®

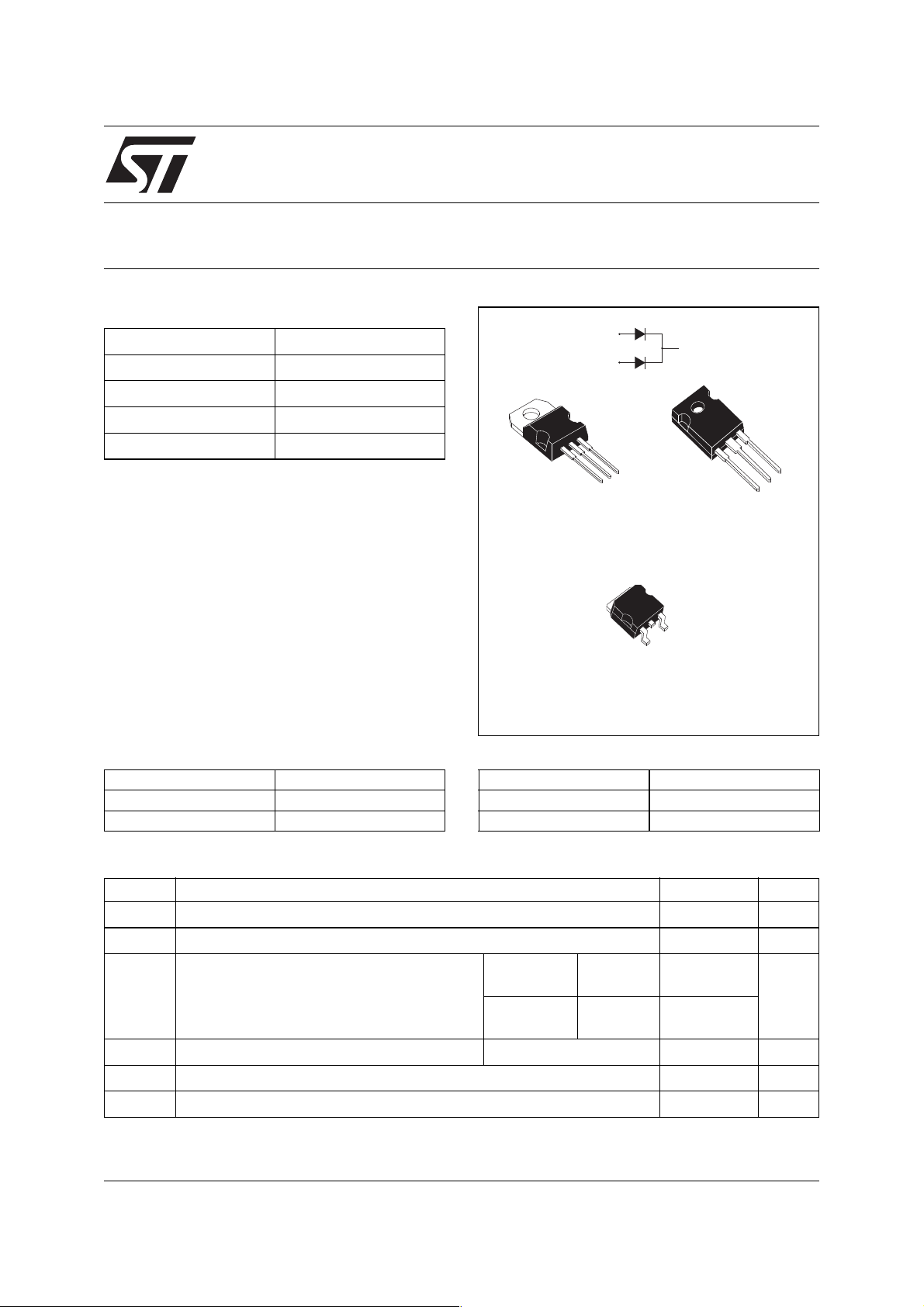

TURBO 2 ULTRAFAST HIGH VOLTAGE RECTIFIER

Table 1: Main Product Characteristics

I

F(AV)

V

RRM

T

j

VF (typ)

(max)

t

rr

Up to 2 x 20 A

600 V

175°C

0.95 V

55 ns

STTH30L06C

A1

K

A2

FEATURES AND BENEFITS

■ Ultrafast switching

■ Low reverse current

■ Low thermal resistance

■ Reduces switching & conduction losses

K

A1

TO-220AB

STTH30L06CT

K

TO-247

STTH30L06CW

A1

K

A2

DESCRIPTION

The STTH30L06, which is using ST Turbo 2 600V

technology, is specially suited for use in switching

power supplies, and industrial applications, as

rectification and discontinuous mode PFC boost

diode.

