Page 1

D 194.8

Content

1. Functions

2. Sensor mounting in open areas

3. Sensor mounting in gutters, on rooftops and on satellite

systems

4. Connection diagrams

5. Commissioning

6. Display and pushbutton functions

7. Operation, menu and error codes

8. Technical data, safety instructions

Ice and Snow Detector Type 1773

for the TF-E System

Introduction

In cooperation with the moisture and temperature sensors of the TF-E system, the 1773 Ice and Snow Detector

is used for early detection of ice and snow and for keeping the monitored surface or gutter free by switching on

a defrosting device. One or two sensors can be connected to the 1773 Ice and Snow Detector. The sensor

function (temperature and/or moisture monitoring) and other settings can be defined for each sensor

individually. The individual parameters and measured values can be diplayed and changed in the menu using

the display and three operating buttons. An LED shows the current operating state.

The sensor type 3354 (or its predecessor 3351) can be used for gutters, flat rooftops or satellite systems. Open

areas such as driveways or parking lots can be monitored with the sensor types 3355 and 3356 (predecessors

3352 and 3353), which resist mechanical load such as cars driving over them.

Most ice and snow detection systems use exposed metal electrodes. Their disadvantage is that these

electrodes can accumulate dirt, suffer from corrosion or get short circuited by external conductive objects.

Therefore their sensors need periodical maintenance work in order to avoid that environmental influences impair

the accuracy of moisture measurement.

The TF-E system takes advantage of the increase of thermal capacity due to moisture, i. e. the availability of

water in liquid or solid form (snow, ice) on the sensor. With the help of a patented measurement and evaluation

method, the temperature variation with regard to the sensor is used to detect moisture on the sensor surface.

This guarantees a maintenance-free and secure operation.

1. Functions

If the sensor temperature is below the defined critical temperature limit, the moisture control is activated. If

moisture is detected, the heating system is switched on. If not, the moisture is measured again periodically. At

the earliest when the defined minimum heating time has expired, the heating system is switched off again if

there is no more moisture on the sensor.

In addition to the limit value of the critical temperature range (0 to +5 °C) a lower value can be set between -5

and –20 °C. This is useful because in case of very low outdoor temperatures there will no longer be any dripping

melt water or snow. If snow falls despite the extreme temperature, it will be dry, light and not slippery. In such a

case the heating would not be powerful enough to completely melt the snow on the surface. Thus the danger of

slippery conditions would rather be increased if the heating were switched on.

- 1 -

Page 2

Connecting the sensor inputs

In order to adapt to the desired monitoring functions, you can choose to wire the inputs in three different ways:

Operation with one sensor

The Type 33.. sensor is connected to sensor input 1 for temperature and moisture monitoring.

Operation with two sensors

Two sensors can be connected to the ice and snow detector: either two combi sensors for moisture/temperature

or one combi sensor and one temperature sensor. This type of operation is recommended in case of differences

in topography or areas with pronounced differences of sun and shadow.

The measured values are collected one by one. If one of the combi sensors indicates moisture, the heating of

the open area will be activated.

The relevant measurement functions of the sensors are set in the configuration menu "Sensor".

Slab idle temperature operation

A combi sensor and a temperature sensor are connected to the ice and snow detector. A Type 33.. sensor is

connected to sensor input 1 for temperature and moisture monitoring; a type 31.. temperature sensor is

connected to sensor input 2 in order to measure the outdoor temperature (also refer to "Slab idle temperature").

Moisture measurement

If the measured temperature falls below the set "high temperature limit", the sensor heating will heat up the

sensor surface and subsquently assess if the sensor is dry or moist. If the set moisture sensitivity is exceeded,

the heating is switched on for the set minimum heating time. After the minimum heating time has passed, there

will be another moisture measurement. If the sensor is still moist, the heating will remain switched on. If the

temperature measured in the sensor reaches the set "high temperature limit" during the second or further

measurements, the switch output will be switched off prematurely.

Note: Also for sensors which are only activated for moisture monitoring, the integrated temperature sensor must

be connected and operational because the sensor temperature is required for determining moisture. Therefore

there will also be an error message for these sensors if "only" the temperature measurement is impaired.

In order to avoid incorrect measurements, the supply voltage of the ice and snow detector is monitored before

and during moisture measurement. In case the value is outside the voltage area for which correct functioning is

guaranteed, there will be an error message (refer to chapter "Error codes").

The system automatically optimizes the duration of one measurement cycle depending on the type of sensor,

the supply voltage and the sensor temperature.

Ambient temperature of moisture sensors

Depending on the type of sensor, the ambient temperature cannot be measured during the moisture

measurement and for a certain time after the measurement. This is because the temperature of the integrated

temperature sensor is influenced by the moisture measurement. During this time the system works with the last

measured ambient temperature.

Slab temperature

If two sensors are used to measure the slab temperature, the relevant slab temperature is calculated according

to the following pattern (with a hysteresis of 0,5K each) :

- Both sensors above or below the range of the high to low temperature limit: The relevant slab

temperature is the average value of both measured values.

- Both sensors within the range of the high to low temperature limit: The relevant slab temperature is the

average value of both measured values.

- One sensor outside and one sensor within the range of the high to low temperature limit: The relevant

slab temperature is the value measured within this range.

- One sensor above and one sensor below the range of the high to low temperature limit: For the relevant

slab temperature an "-!-" is displayed as an indication that there is an installation or configuration problem

(slab heating is not activated).

In this way the moisture measurement is activated at the earliest possible point in time.

Slab idle temperature mode

In the operating mode "Slab idle temperature" a temperature and moisture sensor has to be connected to

sensor input 1 and a temperature sensor (Series 31..) has to be connected to sensor input 2 (terminals 6/7) in

order to measure the outdoor temperature. The sensor types need to be defined accordingly in the configuration

menu!

- 2 -

Page 3

As soon as the outdoor temperature is below the high temperature limit (within the range of the "high and low

temperature limit"), the slab temperature measured by the sensor at input 1 is kept at the level of the setpoint

value (with an hysteresis of 1K). Additionally the moisture is measured regularly. If moisture is detected, the

heating will be switched on. If there is no moisture, the slab temperature will be kept at the setpoint value for as

long as the outdoor temperature is below the temperature limit.

