Tri Tool 576AC User Manual

T ABLE OF CONTENTS

CUSTOMER MESSAGE Inside Front Cover

SAFETY PRECAUTIONS 3

GENERAL DESCRIPTION 5

92-0854 Rev . 030318

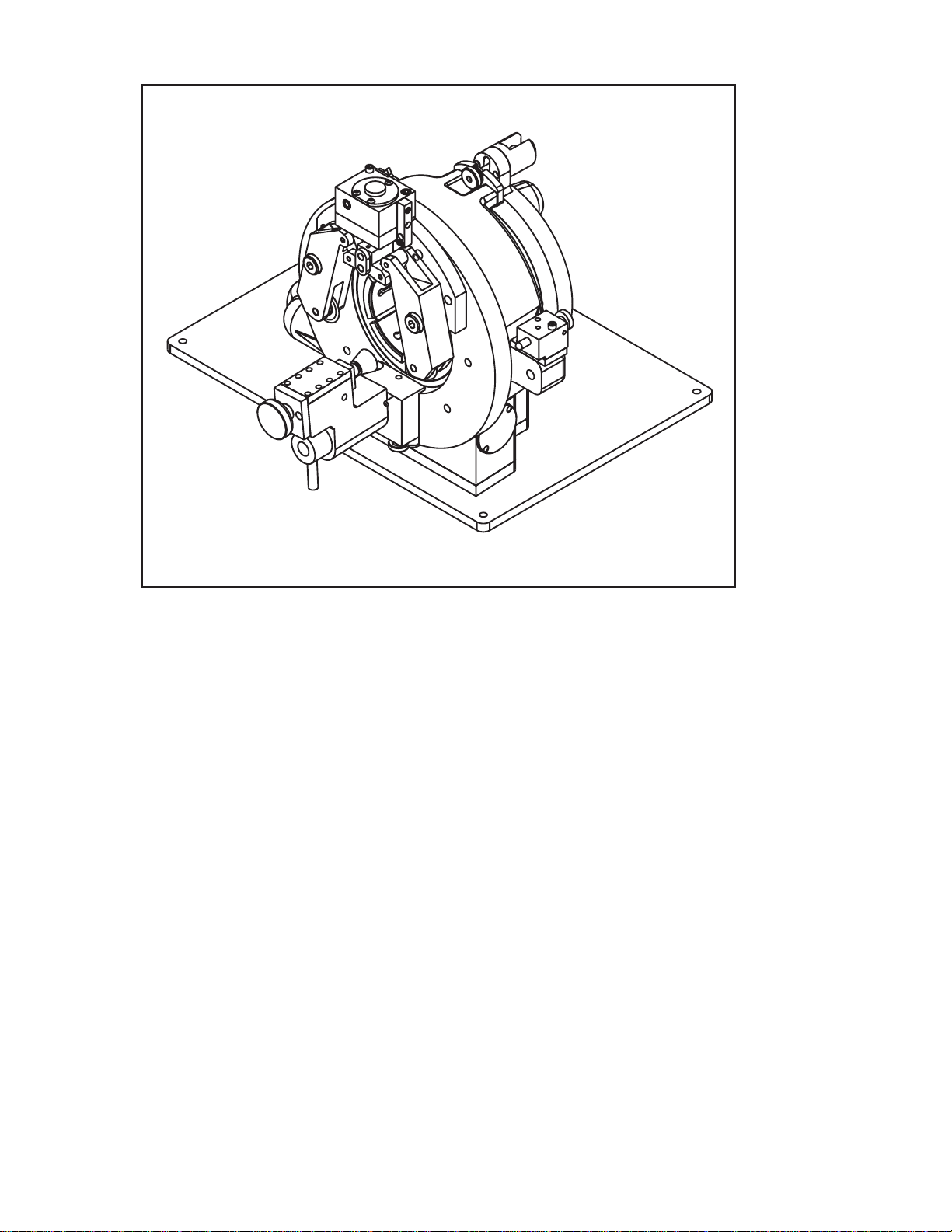

576AC Chipless Sever Module

SPECIFICATIONS 6

MAINTENANCE 7

OPERA TION 8

TROUBLE SHOOTING 11

ILLUSTRA TED P ARTS BREAKDOWN 14

TOOL BIT RESHARPENING POLICY Inside Back Cover

WARRANTY INFORMATION Inside Back Cover

Copyright 1999 proprietary property of TRI TOOL Inc.

No reproduction, use, or duplication of the information

shown hereon is permitted without the express written

consent of TRI TOOL Inc.

