Tri Tool 224B User Manual

TABLE OF CONTENTS

CUSTOMER MESSAGE Inside Front Cover

SAFETY PRECAUTIONS 3

92-0834 Orig. 990603

Model 224B ID Tracking Module

GENERAL DESCRIPTION 6

SPECIFICATIONS 7

MAINTENANCE 8

INSTALLATION 10

OPERATION 12

TROUBLE SHOOTING 17

ILLUSTRATED PARTS BREAKDOWN 19

TOOL BIT RESHARPENING POLICY Inside Back Cover

WARRANTY INFORMATION Inside Back Cover

Copyright 2006

Proprietary property of TRI TOOL Inc.

No reproduction, use, or duplication of the information

shown hereon is permitted without the express written

consent of TRI TOOL Inc.

SAFETY PRECAUTIONS

IN GENERAL

When using rotating head cutting equipment, basic safety precautions should always

be followed to reduce the risk of personal injury.

Operate this tool only in accordance with specific operating instructions.

Do not override the deadman switch on the power unit. Locking down, ob-

WARNING:

DRESS CONSIDERATIONS

structing, or in any way defeating the deadman switch on the power drive unit

may result in serious injury.

Model 224B ID Tracking Module

Use standard safety equipment. Hard hats, safety shoes, safety harnesses, protective clothes, and other safety devices should always be used when appropriate.

Use safety glasses. Do not operate cutting tools without eye protection.

Dress properly. Do not wear loose clothing or jewelry. They can be caught in rotating and moving parts. Avoid slippery floors or wear nonskid footwear. If you have

long hair, wear protective hair covering to contain it.

WORK AREA

Keep the work area clean. Cluttered work areas and benches invite injuries.

Consider the work area environment. Keep the area well lit. Keep electrical cords,

cables, rags, rigging straps, and etc. clear of rotating equipment. Do not use powercutting tools in the presence of flammable liquids and gasses.

Keep visitors away. Do not let visitors or untrained personnel at or near operating

tools. Enforce eye protection requirements for all observers.

Do not over reach. Keep proper footing at all times.

Stay alert. Watch what you are doing. Use common sense. Do not operate tools

when you are tired.

92-0834 : Orig. 990603

3

TRI TOOL INC.

TOOL CARE

Maintain tools with care. Keep tools in good operating condition. Sharp tool bits

perform better and safer than dull tool bits. Well maintained tools function properly

when needed.

Check for damaged parts. If a tool has malfunctioned, been dropped or hit, it must

be checked for damage. Run no-load tests and feed function checks. Do a complete visual inspection.

Electric motors. Use only with proper AC voltage power sources and observe all

normal electric shock hazard procedures.

Do not abuse power and control cords. Pulling or running over cords and cables

can result in electrical shock hazards and malfunctions. Keep control and power

cords out of all cutting fluids and water.

Hydraulic drives. Observe proper procedures for electrically driven power sources.

Avoid damage to hydraulic lines. Keep quick-disconnects clean. Grit contamination

causes malfunctions.

Air tools. Check the exhaust muffler. Broken or damaged mufflers can restrict air

flow or cause excessive noise. Use air motors only with a filtered, lubricated and

regulated air supply. Dirty air, low-pressure air or over pressure air will cause malfunctions, including delayed starting.

AREA EQUIPMENT

Secure work. Whenever possible use clamps, vises, chains and straps to secure

pipe.

Make sure the tool is secured; it is safer to have both hands free to operate the tool.

TOOL USE

Use the right tool and tool bit for the job. Do not use a tool, which is incorrect for the

job you are doing.

Keep the tool bits fully engaged in the tool bit holders. Loose bits are a safety hazard.

4

92-0834 : Orig. 0990603

Model 224B ID Tracking Module

Disconnect power supply during setup and maintenance. Use all ‘Stop’ or Shut off’

features available when changing or adjusting tool bits, maintaining the tool, or when

the tool is not in use.

Remove adjusting keys and wrenches before applying power to the equipment.

Develop a habit of checking the tool before turning it on to make sure that all keys

and wrenches have been removed.

Do not force tools. Tools and tool bits function better and safer when used at the

feed and speed rate for which they were designed.

Do not reach into rotating equipment. Do not reach into the rotating head stock to

clear chips, to make adjustments, or to check surface finish. A machine designed to

cut steel will not stop for a hand or an arm.

Handle chips with care. Chips have very sharp edges and are hot. Do not try to pull

chips apart with your hands; they are very tough.

