Tascam 3030 Service Manual

w

.€

=F-

(

TASCAM

TEAC Professional

Division

.,

il./e

W'qHftT

3'e

k/D"

62ap

71

/

o'.fu

d,

4lP*a4

a'/

---?

-2,-a*e,':t'

Zilz

n

firc-t'4*

SERr/ICE

iAANU

\L

-

3030

Stereo

Tape

Deck

z

NOTES

As regards the

resistors and capacitors, refer

to the

circuit

diagrams

and

the PCB ass'y drawings contained

in

this manual.

*

*

Parts

marked

with

*

require longer

delivery

time.

Resistor values

are

in

ohms

(k

=

1,000

ohms,

M = 1,000,000

ohms).

All

capacitor

values

are in

microfarads

(p

=

picofarads).

A

Parts marked

with this sign are safety

critical

components.

They must

always be

replaced with

identical components

-

refer

to the TEAC Parts List

and ensure exact

replacement.

0 dB

is

referenced

to lV

in

this

manual unless otherwise

specifi-

ed.

PC

boards

shown viewed

from

foil side.

Parts not shown

in the

parts

lists

or

parts,

through

listed, having

no

parts

numbers

are not

general

"ready-to-supply"

parts.

o

dbx Noise Beduction

system

made under

license

from

dbx,

lncorporated. The name'"dbx"

and the dbx symbol are

trademarks of dbx,

Incorporated.

rif,

i+-'+al&.+fi.'.

=>7>+t-

ct€n6 L

<

&>

t)

* ?"

EE6tr

.&u*tEtr

t

+r,q

L

( (

/: a

t..

|

.

jt)

>

F

EtFEti/rt

->ffihrjrr3fu(r'*-f.

2

.

*

EIla)Hlfr

(Jftfr

-pfihrE+h.h,,)

*t

"

b

4 h' c

b

:J

a

(

/: d

t'"

3

.

AEIrtjteiEffi=E**15&('f"

tt*{

6

t

3

$'v't7 4

7

'v

2

]?E.Jj=*fJff

A1trH

L

(T

3

t."

4

.

t/

^)v(todB:

tva4+t: L <t. *

f"

5

.

)

>7>to41il1rF.p:pr(l/F:

1,000,000pF)

6.

ry&rr&=3

fl(r. 6f-&>t,.

$lF"r EE6trr'-*[JE:

<r'6taeh:b() *t"

7

.

U

Z

l- 6 11(

L'

A

t'*ttF.

(i/FF|J

Z

L

<

t

-

C

z

{^lita*Ef.

t L-cEt*8.->

(

r.

*

tl,"

odbxdijLidbx"

?{Sclbxl

> r'-fi1'

-'v

fai,f.3*

ti,'ifii

-d.

r

dbr

) Z

i A l*

dbx

{

>:

tf'

)

--

r

-.t

t-

O'ii

Irfu

tfi:

la

1!

I

t\

Cb!jn-*.1-t Ct\tT.

+\

Effective; March. 1989

930153

5704043400

1

SPECIFICATIONS

AND

SERVICE

DATA

,lx&t.r-c7-7

-t

MECHANICAI

CHARACTE

BISTICS

Tape

Format

2-lrack,

2-channel

recording/

repr00uce

4-trak,

2-channel

reproduce

Max.

Reel

Size 10-112"

,

NAB

hub

Tape

Speed 38

cm/s

(15

ips)

and lg

cm/s

(7.5

ips)

Speed

Accuracy

!0.5

% deviation

Pitch

Control

16

%

Wow

and

Flutter

10.07

%

peak

weighted

(DlN

45507)at

l5 ips,

10.08

%

peak

weighted

(DlN

45507)at

7.5

ips

Fast Wind

Time approx.

100 sec.

for

1,800

ft.

Motors

Capstan

FG

servo DC

motor

Reel

2 DC

slotless motors

Head

Conliguration

4 heads;

2-track

Z-channel

erase, record,

reproduce

and 4-track

2-channel

reproduce

Dimensions

432

x 456

x

268

mm

(17"

x

11-5116"

x l0-9/16")

Weight

{net)

21 kg

(46.5/16

lbs)

ETECTBICAT

CHARACTERISTICS

Mic

Input

Input

lmpedance

10

kohms,

balanced

Applicable

Mic

lmpedance

200

ohms

or

m0re

Minimum

Input

Level

-72

dBV

(0.25

mV)

Line

Input

Balanced/

Unbalanced

Input

lmpedance

-

I

0

koh ms/

50 kohms

Maximum

Source lmpedance

2

kohms/'10 kohms

Nominal

Input

Level

+4

dBm

(1.23v|1-10

dBV

{0.3

V}

Maximum

Input Level

+28

dBm

(t9.5

V)/

+18

dBV

(8.0

V)

Line

Output

Balanced

/

U nbalanced

0utput

lmpedanc,e

100

ohms/

500

ohms

Minimum

Load

lmpedance

600 ohms/3

kohms

Nominal

Load lmpedance

10 kohms/

l0

kohms

Nominal

Output

Level

+4

dBm

(1.23

V)/-10

dBV

(0.3

V)

Maximum

Output level

+28

dBm

(19.5

V)/+lB

dBV

(8.0

V)

Headphone

0utput

Level

(where

applicable)

50 mW

max. into

8

ohms

Bias Frequency

150 kHz

Equalization

3,180

+

50

ps

at

15

ips

and

7.5 ips

Operating

Level

320

nWb/m

or 250

nWb/m

sar itch ab le

Power

RequiremenB

USA/CANAOA 120

V AC,

60

HZ

U.K./AUSTRALTIA

240

V AC,

50 HZ

EUR0PE 220 V

AC.

50 Hz

c

Er{ EBAr

EXP0 RT

1001

1 20

|

220t 240

V AC,

50/60

HZ

Power Consumption

120 Watts

TYPICAT PERFOBMANCE

Frequency

Besponse

(Record/Beproduce)

40

Hz - 22 k1z

12

dB

(0

VU,15

ips)

30 Hz

-

20 kHz

t2

dB

(-10

VU, 7.5 ips)

Total Harmonic

Distortion

(THD)

0.5%at0VU,1kHz

Si

gnal-to-

ltloise Ratio

(

overall

)

(

R ef eren ced

3 %THD at 1 kHz)

dbx-in

98 dB

(NAB

A

Weighted) at l5

and

7.5

ios

dBx-out

68 dB

(NAB

A Weighted) at

l5 and

7.5

ips

Adiacent

Channel Crosstalk better than

55 dB

(1

kHz)

Erasure

better than 70 dB

{1

kHz.

+10

VU)

In these specifications,0

dBm

is referenced

t0 0.775

Volt.

0 dBV is referenced to

1.0 Volt. Actual

voltage

levels are

also

given

in

parentheses.

Changes

in specifications and

features

may

be made without

notice

or obligation.

dbx

is a trademark of dbx Incorporated.

.

J,

A

IXffi+ a 0 dBV

t* 1.0v,

0 dBmtt0.775

v-++L

t

rr\td.

Xlryti'o)€Jrb

(

) <-LTt\*f.

.

I+ +ft

& U

*ffi,

l*e9.

#

a f;

v,>

a L-

t*

(

AE

-r

6a Xh\6t)

*t.

-\

-\

^q

-

Tension arm

guide

roller:0.05mm

to 0.3mm

0.1mm

to

0.25mm

(magnefloat

type)

0.05mm to

0.3mm

0

(spring

type)

0

(spring

type)

2- 1

trl+r*F@z

-

7l.

?

t)

7. > z.

t

-.yj

u-F

tt>zlL(tKffig)

+1')7.5 >.>p

I

l-.

:

0.r-0.2Snn(.t2l-tn-l-.t4i)

h4ts'D

-

;0.05-0.3mm

7)z)=>.7-L.h4

ts.D--

|

0.05-0.3mm

t)

-.)v.t-t

:0(7.jt)

>t.t4

))

7)z)=>.7-/^

'.0(7it,)

>t.t<

))

i+.

+pj7.t> . )tt

t-|J?t+)D

lt4taH,

€,H t"l

*r

tr

t* 7.-

^

F'1

tJ

X

t6t

(j,v

*

14ffi

ti

rhJ )

t-

+ry

dnrr\6SAnEiE:+

6. X.

2=2

4+/7t>.--tO*.&

|

.

+

p

i

^t

>

.

T

-

t ti+^i

6t*+tt.,laz-lf)x11

h\-t<

t

2':t

)

P

ow\It t

J{iE

l.it.Hq6

- &

.

2.q(ff14FWD,

REVA#*E

Ltr&d

,

+pi^t >

.

^1,

l-.

oEliIi.Eh\7-/)-

^t-t1tF.6.

t &ie,iBt

6- t:

.

2-3

Jv-+FEg

1 .

) l/

-+h\h\r\

I

r-ltLq

(-

v

-+

.')

tr

)

-l

F

oFF)

-c,7

L,-+'y

-LX

t,)

)U.T

t. >p

-tA^+1hi+irlt

-*6J

) t

D

-+'

/\>

F

.

) i tt,'t

F.qr1+{tE€AtHt-

d{451.5.

2.ikt.,

)t,-+.yv

)

i F.aoN.oFFt,7r8*o)->)

1'

0)

7

f

rf

-

t

hii(jJznnlr

fa

5 3

-

la,

) l,

-

+.') 1,,

)

4

t-

a

g(ft

ttt'tE

&

D

h

fri

t.ffi#t

6

.

3.)

tr

-+.')

>

)

/ f-. ONjlJiflqov+,

.

t-+.

1- AX) L/

-

+

.

) t

)1,

I

t:

i\{*B*

U

r*

ur

J:

.

la,

)

1,

-

+

.

/ \

>

l-..

€

tJ

a

g(t

tJ

Ii.E6:8,

C, E

h fri

t.

ffi

g?

6

.

4.d4'g1*,'+

^T

a--)+R{Ftftt(,

t>

>

=

>#a>,

i

-

j+Ldl+h\+,

U-d(L\ a

Xt$E"ix.lt

6.

reel motor

chassis

solenoid

plunger

brakg

arm

brake

felt

brake

band

brake solenoid

solenoid

mounting

screws

deck

\

-

2

MECHANICAL

ADJUSTMENTS

AND

CHECKS

&E*Bo]-dH*rrE-#.

2.1 ROTATING PART

THRUST

CLEARANCE

CHECKS

Reference values

Capstan shaft:

I

nertia roller:

Reel motor:

Tension arm:

ilOTE:

Since

the

capstan

shaft

is

a magnefloat

type,

check that

it is

forced

towards

the

rear

of the deck

while rotating.

2.2

CAPSTAN

MOTOR

REPLACEMENT

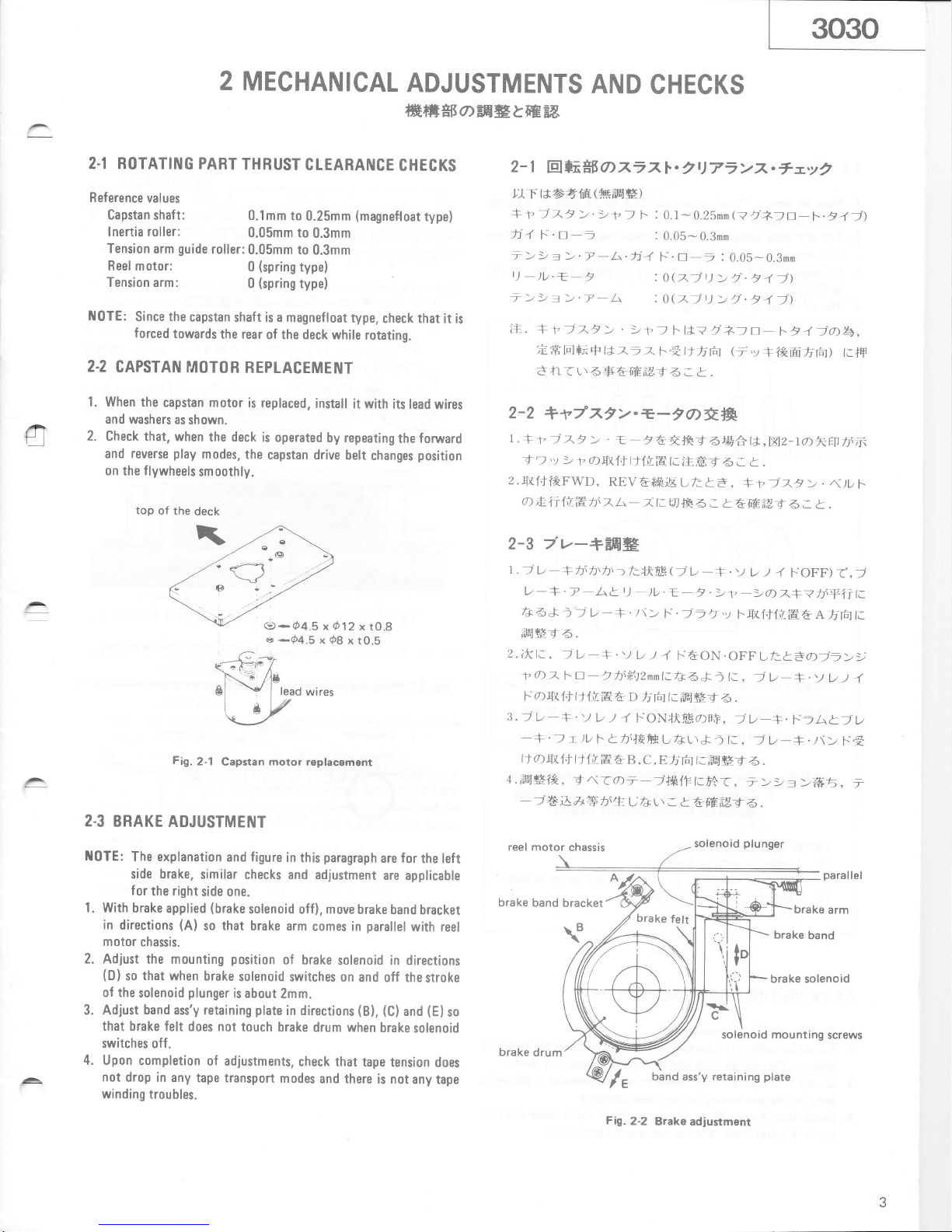

l. When the

capstan

motor is

replaced.

install

itwith

its lead wires

and washers

as

shown.

