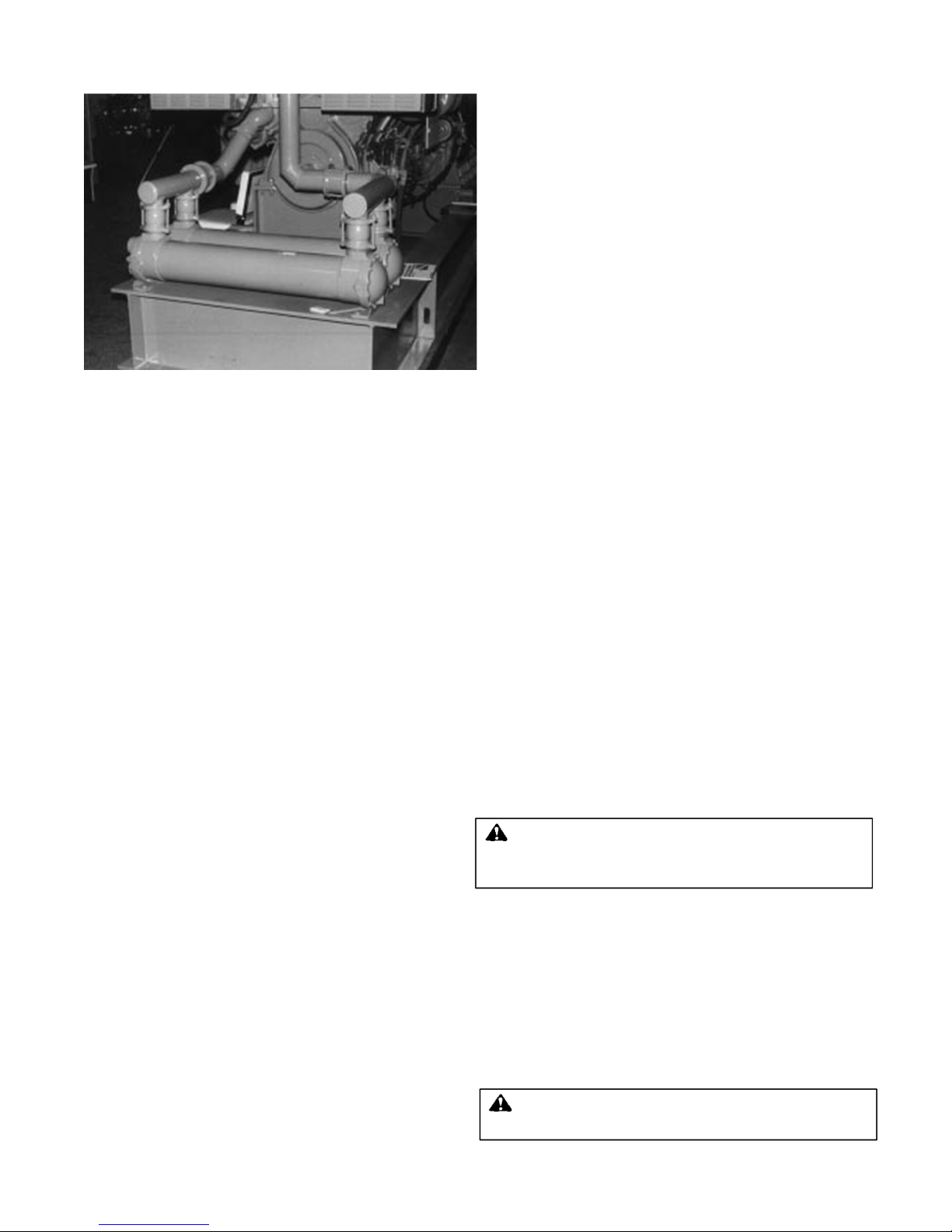

INSTALLATION

1. Before installing this equipment, environment and service

conditions should be checked for compatibility with materials of

construction. Contact your nearest Xylem Representative if you

are not sure what the actual materials of construction are.

2. Provide valves and by-passes in the piping system so that both

the shell and tube sides may be by-passed to permit inspection

or repair.

3. Provide thermometer well and pressure gauge connections in all

piping to and from the unit and locate as near the unit as

possible.

4. Provide convenient means for frequently cleaning the unit as

suggested under “Maintenance.”

5. Provide necessary air vent cocks for units so they can be

purged to prevent or relieve vapor or gas binding of either the

tube or the shell sides.

