Page 1

Page 2

Page 3

Page 4

Page 5

Preliminary Remarks

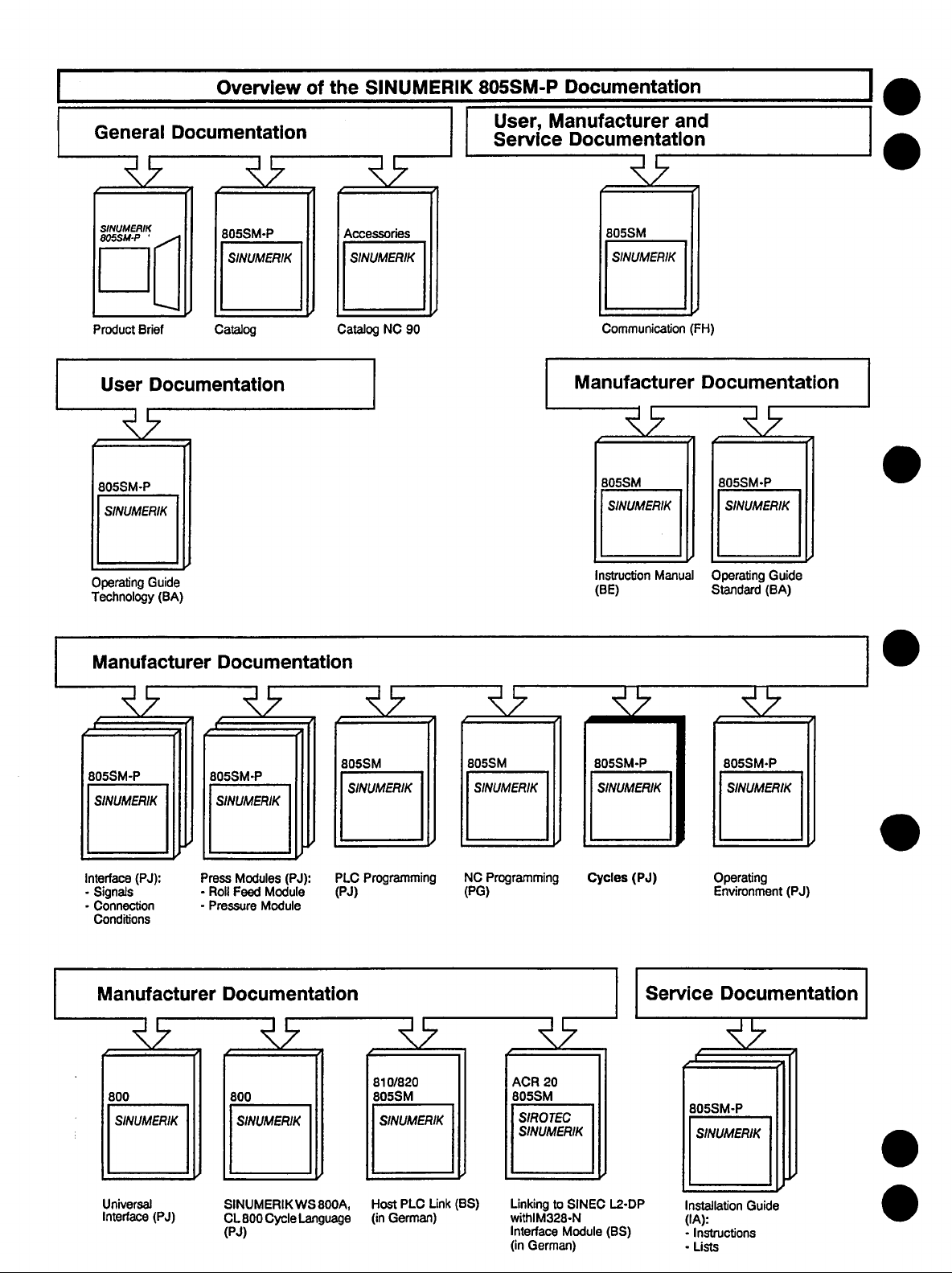

The documentation of the SINUMERIK 805SM-P is subdivided into 4 parts:

l

General Documentation

l

User Documentation

l

Manufacturer Documentation and

l

Service Documentation

The following manuals are part of the Manufacturer Documentation:

l

Instruction Manual

l

Interface Description Part

l

Interface Description Part 2: Connection Conditions

l

PLC Programming Guide

l

Standard Operating Guide

l

NC Programming Guide

l

Roll Feed Module, Planning Guide

l

Pressure Control Module, Planning Guide

l

Cycles, Planning Guide

1:

Signals

This documentation (Cycles, Planning Guide) is intended for the press manufacturer and describes

the start-up of the standard cycles.

This manual is written for technically qualified personnel, especially those having knowledge of or

being trained in automation and control technology.

The knowledge, understanding and correct observance of all the Safety Rules and Warnings are the

necessary preconditions for the safe installation and commissioning as well as for the safe operation

and maintenance of the product described in this manual. This manual describes the General Safety

Rules and Warnings. Only the qualified personnel has the necessary technical knowledge to

properly interpret and apply all the Safety Rules and Warnings in a particular case.

The contents of this instruction manual shall not become part or modify any prior or existing

agreement, commitment or relationship. The Sales Contract between the parties is the sole warranty

of Siemens. Any statements contained herein do not create new warranties or modify the existing

warranty.

If you need further documentation for the SINUMERIK 805SM-P, please contact your local Siemens

representative.

Page 6

-

0

General Remarks

Press Data

Central R Parameters

Channel-Specific R Parameters

Overview of the Data Exchange

Within the Control

1

u

4 .

q

5

rl

.o

Fixed Cycles

Basic Press Functions

Tool Change

Messages of the Standard Cycles

6

cl

7

tl

9

I I

Annex

10

cl

Page 7

Contents

Page

1 General Remarks . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

3 Central R Parameters . . . . . . . . . . . , . . , . . . . , . . . . . . . . . . . . . . .

3.1 General remarks

3.2 R parameter range R800 - R899

3.3 R parameter range R900 - R984

3.4 R parameter range R985 - R999

3.5 Work memory / R parameter range RlOOO - R1499

3.6 Input buffer / R parameter range R1500

3.7 Tool data memory / R parameter range R2000 - Rl9999

4 Channel-Specific R Parameters

4.1

4.2

5 Overview of the Data Exchange Within the Control . . . . . . . s . . . .

Press Data ..,................,..,....................

....................................... 3-l

............................

............................ 3-l

............................ 3-l

. . . , . . . . . . . . . . . . . . . . . . . . , . .

Local parameters R50 - R99

Transfer parameters RO - R49

...............................

.............................. 4-l

. R1999

............... 3-2

................. 3-2

...........

l-l

2-l

3-l

3-l

3-2

4-l

4-l

5-1

6 Fixed Cycles . . . . . . . . . . . . . . . . . , . . . . . . , . . . . . . . . . . . . . . . .

6.1 Continuous stroke

6.1 .l Description

6.1.2 Start-up checklist

6.1.3 Flowchart

6.2 Single stroke

6.2.1 Description

6.2.2 Start-up checklist

6.2.3 Flowchart

6.3 Set up - Main drive JOG-INC mode

6.3.1

6.3.2

6.3.3 Flowchart

6.4 Common subroutines

6.4.1 TDC following L994

6.4.2 Correction of all tool change axes L995

6.4.3 Calculation of the brake angle L 998

Description

Start-up checklist

...........................................

............................................

...........................................

............................................

............................................

......................................

.......................................

..........................................

.......................................

..........................

...........................................

.......................................

....................................

.....................................

.......................

.........................

6-1

6-l

6-l

6-2

6-4

6-7

6-7

6-8

6-l 0

6-l 3

6-l 3

6-14

6-l 6

6-l 9

6-l 9

6-20

6-21

Page 8

7

Basic Press Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-l

7.1

7.1.1

7.1.2

7.1.3

7.1.4

7.2

7.2.1

7.2.2

7.2.3

7.2.4

7.3

7.3.1

7.3.2

7.3.3

7.4

7.4.1

7.4.2

7.4.3

8

8.1

8.1.1

8.1.2

8.2

8.2.1

8.2.2

8.3

8.3.1

8.3.2

8.3.3

8.3.4

8.4

Safety stroke

Description

Start-up checklist

CodesforthePLC

Flowchart

..........................................

...........................................

.......................................

......................................

.............................................

Reversing ............................................

Description

Start-up checklist

CodesforthePLC

...........................................

.......................................

......................................

Flowchart .............................................

Open press

Description

CodesforthePLC

Flowchart

Close press

Description

Codesforthe PLC

...........................................

...........................................

......................................

.............................................

...........................................

...........................................

......................................

Flowchart .............................................

Tool Change ..,.....,.....,...........................

General remarks

Description

........................................

...........................................

Flowchart .............................................

Manual tool change - jog main drive (L9)

Description

Flowchart

Automatic tool change (L8)

Description

...........................................

.............................................

................................

...........................................

......................

Example for the implementation of an automatic tool change

Automatic stroke adjustment during the tool change

...............

Flowchart .............................................

Description of the step cycles

..............................

........

7-l

7-l

7-l

7-l

7-2

7-4

7-4

7-4

7-4

7-5

7-7

7-7

7-7

7-7

7-8

7-8

7-8

7-8

8-l

8-l

8-l

8-2

8-6

8-6

8-7

8-8

8-8

8-8

8-9

8-11

8-12

9

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.8.1

9.8.2

9.9

Messages of the Standard Cycles

CONTINUOUS STROKE cycle

SINGLE STROKE cycle

TOOL CHANGE cycle

REVERSING cycle

....................................

......................................

SAFETY STROKE cycle

CLOSE PRESScycle

OPEN PRESScycle

....................................

.....................................

..............................

..................................

..................................

GENERAL TOOL CHANGE cycle

MANUAL TOOL CHANGE

AUTOMATIC TOOL CHANGE

Step cycles

...........................................

.................................

..............................

. . . . . . . . . . . . . . . . . . . . . . . . .

............................

9-l

9-l

9-4

9-6

9-9

9-l 0

9-11

9-11

9-12

9-13

9-14

9-14

Page 9

10 Annex .,....,........................................

lo-l

10.1

10.1.1

10.1.2

10.1.3

10.2

10.3

10.3.1

10.3.2

10.3.3

10.4

10.5

10.6

Overview of the standard cycles

Technology cycles

......................................

Subroutines for the technology cycles

Step cycles

...........................................

Overview of the work memory

Survey of the R parameters used

Local R parameters

Transfer parameters

Central R parameters

(MO

- R99)

(RO - R49)

....................................

............................

........................

..............................

...........................

............................

.............................

Survey of the @ commands used in the standard cycles

Overview of all cycle-specific machine data

Flag area assigned to standard cycles

....................

........................

...........

10-l

10-l

10-l

10-2

103

10-9

1 o-9

10-11

10-12

10-14

10-15

lo-18

Page 10

06.93

1 General Remarks

General Remarks

Cycles are subroutines which can be stored either in the part program memory or (from software version 2.0 onwards) in the user memory submodule of the control. With these subroutines the technology modes of the press are implemented (continuous stroke, single stroke,

etc.). Furthermore, a (TOOL CHANGE) cycle is necessary for carrying out a tool change.

A subroutine consists of the following program sections:

. ENTRY SECTION

. LOOP SECTION

. TERMINATING SECTION

In the ENTRY SECTION, the starting conditions are checked on start-up of an operating mode.

If a starting condition is not fulfilled, a corresponding “CYCLE MESSAGE” is issued and the

cycle interrupted. These messages also provide hints for the user. Information on the causes

and, if necessary, about a remedy may be found in the Technology Operating Guide and

the Installation Instructions.

After the ENTRY SECTION the program jumps into the LOOP SECTION, which coordinates

the press operating mode and provides press-specific functions (see the general overview of

the data exchange within the control). Only after a cycle stop has been triggered is this loop

section left and the TERMINATING SECTION processed, so that the operating mode and with

it the subroutine are terminated in a defined state.

The flowcharts describe the program flow of the technology cycles in detail.

Apart from the technology cycles there are several further subroutines (L 900 - L 999), which

are mainly calculating programs.

The step cycles provide certain functions which are necessary for the tool change procedure.

Thus the sequence of operations for the tool change may be adapted “individually”to the

press.

Exchange of information with the PLC is carried out via:

Inputs (commands for reading and writing)

l

. outputs

l

Flags (flag interface of the standard cycles, overview in Chapter

l

R parameters (FE 61/62).

10,

Annex)

Exchange of information with the NC is carried out via:

l

Press data (via @ commands, see installation lists)

l

Central R parameters (R965-R999)

The selection of the press operating modes (corresponding menu + subroutine) is carried out

via the operator interface. The subroutine number belonging to the operating mode is preselected automatically.

The I/O fields of the individual operating modes are only updated after the NC-start.

For almost every press operating mode a so-called cycle is necessary. A cycle is a background program of a loop.

@ Siemens AG 1991 All Rights Reserved 6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

l-l

Page 11

1 General Remarks

06.93

Loading of standard cycles:

The cycles are supplied on a floppy disk formatted in MS-DOS. The different language ver-

sions are stored in the following sub-directories:

805SMP-D... German

805SMP-E... English

805SMP-I . . . Italian

805SMP,S... Spanish

805SMP-F . . . French

The cycles on the floppy disks are available in CL 800 source code (extension: ZPQ) and in

DIN code (extension: ZPL).

Information about the loading of the cycles can also be found in the README.TXT file available on the floppy disk.

For the transfer to the control there are the following possibilities:

a) Selection of the batch file: “INSTALLBAT

Procedure:

1) Connect the transfer cable (Order No.: 6FC9 344-4Rn) to COMl.

2.) Preselect and initialize (FITS-Line, 9600 Bd) the correct interface at the control and

start it for input.

3.) Call up the batch file from the corresponding floppy disk drive and state the desired

language version.

Example:

AUNSTALL E and press Enter .

cl

+ The English language version is transferred from the floppy disk in disk drive A to

COMl. At the same time, the programmer interface is initialized correctly.

b) Transfer of the standard cycles with the MS-DOS system command COPY (the batch file

described above uses the same command):

Please make sure that the programmer interface is initialized correctly (7 data bits, 2 stop

bits, parity = even).

Example:

COPY A:U05SMPJV.ZPL COMl

c) With the program PCIN, version 2.0, the transfer may be carried out comfortably in both

directions (PG-NC).

