Page 1

Page 2

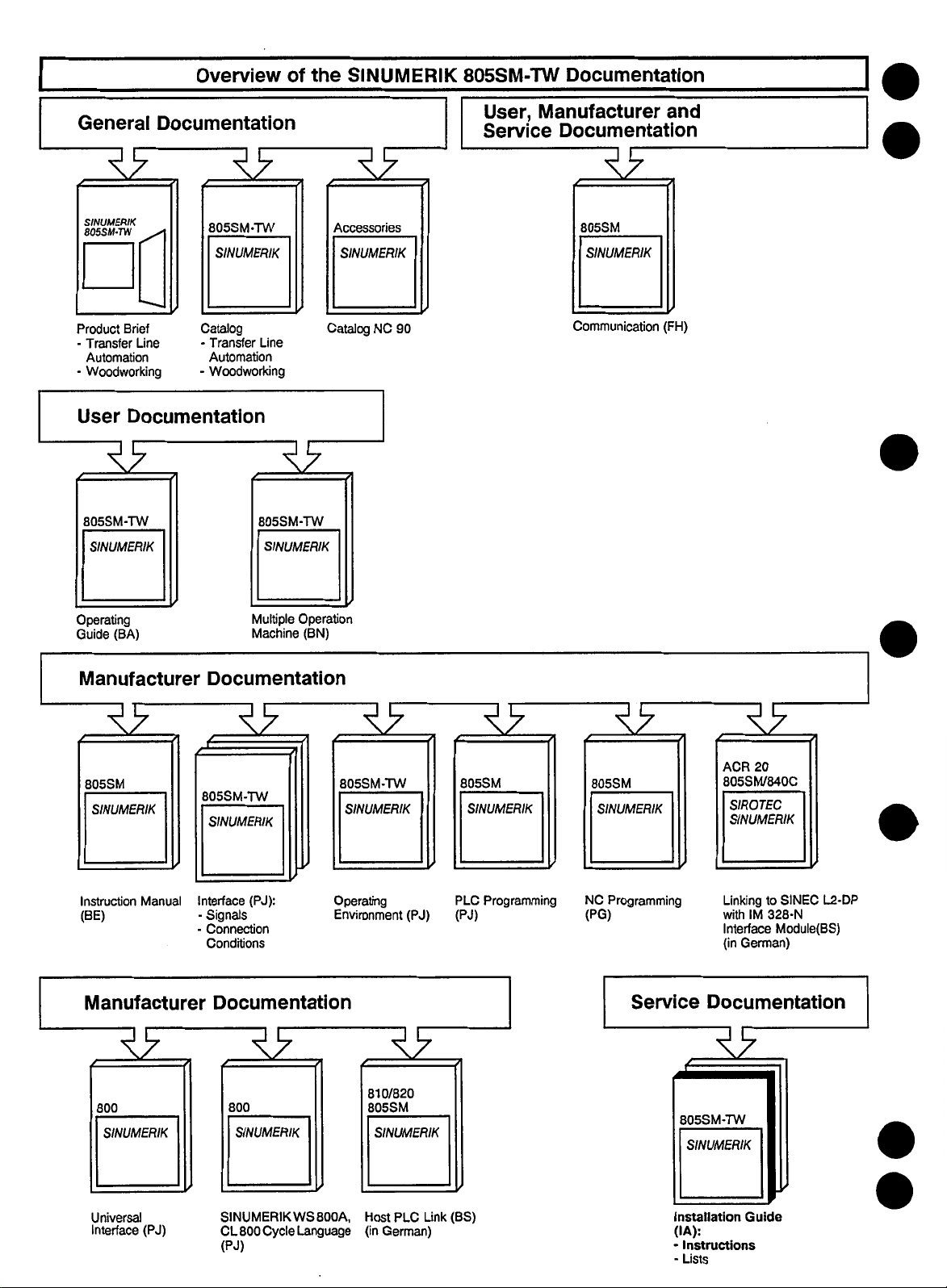

Overview

of

the

SINUMERIK

805SM-TW

Documentation

General

39

SINUMERIK

805SM-TN

Brief

Product

Transfer

Automation

Woodworking

-

User

Line

Documentation

39.

805SM-TW

SINUMERIK

Documentation

39

805SM-TW

SINUMERIK

Catalog

Transfer

-

Automation

Woodworking

-

Line

805SM-TW

SINUMERIK

39

39

Accessories

SINUMERIK

NC

Catalog

90

User,

Service

Manufacturer

Documentation

39

805SM

SINUMERIK

Communication

and

(FH)

Operating

(BA)

Guide

Manufacturer

39

805SM

SINUMERIK

Instruction

(BE)

Manual

Manufacturer

39

Multiple

Operation

Machine

(BN)

Documentation

39

805SM-TW

SINUMERIK

Interface

-

(PJ):

Signals

Connection

Conditions

Documentation

39

39

805SM-TW

SINUMERIK

Operating

Environment

(PJ)

39 39

805SM

SINUMERIK SINUMERIK

PLC

Programming

(PJ)

805SM

NC

Programming

(PG)

Service

39

ACR

20

805SM/840C

SIROTEC

SINUMERIK

Linking

to

IM

with

Interface

German)

(in

328-N

L2-DP

SINEC

Module(BS)

Documentation

39

800

SINUMERIK

Universal

Interface

(PJ)

800

SINUMERIK

SINUMERIK

Cycle

CL

800

(PJ)

WS800A,

Language

810/820

805SM

SINUMERIK

Link

PLC

Host

German)

(in

(BS)

805SM-TW

SINUMERIK

Installation

(IA):

•

Instructions

Lists

-

Guide

Page 3

SINUMERIK

805SM-TW

Software

Version

Installation

Installation

Service

Guide

Documentation

4

Instructions

Valid

for:

Control

SINUMERIK

Edition

02.94

805SM-TW

Software

Version

3

and

4

Page 4

SINUMERIK®

documentation

Printing

detailsofthis

Brief

The

status

Status

A

...

B

.

.

.

C

.

.

.

Edition

09.91

06.92

06.93

02.94

history

each

of

’’Remarks”

in

code

documentation

New

Unrevised

Revised

Changes

edition

date

edition

edition

reprint

edition

the

in

printed

Order

6ZB5

6ZB5

6ZB5

6ZB5

previous

and

new

the

by

:

Order

status.

details

of

top

is

shown

column

with

new

with

technical

at

No.

440-0MJ02-0AA0

440-0MR02-0AA1

440-0MR02-0AA2

440-0MR02-0AA3

editions

the

code

No.

a

on

page.

the

listed

are

in

the

particular

below.

’’Remarks”

page

are

column.

shown

Remarks

by

A

C

C

C

a

change

in

the

functions

Other

executable

gatlon

obll

servicing.

publication

This

Siemens

Subject

to

The

reproduction,

contents

Offenders

by

created

design

are

©

Siemens

in

to

5800

change

Is

not

will

patent

reserved.

not

control.

the

supply

was

Office

transmission

permitted

be

liable

grant

AG

described

such

produced

System.

without

for

or

1991

In

this

This

does

functions

on

notice.

prior

or

without

damages.

registration

Rights

All

documentation

not,

however,

a

new

with

the

of

this

use

express

written

rights,

All

utility

a

of

Reserved

might

represent

controlorwhen

documentorIts

authority.

including

rights

model

or

be

an

Page 5

Preliminary

Remarks

Notes

SINUMERIK

The

General

•

User

•

Manufacturer

•

Service

•

Service

The

Installation

•

Installation

•

present

The

setting

The

More

Siemens

data

supply

information

the

for

documentation

documentation

documentation

documentation

Installation

that

options

of

local

Technical

Reader

805SM-TW

documentation

Instructions

Lists

Guide

be

must

is

other

on

or

national

Notes

fj;

documentation

comprises

specifies

parameterized.

included.

not

SINUMERIK

office.

organized

is

following

the

the

method

805SM-TW

four

in

publications:

of

installation

publications

parts:

and

are

obtainable

explains

all

machine

from

and

your

INTERFACE

•

the

of

4

DESCRIPTION

modules

and

jumper

Very

PART

assignments.

important

by

this

Cables

2:

information

form

presentation.

of

and

will

Hardware

be

emphasized

contains

detailed

a

overview

4

Page 6

Notes

on

safety

requirements

When

under

operating

dangerous

electric

voltage.

WARNING

devices,

some

machine

parts

inevitably

are

A

h

Trained

personnel

A

$

Unqualified

result

accordingly

mounting,

device/system.

Trained

instruction

following

Personnel

•

and

regulations.

Personnel

•

regulations

safety

operation

in

serious

trained

installation

personnel

manuals

qualifications:

typify

devices.

non-observanceof

or

the

damages

personnel

and

according

or

trained,

circuits

trainedorinstructed

in

the

and

fields

human

to

well

operation

WARNING

the

product

the

in

instructed

devices

servicing,

of

warning

machines.

beings

aquainted

shouldbeallowed

safety

authorizedtoswitch

or

according

according

or

regulations

labels)

have,

operating

with

to

to

the

the

may

signs

Only

configuration,

to

operate

(included

for

example,

relevant

relevant

and

in

on/off,

safety

safety

repairing

the

the

the

earth

m

•

•

Make

the

with

mounting,

Personnel

modules

or

Personnel

well

and

Guides.

sure

that

relevant

starting-up

instructed

risk

at

personnel

and

or

from

for

with

operation

electrostatic

the

trained

instructed

aquainted

the

documentations

operation

the

Operating

is

well

regarding

the

for

charges.

aquainted

the

of

operation

automation

of

and/or

installation,

Programming

control.

of

components

techonology

Page 7

Notes

The

hand,

machines.

Notes

servicing

below.

on

on

following

they

on

The

products

the

safety

personnel

A

dangers

notes

may

prevent

regulations

signals

themselves:

serve,

damages

or

have

This

warning

harm

safety

on

the

damages

and

following

the

signal

notes

serious

or

precautions

hand,

one

the

to

warnings

machine

the

to

meanings

signifies

on

damage

for

product

to

prevent

in

the

products

the

have

the

personal

described

damages

itself

are

the

sense

in

DANGER

sense

themselves

the

machine

to

been

not

WARNING

safety

or

connected

life

to

represented

this

of

documentation

the

of

that

will

taken.

user,

signals

and

grievous

the

if

on

and

specified

the

of

devices

and

healthofthe

the

by

documentation

death,

occur

other

the

user

defined

and

the

bodily

or

notes

A

A

m

signal

This

warning

harm

or

safety

precautions

signal

This

warning

damage

have

not

Notes

signifies

notes

serious

signifies

notes

the

to

been

comprise

in

on

the

products

damage

have

in

products

the

on

machine

taken.

important

the

the

may

sense

to

not

sense

the

of

themselves

machine

the

been

taken.

CAUTION

the

of

themselves

occur

the

if

information

documentation

death,

that

may

occur

documentation

that

specified

minor

safety

the

if

bodily

m

and

the

grievous

specified

and

the

harm

precautions

bodily

or

about

the

of

product

the

documentation

or

the

worth

relevant

noticing.

part

Page 8

Use

for

the

actual

purpose

•

•

Active

•

•

catalogue

the

devices

The

product

accordance

descriptions

safety

human

or

Depending

can

faults

example,

messages,

with

message.

This

differentiation

dangerous

supplied.

device/system

The

A

or

in

and

components

described

the

with

of

configuration,

regulations,

beings

passive

under

faults

on

the

dangerous.

be

they

as

undangerous

and

however,

or

system

technical

the

recommended

has

relevant

product

the

normal

an

of

purpose

Active

lead

an

to

may

the

possible

of

Additional

be

generated

dangerous

harm.

bodily

operational

dent

limit

components

description

developed,

been

regulations.

safety

installation,

represents

conditions.

automation

electronic

an

of

faults

illegal

switching

prevent

faults

is

faults

external

in

connection

causing

faults

These

status

switches,

are

to

and

admitted

or

manufactured,

proper

danger

no

device

automation

generally

are

on

of

output

the

and

their

essential

for

WARNING

precautions

with

serious

precautions

in

even

mechanical

case

applied

be

only

in

by

When

operation

with

dangerous

the

a

of

purpose-dependent

safety

all

havetobe

the

damages

must

errors

of

disables

only

connection

Siemens.

tested

adhering

servicing

and

regard

device,

drive.

dangerous

automation

activeaswell

for

Passive

regulations

taken

to

guarantee

(e.g.

etc.).

for

and

to

to

drive

operational

the

by

use

the

with

non-Siemens

documented

corresponding

the

and

machine

controls,

faults

in

division

the

of

or

conditions

device

or

to

machine

enforce

means

of

specified

in

specified

the

or

parts

passive

as

for

connection

status

into

product

have

prevent

or

even

safe

a

indepen¬

in

to

h

Page 9

Notes

Since

the

on

the

undangerous

product

products

product

configuration

are

mostly

parts

integration

of

into

larger

the

systems

Please

unit.

or

units,

note

these

the

notes

following

are

facts

guideline

a

particular:

in

for

7

Further

If

instructions

ations

notes

measuringortesting

for

the

active-part

for

A

h

is

It

inevitable

even

by

Improper

is

prevention

working).

to

high

a

if

configuring

when

means

operation

to

or

generate

required

accidents

of

Use

Devices

Siemens

exchanging

When

quoted

improper

as

well

Always

opening

Only

use

Do

not

danger

recharge

or

exchanging!

when

Dispose

using

When

Improper

installation

increased

the

relevant

operated.

strictly

degree

several

of

prevent

other

the

for

the

proper

supplied

service

inthe

list

servicing

serious

pull

the

device.

the

specified

the

expose

explosion

of

lithium

battery

of

screens:

operation,

of

radiation

safety

observe

of

safety

an

channels,

may

dangerous

sources

active

VBG

electric

by

or

machine

of

spare

may

damage

mains

batteries

(maximum

or

cells

especially

another

of

regulations

instruction

the

has

automation

for

inactivate

faults

of

device,

4.0,

adhere

especially

tools.

