Page 1

- Data Brochure

Difference Setpoint Control 157

D 157

06/10

The Difference Setpoint Control 157 is designed to operate a variable speed pump to transfer heat from a heat source

to a storage tank. Varying the speed of the pump provides fast and accurate temperature control to maintain the target

temperature difference (T). Additional minimum and maximum setpoints turn off the pump when heat transfer is no longer

desirable. Potential applications include using solar collectors or a wood boiler as a heat source.

Additional functions include:

120 V (ac) powered pump outputs

•

Second On/Off pump with 4 modes of operation

•

Optional auxiliary sensor input to be used in heat dump and heat supplement modes

•

Freeze Protection

•

Displays total amount of energy transfer in BTU or kWh

•

Certified to CSA and UL standards for use in the USA and Canada

•

NEW Solar Sensor 085 immersion type sensor included!

•

VIEW

Item

ΔT

F

1

%

2

Black

Red

Blue

Green

Input

Solar Sensor

Included

1 of 16 © 2010 D 157 - 06/10

Input

Universal Sensor

Included

Input

Universal Sensor

Optional

Input

Demand

Signal

Input

24 V (ac)

Power Supply

Input

120 V (ac)

Power Supply

Output

On/Off

Pump

Output

Variable

Speed Pump

Ground

Page 2

How to Use the Data Brochure

This brochure is organized into three main sections.

They are: 1) Sequence of Operation, 2) Installation, and

3) Control Settings

Table of Contents

User Interface ...............................................................2

Display .......................................................................... 3

Symbol Description .......................................................3

Sequence of Operation .................................................4

Section A: General ................................................... 4

Section B: Modes of Operation ................................4

Section C: Targets and Differentials ......................... 5

Section D: Control Features .....................................6

Section E: Energy Calculation .................................. 7

The Control Settings section of this brochure describes

the various items that are adjusted and displayed by the

control. The control functions of each adjustable item are

described in the Sequence of Operation.

Installation ....................................................................8

Control Settings ......................................................... 10

DIP Switch Settings ................................................ 10

VIEW Menu ............................................................ 11

ADJUST Menu ....................................................... 12

Test Routine................................................................ 14

Error Messages .......................................................... 15

Technical Data ............................................................ 16

Limited Warranty ....................................................... 16

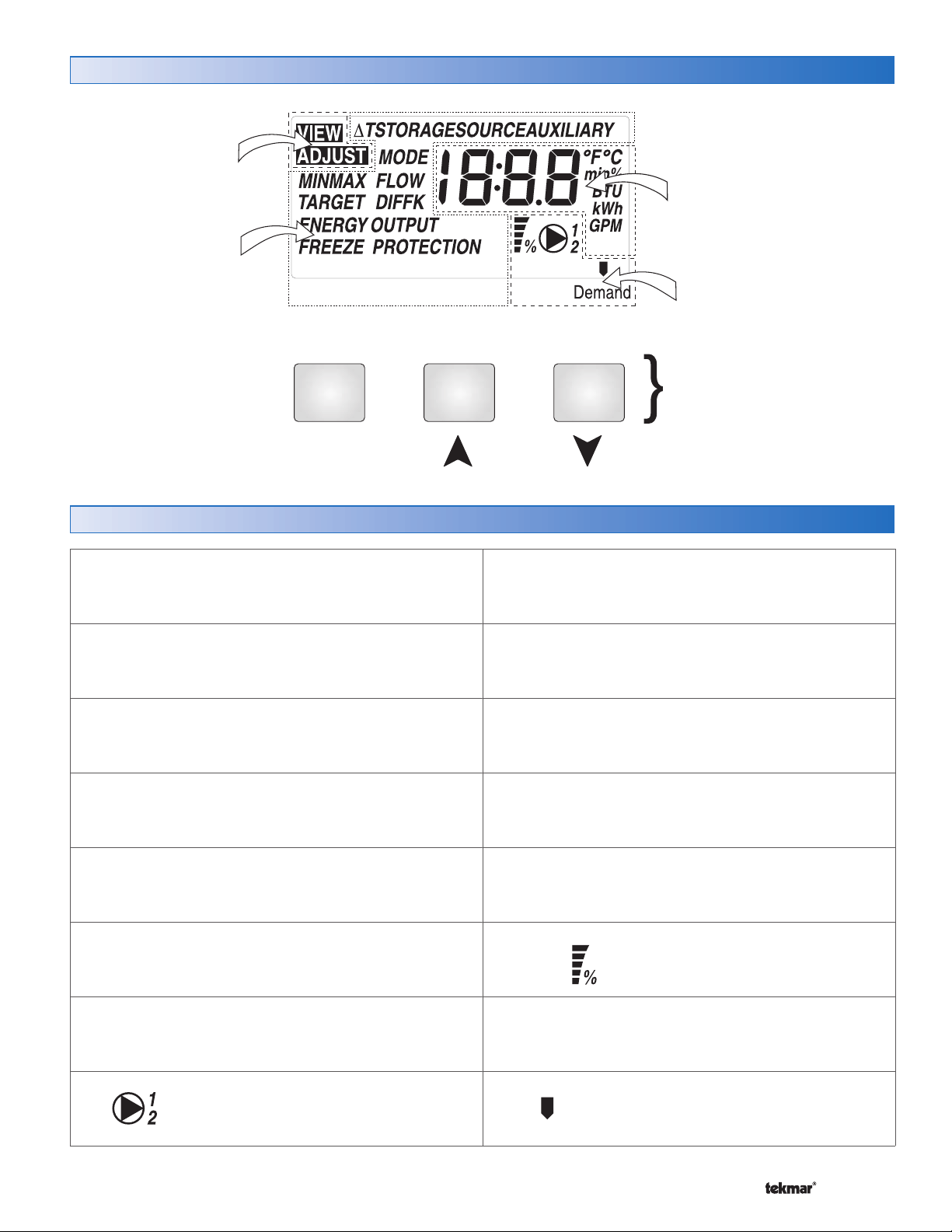

User Interface

The 157 uses a Liquid Crystal Display (LCD) as the method

of supplying information. Use the LCD in order to set up

and monitor the operation of your system. The 157 has

three push buttons (Item, ▲, ▼) for selecting, viewing, and

adjusting settings. When programming the control, record

settings in the Adjust menu table which is found in the

second half of this brochure.

