siemens 880 User Manual

SINUMERIK 840/840C

SINUMERIK 850

SINUMERIK 880/880 GA2

Measuring Cycles Version 20 and higher

Start-up Guide 08.96 Edition

Service Documentation

SINUMERIK 840/840C

SINUMERIK

850

SINUMERIK

880/880 GA2

Measuring Cycles

Version 20 and higher

Start-up Guide

Service Documentation

Valid for:

Control Software Version

SINUMERIK 840 from SW 01

SINUMERIK 840C from SW 01

SINUMERIK 850 from SW 04

SINUMERIK 880 from SW 04

SINUMERIK 880 GA2 from SW 01

08.96 Edition

SINUMERIK® documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the "Remarks" column.

Status code in ”Remarks” column:

A . . . New documentation

B . . . Unrevised reprint with new Order No.

C . . . Revised edition with new status.

If factual changes have been made on a page since the last edition, this is indicated by

a new edition coding in the header on that page.

Edition Order No. Remarks

07.90 6ZB5 410-0EM02-0AA0 A

10.91 6ZB5 410-0EM02-0AA1 C

01.93 6FC5 197-0AB60-0BP0 C

08.96 6FC5 197-0AB60-0BP1 C

Siemens quality for software and training

to DIN ISO 9001, Reg. No. 2160-01

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

This publication was produced on the Siemens 5800 Office

System.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

We have checked that the contents of this publication agree with the

hardware and software described herein. The information given in this

publication is reviewed at regular intervals and any corrections that might

be necessary are made in the subsequent printings. Suggestions for

improvement are welcome at all times.

Subject to change without prior notice.

© Siemens AG 1990, 1991, 1993,1996 All Rights Reserved

Order No. 6FC5 197-0AB60-0BP1

Printed in the Federal Republic of Germany

Preliminary Remarks

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

Technical Comments

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

The symbol shown on the left appears in this

documentation whenever the machine tool manufacturer

has the possibility of influencing/modifying the functional

behaviour described by changing a cycle machine data

(MDC).

Since the cycle machine data range and the cycle setting data range can be set up in different

ways, the relevant data in the examples are explained on the basis of the standard settings.

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

SINUMERIK 850/880 control as from Software Version 4,

SINUMERIK 880 GA2 as from Software Version 1,

SINUMERIK 840 as from Software Version 1,

SINUMERIK 840C as from Software Version 1,

This User's Guide applies to:

measuring cycles as from version 20!

General Preconditions 1

Hardware 2

Functional Test 3

Machine Data for Measuring Cycles 4

Setting Data for Measuring Cycles 5

Auxiliary Cycles for Start-up 6

Start-up Flowchart 7

User Memory Submodule (UMS) 8

Tool and Workpiece Measurement in

JOG Mode (SINUMERIK 880)

Workpiece Measurement in JOG Mode

(SINUMERIK 840 SW2)

Lists 11

Alarms 12

9

10

Abbreviations 13

Contents

Page

1 General Preconditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1 Notes to ensure smooth running of the measuring cycles . . . . . . . . . . . 1–2

2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1 Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1.1 Multidirectional probe (3D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.1.2 Bidirectional probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.1.3 Monodirectional probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.2 Jumpering/connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

3 Functional Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.1 Service display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.2 Test program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

4 Machine Data for Measuring Cycles . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1 Cycle machine data memory (MDC) . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.1 Channel-oriented values, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.2 Channel-oriented bits, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.3 Central values, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.1.4 Central bits, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.2 NC machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

4.2.1 MD 18 Zero offset group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

4.2.2 MD 19 P number (SINUMERIK 850 only) . . . . . . . . . . . . . . . . . . . . . . 4–3

4.2.3 MD 157 Type/software version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.4 MD 208/209 Max. tool wear (parameters P5/P6/P7) . . . . . . . . . . . . . . . 4–4

4.2.5 NC transverse axis bits MD 5011 and MD 572* . . . . . . . . . . . . . . . . . . 4–5

4.2.6 PLC machine data 6026 bit 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

4.3 Channel-oriented values, description . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

4.4 Channel-oriented bits, description . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

4.5 Central values, description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–17

4.5.1 Tool probe (m1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

4.5.2 Workpiece probe (m2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

4.5.3 Calibration element (m3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–26

4.5.4 Tool change position (m4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–31

4.5.5 Reversal dimension (m5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–33

4.6 Central bits, description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–34

5 Setting Data for Measuring Cycles . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1 Cycle setting data memory (SDZ) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.1 Channel-oriented values, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.1.2 Channel-oriented bits, overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.2 Channel-oriented values, description . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

5.3 Channel-oriented bits, description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

6 Auxiliary Cycles for Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6.1 Auxiliary cycle L898 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

7 Start-up Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

8 User Memory Submodule (UMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

8.1 Measuring cycle overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

8.2 Result displays, alarm texts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

8.2.1 Result displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

8.2.2 Include result displays and alarm list in UMS . . . . . . . . . . . . . . . . . . . . 8–6

8.3 Input displays for measuring cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

8.3.1 Input displays for cycle package 3 (measuring cycles for turning machines) 8–7

8.3.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

8.3.1.2 Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–7

8.3.1.3 Outline and branching displays package 3 . . . . . . . . . . . . . . . . . . . . . . 8–8

8.3.2 Input displays for cycle package 4

(measuring cycles for milling machines and machining centres) . . . . . . 8–9

8.3.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

8.3.2.2 Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

8.3.2.3 Outline and branching package 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

9 Tool and Workpiece Measurement in JOG Mode (SINUMERIK 880) 9–1

9.1 General conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

9.2 Necessary machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

10 Workpiece Measurement in JOG Mode (SINUMERIK 840 SW2) . . . . 10–1

10.1 General conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–1

10.2 User Memory Submodule (UMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–2

10.2.1 Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–2

10.2.2 Link lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–2

10.3 FX 34: Measuring for SINUMERIK 840M . . . . . . . . . . . . . . . . . . . . . . . 10–3

10.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

10.3.2 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

10.3.3 Block call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–4

10.3.4 Signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–4

10.3.5 Programming example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

10.3.6 Block data list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

11 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

11.1 Cycle machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

11.1.1 Channel-oriented values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

11.1.2 Channel-oriented bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–2

11.1.3 Central values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

11.1.4 Central bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

11.2 Cycle setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

11.2.1 Channel-oriented values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

11.2.2 Channel-oriented bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–7

12 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–1

12.1 Alarm overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–1

12.2 Measuring cycle alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12–4

13 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13–1

01.93 1 General Preconditions

1 General Preconditions

Option: B78

Software versions: For measuring cycles Version 20 and higher, the following software

versions are required:

SINUMERIK 840 software version 1 and higher

SINUMERIK 840C software version 1 and higher

SINUMERIK 850 software version 4 and higher

SINUMERIK 880 software version 4 and higher

SINUMERIK 880 GA2 software version 1 and higher

PLC program: No PLC program is required for the measuring cycle function. The

measuring function is activated in the cycles by means of command

@720....

FB 116 (850) or FB 121 (840/880) is required when using the function

package "Tool management".

Axis arrangement: For proper operation of measuring cycles it is necessary for the machine

axes to be arranged in accordance with DIN 66217.

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 1–1

©

SINUMERIK 840/850/880 (IA)

1 General Preconditions 08.96

1.1 Notes to ensure smooth running of the measuring cycles

1.1 Notes to ensure smooth running of the measuring cycles

1. To ensure that the measuring cycles operate correctly it is imperative that the machine

axes are set up according to DIN 66217.

2. Reference point approach must already have been performed.

3. GRC/CRC, (coordinate rotation) and scale modification must be deselected before a

measuring cycle is called.

4. Inch/metric switchover.

Measurements must be performed in the input system defined in MD 5002 bit 4, i.e.

switchover with G70/G71 is not permitted.

5. Before the cycles are called, the axes must be positioned in such a way that they do not

change direction when they move from the current position to approach the set position.

Nor must the tool collide with the sensor or the workpiece probe collide with other machine

parts when approaching the starting position with linear interpolation.

6. The parameters of the individual cycles must be defined before the cycles are called.

7. The cycles are automatically skipped in operating modes "Block search", "Dry run" and

simulation.

8. All cycles can be exited with the following initial settings:

T version G01, G90, G95

M version G01, G90, G94

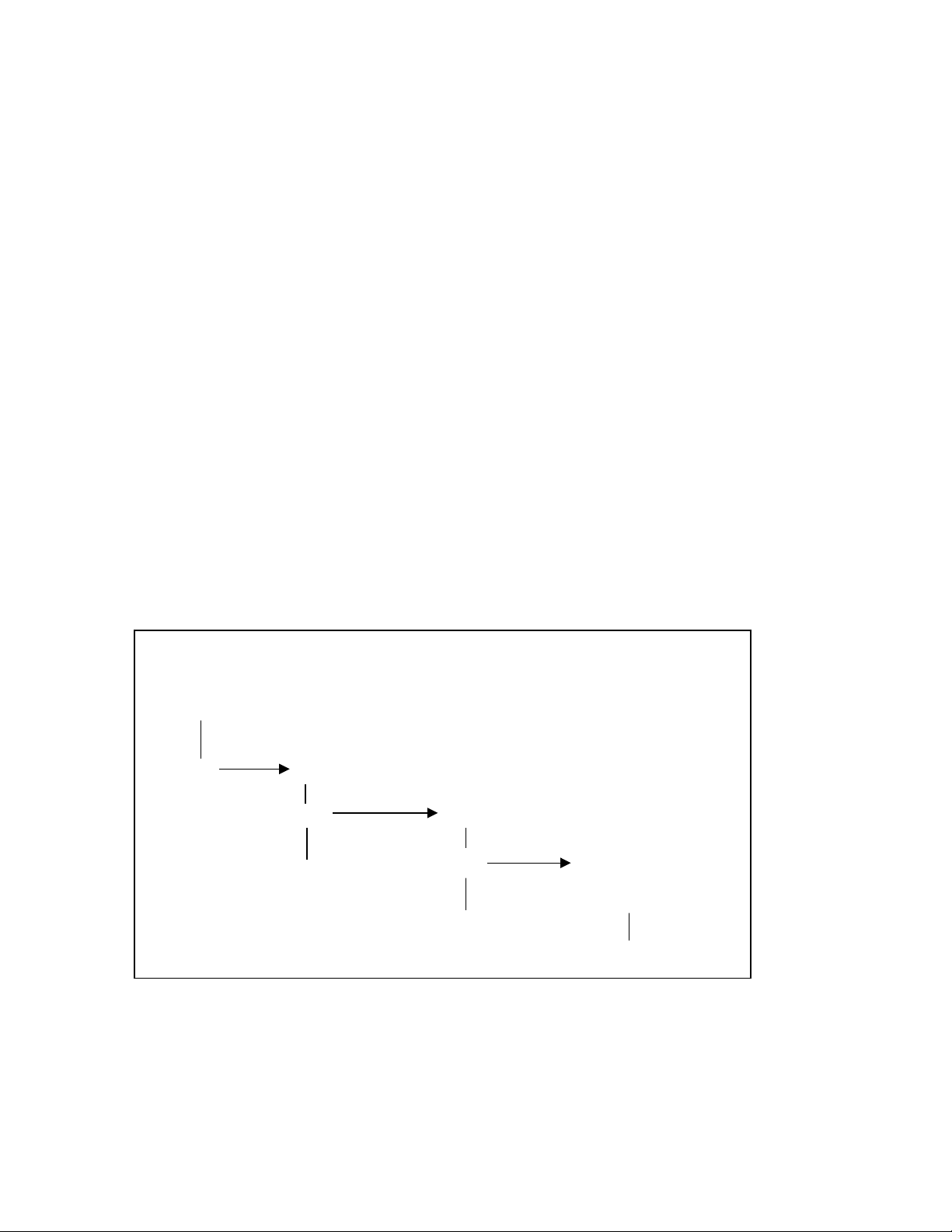

9. The cycle must be called no later than the 1st nesting depth.

10. Call cycle L965. This cycle must be started at least once after start-up and it must always

be programmed when the measuring plane is changed.

