Siemens 8MR6440-5EG30, 8MR6440-5EG40 Installation, Operation And Maintenance Manual

S

g

Installation, operation and maintenance manual

Montage-Betriebs und Wartungsanleitung

Air conditioner for electric enclosure

Schaltschrank-Kühl

erät

8MR6440-5EG30

8MR6440-5EG40

A T T E N T I O N !

Read carefully and completely before installation. Keep the manual until unit decommissioning.

Lesen Sie das vorliegende Handbuch in allen seinen Teilen aufmerksam durch, bevor das Gerät installiert wird. Das

Handbuch muss bis zum Abbau des Geräts aufbewahrt werden.

Warnhinweis: Montage und Installation von elektrischen Betriebsmitteln dürfen nur durch Elektrofachkräfte erfolgen.

Warning: Assembling and installation of electrical equipment may only happen by electro specialists.

A5E03773198A Version 01 Nov.11

F.48.0

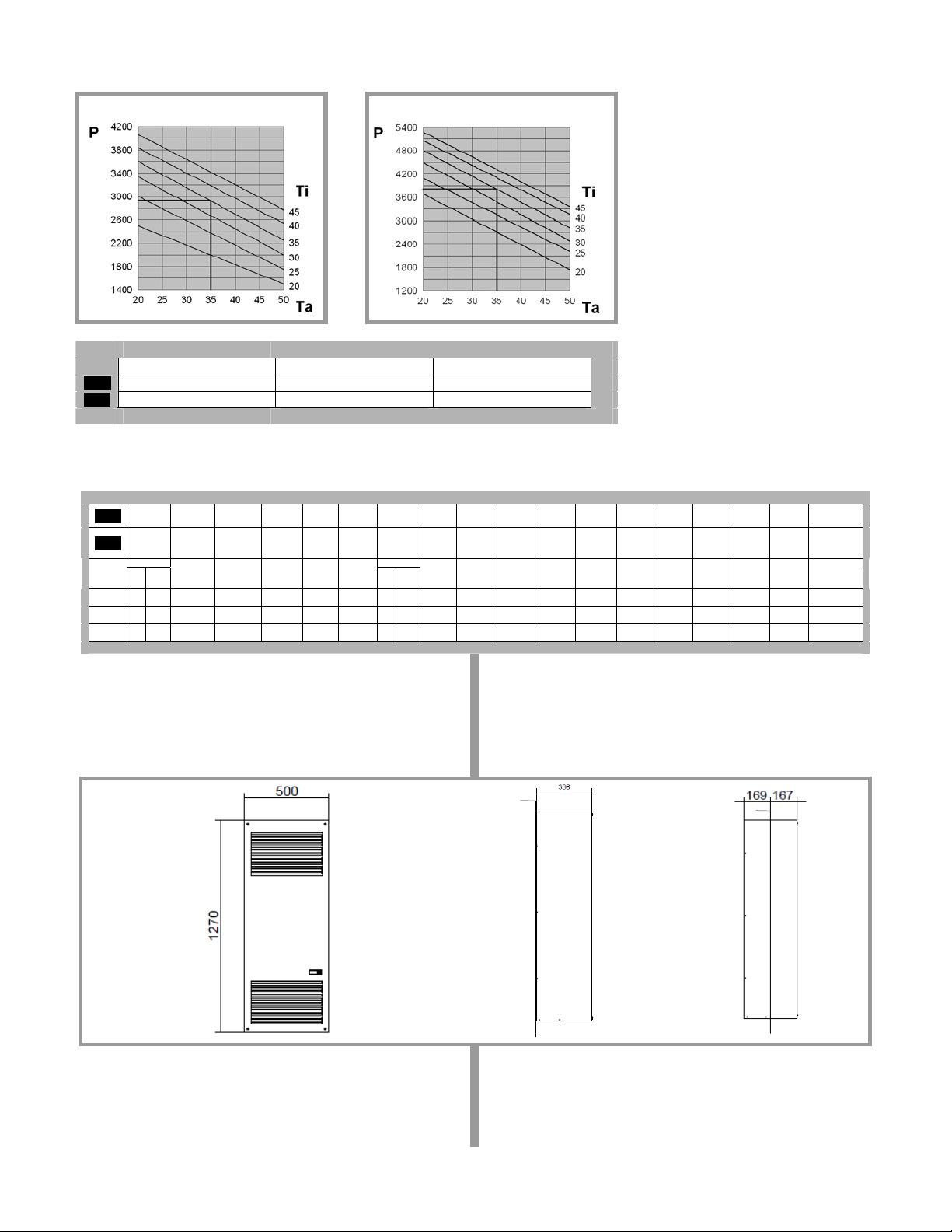

Performances / Leistungen

8MR6440-5EG30

8MR6440-5EG40

Useful cooling output Ambient temperature Enclosure internal temperature

ENG

Nutzkühlleistung Umgebungstemperatur Schaltschrank-Innentemperatur

DEU

P (W) Ta (°C) Ti (°C)