Emergency operation (not in the "Slab idle temperature" mode)

If two sensors are connected (moisture and temperature), the controller will switch to emergency operation in

case one of the two temperature or moisture measurement circuits is impaired and the corresponding function is

activated for both sensors in the "Sensor status". In this case the evaluations will only be made with one

measurement circuit. The LED indicating the operating mode will flash red/green in order to indicate the error.

Moisture value and setting of the moisture limit

The sensors determine the moisture value as a number (without measurement unit). It lies in the range from 1 to

99. The moisture value is determined by the sensor type, the present moisture and the installation situation. By

all means the optimum moisture limit should therefore be determined during installation. In doing so, the user's

preferences need to be taken into account, i. e. if the slab heating should already be switched on in case of very

little moisture or only if a certain amount of moisture has developed. The factory default setting of 50 can be

used as an indicator. If the moisture limit is set to 50, all measured moisture values above 50 lead to the result

"moisture detected" and trigger the heating unit.

Counter for operating hours

The ice and snow detector has a counter for operating hours with two display levels. The first level "Time Mtr 1"

can be reset to zero. In this way it can be monitored for how many hours the heating was switched on since the

last reset (e. g. during one heating period). The second level shows the operating time of the heating unit since

the controller has been taken into use. This level cannot be reset.

Invertible alarm output

In case of an error there is a voltage of 24V between the terminals of alarm output A+ and A-. In this way the

alarm may, for example, be detected by a central control centre via the type 1798 coupling relay.

The state of the alarm output may be inverted using the menu, i. e. in the normal state (no error) the alarm

output is supplied with 24V or in case of an error 0V. Like this the control centre may detect a power failure of

the system.

PC interface

The controller has an interface for connection to a PC. The optional connection cable and software are available

as accessories and allow for a display of all settings and measured values. Please contact us for more

information.

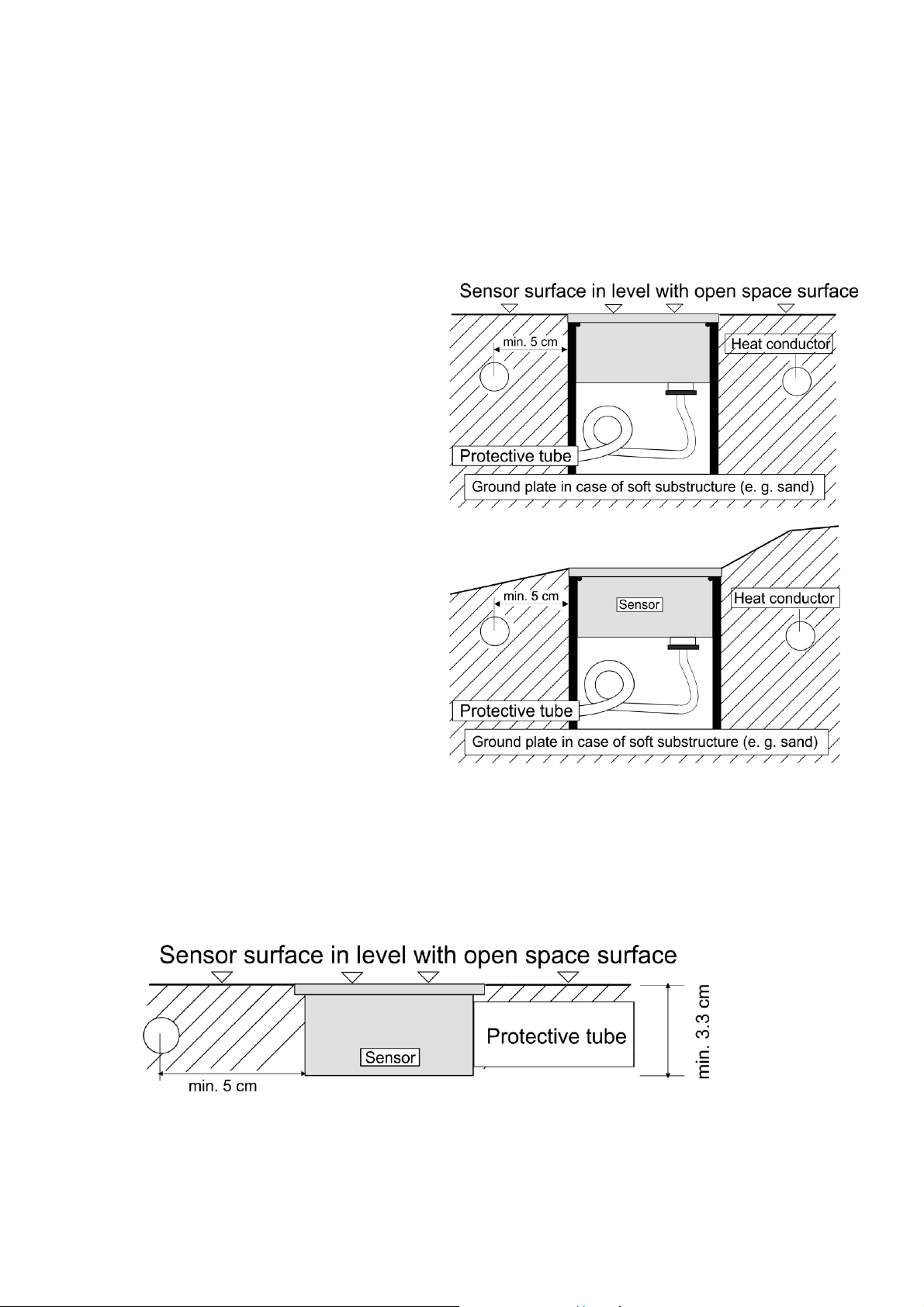

2. Sensor mounting in open areas (sensor type 3352, 3353, 3355 or 3356)

The sensors designed for use in open areas used by vehicles and pedestrians are cast in a body in brass GMs63. The sensors have a fixed supply line. For type 3352 it is fed into the sensor body from the bottom and for

type 3353 from the side. For types 3355 und 3356 the supply line can be variably fed into the body.