It is a menu-driven program which offers the possibility to configure the interfaces

accordingly.

All files with the extension “ZPL” have to be transferred from the sub-directory for the

desired language version (see above).

d) If a workstation (WSSOOA) is available, it can be used for the transfer. The standard cycles

have been created with this software package. Transfer the files from the floppy disk.

l-2

CJ Siemens AG 1991 All Rights Reserved 6265 440-ONX02-OAAl

SINUMERIK 805S.WP (PJ)

Page 12

12.91 2 Press Data

2

This data area can be accessed from the cycle via @-commands.

Press Data

e rndwdual data

INSTRUCTIONS.

and for the access

possibilities,

@ Siemens AG 1991 All Rights Reserved 6285 440.ONX02-OAAl

SINUMERIK 605SM.P (PJ)

2-1

Page 13

06.93

3 Central R Parameters

3.1 General remarks

3

Central R Parameters

3.1 General remarks

Central R parameters exist only once in the control. They can be accessed by all channels. If

you use a workstation to generate your cycles, you have to define a list of the parameters

used in your subroutines. The following two lists are used in standard cycles:

Lists/

File name

Contents

I

3.2 R parameter area R800 - R899

This area can be freely assigned by the user.

3.3 R parameter area R900 - R984

This area is used as an “interface” between cycles, i.e. it is accessed by all cycles. This

parameter area may used only by the cycles.

Use:

Parameters from this area are used for codes to identify operating states or arithmetic values

required by more than one subroutine. The parameters have a fixed significance (such as

saving the “previous tool position”).

For the meaning of these parameters, see Chapter

parameters, say to modify a subroutine, you can use a parameter from area R800 to R899.

3.4

The parameters from this area receive their assigned values from the system and are made

available especially for the cycles. The cycles work with these parameters and respond to

changes in their values.

Exception:

R996 and R994 receive their values from the cycles and are actually part of the parameter

area described in section 3.3.

R parameter area R985 - R999

10

(Appendix). If you need additional

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SMaP (PJ)

6tB5 440.ONX02-OAAl

3-l

Page 14

3 Central R Parameters

3.5 Work memory I R parameter area RlOOO - R1499

06.93

3.5 Work memory / R parameter area RlOOO - R1499

As soon as a tool is changed, the whole of this memory area is newly written and provides the

data for the new tool. The work memory is accessed by both the cycle and the operator

interface.

Distribution

The first 100 parameters have standard assignments.

6 parameters are earmarked for the first axis and 4 for each further axis. Axes can only be

selected in ascending order.

The user can define a maximum of 84 additional tool data (see section 3.56 in the

Operating Instructions on installation of general texts 1 - 84).

The data block for the pressure module needs a maximum of 11 parameters, if 4 sensors

are selected.

Data block for roll feed 1 and 2:

The number of parameters required depends on the maximum number of feeds, which is

defined via machine data.

The tool protection needs up to 32 parameters, depending on the number of monitorings

defined via MO.

In order to make the best possible use of the memory available, the option-dependent data for

pressure module, roll feed and tool protection can be shifted in blocks to any location in the

work memory using a relative initial address.

(see also Chapter 10, Annex):

Note:

A system-supported distribution of the tool data is carried out in the basic display

INSTALLATION via softkey DISTRIBN. OF TL. DATA.

3.6 Input buffer / R parameter area R1500 - R1999

After input, the tool data is stored in this area. The assignment corresponds to that of the work

memory, i.e. R1500 is equivalent to RlOOO. Thanks to this separate buffer, it is possible to edit

a tool during operation.

3.7

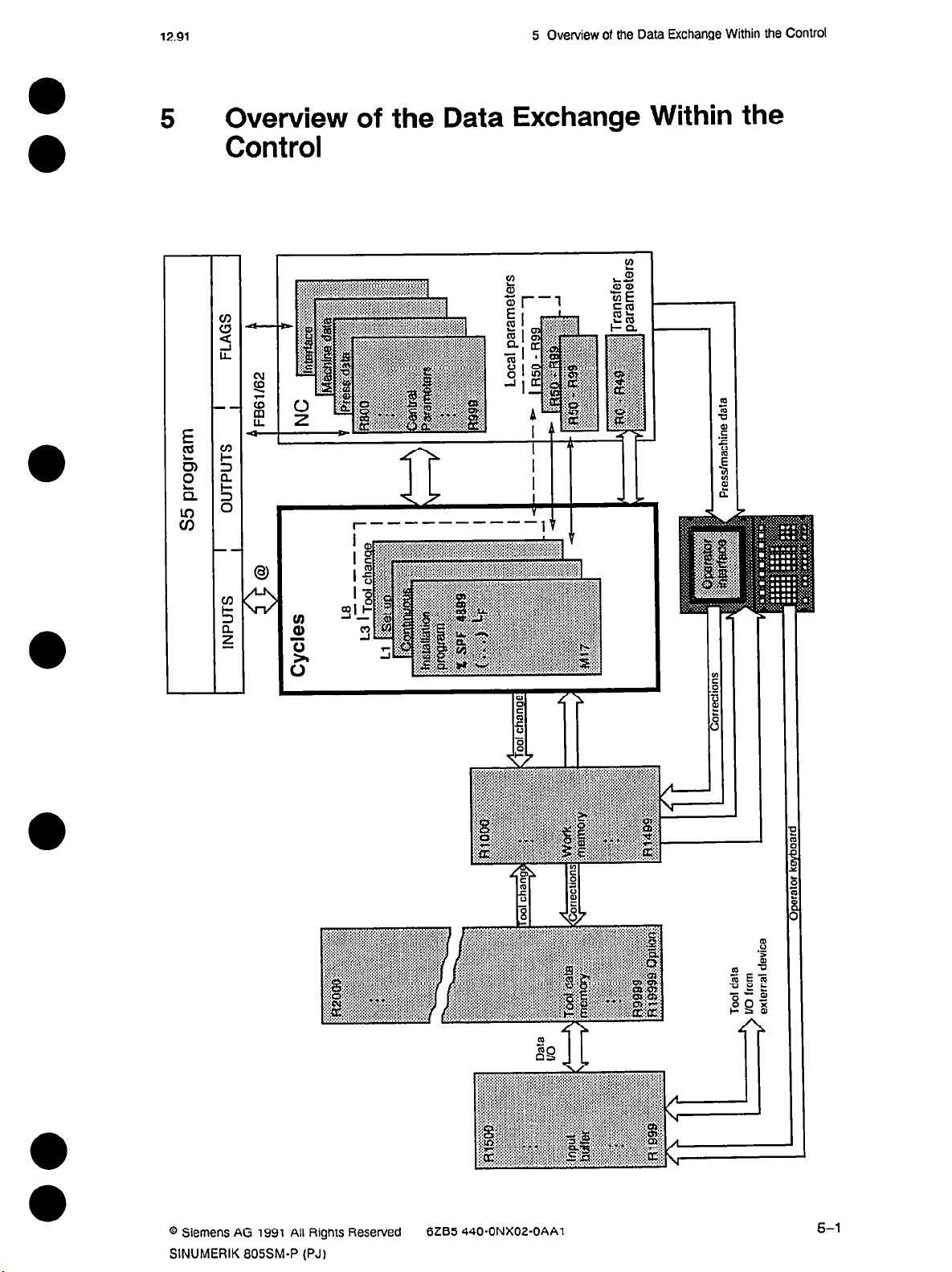

The data of all available tool is stored in the tool data memory. In the standard version, 8000 R

parameters are available (R2000 - R9999). Optionally, the tool data memory can be expanded

to 18000 R parameters (R2000 - R19999). The figure “Overview of the data exchange within

the control” in Chapter 5 shows the access to this memory.

Tool data memory / R parameter area R2000 - R19999

3-2

8 Siemens AG 1991 All Rights Reserved 6265 440.ONX02-OAAl

SINUMERIK 805SM.P (PJ)

Page 15

12.91

4 Channel-Specific R

4.1 Local parameters I350 - R99

Parameters

4 Channel-Specific R Parameters

4.1 Local parameters R50 - R99

Local R parameters are used as a “scratchpad” for calculations and are only valid for one

cycle. As soon as the program level is left by calling a subroutine, the local variables are saved

and preset to “zero” for the following program. Therefore, they can be used as independent

parameters in the program called.

The following two data formats can be defined in the cycle for these parameters:

Local Integer: In this format, the variables can only be integers.

Value range: *I- 99999999

Local Real: In this format, the variables are defined as floating-point numbers.

Value range: + I- 0.00000001 to + I- 99999999.

4.2 Transfer parameters RO - R49

These R parameters have the same significance in all cycles within one NC channel. I.e., the

value of the variable is preserved on branching into a subroutine; the value is, in a way,

transferred.

Definition in the cycle:

Par Real: Transfer parameter as a floating-point number.

Value range: +/- 0.00000001 to +/- 99999999.

An overview of the parameters used in the standard cycles is given in Chapter 10, Annex.

0 Siemens AG 1991 All Rights Resewed 6285 440.ONX02-OAAl

SINUMERIK 605SM-P (PJ)

4-l

Page 16

12.91

5 Overview of the Data Exchange Within the Control

5 Overview of the Data Exchange Within the

Control

I I

l-----------

V

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6ZB5 440.ONX02-OAAl

Page 17

12.91 6 Fixed cycles

6.1 Continuous stroke

6

6.1 Continuous Stroke

6.1.1 Description

If this press operating mode is selected and the cycle is started, the press executes strokes

“continuously” until the program is interrupted or finished.

The interruption may have been triggered in the following ways:

l

l

l

l

The following functions are carried out by the cycle:

l

l

l

Fixed Cycles

cycle stop has been triggered manually

the preset number (specified in counter 1 or 2) has been reached

emergency stop has been triggered

there is a malfunction which leads to an automatic standstill of the press (+ PLC alarm)

checking of the starting conditions (e.g.: safety stroke carried out, etc.)

moving of tool change axes into working position (e.g.: sheet run-in height, etc.)

variation of the number of cycles per minute between preselected cycle speed and

operating cycle speed with the following keys

+

MANU+ : gradual increase of cycles per minute;

•l

El

MANU- : gradual reduction of cycles per minute;

+

la

la

AUTO+ : automatic increase till operating cycle speed is reached

or AUTO-STOP pressed;

AUTO- : automatic reduction till preselected cycle speed is

reached or AUTO-STOP is pressed:

AUTO-STOP: current cycle speed maintained

Ia

a

step-by-step position correction of all tool change axes

l

calculation of brake angle for TDC stop

l

TDC following

@ Siemens AG 1991 All Rights Reserved

SINUMERIK r305SM-P (PJ)

628.5 440.ONX02-OAA7

6-1

Page 18

6 Fixed Cycles

6.1.2 Start-up checklist

6.1.2 Start-up checklist

The following items have to be observed:

1. Has a value been defined for all cycle-specific machine data?

2. Is there a PLC program for disengaging/engaging the clutch?

3. Has the tool change been carried out without fault?

4. Has the safety stroke been carried out without fault?

5. For selecting and starting procedure see OPERATING GUIDE STANDARD and

OPERATING GUIDE TECHNOLOGY

Note:

If a starting condition is not fulfilled, a corresponding message is read out and the cycle is

aborted.

Explanation of the check list items:

Item 1:

l

Machine data bits

12.91

MD 5015 bit 0 = 0

1

MD 5051 bit 1 = 0

1

MD 5052 bit 2 = 0

1

MD 5052 bit 3 = 0

1

MD 5055 bit 4 = 0

1

MD 5055 bit 6 = 0

1

MD 5055 bit 7 = 0

1

l

Machine data values:

MD 302 Brake angle as MD

3D-interpolation not possible

3D-interpolation selected

Safety stroke necessary before start

No safety stroke necessary

Calculation of brake angle according to a parabola with the factors

A, 6, and C

User-specific calculation of brake angle; this calculation has to be

carried out by the manufacturer in a subroutine (L=MD 370) compiled by himself (see also chapter 6.4.3, Calculation of the brake

angle L 998)

TDC following inactive

TDC following active (see also chapter 6.4.1, TDC following L 994)

Brake cam from tool data for cam 17

Brake cam from machine data MD 302

Cycle stop enabled by counter 1

Cycle stop blocked by counter 1

Cycle stop enabled by counter 2

Cycle stop blocked by counter 2

MD 320 Factor A for calculation of the brake angle (X

10-E

in cycle)

MD 321 Factor B for calculation of the brake angle ( X 10-e in cycle)

MD 322 Factor C for calculation of the brake angle ( x 10-s in cycle)

(see also chapter 6.4.3, Calculation of the brake angle L 998)

MD 370 Subroutine no. for user-specific calculation of brake angle

MD 372 Subroutine no. for “Move tool change axes to starting position”

(standard = L 31)