F. 49.1

Technical data / Technische Daten

Useful

Supply

Dimensions

ENG

DEU

8MR6440-

5EG30

8MR6440-

5EG40

F. 50.1

cooling

voltage

output

Nutzkühlleis-

Versorgungstung

spannung

EN814 EN814

A35

A35

W W V ~ Hz mm A A A W W - kg bar °C - °C - - Db(A) kg -

2900 2250 400 3~ 50-60 500x1270x336 2,6 14 6 1220 1440 100% 0,84 25 20-46 Thermostat 20-5 0 IP54 IP34 70 84 CE

3850 2870 400 3~ 50-60 500x1270x336 3,6 18 8 1780 2050 100% 1,14 25 20-46 Thermostat 20-5 0 IP54 IP34 70 85 CE

A35

A50

(W xHxD)

Abmessungen

(BxHxT)

Max current Starting

Höchststrom Anlauf-

current

strom

Pre-fuse T Electric

capacity

Vorsiche-

Nennleistung Einschalt-

rungT

A35

A35

Duty cycle Refrigerant Max

Kältemittel zul. Be-

dauer

R134a

A35

A50

Dimensions / Abmessungen

8MR6440-5EG30

8MR6440-5EG40

pressure

triebsüberdruck

Enclosure

temperature

range

Schaltschranktemperaturbereich

Temperatur e

control

Temperatur regelung

Ambient

temperature

range

Umgebungstemperatur- bereich

Protection

internal

circuit

Schutzart

Innenkreislauf

Protection

Noise level Weight Conformity

external

circuit

Schutzart

GeräuschAußen-

pegel

kreislauf

Gewicht Konformität

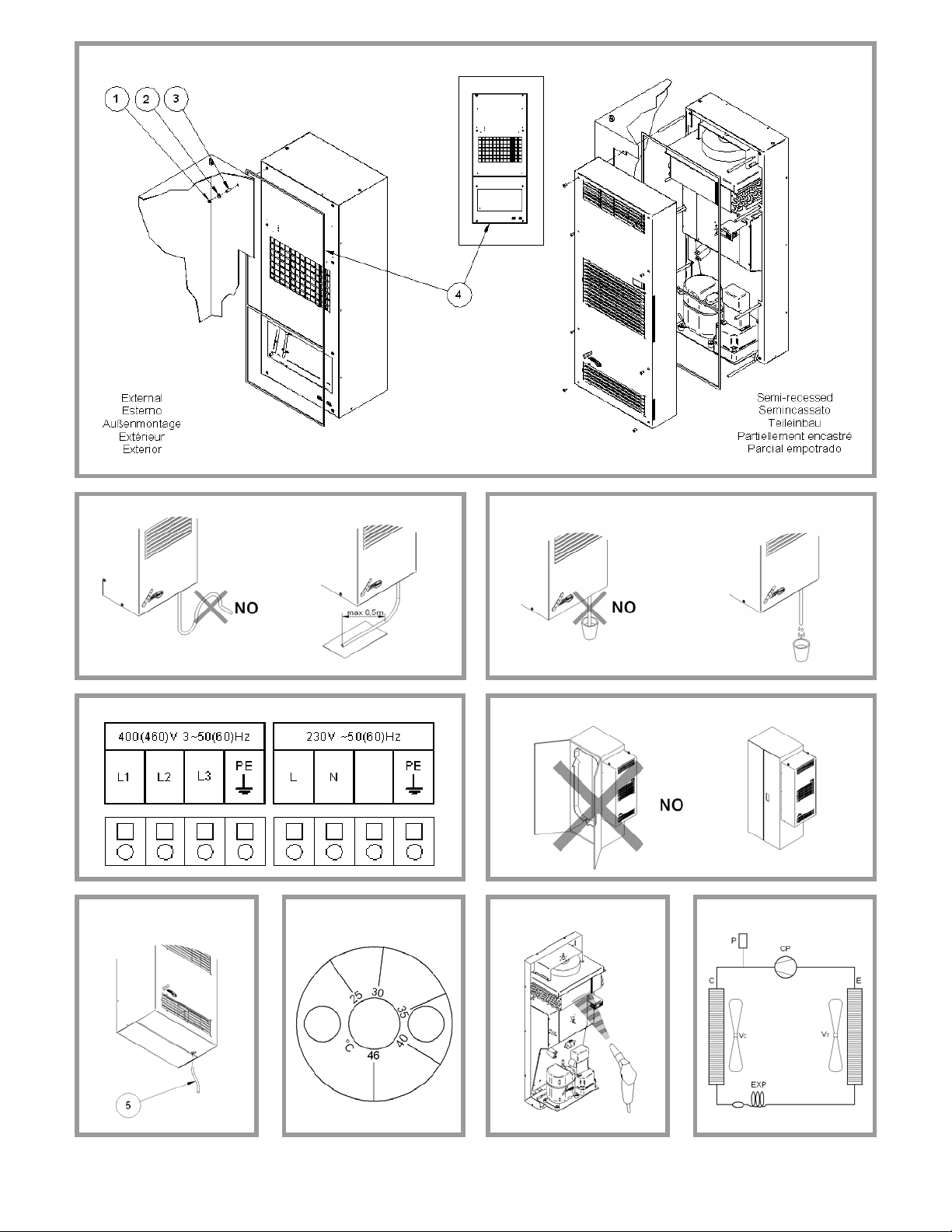

External

Außenmontage

Semi-recessed

Teileinbau

2

F.52.1

F.22.1 F.25.1

F.55.1 F.53.1

F.59.1 F.33.0 F.54.1 F.36.0

3

ENG

3

5

1. Cooling unit application.

The cooling units described in this manual are

designed and built to cool the air inside

switchboards in order to protect components

sensitive to thermal shock and, at the same

time, providing an IP54 protection level against

the infiltration of contaminating and strong substances.

2. Updates.

The manufacturer reserves the right to update

its product and relative manuals based on technical progress without prior notice. Please note

that at the time of sale, this manual and relative

product cannot be considered inadequate only

because they are not subject to abovementioned updates.

3. Technical features.

(Figures F.48.0 and F.49.1)

4. Supply.

Inside the packaging you will find:

cooling unit

1

installation, operating and maintenance

1

manual

