Page 1

Switchgear Type 8DH10

up to 24 kV, Gas-Insulated, Extendable

Medium-Voltage Switchgear

Catalog HA 41.11 · 2008

Answers for energy.

Page 2

Application, RequirementsContents

Features

Application, Requirements Page

Features, typical uses 2 and 3

Technical Data

Electrical data, filling pressure,

temperature 4 and 5

Switchgear installation, shipping data 6 and 7

Product Range

Product range overview 8 to 15

Design

Panel design 16 and 17

Components

3AH vacuum circuit-breaker 18 and 19

Three-position switch-disconnector 20

Busbars 21

Transformers 22 to 27

Cable connection 28

Low-voltage equipment 29

Dimensions

Individual panels, panel blocks 30 to 34

Metering panel combinations 33 and 35

Floor openings and fixing points 36 to 39

Cable connection examples 40

Standards, Transport, Notes

Standards, specifications, guidelines 41

Trans po rt data, classification 42

Notes 43

For further information, please refer to

•

Catalog HA 40.1: (Switchgear Type 8DJ and 8DH,

General Part)

•

Supplements to Catalogs HA 45.31/41.11

The products and systems described in this catalog are

manufactured and sold according to certified quality and

enviromental management system (acc. ISO 9001 and

ISO 14001).

(DQS Certificate Reg. No. DQS 003473 QM UM).

The certificate is accepted in all IQNet countries.

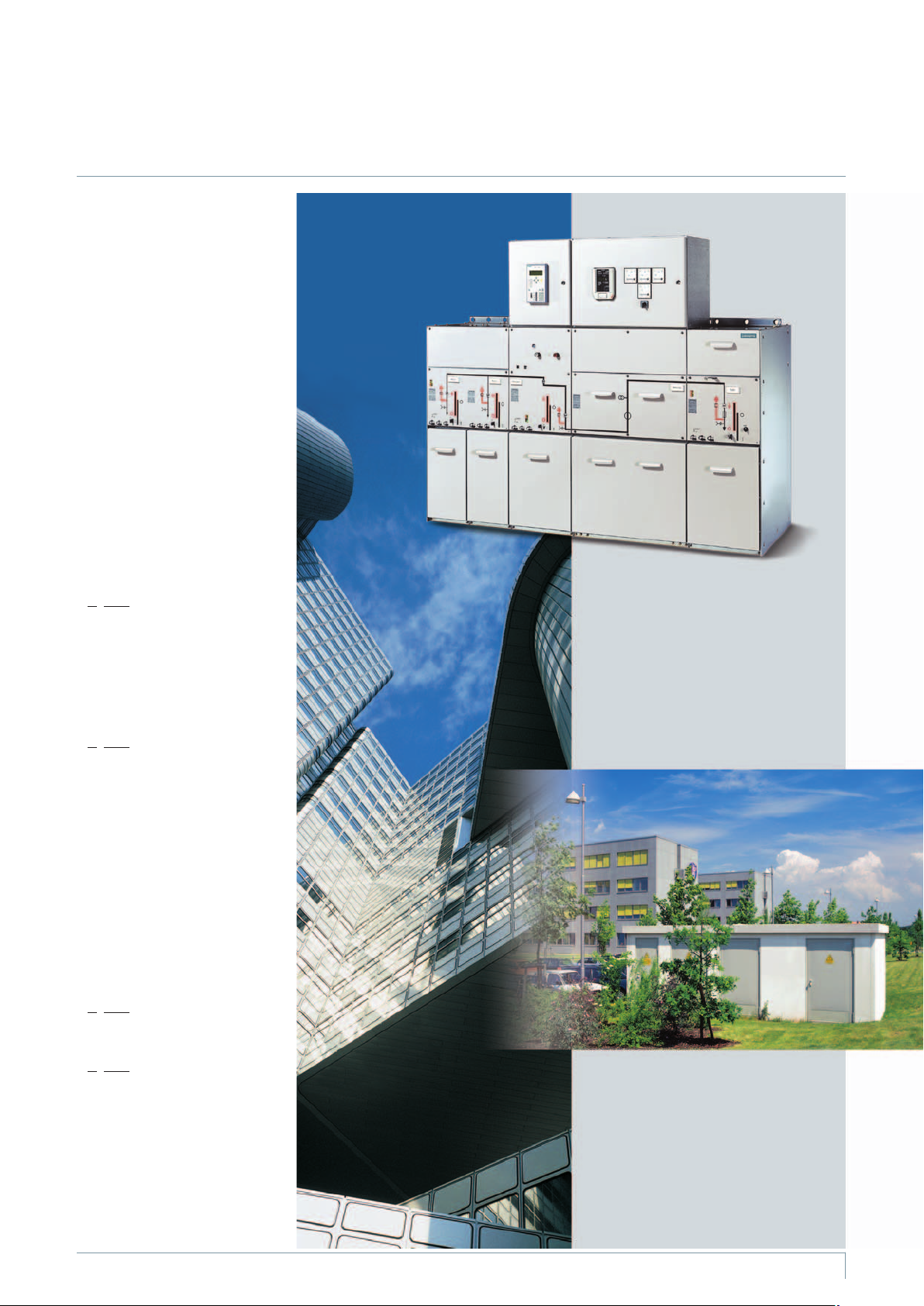

8DH10 switchgear is a factoryassembled, type-tested, three-pole,

metal-enclosed, metal-clad singlebusbar switchgear for in-door in

-

stallation:

Up to 24 kV

•

Feeder currents up to 630 A

•

Busbar currents up to 1250 A

•

Typ ical us es

8DH10 switchgear is used – even

under severe envir onmental conditions – for power distribution in

secondary distribution systems,

such as

Substations, customer transfer

n

substations, distribution substations and switching substa

tions of power supply and

public utilities

Industrial plants, such as:

n

Wind power stations

•

High-rise buildings

•

Airports

•

Lignite open-cast mines

•

Underground railway stations

•

•

Sewage treatment plants

•

Port facilities

•

Traction power supply systems

•

Automobile industry

•

Petroleum industry

•

Chemical industry

•

Cement industry

•

Unit-type heating power stations

•

Textile, paper and food

industry

•

Emergency power supply

installations

Modular design

•

Individual panels and panel

blocks can be freely combined

andextended–without

gas work

on site

•

Low-voltage compartments can

be supplied in two overall heights

and are wired to the panel by

means of plug-in connections

Reliability

•

Type and routine-tested

•

Standardized and manufactured

using numerically controlled

machines

•

More than 500,000 8DJ/8DH

panels in operation worldwide

for many years

Quality and environment

Quality and environmental

management system acc. to

DIN EN ISO 9001 and

DIN EN ISO 14001

Personal safety

Safe-to-touch and hermetically

•

sealed primary enclosure

HV HRC fuses and cable sealing

•

ends are only accessible when

outgoing feeders are earthed

Operation only possible when

•

enclosure is closed

Logical mechanical interlocking

•

Capacitive voltage detecting sys

•

tem to verify saf e isolation from

supply

Feeder earthing by means of

•

make-proof earthing switches

Security of operation

Hermetically sealed primary

•

enclosure independent of

environmental effects (such as

pollution, humidity and small animals) – sealed for life:

– Welded switchgear vessel

– Welded-in bushings and operating

mechanism

•

Operating mechanism parts

maintenance-free

(IEC 62271-1 / VDE 0671-1)

•

Operating mechanisms of switch

ing devices located outside the

switchgear vessel (primary enclo

sure)

•

Switchgear interlocking system

with logical mechanical interlocks

•

Mechanical switch-position

indicators integrated in the

mimic diagram

Cost-efficien c y

Extremely low “life-cycle costs”

throughout the entire product

service life as a result of:

•

Maintenance-free concept

•

Climatic independence

•

Minimum space requirements

•

Maximum availability

Security of investment

Innovative developments, such as:

•

Modular design

•

Switchgear extension without gas

work on site

•

Maintenance-free 3AH vacuum

circuit-breaker

•

SIPROTEC protection device family

-

-

© Siemens AG 2008

2

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Page 3

Technology

Maintenance-free

•

Climate-independent

•

Partition class: Class PM

•

(metallic partition)

Three-pole primary enclosur e,

•

metal-enclosed

Insulating gas SF

•

Welded switchgear vessel without

•

6

seals, made of stainless steel,

with welded-in bushings for elec

trical connections and mechanical

components

Three-position switch-discon-

•

nector with load-break and

make-proof earthing function

Cable connection for bushings

•

with outside cone

Connection with cable plugs

•

– In ring-main feeders and

circuit-br eaker feeders with

bolted contact (M16)

– In transformer feeders with

plug-in contact

Option: Connection with conven-

•

tional cable sealing ends

– For thermoplastic-insulated

cables via elbow adapter

AKE 20 / 630 (make Siemens)

– For paper-insulated mass-

impregnated cables via commercially available adapter systems

•

Easy installation

•

Option: Pressure absorber system

– Maintenance-fr ee

– For rated short-time withstand

current I

£ 20 kA

k

– For single and multi-panel

combinations of 700 mm to

2000 mm width (for panel type

ME1 with max. 1 adjacent panel)

– With 300 mm high pressure ab-

sorber duct below the switchgear

and

– With 115 mm deep pressure

absorber duct for pressure relief

upwards

–Withscrewed-oncable

compartment cover

– Possible for switchgear with stand -

ard cable compartment cover

ption: Deeper cable compart-

O

ment cover: 105 or 300 mm

– For overall height of switchgear,

seepage6

ption: Free-standing arrange-

–O

ment, for overall height of

switchgear 2300 mm and with

rear cover

For further information concerning

thepressureabsorbersystem,

please refer to page 39

and to Catalog HA 40.1

Standards

Seepage41

Application

T ypical uses

s

p

e

a

3

1

0

1

4

A

-

s

p

e

4

1

0

1

4

A

H

R

H

R

Example

Customer transfer switchgear

s

p

e

5

1

0

1

4

A

H

R

Application

Customer transfer substation in an

accessible switchgear building

(transformers, medium-voltage and

low-voltage in a factory-assembled

building)

Application

Power supply of high-rise buildings

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

3

Page 4

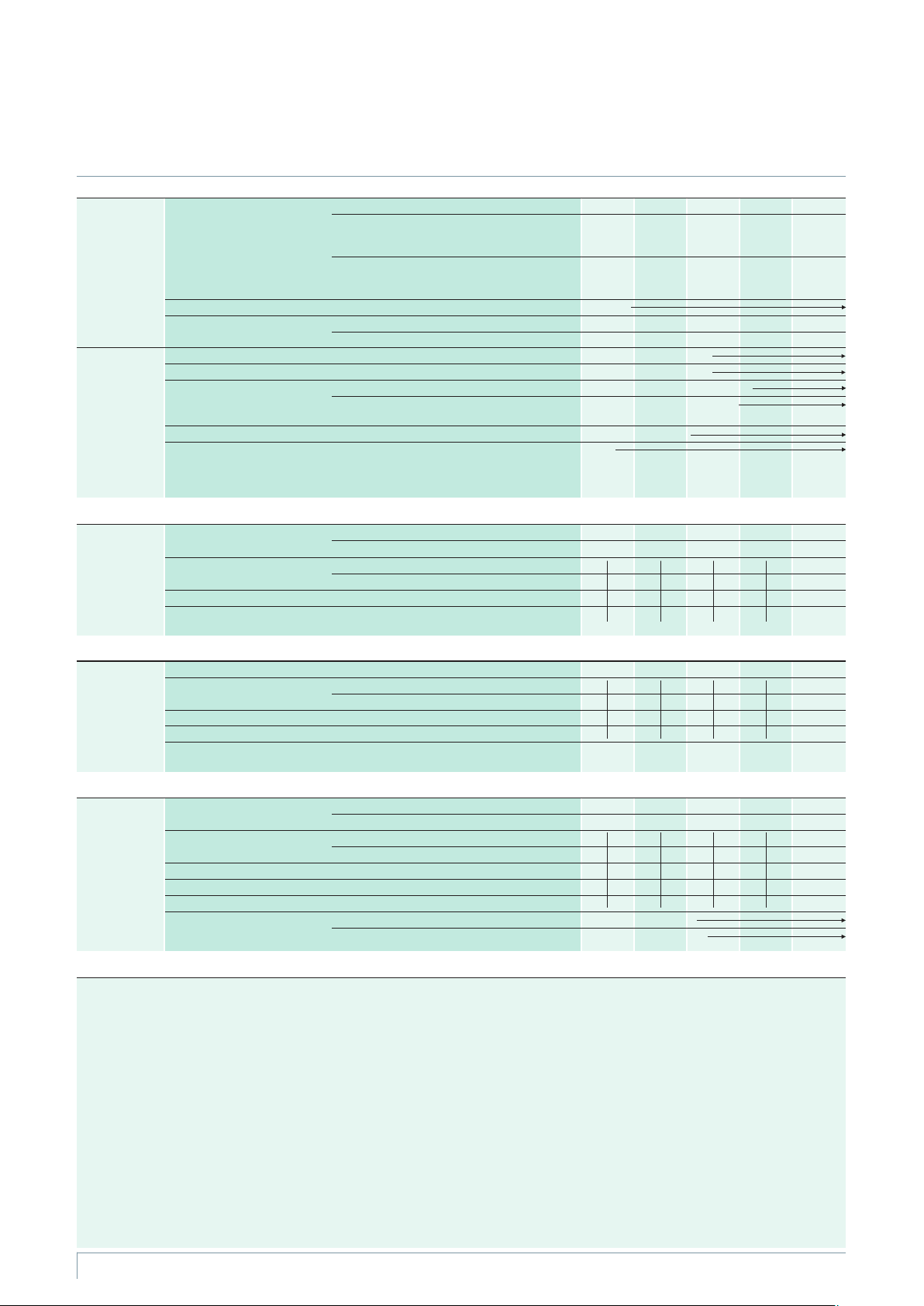

Technical Data

Electrical data

Common

electrical data

Filling pressure,

temperature,

partition class

and

classification

Panel data

Ring-main panel

type RK,

bus sectionalizer

panel type LT2,

cable panel

type K

Rated insulation level Rated voltage U

Rated short-dur. power-freq. withstand voltage U

– phase-to-phase, phase-to-earth, open contact gap kV

– across the isolating distance kV2023

Rated lightning impulse withstand voltage U

– phase-to-phase, phase-to-earth, open contact gap kV

– across the isolating distance kV6070

Rated frequency f

Rated normal current I

r

2)

r

for busbar (standard) up to A 630 630 630 630 630

forbusbar(option)