Item

The selected item will be displayed using the segments

available in the screen. To view the next available item,

press and release the Item button. Once you have reached

the last available item, pressing and releasing the Item

button will return the display to the first item.

Item

Adjust

To make an adjustment to a setting in the control, press

and hold simultaneously for 1 second all three (3) buttons.

The display will then show the word ADJUST in the top left

corner. Select the desired item using the Item button. Finally,

use the ▲ or ▼ button to make the adjustment.

Item

© 2010 D 157 - 06/10 2 of 16

Page 3

Display

Menu Field

Displays the

current menu

Item Field

Displays the current

item selected.

Symbol Description

Number Field

Displays the current value

of the selected item

Status Field

Displays the current

status of the relay.

Buttons

Selects Menus, Items

and adjusts settings

Item

ΔT

SOURCE

MODE

FLOW

DIFF

ENERGY

Delta T

Displays the temperature difference

between the source and storage

sensors.

Source

Displays the temperature at the source

sensor.

Mode

Displays the modes of operation for the

on/off pump, P2.

Flow

Displays the maximum flow rate of the

variable speed pump.

Differential

Displays any differential.

Energy

Displays the total number of BTU’s or

kWh’s accumulated by the control’s

energy calculation.

STORAGE

AUXILIARY

MINMAX

TARGET

K

OUTPUT

Storage

Displays the temperature at the

storage sensor.

Auxiliary

Displays the temperature at the

auxiliary sensor.

Minimum and Maximum

Displays the min and max sensor

temperatures.

Target

Displays any target.

Fluid Constant K

Used to calculate heat transfer. Look

up fluid constant in this data brochure.

Output

Displays the % output of variable speed

pump. Each bar represents 20% output.

FREEZE

PROTECTION

3 of 16 © 2010 D 157 - 06/10

Freeze Protection

Displays the status of the freeze

protection function of the control.

Pump

Displays the status of the variable

speed (1) and secondary (2) pump.

°F,°C, min,

% ,BTU, kWh,

GPM

Units of Measurement

Demand Pointer

Displays if a demand is applied to the

control.

Page 4

Sequence of Operation

Section A – General

Powering Up The Control

When the Difference Setpoint Control 157 is powered up,

all segments are displayed in the LCD for 2 seconds, and

then the type number is displayed for 2 seconds. Next,

Source

Sensor

Heat

Source

Pump

Heat

Storage

Storage

Sensor

the software version is displayed for 2 seconds. Finally,

the control enters into the normal operating mode and by

default the LCD displays the current T temperature.

Turn On

Variable Speed Pump

A manufacturer approved wet rotor circulator is connected to

the 157 at the back of the control (see Table 1 for approved

pumps). The 157 increases or decreases the power output

When the variable speed pump turns on, it will operate

at 100% output for an adjustable amount of time before

operating at a variable speed starting at the minimum

pump speed setting.

to the circulator to vary the speed and maintain the target

difference setpoint temperature (∆T) between the source

and the storage sensors. As the ∆T increases, the pump

speed increases and as the ∆T decreases, the pump speed

decreases. The current % output of the variable speed

pump is displayed in the view menu.

Turn Off

If the temperature difference falls below the ∆T target less

the ∆T differential, or below 1°F (0.5°C), the variable

speed pump will operate at the minimum pump speed for

2 minutes before shutting off. The minimum off time for the

variable speed pump is fixed at 2 minutes.

Table 1: Manufacturer approved pump models

Grundfos (F) Taco B & G Armstrong Wilo

15-42 15-58 26-64 43-75 003 007 0010 0012 NRF 9NRF 22NRF

** *** ** *** 25BU 30 50 * ** *** S21FX 17FX 30F

33

Astro Star S16FX Star

*Speed 1,**Speed 2, ***Speed 3

These circulators have been tested and approved by the manufacturer for use with tekmar variable speed electronics.