test certificate

1

drilling template

1

1

M8 nuts

8

2

8.4x24 mm flat washers

8

M8x30 mm dowels

8

4

10x5 mm self-adhesive sealing strip

1

piece of flexible hose for discharging

1

condensate 12x2x100 mm

M8 eyebolts

2

5. Prior to assembly.

• During transport and storage the cooling

• Upon receipt, check the packaging has not

• Ambient air temperature, where the enclo-

• Make sure switchboard protection level is

• Check that the external environment does

• Check that the flows of air leaving and en-

• The supply voltage available must corre-

• The cooling unit must be installed in the

• The cooling unit must be installed with the

…

1 4

(figure F. 52.1)

(figure F. 59.1)

unit must be kept in the position clearly indicated on the packaging (figure F.1.0),

and must not be exposed to temperatures

higher than 70°C.

been damaged during shipping.

sure is to be installed, must be no higher

than 50°C and should never exceed the

cooling unit’s maximum operating temperature which is specified on its rating

plate. The unit must be positioned far away

from heat sources and flows of hot air.

IP54 or higher. Should this not be the case

excessive condensation could form. Consequently seal well all areas where cables

pass and all other openings in the enclosure.

not contain excessive concentrations of

contaminating solids and/or strong chemicals.

tering the cooling unit are not obstructed

by walls or objects that are too close. For

this purpose, in the case of the external air

flow, verify the minimum distances (figure

F.47.1), while in the case of the internal air

flow, make sure there are no obstructions

caused by the switchboard components.

spond to the features given on the cooling

unit’s rating plate.

position indicated. Maximum permitted deviation from the vertical is 2°.

enclosure air suction hole in the highest

possible point.

• If the cooling unit has to be installed on a

door, make sure the door can take the

weight.

• Before making the holes and slits on the

enclosure make sure the fixing elements

and couplings will not interfere with the

equipment inside the enclosure itself.