Rated filling level p

Min. functional level p

re

me

Ambient air temperature T

for insulation 150 kPa (absolute) at 20 °C

for insulation 130 kPa (absolute) at 20 °C

3)

Panels without secondary equipment Class “Minus 25 indoor” (-25 to +70 °C4))

Panels with secondary equipment, Class

r

)

*

kV 7.2121517.5B)24

:

d

:

p

1)

28

1)

32

1)

75

1)

85

50/60 Hz

A 1250 1250 1250 1250 1250

“Minus 5 indoor” (-5 to +55 °C

circuit-breaker panels

Partition class Class PM (metallic partition)

Loss of service

continuity category

Rated normal current I

5)

2)

r

Rated short-time

withstand current I

k

Rated peak withstand current I

Rated short-circuit making current I

LSC (loss of service continuity) LSC 2

for feeder (for panel types RK ... and K ...) A 400, 630 400, 630 400, 630 400, 630 400, 630

for bus sectionalizer panel type LT2 A

400, 630 400, 630 400, 630 400, 630 400, 630

for switchgear with tk= 1 s up to kA 20 25 20 25 20 25 20 25 20

for switchgear with t

p

ma

= 3 s (option) up to kA – – 20 – 20 – 20 – 20

k

up to kA 50 63 50 63 50 63 50 63 50

up to kA 50 63 50 63 50 63 50 63 50

36

39

95

110

B)

38

45

95

110

4)

)

50

60

125

145

Transformer

panel type TR

Rated normal current I

Rated short-time

withstand current I

Rated peak withstand current I

Rated short-circuit making current I

Reference dimension “e“ of the HV HRC fuse links mm 292

Circuit-breaker

Rated normal current I

panel type LS,

bus sectionalizer

type LK/LT1

Rated short-time

withstand current I

Rated peak withstand current I

Rated short-circuit making current I

Rated short-circuit breaking current I

Electrical service life of

3AH vacuum circuit-breakers

*) Not for billing metering

panels type ME1

B) Data for Russian Federation:

– Rated voltage 12 kV

– Rated Short-duration power-

frequency withstand voltage 42 kV

1) According to some national requirements, higher values of the rated

short-duration power-frequency

withstand voltage available for

=20kAwith:

I

k

- 42 kV for phase-to-phase,

phase-to-earth and open contact

gap as well as

- 48 kV across the isolating distance

2)

r

for feeder

6)

for switchgear with tk= 1 s up to kA 20 25 20 25 20 25 20 25 20

k

2)

r

for switchgear with t

6)

p

6)

ma

for feeder (for panel types LS ...) A 400, 630 400, 630 400, 630 400, 630 400, 630

for bus sectionalizer panel type LT1 A 400, 630 400, 630 400, 630 400, 630 400, 630

for switchgear with tk= 1 s up to kA 20 25 20 25 20 25 20 25 20

k

for switchgear with t

p

ma

8)

sc

at rated normal current 10 000 operating cycles

at rated short-circuit breaking current 50 breaking operations

Higher values of the rated lighting

impulse withstand voltage

=20kA):

(for I

k

- 95 kV for phase-to-phase,

phase-to-earth and open contact

gap as well as

- 110 kV across the isolating

distance

2) The rated normal currents apply

to ambient air temperatures of

max. 40 °C. The 24-hour mean

value is max. 35 °C (according to

IEC 62271-1 / VDE 0671-1)

A 200 200 200 200 200

= 3 s up to kA – – 20 – 20 – 20 – 20

k

up to kA 50 63 50 63 50 63 50 63 50

up to kA 25 25 25 25 25 25 25 25 25

7)

292 442 442 442

= 3 s up to kA – – 20 – 20 – 20 – 20

k

up to kA 50 63 50 63 50 63 50 63 50

up to kA 50 63 50 63 50 63 50 63 50

up to kA 20 25 20 25 20 25 20 25 20

3) Operating conditions according to

IEC 62271-200.

For application, see also pages

2 and 41 (climate and ambient

conditions)

4) Temperature range, reduced

normal currents at ambient air

temperatures > +40 °C

6) Depending on the HV HRC fuse link,

observe the max. let-through

current of the HV HRC fuse links

7) Extension tube (150 mm long)

required additionally for fuse

mounting 442 mm

8) For the 3AH vacuum cir cuit-breaker

5) Classification accordin gto

IEC 62271-200 (see also page 42)

4

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Page 5

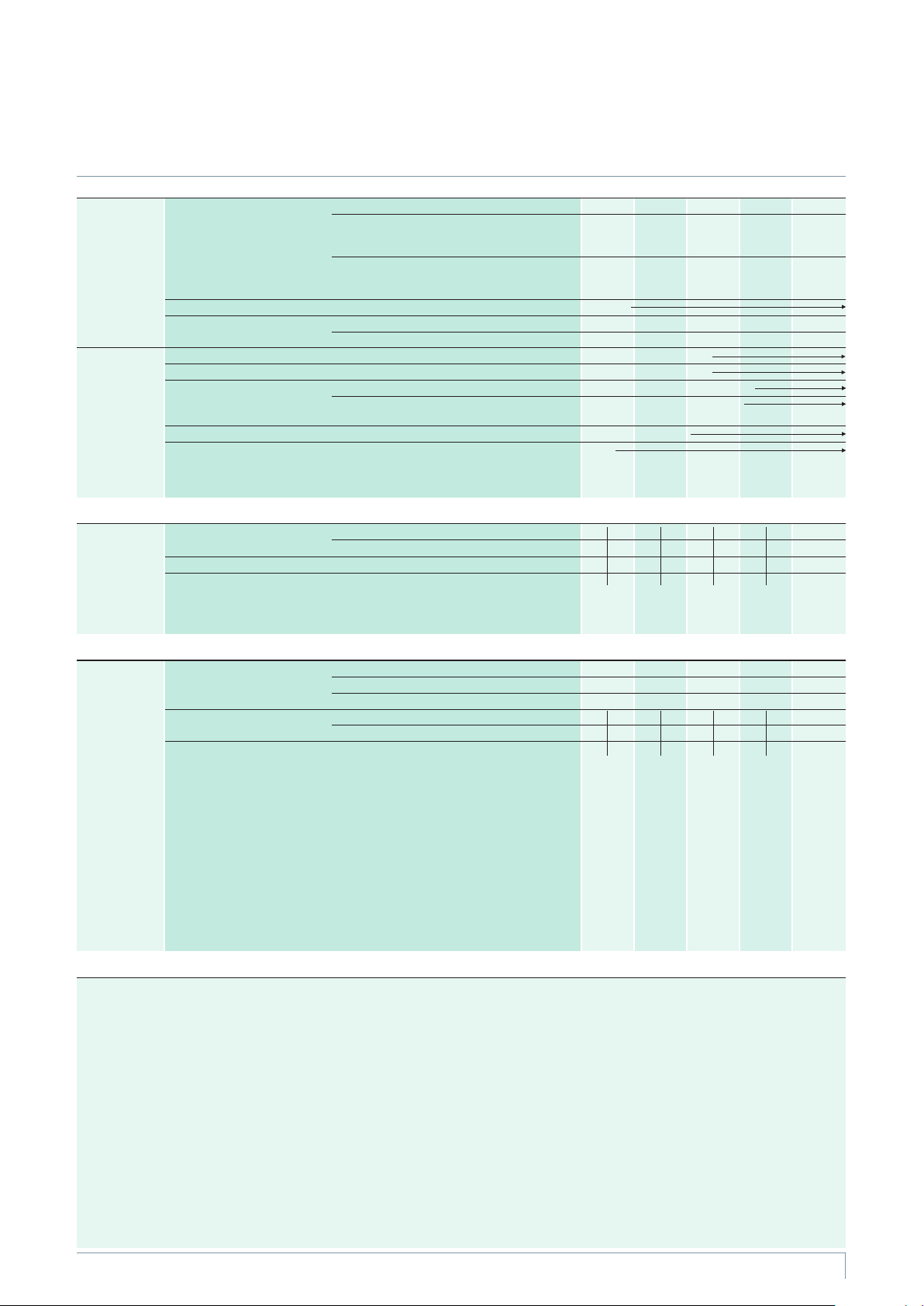

Technical Data

Electrical data

Common

electrical data

Filling pressure,

temperature,

partition class

and

classification

Panel data

Busbar earthing

panel

type SE,

busbar voltag e

metering panel

type MS1V/ME3

Rated insulation level Rated voltage U

Rated short-dur. power-freq. withstand voltage U

– phase-to-phase, phase-to-earth, open contact gap kV

– across the isolating distance kV2023

Rated lightning impulse withstand voltage U

– phase-to-phase, phase-to-earth, open contact gap kV

– across the isolating distance kV6070

Rated freque n cyf

Rated normal current I

r

2)

r

for busbar (standard) up to A 630 630 630 630 630

forbusbar(option)

Rated filling level p

Min. functional level p

re

me

Ambient air temperature T

for insulation 150 kPa (absolute) at 20 °C

for insulation 130 kPa (absolute) at 20 °C

3)

Panels without secondary equipment Class “Minus 25 indoor” (-25 to +70 °C4))

Panels with secondary equipment, Class

r

)

*

kV 7.2121517.5B)24

:

d

:

p

1)

28

1)

32

1)

75

1)

85

50/60 Hz

A 1250 1250 1250 1250 1250

“Minus 5 indoor” (-5 to +55 °C

circuit-breaker panels

Partition class Class PM (metallic partition)

Loss of service

continuity category

5)

Rated short-time

withstand current I

k

Rated peak withstand current I

Rated short-circuit making curr e n tI

LSC (loss of service continuity) LSC 2

for switchgear with tk= 1 s up to kA 20 25 20 25 20 25 20 25 20

for switchgear with t

p

ma

=3s(option) uptokA

k

up to kA 50 63 50 63 50 63 50 63 50

up to kA 50 63 50 63 50 63 50 63 50

– – 20 – 20 – 20 – 20

36

39

95

110

B)

38

45

95

110

4)

)

50

60

125

145

Billing metering

Rated normal current I

panels

types ME1

and ME2

Rated short-time

withstand current I

Rated peak withstand current I

*) Not for billing metering

panels type ME1

B) Data for Russian Federation:

– Rated voltage 12 kV

– Rated Short-duration power-

frequency withstand voltage 42 kV

1) According to some national requirements, higher values of the rated

short-duration power-frequency

withstand voltage available for

=20kAwith:

I

k

- 42 kV for phase-to-phase,

phase-to-earth and open contact

gap as well as

- 48 kV across the isolating distance

2)

r

for transfer up to A 630 630 630 630 630

for fee de r(T with cable pane lastype ME1-K) up to A 630 630 630 630 630

for busbar metering up to A 630 630 630 630 630

for switchgear with tk=1s uptokA– 2520 2520 2520 2520

k

for switchgear with t

p

Higher values of the rated lighting

impulse withstand voltage

=20kA):

(for I

k

- 95 kV for phase-to-phase,

phase-to-earth and open contact

gap as well as

- 110 kV across the isolating

distance

2) The rated normal currents apply

to ambient air temperatures of

max. 40 °C. The 24-hour mean

value is max. 35 °C (according to

IEC 62271-1 / VDE 0671-1)

= 3 s up to kA 20 – 20 – 20 – 20 – 20

k

up to kA 50 63 50 63 50 63 50 63 50

3) Operating conditions according to

IEC 62271-200.