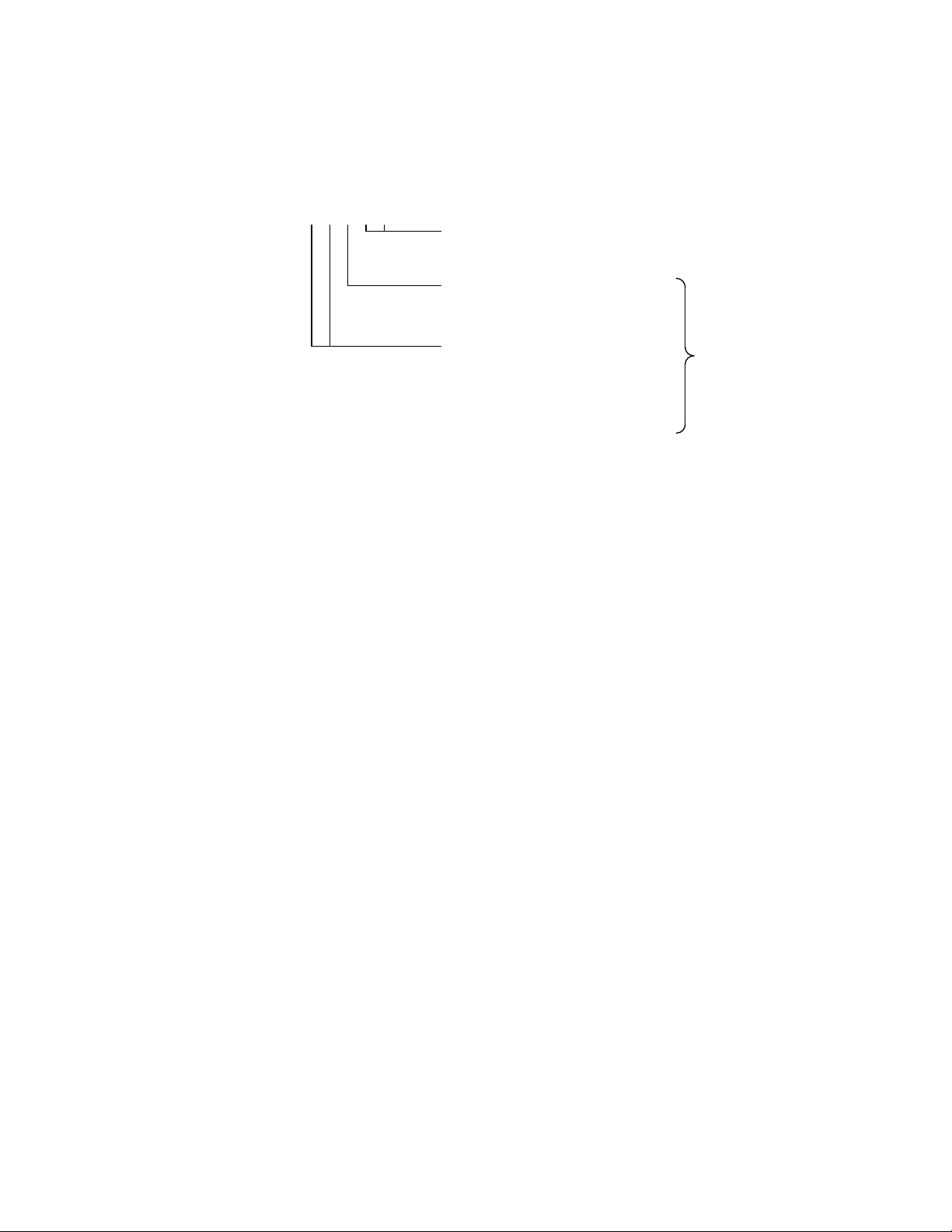

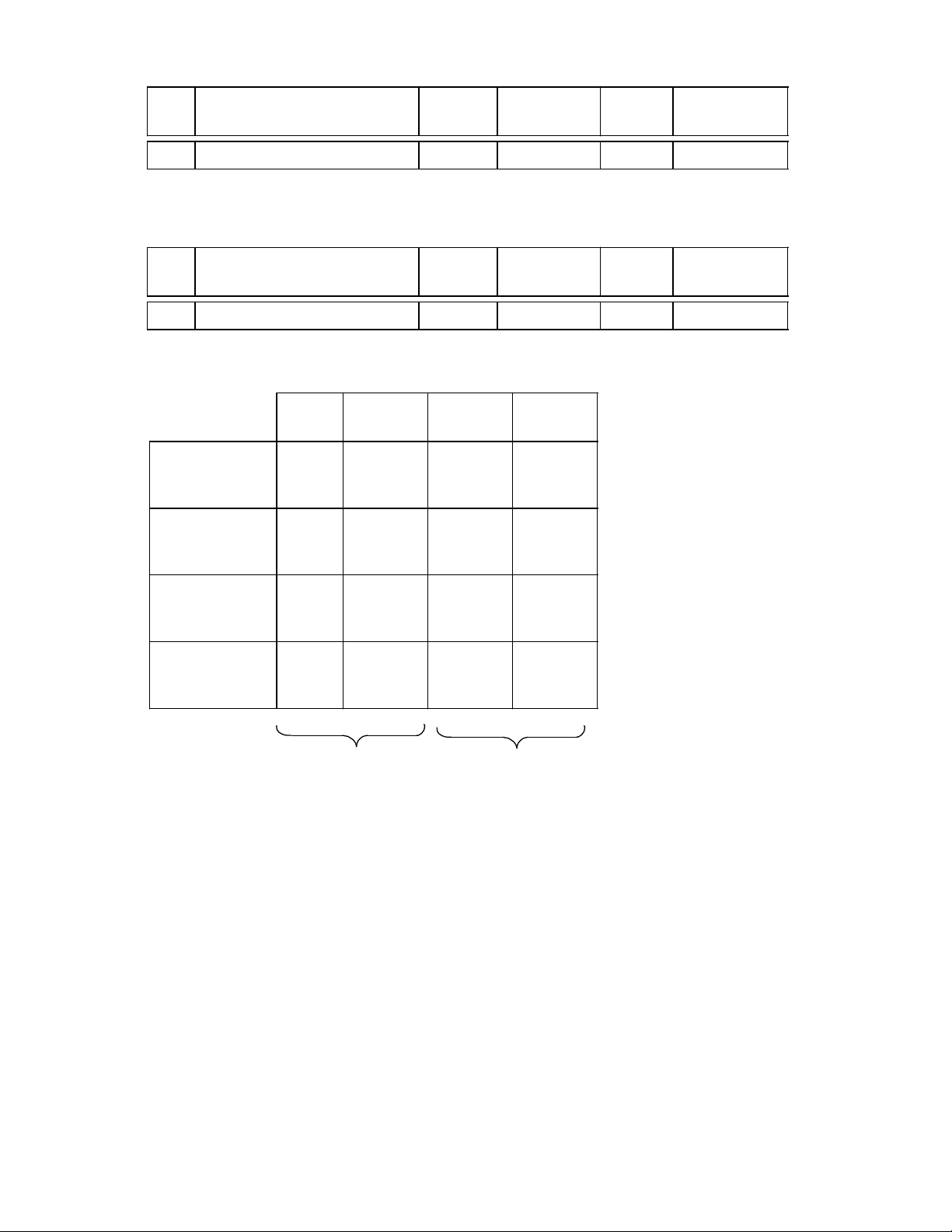

1st nesting depth 2nd nesting depth

3rd nesting depth

%MPF 1234

L01

Measuring cycle call L973

L01

M17

L973

L9xx

L9xx

Measuring cycle

auxiliary programs

M17

Nesting depth when calling measuring cycles

END OF SECTION

1–2 ©

M17

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

07.90 2 Hardware

2.1 Probe

2 Hardware

2.1 Probe

For determining tool and workpiece dimensions, a touch trigger probe is required which

supplies a constant signal (no pulse) when deflected.

The probe must switch with almost no bounce. This is generally achieved by adjusting the

probe mechanically. In addition, "Software debouncing" is carried out in the NC.

