Page 1

- Data Brochure

•

•

•

•

•

•

•

•

•

•

•

•

•

tekmarNet®4 Setpoint Control 162

D 162

08/07

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Rough In

Rough-in

instructions

Wiring

wiring

4

Wiring

Brochure

Wiring and

installation of

specific control

5

Data

Brochure

Control settings

and sequence of

operation

6

Job

Record

Record settings &

wiring details for

future reference

Introduction

The Setpoint Control 162 is a single stage heat or cool setpoint control that can operate on an On / Off differential or can

operate on Pulse Width Modulation. The control includes a second relay contact to operate a system pump. The control

includes special modes for hot tub, indirect domestic hot water tank, radiant floor, and pool applications.

Features

• tN4 Compatible

• On / Off Differential

• Pulse Width Modulation

• System Pump

• Hot Tub Operation

• DHW Tank Operation

• Floor Operation

• Pool Operation

• Exercising

• Scenes

• Temperature Sensor Input

• Programmable Setback Scheduling

• One Stage Heat or Cool

1 of 32 © 2007 D 162 - 08/07

Page 2

Table of Contents

•

•

24 V ±10% 50/60 H

24 V (ac) 2 A

Power:

Relays:

/

•

•

Table of Contents ............................................................2

Display and DIP Switches ..............................................2

Dip Switches ...........................................................2

Access Levels .........................................................3

Display and Symbol Description .............................3

User Interface .........................................................4

Application Overview ......................................................5

On / Off Differential .................................................5

Pulse Width Modulation ..........................................6

Display Menus ................................................................7

VIEW Menu ............................................................7

ADJUST Menu ........................................................9

TIME Menu ........................................................... 15

SCENE Menu .......................................................16

SCHEDULE Menu ................................................ 17

MISCELLANEOUS Menu .................................... 19

Sequence of Operation ................................................20

Mode 1 - On / Off Setpoint ....................................20

Mode 2 - Hot Tub ..................................................20

Mode 3 - DHW Tank .............................................21

Mode 4 - PWM Setpoint .......................................21

Mode 5 - Floor ......................................................22

Mode 6 - Pool .......................................................22

Cycle Length ................................................................23

Relay Minimum On and Off Time .................................23

Remote Enable / Disable ..............................................23

Sensor Input ................................................................. 24

Time Clock ................................................................... 24

Setting the Schedule ....................................................24

Scenes ..........................................................................25

Away Hold ....................................................................26

Restore Factory Defaults ..............................................27

Temperature Units ........................................................26

Backlight ......................................................................26

tN4 Features ................................................................26

Error Messages ............................................................29

Cleaning the Control ....................................................32

Warranty .......................................................................32

Display and DIP Switches

DIP Switches

Lock / Unlock (DIP Switch #1)

Use the Lock / Unlock DIP switch to lock or unlock the

Access Level of the 162.

• To unlock the Access Level, set the DIP switch to the

unlocked (left) position.

• To lock the Access Level, set the DIP switch to the locked

(right) position. Once locked, a padlock is displayed in

the lower right corner of the display and the Access

Level cannot be changed.

Note: The tN4 System Control’s Lock / Unlock DIP switch

overrides the Lock / Unlock DIP switch on the 162. Set

the tN4 System Control’s Lock / Unlock DIP switch to the

Unlock position before Access Levels can be changed on

the setpoint control.

tN4 System Control (DIP Switch #2)

A tN4 System Control is a control, not a thermostat, that

the Setpoint Control 162 connects to through the tN4

bus. All tN4 compatible Outdoor Reset Modules are tN4

System Controls.

• If the thermostat is connected to a tN4 System Control,

set the tN4 System Control DIP switch to tN4 System

Control (left position).

• If the thermostat is not connected to a tN4 System

Control, set the tN4 System Control DIP switch to None

(right position).

For product instructions see brochure

Use at least 194°F (90°C) conductors

tN4 Setpoint Control 162

One Stage Heat / Cool

24 V ±10% 50/60 Hz 2.2 VA

Power:

24 V (ac) 2 A

Relays:

/

Cut jumper to

isolate relay

Feb 2006

Lot 1948

Meets Class B:

Canadian ICES

FCC Part 15

© 2007 D 162 - 08/07 2 of 32

Page 3

Access Levels

•

•

•

•

•

The Access Level restricts the number of Menus, Items

and Adjustments that can be accessed by the user. The

Access Level setting is found in the Miscellaneous (MISC)

menu. Select the appropriate access level for the people

who work with the setpoint control on a regular basis.

The 162 has five Access Levels:

• Advanced (ADV): access to all settings

• Installer (InST): settings required for installation

• User (USER): for property owners

• Limited (LTD): limited temperature adjustment

• Secure (SEC): for commercial and public installations

In the Limited access level, the temperature can only be

adjusted by +/-3°F (1.5°C) from the temperature setting

entered prior to entering the Limited access level.

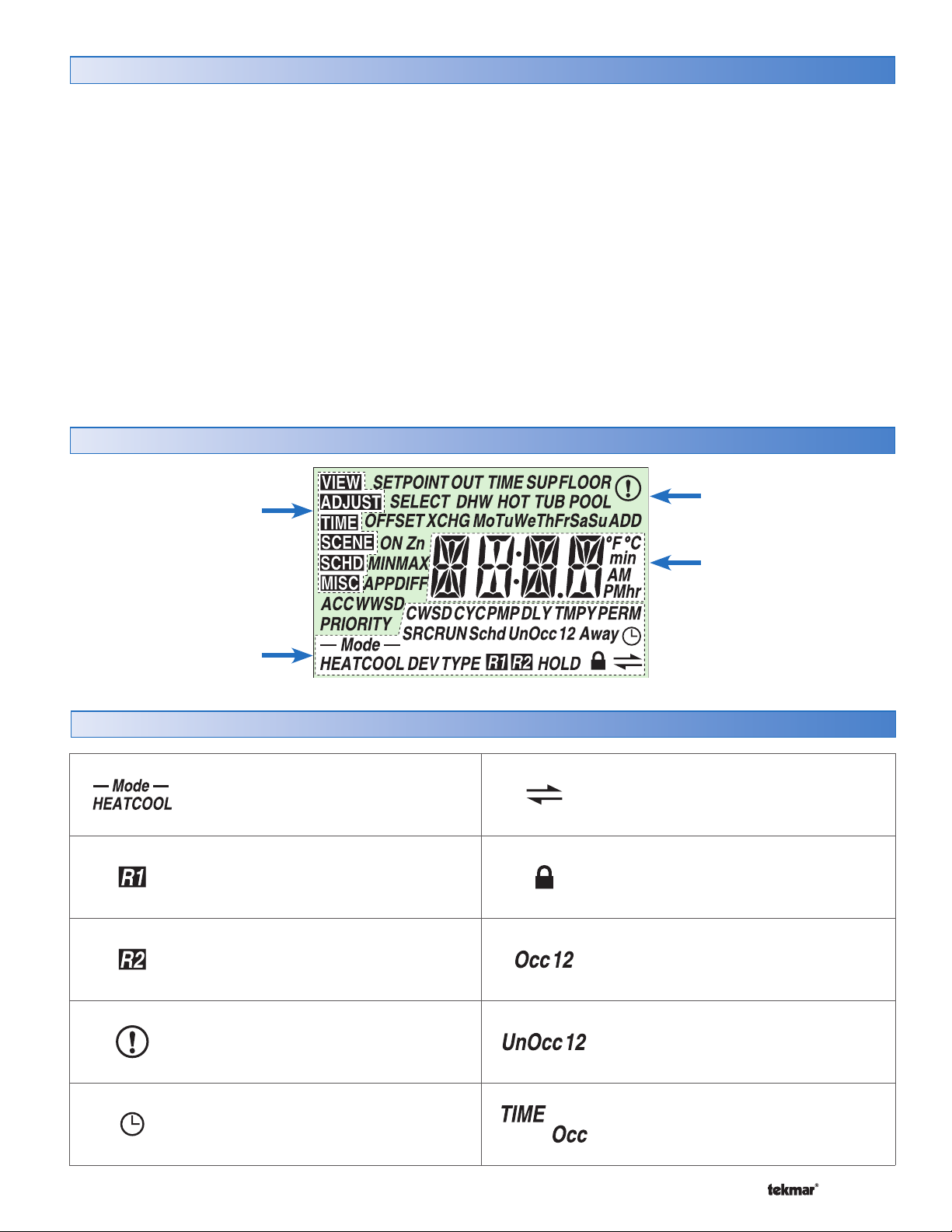

Display

Menu Field

Displays the

current menu

In the Secure access level, all settings, including the

temperature, cannot be changed.

For more information, see the Miscellaneous (MISC) Menu

section.

In the following menu tables, the access level the item is

visible in is shown in the access column.

To adjust the Access Level:

1. Set the Unlock / Lock DIP switch to the unlock position.

If a tN4 System Control is connected to the 162, the

Unlock / Lock DIP switch on the tN4 System Control

must be set to the unlock position.

2. Use the Menu button to select the MISC menu.

3. Use the Item button to select the Access item.

4. Use the Up and Down button to select the required

Access Level.

Item Field

Displays an abbreviated

name of the selected item

Status Field

Displays the current status

of the control’s inputs,

outputs and operation

Symbol Description

MODE OF OPERATION

Displays whether the device is in heating,

cooling or off mode.

RELAY 1

Displays when relay contact 1 is

closed.

RELAY 2

Displays when relay contact 2 is

closed.

Number Field

Displays the current value

of the selected item

tN4 COMMUNICATION

A tN4 network is detected.

LOCK

The Access Levels are locked or a menu

option is visible but not adjustable.

OCCUPIED

Displays when operating at the occupied

temperature.

WARNING

An error is present.

SCHEDULE MASTER

Indicates that the control is a schedule

master.

3 of 32 © 2007 D 162 - 08/07

UNOCCUPIED

Displays when operating at the unoccupied

setback temperature.

TIME OCCUPIED

Displays when operating temporarily at

the occupied temperature due to a remote

enable or manual enable.