The sensors type 3352, 3355 and 3356 may be installed in a ground socket. When the open area is built, this

ground socket is placed into the surface without the sensor in such a way that there will be an even surface after

installation of the sensor. Refer to the mounting example below for detailled information.

Especially in case of surfaces which need a high processing temperature, such as poured asphalt (> 75 °C), the

fitting of a ground socket should be well provided for. In order to avoid that the ground socket sinks into a soft

surface later (e. g. in a sand bed for stone paving), it is recommended to create a firm footing for the socket (e.

g. by putting a concrete slab underneath it).

Note: A protective tube needs to be used for the sensor supply line. This is beneficial both during a new

installation and in case of a necessary replacement. Depending on the weight and material of the surface either

a plastic pipe or an armoured steel tube DN20 can be used. Make sure that the openings of the empty conduit

and the ground socket are securely closed during the construction of the open area to keep out building

material.

- 3 -

Page 4

When choosing the sensor's installation location, unfavourable circumstances such as aisles, shady areas,

Installation in flat open areas

The sensor needs to be installed inside the area

to be monitored and heated in such a way that

the sensor surface is in level with the surrounding

surface material and the sensor surface remains

free. The sensor must not stick out of the open

area but can rather be a few mm lower so that

draining water is collected.

Installation in open areas with a slope

In case of slopes it needs to be made sure that

the sensor surface lies horizontally in order to

be able to collect snow or melt water.

warm air outlets in underground parking lots etc. need to be avoided. The sensor should be installed in a place

where the critical criteria "moisture and low temperature” causing the formation of ice are most likely to occur

first.

To make sure that the ice and snow detection system works properly, take care that the minimum

heating time is long enough so that melt water can moisten the sensor.

The sensor location must be chosen in such a way that the draining melt water runs onto the sensor's

measuring surface. This ensures that moisture is detected as long as there is any.

Installation in open areas with minimum construction height

The type 3353 sensor, which has a supply line at the side of the sensor case, or the type 3355 and 3356

sensors with a variable supply line location are particularly suited to open areas with a low construction height.

Take care not to damage the sensor when constructing the surface, e. g. by an excessive processing

temperature (>75 °C) or by mechanical load due to the use of compactors. Use a suitable protective tube (DN20

in plastic or armoured steel) to ease installation and protect the supply line.

- 4 -

Page 5

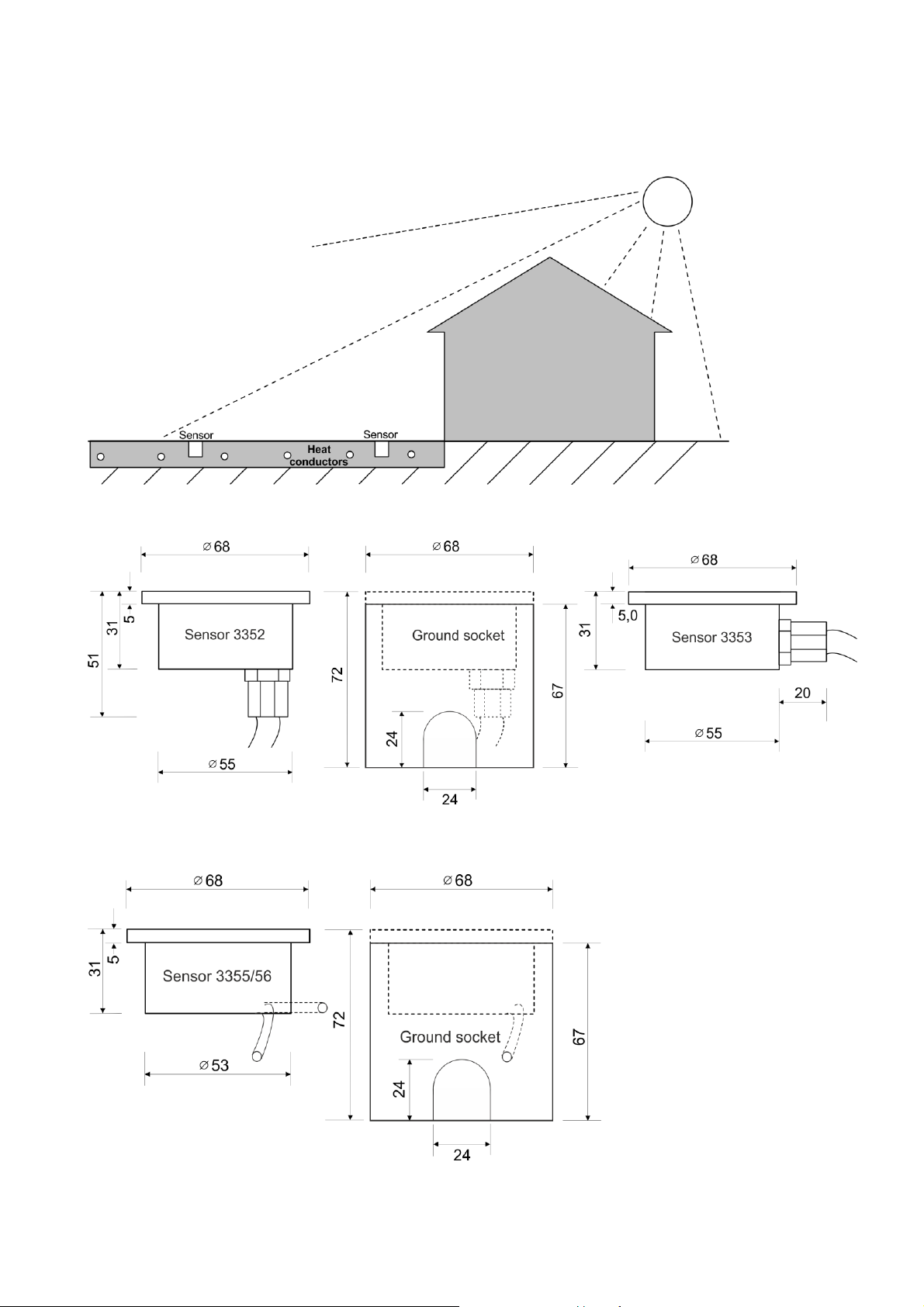

Installation example with two sensors

Two sensors can be connected to the snow and ice detector. In this way it is possible to optimally monitor large

or separated open areas, which may have different local conditions (such as sun in the southern part of the area

and shadow in the northern part or due to shading by a roof as in the illustration below).

