Page 1

Switchgear Type 8DJ20

up to 24 kV, Gas-Insulated

Medium-Voltage Switchgear

Catalog HA 45.31 · 2008

www.siemens.com/energy

Page 2

Contents

Application, Requirements

Features

Application, Requirements

Page

Features, typical use 2 and 3

Technical Data

Electrical data, filling pressure, temperature 4

Product Range

Equipment features 4

Product range overview, schemes 5

Design

Panel design 6

Components

Three-position switch-disconnector,

operating mechanisms 7

HV HRC fuse assembly, secondary

equipment, pressure absorber system 8

Cable connection 9

Dimensions

Switchgear 10 to 13

Floor openings, fixing points 14 and 15

Examples for cable connection 16

Shipping

Types of transport, transport data 17

Designs, Special Designs

LV compartment, outdoor enclosures 18 to 20

Standards, Notes

Standards, specifications,

guidelines, classification 21 to 23

For further information, please refer to

•

Catalog HA 40.1:

Switchgear Types 8DJ and 8DH, General Part

•

HA 45.31/41.11:

Supplements to Switchgear Types 8DJ and 8DH

Invalid:

Catalog HA 45.31 · 2006

The products and systems describedin this catalog

are manufactured and sold according to a certified

quality and environmental managementsystem

(acc. to ISO 9001 and ISO 14001).

(DQS Certificate Reg. No. DQS 003473 QM UM).

The certificate is accepted in all IQNet countries.

8DJ20 switchgear is a factoryassembled, type-tested, metalenclosed switchgear for indoor

installation.

Typ ic al us es

8DJ20 switchgear is used for

power distribution in substations

– even under severe environmen

tal conditions, such as:

Industrial environments

•

Damp, sandy or dusty areas

•

Simple outdoor substations

•

Main uses

Compact substations

•

Compact transformer substations,

•

e. g. for wind power stations

Garage and vault substations

•

Underground and underfloor

•

substations

Sidewalk substations, e.g.

•

containing switchgear with a

very small overall width – in

particular the basic versions

of schemes 10, 32 and 71 –

in conurbations

•

Substations with control aisle

Technology

•

Switchgear design with up to

5 feeders

•

Maintenance-free

•

Climate-independent

•

Partition class: PM

(metallic partition)

•

Three-pole primary enclosure,

metal-enclosed

•

Insulating gas SF

•

Welded switchgear vessel with-

6

out seals, made of stainless

steel, with welded-in bushings

for electrical connections and

mechanical components

•

Three-position switch-discon

nector with load-break and

make-proof earthing function

•

Cable connection for

bushings with outside cone

•

Connection with cable plugs

– In ring-main feeders with

bolted contact (M16)

– In transformer feeders with

plug-in contact

Option: Connection with

•

conventional sealing ends

– For thermoplastic-insulated

cables via elbow adapter

AKE 20/630 (make Siemens)

– For paper-insulated mass-im-

pregnated cables via commercially available adapter systems

Easy installation

•

-

Personal safety

Safe-to-touch and hermetically-

•

sealed primary enclosure

HV HRC fuses and cable sealing

•

ends are only accessible when

outgoing feeders are earthed

Operation only possible when

•

enclosure is closed

Logical mechanical interlocking

•

Capacitive voltage detecting

•

system to verify safe isolation

from supply

Feeder earthing by means of

•

make-proof earthing switches

Security of operation

Hermetically-sealed primary

•

enclosure independent of environmental effects such as

pollution, humidity and small

animals – sealed for life:

– Welded switchgear vessel

– Welded-in bushings and

operating mechanism

•

Operating mechanism parts

maintenance-free

(IEC 62 271-1/VDE 0671-1)

•

Operating mechanisms of

switching devices located out-

side the switchgear vessel

(primary enclosure)

•

Switchgear interlocking system

with logical mechanical inter-

locks

Cost-efficiency

Extremely low “life-cycle costs”

throughout the entire product

service life as a result of:

•

Maintenance-free concept

•

Climatic independence

•

Minimum space requirements

•

Maximum availability

Standards

seepage21

© Siemens AG 2008

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

2

Page 3

Application

Features

Our product range extends from

switchgear installed in a radial

transformer panel (individual

panel) to switchgear with 5

feeders, consisting of

Ring-main feeders

•

Transformer feeders with

•

HV HRC fuse assemblies

Circuit-breaker feeders (for

•

thecompleteproductrange

see Supplements to Catalogs

HA 45.31/41.11 – 2006)

The switchgear is available in

three overall heights:

1200 mm

•

(with low subframe)

1400 mm and 1760 mm

•

(with high subframe)

These overall heights cover all

areas of application, from compact substations to switchgear

rooms with control aisle.

Basic design

Manual operating mechanism

•

Transformer cable connection

•

at the front (standard)

•

With logical mechanical interlocks

•

With ready-for-service indicator

•

With capacitive voltage detecting system at the ringmain feeders

s

p

e

c

9

9

0

5

4

A

H

R

Radial transformer

panel

1 transformer feeder

1 radial cable connection

Scheme 01

s

p

e

b

0

0

1

5

4

A

H

R

Ring-main/

transformer block

2 ring-main feeders

1 transformer feeder

Scheme 10

s

p

e

c

1

0

1

5

4

A

H

R

Ring-main/

transformer block

3 ring-main feeders

2 transformer feeders

Scheme 82

Typical use

Options (others on request)

•

Capacitive voltage detecting

system at the transformer

feeders

•

Motor operating mechanisms

for the three-position switchdisconnectors

•

Auxiliary switch for three-position switch-disconnector and

make-proof earthing switch

•

Short-circuit indicator with

built-in housing

•

Surge arresters for ring-main

feeders

•

Shunt releases for transformer

feeders

•

Secondary equipment for

remote operation or remote

indication, e.g. with localremote switch in the case of

motor operating mechanisms

or ”tripped signal” in the case

of transformer feeders

•

Locking devices

•

Closing lock-out

•

De-earthing lock-out

•

Cable clamps

s

p

e

c

6

8

0

5

4

A

H

R

8DJ20 switchgear in

a compact substation

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

3

Page 4

Technical Data, Product Range

Electrical data, temperature, filling pressure Equipment features of panels

Rated voltage U

Rated insulation level

Rated short-duration kV

power-frequency

withstand voltage U

Rated lightning impulse kV

withstand voltage U

Rated frequency f

Rated normal current I

for ring-main feeders 400 or 630 A

for transformer feeders

depending on the

HV HRC fuse link

for schemes 01 and 21

depending on the

HV HRC fuse link

Rated short-time

withstand current I

at 1 s kA

at 3 s (option) kA 20 20 20 20 20

Rated peak kA

withstand current I

Rated short-circuit

making current I

fortransformerfeeders kA2525252525

for ring-main feeders kA

Ambient air temperature T

(operating conditions acc. to

IEC 62 271-200/Clause 2 or

IEC 62 271-1

– Without secondary equipment

– With secondary equipment,

class “Minus 5 indoor”

Pressure values at 20 °C

for the insulation:

Rated filling level p

Minimum functional level p

1) According to some national requirements, higher values of the

rated short-duration power-frequency withstand voltage

available for I

– 42 kV for phase-to-phase, phase-to-earth and opencontact

gap as well as

– 48 kV across the isolating distance

Higher values of the rated lightning impulse withstand voltage:

– 95 kV for phase-to-phase, phase-to-earth and opencontact

gap as well as

– 110 kV across the isolating distance

2) For overall height of switchgear 1200 mm:

Cable bracket below the feeder

3) Cable fixing by customer

(the switchgear is supplied without cable bracket)

4) In case of scheme 01 the cable compartment cover is bolted.

The transformer connection is effected via the bushings

arranged underneath the switchgear vessel. The transformer

feeder is earthed by the three-position switch

5) Temperature range, reduced normal currents at ambientair

temperatures>+40°C

6) SurgearrestertypeRDAwithRICS(TycoElectronics)not

possible for a height of 1200 mm

o. r. = on request

r

r

ma

)

=20kAwith:

k

k

p

re

kV 7.2121517.524

20 281)36 38 50

d

p

r

60 751)95 95 125

50/60 Hz

200 A

200 A

–

kA

kA

kA

kA

kA

kA

me

–

20

20

25

25

–

–

50

50

63

63

–

–

50

50

63

63

-40to+70°C

-5to55°C

1500 hPa (absolute)

1300 hPA (absolute)

–

16

20

25

–

50

63

–

50

63

5)

5)

16

20

20

25

–

40

40

50

50

63

–

40

40

50

50

63

–

Equipment

Manual operating mechanism for

three-position switch-disconnector:

– As spring-operated mechanism

– As spring-operat./stored-energy mech.