D2PA K

STTH30L06CG

A2

A1

Table 2: Order Codes

Part Number Marking

STTH30L06CT STTH30L06CT

STTH30L06CW STTH30L06CW

Part Number Marking

STTH30L06CG STTH30L06CG

STTH30L06GG-TR STTH30L06CG

Table 3: Absolute Ratings (limiting values, per diode)

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

F(AV)

I

FSM

T

T

Repetitive peak reverse voltage 600 V

RMS forward voltage 30 A

Average forward current

δ = 0.5

Tc = 140°C

Tc = 125°C

Tc = 120°C

Tc = 110°C

Per diode

Per device

Per diode

Per device

Surge non repetitive forward current tp = 10ms sinusoidal 130 A

Storage temperature range -65 to + 175 °C

stg

Maximum operating junction temperature 175 °C

j

15

30

20

40

A2

A

September 2004 REV. 1

1/8

STTH30L06C

Table 4: Thermal Resistance

Symbol Parameter Value (max). Unit

R

th(j-c)

R

th(c)

When the diodes 1 and 2 are used simultaneously:

∆ Tj(diode 1) = P(diode 1) x R

Table 5: Static Electrical Characteristics (per diode)

Symbol Parameter Test conditions Min. Typ Max. Unit

IR * Reverse leakage current Tj = 25°C VR = V

VF ** Forward voltage drop Tj = 25°C IF = 15A 1.55 V

Pulse test: * tp = 5 ms, δ < 2%

To evaluate the conduction losses use the following equation: P = 0.94 x I

Table 6: Dynamic Characteristics (per diode)

Junction to case Per diode 1.7 °C/W

Total 1.15

Coupling 0.6 °C/W

(Per diode) + P(diode 2) x R

th(j-c)

th(c)

RRM

15 µA

Tj = 150°C 40 400

Tj = 150°C 0.95 1.2

Tj = 25°C IF = 30A 1.76

Tj = 150°C 1.15 1.45

** tp = 380 µs,

δ < 2%

F(AV)

+ 0.017 I

F2(RMS)