Avoid unintentional starts. Do not carry or handle tools with your hand on the operating switches or levers. Do not lay the tool down in a manner that will start the

drive. Do not allow the tool to flip around or move when adjusting or changing tool

bits.

Store idle tools properly. Disconnect tools from the power source and store in a safe

place. Remove tool bits for safe handling of the tool.

92-0834 : Orig. 990603

5

TRI TOOL INC.

GENERAL DESCRIPTION

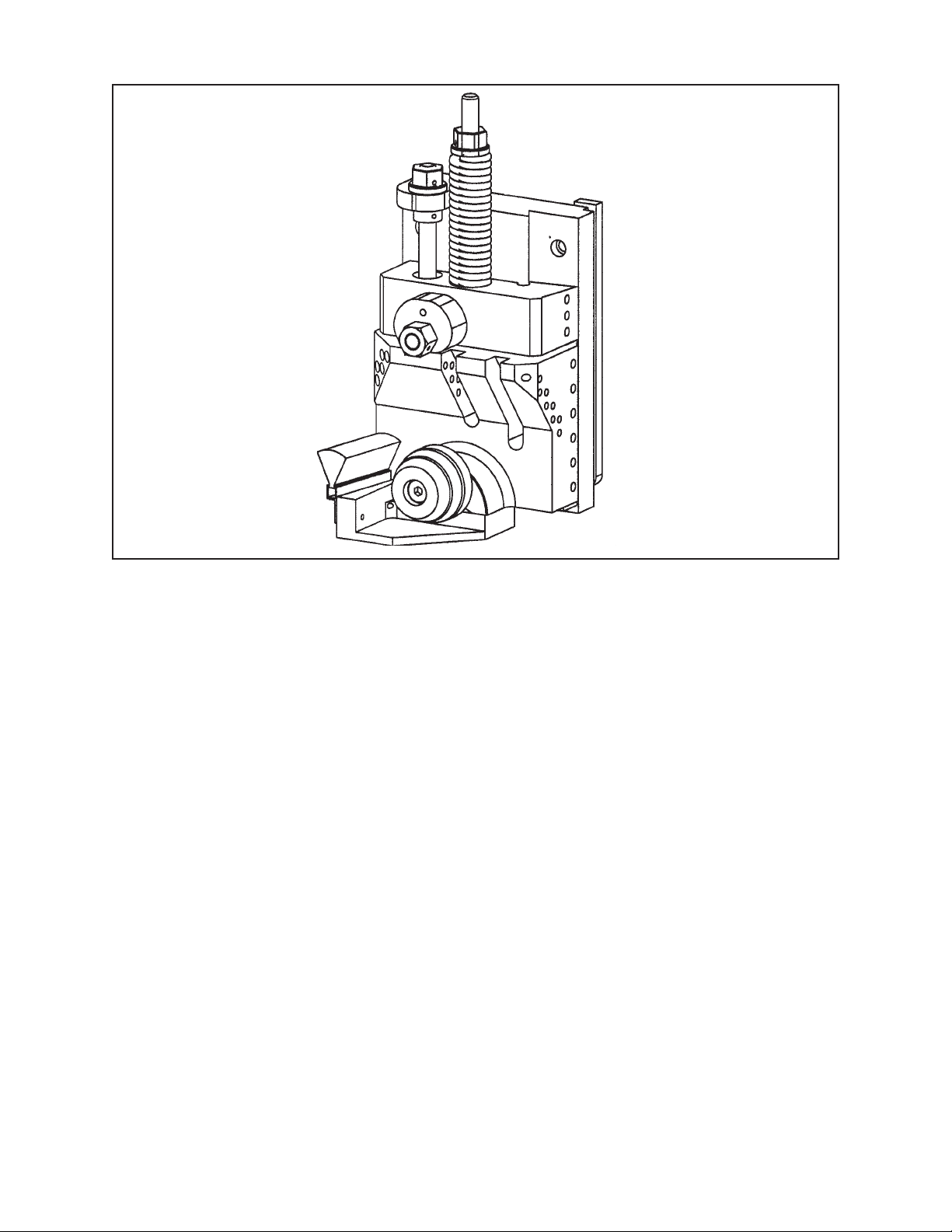

The 224B ID Tracking Module Kit is an accessory option, which is used to expand the

versatility of the Model 224B BEVELMASTERTM.

The ID Tracking Module is designed to track out of round pipe where to control of the

land is critical.

