Page 1

SINUMERIK

SINUMERIK

840D/840Di/810D

Basic logic functions: PLC Basic

program powerline (P3 pl)

Function Manual

Brief description

Detailed description

Supplementary conditions

Examples

Data lists

1

2

3

4

5

Valid for

Control

SINUMERIK 840D sl/840DE sl

SINUMERIK 840Di sl/840DiE sl

SINUMERIK 840D powerline/840DE powerline

SINUMERIK 840Di powerline/840DiE powerline

SINUMERIK 810D powerline/810DE powerline

Software Version

NCU system software for 840D sl/840DE sl 1.3

NCU system software for 840D sl/DiE sl 1.0

NCU system software for 840D/840DE 7.4

NCU system software for 840Di/840DiE 3.3

NCU system software for 810D/810DE 7.4

11/2006

6FC5397-0BP10-2BA0

Page 2

Safety Guidelines

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

Danger

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

with a safety alert symbol, indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

indicates that an unintended result or situation can occur if the corresponding information is not taken into

account.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will

be used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to

property damage.

Qualified Personnel

The device/system may only be set up and used in conjunction with this documentation. Commissioning and

operation of a device/system may only be performed by qualified personnel. Within the context of the safety notes

in this documentation qualified persons are defined as persons who are authorized to commission, ground and

label devices, systems and circuits in accordance with established safety practices and standards.

Prescribed Usage

Note the following:

Warning

This device may only be used for the applications described in the catalog or the technical description and only in

connection with devices or components from other manufacturers which have been approved or recommended by

Siemens. Correct, reliable operation of the product requires proper transport, storage, positioning and assembly

as well as careful operation and maintenance.

Trademarks

All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this

publication may be trademarks whose use by third parties for their own purposes could violate the rights of the

owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software

described. Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the

information in this publication is reviewed regularly and any necessary corrections are included in subsequent

editions.

Siemens AG

Automation and Drives

Postfach 48 48

90437 NÜRNBERG

GERMANY

Order No.: 6FC5397-0BP10-2BA0

Ⓟ 12/2006

Copyright © Siemens AG 2006.

Technical data subject to change

Page 3

Table of contents

1 Brief description......................................................................................................................................... 7

2 Detailed description ................................................................................................................................... 9

2.1 Key PLC CPU data for 810D, 840D and 840Di .............................................................................9

2.2 Reserve resources (timers, FC, FB, DB, I/O) ..............................................................................16

2.3 Starting up hardware configuration of PLC CPUs .......................................................................17

2.4 Starting up the PLC program .......................................................................................................22

2.4.1 Installing the basic program for 810D, 840D ...............................................................................22

2.4.2 Application of basic program........................................................................................................24

2.4.3 Version codes ..............................................................................................................................25

2.4.4 Machine program .........................................................................................................................25

2.4.5 Data backup.................................................................................................................................26

2.4.6 PLC series startup, PLC archives:...............................................................................................26

2.4.7 Software upgrades.......................................................................................................................28

2.4.8 I/O modules (FM, CP modules) ...................................................................................................29

2.4.9 Troubleshooting ...........................................................................................................................30

2.5 Linking PLC CPUs to 810D, 840D...............................................................................................31

2.5.1 General ........................................................................................................................................31

2.5.2 Properties of PLC CPUs ..............................................................................................................31

2.5.3 Interface on 810D and 840D with integrated PLC .......................................................................32

2.5.4 Diagnostic buffer on PLC .............................................................................................................34

2.6 Interface structure ........................................................................................................................36

2.6.1 General ........................................................................................................................................36

2.6.2 PLC/NCK interface.......................................................................................................................36

2.6.3 Interface PLC/HMI .......................................................................................................................42

2.6.4 PLC/MCP/HHU interface .............................................................................................................45

2.7 Structure and functions of the basic program ..............................................................................49

2.7.1 General ........................................................................................................................................49

2.7.2 Startup and synchronization of NCK PLC....................................................................................51

2.7.3 Cyclic operation (OB1).................................................................................................................51

2.7.4 Time-alarm processing (OB 35)...................................................................................................54

2.7.5 Process interrupt processing (OB 40)..........................................................................................54

2.7.6 Response to NC failure................................................................................................................54

2.7.7 Functions of the basic program called from the user program ....................................................56

2.7.8 Symbolic programming of user program with interface DB .........................................................59

2.7.9 M decoding acc. to list .................................................................................................................60

2.7.10 PLC machine data .......................................................................................................................65

2.7.11 Configuration of machine control panel, handheld unit ...............................................................69

2.8 SPL for Safety Integrated.............................................................................................................78

2.9 Assignment overview ...................................................................................................................78

2.9.1 Assignment: NC/PLC interface ....................................................................................................78

2.9.2 Assignment: FB/FC......................................................................................................................78

2.9.3 Assignment: DB ...........................................................................................................................79

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

3

Page 4

Table of contents

2.9.4 Assignment: Timers .................................................................................................................... 81

2.10 Memory requirements of basic PLC program for 840D .............................................................. 81

2.11 Supplementary conditions and NC VAR selector ....................................................................... 84

2.11.1 Supplementary conditions........................................................................................................... 84

2.11.1.1 Programming and parameterizing tools...................................................................................... 84

2.11.1.2 SIMATIC documentation required............................................................................................... 86

2.11.1.3 Relevant SINUMERIK documents .............................................................................................. 86

2.11.2 NC VAR selector ......................................................................................................................... 87

2.11.2.1 Overview ..................................................................................................................................... 87

2.11.2.2 Description of Functions.............................................................................................................. 90

2.11.2.3 Startup, installation...................................................................................................................... 99

2.12 Block descriptions ..................................................................................................................... 100

2.12.1 FB 1: RUN_UP Basic program, startup section ........................................................................ 100

2.12.2 FB 2: Read GET NC variable.................................................................................................... 109

2.12.3 FB 3: PUT write NC variables ................................................................................................... 117

2.12.4 FB 4: PI_SERV General PI services ......................................................................................... 125

2.12.4.1 Overview of available PI services ............................................................................................. 128

2.12.4.2 General PI services................................................................................................................... 129

2.12.4.3 Tool management services....................................................................................................... 134

2.12.5 FB 5: GETGUD read GUD variable .......................................................................................... 150

2.12.6 FB 7: PI_SERV2 General PI services ....................................................................................... 156

2.12.7 FB 9: MzuN Control unit switchover.......................................................................................... 160

2.12.8 FB 10: Safety relay (SI relay).................................................................................................... 166

2.12.9 FB 11: Brake test ...................................................................................................................... 170

2.12.10 FB 29: Signal recorder and data trigger diagnostics................................................................. 176

2.12.11 FC 2: GP_HP Basic program, cyclic section............................................................................. 180

2.12.12 FC 3: GP_PRAL Basic program, interruptcontrolled section .................................................... 182

2.12.13 FC 7: TM_REV Transfer block for tool change with revolver.................................................... 185

2.12.14 FC 8: TM_TRANS transfer block for tool management ............................................................ 189

2.12.15 FC 9: ASUB startup of asynchronous subprograms................................................................. 197

2.12.16 FC 10: AL_MSG error and operating messages....................................................................... 200

2.12.17 FC 12: AUXFU call interface for user with auxiliary functions .................................................. 202

2.12.18 FC 13: BHGDisp display control for handheld unit ................................................................... 203

2.12.19 FC 15: POS_AX positioning of linear and rotary axes .............................................................. 207

2.12.20 FC 16: PART_AX positioning of indexing axes......................................................................... 211

2.12.21 FC 17: YDelta star/delta changeover........................................................................................ 215

2.12.22 FC 18: SpinCtrl spindle control ................................................................................................. 219

2.12.23 FC 19: MCP_IFM transmission of MCP signals to interface..................................................... 230

2.12.24 FC 21: transfer PLC NCK data exchange................................................................................. 238

2.12.25 FC 22: TM_DIR Direction selection for tool management ........................................................ 247

2.12.26 FC 24: MCP_IFM2 Transmission of MCP signals to interface.................................................. 250

2.12.27 FC 25: MCP_IFT transfer of MCP/OP signals to interface ....................................................... 254

2.12.28 FC 26: HPU_MCP Transfer of HPU/HT6 signals to the interface............................................. 257

2.12.28.1 FC 26: HPU_MCP Transfer of HPU/HT6 signals to the interface............................................. 257

2.12.28.2 MCP selection signals to the user interface.............................................................................. 260

2.12.28.3 Checkback signals from user interface for controlling displays................................................ 262

2.12.29 FC 19, FC 24, FC 25, FC 26 source code description.............................................................. 263

2.13 Signal/data descriptions ............................................................................................................ 265

2.13.1 Interface signals NCK/PLC, MMC/PLC, MCP/PLC .................................................................. 265

2.13.2 Decoded M signals.................................................................................................................... 265

2.13.3 G Functions............................................................................................................................... 267

2.13.4 Message signals in DB 2........................................................................................................... 269

Basic logic functions: PLC Basic program powerline (P3 pl)

4 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 5

Table of contents

2.14 Programming tips with STEP 7 ..................................................................................................272

2.14.1 General ......................................................................................................................................272

2.14.2 Copying data..............................................................................................................................272

2.14.3 ANY and POINTER....................................................................................................................273

2.14.3.1 POINTER or ANY variable for transfer to FC or FB...................................................................273

2.14.3.2 General ......................................................................................................................................275

2.14.3.3 Use of POINTER and ANY in FC if POINTER or ANY is available as parameter.....................275

2.14.3.4 Use of POINTER and ANY in FB if POINTER or ANY is available as parameter.....................277

2.14.4 Multiinstance DB ........................................................................................................................278

2.14.5 Strings........................................................................................................................................280

2.14.6 Determining offset addresses for data block structures ............................................................281

3 Supplementary conditions ..................................................................................................................... 283

4 Examples............................................................................................................................................... 285

5 Data lists................................................................................................................................................ 287

5.1 Machine data..............................................................................................................................287

5.1.1 NC-specific machine data ..........................................................................................................287

5.1.2 Channelspecific machine data...................................................................................................287

Index...................................................................................................................................................... 289

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

5

Page 6

Table of contents

Basic logic functions: PLC Basic program powerline (P3 pl)

6 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 7

Brief description

General

The PLC basic program organizes the exchange of signals and data between the PLC user

program and the NCK (Numerical Control Kernel), HMI (Human-Machine Interface) and

MCP (Machine Control Panel) areas. A distinction is made between the following groups for

signals and data:

• Cyclic signal exchange

• Eventdriven signal exchange

• Messages

Cyclic signal exchange

The cyclically-exchanged signals consist primarily of bit arrays.

• They contain commands transmitted from the PLC to the NCK (such as start or stop) and

status information from the NCK (such as program running, interrupted, etc.).

• The bit fields are organized into signals for:

– Mode groups

– channels

1

– Axes/spindles

– General NCK signals

The cyclic exchange of data is performed by the basic program at the start of the PLC cycle

(OB1). This ensures that the signals from the NCK remain constant throughout the cycle.

Event-driven signal exchange NCK → PLC

PLC functions that have to be executed as a function of the workpiece program are triggered

by auxiliary functions in the workpiece program. If the auxiliary functions are used to start

execution of a block, the type of auxiliary function determines whether the NCK has to wait

before executing the function (e.g. during a tool change) or whether the function is executed

in parallel to machining of the workpiece (e.g. for tool preparation on milling machines with

chaintype magazines).

Data transfer must be as fast and yet as reliable as possible, in order to minimize the effect

on the NC machining process. Data transfer is therefore controlled by alarms and

acknowledgments. The basic program evaluates the signals and data, acknowledges this to

the NCK and transfers the data to the application interface at the start of the cycle. If the data

do not require user acknowledgment, this does not affect NC processing.

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

7

Page 8

Brief description

Event-driven signal exchange PLC → NCK

An "eventdriven signal exchange PLC → NCK" takes place whenever the PLC passes a

request to the NCK (e.g., traversal of an auxiliary axis). In this case, the data transfer is also

controlled by acknowledgment. When performed from the user program, this type of signal

exchange is triggered using a function block (FB) or function call (FC).

The associated FBs (Function Blocks) and FCs (Function Calls) are supplied together with

the basic program.

Messages

User messages are acquired and conditioned by the basic program. A defined bit field is

used to transfer the message signals to the basic program. The signals are evaluated there

and entered in the PLC diagnostics buffer on the occurrence of the message events. If a

control unit is present, the messages are displayed on the operator interface.

Note

The function of the machine is largely determined by the PLC program. Every PLC program

in the working memory can be edited with the programming device.