For application, see also pages

2 and 41 (climate and ambient

conditions)

4) Temperature range, reduced

normal currents at ambient air

temperatures > +40 °C

5) Classification accordin gto

IEC 62271-200 (see also page 42)

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

5

Page 6

HA41-2286g eps

³1000775

³10001070

>600

2000

10

³50

³15

10

³50

³1000

³2400

**

7

20

3

4

5

6

7

8

9

11

2

12

1

18

13

19

22

10

14

2300

*

*

***

HA41-2287h eps

115

300

³15

890

828

834

³2400

**

³1000

~

200

15

16

17

15

13

21

21

22

23

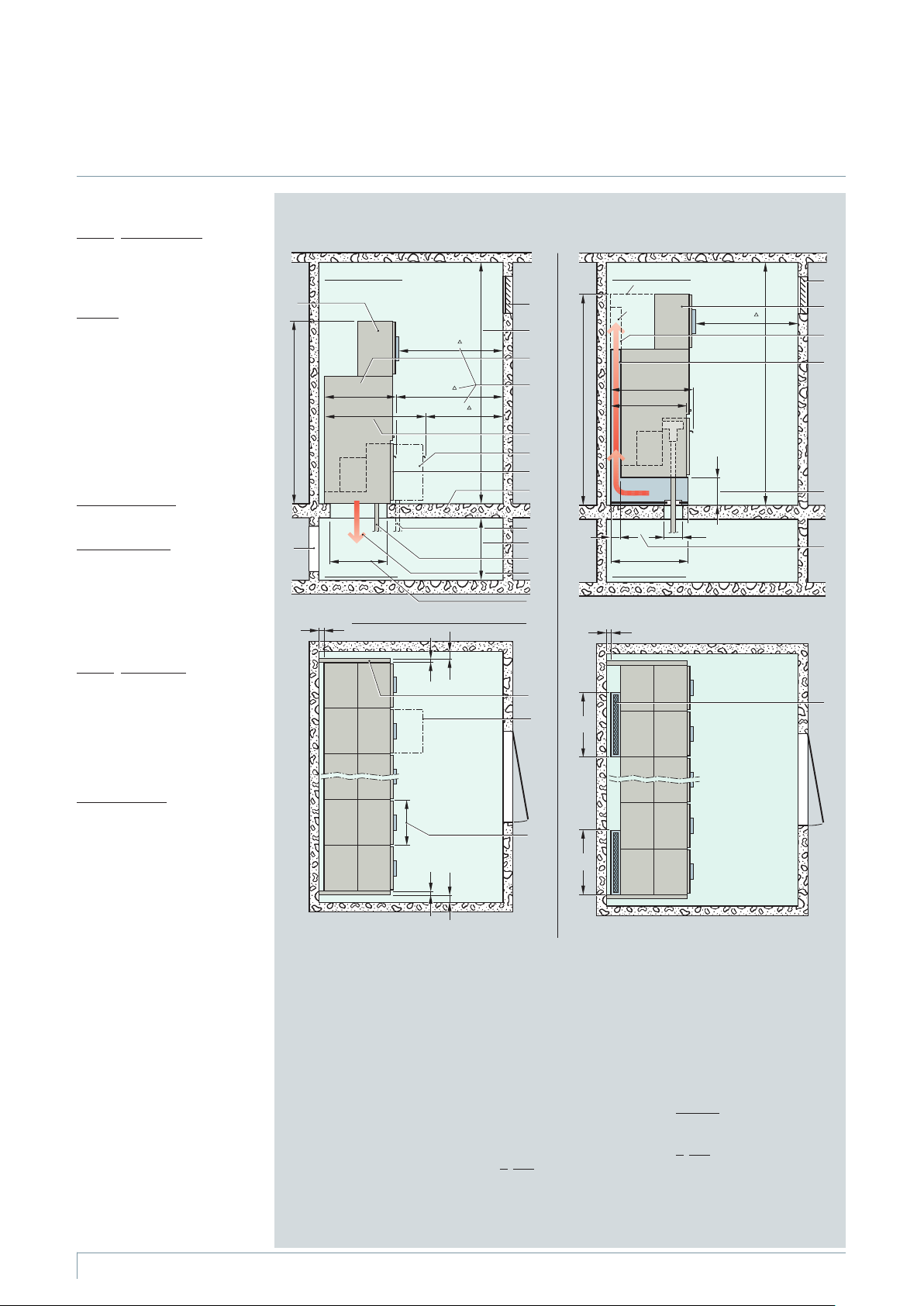

Technical Data

Switchgear installation

Room planning

Switch

gear installation

Wall-standing arrangement

– Single row

– Double row (for face-to-face

arrangement)

Free-standin g

Option:

arrangement

For room planning and

switchgear installation, please

note:

– Floor openings: Dimensions

see pages 36 to 39

– Direction of pressure relief

acc. to serial no. 13

– Respectiv e pressure relief

rooms

Room dimensions

see opposite

dimension drawings

Door dimensions

The door dimensions depend

on the

–Numberofpanelsina

transport unit

– Design with or without

low-voltage compartment

Switchgear installation with

standard panels

Switchgear room

Cable basement

Side view

Switchgear installation with rear-side

pressure absorber duct (option)

Switchgear room

Cable basement

Side view

gear fastening

Switch

•

For floor openings and fixing

points of the switchgear,

see pages 36 to 39

•

Foundations:

– Steel structure

– Steel-reinforced concrete

Panel dimensions

Weight

For details, please refer to page 7.

* Switchgear height for version with

pressure absorber duct:

** Installation conditions for internal

– For wall-standing arrangement

W 1950 mm (panel combination

without metering panel ME1)

W 2300 mm (for combination

with metering panel ME1)

– For free-standing arrangement

W 2300 mm (high end walls, rear

wall and front covers, optional

low-voltage compartment)

arc classification acc. to

IEC 62271-200

*** Height of pressure absorber duct

2100 mm with:

– Wall-standing arrangement with

metering panel ME1

– Free-standing arrangement for all

panel types

B Depending on national

specifications:

– For extension/panel replacement:

Control aisle W 1000 mm

recommended (for Germany

W 800 mm)

6

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

see p. 30 to 34

Top v iew Top v iew

1 Relief opening

2 Opening (e.g. for ventilation

as option)

3 Room height

4 Panel depth of the standard

panel (may be 15 mm deeper

for free-standing arrangement,

depending on the panel design)

5 Control aisle

6 Panel depth of panels with

deep cable compartment

cover

7 Deep cable compartment

cover

8 S tandar d cable compartment

cover

B

9 Foundation

nd

10 2

cable for connection with

of double T-plugs in conjunction with larger floor opening

and design with deep cable

compartment cover

11 Height of the cable

basement corresponding to

the cable bending radius

12 Cable

13 Direction of pressure relief

14 Floor openings:

Dimensions see pages 34 to 37

ption:

15 O

Pressure absorber duct

16 Base height of the pressure

absorber duct beneath the

panel

17 Depth of the pressure absorber

duct behind the panel

18 Wall distance

19 End wall

20 Panel width

21 Width of the pressure absorber duct

– 700 mm for panel combinations

– Approx. 850 mm for metering

panels type ME1

22 Standard:

Low-voltage compartment

for circuit-breaker panels

ption:

O

–Low-voltagecompartment

forallotherpaneltypesor

–Frontcover

23 Relief outlet

Page 7

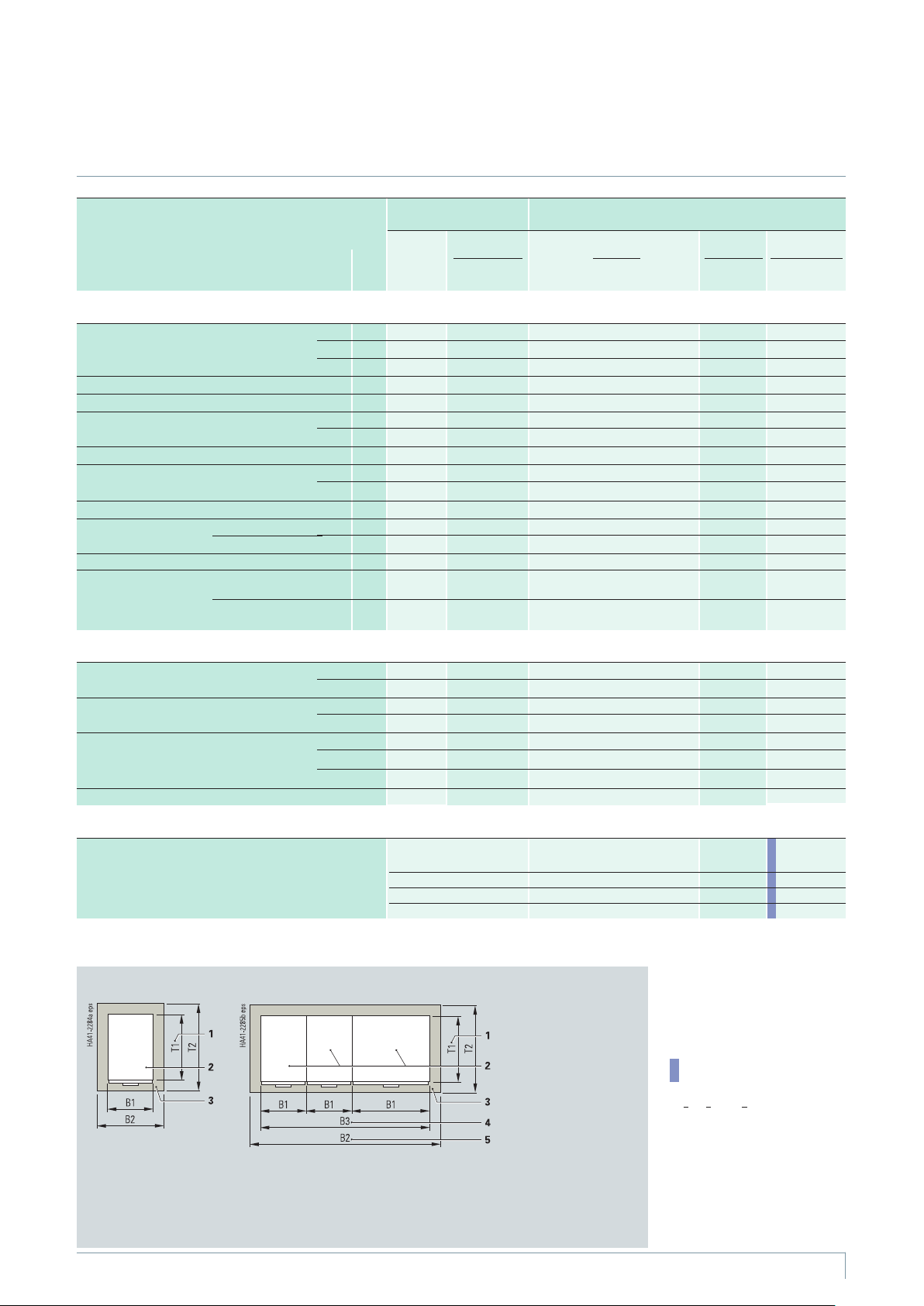

Technical Data

Shipping data

Individual panel, panel block

or combinations thereof

for standard switchgear

(without pressure relief duct)

Transport of individual panels

Ring-main panel (standard)

Cable panel (standard)

Transformer panel

Circuit-breaker panel (standard)

Circuit-breaker panel

Bus sectionalizer panel with circuit-breaker

Bus sectionalizer panel with switch-disconnector LT2 LT

Busbar earthing panel

Busbar voltage metering panel ME3 MS1 V 500 250 / 310 0.70 1.60 / 2.20 1.10 1.23 / 1.69 310 / 370

Billing metering with cast-resin

panels, insulated transformers

air-insulated **

Transport of panel blocks

Ring-main panel block

Transformer panel block

Ring-main/transformer panel block

Cable connection/transformer panel block KT-B2 700 300 / 420 1.08 1.60 / 2.20 1.10 1.90 / 2.61 360 / 480

BB

with voltage transformer

with combined

transformers

Type

Short identification

current in

RK RK

RK1 RK1

RK2 RK1 V 500 200 / 260 0.70 1.60 / 2.20 1.10 1.23 / 1.69 260 / 320

KK

TR TR1

LS1 LS1

LS2 LS1V

LST1 LST1

LT1 LK

LT1-V LK V

SE1 SE

SE2 SE1 V

ME1 ME1 850 250 / 310 1.08 1.60 / 2.20 1.10 1.90 / 2.61 310 / 370

ME2 ME2 600 390 / 450 1.08 1.60 / 2.20 1.10 1.90 / 2.61 450 / 510

R-B2

R-B3

T-B2

T-B3

RT-B2

2RT-B3

3RT-B4

Panel or panel combination Transport unit (including packing) for standard panels (without

B

Width B1mmNet weight

future

350

500

350 145 / 205 0.70 1.60 / 2.20 1.10 1.23 / 1.69 205 / 265

500 180 / 240 0.70 1.60 / 2.20 1.10 1.23 / 1.69 240 / 300

500

500

500 280 / 340 0.70 1.60 / 2.20 1.10 1.23 / 1.69 320 / 380

500

500

500 150 / 210 0.70 1.60 / 2.20 1.10 1.23 / 1.69 210 / 270

350

500

700

1050

1000

1500

700

1050

1400

approx. kg

without / with

*/LVC*

LVC

150 / 210

180 / 240

– / 260

– / 380

– / 280

– / 380

150 / 210

250 / 310

280 / 400

400 / 580

320 / 440

480 / 660

300 / 420

450 / 630

580 / 820

pressure absorber system)

1)

Width B2mHeight

0.70

0.70

0.70

0.70

0.70

0.70

0.70

0.70

1.08

1.40

1.40

2.03

1.08

1.40

2.03

m

without /with

*/LVC*

LVC

1.60 / 2.20

1.60 / 2.20

– / 2.20

– / 2.20

– / 2.20

– / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

1.60 / 2.20

Depth

T2 m

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

1.10

Volume

3

m

without /with

*/LVC*

LVC

1.23 / 1.69

1.23 / 1.69

– / 1.69

– / 1.69

– / 1.69

– / 1.69

1.23 / 1.69

1.23 / 1.69

1.90 / 2.61

2.46 / 3.40

2.46 / 3.40

3.57 / 4.91

1.90 / 2.61

2.46 / 3.40

3.57 / 4.91

Gross weight

approx. kg

without /with

*/LVC*

LVC

210 / 270

240 / 300

– / 320

– / 440

– / 340

– / 440

210 / 270

310 / 370

340 / 460

470 / 650

390 / 510

560 / 740

360 / 480

520 / 700

660 / 900

1)

Transport of combinations of different individual panels or panel blocks

Comprising

– a number of individual panels or

–1panelblockor

– a number of panel blocks or

– individual panels with panel blocks

B Short identifications of the panels have been harmonized

BB Panel type LST1: Please refer to separate Catalog HA 45.31/41.11, Supplements to Catalogs HA 45.31/41.11

Transport units for shipping (top view)

With individual panel

or panel block

With combinations of different individual

panels and/or panel blocks

(option: Panels bolted together and busbars mounted)

Overall width B3

£ 850 mm

£ 1200 mm 1.40 1.60 / 2.20 1.10 2.46 / 3.392)+70***

£ 1800 mm 2.03 1.60 / 2.20 1.10 3.57 / 4.912)+85***

£ 2350 mm 2.53 1.60 / 2.20 1.10 4.49 / 6.172)+100***

B2

1.08 1.60 / 2.20T21.10 1.90 / 2.61

1 T1 = Depth of individual

panel or of panel block

2 Individual panel or panel

block, dimension B1 x T1

3 Transport unit,

dimension B2 x T2

4 B3 = Overall width of

combination of different

individual panels

or panel blocks

5 B2 = Width of the

transport unit

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

2)

+60***

1) The net weight and the gross

weight depend on the extent to

which they are equipped (e.g. with

current transformers, motor operating mechanism, deep cable

compartment cover) and are

therefore given as mean value

2) Sum of the net weights of indi-

vidual panels and / or panel blocks

* Low-voltage compartment,

600 mm high, weight approx.