SAFETY PRECAUTIONS

IN GENERAL:

576AC Chipless Sever Module

When using rotating head cutting equipment, basic safety precautions should always be followed to reduce the risk of personal injury .

Operate this tool only in accordance with specific operating instructions.

WARNING:

DRESS CONSIDERATIONS:

WORK AREA:

Do not override the deadman switch on the power unit. Locking down, obstructing, or in any way defeating the deadman switch on the power drive unit may result

in serious injury .

Use standard safety equipment. Hard hats, safety shoes, safety harnesses, protective clothes, and other safety devices should always be used when appropriate.

Use safety glasses. Do not operate cutting tools without eye protection.

Dress properly . Do not wear loose clothing or jewelry . They can be caught in rota-

ting and moving parts. Avoid slippery floors or wear nonskid footwear . If you have

long hair , wear protective hair covering to contain it.

Keep the work area clean. Cluttered work areas and benches invite injuries.

Consider the work area environment. Keep the area well lit. Keep electrical cords,

cables, rags, rigging straps, etc. clear of rotating equipment. Do not use power

cutting tools in the presence of flammable liquids and gasses.

Keep visitors away . Do not let visitors or untrained personnel at or near operating

tools. Enforce eye protection requirements for all observers.

Do not over reach. Keep proper footing at all times.

Stay alert. W atch what you are doing. Use common sense. Do not operate tools

when you are tired.

TOOL CARE:

Maintain tools with care. Keep tools in good operating condition. Sharp tool bits

perform better and safer than dull tool bits. Well maintained tools function properly

when needed.

Check for damaged parts. If a tool has malfunctioned, been dropped or hit, it must

be checked for damage. Run no-load tests and feed function checks. Do a complete visual inspection.

Electric motors. Use only with proper AC volt age power sources and observe all

normal electric shock hazard procedures.

92-0854 : Rev. 030318

3

TRI TOOL INC.

AREA EQUIPMENT:

TOOL USE:

Do not abuse power and control cords. Pulling or running over cords and cables

can result in electrical shock hazards and malfunctions. Keep control and power

cords out of all cutting fluids and water.

Hydraulic drives. Observe proper procedures for electrically driven power sources.

Avoid damage to hydraulic lines. Keep quick-disconnects clean. Grit contamination causes malfunctions.

Air tools. Check the exhaust muffler . Broken or damaged mufflers can restrict air

flow or cause excessive noise. Use air motors only with a filtered, lubricated and

regulated air supply. Dirty air, low pressure air or over pressure air will cause

malfunctions, including delayed starting.

Secure work. Whenever possible use clamps, vises, chains and straps to secure

pipe.

Make sure the tool is secured; it is safer to have both hands free to operate the

tool.

Us the right tool and tool bit for the job. Do not use a tool which is incorrect for the

job you are doing.

Keep the tool bits fully engaged in the tool bit holders. Loose bits are a safety

hazard.

Disconnect power supply during setup and maintenance. Use all stop or shut-off

features available when changing or adjusting tool bits, maintaining the tool, or

when the tool is not in use.

Remove adjusting keys and wrenches before applying power to the equipment.

Develop a habit of checking the tool before turning it on to make sure that all keys

and wrenches have been removed.

Do not force tools. T ools and tool bit s function better and safer when used at the

feed and speed rate for which they were designed.

Do not reach into rotating equipment. Do not reach into the rotating head stock to

clear chips, to make adjustments, or to check surface finish. A machine designed

to cut steel will not stop for a hand or an arm.

Handle chips with care. Chips have very sharp edges and are hot. Do not try to

pull chips apart with bare hands; they are very tough.

Avoid unintentional starts. Do not carry or handle tools with your hand on the operating switches or levers. Do not lay the tool down in a manner which will start the

drive. Do not allow the tool to flip around or move when adjusting or changing tool

bits.

Store idle tools properly. Disconnect tools from the power source and store in a

safe place. Remove tool bits for safe handling of the tool.

4

92-0854 : Rev. 030318

GENERAL DESCRIPTION

The Model 576 AC SEVERMASTER™ has been converted to accommodate a

Chipless Sever Module. The custom 576 AC retains the Tri T ool Quick Lock Collet

Closure Mechanism™ that actuates the collet with a single lever stroke and provides for simple collet changes. The custom 576 AC is also fitted with a Burnishing Module, which is designed to roll back any burrs that remain after the severing

operation.

576AC Chipless Sever Module

92-0854 : Rev. 030318

5

TRI TOOL INC.