Basic logic functions: PLC Basic program powerline (P3 pl)

8 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 9

Detailed description

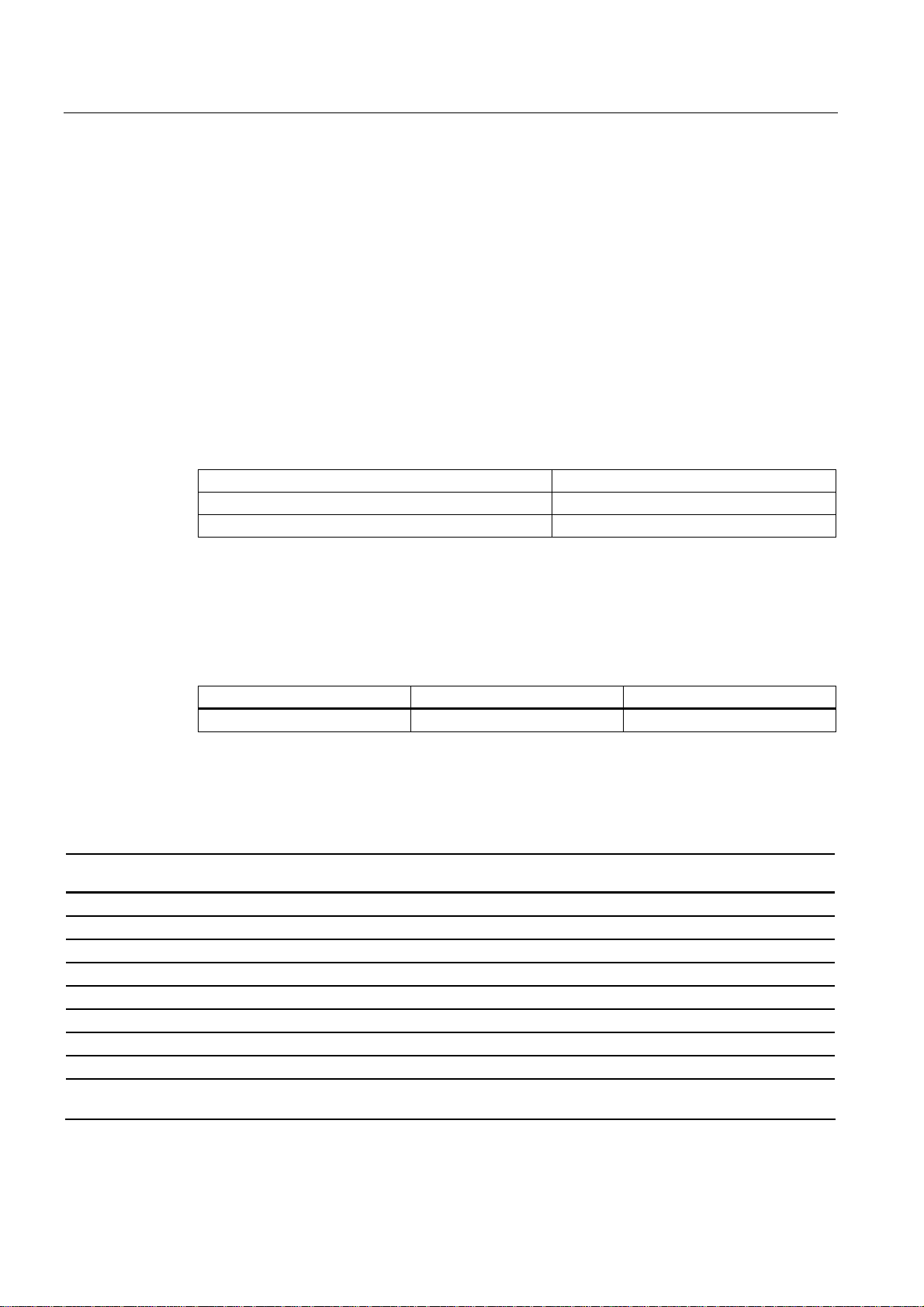

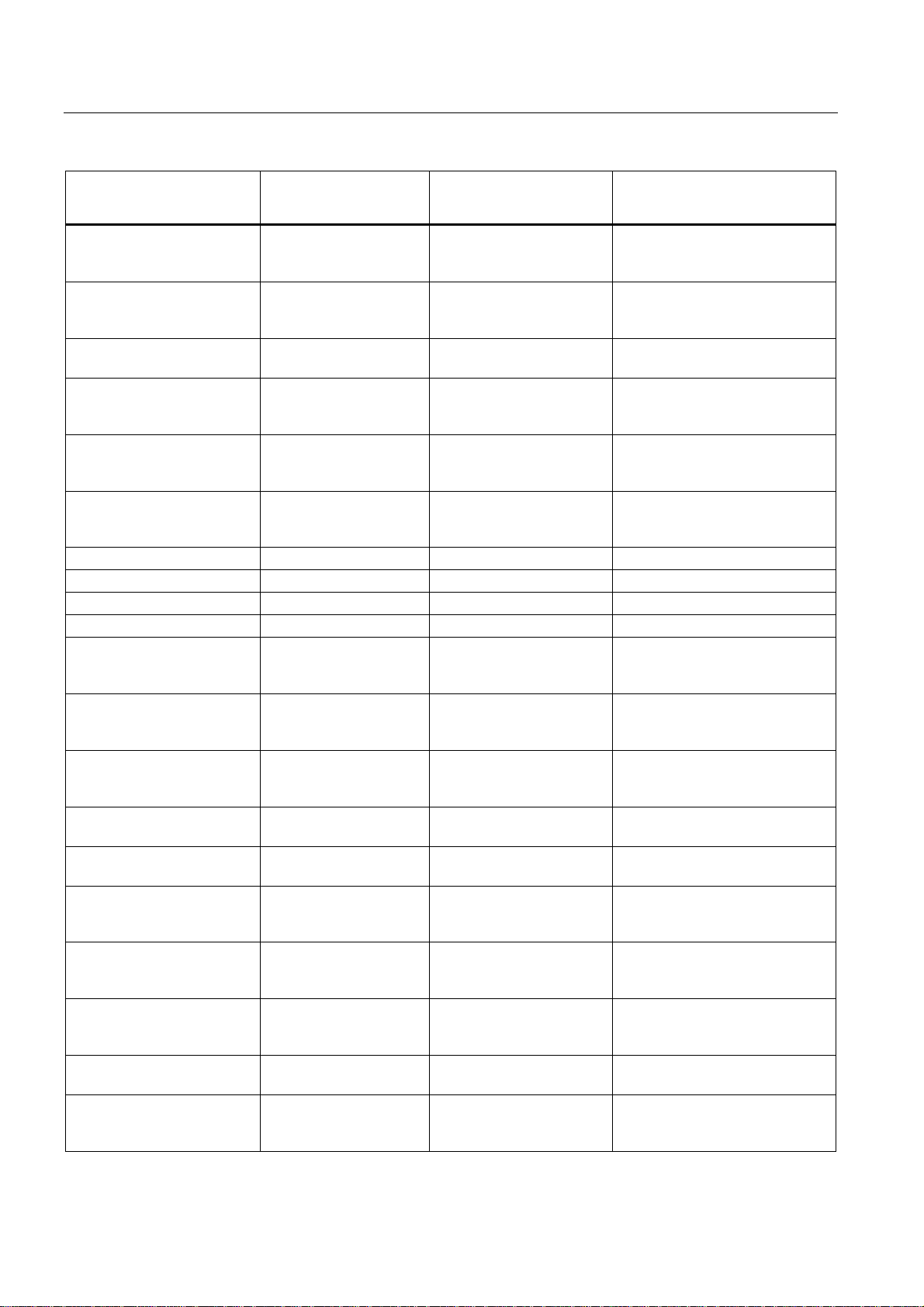

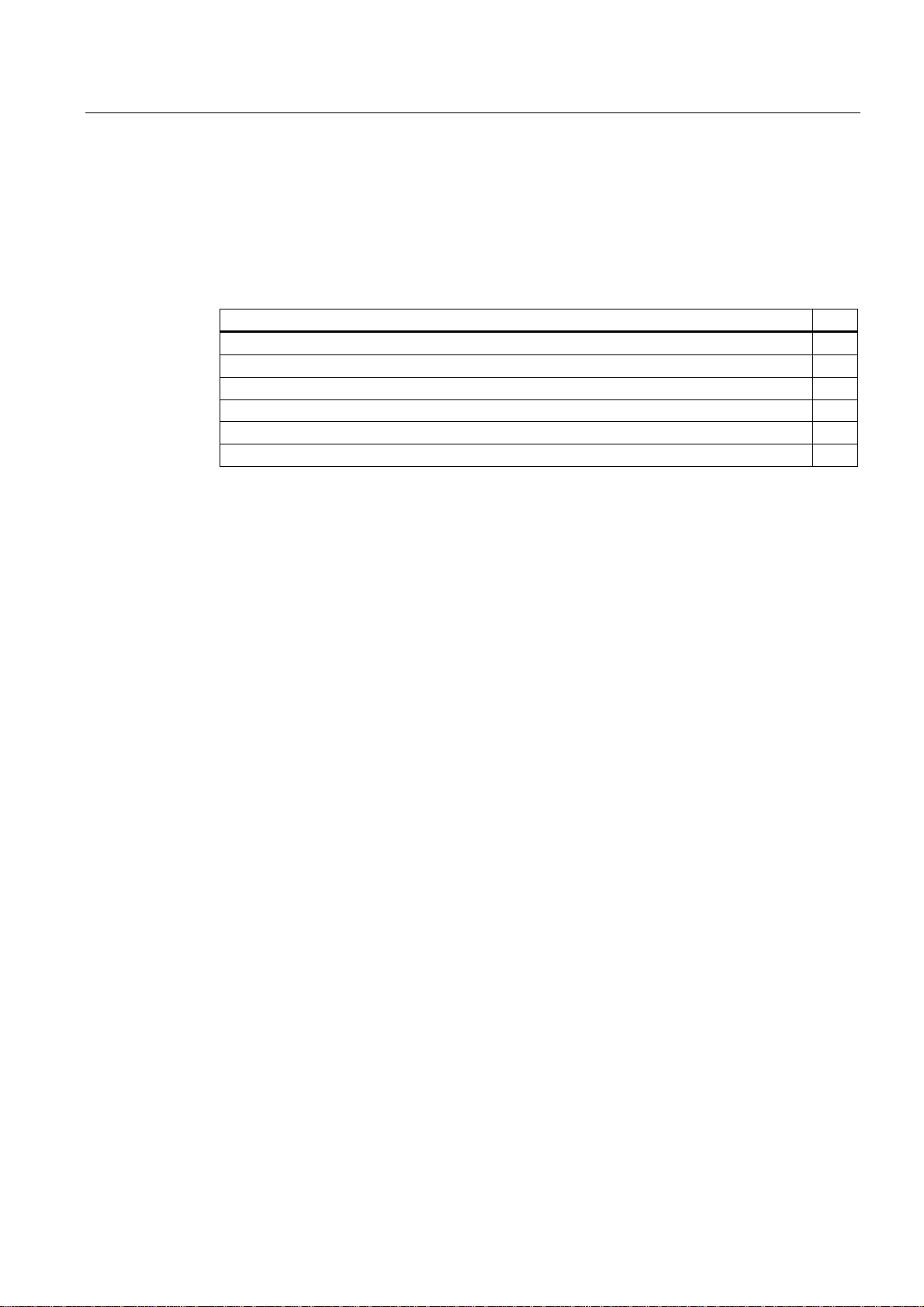

2.1 Key PLC CPU data for 810D, 840D and 840Di

The tables below show the performance range of the PLC CPUs and the scope of the

basic PLC program relative to the various controller types.