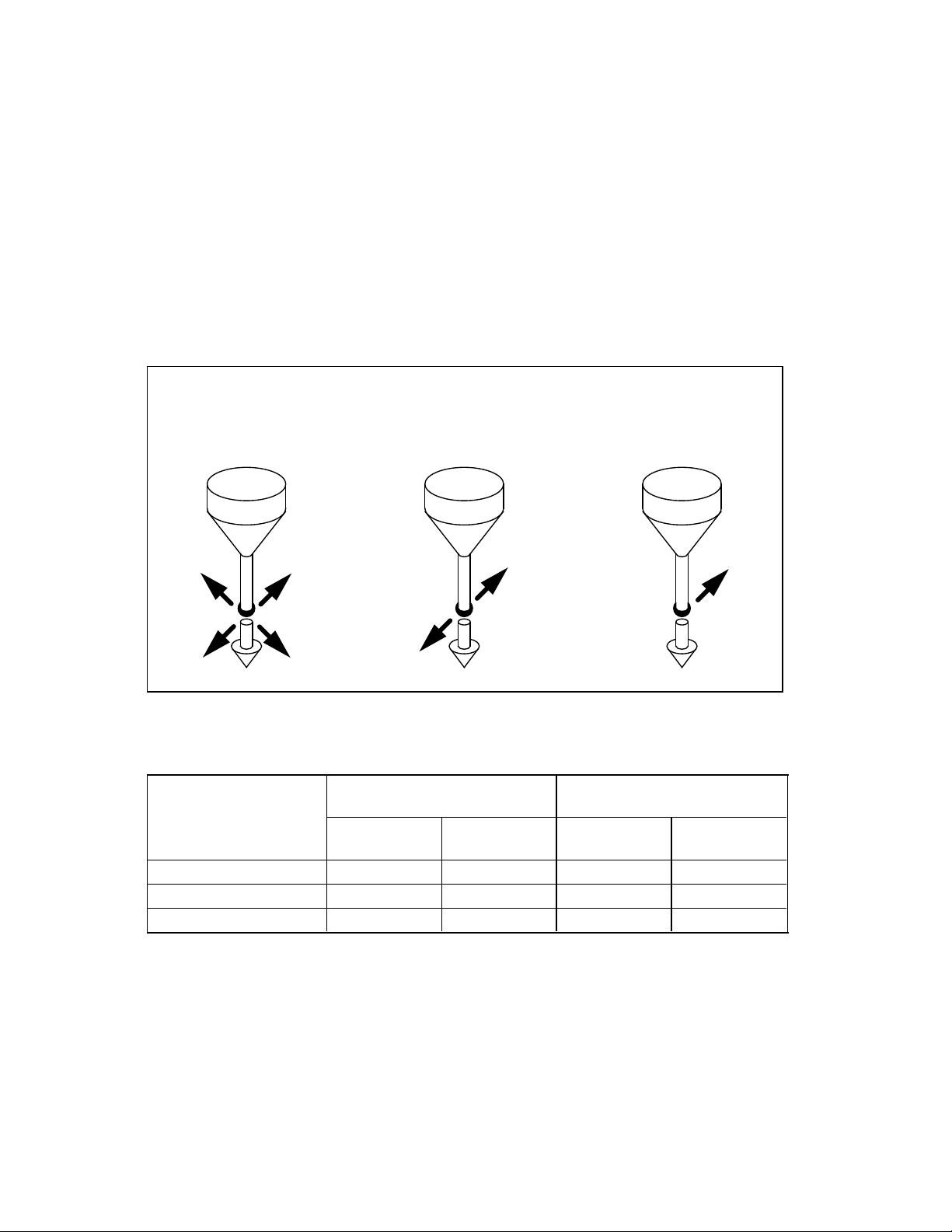

Various types of probe of different make are available on the market. Probes are therefore

classified in three groups according to the number of directions in which the probe can be

deflected (see Fig. below).