60 kg depending on the panel

type and on the extent

to which it is equipped

** The weights depend on the

weights of the mounted

transformers

*** Packing weight

7

Page 8

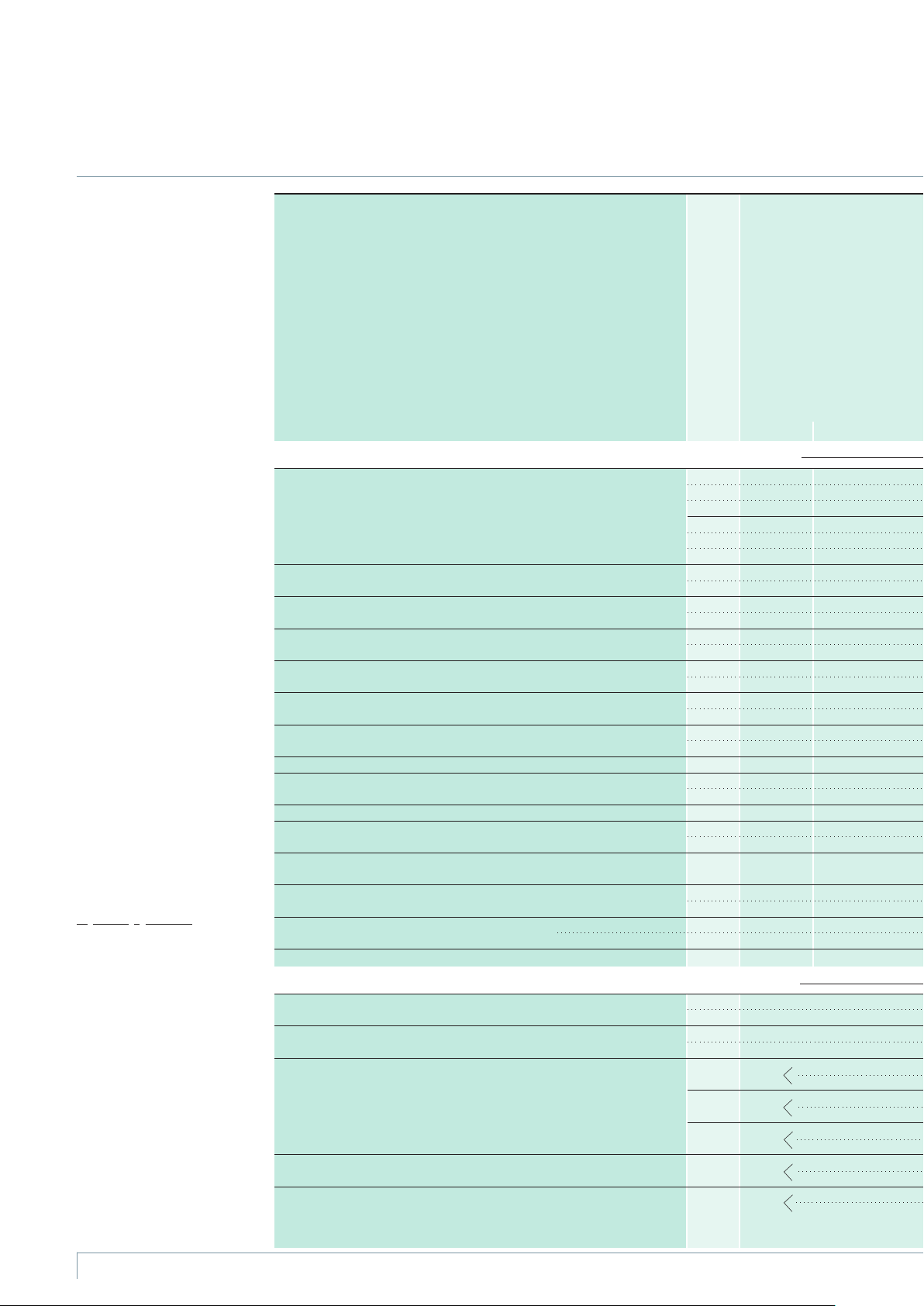

Product Range

Product range overview

Designation of the

individual panels

and panel blocks

Individual panels

Ring-main panel 350 RK RK

Cable panel without earthing switch 350 K K

Cable panel with make-proof earthing switch 350 K K

Transformer panel 500 TR TR1

Transformer panel with plug-in voltage transformers 500 TR-V TR1-V

Circuit-breaker panel 500 LS1 LS1

Circuit-breaker panel with plug-in busbar voltage transformers 500 LS2 LS1 V

Circuit-breaker panel (with disconnecting circuit-breaker)

Bus sectionalizer (with vacuum circuit-breaker) 500 LT1 LK

Bus sectionalizer (with switch-disconnector)

Busbar earthing panel 350 SE1 SE

Busbar voltage metering panel 500 ME3 MS1 V

BB

Panel

width

Type

Short identifications *

current in future

Column no.

500 RK1 RK1

500 RK2 RK1V

350 RK-U RK-U

500 RK1-U RK1-U

500 RK2-U RK1V-U

350 K-U K-U

350 K-U K-U

500 TR-U TR1-U

500 TR/V TR1/V

500 LS1-U LS1-U

500 LS2-U LS1 V-U

500 LST1 LST1

500 LT1-V LK V

500 LT2 LT

500 SE2 SE1 V

Billing metering panel 850 ME1 ME1

Legend for pages 8 and 9

* Short identifications of the panels

have been harmonized

** LVterminalsasanoptionintheLV

compartment (compartment to be

ordered as an option)

B Three-position switch as

three-position switch-disconnector

(switch-disconnector

CLOSED-OPEN-EARTHED)

BB Three-position switch as

three-position circuit-breaker

(disconnecting circuit-break er

CLOSED-OPEN-EARTHED), see

Supplements to Catalogs

HA 45.31/41.11-2007

1) The equipment applies to the entire

panel block, but it is located in the

first feeder panel from the left

2) Low-voltage terminals arranged in

thelow-voltagenicheofthe

ring-main or cable feeder

8

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Billing metering panel for busbar connection 850 ME1-S ME1-S

Billing metering panel with combined transformers

Panel blocks

Ring-main panel block 700 R-B2

Transformer panel block 1000 T-B2

Ring-main/transformer panel block

Cable connection/transformer panel block

(cable panel without make-proof earthing switch)

Cable connection/transformer panel block

(cable panel with make-proof earthing switch)

850 ME1-K ME1-K

cable connection 850 ME1-KS ME1-K

600 ME2 ME2

Column no.

1050 R-B3

1500 T-B3

700 RT-B2

1050 2RT-B3

1400 3RT-B4

700 KT-B2

700 KT-B2

RK

T

RK

T

RK

T

K

T

K

T

Page 9

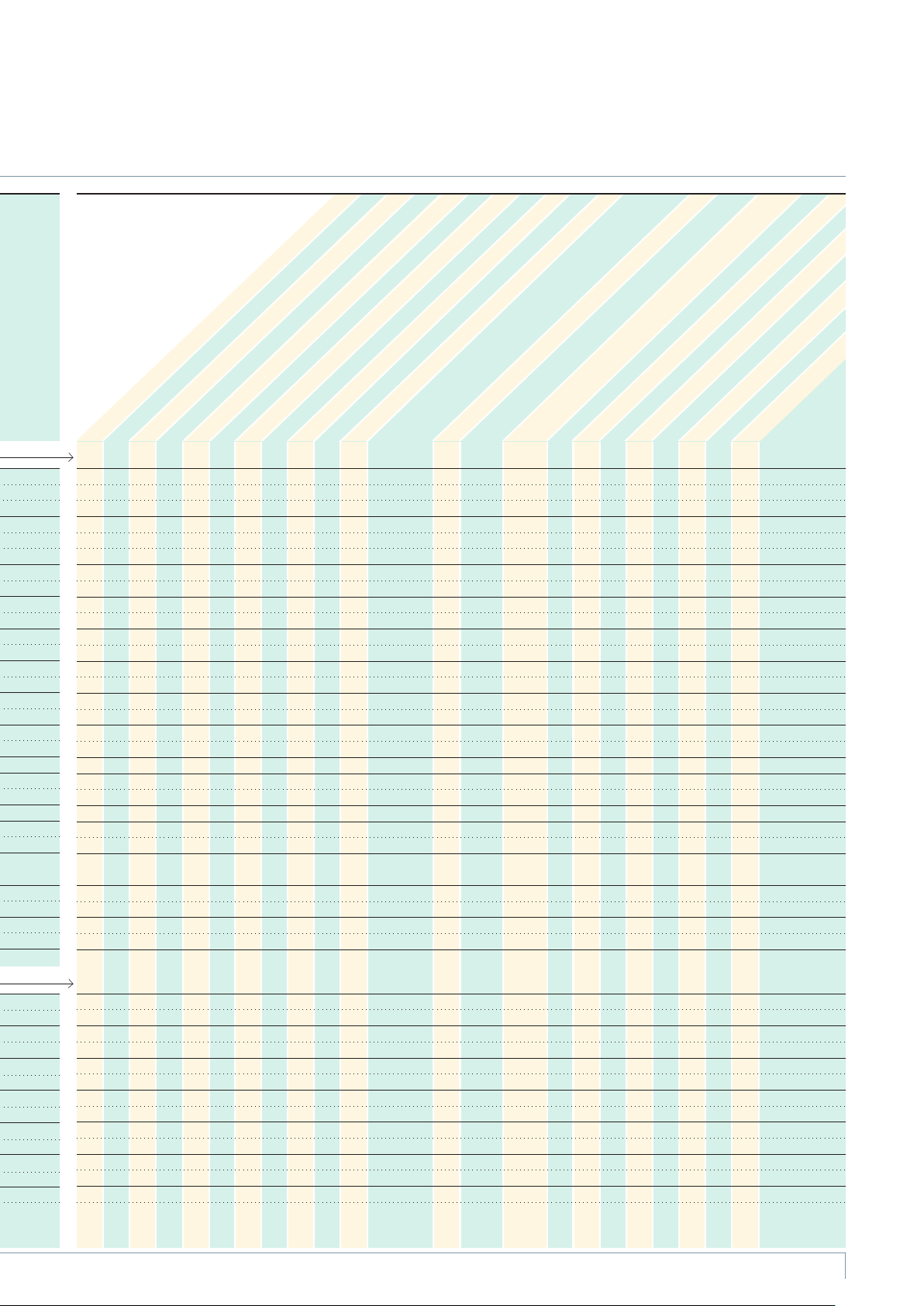

Product Range

Equipment features

• Basic equipment

Additional equipment

°

(option), further additional

equipment on request

– Not available

Low-voltage niche as terminal comp. above the operating mechanism box

C-rail as cable bracket

Manual operating mechanism for three-position switch

Manual operating mechanism for three-position circuit-breaker

1234 567 891011 12 1314 15161718192021222324

–

•

–

•

–

•

–

•

–

•

–

•

–––

–––•–

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

••–•••

––•––––

•

––•––––

•

––•–

•

–

•

–

•

––•–

•

–––•–––•––– – – – – –––––

–––

–––•–––•––– – – – – –––––

–––

–––•––––––– – – – – –––––

1234 567 891011 12 1314 15161718192021222324

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–

•

–––

–––

•

–

•

–

•

Cable compartment cover locked in place/screwed on

Interlock for cable compartment cover

–

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

••

–

••

–

••

––•–––

––•–––

––•–––

•••

–

––•–––

–

–––•–

–

–––•–

–

–––––

–

–––––

––•–––

––•–––

••

••

–

–

–

–

–

–

–

–

–

–

•••

–

–

•

••

–

•

–

•

–––

•

–––

•

•

•

––•––– – – – – –––––

––•––– – – – – –––––

••

••

–––

•

–––

•

••

2)

•

••

2)

•

••

2)

•

2)

•

••

2)

•

B)