Page 4

•

•

•

•

•

•

User Interface

•

•

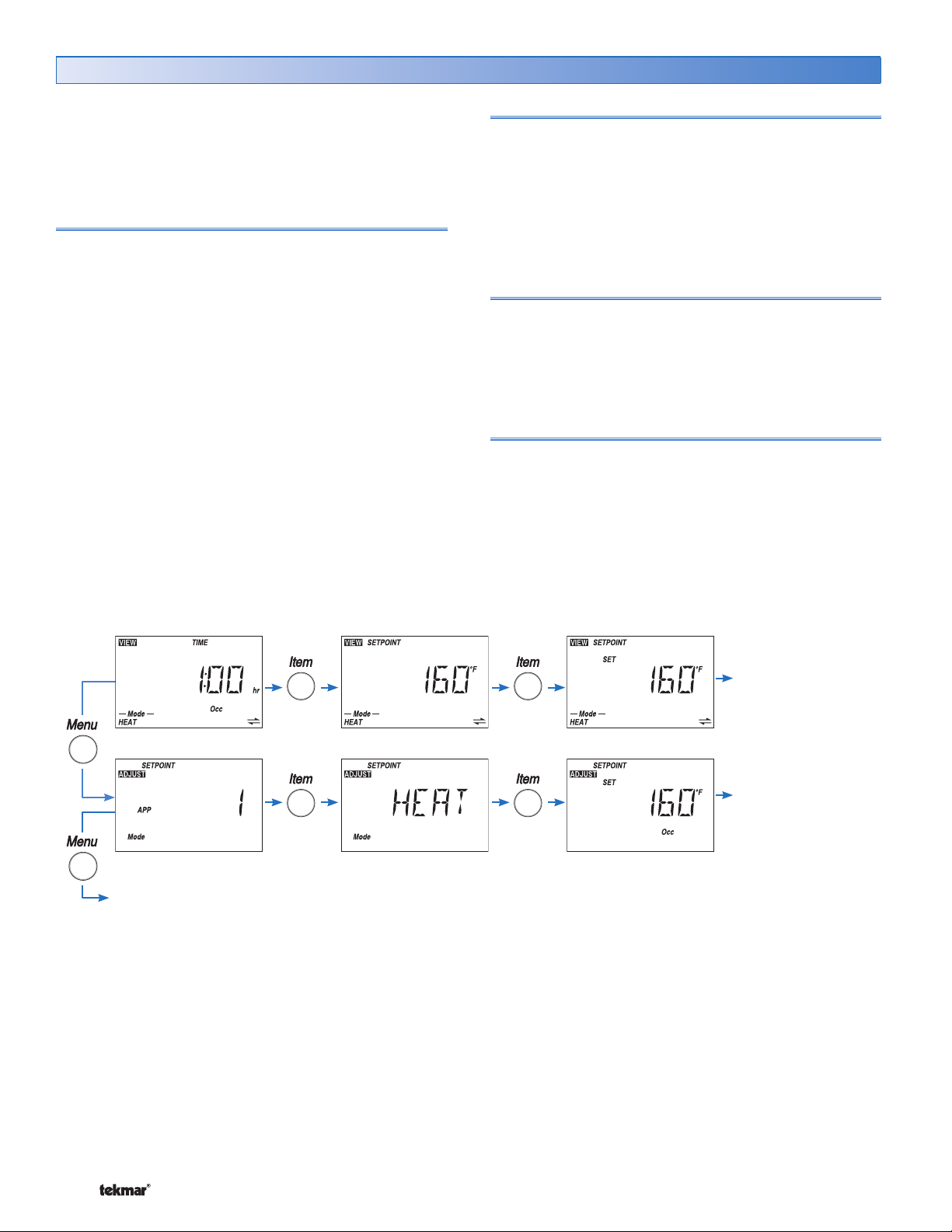

Use the User Interface available on the Liquid Crystal

Display (LCD) to setup and monitor the operation of the

setpoint control. Use the four push buttons below the LCD

(Menu, Item, Up, Down) to select settings. As the settings

are entered, record the settings in the Job Record J 162.

Menu

The menus display in the Menu Field at the left of the

LCD.

Up to 6 menus are available:

• VIEW

• ADJUST

• TIME

• SCENE

• SCHD (Schedule)

• MISC (Miscellaneous)

To select a menu, press and release the Menu button.

Item

In each menu, a group of items can be selected. The

abbreviated name of the selected item displays in the Item

field of the LCD display.

• To view the next available item, press and release the

Item button.

• To view the previous item, hold down the Item button

and press and release the Up button.

Adjusting a Setting

To adjust a setting:

1. Use the Menu button to select the appropriate menu.

2. Use the Item button to select a menu item.

3. Use the Up or Down button to adjust the setting.

Default Item

To set the default item in the VIEW Menu, display item for

more than five seconds.

After navigating menus, the display reverts back to the

default item after 60 seconds of button inactivity.

The Time can also be made the default item.

Continue to next Menu

Continue to next Item

Continue to next Item

© 2007 D 162 - 08/07 4 of 32

Page 5

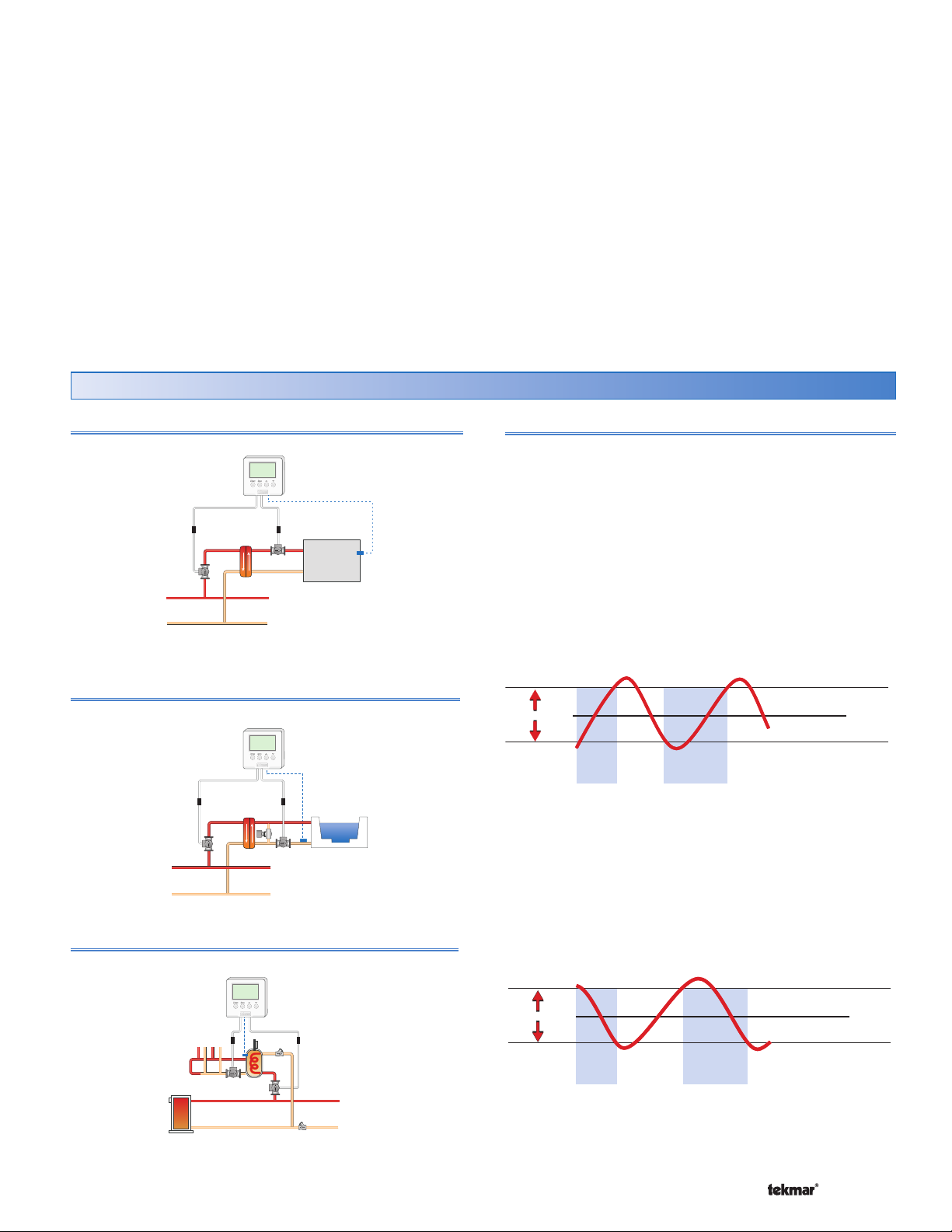

Application Overview

The Setpoint Control 162 is designed to support six different

applications. The items shown in the VIEW and ADJUST

Menu change depending on the Application Mode.

Set the application mode as follows:

1) On / Off Setpoint

2) Hot Tub

3) Indirect DHW Tank

4) PWM Setpoint

5) Floor

6) Pool

Applications: On / Off Differential

Mode 1 Setpoint (On / Off)

Load

The VIEW and ADJUST menus list which of the six application

items are visible based upon the mode column.

The TIME, SCHD (Schedule) and MISC (Miscellaneous)

menus are the same for the six application modes.

Relay 1 On / Off Differential Operation

The On / Off Differential operates by centering a differential

range around the target setpoint temperature. On / Off

differentials are best suited to heating or cooling loads

that quickly change temperature.

Heating Operation

When heating, the setpoint control turns on Relay 1 when

the temperature falls to 1/2 of the differential below the

setpoint and turns off Relay 1 once the temperature reaches

1/2 of the differential above the setpoint.

Mode 2 Hot Tub

Mode 3 DHW Tank

Heating On / Off Differential

Target + ½ Differential

Differential

Relay 1

On

Target – ½ Differential

Relay 1

On

Tar get

Cooling Operation

When cooling, the setpoint control turns on Relay 1 when

the temperature rises to 1/2 of the differential above the

setpoint and turns off Relay 1 once the temperature falls

1/2 of the differential below the setpoint.