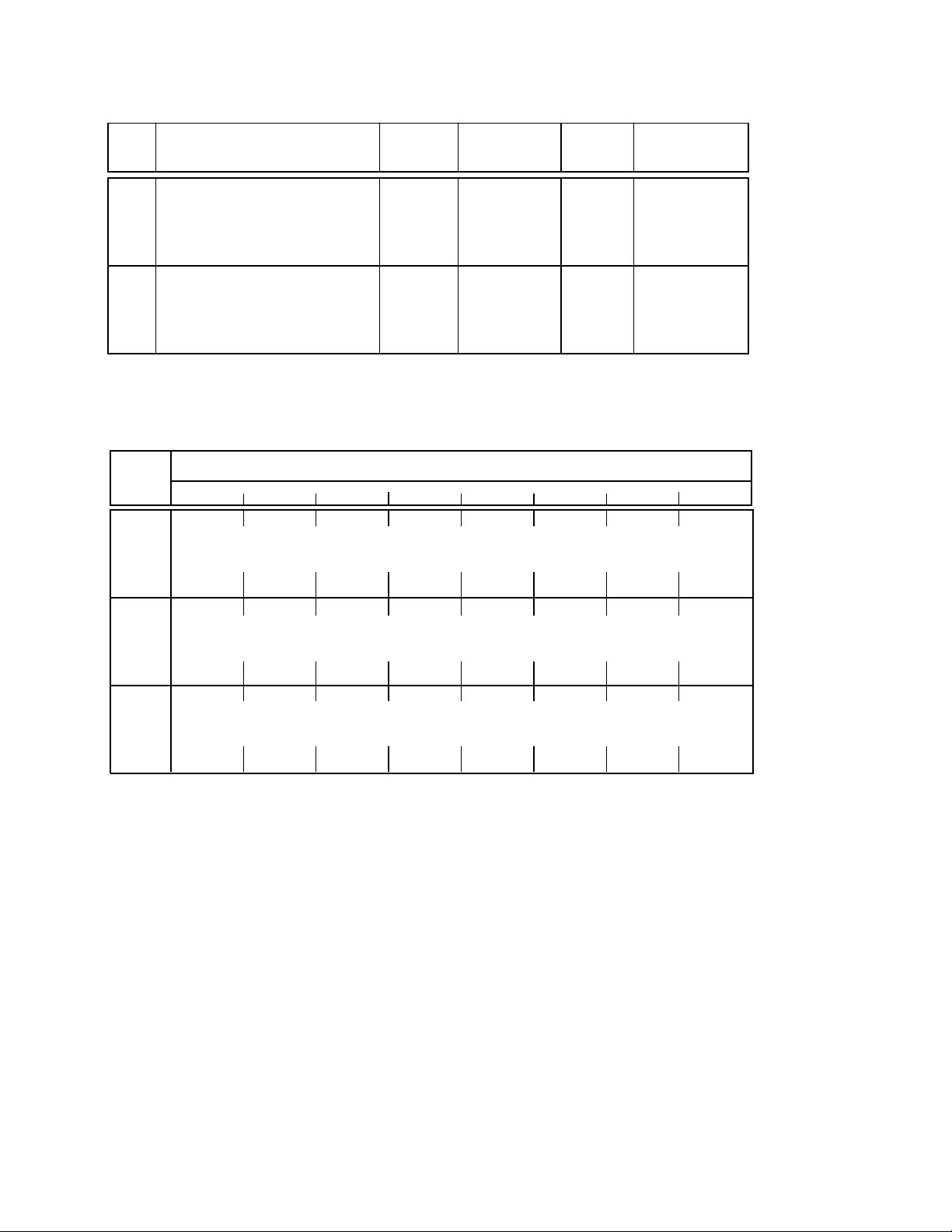

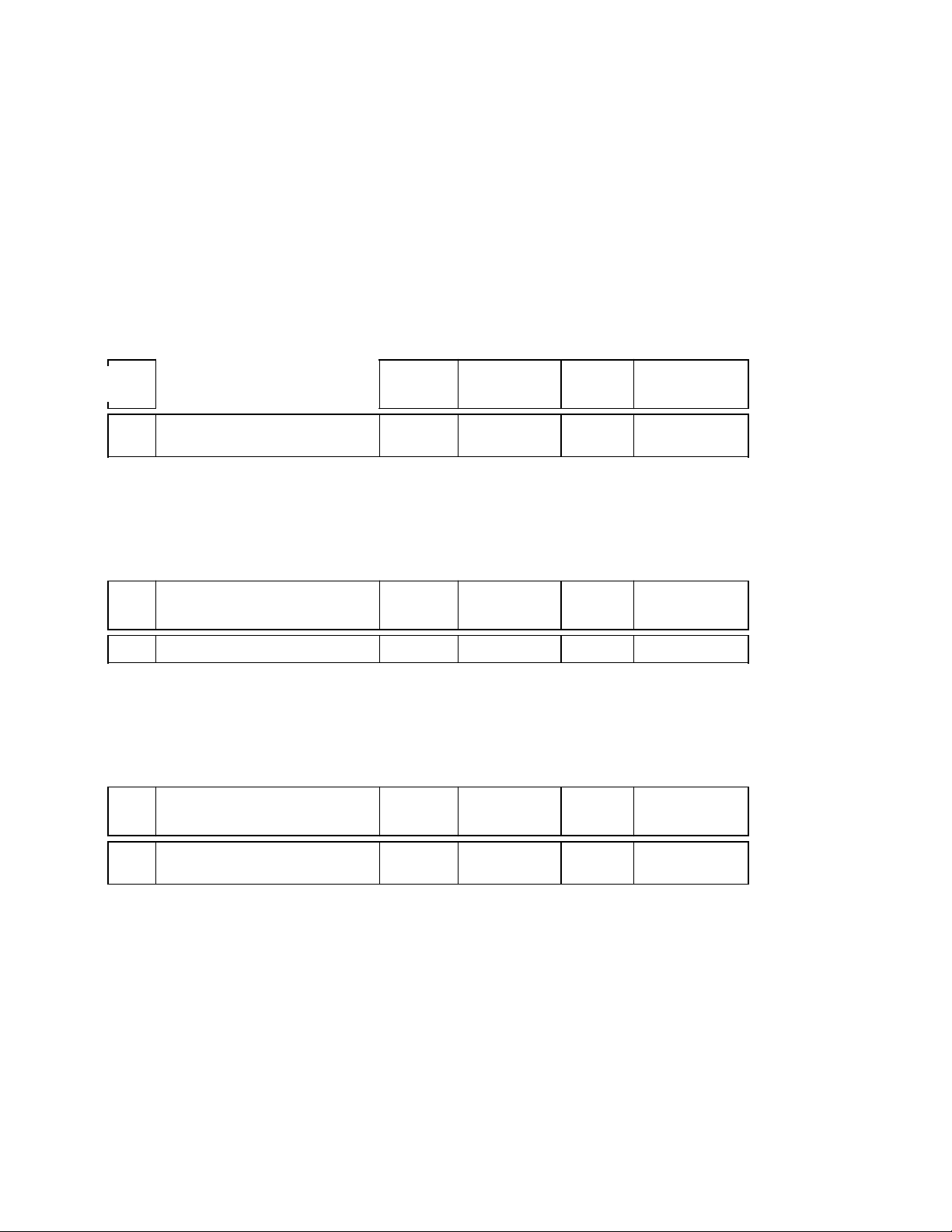

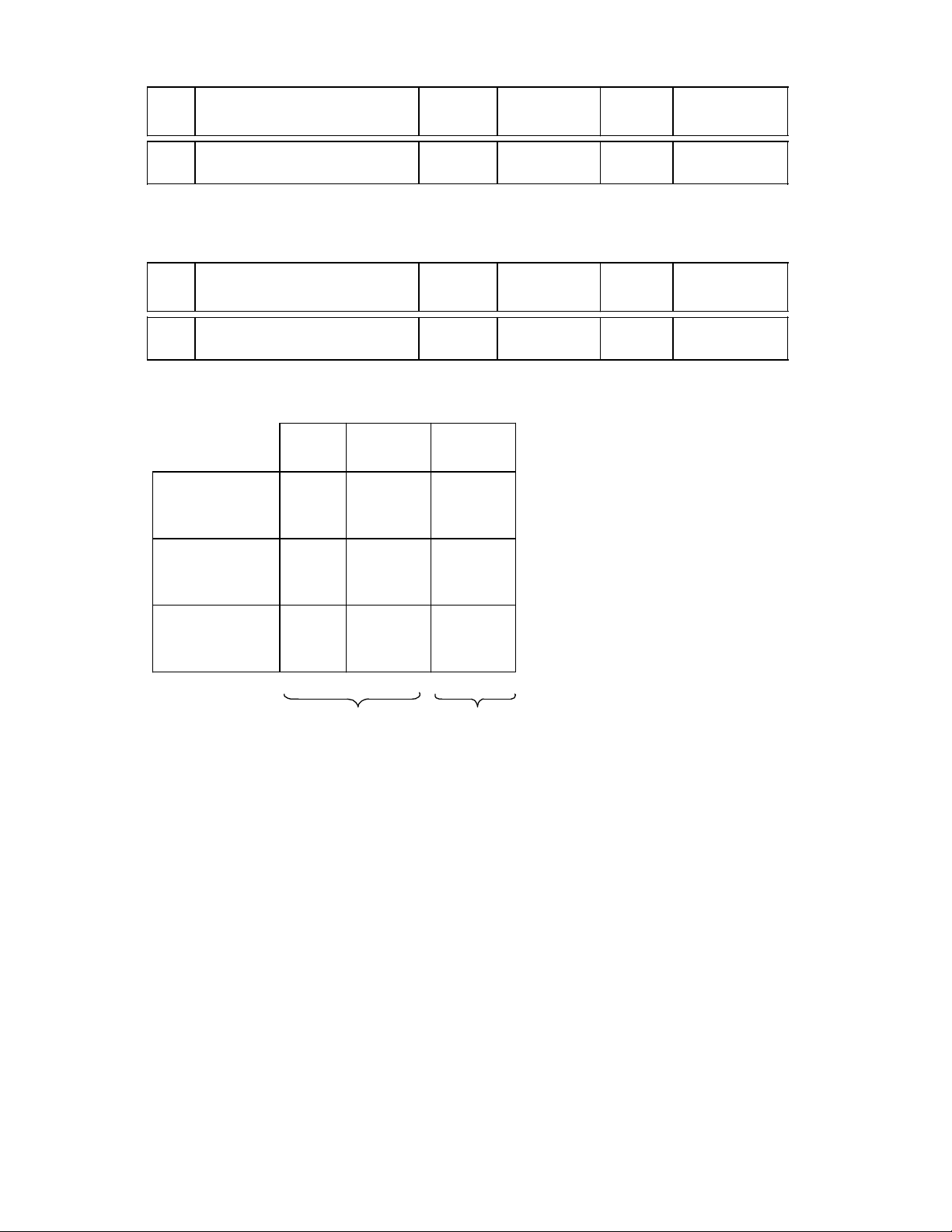

Multidirectional

probe

Types of probe

Turning machines

Tool measure-

ment

Multidirectional probe yes yes yes yes

Bidirectional probe

Monodirectional probe

—

Bidirectional

probe

Workpiece

measurement

yes

Tool

measurement

Monodirectional

probe

Milling machines and

machining centres

Workpiece

measurement

—

———

yes

yes

While on turning machines a bidirectional probe can be used, milling machines and machining

centres also permit the use of a monodirectional probe for workpiece measurement. In the

cycles for milling machines and machining centres, the probe type is to be specified by an R

parameter.

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 2–1

©

SINUMERIK 840/850/880 (IA)

2 Hardware 07.90

2.1.1 Multidirectional probe (3D)

2.1.1 Multidirectional probe (3D)

With this type of probe, tool and workpiece measuring cycles can be used without restriction.

2.1.2 Bidirectional probe

This type of probe can be used on turning machines for workpiece measurement. When

performing workpiece measurement on milling machines and machining centres, this probe

type is treated as a monodirectional probe.

2.1.3 Monodirectional probe

This type cannot be used on turning machines. It can be used for workpiece measurement on

milling machines and machining centres with some few restrictions (more information is given

in the respective cycles).

It must be possible to position the spindle with the NC function "M19" and to transmit the

probe switching signal through 360° to the receiving station (on the machine column).

The probe must be mechanically aligned in the spindle in such a way that measurements can

be performed in the following directions with the spindle being positioned to 0 degrees.

Measurement with 0 degr. spindle position

X-Y plane (G17) Positive X direction

Z-X plane (G18) Positive Z direction

Y-Z plane (G19) Positive Y direction

Measurement takes longer with a monodirectional probe because the spindle must be

positioned in the cycle several times with M19.