Type of control: 810D and 840D

Key CPU data

810D / 840D 810D / 840D 810D / 840D

PLC CPU

MLFB

Memory for user and basic

program

Data block memory Like user memory Like user memory Up to 96 KB

Memory submodule no no no

Bit memories 2048 2048 2048/ 4096 with PLC

Timers 128 128 128

Counters 64 64 64

Clock memories 8 8 8

Program/data blocks

OB

FB

FC

DB

Max. data block length 16 KB 16 KB 16 KB

Max. block length FC, FB 16 KB 24 KB 24 KB

Inputs/outputs

(address capacity)

- digital

- analog

Integrated PLC

CPU314

64, 96, 128 KB 64, 96 128, 160, 192, 224,

1, 10, 20, 35, 40,

80-82, 85, 87, 100,

121-122

1-127

1-127

1-127

768

64

Integrated PLC

CPU315-2DP

6ES7 315-2AF00-0AB0

256, 288 KB

(dependent on option)

1, 10, 20, 35, 40,

80-82, 85-87, 100,

121-122

1-127

1-127

1-127

1024/1024

64

Integrated PLC

CPU315-2DP master/slave

6ES7 315-2AF01-0AB0

96, 160, 224, 288, 352, 416,

480 kByte

(dependent on option)

operating system 03.10.13 or

later

1, 10, 20, 35, 40,

80-82, 85-87, 100,

121-122

0-255

0-255

1-399

1024/1024

64

2

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

9

Page 10

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

810D / 840D 810D / 840D 810D / 840D

Inputs/outputs 1)

(addressing)

- digital

- analog

Processing time

- Bit commands (I/O)

- Word commands

PDIAG (Alarm S,SQ) no no yes

PROFIBUS N/A Master Master/Slave

Number of PROFIBUS

slaves

programmable block

communication PBK

Consistent Data to standard

slave via SFC 14, 15

1) Subrack 0 is integrated in the NC. Subracks 1 to 3 are available for I/O devices.

Subrack 0 is not available for

I/O devices:

from I/O byte 32 onwards

from PI/PO byte 384

onwards

0.3 ms/kA

1-4 ms/kA

Min. 16, max. 64

no no yes

N/A 26 26

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

0.3 ms/kA

1-4 ms/kA

SDB 2000 ≤ 8 KB

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

0.3 ms/kA

1-4 ms/kA

Min. 16, max. 64

SDB 2000 ≤ 32 KB

I/O expansion

810D / 840D 810D / 840D 810D / 840D

PLC CPU

MLFB

I/O modules 24 24 24

PROFIBUS DP modules N/A yes yes

Interfaces (MPI) 1 1 1

Integrated PLC

CPU314

Integrated PLC

CPU315-2DP

6ES7 315-2AF00-0AB0

Integrated PLC

CPU315-2DP master/slave

6ES7 315-2AF01-0AB0

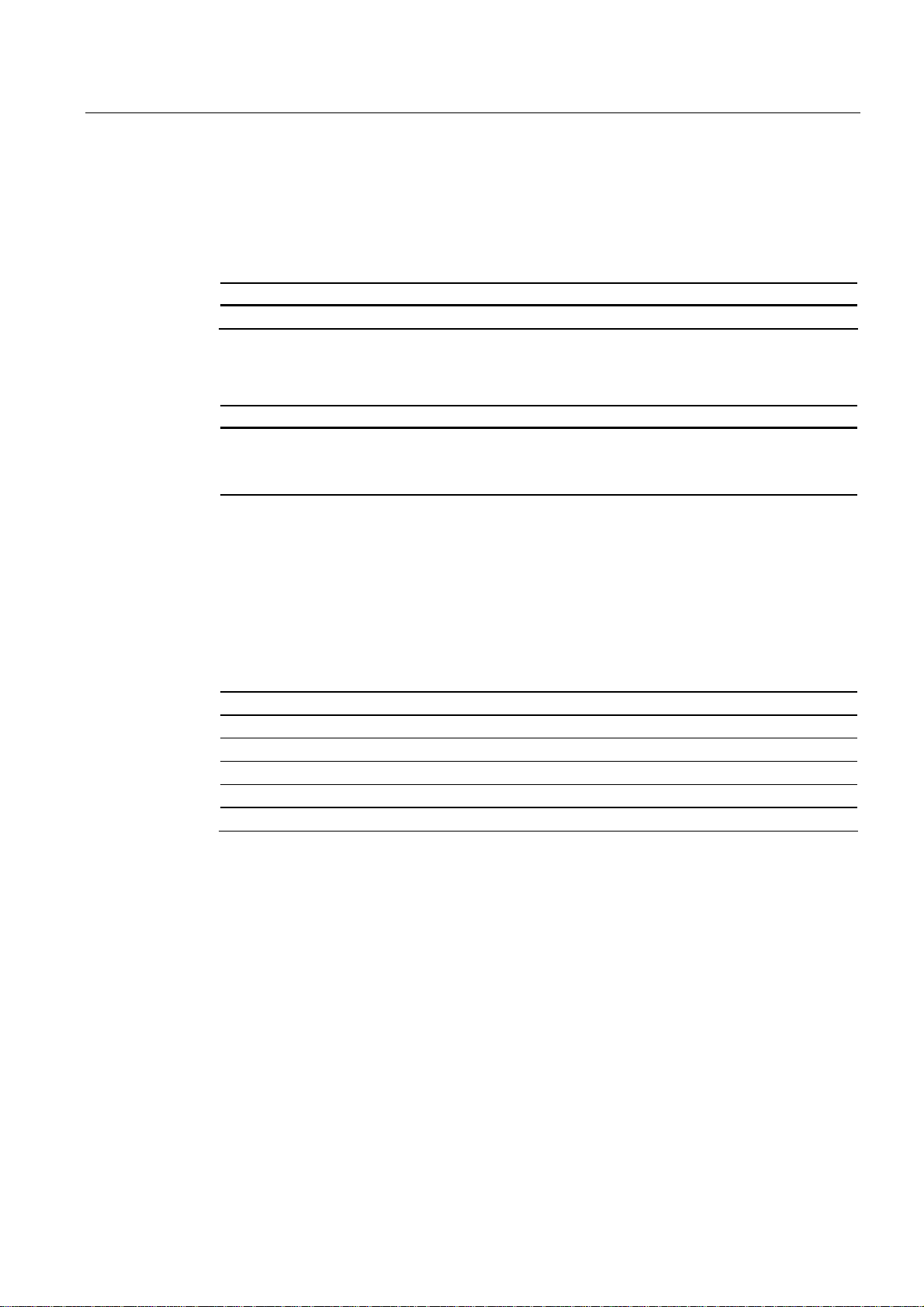

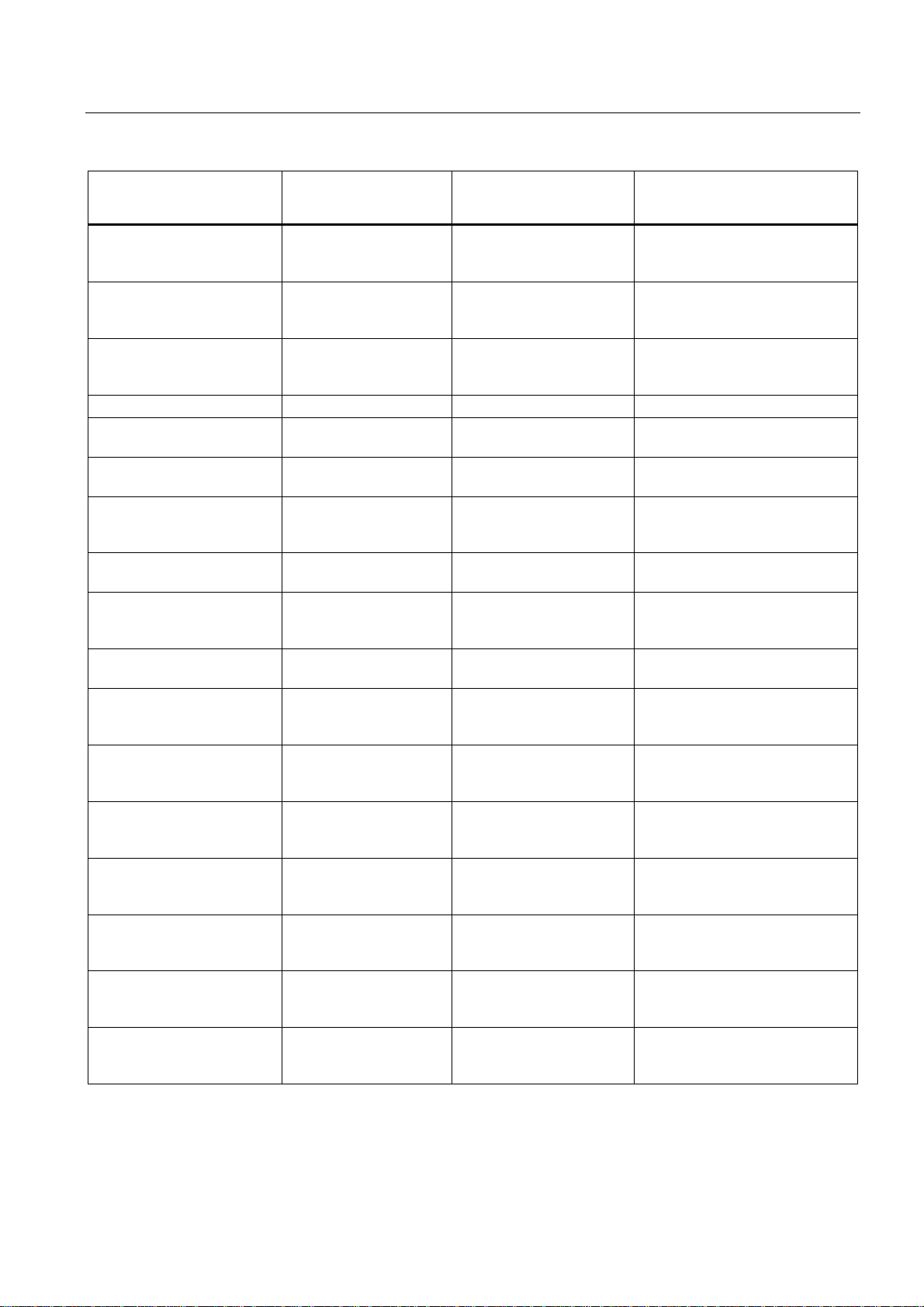

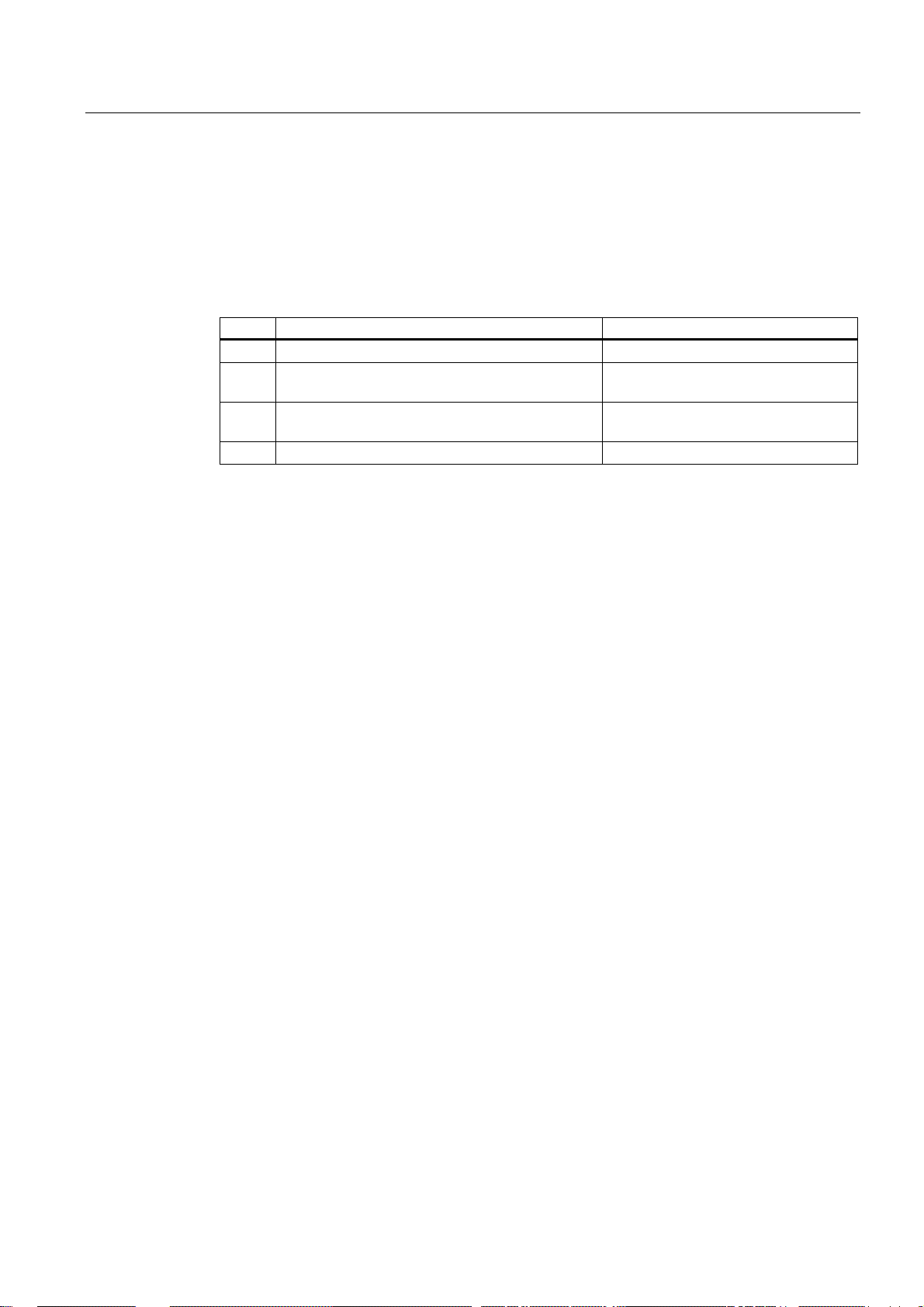

Types of control: 840Di, 810D and 840D

Key CPU data

840Di 810D 840D

PLC CPU

MLFB

Memory for user

and basic program

Data block memory Like user memory Like user memory Up to 96 KB

Memory submodule no no no

Bit memories 4096 4096 4096

Timers 128 128 256

Counters 64 64 256

Integrated PLC 315-2DP

master/slave

6ES7 315-2AF03-0AB0

64, 96, 128, 160, 192, 224,

256 KB

Integrated PLC 315-2DP

master/slave

6ES7 315-2AF03-0AB0

64, 96, 128, 160, 192, 224,

288 KB

Integrated PLC 314C-2DP

master/slave

6FC5 314-6CF00-0AB0

96, 160, 224, 352, 416, 480

KB

(dependent on option)