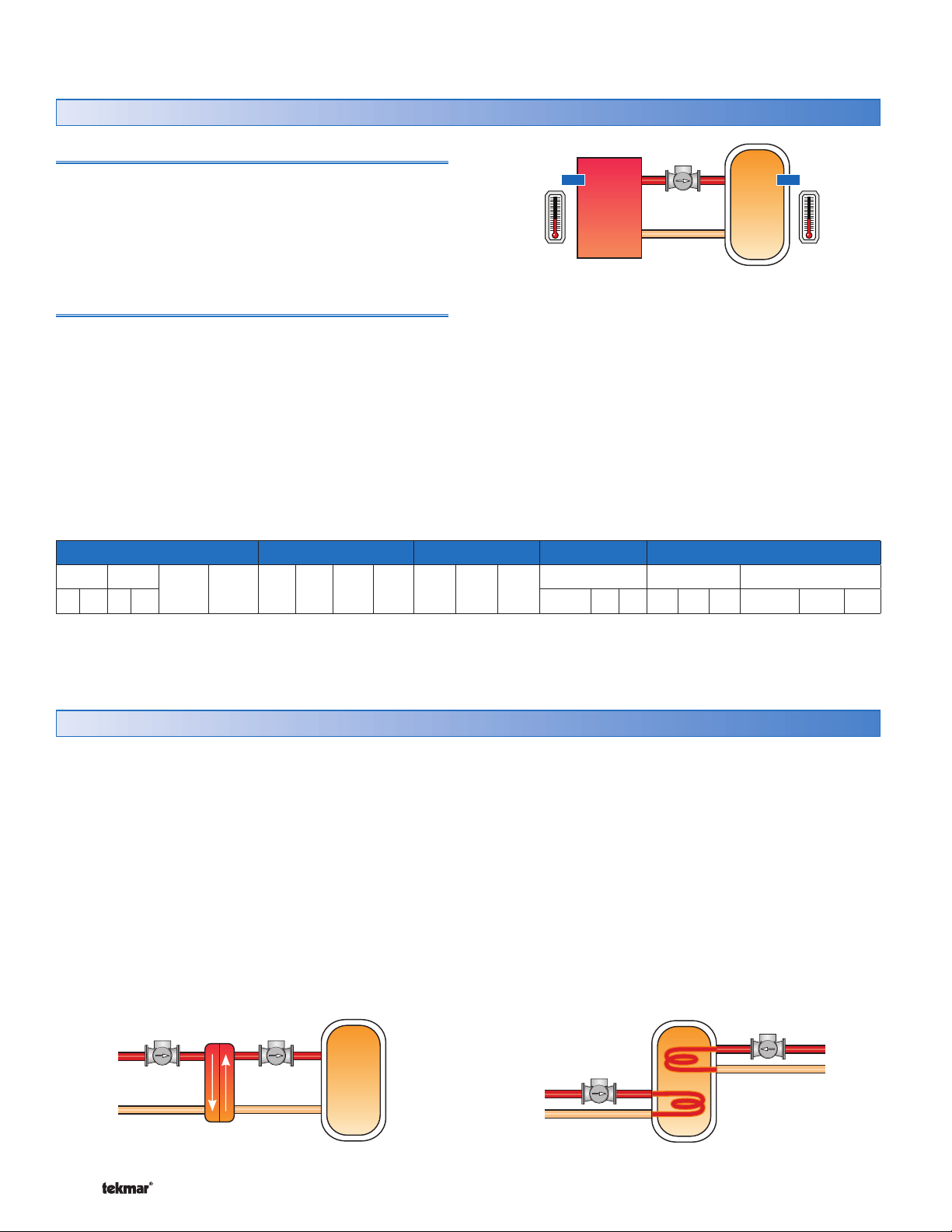

Section B – Modes of Operation

The 157 has a second 120 V (ac) powered output wired

through the back of the control for an on/off pump. The

second pump has 4 adjustable modes of operation

depending on the application.

Mode Off

is for applications where the second pump is

not used. The second pump relay is non-operational. Refer

to application A157-1.

Mode 1 Heat Exchanger is for applications where the

heat exchanger pump is needed to transfer heat between

an external heat exchanger and the storage tank. The heat

exchanger pump relay will operate whenever the variable

speed pump is above 0% output. Refer to application

A157-2.

Variable

Speed Pump

Heat Exchanger

Pump

Heat

Storage

Mode 2 Heat Supplement

is for applications where the

heat supplement pump transfers heat from a supplemental

heat source (i.e. back-up boiler) to maintain the storage tank

above the minimum storage target. The auxiliary sensor is

optional in this mode. Install the auxiliary sensor in the upper

portion of the storage tank. Refer to application A157-3.

If the boiler is not flow activated, the heat supplement pump

output could provide a heat demand to another controller

to turn on the boiler.

In this mode, the minimum on and off time for the heat

supplement pump is fixed at 30 seconds.

Supplemental

Heat Pump

Variable

Speed Pump

Heat

Storage

© 2010 D 157 - 06/10 4 of 16

Page 5

Mode 3 Heat Dump is for applications where an

alternative heat sink can be utilized when the storage tank

and collector are both above their maximum target. The

variable speed pump turns off when the tank exceeds its

max setpoint. The heat dump pump turns on when both

the tank and collectors exceed their max setpoints. If

during a heat dump the storage temperature falls below

its maximum targets less differential, the heat dump pump

relay is turned off and the variable speed pump is allowed

to operate normally. The auxiliary sensor is optional in this

mode. Install the auxiliary sensor in the heat dump. Refer

to application A157-4.

Mode 4 Booster Pump

is for drain back applications

where a booster pump is used to overcome high head upon

system startup. When the T rises above the T target,

the control turns on the booster pump and operates the

variable speed pump at 100% output. After an adjustable

time, the control turns off the booster pump and operates

the variable speed pump above the minimum pump speed

setting. Refer to application A157-5.

Variable

Speed Pump

Heat Dump

Pump

Heat

Storage

Booster

Pump

Variable

Speed

Pump

Heat

Storage

Table 2: Second Pump Mode Summary

MODE NAME DESCRIPTION APPLICATION

Off Off Only the variable speed pump is operational. A157-1

1

2

3 Heat Dump

4

Heat

Exchanger

Heat

Supplement

Booster

Pump

Heat exchanger pump operates together with the variable speed pump. A157-2

Heat supplement pump operates independently of the variable speed pump

to maintain the storage tank at the minimum storage target.

Heat dump pump operates when the storage and source temperatures rise

above their max targets to dump excess heat from the collectors.

Booster pump operates together with the variable speed pump at start up for

an adjustable amount of time to overcome high head in drain back systems.

A157-3

A157-4

A157-5

Section C: Targets and Differentials

MAXIMUM SOURCE TARGET

(Mode = off, 1, 2, and 4)

If the source temperature rises above the maximum source

target, the variable speed pump is turned off. In a drain

back system, turning off the pump allows the fluid to drain

back into a separate tank which protects the collectors from

overheating. Ceasing operation may also protect equipment

like the pump impeller from damage. The pump remains

off until the source temperature falls below the maximum

source target less differential.

Table 3: Outlines when the variable speed pump and heat

dump pump are allowed to operate normally in mode 3.