Dimensions: Type 3352 and 3353 sensors [mm]

Dimensions: Type 3355 and 3356 sensors [mm]

- 5 -

Page 6

Technical data: Types 3352, 3353, 3355, 3356

3

1

2

5

1

4

2

6

Supply line: SL-Y11Y, length 6 m, 20 m, 50 m

resistant to microbes and oil according to DIN VDE 0472/9.21 para. 8036

Degree of protection: IP 68

Temperature resistance: –30 ...+75 °C

Sensor 3352/3353 Sensor 3355 Sensor 3356

Length of supply lines

The total length of the type SL-Y11Y supply line must not exceed 50 m. Provided that the clamping point

between the standard supply line and the extension is absolutely watertight and contact secure, the standard

supply lines may be extended by 6 m or 20 m up to the total length listed in the following overview. In order to

ensure operational safety, it is recommended to use a line extension only inside a building where it is dry.

Starting from the standard supply lines of 6 m or 20 m the total line length is as follows:

Standard line 6 m + Extension in 1.0 mm² (44 m) = Total length 50 m

Standard line 6 m + Extension in 1.5 mm² (66 m) = Total length 72 m

Standard line 6 m + Extension in 2.5 mm² (110 m) = Total length 116 m

Standard line 6 m + Extension in 4.0 mm² (176 m) = Total length 182 m

Standard line 20 m + Extension in 1.0 mm² (30 m) = Total length 50 m

Standard line 20 m + Extension in 1.5 mm² (45 m) = Total length 65 m

Standard line 20 m + Extension in 2.5 mm² (75 m) = Total length 95 m

Standard line 20 m + Extension in 4.0 mm² (120 m) = Total length 140 m

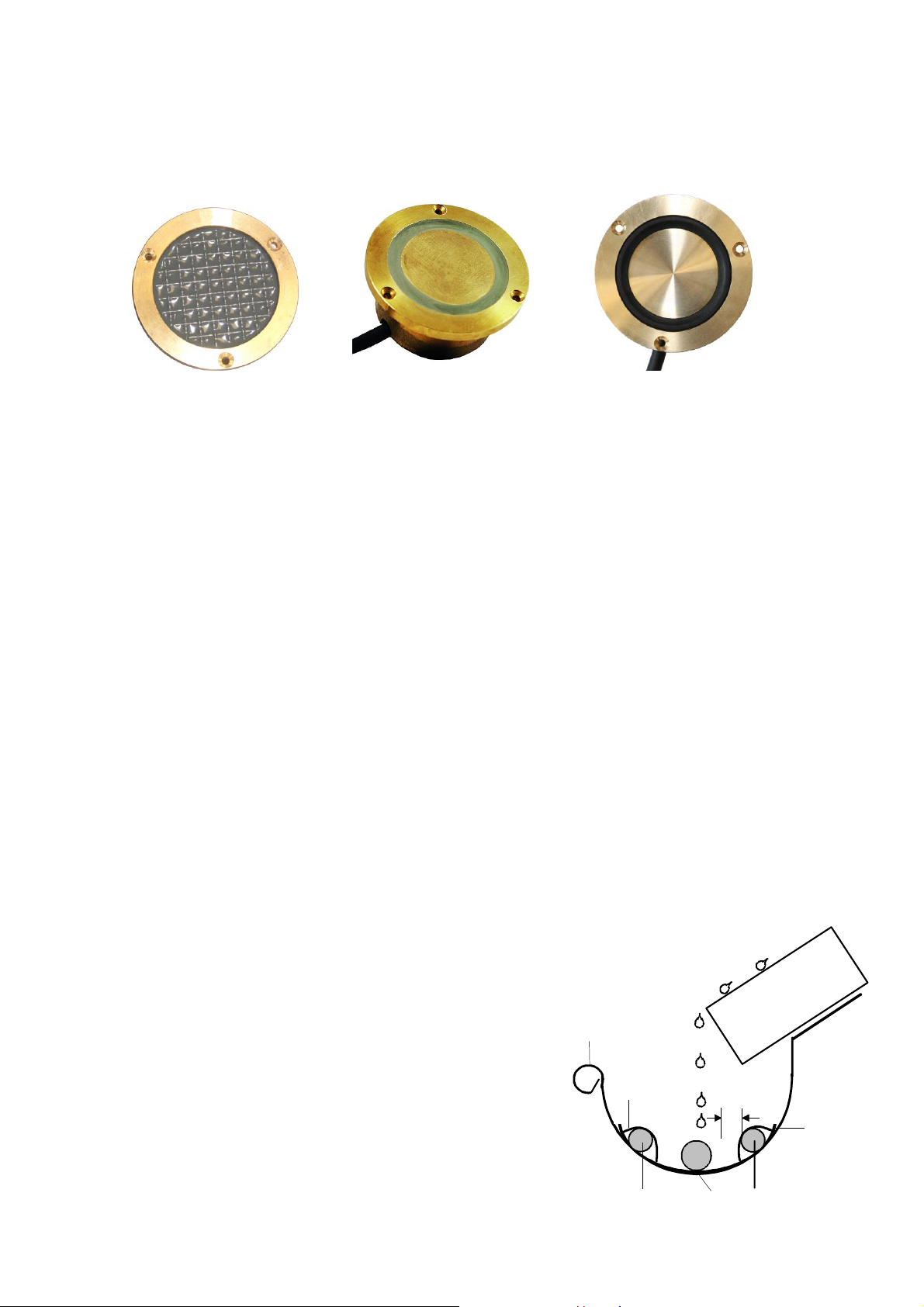

3. Sensor mounting in gutters, on rooftops and on satellite systems

(sensor type 3354)

The sensor must be installed in such a way that draining melt water runs off across the sensor. This ensures

that moisture is detected, if there is any.

In case the sensor is installed in a gutter or on a flat rooftop, it should be located as close as possible to the

downpipe or the drain In case it is used in connection with a parabolic aerial, the sensor should be placed

horizontally below the drip edge.