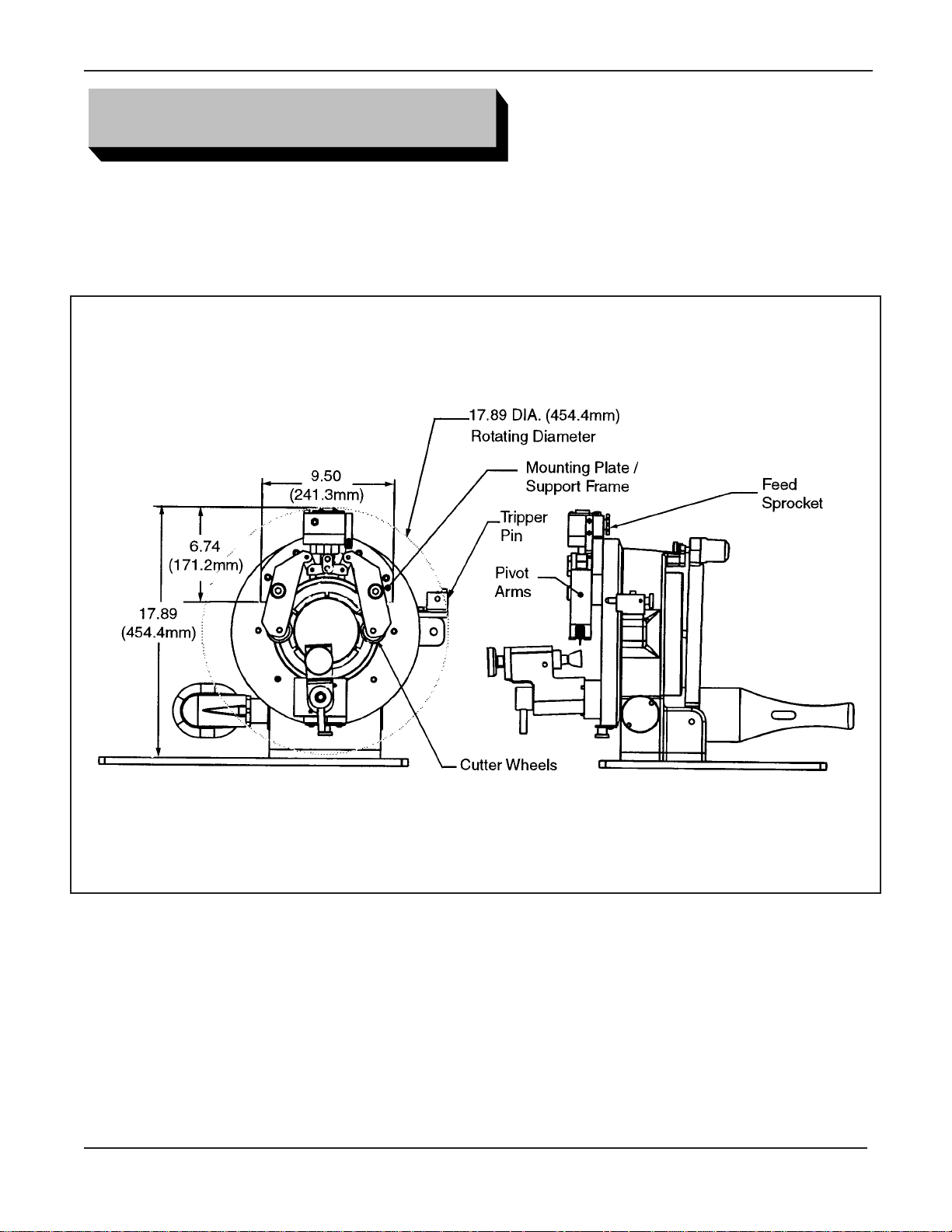

SPECIFICATIONS

576 AC with Chipless Sever Module:

Weight: 140 lbs. (308 kg)