Basic logic functions: PLC Basic program powerline (P3 pl)

10 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 11

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

840Di 810D 840D

Clock memories 8 8 8

Program/data blocks

OB

FB

FC

DB

Max. length of data block 16 KB 16 KB 16 KB

Max. block length FC, FB 24 KB 24 KB 24 KB

Inputs/outputs

(address capacity)

- digital

- analog

Inputs/outputs 1)

(addressing)

- digital

- analog

Processing time

- Bit commands (I/O)

- Word commands

PDIAG (Alarm S,SQ) Yes Yes Yes

PROFIBUS Master Master/Slave Master/Slave

Number of PROFIBUS

slaves

Max. number of PROFIBUS

slots

programmable block

communication PBK

Consistent Data to standard

slave via SFC 14, 15

1) Subrack 0 is integrated in the NC. Subracks 1 to 3 are available for I/O devices.

1, 10, 20, 35, 40,

80-82, 85-87, 100,

121-122

0-255

0-255

1-399

1024/1024

64

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

(Profibus only)

0.3 ms/kA

1-4 ms/kA

Max. 64

SDB 2000 ≤ 32 KB

256 256 256

Yes Yes Yes

26 26 32

1, 10, 20, 35, 40,

80-82, 85-87, 100,

121-122

0-255

0-255

1-399

1024/1024

64

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

0.3 ms/kA

1-4 ms/kA

Max. 64

SDB 2000 ≤ 32 KB

1, 10, 20, 35, 40,

80-82, 85-87,100,

121-122

0-255

0-255

1-399

1024/1024

64

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

0.1 ms/kA

0.25-1.2 ms/kA

Max. 32

SDB 2000 ≤ 32 KB

I/O expansion

840Di 810D 840D

PLC CPU

MLFB

I/O modules PROFIBUS only 24 24

PROFIBUS DP modules Yes Yes Yes

Interfaces (MPI) 1 1 1

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Integrated PLC 315-2DP

master/slave

6ES7 315-2AF03-0AB0

Integrated PLC 315-2DP

master/slave

6ES7 315-2AF03-0AB0

Integrated PLC 314C-2DP

master/slave

6FC5 314-6CF00-0AB0

11

Page 12

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

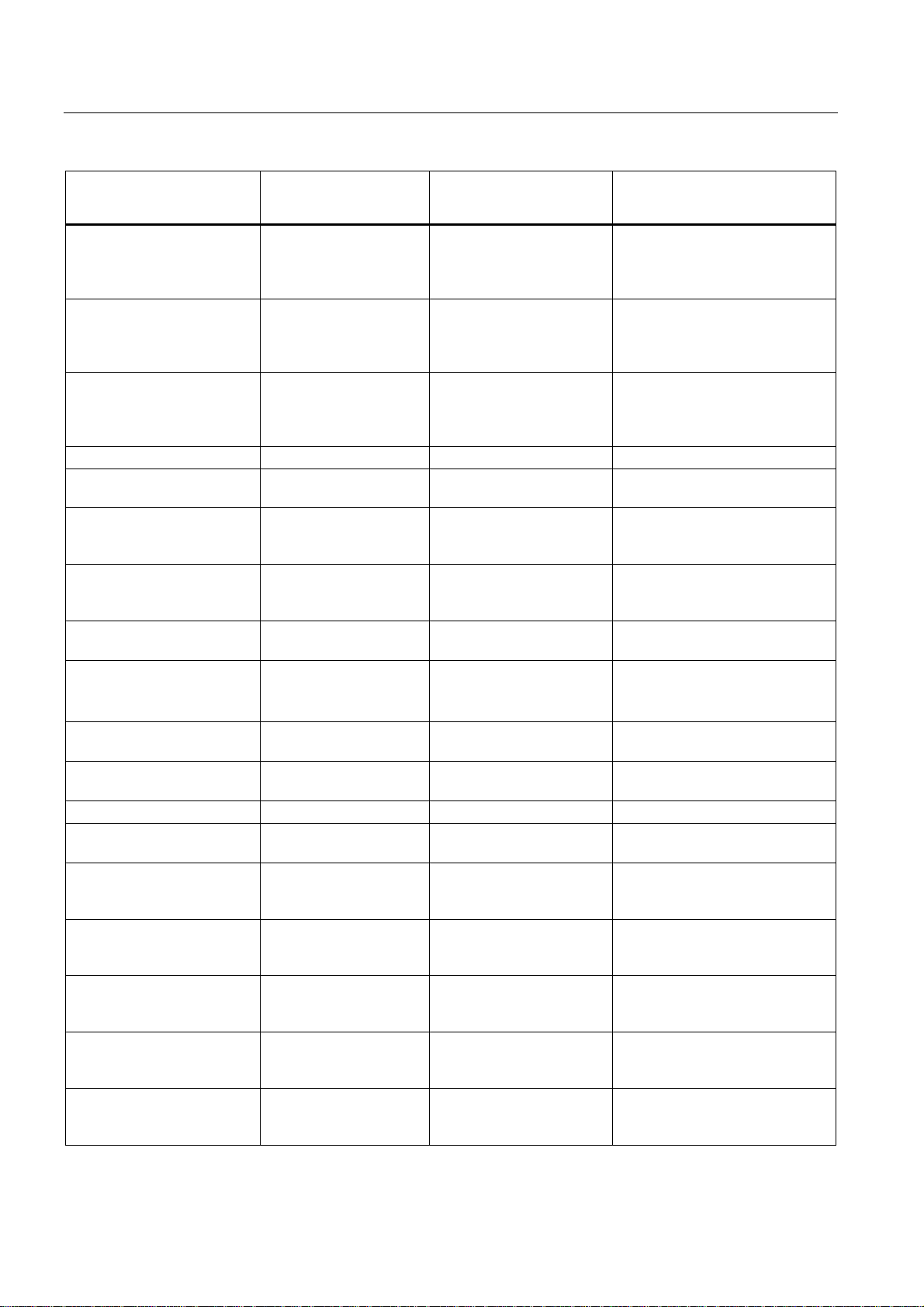

Types of control: 840Di and 840D

Key CPU data

840Di 840D

PLC CPU

MLFB

Memory for user

and basic program

Data block memory Max. 256 KB Max. 256 KB

Memory submodule no no

Bit memories 32768 32768

Timers 512 512

Counters 512 512

Clock memories 8 8

Program/data blocks:

OB

FB

FC

DB

Max. length of data block 32 KB 32 KB

Max. block length FC, FB 64 KB 64 KB

Inputs/outputs 1)

(address capacity in bytes):

- digital / - analog

- incl. reserved area

- process image

Note: The inputs/outputs

above 4096 are reserved for

integrated drives.

Inputs/outputs 2)

(addressing):

- digital

- analog

Machining time:

- Bit commands (I/O)

- Word commands

PDIAG (Alarm S,SQ) Yes Yes

PROFIBUS Master/Slave Master/Slave

Number of PROFIBUS

slaves

Max. number of PROFIBUS

slots

DP master system no. DP 1 1

Integrated PLC 317-2DP

master/slave

6FC5 317-2AJ10-0AB0

128 to 768 KB 128 to 768 KB

10, 20-21, 32-35, 40, 55-57,

80, 82, 85-87, 100,

121-122

0-2048

0-2048

1-2048

4096/4096

8192/8192

256/256

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

(Profibus only)

≤ 0.03 ms/kA

0.1 ms/kA

max. 125 max. 125

512 512

Integrated PLC 317-2DP

master/slave

6FC5 317-2AJ10-1AB0

10, 20-21, 32-35, 40, 55-57,

80, 82, 85-87,100,

121-122

0-2048

0-2048

1-2048

4096/4096

8192/8192

256/256

Through optional configuring

of I/O devices:

from I/O byte 0 onwards

from PI/PO byte 272

onwards

≤ 0.03 ms/kA

0.1 ms/kA

Basic logic functions: PLC Basic program powerline (P3 pl)

12 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 13

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

840Di 840D

DP master system no.

MPI/DP

programmable block

communication PBK

Consistent Data to standard

slave via SFC 14, 15

1) Notice!: The inputs/outputs above 4096 are reserved for integrated drives.

2) Subrack 0 is integrated in the NC. Subracks 1 to 3 are available for I/O devices.

2 N/A

Yes Yes

128 128

I/O expansion

840Di 840D

PLC CPU

MLFB

I/O modules PROFIBUS only 24

PROFIBUS DP modules 1 (2) 1

Interfaces (MPI) 1 (0) 1

Integrated PLC 317-2DP

master/slave

6FC5 317-2AJ10-0AB0

Integrated PLC 317-2DP

master/slave

6FC5 317-2AJ10-1AB0

Note

Number of PROFIBUS slaves

Because SDB 2000 and other SDBs must be stored by the PLC operating system in the

static RAM area, which the Profibus ASIC can also access, the information from SDB2000

can continue to be transferred to the NCK and the PLC basic program in conditioned form

(CPI interface).

This is necessary for controlling the drives and PROFIsafe modules on Profibus. A memory

area defined by the PLC is available for these data structures. Its size is limited by the

maximum number of slots. This means that during loading, SDBs with fewer slaves than

listed above may be rejected. A slot is usually a slave module or the slave itself. Only in a

module with both I and Q areas does one module count as 2 slots.

It is, therefore, not possible to specify the size of SDB 2000 exactly.

It is only possible to say whether the configuration is permssible after the SDB container has

been loaded into the CPU. The values specified in the tables mentioned above are therefore

only intended as guidelines.

If the configuration is impermissible, a request for a general reset is issued when the SDBs

are loaded. The cause of the configuring error can be found in the diagnostic buffer on

completion of the general reset.

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

13

Page 14

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

PLC versions

In SW 3.5 and higher on the 840D, version 6 (version code 35.06.03) is installed with PLC

314 and version 3 (version code 35.03.03) with PLC 315-2DP or higher.

These versions are compatible with the corresponding SIMATIC CPU300.

All modules and software packages approved by SIMATIC for these versions and CPUs are

therefore suitable. Modules that can only be installed in subrack 0 are the exception

(modules FM NC and FM 357 are also exceptions).