6. Assembly.

Disconnect power before starting any work inside the switchboard. The cooling unit can be

applied externally to, or semi-recessed (figure

F.50.1) on the electric enclosure as preferred

without the need for any additional accessories

(just those you will find inside the standard kit

supplied with the unit). Depending on the installation type chosen, drill the holes and make

the necessary cuts on the switchboard (figure

F.51.1) using the drilling template supplied with

the unit. Fit the sealing strip on the cooling unit

on the side connected to the enclosure and follow the assembly diagram (figure F.52.1).

To lift the cooling unit in a safe manner the two

M8 eyebolts may be used fitted into the

threaded inserts located on the top of the cooling unit (figure F. 56.1).

7. Condensate discharge hose.

The condensate which, depending on the ambient temperature and humidity conditions,

forms on the exchanger that cools the enclosure air, is not a malfunction but a normal phenomenon of the cooling unit. The condensate is

taken outside through a hose at the bottom of

the cooling unit. The transparent plastic hose,

supplied with the unit, must be connected to

this discharge (figure F.59.1).

This plastic hose can be connected to another

one with the same diameter to carry the condensate to another point so when it is discharged it is where there can be no slipping

hazard for personnel. In this case, make sure

the condensate flows without any hindrance.

Avoid horizontal lengths of more than 0.5 metres, lengths with a reverse gradient and the

accidental formation of traps (figure F.22.1).

The end of the condensate discharge hose

must always be free, never immersed, so never

place the end of the discharge hose inside condensate collection trays (figure F.25.1).

If the cooling unit is used with the doors of the

enclosure open, excessive quantities of condensate will form and this is an unauthorised

condition of use (figure F.53.1).

We suggest using a position switch on the door

that will stop the cooling unit if the door is

opened.

8. Electrical connection.

8.1 Safety

Attention! The electrical connection must be

done by specialised and authorised personnel. Switch power off to the enclosure before making the connection.

Check that the available supply voltage corresponds to the characteristics given on the cooling unit’s data plate. The supply of electricity to

the cooling unit must be protected by an isolating device / fuse or circuit breaker with a distance between the contacts of at least 3 mm

when open according to the indicated settings

(figure F.49.1).

Wire to the terminal board following the instructions on the wiring diagram and paying attention

to the terminals (figure F.55.1). After a stop the

cooling unit must not be started again immediately. For this reason we suggest using a timed

control that delays restarting 3 minutes. Disconnect the cooling unit before electrically testing the enclosure.

9. First start up and adjustment.

If, prior to installation, the cooling unit was left in

an incorrect position (figure F.1.0), wait at least

8 hours before switching it on otherwise 30

minutes are more than enough for the oil to return to the compressor after which the cooling

unit can be powered. The enclosure air suction

fan starts working immediately, rendering the

temperature even inside the enclosure. If this

temperature is higher than the threshold value

set on the adjustment thermostat both the compressor and external air fan start working, causing the cooling cycle to start. The latter stops

when the inside temperature reaches the low

limit of the operating differential that has a fixed

value of 4 K. The thermostat is factory set at 35

°C. To alter this set value access the thermo-

stat, situated at the back of the cooling unit,

from the inside of the electric enclosure (figure

F.33.0).

With the graduated scale, from 20 to 46 °C, you

may alter the set temperature as wanted. To

save energy and minimise the production of

condensation we recommend not to go below

30 °C.

9.1 Electronic thermostat (optional)

9.1.1 Setting the set point

Press key P and then release it, the SET LED

turns on and the display shows the SET POINT.

If necessary, use the UP key to increase the

value or the DOWN key to reduce it. These

keys act in one-digit steps but if you keep them

pressed for more than two seconds the value

increases or drops quickly to reach the value

wanted. This mode is exited automatically if you

fail to press any keys for about 5 seconds: the

display returns to displaying the probe measured temperature.

10. Maintenance.

Caution! Before embarking on any maintenance work, switch current off to the enclosure.

The cooling unit is the low maintenance type so

no filter change is required. The only jobs that

need doing are the internal components with

compressed air at a maximum pressure of 4 bar

(figure F.54.1) and which should be checked

regularly.

Job Frequency

Check the external air heat

exchanger and clean if

Every 3

months

necessary

Check effectiveness of the

condensate discharge

Check the fans for any

overheating or excessive

Every 3

months

Every 6

months

vibrations

Any repairs that may need doing must only be

done by specialised and authorised personnel

and using original spare parts only.

4

Loading...

Loading...