Motor operating mechanism for

three-position switch-disconnector

Interlock for cable compartment

cover

Cable compartment cover locked

in place/screwed on

2)

Cable bracket

feeders, cable routing downwards

Cable bracket in transformer feeder:

For cable routing

– Downwards (standard), f. cable elb. plugs

or

– Downwards, for straight cable plugs

or

– To the rear, for cable elbow plugs

Low-voltage terminals in the

operating mechanism

(option for secondary equipment)

Shunt release

Auxiliary switch for

– Switch-disconnector

CLOSED/OPEN:1NO+2NC

–EARTHINGCLOSED/OPEN:

1NO+1NC

Locking device for

three-position switch-disconnector

Short-circuit or earth-fault indicator

– Wiring at the indicator

(standard)

– Wiring to terminal (option)

De-earthing lock-out for

make-proof earthing switch

in transformer feeder

Closing lock-out for

three-position switch-disconnector

Double cable connection for

– Overall height of switchgear 1200 mm

– Overall height of switchgear 1400 mm

– Overall height of switchgear 1760 mm

Surge arrester for

– Overall height of switchgear 1200 mm

– Overall height of switchgear 1400 mm

– Overall height of switchgear 1760 mm

Cable clamps for cable fixing

– Supplied separately

– Preassembled (option)

in ring-main and cable

• Basic equipment

Additional equipment

°

(option), further

additional equipment

on request

xNot

applicable

– Not avail-

able

Radial cable connection, panel K(E) for scheme 21

(with additional earthing switch)

Radial cable connection,panelKforscheme02

Ring-main feeders

panel RK

(without earthing switch)

•

x

–

x

–x

•

–•••

–•–––

••••

x

x

x

x

x

x

•–•••

–––

x

°

x

°

x

°

°

°

°

°

xxx

°

–x

°

°

°

°

°

°

–

–

°

°

°

°

°

°

°

°

Transformer feeder

panel1Tinscheme01

Transformer

•

–

–

•

°°°

x

x

x

•

without

3)

without

3)

x

°°

°

°

°

°

°°°

–

°

–

°

4)

––

°

x

°

x

°

x

°

6)

o. r.

x

x

°

x

°

°

°

–

°

feeders

–

•

x

•

•

°

°

–

–

°

x

x

x

x

x

x

°

°

panel T

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

4

Page 5

T

HA45-2294d eps

K

HA45-2295c eps

RK K

HA45-2296c eps

RK TRK

HA45-2302c eps

RK TRK RK

HA45-2304c eps

RK TRKT

HA45-2297c eps

RK RK

HA45-2301c eps

RK RKRK RK

RK RKRK RK RK

HA45-2306c eps

HA45-2300c eps

RK RKRK

HA45-2305c eps

RK TRKT RK

HA45-2303c eps

RK TRK RK RK

HA45-2298c eps

TRK

HA45-2299c eps

TK(E)

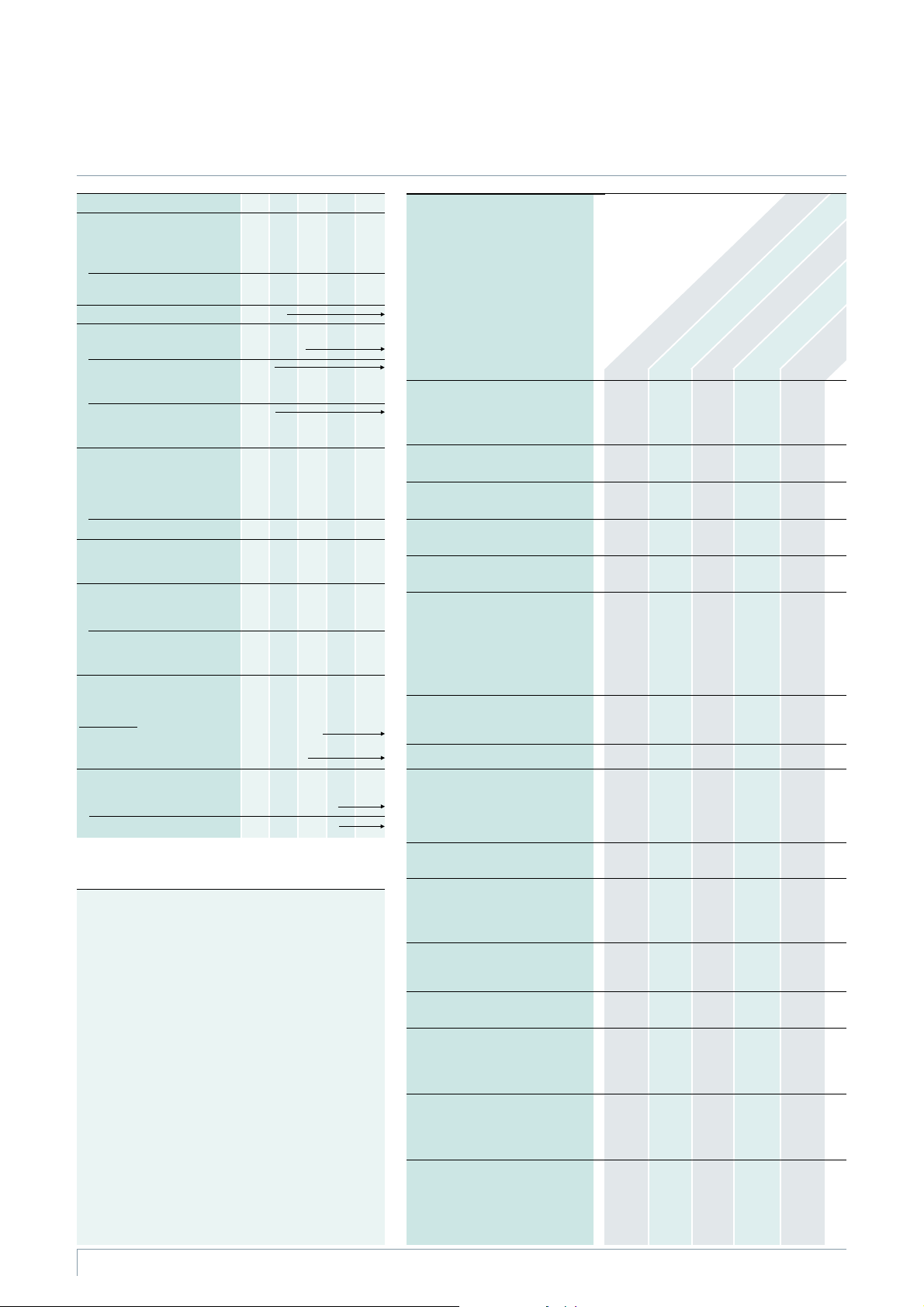

Product Range

Product range overview, schemes

1)

Scheme

Components shown in dotted

lines can be used optionally.

Overall dimensions Net

WidthmmDepth

2) 3)

mm

Height

mm

weight

approx.

kg

Scheme

Components shown in dotted

lines can be used optionally.

Radial transformer panels

Scheme 01 * 1 transformer feeder,

K Radial cable

connection as

infeed

1 radial cable connection

(Abbreviation 1T)

510 775 1200

1400

1760

140

160

200

Scheme 21 1 radial cable connection,

Radial panel

Scheme 02 1 ring-main feeder with

radial cable connection

(Abbreviation 1RK)

710 775 1200

1400

1760

150

170

210

Block versions, consisting of ring-main andtransformer feeders (with HV HRCfuse assembly)

Scheme 10

* 2 ring-main feeders,

Scheme 20 1 ring-main feeder,

1 transformer feeder

(Abbreviations 2RK+1T)

1060 775 1200

1400

1760

280

300

340

K(E) Radial cable

connection, K as

K(E) with make-proof

earthing switch

Overall dimensions Net

WidthmmDepth

2) 3)

mm

Height

mm

weight

approx.

kg

1 transformer feeder

(Abbreviations 1K(E)+1T)

710 775 1200

1400

1760

200

210

250

1 transformer feeder

(Abbreviations 1RK+1T)

710 775 1200

1400

1760

200

210

250

1)

Scheme 71 * 3 ring-main feeders,

1 transformer feeder

(Abbreviations 3RK+1T)

1410 775 1200

1400

1760

340

360

400

Scheme 81 * 2 ring-main feeders,

2 transformer feeders

(Abbreviations 2RK+2T)

1410 775 1200

1400

1760

400

420

460

Block versions, consisting of ring-main feeders (withoutHV HRC fuse assembly)

Scheme 11 2 ring-main feeders

(Abbreviation 2RK)

710 775 1200

1400

1760

160

170

210

Scheme 70 * 4 ring-main feeders

(Abbreviation 4RK)

1410 775 1200

1400

1760

280

300

340

Scheme 72 4 ring-main feeders,

1 transformer feeder

(Abbreviations 4RK+1T)

1760 775 1200

Scheme 82 3 ring-main feeders,

2 transformer feeders

(Abbreviations 3RK+2T)

1760 775 1200

Scheme 32

* 3 ring-main feeders

(Abbreviation 3RK)

1060 775 1200

Scheme 84 5 ring-main feeders

(Abbreviation 5RK)

1760 775 1200

1400

1760

1400

1760

1400

1760

1400

1760

420

440

480

470

500

540

210

230

270

350

380

420

1) Depending on the relevant equipment, e.g. motor operating mechanism

2) Additional wall distance required: W 15 mm

3) For cable routing of transformer cables downwards

* Scheme is also suitable for outdoor enclosure (see pages 18 and 19)

Abbreviations:

RK = Ring-main feeder K = Cable feeder T = Transformer feeder

K(E) = Cable feeder forradial cable connection with make-proofearthing switch

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

5

Page 6

HA45-2337d eps

L1 L2 L3

5

3

2

1

4

B

A

B

A

6

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

25

26

27

28

10

19

20

31

22

23

32

24

27

33

31

36

10

16

30

29

34

35

38

38

HA45-2308e eps

31

32

29

24

30

22

HA45-2309e eps

31

32

29

22

23

24

37

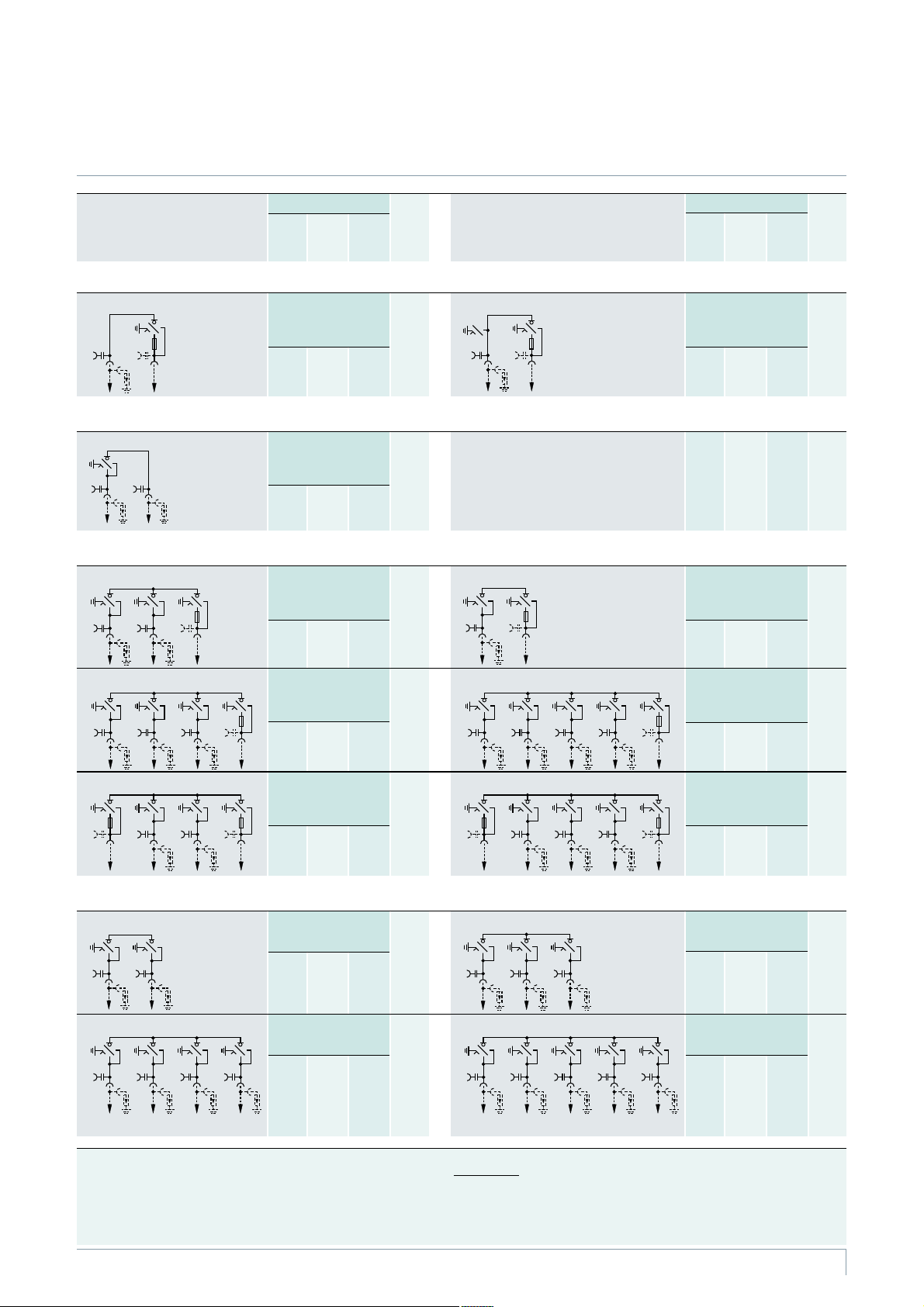

Design

Panel design (example)

Ring-main/transformer block

Scheme 10

Transformer feeder

Section A-A

Standard

Cable connection for cable elbowplugs

(option: for cable T-plugs),

cable routing downwards

Ring-main feeder

Section B-B

Cable connection with bolted contact (M16):

– For cable T-plug or cable elbow plug

– For conventional cable sealing ends via

elbow adapter AKE 20/630

1 Niche for customer-side low-voltage equipment

2 Feeder designation label

Position indicators

in the ring-main feeder:

3 Load-break function ”CLOSED – OPEN”

4 Earthing function ”OPEN – EARTHED”

5 Rating and type plate

6 Ready-for-service indicator

7 Mimic diagram

8 Short-circuit/earth-fault indicator (option)

9 Sockets for voltage detecting system

10 Interlock of the cable compartment cover

11 HV HRC fuse assembly, cover removed

12 Handle for replacing the HV HRC fuse link

13 Interlock for HV HRC fuse assembly

Position indicators

in the transformer feeder:

14 Earthing function ”OPEN – EARTHED”

15 Load-break function ”CLOSED – OPEN”

with ”HV HRC fuse tripped” or”shunt release

tripped”, where applicable

16 Locking device

(option for three-position switch-disconnector)

17 Manual operation for the mechanism of

the earthing function

Personal safety

All feeder-related covers can only be

opened if the associated three-position

switch-disconnector has been switched to

the “EARTHED” position.

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

6

Option

Cable connection for cable elbow

plugs, cable routing tothe rear

(cable fixing by customer)

Option

Cable connection for

straight cable plugs,

cable routing downwards

18 Manual operation for the mechanism of

the load-break function

19 Switchgear vessel, filled with gas

20 Connecting bar to cable connection

21 Arrangement of cable connections

22 Cable compartment

23 Cable bracket

24 Cable (not included in the scope ofsupply)

25 Cover of the HV HRC fuse compartment

26 Connecting bar to the bushings

for the HV HRC fuse

27 Three-position switch-disconnector

28 Spring-operated/stored-energy mechanism

29 Bushing as interface type “A” for

cable plug with plug-in contact

O

ption: Bushing as interface type “C”

for cable plug with bolted contact (M16)

30 O

ption: Cable elbow plug with

plug-in contact

31 Cable compartment cover

32 M12 earthing connection

33 Spring-operated mechanism

34 Bushing as interface type “C“ for cable

plug with bolted contact (M16)

35 O

ption: Cable T-plug with bolted contact

36 Pressure relief device

37 O

ption: Straight cable plug with

plug-in contact

ption: Low-voltage compartment

38 O

Page 7

Components

Three-position switch-disconnector, operating mechanisms

Three-position

switch-disconnector

The switching device used

is the proven three-position

switch-disconnector

Functions

Load-break function

•

Earthing function with

•

short-circuit making capacity

Switch positions

•

CLOSED – OPEN – EARTHED

Operating mechanisms

The three-position switchdisconnector is operated from

the switchgear front via

Detachable lever mechanism

(standard)

• Spring-operated mechanism

– With ”spring-operated

CLOSED” and ”spring-operated OPEN” for installation

in ring-main feeders

Spring-operated/stored-

•

energy mechanism

– With ”spring-operated

CLOSED” and ”spring-operated OPEN” for installation

in transformer feeders

–Withanadditionalenergy

store for the function ”storedenergy OPEN” after tripping

by the HV HRC fuse (striker

tripping) or by the shunt

release

ptions

O

•

Motor operating mechanism

for switch-disconnector

•

Rotary operating mechanism

•

Locking devices

•

Auxiliary contacts for three

position switch-disconnector

and make-proof earthing

switch

•

Shunt release for transformer

feeders

•

Closing lock-out for ringmain feeders

•

De-earthing lock-out for

transformer feeders

•

Different operating levers1)for

the operating mechanisms of

the switch-disconnector and of

the make-proof earthing switch

1) According to VDN */VDEW**

recommendation

* AssociationofGermanNetwork

Operators VDN e.V. at the VDEW in

Germany (as of 2003)

** Association of German

Power Stations – VDEW e.V.

Three-position switch-disconnector

s

p

e

2

0

1

5

4

A

H

R

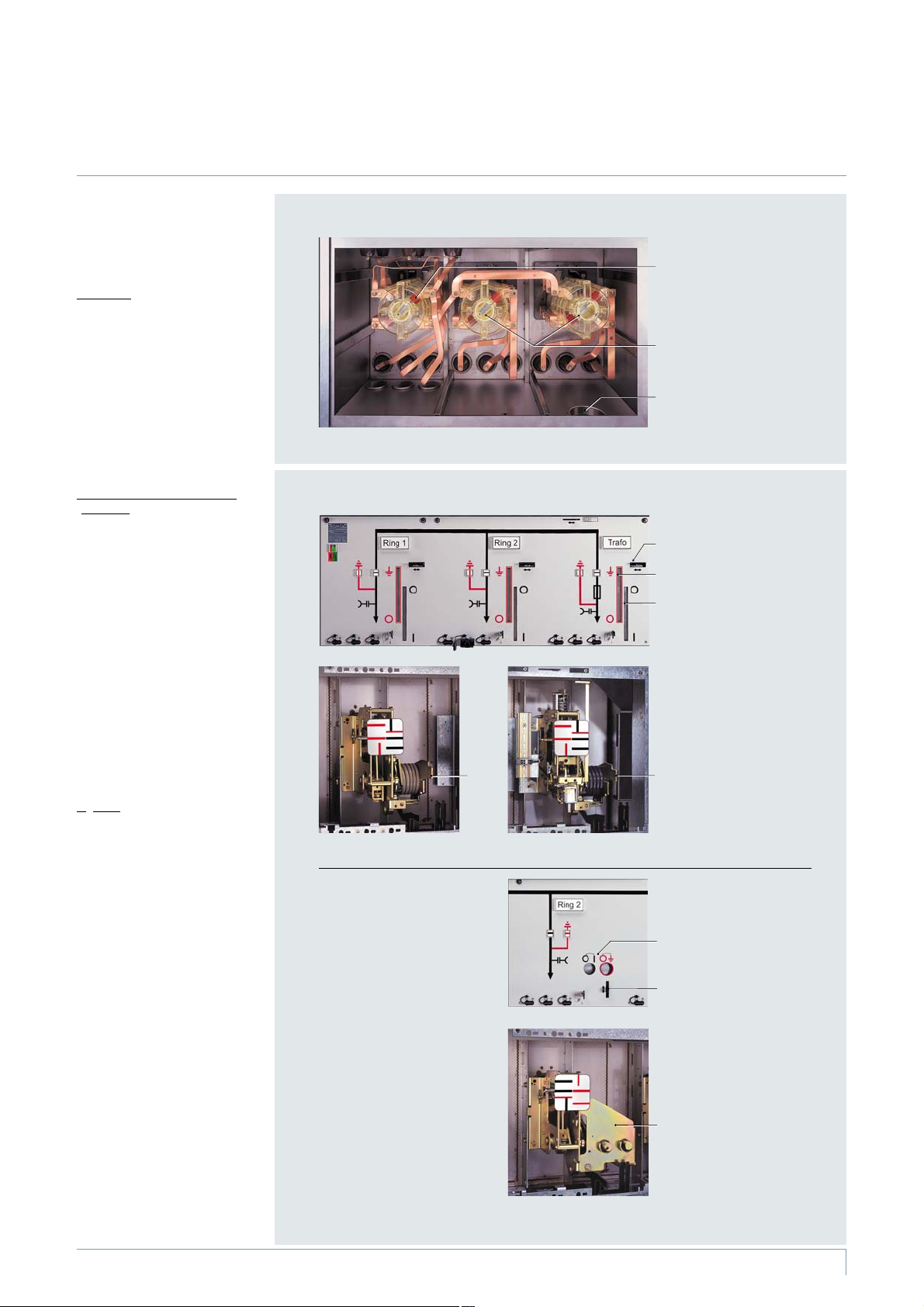

Switchgear vessel of a

ring-main/transformer

block, scheme 10

1

(rear view)