Version code: XX.YY.ZZ

• XX: SIMATIC CPU PLC version

• YY: Firmware transfer increment

• ZZ: Internal increment

Example

PLC 315-2DP with MLFB 6ES7 315-2AF00-0AB0: 04.02.14

PLC 315-2DP with MLFB 6ES7 315-2AF01-0AB0: 03.10.23

PLC 314: 07.02.12

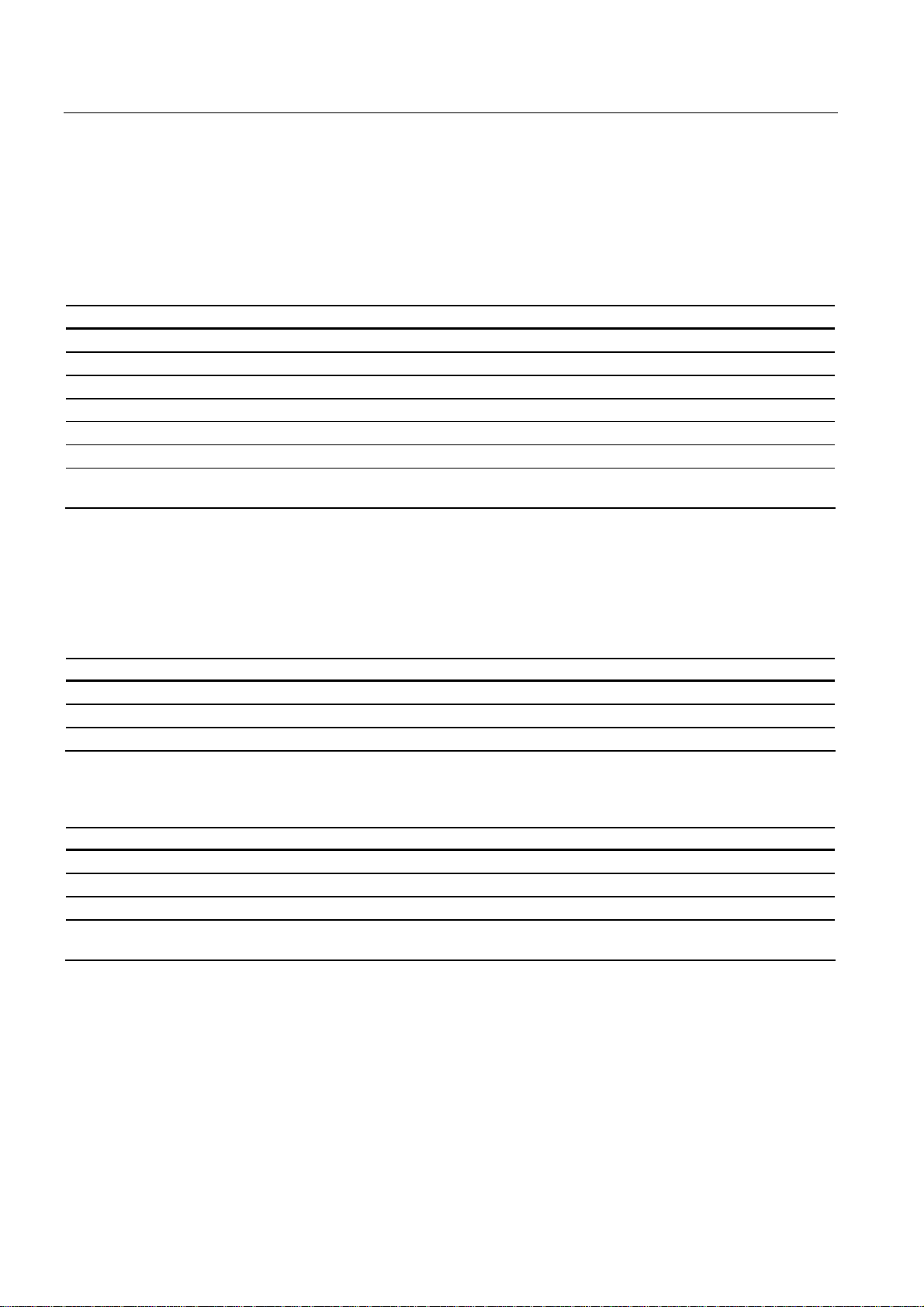

HMI version display

The PLC module, the PLC operating system version and the module code appear in the last

line of the HMI version display.

Example

PLC module PLC operating system version Module code

S7 PLC_315-2DP system 03.10.23 1200

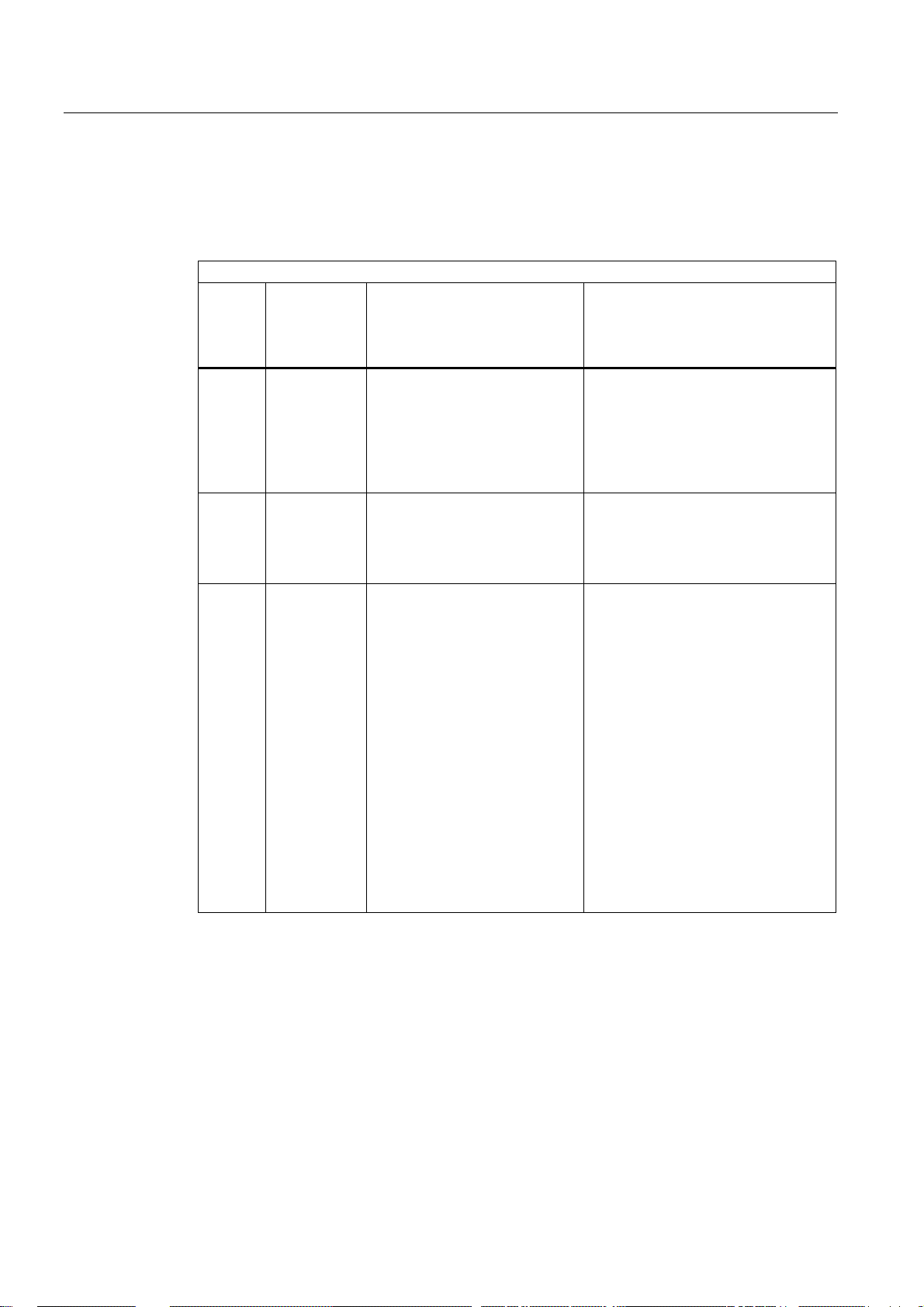

Module codes

The table below shows the relationship between the module code and the corresponding

PLC module, the suitable PLC operating system and its current software version:

Module code PLC module Suitable PLC operating systems

(corresponding SIMATIC MLFB)

0208 PLC 314 6ES7 314–1AE0–0AB0 07.02.12

1008 PLC 3152DP with ASPC 2 Step C 6ES7 315–2AF00–0AB0 04.02.14

1100 PLC 3152DP with ASPC 2 Step D 6ES7 315–2AF01–0AB0 03.10.23

1200 PLC 3152DP with ASPC 2 Step E 6ES7 315–2AF01–0AB0 03.10.23

6ES7 315–2AF03–0AB0 FW1.2 12.30.10

1400 PLC 314C2DP with IBC 16 6ES7 314–6CF00–0AB0 FW1.0.2 10.60.20

2200 PLC 317-2DP with IBC 32 6ES7 317–2AJ10–0AB0 FW2.1 20.71.15

MCI 1 (840Di) PLC 3152DP with ASPC 2 Step E 6ES7 315–2AF03–0AB0 FW1.0 04.20.36

MCI 2 (840Di)

2100

PLC 317-2DP with IBC32 6ES7 317–2AJ10–0AB0 FW2.1 20.70.17

PLC operating

system SW version

Basic logic functions: PLC Basic program powerline (P3 pl)

14 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 15

Detailed description

2.1 Key PLC CPU data for 810D, 840D and 840Di

810 D, 840D

The tables below show the key data of the OPI interface and the PLC basic program

functionality with reference to SINUMERIK 810D, 840D and 840Di:

OPI interface

840Di 810D 840D

Number N/A N/A 1

PLC basic program functions

840Di 810D 840D

Axes/spindles

channels

Mode groups

Status/control signals

M decoders (M00-99)

G group decoders

Aux. function distributors

Interrupt-driven output of auxiliary functions

Move axes/spindles from PLC

Async. subprogram interface

Error/operating messages

MCP and handheld unit signals via NCK

Reading/writing of NC variables + + +

PI services + + +

Tool management + + +

Star/delta switchover + + +

Display control handheld unit + + +

1)

Depends on chosen system software package

1)

1)

1)

+

+

+

+

+

+

+

+

5

2

1

+

+

+

+

+

+

+

+

31

10

10

+

+

+

+

+

+

+

+

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

15

Page 16

Detailed description

2.2 Reserve resources (timers, FC, FB, DB, I/O)

2.2 Reserve resources (timers, FC, FB, DB, I/O)

Reserved components

The components below are reserved for the basic program:

Component Reserved range

Timers T0 - T9

Functions (general) FC 0 - FC 29

Functions (in ShopMill/ShopTurn) FC 0 - FC 35

Function blocks FB 0 - FB 29

Data blocks (general)1) DB 1 - DB 62; DB 71 - DB 80

Data blocks (in ShopMill/ShopTurn) 1) DB 1 - DB 62; DB 71 - DB 89

1) The data blocks for channels, axes/spindles and tool management functions that are not activated may be assigned as

required by the user.

PLC 317-2DP

PLC CPU: PLC 317-2DP are reserved for further number bands for SIEMENS applications

referring to FC, FB, DB and I/O areas.

FC, FB and DB

Component Reserved range

Functions FC 1000 - FC 1023

Function blocks FB 1000 - FB 1023

Data blocks DB 1000 - DB 1099

I/O range

Component Reserved range

Address area 256 - 271 1)

Inputs/outputs 4096 upwards2)

1) Reserved for the NC module and future expansions

2) Reserved for integrated drives However, diagnostics addresses for modules can only be placed in the uppermost

address range, as suggested by STEP7.