WARNING

Siemens

by

plug

types

mercury

type

X-rays.

may

services

parts

parts.

cause

the

to

initiate

or

when

fire

to

storage

or

picture

of

These

manuals

been

reached

device

example.

measures

danger.

to

the

Section

only

be

authorized

components,

or

Unauthorized

death

machine.

or

temperature

batteries,

changes

and

grievous

or

disconnector

the

exchanging

solder

on

use

batteries

in

the

may

tube

changes

the

device

regulations

(Permissible

8

reparied

the

100

the

as

by

by

Siemens.

only

opening

bodily

fuses.

cells

for

°C).

same

hazardous

high

voltage

lead

to

not

do

must

not

and

the

parts

use

and

harm

before

the

Do

not

types

waste.

or

an

comply

be

devi¬

as

open

the

with

Page 10

Preconditions

and

Visual

Control

0

Installation

Module

Voltage

Standard

Service

Data

Overview

and

Installation

Displays

Checklist

Validity

0

0

Check

m

0

0

0

Machine

NC

PLC

Data

Functional

Monitoring

Description

Saving

Data

Programmer

with

Description

0

9

(PG)

0

0

0

Page 11

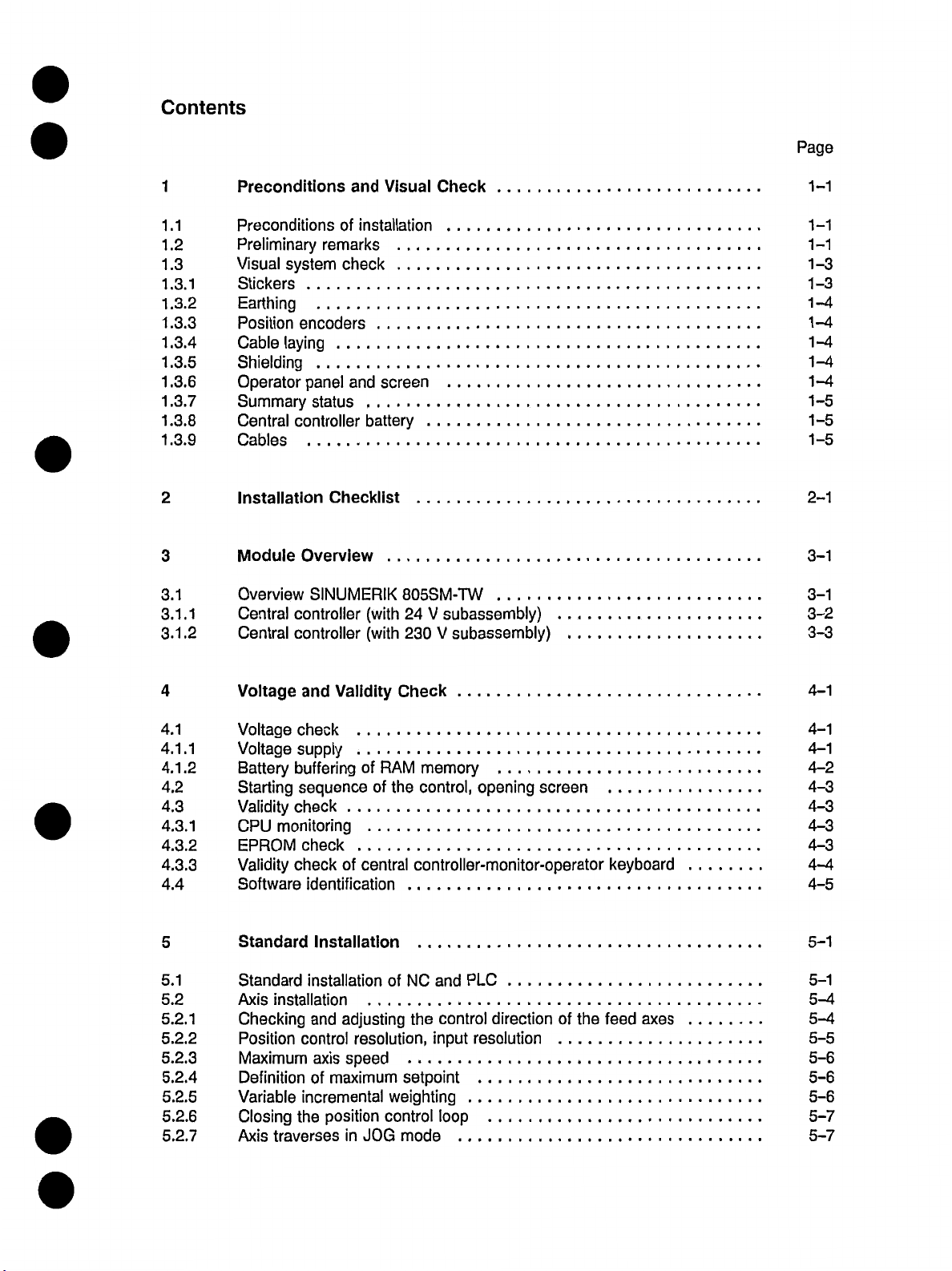

Contents

Page

1

1.1

1.2

1.3

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

.3.6

1

.3.7

1

1.3.8

1.3.9

2

3

3.1

3.1.1

3.1

.2

Preconditions

Preconditions

Preliminary

Visual

remarks

system

Stickers

Earthing

Position

Cable

encoders

laying

Shielding

Operator

Summary

Central

panel

status

controller

Cables

Installation

Module

Overview

Central

Central

Checklist

Overview

SINUMERIK

controller

controller

Visual

and

installation

of

....

and

battery

(with

(with

....

screen

check

Check

.

805SM-TW

subassembly)

V

24

subassembly)

V

230

1-1

1-1

1-1

1-3

1-3

1-4

1-4

1-4

1-4

1-4

1-5

1-5

1-5

2-1

3-1

3-1

3-2

3-3

4

4.1

4.1.1

4.1.2

4.2

4.3

4.3.1

4.3.2

4.3.3

4.4

5

5.1

5.2

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

Voltage

Voltage

Voltage

Battery

Starting

Validity

CPU

EPROM

Validity

and

check

supply

buffering

sequence

check

monitoring

check

checkofcentral

Software

Standard

Standard

installation

Axis

Checking

Position

control

Maximum

Definition

Variable

Closing

Axis

incremental

the

traverses

Validity

of

RAM

of

the

identification

Installation

installation

and

of

adjusting

resolution,

axis

speed

maximum

of

weighting

position

in

control

JOG

Check

memory

control,

opening

screen

controller-monitor-operator

and

NC

the

PLC

control

input

directionofthe

resolution

setpoint

loop

mode

keyboard

axes

feed

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4-3

4-4

4-5

5-1

5-1

5-4

5-4

5-5

5-6

5-6

5-6

5-7

5-7

Page 12

5.2.8

5.2.9

5.2.10

5.2.11

5.2.11.1

5.2.11.2

5.2.12

5.2.13

5.2.14

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

5.5

5.6

Multgain

Servo

NC

gain

Kv

Acceleration

Reference

Reference

Reference

MD

NC

MD

NC

Contour

Spindle

point

point

point

204*

212*

monitoring

installation

Preconditions

Speed

inputs

Acceleration

Spindle

Testing

Installation

Selection

Input

Setting

Definition

Selection

Tool

User

Memory

setting

spindle

of

of

aggregate

of

vertical

of

of

of

carrier

Memory

allocation

machine

the

spindle

configuration

260*

MD

factor

approach

approach

approach

and

NC

MD

(clamping

gears

for

time

constants

data

in

MDA

the

tool

carrier

coordinate

offsets

drilling

visualization

designations

Submodule

without

automatic

with

(exact

208*

tolerance)

mode

spindles

display

(UMS)

automatic

stop

system

direction

direction

coarse

limit

determination

determination

fine)

and

5-8

5-10

5-12

5-14

.

..

5-14

5-17

5-18

5-18

5-19

5-20

5-20

5-22

5-22

5-22

5-22

5-24

5-24

5-26

5-27

5-28

5-30

5-32

5-34

5-35

6

6.1

6.2

6.3

7

7.1

7.2

7.3

7.3.1

7.3.2

7.3.3

7.3.4

7.3.5

7.3.6

7.3.7

7.3.8

7.3.9

7.4

7.5

7.6

Service

Selection

Service

Service

Data

General

R

Setting

Working

Spindle

Dry

Displays

of

data

data

notes

parameters

data

area

data

run

feedrate

service

for

for

(SD)

limitations

Spindle-specific

data

data

data

data

data

for

for

for

for

bits

data

data

data

Setting

Setting

Setting

Setting

Setting

machine

NC

machine

NC

machine

PLC

displays

for

axes

spindles

and

incremental

values

offset

technology

user

the

drilling

files

modules

communication

(NC

values

(NC

bits

values

MD

MD

(PLC

and

axes

dimension

values)

bits)

MD)

spindle

.

6-1

6-1

6-2

6-3

7-1

7-1

7-1

7-2

7-2

7-2

7-4

7-4

7-5

7-6

7-6

7-8

7-8

7-12

7-12

7-12

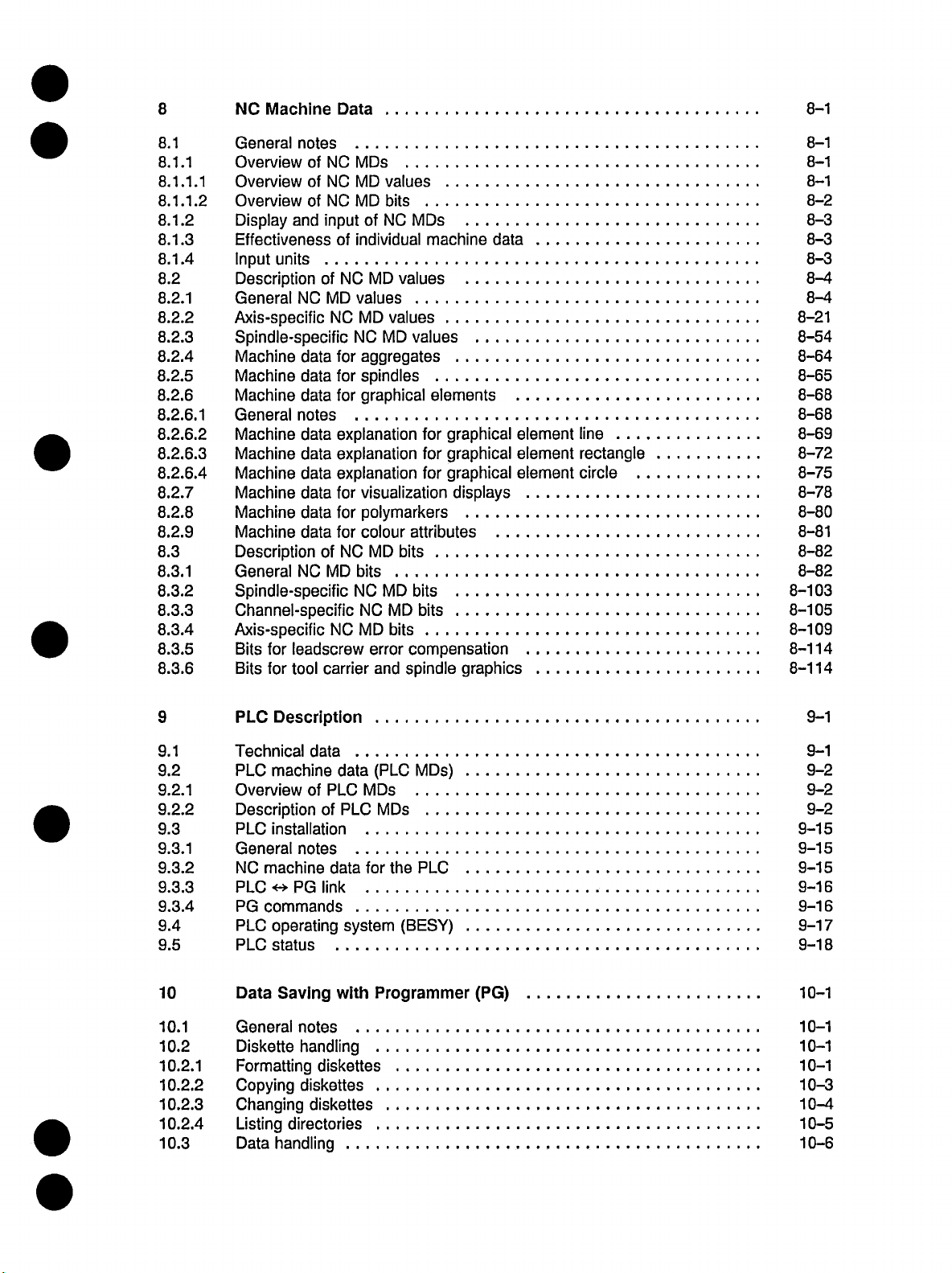

Page 13

8

NC

Machine

Data

8—1

8.1

8.1.1

8.1.