1 Three-position switch-

disconnector in the

transformer feeder

2 Three-position switch-

2

disconnector in the

ring-main feeders

3 Pressure relief device

3

Operating mechanisms

s

p

e

a

3

0

1

5

4

A

H

R

s

p

e

4

0

1

5

4

A

H

R

s

p

e

5

0

1

5

4

A

H

R

7

s

p

e

a

6

0

1

-

5

4

A

H

R

s

p

e

7

0

1

5

4

A

H

R

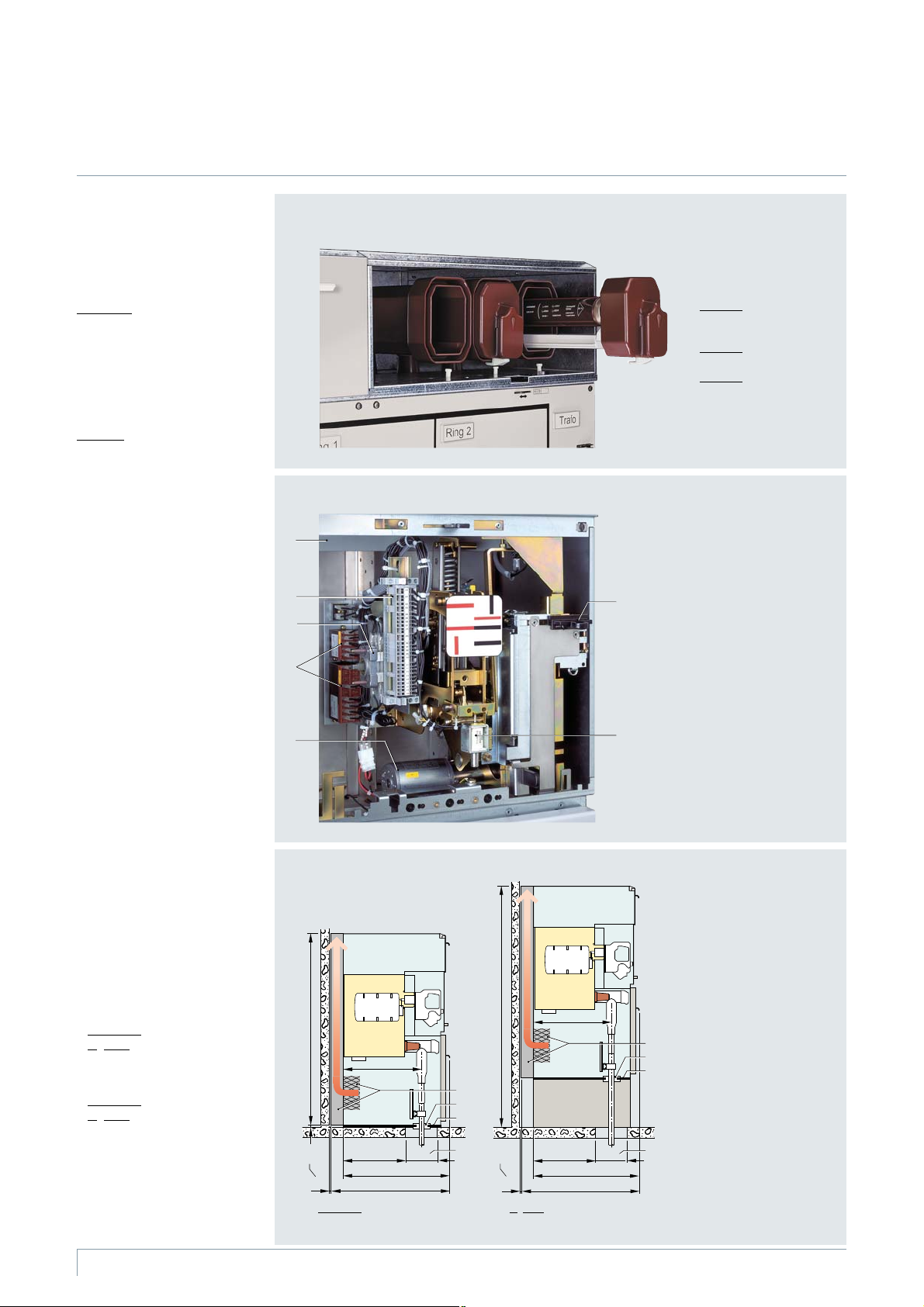

Control board for detachable lever mechanisms

(standard)

4

Example:

Ring-main/transformer block,

5

scheme 10

4 Locking device (option)

6

for the detachable lever

mechanism

5 Detachable lever

operation for the

earthing function

6 Detachable lever

operation for the

load-break function

7 Detachable lever

mechanism for the

ring-main feeder

8 Detachable lever

8

mechanism for the

transformer feeder

Control board for rotary

operating mechanisms

(option)

Example: Ring-main feeder

9

9 Symbols for the actuating

direction of the rotary

operating mechanism

10 Locking device for the ro-

10

tary operating mechanism

11 Rotary operating

mechanism (option)

11

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

7

Page 8

HA45-2364 eps

1400

~2

880

³

15

775

240

435

~560

2

3

5

1

4

HA45-2363 eps

~1762

880

³

15

775

240

435

~560

5

1

2

3

4

Components

HV HRC fuse assembly, secondary equipment, pressure absorber system

HV HRC fuse assembly

The HV HRC fuse boxes are

single-phase insulated and located above the transformer

feeder outside the switchgear

vessel.

Standards

(see page 21)

HV HRC fuse links with striker in

“medium” version according to

IEC 60 282-1

•

VDE 0670 Parts 4 and 402

•

DIN 43 625 main dimensions

•

Features

Requirements fulfilled as HV

•

alternating current switchfuse combination

Selection of HV HRC fuses for

•

transformers

For further features

•

see Catalog HA 40.1

Secondary equipment (option)

Auxiliary switches, motor

•

operating mechanisms or

shunt releases wired to a

terminal strip

•

Location of the terminal strip

next to the operating mechanism module of the feeder

concerned

•

Customer-side cable routing

to the terminal strip from the

side or rear

Pressure absorber system

(option)

•

Maintenance-free

•

For all schemes (except radial

transformer panel, scheme 01)

•

For rated short-time with

stand current I

with IAC (internal arc

w 16 kA,

k

-

classification, see page 22)

•

With 105 mm deep pressure

relief duct for pressure relief

upwards

•

For overall height of switch-

gear:

–Standard:

–O

•

For wall-standing arrangement

•

Transformer cable routing:

–Standard:

–O

schemes 10, 71 and 72

•

Weight approx. 110 kg

1400 mm

ption: 1760 mm

Downwards

ption: To th e r ear for

HV HRC fuse compartment

s

p

e

8

0

1

5

4

A

H

R

Secondary equipment (option)

1

2

3

4

5

s

p

e

3

3

1

5

4

A

H

R

Pressure absorber system

(option)

Standard: Overall height 1400 mm

6

7

O

ption: Overall height 1760 mm

HV HRC fuse compartment

with cable compartment

cover removed

Phase L1:

HV HRC fuse box with

HV HRC fuse slide removed

Phase L2:

HV HRC fuse box closed

Phase L3:

Replacement of HV HRC fuses

Auxiliary switch, motor

operating mechanism and

shunt release

Example: Transformer feeder

1 Wiring duct

2 Te rm ina l str ip

3 Auxiliary switch at spring-

operated mechanism of a

ring-main feeder

4 Auxiliary contactors

(standard for motor

operating mechanism)

5 Motor operating mechanism

at spring-operated/

stored-energy mechanism

6 Locking device

(standard for motor

operating mechanism)

7 Shunt release at spring-

operated/stored-energy

mechanism

Sectional views of the

pressure absorber system

1 Wall distance

2 Pressure absorber system

with rear pressure relief

duct directed upwards

3 Cable bushing

4 Divided floor plate for

cable entry for on-site

installation

5 Floor opening for the

cable feeder

8

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

Page 9

Bushings according to

•

EN 50 181/DIN EN 50 181

with outside cone

Cable connection at one level

•

Access to the cable compart

•

ment only if the feeder has

been isolated and earthed

Ring-main cable connection

With bolted contact (M16) as

•

interface type ”C” according

to EN 50 181/DIN EN 50 181

For thermoplastic-insulated

•

cables

For paper-insulated mass-

•

impregnated cables with

adapter systems

For conventional cable sealing

•

ends via elbow adapters

AKE 20/630 (make Siemens)

ForcableT-plugsorcable

•

elbow plugs with bolted

contact (M16)

For connection cross-sections

•

up to 300 mm

Cable routing downwards,

•

2

(standard)

cable connection at front

•

For rated normal currents of

400/630 A

O

ptions

•

Suitable for the connection of

surge arresters

•

Short-circuit/earth-fault

indicator

•

Mounted cable clamps

•

Double cable connection with

corresponding cable plugs

Components

Cable connection

1)

