Page 1

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

3D simulation, finished part

Option P25

Article No.:

6FC5800-0AP25-0YB0

Access MyMachine /P2P

Option P30

Article No.:

6FC5800-0AP30-0YB0

Advanced technology functions

Option P58

Article No.:

6FC5800-0AP58-0YB0

Axis/spindle, each additional

Option

Article No.:

6FC5800-0AC20-0YB0

(6FC5800-0AA00-0YB0

for V 2.x)

Required for enabling 3D view in part program simulation. 3D simulation can be viewed even in

real-time simulation. Without this option, it is possible to see 2D simulation (with different views)

in the system.

If simultaneous recording option already exists in the system, then it is possible to have 3D view

during the real-time simulation.

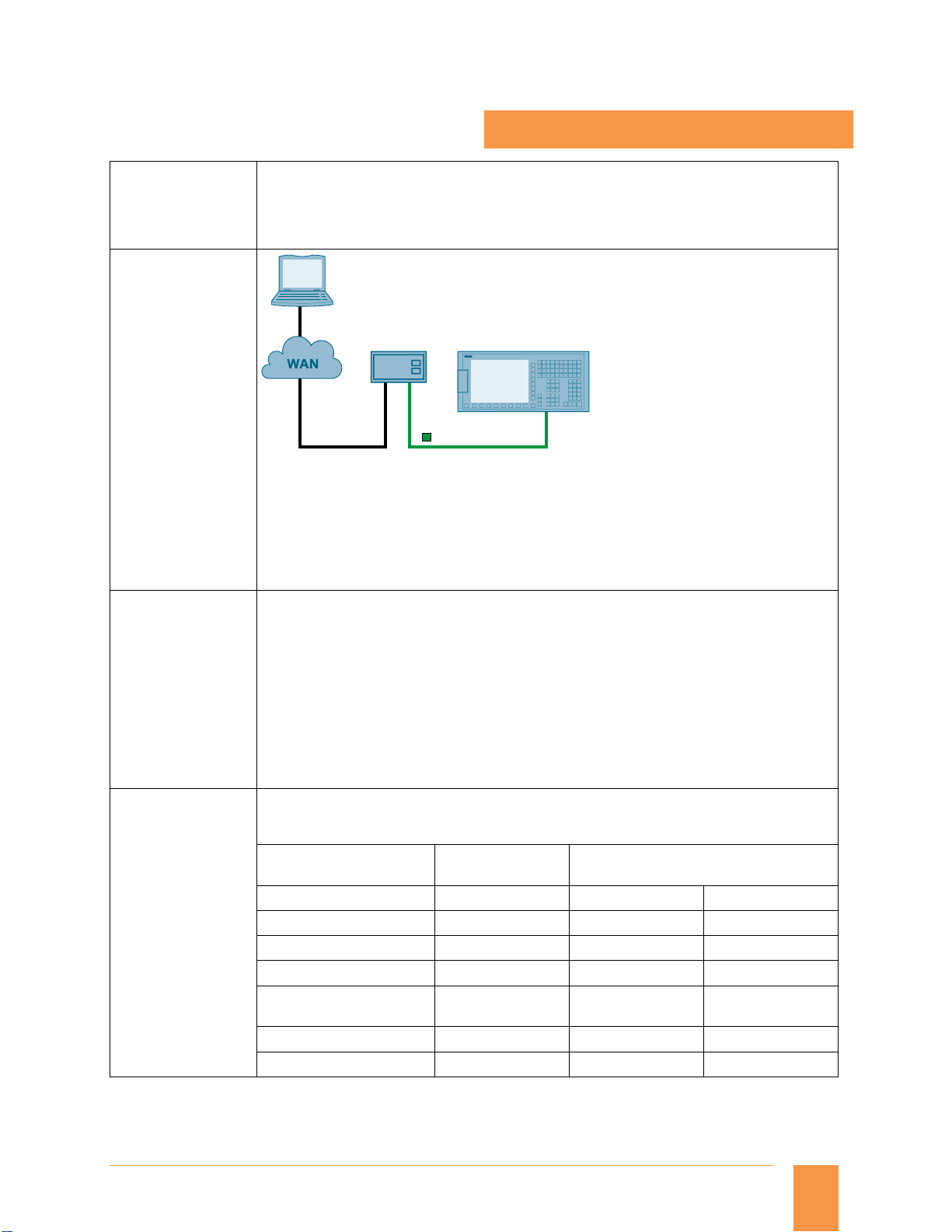

PC/PG

Modem router

Analog ISDN

SINUMERIK 828D

PROFINET

G_NC01_EN_00582

RCS Host remote diagnostics software for connection of a modem router to the X127 is solely

necessary in case of connection via Modem router. It is possible to monitor and influence a control

from a remote PC. The remote viewer gets the same display of SINUMERIK 828. A modem router is

required for connecting SINUMERIK 828 to a viewer on a telephone line /internet

Remote diagnosis has the following services:

Direct access to SINUMERIK 828

Data exchange (file transfer)

The following extended technologies are only available in SINUMERIK 828D BASIC.

Asymmetric grooves (only turning)

Drill and thread milling

Thread milling

Multi-edge milling

Engraving

Extended stock removal along contour with segmentation of blank (only turning)

Contour grooving and plunge turning (only turning)

Milling of contour pockets and spigots (with up to 12 islands)

Position pattern - hide position

Asymmetrically turn a shoulder

DIN thread undercut

This option must be selected if the required number of interpolating axes/spindles is more than the

basic quantity of axes/spindles. The basic quantity of axes offered by panel processing units/

SINUMERIK 828D family is given in the table below:

SINUMERIK 828D

SINUMERIK 828D

BASIC

PPU 24x.3 PPU 26x.3 PPU 28x.3

Basic quantity of axes

Turning

Milling

Max. possible quantity of

axes/spindles

Turning

Milling

3 3 3

4 4 4

5 6 8

5 6 6

Siemens NC 82 · 2014

1

Page 2

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Contour handwheel

Option M08

Article No.:

6FC5800-0AM08-0YB0

Evaluation of internal drive variables

Option S53

Article No.:

6FC5800-0AS53-0YB0

(6FC5800-0AM41-0YB0

for V 2.x)

Extended operator functions

Option P16

Article No.:

6FC5800-0AP16-0YB0

When the contour handwheel function is activated, the handwheel has a velocity-generating

effect in AUTOMATIC and MDI modes on all programmed traversing movements of the path and

synchronized axes.