2. Check that,

when

the deck

is operated

by repeating

the forward

and reverse

play

modes,

the

capstan drive

belt

changes

position

on the flywheels

smoothly.

top

of

the

Fig.

2.1

Capstan motor replacoment

2-3 BRAKE

ADJUSTMENT

ttl0TE:

The explanation

and figure

in this

paragraph

are for

the left

side brake,

similar

checks and

adjustment

are applicable

for

the right

side one.

1.

With brake

applied

(brake

solenoid off), move

brake

band bracket

in directions

(A)

so

that

brake

arm

comes

in

parallel

with reel

motor

chasis.

2.

Adiust the mounting

position

of brake

solenoid in directions

(D)

so

that

when brake

solenoid

switches on and

off the

stroke

of the

solenoid

plunger

is

about

2mm.

3. Adjust

band

ass'y retaining

plate

in directions

(B), (C)

and

(E)

so

that brake

felt

does not

touch brake

drum when

brake

solenoid

switches off.

4. Upon

completion

of adjustments,

check that tape

tension

does

not drop

in any

tape transport

modes

and there

is notanytape

winding

troubles.

G)-O4.5

x O12

x tO.8

<s

-Q4.5

x 08

x t0.5

*=€,07

]\-- 1i5

brake

drum

Fig.

2-2

Brake adjustment

-

2.

3.

4.

24

BRAKE

TOBOUE MEASUREMENT

l. Pface

an empty 7" reel,

connected to

a spring

scale

by

a

string,

on

the reel table.

Pull

the

scale away

from

the reel

and read the

scale

indication

only

when the reel

table is

steady motion.

Do steps 1 and

2

for

each measuring

condition,

(A)

through

(01

in Fig.

2-3.

The values

are as chart in Fig.

2-3.

Fig.2-3

2.5

PAUSE

POSITION

ADJUSTMENT

1.

Place

the

deck

in the

pause

mode.

2. Adjust

by

turning

the

pause positioning

nut

so

that

the clearance

between

the capstan

shaft and the tape is

0.5mm

to 1.0mm.

3. 0f the two

capstan shaft/pinch rollen,

adjustment is allowable

only

for

the

side

having the

narrower

clsarance.

4.

Check

that,

by repetition

of

play

mode t0

pause

mode and

stop

mods to

pause

mode, there is

clearance at

both

sides.

2-4 7v-+.ttv2iillft

2-5

€

>*

-

E-r.

tr'-.Z.ftr

f EFIB

i'y*&fi-*ftfuq1.U,

,fj-7.{rtEffi#J'y

Ft..J:r.l

. +

p

i

].t

>

t_ t >

+

D--

trto)t-

F{

to.

s

-

1

. Omntr

iE#A

6.

+r )

^5

>

X

E >+D--o)d-rdt*,

tifr<+e+

t

6

h\,

ffi

H

|tt

-

fd

o,!

f+

rtIF.\

a

&

1 r

t*

)

.

ffi#1*PLAy-

PA

USE,

S

TO

P- PAU

SE

E

iFJ

Fl

/r\

ir

l.d(

r

\,

t t

fA

& 6E ne.t

6

pause positioning

nut

pressure

stroke

adjusting nu1

Fig.24 Pause

position

and

pinch

roller

pressure

stroke adjustments

Fig.2-S

Pause

position

adiustment

t

t

a

L

,/7 tal

F. n lal

Eh+

E )

-)V

t.2-1

.9

0.7

0.zt-l

F

Et)

-)l)

r.2-1

.9

0.7

Htl

:

kg.cm

(ts

)vt

6+tlg)

Itr

Il

spring

scale

t

Forward

direction

(Bl (C)

1

.2

to I

.9kg-cm

(

I 7 to

26oz-inch)

1

Reverse direction

(A) (Dl

0.7kgrm

(9.702-inch)

or

les

Left/right deviation

0.2kg-cm

(2.802-inch)

or les

ItOTES:

l.

The

revene

direction

values are

reference.

2.

The

specification of left/right

deviation

only

applies for

fonvard

direction

torques.

Torque calculating formulas:

(l)

Torque

(in

g-cm

or oz-inch)

=

Force

or Weight

(in

g

or oz)

x Badius

(in

cm or inch)

l2l

Conversion

of

g-cm

to oz-inch:

g+mx0.0139=oz-inch

fr,

I_

-

2.6 PINCH

ROLLER PRESSURE

STROKE

AOJUSTMENT

1.

Set

the deck

in the

fonrvard

or reverse

play

mode.

2. Adjust by turning

the

pressure

stroke

adj. nut

(Fig.24)

so

that

the clearance

between the

pin

and the

stopper cushion

is

about

1.0mm.

3.

Since

the clearance is

produced

at one

side

(left

or right),

adiust-

ment f or this

side only is

permissible.

2-

6

e

>

U

a

-

-

EEfi

71.

a

-

2##.

1,ffi45F+ot'y

*alFLlt=

F......--......'..

.PLAY

2.v12-41.^-{ta€z

F

t]

2iw*t'y

l-.

t.J

r],

E2-6t.7ji

t* )

l. t>

t

),

F'y

/\-.)'y

)= >atdffrti('tlnnl:

ffi#T

6

(E>

t z

F'y

/\-.

2'y

)t

=

>r\HEfi(t\<,

_f

-

ffi

,.rE-;U.,u

*ft

lt.C t\

)

.

3. a0')adf,El{t,

It

EAtt)

>t0))\-'y

+t-&

tJ

,

}-l'u.\

t

nh,

-t

t.

L

r\,lH*Ar\r\,

T3 F,i')fi.*hl$la

a)ffi#

Til

rsE

r\.

2-7

e>*rr--lEfrhiillft.

I+,Eh : r.35-1.gke

(F

t-i'*)

)*.. liht>+rt--B.ah

t*ElsrF!t.!,y

t-dfl,

*t:*

t"a,#

h

r\

f+

a

t t

; d

tF,

t5

A

iffi E

tr

-d

r

\ rg

A

t

t *11,fi

{

+F tt

a'ryti.

pinch

roller

Either the

left or right

should

have

a

clearance of about

1.0mm.

7+?1mmiEE

(t6L'bbh')

Fig.

2-6

2.7 PINCH ROLLER PRESSURE MEASUREMENT

t{OTES:

1.

The

explanation

below applies to both

the

left and

right

pinch

rollers.

2. Both

pinch

roller

pressures

are automatically

set

with

equal

value.

l. Hold both the left

and

right

tension arms in the upper

positions

using

rubber

bands,

string

etc.

2.

Set

the

deck in either

play

mode with no tape loaded.

3. Attach the

spring scale

to the

pinch

roller

as shown in the

figure.

4. Draiv the

pinch

roller

away

from

the capstan

shaft

(in

the direc-

tion of a line intersecting

the centers of the capstan

shaft

and the

pinch

roller)

until the

capstan shaft and the

pinch

roller are

se-

parated.

Return the

scale back

until

the

pinch

roller

just

begins to turn.

The

scale should

then be reading

as

follow.

Reference

value: 1.35k9 to 1.9k9

(3.0

lbs to

4.2

lbs)

lf the reading is out of

specification, replace defective

part(s).

There are no adiustable

parts.

Fig.2-.

5.

6.

raght

capstan

right

t

2.8 TAPE TE]IISIOil ADJUSTMENT

TENTELO

METER

2-8

7-7.7>2=>##

{FF. REW SPEED}

R 150

TENTELO

METER

r

lkw

b-

$

B

PLAY,

REW

A

PLAY,

FF

FiS,28

Tape

tension

measuring

point3

il0TES

l. Since

these

ssttings

are

precisely

factory

adiusted,

in

general,

they

should

not be re-adjustsd. lf it is

specifically

required, a

special

metor

is

needed.

Tentef o meter:

Model

T2-H20-1 or T2-H l5-UM.

2. To

facilitate adjustment,

the

deck

should

be

placed

in a vertical

position.

3.

For

the rsels mounted on both

left

and

right reel tables,

use

the

same size ones.

4. Before all the

following adlustments

(2-8-1

-

2-84),

perform

next

instructions in order to activate the relevant circuit.

a..Thread the tape to lift up both tension/shut-0ff arms.

b.

s8t

the

PowER

switch

to 0N.

c. Lsave

the deck

as

it is for

5

to

l0

minutes.

2-8-1

ttrl PIAY

M00E

l.

Place

a reel loading

TEAC

YTT-8013

test tape 0n the left reel

table

and an

empty rsel

on the right reel

table, then thread the

tape.

2.

Let the tape

run

in

fast

foruvard mode

until both

reels have

nearly

the same tape winding

diameter.

3.

0uring

play

with a LOW

speed.

measure

tape tension at

points

A

and B.

4. Adiust Rl22 and R222

so

that

the specified tape tension

of

509

t

l0g

11.4oz-2.102)

is obtained.

(0btain

a

509

or l.8oz value

as

far

as

possible).

(REW}

R255

(FFl

R257

(PLAY)

R122

IPLAYI

R222

Fig.2-g

Tape

tension adiuster location

.T

tif;

1.7-J.->>

=

>.d]'.ifu\ft.t.61kAj>> = >.

)-9

h\.L'

->-rf

'J'-5

(*tr1

,

7>=)t/119P)

=

-

)v T2-H20-IXttT2-H15-UM

2.iH|J€&(,|ffi55t*,

7'v +A+E{nEt.t:T|if+->

(<

r:a

3./i-hlat1

lau )t

&ifr.ffi t,r< r:dL\.

a

.

j'y

*

o

E

iE,

t

>

1A

5

-

10tJ-ll

t*lr6 tr

(

r\'- iRri

€

.

;Eg

&I=rt*'>

((

/-dur.

2-8-f

PLAYT>22>ffi#.

1.;-i

Q+ U

-)v,70+U -)D

X1-,-t€&

r\)&h\lt, E

frF:t9p.a+1&t.t6.

z.-

-)

&Low

SPEED,

PLAY=-

F. ?+',iid1j6.

3.

.46'&

UBAIILE

l.=

>

-

D.

)-

-

5

&

*7,

R722,R2224

tb

a<

-

> >

=

)

&5og

+

70g

(<

3

6t

i50s

l-

jEu\iE)

l.

#t*t6.

:lEEloool=

o

l^--::{

o

EEEEE

O

=

c

2.8-3

ItU

FAST

FOBWABD

MODE

1.

Load

a

TEAC

YTT-9013

test

tape

on

the

left

reel

table

and

an

empty

reel

on the

right

reel

table,

then

thread

the

tape.

2.

stop the

left

reer

by

hand

and

set the

deck

in fast

fonaard

mode.

3.

Adjust

R257

to

obtain

a

t00g

to

l20g

(3.boz

-4.2ozl

value

at

point

A

(0btain

a

I

l0g

or

3.g

oz

value

as

far

as

possible).

REMARK:

Back

tension in

fast

forward

(or

fast

rewindl

is

auto_

matically

set when

tape

speed

is

adjusted

as in

paragraph

2-12_2.

2-84

ItT

BEWIND

MOOE

1.

Load

a

TEAC

yTT-9013

testtape

on

the

right

reel

table

and

the

empty

reel

on

the

left

reel

table,

then

thread

the

tape.

l. !,9.0

the

right

reel

by

hand

and

ser

the

deck

in

the

rewind

mode.

3.

Adjust

R255

ro

obtain

a

l00g

to

l20g

(3.502

-4.2ozlvalueat

point B (0btain

a

l00g

or

3.goz

as far

is

possible).