Cooling On / Off Differential

Target + ½ Differential

Differential

Relay 1

On

Target – ½ Differential

Relay 1

On

Tar get

5 of 32 © 2007 D 162 - 08/07

Page 6

Applications: Pulse Width Modulation

S

e

t

p

o

i

n

t

S

e

t

p

o

i

n

t

Mode 4 Setpoint (PWM)

Mode 5 Floor

Load

Relay 1 Pulse Width Modulation (PWM) Operation

PWM operates by centering the throttling range around

the target setpoint temperature. PWM is best suited for

large heating or cooling loads that do not change rapidly

in temperature. The Differential setting in the ADJUST

menu changes the throttling range while in Application

Mode 4 (Setpoint). The throttling range is not adjustable

in Application Modes 5 (Floor) or 6 (Pool).

Heating Operation

When the temperature is at the setpoint, Relay 1 is on

for 50% of a cycle and off for 50% of a cycle. When the

temperature is 1/2 of the throttling range below the setpoint,

Relay 1 is on for 100% of a cycle. When the temperature is

1/2 of the throttling range above the setpoint, Relay 1 is off

for 100% of a cycle. For ranges within the throttling range,

Relay 1’s on time increases linearly as temperature falls.

Heating PWM Operation

Set Heat

Warmer

Heat

Relay 1

On

Relay 1

On

Relay 1

On

Cycle Length

Mode 6 Pool

Cooling Operation

When the temperature is at the setpoint, Relay 1 is on

for 50% of a cycle and off for 50% of a cycle. When

the temperature is 1/2 of the throttling range below the

setpoint, Relay 1 is off for 100% of a cycle. When the

temperature is 1/2 of the throttling range above the

setpoint, Relay 1 is on for 100% of a cycle. For ranges

within the throttling range, Relay 1’s on time increases

linearly as temperature rises.

Cooling PWM Operation

Set Heat

Cool

Relay 1

On

Relay 1

On

Relay 1

On

Cycle Length

Cooler

© 2007 D 162 - 08/07 6 of 32

Page 7

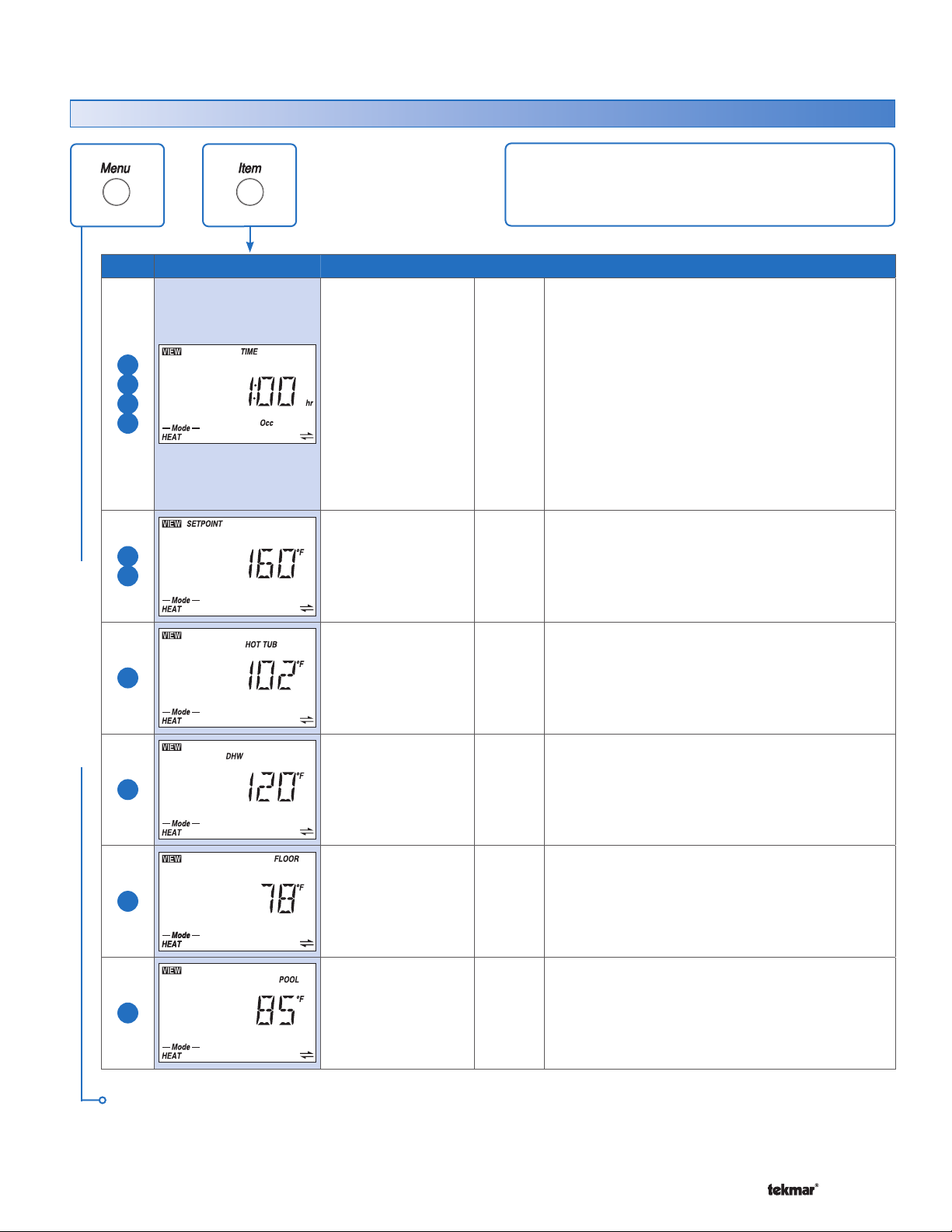

Display Menus

VIEW Menu (1 of 2)

The VIEW menu items display the current operating

temperatures and status information of the system.

Mode Item Field Range Access Description

OCCUPIED TIME SECTION B, E, I

Displays the amount of time left on the manual

override. The setpoint device operates at the

Occupied temperature and then reverts back

1

2

4

5

0:01 to 24:00 hr

LTD

USEr

InST

ADV

Scheduled temperature. Time counts down to

0:00 hours.

Cancel the override by pressing the Up and Down

buttons together at the same time or through the

user switch or gateway.

Note: This item is only available when a

programmable setback schedule or normally

unoccupied has been selected.

1

4

2

VIEW MENU

3

5

6

-31 to 266°F

(-35.0 to 130.0°C)

-31 to 266°F

(-35.0 to 130.0°C)

-31 to 266°F

(-35.0 to 130.0°C)

-31 to 266°F

(-35.0 to 130.0°C)

-31 to 266°F

(-35.0 to 130.0°C)

SEC

LTD

USEr

InST

ADV

SEC

LTD

USEr

InST

ADV

SEC

LTD

USEr

InST

ADV

SEC

LTD

USEr

InST

ADV

SEC

LTD

USEr

InST

ADV

SETPOINT SECTION A, D

Displays the measured setpoint sensor

temperature.

HOT TUB SECTION B

Displays the measured hot tub temperature.

DHW TANK SECTION C

Displays the measured indirect domestic hot

water tank temperature.

FLOOR SECTION E

Displays the measured floor temperature.

POOL SECTION F

Displays the measured pool temperature.

Continued on next page.

7 of 32 © 2007 D 162 - 08/07

Page 8

VIEW Menu (2 of 2)

Mode Item Field Range Access Description

OFF, -4°F (-20.0°C)

1

2

3

4

to Setpoint Maximum

(variable)

OFF, -4°F (-20.0°C)

to Hot Tub Maximum

(variable)

OFF, -4°F (-20.0°C)

to DHW Maximum

(variable)

OFF, -4°F (-20.0°C)

to Setpoint Maximum

(variable)

USEr

InST

ADV

USEr

InST

ADV

USEr

InST

ADV

USEr

InST

ADV

SET SETPOINT (ON / OFF) SECTION A

Display the desired temperature.

SET HOT TUB SECTION B

Display the desired temperature.

SET DHW SECTION C

Display the desired temperature.

SET SETPOINT (PWM) SECTION D

Display the desired temperature.

5

VIEW MENU

6

1

2

3

4

5

6

1

2

3

4

5

6

OFF, -4°F (-20.0°C)

to Floor Maximum

(variable)

OFF, -4°F (-20.0°C)

to Pool Maximum

(variable)

-31 to 266°F

(-35.0 to 130.0°C)

-31 to 266°F

(-35.0 to 130.0°C)

USEr

InST

ADV

USEr

InST

ADV

SEC

LTD

USEr

InST

ADV

InST

ADV

SET FLOOR SECTION E

Display the desired temperature.

SET POOL SECTION F

Display the desired temperature.

OUTDOOR SECTION R

Displays the measured outdoor temperature.

Note: This item is only available when the setpoint

control is connected to a tN4 bus and the Outdoor

item in the ADJUST menu is set to On.

SUPPLY TEMP OF tN4 BUS SECTION R

Actual water temperature of the tN4 bus for

heating.

Note: This item is only available when the

setpoint control is connected to a tN4 System

Control, DIP switch 2 is set to tN4 System

Control, and the Heat Source item in the ADJUST

menu is set to hydronic (HYDr).

After the last item, the control returns to the first item in the menu.

© 2007 D 162 - 08/07 8 of 32

Page 9

ADJUST Menu (1 of 6)

The ADJUST Menu items are the programmable

settings used to operate the mechanical equipment.

Mode Item Field Range Access Description

APPLICATION MODE

1

2

3

4

5

6

1, 2, 3, 4, 5, 6

Default = 1

InST

ADV

Select the application for the setpoint control.