Table 3 Scenario

1234

Max Storage Setpoint below

Max Source Setpoint below below

above above

above above

below

Variable Speed Pump on off off on

Heat Dump Pump off off on off

(Mode = 3, Heat Dump)

In order for the heat dump pump to turn on, the storage

temperature must be above the Maximum Storage Setpoint

and the source temperature must be above the Maximum

Source Setpoint. If the source or storage temperatures

fall below their maximum targets less differential, the heat

dump pump is turned off. The variable speed pump operates

normally whenever the storage temperature falls below its

maximum setpoint less differential. This setting ensures

MINIMUM SOURCE TARGET

If the source temperature drops below the minimum source

target, the variable speed pump is turned off. In a drain

back system, turning off the pump allows the fluid to drain

back into a separate tank which protects the collectors from

freezing. The pump remains off until the source temperature

rises above the minimum source target plus differential. This

item is only available if freeze protection is turned off.

that the water being supplied to the heat dump is at least

the Maximum Source Target temperature.

5 of 16 © 2010 D 157 - 06/10

Page 6

MAXIMUM STORAGE TARGET

If the storage temperature rises above the maximum storage

target, the variable speed pump is turned off. This protects

the tank from overheating by stopping the transfer of heat

from the collectors. The pump remains off until the storage

temperature falls below the maximum storage target less

differential.

MINIMUM STORAGE TARGET

(Mode = 2, Heat Supplement)

This item is only available in Heat Supplement Mode 2.

The heat supplement pump will operate independently of

the variable speed pump to maintain the minimum storage

target at the storage sensor, or optional auxiliary sensor

if connected. If the temperature falls below the minimum

storage target, the heat supplement pump will turn on and

remain on until the temperature rises above the minimum

storage target plus differential. This ensures that there is

heat available in the storage tank for important loads like

domestic hot water.

CAUTION: If storage is used for domestic hot water,

anti-scald protection may be required by some local

codes.

Figure 1 shows an example of how to set up the max and

min storage targets and differentials.

ΔT TARGET

The T target is the turn on point for the variable speed

pump. Once the T rises above this target the variable

speed pump will operate based on the minimum output

(%), and maximum output (minutes) settings. The control

will continue to vary the speed of the pump until the T

falls below the T target less differential at which point

the pump will run at the minimum output (%) for 2 minutes

before turning off.

MAX AUXILIARY TARGET

This item is only available in Heat Dump Mode 3. If the

auxiliary sensor temperature rises above the maximum

auxiliary target, the heat dump pump is turned off. The

heat dump pump remains off until the auxiliary sensor

temperature drops below the maximum auxiliary target less

differential. Using the auxiliary sensor will prevent the heat

dump, like a pool or second tank, from overheating. There

are no minimum on/off times for the heat dump pump.

MAX AUX TARGET Operation

MAX AUX

Target

OFF

OFF

Supplemental Heat Operation

200

P1

190

OFF

180

170

160

150

140

130

120

MIN Storage

Storage Temperature (°F)

110

100

Target

MAX Storage

Differential

P1

ON

ON

P2

Time

P2

OFF

P1

OFF

MIN Storage

Differential

P1

ON

MAX Storage

Target

P2

OFF

P2

ON

Figure 1: Turn on /off points for the variable speed pump

(P1) and the heat supplement pump (P2) in Mode 2. The

min storage target is below the max storage target. Each

have a 10°F (5.5°C) differential.

Section D – Control Features

FREEZE PROTECTION

If freeze protection is enabled and the source temperature

falls below 35°F (2°C), the variable speed pump will

operate at 100% output for twice as long as it takes the

source temperature to increase to 40°F (4°C). This is

limited to 20 minutes after source temperature reaches

40°F (4°C). This allows the water from the storage tank

to reach the collectors AND flow back to the storage tank

to provide freeze protection to ALL outdoor components.

This item is only available if not in Mode 4.

MAX AUX

Differential

ON ON

Increasing Temperature

Time

Figure 2: On and off points of the heat dump pump, using

an auxiliary sensor in heat dump mode.

This item should only be turned on if:

1) other forms of freeze protection, like drain back, are

not being used

and

2) the heat transfer fluid in the collectors is 100% water

and

3) the outdoor air temperature rarely falls below 35°F

(2°C)

© 2010 D 157 - 06/10 6 of 16

Page 7

MINIMUM OUTPUT, %

This item selects the minimum speed the variable speed

pump will run in order to avoid unwanted drain back when

the pump is running at low speeds in a drain back system.

At low speeds, some pumps stall and provide no flow. It is

important to set the minimum pump speed above this stall

point. This setting is adjustable between 0% and 100%.

At 100% output the variable speed pump operates as an

on/off pump.

MAXIMUM OUTPUT, minutes

When the variable speed pump turns on, it will operate at

100% output for this adjustable amount of time to overcome

high head when filling a drain back system. If the control

is in booster pump mode 4, the variable speed pump and

the booster pump will operate together at 100% output for

this adjustable amount of time.

This item can be used in drainback applications with or

without a booster pump. Set this item to the time it takes

the fluid to circulate through the collectors and into the

drainback tank.

This item can also be used to prevent short cycling of

the pump upon startup in non-drain back applications.

When the variable speed pump turns on, the warm water

in the collector passes by the source sensor causing its

temperature to rise. Once all this water has passed, the

cooler water in the pipe before the collector will pass by the

source sensor causing the temperature to drop; potentially

enough to loose the delta T and thus turn off the pump.

This sequence could happen a number of times before

the system stabilizes and the variable speed pump runs

continuously.

Setting the maximum pump speed (minutes) to the time it

takes the fluid in the storage tank to reach the collectors

will force the system to stabilize and thus reduce any short

cycling of the pump at startup. This is especially important

when the ambient outdoor temperature is very cool.

MONITORING TEMPERATURES

The control includes monitoring of minimum and maximum

Source, Storage, and Auxiliary temperatures in the view

menu. These items may be reset to their respective current

sensor temperature by pressing and holding the ▲ and

▼ buttons simultaneously for 1 second while viewing the

selected item. ‘Clr’ will then be displayed followed by

the value being reset to its respective current sensor

temperature when the buttons are released.

PUMP 2 RUNNING HOURS

The control includes monitoring of the second pump’s

running hours in the view menu where 1 count equals 1

hour. This item may be reset to zero by pressing and holding

the ▲ and ▼ buttons simultaneously for 1 second while

viewing this item. ‘Clr’ will then be displayed followed by the

value being reset to zero when the buttons are released.