6-2

0 Siemens AG 1991 All Rights Reserved 6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

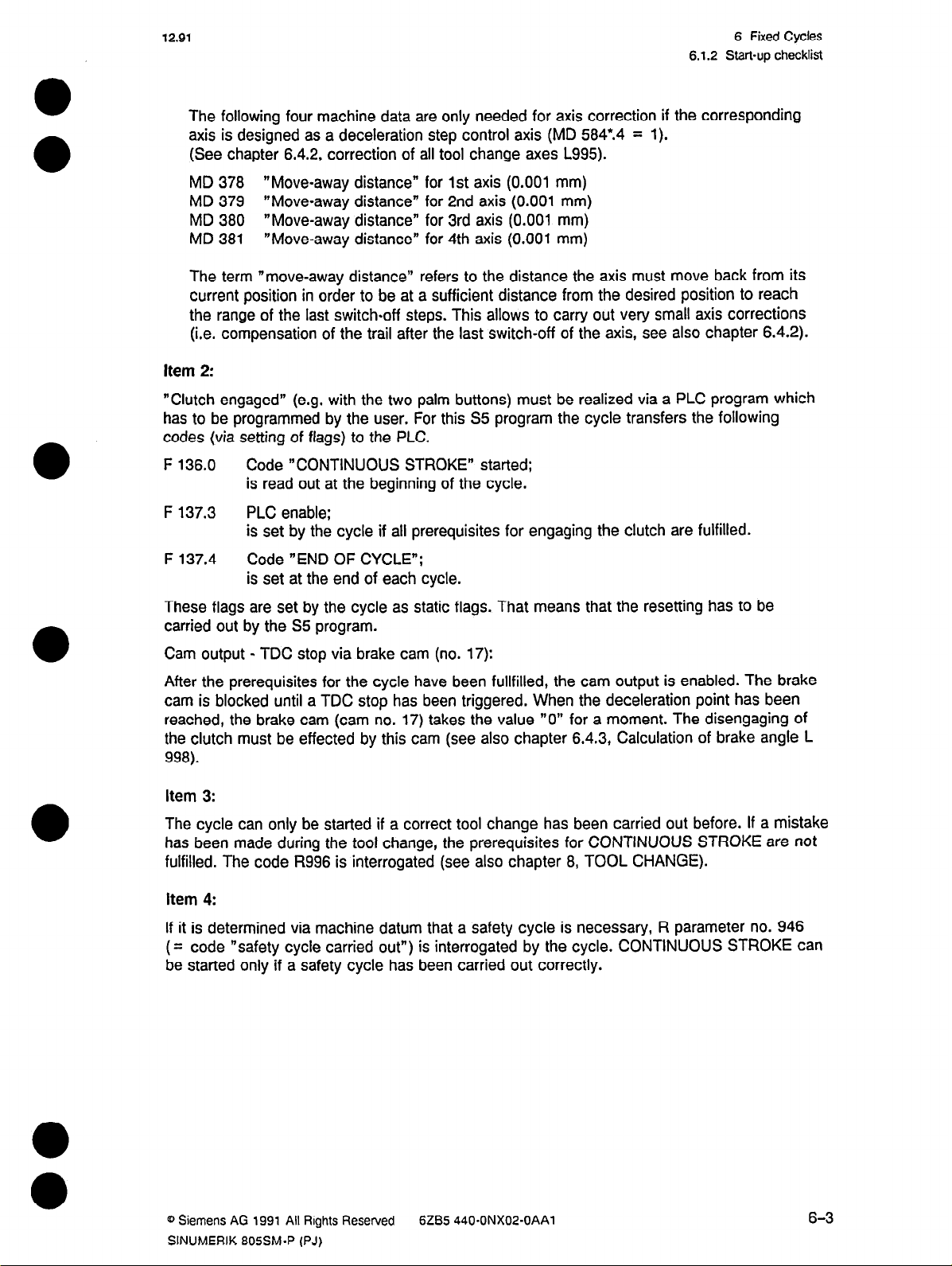

Page 19

12.91

6 Fixed Cycles

6.1.2 Start-up checklist

The following four machine data are only needed for axis correction if the corresponding

axis is designed as a deceleration step control axis (MD 584*.4 = 1).

(See chapter 6.4.2, correction of all tool change axes L995).

MD 378 “Move-away distance” for 1st axis (0.001 mm)

MD 379 “Move-away distance” for 2nd axis (0.001 mm)

MD 380 “Move-away distance” for 3rd axis (0.001 mm)

MD 381 “Move-away distance” for 4th axis (0.001 mm)

The term “move-away distance” refers to the distance the axis must move back from its

current position in order to be at a sufficient distance from the desired position to reach

the range of the last switch-off steps. This allows to carry out very small axis corrections

(i.e. compensation of the trail after the last switch-off of the axis, see also chapter 6.4.2).

Item 2:

“Clutch engaged” (e.g. with the two palm buttons) must be realized via a PLC program which

has to be programmed by the user. For this S5 program the cycle transfers the following

codes (via setting of flags) to the PLC.

F 136.0 Code “CONTINUOUS STROKE” started;

is read out at the beginning of the cycle.

F 137.3 PLC enable:

is set by the cycle if all prerequisites for engaging the clutch are fulfilled.

F 137.4

Code “END OF CYCLE”:

is set at the end of each cycle.

These flags are set by the cycle as static flags. That means that the resetting has to be

carried out by the 5% program.

Cam output - TDC stop via brake cam (no. 17):

After the prerequisites for the cycle have been fullfilled, the cam output is enabled. The brake

cam is blocked until a TDC stop has been triggered. When the deceleration point has been

reached, the brake cam (cam no. 17) takes the value “0” for a moment. The disengaging of

the clutch must be effected by this cam (see also chapter 6.4.3, Calculation of brake angle L

998).

Item 3:

The cycle can only be started if a correct tool change has been carried out before. If a mistake

has been made during the tool change, the prerequisites for CONTINUOUS STROKE are not

fulfilled. The code R996 is interrogated (see also chapter 8, TOOL CHANGE).

item 4:

If it is determined via machine datum that a safety cycle is necessary, R parameter no. 946

code “safety cycle carried out”) is interrogated by the cycle. CONTINUOUS STROKE can

(=

be started only if a safety cycle has been carried out correctly.

0 Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6285 440.ONX02-OAAl

6-3

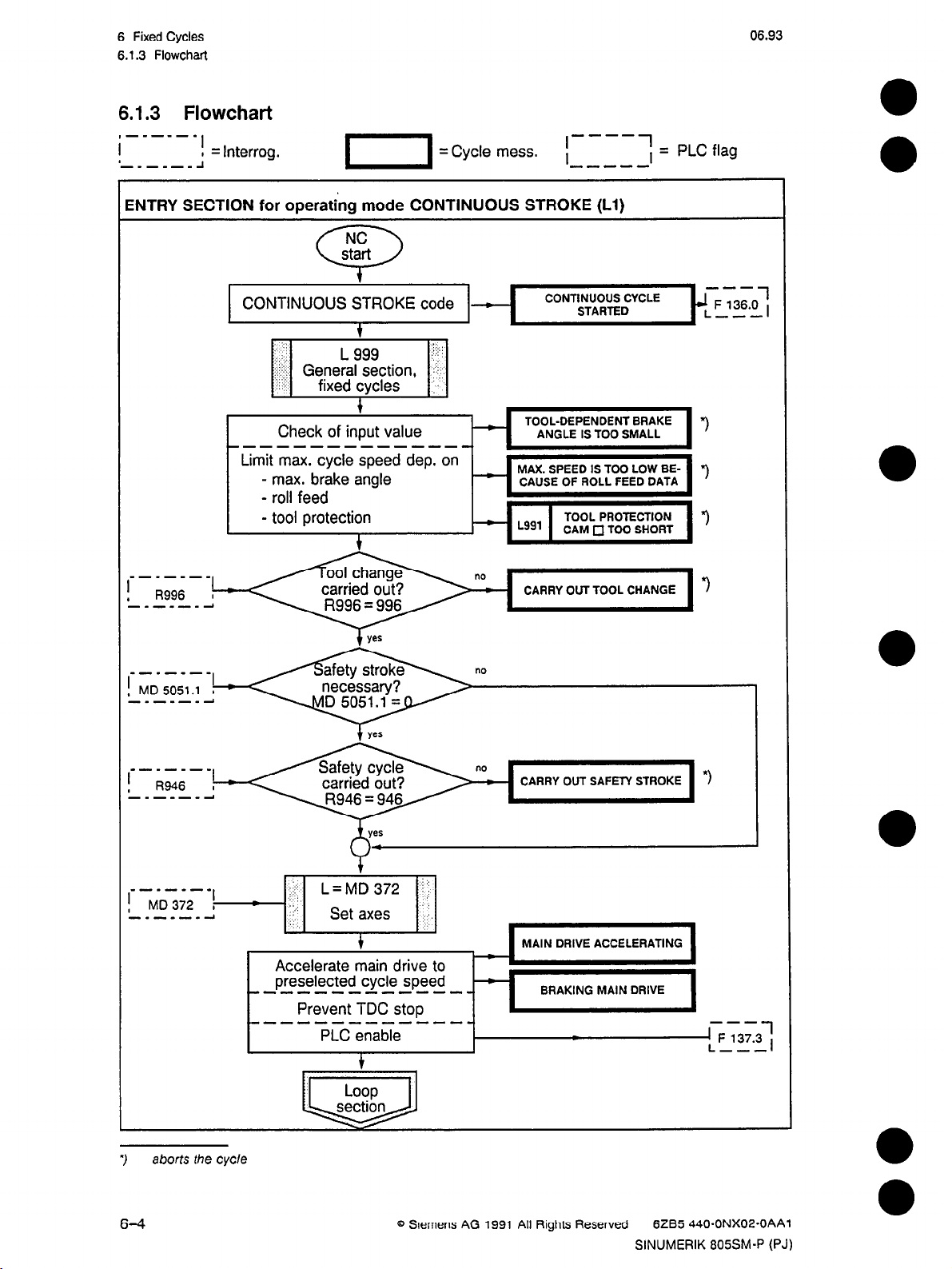

Page 20

6 Fixed Cycles

6.1.3 Flowchart

6.1.3 Flowchart

,-----.

I

1

-_-_-_ J

iNTRY SECTION for operating mode CONTINUOUS STROKE (Ll)

I

I = Interfog.

06.93

.-_-_-_

CONTINUOUS STROKE code -

.,

‘:

:,I

::.‘j;:: General section, <I, :

.: ,.’

,.

:-

---------------

Check of input value

Lggg .!.‘!i

fixed cycles :,

Limit max. cycle speed dep. on

- max. brake angle

- roll feed

- tool protection

CONTINUOUS CYCLE

STARTED

TOOL-DEPENDENT BRAKE “)

ANGLE IS TOO SMALL

- MAX. SPEED IS TOO LOW BECAUSE OF ROLL FEED DATA

CARRY OUT TOOL CHANGE

---

JLF 136.0

---

*)

1

,

.------

aborts the cycle

3

6-4

Accelerate main

preselected cycle speed

w------------m

--------------

Prevent TDC stop

PLC enable

CARRY OUT SAFETY STROKE

MAIN DRIVE ACCELERATING

drive to

-

Q Slemens AG 1991 All Rights Reserved

BRAKING MAIN DRIVE

/

“1

---

1 F 137.3

L ---

6285 440-ONXOZ-OAAl

SINUMERIK 805SM-P (PJ)

1

,

Page 21

12.91 6 Fixed Cydes

6.13 Flowchart

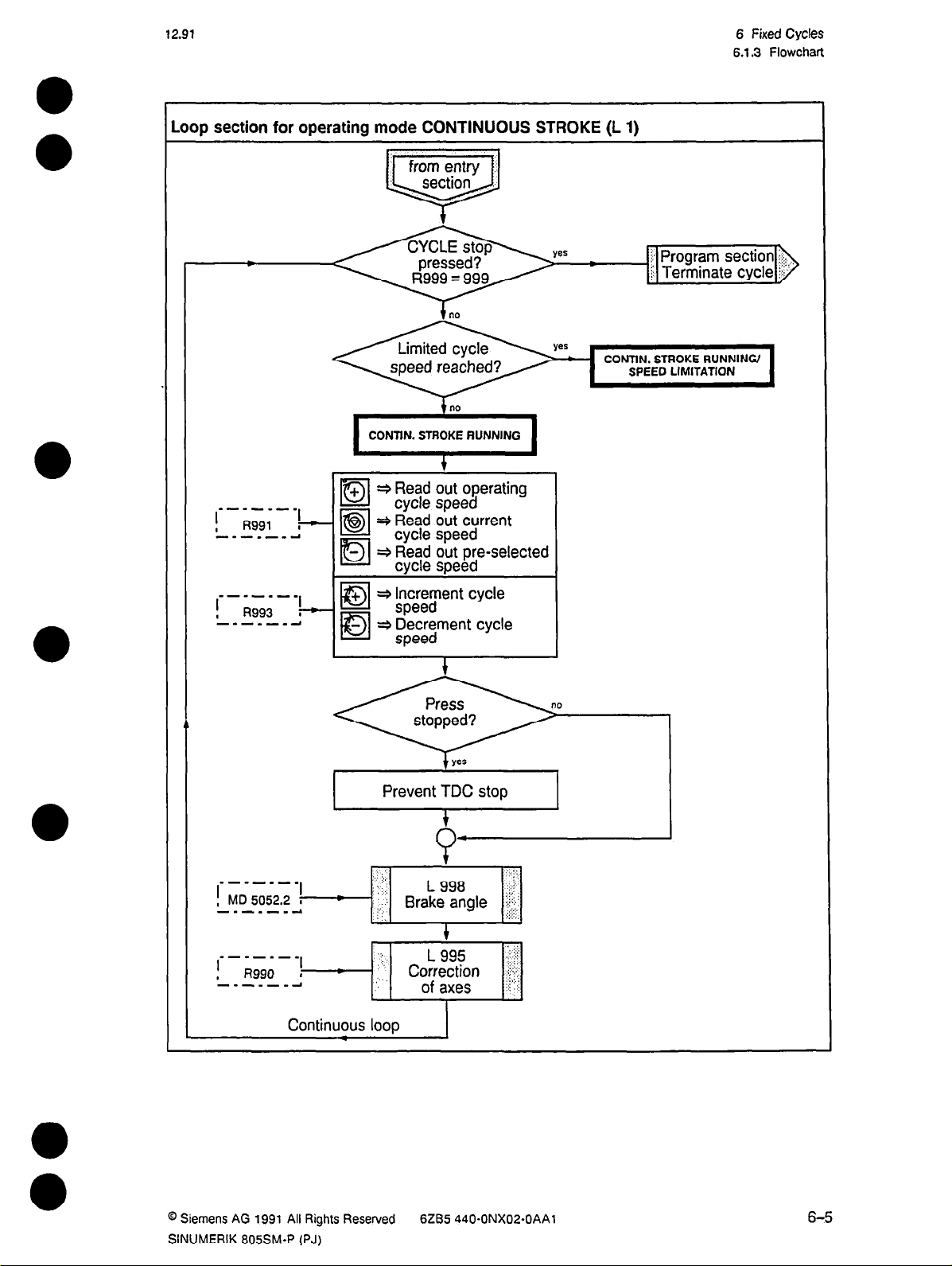

.oop section for operating mode CONTINUOUS STROKE (L 1)

from entry

section

0

I

, R991 I ?