1 = On / OFF Setpoint (Heat and Cool)

2 = Hot Tub (Heat only)

3 = DHW Tank (Heat only)

4 = PWM Setpoint (Heat and Cool)

5 = Floor (Heat only)

6 = Pool (Heat only)

SECTION A - F

1

4

2

6

1

4

ADJUST MENU

1

4

COOL, HEAT

Default = HEAT

HEAT, OFF

Default = HEAT

OFF, -4°F (-20°C)

to Setpoint

Maximum

Default = 160°F

(71.0°C)

OFF, -4°F (-20°C)

to Setpoint

Maximum

Default = OFF

InST

ADV

USEr

InST

ADV

LTD

USEr

InST

ADV

USEr

InST

ADV

MODE OF OPERATION SECTION A, D

Select the mode of operation of the setpoint

control. Choose between Heat or Cool.

MODE OF OPERATION SECTION B, F

Select to either heat or turn off the hot tub or

pool.

SET SETPOINT OCCUPIED SECTION A, D

Select the setpoint temperature for the occupied

period.

Note: In the Limited Access Level, the temperature

can only be adjusted by +/-3°F (1.5°C) from the

temperature setting entered prior to entering the

Limited access level.

SET SETPOINT UNOCCUPIED

Select the setpoint temperature for the unoccupied

period.

Note: This item is only available when a

programmable setback schedule has been

selected.

SECTION A, D

OFF, -4°F (-20°C)

1

4

2

Continued on next page.

9 of 32 © 2007 D 162 - 08/07

to Setpoint

Maximum

Default = OFF

OFF, 40°F

(4.5°C) to Hot Tub

Maximum

Default = 102°F

(39.0°C)

USEr

InST

ADV

LTD

USEr

InST

ADV

SET SETPOINT AWAY SECTION A, D

Select the setpoint temperature for the away

period.

Note: This item is only available when scenes

are set to On.

SET HOT TUB OCCUPIED

Select the hot tub temperature for the occupied

period.

Note: In the Limited Access Level, the temperature

can only be adjusted by +/-3°F (1.5°C) from the

temperature setting entered prior to entering the

Limited access level.

SECTION B

Page 10

ADJUST Menu (2 of 6)

Mode Item Field Range Access Description

OFF, 40°F

(4.5°C) to Hot Tub

2

Maximum

Default = 95°F

(35.0°C)

USEr

InST

ADV

SET HOT TUB UNOCCUPIED

Select the hot tub temperature for the unoccupied

period.

Note: This item is only available when a

programmable setback schedule has been

selected.

SECTION B

2

3

3

3

ADJUST MENU

5

5

OFF, 40°F

(4.5°C) to Hot Tub

Maximum

Default = 50°F

(10.0°C)

OFF, 40°F (4.5°C)

to DHW Maximum

Default = 130°F

(54.5°C)

OFF, 40°F (4.5°C)

to DHW Maximum

Default = 110°F

(43.5°C)

OFF, 40°F (4.5°C)

to DHW Maximum

Default = OFF

OFF, 40°F (4.5°C)

to Floor Maximum

Default = 80°F

(26.5°C)

OFF, 40°F (4.5°C)

to Floor Maximum

Default = 70°F

(21.0°C)

USEr

InST

ADV

LTD

USEr

InST

ADV

USEr

InST

ADV

USEr

InST

ADV

LTD

USEr

InST

ADV

USEr

InST

ADV

SET HOT TUB AWAY SECTION B

Select the hot tub temperature for the away

period.

Note: This item is only available when scenes

are set to On.

SET DHW TANK OCCUPIED SECTION C

Select the indirect domestic hot water tank

temperature for the occupied period.

Note: In the Limited Access Level, the temperature

can only be adjusted by +/-3°F (1.5°C) from the

temperature setting entered prior to entering the

Limited access level.

SET DHW TANK UNOCCUPIED SECTION C

Select the indirect domestic hot water tank

temperature for the unoccupied period.

Note: This item is only available when a

programmable setback schedule has been

selected.

SET DHW TANK AWAY SECTION C

Select the indirect domestic hot water tank

temperature for the away period.

Note: This item is only available when scenes

are to set to On.

SET FLOOR OCCUPIED SECTION E

Select the floor temperature for the occupied

period.

Note: In the Limited Access Level, the temperature

can only be adjusted by +/-3°F (1.5°C) from the

temperature setting entered prior to entering the

Limited access level.

SET FLOOR UNOCCUPIED SECTION E

Select the floor temperature for the unoccupied

period.

Note: This item is only available when a

programmable setback schedule has been

selected.

OFF, 40°F (4.5°C)

5

Continued on next page.

© 2007 D 162 - 08/07 10 of 32

to Floor Maximum

Default = OFF

USEr

InST

ADV

SET FLOOR AWAY

Select the floor temperature for the away

period.

Note: This item is only available when scenes

are set to On.

SECTION E

Page 11

ADJUST Menu (3 of 6)

Mode Item Field Range Access Description

SET POOL OCCUPIED

Select the pool temperature during the occupied

period.

Note: In the Limited Access Level, the temperature

can only be adjusted by +/-3°F (1.5°C) from the

temperature setting entered prior to entering the

Limited access level.

6

OFF, 40°F (4.5°C)

to Pool Maximum

Default = 78°F

(25.5°C)

LTD

USEr

InST

ADV

SECTION F

1

4

2

3

5

ADJUST MENU

50 to 239°F

(10.0 to 115.0°C)

Default = 200°F

(93.5°C)

50 to 104°F

(10.0 to 40.0°C)

Default = 104°F

(40.0°C)

50 to 200°F

(10 to 93.5°C)

Default = 140°F

(60.0°C)

50 to 110°F

(10.0 to 43.5°C)

Default = 85°F

(29.5°C)

ADV

ADV

ADV

ADV

SETPOINT MAXIMUM SECTION A, D

Select the maximum setpoint temperature range

adjustment.

Note: This item is only available when the mode

of operation is set to Heat.

HOT TUB MAXIMUM SECTION B

Select the maximum hot tub temperature range

adjustment.

DHW MAXIMUM SECTION C

Select the maximum indirect domestic hot water

tank temperature range adjustment.

FLOOR MAXIMUM SECTION E

Select the maximum floor temperature range

adjustment.

50 to 120°F

6

4

5

6

1

2

3

4

Continued on next page.

11 of 32 © 2007 D 162 - 08/07

(10 to 49.0°C)

Default = 90°F

(32.0°C)

CTRL, SYNC, 5 to

30 minutes

Default = CTRL

1 to 40°F

(0.5 to 22.0°C)

Default = 10°F

(5.5°C)

ADV

InST

ADV

InST

ADV

POOL MAXIMUM SECTION F

Select the maximum pool temperature range

adjustment.

CYCLE LENGTH

Select the heating or cooling cycle length in

minutes for PWM applications.

DIFFERENTIAL

Select the differential to cycle on and off around

the setpoint temperature.

SECTION G

Page 12

ADJUST Menu (4 of 6)

Mode Item Field Range Access Description

1

2

3

1

2

3

1

2

3

4

5

6

1

2

3

4

5

6

1

ADJUST MENU

2

3

4

5

6

1

2

3

4

5

6

0 to 20:00 min in

10 sec increments

Default = 0:30

0 to 20:00 min in

10 sec increments

Default = 0:30

HYDr, OTH

Default =

60 to 220°F

(15.5 to 104.5°C)

Default = 180°F

(82.0°C)

80 to 220°F

(26.5 to 104.5°C)

Default = 200°F

(93.5°C)

STAT, OFF, LO,

MED, HI

Default = OFF

r

HYDr

ADV

ADV

InST

ADV

InST

ADV

ADV

InST

ADV

MINIMUM ON SECTION H

Select the minimum on time of relays R1 and R2.

This helps prevent short cycling.

MINIMUM OFF SECTION H

Select the minimum off time of relays R1 and R2.

This helps prevent short cycling.

HEAT SOURCE SECTION R

Select whether the heat source is hydronic

(HYDr) or other (OTHr) when the setpoint control

is connected to a tN4 System Control.

Note: This item is only available when DIP switch

2 is set to tN4 System Control and the mode of

operation is set to Heat.

EXCHANGE SUPPLY OCCUPIED

Select the desired supply water temperature

required on the tN4 bus to heat the setpoint load

during the occupied period.

Note: This item is only available when DIP

switch 2 is set to tN4 System Control, the mode

of operation is set to Heat, and the Heat Source

item in the ADJUST menu is set to hydronic

(HYDr).

MAXIMUM SUPPLY SECTION R

Select the maximum exchange supply water

temperature allowed on the tN4 bus to heat the

setpoint load.

Note: This item is only available when DIP switch

2 is set to tN4 System Control, the mode of

operation is set to Heat, and the Heat Source

item in the ADJUST menu is set to hydronic

(HYDr).

PRIORITY SECTION R

Select the priority level of the setpoint control

over other devices on the tN4 system.

Note: This item is only available when DIP switch

2 is set to tN4 System Control, the mode of

operation is set to Heat, and the Heat Source

item in the ADJUST menu is set to hydronic

(HYDr).

Note: STAT, OFF, LO, MED, HI are available when

the control is connected to a boiler bus.

STAT and OFF are available when the control is

connected to a mix bus.

SECTION R

Continued on next page.

© 2007 D 162 - 08/07 12 of 32

Page 13

ADJUST Menu (5 of 6)

Mode Item Field Range Access Description

RELAY 1 PUMP

1

2

3

4

5

6

1

4

5

OFF, On

Default = On

OFF, On

Default = OFF

InST

ADV

InST

ADV

Select whether a system pump from a tN4

system control should operate whenever relay

1 is closed.

Note: This item is only available when DIP switch

2 is set to tN4 System Control, the mode of

operation is set to Heat, and the Heat Source

item in the ADJUST menu is set to hydronic

(HYDr).

RELAY 1 PUMP DELAY SECTION R

Select whether a system pump is delayed from

operating whenever relay 1 is closed. The delay

allows a thermal motor zone valve to fully open.

The delay is 3 minutes.

Note: This item is only available when DIP switch

2 is set to tN4 System Control, the mode of

operation is set to Heat, and the Heat Source

item in the ADJUST menu is set to hydronic

(HYDr).