A feedrate specified via the CNC program becomes ineffective and a programmed velocity profile is

no longer valid. The feedrate, in mm/min, results from the handwheel pulses as based on pulse

weighting (machine data) and the active increment. The handwheel's direction of rotation

determines the direction of travel:

Clockwise:

in the programmed direction of travel (even beyond block boundaries)

Counter-clockwise:

against the programmed direction of travel (continuation beyond the start of the block is

prevented).

The following real-time drive variables can be accessed/evaluated in part program:

$AA_LOAD drive capacity utilization in Percentage (%)

$AA_POWER drive active power in Watts (W)

$AA_TORQUE drive torque set point in Newton meters (Nm)

$AA_CURR actual axis/spindle current in Ampere (A)

These variables can be used along with synchronized options

These variables can be also read through PLC interface, NC variables DB1200.DBxxxxx. For the PLC

purpose, evaluation of internal drives is standard.

Application examples :

Evaluation of these drive variables also permits machines and tools to be protected from

overloading, as well as shorter machining times and an improved surface quality for the

workpieces to be achieved. Evaluation of internal drive variables is a prerequisite for implementing

adaptive control (AC).

Adaptive control can be parameterized within the part program as follows:

Additive influence: The programmed feed value is corrected by adding.

Multiplicative influence: The feed value is multiplied by a factor (override).

Number of levels for skip blocks 10 (default value 2)

Teach-in function

Backup workpiece setup data

Display active synchronized actions

DRF offset

Overstoring

Extended block search (program/search pointer, level up/down, interrupt position)

Manual workpiece measurement: advanced strategies for part probing

Additional measuring version beyond standard scope

(standard scope workpiece zero: Set edge, align edge, right-angled corner, 1 hole, and 1 circular

spigot.

Expansion of the measurement window via combo box)

Load/save MDI program

2

Siemens NC 82 · 2014

Page 3

© Siemens AG 2014

Extended stop and

retract ESR, driveautonomous

Option M60

Article No.:

6FC5800-0AM60-0YB0

Generic coupling Basic: CP-Basic

Option M72

Article No.:

6FC5800-0AM72-0YB0

Glossary

Functions and terms

SINUMERIK 828

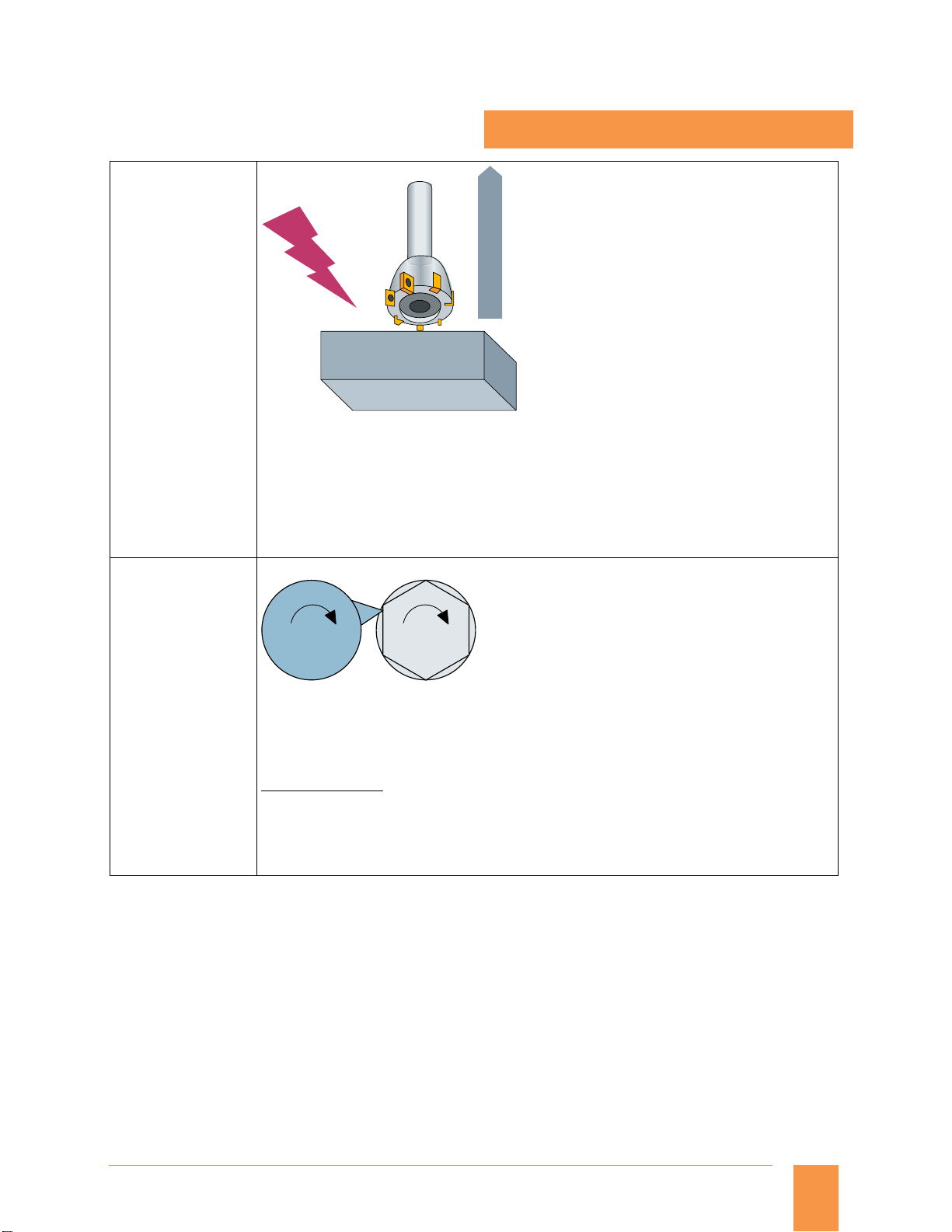

Power failure

retraction

Work-piece

G_NC01_EN_00583

A safe position is assumed from the machining level without any collision between tool and

workpiece.

As well as the drive-autonomous stop and retract function, the CNC-controlled stop and retract

functionality is also provided. To permit gentle interpolated retraction on the path or contour, the

path interpolation can be processed further for a definable period following the triggering event.

The retraction axes are subsequently traversed in synchronism to an absolute or incremental

position as programmed.