-

Cable connection (examples)

L1

1

s

p

e

1

1

1

5

4

A

H

R

Cable compartment,

as delivered

L1

5

s

p

e

3

1

1

5

4

A

H

R

Cable compartment,

as delivered

L3

L2

L3

L2

L1

2

3

4

s

p

e

8

2

1

0

4

A

H

R

Cable plugs with

bolted contact (M16)

L1

6

7

8

s

p

e

4

1

1

5

4

A

H

R

Cable elbow plugs with

plug-in contact

L3

L2

Cable connections

in ring-main feeder

1 Prepared for cable plugswith

bolted contact (M16)

2 Phase L1:

Make: Euromold

type K400 LB

as cable elbow plug

3 Phase L2:

Make: Euromold

type K400 TB

as cable T-plug

4 Phase L3:

Make: Euromold

type AGT 20/630

as cable T-plug

ption:

O

Mounted cable clamps

L3

L2

Cable connections

in transformer feeder

5 Prepared for cable elbowplugs

with plug-in contact

6 Phase L1:

Make: Euromold

type K158 LR

7 Phase L2:

Make: nkt cables

type EASW 20/250

8 Phase L3:

Make: Cooper

type DE 250-R-C

ption:

O

Mounted cable clamps

Transformer cable connection

•

With plug-in contact as inter-

face type “A” according to

EN 50 181/DIN EN 50 181

•

For cable elbow plugs

(standard) or straight cable

plugs with plug-in contact

•

For thermoplastic-insulated

cables

•

For connection cross-sections

up to 120 mm

•

For rated normal currents

2

of 200 A

O

ptions

•

With bolted contact (M16) as

interface type “C” according

to EN 50 181/DIN EN 50 181

•

Mounted cable clamps

•

Cableroutingtotherear

(for cable elbow plugs)

Transformer cable connection for cable plugs

Standard:

ption: With bolted contact (M16) as interface type “C”

O

Arrangement of

connections

For all schemes (except scheme 01)

At the front

(standard)

At the bottom

(option)

Only for scheme 01 (radial transformer panel 1T)

At the bottom

(standard)

1) Standard EN 50 181/DIN EN 50 181:

“Plug-in bushings above 1 kV up to

36 kV and from 250 A to 1.25 kA for

equipment other than liquid-filled

transformers.”

With plug-in contact as interface type “A”

Cable routing Cable plug

Downwards Cable elbow plug with plug-in contact

To the rear

Downwards Straight cable plug with plug-in contact

To the rear

Downwards (option) Straight cable plug with plug-in contact

2)

2)

(standard) Cable elbow plug with plug-in contact

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

version

ption: Cable plug with bolted contact (M16)

O

Cable elbow plug with plug-in contact

ption: Straight cable plug with bolted contact (M16)

O

ption: Straight cable plug with bolted contact (M16)

O

2) For cable routing of the transformer feeder to the rear:

Cable fixing by customer

Cable plugs, cable

sealing ends and cable

clamps are not included

in the scope of supply.

9

Page 10

220/420

**

***

M12

~520*, ~560

*

750

775

367

515

375/ 575

**

a

1

2

HA45-2312h eps

A

A

710

K (E)

T

350 350

B

B

1200/1400

375/ 575

**

~560

750

775

553

a

1760

935

935

780

1200/ 1400

T

B

B

HA45-2345e eps

510

4

1760

500

220/ 420

**

***

M12

~520*, ~560

*

750

775

375/ 575

**

a

1

2

515

935

780

***

M12

~520*, ~560

*

750

775

375/ 575

**

240

a

515

1

3

935

Dimensions

Switchgear (for floor openings and fixing points refer to page 14)

Radial transformer panels · optionally in 3 overall heights

Section B-B Section B-B

Tra nsf orm er

feeder T

Cable routing

of feeder

to the rear

with cable

elbow plugs

(on request)

Scheme 01

(with radial cable

connection as infeed)

1 Bushing at the front for cable routing downwards (infeed)

Standard:

O

2 Bushing at the bottom as interface type “A” with plug-in contact

for cable routing to the rear (feeder T)

3 Bushing at the bottom as interface type “A” with plug-in contact

for cable routing downwards (feeder T)

4 Bolted joint of cable compartment cover (only for scheme 01)

For cable elbow plugs with plug-in contact

ption: For cable T-plugs with bolted contact(M16)

* Dimension depending on the bushing size and make/type of cableplug

** Dimensions depending on the overall heights of switchgear 1200 and 1400 mm

*** For cable routing to the rear, the depth dimensions are 10 mmdeeper

BB Dimension for bushing as interface type “A” with plug-in contact

Tra nsf orm er

feeder T

Cable routing

of feeder

downwards

with straight

cable plugs

Dimension a

–40mmfor

overall height 1400 mm

– 130 mm for

overall height 1200 mm

Section B-BSection A-A

Radial cable

connection K(E)

with make-proof

earthing switch

Scheme 21

1 Bushing at the front (standard) for cable routingdownwards

2 Bushing at the bottom (option) for cable routing to the rear or

downwards

** Dimensions depending on the overall heights ofswitchgear 1200 and 1400 mm

*** For cable routing to the rear, the depth dimensions are 10 mm deeper

B Dimension for bushing as interface type “C” with bolted contact (M16)

BB Dimension for bushing as interface type “A” with plug-in contact

* Dimension depending on the bushing size and make/type of cable plug

Tra nsf orm er

feeder T

Dimension a

–40mmfor

overall height 1400 mm

– 130 mm for

overall height 1200 mm

10

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

Page 11

A

A

710

RK

350

RK

350

A

A

1060

RK

350

RK RK

350 350

A

A

1410

1200/ 1400

RK

350

RK RK RK

350 350 350

1760

A

A

710

RK

350 350

HA45-2315f eps

4

375/ 575

**

~560

750

775

553

a

935

HA45-2319f eps

A

A

1760

1200/ 1400

RK

350

RK RK RK RK

350 350 350 350

1760

Switchgear (for floor openings and fixing points refer to page 14)

Block versions, consisting of ring-main feeders · optionally in 3 overall heights

Section A-A

Scheme 84

Dimensions

Ring-main

feeder RK

Dimension a

–40mmfor

overall height 1400 mm

– 130 mm for

overall height 1200 mm

** Dimensions depending on the overall heights ofswitchgear 1200 and 1400 mm

B Dimension for bushing as interface type “C” with bolted contact (M16)

Further scheme types (sideviews,sectionA-A,seescheme84)

Scheme 02 (1RK with

radial cable connection)

4 Bolted joint of cable compartment cover

Scheme 11 Scheme 32 Scheme 70

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

11

Page 12

HA45-2321e eps

A

710

RK

T

B

A

350 350

B

A

1060

RK RK

T

B

A

350 350 350

B

A

1410

1200/ 1400

RK RK RK

T

B

A

350 350 350 350

B

1760

375/ 575

**

~560

750

775

553

a

935

HA45-2324f eps

A

A

1760

1200/ 1400

RK

350

RK RK RK

T

350 350 350 350

B

B

1760

220/ 420

**

***

M12

~520*, ~560

*

750

775

367

515

375/ 575

**

a

1

2

935

780

Dimensions

Switchgear (for floor openings and fixing points refer to page 15)

Block versions, consisting of ring-main feeders and 1 transformer feeder · optionally in 3 overall heights

Scheme 72

1 Bushing at the front (standard) for cable routingdownwards

2 Bushing at the bottom (option) for cable routing to the rear or

downwards

Dimension a

– 40 mm for overall height 1400 mm

– 130 mm for overall height 1200 mm

Section A-A

Ring-main

feeder RK

Section B-B

Tra nsformer

feeder

T

* Dimension depending on the bushing size and make/type of cable plug

** Dimensions depending on the overall heights of switchgear 1200 and 1400 mm

*** For cable routing to the rear, the depth dimensions are 10 mm deeper

B Dimension for bushing as interface type “C” with bolted contact (M16)

BB Dimension for bushing as interface type “A” with plug-in contact

Further scheme types (for side views, sections A-A and B-B, see scheme 72)

Scheme 20

Scheme 10 Scheme 71

12

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

Page 13

HA45-2325e eps

A

A

1410

1200/ 1400

T

350

RK RK T

350 350 350

B

B

1760

HA45-2326f eps

A

1760

1200/ 1400

T RK RK RK T

B

1760

A

350 350 350 350 350

B

375/ 575

**

~560

750

775

553

a

935

220/ 420

**

***

M12

~520*, ~560

*

750

775

367

515

375/ 575

**

a

1

2

935

780

Dimensions

Switchgear (for floor openings and fixing points refer to page 15)

Block versions, consisting of ring-main feeders and 2 transformer feeders · optionally in 3 overall heights

Scheme 82

1 Bushing at the front (standard) for cable routingdownwards

2 Bushing at the bottom (option) for cable routing to the rear or

downwards

Dimension a

– 40 mm for overall height 1400 mm

– 130 mm for overall height 1200 mm

Section A-A

Ring-main

feeder RK

Section B-B

Tra nsformer

feeder

T

* Dimension depending on the bushing size and make/type of cable plug

** Dimensions depending on the overall heights ofswitchgear 1200 and 1400 mm

*** For cable routing to the rear, the depth dimensions are 10 mm deeper

B Dimension for bushing as interface type “C” with bolted contact (M16)

BB Dimension for bushing as interface type “A” with plug-in contact

Further scheme type (for side views, sections A-A and B-B, see scheme 82)