Separate low-voltage niche as terminal compartment

Low-voltage terminals in the operating mechanism box **

–––

–––

–––

–––

–––

–––

–

•

–

•

–

–––

–––

–––

–––

–––

––

–––

––

–––

––

–––

––

–––•

––

BB)

OPEN: 2NO + 2NC, EARTHING CLOSED/OPEN: 2NO + 2NC; circuit-breaker

Release as shunt release for three-position switch

°

°

°

°

°

°

°

°

°

°

°

°

°

°

°

°

°

°

Signalling switch (1 NO) for remote electrical ready-for-service indication

Mechan. ready-for-servi ce indicator(e.g.for switching devices)

•

°°°

•

°°°

•

°°°

•

°°°

•

°°°

•

°°°

•

°

•

°

•

°°

•

°°

•

°°°

•

°°°

•

°°°

•

°°°

•

°°°°

•

°°°°

•

°°°°

•

°°°°

•

°

•

°°°°

•

°°°°

•

°°°

•

°°

•

°°

•

°°°

1)

1)

•

°

1)

1)

•

°

1)

1)

•

°

1)

1)

•

°

1)

1)

•

°

1)

1)

1)

1)

•

°

1)

1)

1)

1)

•

°

1)

1)

1)

1)

•

°

1)

1)

1)

1)

°

1) 1)

type LST CLOSED/OPEN:2NO + 2NC, EARTHING CLOSED/OPEN:2NO + 2NC

Aux. switch for three-position switch

––––––°––

– – – – –––––

•

Motor-operat. mechan. f. three-pos. switch

–– ––

–– ––°–––

°

–– ––•–––

–– ––•–––

°°

°°

°°

°°

°°

°°

°°

°°

°°

°°

––––––°––

°°

–– ––

°

°°

BB)

and

B)

: Switch-disconnector CLOSED/

BB)

and

B)

vacuum circuit-breaker

De-earthing lock-out for make-proof earthing switch

Interlock in circuit-breaker panel between three-position switch

––

––

––

––

––

––

–

–

–

–

–

–––•–––

–––°–––

–––

–––

–

–

––

–

––

–

––

–

–

–

of three-position switch

Closing lock-out for three-position switch

°°°

°°°

°°°

°°

°°

°°°

–

°

–

°

–

°

–

°

–

°°°°°

–

°°–°°

–

°°°°°

–

°°–°°

° °°°–°°°°°

––•–

––•–

–

°

–

°

°°°

–

°

°°°

–

°

°°°

–

°

–

°

–

°

(f. CLOSED and OPEN)

BB)

and

B)

BB)

and

B)

Locking device for three-position switch

°°

°

°

°

°

Motor operating mechanism for 3AH vacuum circuit-breaker

Short-circuit or earth-fault indicator

––

––

––

–––

–––

––

––

–––

–––

–––

–––

°°

°°

°°

°°

°

°

°

°

°

°

°°

°

––

––

–––

–––

––

–––

––

–––

––

–––

–––

––

–––

and

B)

BB)

BB)

and

and

B)

B)

Low-voltage compartment **

Release as current-transformer operated release

Mounted cable clamps

Low-voltage cover

°°°°

°°°°

°°°°

°°–°

°°–°

°°–°

°°°°

°°–°

°°°°

°°–°

°°°°

°°–°

°°°°

°°–°

–

•

•

•

•

•

•

°°

––

–

°°

––

––

––

°

°

°

°

°°–°

°°–°

°°–°

°°–°

°°–°

°°°°

°°–°

°°°°

°°–°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

°°°°

)

Secondary equipment

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

9

Page 10

HA41-2224_1d eps

HA41-2216_1d eps

HA41-2227_1d eps

HA41-2225_1d eps

HA41-2226_1d eps

HA41-2215_1d eps

HA41-2214_1e eps

**

HA41-2217_1d eps

HA41-2219_1e eps

**

HA41-2213_1d eps

HA41-2218_1d eps

HA41-2220_1d eps

HA41-2221_1d eps

HA41-2222_1d eps

HA41-2223_1d eps

Product Range

**

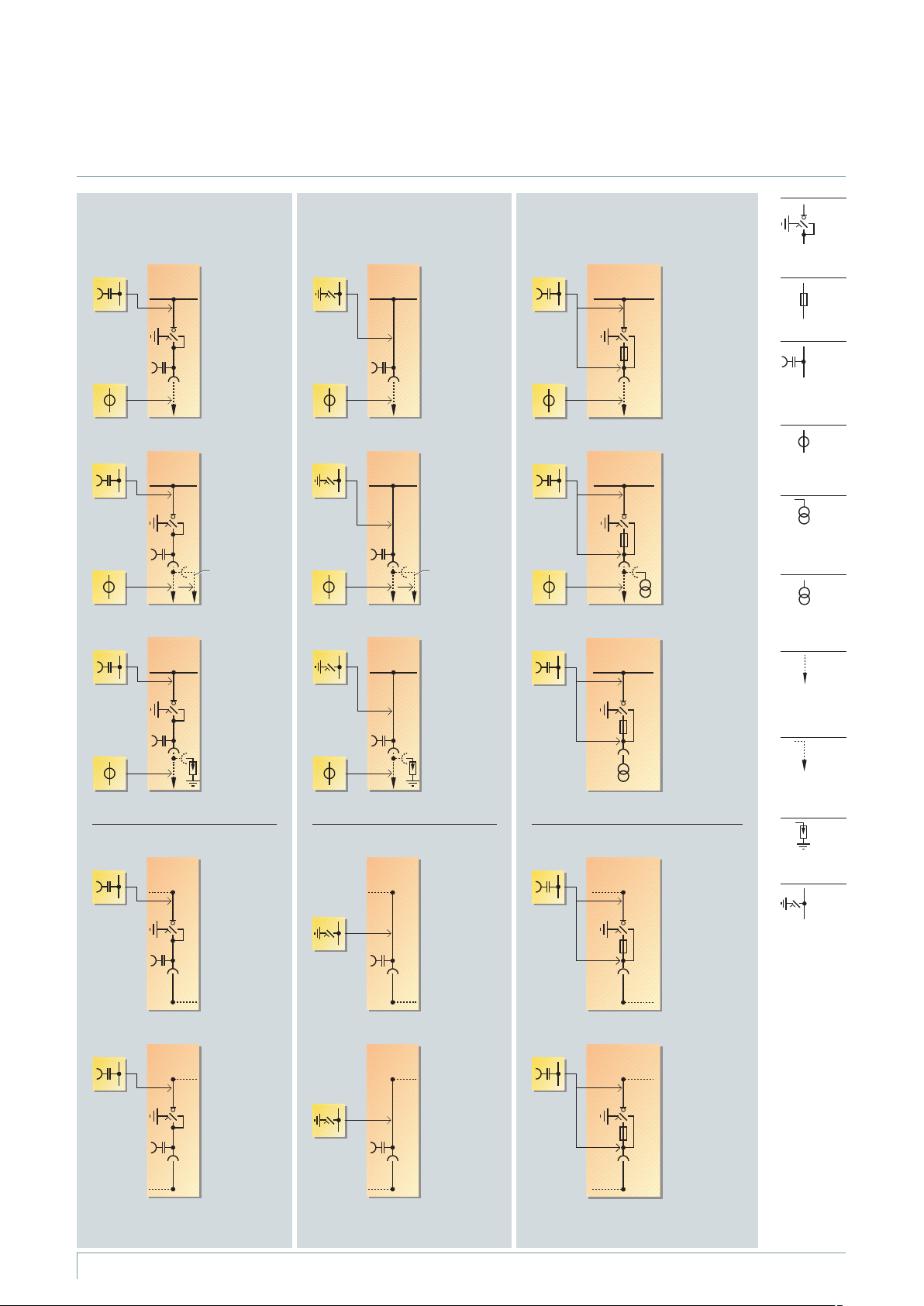

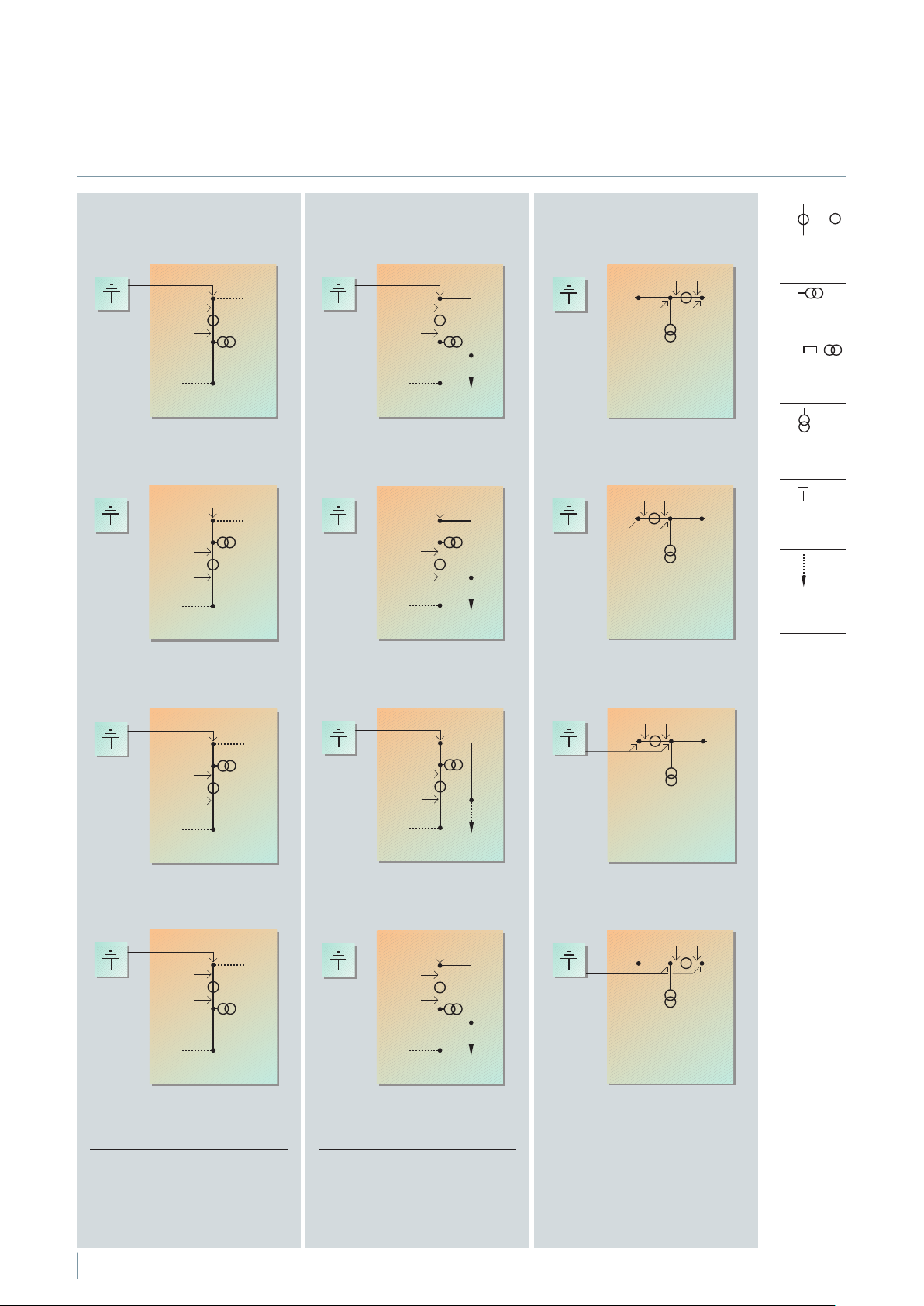

Ring-main, cable and transformer panels as individual panels

Ring-main panels

as feeder panels

option

option

option

option

option

option

Typ e R K

350 mm wide

1) 3)

Typ e R K1

500 mm wide

Option:

Typ e RK1 V

500 mm wide

Typ e R K *

350 mm wide

nd

for 2

cable*

Typ e R K *

350 mm wide

with plug-in

surge

arresters *

1) 2) 3)

Cable panels

as feeder panels

option

option

option

option

option

option

Typ e K

350 mm wide

Typ e K *

350 mm wide

nd

for 2

cable *

Typ e K *

350 mm wide

with plug-in

surge

arresters *

Transformer panels

as feeder panels

option

option

option

option

option

Typ e T R1

500 mm wide

Typ e T R1- V

500 mm wide

B

with plug-in

voltage trans

formers

Typ e T R-V

500 mm wide

-

B

(105 mm deeper

cable compartment cover)

with plug-in

voltage trans

formers instead of cable

connection

Three-position

switch-disconnector

HV HRC fuse

Capacitive

voltage detecting

system

Cable-type current

transformer

4MT8 plug-in voltage

transformer at the

cable connection

4MT8 plug-in voltage

transformer at the

connection

Cable (not

included in the

scope of supply)

2ndcable (not

included in the

scope of supply)

as transfer panels as transfer panels as transfer panels

option

Typ e R K-U

350 mm wide

for transfer

option

to the right

Option:

Typ e RK1- U

Typ e RK1V -U

500 mm wide

Typ e R K-U

350 mm wide

option

3)

2) 3)

for transfer

to the left

Option:

Typ e RK1- U

Typ e RK1V -U

500 mm wide

10

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

option

3)

2) 3)