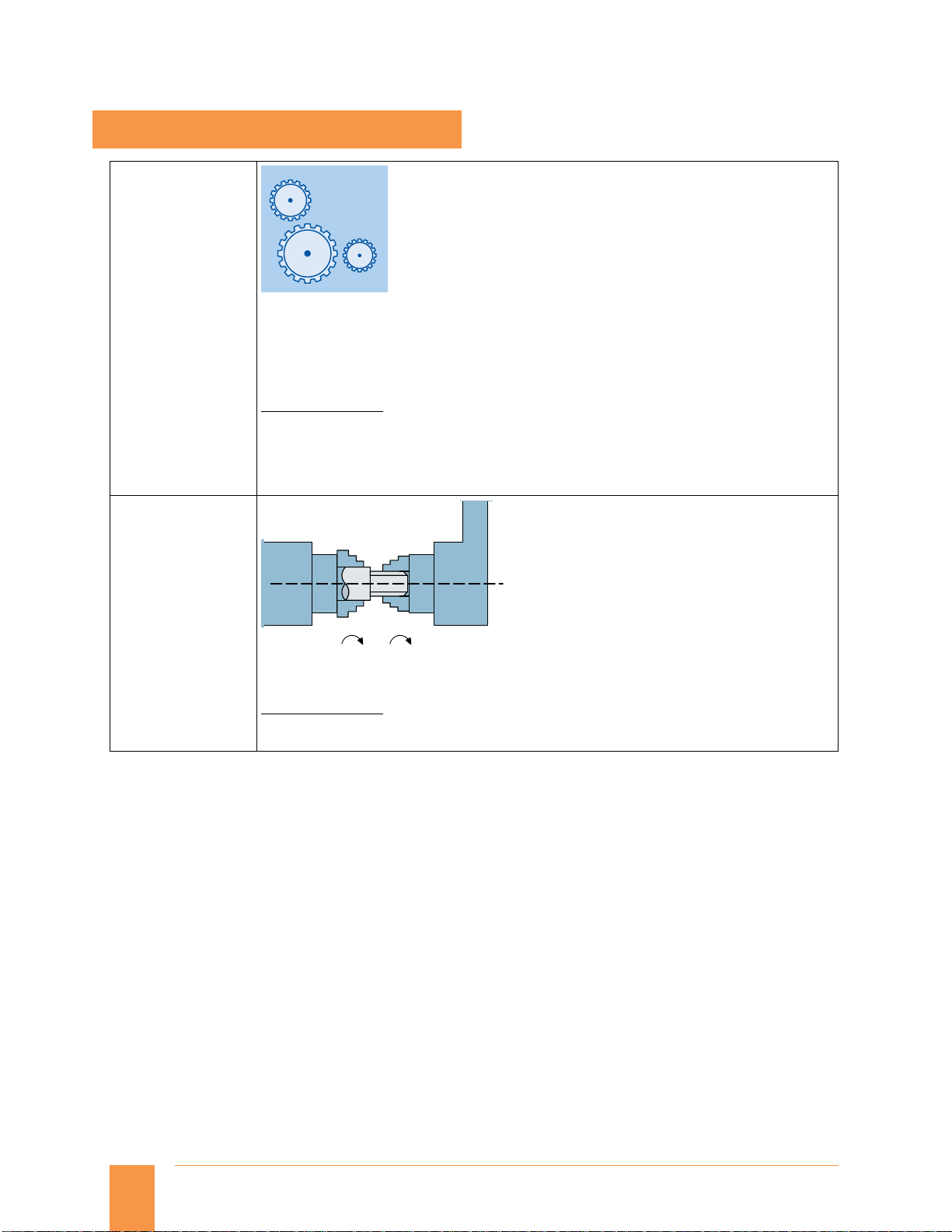

These functions are primarily used for gearing and grinding technologies.

n

2

n

1

G_NC01_EN_00575

Spindle 1 Spindle 2

Up to 4 × simple coupled motion and

Up to 1 × synchronous spindles/multi-edge turning or master value coupling/curve table

interpolation or axial coupling in the machine coordinate system

Application example:

Multi-edge machining (polygonal turning)

The synchronous spindle function provides the basis for multi-edge machining through

specification of an integer gear ratio between leading spindle and following spindle. In the picture

above, spindle 2 contains the job and spindle 1 has the cutting tool. Both the spindles are

synchronized and run at a ratio (e.g.: 1:6), in order to get polygon shape on the job.

Siemens NC 82 · 2014

3

Page 4

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Generic coupling Comfort: CP-Comfort

Option M73

Article No.:

6FC5800-0AM73-0YB0

Generic coupling Static: CP-Static

Option M75

Article No.:

6FC5800-0AM75-0YB0

Up to 4 × simple coupled motion and

Up to 4 × synchronous spindle/multi-edge turning and/or master value coupling/curve table

interpolation and/or axial coupling in the machine coordinate system

Also:

1 × electronic gear for up to 3 leading axes is possible (without curve table interpolation and

without cascading)

Application example:

This option is suitable for the hobbing process. Gear hobbing machines are machines which have a

rotating multiple-tooth cutting tool to produce teeth on helical gears, worm gears, cycloid gears,

etc.

When two axes (e.g. tool axes) with different ratio must be coupled on to third axes (e.g. blank

axes).

G_NC01_EN_00576

Spindle 1 Spindle 2

n

n

1

2

One simple synchronous spindle (with coupling ratio 1:1, no multi-edge machining)

Application example:

Reverse side machining in a double-spindle lathe with on-the-fly transfer of the work piece from

the position-synchronous LS to the FS (or vice versa), without having to decelerate to standstill.

4

Siemens NC 82 · 2014

Page 5

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Inclined axis

Option M28

Article No.:

6FC5800-0AM28-0YB0

Leadscrew error

compensation,

bidirectional:

Bidirectional

threaded spindle

error compensation

Option M54

Article No.:

6FC5800-0AM54-0YB0

JOG "X"

JOG "U"

X

G07 X70 Z40 F4000

100

70

W

0

Oblique plunge-cut grinding: machine with non-Cartesian X axis (U)