2.9

TENSION

ARM

HEIGHT

ADJUSTMENT

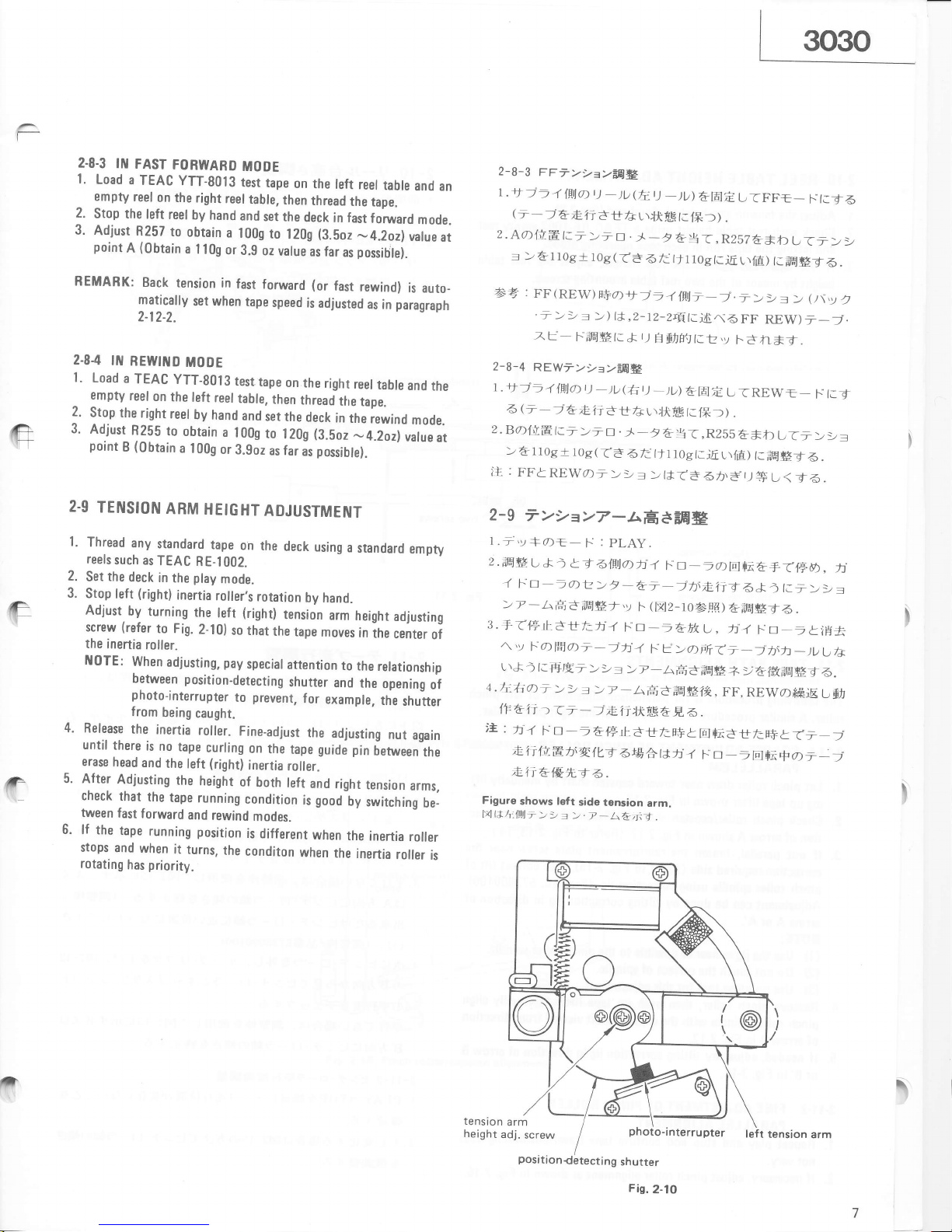

1.

Thread

any

standard

tape

oh

the

deck

using

a

standard

empty

reels

such as

TEAC

RE-1002.

2.

Set

the

deck

in

the

play

mode.

3.

Stop

left

(right)

inertia

roller's

rotation

by

hand.

Adjust

by

turning

the

left

(right)

tension

arm

height

adjusting

screw

(refer

to Fig.

2-10)

so that

the

tape

moves

in

the

center

of

the

inertia

roller.

II0TE:

When

adjusting, pay

special

attention

to

the

relationship

between position-detecting

shutter

and

the

opening

of

photo-interrupter

to

prevent,

for

example,

the

shutter

from

being

caught.

4. Release

the

inertia

roller.

Fine_adjust

the

adjusting

nut

again

until

there

is

no

tape

curling

on

the

tape

guide

pin

between

the

erase

head

and

the

left

(right)

inertia

roller.

5.

After

Adjusting

the

height

of

both

left

and

right

tension

arms,

check

that

the

tape

running

condition

is

good

by

switching

be_

tween

fast

forward

and

rewind

modes.

6.

lf the

tape

running position

is

different

when

the

inertia

roiler

stops

and

when

it

turns,

the

conditon

when

the

inertia

roller

is

rotating

has

priority.

2-8-3

FF7>2e>=:dl*

1.'ti-4|F.\at.)

-)tJ(Eu

_)D)

atrt

U<FF=_

t-.trr5

(

i

-

i

t

+_1-

d

t

rs

Lr#i

f-E

t.

f+

I

)

.

2.

AaltE

I.-

>-

D

.

J_

_

t

&

\7,R257

&

*b

t

T _ > >

=

>

t

ltog

+

10g

(

t

g

a t: ttl 10s

t.iE.

r\1d)

lr

6gq 5

.

aa

:

FF(REW)Wo)tj-_t

ftrlj-j.

->>

=

>

(/\,y

j

.

-

> >

=

>)

I*,2_72-zrFt.i6^6

FF

REW)

r_7.

7.u

l-.;iEgt..k

u

HsrF!t.Ev

t_dfi*d.

2-8-4

REWT>!=>EB*

1.ti-4lFtlat.)

-)D(x71.)

_)t

)6Hf

t,

rREW=_

F

t.d

4

(=

t

&

rt.fi

tt

td.r\)DiLq

t.{*l)

.

2.

Bo)[XEI.-

>,

D.

)_

_

t & liT,R2556

*b l:T

i

>

)

=

>

t

tt}g

+

r0g

(

t6

6

fc 111

tOg

tti[

urifi

)

tr

694 5

.

i+.

:

FFSREWd)t>

j/=

>l3:t6.6r\-

U+

U

< T6.

2-9

7>>=>7-L.A+EH#

f .i.y.FO=-

F

:pLAy.

2.ffi#

l,

e.

-

xt

3l1tl.:

h

4

ts

E

-

-

alpld,^&

+<

tr..r,

fi

-r

h.tr

-oE>t_tj

)h\rt.ftt6&)t.j>)=

>

p

-

1lF,d

AEISJ-,y

F

(Blz-r\+Hil

&ffi#-{

6.

3.

+f{Frtd11

t:h

-(

ts

E

-

-

tfh.

L,,i-l

t-.

tr

_-

tiH*

^'y

f a

ffra-

-

i

fi

4

I-

L

>

aFfr<

=

_

)

h\h

_

)t,

U

f+

L\A

)

l.BE-

) )t

=

)t

7

-

Ata'dffig

+

jl,&

lffiffilgt

6.

4.thD-))

=

):p

-A€:dffi#1*.,

FF,

REWr)ffiE

tJ$,

lF6: 1i'>

T

-

-

)

rt.Tr

ltffi&

n 6

.

i*.

:

h'(

t-

D

*

-

&E

tldiltE+-

E*ndlitrF*t

< t

_

j

rt.1iln-Eh\qILt

6t+.*ttti-r

F.

!

--tEl$x

+a

j_J

+J

re@%t

6

.

Figure

shows left

side

tansion

arm.

I'xl

l*

lr.lF.tli

> >

=

>.

p

-

A&it

.

\

c

tension

arm

height

adj.

screw

positiondetecting

shutter

Fis.2-1o

left

tension

arm

{

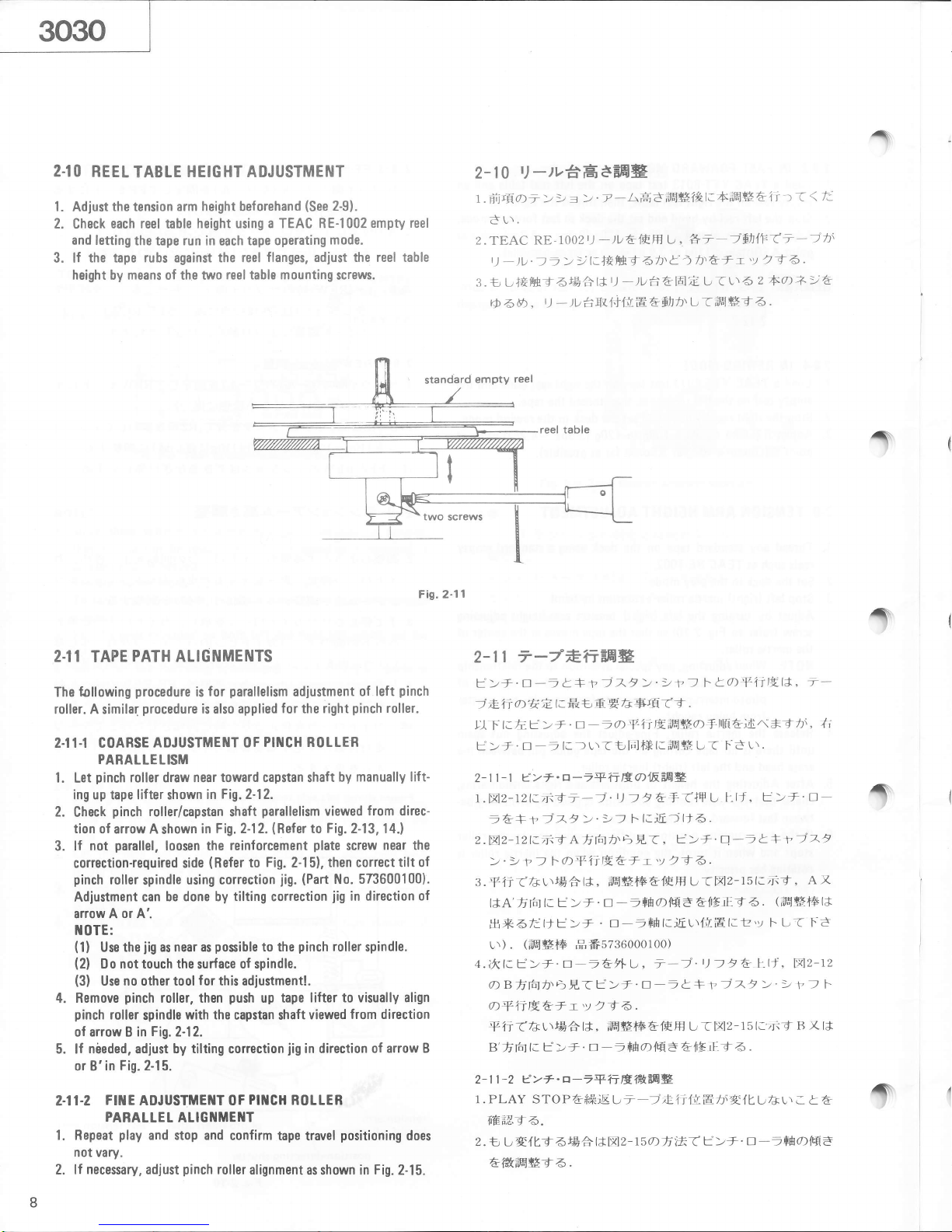

2.I|l

REEL

TAELE

HEIGHT ADJUSTMENT

1. Adjust

the tension arm height beforehand

(See

2-91.

2. Check each reel table

height using a TEAC RE-l 002

empty reel

and letting

the

tape

run

in each

tape operating

mode.

3. lf

the tape rubs against the reel

flanges, adjust the reel table

height by means of the two

reel table mounting

screws.

Fis.2-11

2.II TAPE

PATH ALIGNMENTS

The

following

procedure

is for

parallelism

adjustment

of left

pinch

roller. A similat

procedure

is also applied

for the right

pinch

roller.

2.1I.I COABSE

ADJUSTMEI{T OF

PIttICH ROtLEf

PARAttEtISM

l.

Let

pinch

roller draw near

toward

capstan shaft

by manually lift-

ing up tape lifter shown

in Fig.2-12.

2.

Check

pinch

roller/capstan

shaft

parallelism

viewed

from

direc-

tion

of arrow A

shown

in Fig. 2-l 2.

(

Ref er to Fig. 2-13, 14.)

3. lf

not

parallel,

loosen the

reinforcement

plate

screw

near the

corrocti0n-required side

(Refer

to

Fig.

2-15),

then correct tilt of

pinch

roller

spindle

using correction

iig.

(Part

No.

573600100).

Adlustment can

be done by tilting correction

jig

in direction

of

arrow A

or

A'.

IIOTE:

(l)

Use

the

iig

as near as

posible

to the

pinch

roller spindle.

(2)

Do not touch the

surface

of spindle.

(3)

Use no other tool

for

this adjustment!.

4.

Remove

pinch

roller, then

push

up tape

lifter to visually align

pinch

roller

spindle

with the

capstan shaft

viewed

from direction

of

arrow

B

in

Fig.

2-12.

5. lf nbeded, adiust

by tilting

correction

jig

in direction

of arrow B

or B' in

Fig. 2-15.

2.11.2

FITTE

ADJUSTUETIT OF

PITICH BOLTER

PABAttEL

ALIGIIME]IT

1. Repeat

play

and stop and

confirm tape

travel

positioning

does

n0t vary.

2. lf

necessary,

adjust

pinch

roller

alignment

as shown in

Fig.

2-15.

2-10

t)-/t,6H*eB:g

\.-w1tRcl

7

)

) = )'

7

-

/lHtffif'1Al-+ffi*& 1 i

) < <

T:

d

L\.

2.TEAC RE-1002

t)

-)vtl€,ffil',

&7-)6h1ts<--ih\

|

) )u. )

->

tl.+*ffit 6h,x-

h,&*

t'v 2t

4.

3.€

t

{*f;4t6t*+t*t)

-)ve&taa

u(t\6 2 +o+>&

vi

6b. u

-

)t

awftlaa&atlh'

t'<ffi#-{

4.

2-11 7_J€FEE#

t>+-

D-- t-+p ) t

>' >

t,

t t-

t-a+1it€.l*,

--

i 811

a

EE

l.

ft

b €

4

rd=F{tr<t

.

D)

f

I.E t- >

+.

D

-

-

at'1-r

trffi1go1tV6:S^*dr\,

{i

t>+.

D

7l.lLrT5[n']tfr1.ffi#

l,(

|

dt\.

2-

| 1 - |

e>r.

tr--+

tr

EalF.##

r.

-&+1')t

t>.>) t'

l-iEilJ.6.

2.82-r2L4it

A

E6.th'"]-

nT,

E>+'

D.-- X+1- 2

^t

>'>

P)

lc.]+11EtJ

rv

2-{

4.

3.

Y 11 T

f+v:t$A

l*,

ffi

*tF A lfffi

U T

E<12-

15

l.