6

92-0854 : Rev. 030318

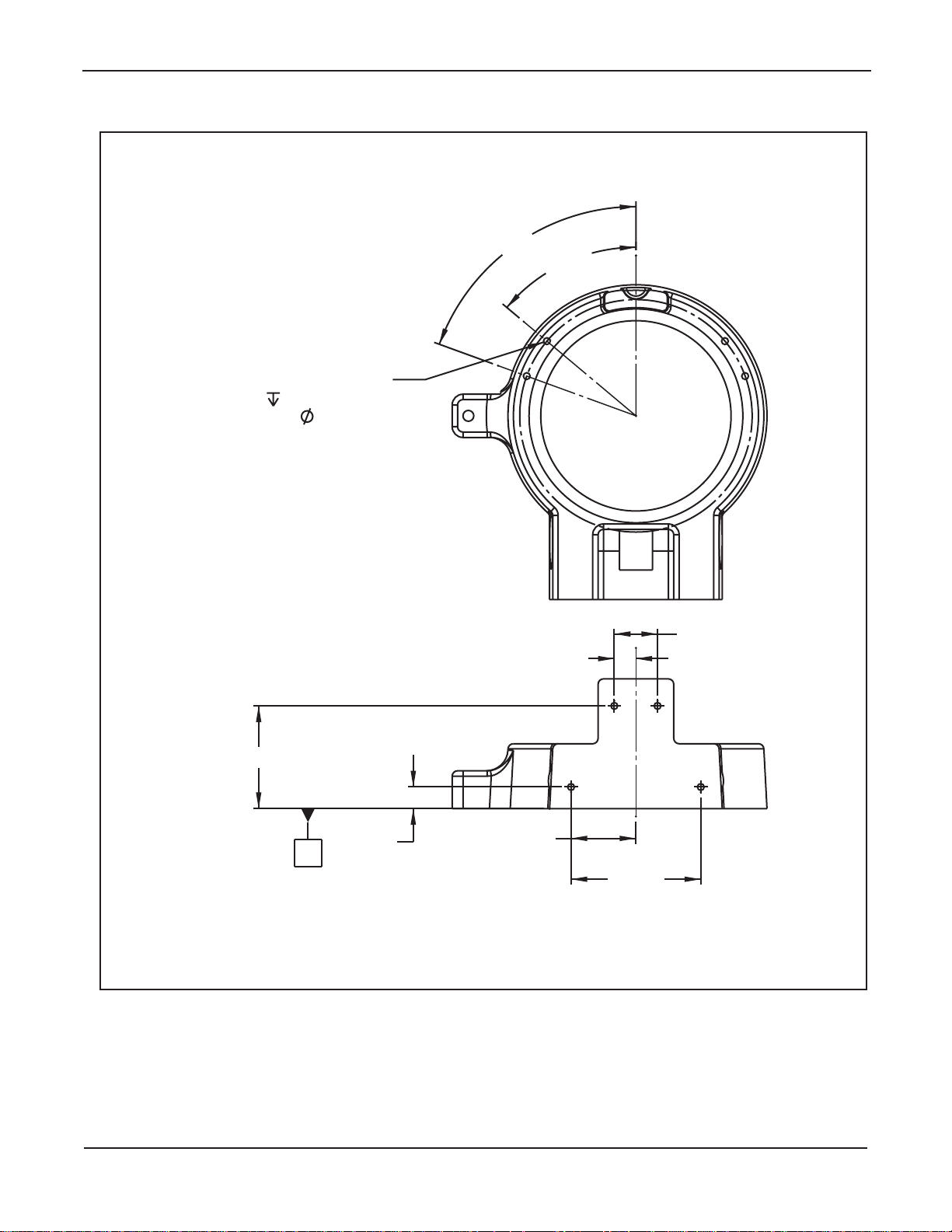

Housing Hole Pattern

4x 5/16-18 UNC-2B

ON A

1.000

10.750 B.C.

70.0

576AC Chipless Sever Module

o

o

50.0

4.750

2.000

1.000

A

1.000

3.000

6.000

92-0854 : Rev. 030318

7

TRI TOOL INC.

MAINTENANCE

All Components should be cleaned and coated with a light film of oil prior to use.

Use a clean non-detergent oil, preferably SAE 10 (90 SSU) or lighter.

Daily Maintenance Schedule:

Daily Maintenance should include a visual inspection of all parts for damage due

to chips, impact or improper use.

Repair or replace broken or damaged parts as necessary.

Wipe the machine clean of cutting fluids, dirt and grime and then coat it with a light

film of oil.

After every 20 hours of operation:

Lubricate the slides on the carriage block, the hinges, cutter wheel and the pivot

posts.

Non-scheduled Maintenance:

Thoroughly clean and check the Chipless Sever Module in the event of feed problems.

Storage:

If the Chipless Sever Module is to be stored or if it will remain out of service for a

significant period of time (30 days or more), it should be thoroughly cleaned, lubricated and sprayed with a rust preventative prior to storage.

8

92-0854 : Rev. 030318

576AC Chipless Sever Module

OPERATION

Become familiar with the custom 576 AC SEVERMASTER™ before attempting to

operate.

CAUTION:

NOTE:

NOTE:

Use eye protection at all times when operating this machine.

Use of dull cutter wheels, cutter wheels not manufactured by Tri T ool, Inc. or cutter

wheels not originally provided with the system may result in poor performance.

This also constitutes abuse of this machine and therefore voids the Tri Tool, Inc.

factory warranty .