G05 X70 F100

40

U

Z

G_NC01_XX_00121

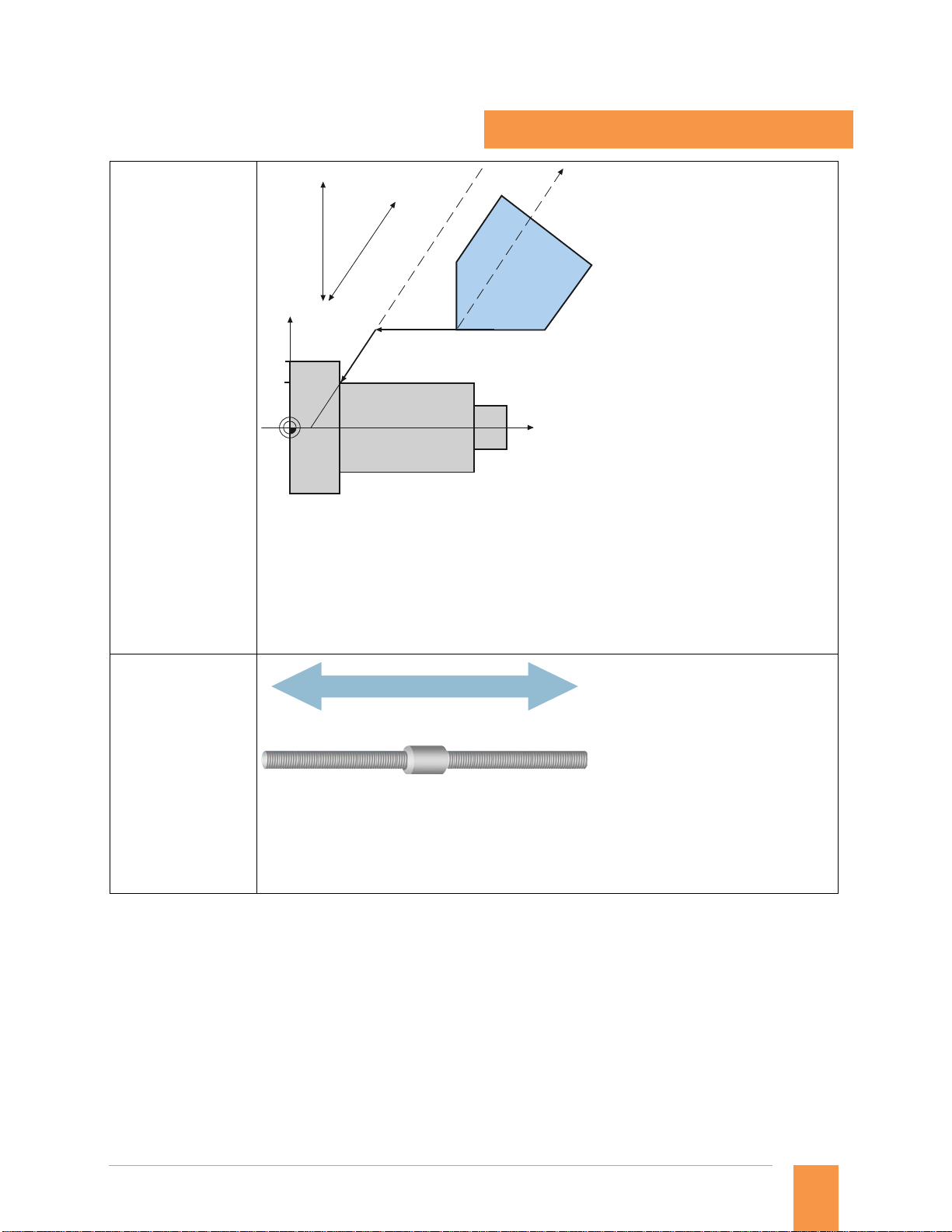

The Inclined axis function is used for fixed-angle interpolation using an oblique infeed axis (used

primarily in conjunction with cylindrical grinding machines). The axes are programmed and

displayed in the Cartesian coordinate system.

Tool offsets and work offsets are also entered in the Cartesian system and transformed to the real

machine axes.

For oblique plunge-cutting with G05, it is necessary to program the start position with G07.

Bi-directional compensation

G_NC01_EN_00585

Bidirectional compensation is an expansion to the leadscrew error compensation function (LEC) or

the measuring system error compensation function (MSEC). By contrast to LEC and MSEC,

bidirectional compensation works in both directions.

The option supports price sensitive front-face and peripheral side machining applications on lathes

without a mechanical Y axis.

Siemens NC 82 · 2014

5

Page 6

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Machining step programming ShopTurn/ShopMill

Option P17

Article No.:

6FC5800-0AP17-0YB0

Master-slave for drives, basic

Option S52

Article No.:

6FC5800-0AS52-0YB0

(6FC5800-0AM03-0YB0

for V 2.x)

Measure kinematics

Option P18

Article No.:

6FC5800-0AP18-0YB0

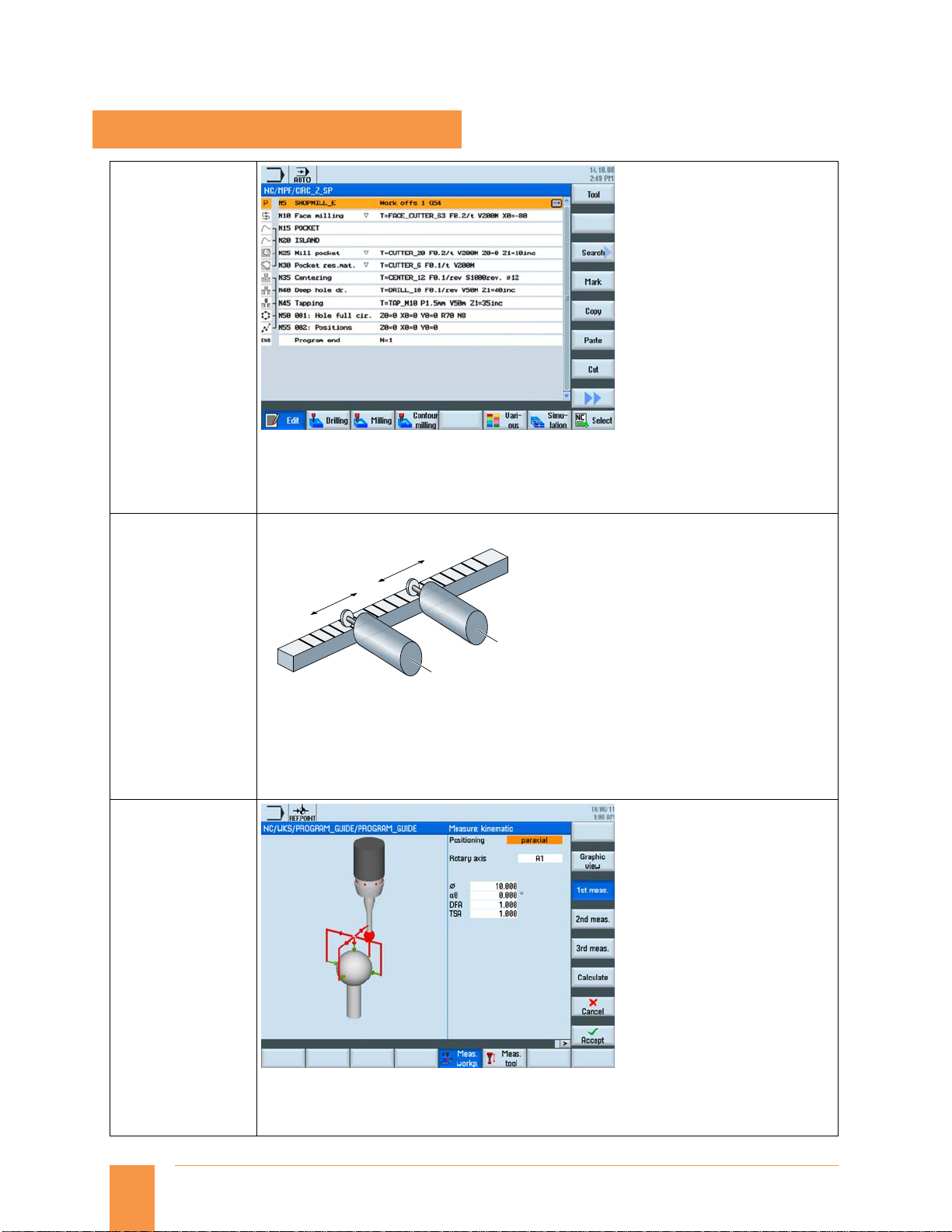

Processes such as drilling, centering, plunging or pocket milling are represented as machining

steps in a simple and clear manner. In this way, part programs – even for complex machining

operations – are very compact and easily read. Associated sequences are automatically interlinked

and can be assigned any position patterns. This unique programming convenience allows you to

achieve the shortest programming times even for highly demanding machining tasks.

Coupling: "OPEN"

Motion: A xis 2

Motion: A xis 1

Axis 1

G_NC01_EN_00586

Axis 2

A master-slave coupling is a speed setpoint coupling between a master and slave axis performed at

the position controller level – with and without torque equalization control. The coupling can be

permanently closed.

Possible applications of a master-slave coupling include:

Increase the power for mechanically coupled drives

Compensating gear and gear tooth flank play by entering a pre-tensioning torque

6

This option is able to determine the parameters of kinematic transformations of the digitally or

manually alignable rotary axes quickly and automatically. The function is ideal for initial startup,

because a dimensioned drawing of the machine is not required. The function can also be used for

regular checking of the production process, when high precision is required.

Siemens NC 82 · 2014

Page 7

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Measuring cycles for drilling/milling and turning

Option

Article No.:

6FC5800-0AP28-0YB0

Measuring cycles are subroutines designed to perform specific measurement tasks. They can be

adapted to specific requirements via parameter settings.

Workpiece measurements

Example: Milling machine

Z

Y

W

G_NC01_EN_00587

X

Workpiece measurement

A measuring probe is moved up to the clamped workpiece in the same way as a tool and measured

values are acquired. The flexibility of measuring cycles makes it possible to perform nearly all

measurements required on a milling or turning machine. An automatic tool offset or zero offset

correction can be applied to the workpiece measurement result.

Too l mea s urem e n ts

Measure turning tool length 1, length 2

Multiple clamping of

various workpieces

(included in

ShopMill/ShopTurn)

Option P17

Article No.:

6FC5800-0AP17-0YB0

X

Z

Tool measurement

G_NC01_EN_00588

The selected tool is moved up to the probe and the measured values are acquired. The probe is

either in a fixed position or is swung into the working area with a mechanism. The tool geometry

measured is entered in the appropriate tool offset data set.

G_NC02_XX_00381

Several identical workpieces can be clamped onto the machine table. With the multiple clamping

function, an entire program is generated from the graphic program of the relevant single

machining operation. The machining steps are sorted in this program so that the number of tool

changes (and thus idle times) is reduced to a minimum.

This function allows different workpieces to be finished on multiple vises or gripping yokes, while

saving time.

Note:

Since SW V4.5 multiple clamping (6FC5800-0AP14-0YB0) is part of ShopMill/ShopTurn

(6FC5800-0AP17-0YB0).

Siemens NC 82 · 2014

7

Page 8

Glossary

g

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Pair of synchronized axes (gantry axes), basic

Option S51

Article No.:

6FC5800-0AS51-0YB0

(Option M02

Article No.:

6FC5800-0AM02-0YB0

for V 2.x)

Positioning axis/auxiliary spindle, each additional

Option

Article No.:

6FC5800-0AC30-0YB0

(6FC5800-0AB00-0YB0

for V 2.x)

Program management on network drive

Option

Article No.:

6FC5800-0AP01-0YB0

Y

Z

X

X1

G_NC01_XX_00112

Gantry axes (pair of synchronous axes X/X1)

The gantry axes function can be used to traverse mechanically-coupled axes simultaneously

without mechanical offset. The actual values are continuously compared and even the smallest

deviations corrected.

During both operation and programming, the axes defined in a gantry grouping are treated like

one machine axis.

A maximum of one gantry pair is possible with this option.

This is an option for any positioning axis that is required in addition to the basic quantity of

axes/spindles. The total number of axes/spindles is limited by the maximum number of axes

offered by the SINUMERIK 828D family.

Please refer to the table below for the maximum number of axes/spindles offered by all the PPU

variants.

→ Axis/spindle, each additional

Application examples:

For applications like magazine of ATC, pallet, auxiliary spindle (without tapping/threading), or any

positionin

axis.

8

Allows execution of part-programs from external server by Windows Share/FTP client

Max 4 additional drives can be defined on Ethernet

Part program execution can be done from any of these network drives

Program/workpiece data management can also be done

Siemens NC 82 · 2014

Page 9

© Siemens AG 2014

Replacement tools for tool management

Option M78

Article No.:

6FC5800-0AM78-0YB0

Glossary

Functions and terms

SINUMERIK 828

Residual material detection

Option P13

Article No.:

6FC5800-0AP13-0YB0

Option for defining replacement sister-tool. Tool life is monitored on the basis of machining time

or number of components. If the tool life is completed (or if the tool finishes number of

components) the defined sister-tool is automatically selected.

Y

20

10

0

-10

Milling

-20

-30

0102030405060708090100110

Turning

Pre-machining

with large cutter

X

Stock removal

longitudinal

with blank

segmentation

Contour ranges which cannot be machined with large tools are automatically recognized by the

cycle for contour pockets or the stock removal cycle. The operator can rework these regions using

a smaller tool.