2–2 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

01.93 2 Hardware

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

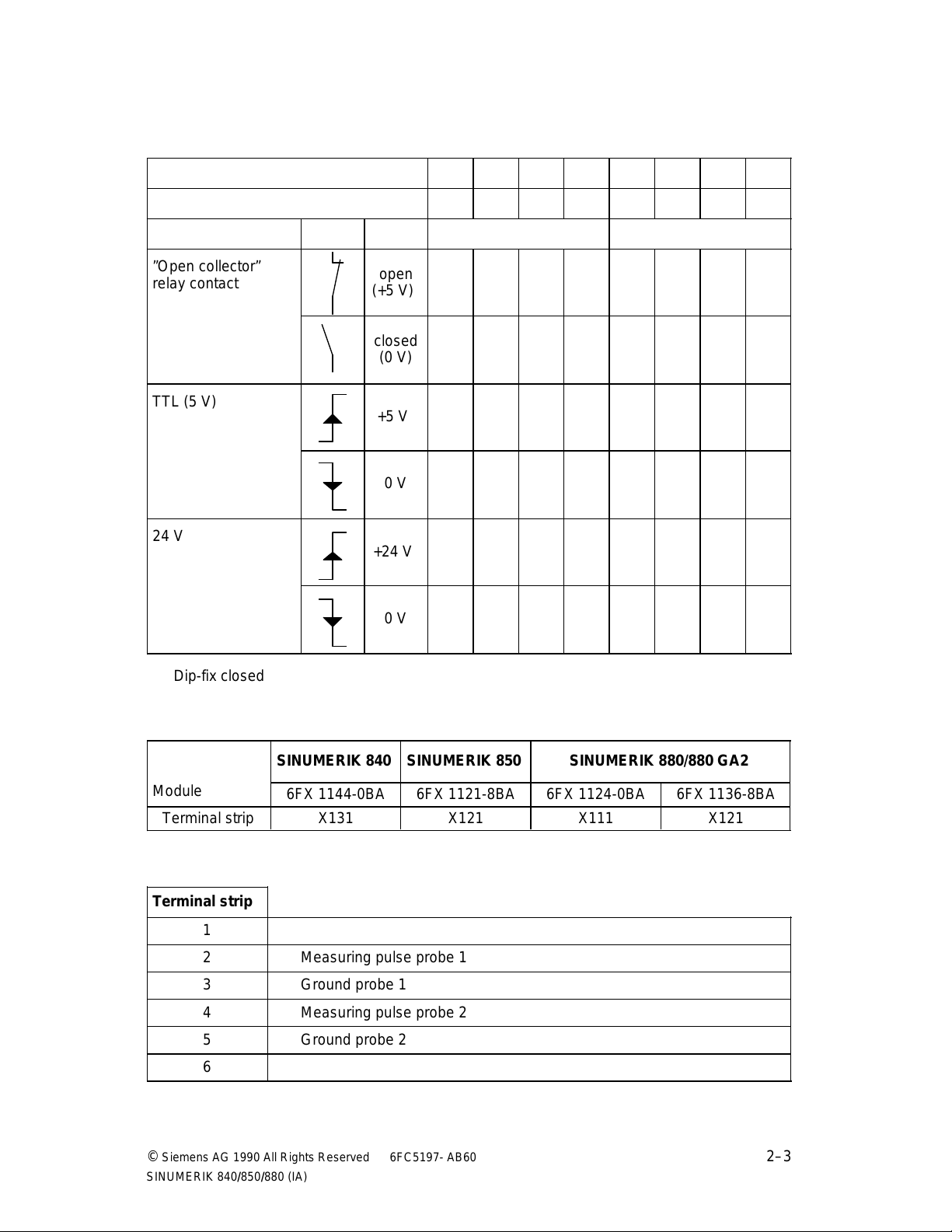

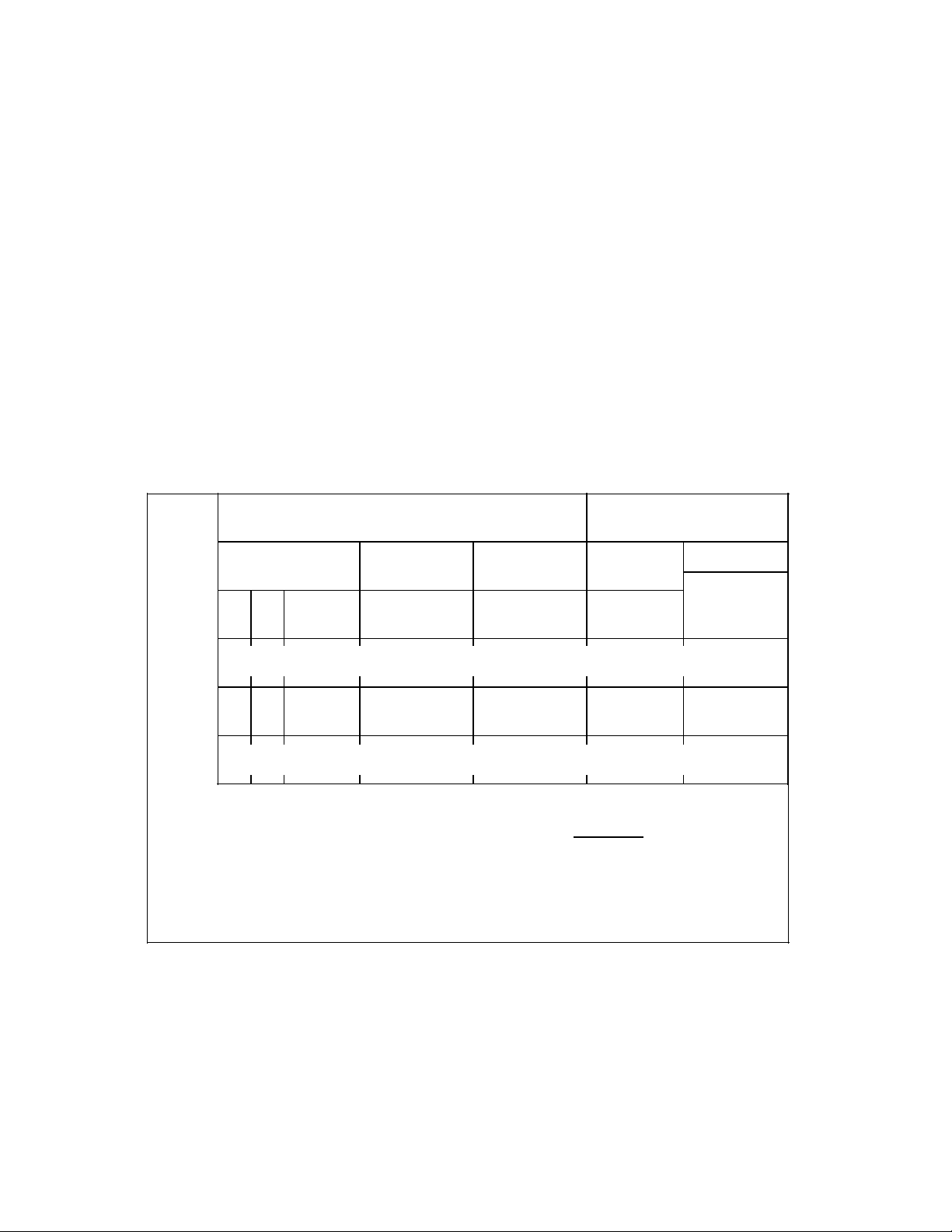

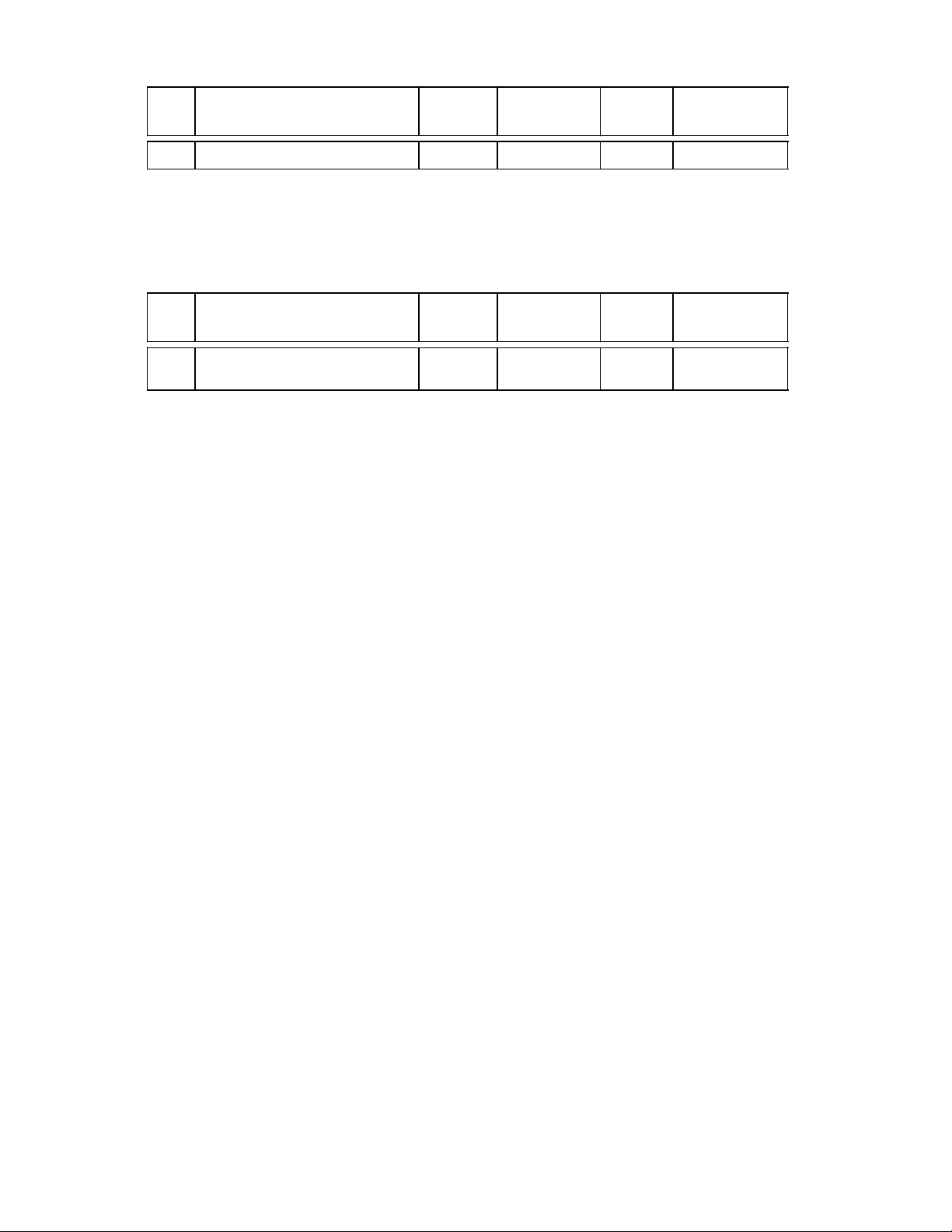

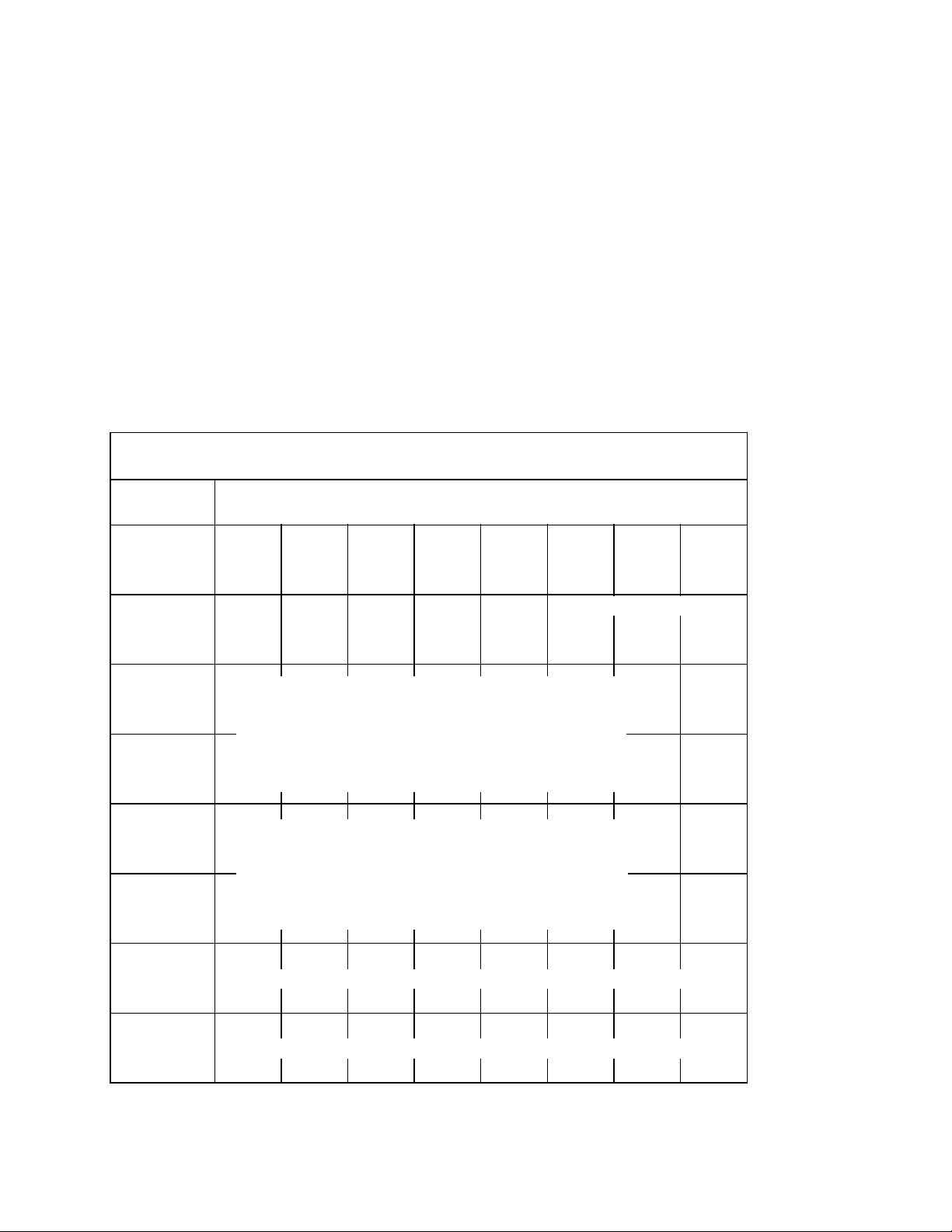

2.2 Jumpering/connection

2.2 Jumpering/connection

Jumpering on the interface module depends on the probe/probe interface used.

SINUMERIK 850/880/880 GA2 S1.1 S1.2 S2.1 S2.2 S1.3 S1.4 S3.1 S3.2

SINUMERIK 840 S3.1-3 S3.1-4 S1-1 S1-2 S3.3-1 S3.3-2 S2-1 S2-2

Type of operation Edge Level Probe 1 Probe 2

”Open collector”

relay contact

TTL (5 V)

24 V

Dip-fix closed

open

(+5 V)

closed

(0 V)

+5 V

0 V

+24 V

0 V

Module

SINUMERIK 840

6FX 1144-0BA

SINUMERIK 850

6FX 1121-8BA

SINUMERIK 880/880 GA2

6FX 1124-0BA 6FX 1136-8BA

Terminal strip X131 X121 X111 X121

Terminal strip

1

2 Measuring pulse probe 1

3 Ground probe 1

4 Measuring pulse probe 2

5 Ground probe 2

6

© Siemens AG 1990 All Rights Reserved 6FC5197- AB60 2–3

SINUMERIK 840/850/880 (IA)