Symbol Parameter Test conditions Min. Typ Max. Unit

V

I

RM

t

t

Reverse recovery

rr

time

Reverse recovery

current

Forward recovery

fr

time

Forward recovery

FP

voltage

Tj = 25°C IF = 0.5A Irr = 0.25A IR =1A 55 ns

IF = 1A dIF/dt = 50 A/µs VR =30V 60 85

Tj = 125°C IF = 15A VR = 400V

8.5 12 A

dIF/dt = 100 A/µs

Tj = 25°C IF = 15A dIF/dt = 100 A/µs

VFR = 1.1 x V

Fmax

Tj = 25°C IF = 15A dIF/dt = 100 A/µs

VFR = 1.1 x V

Fmax

300 ns

3.0 V

2/8

STTH30L06C

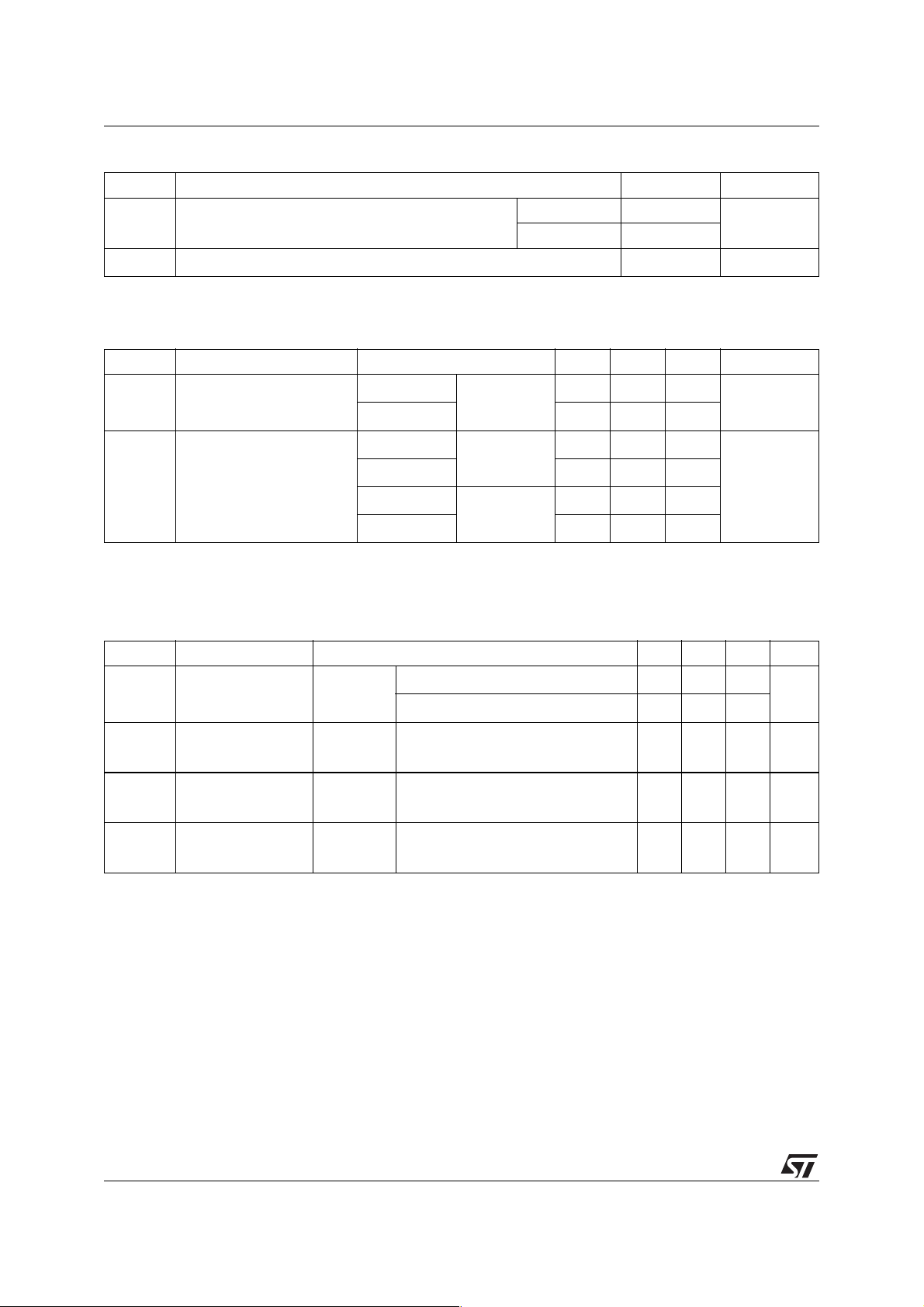

Figure 1: Conduction losses versus average

forward current (per diode)

P(W)

24

22

20

18

16

14

12

10

8

6

4

2

0

02468101214161820

δ = 0.05

δ = 0.1

δ = 0.2

I (A)

F(AV)

δ = 0.5

δ

=tp/T

δ = 1

T

tp

Figure 3: Relative variation of thermal

impedance junction to case versus pulse

duration

Z/R

th(j-c) th(j-c)

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

Single pulse

0.1

0.0

1.E-03 1.E-02 1.E-01 1.E+00

t (s)

p

δ

=tp/T

T

tp

Figure 2: Forward voltage drop versus forward

current (per diode)

I (A)

FM

100

T =150°C

90

80

70

60

50

40

30

20

10

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0

(maximum values)

T =150°C

j

(typical values)

j

T =25°C

j

(maximum values)

V (V)

FM

Figure 4: Peak reverse recovery current versus

dIF/dt (typical values, per diode)

I (A)

RM

35

V =400V

R

T =125°C

j

30

25

20

15

10

5

0

0 50 100 150 200 250 300 350 400 450 500

I =0.5 x I

FF(AV)

I=I

dI /dt(A/µs)

F

FF(AV)

I =2 x I

FF(AV)

Figure 5: Reverse recovery time versus dIF/dt

(typical values, per diode)

t (ns)

rr

800

700

600

I =2 x I

500

400

300

200

100

0

FF(AV)

I=I

FF(AV)

0 50 100 150 200 250 300 350 400 450 500

I =0.5 x I

F F(AV)

dI /dt(A/µs)

F

V =400V

R

T =125°C

j

Figure 6: Reverse recovery charges versus

dIF/dt (typical values, per diode)

Q (nC)

rr

1800

V =400V

R

T =125°C

j

1600

1400

1200

1000

800

600

400

200

0

0 100 200 300 400 500

I =2 x I

FF(AV)

I=I

FF(AV)

I =0.5 x I

FF(AV)

dI /dt(A/µs)