---*---I

-mm----

l

,

R993 I 7

--m----1

no

1

CONTIN. ST*; ~~UNNINO 1

+ + Read out operating

Dl

EBI

Dl

la

IBI

cycle speed

3 Read out current

cycle speed

- 3 Read out pre-selected

cycle speed

+ * Increment cycle

speed

+ Decrement cycle

speed

I

i Terminate

CONTIN. STROKE RUNNING/

SPEED LIMITATION

cycle

section i: Program

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM.P (PJ)

yes

t

Prevent TDC stop

6ZB5 440.ONX02-OAAl

6-5

Page 22

6 Fixed Cycles

6.1.3 Flowchart

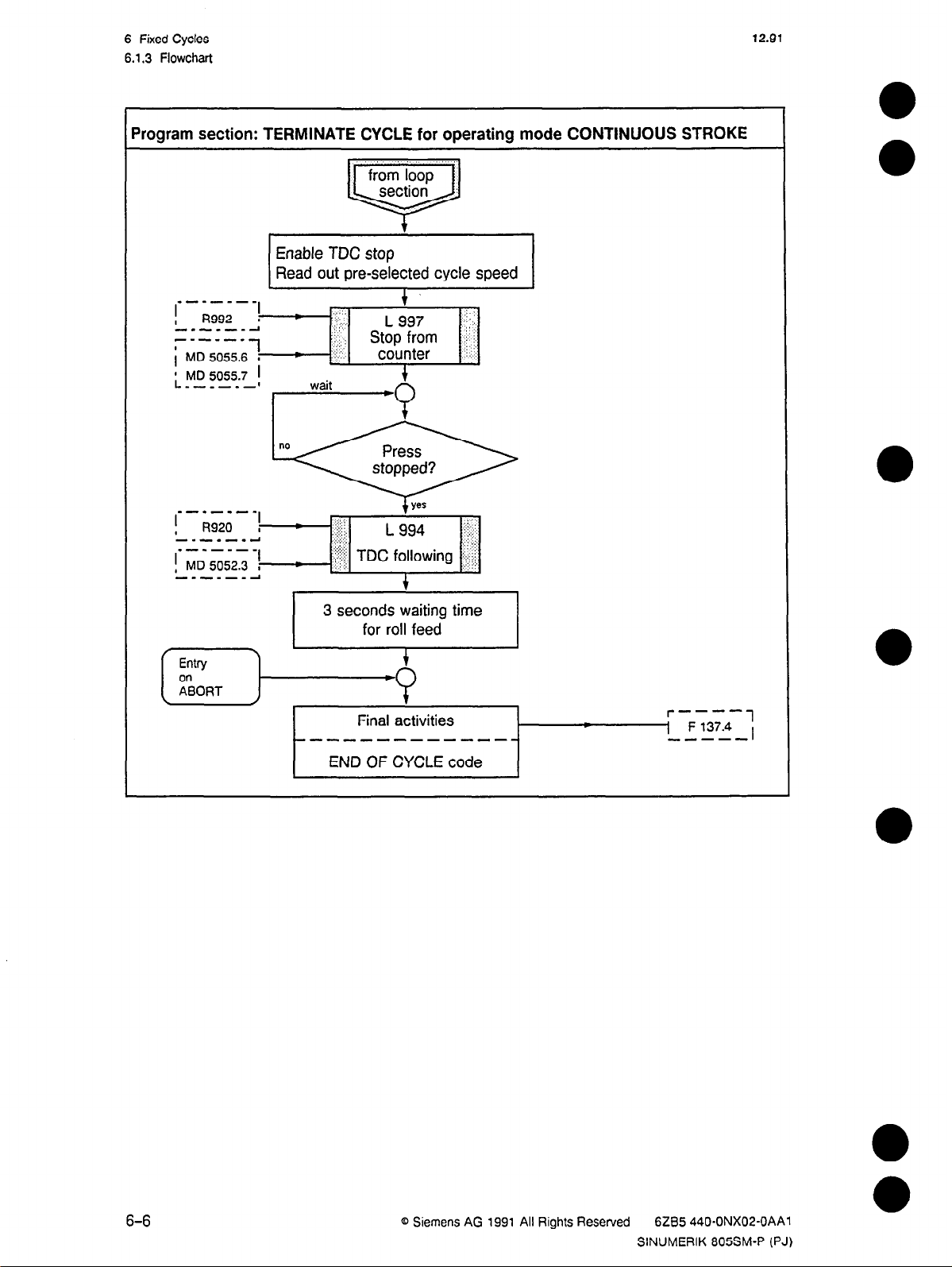

‘rogram section: TERMINATE CYCLE for operating mode CONTINUOUS STROKE

Enable TDC stop

Read out pre-selected cycle speed

12.91

Final activities

we-------m--v-

END OF CYCLE code

r----

1 F 137.4

----a

1

,

6-6

@ Siemens AG 1991 All Rights Reserved

6ZB5 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 23

12.91

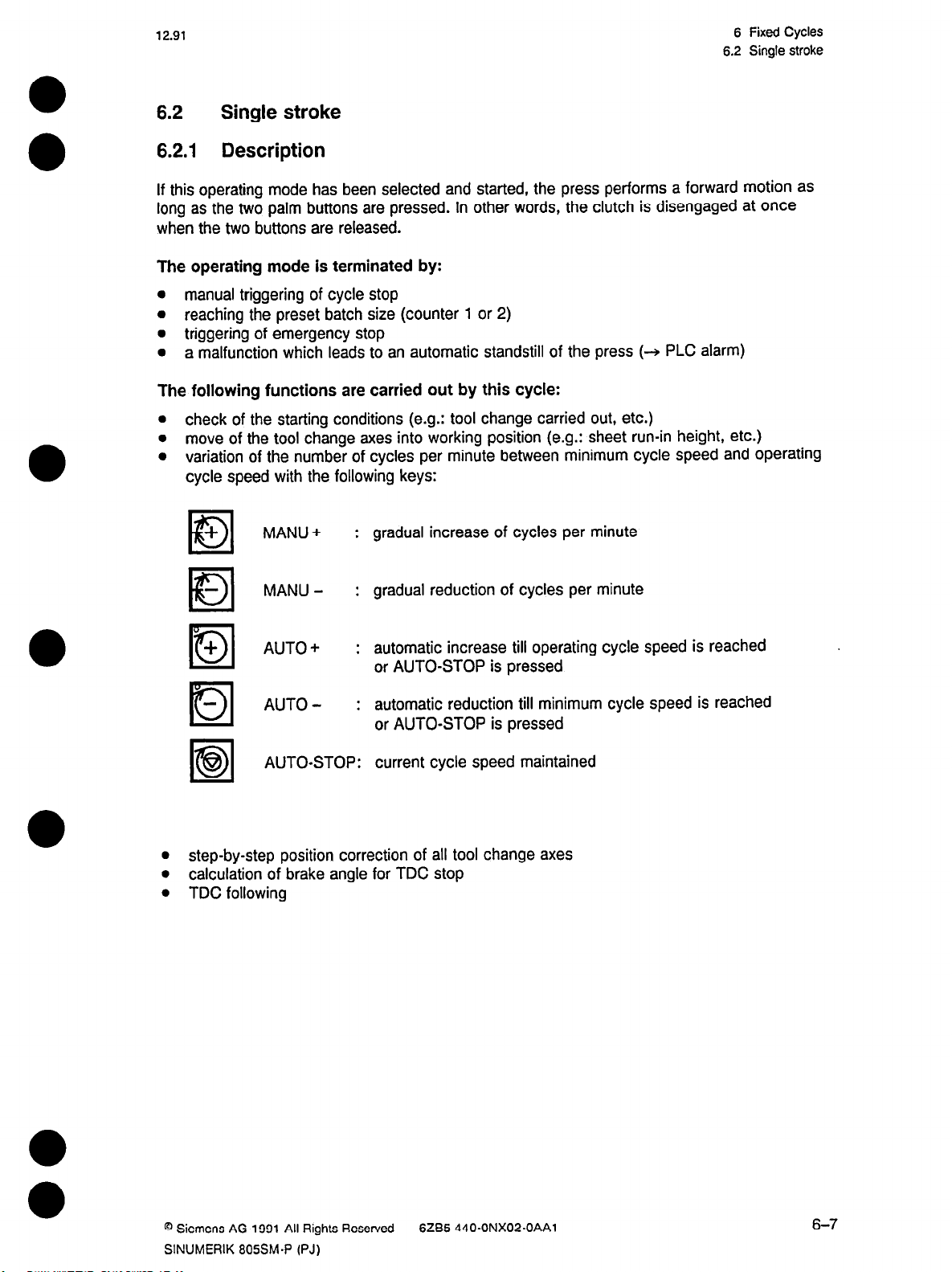

6.2 Single stroke

6.2.1 Description

If this operating mode has been selected and started, the press performs a forward motion as

long as the two palm buttons are pressed. In other words, the clutch is disengaged at once

when the two buttons are released.

The operating mode is terminated by:

l

manual triggering of cycle stop

l

reaching the preset batch size (counter 1 or 2)

l

triggering of emergency stop

l

a malfunction which leads to an automatic standstill of the press (+ PLC alarm)

The following functions are carried out by this cycle:

l

check of the starting conditions (e.g.: tool change carried out, etc.)

l

move of the tool change axes into working position (e.g.: sheet run-in height, etc.)

l

variation of the number of cycles per minute between minimum cycle speed and operating

cycle speed with the following keys:

6 Fixed Cycles

6.2 Single stroke

+

MANU+ :

gradual increase of cycles per minute

Dl

MANU- :

gradual reduction of cycles per minute

Ial

+

Dl

la

AUTO+ :

AUTO- :

AUTO-STOP:

automatic increase till operating cycle speed is reached

or AUTO-STOP is pressed

automatic reduction till minimum cycle speed is reached

or AUTO-STOP is pressed

current cycle speed maintained

la

l

step-by-step position correction of all tool change axes

l

calculation of brake angle for TDC stop

l

TDC following

0 Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6285 440.ONX02-OAAl

6-7

Page 24

6 Fixed Cycles

6.2.2 Start-up checklist

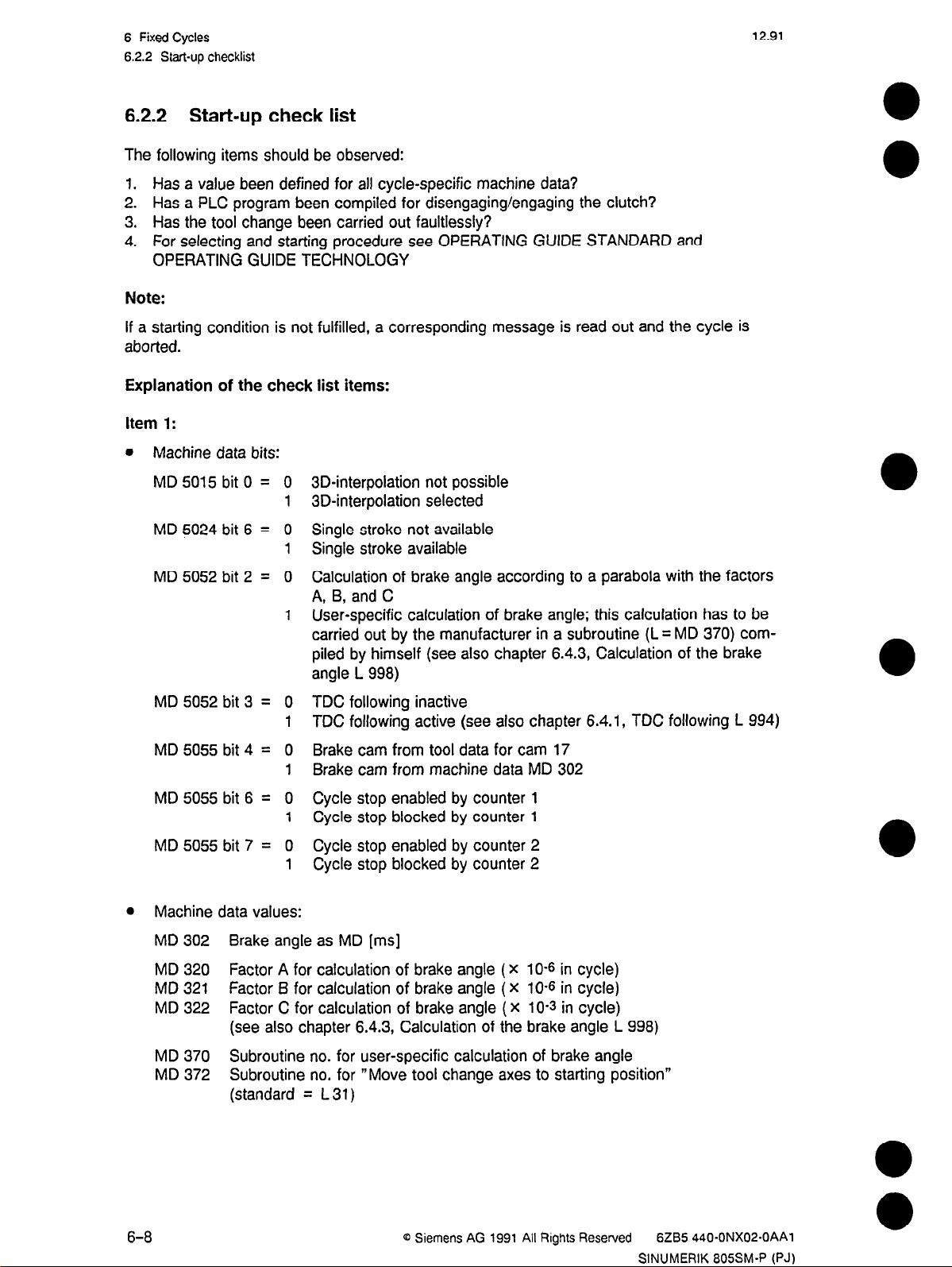

6.2.2 Start-up check list

The following items should be observed:

1. Has a value been defined for all cycle-specific machine data?

2. Has a PLC program been compiled for disengaging/engaging the clutch?

3. Has the tool change been carried out faultlessly?

4. For selecting and starting procedure see OPERATING GUIDE STANDARD and

OPERATING GUIDE TECHNOLOGY

Note:

If a starting condition is not fulfilled, a corresponding message is read out and the cycle is

aborted.