Basic logic functions: PLC Basic program powerline (P3 pl)

16 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 17

Detailed description

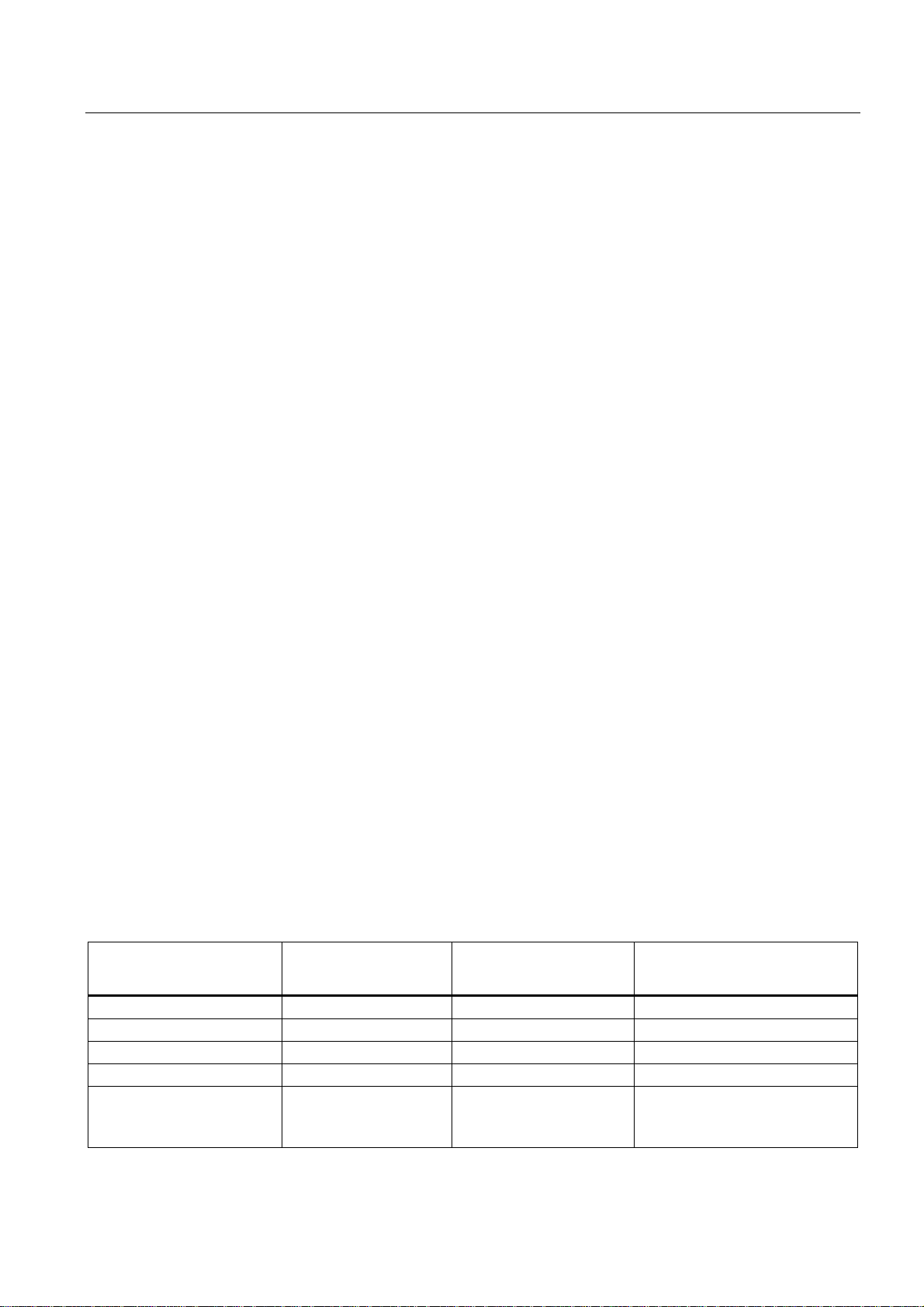

2.3 Starting up hardware configuration of PLC CPUs

2.3 Starting up hardware configuration of PLC CPUs

General procedure

STEP 7 is used to define the hardware configuration for a PLC CPU, including the

associated I/O.

The procedure to be followed is shown below:

1. Load tool box to PG/PC

2. Create a new project (File, New, Project)

3. Insert, Hardware, SIMATIC 300 station

4. Select SIMATIC 300 station1 with mouse

5. Open object by right-clicking with the mouse to start the HWConfig

6. Destination system, load to PG, the hardware equipment complement is read back from

the central system

7. Configure distributed I/Os

8. Insert PLC basic program

The addresses for the I/O modules can be changed if necessary (permissible only on certain

PLC CPUs, e.g. PLC 3152DP).

As an alternative, the entire hardware configuration can be entered manually (see also

appropriate STEP7 documentation). The notices below must be observed.

STEP7, Version 3

With STEP7 Version 3 and higher, the hardware configuration of the SINUMERIK

components must be defined via the entries in SIMATIC\RACK 300. The install or setup

program of the basic program on the tool box diskettes is required for this purpose.

STEP7 Version 5.1 SP2 and Toolbox 6.03.02

With STEP7 V5.1 SP2 and Toolbox 6.03.02 or later, the SINUMERIK components are stored

under SIMATIC 300\SINUMERIK. The current hardware expansion for STEP 7 can also be

found under eSupport.

Current path (02/13/2004): sinumerik_software > 840d/810d/fm-nc > patches & fixes > plc >

Hardware_fuer_STEP7 > Hardware upto NCU*.5/CCU3/840Di_MCI2 > V6.5.2.0

NCU

CCU1 810D CPU 6FC5 410-0AA00-0AA0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

CCU2 810D CPU 6FC5 410-0AA01-0AA0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

CCU1 810DE CPU 6FC5 410-0AY01-0AA0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

CCU2 810D CPU 6FC5 410-0AX02-0AA0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

SINUMERIK 810DE Light

CCU1 module

with system software (export)

MLFB

6FC5 410-0AY00-0AA0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

Comparable

SIMATIC CPU MLFB

included

Selection from STEP7 hardware

catalog

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

17

Page 18

Detailed description

2.3 Starting up hardware configuration of PLC CPUs

NCU

SINUMERIK 810D CCU2

module with system software

(standard)

SINUMERIK 840DE NCU

561.2 without system

software

SINUMERIK 840D NCU 571

(export version)

SINUMERIK 840D NCU 571

(export version) with

PROFIBUS DP

SINUMERIK 840D NCU

571.2 (export version) with

PROFIBUS DP

SINUMERIK 840DE NCU

571.2 without system

software

SINUMERIK 840D NCU 572 6FC5 357-0BA20-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

SINUMERIK 840D NCU 572 6FC5 357-0BA20-1AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

SINUMERIK 840D NCU 572 6FC5 357-0BA21-0AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

SINUMERIK 840D NCU 572 6FC5 357-0BA21-1AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

SINUMERIK 840D NCU

572.2 (export version) with

PROFIBUS DP

SINUMERIK 840D/DE NCU

572.2 without system

software

SINUMERIK 840D/DE NCU

572.3 without system

software

SINUMERIK 840D NCU 572

(export version)

SINUMERIK 840D NCU 572

(export version)

SINUMERIK 840D NCU 572

(export version) with

PROFIBUS DP

SINUMERIK 840D NCU 572

(export version) with

PROFIBUS DP

SINUMERIK 840D NCU

572.2 (export version) with

PROFIBUS DP

SINUMERIK 840D NCU 572

with digitizing

SINUMERIK 840D NCU

572.2 with digitizing and

PROFIBUS DP

MLFB

6FC5 410-0AX02-1AA0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 356-0BB11-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BA10-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BA11-0AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BA11-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB11-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BA21-1AE1 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB21-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB22-0AE0 6ES7 315-2AF01-0AB0 10D/840D with PLC315-2AF01

6FC5 357-0BY20-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BY20-1AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BY21-0AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BY21-1AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BY21-1AE1 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BA24-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BA24-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

Comparable

SIMATIC CPU MLFB

included

Selection from STEP7 hardware

catalog

Basic logic functions: PLC Basic program powerline (P3 pl)

18 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 19

Detailed description

2.3 Starting up hardware configuration of PLC CPUs

NCU

SINUMERIK 840D/DE NCU

572.2 without system

software

SINUMERIK 840D NCU 572

(export version) with

digitizing

SINUMERIK 840D NCU

572.2 (export version) with

digitizing and PROFIBUS DP

SINUMERIK 840D NCU 573 6FC5 357-0BA30-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

SINUMERIK 840DE NCU

573 (export version)

SINUMERIK 840D NCU 573

with digitizing

SINUMERIK 840D NCU 573

(export version) with

digitizing

SINUMERIK 840D NCU 573

with PROFIBUS DP

SINUMERIK 840D NCU 573

(export version) with

PROFIBUS DP

SINUMERIK 840D NCU 573

with PROFIBUS DP

SINUMERIK 840D NCU 573

(export version) with

PROFIBUS DP

SINUMERIK 840D NCU

573.2 (Pentium Pro) up to 12

axes with PROFIBUS DP

SINUMERIK 840D NCU

573.2 (Pentium Pro) up to 31

axes with PROFIBUS DP

SINUMERIK 840D/DE NCU

573.2 without system

software

SINUMERIK 840D/DE NCU

573.2 Pentium II without

system software

SINUMERIK 840D NCU

573.2 (Pentium Pro) for

digitizing with PROFIBUS DP

SINUMERIK 840D/DE NCU

573.2 without system

software

MLFB

6FC5 357-0BB24-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BY24-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BY24-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BY30-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BA31-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BY31-0AE0 6ES7 314-1AE01-0AB0 810D/840D with PLC314

6FC5 357-0BA32-0AE1 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BY32-0AE1 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BA33-0AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BY33-0AE0 6ES7 315-2AF00-0AB0 840D with PLC3152AF00

6FC5 357-0BA32-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BA33-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB33-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB33-0AE1 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BA31-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB31-0AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

Comparable

SIMATIC CPU MLFB

included

Selection from STEP7 hardware

catalog

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

19

Page 20

Detailed description

2.3 Starting up hardware configuration of PLC CPUs

NCU

SINUMERIK 840D NCU

573.2 (Pentium Pro) (export

version) for 12 axes with

PROFIBUS DP

SINUMERIK 840D NCU

573.2 (Pentium Pro) (export

version) for 31 axes with

PROFIBUS DP

SINUMERIK 840D NCU

573.2 (Pentium Pro) (export

version) for digitizing with

PROFIBUS DP

SINUMERIK 840Di 6FC5 220-0AA00-1AA0 6ES7 315-2AF03-0AB0 810D/810Di with PLC315-2AF03

SINUMERIK 840Di with PK

bus

SINUMERIK 840D NCU

572.3

SINUMERIK 840D NCU

572.3

SINUMERIK 840D NCU

573.3

SINUMERIK 840D NCU

573.3

SINUMERIK 840D NCU

572.4

SINUMERIK 840D NCU

573.4

SINUMERIK 810D CCU3 6FC5 410-0AY03-0AA0 6ES7 315-2AF03-0AB0 810D/840D with PLC315-2AF03

SINUMERIK 840D NCU

571.3

SINUMERIK 840D NCU

561.3

SINUMERIK 840D NCU

571.4

SINUMERIK 840D NCU

561.4

SINUMERIK 840D NCU

573.5

SINUMERIK 840Di with

MCI2

MLFB

6FC5 357-0BY32-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BY33-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BY31-1AE0 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6ES7 315-2AF03-0AB0 810D/810Di with PLC315-2AF03,

6FC5 357-0BB22-0AE0 with operating system

6FC5 357-0BB22-0AE0 with operating system

6FC5 357-0BB33-0AE2 6ES7 315-2AF01-0AB0 810D/840D with PLC3152AF01

6FC5 357-0BB33-0AE2 with operating system

6FC5 357-0BB23-0AE0 6ES7 314-6CF00-0AB0 810D/840D with PLC314C-2DP

6FC5 357-0BB34-0AE1 6ES7 314-6CF00-0AB0 810D/840D with PLC314C-2DP

6FC5 357-0BB11-0AE1 6ES7 315-2AF03-0AB0 810D/840D with PLC315-2AF03

6FC5356-0BB11-0AE1 6ES7 315-2AF03-0AB0 810D/840D with PLC315-2AF03

6FC5357-0BB12-0AE0 6ES7 314-6CF00-0AB0 810D/840D with PLC314C-2 DP

6FC5356-0BB12-0AE0 6ES7 314-6CF00-0AB0 810D/840D with PLC314C-2 DP

6FC5357-0BB35-0A E0 6ES7 317-2AJ00-0AB0 810D/840D with PLC317-2 DP

6FC5 222-0AA02-1AA0 6ES7 317-2AJ00-0AB0 810Di with PLC317-2 DP

Comparable

SIMATIC CPU MLFB

included

03.10.23:

6ES7 315-2AF01-0AB0

12.30.07:

6ES7 315-2AF03-0AB0

12.30.07:

6ES7 315-2AF03-0AB0

Selection from STEP7 hardware

catalog

PK bus

810D/840D with PLC3152AF01

810D/840D with PLC315-2AF03

810D/840D with PLC315-2AF03

(as of STEP7 V5.0 and Toolbox

05.03.05)

(as of STEP7 V5.0 and Toolbox

05.03.05)

(STEP7 V5.1 SP3 and higher

and Toolbox 06.03.02)

(STEP7 V5.1 SP3 and higher

and Toolbox 06.03.02)

(STEP7 V5.2 SP1 and higher

and Toolbox 06.05.02)

(STEP7 V5.2 SP1 and higher

and Toolbox 06.05.02)

Basic logic functions: PLC Basic program powerline (P3 pl)