1.1

1.2

8.1.

8.1.2

8.1.3

8.1.4

8.2

8.2.1

8.2.2

8.2.3

8.2.4

8.2.5

8.2.6

8.2.6.1

6.

8.

2.

6.3

8.2.

8.2.6.4

8.2.7

8.2.8

8.2.9

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.3.5

8.3.6

General

Overview

Overview

Overview

Display

Effectiveness

Input

units

Description

General

Axis-specific

Spindle-specific

Machine

Machine

Machine

General

2

Machine

Machine

Machine

Machine

Machine

Machine

Description

General

Spindle-specific

Channel-specific

Axis-specific

Bits

for

Bits

for

notes

of

NC

MDs

NC

of

MD

of

MD

NC

input

and

individual

of

NC

of

MD

NC

values

MD

NC

NC

data

data

data

notes

data

data

data

data

data

data

NC

aggregates

for

spindles

for

graphical

for

explanation

explanation

explanation

for

polymarkers

for

colour

for

NC

of

MD

bits

NC

NC

NC

MD

leadscrew

tool

carrier

values

bits

MDs

NC

of

machine

values

MD

values

values

MD

elements

graphical

for

graphical

for

graphical

for

visualization

attributes

MD

bits

MD

bits

bits

MD

bits

compensation

error

and

spindle

data

displays

graphics

element

element

element

line

rectangle

circle

.

8-1

8-1

8-1

8-2

8-3

8-3

8-3

8-4

8-4

8-21

8-54

8-64

8-65

8-68

8-68

8-69

8-72

,

.

8-75

8-78

8-80

8-81

8-82

8-82

8-103

8-105

8-109

8-114

8-114

9

9.1

9.2

9.2.1

9.2.2

9.3

9.3.1

9.3.2

9.3.3

9.3.4

9.4

9.5

10

10.1

10.2

10.2.1

10.2.2

10.2.3

10.2.4

10.3

PLC

Description

Technical

PLC

Overview

data

machine

of

Description

PLC

installation

General

NC

PLC

PG

PLC

PLC

Data

General

Diskette

Formatting

Copying

Changing

Listing

Data

notes

machine

«ÿ>

PG

commands

operating

status

Saving

notes

handling

diskettes

diskettes

directories

handling

(PLC

data

MDs

PLC

of

PLC

data

for

link

system

Programmer

with

diskettes

MDs

the

(BESY)

MDs)

....

..

.

PLC

(PG)

9-1

9-1

9-2

9-2

9-2

9-15

9-15

9-15

9-16

9-16

9-17

9-18

10-1

10-1

10-1

10-1

10-3

10-4

10-5

10-6

Page 14

10.3.1

10.3.2

10.4

10.4.1

10.4.2

10.4.3

10.4.4

10.4.5

10.5

10.6

Listing

Copying

NC

<->

files

files

PG

Cable

Interface

Interface

Additional

initial

Data

Procedure

Procedure

data

transfer

parameters

parameters

baud

rates

identifiers

data

for

data

for

transfer

on

the

on

the

(for

transfer

SINUMERIK

PG

PG

from

from

635,

PG

the

the

805SM

PG

675,

685

SINUMERIK

SINUMERIK

the

to

PG

only)

805SM

the

to

805SM

PG

10-7

10-7

10-8

10-8

10-8

10-9

10-9

10-10

10-10

..

10-12

.

11

11.1

11.2

11.2.1

11.2.2

11.2.3

11.2.4

11.3

11.3.1

11.3.2

11.4

11.4.1

11.4.2

11.4.3

11.4.4

11.4.5

11.4.6

11.5

11.5.1

11.5.2

11.5.3

11.5.4

11.6

11.6.1

11.6.2

11.6.3

11.6.4

11.6.5

11.7

11.7.1

11.7.2

11.8

11.9

11.9.1

11.9.2

11.9.3

11.9.3.1

11.9.3.2

11.9.3.3

11.9.4

11.10

Functional

Leadscrew

Spindle

Corresponding

analog

S

9,

M1

Influence

Rotary

Corresponding

Functional

Link

to

General

System

Jumper

Function

Illustrationofthe

Description

error

control

M4,

(M3,

Oriented

the

of

function

axis

description

PLC

host

notes

configuration

assignments

blocks

compensation

MDs

M5)

spindle

on

PLC

data

and

error

monitoring

Example

Synchronism

General

Reference

Activating/deactivating

Interface

notes

point

signals

approach

and

machine

Joblist

Functional

Preconditions

Procedure

Messages

Trouble

Tapping

description

of

joblist

of

shooting

dynamic

with

joblist

installation

Description

Machine

Actual

Connecting

value

General

System

SINUMERIK

Basic

program

Interface

Compatibility,

Procedure

Spline

interpolation

description

data

measurement

an

external

notes

configuration,

805SM-TW

for

external

signals,

machine

performance

external

of

stop

the

spindle

of

link

messages

with

the

function

modules

principle

synchronous

data

installation

following

with

error

absolute

PLC

assignments

external

with

PLC

data

characteristics,

installation

PLC

axes

compensation

encoder

PLC

synchronization

11-1

11-1

11-10

11-10

11-10

11-11

11-18

11-19

11-19

11-19

11-22

11-22

11-22

11-23

11-27

11-28

11-29

11-31

11-31

11-33

11-35

11-36

11-37

11-37

11-37

11-38

11-38

11-40

11-41

11-41

11-42

11-46

11-48

11-48

11-49

11-50

11-50

11-52

11-52

11-53

11-54

Page 15

11.11

11.11.1

11.11.2

11.11.3

11.12

11.13

11.13.1

11.13.2

11.13.3

11.14

11.14.1

11.14.2

11.14.3

11.14.4

11.15

11.16

Operation

General

without

notes

Start-up

Programming

Gauging

Operation

General

Functional

Control

NC

General

Functional

PC

on

without

notes

description

restart-up

operation

notes

preconditions

connection

Operation

PTP

software

Precontrol

the

via

for

NC

fly

VGA

PC

MS-DOS

....

...

PC

11-54

11-54

11-55

11-55

11-56

11-58

11-58

11-59

11-61

11-63

11-63

11-64

11-65

11-66

11-67

11-69

12

12.1

12.2

12.3

12.4

Monitoring

General

Alarm

Display

List

notes

numbers

of

alarms

of

and

alarms

groups/clearing

and

messages

alarms

12-1

12-1

12-1

12-3

12-4

Page 16

06.92

1

Preconditions

and

Visual

Check

1

1.1

a)

b)

c)

d)

e)

Preconditions

Preconditions

The

electrical

prepared

axes

The

customer

measuring

The

If

customer

the

especially

The

cables

the

control

Flexible

•

•

Support

unit,

earth

bar

earth

barinmachine

earth

must

machine,

Recommendation:

the

Limit

switches)

travel

for

and

for

PLC

systems

has

specified

the

to

neutral

wires

SINUMERIK

in

be

provided

machine

ranges

greater

installation

of

mechanical

operation

program

installed

screening.

machine

point

installed

(confirmedbycustomer).

must

must

adapter

must

according

column

by

operation

by

transferring

clearance

and

configuration

operational

be

be

installed

plugs,

be

connected.

the

to

(visual

805SM

the

check):

interface

interface

customer’s

and

the

cam

distances.

Visual

the

of

and

wired

and

check

The

Interface

unit:

unit:

personnel

customer

switches

limit

Check

machine

correct

cable

Description.

PLC

must

have

must

control

the

to

installation,

shields

10

mm2

10

mm2

dealing

when

program.

(EMERGENCY

complete

be

been

(visual

must

pretested

check).

tension

connected

be

with

the

STOP

and

the

possible.

if

and

relief

interface

limit

to

f)

g)

1.2

Synthetic

charges

regarding

previously

Modules

necessary

The

Test

tapes

Preliminary

or

of

high-voltage

and

rubber

several

discharging

power

disconnected.

Even

circuiting

RAM

control

the

if

across

memories

machine

availabletocheck

be

must

remarks

soles

and

kilovoltsinhuman

discharges.

yourself

supply

is

the

may

cables

disconnected,

RAM

V<x

be

corrupted

must

data

especially

Therefore,

on

an

can

it

printed

or

be

available.

machine-specific

the

synthetic

beings.

Integrated

never

earthed

only

hastobe

part

be

conductors.

printed

conductors

rubber

or

touch

the

of

pulled

or

reckoned

Otherwise,

functions.

flooring

circuits

have

conductors

system.

inserted

static

with

data

may

even

may

when

load

buffered

burn

produce

a

great

and

components

control

the

to

out.

static

sensitivity

is

prevent

CMOS

in

the

without

short-

©Siemens

SINUMERIK

AG

All

1991

805SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

1-1

Page 17

Preconditions

1

and

Visual

Check

09.91

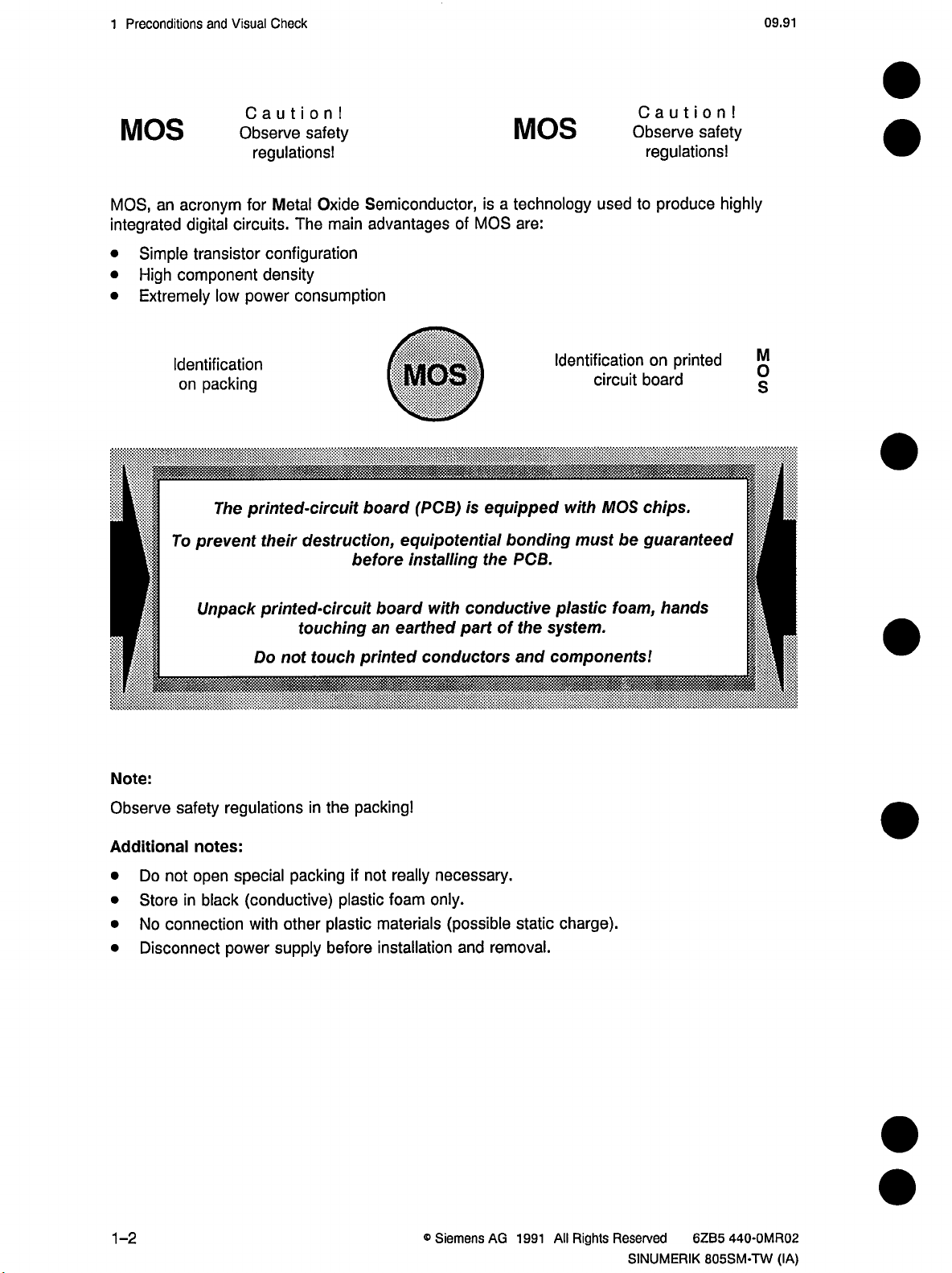

MOS

MOS,

an

integrated

Simple

•

High

•

Extremely

•

Identification

To

Caution!

Observe

acronym

digital

transistor

component

on

for

circuits.

power

low

packing

.

The

printed-circuit

prevent

safety

regulations!

Metal

Oxide

main

The

configuration

density

consumption

their

destruction,

Semiconductor,

advantages

MOS

board

before

(PCB)

equipotential

installing

of

MOS

is

MOS

technology

a

is

are:

equipped

bonding

PCB.

the

Caution!

Observe

used

to

Identification

circuit

MOS

with

be

must

safety

regulations!

produce

on

printed

board

chips.

guaranteed

highly

M

s

I

P

Note:

Observe

Additional

•

•

•

•

Unpack

safety

notes:

Do

not

open

in

Store

No

Disconnect

black

connection

printed-circuit

not

Do

regulations

special

power

packing

(conductive)

other

with

supply

touching

touch

in

the

plastic

plastic

before

board

an

earthed

printed

packing!

really

if

not

foam

materials

installation

conductive

with

part

conductors

necessary.

only.