Installation position in the gutter

Explanation of the graphic:

1 cable tie for fastening the heat conductors

2 heat conductor

3 sensor 3354

4 distance of sensor and heat conductor minimum 2.0 cm

5 gutter

6 protruding roof surface

- 6 -

Page 7

Installation location in the gutter

The sensor has to be installed below the drip edge

and close to the downpipe in such a way that melt

water drips on the sensor. The heating cables, which

are also installed in the lower part of the roof surface

in the example on the right, ensure that a sufficient

area inside and above the gutter are kept free from

snow and ice. In this way the melt water can run off.

Installation location in case of satellite

systems

The sensor is fixed to the lower edge of the satellite

dish in order to detect melt water until the dish is free

from snow and ice. The heat conductors are fixed to

the back side of the dish and switched on until the

snow or ice in the dish are completely melted.

Fasten the sensor only with the supplied

fastening material (plastic)!

Dimensions: Type 3354 sensor [mm]

Side view (cross section)

Technical data: Type 3354

Supply line: SL-Y11Y, 6 m, 20 m, 50 m

resistant to microbes and oil according to DIN VDE 0472/9.21 para. 8036

Degree of protection: IP 68

Temperature resistance: –30 ...+75 °C

- 7 -

Page 8

4. Connection diagrams

Note for service cases: The sensors are delivered with a four-wire cable. In existing installations there may be

sensors with a five-wire cable. Note that in this case the black wire is not connected.

Important commissioning note related to wiring

The ice and snow sensors of the T-FE series come with a four-core cable. One pair of wires (colour of wires

either brown and blue or white and white-black) is needed for temperature measurement, the other one (colour

of wires red and red-black) for moisture measurement.

The connection diagrams above show which wire is to be connected to which terminal. To ensure a successful

operation it is essential to follow these instructions strictly.

- 8 -

Page 9

Prior to powering up it is strongly recommended to check the wiring at the sensor terminals of the socket with an

First Sensor

Second Sensor

Resistance

value

Temperature

sensor (see

instructions)

Resistance

value

Temperature

sensor (see

instructions)

Resistance

value

Moisture

sensor (see

instructions)

Resistance

value

Moisture

sensor (see

instructions)

infinite

resistance

(no

connection)

infinite

resistance

(no

connection)

°C

Ohm

°C

Ohm

°C

Ohm

-20

14.626

-8

8.132

+4

4.721

-18

13.211

-6

7.405

+6

4.329

-16

11.958

-4

6.752

+8

3.974

-14

10.839

-2

6.164

+10

3.652

-12

9.838

0

5.634

+12

3.360

-10

8.941

+2

5.155

+14

3.094

Type

Ohm

3351

25 - 40

3352

25 - 40

3353

25 - 40

3354

~ 80

3355

~ 53

3356

~ 72

The sensor cables connected to the T1/T1 und

T2/T2 terminals can be measured with the help

of an ohmmeter.

The table on the left shows the relationship

between sensor temperature and sensor

resistance.

For a fully functional moisture sensor the resistance

value between the two terminals M1/M1 or M2/M2 is:

ohmmeter before plugging the controller into the socket. The expected electrical resistance values can be found

below in the instructions in section "Characteristic values of sensors". With a single sensor connected, perform

the checks shown in the left column of the table, and with two sensors connected perform the checks in both

columns.

Do not connect a wire of a temperature measurement circuit to a terminal of a moisture measurement circuit! Do

not connect both circuits! This may cause the immediate destruction of the sensor and/or the controller. We

strongly recommend to check the wiring before inserting and powering up the controller. A damage of the

sensor or controller as a result of faulty wiring will not be accepted as a case of warranty.

Switching off the heating system

If there is a central switch-off function for the whole heating system, also the power supply of the ice

and snow detector must be included. If this is not the case, there is the danger that a snow and ice

condition is not detected when the heating system is switched on.

Characteristic values of sensors

In order to measure the sensor values, disconnect the ice and snow detector from voltage and remove it

from the socket!

Temperature sensor

Moisture sensor

- 9 -

Page 10

5. Commissioning

Setting the language

When the ice and snow detector is switched on for the first time, you will be asked to set the language for the

menu navigation. This language will be used as the menu language and saved as a factory default setting. The

language can be selected with the help of the '+' and '-' keys. 'SET' saves the setting, 'ESC' discards the change

and postpones it until the detector is switched on the next time.

Sensor and parameter configuration

A type 3354 sensor is preset in the factory default setting; all parameters are set to the usually suitable values.

If a type 3355/3356 sensor (or one of its predecessor types 3351, 3352 or 3353) is used or another sensor

arrangement (two sensors, slab idle temperature operation etc. ) is desired, the sensor type(s) need to be set in

the menu (more information in the chapters below). Additionally the parameters for the switch-on and switch-off

temperatures and the minimum heating time need to be adapted to the desired operating mode.

Setting the moisture limit

The limit for moisture detection is factory set to 50. With the help of a test measurement when the sensor is dry,

it can be determined if this value needs to be adapted. Depending on the requirement for an early or late

detection of moisture, the moisture limit should be set to 10 (early) to 20 (late) units higher than the value

determined during the "dry" test measurement. Note that the power consumption may rise in case of an "early"

setting.

If the heating is activated too early or too late in actual operation, the moisture limit should be corrected

accordingly. It is recommended to change the setting in steps of 5 until the system works in a satisfactory way.

Type 3354 sensor

If the sensor is installed in a gutter or a similar location, the factory default setting usually does not need to be

changed. If necessary, however, a test measurement can be done and the moisture limit can be adapted

accordingly.

Type 3355, 3356 sensor

As the sensor environment and the installation situation may influence moisture detection in case of slab

installations, it is highly recommended to make a dry test measurement up to 30 °C and adapt the moisture limit

according to the requirements (see above).

Type 3352, 3353 sensor

The same applies as for the type 3355/3356 sensor. Please note, however, that a dry test measurement will

only result in reliable values if the ambient temperature is below 5 °C.

Functional test of the sensors

Attention: In case of functional tests with simulated temperatures the following needs to be taken into account:

After a moisture measurement the moisture sensors (due to their functional principle) have inhibit times of

approx. 15 to 25 minutes (depending on the type) before the ambient temperature can be measured and of

approx. 20 to 30 minutes before the moisture can be measured again. The functions of the snow and ice

detector and of the sensors are adapted to this behaviour and to the slab and outdoor temperature which in

reality only change very slowly. If very quick temperature changes are simulated during a functional test or the

detector is reset by switching it off and back on, this may lead to faulty measurements and a temporarily

"unreasonable" reaction of the system.