Slowly rotate machine to insure that no machine parts violate the maximum rotating

diameter . Then increase RPM to cutting speed.

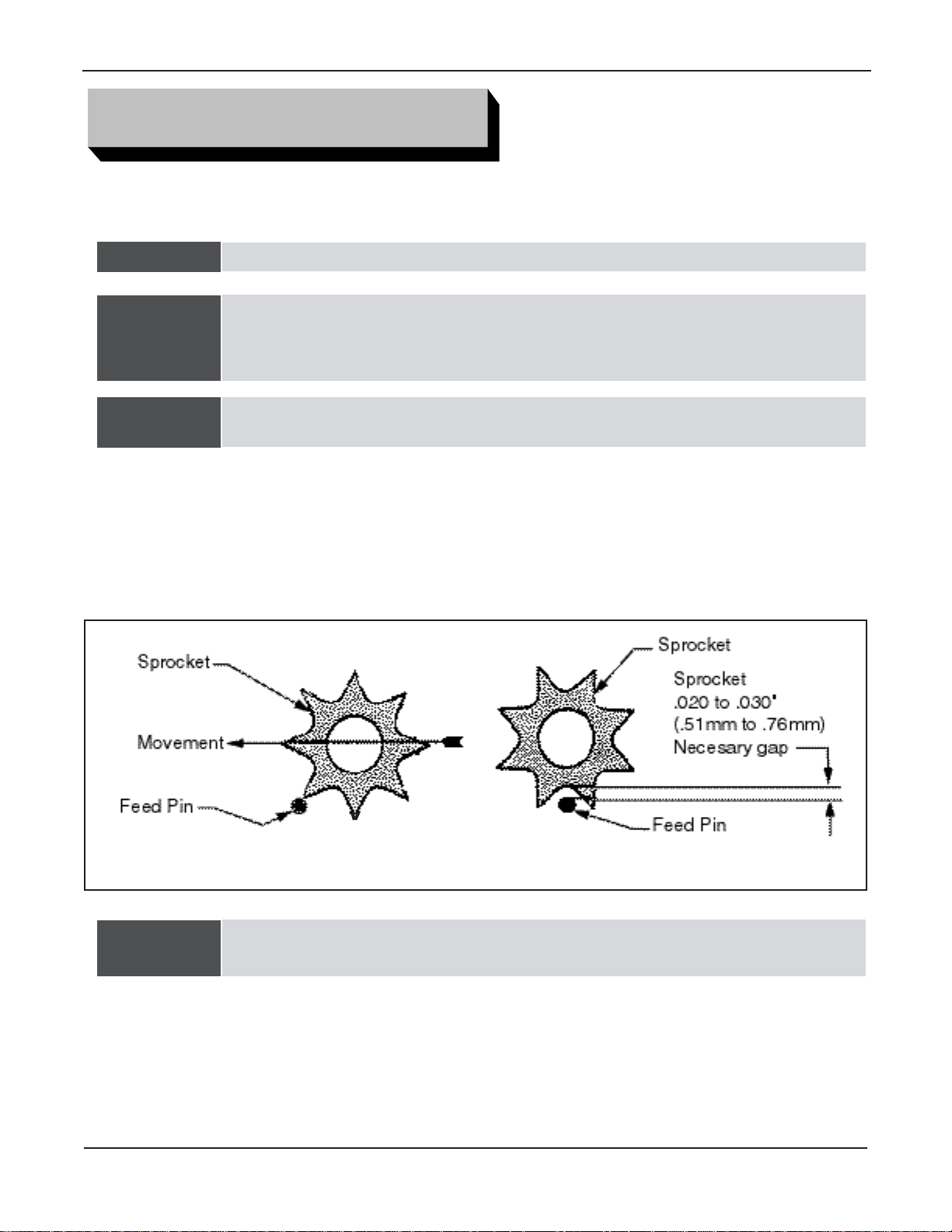

Tripper Pin Alignment:

1. Rotate the Chipless Sever Module until the feed sprocket is in the proximity

of the tripper pin.

2. Set the tripper pin to engage the feed sprocket with a .020 - .030” gap from

the roof of the sprocket.

Correct alignment of the Feed Pin Feed Pin positioning

CAUTION:

If the feed sprocket is not correctly aligned before operation, serious damage

could occur or destroy the Tripper Pin Assembly and/or the feed sprocket .

Do not bump the cutter wheels.

Cutting Wheel Replacement

T o remove the cutting wheels, loosen the retaining set screws at the bottom of the

cutting arms.

92-0854 : Rev. 030318

9

Loading...

Loading...