SECTION R

2

6

2

6

ADJUST MENU

2

1

2

4

5

1

2

3

4

5

6

OFF, 12:00 AM to

11:50 PM

or

OFF to 23:50

Default = OFF

OFF, 0:30 to 24:00

Default = 8:00 hr

OFF, On

Default = On

OFF, 1 to 12

Default = 1

OFF, On

Default = OFF

ADV

ADV

ADV

ADV

ADV

RELAY 2 PUMP ON SECTION B, F

Select the time of day at which Relay 2 turns on

for daily hot tub or pool filtration.

Note: This item is only available when a

programmable setback schedule is selected.

RELAY 2 PUMP RUN TIME SECTION B, F

Select the amount of time Relay 2 should operate

for daily hot tub or pool filtration.

Note: This item is only available when a

programmable setback schedule and Relay 2

Pump On is set to a time.

RELAY 2 SAMPLE SECTION B

Select whether Relay 2 must cycle the Hot Tub

pump during the unoccupied and away periods

to sample the water temperature.

Note: This item is only available when DIP switch

2 is set to tN4 System Control and the Heat

Source item is set to hydronic (HYDr).

SETPOINT DEVICE ENABLE SECTION I

Select the Setpoint Device Enable number to

allow a remote device such as a User Switch to

activate the Time Occupied override. The control

then maintains the occupied temperature for a

preset amount of time.

Note: This item is only available when the setpoint

control has tN4 communication.

OUTDOOR

Select whether the outdoor temperature is to be

shown in the VIEW menu.

Note: This item is only available when the control

is connected to a tN4 system and an outdoor

sensor is connected to one of the devices in the

tN4 system.

SECTION R

Continued on next page.

13 of 32 © 2007 D 162 - 08/07

Page 14

ADJUST Menu (6 of 6)

Mode Item Field Range Access Description

1

2

4

5

6

1

2

4

5

6

1

2

4

5

ADJUST MENU

1

4

1

4

NONE, ZONE,

CTRL

Default = NONE

40 to 100°F, OFF

(4.5 to 38.0°C,

OFF)

Default = 70°F

(21.0°C)

40 to 100°F, OFF

(4.5 to 38.0°C,

OFF)

Default = 62°F

(16.5°C)

OFF, 30 to 100°F

(OFF, -1.0 to

38.0°C)

Default = OFF

OFF, 30 to 100°F

(OFF, -1.0 to

38.0°C)

Default = OFF

ADV

ADV

ADV

ADV

ADV

WWSD

Select the type of Warm Weather Shut Down

desired. When the outdoor temperature rises

above the WWSD, heating is disabled.

Note: This item is only available when the control

is connected to a tN4 system, an outdoor sensor

is connected to one of the devices in the tN4

system, and Mode of Operation is set to Heat.

WWSD OCCUPIED SECTION R

Select the outdoor temperature at which the Warm

Weather Shut Down occurs for the occupied

period. Heating is disabled when the outdoor

temperature rises above the WWSD.

Note: This item is only available when Mode

of Operation is set to Heat and WWSD is set

to Zone.

WWSD UNOCCUPIED SECTION R

Select the outdoor temperature at which the Warm

Weather Shut Down occurs for the unoccupied

period. Heating is disabled when the outdoor

temperature rises above the WWSD.

Note: This item is only available when the Mode

of Operation is set to Heat, WWSD is set to

Zone, and a programmable setback schedule

has been selected.

CWSD OCCUPIED SECTION R

Select the outdoor temperature at which the Cold

Weather Shut Down occurs for the occupied

period. Cooling is disabled when the outdoor

temperature falls below the CWSD.

Note: This item is only available when the control

is connected to a tN4 system, an outdoor sensor

is connected to one of the devices in the tN4

system, and Mode of Operation is set to Cool.

CWSD UNOCCUPIED

Select the outdoor temperature at which the Cold

Weather Shut Down occurs for the unoccupied

period. Cooling is disabled when the outdoor

temperature falls below the CWSD.

Note: This item is only available when the control

is connected to a tN4 system, an outdoor sensor

is connected to one of the devices in the tN4

system, Mode of Operation is set to Cool, and

a programmable setback schedule has been

selected.

SECTION R

SECTION R

After the last item, the control returns to the first item in the menu.

© 2007 D 162 - 08/07 14 of 32

Page 15

TIME Menu (1 of 1)

The TIME Menu items set the time clock, and day.

Item Field Range

TIME MENU

0 to 59

Default = 00

12 AM to 11 PM

or

00 to 23

Default = 12 AM

Su, Mo, Tu, We,

Th, Fr, Sa

Default = Su

Access

USEr

InST

ADV

USEr

InST

ADV

USEr

InST

ADV

USEr

InST

ADV

Description

CURRENT TIME AND DAY SECTION K

Displays the current time and day of the week. The

time and date flash if the time is not set.

CLOCK MINUTES SECTION K

Set the minutes.

CLOCK HOURS SECTION K

Set the hours.

DAY OF THE WEEK SECTION K

Set the day of the week.

12 hr or 24 hr

Default = 12 hr

After the last item, the control returns to the first item in the menu.

ADV

MODE SECTION K

Select whether time should be displayed using a 12

or 24 hour clock.

15 of 32 © 2007 D 162 - 08/07

Page 16

SCENE Menu (1 of 2) Note: The SCENE menu is not available when the Application Mode is set to Pool (6)

The SCENE Menu items set the current scene as

well as the scene settings.

Item Field Range

SCENE MENU

Occ, Away,

PERM 1, PERM Away 2,

PERM UnOcc 3, PERM

4, PERM 5, TMPY Occ

6, TMPY 7, TMPY 8

Default = Occ PERM 1

INF, 1 to 180 days

Default = INF

Schd, UnOcc,

Occ, Away

Default = Schd

Schd, UnOcc,

Occ, Away

Default = Schd

Schd, UnOcc,

Occ, Away

Default = Schd

Access

USEr

InST

ADV

USEr

InST

ADV

InST

ADV

InST

ADV

InST

ADV

Description

SELECT

Select the scene for the building.

Note: Only Occupied and Away are available when

a programmable setback schedule is not selected.

Note: This item is only available when SCENE menu

is set to On.

AWAY HOLD SECTION M

Set the number of days for the Away 2 scene. When

the scene is selected, the tN4 system remains in that

scene for the set number of days then reverts to the

last permanent scene.

Note: This item is only available when SCENE menu

is set to On.

SET PERMANENT 1 SECTION M

Select an action for the Permanent 1 scene.

Note: This item is only available when SCENE menu

is set to On and a programmable setback schedule

is selected.

SET PERMANENT 4 SECTION M

Select an action for the Permanent 4 scene.

Note: This item is only available when SCENE menu

is set to On and a programmable setback schedule

is selected.

SET PERMANENT 5 SECTION M

Select an action for the Permanent 5 scene.

Note: This item is only available when SCENE menu

is set to On and a programmable setback schedule

is selected.

SECTION M

Schd, UnOcc,

Occ, Away

Default = Schd

Schd, UnOcc,

Occ, Away

Default = Schd

Continued on next page.

© 2007 D 162 - 08/07 16 of 32

InST

ADV

InST

ADV

SET TEMPORARY 7 SECTION M

Select an action for the Temporary 7 scene.

Note: This item is only available when SCENE menu

is set to On and a programmable setback schedule

is selected.

SET TEMPORARY 8 SECTION M

Select an action for the Temporary 8 scene.

Note: This item is only available when SCENE menu

is set to On and a programmable setback schedule

is selected.

Page 17

SCENE Menu (2 of 2) Note: The SCENE menu is not available when the Application Mode is set to Pool (6)

Item Field Range

OFF, 0:05 to

24:00 hr, On

(in 5 min. increments)

Default = 1:00

SCENE MENU

After the last item, the control returns to the first item in the menu.

OFF, On

Default = OFF

Access

LTD

USEr

InST

ADV

InST

ADV

SCHD (Schedule) Menu (1 of 2)

Description

RUN TIME OCCUPIED

Select the amount time for the setpoint control to

operate at the occupied temperature when a Setpoint

Device Enable is provided.

Note: This item is only available in Application Mode

2 (Hot Tub) or 5 (Floor) if a programmable setback

schedule is selected.

Note: This item is only available in Application Mode 1

and 4 (Setpoint) if a programmable setback schedule

is selected and the Setpoint Device Enable setting

in the ADJUST menu is set from 1 through 12.

SCENE MENU

Select whether or not to use the scene feature on the

setpoint control. When set to OFF, this item displays

first in the Scene Menu.

SECTION M

SECTION B, E, I

Item Field Range

NONE, ZONE, MST1,

MST2, MST3, MST4,

24 hr, 5-2, 5-11, 7dAY

SCHEDULE MENU

Mbr1, Mbr2, Mbr3,

Mbr4, UnOc

Default = NONE

Default = 5-11

Access

InST

ADV

InST

ADV

The SCHEDULE menu items set the schedule type,

the number of events per day, and the event times.

Description

HEAT OR COOL SCHEDULE SECTION L

Selects the schedule used by the setpoint control.

If a schedule is not required, select NONE.

If the schedule is only used by this setpoint control,

select ZONE.

If the schedule is shared with other thermostats or

setpoint controls, select MST1 to MST4.

If the schedule is set on another thermostat or setpoint

control, select Mbr1 to Mbr4.

UnOc is not available in Mode 3.

Note: This item can be viewed in the USER and INST

(Installer) access levels but can only be adjusted in

the ADV (Advanced) access level.

SCHEDULE TYPE SECTION L

Select the type of schedule.

Note: This item is only available when the Heat or

Cool Schedule is set to ZONE or MST1 to MST4.

2 (Occ, UnOcc),

4 (Occ 1, 2,

UnOcc 1, 2)

Default = 4

Continued on next page.

17 of 32 © 2007 D 162 - 08/07

InST

ADV

SCHEDULE MODE SECTION L

Select the number of events per day.