Explanation of the check list items:

Item 1:

l

Machine data bits:

12.91

MD 5015 bit 0 = 0

MD 5024 bit 6 = 0

3D-interpolation not possible

1

3D-interpolation selected

Single stroke not available

Single stroke available

MD 5052 bit 2 = 0

Calculation of brake angle according to a parabola with the factors

A, 6, and C

User-specific calculation of brake angle; this calculation has to be

carried out by the manufacturer in a subroutine (L = MD 370) com-

piled by himself (see also chapter 6.4.3, Calculation of the brake

angle L 998)

MD 5052 bit 3 = 0

MD 5055 bit 4 = 0

MD 5055 bit 6 = 0

MD 5055 bit 7 = 0

l

Machine data values:

TDC following inactive

1

TDC following active (see also chapter 6.4.1, TDC following L 994)

Brake cam from tool data for cam 17

1

Brake cam from machine data MD 302

Cycle stop enabled by counter 1

1

Cycle stop blocked by counter 1

Cycle stop enabled by counter 2

1

Cycle stop blocked by counter 2

MD 302 Brake angle as MD [ms]

MD 320 Factor A for calculation of brake angle

(X

10-s in cycle)

MD 321 Factor B for calculation of brake angle ( X 10-s in cycle)

MD 322 Factor C for calculation of brake angle (X 10-s in cycle)

(see also chapter 6.4.3, Calculation of the brake angle L 998)

MD 370 Subroutine no. for user-specific calculation of brake angle

MD 372 Subroutine no. for “Move tool change axes to starting position”

(standard = L 31)

6-8

0 Siemens AG 1991 All Rights Reserved

6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 25

12.91

6 Fixed Cycles

6.2.2 Start-up checklist

The following four machine data are only needed for axis correction if the corresponding

axis is designed as a deceleration step control axis (MD 584’.4 = 1). (See chapter 6.42,

Correction of all tool change axes).

MD 378 “Move-away distance” for 1st axis (0.001 mm)

MD 379

“Move-away distance” for 2nd axis (0.001 mm)

MD 380 “Move-away distance” for 3rd axis (0.001 mm)

MD 381 “Move-away distance” for 4th axis (0.001 mm)

The term “move-away distance” refers to the distance the axis must move back from its

current position in order to be at a sufficient distance from the desired target position to

reach the range of the last switch-off steps. This allows to carry out very small axis

corrections (i.e. compensation of the trail after the last switch-off of the axis, see also

chapter 6.4.2).

Item 2:

“Clutch engaged” (e.g. with the two palm buttons) has to be realized via a PLC program,

which has to be programmed by the user. For this %-program the cycle transfers the following

codes (via setting of flags) to the PLC.

F 136.1

Code “SINGLE STROKE” started:

is read out at the beginning of the cycle.

F 137.3 PLC enable:

is set by the cycle if all prerequisites for engaging the clutch are fulfilled.

F 137.4 “END OF CYCLE” code;

is set at the end of each cycle.

These flags are set by the cycle as static flags. That means that the resetting has to be

carried out by the 55 program.

Cam output - TDC stop via brake cam (no. 17):

After the prerequisites for the cycle have been fullfilled, the cam output is enabled. The brake

cam is always enabled during this cycle, i.e. during every stroke the brake cam (no. 17) takes

the value “0” for a moment when the deceleration point is reached. The disengaging of the

clutch must be effected by this cam (see also chapter 6.4.3, Calculation of brake angle L 998).

Item 3:

The cycle can only then be started if a correct tool change has been carried out before. If a

fault has ocurred during the tool change, the prerequisites for SET UP are not fulfilled. The

code R996 is interrogated (see also chapter 8, TOOL CHANGE).

@ Siemens AG 1991 All Rights Reserved 6ZB5 440*ONXO2-OAAl

SINUMERIK 805SM-P (PJ)

6-9

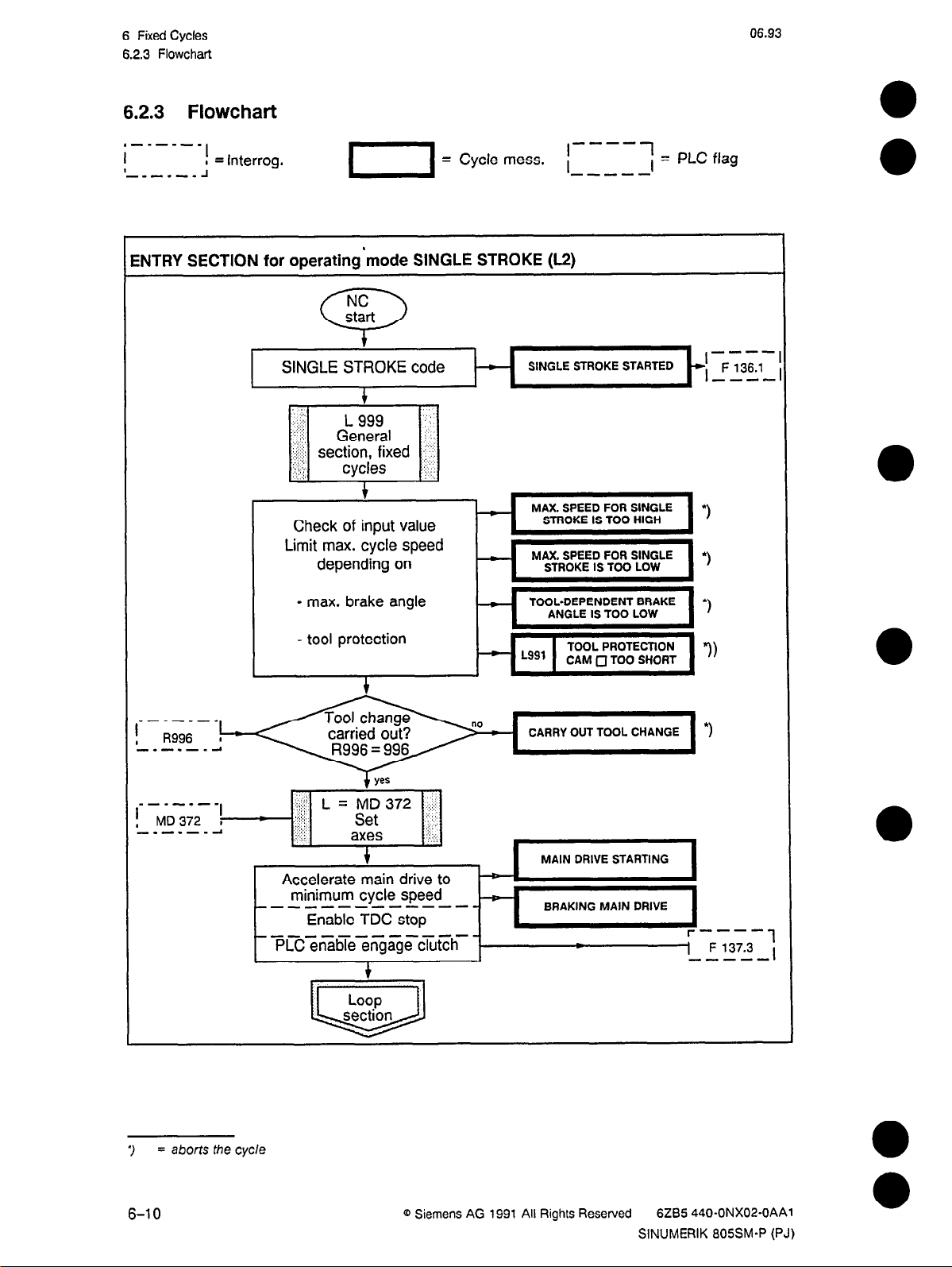

Page 26

6 Fixed Cycles

6.2.3 Flowchart

6.2.3 Flowchart

,---w-e

I

I

-,-.-.A

ENTRY SECTION for operating’tnode SINGLE STROKE (L2)

I

I = Interrog.

1 = Cycle mess. i

NC

start

0

t

SINGLE STROKE code

i

- SINGLE STROKE STARTED

06.93

,----7

;=

PLC flag

-I--

I

, F 136.1

----

Check of input value

Limit max. cycle speed

depending on

- max. brake angle

- tool protection

Accelerate main drive to

minimum cycle speed

-m-v-------Enable TDC stop

~~e~~e~<g~get~h-

MAX. SPEED FOR SINGLE

STROKE IS TOO HIGH

ANGLE IS TOO LOW

CAM 0 TOO SHORT

MAIN DRIVE STARTING

BRAKING MAIN DRIVE

r----i

1 F 137.3

-----

i

3

6-10

= aborts

the cycle

0 Siemens

AG 1991 All Rights Reserved 6ZB5 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

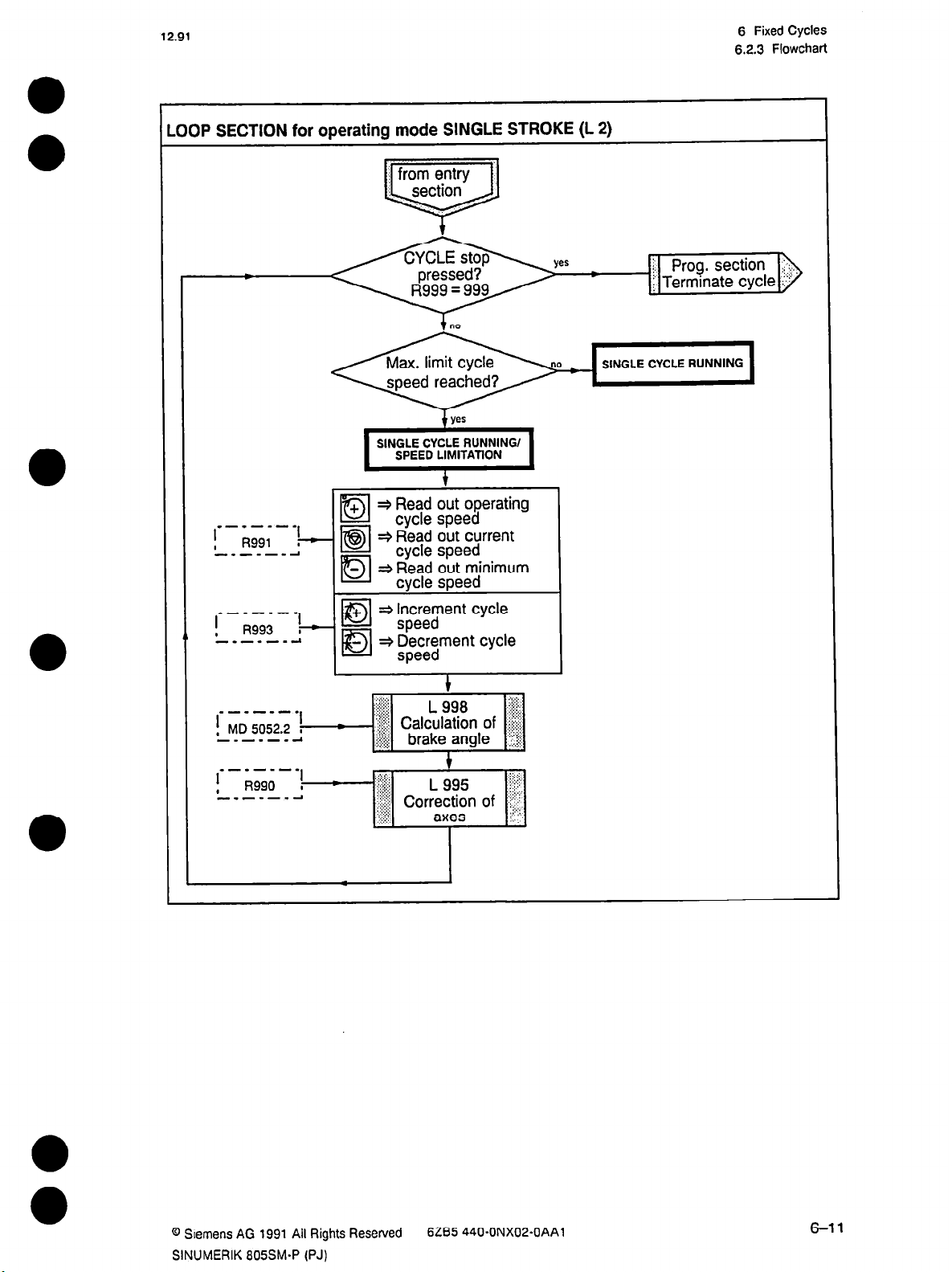

Page 27

12.91

OOP SECTION for operating mode SINGLE STROKE (L 2)

SINGLE CYCLE RUNNING/

SPEED LIMITATION

#

=$ Read out operating

*-*em-.

I

, I?991

------A

la

cycle speed

~4 Read out current

cycle speed

* Read out minimum

cycle speed

* Increment cycle

speed

=+ Decrement cycle

speed

6 Fixed Cycles

6.2.3 Flowchart

SINGLE CYCLE RUNNING

------.

I

, MD 5052.2 I

------A

--.-mm*

I

,

R990

-.---.A

+

I

I

*

:;:::;.:

,:,q::

%$ Correction of ‘i.jr:i;

.,. :,.,j

,:>:::’

1

L 995

i fix;;

:‘,; >

axes iii’::

@ Slemens AG 1991 All Rights Resewed

SINUMERIK 805SM-P (PJ)