Contour turning offers:

Contour/axis-parallel cutting with residual material detection

Contour cutting with residual material detection

Plunge-turning with residual material detection

Contour milling offers:

Contour spigot with residual material detection

Contour pocket with residual material detection

Machining, e.g. in the steps: centering, predrilling, rough machining and rough machining

residual material, smoothing, edge/base, gripping

Y

20

10

0

-10

MillingTurning

-20

-30

0102030405060708090100110

Cutting residual

material with

small cutter

X

Cutting residual

material with

contour grooving

G_NC01_EN_00589

Siemens NC 82 · 2014

9

Page 10

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

Safety Integrated Extended Functions

Option C50

Article No.:

6FC5800-0AC50-0YB0

(6SL3074-0AA10-0AA0

for V 2.x)

Sag compensation, multi-dimensional

Option M55

Article No.:

6FC5800-0AM55-0YB0

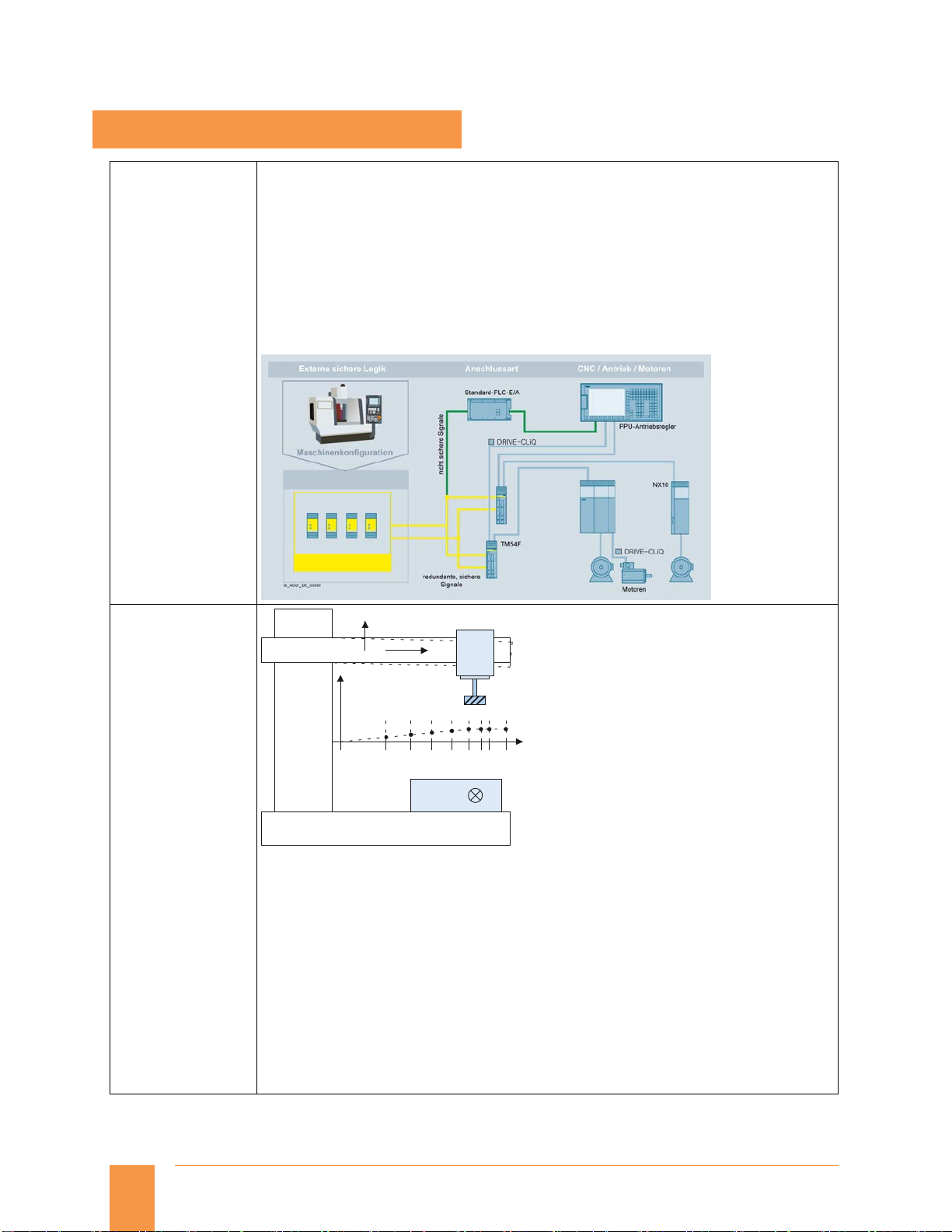

SINUMERIK 828 has as standard the following Safety Integrated functions:

Safe Torque Off (STO)

Safe Brake Control (SBS)

Safe Stop 1 (SS1)

Option for extended Safety Integrated Functions for one CNC axis

Safe Operating Stop (SOS)

Safe Stop 2 (SS2)

Safely Limited Speed (SLS)

Safe Speed Monitor (SSM)

Safe Acceleration Monitor (SAM)

Safe Direction

SINAMICS S120 Terminal Module Cabinet TM54F is required to configure the above options.

Z

-Y

Z

10

Sag compensation

Multi-dimensional compensation is also possible for the effects of physical influences and

manufacturing tolerances such as sag or leadscrew pitch errors. The compensation tables can be

switched from the PLC.

When the reference axis and the compensating axis are identical, leadscrew pitch errors can be

compensated. By transferring weighting factors (PLC interface), stored compensating

characteristics can be adapted to different conditions (e.g.: tools).

The most important features of interpolation and compensation using tables are as follows:

Independent error characteristics can be defined, in number twice the maximum number of axes

Freely selectable compensating positions, the number of which is configurable (dependent on

the configuration of CNC user memory)

Interpolating inclusion of the compensation values

Weighting factor for compensation of tool weights

Reference axis and compensating axis are selectable

Siemens NC 82 · 2014

-Y

X

G_NC01_XX_00108

Page 11

© Siemens AG 2014

Simultaneous recording

Option P22

Article No.:

6FC5800-0AP22-0YB0

Glossary

Functions and terms

SINUMERIK 828

With real-time simulation, the simulation can be viewed in the ‘machine’ screen of control the

when the part program is running in automatic mode. The tool movement in the simulation screen

is dependent on the actual tool (axes) movement and gives an accurate view of the machining

going on.

Note:

Activate simultaneous recording prior to CNC start in order to avoid incomplete displays.