Section E – Energy Calculation

To calculate the amount of heat the system has transferred

from the solar collectors to the storage tank, the control

uses the following equation and displays ENERGY in the

view menu in BTU’s or kWh:

Total Heat Transferred = (%T hours) x (Flow) x K

Where:

%T hours is calculated by the control.

•

Flow is the amount of fluid the variable speed pump moves

•

through the system in US Gallons per minute.

K is a fluid constant to be programmed in the adjust menu.

•

K

K is a constant calculated by multiplying the properties of the

fluid; specific heat (BTU/lbm°F) by density (lbm/USGal) by

60 (min/hr). For example, 100% water has a specific heat of

1 BTU/lbm°F and a density of 8.33 lbm/USGal. Therefore

the value of K in this case is 1 x 8.33 x 60 = 500.

The value of K depends on the percent of glycol added to

the heat transfer fluid. Select an appropriate K value from

table 1 and program it into the adjust menu. If 100% water

is used, select K = 500.

Table 4: K values for different heat transfer solutions based

on % glycol.

Ethylene Glycol Solution

% Freezing

Point (°F)

0 32 500 0 32 500

10 23 492 10 26 495

20 14 483 20 18 489

30 2 471 30 7 480

40 -13 453 40 -8 463

50 -36 433 50 -29 443

60 -70 412 60 -55 422

K @

40°F

Propylene Glycol Solution

% Freezing

Point (°F)

K @

40°F

FLOW

In the adjust menu, enter the actual flow rate of the variable

speed pump operating at 100% output in US Gallons per

minute (GPM).

Note: BTU = British Thermal Unit

lbm = Pound Mass

USGal = US Gallon

GPM = Gallon Per Minute

7 of 16 © 2010 D 157 - 06/10

Page 8

Installation

Caution

Improper installation and operation of this control could

result in damage to the equipment and possibly even

personal injury. It is your responsibility to ensure that this

control is safely installed according to all applicable codes

and standards. This electronic control is not intended

for use as a primary limit control. Other controls that are

intended and certified as safety limits must be placed into

the control circuit.

Step One — Getting Ready

Check the contents of this package. If any of the contents

listed are missing or damaged, please contact your

wholesaler or tekmar sales representative for assistance.

Type 157 includes: One Difference Setpoint Control 157, One

Universal Sensor 071, One Solar Sensor, 085, Data Brochures

D 157, D 070, D 085, D 001, Application Brochure A 157.

Note: Carefully read the details of the Sequence of

Operation to ensure that you have chosen the proper

control for your application.

Step Two — Mounting

The control is mounted in accordance with the instructions in the Data Brochure D 001.

Step Three — Rough-in Wiring

The variable speed pump and second pump wiring

terminates in the electrical box. All other wiring terminates

in the two wiring chambers on the control. Determine

whether the low voltage wiring enters the wiring chamber

through the back or the bottom of the control. The wiring

is roughed-in to the electrical box prior to installation of the

control (see Brochure D 001). Standard 18 AWG solid wire

is recommended for all low voltage wiring, and multi-strand

16 AWG wire is recommended for 120 V (ac) wiring.

Power must not be applied to any of the wires during

the rough-in wiring stage.

Install the Source Sensor 085 and Storage Sensor 071

•

according to the instructions in the Data Brochures D 085

and D 070, and run the wiring back to the control.

Run wires from the 24 V (ac) power to the control. Use a

•

clean power source to ensure proper operation.

Step Four — Testing the Wiring

No wires should be connected to the control during testing.

The following tests are to be performed using standard

testing practices and procedures, and should only be

carried out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from

at least 0 - 300 V (ac) and at least 0 - 2,000,000 Ohms, is

essential to properly test the wiring and sensors.

Test the Sensors

In order to test the sensors, the actual temperature at

each sensor location must be measured. A good quality

digital thermometer with a surface temperature probe is

recommended for ease of use and accuracy. Where a

© 2010 D 157 - 06/10 8 of 16

digital thermometer is not available, a spare sensor can be

strapped alongside the one to be tested, and the readings

compared. Test the sensors according to the instructions

in the Data Brochures D 085 and D 070.

Page 9

Test the Power Supply

Make sure exposed wires and bare terminals are not in

contact with other wires or grounded surfaces. Turn on

the power and measure the voltage across the 24 V (ac)

power supply with an AC voltmeter. The reading should be

between 20 and 28 V (ac).

LN

Class 2

Transformer

RC

Step Five — Electrical Connections to the Control

Test the Outputs

Variable Speed and Second Pump

Connect the power supply L and N directly to each pump

and use the panel breaker switch to test for 100% output.

If the pump does not operate, check the wiring and refer

to any installation or troubleshooting information supplied

with the pump. If the pump operates properly, turn off the

power at the breaker and follow wiring instructions to provide

power through the control.

The installer should test to confirm that no voltage is present

at any of the wires.

Powered Input Connections

24 V (ac) Power

Connect the 24 V (ac) power supply to the Power C and

Power R terminals (6 and 7). This connection provides

power to the microprocessor and display of the control.

LN

567

Power

RC

Enable/Disable Demand

To generate a demand, terminal 5 must be connected to

terminal 7 (R) through a switching device.

24 V (ac)

Demand

Switch

Dem C R

567

Power

Dem C R

2.5A 250V (ac). Contact your tekmar sales representative

for details on the repair procedures if this circuit is blown.

Connect one of the wires from the variable speed pump

to the blue wire at the back of the control. Connect the

black wire from the back to the live (L) side of the 120 V

(ac) power source. The other wire on the variable speed

injection pump must be connected to the neutral (N) side

of the 120 V (ac) power supply. Connect the green wire on

the back of the control to ground.