6285 440.ONX02-OAAl

6-11

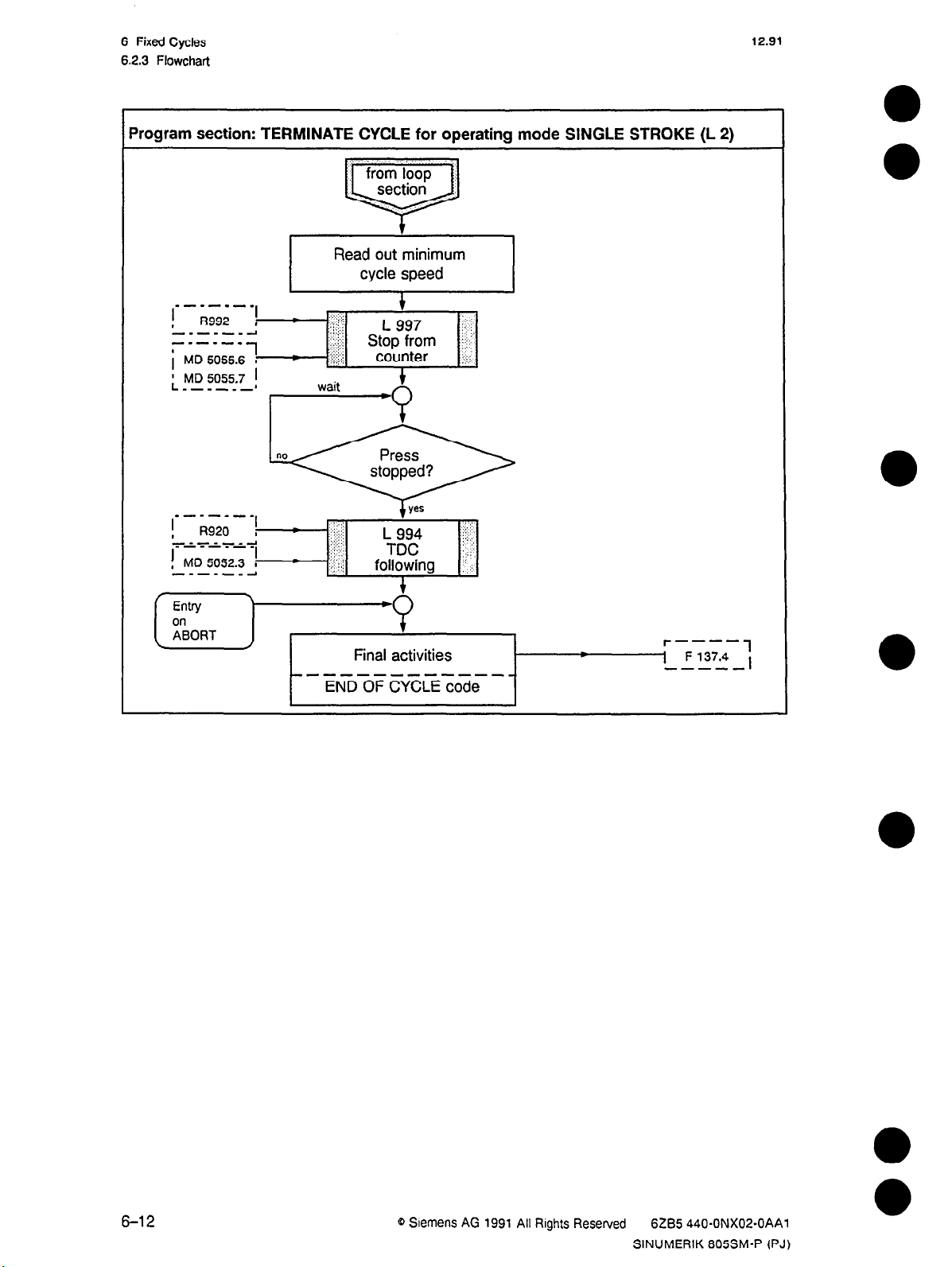

Page 28

6 Fixed Cycles

62.3 Flowchart

Program section: TERMINATE CYCLE for operating mode SINGLE STROKE (L 2)

Read out minimum

cycle speed

12.91

m-.-.-s

I

, R992 ,

-.-e---1

---e-w

MD 5055.6 I

i

; MD 5055.7 1

----m-1

1

I

,

.‘:I :y:j

,::: :

‘;;,I; ,t;,9;;m ;jj.

..:,:j,

;j :)x;

wait

+

counter ::jj:,

1

-zivr = ;-FyLFj

-----------END OF CYCLE code

6-12

0 Slemens AG 1991 All Rights Reserved

6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 29

12.91

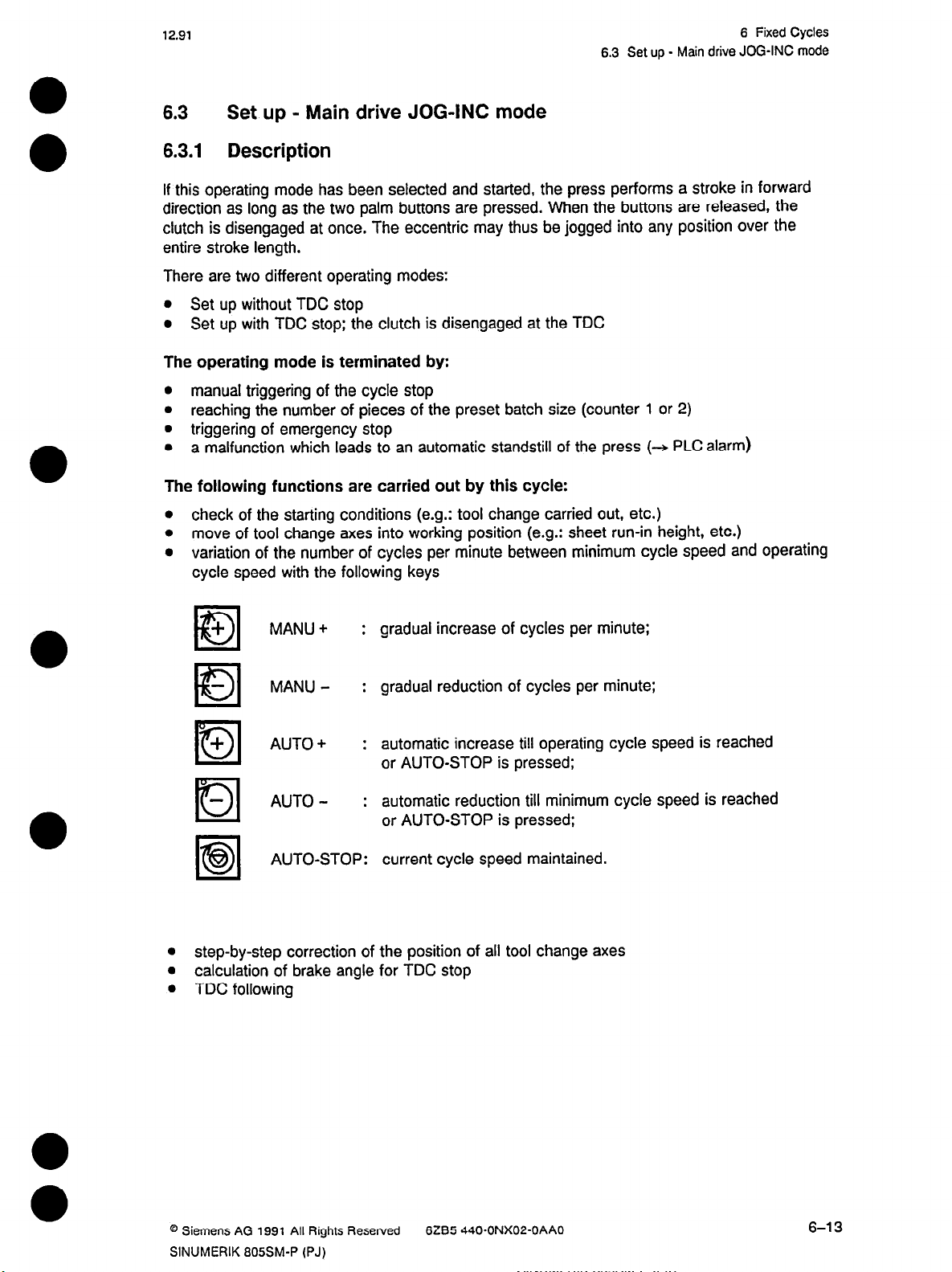

6.3 Set up - Main drive JOG-INC mode

6.3 Set up - Main drive JOG-INC mode

6.3.1 Description

If this operating mode has been selected and started, the press performs a stroke in forward

direction as long as the two palm buttons are pressed. When the buttons are released, the

clutch is disengaged at once, The eccentric may thus be jogged into any position over the

entire stroke length.

There are two different operating modes:

l

Set up without TDC stop

l

Set up with TDC stop; the clutch is disengaged at the TDC

The operating mode is terminated by:

l

manual triggering of the cycle stop

l

reaching the number of pieces of the preset batch size (counter 1 or 2)

l

triggering of emergency stop

l

a malfunction which leads to an automatic standstill of the press (3 PLC alarm)

The following functions are carried out by this cycle:

6 Fixed Cycles

l

check of the starting conditions (e.g.: tool change carried out, etc.)

l

move of tool change axes into working position (e.g.: sheet run-in height, etc.)

l

variation of the number of cycles per minute between minimum cycle speed and operating

cycle speed with the following keys

+

MANU +

: gradual increase of cycles per minute;

tiol

MANU -

: gradual reduction of cycles per minute:

El

+

Dl

la

AUTO +

AUTO -

AUTO-STOP: current cycle speed maintained.

: automatic increase till operating cycle speed is reached

or AUTO-STOP is pressed;

: automatic reduction till minimum cycle speed is reached

or AUTO-STOP is pressed:

•5l

0

step-by-step correction of the position of all tool change axes

l

calculation of brake angle for TDC stop

l

TDC following

0 Siemens AG 1991 All Rights Reserved

SINUMERIK 605SM-P (PJ)

6285 440.ONX02-OAAO

6-13

Page 30

6 Fixed Cycles

6.3.2 Start-up checklist

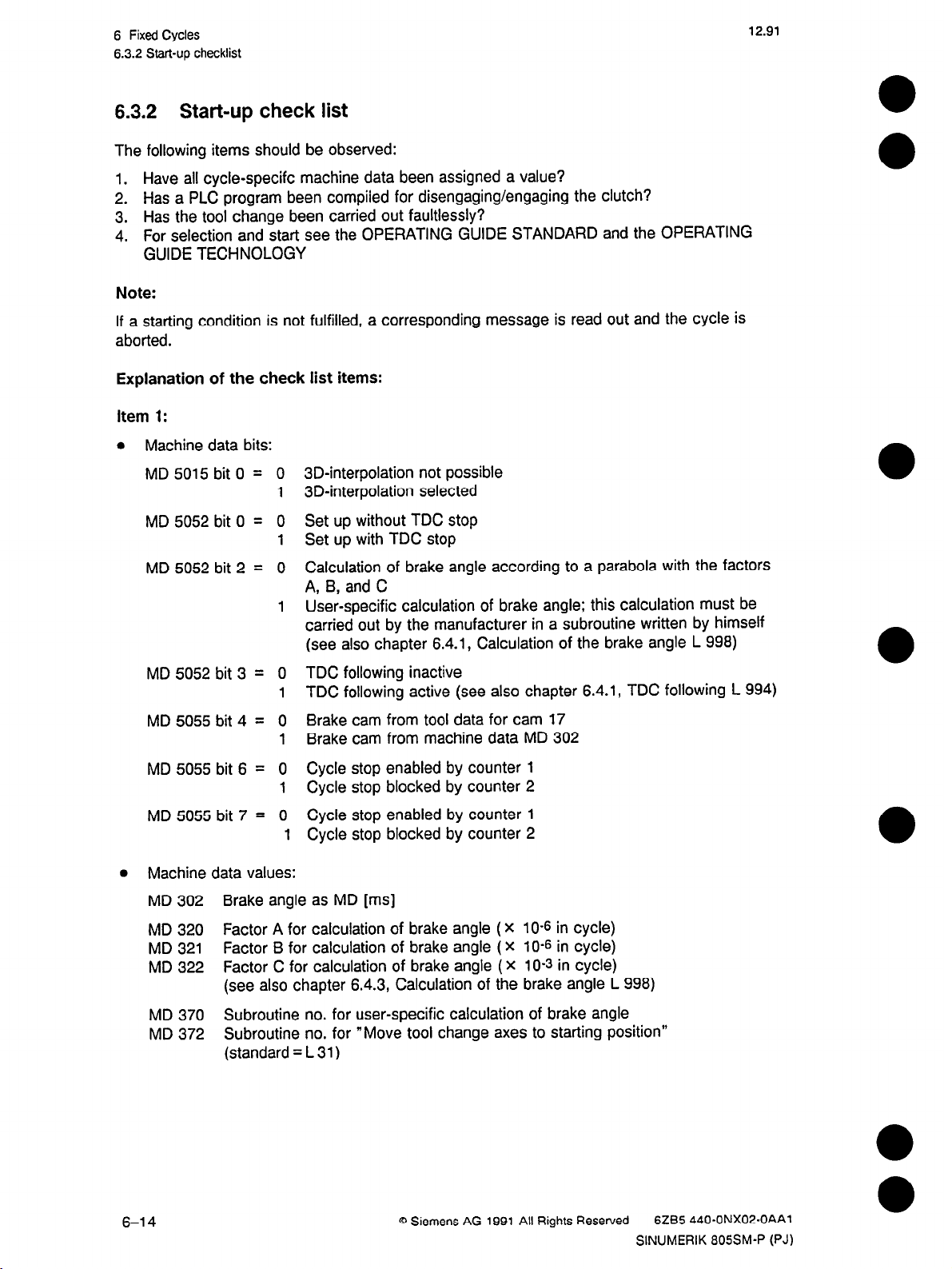

6.3.2 Start-up check list

The following items should be observed:

1. Have all cycle-specifc machine data been assigned a value?

2. Has a PLC program been compiled for disengaging/engaging the clutch?

3. Has the tool change been carried out faultlessly?

4. For selection and start see the OPERATING GUIDE STANDARD and the OPERATING

GUIDE TECHNOLOGY

Note:

If a starting condition is not fulfilled, a corresponding message is read out and the cycle is

aborted.

Explanation of the check list items:

Item 1:

l

Machine data bits:

12.91

MD5015bitO = 0

MD 5052 bit 0 = 0

MD 5052 bit 2 = 0

3D-interpolation not possible

1

3D-interpolation selected

Set up without TDC stop

1

Set up with TDC stop

Calculation of brake angle according to a parabola with the factors

A, B, and C

1

User-specific calculation of brake angle; this calculation must be

carried out by the manufacturer in a subroutine written by himself

(see also chapter 6.4.1, Calculation of the brake angle L 998)

MD 5052 bit 3 = 0

MD 5055 bit 4 = 0

MD 5055

bit 6 = 0

TDC following inactive

1

TDC following active (see also chapter 6.4.1, TDC following L 994)

Brake cam from tool data for cam 17

1

Brake cam from machine data MD 302

Cycle stop enabled by counter 1

Cycle stop blocked by counter 2

MD 5055 bit 7 = 0

l

Machine data values:

MD 302

Brake angle as MD [ms]

MD 320 Factor A for calculation of brake angle ( X

MD 321

Factor B for calculation of brake angle ( X 10-s in cycle)

Cycle stop enabled by counter 1

1

Cycle stop blocked by counter 2

10-6

MD 322 Factor C for calculation of brake angle (X 10-s in cycle)

(see also chapter 6.4.3, Calculation of the brake angle L 998)

in cycle)

MD 370 Subroutine no. for user-specific calculation of brake angle

MD 372

Subroutine no. for “Move tool change axes to starting position”

(standard = L 31)

6-14 Q Siemens AG 1991 All Rights Reserved 6285 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 31

12.91 6 Fixed Cycles

6.3.2 Start-up checklist

The following four machine data are only needed for axis correction if the corresponding

axis is designed as a deceleration step control axis (MD 584”.4 = 1). (See chapter 64.2,

Correction of all tool change axes).