Siemens NC 82 · 2014

11

Page 12

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

SINUMERIK Integrate Run MyScreens

Option P64

Article No.:

6FC5800-0AP64-0YB0

SINUMERIK Operate Runtime license OA Easy Screen

EASY SCREEN

Own operator

areas

Easy Screen

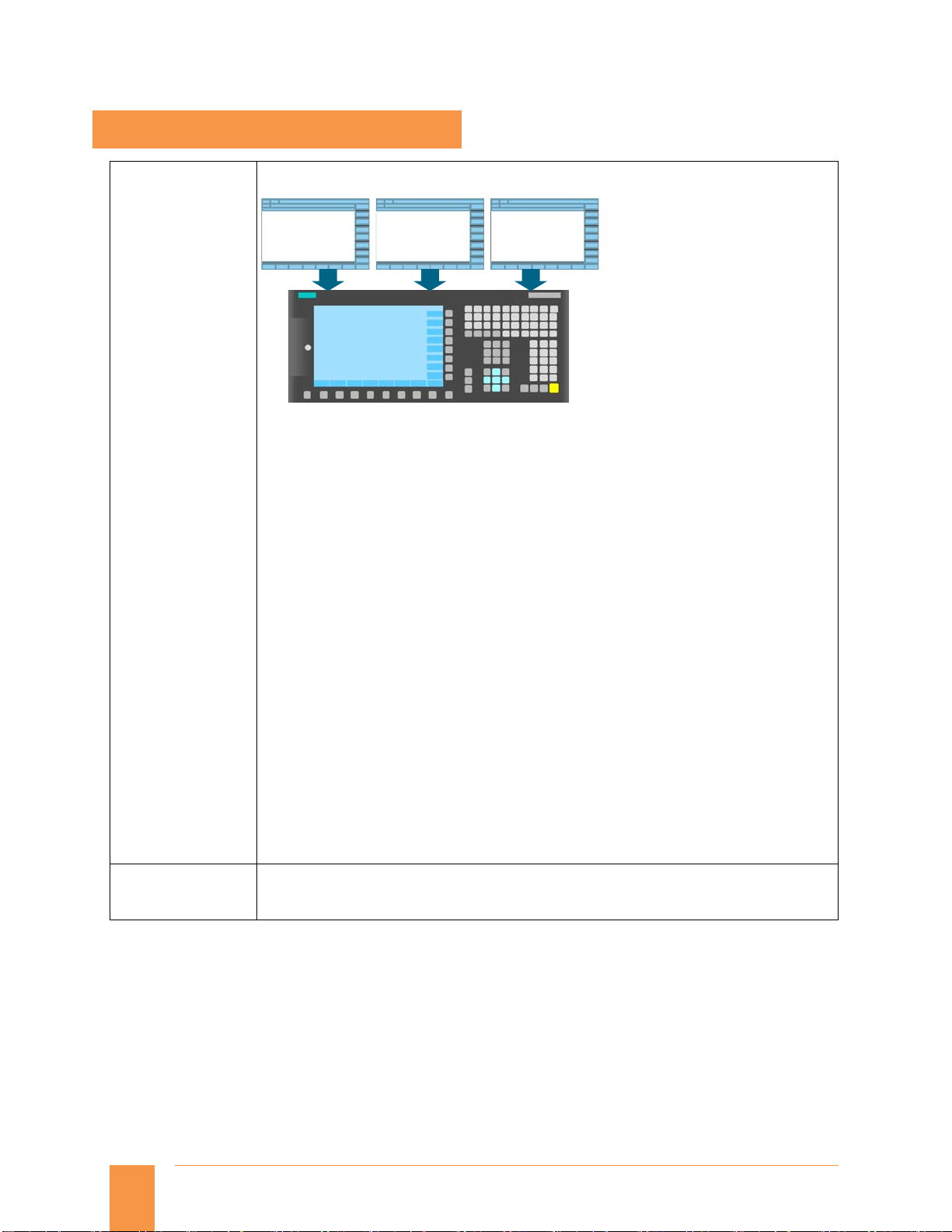

The Easy Screen functionality allows SINUMERIK users to design their own user interfaces for the

purpose of displaying either machine-manufacturer or end-user-specific functional expansions or

simply their own screen form layouts.

User interfaces configured by Siemens or other machine manufacturers can be modified or

replaced. This function is implemented via an integrated interpreter and via configuring files

containing the description of the user interface.

The screen forms can be designed directly on the control itself. A graphic tool is required to create

graphics and pictures. Part programs can be processed with newly created user interfaces.

Configuring examples for new screen forms, which can also be used as the basis for the user's own

new screen forms, can be found in the supplied toolbox.

The following functions can be implemented using Easy Screen:

Display screen forms and provide softkeys, variables, tables, texts, help texts, graphics, and

help screens

Start actions when screen forms are displayed and exited, press softkeys, and enter values

(variables)

Dynamic restructuring of screen forms, including changing softkeys, designing arrays and

displaying, replacing and deleting display texts and graphics

Read and write variables, combine with mathematical, comparative or logical operators

Execute subprograms, file functions, program instance services (PI services) or external

functions (HMI-Advanced)

Enable data exchange between screen forms

Easy Screen is configured using ASCII files that can be stored on the PCU. Files that contain ASCII

descriptions for the layout of interactive screen forms, softkey functions and display texts and

graphics are interpreted. These configuring files are created with the ASCII editor, taking into

account certain special rules of syntax.

The user interface can be expanded even in the basic version by up to 5 screen forms via

predefined softkeys with the integrated editor.

More than 5 screen forms with Operate Runtime license OA Easy Screen (option P64).