)t.d' A X

l*A'

tftr

t(. L >

+'

n

-

=tfro:l€'d

6:lttLi

6.

(##t+

l*

,1l1r< 6

-:

It E >

+'

tr

-

-+ts

l-i[

t\{rIE l-

1u'v

l- U

(

I'

d

L\)

.

(ffigt+

5A#57360001oo)

4.ikt.t>+.D--&t+t,

--t.

t)t

t& l,tJ,

x2-12

a

Bfifi1nt6

aT

L>+.

E

--

t

+p

t

7.t >'

>

p

)

f

a*118&+r'v it6.

*11Tt*.v:t*,a^l*, ffigtFtftH

t Ttrlz-ls

l.-q

R

X l*

B',

fr

6t

t.

t_ >

+.

o

-

-*fi

/){r€-

t

It*

*,t

6

.

2- | | -2

C >

+.

E

-

-

+,t':, tr'ffiffig

r.

pLAy

sTopaf*iq

u

--i+-ft1nEh\q4Lur{u\

-

t_&

6E7Et6.

2 .

E U

*. +L-{

4

tE

e

,dxl2

-

1

5

0)

h

i*<

t- >

+

.

D

-

-

*fr

o

lq.3

&'{&ffiM-{ 6

.

T

('

capstan

shaft

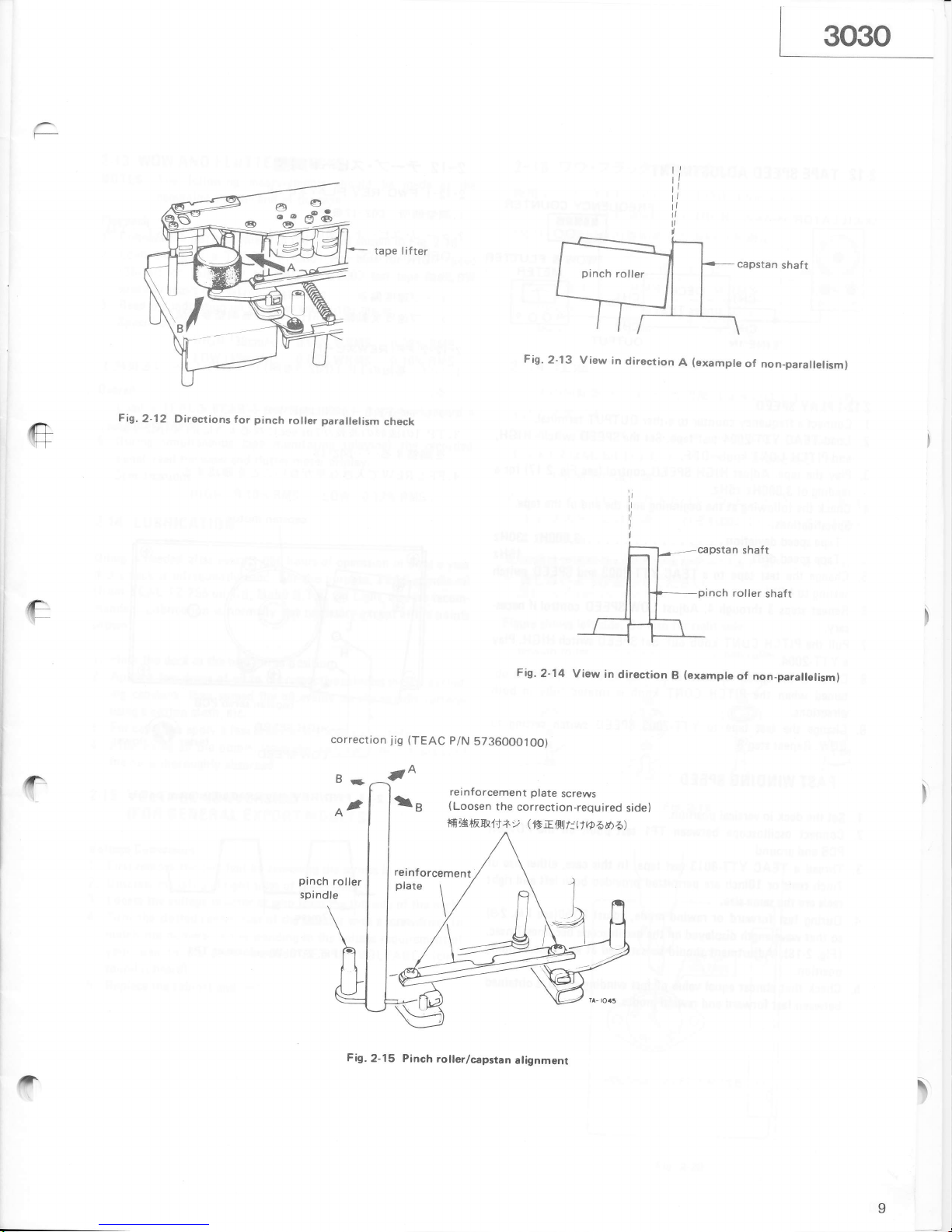

Fig.

2-13

View

in

direction

A

(example

of

non-paralletisml

FiS.2-12

Directions for pinch

roller

parallelism

check

pinch

roller

spindle

pinch

roller

shaft

FiS.2-14

View

in

direction

B

(example

of

non_parallelism)

correction

jiS

(TEAC

P/N

5736000tOO)

I |

^

reinforcement plate

screws

o, I lft

(Loosen

the

correction-required

side)

f

)

FiS,

2-15 Pinch

roller/capstan

alignment

$

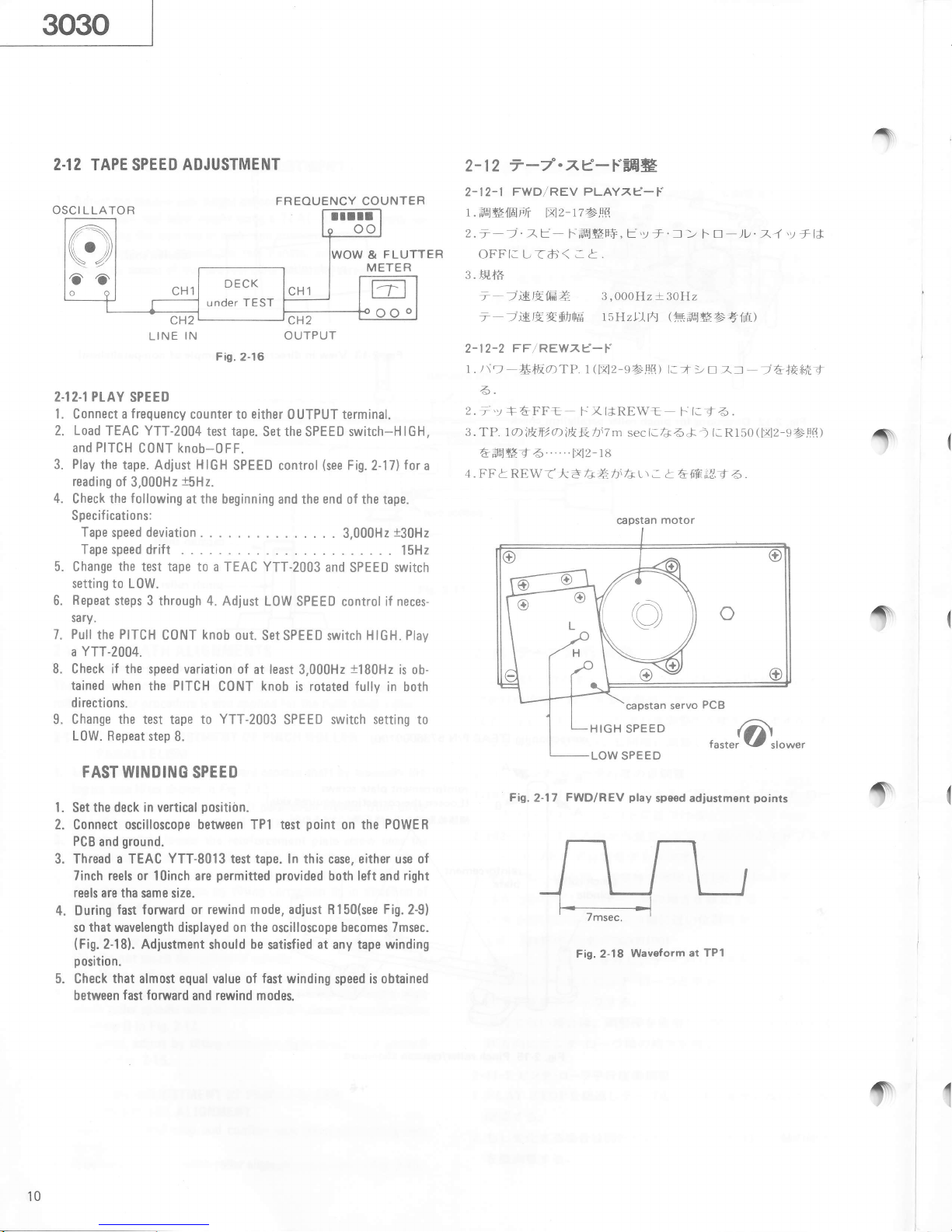

2-12

TAPE SPEED

ADJUSTMENT

OSCI

LLATOR

FREOUENCY COUNTER

cH2

LINE

IN

cH2

OUTPUT

Fis.

2-16

2-12.I PtAY

SPEED

1. Connect a

frequency

counter to

either

0UTPUT

terminal.

2.

Load

TEAC YTT-2004

test

taoe.

Set

the

SPEED switch-HlGH.

and

PITCH

C0NT knob-0FF.

3.

Play

the

tape. Adjust HIGH

SPEED control

(see

Fig.2-17llora

reading

of 3,000H2

t5Hz.

4.

Check the

following

at the beginning and

the

end

of the tape.

Specifications:

Tape

speed deviation

3,000H2

130H2

Tapespeeddrift..

......15H2

5. Change

the

test tape to a

TEAC

YTT-2003

and SPEED switch

setting to L0W.

6.

Bepeat

steps

3 through 4. Adjust

LOW SPEED

control

if neces-

sary.

Pull

the

PITCH

C0NT

knob

out.

Set SPEED switch

H lGH. Play

a

YTT-2004.

Check if the speed variation

of at least

3,000H2

+180H2

is ob-

tained when

the

PITCH

C0NT

knob

is rotated fully

in both

directions.

Change the test tape to

YTT-2003

SPEED

switch setting to

L0W.

Repeat step

8.

FAST WINDING

SPEED

l.

Set

the

deck in vertical

oositi6n.

2. Connect oscilloscope between TPI test

point

on the

P0WER

PCB

and

ground.

3. Thread a TEAC

YTT-8013

test tape. In this case, either use of

Tinch reels or l0inch are

permitted

provided

both leftand

right

reels are tha

same size.

Ouring

fast fonrvard or rewind

mode, adjust R150(see Fig.

2-9)

so

that wavelength displayed on the oscilloscope becomes 7msec.

(Fig.

2-18). Adjustment should be

satisfied

at any tape

winding

position.

Check

that almost equal value

of

fast winding

speed

is obtained

between

fast forward

and rewind modes.

2-12 7-/.zH-t"EEg

2-12-I

FWD/REV PLAYZE'-F

\.ffi#lqFfr

X2-17+nq

2.--).7.tr-

l-.iiEgF+

,E'y

J.

r l/

F

tr

-)1,,

.).4

'y

jl*

oFFt-t

rdi<.t.

3.ffi.t&

-

-;

2-12-2

FF/REW.XTJ-l.r

7.)\.)

*+Fa.]_TP.

1(Bl2-s8F1.) t-t>D7-_t

)e#frft:+

4.

z

.

i

'y

*?I*FF.E

-

l--

X I*REW=

F.

l.

t

.6

.

3.TP.loiEfrtaiQF<h\7

m

sec

{if*5S

-

l. R150

(X2-s+n4.\

effi*'q

6----..[x2-r8

4.

FFt REW(z\A

faf;/lfaY:.

X&6EAEd

6

.

Fig.2-17 FWD/REV

play

speed adjustment

points

Fig. 2-18

Waveform

at TPl

f

7.

8.

9.

4.

5.

!

DECK

under TEST

capstan

motor

HIGH

SPEED

LOW SPEED

10

2.13 WOW

AND FLUTTER

CHECKS

N0TES:

The following

measurements

should be made

at the

beginning

and the end

of

the tape.

Playback

1. Connect the test equipment

to the deck

as

shown in Fig.

2-,|6.

2. Load and

play

a TEAC YTT-2004

test tape

for

HIGH

speed

(38cm/s

or

l5ips), or a

TEAC YTT-2003

test tape for LOW

speed

(19cm/s

or

7-Yrl.

3.

Read

the indication

on

the wow

and

flutter

meter.

Specifications:

2-13

,r.72y?.7-.y2

I*,lHi-j

YTT 2003

""""LOW(l9cm/sec)

YTT 200,1.........HIGH

(38cm/sec)

7

\'r

|

)

)lrI€.ll11+o

E|lf;Vt

/kr-t'El*

|.)

&iHI

i.

+J-

tl,.

iJ:

s*

++ iJ:

T ) l{t2 RMS

WRMS

RMS

1

9cm/s

0.10?l

o.o5o.4

0 . r2?z

38cm/s

o.o8?z

0.04?l

o . r)az

2-14

iiifi

i'v

*

d)

lpl *r;1[

r]

(.

t*

1

000H+

Ffl ft ffi

fu

"t

r".

tJ I

4.

t.

I

tpl f?E

ii,ifrrr,z'*rd.

n

1

)ttt,

TEAC^U>

|

)r.t

I

)t(TF,AC

TZ.255t

1

)U.