F

3/8

STTH30L06C

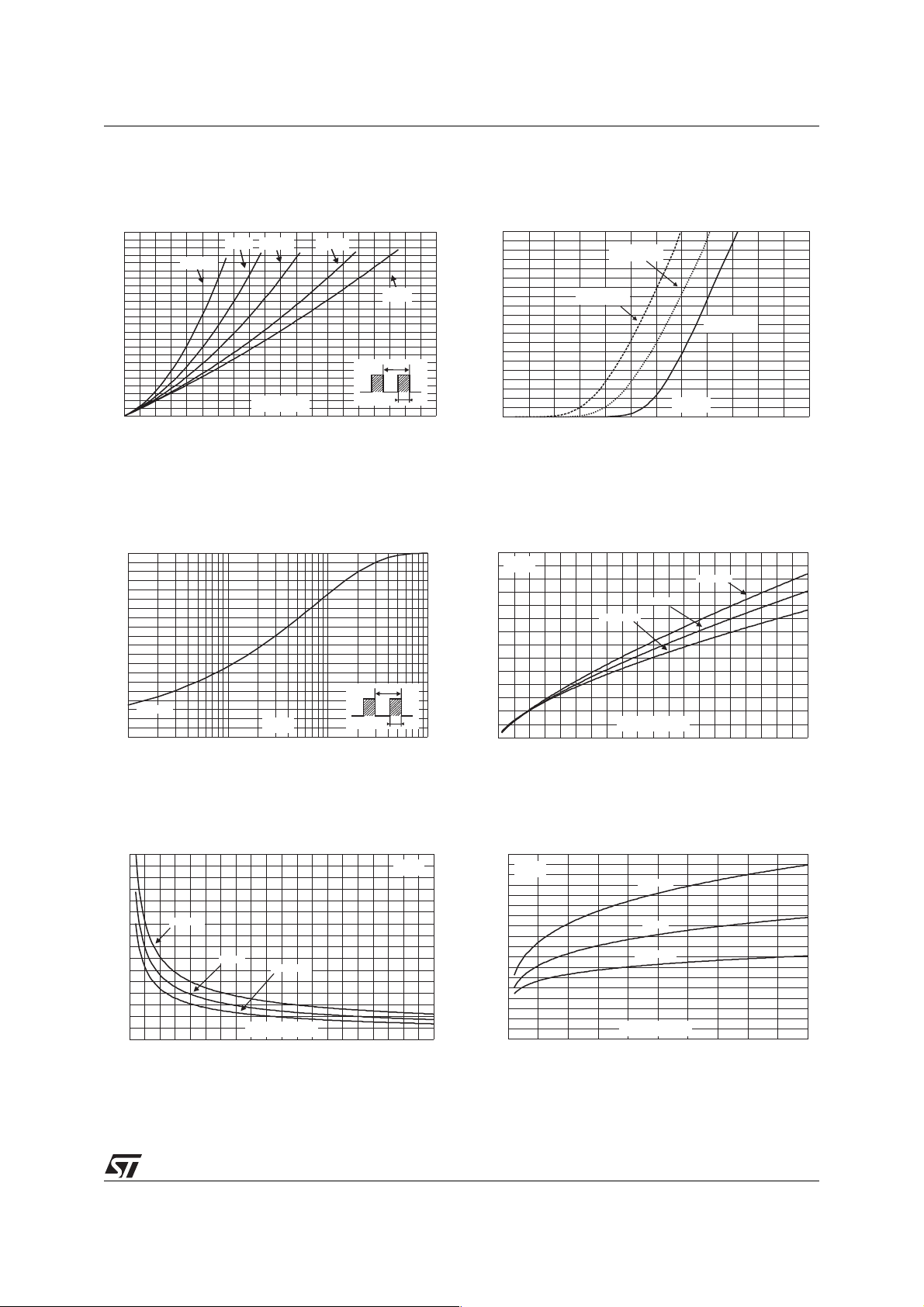

Figure 7: Reverse recovery softness factor

versus dIF/dt (typical values, per diode)

S factor

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 50 100 150 200 250 300 350 400 450 500

dI /dt(A/µs)

F

I< 2 xI

F F(AV)

V =400V

R

T =125°C

j

Figure 9: Transient peak forward voltage

versus dIF/dt (typical values, per diode)

V (V)

FP

12

I=I

FF(AV)

11

T =125°C

j

10

9

8

7

6

5

4

3

2

1

0

0 50 100 150 200 250 300 350 400 450 500

dI /dt(A/µs)

F

Figure 8: Relative variations of dynamic

parameters versus junction temperature

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

25 50 75 100 125

Q

RR

t

rr

S factor

I=I

FF(AV)

V =400V

R

Reference:T =125°C

I

RM

T (°C)

j

j

Figure 10: Forward recovery time versus dIF/dt

(typical values, per diode)

t (ns)

fr

260

240

220

200

180

160

140

120

100

80

60

40

20

0

0 100 200 300 400 500

dI /dt(A/µs)

F

I=I

FF(AV)

V =1.1 x V max.