→ SINUMERIK Integrate Run MyScreens

Overlap of

system

screens

Cycle support

screens

G_NC01_EN_00591

12

Siemens NC 82 · 2014

Page 13

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

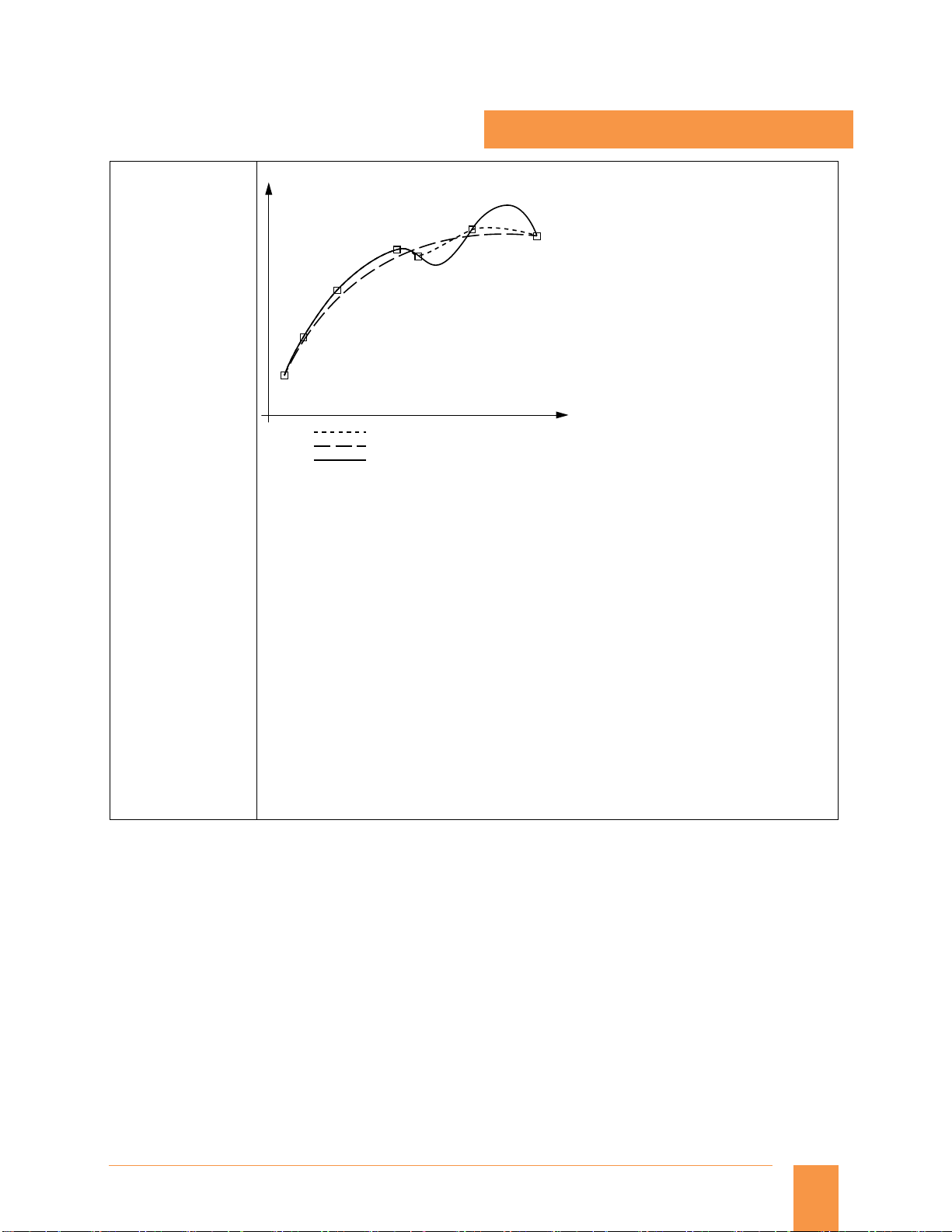

Spline interpolation (A, B and C splines)

Option S16

Article No.:

6FC5800-0AS16-0YB0

P6

P1

A spline

B spline

C spline

P4

P5

P3

P2

P7

G_NC01_EN_00594

Using spline interpolation, it is possible to obtain a very smooth curve from just a few defined

interpolation points along a set contour. The intermediate points are connected by polynomials.

The compressor converts linear motions (e.g.: from CAD) at block transitions to splines of constant

speed (COMPON) or splines of constant acceleration (COMPCURV). This yields soft transitions that

reduce wear on the mechanical parts of the machine tool. However, if the intermediate points are

placed close together, quite sharp edges can also be programmed. Spline interpolation also

considerably reduces the number of program blocks required.

Extremely smooth workpiece surfaces are often very important in mold and tool making, both

optically and technologically, e.g.: for rubber gaskets.

Tool radius compensation is also possible in spline interpolation, as it is in linear or circular

interpolation.

Every polynomial can represent a spline. Only the algorithm determines the type of spline.

A spline is only true to the tangents.

B spline is true to the tangents and the curvature, but does not run through the nodes

(intermediate points).

C spline is true to the tangents and the curvature and runs through the nodes.

With the COMPCAD compressor, smooth curves of this kind can be approximated within the

boundaries of compressor tolerance (parallel tool paths) so that surfaces of a high optical quality

can also be obtained in the case of increased tolerances.

Spline interpolation for 3-axis machining is suitable for simple applications and for the JobShop

area.

Siemens NC 82 · 2014

13

Page 14

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

TRANSMIT/cylinder surface transformation

Option M27

Article No.:

6FC5800-0AM27-0YB0

X

Y

C

Z

Face machining with TRANSMIT

G_NC01_XX_00127

Y

Y'

Pole

(center)

Workpiece

Tool-center-point path through the pole

Too

l

C

X'

X

Rotary table

G_NC01_en_00128

TRANSMIT is used for milling outside contours on turned parts, e.g.: square parts (linear axis with

rotary axis).

As a result, programs become much simpler and complete machining increases machine

efficiency. Turning and milling can be performed on one machine without rechucking.

3D interpolation with 2 linear axes and one rotary axis is possible. The two linear axes are mutually

perpendicular and the rotary axis lies at right angles to one of the linear axes.

TRANSMIT can be called up in different channels simultaneously. The function can be selected and

deselected with a preparatory function (straight line, helix, polynomial and activating tool radius

compensation) in the part program or MDI.

With TRANSMIT, the area of the transformation pole is reached when the tool center can be

positioned at least to the turning center of the rotary axis entering the transformation.

TRANSMIT through the pole is implemented in different ways:

When traveling through the pole, the rotary axis is turned automatically by 180° when the

turning center is reached and the remaining block is then executed.

When traveling close by the pole, the control automatically reduces the feedrate and the path

acceleration.

If the path contains a corner in the pole, the position jump in the rotary axis is compensated by

the control through automatic block insertion.

Cylinder surface transformation is used on turning machines and milling machines, and enables

cylinder surface transformation, e.g.: for turned parts.

The TRACYL cylinder surface transformation can be used to manufacture grooves of any shape on

the surface of cylindrical bodies with or without groove side offset. The shape of the grooves is

programmed in reference to the plane cylinder surface processed.

14

Siemens NC 82 · 2014

Page 15

Glossary

© Siemens AG 2014

Functions and terms

SINUMERIK 828

TRANSMIT/cylinder surface transformation without Y axis

Option S50

Article No.:

6FC5800-0AS50-0YB0

Travel to fixed stop with Force Control

Option M01

Article No.:

6FC5800-0AM01-0YB0

X

C

G_NC01_EN_00592

This option – similarly to TRANSMIT and cylinder surface transformation on a cylindrical

component – enables to perform front face machining using Cartesian coordinate system and

TRACYIL to perform machining on the surface of the cylinder, when physically Y axis is not

required.

Actual position after

"travel to fixed stop"

G_NC01_EN_00593

Fixed stop

monitoring

windows

Program end position Start position

The extended travel to fixed stop function can be used to adapt torque or force on a modal or nonmodal basis; travel with limited torque/limited force (force control, FOC) can be initiated, or

synchronized actions can be used at any time to program traversing functions.

Application example:

Servo tail stock function with force control requirement. This also can be combined along with

synchronized actions.

Siemens NC 82 · 2014

15

Loading...

Loading...