Typ e K-U

350 mm wide

for transfer

to the right

Typ e K-U

350 mm wide

for transfer

to the left

option

option

Typ e T R1- U

500 mm wide

for transfer

to the right

Typ e T R1- U

500 mm wide

for transfer

to the left

Plug-in

surge arrester

Make-proof

HA41-2278e eps

earthing switch

Footnotes

seepage11

Page 11

HA41-2229_1c eps

HA41-2233_1c eps

HA41-2232_1d eps

HA41-2234_1c eps

HA41-2235_1e eps

HA41-2228_1d eps

HA41-2231_1c eps

HA41-2230_1c eps

Product Range

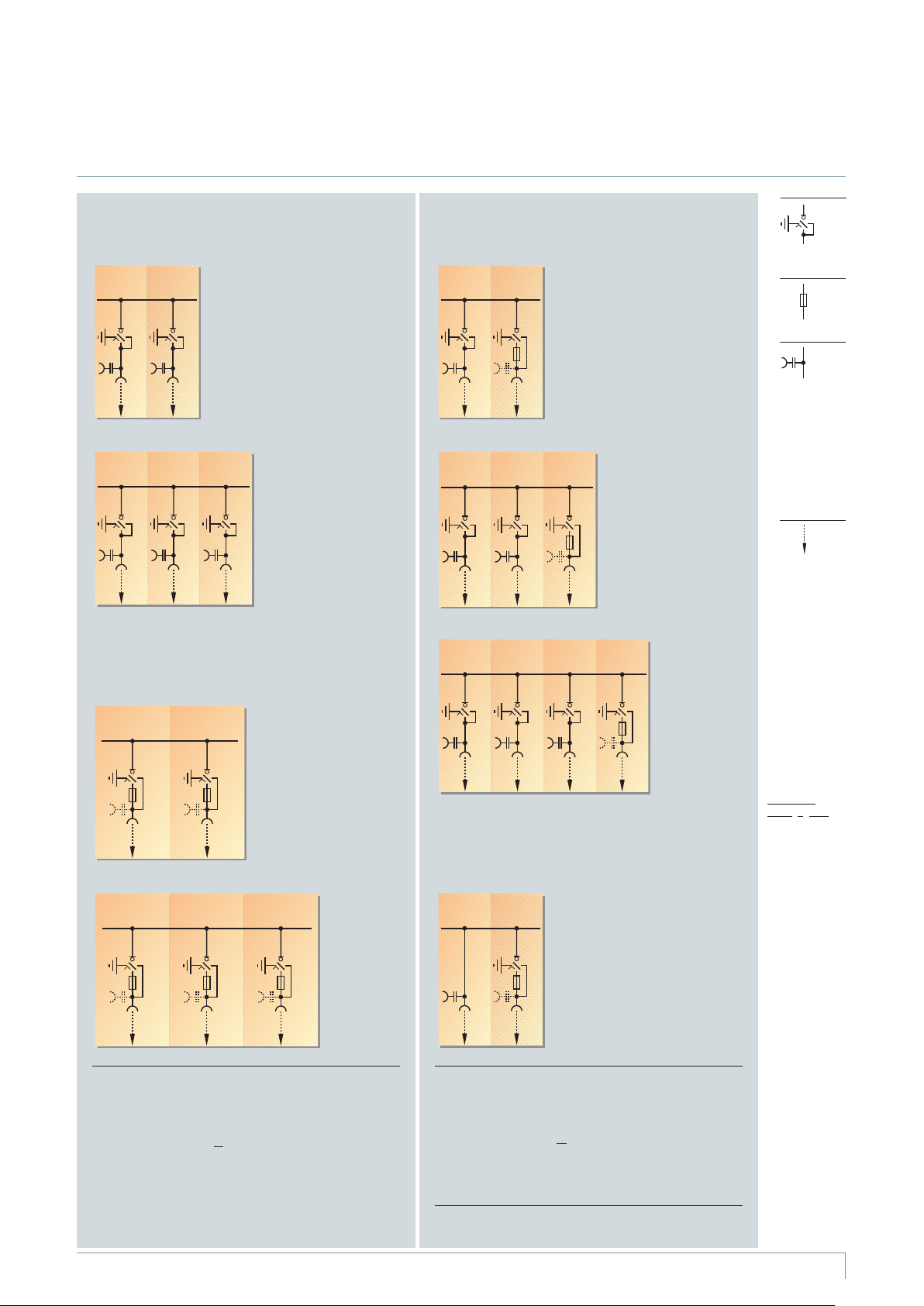

Ring-main, cable and transformer panels in panel blocks

BB

Ring-main panel blocks

Designs and options for each panel, see page 10

RK RK

RK

Typ e R -B2

700 mm wide

consisting of

2 ring-main panels

RK RK

Typ e R -B3

1050 mm wide

consisting of

3 ring-main panels

Transformer panel blocks

Designs and options for each panel, see page 10

TR TR

Typ e T- B2

1000 mm wide

consisting of

2 transformer panels

Ring-main/transformer panel blocks

Designs and options for each panel, see page 10

RK

RK

RK

c

TR

Typ e R T-B2

700 mm wide

consisting of

1 ring-main panel and

1 transformer panel

RK

RK RK

c

TR

Typ e 2 RT-B3

1050 mm wide

consisting of

2 ring-main panels and

1 transformer panel

c

TR

Typ e 3 RT-B4

1400 mm wide

consisting of

3 ring-main panels

and

1 transformer

panel

Three-position

switch-disconnector

HV HRC fuse

Capacitive

voltage detecting

system

BB Capacitive voltage

detecting system at

the busbar of the

panel blocks: Only

located once in the

first panelof the

block!

HA41-2278e eps

Cable (not

included in the

scope of supply)

TR

Designs

•

Busbar connection system for connection of individual

panels or panel blocks: Arranged in the left-hand panel of the

panel block (therefore extendable at a later date)

•

Only either the left-hand or the right-hand panel of the panel block

can be designed as a transfer panel with busbar connection

•

Panel blocks are also available without a busbar connection

system (extendable at a later date only via the cable feeder)

TR TR

Typ e T- B3

1500 mm wide

consisting of

3 transformer

panels

Cable connection/transformer panel block

Designs and options for each panel, see page 10

K

Designs

•

Busbar connection system for connection of individual

panels or panel blocks: Arranged in the left-hand panel of the

panel block (therefore extendable at a later date)

•

Only either the left-hand or the right-hand panel of the panel block

can be designed as a transfer panel with busbar connection

•

Panel blocks are also available without a busbar connection

system (extendable at a later date only via the cable feeder)

c

A plug-in voltage transformer cannot be provided at the connection

c

TR

Typ e K T-B 2

700 mm wide

consisting of

1 cable connection panel

1 transformer panel

Footnotes

from page 10

B Deep cable

compartment

cover required

* Depending on

the make/type of

the cable

plug or arrester:

Deep cable

compartment

cover required

** Cable-type

current transformer on the

nd

cable:

2

For 300 mm

deeper cable

compartment

cover

1) Suitable for

voltage

transformer

type 4MT8

2) Suitable for

voltage

transformer

type 4MT3

3) Suitable for

three-phase

current transformers

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

11

Page 12

HA41-2247_1d eps

1

)

HA41-2241_1d eps

1

)

HA41-2246_1d eps

1

)

HA41-2240_1d eps

1

)

HA41-2245_1d eps

1

)

2

)

HA41-2243 _1d eps

1

)

2

)

HA41-2239_1d eps

1

)

2

)

HA41-2237_1d eps

1

)

2

)

HA41-2244_1e eps

**

1

)

2

)

HA41-2242_1e eps

1

)

2

)

HA41-2238_1e eps

**

1

)

2

)

HA41-2236_1e eps

1

)

2

)

Product Range

2

)

1

)

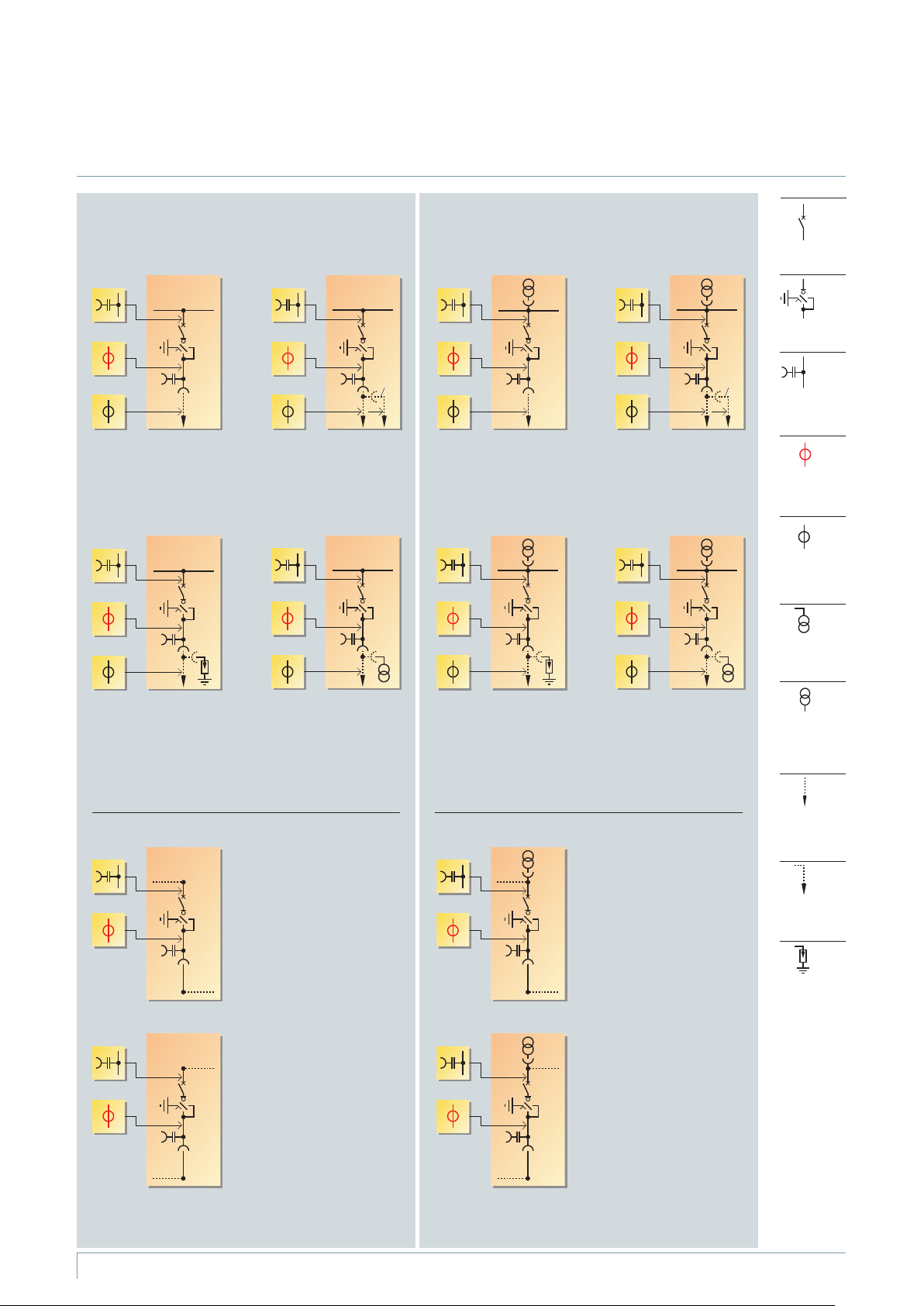

Circuit-breaker panels as individual panels

BB

Circuit-breaker panels

Circuit-breaker panels with plug-in

busbar voltage transformers

as feeder panels

option

option

option option option option

Typ e L S1

500 mm wide

Basic panel

option

option

option option

option

option

option

option

Typ e L S1

*

500 mm wide

nd

for 2

cable *

as feeder panels

option

option

Typ e L S 1V/LS2

500 mm wide

Basic panel

option

option

option option

option

option

option

option

Typ e L S2

*

500 mm wide

nd

for 2

cable *

Vacuum

circuit-breaker

Three-position

switch-disconnector

Capacitive

voltage detecting

system

4MC63... threephase current

transformer

Cable-type current

transformer

on the cable

4MT8 plug-in voltage

transformer at the

cable connection

Typ e L S1

500 mm wide

with plug-in

surge arresters or

limiters *

as transfer panels

option

option

option

option

*

Typ e L S1-U

500 mm wide

for transfer

to the right

Typ e L S1-U

500 mm wide

for transfer

to the left

B

Typ e L S1

500 mm wide

with plug-in

voltage trans

B

formers

Typ e L S 1V/LS2

500 mm wide

with plug-in

-

surge arresters

or limiters *

*

Typ e L S 1V/LS2

500 mm wide

with plug-in

voltage transformers

as transfer panels

option

Type LS1V-U/LS2-U

B

4MT3 plug-in

voltage

B

transformer

at the busbar

Cable (not

included in the

scope of supply)

500 mm wide

for transfer

option

to the right

nd

cable (not

2

included in the

scope of supply)