Note: This item is only available when the Heat or

Cool Schedule is set to ZONE or MST1 to MST4.

Page 18

SCHD (Schedule) Menu (2 of 2)

Item Field Range

– –:– – ,

12:00 AM to 11:50 PM

or

Occupied 1

Unoccupied 1

Occupied 2

Unoccupied 2

12:00 AM to 11:50 PM

Occupied 1

Unoccupied 1

Occupied 2

– –:– –,

00:00 to 23:50

Default = – –:– –

– –:– – ,

or

– –:– –,

00:00 to 23:50

Default = – –:– –

Access

USEr

InST

ADV

USEr

InST

ADV

Description

ALL DAYS OF THE WEEK

Select the times for the scheduled events.

Note: This item is only available when the Heat or

Cool Schedule is set to Zone or to a Schedule Master

and the Schedule Type is set to 24 hr.

MONDAY THROUGH FRIDAY SECTION L

Select the time for the scheduled events.

Note: This item is only available when the Heat

or Cool Schedule is set to Zone or to a Schedule

Master and Schedule Type is set to 5-2 or 5-11.

SECTION L

Unoccupied 2

12:00 AM to 11:50 PM

SCHEDULE MENU

Occupied 1

Unoccupied 1

Occupied 2

Unoccupied 2

12:00 AM to 11:50 PM

Occupied 1

Unoccupied 1

Occupied 2

– –:– – ,

or

– –:– –,

00:00 to 23:50

Default = – –:– –

– –:– – ,

or

– –:– –,

00:00 to 23:50

Default = – –:– –

USEr

InST

ADV

USEr

InST

ADV

SATURDAY AND SUNDAY SECTION L

Select the times for the scheduled events.

Note: This item is only available when the Heat or

Cool Schedule is set to Zone or to a Schedule Master

and the Schedule Type is set to 5-2.

SATURDAY TO FRIDAY SECTION L

Select the times for the scheduled events for Saturday,

Sunday, Monday, Tuesday, Wednesday, Thursday,

Friday.

Note: This item is only available when Heat or Cool

Schedule is set to Zone or to a Schedule Master and

the Schedule Type is set to 7 day.

Unoccupied 2

After the last item, the control returns to the first item in the menu.

© 2007 D 162 - 08/07 18 of 32

Page 19

MISC (Miscellaneous) Menu (1 of 1)

The Miscellaneous menu items set display and control

options such as access level and temperature units.

Item Field Range

SEC, LTD, USEr,

InST, ADV

Default = USEr

°F, °C

Default = °F

ON, TMPY, OFF

Default = TMPY

– – –, 1 to 24 ADV

Access

SEC

LTD

USEr

InST

ADV

USEr

InST

ADV

InST

ADV

Description

ACCESS LEVEL

The access level of the setpoint control. The access

column shows which items are visible in each access

level.

Note: This item is only available when DIP switch

1 is set to the Unlock position and the tN4 system

control DIP switch is set to the Unlock position.

UNITS SECTION P

Select Fahrenheit or Celsius as the temperature

units.

BACKLIGHT SECTION Q

Select whether the backlight displays permanently,

temporarily, or is off. The temporary backlight lasts

for 30 seconds.

NUMBER OF DEVICES SECTION R

Number of tN4 devices connected to this tN4 bus.

Note: This item is only available when the setpoint

control has tN4 communication.

MISC MENU

SEC

bus#:01 to bus#:24,

AUTO

Default = AUTO

162, Software Version

After the last item, the control returns to the first item in the menu.

LTD

USEr

InST

ADV

InST

ADV

SEC

LTD

USEr

InST

ADV

ADDRESS SECTION R

The tN4 bus address of this setpoint control.

Auto allows the tN4 system to automatically assign

an address to the setpoint control.

To manually set the address, use the Up or Down

buttons while in the ADV (Advanced) or InST (Installer)

access level.

Note: This item is only available when the setpoint

control has tN4 communication.

RESTORE DEFAULTS

Press the Up and Down buttons together to load the

factory defaults. The SELECT icon appears and then

the display shows DONE when the factory defaults

have been completed.

TYPE

Product number of this setpoint control. Hold the Up

button to view the software version.

19 of 32 © 2007 D 162 - 08/07

Page 20

Sequence of Operation

Application Mode 1 - On / Off Setpoint SECTION A

Application Mode 1 is a generic setpoint control operation

using an on/off differential for heating or cooling. The sensor

is required to be located at the temperature control point.

The setpoint control can have an occupied, unoccupied,

and away temperature setting.

Relay 2 Operation

Relay 2 operates continuously while in the occupied period to

provide constant circulation and reduce temperature swing.

Relay 2 operates together with Relay 1 while in the

unoccupied and away periods.

Setting the Setpoint Off

The setpoint temperature can be set to Off. When set to

Off, Relay 1 and 2 will not turn on. If the heating area is

Load

Relay 1 Operation

Relay 1 operates using an on/off differential to maintain the

load at the Occupied, Unoccupied, or Away temperatures

depending on the schedule and scene.

outdoors, or the heating system has the potential to freeze,

it is recommended that the setpoint always be set to a

temperature and not set to Off.

The setpoint can be set to Off if the heating system can

be drained or the pump should remain off.

The setpoint control power should never be shut off,

otherwise an error message will appear on the rest of the

tN4 system.

Application Mode 2 - Hot Tub SECTION B

Application Mode 2 is designed specifically to heat hot tubs

using an on/off differential. A sensor must be located in

a temperature well on the recirculation pipe. The hot tub

can have an occupied, unoccupied, and away temperature

setting.

Hot Tub Filtration

The hot tub application includes special logic to operate

the pump controlled by Relay 2. The Relay 2 Pump On

setting in the Adjust menu allows installers to choose a

time at which Relay 2 starts a pump for filtration of the

hot tub. The Relay 2 Pump Run Time setting in the Adjust

menu determines how long Relay 2 should run the pump

for filtration.

The Hot Tub Filtration feature can only be used when a

programmable setback schedule is set to Zone, Schedule

Master, Schedule Member, or set to Unoccupied.

Relay 1 Operation

Relay 1 operates using an on/off differential to maintain the

load at the Occupied, Unoccupied, or Away temperatures

depending on the schedule and scene.

Relay 2 Operation

Relay 2 operates continuously while in the occupied period to

provide constant circulation and reduce temperature swing.

Relay 2 operates together with Relay 1 while in the

unoccupied and away periods.

Relay 2 can optionally operate to provide Hot Tub

Filtration.

When connected to a tN4 system control, Relay 2 can

optionally operate to provide temperature sampling of

the hot tub.

© 2007 D 162 - 08/07 20 of 32

Temperature Sampling

When the setpoint control is connected to a tN4 System

and the hot tub pump operated by Relay 2 is off during

the unoccupied and away periods, the setpoint sensor

may not accurately read the hot tub temperature due to a

lack of flow past the sensor. In order to accurately sample

the hot tub temperature, the Relay 2 Sample setting can

be set to On. Relay 2 then turns on the hot tub pump for

approximately one minute at the end of each heating

cycle to allow the control to accurately measure the hot

tub temperature.

Mode of Operation

The hot tub mode of operation can be set to either Heat

or Off. While set to Off, Relay 1 and Relay 2 remain off.

The Off setting should only be used when the hot tub is

drained or when there is no possibility of freezing. Power

should never be removed from the setpoint control as this

will result in an error message on the tN4 system.

Page 21

Occupied Time

The setpoint control can temporarily override the scheduled

temperature and operate at the occupied temperature on

a timer.

Press the Up or Down buttons while in the View menu

to set the amount of time that the occupied temperature

should remain in effect.

To use this feature, a programmable schedule must be set

or the schedule be set to normally operate at the unoccupied

setting. When the schedule is set to unoccupied, the

setpoint control operates at the unoccupied setting until

activated.

The length of time the setpoint remains at the occupied

temperature is preset by the Run Time Occupied item

located in the Scene menu.

To cancel the temporary occupied time, press and hold the

Down button until the display shows OFF, at which point,

the setpoint control returns to the schedule.

Pressing the UP button while in the VIEW menu

starts operation of the Hot Tub for the time set.

To Stop operation press the DOWN button until

the time shows OFF.

Application Mode 3 - DHW Tank SECTION C

Application Mode 3 is designed specifically to operate a

Relay 1 Operation

domestic hot water (DHW) tank using an on/off differential.

A sensor must be located in a temperature well inside

the DHW tank. The DHW tank can have an occupied,

unoccupied, and away temperature setting.

Relay 1 operates using an on/off differential to maintain the

load at the Occupied, Unoccupied, or Away temperatures

depending on the schedule and scene.

Relay 2 Operation

Relay 2 operates a DHW recirculation pump continuously

during the occupied period.

Relay 2 remains off during the unoccupied and away

periods.

Application Mode 4 - PWM Setpoint SECTION D

Application Mode 4 is a generic setpoint control operation

using pulse width modulation for heat or cooling. The sensor

is required to be located at the temperature control point.

The setpoint control can have an occupied, unoccupied,

and away temperature setting.

Relay 2 Operation

Relay 2 operates continuously while in the occupied period

to provide constant circulation and reduce temperature

swing.

Relay 2 operates together with Relay 1 while in the

unoccupied and away periods.

Setting the Setpoint Off

The setpoint temperature can be set to Off. When set

Load

Relay 1 Operation

Relay 1 operates using pulse width modulation to maintain

the load at the Occupied, Unoccupied, or Away temperatures

depending on the schedule and scene.

21 of 32 © 2007 D 162 - 08/07

to Off, Relay 1 will not turn on. If the heating area is

outdoors, or the heating system has the potential to freeze,

it is recommended that the setpoint always be set to a

temperature and not set to Off.

The setpoint can be set to Off if the heating system can

be drained or the pump should remain off.

The setpoint control power should never be shut off,

otherwise an error message will appear on the rest of the

tN4 system.