In order to determine the current moisture value the menu "Sensor test" is used. In this menu the moisture

measurement can be started independently from the whole system and the measured moisture value can be

read. This can be done during a typical switch-on situation (temperature and moisture correspond to a typical

case of moisture) or with the help of a "dry" measurement during which the sensor surface is absolutely dry. In

case the dry measurement is done in the summer, it needs to be taken care that the sensor is protected from

direct sunlight during and at least 30 minutes before the measurement.

Functional test of the heating

The heating may be activated and deactivated manually for test purposes; refer to chapter "Operation, menu

and error codes".

- 10 -

Page 11

6. Display and pushbutton functions

Operating state indicator

The display on the front shows the following operating states:

Green flashing System initialization

Green System in service

Green/red flashing System in service, at least one sensor faulty (alarm active)

Red flashing System not in service (alarm active)

Red System manually switched off

Pushbutton functions

Set:

general function "Select" or "Confirm"

go from home display to main menu

select the currently displayed submenu

select the currently displayed module number

select the currently displayed parameter for modification

save the current setting

" + " or " – ":

general function "Modify"

go to the previous/next menu item

modify the displayed sensor number

modify the displayed setting

activate or deactivate the heating system

" + " and "- " at the same time:

general function "Abort" (ESC)

return to the previous menu

return to the home display from the main menu

abort the current parameter modification without saving

Display symbols

The device communicates with the user with the help of a display with two rows of eight characters each. The

following symbols are used, independent of the current menu selection:

" - " Parameter value is being read

" –x– " Value is (currently) undefined

" –– " Sensor loop impedance too high, e. g. due to open loop

" –– " Sensor loop impedance too low, e.g. due to short circuit

" ... " Secure function; "Yes" needs to be selected in order to start the function

" OK" Secure function successfully completed

"Err" Secure function terminated

"act" Execution of current function still active

Within a display row a parameter which can currently be changed is displayed with a flashing cursor.

Menu operation will be terminated three minutes after the last pushbutton action and the home display will be

shown.

In order to indicate the operating or switching modes, the following symbols are used:

" " Mode = Off

" " Mode = On

" ! " Mode = On, slab being preheated (refer to "Slab idle temperature")

7. Operation, menu and error codes

- 11 -

Page 12

Menu level 1

Explanation

Language --

Presetting of menu language

Home display

Menu level 1

Menu level 2

Menu level 3

Explanation

...°c 0

Active

Slab temperature, Remaining

heating time, Operating state

Basic

Config.

Language

Setting: language version

Sensor n

Typ

Setting: sensor type

Temp Hi

Lim. ..°c

Setting: high temperature limit

HeatTime

min. ...m

Setting: minimum heating time

back

Show

status

State

-----------

Display: operating mode ice and

snow detector

Error

Code x

Display: error code ice and snow

detector

Slab

Heating

Slab

Heat.

Display: heating on/off

Time Mtr

1: .h

Display: counter level operating

hours

Time Mtr

2: .h

Display: counter level operating

hours

Reset

Mtr1

Command: delete counter level 1

RemHeat

Tim ...m

Display: remaining heating time

Slab

T ...°c

Display: slab temperature

Outdoor

T---x-°c

Display: outdoor temperature

Status

Sensor

State S.

-----------

Display: operating mode sensor

Error

Code

Display: error code sensor

Sensor

T. ...°c

Display: sensor temperature

Ambient

T. ...°c

Display: ambient temperature

Direct functions

Manual activation/deactivation of the slab heating

From the home display the heating can be activated by pressing the"+" pushbutton for a least two seconds. The

heating duration corresponds to the minimum heating time. If the heating has already been active, the remaining

heating time will be reset to the minimum heating time.

By pressing the "-" pushbutton from the home display, the heating is switched off, no matter if the heating has

been switched on manually or automatically.

If the device is in the "Off" mode, the "+" and "-" pushbuttons have no effect.

Menu structure

ESC function: If you press the "+" and "–" pushbuttons at the same time, you will go back to the previous

menu from any menu or to the home display from the main menu.

Initial commissioning

Operation

- 12 -

Page 13

Home display

Menu level 1

Menu level 2

Menu level 3

Explanation

Last

Moist. -x

Display: last moisture value

InhibTim

Tmp. ..m

Display: inhibit time for temperature

measurement

InhibTim

MDet. ..m

Display: inhibit time for moisture

measurement

back

back

Test

HeatTime

Test

Command: start/stop for minimum

heating time

Sensor

Test

State S.

---------

Display: sensor state

Sensor

T. ..°c

Display: sensor temperature

InhibTim

MDet ..m

Display: blocking time for

measurement

Start

MDet

Command: start measuring test

Last

Moist. -x

Display: latest measured moisture

value

back

back

Configuration

Operat.

Mode

Setting: operating mode

Temp Hi

Lim. ..°c

Setting: high temperature limit

value

Temp Lo

Lim. ..°c

Setting: low temperature limit value

SlabIdle

Temp ..°c

Setting: slab idle temperature

Moisture

Limit xx

Setting: moisture limit, ice and

snow detectore

HeatTime

min. ...m

Setting: minimum heating time

Config.

Sensor n

Sensor

Typ xxxx

Setting: sensor type

Method

Meas. ----

Setting: measurement method of

sensor

Moisture

Limit -x

Setting: moisture threshold of

sensor

back

Invert

Alarm 0/1

Setting: alarm output

back

Administration

Language

--

Setting: language version

Temp.

Units -

Setting: temperature unit

Factory

Def.

Reset to "factory default settings"

SW-Vers.

--.--

Display of software version

Internal

Status

Display of internal status

back

back

back

- 13 -

Page 14

Menu structure

Display

Explanation

+xx° yyy

zzzzzzzz

xx = effective slab temperature

yyy = remaining minimum heating time (0 if heating according to demand or heating off)

zzzzzzzz = current state of the ice and snow detector

Display

Explanation

Basic

config.