(possible

and

the

of

and

static

removal.

plastic

system.

components!

charge).

foam,

hands

1-2

®

Siemens

AG

1991

All

Rights

Reserved

SINUMERIK

6ZB5

440-0MR02

805SM-TW

(IA)

Page 18

09.91

Preconditions

1

and

Visual

Check

1.3

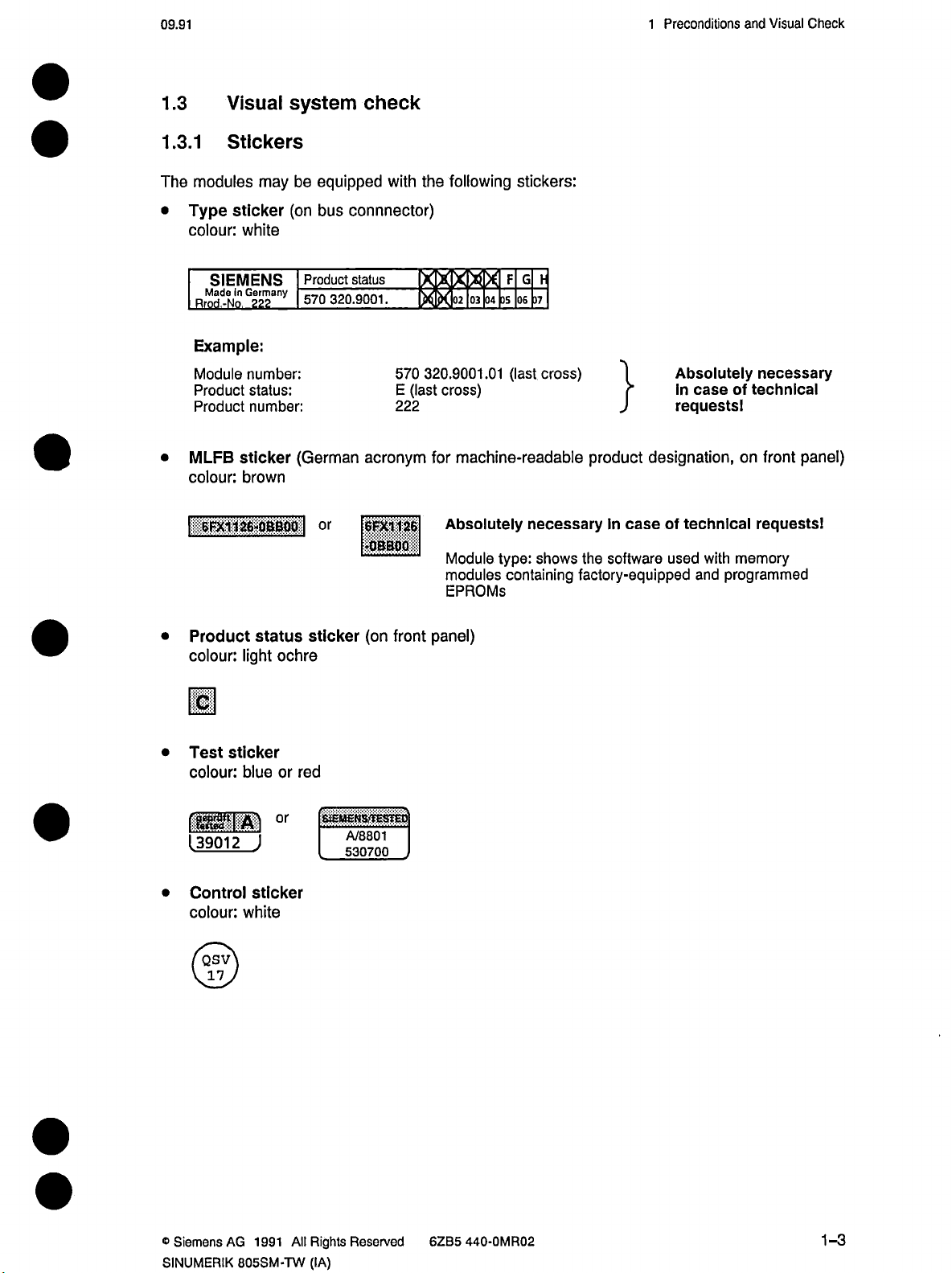

1.3.1

The

Type

•

colour:

MLFB

•

colour:

|

Visual

system

Stickers

modules

SIEMENS

Ma

Rrnri

Example:

Module

Product

Product

I-6FX1

may

be

sticker

(on

white

Product

ld.N0nG2e22any

number:

status:

number:

sticker

570

(German

brown

1

26-0BB00

|

check

equipped

connnector)

bus

status

320.9001.

acronym

or

[|§$|||||

•QBBQO

following

the

with

IBQI3BI

X

X

IS331B381

320.9001.01

570

cross)

(last

E

222

for

Absolutely

Module

modules

EPROMs

stickers:

FGF

37

05

06

(last

cross)

machine-readable

necessary

shows

type:

containing

the

factory-equipped

}

product

case

In

software

Absolutely

case

In

requests!

designation,

technical

of

used

with

programmed

and

necessary

technical

of

on

front

requests!

memory

panel)

•

•

mm

•

Product

colour:

sticker

Test

colour:

[39012

Control

colour:

/QSV\

status

light

blue

J

sticker

white

ochre

red

or

°r

sticker

(on

front

StEMENS'TESTEO

A/8801

530700

panel)

®

Siemens

SINUMERIK

AG

All

1991

805SM-TW

Rights

(IA)

Reserved

62B5

440-0MR02

1-3

Page 19

Preconditions

1

and

Visual

Check

06.92

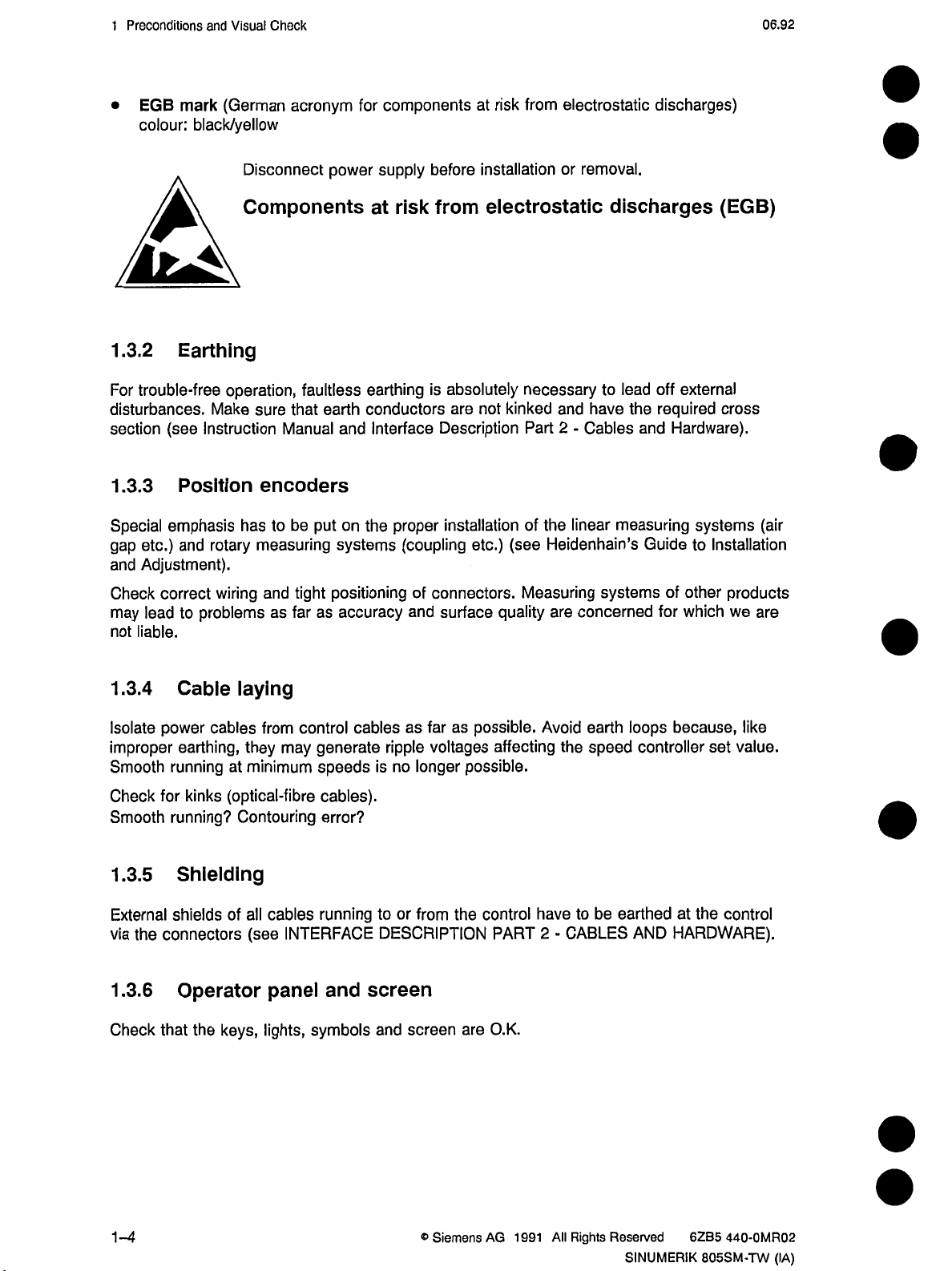

•

colour:

1.3.2

For

trouble-free

black/yellow

Earthing

mark

EGB

disturbances.

(see

section

1.3.3

Special

etc.)

gap

and

Adjustment).

Instruction

Position

emphasis

and

(German

Disconnect

Components

operation,

sure

Make

encoders

has

to

measuring

rotary

acronym

faultless

earth

that

Manual

be

put

for

power

conductors

and

the

on

systems

components

supply

risk

at

earthing

Interface

proper

(coupling

risk

at

before

is

installation

from

electrostatic

absolutely

are

not

Description

installation

etc.)

from

necessary

kinked

Part

the

of

(see

Heidenhain’s

electrostatic

removal.

or

discharges

lead

to

have

and

2

-

linear

the

Cables

measuring

discharges)

external

off

required

Hardware).

and

systems

Guide

to

(EGB)

cross

(air

Installation

Check

may

not

correct

lead

liable.

1.3.4

Isolate

improper

Smooth

Check

Smooth

power

for

1.3.5

External

via

the

connectors

1.3.6

Check

that

wiring

problems

to

Cable

cables

earthing,

running

running?

(optical-fibre

kinks

at

Shielding

shields

of

Operator

the

keys,

tight

and

far

as

laying

control

from

may

they

minimum

Contouring

all

cables

INTERFACE

(see

panel

lights,

positioning

accuracy

as

cables

generate

speeds

cables).

error?

running

and

symbols

of

connectors.

and

surface

as

far

as

voltages

ripple

longer

no

is

to

or

from

the

DESCRIPTION

screen

and

screen

are

quality

possible.

affecting

possible.

control

PART

O.K.

Measuring

are

concerned

Avoid

the

have

to

2

CABLES

-

systems

earth

speed

be

earthed

of

for

because,

loops

controller

at

HARDWARE).

AND

other

which

set

the

products

are

we

like

value.

control

1-4

®

Siemens

AG

1991

All

Rights

Reserved

SINUMERIK

6ZB5

440-0MR02

805SM-TW

(IA)

Page 20

06.92

1

Preconditions

and

Visual

Check

1.3.7

Make

screwed

Packing

Make

(Parts

Check

Summary

that

sure

the

to

directions:

that

sure

list

attatched

all

socket

ones.

Check

1.3.8

The

off

1.3.9

Check

HARDWARE,

conductor

The

guidelines

jumper

Central

write-read

(see

chapter

Cables

all

cables

is

respective

and

status

modules

the

devices,

log-book

the

to

ICs

for

assignments

controller

memory

BATTERY

according

especially

necessary!

department

sales

remedial

and

check

(RAM)

complete

and

original

proper

on

the

fit

the

must

BUFFERING

the

to

the

cables

(Special

measures

cover

plates

connections.

earth

parts

delivery

positioning

and

modules.

battery

be

buffered

OF

manual

prepared

emphasis

hastobe

have

to

properly

are

are

list

note

hastobe

at

hand.

when

byabattery

MEMORY).