.F'y

F)

XlJMobil

D.T.E.n

{

)r--1

t-+6'l*.H1t,r<tar\.

f

.i'v*t*'f-ir:Et-H<.

2.7>>=>.D

-,ti1

l-..tr

-,tr)

f.tr

-t.t**tiffi,

+

p

-

7

t

>

tr ts'iff

,

?

n<

nvlz-

I

9 tr

it-Ffi

?a;a,fElFf

t.ii,ifi

f

5.

3.

iiifi

l*

?r& 5

f+

rr&

),

*/:7 1

E1 i

#Bt, t-

t 4

)th\

l.f

??

L

r*Lrt

-r

ii.na

L r

<

f:A

r\.

Figure

shows left

side. 0o also for right

side.

tension

roller

inertia roller

,r'----\

n|l

\2

\+-,,

J_

6-

g

tra5'h

YV

A.z E"

-

-q

z4Y:t

/(4).\

Fis.2-19

HIGH

(38cm/s):

0.04%

WBMS

LOW

(l9cm/s):

0.05%

WRMS

0.08% RMS

0.10%

BMS

r

IF

0verall

4.

Load a TEAC YTT-8013

test tape

(blank).

Apply

3,000H z signal.

5. During

simultaneous

tape monitoring

(playing)

signal, read

the wow

and

flutter

meter

display.

Specifications:

and

record

a

the recorded

HIGH:

0.10%

RMS

LOW: 0.12% RMS

2-14 tUBRTCATt0N

0iling

is

needed

after every

1.000 hours

of operation

or

once a

year

if the

deck is infrequently

used. For

this

purpose,

TEAC

spindle oil

(from

TEAC TZ-255

oil kit). Mobil

D.T.E.

0il Light, etc.

are

recom-

mended.

Lubrication

is normally

not

necessary

except

at the

points

shown

.

l. Place

the deck

in the horizontal

position.

2. Apply

a few

drops of

oil to therespectivespindlesshown,exclud-

ing

capstans, then

spread the

oil evenly

on the

spindle

surfaces

using

a cotton

cloth,

etc.

3. For

capstans, apply

a

few

drops to

the indicated

position.

4. After

oiling

all the

points,

leave

the deck for

1 to

2 hours

until

the

oil is thoroughly

absorbed.

2-15 VOLTAGE

CONVEBSION

(FOR

GENERAL

EXPORT

MODELS)

Voltage Gonversion

1.

First

remove the two feet

by removing

the

screws

in

each one.

2. Unscrew the

left and

right

sides

of

the cabinet.

3. Locate the voltage

selector

as

seen

from

the top

side

of the deck.

4. Turn the

slotted

center

post

0f the

selector

with

a screwdriver to

match the numerals

corresponding

to the voltage requirement

of

your

area

to the

point

marked

"SET

UP

V0LTAGE"

(click

sound is heard).

5. Replace the cabinet

and

feet.

capstan

tu

r

pinch

roller

r.-\

\-!=r'

g

a/€t$\

|.'=-]

v

H

\ cl/

I

f

Fig.2-2O

11

^

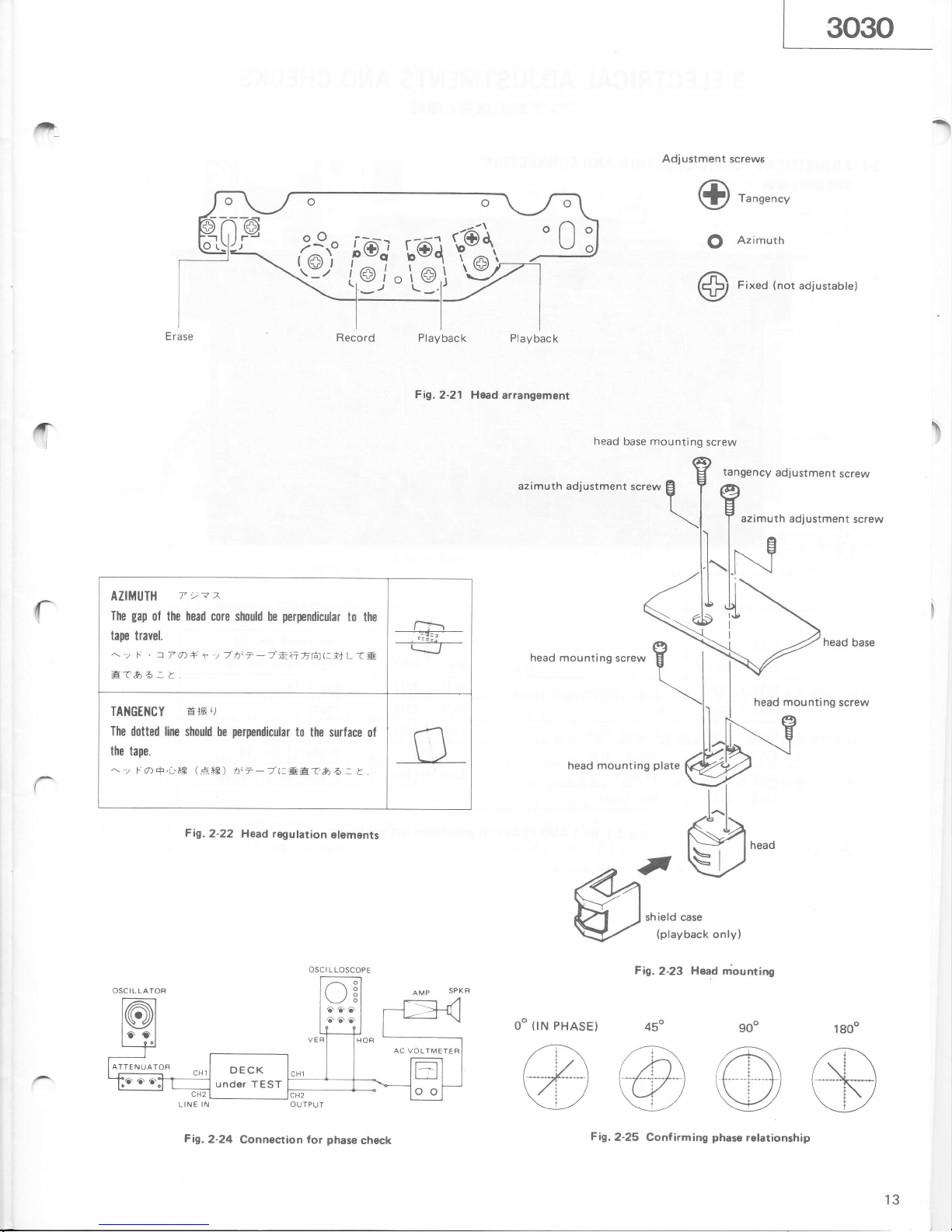

2.16

HEAD ALIGNMENT

There is no

need for head height and tilt adiustments

because

the

record and

playback

heads

of 3030

are a semi-fixed

type

(erase

head

fully-fixed).

2-I6.I

HEAD

MOUt{TIttIG

(BECOBD

AND

PLAYBACK

HEADS)

1. Refer

ro

Fig.2-23.

2.

With head mounting screws,

mount

heads to

head mounting

plate.

Attach shield

case

to the

playback

head.

3.

Mount

head as'y to

head base using

mounting screw

and mount

tangency

adjustment screw.

4.

Mount azimuth adjustment

screws.

2.I6.2

PTAYBACK HEAO

AOJUSTMETTT

1.

See

Fig.

2-24

tor

necessary

connections.

2. Set

the 0UTPUT switch

to

REPR0.

3.

Run the test t3pe TEAC

YTT-I003 in

play

mode to

reproduce

the

400H2

signal

on the

tape.

4. Slightly

loosen

the

mounting screws

which

hold

playback

head

in

place

and adjust

the tangency using

adiustment screws,

for

maximum

output.

When the maximum

output

is

attained,

retighten both

mounting screws.

5.

Play the l6kHz

signal

on the

tape and adiust

the azimuth

of

the

playback

head using adjustment

screws

for

les

than 45"

of

phase

difference between

the two channels

(see

Fig.

2-251.

I{OTE: Azimuth

adjustment should

be

completed

by turning

adjustment screws

in

tightening direction

(clockwise).

6.

Set the

PLAYBACK

HEAD

wrritch

to

4T and

perform

thesame

tangency

and azimuth adjustment

procedures

to

4 Track

play'

back

head.

2-I6-3

RECORO

HEAD ADJUSTMEIIT

Proceed to

record head adjustment

only

after

playback

head

adjustment

has been completed.

1.

See

Fig.

2-24

for

necessary connections.

2. Set

the 0UTPUT switch

to REPB0.

3.

Load

the blank

test tape AMPEX

456

and

record

a 400H2

-10dBV

(316mV)

signal

in

recording

mode

to reproduce

it

simu

ltaneously.

4.

Adjust the tangency

of

the recording head as

in step

4

under

paragraph

2-1

6-2.

5. Simultaneously

record and reproduce a l

kHz.

-20dBV

(100mV)

signal and adjust

the azimuth

of the recording

head using adiust-

ment screws

for less than 0o

of

phase

difference

between

the

two channels

(see

Fig. 2-25).

tt0TES:

oAzimuth

adjustment should

be completed

by turning

'

adiustment

screws

in tightening

direction

(clockwise).

rBe

carefull

not to

confuse

the

bias signal

(150kHz)

in measurement.

2-16

r'7

l."FEiE

i:t030o$*#,\)i

l-

LE4E,r

y

l-

l*'+.16l€il(i'Hli,\'y

l-.

l*i,1:

El €-\

)

l.

/.r

r

(

\,\

t

3

.

- a T.

&)

\'t

t-

O

E

d JhItE

t:

t

),

F

-,;r4*ttTt<-{.

2-l 6-l

IzFIF'f{

(i*E^

vlj,

t*.^'zF)

t.Fig.z-234F.H

2.

r.

v

l- 4Uf ?

)i,r'v

t--

€z\

v

F

qrf'f+E

l.

tr €d

6

(^'v

t-Ass'y)

.

-D t dF4,r'v F.

la l*i/-r,

f

'

lt-)-&E'v

F-f5.

3.rr.'y

FAss'yA^\'y t-. 16l€+

jit,\'y

t-.EfErJ*:u

-C^'v

F'

rr-z.ll4f

{,lli6.

4.7

tn

)-ffi#+t&n\fti6.

2-16-2

E*;.y1.'38#

I

.

t**fi

Fis.2-24

2.OUTPUT^4'Y7

:

REPRO

3.TEAC

YTT-1003-

).

-

7.

h.

aPLAY€-l-.t€iiat,

aooHzZ5ltE+.t6.

+.F4zr.v

l-r)^.y

FIfl€+yat1r*EdD,

,r'v

l- ElFrJT

)

& E t-

l.€hh\ u

(

4

00 H

z$'{ts

iE i

n\ft

/<

l-

f*5

& f

^'v

l-

a

6+R

|

)

Atr

&ffi# {

4.

t1t€+'la

&tfii

+

)

tt#

b 6.

5 . it

r- YTT- 1003o)

I

6kH

zF tl

&Hry U,CHILCIr2o

ff iH+.

7)\4s" J--ltt l:fs.45- 7 t.?

^ffi'g+ttffi#t

6.

(Fis.2-2s)

tt

.

v

).2 z.ffi#.+) tttFb

6fr

6t

(A

tol

l-)

<ffi#tft*

6J_t_.

6.iAI'PLAYBACK HEADA4TI'

L,

F;CtEtFd)+ltIFi,

4TB+.,\'y f-t)^'y

t--H+&

rJ

t

7

)? 7otffi*&11r+).

2-16-3

i*€r'vl'iE#

$*#,r'v F.

ffi

gd)Hil

t.EaF^\'y

l-'

;Egrif{

-)

(

rr

5

i t

.

1.itfifi

Fis.2-24

z.OUTPUT;4'yf :

REPRO

3.AMPEX

4567

zxP'y I

to,

400H2/ 10dBV(316mV)

I=;

\

| & 11.

u

L

/.rz5i

D

ld

FtEi+t

6.

4.

E.

aE

^'y

t-

-;.Fj

43 t

E i*

r.

S*

F

^

.y

l--

d)

H

l,F

|

)

fu

E

&

ill+

-r

6.

.r

.

ikt. tkHz

/

20dBV

(

1 00mV

) t,; 4

e

*.H's:++.

a cllt

L CH2

altt.+tr*h\

0"

tllFl l-fa53

-7

t.?

^ffi#t6.

(Fie.2-25)

.

t*.

.

7t.?

tffi#?-tttffiet6fr6t

(fifElL)

<ffi+t

*&6-

t

.

.

)\4

7

t

t€+

(lsokHz)

AiRl

-€

L

f+

tr

& i itHi

6.x.

$

f

f

tz

29..o

\9.j

d6)

\@

io:

ig,i

10i

"\@j

\-'|

\

t*-

Playback

Playbac

k

Fig.

2-21 Head

arrangement

Adjustment

screws

head

base

mounting

screw

Tangency

Azimuth

Fixed

(not

adiustable)

tangency

adiustment

screw

azimuth adiustment

screw

head

base

head

mounting

screw

O

o

@

q

(-

azimuth adiustment

screw

head mounting

screw

head

mounting

AZf MUTH

7'/

?

7

The

gap

of

lhe

head

core should be

perpendicular

to the

tape travel.

^./

l.

:

7o+

?./ Jh:-

_7

fri-tf"-l{_liL

(*

E<'bb

-

t .

Fig.2-22

Head regulation

elements

LINE

IN

OUTPUT

Fig.2-24

Connection for

phase

check

shield case

(playback

only)

FiS.

2-23

Head

niounting

oO

(tN

PHASE}

go"

(A

\r/

TANGEI{CY

I

1'RI)

The

dolled line

should be

perpendicular

to the

surface of

the tape.

r'v

l.of,L.fiR

(F,tR)

ht--J{:*E<'64:

a.