Opens the basic configuration menu

Show status

Opens the menu for the display of the current measured values and states

Test

Opens the menu to start/stop the minimum heating time and to start a sensor measurement

Configu-

ration

Opens the configuration menu for the heating and the sensors

Administra-

tion

Opens the administration menu for the system

Back

Return to Home display

Display

Explanation

Factory

default

Settings

Language

xx

Displays the set menu language; adapt setting with "Set" and then

"+" / "-"; save with "Set".

refer to "Initial

installation"

DE, EN,

FR, IT, NL,

CZ, PL

Sensor 1

Typ xxxx

Displays the setting of the connected sensor type for sensor 1;

adapt setting with "Set" and then "+" / "-"; save with "Set". When

saving the sensor type, the appropriate measurement method of

sensor 1 is set automatically to the method specified for the sensor

and the sensor state is reset automatically.

3354

3351

3352/53,

3354,

3355

3356

----

Temp Hi

Lim. xxx°

Displays the high temperature limit; adapt setting with "Set" and

then "+" / "-"; save with "Set".

+3°C

0° to +5°C

HeatTime

min.xxxm

Displays the set minimum heating time; adapt setting with "Set"

and then "+" / "-"; save with "Set". Can be set in steps of 10.

90 min.

30 to

600 min.

back

Returns to Main menu

Display

Explanation

State

--------

Displays operating state of ice and snow detector

Error

Code xx

Displays the current error code of the ice and snow detector (0 =

no error, refer to "Error codes")

Slab

Heating

Displays switching state of heating and operating hour counter

RemHeat

Tim xxxm

Displays the remaining heating time (0 if heating according to

demand or slab heating off)

Slab

T---,-°

Displays the effective slab temperature

Outdoor-

T---,-°

Displays the latest measured outdoor temperature (measured

value only available in Slab idle temperature mode)

1. Home display

2. Main menu

3. Basic configuration menu

4. Show status menu

- 14 -

Page 15

Status

Sensor n

Opens menu to display sensor n (after the first "Set" select n,

select sensor with "+" / "-" and then press "Set" again)

Back

Returns to Main menu

Display

Explanation

HeatTime

Test x

Displays the switching state of the slab heating; adapt setting with

"Set" and then "+" / "-"; save with "Set".

Select " " to interrupt the heating time, select " " to start again.

Sensor

Test n

Opens the menu for testing sensor n (after the first "Set" select n,

call sensor with "+" / "-" and then press "Set" again)

Back

Returns to Main menu

Display

Explanation

Factory

default

Settings

Operat.

Mode x

Displays the operating mode; adapt setting with "Set" and then "+"

/ "-"; save with "Set";

" " = system out of service,

" " = system in service,

" !" = system in service with additional function "Slab idle

temperature"

" " =

System in

service

" "

" "

" !"

Temp Hi

Lim. xxx°

Displays the high temperature limit; adapt setting with "Set" and

then "+" / "-"; save with "Set".

3°C

0 to 5°C

Temp Lo

Lim. xxx°

Displays the low temperature limit; adapt setting with "Set" and

then "+" / "-"; save with "Set".

-15°C

-20°C to

-5°C

SlabIdle

Temp---°

Displays the targeted slab idle temperature ; adapt setting with

"Set" and then "+" / "-"; save with "Set".

- 5°C

-15 to

+ 5°C

Moisture

limit xx

Displays the set moisture limit ; adapt setting with "Set" and then

"+" / "-"; save with "Set". Can be set in steps of 5.

5 = very sensitive sensor, little moisture required to trigger heating

(might cause continuous)

95 = very insensitive sensor; sensor must be immersed in water to

detect moisture (might cause no moisture detection at all)

50

5 to 95

HeatTime

min.xxxm

Displays the set minimum heating time ; adapt setting with "Set"

and then "+" / "-"; save with "Set". Can be set in steps of 10.

90 min.

30 to 600

min.

Config.

Sensor n

Opens the menu to configure sensor n (after the first "Set" select n,

call sensor with "+" / "-" and then press "Set" again)

1

1 or 2

Invert

Alarm

Invert alarm output

0

0 normal

1 invert.

Back

Returns to Main menu

Display

Explanation

Factory

default

Settings

Language

xx

Displays the set menu language; adapt setting with "Set" and

then "+" / "-"; save with "Set".

refer to "Initial

installation"

DE, EN,

FR, IT, NL,

CZ,PL

Temp

Units X

Displays the set temperature unit; adapt setting with "Set" and

then "+" / "-"; save with "Set".

°C

°C or °F

Factory

Def. ...

Restores all parameters to factory default settings. Adapt

setting with "Set" and then "+" / "-". After selecting "Yes" and

5. Test menu

6. Configuration menu

7. Administration menu

- 15 -

Page 16

setting with "Set" there will be a security prompt and after

confirming with "+" an acknowledgement will be displayed (OK).

SW-Vers.

Displays the software version

Internal

Status

Information only for the manufacturer

Back

Returns to Main menu

Display

Explanation

Slab Heat.

--------

Operating state of the slab heating (On/Off)

Time Mtr 1

Operating hour counter for heating 1, can be reset

Time Mtr 2

Operating hour counter for heating 2, cannot be reset

Reset Mtr 1

Reset counter 1 and start counter again from 0

Display

Explanation

State S.

--------

Displays operating state of selected sensor

Sensor

T.xxx,x°

Displays current temperature of selected sensor

InhibTim

MDet xxm

Displays remaining time before the next moisture detection cycle can begin

Start

MDet ...

Starts moisture detection for the selected sensor. Adapt setting with "Set" and then "+" / "". After selecting "Yes" and setting with "Set" an acknowledgement will be displayed (OK).

Only possible if measuring method "F" or "T+M" are set and no moisture measurement is

ongoing for another sensor. The inhibit time until the next measurement is interrupted

when this command is given. .

Last

Moist. xx

Displays the last measured moisture value of the selected sensor

back

Returns to Test menu

Display

Explanation

Factory

default

Settings

Sensor

Typ xxxx

Displays the setting of the connected sensor type for the selected

sensor; adapt setting with "Set" and then "+" / "-"; save with "Set".