2 Hardware 01.93

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

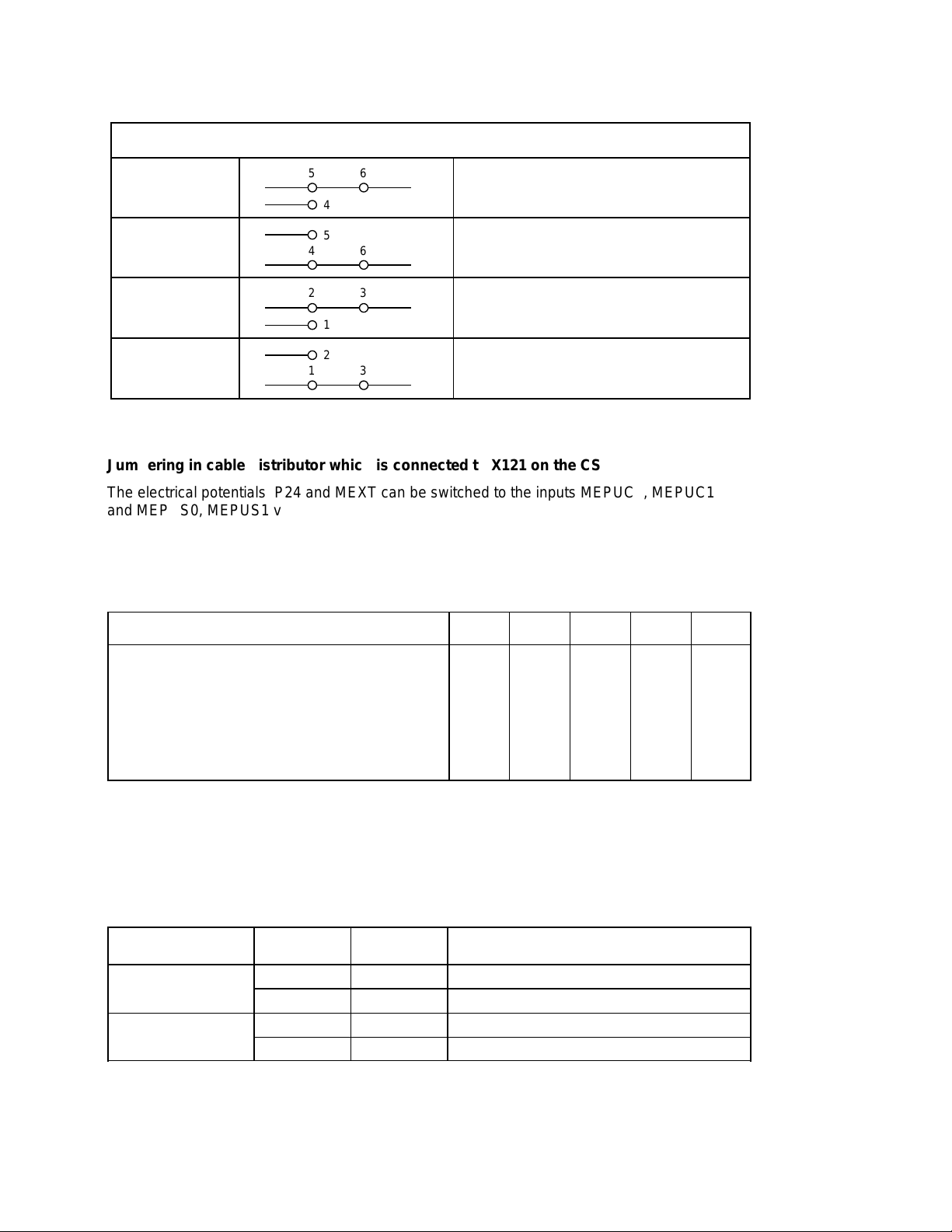

2.2 Jumpering/connection

Jumpering on module CSB 6FC5 114-0AA02

SINUMERIK 840C

SENS 0 active at 24 V input signal

or active o. c. transistor

sensor 1

SENS 0 active at 0 V input signal

or passive o. c. transistor

sensor 1

SENS 1 active at 24 V input signal

or active o. c. transistor

sensor 2

SENS 0 active at 0 V input signal

or passive o. c. transistor

sensor 2

S4

S4

S4

S4

5

6

a

a

4

5

4

2

6

a

a

a

3

a

1

2

1

3

a

a

Jumpering in cable distributor which is connected to X121 on the CSB

The electrical potentials P24 and MEXT can be switched to the inputs MEPUC0, MEPUC1

and MEPUS0, MEPUS1 via switches S1 ... S5 (dip fix) and can thus be used as a ”sensor

connection” or ”rapid NC input”.

Table showing state of switches S1 ... S5

Measuring pulse inputs as NC inputs S1 S2 S3 S4 S5

Measuring pulse inputs 00111

Level (24 V) 00000

Open collector 11000

Relay to earth 11000

Relay to P24 00110

0: open

1: closed

Sensor connection to cable distributor 6FC5147-0AA01

Cable connector Pin Switch

X4

X1

1

3

1

3

S1

S3

S2

S4

Measuring pulse sensor 1 (MEPUS0)

Earth sensor 1 (MEPUC0)

Measuring pulse sensor 2 (MEPUS1)

Earth sensor 2 (MEPUC1)

END OF SECTION

2–4 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

08.96 3 Functional Test

3.1 Service display

3 Functional Test

3.1 Service display

The measuring signal can be checked via the diagnostics menu "PLC status".

Status display

Probe 1 deflected F 24.7

Probe 2 deflected F 24.6

3.2 Test program

With the following example of a test program, the measuring function (repeatability of the

machine and the probe) can be checked without using the measuring cycle subroutines.

Example:

% 1

N5 G00 G94 Z... F150 Pre-positioning approx. 1 mm in front of measuring point

N10 G01 @720 R1 K1 Z... Move onto probe;

set value approx. 1 mm behind measuring point

N15 @714 Stop decoding

N20 R0=R1 Reload actual value of measuring point in parameter R0

N25 G04 F2 Note value of parameter R0

N30 @100 K-5 Return to N5

N35 M30

In addition, the program can be used to determine the scattering of measured values (repeat

accuracy) for the entire measuring system (machine-probe-signal transmission to NC). In other

words, the random dimensional deviations can be determined that follow no trend.

END OF SECTION

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 3–1

©

SINUMERIK 840/850/880 (IA)

07.90 4 Machine Data for Measuring Cycles

4.1 Cycle machine data memory (MDC)

4 Machine Data for Measuring Cycles

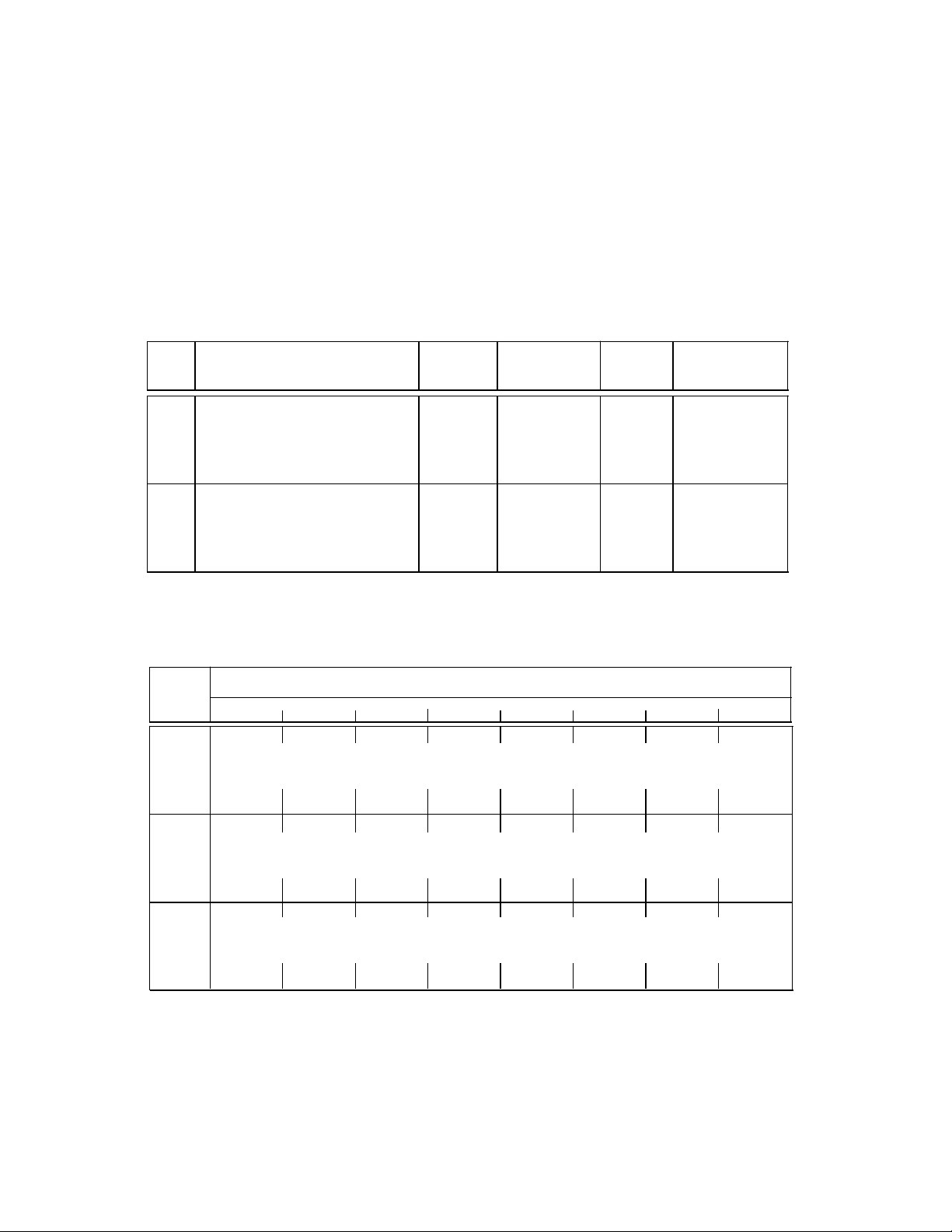

4.1 Cycle machine data memory (MDC)

The machine data for measuring cycles are stored in the cycle machine data

memory (MDC).

The MDC memory is subdivided in the following areas:

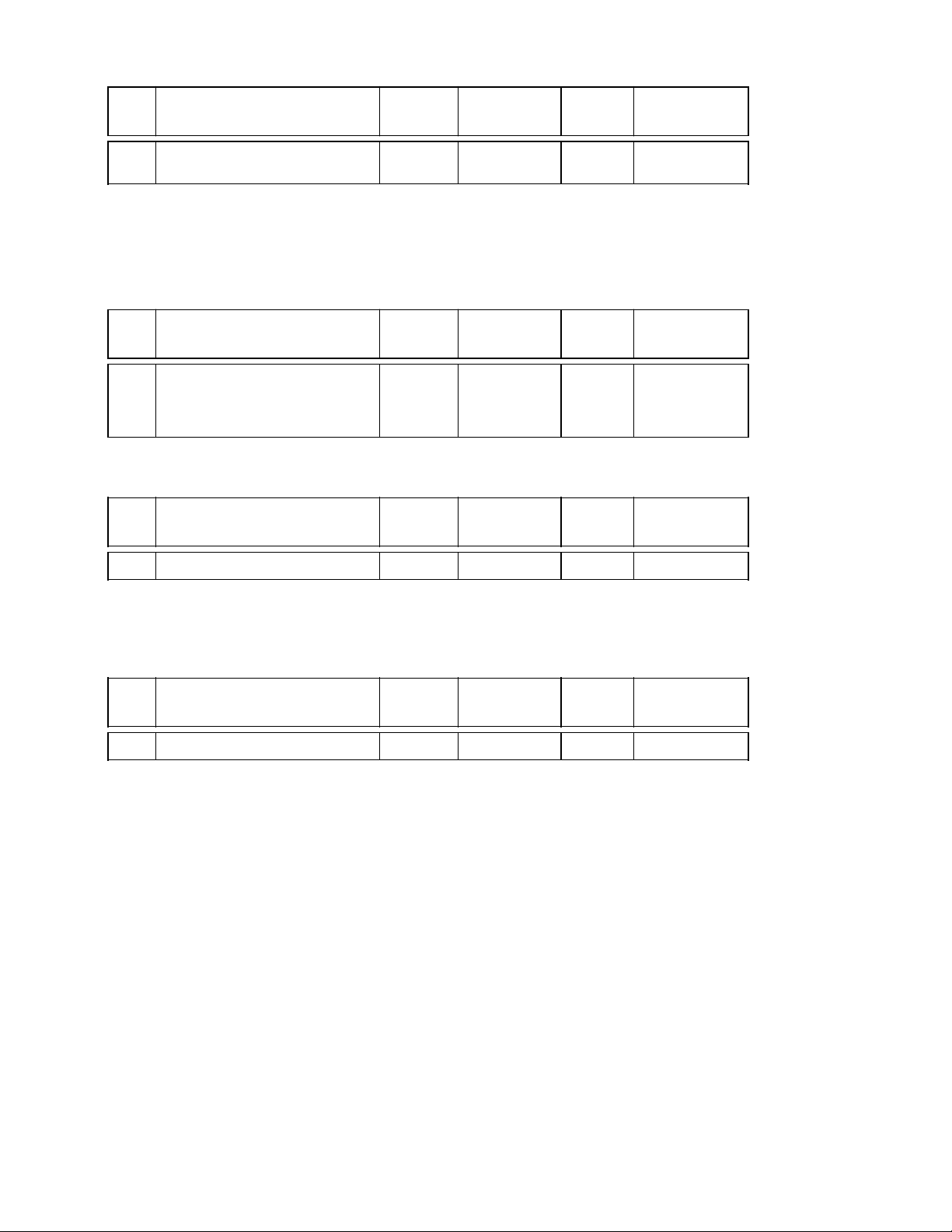

4.1.1 Channel-oriented values, overview

MDC

No.