MD 378 “Move-away distance” for 1st axis (0.001 mm)

MD 379 “Move-away distance” for 2nd axis (0.001 mm)

MD 380 “Move-away distance” for 3rd axis (0.001 mm)

MD 387 “Move-away distance” for 4th axis (0.001 mm)

The term “move-away distance” refers to the distance the axis must move back from its

current position in order to be at a sufficient distance from the desired target position to

reach the range of the last switch-off steps. This allows to carry out very small axis

corrections (i.e. compensation of the trail after the last switch-off of the axis).

Item 2:

“Clutch engaged” (e.g. with the two palm buttons) has to be realized via a PLC program,

which has to be programmed by the user. For this S5 program the cycle transfers the following

codes (via setting of flags) to the PLC.

M 136.2 Code “SET UP jog main drive with TDC stop”;

is read out at the beginning of the cycle.

M 136.3

M 137.3

Code “SET UP jog main drive without TDC stop”;

PLC enable;

is set by the cycle if all prerequisites for engaging the clutch are fulfilled.

M 137.4 “END OF CYCLE” code:

is set at the end of each cycle.

These flags are set by the cycle as static flags. That means that the resetting has to be

carried out by the S5 program.

Cam output - TDC stop via brake cam (no. 17):

After the prerequisites for the cycle have been fullfilled, the cam output is enabled.

Set up without TDC stop: The brake cam for TDC stop is always blocked.

Set up with TDC stop:

The brake cam is always enabled, i.e. the brake cam takes the

value “0” each time the deceleration point is reached. The

disengaging of the clutch must be effected by this cam (see also

chapter 6.4.3, Calculation of the brake angle L 998).

Item 3:

The cycle can only be started if a correct tool change has been carried out. If a fault has

occurred during the tool change, the prerequisites for SINGLE STROKE are not fulfilled. The

code R996 is interrogated (see also chapter 8, TOOL CHANGE).

Q Siemens AG 1991 All Rights Reserved 6265 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

6-l 5

Page 32

6 Fixed Cycles

6.3.3 Flowchart

6.3.3 Flowchart

,-m-.-e

I

I

-e-m-,J

iNTRY SECTION for operating mode SET UP jog main drive (L 3)

I

, = Interrog.

looL CHANGE STARTED

06.93

s-.-w-.

m-w-e-e

MD 372 1

------d

Check of input values

Limit max. cycle speed

depending on

-

max. brake angle

- tool protection

l-i

I

l-l

MAX. SPEED FOR TOOL

CHANGE IS TOO LOW

I

TOOL-DEPENDENT BRAKE

ANGLE IS TOO SMALL

CARRY OUT TOOL CHANGE 3

*)

I

I

*)

I

/

*) aborts the cycle

6-16

PLC

enablehengage clutch

1

1-1 F 137.4 ,

0 Siemens AG 1991 All Rights Reserved

r----

6ZB5 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

1

Page 33

12.91

,OOP SECTION for operating mode SET UP (L 3)

6 Fixed Cycles

6.3.3 Flowchart

e-m-m-m

I

, R991

------m.4

“-.--mm

I

, R993 ;-c

-------I

I

;-c

- t Terminate cycle

+ + Read out operating

Dl

ls3l

IDI

I

la

IDI

cycle speed

+ Read out current

cycle speed

+ Read out minimum

cycle speed

3 Increment cycle

+

speed

+ Decrement cycle

speed

j Program section

4

@ Siemens AG 1991 All Rights Reserved

SINUMERIK SOSSM-P (PJ)

6285 440.ONX02-OAAl

6-l 7

Page 34

6 Fixed Cycles

6.33 Flowchart

12.91

Program section

: TERMINATE CYCLE

Read out minimum

cycle speed

.--------m----s

END OF CYCLE code

for operating mode

SET UP (L 3)

r----

1 F 137.4

m--m-

1

,

6-l 8

0 Siemens AG 1991 All Rights Reserved

6285 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 35

12.91

6.4 Common subroutines

6 Fixed Cycles

6.4 Common subroutines

6.4.1

TDC following L 994

Condition: Calculation of brake angle with a polynomial of 2nd degree (MD 5052 bit 2 = 0).

If an exact TDC stop position in the operating modes CONTINUOUS STROKE and SINGLE

STROKE is required, the calculation of the brake angle may be adapted to the non-constant

mechanical conditions. The factor A is adjusted within the preset limits in case of a positioning

error. The corrected value is transferred into MD

320.

The tolerance band to the right and to

the left of the TDC position where a correction of factor A seems reasonable must be

determined by the user via machine data. The following figure illustrates these facts.

If the main drive is not within this window, a code is transferred to the PLC, which the user has

to evaluate.

MD 137.2 Main drive not within tolerance window

If a TDC following has to be carried out, the following MD must be loaded:

MD 5052 Bit 3 = 0 TDC following deselected

1 TDC following selected

MD 300 right maximum tolerance limit

MD 301 left maximum tolerance limit

MD 330

right minimum tolerance limit

MD 331 left minimum tolerance limit

In these areas the TDC

following is effective

1800;

I

“BDC”

“TDC following” for CONT/NUOUS STROKE and SlNGLE STROKE; the indicated degree values are meant as

examples!

@ Siemens AG 1991 All Rights Reserved 6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

6-19

Page 36

6 Fixed Cycles

6.4.2 Correction of all tool change axes (L 995)

6.4.2 Correction of all tool change axes (L 995)

This subroutine is executed if the user has selected the axes correction and pressed

step + or -.

Each time the softkey is actuated

l

R990 is loaded with the corresponding axis number

l

the corresponding axis-specific parameter

parameters in work memory) is decremented or incremented by one.

The program now calculates the correction values from this number of steps and from the

defined step size, e.g. 1st axis = R1103 X R1104

The axis position of the corresponding tool change axis is corrected by this value during

operation. Subsequently, R990 is deleted again by the cycle. Example of the corrected axis

position of the 1st axis: =

R1102+(R1103xR1104).

for

the number of steps (see distribution of the

The following characteristics apply for deceleration step control axes:

Owing to the fact that these axes have an open-loop position control, a desired position can

only be approached if it lies outside the mechanic trail beyond the last switch-off position.

12.91

In order to be able to carry out very small corrections, the axis is moved away from the actual

position by the “move-away distance” determined in MD before the final desired position is

approached. It is only a matter of leaving the switch-off stage. The following figure illustrates

these facts. The user only has to determine a sufficiently large “move-away distance”. The

cycle realizes automatically whether the corrected axis is a deceleration step control axis or

not.

MD 378 “Move-away distance” for 1st axis (0.001 mm)

MD 379 “Move-away distance” for 2nd axis (0.001 mm)

MD 380 “Move-away distance” for 3rd axis (0.001 mm)

MD 381 “Move-away distance” for 4th axis (0.001 mm)

Axis position before the correction

I

I

ve away distance

\I

\

=F2=F3 ----

I’

:s

l Trail after last

so I-

Sl=S2= S3 I

1 switch-off stage

Axis correction for deceleration step control axes with analog output and two switch-off stages

For this example applies:

If corrections < SO are to be carried out, the axis has to be moved away from the actual

position by a move away distance > SO (1st step) before the corrected axis position can be

approached (2nd step).

6-20

0 Siemens AG 1991 All Rights Reserved

6285 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

0

0

Page 37

12.91 6 Fixed Cycles

6.4.3 Calculation of the brake angle L 998

6.4.3 Calculation of the brake angle L 998

In order to guarantee that the press stands in the top dead center when “TDC stop” has been

triggered, the brake angle must be calculated continuously during a cycle.

Standard: Calculation of the brake angle with a polynomial of 2nd degree

(MD 5052 bit 2 = 0)

The cycle calculates the brake angle according to the following formula:

a = axHa+bXH+c

a: brake angle in relation to cycles per minute

H: cycles per minute

The factors a, b and c have to be stored in machine data with the correct multiplier:

MD 320 factor A = a X 10s

MD 321 factor B = b X 10s

MD 322 factor C = c

For the calculation of these factors the program “Factor” is at your disposal, which is supplied

on a floppy disk together with the standard cycles and is thus executable in MS-DOS.

X 103

Call:

“Factor”; You are prompted by the program to input 3 points of the characteristic brake curve

which you have established before via trial stops with minimum, maximum and medium cycle

speed. It is likely that the shortest stroke length has to be selected so that the machine may

be operated in the maximum cycle speed range. Please use the standard assignment for the

machine data (MD 320 - 322 = l),‘because in this manner a brake angle of 0 degrees is calculated for each cycle speed and therefore the indicated angle after the stop corresponds to the

brake angle for the set cycle speed. With the values established, the program calculates the

machine data, which can then be entered by the user.

With this brake angle, the TDC offset and the stop position, the deceleration point is established. This angle is loaded into the press datum no. “0”. If the brake cam is enabled, it takes

the value “0” for a moment each time this angle is passed. You determine in the tool data

(cam parameters) or in the machine datum MD 302 how long the brake cam remains in “low”

position.

The following applies:

MD 5055 bit 4 =

1

+ Brake cam from MD 302 [ms]

0 + Brake cam from cam parameter

User-specific calculation of the brake angle (MD 5052 bit 2 = 1)

If the manufacturer wants to calculate the brake angle according to his own formula, this must

be done in a subroutine designed for that purpose, The number of this subroutine must be

defined in MD 370.

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6285 440-ONX02-OAAl

6-21

Page 38

12.91

7 Basic Press Functions

7 Basic Press Functions

7.1 Safety stroke

7.1

Safety stroke

7.1 .l Description

In “Safety stroke”, the press executes a slow forward stroke at creep speed. This is to prevent

the destruction of incorrectly clamped tools. The clutch can only be engaged when the creep

speed has been reached, Now the two palm buttons must be pressed until the clutch has

been automatically disengaged. If the press is stopped within the tolerance window, the

message SAFETY CYCLE CARRIED OUT is displayed and the acknowledge code for “Safety

stroke executed” (R946 = 946) is set.

After the clutch has been disengaged, the cycle terminates itself.

The cycle is aborted in the following cases:

l

if the cycle stop key is pressed

l

if the tolerance window is not reached

l

if the two palm buttons are released too early

l

if the set creep speed is outside the permitted range (

+ Messages of the standard cycles,

Chapter 9)

7.1.2 Start-up check list

l

Correct values assigned to machine data?

- MD 304 = Creep speed

- MD 332 = Tolerance window for safety stroke

- MD 373 =

Subroutine No. for additional user program

l

Tool change correctly carried out?

7.1.3 Codes for the PLC:

M 136.5 Safety stroke started

M 137.3 PLC enable for engaging clutch

M 137.4

These flags are set as static flags in the PLC.

Cycle terminated

The engaging of the clutch must be implemented in an

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6ZB5 440.ONX02.OAAl

7-l

Page 39

7 Basic Press Functions

7.1.4 Flowchart

7.1.4 Flowchart

,---m-m

I

1

-,-,--J

PREPARE ENGAGING OF THE CLUTCH for basic function SAFETY STROKE (L 4)

I

I = Interrogation

I[ = Cycle mess. ~~~--~ = PLC Flags

12.91

*-.--mm

I

, MD 304 ,

------A

--.----

-------I

SAFETY STROKE code

I

Reset o.k. code:

Load MD

i

check input limits

( Accelerr;mfnd$fe to /

-------mm-----

Enable TDC stop

Start enable to PLC

k

CARRY OUT

TOOL CHANGE

/

3

r----

1 F 137.3

-----

1

I

*) aborts the cycle

7-2 @ Siemens AG 1991 All Rights Reserved

6ZB5 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 40

12.91

XECUTION SECTION for SAFETY STROKE (L 4)

wait

-6

7 Basic Press FunctionS

SAFETY CYCLE

RUNNING

7.1.4 Flowchart

-3-m

Entry

on

ABORT

-----------m-m

0 Slemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

Terminating

CYCLE END code

‘I

jobs

6285 440.ONX02-OAAl

l-----

1 F 137.4

--me-

1

,

7-3

Page 41

7 Basic Press Functions

7.2 Reversing

12.91

7.2 Reversing

7.2.1 Description

In “Reversing”, the press executes a slow stroke backward. With this mode it is possible to

move the press back to TDC if the forward motion is mechanically blocked.

The press moves back at creep speed as long as the two palm buttons are pressed. When the

TDC is reached, the clutch is automatically disengaged.

After the clutch has been disengaged, the cycle terminates itself.

The cycle is aborted in the following cases:

l

if the cycle stop key is pressed

l

if the set creep speed is outside the permitted range (+ Messages of the standard cycles,

Chapter 9)

7.2.2 Start-up check list

l

Correct values assigned to machine data?

- MD 304 = Creep speed

- MD 332 = Tolerance window for reverse

- MD 373 = Subroutine No. for additional user program

l

Tool change correctly carried out?

7.2.3 Codes for the PLC:

F 136.4 Reversing started

F 137.3 PLC enable for engaging clutch

F 137.2 Main drive outside tolerance range

F 137.4 Cycle terminated

These flags are set as static flags in the PLC.

The engaging of the clutch must be implemented in an

SS program written by the user!

7-4

0 Siemens AG 1991 All Rights Reserved 6285 440-ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 42

12.91

7.2.4 Flowchart

7 Basic Press Functions

7.2.4 Flowchart

,---m-m

I

I

-,-m--J

I

I = Interrogation

I1 = Cycle mess. I----; = PLC flags

= Assignment

PREPARE ENGAGING OF THE CLUTCH for basic function REVERSING (L 5)

--m-.-.,

! MD304

---e-*4

Gi-:;T,Y

REVERSE code

Disable counter

I

,

Load MD

Reset codes

check input limit

REVERSING

CREEP SPEED

TOO HIGH

I

3

m-a-m-m

I

, MD 5052.2 ,

---w--d

I

-1

z.:.:,>:

,g Brake

.::;.:.:.

*~r-EGc;

.;. .:.

:.:,x;

,$g

L 998

angle

:3 ;:,.

ijj: ;j/

,:::,:‘;

f!,

t::..:..

l

) abortsthecycle

@ Siemens AG

SINUMERIK 805SM-P (PJ)

1991

All Rights Reserved

6285 440-ONX02-OAAl

7-5

Page 43

7 Basic Press Functions

7.2.4 Flowchart

EXECUTION SECTION for basic function REVERSING (L 5)

12.91

F-F--

/

-------------CYCLE END code

1

REVERSING

OVER

+

Terminating

jobs

REVERSING

RUNNING

---[,,,,(I

.

r---1 F 137.2

m---m

r----

‘I F 137.4 :

-----

-I

,

1

7-6

Q Siemens AG 1991 All Rights Reserved 6iY35 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 44

12.91

7

Basic Press Functions

7.3

Open press

7.3

Open press

7.3.1 Description

In this mode, the stroke adjustment axis is moved to its upper position (RllOO). For this, the

clutch must be disengaged.