Scheme 81

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

13

Page 14

125106

19

150

500

623

713

55

35

³

15

44

233197

47

250

31147

40

610

63

420

125

HA45-2365 eps

150

14 x 28

28 x 14

2

3

9

10

2

1

4

100

HA45-2367a eps

100

106

19

1750

623

713

55

35

³

15

44

233197

47

175

31147

40

610

63

1670

350

350

28 x 14

2

5

9

10

1

110110110110

350

14 x 28

65

350 350 350

110110

350

110110

350

110110

350

15

1720

437

125

11

11

350 350 350 312350

19

HA45-2366a eps

100

106

19

700

623

713

55

35

³

15

44

233197

47

175

31147

40

610

63

620

350

350

28 x 14

110110110110

350

14 x 28

65

15

670

125 227

125

85

2

7

8

11

12

10

9

1

6

11

312350

19

700

HA45-2368a eps

15

670

40

620

713

1050

HA45-2369a eps

15

1020

40

970

713

713

1400

HA45-2370a eps

15

1370

40

1320

700

HA45-2371b eps

³

15

1

40

620

435

713

105

240

13

700

³

15

1

13

40

970, 1320, 1670

435

713

105

240

HA45-2372b eps

Dimensions

Floor openings (dimensions1)in red) and fixing points

For transformer panels For block versions, consisting of ring-main feeders

Scheme 01

Scheme 84

Scheme 02 * and 11 *

Scheme 32 *

Scheme 21

1 Wall distance

2 Fixing points

3 Position of the incoming cables for the incoming feeder

4 Position of the incoming cables for the outgoing feeder

5 Position of the incoming cables in the ring-main feeder

6 Position of the incoming cables in the cable feeder

7 Position of the incoming cables in the transformer feeder

8 Position of the incoming cables in the transformer feeder (option)

9 Floor opening for HV cables (and, if applicable, controlcables)

Scheme 70 *

10 Fixing frame (base) of the switchgear

nd

11 Cutouts for an overall height of switchgear of1200 mm

12 Cutouts for an overall height of switchgear of1200 mm only when

connecting the transformer cables to the bushing via straightcable

plugs

1) Depending on additional options (e.g. surge arrester, 2

current transformer) thecorresponding floor openingshave to beprovided as

standard (see also page 16)

* Complete dimensions see top figure on the right

cable, cable-type

Position of the floor openings for switchgear with pressure absorber system (for overall heights 1400 and 1760 mm)

1 Wall distance

13 Pressure relief duct

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

14

:

Further

connection

combinations

Pressure absorber

system for

schemes

02, 11, 20 and 21

•

For double cable connection

on request

Pressure absorber

system for

all other

schemes

•

For surge arrester – Standard

possible for the following –25 mm deeper

cable compartment covers: – 150 mm deeper

Page 15

HA45-2373a eps

623

713

55

40

610

63

1670

350

28 x 14

14 x 28

350 350 350

³

15

44

233197

47

31147

1

1750

175

350

11011011011065 110110 110110 110110

100

106

19

35

350 350 350 350

15

1720

125 227

125

85

5

11

2

7

8

11

12

10

9

350350350 350 312

19

HA45-2377a eps

1750

623

713

³

15

44

233197

47

175

31147

610

63

1670

350

350

28 x 14

1

350 350 350

55

19

35

40

65

100

106

14 x 28

110110110110

350

110110

350

110110

350

110110

350

125 227

125

85

15

1720

7

11

2

5

8

11

12

10

9

12

350 350 350 312350

19

700

15

670

HA45-2374a eps

40

620

713

1400

HA45-2378a eps

713

15

1370

40

1320

1050

700

HA45-2379c eps

40

620

713

³

15

44

233197

31147

65

350

132150

~245

**

1013

RKRK T

610

63

(900

***

/ 715

****

)

662

19

1400

713

15

1370

HA45-2376a eps

40

1320

1050

15

1020

HA45-2375a eps

40

970

713

Dimensions

Floor openings (dimensions1)in red) and fixing points

For block versions, consisting of ring-main feeders

and 1 transformer feeder

Scheme 72

For block versions, consisting of ring-main feeders

and 2 transformer feeders

Scheme 82

Scheme 20 *

Scheme 71 *

1) Depending on additional options (e.g. surge arrester,

nd

cable, cable-type current transformer) other floor

2

openings have to be provided as standard accordingly

(see also page 16)

Position of the floor openings and fixing points for double cable connection in ring-main feeders

Scheme 10 *

Scheme 10 *

(example)

Scheme 81 *

1 Wall distance

2 Fixing points

5 Position of the incoming cables in the ring-main feeder

7 Position of the incoming cables in the transformer feeder

8 Position of the incoming cables in the transformer feeder (option)

9 Floor opening for HV cables (and, if applicable, controlcables)

10 Fixing frame (base) of the switchgear

11 Cutouts for an overall height of switchgear of1200 mm

12 Cutouts for an overall height of switchgear of1200 mm only when

connecting the transformer cables to the bushing via straightcable

plugs

Complete dimensions see top figures on the right and left

*

Note:

Double cable connection in ring-main feeders

only possible for switchgear with an overall

height of 1400 mm

Abbreviations

RK = Ring-main feeder

T = Transformer feeder

* Complete dimensions see top figure on the left

** Depending on the cable plug used (see also page 16)

*** 300 mm deeper cable compartment coverversion

**** 105 mm deeper cable compartment cover version

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

15

Page 16

HA45-2342e eps

553

575

~560

750

775

635**

63

101

290,5*

3

715**

~560

852

880

575

~190

4

HA45-2340f eps

553

575

~560

750

775

610**

63

8

7

HA45-2328h eps

9

553

575

~560

772

800

610**

63

10

HA45-2329f eps

553

575

~560

897

925

610

**

63

11

12

HA45-2341e eps

553

~560

750

775

610**

63

2

575

750

775

610**

~560

1

575

HA45-2327h eps

553

575

~560

750

775

a

**

63

5

6

Dimensions

Examples *** for cable connection in ring-main feeders

Cable connection (examples for overall height 1400 mm)

1 Elbow adapter,make Siemens,

type AKE 20/630 with conventional

cable sealing end, make

Lovink Enertech, type IAE 20

2 Cable T-plug, make Euromold,

type (K)400 TB/G

Standard cable compartment cover

Cable compartment cover for doublecable connection

Cable connection with surge arresters (examples for overall height 1400 mm)

Combination on request

Overall hei

5 Cable plug,

6 Surge arrester,

Overall hei

Numbers 5 and 6not possible

ght of switchgear: 1400 mm

make Tyco Electronics,

type RICS 5139

make Tyco Electronics,

up to type RDA21 and

type RDA24

Dimension a

– 610 mm up to type RDA21

– 635 mm for type RDA24

ght of switchgear: 1200 mm

3 Cable T-plug, make nkt cables,

type CB 24-630 and

CC 24-630

4 Cable T-plug, make Südkabel,

type SET (12/24) and SET (12/24)

with coupling insert KU 23.2

7 Elbow adapter,

make Siemens,

type AKE 20/630

with conventional cable

sealing end,

make Lovink Enertech,

type IAE 20

On request:

8 Surge arrester,

make Siemens

Standard

cable compartment cover

9 Cable plug,

make Südkabel,

type SET (12/24)

10 Surge arrester,

make Südkabel,

type MUT (13/23)

B Dimension for bushing with bolted contact (M16)

25 mm deeper cable

compartment cover

* Max. mounting space for cable and/or surge arrester

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

16

Standard

cable compartment cover

11 Cable plug,

make Südkabel,

type SEHDT (13/23)

12 Surge arrester,

make Südkabel,

type MUW (12/22)

or

11 Cable plug,

make Euromold,

type (K)400 TB/G

12 Surge arrester,

e.g. make Euromold,

type 400 Pb

or similar types of

construction

150 mm deeper cable

compartment cover

** Depth of floor opening

*** Non-binding examples; further examples see Catalog HA 40.1

Page 17

Shipping

Types of transport

8DJ20 switchgear is

delivered as complete

transport unit.

The following must be

noted:

Transport facilities on

•

site

Transport dimensions

•

and weights

Size of door open-

•

ings in building

Switchgear with LV

•

compartment:

Please take other

transport dimensions

and weights into

account

Packing

Place of destination in

side Germanyorother

European countries

Means of transport:

•

Rail and truck

Type of packing:

•

–Panelsonopen

pallets

– Covered with PE

protective foil

Place of destination

overseas

•

Means of transport:

Ship

•

Type of packing:

–Panelsonopen

pallets

– In closed crates with

sealed PE protective

foil

– With desiccant bags

– With sealed wooden

base

– Max. storage time:

6months

-

Sche-

Version

me

(abbre-

no.

viations)

Transport in Europe by rail, truck, container

Packing with PE protective foil and wooden base

01 1T 1200 1.10 1.4 1.10 1.69 170

02 1RK 1200 1.10 1.4 1.10 1.69 210

10 2RK+1T 1200 1.45 1.4 1.10 2.23 370

11 2RK 1200 1.10 1.4 1.10 1.69 210

20 1RK+1T 1200 1.10 1.4 1.10 1.69 260

21 1K(E)+1T 1200 1.10 1.4 1.10 1.69 260

32 3RK 1200 1.45 1.4 1.10 2.23 300

70 4RK 1200 1.80 1.4 1.10 2.77 380

71 3RK+1T 1200 1.80 1.4 1.10 2.77 440

72 4RK+1T 1200 2.05 1.4 1.10 3.16 510

81 2RK+2T 1200 1.80 1.4 1.10 2.77 500

82 3RK+2T 1200 2.05 1.4 1.10 3.16 570

84 5RK 1200 2.05 1.4 1.10 3.16 450

Transport

Switchgear

dimensions

height

(with-

Width Height Depth

1)

out

LV

compartment)

mm

mmm

1400 1.10 1.6 1.10 1.94 180

1760 1.10 1.96 1.10 2.37 210

1400 1.10 1.6 1.10 1.94 230

1760 1.10 1.96 1.10 2.37 260

1400 1.45 1.6 1.10 2.55 400

1760 1.45 1.96 1.10 3.13 440

1400 1.10 1.6 1.10 1.94 230

1760 1.45 1.96 1.10 3.13 260

1400 1.10 1.6 1.10 1.94 280

1760 1.10 1.96 1.10 2.37 310

1400 1.10 1.6 1.10 1.94 280

1760 1.10 1.96 1.10 2.37 310

1400 1.45 1.6 1.10 2.55 330

1760 1.45 1.96 1.10 3.13 370

1400 1.80 1.6 1.10 3.17 420

1760 1.80 1.96 1.10 3.88 470

1400 1.80 1.6 1.10 3.17 480

1760 1.80 1.96 1.10 3.88 530

1400 2.05 1.6 1.10 3.61 560

1760 2.05 1.96 1.10 4.42 620

1400 1.80 1.6 1.10 3.17 540

1760 1.80 1.96 1.10 3.88 590

1400 2.05 1.6 1.10 3.61 620

1760 2.05 1.96 1.10 4.42 680

1400 2.05 1.6 1.10 3.61 500

1760 2.05 1.96 1.10 4.42 560

1)

Volume

m

3

Gross

weight

approx.

kg

Transport data

2)

Sche-

Version

Switchme

no.