Page 22

Application Mode 5 - Floor SECTION E

Application Mode 5 configures the setpoint control for floor

warming and floor heating applications using pulse width

modulation. Floor warming is not necessarily designed to

heat the room, but to make the floor feel warm to the touch.

This is common especially in bathrooms. For bathroom

applications, Relay 2 can also heat a towel warmer radiator

while in the occupied period. A sensor must be located

within the slab between the heating pipes. The setpoint

control allows a Floor temperature to be set for the occupied,

unoccupied, and away events.

Relay 1 Operation

Relay 1 operates using pulse width modulation to maintain

the load at the Occupied, Unoccupied, or Away temperatures

depending on the schedule and scene.

Occupied Time

The setpoint control can temporarily override the scheduled

temperature and operate at the occupied temperature on

a timer.

Press the Up or Down buttons while in the View menu

to set the amount of time that the occupied temperature

should remain in effect.

To use this feature, a programmable schedule must be set

or the schedule be set to normally operate at the unoccupied

setting. When the schedule is set to unoccupied, the

setpoint control operates at the unoccupied setting until

activated.

The length of time the setpoint remains at the occupied

temperature is preset by the Run Time Occupied item

located in the Scene menu.

To cancel the temporary occupied time, press and hold

the Down button until the display shows off, at which point,

the setpoint control returns to the schedule.

Relay 2 Operation

Relay 2 operates continuously while in the occupied period

to heat a towel warmer.

Relay 2 remains off during the unoccupied and away

periods.

Pressing the UP button while in the VIEW menu

starts operation of the Hot Tub for the time set.

To Stop operation press the DOWN button until

the time shows OFF.

Application Mode 6 - Pool SECTION F

Application Mode 6 configures the setpoint control for pool

heating using pulse width modulation. A sensor is located

in a temperature well on the pool return recirculation pipe.

The pool can have an occupied temperature. During the

unoccupied and away periods, the pool is not heated.

Relay 2 Operation

Relay 2 operates continuously while in the occupied period

to provide constant circulation and reduce temperature

swing.

Relay 2 remains off during the unoccupied and away

periods.

Relay 2 operates to provide pool filtration.

Pool Filtration

The pool application includes filtration logic to operate the

pump controlled by Relay 2. The Relay 2 Pump On setting

allows installers to choose a time at which Relay 2 starts

a pump for filtration of the pool. The Relay 2 Pump Run

Time setting determines how long Relay 2 should run the

pump for filtration.

Relay 1 Operation

Relay 1 operates using pulse width modulation to maintain

the load at the occupied temperature. Relay 1 remains off

during the unoccupied and away periods.

© 2007 D 162 - 08/07 22 of 32

Mode of Operation

The pool mode of operation can be set to either Heat or

Off. While set to Off, Relay 1 and Relay 2 remain off. The

OFF setting should only be used when the pool is drained

or there is no possibility of freezing. Power should never

be removed from the setpoint control as this will result in

an error message on the tN4 system.

Page 23

Cycle Length SECTION G

Select the heating or cooling cycle length in minutes for

Application Modes 4 (Setpoint), 5 (Floor), and 6 (Pool). The

cycle length is the total on time and off time of Relay 1. This

helps prevent short cycling. The following settings are

available:

CTRL = The cycle length is the same as the tN4 system

control. This is the factory default.

SYNC = The cycle length synchronizes with other ther-

mostats and setpoint controls that have also

been set to the SYNC setting.

5 to 30 minutes = The cycle length is manually set.

Note: The factory default changes to synchronize (SYNC)

when a tN4 control is not present. The factory default

changes to 15 minutes when the mode of operation is

set to Cool.

Relay Minimum On and Off Time SECTION H

Relays 1 and 2 have adjustable Minimum On and Minimum

Off time settings available in the Adjust menu only with

Application Modes 1, 2, and 3 (using on-off differential).

These settings help prevent short cycling of the relays and

the heating or cooling equipment.

Remote Enable / Disable SECTION I

To use the Remote Enable / Disable feature, the setpoint

control must be set to Mode 1 (Setpoint), 2 (Hot Tub), 4

(Setpoint), or 5 (Floor). When the setpoint control is connected

to a tN4 system, a User Switch or tN4 Gateway can remotely

signal a setpoint control (or multiple setpoint controls) to

override the unoccupied temperature to temporarily operate

at the occupied temperature. The Setpoint Control, User

Switch and tN4 Gateway each have a setting called Setpoint

Device Enable that can be assigned a number between

1 and 12. When devices have the same Setpoint Device

Enable number, then either pressing the button on the

User Switch or activating the feature on the tN4 Gateway

causes the Setpoint Control to operate at the occupied

temperature. Sending a second Setpoint Device Enable

cancels the override and the setpoint control returns to the

unoccupied temperature. A total of 12 different Setpoint

Devices Enables can be configured on the tN4 system.

To create a Setpoint Device Enable:

1) DIP switch 2 must be set to tN4 system control.

2) A User Switch or tN4 Gateway should be connected to

one of the tN4 buses.

3) Set the Setpoint Device Enable item in the Adjust menu

to a number between 1 and 12.

4) Set the Setpoint Device Enable on the User Switch or

tN4 Gateway to the same number between 1 and 12.

The schedule on the setpoint control must be set to either

Zone, Schedule Master, Schedule Member, or to Unoccupied

to allow the temporary occupied time override to operate.

Wh en t he s chedule is set to Unoccup ied, the s etpo int cont rol

operates at the unoccupied setting until activated.

The length of time the setpoint remains at the occupied

temperature is preset by the Run Time Occupied item

located in the Scene menu.

Remote activation of the setpoint control requires the same

Se tpoin t Dev ice en able n umbe r to b e set on th e se tpoin t cont rol

and on a User Switch 480 or 481 (or tN4 Gateway).

Setpoint

Control

UnOcc Occ

User Switch

User

Button

1

User

Button

2

User

Button

3

Press Button

Setpoint

Control

Control

Setpoint Device

Enable Number

23 of 32 © 2007 D 162 - 08/07

User SwitchSetpoint

=

Setpoint Device

Enable Number

User

Button

1

User

Button

2

User

Button

3

Page 24

Sensor Input SECTION J

•

•

•

• •

• •

• •

•

•

•

•

•

•

•

•

•

3

6

The Setpoint Control 162 requires a temperature sensor

(Universal Sensor 071 included) to be connected to the

sensor input on the back of the control. All tekmar sensors

are compatible. Choose the sensor type that best meets

the requirements of the application. See application mode

diagrams for the recommended location of the sensor.

Time Clock SECTION K

• Use the Time menu to set the correct time.

The setpoint control has a built-in time clock to allow the

control to operate on a programmable schedule. A battery

less backup allows the control to keep time for at least 4

hours without power.

Setting the Schedule SECTION L

To provide greater energy savings, the setpoint control

can operate on a programmable schedule. The schedule

is stored in memory and is not affected by loss of power

to the control. A single zone or multiple devices on the

tN4 system can be assigned to follow the schedule of the

setpoint control.

Zone Schedule

A zone schedule only applies to the setpoint control on which

the schedule is programmed. The setpoint control follows

the zone schedule and the events are not communicated

to other devices on the tN4 system.

Master Schedule

If the setpoint control is connected to other devices on

the tN4 system, then the setpoint control can operate on

a master schedule. The master schedule stores the event

times in memory and sends messages to the member

thermostats when to change from one event to the next.

A maximum of four master schedules can be set up on the tN4

system. A master schedule is available to all devices on the

tN4 system. Master schedules simplify installation by allowing

one master schedule to be used by multiple devices.

Members of

Schedule 1

Zone 12

Master

Schedule 1

4 5

None

Zone

Schedule

Master

Schedule 2

7 8

Members of

Schedule 2

Schedule Member

If a Master Schedule is available on the tN4 system, the

setpoint control can follow the Master Schedule as a

member.

To follow a master schedule as a member:

1. Assign the setpoint control to follow a master schedule

by setting the Schedule menu item in the Schedule

menu to Member (MBR) 1 to 4. The number must match

that of the Master.

Normally Unoccupied

The setpoint control can be set to normally operate at the

unoccupied temperature. This allows the setpoint control

to temporarily be set to the occupied temperature by either

pressing the Up or Down buttons in the View menu or by

a remote enable.

Schedule Types

The schedule type determines when the schedule repeats

itself.

The setpoint control includes four schedule types:

• 24 Hour: Repeats every 24 hours.

• 5-2: Repeats on a weekly basis. However, it breaks the

week into the weekend and weekdays. This reduces the

amount of schedule event settings.

• 5-11: Repeats on a weekly basis. However, it breaks

the week into Saturday and Sunday followed by the

weekdays. This reduces the amount of schedule event

settings.

• 7 Day: Repeats on a weekly basis and allows for

separate event times for each day.

To create a master schedule:

1. Assign the setpoint control as a master schedule by

setting the Schedule item in the Schedule menu to

Master (MST) 1 to 4.

If the setpoint control is a master schedule, a clock symbol

appears in the display while in the View menu. This helps

locate the master schedule if changes to the schedule

are required.

© 2007 D 162 - 08/07 24 of 32

Schedule Type

Day 24 Hour 5-2 5-11 7 day

Sa

Su

Mo

Tu

We

Th

Fr

Page 25

Schedule Mode

•

•

•

•

The schedule mode can have either 4 or 2 events

per day:

4 Event 2 Event

Occupied 1 Occupied

Unoccupied 1 Unoccupied

Occupied 2

Unoccupied 2

An event is a time at which the thermostat changes

the set temperature. The event time can be set to the

nearest 10 minutes. If you wish to have the thermostat

skip the event, enter “– –:– –” as the time. The “– –

See the table labeled Schedule Mode, for more details

regarding types of events.

Schedule

Mode

Event

24hr

Sat

Sun

Mon

Tue

We

Thu

Occupied 1

4 events

per day

Unoccupied 1

Occupied 2

Unoccupied 2

or

2 events

per day

Occupied

Unoccupied

:– –” time is found between 11:50 PM and 12:00 AM.