Second Pump

Connect one of the wires from the Second pump to the

red wire at the back of the control. Connect the black

wire from the back of the control to the live (L) side of the

120 V (ac) power source if not already connected. The

other wire on the Second pump must be connected to the

neutral (N) side of the 120 V (ac) power supply. Connect

the green wire on the back of the control to ground if not

already connected.

157 bottom view

Second

Black

Red

Blue

Green

Pump

(Connect

Pump

to Red

on 157)

Output Connections

Variable Speed Pump

The 157 can vary the speed of a permanent capacitor,

impedance protected, or equivalent pump motor that has a

locked rotor current of less than 2.4A. Most small wet rotor

circulators are suitable as described in table 1. The 157

has an internal overload protection circuit which is rated at

9 of 16 © 2010 D 157 - 06/10

Variable

Speed

Pump

(Connect

to Blue

on 157)

Pump

LN

G

120 V (ac)

Page 10

Sensor and Un-powered Input Connections

Do not apply power to these terminals as this will damage

the control.

Source Sensor

Connect the two wires from the Source Sensor 085 to the

Com and Src terminals (1 and 2). The Source Sensor is

used by the 157 to measure the solar collector temperature.

Insert the Solar Sensor 085 into a temperature well, or

alternatively strap the Solar Sensor 085 on the outlet pipe

close to the heat source with a stainless steel clamp.

Storage Sensor

Connect the two wires from the Storage Sensor 071

to the Com and Stor terminals (1 and 3). The Storage

Sensor is used by the 157 to measure the Storage tank

temperature.

Auxiliary Sensor

The auxiliary sensor can only be used when the control is

in either mode 3, heat supplement, or mode 4, heat dump.

The 157 will auto detect when an auxiliary sensor is wired

to terminals 1 and 4.

Connect two wires from the Auxiliary Sensor 071 to the Com

and Aux terminals (1 and 4). The Auxiliary Sensor is used

by the 157 to measure either the heat dump temperature

or the upper storage tank temperature.

Do not apply power

1234

Com

Src Stor Aux

Do not apply power

1234

Com

Src Stor Aux

Do not apply power

1234

Com

Src Stor Aux

Solar Collector

Mode 3

Auxiliary

Heat

From

Collector

Mode 4

From

Collector

Control Settings

DIP Switch Settings

Demand: Enable / Disable

The Enable / Disable DIP switch is used to select whether

the demand will enable or disable the control. If a demand is

present, a pointer will be displayed at the bottom right hand

corner of the LCD pointing to the word Demand. Applying

a demand resets any minimum on/off times.

If Enable is selected, the outputs will remain off until the

demand is powered and the control is enabled, allowing

the outputs to operate normally.

If Disable is selected, the outputs will operate normally

until the demand is powered and the control is disabled,

turning off all outputs.

Item

Heat

Dump

1

%

2

© 2010 D 157 - 06/10 10 of 16

Page 11

Display Menus

View Menu (1 of 2)

View Next Item

Item

Item Field Range Description

-99 to 300°F

(-73 to 149°C)

2 to 90°F

(1 to 50°C)

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

The View menu items display current operating

temperatures and system status information.

Item button to view items in this menu.

DELTA T

Current temperature difference between the source and storage

sensors.

DELTA T TARGET

The target temperature difference between the source and

storage sensors as programmed in the adjust menu.

SOURCE TEMPERATURE

Current source temperature as measured by the source

sensor.

STORAGE TEMPERATURE

Current storage temperature as measured by the storage

sensor.

Use the

VIEW MENU

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

-30 to 300°F

(-34 to 149°C)

AUXILIARY TEMPERATURE

Current auxiliary temperature as measured by the auxiliary

sensor. Note: this item is only available if the auxiliary sensor is

connected to the control.

SOURCE MAXIMUM

Maximum source temperature since this item was last cleared. To

clear, press and hold the up and down buttons for 1 second.

SOURCE MINIMUM

Minimum source temperature since this item was last cleared. To

clear, press and hold the up and down buttons for 1 second.

STORAGE MAXIMUM

Maximum storage temperature since this item was last cleared. To

clear, press and hold the up and down buttons for 1 second.

STORAGE MINIMUM

Minimum storage temperature since this item was last cleared. To

clear, press and hold the up and down buttons for 1 second.

AUXILIARY MAXIMUM

Maximum auxiliary temperature since this item was last cleared.

To clear, press and hold the up and down buttons for 1 second.

Note: this item is only available if the auxiliary sensor is connected

to the control.

Continued on next page.

11 of 16 © 2010 D 157 - 06/10

Page 12

View Menu (2 of 2)

Item Field Range Description

-30 to 300°F

(-34 to 149°C)

AUXILIARY MINIMUM

Minimum auxiliary temperature since this item was last cleared.

To clear, press and hold the up and down buttons for 1 second.

Note: this item is only available if the auxiliary sensor is connected

to the control.

0 to 100%

0 to 1,999,999

BTU or kWh

VIEW MENU

0 to 1,999,999 hours

After the last item, the control returns to the first item in the menu.

PUMP SPEED

Current % output of the variable speed pump.

ENERGY TRANSFER

Total amount of BTU’s or kWh’s transferred from the source to

the storage since this item was last cleared. To clear, press and

hold the up and down buttons for 1 second.

1 count = 1000 BTU.

PUMP 2 RUNNING HOURS

The total running time of pump 2 since this item was last cleared.

To clear this item, press and hold the up and down buttons for

one second. 1 count = 1 hour.

Adjust Menu (1 of 3)

Next ItemEnter Adjust Menu

ItemItem

Change Value

The Program menu items are the programmable settings

used to operate the system. Press and hold all three

buttons simultaneously to enter the Program menu.

Item Field Range Description Actual Setting

MODE

OFF, 1, 2, 3, 4

Default = OFF

2 to 90°F

(1 to 50°C)

Default = 15°F

(8°C)

2 to 45°F

(1 to 25°C)

Default = 10°F

ADJUST MENU

Continued on next page.