RAM

INTERFACE

by

the

customer.

be

to

informed

be

taken

on

put

if

necessary.

if

the

log-book.)

in

modules

voltage

and

if

secured

filed

renewing

DESCRIPTION

check

Visual

conductive

cables

elastomer

do

not

that

or

control

the

PART

comply

connectors

the

replacing

switched

is

CABLES

2

-

least

of

at

connections!)

our

with

are

faulty

AND

one

sure

Make

accordance

optical-fibre

that

the

with

cables

installation

are

properly

instructions).

installed,

e.g.

that

the

bending

radius

is

in

©Siemens

SINUMERIK

AG

All

1991

805SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

1-5

Page 21

06.92

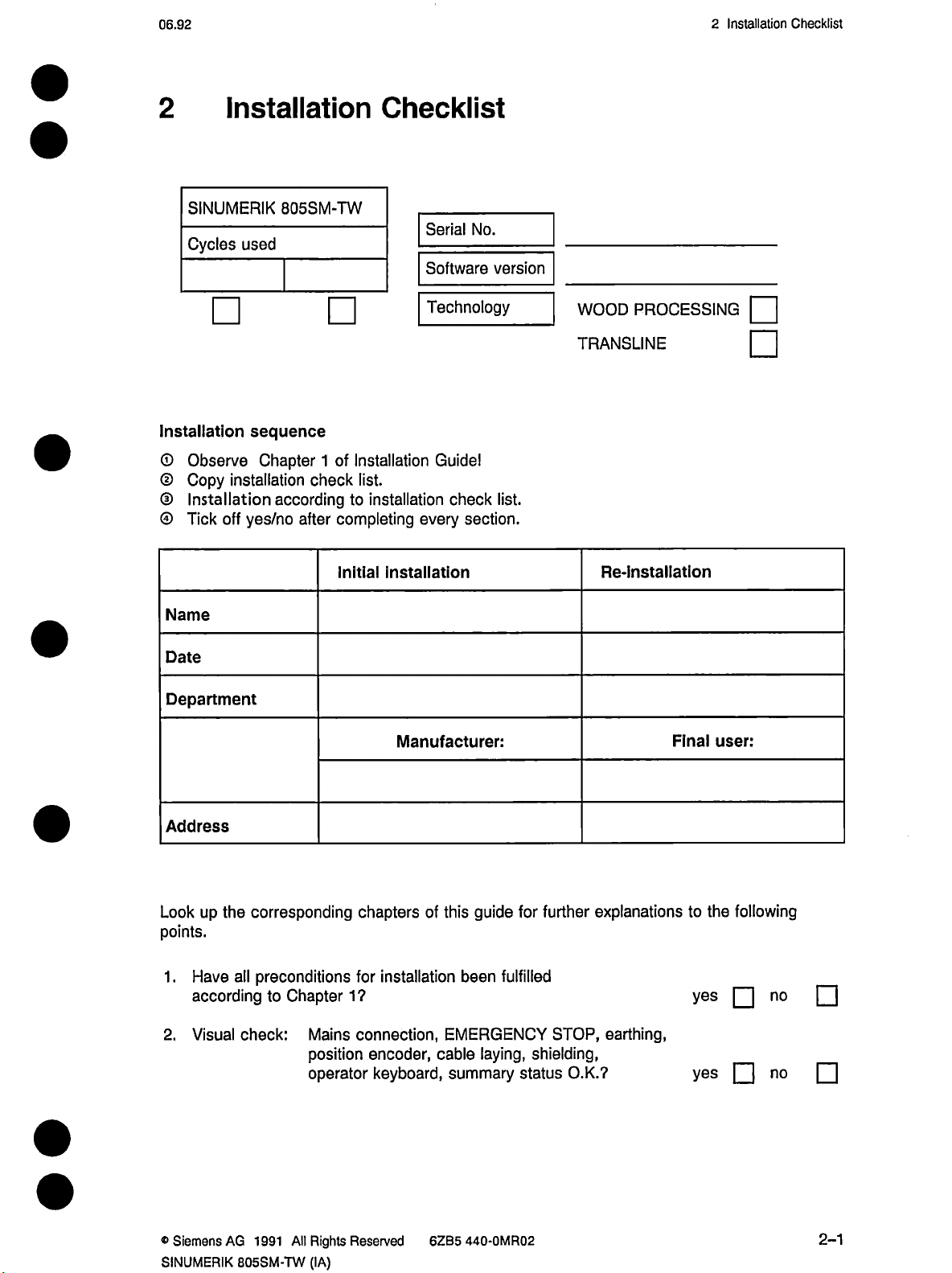

2

Installation

Checklist

2

Installation

SINUMERIK

Cycles

Installation

©

Observe

Copy

©

Installation

®

Tick

©

off

805SM-TW

used

sequence

Chapter

installation

according

yes/no

after

of

1

Installation

check

to

completing

Initial

Checklist

Serial

Software

Technology

Guide!

list.

installation

every

installation

No.

check

section.

version

list.

WOOD

TRANSLINE

PROCESSING

Re-Installation

|

|

Name

Date

Department

Address

Lookupthe

points.

all

Have

1

.

according

Visual

2.

corresponding

preconditions

Chapter

to

check:

Mains

position

operator

Manufacturer:

chapters

installation

for

1?

connection,

encoder,

keyboard,

guide

this

of

fulfilled

been

EMERGENCY

laying,

cable

summary

for

further

STOP,

shielding,

status

explanations

earthing,

O.K.?

Final

to

yes

yes

user:

the

following

no

no

®

Siemens

SINUMERIK

AG

1991

All

805SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

2-1

Page 22

Installation

2

Checklist

06.92

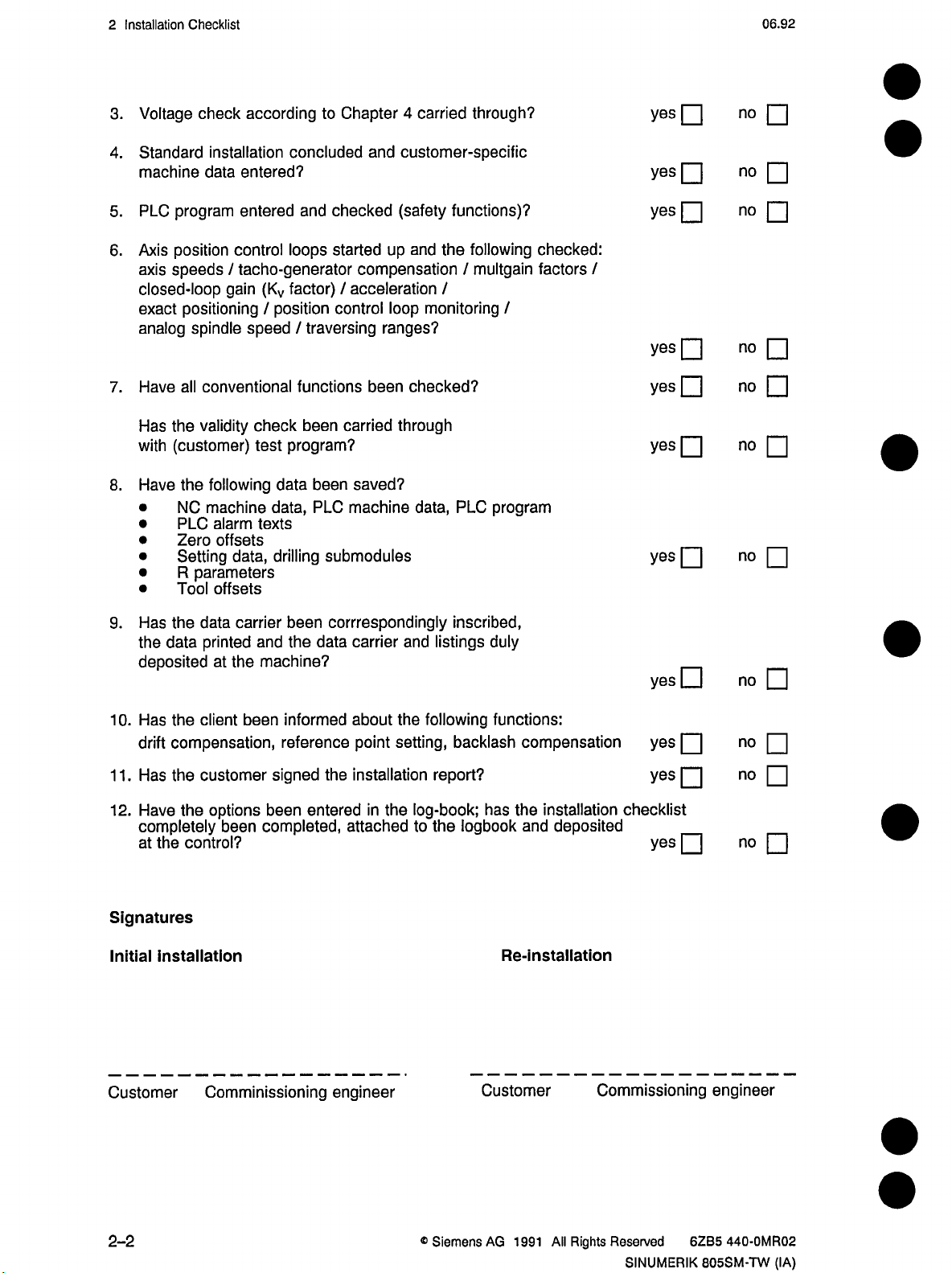

Voltage

3.

Standard

4.

machine

PLC

5.

Axis

6.

axis

closed-loop

exact

analog

Have

7.

Has

with

Have

8.

•

•

•

•

•

•

check

installation

data

program

position

speeds

positioning

control

/

gain

spindle

all

conventional

validity

the

(customer)

following

the

machine

NC

alarm

PLC

Zero

offsets

Setting

R

Tool

data,

parameters

offsets

according

Chapter

to

concluded

entered?

and

entered

tacho-generator

(Kv

position

/

speed

check

test

data

data,

texts

drilling

checked

loops

started

factor)

/

control

traversing

/

functions

carried

been

program?

been

PLC

submodules

4

carried

customer-specific

and

(safety

and

up

compensation

acceleration

monitoring

loop

ranges?

been

checked?

through

saved?

machine

data,

through?

functions)?

following

the

multgain

/

/

program

PLC

/

checked:

factors

/

yes

yes

yes

yes

yes

yes

yes

no

no

no

no

no

no

no

Has

9.

1

0.

1

1

12.

Signatures

Initial

the

the

data

deposited

Has

the

compensation,

drift

Has

the

.

Have

completely

the

at

installation

data

printed

at

client

customer

options

the

been

control?

carrier

and

machine?

the

been

signed

been

completed,

correspondingly

been

data

the

informed

reference

the

enteredinthe

carrier

about

point

and

the

setting,

installation

attached

inscribed,

listings

following

backlash

report?

log-book;

logbook

the

to

duly

functions:

compensation

has

the

installation

and

deposited

Re-installation

yes

yes

yes

checklist

yes

ED

no

no

no

no

Customer

2-2

Comminissioning

engineer

®

Siemens

Customer

AG

1991

Commissioning

Rights

All

Reserved

6ZB5

SINUMERIK

engineer

440-0MR02

805SM-TW

(IA)

Page 23

06.93

2

Installation

Checklist

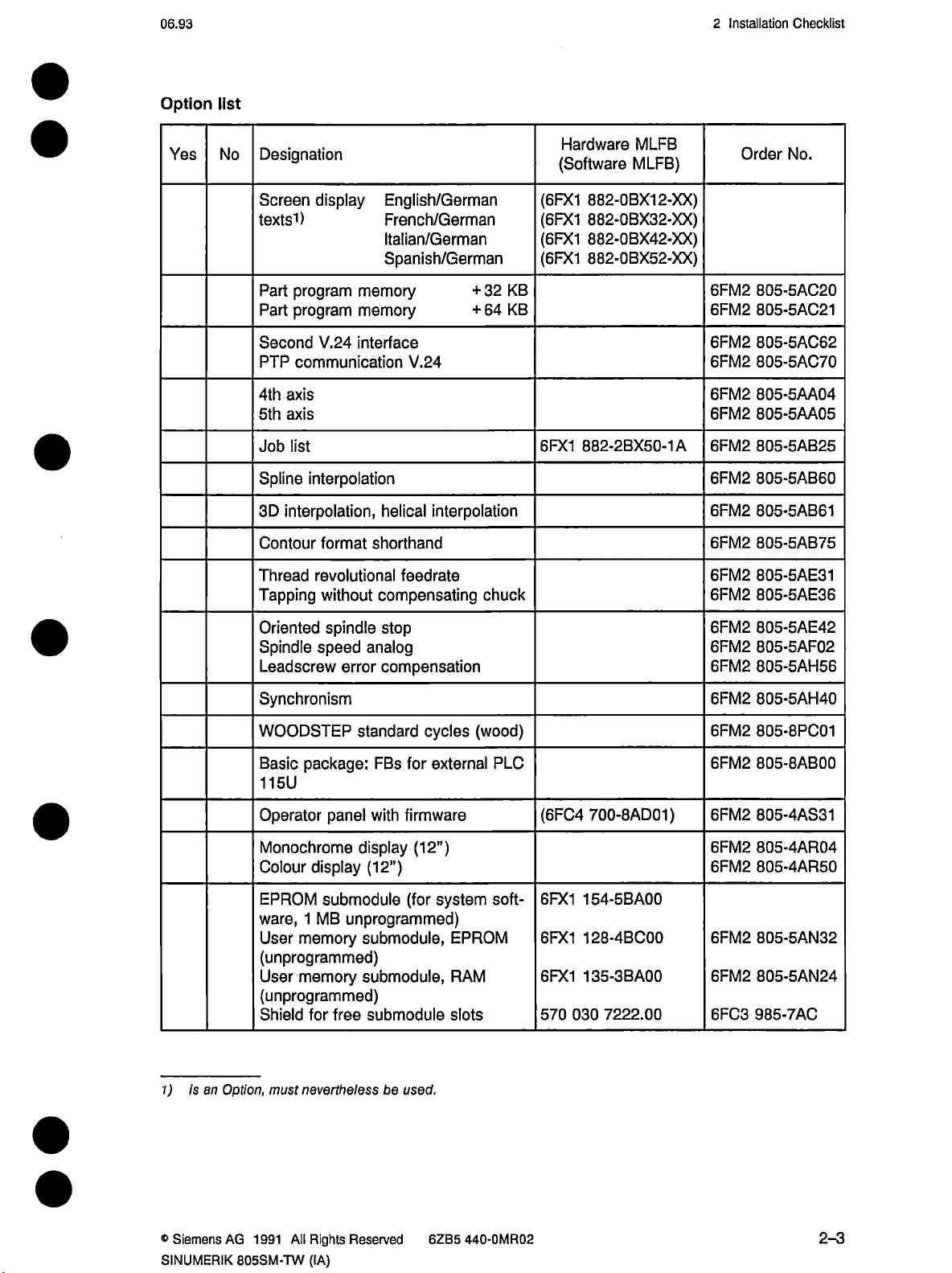

Option

Yes

list

No

Designation

Screen

texts1)

Part

Part

Second

PTP

4th

5th

Job

Spline

3D

Contour

display

program

program

V.24

communication

axis

axis

list

interpolation

interpolation,

format

English/German

French/German

Italian/German

Spanish/German

memory

memory

interface

V.24

helical

interpolation

shorthand

Hardware

(Software

(6FX1

(6FX1

(6FX1

(6FX1

32

KB

+

KB

64

+

882-2BX50-1A6FM2

6FX1

MLFB

MLFB)

882-0BX12-XX)

882-0BX32-XX)

882-0BX42-XX)

882-0BX52-XX)

Order

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

No.