DECK

undor

TEST

n

oo

F iS.

2-25 Conf irming

phase

relationship

13

3 ELECTRICAL

ADJUSTMENTS

AND

CHECKS

7>/*ggr-ffi#tfE-#.

$

3-r ADJUSTMENT

POINTS

LOCATION AND

CONNECTION

'EEIEFEI'*fT

f

f

f

Fig.

3-1 REC AND PLAYPCB

adjustm€nt and test

points

f

R550

/

R950

2I

P

layback

IQ

R563

/ R963 Low

soeed

Rec t0

R551

/

R951

4T

R56i

/

R96i

Hish

speed

Rec [Q

R554

/

R954

2t

Playback level

R51?

/

R972

Rec

bias

R555

/

R955

4T

R576

/

R976

Phase

shi ft

R556

/ R956

0utput

level

t301

/ 1401

Bias

trap

(playback)

R557

/

R957

Input level

L 304

Honaural

Rec t0

|i55B / R958

VU meter

1306

/ t406

Bias trap

(record)

Rs59

/

R959

Rec I eve I

14

t

;

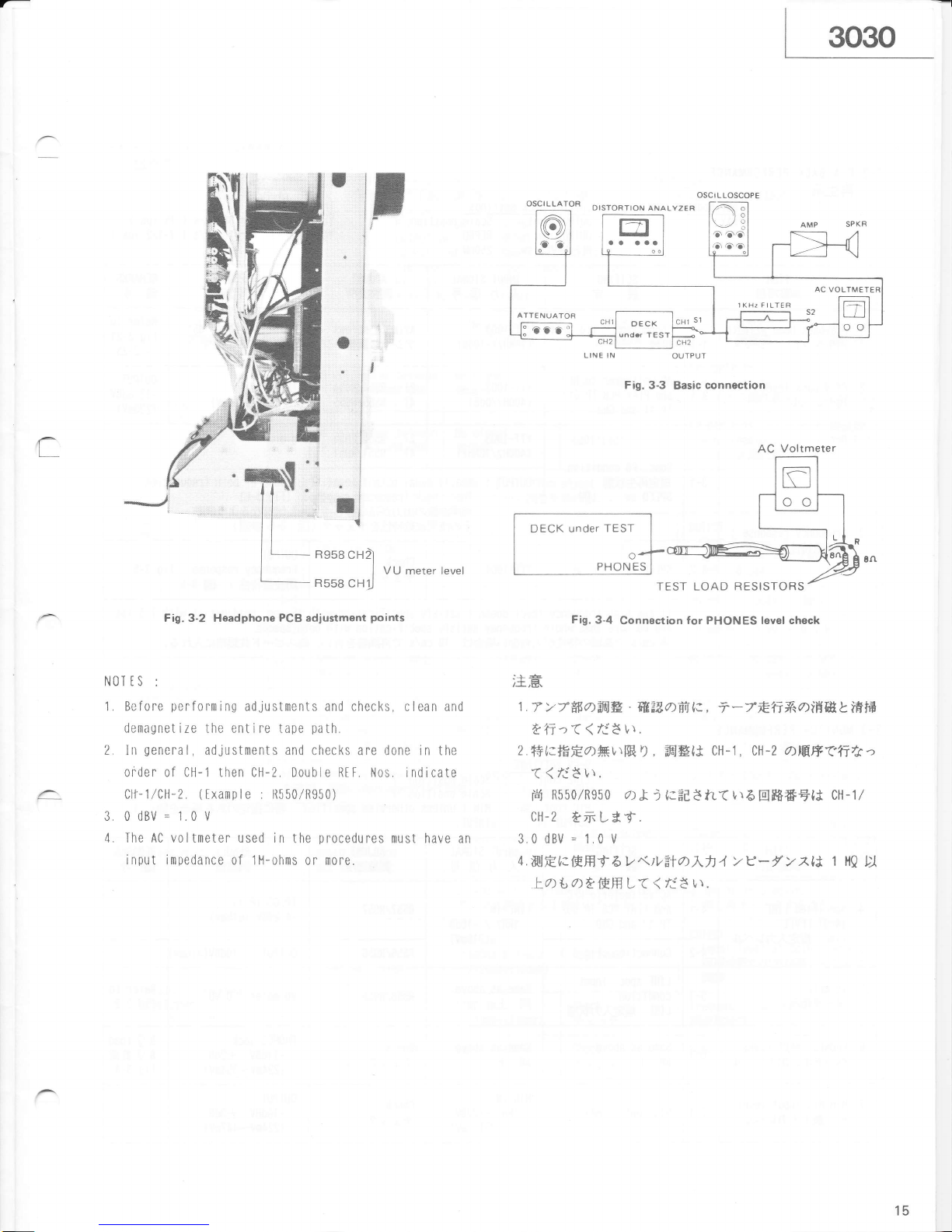

I

Fig.3-2 Headphone PCB adjustment

points

NOI tS

:

1. Before

perf0rtning

adlustments and checks, clean and

delnagnet ize the enti fe

tape

path.

2.

In

general,

adjustntents and checks

are done in the

0fder 0f Ci]-1 then CH-2. Double RIF.

Nos, indicate

Cll-l/C|.l-2.

(txample

: R550/R950)

3.0dBV=1.0V

4. The AC v0l tI|leter used in

the

procedures

|tlust have

an

i nput impedance

of 1H-ohms

0r

lll0re.

LINE IN

Fig.

3-4

Connection

for

PHONES

level check

it,a

1.7

>7ffioffi&

.

MZLoffiIx, i-7ft.',fr*/)iHBL

iHtfi

t'fi',(

(

/jE lt.

2.++titFft.a*!\[E

D, AfilBlJ

CH-1, cT-z

a]EftT'frfc ")

( (

/i3

t,t.

r{

Rs50/R950

/)}

i {t;d,3fL(lr5gg*utJ

cH-1/

cl|-2

tzrL*,f.

3.0 dBv

=

1.0

v

4.WlEirlHHf

bv<)va+a^fi4

Yv-yvxtJ

1 HQ

ttl

La{rattf.ffi L(

(

t3

t,r.

oscr

LLoscoPE

DECK

under

TEST

AC Voltmeter

TEST

LOAD RESISTORS

15

$

3-2

PLAYBACK PIRFORMANCI

g.++

Test mode

FIIV-

lnitial deck settings

0UTPUT cont. : Scale

position

"7"

OUTPUI sl

: REPRO

REF LEVTL sw : 250ntl

Test tapes

YTI-

1

004

YiT-1003 :

15 ips

)

t-1/2 ips

)

For 38 cm/s

(

for 19 cm/s

(

And be sure lhat vhole

frequency satisfy specificati0n with both speeds,

38

c[l/s

TF,ffiaw++ir

xr,/rl

uf,etj

1 I cm/s

(.FiFEt6r,

),

Ex

U*

l:*fi$gtlr'.r-16

.

$

$

f

3-3

MONITOR PiRTORMANCi

I

Deck

settings

LIili cont. :

OUTPUT c0nt,

l'll0

cont. sw I

0UTPUT sit

Scale

position "7"

Sca le

posi

t ion

"7"

HIN

(

unless

other.lise specif ied

++t.+AftCIbb8Ath< )

INPUT

I

iiH

;ffi]FE

SIITING

I

INPUT SIGilAL

-#

E

',

xhEE

ADJUST

ffiHFf

RESULI

#EG

REilARKS

ffit

1. Playback head azimuth

E/*r'y

F

.7i?7

11

l-l

Connection . FiS.2-24

t*ffi

YTI- 1 003

(

16kflz/-10d8)

Azi[luth

screl{s

7r?^3w

y

Phase

{ilffi

within 45"

4s''IIFJ

Refef

to

F

is.2-21

-

2-?5

2. Play back level

Nkv\tv

l-l

AC voltlnetef to litC

and PLAY PCB TP,O,I/

iP.11 and oND

YTT- 1

003

(

400|-|r/0dB

)

2I

4l

R554/R954

R555/R9ss

TP.01/TP.11

-6.8dBV

(450mV)

OUTPUT :

-12.6d8V

(230|[v)

3. Frequency fesponse

Htdffi++tt

J- |

Spec. PB condition

ffiErF4ttE

SPEED sv : L0l,l

Ytr-1003

| zi , nssoznsso

I

(4ooru/lokltz)

|

at : nsstuRsst

I

0UIPUT : Nearly equal output level

(+1.5d8)

at

both frequencies.

Then check

frequency

response.

(Fis.3-6)

ffiH6ofr)1n{itrgL

<

(

+

1.

5dB)rr6

}

j

iffi

.

tofibffiWffi**tt'v2

(tr

3-6

*ffi)

3-2 SPiIO sw || IG|'| YTT-

1 004

Check

4-

^.

,.,

t

OUTPUI :

Frequency

response : Fig.3-5

Hiffiffitt

:

EI

3-5

If the high frequency

level doesn't satisfy specificati0n with 15 ips. readjust it with 7.5 ips.

I TEH

iffiIFH

SITT

I

NO

ax

rb

INPUT

SIGNAL

^fitr8

ADJUST

4ffi6-Ff

RESULT

dffiG

RTHARKS

ffi*

4. Spec i f ied

LINt

INPUT

LEVEL

LINI

flEl'rl,^Vt

AC

voltmeterto REC

And

PLAY PCB TP. 03/

TP.13

and Gt{D

LIi{E II{ :

lkHz

/

-10d8

(316|[V)

R557/R957

IP.03/TP.13

-4.2dBV

(61snv)

A-t

Connec t i on :

F i

S.

3-3

R556/R956

0UIPUT

:

-1OdBV(316nV

5, VU ll|etsr

t-tffi

t-1

LINt

spec. i

nput

condition

rrr{E

ffit/'rfitr

Same

as above

ItrJ I

R55B/R958 VUllleter:0VU

Refer to

Fig.3-2

i,

I

PHOIIIS

II{PUT TEVTL

\.7

l.frYHitJL"VI,

o-t

Same as

above

IqJ

-r,

Same

as above

lHl l_

Check

ts.'v ?

PH0NES

jack

:

-1',ldBV

+2dB

(224mV-354mV

)

8

Q

load

8QF?ff

Fis.3-4

l7

l,lin. HIC

input level

HIC

frzhl.,l:l,"Vt,

1a

t-l HIC

cont, : HAX

HIC II{:

lk{t/-7zdBV

(251

rrV)

Check

*t'y 2

OUTPIJT

:

-1odBV

+3dB

(224mV-447nV)

16

e

2-l

RTCORD I NG PIRFORMANCI

$?€fi

Test mode

R-EeTpllv-

Deck sett i ngs

REc--IUileTI0[lw

:

DBX

sw

:

RtF t.tVtL sw r

OUIPUI

Sw ;

OUTPUI cont.

:

LII{F cont, :

HIC cont.

BIAS

FINI

cont, :

C|-| 1,

2

both

0N

OUT

250nl,l

REPRO

Spec, PB condition

Spec. input

condition

Il

IN

Centef

Test taoe

nttPEXJS6-:

Blank tape

I ITH

iHg'qE

SITT II{G

tl ,tl

II{PUI SIOI{At

^htrn

ADJUST

ffitr'Ff

RTSUTI

iffilH

REMRKS

ffit

B. Bias tlap

)\477

F1y7

B-1

AC volt

meter between

TP.05/TP.'15 and

GliD

No

signal

#lzE

1306/t406

TP.05/TP. l5

Hin. reading

,'{,f

7xifil'ujFzjr

B

ias

f requency

)\477

Eiffi

150 kHz

B-2

AC volt

meter between

TP. 01/TP.

1 1 and GND

No

signal

ff=g

*tE ?

1301/140'l

1P.01/TP. 11

Hin. reading

,'{4

7:,if;*rjFzJi

Record b i as

g*E)\4

7

^

9-1

First set adjuster

ful ly CCl,l

(

O ),

then

adjust,

&l/Ji3+EE[tntE

-{tr{,rF]

L(r' 63ffi

tf6D6

.

SPttD sw : L0l,l

LIt{I It{ :

1 0kHz/-20dBV

(

1 00mV)

R572/R972

OUTPUT :

Over-bias

value

t-i

l-

.)\477rG:

7dB

+0.5d8

10.

Record lcvel

$*€L'&1.

'10-

1

SPEE0

stl : HIGIi

IINI IN:

1 kHzl-

1 0dBV

(316mV)

R559/R959

0UTPUT:

-10dBV

(316uV)

1

0-2

Check

tt't 2

VU

metef : 0 VU

+

0.5

VU

1 0-3

Same as above

F"lI

DBX

sw

:

IN

Check

4-.

.',

t

0UTPUT :

-10

dBV

+1.5d8

(266ltt/

-376tnv)

Same

as above

tiilt

rn-,,!

OBX sw:OUT

0UTPUI

sw :

I

Rt

PR0/

INPU)

No signal

F,f=kj

Check

tt'v?

OUTPUT :

Bias leak :

t\477Wt:

less than

-50dBV

(3.16mV)

After adiusting

overal

I

frequency

response

(ite|r|

12 and 13), re-do

this item's checks

and adjustment.

^ffiB

.

;Jffill$*l4tdr4ffiffi+tiJ:I#(12

13

E) ?{,

HF.rla.L.

1 1, Record head

az i |Iluth

S*H'.:

v

l:

.7r?].

11-1

SPttD sry

OBX

sw

L0t4

0tJl

LINI

IN :

1

kHzl-20dBV

(100|llv)

Record head

azimuth

scfeys

$*F'r'v

F

7y?7w

i

Phase :

0'

{ilffi

:

0"

Refer to

F is.2-21

-

2-25

lf

you

adjust azimuth

smerys, check

pafagraph

10-1-3 again.