The tool change axis is normally moved by step cycle L 46. As a prerequisite for this, the

stroke adjustment axis must be the first axis.

If the user has written his own program for this purpose, its number must be entered in

MD 375.

7.3.2

Codes for the PLC

F 136.6 “Open press” code

F 137.3 PLC enable

F 137.4 Cycle terminated

These flags are set as static flags in the PLC.

7.3.3 Flowchart .------

I

I

-m-m-m J

I

a = Interrogation

basic function OPEN PRESS (L 6)

NC

start

0

Disable counter

-------------OPEN PRESS code

PLC enable

1

Terr$nnting

-------mm-----

CYCLE END code

r----

1 F 136.6

-----

MAIN DRIVE

OPENING

PRESS

-

PRESS

OPEN

r----

-j F 137.3

--m-c

r----

1 F 137.4

-----

1

,

1

,

1

,

~3 Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6ZS5 440*ONX02-OAAl

7-7

Page 45

7 Basic Press Functions

7.4 Close press

12.91

7.4

Close press

7.4.1 Description

In this mode, the stroke adjustment axis is moved to its working position

clutch must be disengaged.

The tool change axis is normally moved by step cycle L 30. As a prerequisite for this, the

stroke adjustment axis must be the first axis.

If the user has written his own program for this purpose, its number must be entered in

MD 376.

7.4.2

Codes for the PLC

F 136.7 “Close Press” code

F 137.3 PLC enable

F 137.4 Cycle terminated

These flags are set as static flags in the PLC.

(R1102).

For this, the

7.4.3 Flowchart

Basic function CLOSE PRESS (L 7)

7-8

PLC enable

---------- ----

CYCLE END code

Q Siemens AG 1991 All Rights Reserved

MAIN DRIVE

RUNNING

r----

CLOSED

--I F 137.4

SINUMERIK 805SM-P (PJ)

r----

-----

6285 440.ONX02-OAAl

1

I

Page 46

8 Tool

12.91

8.1

General remarks

Change

8 Tool Change

8.1 General remarks

8.1 .l Description

With the TOOL CHANGE cycle, the tool change in the press is executed.

The TOOL CHANGE cycle has two different tasks:

a) it provides the new data for the tool

b) it is the prerequisite for the mechanical tool change

Item a):

Implemented in subroutines L 990, L 992 and L 993.

The tool data is stored in the work memory, and the tool selection is checked (is the selected

tool number available in the memory?). After this, the data can be modified in the work

memory, if desired. For this, a user-written subroutine must be used, whose number can be

freely defined in machine datum MD 371 (application example: definition of permanent, pressspecific cams which are identical for all tools).

The new data is now transferred to the hardware (e g. cam-specific data to the cam controller

RAM). In doing so, the system checks this data for plausibility. If it detects a fault, the tool

change cannot be executed. The cycle is aborted, and a message is output for the user.

If the tool data is checked and found correct, the system loads into central R parameters

machine data required for the operating cycles (example: copying the stroke length table from

the MD). The cycle checks this data for correctness.

With the ROLL FEED (RF) option, the cycle additionally calculates the “maximum speed

because of roll feed data”, which is also needed by the operating cycles to set the speed limit.

The following start cams are assumed: cam 18 for RF1 and cam 20 for RF2.

In general, the cam output is disabled in this cycle.

Machine data to be set for the cycle:

MD 303 Minimum speed

MD 305

Maximum speed for SINGLE STROKE

MD 320-322 Factors for calculation of the brake angle

MD 371

No. of the user-defined subroutine

Stroke length table

MD 5051 Bit 1 = 0 Carry out safety stroke

1 No safety stroke required

With roll feed option:

MD 728 1st R parameter for roll feed

MD 811 Number of roll feed blocks

0 Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6tB5 440-ONX02-OAAl

8-l

Page 47

8 Tool Change

8.1 .l Description

Item

b):

If all prerequisites described under a) are fulfilled, the mechanical tool change can be carried

out. This can be done either by:

l

manual tool change or by

l

automatic tool change

8.1.2 Flowchart

12.91

,----me

I

I

-.--w-J

I

, = Interrogation

rJ= [---Il= PLC flags

II

Cycle messages

= Parameters receiving values

rooL CHANGE GENERAL (L 990)

‘ROVIDE TOOL DATA AND CHECK PLAUSIBILITY

Reset o.k. codes

_-_-_-_

CHECK TOOL SELECTION 2

n

) aborts the cycle

8-2

Q Siemens AG 1991 All Rights Reserved

6285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 48

12.91

8 Tool Change

8.1.2 Flowchart

1 MD321 i

;. MD 322

v-.-,2

Reset safety stroke o.k. code

(R946 = 0)

A

r---1

--m-e

CHECK STROKE LENGTH “)

MIN. SPEED TOO HIGH 7

I3946

1

,

t

11 Return to 1’1

7 aborts the cycle

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6265 440-ONX02-OAAl

r----

I F 137.3 j

-----

8-3

Page 49

8 Tool Change

8.1.2 Flowchart

OPTION: TOOL CHANGE - ROLL FEED SECTION (L 992)

12.91

--m-e-

! MD 728 !

I

, MD811 r

L--*-.-l

,---e-m

1 Option RF2 ‘W

‘---m-m

J

RF1

Calculate total

program length

RF2 Calculate total

--w----------e

program length

Reset number of steps in

RF1 and RF2

+

Calculate max. speed

from roll feed data

RF1 = Start cam

RF2 = Start cam 20

+

18

r----

j R931

-----

r---1 A926

-----

r----

1 A924

-----

1

1

1

,

I

,

8-4

0 Siemens AG 1991 All Rights Reserved

6285 440-ONXO2-OAAl

SINUMERIK 805SM-P (PJ)

Page 50

12.91

rERMlNATE TOOL CHANGE (L 993)

Store the previous

- tool change position

-

stroke number

-

stroke referred to zero

-------------Reset loop flag

Automatic TOOL CHANGE

6 Tool Change

6.1.2 Flowchart

Read interface flags

(F24.6 and F24.7)

4

Reset data transfer

code

-

--

DATA TRANSFER

!STlLL RUNNING

TOOL CHANGE

----

I

+, F 139.3 I

--e-m

1

@ Siemens AG 1991 All Rights Reserved

SINUMERIK 805SM-P (PJ)

6285 440-ONX02-OAAl

8-5

Page 51

8 Tool Change

8.2 Manual tool change - jog main drive (L 9)

12.91

8.2 Manual tool change - jog main drive (L 9)

8.2.1 Description

If the tool data of a new tool are not known, the tool can be mounted and dismounted by hand

with this cycle.

For this purpose, the subroutine provides, in its basic version, the possibility to jog the main

drive at creep speed via the two “palm buttons” and to move the axes by means of the

direction keys (selection via softkeys). Any further functions required for the tool change can

be executed as so-called step cycles in a step sequence (example: step cycle No. 43: “Start

data transfer to an external device”).

For this step sequence, MD 335 - 339 are available to define the order of the subroutine

functions to be called. In our example, it would suffice to enter the subroutine number 43 in

MD 335 in order to trigger the data transfer during the tool change procedure. Furthermore,

the notes on the individual step cycles must be borne in mind. The available step cycles can

be found in the overview of standard cycles in Chapter 10.

Machine data to be set:

MD 304

Creep speed

MD 335

Step sequence MANUAL TOOL CHANGE

: >

MD 339

Please pay attention to the machine data of the step cycles!

PLC codes

F 137.0

F 137.3

MANUAL TOOL CHANGE code

PLC enable

F 137.4 Cycle terminated

Please pay attention to the codes of the step cycles used!

These flags are set as static flags in the PLC.

8-6

@ Siemens AG I 991 All Rights Reserved 6285 440-ONX02-OAAl

SINUMERIK 805&M-P (PJ)

Page 52

12.91

8.2.2 Flowchart

,-m---m

I

I

-s---m J

MANUAL TOOL CHANGE - jog main drive (L 9)

I

a = Interrogation

8 Tool Change

8.2.2 Flowchart

--.-e-

! MD 335

I

a MD:339 r

L.---w-l

f

Enter subrout. no.

from MD

.

MANUAL TOOL

RUNNING

CHANGE

loop parameter (R913)

. . . . . .

,. :.:.:

1

:jj ;

,j$: L= MD(R913) ‘;$

,\$i9: Step cycles $:i

..,.,_

:j :‘;:I

(I

@ Siemens AG 1991 All Flights ReSet’Ved 8285 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

r-e--

1 F 137.4

-----

1

a-7

Page 53

8 Tool Change

8.3 Automatic tool change (L 8)

12.91

8.3 Automatic tool change (L 8)

8.3.1 Description

If the tool data of a new tool are known, it is also possible to carry out a manual operatorguided tool change.

The press-specific sequence of operations to mount and dismount a tool can be defined in this

cyle via machine data. Just as in Manual tool change, a number of step cycles is available to

the user which can be integrated in the tool change procedure as “function macros” (on this,

see the overview of standard cycles in Chapter 10).

An example of the aforesaid is given below, along with a detailed description of how to

implement an automatic stroke adjustment with the available step cycles.

Overview of the machine data

MD 5040.0 = 0: Re-entry at the interruption point

1:

Permit only MANUAL TOOL CHANGE after the interruption

Step sequence for AUTOMATIC TOOL CHANGE

to

be set:

PLC codes:

F 137.1 MANUAL TOOL CHANGE code

F 137.3

F 137.4

Please pay attention to the codes of the step cycles used!

These flags are set as static flags in the PLC.

8.3.2

This example describes the automatic removal of a tool using standard cycles for the tool

change operations.

Pre-defined sequence of operations:

PLC enable

Cycle terminated

Example for the implementation of an automatic tool change

Step 1: Move punch to TDC position L 24

Step 2: Acknowledge message ‘Remove residual strip” L 35

Step 3: Move to previous tool hange position

Step 4: Move punch to LDC position

Step 5:

Step 6: Move punch to TDC position

Step 7: Acknowledge message “Remove tool” L 35

Each of these steps is implemented by an individual subroutine (standard cycles for tool

change operations). It suffices to enter the subroutines in the above order in the machine data

(MD 340 - MD 369).

8-8

Release tool clamp

Q Siemens AG 1991 All Rtghts Reserved

L 29

L 25

L 36

L 24

6ZB5 440.ONX02-OAAl

SINUMERIK 805SM-P (PJ)

Page 54

05.94 8 Tool Change

8.3.2 Example for the implementation of an automatic tool change

In this example, therefore, the following subroutine numbers would have to be entered:

MD 340 = 24

MD 341 = 35

MD 342 = 29

MD343=25

MD344=36

MD345 = 24

MD 346 = 35

MD 347 = 50

Subroutine No. 50 marks the terminating cycle and must always be entered for the reset of

the loop flag in the main program and thus for the correct termination of the tool change cycle.

Before starting the actual tool change, it must now be checked whether the step cycles used

require a PLC program supplement (see description of the individual step cycles in

Section 8.4).

8.3.3

Automatic stroke adjustment during the tool change

Depending on the type of blocking mechanism used,’ two ways of positioning are possible:

1. Absolute positioning (MD 5051.4 = 0)

A shaft can only be blocked and released in an absolute way in the “stroke adjustment

position”. For the stroke adjustment, the following sequence of subroutines must be called:

L 26: Move to the previous adjustment position (MD 420 - 439)

L 40: Block shaft and release eccentric

L 27: Move to the new adjustment position (MD 420 - 439)

L 41: Release shaft and block eccentric

2 Relative positioning (MD 5051.4 = 1)

The shaft can be blocked in any position (e.g. by a holding brake). The following sequence of

subroutines must be called:

L 40: Block shaft and release eccentric

L 27: Move to the new adjustment position (MD 420 - 439)

L 41: Release shaft and block eccentric

Depending on the hardware used, positioning in cycles L 26 and L27 can be implemented

either with NC function Ml9 or with press function “Brake cam positioning”.

You make your choice by means of a machine data bit.

MD 5051.3

= 0: Positioning with brake cam (cam 17)

1: Positioning with Ml9

@ Siemens AG 1991 All Rights Reserved 8ZB5 440-ONXOZ-OAA1

SINUMERIK 805SM-P (PJ)

8-9

Page 55

8 Tool Change

8.3.3 Automatic stroke adjustment during the tool change

Overview of machine data to be set for the stroke adjustment:

MD 5051.2

= 0: No correction of the anticipation angle

1: Automatic correction of the anticipation angle after the first positioning

attempt

MD 5051.3 = 0: Positioning with brake cam (cam 17)

1: Positioning with Ml9

MD 5051.4 = 0: Absolute positioning to the new adjustment position

1: Relative positioning, considering only the difference between the new

and the previous adjustment position

MD 377.. Anticipation angle to calculate the deceleration point (l/l0 degree)

MD 420

.

.

.

MD 439

>

Stroke adjustment position of the individual strokes

OS.94

9-10

0 Siemens AG 1991 All Rights Reserved

8ZB5 440-ONX02-OAAl

SINUMERIK 805SWP (PJ)

Page 56

12.91

8.3.4 Flowchart

,-m-e-.

I

4

-,-.,,J

Al JTOMATIC TOOL CHANGE (L 8)

I

I = Interrogation

8 Tool Change

8.3.4 Flowchart

--w-c--

------

1

AUTOMATIC TOOL CHANGE code

-----------a--

Disable cam

Enter subroutine no. from MD in - AUTOMAnC TOOL CHANGE

AUTOMATIC TOOL CHANGE

STARTED

ERROR’ DURING AUTOM. =3

MANUAL TOOL CHANGE

RUNNING

--we

-1

, F 137.1 ,

-----

1

a

a

CYCLE

END code

0 Siemens AG 1991 All Rights Reserved 6285 440=ONX02-OAAl

SINUMERIK 805SM-P (PJ)

r----

1 F 137.4

--e-w

1

,

8-l 1

Page 57

8 Tool Change

8.4 Description of the step cycles

12.91

8.4

L 20

L 21

L 22

Description of the step cycles

Decelerate main drive and wait for speed = 0

This cycle defines a setpoint of 0 for the main drive

+ The drive decelerates after the acceleration ramp (MD). The step cycle waits for