Transport overseas by seafreight

Packing with PE protective foil and seaworthy crate

01 1T 1200 1.10 2.0 1.15 2.53 230

02 1RK 1200 1.10 2.0 1.15 2.53 270

10 2RK+1T 1200 1.45 2.0 1.15 3.34 450

11 2RK 1200 1.10 2.0 1.15 2.53 280

20 1RK+1T 1200 1.10 2.0 1.15 2.53 320

21 1K(E)+1T 1200 1.10 2.0 1.15 2.53 310

32 3RK 1200 1.45 2.0 1.15 3.34 380

70 4RK 1200 1.80 2.0 1.15 4.14 470

71 3RK+1T 1200 1.80 2.0 1.15 4.14 530

72 4RK+1T 1200 2.05 2.0 1.15 4.72 640

81 2RK+2T 1200 1.80 2.0 1.15 4.14 590

82 3RK+2T 1200 2.05 2.0 1.15 4.72 700

84 5RK 1200 2.05 2.0 1.15 4.72 580

gear

(abbre-

height

viations)

(with-

out

compart-

ment)

mm

1400 1.10 2.0 1.15 2.53 250

1760 1.10 2.0 1.15 2.53 270

1400 1.10 2.0 1.15 2.53 290

1760 1.10 2.0 1.15 2.53 320

1400 1.45 2.0 1.15 3.34 470

1760 1.45 2.0 1.15 3.34 510

1400 1.10 2.0 1.15 2.53 290

1760 1.10 2.0 1.15 2.53 320

1400 1.10 2.0 1.15 2.53 340

1760 1.10 2.0 1.15 2.53 370

1400 1.10 2.0 1.15 2.53 340

1760 1.10 2.0 1.15 2.53 370

1400 1.45 2.0 1.15 3.34 400

1760 1.45 2.0 1.15 3.34 440

1400 1.80 2.0 1.15 4.14 500

1760 1.80 2.0 1.15 4.14 550

1400 1.80 2.0 1.15 4.14 560

1760 1.80 2.0 1.15 4.14 610

1400 2.05 2.0 1.15 4.72 670

1760 2.05 2.0 1.15 4.72 730

1400 1.80 2.0 1.15 4.14 620

1760 1.80 2.0 1.15 4.14 670

1400 2.05 2.0 1.15 4.72 730

1760 2.05 2.0 1.15 4.72 790

1400 2.05 2.0 1.15 4.72 610

1760 2.05 2.0 1.15 4.72 670

Transport

dimensions

Width Height Depth

1)

LV

mmm

1)

Volume

m

3

Gross

weight

approx.

kg

2)

1) With LV compartment:

Other transport

dimensions and

weights

2) Depending on

the relevant

equipment, e.g.

motor operating

mechanism

Abbreviations:

RK = Ring-main feeder

T = Transformer feeder

K(E) = Cable feeder for radial cable connection

with make-proof earthing switch

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

17

Page 18

RK

LST

1600

1200

1800

2100

HA45-2422 eps

RK

LST

1800

1400

2000

2300

HA45-2423 eps

RK

LST

2160

1760

HA45-2424 eps

700

700

HA45-2384c eps

1

2

3

4

5

5

7

HA45-2432a eps

700 ´ 700

3

1

4

5

6

5

7

8

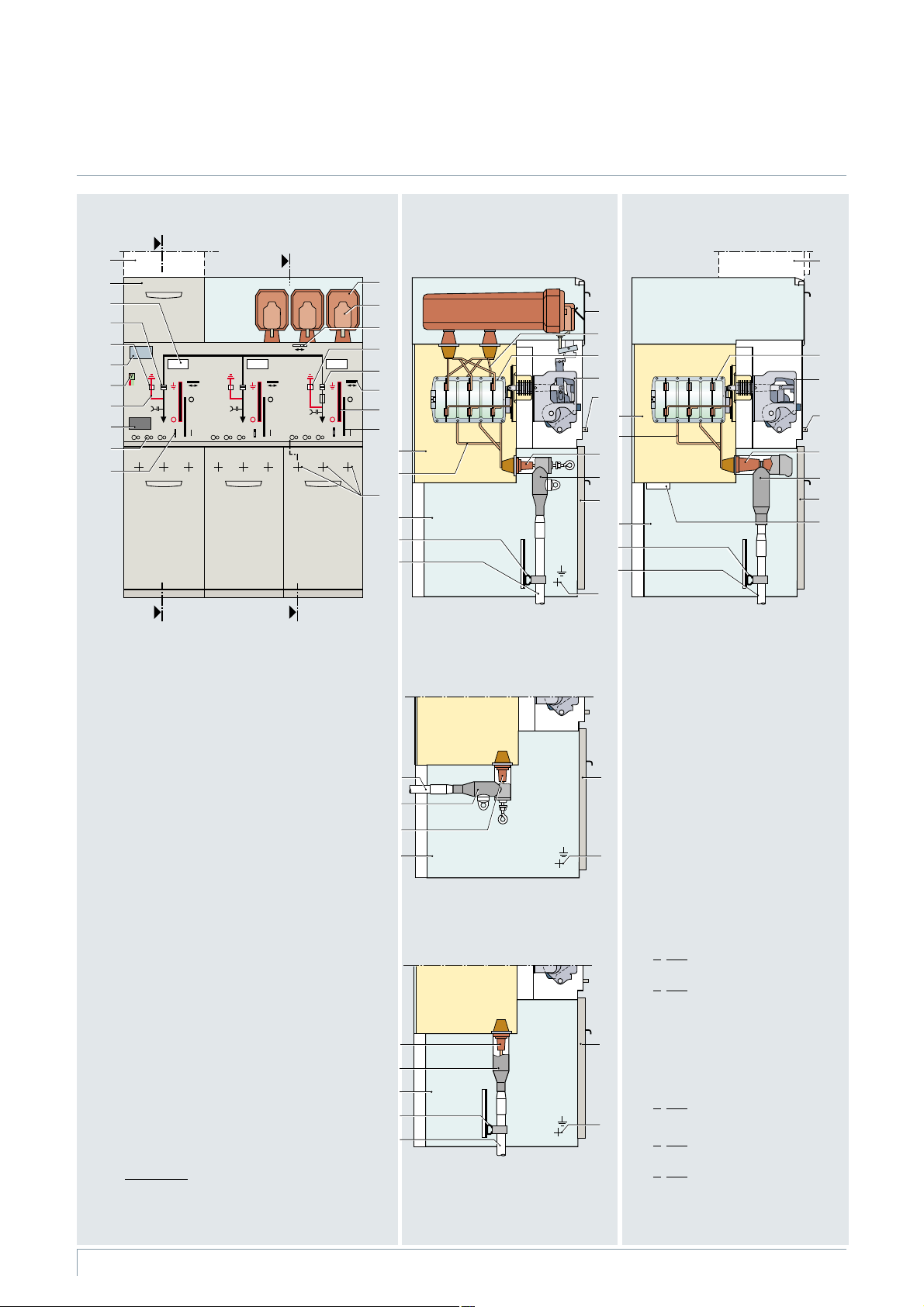

Designs

Switchgear with low-voltage compartment, switchgear installation

Option low-voltage

compartment

Overall height

•

– Standard: 400 mm

ption: 600 or 900 mm

–O

ption: Cover

–O

Installation on the switchgear

•

– Possible per feeder

– Customer-specific

configuration

– Separate cable duct on the

switchgear next to the

low-voltage compartment

Shipping and transport data

If the switchgear is delivered

with low-voltage compartment,

other transport dimensions and

weights have to be taken into

account.

Switchgear height

1200 mm 1400 mm 1760 mm

gear installation

Switch

Wall-standing arrangement

Direction of

pressure relief

Overall height 1200 mm

Downwards

Overall height 1400 mm

Downwards

Option: to the rear

Overall height 1760 mm

Downwards

Option: to the rear

Free-standing arrangement

(on request)

(Switchgear installation only for

pressure relief downwards)

Combinations with low-voltage compartment

Dimensions e.g. for scheme 20

Pressure relief downwards

(all overall heights)

Option: Pressure relief to

the rear, overall height of

switchgear 1400 or 1760 mm

(only for transformer cable

connection downwards)

1 Switchgear

2 Floor opening into cable duct

3 Expanded metal

(not included in the scope

of supply)

4 Direction of pressure relief

5 Cable

6 Partition (e.g. of sheet-

metal, not included in the

scope of supply)

7 Wall distance

8 Rear cutout in the

switchgear (size approx.

350 mm x 615 mm, not

for scheme 01/ = 1T)

18

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

Page 19

HA45-2296c eps

RK TRK

HA45-2300c eps

RK RKRK

HA45-2301c eps

RK RKRK RK

HA45-2302c eps

RK TRK RK

HA45-2304c eps

RK TRKT

Special Designs

Outdoor enclosures with 8DJ20 switchgear

Application

8DJ20 switchgear in outdoor

enclosures is used where the

network structure requires this,

but without transformers and

low-voltage distribution

boards.