When saving the sensor type, the appropriate measurement method

of the selected sensor is set automatically to the method specified for

the sensor and the sensor state is reset automatically.

3354

3351,

3352/53,

3354,

3355,

3356

31xx,

---

Method

Meas. xxx

Displays the setting of the measurement method for the selected

sensor; adapt setting with "Set" and then "+" / "-"; save with "Set".

"OFF" = sensor not in service,

" T " = only temperature,

" M " = only moisture,

"T+M" = temperature and moisture

The measurement methods "M" and "T+M" are not available for

temperature-only sensors (depending on the set sensor type). When

saving the measurement method, the sensor state is reset

automatically.

T+M

T+M,

T,

M,

Off

8. Status of slab heating

9. Sensor test

10. Sensor configuration

- 16 -

Page 17

Moisture

limit xx

Displays the set moisture limit for the selected sensor; adapt setting

with "Set" and then "+" / "-"; save with "Set".

Setting "-x" = the moisture limit set in the "Configuration" menu will be

used.

-X

-X to 95

back

Returns to Configuration menu

Error code

Description

Possible cause

1

Slab/gutter temperature cannot be determined;

all active temperature sensors report

temperature measurement failure.

• see sensor error code 1 (slab/gutter sensors

only)

• internal detector failure

2

Outdoor temperature required but not available

(slab idle mode only);

outdoor temperature sensor reports

temperature measurement failure.

• see sensor error code 1 (outdoor temperature

sensor only)

• internal detector failure

4

Moisture cannot be determined;

all active moisture sensors report temperature

measurement and/or moisture detection failure.

• see sensor error codes 2 or 4 respectively

• temperature loop of affected sensor faulty

• internal detector failure

8

Configuration problem

• no sensor defined for temperature

measurement

• no sensor defined for moisture detection

• slab idle mode enabled but no valid sensor

defined for outdoor temperature measurement

Error code

Description

Possible cause

1

Temperature sensor faulty

• temperature detector inside the sensor faulty

• internal detector failure

• open loop or short circuit in sensor cable

2

Supply voltage prior to start of the last

moisture detection cycle not within the defined

voltage range; detection cycle was not started.

• detector supply voltage more than + 10 %

above rated voltage

• detector supply voltage more than - 15 %

below rated voltage

• internal detector failure

4

Last moisture measurement faulty

• supply voltage too low during last moisture

detection cycle

• open loop or short circuit in sensor cable

• moisture detector inside the sensor faulty

• internal detector failure

8

Internal failure during last moisture

measurement

• configuration problem

• internal detector failure

16

Internal failure during interval between two

moisture detection cycles

• current > 25 mA although no detection cycle

is active on any sensor

• internal detector failure

32

Measurement is not executed because

measurement values are not meaningful or in

order to avoid damage to the sensor.

• temperature too high (> 30 °C) when

measurement cycle begins

64

Measurement is aborted to avoid damage to

the sensor.

• temperature too high (> 55 °C) during the

measurement

Error codes

In case of a failure, the menu "Show Status” will display an error code for the detector or the sensor(s). The

value "0” indicates that currently there is no error. The error codes are explained in the following tables. If more

than one error condition is active at any one time the display will show the sum of the related error codes (e. g.

error 1 and error 4 active at the same time will cause an error code 5 to be displayed).

a) Ice and snow detector

Note: As long as a single sensor failure does not cause the entire ice and snow detection system to fail, this will

not be shown as a system error in one of the above error codes. In this case please check the error codes of the

individual sensors.

b) Sensors

- 17 -

Page 18

Note: The sensor error codes 2, 4 and 8 will only be set during a moisture detection cycle and will remain visible

at least until the completion of the next moisture detection cycle of the affected sensor. This is even the case if

no more moisture detection cycles are started because the slab/gutter temperature is outside the active

temperature window. To reset the error code after fixing the problem, start a test measurement from the test

menu (menu "Test/Sensor X").

- 18 -

Page 19

Rated voltage

230 V~ ± 6%, 50 Hz

Power consumption

approx. 10 VA

Type of moisture sensor

tekmar 3354, 3355, 3356 (also predecessors 3351, 3352 and 3353)

Type of temperature sensor

tekmar Series 31

Number of sensors

1 or 2

Heating output

low-voltage relay, switching capacity max. 6 A, 250 V~

Alarm output

SELV 24 V= 20%, load capacity 15 mA, short-circuit protected

Ambient temperature

0 to +50 °C, no condensation; sensor –30...+75 °C

Storage temperature

-10 to +60 °C, no condensation; sensor –30...+75 °C

Degree of protection

IP 20; sensor IP 68 (according to EN 60529)

Class of protection

II according to DIN 57700, when installed in distribution cabinet

Pollution degree

2 (normal)

Space required

6 HP according to DIN 43880

Mounting

on mounting rail 35 mm according to DIN EN 60715

Weight

approx. 0,4 kg

Standards

DIN EN 60730-1, DIN EN 730-2-9

Heat and fire resistance

category D

Ball pressure test

+ 125 °C

Rated surge voltage

4 kV

Action type

type 1B

Rated power and load for EMC

emission test

230 V~, load 0,5 A

8. Technical data, safety instructions

Dimensions [mm]

Safety and functional instructions

Only qualified specialists may install the devices. The relevant VDE regulations must be observed. According to

VDE guideline 0100 cables carrying low voltage must be routed separately, away from cables carrying safety

extra low voltage. In case an inductive load (for example a contactor) is connected, it is possible that additional

measures to elimintate EMC interference must be taken during installation.

Many electronic devices may cause interference which may cause errors in other devices despite all technical

precautions. If the snow and ice detector is affected by such an error and does not react at all or faultily,

switching the power supply on and off often solves the problem. The device can also be reset by switching the

upstream circuit breaker off for approximately 10 seconds. In most cases the device functions without problems

after the reset. If this is not the case, contact the tekmar Service.

- 19 -

Page 20

Notes

0716

tekmar Regelsysteme GmbH Tel +49 201 48611-0 mail@tekmar.de

Möllneyer Ufer 17 Fax +49 201 48611-11 www.tekmar.de

D-45257 Essen

© Copyright tekmar Regelsysteme GmbH 2017, subject to change

- 20 -

Loading...

Loading...