6. Foundations must be adequate so that exchangers will not settle

and cause piping strains. Foundation bolts should be set to

allow for setting inaccuracies. In concrete footings, pipe sleeves

at least one size larger than bolt diameter slipped over the bolt

and cast in place are best for this purpose, as they allow the bolt

center to be adjusted after the foundation has set.

7. Loosen foundation bolts at one end of unit to allow free

expansion of shells. Oval holes in foundation brackets are

provided for this purpose.

8. Set exchangers level and square so that pipe connections may

be made without forcing.

9. Inspect all openings in exchanger for foreign material. Remove

all thread protectors and shipping pads just before installing. Do

not expose units to the elements with pads or other covers

removed from openings since rain water may enter the unit and

cause severe damage due to freezing.

10.Be sure the entire system is clean before starting operation to

prevent plugging of tubes with sand or refuse. The use of

strainers in settling tanks in pipe lines leading to the unit is

recommended.

11.Drain connections should not be piped to a common closed

manifold.

12.Location of the operating fluids in the heat exchanger can be a

function of the application. A few tips for the location of the

operating fluids are:

a. As a cooler, the preferred arrangement is with the hot

medium through the shell and the cooling medium through

the tubes. When the hot fluid is dirty or fouling, it is better to

put it through the tubes because they are easier to clean.

With single pass units be sure the shell inlet is on the same

end as the tube side outlet. In two pass units, the shell inlet

should be at the inlet-outlet bonnet end. It is customary for

the cooling medium to enter the lower bonnet connection,

although this can be reversed if necessary.

b. As a heater, the hot medium, usually steam or hot water,

must be in the shell. If it is steam, either of the shell

connections, or both, can be used, dependent on the actual

entering velocities.

c. For the above applications and for temperatures above

150°F, the higher temperature fluid should be circulated

through the shell side of the exchanger and precaution

should be taken to avoid shock from abrupt changes in fluid

circulation temperatures.

13.Steam hammer can cause serious damage to the tubes of any

heat exchanger. A careful consideration of the following points

before an installation is made can prevent costly repairs which

may be caused by steam hammer.

a. A vacuum breaker and/or vent, should be used in accordance

with the type of steam system installed.

b. The proper trap for the steam system installed should be

used.

c. The trap and the condensate return line to the trap should be

properly sized for the total capacity of the convertor.

d. The trap should be sized for the pressure at the trap, not the

inlet pressure to the steam controller.

e. The trap must drain into an unpressurized condensate return

system. Condensate return lines must not be run at an

elevation above the bottom of the heat exchanger. To do so

may result in a buildup of the condensate level in the heat

exchanger, which could cause water hammer and damaged

tubes.

CAUTION: During times of shutdown, volumetric expansion

can occur. We recommend the installation of a properly sized relief

valve on both sides of the heat exchanger.

OPERATION

1. When placing a unit in operation, open the vent connections and

start to circulate the cold medium only. Be sure that the

passages in the exchanger are entirely filled with the cold fluid

before closing the vents. The hot medium should then be

introduced gradually until all passages are filled with liquid,

close vents and slowly bring the unit up to temperature.

2. Start operation gradually. Do not admit hot fluid to the unit

suddenly when empty or cold. Do not shock unit with cold fluid

when unit is hot.

CAUTION: Fluids must be gradually introduced to the unit.

Failure to do so can cause damage to the heat exchanger.

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual 6

Page 8

3. In shutting down, flow of hot medium should be shut off

f

irst. If it is necessary to stop circulation of cooling medium

the circulation of hot medium should also be stopped by

by-passing or otherwise.

4. Do not operate equipment under conditions in excess of

those specified on nameplate.

5. Do not blow out heat exchangers with air when operating

f

luids are of a flammable or otherwise hazardous nature.

WARNING: P

clothing, equipment, etc.) to protect personnel from injury

due to escaping fluids.

roper precautions must be taken (special

WARNING: F

within the design pressure and temperature on the

nameplate may result in damage to the heat exchanger and

potential injury to adjacent personnel.

5. Drain all fluids when shutting down to eliminate possibility

of freezing and corrosion. To guard against water

hammer, condensate should be drained from steam

heaters and similar apparatus both when starting up and

when shutting down.

6. In all installations there should be no pulsation of fluids

since this causes vibration and strain with resulting leaks.

7. All gasketed joints should be checked after starting for

leaks and tightened if necessary.