© 2010 D 157 - 06/10 12 of 16

(5.5°C)

50 to 200°F

(10 to 93°C)

Default = 180°F

(82°C)

Mode of operation for Second pump, P2.

Mode 1 = Heat Exchanger, Mode 2 = Heat

Supplement, Mode 3 = Heat Dump, Mode 4 =

Booster Pump, Mode = Off (no P2 operation)

DELTA T TARGET

The variable speed pump, P1, will try to maintain

the temperature difference between the source and

storage at this target.

DELTA T DIFFERENTIAL

When the delta T drops this differential below the

delta T target the variable speed pump, P1, will

run at the minimum % output for 2 minutes then

turn off.

MAXIMUM STORAGE TARGET

If the storage temperature rises above this maximum

target, the variable speed pump is turned off.

Page 13

Adjust Menu (2 of 3)

Item Field Range Description Actual Setting

ADJUST MENU

2 to 45°F

(1 to 25°C)

Default = 10°F

(5.5°C)

70 to 190°F

(21 to 88°C)

Default = 140°F

(60°C)

2 to 45°F

(1 to 25°C)

Default = 10°F

(5.5°C)

190 to 260°F,

OFF

(88 to 127°C,

OFF

Default = OFF

2 to 45°F

(1 to 25°C)

Default = 10°F

(5.5°C)

OFF, 50 to

185°F

(OFF, 10 to

85°C)

Default = OFF

2 to 45°F

(1 to 25°C)

Default = 10°F

(5.5°C)

MAXIMUM STORAGE DIFFERENTIAL

The variable speed pump will turn back on when

the storage temperature falls this differential below

the Max Storage Target.

MINIMUM STORAGE TARGET

(Mode 2)

The supplemental heat pump, P2, will turn on when

the storage temperature falls below this target.

Optional Auxiliary Sensor.

MINIMUM STORAGE DIFFERENTIAL

(Mode 2)

The supplemental heat pump will turn off when the

storage temperature rises this differential above the

Min Storage Target. Optional Auxiliary Sensor.

MAXIMUM SOURCE TARGET

The variable speed pump will turn off if the source

temperature rises above the Maximum Source

Target. See Table 3 for Mode 3 operation.

MAXIMUM SOURCE DIFFERENTIAL

(Maximum Source Target

The heat dump pump will turn off when the

storage temperature falls this differential below

the Maximum Source Target.

MINIMUM SOURCE TARGET

If the source temperature drops below this setpoint

the injection pump is turned off

MINIMUM SOURCE DIFFERENTIAL

(Min Source Target ≠ Off)

The variable speed pump will turn back on when

the source temperature rises this differential above

the Minimum Source Target.

≠

Off)

50 to 220°F

(10 to 104°C)

Default = 100°F

(38°C)

2 to 45°F

1 to 25°C

Default = 10°F

(5.5°C)

ON, OFF

Default = OFF

Continued on next page.

13 of 16 © 2010 D 157 - 06/10

MAXIMUM AUXILIARY TARGET

(Mode 3)

The heat dump pump will turn off when the auxiliary

temperature rises above this target.

MAXIMUM AUXILIARY DIFFERENTIAL

(Mode 3)

The heat dump pump will turn on when the

auxiliary temperature falls this differential below

the Maximum Auxiliary Target.

FREEZE PROTECTION

(Mode ≠ 4)

If the source temperature falls below 35°F (2°C),

the variable speed pump will turn on at 100% output

until the source temperature rises to 40°F (4°C).

Page 14

Adjust Menu (3 of 3)

Item Field Range Description Actual Setting

0% to 100%

Default = 0%

OFF,

0:10 to 10:00

minutes

Default = 3:00

Min

MINIMUM OUTPUT, %

Minimum pump speed for the variable speed pump

to prevent unwanted drainback at low speeds. At

100% Output, the pump operates as an On/Off

pump.

MAXIMUM OUTPUT, MINUTES

Time the variable speed pump operates at 100%

output upon startup to fill a drainback system. If in

Mode 4, Booster Pump, this is also the time the

booster pump will run upon startup.

400 to 500

Default = 500

0 to 45 GPM

Default = 5.0

ADJUST MENU

°F, °C

Default = °F

After the last item, the control returns to the first item in the menu.

K

Fluid constant to be used to calculate total energy

transfer in BTU’s or kWh.

MAXIMUM FLOW

The actual flowrate of the variable speed pump, P1,

at 100% output. Used to calculate the total energy

transfer in BTU’s. (Depends on head, see pump

curve or measure independently).

UNITS

Pressing the up or down button on this item changes

the units of measure for the control between Celsius

and Fahrenheit.

ESCAPE

This item exits the ADJUST menu by pressing

either the up or down button.

Field Test

Press and hold the up button for 3 seconds to enter the test

routine. The number field will display tSt until the button is

released and then the test routine will begin.

Step 1: The variable speed pump ramps up to 100% over

10 seconds.

Step 2: The variable speed pump ramps down to 0% over

10 seconds.

Step 3: The second pump turns on for 10 seconds.

Once step 3 is completed the test routine is finished. The

control will then resume normal operation.

The test routine can be paused at any time by pressing the

up button during any of the 3 steps. This is important so that

the installer can fill the system or check to see where the

stall point is or check the operation of the second pump. If

the test is paused for 24 hours, the control will exit the test

routine and resume normal operation.

© 2010 D 157 - 06/10 14 of 16

The down button can be pressed during step 1 to toggle on

and off P2. The down button can be pressed during step 3

to turn off the second pump and exit the test routine. This

test sequence is only available in the View menu.

Item

Page 15

Error Messages

All errors are latching. If the error condition has been repaired, the control will continue to operate normally. The error

message can be manually cleared by pressing the item button.

EEPROM READ ERROR

The control was unable to read a piece of information from its EEPROM. This error can be

caused by a noisy power source. The control will load the factory defaults and stop operation

until all the settings are verified. To clear, view all items in the ADJUST menu.

STORAGE SENSOR ERROR

The control is no longer able to read the Storage Sensor due to an open or short circuit.