FR F

T =125°C

j

Figure 11: Junction capacitance versus

reverse voltage applied (typical values, per

diode)

C(pF)

1000

100

V (V)

10

1 10 100 1000

R

4/8

F=1MHz

V =30mV

OSC RMS

T =25°C

j

Figure 12: Thermal resistance junction to

ambient versus copper surface under tab

(epoxy FR4, eCU=35µm) (D2PAK)

R (°C/W)

th(j-a)

80

70

60

50

40

30

20

10

0

0 5 10 15 20 25 30 35 40

S (cm²)

CU

Figure 13: TO-247 Package Mechanical Data

V

V

H

L5

L

F1

V2

F(x3)

= =

F4

G

Dia.

A

L4L2

F2

L1

F3

L3

D

ME

STTH30L06C

DIMENSIONS

REF.

A 4.85 5.15 0.191 0.203

D 2.20 2.60 0.086 0.102

E 0.40 0.80 0.015 0.031

F 1.00 1.40 0.039 0.055

F1 3.00 0.118

F2 2.00 0.078

F3 2.00 2.40 0.078 0.094

F4 3.00 3.40 0.118 0.133

G 10.90 0.429

H 15.45 15.75 0.608 0.620

L 19.85 20.15 0.781 0.793

L1 3.70 4.30 0.145 0.169

L2 18.50 0.728

L3 14.20 14.80 0.559 0.582

L4 34.60 1.362

L5 5.50 0.216

M 2.00 3.00 0.078 0.118

V5° 5°

V2 60° 60°

Dia. 3.55 3.65 0.139 0.143

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

5/8

STTH30L06C

Figure 14: D2PAK Package Mechanical Data

A

L2

E

L

L3

B2

B

G

C2

D

A1

C

A2

M

* FLAT ZONE NO LESSTHAN 2mm

R

*

V2

DIMENSIONS

REF.

Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

B 0.70 0.93 0.027 0.037

B2 1.14 1.70 0.045 0.067

C 0.45 0.60 0.017 0.024

C2 1.23 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

E 10.00 10.40 0.393 0.409

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

M 2.40 3.20 0.094 0.126

R 0.40 typ. 0.016 typ.

V2 0° 8° 0° 8°

Figure 15: D2PAK Foot Print Dimensions

(in millimeters)

16.90

10.30

1.30

8.90

3.70

5.08

6/8

Figure 16: TO-220AB Package Mechanical Data

A

C

L7

D

M

E

L2

F2

F1

H2

Dia

L5

L6

L9

L4

F

G1

G

STTH30L06C

DIMENSIONS

REF.

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

F2 1.14 1.70 0.044 0.066

G 4.95 5.15 0.194 0.202

G1 2.40 2.70 0.094 0.106

H2 10 10.40 0.393 0.409

L2 16.4 typ. 0.645 typ.

L4 13 14 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6 typ. 0.102 typ.

Diam. 3.75 3.85 0.147 0.151

Millimeters Inches

Min. Max. Min. Max.

Table 7: Ordering Information

Ordering type Marking Package Weight Base qty Delivery mode

STTH30L06CT STTH30L06CT TO-220AB 2.23 g 50 Tube

STTH30L06CG STTH30L06CG

STTH30L06CG-TR STTH30L06CG

D2PAK

D2PAK

1.48 g 50 Tube

1.48 g 1000 Tape & eel

STTH30L06CW STTH30L06CW TO-247 4.46 g 50 Tube

■ Epoxy meets UL94, V0

■ Cooling method: by conduction (C)

■ Recommended torque value: 0.8 m.N. (TO-220FPAC) / 0.55 m.N. (TO-220AB)

■ Maximum torque value: 1.0 m.N. (TO-220FPAC) / 0.70 m.N. (TO-220AB)

Table 8: Revision History

Date Revision Description of Changes

07-Sep-2004 1 First issue

7/8

STTH30L06C

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

8/8

Loading...

Loading...