Plug-in

HA41-2278e eps

surge arrester

or limiter

option

Type LS1V-U/LS2-U

500 mm wide

for transfer

option

to the left

12

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Footnotes

seepage13

Page 13

HA41-2253_1c eps

HA41-2250_1c eps

HA41-2249_1e eps

HA41-2254_1c eps

HA41-2252_1b eps

HA41-2248_1c eps

Product Range

Bus sectionalizer with circuit-breaker , bus sectionalizer with switch-disconnector,

busbar earthing panels and busbar voltage metering panel as individual panels

BB

Bus sectionalizer

with circuit-breaker

option

option

Typ e L K/ LT 1

500 mm wide

with vacuum

circuit-breaker

option

option

Busbar earthing

panels

Typ e S E

350 mm wide

Busbar voltage metering

panel

Typ e M S 1V / ME 3

500 mm wide

Vacuum

circuit-breaker

Three-position

switch-disconnector

Capacitive

voltage detecting system

Cable-type

current trans

former on the

screened busbar

Make-proof

earthing switch

4MT8 plug-in

voltage

transformer

at the connection

-

Typ e L K V/LT1- V

500 mm wide

with vacuum

circuit-breaker and

plug-in voltage

transformers

Bus sectionalizer

with switch-disconn e ctor

option

option

Typ e LT 2

500 mm wide

Typ e S E1 V/ SE2

500 mm wide

with plug-in

voltage

transformers

4MT3 plug-in

HA41-2278e eps

voltage

transformer

at the busbar

Footnotes from

page 12 and 13

B Deep cable

compartment

cover required

BB Short identi-

fications of the

panels have

been harmonized

* Depending on

the make/type of

the cable

plug or arrester:

Deep cable

compartment

cover required

** Cable-type

current transformer on the

nd

cable:

2

For 300 mm

deeper cable

compartment

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

13

Page 14

HA41-2259_1c eps

P2

P1

1

)

HA41-2258_1c eps

P2

P1

1

)

HA41-2262_1b eps

P2

P1

HA41-2260_1c eps

P1

P2

1

)

HA41-2261_1c eps

P1

P2

1

)

HA41-2263_1b eps

P2

P1

HA41-2264_1b eps

P1

P2

HA41-2265_1b eps

P1

P2

HA41-2267_1c eps

P2

P1

HA41-2266_1c eps

P2

P1

HA41-2436_1a eps

P1

P2

HA41-2437_1a eps

P1

P2

Product Range

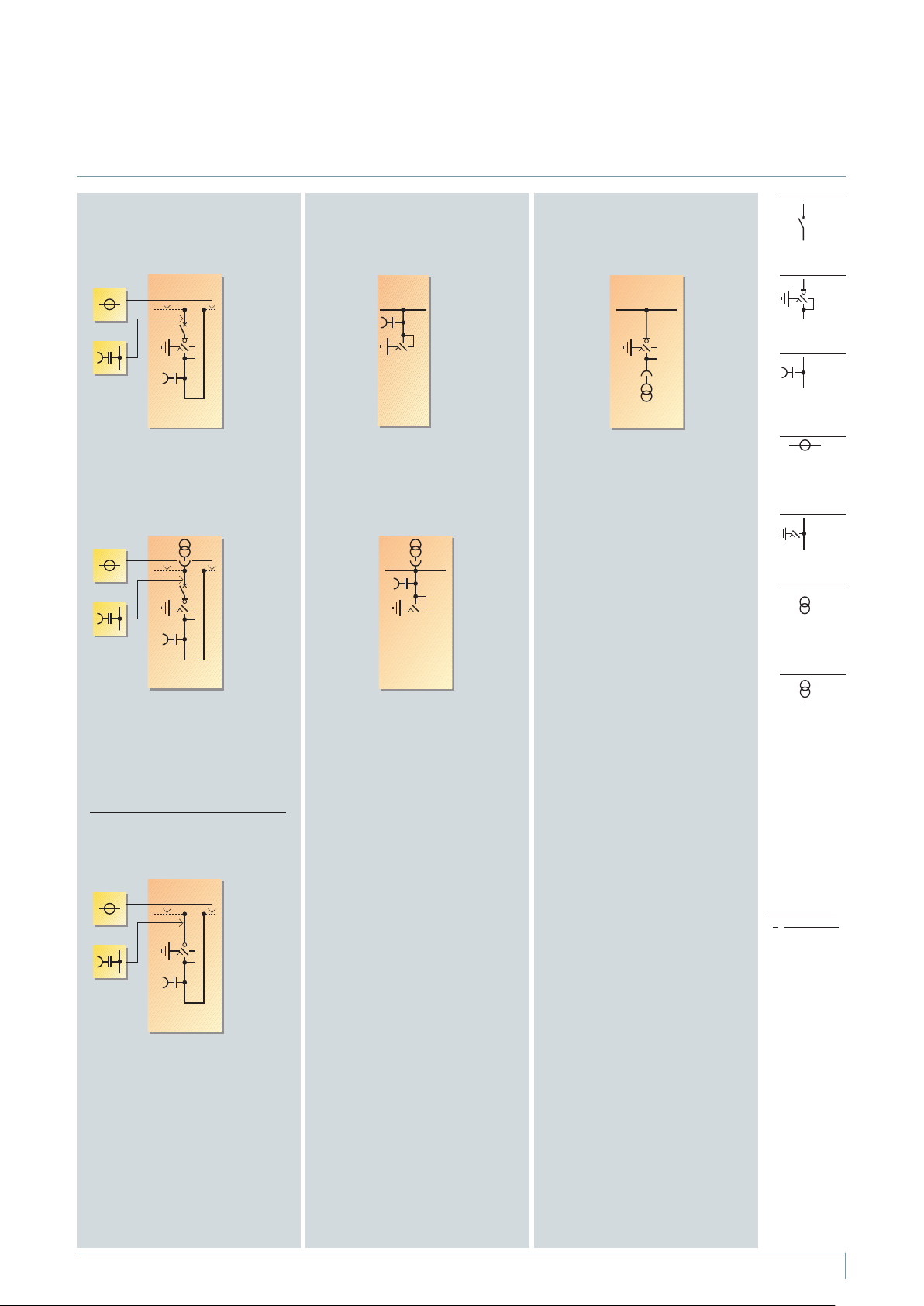

Air-insulated metering panels as transfer panels

Billing metering panels

(standard)

option

Scheme 1

Typ e M E1, 850 mm wide

for transfer to the right

option

Scheme 2

Typ e M E1, 850 mm wide

for transfer to the right,

transformer terminals

interchanged

option

Billing metering panels as end

panels, for cable connection

option

Scheme 1

Typ e M E1- K, 850 mm wide

for transfer to the right

option

Scheme 2

Typ e M E1- K, 850 mm wide

for transfer to the right,

transformer terminals

interchanged

option

Billing metering panels for

busbar connection

option

Scheme 1

Typ e M E1- S, 850 mm wide

forbusbarmetering

option

Scheme 2

Typ e M E1- S, 850 mm wide

forbusbarmetering,

transformer terminals

interchanged

option

Current transformer, cast-resin

insulated

1

)

Voltage transformer,

cast-resin insulated

or on request:

Voltage transformer,

cast-resin insulated,

with HV HRC fuse

Voltage transformer, cast-resin

insulated

Fixed earthing

points for busbar

earthing

Cable (not

HA41-2278d eps

included in the

scope of supply)

P1 and P2

are terminal

designations

of the current

transformer

Scheme 3

Typ e M E1, 850 mm wide

for transfer to the right

option

option

Scheme 4

Typ e M E1, 850 mm wide

for transfer to the right,

transformer terminals

interchanged

Note

Schemes 1 to 4 also feasible

for transfer to the left

14

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Note

Schemes 1 to 4 also feasible

for transfer to the left

Scheme 3

Typ e M E1- K, 850 mm wide

for transfer to the right

Scheme 4

Typ e M E1- K, 850 mm wide

for transfer to the right,

transformer terminals

interchanged

Scheme 3

Typ e M E1- S, 850 mm wide

for busbar metering,

transformer terminals

interchanged

option

Scheme 4

Typ e M E1- S, 850 mm wide

for busbar metering,

transformer terminals

interchanged

Page 15

HA41-2268_1e eps

P2

P1

1

)

HA41-2269_1e eps

P2

P1

1

)

HA41-2270_1e eps

P1

P2

1

)

HA41-2271_1e eps

P1

P2

1

)

Product Range

HA41-2277_1d eps

2

)

3

)

P2

P1

HA41-2276_1d eps

P2

P1

2

)

3

)

HA41-2439_1b eps

P1

P2

2

)

3

)

HA41-2438_1b eps

P1

P2

2

)

3

)

HA41-2473a eps

P2

P1

1

)

HA41-2474a eps

P2

P1

1

)

HA41-2475a eps

P1

P2

1

)

HA41-2476a eps

P1

P2

1

)

3

)

Air-insulated metering panels as transfer panels

Billing metering panels as end

panels, for cable connection

option

Scheme 1

Typ e M E1- KS , 850 mm wide

for transfer to the right

option

Scheme 2

Typ e M E1- KS , 850 mm wide

for transfer to the right,

transformer terminals

interchanged

option

Billing metering panels

as individual panels, for cable

connection

option

Scheme 1

Type ME1-KK, 850 mm wide

for cable connection

option

Scheme 2

Type ME1-KK, 850 mm wide

for cable connection,

transformer terminals

interchanged

option

Billing metering panels *

with metal-enclosed

combined transformers

Scheme 1

Typ e M E2, 600 mm wide

for transfer to the right

Scheme 2

Typ e M E2, 600 mm wide

for transfer to the right,

transformer terminals

interchanged

Current transformer, cast-resin

insulated

1

)

Voltage transformer,

cast-resin insulated

or on request:

Voltage transformer,

cast-resin insulated,

with HV HRC fuses

4MK plug-in

combined current

transformer,

metal-enclosed

4MK plug-in

combined voltage

transformer,

metal-enclosed

Fixed earthing

points for busbar

earthing

HA41-2278e eps

Cable (not

included in the

scope of supply)

option

Note

Schemes 1 to 4 also feasible

as left-hand end panel

for transfer to the left

Scheme 3

Typ e M E1- KS , 850 mm wide

for transfer to the right

Scheme 4

Typ e M E1- KS , 850 mm wide

for transfer to the right,

transformer terminals

interchanged

option

Scheme 3

Type ME1-KK, 850 mm wide

for cable connection

Scheme 4

Type ME1-KK, 850 mm wide

for cable connection,

transformer terminals

interchanged

Scheme 3

Typ e M E2, 600 mm wide

for transfer to the left

Scheme 4

Typ e M E2, 600 mm wide

for transfer to the left,

transformer terminals

interchanged

* Mainly for connection to

bus sectionalizer with switch-disconnector

LT1, LT1 -V an d LT 2

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

P1 and P2

are terminal

designations

of the current

transformer

15

Page 16

HA41-2279e eps

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2

24

15

25

26

27

28

29

61

62

HA41-2280d eps

1

3

38

5

6

7

9

10

11

12

13

14

15

16

17

18

19

20

21

22

33

32

31

34

23

35

15

36

37

27

28

29

61

62

HA41-2281e eps

1

2

11

39

6

7

41

40

42

39

2

22

61

62

30

62

62

Design

Panel design (examples)

Ring-main panel Section Transformer panel Section

Type RK Type TR

Billing metering panel, air-insulated Section

16

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Type ME1

Legend for pages 16 and 17

1 O

ption: Low-voltage compartment

2 Niche for customer-side low-voltage equipment,

with hinged cover

3 Switch-position indicator for load-break

function “CLOSED – OPEN”

4 Switch-position indicator for earthing

function “OPEN – EARTHED”

5 Ready-for-service indicator

6 Rating and type plate

7 Mimic diagram

8 O

ption: Short-circuit / earth-fault indicator

9 Sockets for voltage detecting system

10 Arrangement of the busbars

11 Feeder designation label

12 O

ption: Locking device for three-position

switch-disconnector

13 Manual operation for the mechanism of

the earthing function

14 Manual operation for the mechanism of

the load-break function

15 Interlock of the cable compartment cover

16 Arrangement of the cable connections

17 Busbar system

18 Switchgear vessel filled with gas

19 Busbar connection

20 Pressure relief device

Page 17

HA41-2282e eps

51

52

12, 53

13

3

4

7

14

23

16

17

18

19

20

21

22

43

44

45

46

47

48

49

50

11

5

6

8

9

15

10

46

24

15

25

26

54

27

28

29

55

61

63

62

HA41-2283c eps

58

59

60

57

56

61

Circuit-breaker panel Section

Type LS1 (without voltage transformers)

Type LS2-V (with voltage transformers)

Design

Panel design (examples)

21 Partition for busbar

22 Earthing busbar with earthing connection

23 Three-position switch-disconnector

24 Spring-operated mechanism

25 Bushing for cable plug with bolted contact (M16)

26 O

ption: Cable T-plug

27 Cable compartment cover

28 Cable compartment

29 Cable bracket

30 Earthing connection for earthing accessories

31 HV HRC fuse assembly, cover removed

32 Handle for replacing HV HRC fuse links

33 Interlock for HV HRC fuse assembly

34 Cover of the HV HRC fuse compartment

35 Spring-operate d / stored-energy mechanism

36 Bushing for cable plug with plug-in contact

37 Cable elbow plug with plug-in contact

38 Switch-position indicator for load-break function

“CLOSED – OPEN” and, if applicable,

“HV HRC fuse tripped” or “shunt release tripped”

39 Cover for access to the busbar connection and to

the instrument transformers, screwed on

40 4MR voltage transformer

41 4MA7 current transformer

42 Covertobusbarconnection

compartment, scre wed on

43 O

ption: SIPROTEC bay control unit

44 Low-voltage compartment (standard)

Vacuum circuit-breaker:

45 Opening for the hand crank

– for closing with manual operating mechanism

– for emergency operation with motor operating

mechanism

46 Operating mechanism box

47 Mechanical “ON” pushbutton (not supplied with

spring-operated mechanism)

48 Mechanical “OFF” pushbutton

49 Operating cycle counte r

50 “Spring charged” indicator

51 Vacuum interrupter

52 Switch-position indicat or

53 O

ption: Interlock between vacuum circuit-breaker

and three-position switch-disconnector

ption: Three-phase current transformer

54 O

(protection transformer)

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

55 Cable-type current transformer

56 4MT3 plug-in voltage transformer at the busbar

57 Bushing for connection of plug-in voltage transformers

58 Plug-in connection according to EN 50 181 /

DINEN50181asinterfacetype“A”

59 O

ption: 4MT8 plug-in voltage transformer at the connection

60 Deep cable compartment cover

61 Wiring duct, removable, for control cables and/or bus wires

62 Cover screwed on

63 O

ption: Interlock be tween three-position

switch-disconnector and circuit-breaker

17

Page 18

Components

3AH vacuum circuit-breaker

Features

According to IEC 62271/

•

VDE 0671-100

(standards see page 41)

Application of all 8DH10

•

switchgear in hermetically

sealed vessel in conformity

with the system

Climate-independent vacuum

•

interrupter poles in the

gas-filled switchgear vessel

Maintenance-free for indoor

•

installation according to

IEC 62271-1/ VDE 0671-1

(standards see page 41)

Individual secondary equipment

•

A metal bellows is used for

•

gasketless separation of the

-insulation and the operat-

SF

6

ing mechanism – as already

used with success for over

100,000 vacuum interrupters

Switching duties and

operating mechanisms

The switching duties of the

vacuum circuit-breaker are dependent, among other factors, on

its type of operating mechanism.