20 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 21

Detailed description

2.3 Starting up hardware configuration of PLC CPUs

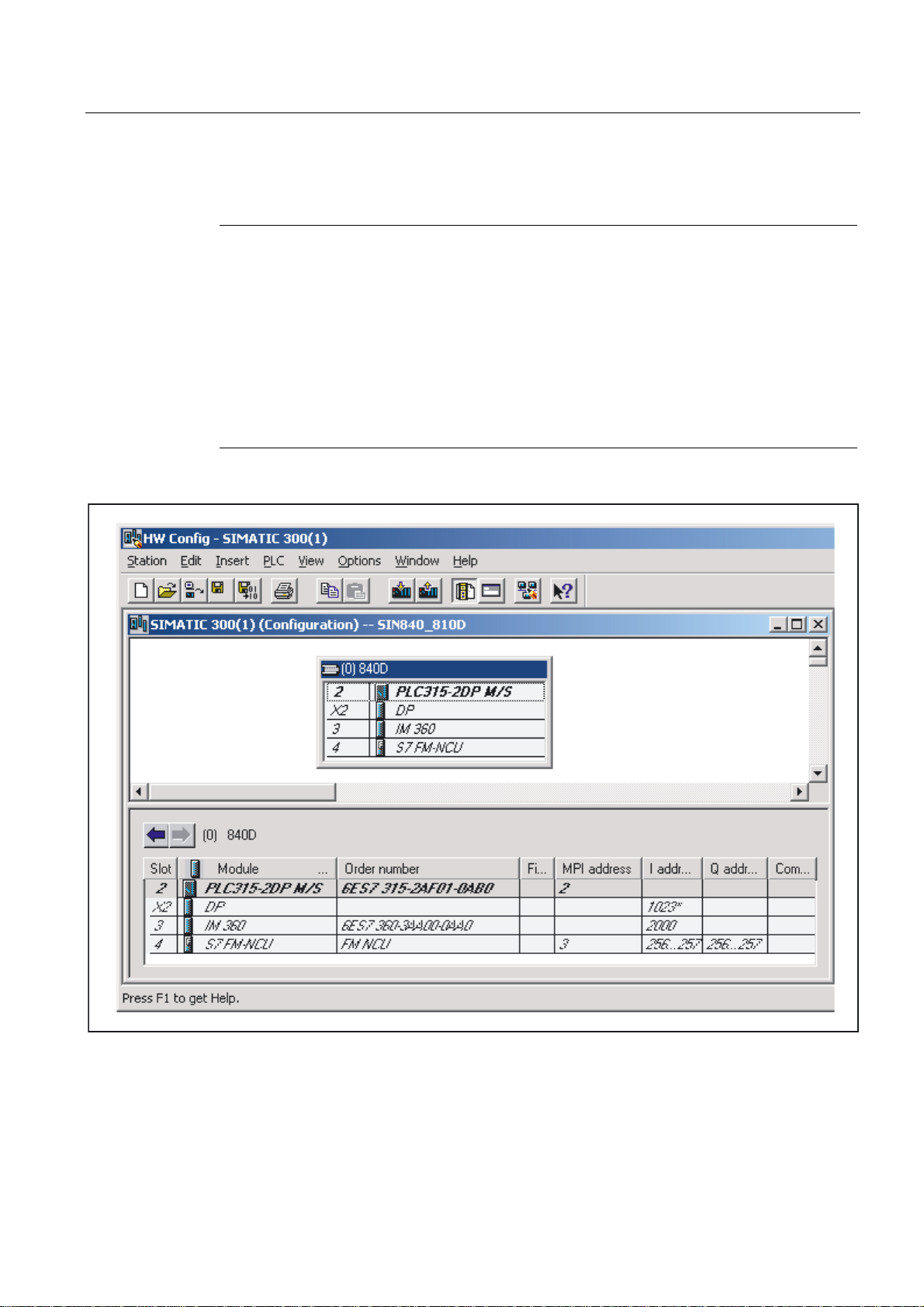

Note

On the SINUMERIK 810D or 840D, SIMATIC subrack 0 is integrated in the NC. The

following components are plugged into this subrack:

- Slot 2: The integrated PLC (PLC 314 or PLC 315-2DP)

- Slot 3: An IM 360

- Slot 4: The FM NCU.

With PLC 314, NC software version 3.5 and higher, the FM NCU must also be defined if

further MPI (C bus) devices are included in subrack 1 to subrack 3 (e.g., FM modules with C

bus connection). The properties of the FM NCU must not be changed, as process interrupts

(e.g. auxiliary functions) of the NCU may, in this case, no longer function.

Figure 2-1 Hardware configuration of row 0 on 810D, 840D

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

21

Page 22

Detailed description

2.4 Starting up the PLC program

MCP (Machine Control Panel) and HHU (HandHeld Unit)

(only for SINUMERIK 810D to SW 3.x)

If the MCP or HHU is configured (deviation from the norm), an additional SIMATIC 300

station must be inserted into the machine project for each operator component. Any type of

CPU must be inserted in location 2 on row 0 in this station by means of the hardware

configuration (HW config.). The MPI address of the operator component must be set as the

MPI address. MPI network (1) can then be marked in the SIMATIC manager. The global data

can then be activated via the "Tools" menu item.

The rest of the procedure is described in detail in the Commissioning Manual.

2.4 Starting up the PLC program

2.4.1 Installing the basic program for 810D, 840D

Before initial startup of the NC, an NC and PLC general reset must be carried out to initialize

the relevant memory areas. To do this, set switch S3 to setting 1 and switch S4 to setting 3

and switch the control off and on again (POWER ON reset).

Installation

General

With Toolbox SW 6.1 and higher, the installation is performed by a WINDOWS-compliant

setup program for the basic program, hardware selection in STEP7 (SINUMERIK

810D/840D option package) and the NC-Var Selector. To start the installation, run

"setup.exe" in the main CD directory. You can then choose which components to install.

After the installation, you can select the basic program library directly from STEP 7

(gp8x0d61, 61 is the main basic program version).

The concrete version of the basic program can be scanned for the object properties of the

library or the program folder in the comment field.

From software version 3.7 to version 4.2, installation is carried out using INSTALL.BAT

(INSTALL1.BAT, INSTALL4.BAT).

This program installs the basic program and additional files for the relevant STEP7 version.

With automatic installation in STEP 7 V3 and higher, the TYP, GSD and meta files in the

hardware catalog are also augmented and updated.

The hardware components of the SINUMERIK system are then also available for hardware

configuration under STEP 7. This eliminates the need for unzipping, mentioned below.

The basic program is supplied in zipped format as a project for STEP 7 Version 1.x or as a

library for STEP 7 Version 2.x and subsequent versions.

The OB source programs, including standard parameterization, interface symbols and DB

templates for handheld unit and M decoding functions are enclosed in the SIMATIC project

or SIMATIC library of the basic program.

STEP 7 must be installed before the basic program.

Basic logic functions: PLC Basic program powerline (P3 pl)

22 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 23

Detailed description

2.4 Starting up the PLC program

STEP7 V1.x

The basic program is stored as a compressed file with the name GP840D.EXE (or

GP810D.EXE and GPFMNC.EXE) in the main directory on the diskette. The basic program

(GP840D.exe) must be copied to the main directory (root) of a drive (e.g., c:\) and then

called. The project structure required for the basic program is generated automatically. The

catalog name of the basic program is GP840Dxy.S7A. In this case, xy stands for the basic

program version.

STEP7 V2.x, 3.x

Note

When STEP 7 V1 is used, the GP840Dxy.S7A catalog must be copied to the root directory.

Any existing catalog with the same name GP840Dxy.S7A must be deleted beforehand.

The basic program is stored as a compressed file with the name "GP840D.EXE" in directory

S7V2.840 or S7V2.810 or S7V2 on the basic program diskette. The basic program

(GP840D.exe) must be copied to subcatalog "S7LIBS" of STEP7 V2 (step7_v2) or

subsequent versions thereof and then called. The library structure required for the basic

program is generated automatically. The catalog name of the basic program is GP840Dxy. In

this case, xy stands for the basic program version. The file "MET.EXE" must be copied to the

basic catalog of STEP 7 and called from there via the DOS window with "MET.EXE –O".

Note

The name GP840D specified above refers to the basic program of the SINUMERIK 840D.

The basic program is named GP810D on the SINUMERIK 810D and GPFMNC on the FMNC. With effect from SW 4.2, the basic program for 810D and 840D is combined. It is now

called GP8x0D.

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

23

Page 24

Detailed description

2.4 Starting up the PLC program

2.4.2 Application of basic program

A new CPU program (e.g., "Turnma1") must be set up in a project by means of the STEP7

software for each installation (machine).

Comment

The catalog structures of a project and the procedure for creating projects and user

programs are described in the relevant SIMATIC documentation.

STEP7 V1

A network link to the PLC must be activated for the machine CPU program under menu

items "Edit", "Configuration". This is done in the "Services", "Parameterize" menu followed by

selection of the MPI parameters.

Default:

• "Networked"

• "MPI subnetwork number = 0"

STEP7 V2

• "CPU MPI Addr = 2"

The following must be copied into the CPU program for the machinespecific program files:

1. The basic-program blocks (FCs, FBs, DBs, OBs, SFCs, SFBs, and UDTs) ("File",

"Manage Project" menu in the Step7 program editor).

2. File GPOB840D.AWL (or GPOB810D.AWL or GPOBFMNC.AWL) and other STL (AWL)

files if appropriate must also be copied from the basic program catalog into the CPU

program. The OBs contained in this file are the basis for the user program with the

associated basic program calls. Existing user blocks must be copied as STL files to the

newly created CPU program (catalog name CPU1.S7D) and compiled.

3. We also recommend that the symbolic names are transferred with the files from the basic

program package using the symbol editor.

The basic-program blocks are copied using the SIMATIC Manager and

"File"/"Open"/"Library".

The following sections must be copied from the library:

AP off: FCs, FBs, DBs, OBs, SFC, SFB, UDT and the SDB container.

For the 810D, the SDB container includes:

• The source_files (SO):

– GPOB810D or GPOB840D

– Possibly MDECLIST, HHU_DB and others

• Symbol table (SY)

Basic logic functions: PLC Basic program powerline (P3 pl)

24 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Note

The SDB container is only included for these control variants.

Page 25

Detailed description

2.4 Starting up the PLC program

Compatibility with STEP 7

No interdependencies exist between the basic program (including older program versions)

and currently valid versions of STEP 7.

2.4.3 Version codes

Basic program

The version of the basic program is displayed on the version screen of the HMI software

along with the controller type.

User Program

The user can define his/her own version code for the PLC user program in any data block in

the form of a data string containing a maximum of 54 characters. The data can contain a text

of the user's choice. Parameter assignments for this string are made via a pointer in FB 1.

Parameterization requires symbolic definition of the data block.

References::

/FB1/ Function Manual, Basic Functions; PLC – Basic Program (P3);

Chapter: Block Description

2.4.4 Machine program

The machine manufacturer creates the machine program using the library routines supplied

with the basic program. The machine program contains the logic operations and sequences

on the machine. The interface signals to the NC are also controlled in this program. More

complex communication functions with the NC (e.g., read/write NC data, tool-management

acknowledgments, etc., are activated and executed via basic-program FCs and FBs). The

machine program can be created in different creation languages (e.g., STL, LAD, CSF, S7

HIGRAPH, S7GRAPH, SCL). The complete machine program must be generated and

compiled in the correct sequence. This means that blocks that are called by other blocks

must generally be compiled before the blocks, which call them. If blocks that are called by

other blocks are subsequently modified in the interface (VAR_INPUT, VAR_OUTPUT,

VAR_IN_OUT, VAR) as the program is developed, then the call block and all blocks

associated with it must be recompiled. This general procedure applies analogously to

instance data blocks for FBs. If this sequence of operations is not observed, timestamp

conflicts occur when the data are retranslated into STEP7. In some cases, therefore, it may

not be possible to recompile blocks, creating problems, for example, with the "Block status"

function. It is moreover advisable to generate blocks in ASCIISTL by means of the STEP7

editor when they have been created in the ladder diagram or in single statements

(incremental mode).

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

25

Page 26

Detailed description

2.4 Starting up the PLC program

2.4.5 Data backup

The PLC-CPU does not save any symbolic names, but instead data type descriptions of the

block parameters:

• VAR_INPUT, VAR_OUTPUT, VAR_IN_OUT, VAR and

• the data types of the global data blocks.

Note

No sensible recompilation is possible without the related project for this machine. This

especially affects, for instance the function status of the block or the necessary changes

done in the PLC-CPU programs later. It is, therefore, necessary to keep a backup copy of

the STEP7 project located in the PLC CPU on the machine. This is a great help for the

service case and saves unnecessary consumption of time in restoring the original project.

If the STEP7 project exists and has been created according to the instructions given above,

then symbols can be processed in the PLCCPU on this machine. It may also be advisable to

store the machine source programs as AWL files in case they are required for any future

upgrade.

The source programs of all organization blocks and all instance data blocks should always

be available.