Locate and repair the problem as described in the Data Brochure D 070. The relays will

remain off until the error is cleared and the 5 minute minimum off time has elapsed.

SOURCE SENSOR ERROR

The control is no longer able to read the Source Sensor due to an open or short circuit.

Locate and repair the problem as described in the Data Brochure D 085. The relays will

remain off until the error is cleared and the 5 minute minimum off time has elapsed. If freeze

protection is enabled, the relays will remain on as a fail safe.

AUXILIARY SENSOR ERROR

The control is no longer able to read the Auxiliary Sensor due to an open or short circuit.

Locate and repair the problem as described in the Data Brochure D 070. The relays will

remain off until the error is cleared. If the sensor was connected then deliberately removed

after power up, power cycle the control to clear the error.

15 of 16 © 2010 D 157 - 06/10

Page 16

Technical Data

Difference Setpoint Control 157 Variable Speed

Literature — D 157, A 157, D 001, D 070, D 085

Control — Microprocessor control; This is not a safety (limit) control

Packaged weight — 1.5 lb. (670 g)

— Enclosure C, White PVC Plastic

Dimensions — 4-3/4” H x 2-7/8” W x 7/8” D (120 x 74 x 22 mm)

o

Approvals — CSA C US, CSA 22.2 N

ICES & FCC Part 15

Ambient conditions — Indoor use only, -20 to 120°F (-30 to 50°C),

< 90% RH non-condensing

Power supply — 24 V (ac) ±10%, 50/60 Hz, 3 VA

Var. Pump — 120 V (ac) 2.4 A 1/6 hp, fuse T2.5 A 250 V

Pump 2 — 120 V (ac) 5 A 1/6 hp

Demand — 24 V (ac) 2 VA

Sensors — NTC thermistor, 10 kΩ @ 77°F (25°C ±0.2°C) ß=3892

included: — 1 of Solar Sensor 085

— 1 of Universal Sensor 071

24 and UL 873, meets class B:

Limited Warranty and Product Return Procedure

Item

ΔT

F

1

%

2

Limited Warranty The liability of tekmar under this warranty is limited. The Purchaser, by taking receipt of any tekmar product (“Product”), acknowledges the terms of the Limited Warranty in effect at

the time of such Product sale and acknowledges that it has read

and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold

hereunder is a manufacturer’s pass-through warranty which the

Purchaser is authorized to pass through to its customers. Under

the Limited Warranty, each tekmar Product is warranted against

defects in workmanship and materials if the Product is installed and

used in compliance with tekmar’s instructions, ordinary wear and

tear excepted. The pass-through warranty period is for a period of

twenty-four (24) months from the production date if the Product is

not installed during that period, or twelve (12) months from the documented date of installation if installed within twenty-four (24) months

from the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at

tekmar’s sole discretion: the cost of parts and labor provided by tekmar

to repair defects in materials and/or workmanship of the defective product; or to the exchange of the defective product for a warranty replacement product; or to the granting of credit limited to the original cost of the

defective product, and such repair, exchange or credit shall be the sole

remedy available from tekmar, and, without limiting the foregoing in any

way, tekmar is not responsible, in contract, tort or strict product liability, for any other losses, costs, expenses, inconveniences, or damages,

whether direct, indirect, special, secondary, incidental or consequential,

arising from ownership or use of the product, or from defects in workmanship or materials, including any liability for fundamental breach of

contract.

The pass-through Limited Warranty applies only to those defective Products returned to tekmar during the warranty period. This Limited Warranty does not cover the cost of the parts or labor to remove or transport

the defective Product, or to reinstall the repaired or replacement Product,

all such costs and expenses being subject to Purchaser’s agreement and

warranty with its customers.

Any representations or warranties about the Products made by Purchaser

to its customers which are different from or in excess of the tekmar Limited Warranty are the Purchaser’s sole responsibility and obligation. Purchaser shall indemnify and hold tekmar harmless from and against any

and all claims, liabilities and damages of any kind or nature which arise

out of or are related to any such representations or warranties by Purchaser to its customers.

The pass-through Limited Warranty does not apply if the returned Product has been damaged by negligence by persons other than tekmar,

accident, fire, Act of God, abuse or misuse; or has been damaged by

modifications, alterations or attachments made subsequent to purchase

which have not been authorized by tekmar; or if the Product was not

installed in compliance with tekmar’s instructions and/or the local codes

and ordinances; or if due to defective installation of the Product; or if the

Product was not used in compliance with tekmar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, WHICH THE GOVERNING LAW ALLOWS PARTIES TO

CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION,

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE

PRODUCT, ITS NON-INFRINGEMENT OF ANY RELEVANT PATENTS

OR TRADEMARKS, AND ITS COMPLIANCE WITH OR NON-VIOLATION OF ANY APPLICABLE ENVIRONMENTAL, HEALTH OR SAFETY

LEGISLATION; THE TERM OF ANY OTHER WARRANTY NOT HEREBY

CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT

EX TEND BEYOND TWEN TY- FOU R (24) MON THS FRO M TH E PROD UCTION DATE, TO THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY

THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to

have defects in workmanship or materials must be returned, together

with a written description of the defect, to the tekmar Representative

assigned to the territory in which such Product is located. If tekmar

receives an inquiry from someone other than a tekmar Representative,

including an inquiry from Purchaser (if not a tekmar Representative) or

Purchaser’s customers, regarding a potential warranty claim, tekmar’s

sole obligation shall be to provide the address and other contact information regarding the appropriate Representative.

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head Office: 5100 Silver Star Road

Vernon, B.C. Canada V1B 3K4

(250) 545-7749 Fax. (250) 545-0650

Web Site: www.tekmarcontrols.com

Product design, software and literature are Copyright © 2010 by:

tekmar Control Systems Ltd. and tekmar Control Systems, Inc.

16 of 16

All specifications are subject to change without notice.

Printed in Canada. D 157 - 06/10.

Loading...

Loading...