805-5AC20

805-5AC21

805-5AC62

805-5AC70

805-5AA04

805-5AA05

805-5AB25

805-5AB60

805-5AB61

805-5AB75

Thread

Tapping

Oriented

Spindle

Leadscrew

revolutional

without

spindle

speed

analog

error

Synchronism

WOODSTEP

package:

Basic

standard

FBs

115U

Operator

Monochrome

Colour

display

EPROM

1

ware,

User

MB

memory

with

panel

display

(12”)

submodule

unprogrammed)

submodule,

(unprogrammed)

User

memory

submodule,

(unprogrammed)

Shield

for

submodule

free

feedrate

compensating

stop

compensation

cycles

external

for

firmware

(12”)

(for

system

EPROM

RAM

slots

chuck

(wood)

PLC

soft¬

(6FC4

6FX1

6FX1

6FX1

030

570

700-8AD01)

154-5BA00

128-4BC00

135-3BA00

7222.00

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FM2

6FC3

805-5AE31

805-5AE36

805-5AE42

805-5AF02

805-5AH56

805-5AH40

805-8PC01

805-8AB00

805-4AS31

805-4AR04

805-4AR50

805-5AN32

805-5AN24

985-7AC

1)

®

Siemens

SINUMERIK

is

an

Option,

AG

must

All

1991

805SM-TW

neverthelessbeused.

Rights

Reserved

(IA)

62B5

440-0MR02

2-3

Page 24

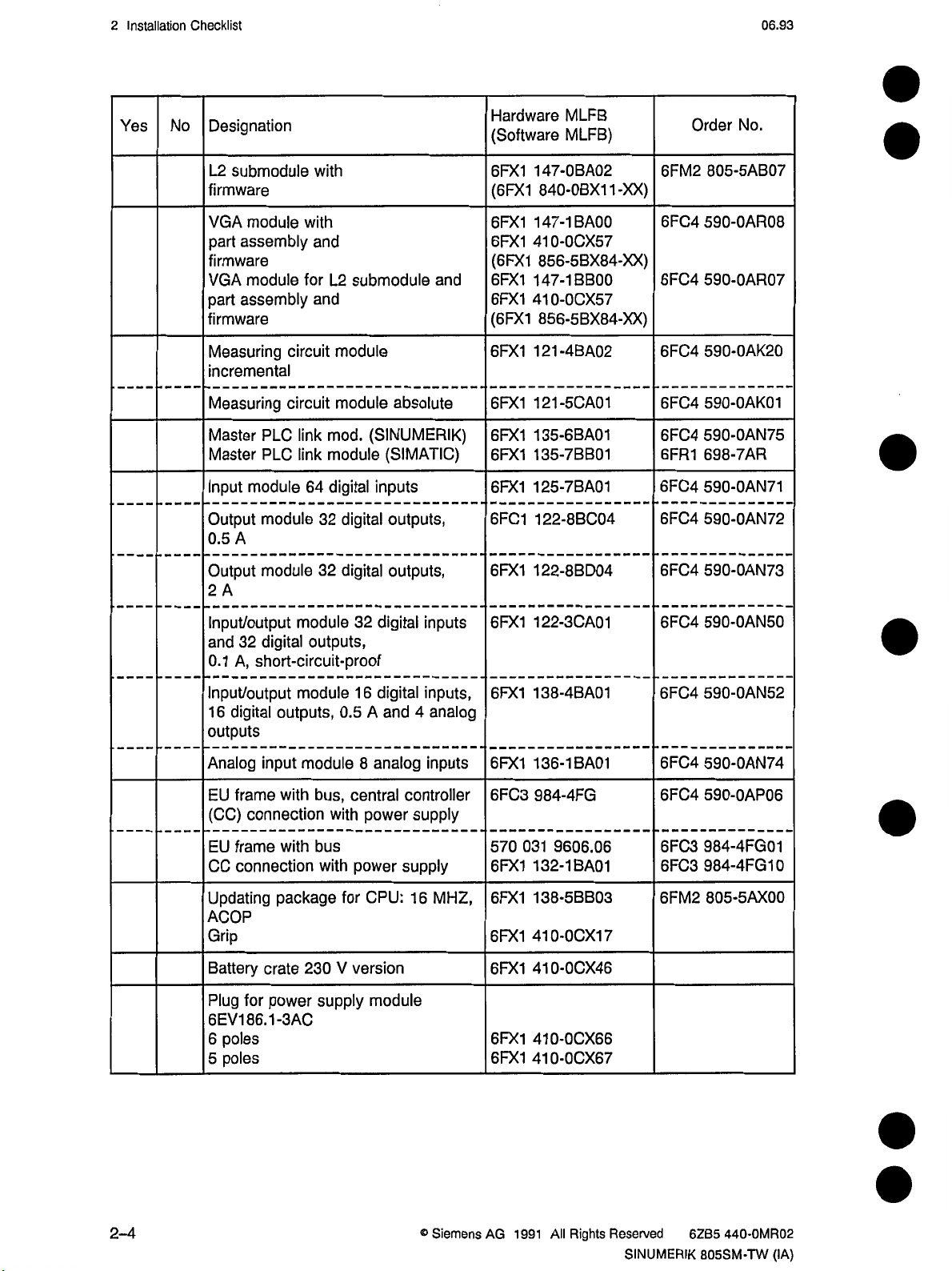

2

Installation

Checklist

06.93

Yes

Designation

No

L2

firmware

VGA

part

firmware

VGA

part

firmware

Measuring

incremental

Measuring

Master

Master

Input

Output

0.5

Output

2

submodule

module

assembly

module

assembly

PLC

PLC

module

module

A

module

A

with

with

and

for

and

circuit

circuit

link

link

64

32

32

L2

submodule

module

module

mod.

(SINUMERIK)

module

digital

inputs

digital

digital

and

absolute

(SIMATIC)

outputs,

outputs,

Hardware

(Software

6FX1

147-0BA02

(6FX1

(6FX1

6FX1

6FX1

(6FX1

6FX1

6FX1

6FX1

6FX1

6FX1

6FC1

6FX1

840-0BX11-XX)

147-1BA00

6FX1

41

6FX1

856-5BX84-XX)

147-1BB00

410-0CX57

856-5BX84-XX)

121-4BA02

121-5CA01

135-6BA01

135-7BB01

125-7BA01

122-8BC04

122-8BD04

0-0CX57

MLFB

MLFB)

Order

6FM2

6FC4

6FC4

6FC4

6FC4

6FC4

6FR1

6FC4

6FC4

6FC4

No.

805-5AB07

590-0AR08

590-0AR07

590-OAK20

590-0AK01

590-0AN75

698-7AR

590-0AN71

590-0AN72

590-0AN73

Input/output

32

and

0.1

A,

Input/output

digital

16

outputs

Analog

EU

frame

(CC)

connection

EU

frame

CC

connection

Updating

module

digital

outputs,

short-circuit-proof

module

outputs,

input

module

with

with

package

ACOP

Grip

230

for

crate

power

Battery

Plug

6EV186.1-3AC

poles

6

poles

5

0.5

bus,

with

bus

with

for

V

supply

digital

32

16

digital

and

A

analog

8

central

power

power

CPU:

version

module

inputs

inputs,

4

analog

inputs

controller

supply

supply

16

MHZ,

6FX1

6FX1

6FX1

6FC3

570

6FX1

6FX1

6FX1

6FX1

6FX1

6FX1

031

122-3CA01

138-4BA01

136-1BA01

984-4FG

9606.06

132-1BA01

138-5BB03

410-0CX17

410-0CX46

410-0CX66

410-0CX67

6FC4

6FC4

6FC4

6FC4

6FC3

6FC3

6FM2

590-0AN50

590-0AN52

590-0AN74

590-0AP06

984-4FG01

984-4FG10

805-5AX00

2-4

®

Siemens

AG

1991

All

Rights

Reserved

SINUMERIK

6ZB5

440-0MR02

805SM-TW

(IA)

Page 25

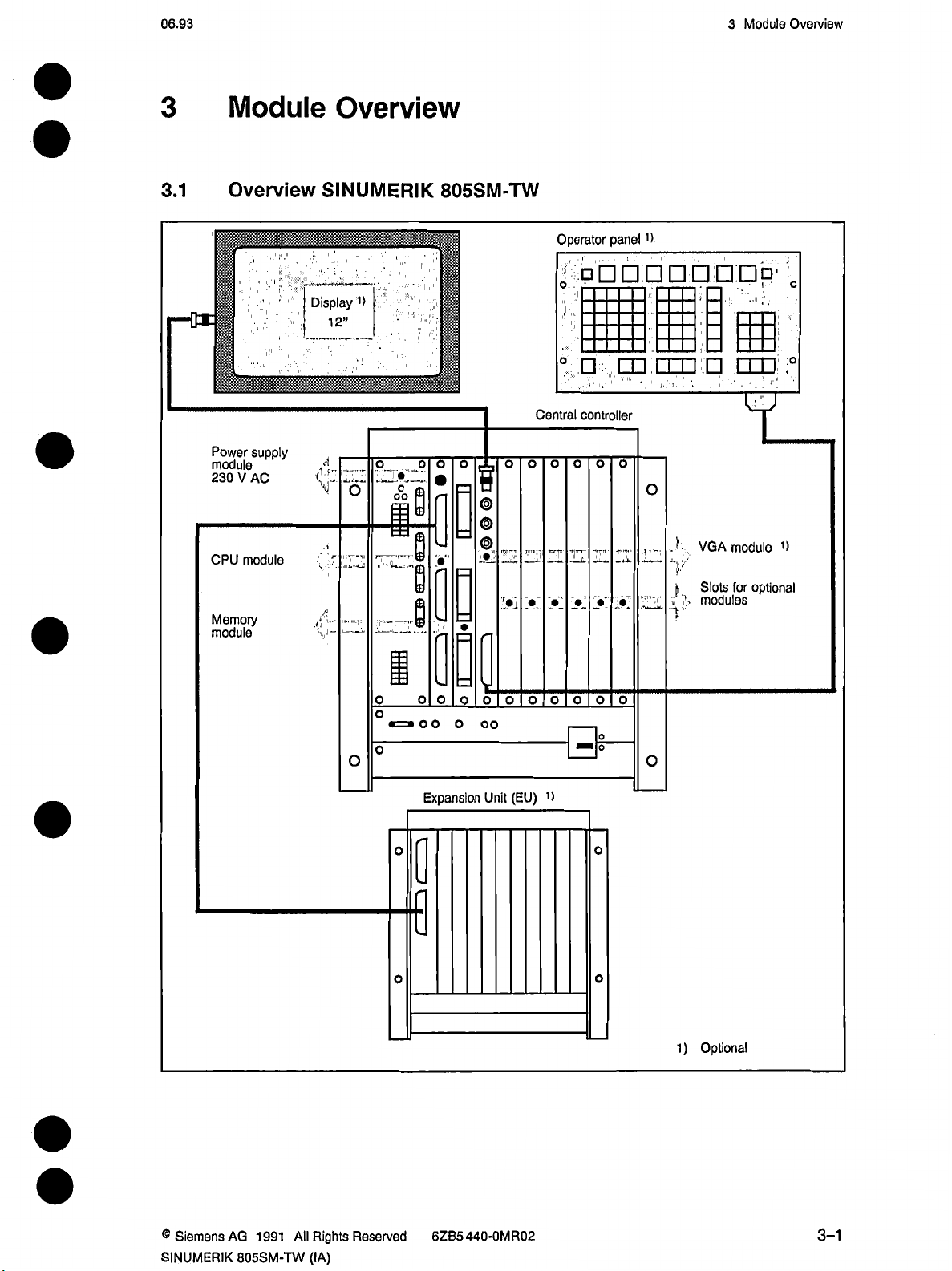

06.93

Modulo

3

Overview

3

3.1

Module

Overview

_

l"

supply

V

AC

modulo

I

:

Power

module

230

CPU

Memory

module

Overview

SINUMERIK

•

Display

’ii

12”

d

f.f

V

A

v-

1>

—

”

|

§

oo

.