WARNING: T

suit able for use as heaters using steam as the heating

medium. These exchangers are, however, fixed tubesheet

units and, therefore, not designed to absorb thermal shock

inherent in the intermittent service of on and off heating with

frequent short intervals of demand. Their recommended use

is where service is continuous or steady, with relatively long

periods between shutdown and start-up. Heat exchanger

failure due to thermal shock may result in potential personal

injury.

ailure to operate the heat exchanger

he BCF, HCF & SSCF exchangers are

MAINTENANCE

1

. Do not open heads until all pressure is off equipment and

the unit is drained.

f. Provide convenient means for frequently cleaning heat

exchangers as suggested below:

a. Circulating hot wash oil or light distillate through tubes

or shell at good velocity will effectually remove sludge or

other similar soft deposits.

b. Soft salt deposits may be washed out by circulating hot

fresh water.

c. Some cleaning compounds on the market, such as

“Oakite” may be used to advantage for removing sludge

or coke, provided hot wash oil or water, as described

above, does not give satisfactory results.

d. If none of the above described methods are effective for

the removal of hard scale or coke a mechanical means

may be used. The interior of the tubes may be rodded.

e. The exterior or shell side of the tubes of a fixed sheet

heat exchanger can only be cleaned chemically by

using a chemical dissolved in water solution. We

suggest that the user contact the manufacturer of the

cleaning chemical for instructions.

WARNING: P

clothing, equipment, etc.) to protect personnel from injury

due to escaping fluids.

roper precautions must be taken (special

2. Remove the bonnets. Inspect all tubes carefully for

p

ossible erosion, corrosion, or foreign material.

3. Inspect all anodes to be sure they are neither excessively

corroded nor insulated with scale. Scrape to a bright

surface.

4. Inspect filters in the system to prevent foreign matter from

entering the exchanger.

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual 7

7. When replacing heads, use a torque wrench.* Tighten 1/4“

d

iameter bolts (2” diameter units) to 6 ft-lbs., 5/16“

diameter bolts (3" & 4" diameter units) to 16 ft-lbs., and 3/8“

diameter bolts (5", 6", & 8" diameter units) to 24 ft-lbs. If the

gasket joint still leaks, tighten in 2 ft-lb. increments until

leak stops.

*The above torque values apply to well lubricated nut

bearing surfaces.

Page 9

8. All bolted joints should be tightened uniformly and in a

diametrically staggered pattern as illustrated below:

START

1

1

6

9

14

4

7

12

15

6

11

8

3

13

10

5

2

9. Frequently and at regular intervals, observe interior and

exterior condition should be according to scale build-up.

CAUTION: N

eglect in keeping all tubes clean may result

in complete stoppage of flow through some tubes with

consequent overheating of these tubes, resulting in severe

expansion strains, leaking tube joints, and damage to the heat

exchanger.

F

RONT HEAD GASKET

FRONT HEAD

(BUNDLE & SHELL ASSEMBLY)

10.Exchangers subject to fouling or scaling should be cleaned

periodically. A light sludge or scale coating on the tube

greatly reduces its effectiveness. Therefore, low-fouling

fluids should be used in the shell side of all heat

exchangers with non-removable tube bundles. A marked

increase in pressure drop and/or reduction in performance

usually indicates cleaning is necessary, especially if the

unit has been checked for air or vapor binding and this has

been found not to be the cause. Since the difficulty of

cleaning increases rapidly as the scale thickens or deposits

increase, the interval between cleanings should not be

excessive. interior and exterior condition should be

according to scale build-up.

ANODES

1. Some exchangers may be equipped with renewable

anodes. The purpose of the anodes is to inhibit electrolytic

corrosion. In order to remain active the anodes must be

kept free of scale or other surfaces coatings.

2. On some applications where electrolytic corrosion is not a

problem, pipe plugs may be substituted for the anode. The

pipe plug material selected should be softer than the base

part to avoid pipe thread damage.

CORE

REAR HEAD

RENEWABLE ANODES

(ZINC)

BCF HCF & SSCF Heat Exchangers Installation, Operation, and Maintenance Manual 8

REAR HEAD GASKET

MOUNTING LEGS

Page 10

Xylem

www.xylem.com/standardxchange

Standard Xchange is a trademark of Xylem Inc. or one

of its subsidiaries.

© 2018 Xylem Inc. BCF HCF SSCF September 2018

Loading...

Loading...