Features

Two s iz es

•

– For switchgear with 3 feeders

– For switchgear with 4 feeders

Degree of protection IP 44

•

8DJ20 switchgear installed in

•

outdoor enclosure

Cable compartment parti-

•

tioned off adjacent feeders

With lockable door

•

Complete interlocking

•

functions

Cable connection

See pages 9 and 16.

Cable entry from below

•

Floor cover

•

– Divided and bolted

– Removable for inserting the

cables

•

Cable bracket movable

upwards or to the rear to suit

cable sealing ends

•

Cables fixed by cable clamps

(option) on C-rails of cable

bracket

•

Option:

Cable clamps

For 3-panel switchgear

s

p

e

c

5

1

1

5

4

A

H

R

Outdoor enclosure

with 2-wing door

Overall width 1150 mm

s

p

e

d

6

1

1

5

4

A

H

R

For 4-panel switchgear

s

p

e

c

7

1

1

5

4

A

H

R

Outdoor enclosure

with 2-wing door

Overall width 1500 mm

s

p

e

d

8

1

1

5

4

A

H

R

Schemes

•

For 3-panel outdoor

enclosure:

–Scheme10

–Scheme32

•

For 4-panel outdoor

enclosure:

–Scheme70

–Scheme71

–Scheme81

Option: Surge arrester

**

Only such surge arresters can

be used which are suitable for a

cable compartment cover flush

with the operating front,

e.g. make Tyco Electronics,

type RDA (see also Catalog HA 40.1

“Cable connections”).

As above,

however with

doors removed, some cable

compartment covers removed

As above,

however with doorsremoved

Scheme

**

10

Scheme

**

32

Scheme

**

70

Scheme

**

71

Scheme

**

81

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

19

Page 20

1160

HA45-2343e eps

1

890

150

*

~540

852

1140

2005

M12

200

150

*

³200

1110

*

1150

2

3

7

6

5

4

9

10

4 x Æ14

*

890

150

*

~580

852

1140

2005

200

150

*

1510

HA45-2344e eps

1

³200

1460

*

1500

4 x Æ14

*

8

6

5

4

9

10

2

Special Designs

Outdoor enclosures with 8DJ20 switchgear

Dimensions

Outdoor enclosure

with 2-wing door

for 3-panel switchgear

Outdoor enclosure

with 2-wing door

for 4-panel switchgear

Sectional view of transformer feeder

1 Door of outdoor enclosure

2 Floor fixing 4 x ;14 mm

3 HV HRC fuse assembly

4 Operating mechanism

5 Switchgear vessel

6 Bushing for cable connection

7 Cable elbow plug with plug-in contact

8 Cable T-plug with bolted contact (M16)

9 Pressure relief device

10 Wall distance W 200 mm

Floor fixing dimension

*

For position of incoming cables

see pages 14 and 15

For cable connections with

surge arresters see page 16

Sectional view of ring-main feeder

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

20

Page 21

Standards

Standards, specifications, guidelines

Overview of standards (March 2008)

IEC standard VDE standard EN standard

Switchgear 8DJ20 IEC 62 271-1 VDE 0671-1 EN 62 271-1

IEC 62 271-200 VDE 0671-200 EN 62 271-200

Switching devices Circuit-breaker IEC 62 271-100 VDE 0671-100 EN 62 271-100

Disconnector and

earthing switch

Switch-disconnector IEC 60 265-1 VDE 0670-301 EN 60 265-1

Switch-disconnector /

fuse combination

HV HRC fuses IEC 60 282-1 VDE 0670-4 EN 60 282

Voltage detecting systems IEC 61 243-5 VDE 0682-415 EN 61 243-5

Degree of protection – IEC 60 529 VDE 0470-1 EN 60 529

Insulation

Instrument transformers Current transformers IEC 60 044-1 VDE 0414-1 EN 60 044-1

Installation – IEC 61 936-1 VDE 0101 –

–

Voltage transformers IEC 60 044-2 VDE 0414-2 EN 60 044-2

Combined transformers

1) Only for switchgear type 8DH10

1)

IEC 62 271-102 VDE 0671-102 EN 62 271-102

IEC 62 271-105 VDE 0671-105 EN 62 271-105

IEC 60 071 VDE 0111 EN 60 071

IEC 60 044-3 VDE 0414-5 EN 60 044-3

Standards

The 8DJ20 switchgear

complies with the relevant

standards and specifications

applicable at the time of

type tests.

In accordance with the

harmonization agreement

reached by the countries of the

European Community, their

national specifications

conform to the IEC standard.

Dielectric strength

See also Catalog HA 40.1

“Standards”.

Ter ms

“Make-proof earthing switches”

are earthing switches with

short-circuit making capacity

according to IEC 62 271-102/

VDE 0671-102.

Type of service location

8DJ20 switchgear can be

used as indoor installations in

accordance with IEC 61 936

(Power installations exceeding

1 kV AC) and VDE 0101:

•

Outside lockable electrical

service locations at places

which are not accessible to

the public. Enclosures of

switchgear can only be

removed with tools.

•

Inside lockable electrical

service locations. A lockable

electrical service location is a

place outdoors or indoors that

is reserved exclusively for

housing electrical equipment

and which is kept under lock

and key. Access is restricted

to authorized personnel and

persons who have been prop

erly instructed in electrical

engineering. Untrained or

unskilled persons may only

enter under the supervision of

authorized personnel or prop

erly instructed persons.

Internal arc classification

(option)

The possibility of arc faults in

gas-insulated switchgear type

8DJ20 is improbable and a

mere fraction of that typical of

earlier switchgear types, due

to:

•

Use of gas-filled switchgear

compartments

•

Use of suitable switching

devicessuchasthreeposition switches with makeproof earthing switch

•

Logical mechanical interlocks

•

Use of ring-core current trans

formers (option)

Optionally, switchgear type

8DJ20 can be designed with

internal arc classification:

-

•

Internal arc classification IAC

•

Type of accessibility A

(for authorized personnel

only)

-

•

Accessible sides

–SideF (front)

–SideL (lateral)

–Onrequest:SideR (rear)

•

Arc test current

up to 21 kA /1 s

Climate and environmental

influences

8DJ20 switchgear is completely

enclosed and insensitive to

climatic influences.

Climatic tests fulfilled in

•

accordance with IEC 60 932

(report)

•

All medium-voltage devices

(except for HV HRC fuses)

are installed in a gas-tight,

welded stainless-steel

switchgear vessel which is

filled with SF

•

Live parts outside the switchgear vessel are provided with

single-pole enclosure

•

At no point can creepage

gas

6

currents flow from highvoltage potentials to earth

•

Operating mechanism parts

which are functionally impor

tant are made of corrosionproof materials

•

Bearings in operating mechanisms are designed as drytype bearings and do not

require lubrication

•

Suitable instrument trans

former designs

-

-

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

21

Page 22

Standards

Classification

Classification of 8DJ20 switchgear according to IEC 62 271-200

Design and construction

Partition class PM (metallic partition)

Loss of service continuity category

Switchgear

–WithHVHRCfuses

– Without HV HRC fuses (RK, T, LST)

Accessibility to compartments

(enclosure)

– Busbar compartment

– Switching-device compartment

– Low-voltage compartment (option)

– Cable compartment

– Switchgear with HV HRC fuses (T…)

– Switchgear without HV HRC fuses

–Switchgearscheme01(1T)

Internal arc classification (option)

Designation of

internal arc classification IAC

IAC for

– Wall-standing arrangement (standard)

Type of accessibility A

–F

–L

Arc test current

Test duration 1 s

2)

1)

LSC 2A

LSC 2B

Access option

– Non-accessible

– Non-accessible

– Tool-based

– Interlock-controlled

– Interlock-controlled

– Tool-based

Ratedvoltage7.2kVto24kV

IAC A FL 21kA, 1 s

Switchgear in closed electrical service location,

access “for authorized personnel only” (acc. to IEC 62 271-200)

Front

Lateral

Up to 21 kA

1) The loss of service continuity category

is always referred to the complete

switchgear,i.e. the panel withthe

lowest category defines the loss of

service continuity category of the

complete switchgear.

2) 8DJ20 switchgear with pressure

absorber:

Arc test current up to16 kA,

for overall height of switchgear

1400 and 1760 mm.

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

22

Page 23

If not stated otherwise on

the individual pages of this

catalog, we reserve the right

to include modifications, especially regarding the stated values, dimensions and weights.

Drawings are not binding.

All product designations used

are trademarks or product

names of Siemens AG or other

suppliers.

If not stated otherwise, all

dimensions in this catalog are

giveninmm.

Notes

Responsible for

Technical contents:

Christoph Maul

Siemens AG, Dept. PTD M 2 PPM

Erlangen

General editin

Gabriele Pollok

Siemens AG, Dept. PTD CC M

Erlangen

Switchgear Type 8DJ20 up to 24 kV, Gas-Insulated· Siemens HA 45.31 · 2008

g:

23

Page 24

Siemens AG

Energy Sector

Medium Voltage Division

Postfach 32 40

91050 Erlangen

Germany

For questions concerning

Power Transmission and Distribution:

You can contact our Customer Support

Center 24 hours a day, 365 days a year.

Tel.: +49 180/524 70 00

Fax: +49 180/524 24 71

Subject to change without notice

Order No.: E50001-K1445-A311-A7-7600

Printed in Germany

Dispo 31606

KG 04.08 6.0 24 En

103135 6101/6528

(Charges depending on provider)

www.siemens.com/

medium-voltage-switchgear

The information in this document contains general descriptions of the technical options available, which do not always have to be present in individual cases.

The required features should therefore be specified in each individual case at the time of closing the contract.

E-Mail: support.energy@siemens.com

www.siemens.com/energy-support

Loading...

Loading...