D e s i g n a t i o n

Standard

value

0

.

.

Siemens (Measuring Cycles)

——— —

.

49

400

.

.

User

——— —

.

449

4.1.2 Channel-oriented bits, overview

MDC

No.

800

819

76543210

.

.

Siemens (Measuring Cycles)

.

Bit No.

Input

limits

Ref.

system

Input

unit

820

.

.

Siemens

.

849

900

.

.

User

.

949

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–1

©

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 07.90

4.1.3 Central values, overview

4.1.3 Central values, overview

MDC

No.

D e s i g n a t i o n

1000

.

.

Siemens (Measuring Cycles)

.

1149

4000

.

.

User

.

4149

4.1.4 Central bits, overview

SDC

No.

7000

7009

76543210

.

.

.

Standard

value

——— —

——— —

Input

limits

Bit No.

Siemens (Measuring Cycles)

Ref.

system

Input

unit

7010

7049

8000

8049

.

.

Siemens

.

.

.

User

.

4–2 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

01.93 4 Machine Data for Measuring Cycles

4.2 NC machine data

4.2 NC machine data

4.2.1 MD 18 Zero offset group

Considering the fact that the 800 systems have just one ZO group while several users require

more than just one group, this need has been met by the use of a cycle "ZO groups L960".

When starting up the measuring cycles, MD 18 must be preset with "1", otherwise an alarm

would be issued on ZO determination.

Cycle L960 stores the current ZO group number in DB 18 to enable the ZO memory to be

transferred to the ZO group memory (R240 - R299 or MIB 200 - MIB 399) on completion of

ZO determination (by the measuring cycles).

MD 18 is a "System cell" and must not be modified manually after completion of start-up.

4.2.2 MD 19 P number (SINUMERIK 850 only)

The NC machine data 19 (MD 19) is only significant when the PLC function package "Tool

management" is used and if the tools are to be compensated by workpiece measuring cycles.

In MD 19 the P number (5-32) is to be stated under which the G number of the next cutting

edge is to be found.

Minimum number of P memories settable with NC MD 13

Fixed allocation by

NC software

T No.P0TypeP1Geometry

MD211 D1

TOA area 1

Dn

MD212 D1

MD216 D1

TOA area m

Dn

TOA areas are determined via NC MD210 (max. 16)

Start address of TOA areas in NC MD211-216

1) Addition to geometry values with

NC MD5007.6="0"(with standard machine data "0")

2) Addition to geometry values with

NC MD5007.3="1"

3) Depending on NC MD

P2 P3 P4

Determination by

NC MD 5007.6

Wear

P5 P6 P7

Quantity is determined with

NC MD 13

Determination by

1

)

NC MD 5007.32)

Add. TO

P8 P9

Formula for TOA memory

W

= INT

NUMB

= Number of single-edged tools

W

NUMB

k1 = Total capacity of TOA memory 8192 bytes

K2 = Width of one P memory 4 bytes

P

= Number of desired P memories

NUMB

Reference to next

cutting edge

P10

k1

· K2

P

NUMB

User-assignable

P11-P32

3)

© Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–3

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 01.93

4.2.3 MD 157 Type/software version

4.2.3 MD 157 Type/software version

NC MD 157 is always evaluated in the measuring cycles.

The type of control and the NC software version are stored in MD 157.

MD 157= XXXXX

NC software version

1 = T version

2 = M version

04 = SINUMERIK 840

05 = SINUMERIK 850

06 = SINUMERIK 840C

08 = SINUMERIK 880

09 = SINUMERIK 880 GA2

4.2.4 MD 208/209 Max. tool wear (parameters P5/P6/P7)

These measuring cycles are used to check the maximum wear when performing tool offset.

When the maximum wear is exceeded, no offset is made but an alarm is output.

MD 208: Wear L1/L2

MD 209: Wear radius

Max. input value: 99999 ˆ= 9.99999

Type

4–4 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

07.90 4 Machine Data for Measuring Cycles

4.2.5 NC transverse axis bits MD 5011 and MD 572*

4.2.5 NC transverse axis bits MD 5011 and MD 572*

The NC transverse axis bits are taken into account in all measuring cycles with the following

combinations.

5011

Bit No.

7 6 5 4 3 2 1

0

572*

Bit No.

1

0000000-0

0000000-1

- -01000-1

- -01001-1

- -01010-1

- -01011-1

- -01100-1

- -01101-1

- -01110-1

- -01111-1

- -11000-1

- -11001-1

- -11010-1

- -11011-1

- -11100-1

- -11101-1

- -11110-1

- -11111-1

01-1----1

1--1----1

11-1----1

* - means: 0 for 1st axis

1 for 2nd axis

2 for 3rd axis

3 for 4th axis

.

.

.

etc.

©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–5

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 10.91

4.2.6 PLC machine data 6026 bit 2

4.2.6 PLC machine data 6026 bit 2

When the measuring cycle functions

• result display selection

• tool management (840/880)

are used the above-mentioned bit must be ”0”.

FB 89 must be available.

4.3 Channel-oriented values, description

Standard values can be loaded from the measuring cycle diskette.

MDC

No.

D e s i g n a t i o n

0 Start address of empirical values

Standard

value

Input

limits

Ref.

system

1 1 to 99 — —

Input

unit

in the setting data (SDC).

Start address of empirical values in the area of the channel-specific cycle setting data (SDC).

Here, the value "0" is to be input when no empirical values are required.

The input value must not overlap with the MDC 2 and MDC 3.

MDC

No.

D e s i g n a t i o n

1 Number of empirical values 49 0 to 99 — —

Standard

value

Input

limits

Ref.

system

Input

unit

Here, the number of memories for empirical values in the area of the channel-specific SDC is

to be stated. Value "0" is to be input if empirical values are not required.

The input value must not overlap with the MDC 2 and MDC 3.

MDC

No.

D e s i g n a t i o n

Standard

value

Input

limits

Ref.

system

Input

unit

2 Start address of empirical values

51 1 to 99 — —

in the setting data (SDC).

Start address of the average values in the area of the channel-specific cycle setting data.

Value "0" is to be input when average values are not required.

The input value must not overlap with the MDC 0 and MDC 1.

4–6 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

08.96 4 Machine Data for Measuring Cycles

4.3 Channel-oriented values, description

MDC

No.

D e s i g n a t i o n

Standard

value

Input

limits

Ref.

system

Input

unit

3 Number of average values 49 0 to 99 — —

Here, the number of memories for average values is to be stated in the area of the channelspecific SDC. Value "0" must be input when no average values are required.

The input value must not overlap with the MDC 0 and 1.

MDC

No.

4 Rapid traverse rate

Intermediate positioning

D e s i g n a t i o n

Standard

value

Input

limits

Ref.

system

100 1 to 100 — %

Input

unit

The intermediate positions calculated by the measuring cycles are approached at maximum

axis speed (NC MD 280*) in percent.

The machine data is only effective with the collision monitor (MDC 800 Bit 0 = 0) switched

off.

Example:

MDC 4 80

MDC 800 bit 0 0

NC MD 2800 10000 (X axis)

NC MD 2801 8000 (Y axis)

NC MD 2802 10000 (Z axis)

Intermediate positions are approached at a rate of 6400 mm/min (80 % of 8000) when

measuring in the X/Y plane.

Intermediate positions are approached at a rate of 8000 mm/min (80 % of 10000) when

measuring in the Z/X plane.

Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–7

©

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 10.91

4.3 Channel-oriented values, description

MDC

No.

D e s i g n a t i o n

5 Positioning speed with collision

Standard

value

Input

limits

Ref.

system

0 1 to 15.000 — mm/min

Input

unit

monitor active

Intermediate positions calculated by measuring cycles are approached at the input speed rate.

The machine data is only effective with activated collision monitoring (MDC 800 bit = 1) and

must be > 0; otherwise alarm message 4008 is issued.

MDC

No.

6

Reserve — —

D e s i g n a t i o n

.

.

13

MDC

No.

D e s i g n a t i o n

Standard

value

Standard

value

Input

limits

Input

limits

Ref.

system

Ref.

system

Input

unit

Input

unit

14 PLC number for logging 1 1 to 4 — —

Here, the number of the PLC must be stated in which the function blocks for the logging

function (with CP 315) are called.

MDC

No.

D e s i g n a t i o n

15 PLC number for MDC 16-19 1 1 to 4 — —

Standard

value

Input

limits

Ref.

system

Input

unit

Here, the number of the PLC must be stated in which the measurement abort signal (MDC 16

and MDC 17) or selection of a result display (MDC 18 and MDC 19) is processed.

4–8 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

07.90 4 Machine Data for Measuring Cycles

4.3 Channel-oriented values, description

MDC

No.

16 Meas. abort signal ident. coarse 0 see table — —

D e s i g n a t i o n

Standard

value

Input

limits

Ref.

system

See MDC 17 for description.

MDC

No.

17 Meas. abort signal ident. fine 0 see below — —

D e s i g n a t i o n

Type Bit

DB No.

DX No.

Input

Flag

82

84

0000

0000

Standard

value

Byte

DW

:

127

:

255

Input

limits

0

.0

Ref.

system

:

.7

0

.0

:

.7

Input

unit

Input

unit

DB

DX

87

87

88

88

0001

:

:

0255

1000

:

:

1255

0

:

2048

0

:

2048

MDC 16 MDC 17

.00

:

.15

.00

:

.15

© Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–9

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 07.90

4.3 Channel-oriented values, description

Use without measurement abort signal

The machining program cannot be continued when a cycle reset alarm (alarm numbers 4000-

4039) occurs. It can only be stopped by program abort (reset). Following program abort,

further measuring points or measuring or machining operations programmed in the part

program can no longer be executed.

To enable these measuring points or machining operations to be likewise executed, first of all,

the cause that has led to the reset alarm must be eliminated. Re-entry in the machining

program is then possible with block search.

Use with measurement abort signal

The function "Measurement abort signal" provides the possibility of continuing the machining

program when cycle reset alarms (4011, 4019, 4020, 4026, 4027, 4030, 4031, 4032, 4033)

have occured.

The measurement abort signal is generally released by the operator by pressing a key

arranged on the machine control panel.

The signal can be read out by the measuring cycles directly from the PLC input from a flag or

a data word.