805SM-TW

o o

O

i

A

V

SI

A

Central

o

II

Hi

Operator

.

v®.\W

controller

o

o

n

o

777

panel

'

o

H

1>

o

J;

y

;

(,

1

VGA

,

Slots

modules

1?

1.

module

optional

for

oo

o

o

1>

o

o

o

o

o

o

o

o

o

)

Optional

1

o

o

o

o

«=»oo

o

o

o

0

o

Expansion

o

o

oo

(EU)

Unit

®

Siemens

SINUMERIK

AG

All

1991

805SM-TW

Rights

(IA)

Reserved

62B5440-0MR02

3-1

Page 26

3

Module

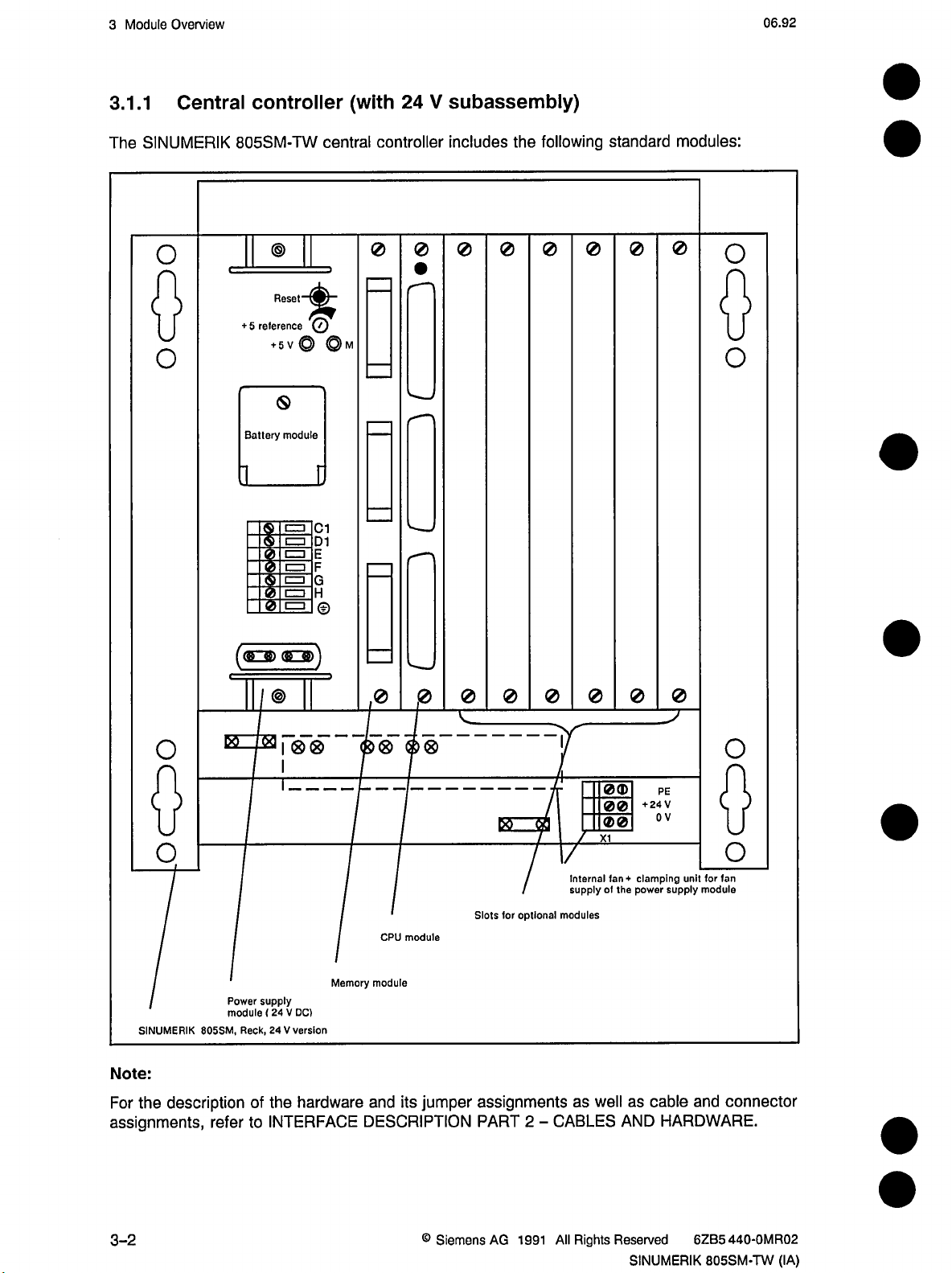

3.1.1

Overview

Central

controller

(with

24

V

subassembly)

06.92

SINUMERIK

The

o

o

805SM-TW

Reset

reference

%

@

+

5

<9

Battery

module

C=3

S

~<5

central

C1

D1

E

G

©

controller

0

0

includes

0

0

the

following

0

0

standard

0

modules:

0

o

O

o

o

SINUMERIK

Note:

description

the

For

assignments,

M

805SM,

refer

(<£3)

I&

supply

Power

(

24

module

24

Reck,

of

the

INTERFACE

to

(BZg))

|

®

®

I

T

Memory

DC)

V

version

V

hardware

,0

CPU

module

and

module

its

0

jumper

DESCRIPTION

0 0

DO

optional

for

Slots

assignments

CABLES

2

PART

-

I

/

7

Internal

supply

modules

as

0

well

0®

00

00

X1

of

fan-*-

the

0

0

PE

V

24

+

V

0

clamping

supply

power

cable

as

HARDWARE.

AND

unit

and

o

o

for

fan

module

connector

3-2

©

Siemens

AG

1991

All

Rights

Reserved

SINUMERIK

6ZB5

440-0MR02

805SM-TW

(IA)

Page 27

06.92

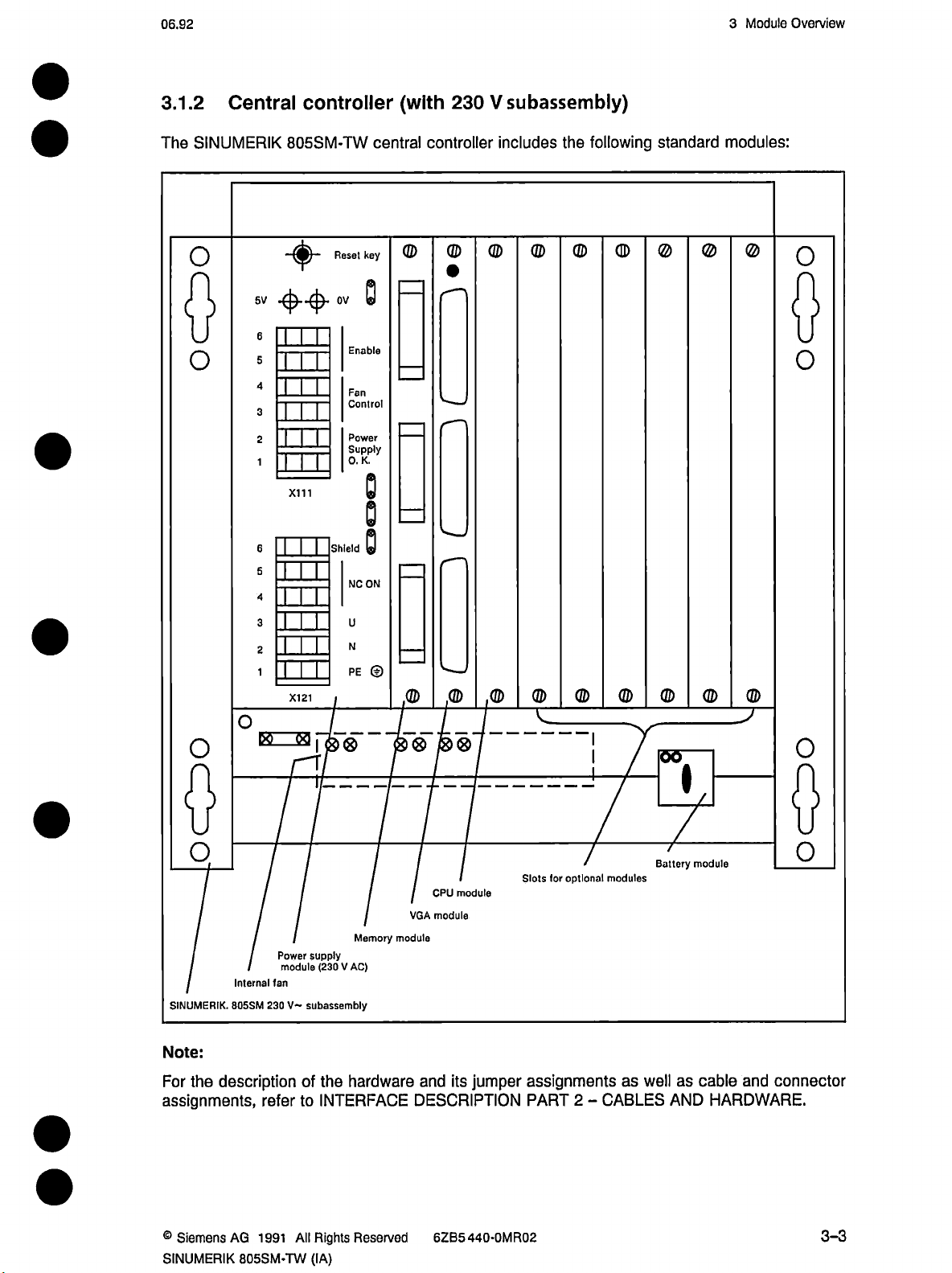

3.1.2

Central

controller

(with

230

V

subassembly)

3

Module

Overview

SINUMERIK

The

o

o

o

o

805SM-TW

+

5V

6

5

4

3

2

EH

1

Ml

X111

6

s

TTT

4

3

2

1

X121

00

DO

I

0®

Reset

0V

Enable

Fan

Control

Power

Supply

0.

Shield

key

K.

NC

U

N

PE

central

ON

©

controller

©

,©

©®®

©

,©

includes

©

,©

©

©

following

the

©

©

I

I

©

©

standard

©

©

©

© ©

modules:

©

o

o

o

o

Internal

SINUMERIK.

Note:

For

assignments,

®

Siemens

SINUMERIK

805SM

the

description

AG

805SM-TW

fan

230

refer

1991

supply

Power

(230

module

subassembly

V-

the

of

INTERFACE

to

All

Rights

(IA)

Memory

module

AC)

V

hardware

Reserved

CPU

module

VGA

module

and

its

jumper

DESCRIPTION

6ZB5440-0MR02

optional

tor

Slots

assignments

2

PART

-

modules

Battery

wellascable

as

CABLES

»

7

module

AND

HARDWARE.

and

o

connector

3-3

Page 28

06.92

Voltage

4

and

Validity

Check

4

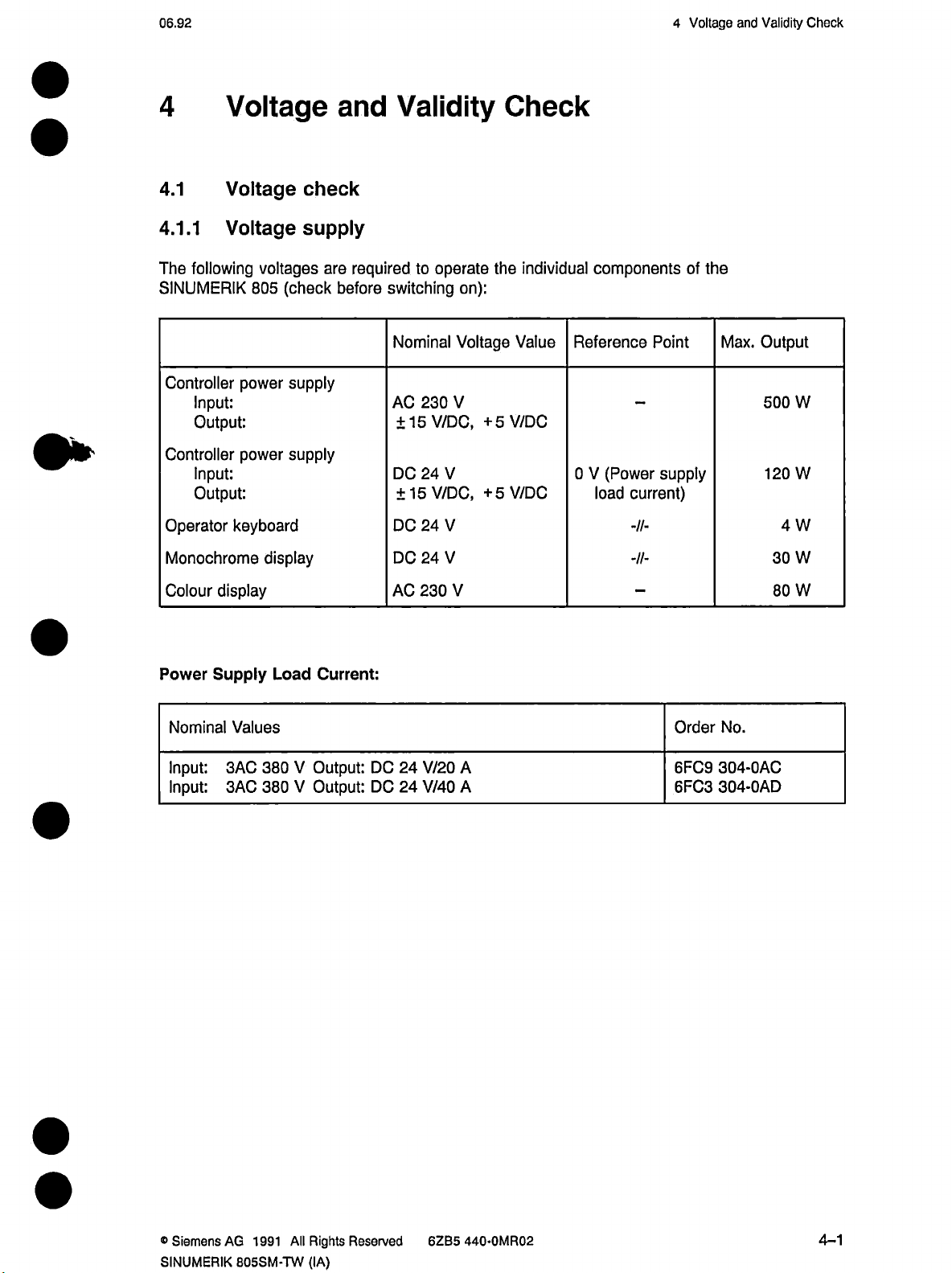

4.1

4.1.1

The

Voltage

Voltage

Voltage

following

SINUMERIK

Controller

power

Input:

Output:

Controller

power

Input:

Output:

Operator

keyboard

Monochrome

voltages

(check

805

supply

supply

display

and

check

supply

are

before

Validity

required

switching

Nominal

AC

±15

DC

±15

DC

DC

to

operate

230

V/DC,

24

V/DC,

24

24

on):

Voltage

V

V

V

V

Check

the

individual

Value

+5V/DC

V/DC

+5

components

Reference

0

(Power

V

current)

load

-//-

-II-

Point

supply

of

the

Max.