Three operating mechanism versions are available:

•

Motor operating stored-energy

mechanism

– For auto-reclosing (K),

– For synchronization and

rapid load transfer (U)

•

Manual operating stored-

energy mechanism

– For auto-reclosing (K)

•

Manual spring-operated me-

chanism (= spring CLOSED,

stored-energy OPEN)

for auto-reclosing (K)

–Not

– For normal closing and

– For storage of one

opening

operation

Further o

perating mechanism

features

•

Located outside the switch-

Operating mechanism

functions

Motor operating mechanism

(M1 *)

Inthecaseofthemotoroperating mechanism, the closing

spring is charged by means of

a motor and latched in the

charged position (the “spring

charged” indication is visible).

Closing is effected either by

means of an ON pushbutton or

a closing solenoid. The closing

spring is recharged automati

cally (for auto-reclosing).

Manual operatin

gstored-

energy mechanism

The closing spring is charged

by means of the hand crank sup

plied until latching of the closing

latch is indicated

(= “spring charged” indication).

Subsequently the vacuum

circuit-breaker can be closed

either manually or electrically

and the closing spring can be

recharged manually. The “possibility to close” is thus stored

once more (for auto-reclosing).

Manual s

pring-operated

mechanism

(= spring CLOSED, stored-energy

OPEN)

The closing spring of the vacuum

circuit-breaker is charged by

means of the hand crank supplied until the vacuum circuitbreaker closes. Subsequently

either manual or electrical open

ing is possible.

Vacuum circuit-breakers with

spring-operated mechanism are

not suitable for auto-reclosing.

Trip-free mechanism

The vacuum circuit-breaker

is fitted with a trip-free

mechanism.

gear vessel in the operating

mechanism box and behind

the control board

•

Stored-energy spring

mechanism for 10,000

operating cycles

Abbreviations for switching

duties and applications:

U = Synchr onization and

rapidloadtransfer

(make time £ 90 ms)

K=Auto-reclosing

O = OPEN operation

For further technical data and description of typical applications,

please refer also to Catalog HG 11.11 “3AH Vacuum Circuit-Breakers”

1) Motor rating at

24 V to 220 V DC: 350 W

110 V and 230 V AC: 400 VA

2) With closing solenoid

* Item designation

CO = CLOSE operation with subsequent

OPEN operation at the short est

internal close-open time of the

vacuum circuit-breaker

t = Dead time 0.3 s

t ‘ = Dead time 3 min

1)

1

2

3

4

5

6

7

8

10

11

13

-

15

-

s

p

e

6

1

0

1

4

A

H

R

Operating mechanism of the vacuum circuit-breaker

(forthelegend,seepage19)

Differentiation features between the vacuum circuit-breakers

depending on the operating mechanism version

Operating

mechanism

version

Typical uses Utility

-

Mechanism

function

Mechanism

operation

Closing the

vacuum

circuit-breaker

Closing

solenoid, e.g.

for remote

electrical

closing

Rated

operating

sequence

Autoreclosing (K)

Motor operating

stored-energy

mechanism

substations

and industrial

plants

Stored-energy

CLOSED,

stored-energy

OPEN

1)

With motor

manual (emergency) operation at the panel

including antipumping

Electrically

mechanically at

the panel with

pushbutton

Always provided, with electrical signal

“closing spring

charged”

O-t-CO

or

O-t-CO-t’-CO

Suitable (multiple auto-reclosing possible)

,

2)

or

Manual

operating

stored-energy

mechanism

Classic transfer

substations and

substations

without auxiliary

voltage supply

Stored-energy

CLOSED,

stored-energy

OPEN

With hand

crank

Mechanically

at the panel

with pushbutton, option:

electrically

Option Without

O-t-CO O or CO

Suitable (only

with closing

solenoid)

Manual springoperated

mechanism

Simple utility

substations

(circuit-breaker

employed as

transformer

switch)

Spring

CLOSED,

stored-energy

OPEN

With hand

crank

Mechanically

at the panel

with hand

crank (charging

2)

process)

–

18

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Page 19

HA41-2296b eps

9

1

3

11

17

13

5

HA41-2297a eps

8

1

2

3

4

5

6

7

10

11

12

13

14

15

16

Components

Secondary equipment of the 3AH vacuum circuit-breaker

Thescopeofthe3AHvacuum

circuit-brea ker secondary equipment depends on the type of application and offers a wide range of

options, thus allowing even the

highest requirements to be satis

fied.

Closing solenoid

Typ e 3 AY15 10 (Y9 *)

•

For electrical closing

•

Shunt releases

Typ es:

•

–Standard:3AY1510(Y1*)

ption: 3AX1101(Y2*),

–O

with energy store

Tripping by protection device or

•

electrical operation

Current-transformer

operated release

Type3AX1104(Y6*)fortrip-

•

ping pulse W 0.1 Ws in conjunction with suitable protection systems, e.g. 7SJ4 protection system, 4MC6.. transformer

protection system, SEG relay

(other designs on request)

•

Used where no external

auxiliary voltage is available,

tripping by protection device

Undervoltage release

•

Type3AX1103(Y7*)

•

Comprising:

– Energy store and unlatching

mechanism

– Electromagnetic system which is

permanently connected to voltage

while the vacuum circuit-breaker

is closed; tripping is initiated

when this voltage drops

•

Connection to voltage trans

formers possible

Anti-pumping (standard)

(mechanical and electrical)

•

Function: If constant CLOSE and

OPEN commands are present at

the vacuum circuit-breaker at

thesametime,thevacuumcir

cuit-breaker will return to the

open position after closing. It

remains in this position until a

new CLOSE command is given.

In this manner, continuous clos

ing and opening (= pumping) is

avoided.

1) For utilization

by the

customer

For further technical data and description of typical applications,

please refer also to Catalog HG 11.11 “3AH Vacuum Circuit-Breakers”

*Item

designation

Circuit-breaker tripping signal

(standard)

For electrical signalling (as pulse

•

>10ms),e.g.toremotecontrol

systems, in the case of automatic

tripping (e.g. protection)

Via limit switch (S6 *) and

•

cut-out switch (S7 *)

Varistor module

To limit overvoltages to approx.

•

500 V for protection devices

(when inductive devices are

mounted in the vacuum circuitbreaker)

For auxiliary voltages W 60 V DC

•

Auxiliary switch

Typ e 3SV 9 (S1 *)

•

Standard: 6 NO+6 NC, of which

•

2NO+2NC+2changeover

contacts are free

Option: 12 NO+12 NC, of which

•

7NO+4NC+2changeover

contacts are free

Position switch

• Type 3SE4 (S4 *)

•

For signalling “closing spring

charged”

•

Only in conjunction with storedenergy mechanisms

Mechanical interlocking

•

Dependent on the type of

operating mechanism

•

Option: Switchgear interlocking

with the three-position switchdisconnector (option: Closing

lock-out for the three-position

switch-disconnector in circuit-

-

breaker panels type LS and LT1)

•

Option: Operating mechanism

with mechanical interlocking as

– Spring-operated mechanism:

Hand crank opening is blocked

– Stored-energy mechanism with

closing solenoid (Y9 *) and

pushbutton (S12 *): The pushbutton (S12 *) operated by the

-

mechanical interlock prevents a

continuous command to the

closing solenoid

•

During operation of the threeposition switch-disconnector

from CLOSED to OPEN:

Vacuum circuit-breaker

cannot be closed.

Abbreviations:

NO = normally-open contact

NC = normally-closed contact

1)

1)

Basic equipment with manual spring-operated mechanism

Maximum equipment with motor operating stored-energy mechanism

Secondary equipment (view into the operating mechanism box)

1 Gear

2 Position switch (S4

3 Closing spring

4 Mot or (M1

5 Operating cycle counter

6 “Closing spring charged”indica tor

7 Closing solenoid (Y9

8 O

ption: Auxiliary switch

12 NO+12 NC

9 Auxiliary switch

6NO+6NC(S1*)

10 Circuit-breaker “CLOSED”

*)

*)

*)

11 Circuit-breaker “OPEN”

12 O

ption: 2ndrelease

st

13 1

release (Y1 *)

14 O

ption: Mechanical interlocking with interrogation

of the three-position

switch-disconnector

15 Operating rod with contact

pressure springs

16 Interlocking to the three-

position switch-disconnector

17 Actuation for closing the

vacuum circuit-breaker

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

19

Page 20

HA41-2288a eps

321456

Components

Three-position switch-disconnector

Features

Switch positions: CLOSED –

•

OPEN – EARTHED

Switching functions as

•

general-purpose switchdisconnector (class E3)

according to

– IEC 60265-1/ VDE 0670-301

– IEC 62271-102/ VDE 0671-102

(standards see page 41)

Designed as a multi-chamber

•

switch with the functions

– Switch-disconnector

proof earthingswitch

–Make-

Operation via gas-tight welded-in

•

and

metal bellows at the fr ont of the

switchgear vessel

s

p

e

2

1

0

1

4

A

H

R

Three-position switch-disconnector

SF

insulation

6

Detachable lev e r mech anis m

with three-position switch-disconnector

1 Three-position switch-disconnector

2 Coupling linkage

3 Switchgear vessel

4 Operating mechanism rocker

5 Detachable lever mechanism

6 Operating lever inserted

EARTHED

OPEN

CLOSED

Switch positions

For further details, please refer to

Catalog HA 40.1 “Switchgear

Types 8DJ and 8DH for Secondary

Distribution Systems up to 24 kV,

Gas-Insulated (General Part)”

20

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

Page 21

Features

HA41-2289b eps

1

2

3

4

5

6

7

10

8

9

Safe-to-touch as a result of

•

use of metal covers

Plug-in type

•

Consisting of round-bar

•

copper , insulated by means of

silicone rubber

Busbar joints with cross and

•

end adapters, insulated by

means of silicone rubber

Insensitive to pollution and

•

condensation

Switchgear extension or

•

panel replacement is possi-

ble without

Special busbar connections

•

gas work

to metering panels type ME1

are possible. Connection to

the

– Cable connection bushings

of the adjacent panel

or to the

– Busbar bushings

Busbar arrangement in panel

•

blocks within the switchgear

vessel filled with gas

Option screened busbar:

•

– Field control by means of

electrically conductive layers

on the silicone-rubber

insulation

– Installation of 4MC70 32

current transformers is thus

possible

– Independent of the site

altitude

•

Option: Capacitive voltage

detecting system for the

busbar, refer also to the

product range, pages 10

to 15

s

p

e

a

7

1

0

1

4

A

H

R

2

3

7

Busbar compartments over 2 panels

with busbar connections, busbar covers removed

Top v iew

Insulated plug-in type busbar

unscreened design

Components

Busbars

8

ystem

Busbar s

1 End adapter

2 Cros s adapter

3 Busbar insulation of silicone rubber

4 Threade d bolt M12 / M16

5 Busbar , Cu, diameter 32 mm

6 S t oppe r

Switch

gear vessel

7 Primary enclosure panel 1

8 Primary enclosure panel 2

9 Bushing

10 Capacitive tap at the bushings,

earthed (standard)

Switchgear Type 8DH10, up to 24 kV, Gas-Insulated, Extendable Siemens HA 41.11 2008

21

Page 22

HA41-2290b eps

1

2

Components

4MT3 * and 4MT8 * plug-in voltage transformers for panel types LS, TR, SE and ME3

Panel section

type LS2-V

* for the busbar

1 4MT3

* at the cable connection

2 4MT8

Common features

According to IEC 60044-2/ VDE 0414-2

•

• Designed as single-pole voltage trans-

formers, plug-in type

•

Inductive type

•

Climate-independent

•

Secondary connection by means of

plugs inside the panel

•

Connection with plug-in contact

•

Installation behind metallic cover

Features type 4MT3

•

Inside-cone system, metal-coated

Features type 4MT8

•

Outside-cone system, metal-enclosed

•

For deep cable compartment cover

Installation

•