2.4.6 PLC series startup, PLC archives:

Generate series archive

Once the blocks have been loaded into the PLC CPU, a series archive can be generated via

the HMI operator interface for data backup on the machine. To ensure data consistency, this

backup must be created immediately after block loading when the PLC is in the Stop state. It

does not replace the SIMATIC project backup as the series archive saves binary data only,

and does not back up, e.g., symbolic information. In addition, no CPU DBs (SFC 22 DBs) or

SDBs generated in the CPU are saved.

In Toolbox 06.03.03 and STEP 7 V5.1 and higher, the PLC series archive can be generated

directly from the corresponding SIMATIC project.

To do this, select the "Options" → "Settings" menu item and the "Archive" tab in STEP 7. This

contains an entry "SINUMERIK (*.arc)", which must be selected to create a series startup

file. After selection of the archive, select the "File" → "Archive" menu item. The relevant

series archive will then be generated. If the project contains several programs, the program

path can be selected. A series archive is set up for the selected program path. All blocks

contained in the program path are incorporated into the archive, except for CPU-DBs (SFC

22 DBs).

The process of generating a series archive can be automated (comparable to the command

interface in STEP 7, V5.1 and higher). In generating this series archive, the command

interface is expanded.

Basic logic functions: PLC Basic program powerline (P3 pl)

26 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 27

Detailed description

2.4 Starting up the PLC program

Functions

The following functions are available for this expansion:

The functions (shown here in VB script) are not available until server instantiations and

Magic have been called:

Functions:

Const S7BlockContainer = 1138689, S7PlanContainer = 17829889

Const S7SourceContainer = 1122308

set S7 = CreateObject("Simatic.Simatic.1")

rem Instance command interface of STEP7

Set S7Ext = CreateObject("SimaticExt.S7ContainerExt")

Call S7Ext.Magic("")

Function Magic(bstrVal As String) As Long

Call gives access to certain functions. The function must be called once after server

instantiation. The value of bstrVal can be empty. This initiates a check of the correct Step7

version and path name in Autoexec. The functions are enabled with a return parameter of 0.

Return parameter (-1) = incorrect STEP 7 version

Return parameter (-2) = no entry in Autoexec.bat

Function Magic(bstrVal As String) As Long

Function MakeSeriesStartUp(FileName As String, Option As Long, Container As

S7Container) As Long

"Option" parameter:

0: Normal series startup file with general reset

Bit 0 = 1: Series startup file without general reset. When project contains SDBs, this

option is inoperative.

A general reset is then always executed.

Bit 1 = 1: Series start-up file with PLC restart

Return parameter value:

0 = OK

-1 = Function unavailable, call Magic function beforehand

-2 = File name cannot be generated

-4 = Container parameter invalid or container block empty

-5 = Internal error (memory request rejected by Windows)

-6 = Internal error (problem in STEP 7 project)

-7 = Write error when generating series startup files (e.g., diskette full)

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

27

Page 28

Detailed description

2.4 Starting up the PLC program

Use in script

If S7Ext.Magic("") < 0 Then

Wscript.Quit(1)

End If

Set Proj1 = s7.Projects("new")

set S7Prog = Nothing

Set s7prog = Proj1.Programs.Item(1) 'if there is only one program'

For i = 1 to S7Prog.Next.Count

Next

Error = S7Ext.MakeSerienIB("f:\dh\arc.dir\PLC.arc", 0, Cont)'Error analysis now'

Set Cont = S7Prog.Next.Item(i)

Check block container

If (Cont.ConcreteType = S7BlockContainer) Then

Exit For

End if

2.4.7 Software upgrades

Software upgrade

Whenever you update the PLC or NCK software, always reset the PLC to its initial state first.

This initial clear state can be achieved by means of a general PLC reset. All existing blocks

are cleared when the PLC is reset.

It is usually necessary to include the new basic program when a new NC software version is

installed. The basic programs blocks must be loaded into the user project for this purpose.

OB 1, OB 40, OB 100, FC 12 and DB 4 should not be loaded if these blocks are already

included in the user project. These blocks may have been modified by the user. The new

basic program must be linked with the user program.

To do this, proceed as follows:

1. Generate the text or source file of all user blocks before copying the basic program.

2. Then copy the new basic program blocks to this machine project (for a description, see

Subsection "Application of basic program")

3. All user programs *.awl must then be recompiled in the correct order! (See also the

"Machine program" section.)

This newly compiled machine program must then be loaded to the PLC CPU using STEP

7.

However, it is normally sufficient to recompile the organization blocks (OB) and the instance

data blocks of the machine program. This means you only need to generate sources for the

organization blocks and the instance data blocks (before upgrading).

Basic logic functions: PLC Basic program powerline (P3 pl)

28 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 29

Detailed description

2.4 Starting up the PLC program

Overall reset

A description of how to perform a general PLC reset appears in the Installation and Startup

Guide. However, a general reset does not delete the contents of the diagnostic buffer nor the

node address on the MPI bus. Another possible general reset method is described below.

This method must be used when the normal general reset process does not work.

Proceed as follows:

No. Action Effect

1 Control system is switched off

2 PLC switch setting 3 (MRES) and switch control on

again or perform hardware reset.

3 Set PLC startup switch to position 2 (STOP) and

back to position 3 (MRES).

4 Set PLC startup switch to setting 2 or 0.

NC variables

The latest NC VAR selector can be used for each NC software version (even earlier

versions). The variables can also be selected from the latest list for earlier NC software

versions. The data content in DB 120 (default DB for variables) does not depend on the

software version, i.e., selected variables in an older software version must not be reselected

when the software is upgraded.

LED labeled PS flashes slowly.

The LED labeled PS starts to flash

faster.

2.4.8 I/O modules (FM, CP modules)

Special packages for STEP7 are generally required for more complex I/O modules. Some of

these special packages include support blocks (FC, FB) stored in a STEP7 library. The

blocks contain functions for operating the relevant module which are parameterized and

called by the user program. In many cases, the FC numbers of the CP and FM module

handling blocks are also included in the number range of the basic program for the 810D and

840D systems.

What action can be taken if such a conflict occurs?

The block numbers of the basic program must remain unchanged. The block numbers of

handling blocks can be assigned new, free numbers using STEP7. These new blocks (with

new FC numbers) are then called in the user program with the parameter assignments

required by the function.

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

29

Page 30

Detailed description

2.4 Starting up the PLC program

2.4.9 Troubleshooting

This section describes problems which may occur, their causes and remedies and should be

read carefully before hardware is replaced.

Errors, cause/description and remedy

Serial

no.

error

informati

on

1 No connection

2 PLC cannot

3 All four LEDs

Errors Cause/description To correct or avoid errors

via MPI to

PLC.

be accessed

in spite of

PLC general

reset.

on the PLC

flash (DI

disaster)

The MPI cable is not plugged in

or is defective. Possibly, the

STEP 7 software is also not

correctly configured for the MPI

card.

A system data block SDB 0 has

been loaded with a modified MPI

address. This has caused an

MPI bus conflict due to dual

assignment of addresses.

A system error has occurred in

the PLC.

Measures: The diagnostic buffer

on the PLC must be read to

analyze the system error in

detail. To access the buffer, the

PLC must be stopped (e.g., set

"PLC" switch to position 2). A

hardware reset must then be

performed. The diagnostic buffer

can then be read out with

STEP7. Relay the information

from the diagnostic buffer to the

Hotline / Development Service. A

general reset must be carried out

if requested after the hardware

RESET. The diagnostic buffer

can then be read with the PLC in

the Stop state.

Test: Create a link with the

programmer in the STEP7 editor by

means of connection "Direct_PLC". A

number of node addresses must be

displayed here. If they do not appear,

the MPI cable is defective/not plugged

in.

Disconnect all MPI cables to other

components. Create the link

"Direct_PLC" with the programmer.

Correct the MPI address.

Once the PLC program has been

RESET or reloaded, the system may

return to normal operation. Even in this

case, the content of the diagnostic

buffer should be sent to the

Development Office.

Basic logic functions: PLC Basic program powerline (P3 pl)

30 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 31

Detailed description

2.5 Linking PLC CPUs to 810D, 840D

2.5 Linking PLC CPUs to 810D, 840D

2.5.1 General

The AS 300 family is used as the PLC for all systems. The essential difference between the

NCU variants lies in the method by which they are linked. On the 840D and 810D, the PLC

314 CPU (user memory capacity up to 128 KB) or PLC 315-2 DP (user memory capacity up

to 288 KB) is integrated as a submodule into the NC unit.

The PLC/CPU 315-2 DP also supports distributed I/Os on the PROFIBUS (L2DP). The

relevant performance data for individual PLC CPUs can be found in the above table or in

Catalog FT70.

2.5.2 Properties of PLC CPUs

SINUMERIK 810D/840D/840Di PLC CPUs are based on standard SIMATIC CPUs in the S7300 family. As a result, they generally possess the same functions. Functional deviations are

shown in the table above. Owing to differences in their memory system as compared to the

S7 CPU, certain functions are not available (e.g., blocks on memory card, project on memory

card).

Note

With the current SIMATIC CPUs, the PLC is not automatically started after voltage failure

and recovery when a PLC Stop is initiated via software operation. In this instance, the PLC

remains in the Stop state with an appropriate diagnostic entry for safety reasons. You can

start the PLC only via software operation "Execute a restart" or by setting the switch to

"Stop" and then "RUN". This behavior is also integrated in the current versions of the

SINUMERIK PLC.

Basic logic functions: PLC Basic program powerline (P3 pl)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

31

Page 32

Detailed description

2.5 Linking PLC CPUs to 810D, 840D

2.5.3 Interface on 810D and 840D with integrated PLC

Physical interfaces

As the 810D and 840D systems have an integrated PLC, signals can be exchanged between

the NCK and PLC directly via a dualport RAM.

Exchange with operator panel and MCP

Data are generally exchanged with the operator panel (OP), machine control panel (MCP)

and handheld unit (HHU) on the 840D via the operator panel interface (OPI), the COM

module being responsible for data transport.

All devices specified above can also be operated on the multipoint interface (MPI) in the

case of the 840 D. With the 810D, data communication with the operator panel (OP),

machine control panel (MCP) and handheld unit (HHU) takes place only via the MPI.

The programming device is connected directly to the PLC via the MPI (multipoint interface).

)&)%

3/&,2V

3*++8

230&3

3EXV

&%XV

03,

23,

0D

FKLQH

SURJU

'%

8VHU

LQWHU

IDFH

2SV\V

P&

P&

%DVLF

SURJU

3/&PRGXOH

&20PRGXOH

0&3

Figure 2-2 NCK/PLC connection on 810D, 840D (integrated PLC)

'35

'%

,QWHUQDO

LQWHU

IDFH

'35

1&.'3/&$6

9',

GHFRG

1&

IXQFW

([WHUQ

FRPP

Basic logic functions: PLC Basic program powerline (P3 pl)

32 Function Manual, 11/2006, 6FC5397-0BP10-2BA0

Page 33

Detailed description

2.5 Linking PLC CPUs to 810D, 840D

NCK/PLC interface

The data exchange NCK/PLC is organized on the PLC-side by the basic program.

The Status information stored by the NC in the internal Dual–Port–RAM (DPR) (such as

"Program is running") are copied by the basic program in the data blocks at the start of the

cycle (OB 1), which the user can then access (user interface). The user also enters NC

control signals (e.g. NC start) in the interface data blocks, and these are also transferred to

the NC at the start of the cycle.

Auxiliary functions transferred to the PLC dependent on the workpiece program are first

evaluated by the basic program (alarmdriven) and then transferred to the user interface at

the start of OB1. If the relevant NC block contains auxiliary functions that require the

interruption of the NC machining process (e.g. M06 for tool change), the basic program halts

the execution of the block on the NC for one PLC cycle. The user can then use the "read

disable" interface signal to halt the block execution until the tool change has been

completed. If, on the other hand, the relevant NC block does not contain auxiliary functions

requiring the interruption of the NC machining process (e.g. M08 for "Cooling on"), the

transfer of these "rapid" auxiliary functions is enabled directly in OB 40, so that block

execution is only marginally influenced by the transfer to the PLC.

The evaluation and enabling of the G functions transferred from the NCK are also alarmdriven, however they are transferred directly to the user interface. Where a G function is

evaluated at several points in the PLC program, differences in the information of the G

function within one PLC cycle may arise.

In the case of NC actions triggered and assigned with parameters by the PLC (e.g. traverse

concurrent axes), triggering and parameter assignment is performed using FCs and FBs, not

interface data blocks. The FCs and FBs belonging to the actions are supplied together with

the basic program. The FCs must be loaded by the user and called in the PLC program of