Output

500

W

120

W

4

W

W

30

Colour

Power

Nominal

Input:

Input:

display

Supply

Values

3AC

3AC

Load

380

380

Current:

V

Output:

V

Output:

230

AC

DC24V/20

24

DC

V/40

W

V

Order

No.

304-0AC

A

A

6FC9

6FC3

304-0AD

80

®

Siemens

SINUMERIK

AG

1991

All

B05SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

4-1

Page 29

Voltage

4

and

Validity

Check

06.92

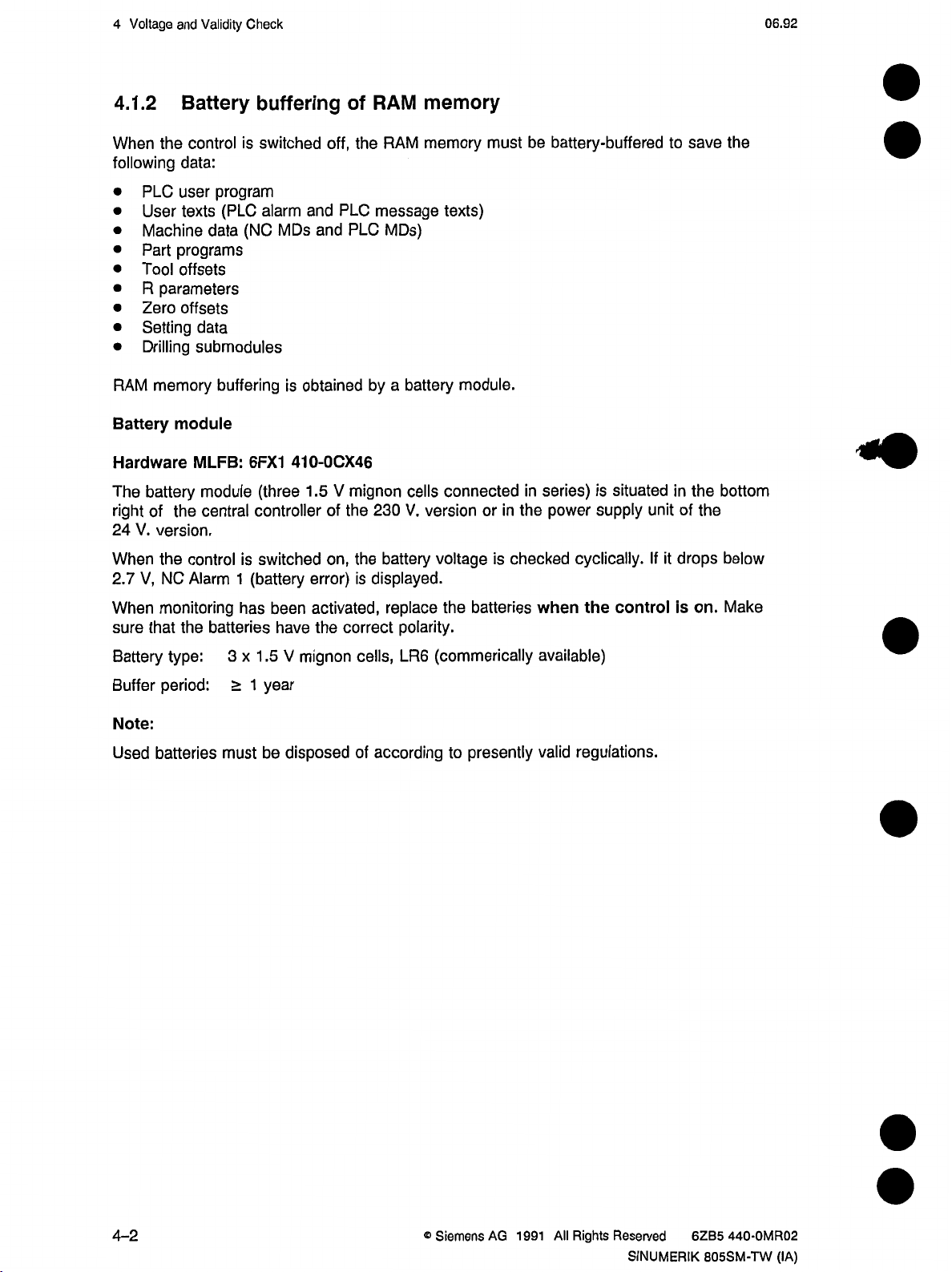

4.1.2

When

the

following

PLC

•

User

•

Machine

•

Part

•

Tool

•

parameters

R

•

Zero

•

Setting

•

Drilling

•

memory

RAM

Battery

Hardware

battery

The

right

of

V.

24

version.

When

the

V,

2.7

NC

Battery

control

data:

program

user

(PLC

texts

data

programs

offsets

offsets

data

submodules

buffering

module

MLFB:

module

central

the

control

1

Alarm

buffering

switched

is

alarm

MDs

(NC

is

410-0CX46

6FX1

(three

controller

is

switched

(battery

of

off,

the

and

PLC

and

PLC

obtained

mignon

V

1.5

the

of

on,

the

error)

is

RAM

MDs)

battery

a

cells

V.

battery

memory

memory

version

RAM

message

by

230

displayed.

must

texts)

module.

connected

in

or

voltage

is

battery-buffered

be

series)

in

power

the

checked

cyclically.

situatedinthe

is

supply

unit

If

it

save

to

of

drops

the

bottom

the

below

When

that

sure

Battery

Buffer

Note:

Used

monitoring

the

batteries

type:

period:

batteries

has

3

x

>

must

1

.5

1

year

be

activated,

been

have

mignon

V

disposed

the

correct

cells,

according

of

replace

polarity.

LR6

batteries

the

(commerically

presently

to

the

when

available)

regulations.

valid

control

is

on.

Make

4-2

Siemens

•

AG

1991

All

Rights

Reserved

SINUMERIK

6ZB5

440-0MR02

805SM-TW

(IA)

Page 30

06.92

Voltage

4

and

Validity

Check

4.2

The

unit

all

first

(e.g.

switching

error

an

"frozen”

unit

•

•

After

displayed

If

with

4.3

4.3.1

CPU

The

axes

the

The

LED

switching

CPU

•

EPROM

•

Incorrect

•

Incorrect

•

Faulty

•

CPU

•

CPU

•

Starting

be

may

all

via

during

switched

components

external

NC-ON

on

the

occurs

opening

Validity

CPU

monitoring

shows

LED

are

stopped

while

is

on

is

on

or

error

error

machine

jumper

module

loop

in

previously

sequence

on

are

components

switch).

control,

the

period

during

the

screen.

check

the

status

and

the

the

control

being

illuminated

data

assignment

or

back

loop

in

the

of

as

follows:

simultaneously

are

switched

opening

an

initialization

of

period

PLC

panel

whereas

of

the

of

outputs

booting

is

during

monitoring

initialization,

control.

control,

switched

(e.g.

on

screen

of

are

up

operation

showing

the

central

When

switched

(power

has

opening

on

via

main

software

controller.

corresponding

the

monitoring

off.

on

routine).

if

one

of

been

activated

screen

switch),

is

The

the

following

then

version

alarm

being

LED

the

central

languages

and

will

be

activated

on

is

still

conditions

unit

is

displayed

(LED

on),

after

applies:

4.3.2

the

With

(EPROM

error

an

If

EPROM

SINUMERIK

module)

occurs

check

is

carried

during

805SM,

out

the

cross-check

a

every

time

cross-check

the

sum

sum

control

test,

test

the

of

the

is

switched

control

system

is

not

program

on.

booting

memory

up.

®

Siemens

SINUMERIK

AG

All

1991

805SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

4-3

Page 31

Voltage

4

and

Validity

Check

06.92

4.3.3

functions

The

Power

•

Central

Monitor

Operator

Cables

•

Interface

Coaxial

CPU

•

case

In

above:

Miniature

•

(see

Adjustment

•

(see

SCREEN

•

DISABLE

•

DISABLE

•

Validity

of

these

supplies

controller

keyboard

are

connected

cable

cable

from

running

is

an

error

of

fuses

INTERFACE

possibilities

INTERFACE

BLANK

KEYBOARD

KEYBOARD

check

O.K.

from

(-»ÿ

the

for

of

components

:

230

unit.

230

AC

:

DC

Measure

+

:

24

Measure

central

central

red

following

operator

DESCRIPTION

controller

LED

monitor

for

DESCRIPTION

interface

signal

interface

PARTLY

central

depend

V~

(A

24

controller

is

items

keyboard

or

power

V

V

voltage

V

from

voltage

not

PART

PART

(Q79.6)

signal

interface

+

for

for

on)

must

controller-monitor-operator

following

the

on

V

external

24

colour

unit

monitor

supply

monochronous

(make

power

(make

(VGA

(VGA

be

and

2

2

(Q79.7)

signal

sure

supply

sure

module

module)

checkedinaddition

monitor

CABLES

-

CABLES

-

suppy

with

load

X141)

to

that

that

monitor

AND

AND

conditions:

the

to

220

V

or

monitor

polarity

current

polarity

keyboard

to

to

HARDWARE)

HARDWARE)

internal

24

+

is

is

the

keyboard

power

may

V

correct)

correct)

conditions

supply

be

available).

listed

4-4

©Siemens

AG

1991

All

Rights

Reserved

SINUMERIK

62B5

440-0MR02

805SM-TW

(IA)

Page 32

06.93

Voltage

4

and

Validity

Check

4.4

For

system

Restart

Restart

System

Screen

Software

operating

software

EPROM

EPROM

software

display

the

and

texts

English/German

French/German

Italian/German

Spanisch/German

Notes:

XX:

The

identifier

module

for

for

used.

on

language

again.

The

off

second

and

identification

SINUMERIK

screen

Designation

(D94

(D95

(module

(module

software

the

CPU

on

CPU

on

1

screen

is

display

)

version

defined

805SM-TW,

texts

module)

module)

2)

display

texts

by

modifying

2

restart

are

required.

(module

EPROMs

Product

570.882.0801

570.882.0802.XX

570.882.9001

570.882.901

570.882.9032.XX

570.882.9042.XX

and

number

.XX

.XX

2.XX

570.882.9052.XX

an

NO

2)

MD

is

option,

5149

bit

plug-in

1

/

it

and

0

module

Order

6FX1

6FX1

6FX1

6FX1

6FX1

6FX1

nevertheless

must

switching

for

each

number

882-0BX80-XX

882-OBX01-XX

882-0BX12-XX

882-0BX32-XX

882-0BX42-XX

882-0BX52-XX

be

the

control

©Siemens

SINUMERIK

AG

1991

All

805SM-TW

Rights

(IA)

Reserved

6ZB5

440-0MR02

4-5

Page 33

06.93

Standard

5

Installation

5

5.1

In

•

•

•

•

•

The

•

•

•

•

•

this

Standard

Standard

Section

system

The

CHECK.

The

power

AND

VALIDITY

The

devices

CABLES

The

feed

started

The

INITIALIZATION

Softkey

Key

Softkey

Enter

Softkey

up

PLC

password

Installation

installation

following

the

has

been

supply

CHECK.

have

AND

HARDWARE.

and

main

(EMERGENCY

program

user

menue

DIAGNOSTICS

MORE

INITIALIZATION

INITIALIZATION

(menu

and

preconditions

checked

all

to

components

been

jumpered

spindle

(STEP

may

expansion

press

according

drives

STOP).

5)

be

INPUT

NC

of

must

has

according

disabled

are

is

executable.

selected

key)

key

and

PLC

have

Chapter

to

been

checked

INTERFACE

to

until

as

follows

fulfilled:

been