The 224B IDTM bolts directly to the to the 224B BEVELMASTERTM in lieu of the

standard tool modules.

The tool holder has two tool bit slots to allow facing and beveling simultaneously.

1.00” (25.4 mm) of radial tool holder spring travel accommodates pipes that are

out of round.

6

92-0834 : Orig. 0990603

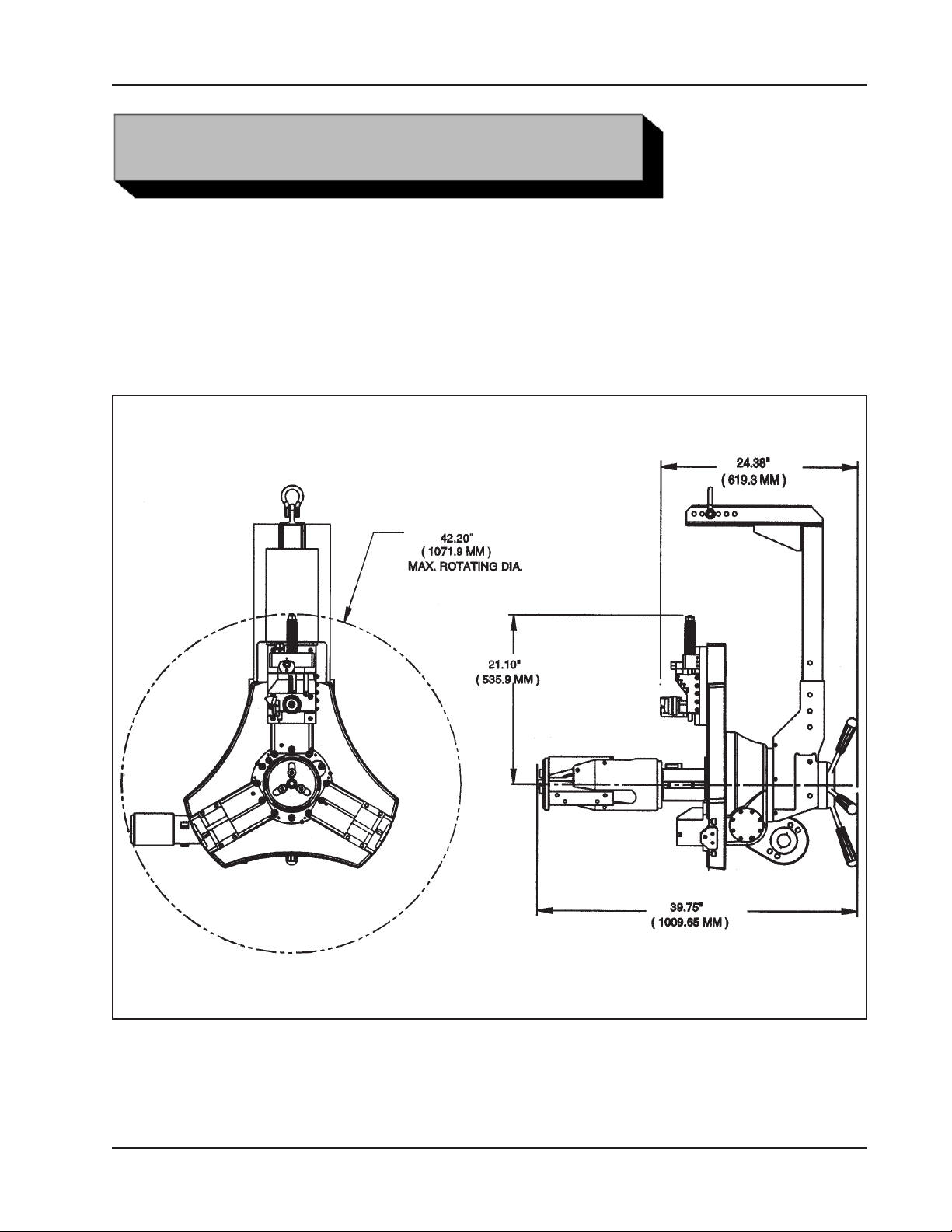

SPECIFICATIONS

PIPE CUTTING CAPACITIES

Basic Pipe Sizes: 12” schedule 80 through 24” pipe

Maximum Rotating Diameter: 42.20” (1071.9 mm)

Radial Tracking Travel: 1.00” (25.4 mm)

Envelope, Model 224B-ITDM

Model 224B ID Tracking Module

92-0834 : Orig. 990603

7

Loading...

Loading...