Scenes SECTION M

A Scene function is available on the setpoint control.

• To use the scene function, go to the Scene menu and

set the Scene setting to On.

Scenes are overrides that affect devices on the tN4 system.

Scenes provide a method of changing the temperature

throughout an entire building from a single tN4 device.

Each tN4 device is programmed to operate at either at a

temperature (Occupied, Unoccupied, Away) or follow the

regular setback schedule. If a programmable schedule is

not used, only the occupied and away temperatures are

available. A permanent scene remains in place until another

scene is selected. When a temporary scene is selected

(Scenes 6, 7, 8), a timer counts down and when it times out,

devices return to the last permanent scene selected.

See the Scene table for details regarding the operation of

Scenes. There are a total of eight Scenes available.

• Default Scene: The default scene is Permanent 1. In a

typical installation, the setpoint control is set to follow

the schedule in the Permanent 1 scene.

• Factory Set Scenes: Scenes 2, 3 and 6 are factory set

and force the setpoint control to the Away, Unoccupied

or the Occupied temperature respectively.

• Customized Scenes: Scenes 1, 4, 5, 7, and 8 can be

customized to either follow the scheduled event, or the

temperature can be forced to the Occupied, Unoccupied,

or the Away temperature.

Scene Description Setpoint Operation

1 Permanent 1 Scheduled event, Unoccupied,

Occupied, Away

2 Permanent

Away

Away 2

3 Permanent

Unoccupied

Unoccupied 3

4 Permanent 4 Scheduled event, Unoccupied,

Occupied, Away

5 Permanent 5 Scheduled event, Unoccupied,

Occupied, Away

6 Temporary

Occupied for 3 hours

Occupied 6

7 Temporary 7

4 hour: Schedule, Unoccupied,

Occupied, or Away

8 Temporary 8

8 hour: Schedule, Unoccupied,

Occupied, or Away

Example:

A house is normally in scene 1. There is a living room

that operates on a schedule and there is a hot tub

that is normally at the unoccupied temperature. When

entertaining guests, the scene is changed to scene 4.

Scene 4 has been pre-programmed to change the hot

tub to operate at the occupied temperature.

Living room thermostat:

Scene 1 is set to Schedule.

Scene 4 is set to Schedule.

Hot tub setpoint control:

Scene Permanent 1 is set to Unoccupied.

Scene Permanent 4 is set to Occupied.

Fri

70°F

Scheduled

Event

25 of 32 © 2007 D 162 - 08/07

95°F

Hot Tub

Unoccupied

70°F

Living RoomLiving Room

Scheduled

Event

104°F

Hot Tub

Occupied

Page 26

Away Hold SECTION N

•

•

•

•

•

To setback the temperature while the occupants are away,

use the Permanent Away 2 scene. This scene changes all

the devices on the tN4 system to the Away temperature

setting.

To set the Away temperature, go to the Adjust menu and

select the Setpoint (or Hot Tub, DHW, Floor) Away item.

When operating a pool, the away scene no longer heats

the pool. The Access Level must be set to User, Installer

or Advanced.

The Away Hold feature allows you to set the number of

days the Away temperature applies.

To set the number of days away, go to the Scene menu

and select Away Hold.

When set to Infinite, the Away 2 scene remains until a

new scene is selected. If it is known in advance how long

the building occupant will be away, the Away Hold can be

set to the number of days. Once the number of days have

elapsed, the thermostat automatically changes from the

Away 2 scene to the previous permanent scene.

Example:

The home occupants are traveling for 14 days.

The occupants want the home to be at the Away

temperatures for 14 days and then automatically return

to the normal schedule.

• Locate the Scene Menu.

• Set the Away Hold to 14 days.

• Select Scene 2 Away.

62°F

Away

62°F

Away

Away

Away

62°F

62°F

50°F

Away

Restore Factory Defaults SECTION O

To restore the factory defaults, locate the Default item in

the Miscellaneous menu and press and hold the Up and

Down buttons for 1 second. The display will show “SELECT”

and when completed it will show “DONE”.

Temperature Units SECTION P

• Locate the units setting in the Miscellaneous menu.

The thermostat can display temperatures in either Fahrenheit

(°F) or in Celsius (°C).

Backlight SECTION Q

Use the control’s backlight to increase the visibility of

the display. The backlight can be set to On, Temporary,

or Off. If Temporary is selected, the backlight comes on

for 30 seconds when a button is pressed. By default, the

backlight is Temporary. If Off is selected the backlight

remains permanently off.

• Locate the Backlite setting in the Miscellaneous

menu.

tN4 Features SECTION R

When the setpoint control is connected to a tN4 system,

the setpoint control has additional features not present

when operating alone.

tN4 Bus

When connecting the setpoint control to a tN4 system, there

may be several tN4 busses available. The setpoint control

should be connected to the tN4 bus that best represents the

water temperature required for the setpoint load. Typically,

the setpoint control should be connected to the boiler tN4

bus for Application Modes 2 (Hot Tub) and 3 (DHW Tank).

Typically the setpoint control should be connected to a mix

tN4 bus for Application Mode 5 (Floor).

Heat Source

When the setpoint control is part of a tN4 system, the Heat

Source item in the Adjust menu a llows the setpoint control to

inform the tN4 system control whether the heat is hydronic

(HYDr) or provided by another (OTHr) heat source.

Exchange Supply

When the setpoint control is connected to a tN4 system

control and Heat Source item is set to hydronic (HYDr),

the setpoint control requests that the Exchange Supply

Occupied water temperature be maintained on the tN4

bus whenever Relay 1 is heating the setpoint load during

© 2007 D 162 - 08/07 26 of 32

Page 27

the occupied period. During the unoccupied periods,

the exchange supply water temperature is lowered by

the difference between the occupied and unoccupied

setpoints. During the away period, the exchange supply

is lowered by the difference between the occupied and

the away setpoints.

Maximum Supply

When the setpoint control is connected to a tN4 system

control and the Heat Source item is set to hydronic (HYDr),

the setpoint control requests an Exchange Supply water

temperature on the tN4 bus. The setpoint control also

includes a Maximum Supply setting. Should the water

temperature on the tN4 bus exceed this water temperature,

then the setpoint control discontinues heating by shutting

off Relay 1.

and Relay 1 is turned on, the “system” pump waits for 3

minutes before turning on.

When the setpoint control is connected to the tN4 boiler

bus, the “system” pump is the primary pump located on

the tN4 system control.

When the setpoint control is connected to a tN4 mix bus,

the “system” pump is the mix system pump located on the

tN4 system control or on a mixing expansion module.

Purging

When the setpoint control is used with a tN4 system control,

the setpoint control purges heat from the boiler into the

setpoint zone if it is the last zone to shut off. The length

of the purge is dependent on time, the temperature of the

boiler, and the temperature of the setpoint load.

Relay 1 System Pump

In order to accommodate many different piping and pumping

configurations, the setpoint control is able to choose whether

a “system” pump is required to operate at the same time as

Relay 1. This allows each manifold on a water temperature

to have a “system” pump when using zone valves or when

using zone pumps together with primary secondary piping.

Only the manifold that has zones requiring heat should

have their “system” pump turned on.

When the setpoint control is connected to the tN4 boiler

bus, the “system” pump is the primary pump located on

the tN4 system control.

When the setpoint control is connected to a tN4 mix bus,

the “system” pump is the mix system pump located on the

tN4 system control or on a mixing expansion module.

To turn on the “system” pump together with Relay 1, set

the Relay 1 Pump item in the Adjust menu to On. This is

the factory default.

To turn on Relay 1 without the “system” pump, set the

Relay 1 Pump item in the Adjust menu to Off.

tN4

System

Control

Boiler

tN4 Mix Bus

Zone

Manager

Zone

Group

Pump

Mix System

Pump

Setpoint

Control

Relay 1 Delay System Pump

In applications where a thermal motor zone valve (telestat)

is operated by Relay 1, a time delay is required to allow

the zone valve to fully open before the “system” pump is

turned on. The time delay is set using the Relay 1 Delay

item in the Adjust menu. When the time delay is set to On

Priority

When the setpoint control is used with a tN4 system

control, the setpoint control has up to 5 levels of priority

when connected to a tN4 boiler bus and 2 levels of priority

when connected to a tN4 mixing bus. Devices are shut

off in order of their tN4 address, with address ending in

24 having the lowest priority and addresses ending in 01

having the highest priority. See “tN4 Address” for more

information.

Locate the Priority item in the Adjust menu.

When the setpoint control is connected to a tN4 boiler bus,

the priorities are as follows:

STAT = Thermostats have priority over the setpoint control.

The setpoint control no longer heats whenever any

thermostat calls for heat.

OFF = All devices have equal priority.

LO = The setpoint control has priority over the ther-

mostats. First, all mixing outputs are reduced.

Second, boiler temperature second stage heating

zones are shut off in order of their tN4 address

from 24 to 1. Last, boiler temperature thermostat

zones are shut off in order of their tN4 address

from 24 to 1.

MED = The setpoint control has priority over the thermo-

stats. First, all heating zones are shut off. If there

is sufficient boiler capacity, boiler temperatures

zones are turned on in order of their tN4 address

from 1 to 24. Second, boiler temperature second

stage heating zones are turned on in order of their

tN4 address from 1 to 24. Last, all mixing outputs

are increased up to normal operating levels.

HI = All thermostat heating zones are shut off whenever

the setpoint control calls for heat.

When the setpoint control is connected to a tN4 mix bus,

the priorities are as follows:

STAT = Thermostats have priority over the setpoint control.

The setpoint control no longer heats whenever

any thermostat calls for heat.

OFF = All devices have equal priority.

27 of 32 © 2007 D 162 - 08/07

Page 28

Outdoor Temperature

•

•

•

•

•

The setpoint control can display the outdoor temperature

in the View menu when connected to a tN4 bus with a

device measuring the outdoor temperature. To display

the outdoor temperature, set the Out item in the Adjust

menu to On.

Warm Weather Shut Down

The Warm Weather Shut Down (WWSD) feature prevents