7' ?

^iw|^

J

tfih't-/:BhH,

1 0-',1

-3

trtE*

r

.y

2

t

b

J.

t

12. Frequency fesponse

J*ltwi+t+

(SPtt0:

lllGH)

I L' I

SPIE0

sw : lllGtl

DBX

sw : OUT

IIt{I It{ :

400H2 &

2zkltz

/-20dBV( 1 00mV)

R567/R967

OUTPIJT :

tqual level at

both frequency

Wlili}s.othnsL(*16

j

j

iffi

I

tt-L

l

i

tINI

IN :

-10dBV(316[|V)

Check

tz'v?

Frequency response

: Fig.3-7

Eliffiffitf

:

E

3-7

12-3

Same

as above

Et

DBX

sw

: Il{

Same

as above

lql_t

Check

*r.'v ?

Sane as above

Itrlr

17

I TEt{

;ffiFE

StTT IIIG

dx. ,lt:

IliPUT SIGIiAL

X)itrA

ADJUST

iffiH-Ft

RISULT

tffitE

REMRKS

ffi+

13. Frequency response

ffli4&f+tt

(SPEtD:

L0l4)

1 3-1

SPIID ST

OBX

s'r :

: L0ll

OUI

LIilt

IN :

400H2 & 20kHz

/-30dBV(31.

6[lV)

R563/R963

OUTPUT :

[qual level at both frequercy

ffiHffiCIfrfii$L(116

j j

ffi

IJ-Z

LINI II{:

-20d8

(100|llv)

Check

1- - ,,,4

Frequency response : Fig.3-B

Eiffiffitt

:

El

3-8

I J-J

Same as above

l-til-.]L

DBX sw : li{

Same as

above

Itrtr

Check

*t'v7

Sane as above

ItrJl

14. Honaura I record i ng

t,,t1)W*E

't4-1

SPIID stv :

L0l,l

DBX stt

: OUT

RIC Ftit'{().

sw

:

0lll

:Oti, Cll2:0fI LIt{t Iil:

-30dBv(3'l.ornv)

t 304

I requency response : F i

g.

3-B

HtffiC+tt

:

El

3-B

1i-t

Same as above

Et

RIC FUI{C.

sw

:

()tl1:0FF,

Cll2:0N

Chect(

+-..,4

15

BIAS

FINI

)\472.2r4/

15-1

SPItD

sw: L0l,]

DBX sw :

OUI

LINt

I|{

:

1 kllz/-10dBV

(316mV)

Assurl|e 0n outout refefence level obtained \vhen the

BIAS FINI button is set t0 center. Turn

BIAS FINI

coll|pletely t0 left and right and check that output

level varies

between

-2.5

dB and

+1.5

dB or hisher

against

the

refefence lever.

B I

AS

FINI tJ.

alht+y,

tiltr.0>6o1g7tt##L^Jt.

Lf6.

BiAS FINE -t*.h*ffi*fil3,qLf:Wo>frfi

,arp73t8Flz^JHtf'l

L

-2.

5dB,

+1.

SdB

t)llgYLf

6ZL.*1-t'v2t6.

After

checking, be sure

t0 set BIAS FINE EAC|( t0 the center

Dosition

*

e'y

?l*,

BrAS

FINE 2r.4t+.>

t{ilECtFL(*i<

:

L

.

16. Di stort ion

E+

16- 1

Same as above

IAI

SPI

iD sw : tilG|l

LINE IN :

1 kHzl-10dBV

(316mV)

Check

tt'v ?

DBX

sw

:

both

Iil

& OuT

Total

hurnonic

distortion

+HiEifttE

less

than 0.8

x

17.

Signal to noise ratio

s/ti

!L

17

-1

SPtID sw :

l]lGtl & t0ll No

signal

*f=€

Check

tz'y?

iach

sPeed

ffiJE

:

better than 52 dB

18. Erase

efficiency

iH*4FR

18- 1

Record

a 1 kltz signal,

rewind

and

erase

portion

of

the recording. Playback

the tape t0 conpare

the

output level from

the original

'l

kHz recording

yith

the level from

the erased

pofti0n.

1 kilz

€Bt$**f**FL(--StiFi*,

*iH*#j}LiH*#$h0>

1 kHz

firr,^('Ltaflft.

Connection

is same as in

Fig.3-3, but

engage l kHz filter.

'l

kflz B.P.F.

lFffi.

Thc ryorst

value should

be within spec.

&Effin*t&tlEEf6:L.

Specifications should

be |net

even

yhen

BIAS FINI

is

turned

down to

its

minimum setting.

BIAS

Fllit

.;:t

ts&y'r?L1tffi

trEEf

zo

:

L

.

SPIEO

sy : |-il0tl

LINT IN:

1 kllzlodBV

(1V)

Check

7t'v

7

Better than 68

dB

19. Channel separat ion

Ar4'tV'

t)\V-:z

z

Y

t9-

1

.Connecti0n:

Fig.3-3,

but do not

cOnnect LINE lN

(CHz),

and

engaoe 1 kHz filter.

1 kHz

B,

P. F.

ffrffi

.Set

the deck to record

mode. Find

the difference

between the 1 kHz recOrded

p0fti0n (Ctl1)

and

check reverse

portion.

1 kHz

$*#*il,}

(Ctil)

L*f=+$**#r|

(CHz)

o

1ktlz

F4,fr)1v<tw)#tu[8.

cH1,

CHz

t

MtE

it:&# i:?!

\(

LA

t'y

?

.

SPttD sw : HIGII

LII.IE ItI

:

Ctl 1 : lkHz/

-1OdBV(316nV)

CH2:Nosiona

Check

ttv2

Better

than 50 dB

s

f

f

f

t*

18

,f_

a

3-5 FREOUENCY

BESPONSE

Itl)&fit+,lt

3-5-1

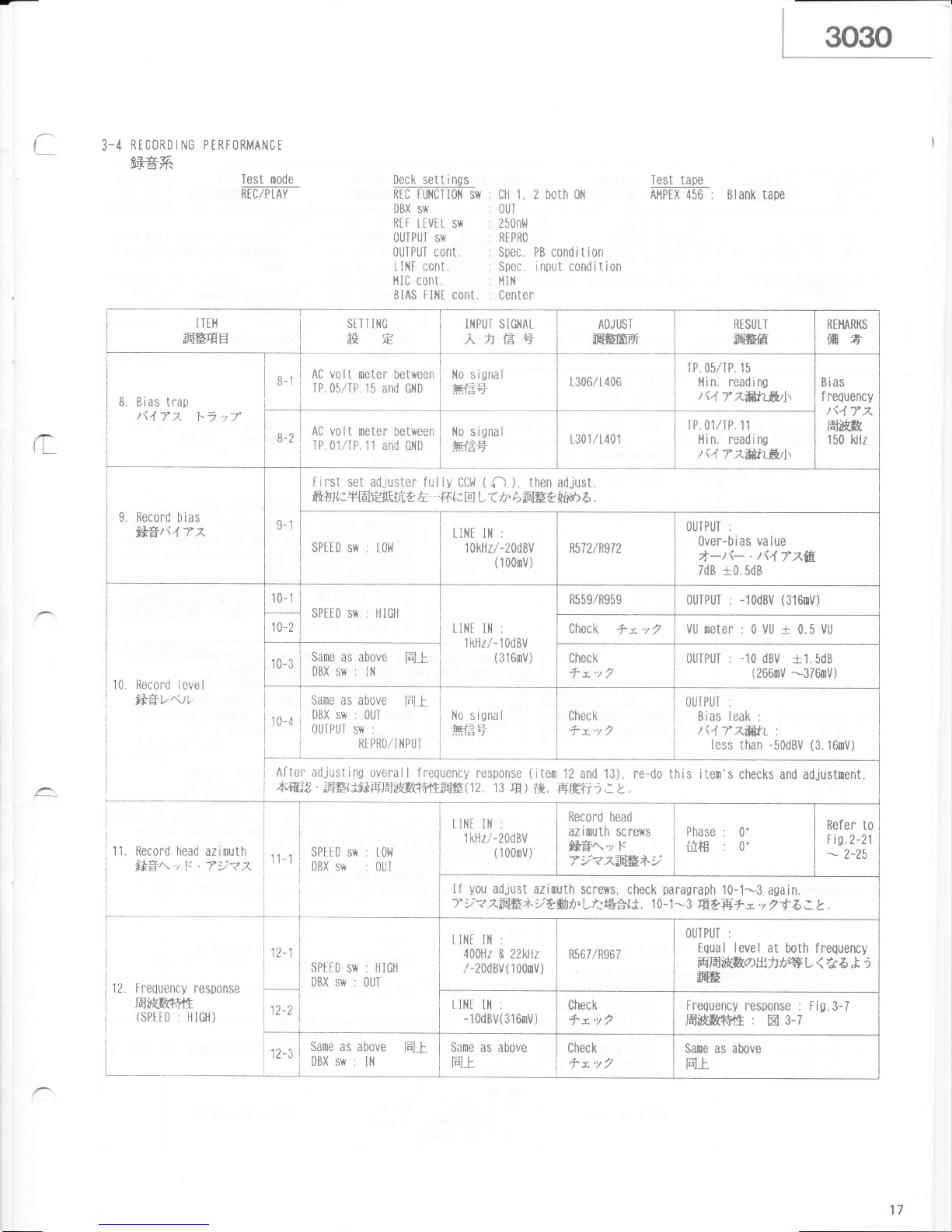

(dB)

+4

+3

o

-3

PLAYBACK

22k I Hz7

Fig.

3-S

Playback

frequency

response

(38

cm/s)

40

tk

Z?kt1z!

Fig.3-7

Overall frequency

response

(38

cm/s)

----------1

-6

t-------

J

\-----

---_J

IK

2Ok IHz]

Fig.

3-8 Overall frequency

response

(19

cm/sl

IN

0ur

3-5-2

(dB)

+6

+3

o

-3

-6

OVERALL

t------

--\

(

dB)

+6

(dB)

+3

0

-3

+3

o

-3

-

---

dBx

-

dBX

----

dBX rN

-

dBX

oul

400

20k

tHzl

Fig.

3-6

Playback frequency

response

(19

cmls)

I IEH

;FgFE

SITI I

t{G

eftE

Il{PUT

SIGNAT

xrtrE

ADJUST

iffifif-ff

llISULI

iffiG

RIHARKS

ffi*

20. RTC

HUTI

RtC

HUTI

funct

i on

YrX

20-1

.

Connection

: Fig.3-3,

but

ensaoe 1

kHz f ilter.

1 kHz

B.

p.

F.

l"fH.

.Record

a 1

kHz signal. Push

REC HUTI

button for

several

seconds.

(

At this time,

make

sure

LtO

0n the button

lights

)

Reyind

and

play

the tape.

Find

the difference

betleen

tfp 1 kHz

porti0n

and

"rec-mute"

pOfti0n.

1 kHz

{E€t$**L,

B+?

Rtc HUTI

fitffiL(*Ff=€#r}ttFb.

.o)i-ztH&Ls*Fg6j}l

*lEE#h t

o)flh

v,eratfiIef

6

.

SPTED

sw : HIGH

LINi

II{:

'l

kHzl10dBV

(316ltV)

Check

4-

-

,,,4

Bettef

than

65 dB

21. Phase

sh i ft

,/

I*./\

.

>/ /

L t' I

SPtiD

sw :

H IC,tl

L0ti

LINI

IN :

4Kllz sawtooth

trfrffi.

/-30dBV(31.6|l|V)

R576/R976

Cofrect

waveform

J&

Incorrect

yaveform

4E

19

$

3€

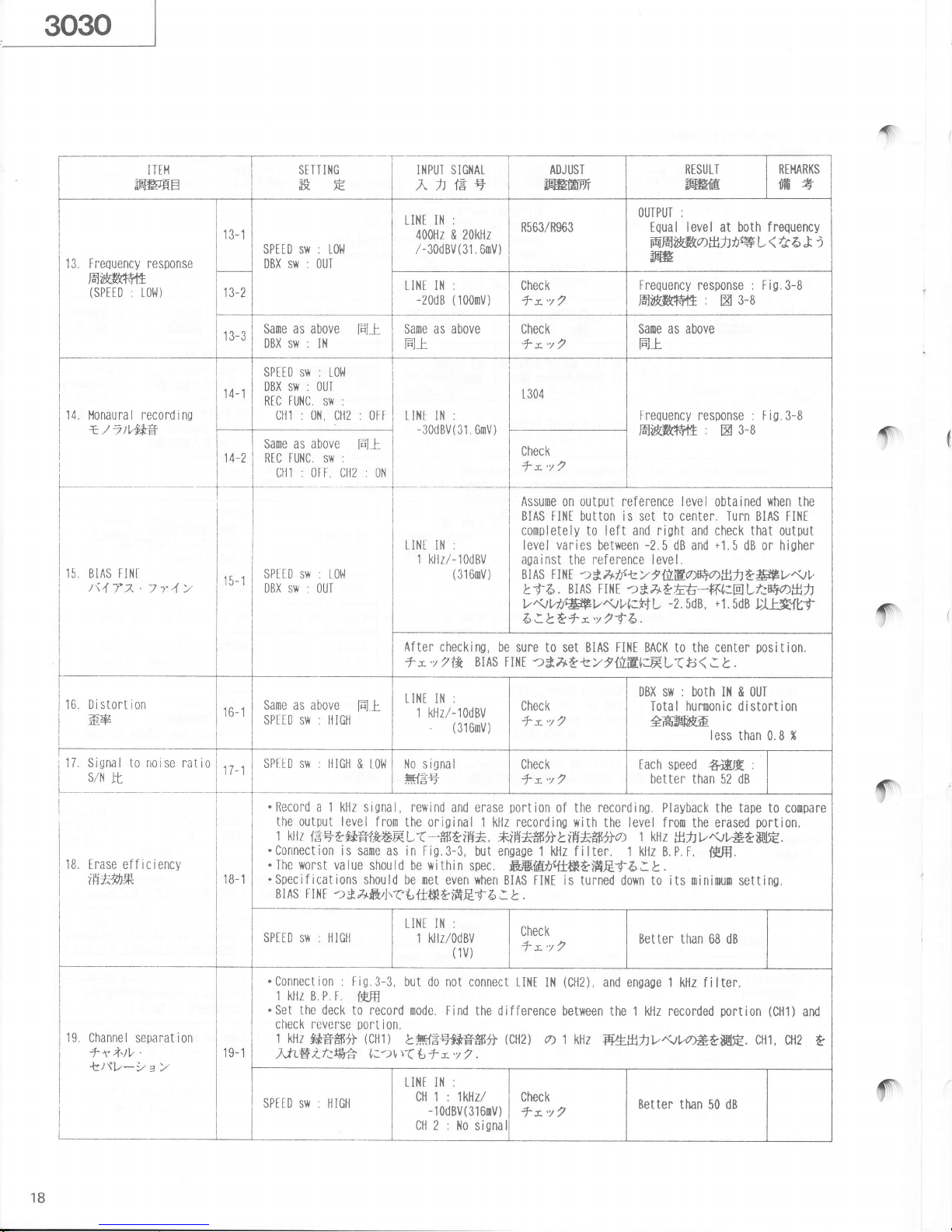

DBX PCB

ADJUSTMENT

TIOTES:

l.