Example:

a) Measurement abort signal on input: I 15.4

MDC 16 = 820000

MDC 17 = 15.4

b) Measurement abort signal from flag: F 200.2

MDC 16 = 840000

MDC 17 = 200.2

c) Measurement abort signal from data block: DB 200 D 10.9

MDC 16 = 870200

MDC 17 = 10.09

d) Measurement abort signal from DX data block: DX 200 D 10.9

MDC 16 = 881200

MDC 17 = 10.09

The function "Measurement abort signal" is activated as soon as MDC 16 > 0.

4–10 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

07.90 4 Machine Data for Measuring Cycles

4.3 Channel-oriented values, description

MDC

No.

18 Selection result display

identifier coarse

D e s i g n a t i o n

See MDC 19 for description.

MDC

No.

19 Selection result display

identifier fine

D e s i g n a t i o n

Type

Flag

DB

84

87

87

:

DB No.

DX No.

0000

0001

:

0255

Standard

value

0 see table — —

Standard

value

0 see below — —

Input

limits

Input

limits

Ref.

system

Ref.

system

Byte

DW

0

:

255

0

:

2048

Input

unit

Input

unit

DX

88

:

88

1000

:

1255

MDC 18 MDC 19

0

:

2048

© Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–11

SINUMERIK 840/850/880 (IA)

4 Machine Data for Measuring Cycles 08.96

4.3 Channel-oriented values, description

The cycle can perform a menu selection (insertion of a result display) on completion of a

measuring operation (see MDC 7001 bit 2).

The function "Menu selection" is performed via the PLC, i.e. the cycle enters the relevant

menu number directly in the PLC and also triggers menu selection.

The interface area must be determined via MDC 18 and 19 to avoid collision with other "Menu

selectors", otherwise alarm 4049, Display cannot be selected, is called.

The following definitions are possible:

a) Measuring Cycles use DB 40 directly

b) " use another DB (image of DB 40)

c) " use a flag area (image of DB 40)

In cases b and c, the PLC user program must take care of data transfer

(interface DB 40

assigned interface).

Special case:

If MDC 18=0, the menu selection is performed through DB 40.

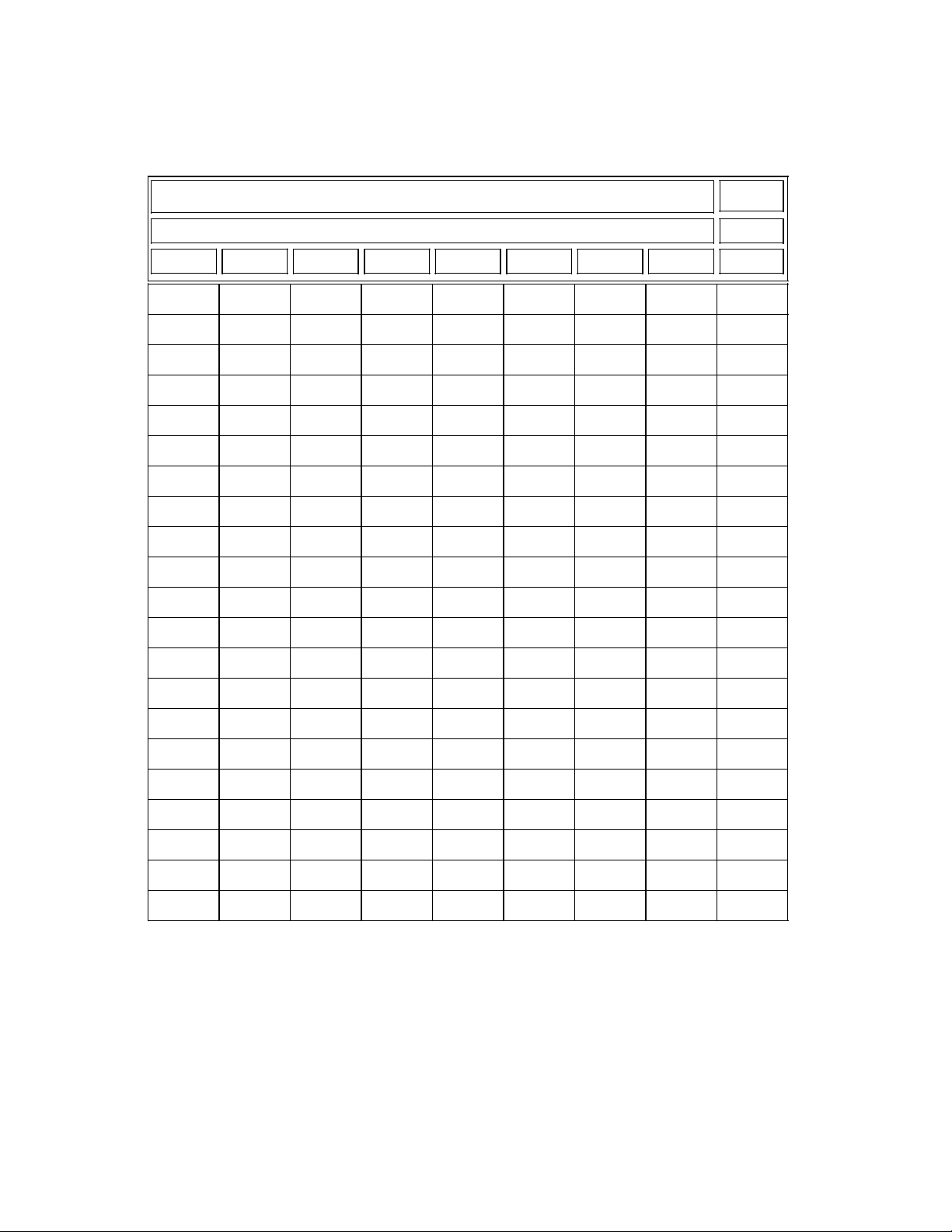

Interface for display selection

Byte

DB 40 DL51

(DBm DLn)

DB 40 DR51

(DBm DRn)

DB40 DL52

(DBm DLn+1)

DB40 DR52

(DBm DRn+1)

DB40 DL53

(DBm DLn+2)

DB40 DR53

(DBm DRn+2)

Bit

(M n)

(M n+1)

(M n+2)

(M n+3)

(M n+4)

(M n+5)

15 14 13 12 11 10 9 8

76 54321 0

Triggered

by user

Insertion

from other

PLC act.

Insertion

own PLC

active

Function ident No. 1 - 15

1System area

2User area

Menu number

Acknowledgements

Insertion

already

active

Error

H

L

H

L

Insertion

carried

out

DB40 DL54

(DBm DLn+3)

(M n+6)

DB40 DR54

(DBm DRn+3)

(M n+7)

Mode group number 1 - 8

Channel number 1 - 8

4–12 © Siemens AG 1990 All Rights Reserved 6FC5197- AB60

SINUMERIK 840/850/880 (IA)

07.90 4 Machine Data for Measuring Cycles

4.3 Channel-oriented values, description

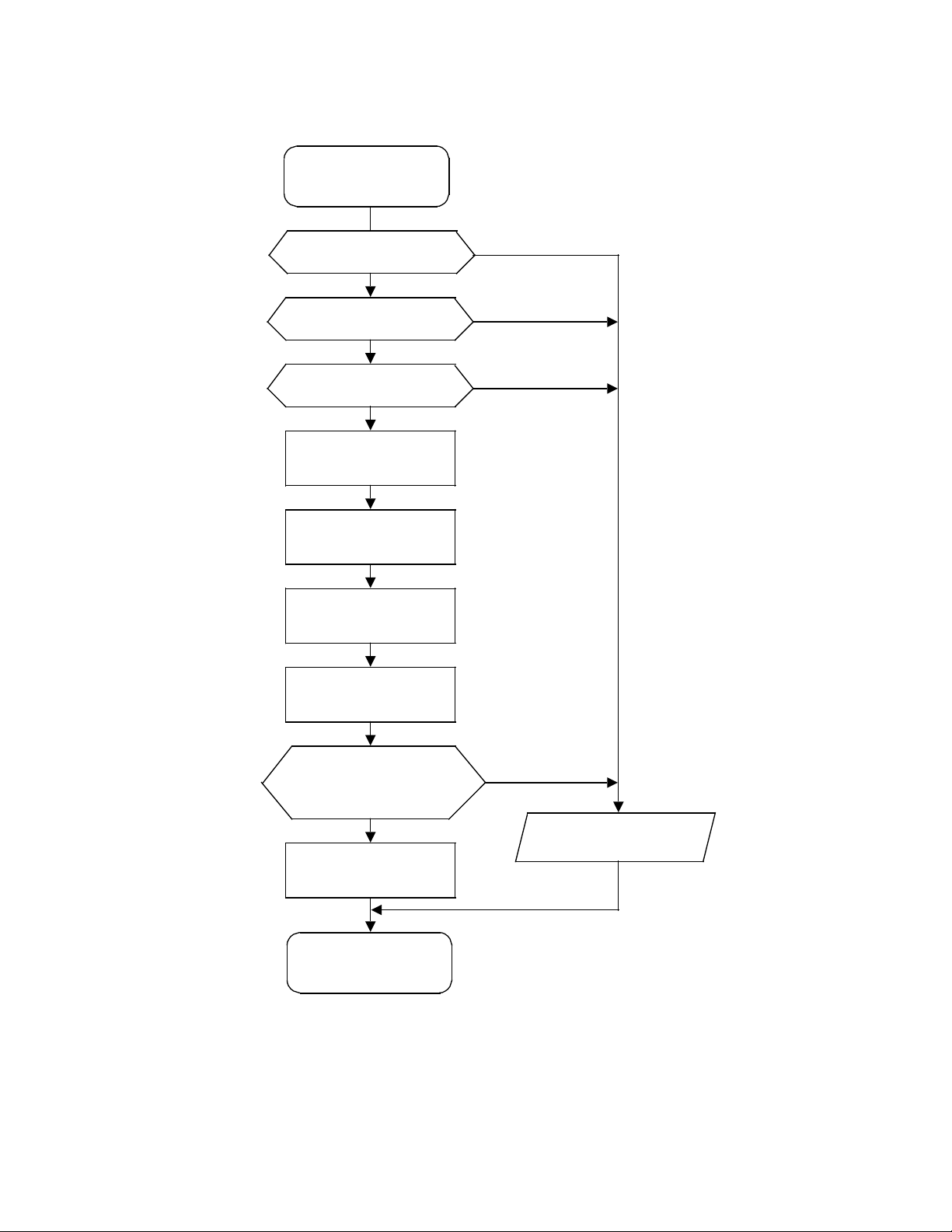

Outline flowchart of insertion by means of measuring cycles via user interface DB40, DW51 DW54, for example.

Display selection

D 51.1=0

Yes

D 51.2=0

Yes

D 51.7=0

Yes

Enter function ident.

number in DW 52

Enter menu number

in DW 53

Enter mode group

number and channel

number in DW 54

Trigger

D 51.8=1

No

No

No

Insertion was carried out

D 51.0

Reset trigger

D 51.8=0

Yes

No

Alarm 4049

Display selection not poss.

End

© Siemens AG 1990 All Rights Reserved 6FC5197- AB60 4–13

SINUMERIK 840/850/880 (IA)

Loading...

Loading...