This

section adjustment

is not

usually

needed

unless

an ad-

justor(sl

have

been

changed

0r a

component(sl

on

the

pC

board

have

sustained

damage,

since the PC

board

has

been

precisely

adjusted

in the factory.

2.

Turn the

deck

0FF to

prevent

accidental

damage

when

removing

or replaceing PC

board.

3-6-t

ADJUSTMETIT

p0tilTS

L0CAT|0trl

N*fiEF

3-6

DBX*+E+,f+EE#

rit

1

.

D B X

+

fh

o

&Y, F"

\ t*E li

f+'>

t;

r*

6

a

|tt,

i6'H I

A

DB X*tE

HfTd);iE45l*4iX<i

.

z.*tEr,I

+t t&rttt*?;t&,L't

j'y

+aEttR&tJJ )Th\

411t*';

(<

/:at\.

lcilRch

EilCODER

\L/)-t )

n27/W28

YGA

symmelry

VCA'>>./lt)-

R723/R724

l{ominal level

,S+v

^

)v

R753/R754

RilS

symmetry

RMS

7

>r/

l-

rJ

-

IIECODER

R627lR628

YCA

symmetry

vca->>t

t-t)-

R623/R624

llominal

level

z*Ev

^)v

R653/R651

RMS

symmetry

RMS'>>.'1

lt)-

Fig.3-9

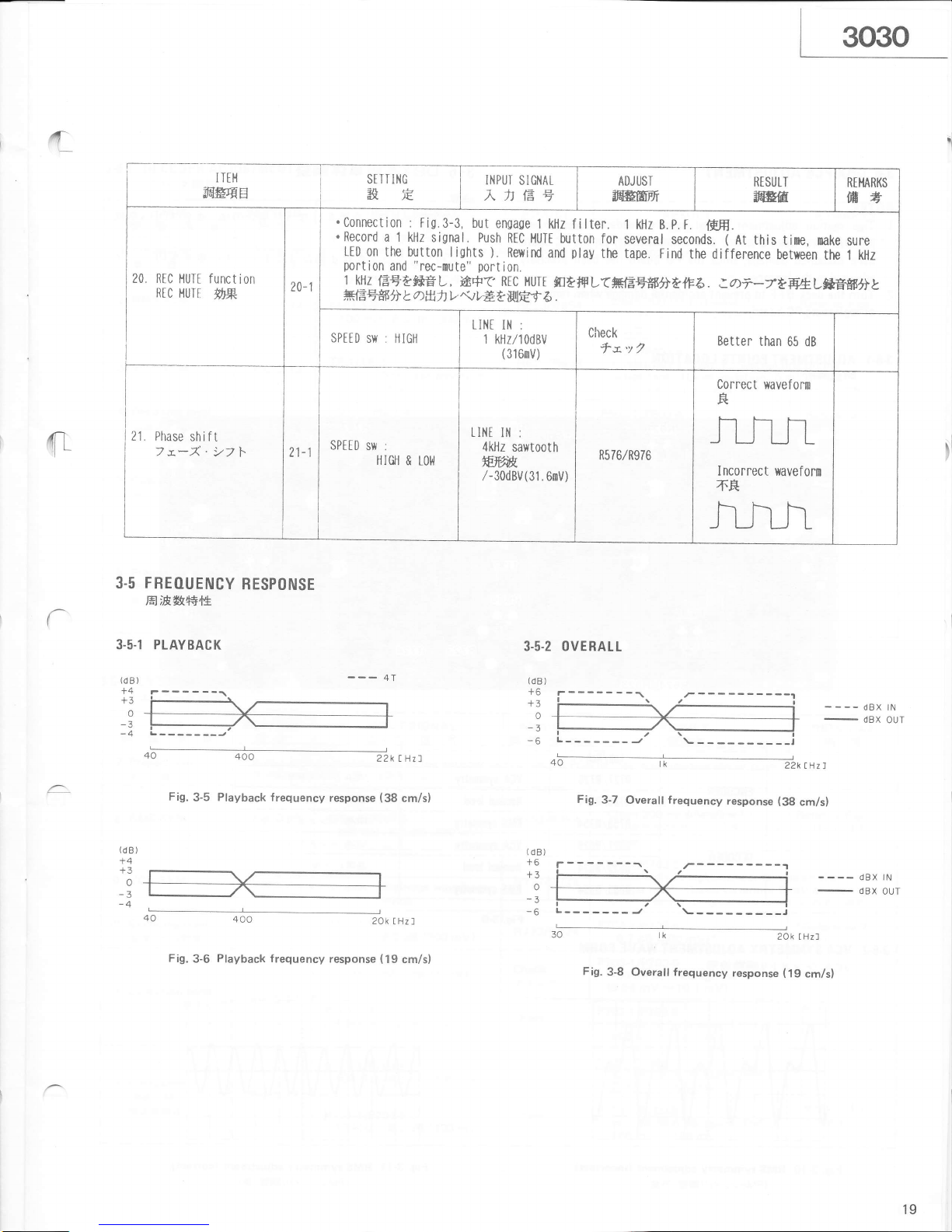

3-6-2

VCA

SYMMETBY

AOJUSTMEITIT

WAVE FORM

VCA i>ttt)8#.iEY..

Fig.

3-1O RMS

symmatry adjustment

(incorrect)

(RMSr>./l'rffilE.TF)

Fig.

3'11

RMS

symmetry adjustment

(correct)

(RMS>>./l.U-aEE.H)

A

J\ .A

A t \ I

\ \ \

\ \

LI

\/

1

IVI

\ \ \/

V

\/

l V

20

OECODER

ADJUSTMET{T

ta-tgE.

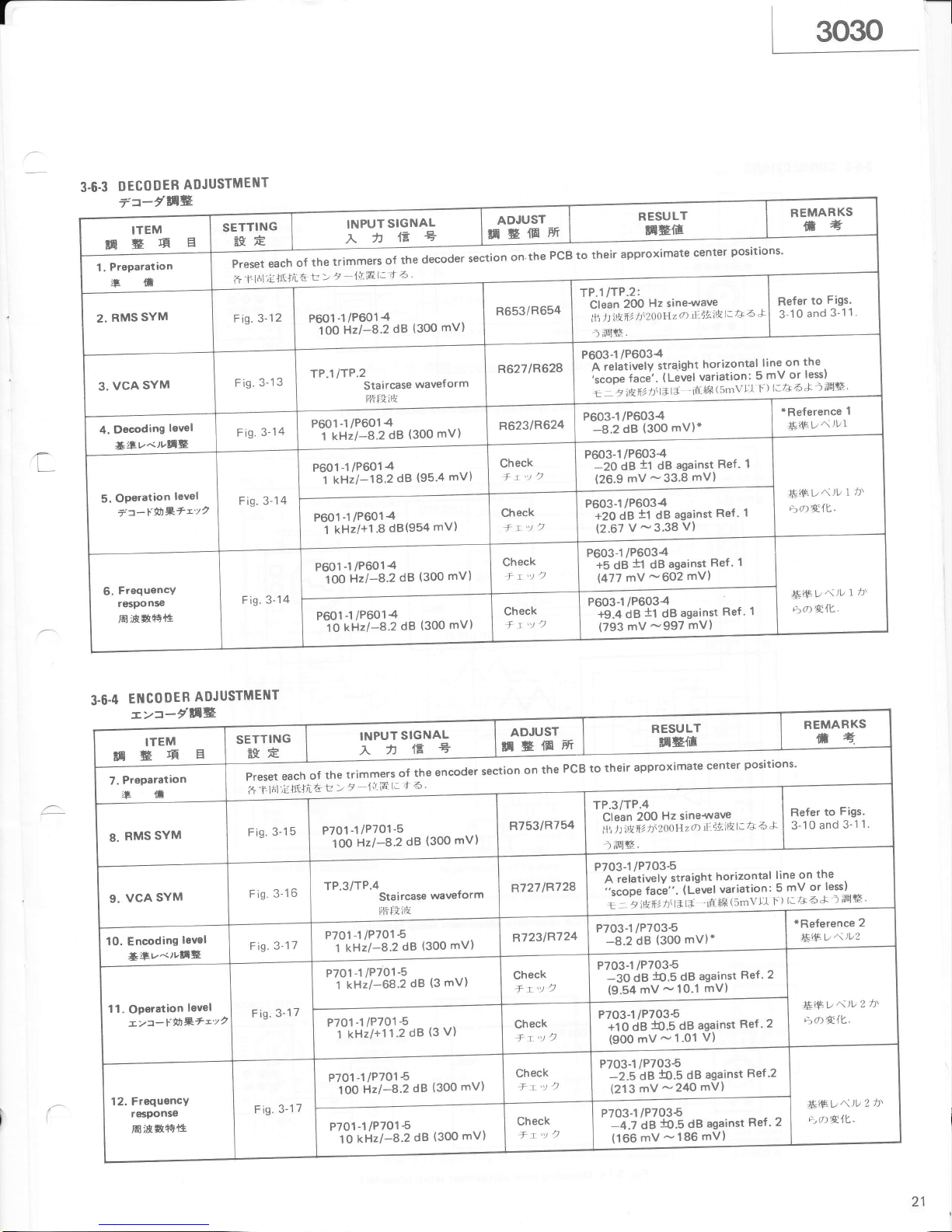

preset

each

of

the

trimmers

of

the

decoder

section

on

the

PCB

to

their

approximate

center

positions'

'*Yltl{'Jl1iit&P>t

-lit'Et''t

6

'

Refer

to

Figs.

3-10

and

3-1

1.

TP.1 ITP.2:

Clean

200

Hz

sineryvave

*,

h

iENt

h\zo

OHz

a

tt'lilxiq

t-

f4

4

&

P601

-1

/P601

4

1oo

nil-e.z

dB

(3oo

mv)

Ftg.

J-lz

i

-'g

in*zx't*tt

-E{R (smvl'-l

}

)

l.l:*6&

lffiE'

P603-1

/P6O34

'

Xi"iiii""tv

stra.ight

horizontal

line

on

the.

;s;o;-i;;;'.

(Leiel

variation:

5

mV

or

less)

TP.1ITP.2

Staircase

waveform

[ffiiE

Flg.

J-

lJ

P603-1

/P6034

-8.2

dB

(300

mV)*

P6O1

-1

/P601

4

1 kAzl-8.2

dB

(300

mV)

Fig.3-14

4.

Decoding

level

*,+v<)vgtr

E:+V\)v

I h\

4a*IL.

P6O3-1

/P6O34

-20

dB

t1

dB

against

Ref .

1

{26.9

mV

-33.8

mV}

P601-1

/P6014

1-u'l.il-ta.z

dB

(95.4

mv)

F

is.

3-14

5,

Operation

level

7a-ffri*7r'Y2

P603-1

/P6034

+2O

dB

!1

dB

against

Ref.

1

Q.67

v

-3.38

V)

P601-1

/P6O1

-4

1

kHz/+l

.8

dB(954

mV)

P603-1

/P6034

+5

dB

tl

dB

against

Ref.

1

@77

mY

-602

mV)

P6O1-1 /P6014

1oo

tt.t-g:

dB

(3oo

mV)

6,

FrequencY

response

B;A*4+tt

P603-1

/P6O34

+9.4

dB

+1

dB

against

Ref .

1

(793

mV

-997

mV)

P601-1 /P6014

1O

kHz/-8.2

dB

(3OO

mV)

EI{COOER

ADJUSTMET{T

->a-rfi'g

ffioftheencodersectiononthePCBtotheirapproximatecenterpositions.

?i'f

$I'EtEti,&

1z

>

t

-iit-E

t:t

4

Refer

to

Figs.

3-10and3-11

TP.3/TP.4

Clean

2O0

Hz sinerivave

N\ ) r

ifr.t,

h\200H

z

a tLlt'ir?

l'

1+

4'J

P701-1/P701-5

1OO

H4-a.2

dB

(30O

mV)

F

tg. J-

l3

i-:'iip-nzt,te[-E*n6-v;1

F)

Ir./*6.r

f

ffi#.

P703-1

/P703-5

'

ni"ijtiu"rv

straight

horizontal

line

on

the