Page 1

SIROTEC ACR 20

SINUMERIK 805SM/840C

Link to SINEC L2–DP

with IM 329–N Module

Description 04.95 Edition

Manufacturer Documentation

Page 2

SIROTEC ACR 20

SINUMERIK 805SM/840C

General 1

Hardware 2

COM ET 200 for IM 329–N 3

Link to SINEC L2–DP

with IM 329–N Module

Description

Manufacturer Documentation

Description of the

Slave Functionality

Description of the

Master Functionality

Abbreviations A

References B

Index C

4

5

04.95 Edition

Page 3

3ls

SINUMERIK documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column.

A New documentation.. . . .

B Unrevised reprint with new Order No.. . . .

C Revised edition with new status.. . . .

If factual changes have been made on the page since the last edition, this is

indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

04.95 6ZB5 430–0BH02–0AA1 A

Siemens quality for software and training

to DIN ISO 9001, Reg. No. 2160–01

This publication was produced with Interleaf V 5.3

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG 1995. All rights reserved.

Order No. 6ZB5 430–0BH02–0AA1

Printed in the Federal Republic of Germany

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this publication agree with the

hardware and software described herein. The information given in this

publication is reviewed at regular intervals and any corrections that

might be necessary are made in the subsequent printings.

Suggestions for improvement are welcome at all times.

Subject to change without prior notice.

Siemens–Aktiengesellschaft

Page 4

04.95 Description

PRELIMINARY REMARKS

Notes to the reader

Target group

Contents

This description is aimed at machine manufacturers and service personnel

and describes the use of the IM 329–N module in SINUMERIK and SIROTEC as a slave and master in the ET 200 Distributed I/O System.

This manual provides information on

jumper settings on the module as well as interfaces and operating

elements

data required for configuring the module

installation and startup of the module

error messages and application examples

Note

The description of the ET 200 Distributed I/O System is to be found in:

Reference: /1/, ET 200 Distributed I/O System Manual

For the distributed I/O stations ET 200U, ET 200B and ET 200C etc. the

following separate manuals are available:

Reference: /2/, Distributed I/O Station Manual

Objective

Corrections/

suggestions

Searching aids

This description contains the information required for start–up and service.

A page for your corrections and suggestions is provided at the end of this

manual. Please fill in this form and send it back to us. This will help us to

improve the next edition.

So that you can find the information you need, this document not only contains a table of contents, a list of figures and a list of tables, but in the appendix you will also find:

1. A list of abbreviations

2. A list of references

3. An index

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

i

Page 5

04.95Description

Note

T ext marked in this way is important information to which the reader must

pay special attention.

Important

!

This symbol appears in documents wherever important information is given.

Ordering data option

This symbol indicates functions for which an ordering data option is required

(options). The function described can only be executed if the option designated is present.

ii

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 6

04.95 Description

Safety notes

Warning

!

Qualified

personnel

!

When electrical devices are in operation, certain parts of them are inevitably

subjected to hazardous voltages.

Improper interference with the device/system or failure to observe the

warning advice can result in serious physical injury or material damage.

Only appropriately trained personnel familiar with the assembly, installation, starting up or operation of the product are permitted to interfere with

this device/sytem.

Warning

Qualified persons as referred to in the safety guidelines (in the documentation or affixed to the product itself) are persons who, for instance:

Have received training or instruction and authorization to energize and

de-energize, ground and tag electric circuits and equipment in accordance with established safety practices.

Have received training or instruction in accordance with established

safety practices in the care, use and repair of appropriate safety

equipment.

Have received training or instruction in working with electrostatically

sensitive components or modules.

Have been instructed as operators to work with automation technology

equipment and are familiar with the contents in the Operator’s and/or

Programming Guide referring to operation.

Note

When planning, installing, starting up and operating the control, personnel

concerned must be familiar with the documentation relevant to their jobs.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

iii

Page 7

Danger notices

!

!

04.95Description

The notices and guidelines that follow are intended to ensure personal safety

and to protect the product described here or connected devices and machines

against damage.

The safety notices and guidelines intended to avert danger to human life and

health and to avoid material damage are emphasized in this Manual by the

terms defined below. The terms have the following meanings in the context

of this Manual and the notices on the product itself:

Danger

This symbol means that death, serious injury or considerable material damage will occur, if the precautionary measures indicated are not taken.

Caution

indicates that personal injury or property damage can result if proper precautions are not taken.

!

Intended use

Warning

indicates that death, severe personal injury or substantial property damage

can result if proper precautions are not taken.

The device/system or system component must be used only for the

applications specified in the Catalog and Reference Manual and only in

conjunction with such non-Siemens devices and components as have been

recommended and approved by Siemens.

The product described in the manual has been developed, manufactured,

tested and documented in compliance with the relevant safety standards.

Provided the handling instructions and safety guidelines described for

planning, assembling, proper operation and maintenance are observed, the

product will not normally be a source of danger leading to material

damage or physical injury.

iv

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 8

04.95 Description

Notes on product planning

As the product is generally part of larger systems or plants, these notes are

intended as a guideline for safe integration of a product in its environment.

Note the following in particular:

Note

Even when a maximum of safety has been included in the design of automation equipment, e.g. by means of a multi-channel configuration, the instructions given in the documentation must be followed exactly because incorrect

handling can render ineffective the preventive measures incorporated to

protect against dangerous faults or create new sources of danger.

Active and passive faults in automation equipment

Depending on the paricular task for which the electronic automation

equipment is used, both active and passive faults can be dangerous

faults. In the case of a drive control, for example, active faults are generally dangerous because they lead to unauthorized startup of the drive.

On the other hand, a passive fault can result in a dangerous operating state

not being reported to the operator.

This differentiation between possible faults and their task-related classifi-

cation as dangerous and non-dangerous faults is important for all the

safety considerations in respect of the product supplied.

Warning

!

Wherever a fault in the automation equipment can cause serious material

damage or even physical injury, in other words wherever dangerous faults

can occur, additional external precautions must be taken or devices provided

which will insure or enforce safe operating conditions even in the event of a

fault (e.g. by means of independent limit switches, mechanical interlocks

etc.).

Note

The information contained in this documentation is checked and updated

regularly and can be changed at any time without further notice.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

v

Page 9

Technical notes

04.95Description

Checking the

assignments

Operating the

module

Response of the

module

Difference between

the IM 328–N and

IM 329–N modules

Before start–up, please set the assignments on the module and on the front

panel as required for the application or check that they are set.

The IM 329–N module can be operated as follows:

Straight slave operation

Straight master operation

Simultaneous slave and master operation

From the point of view of the control, the module responds like an I/O

module.

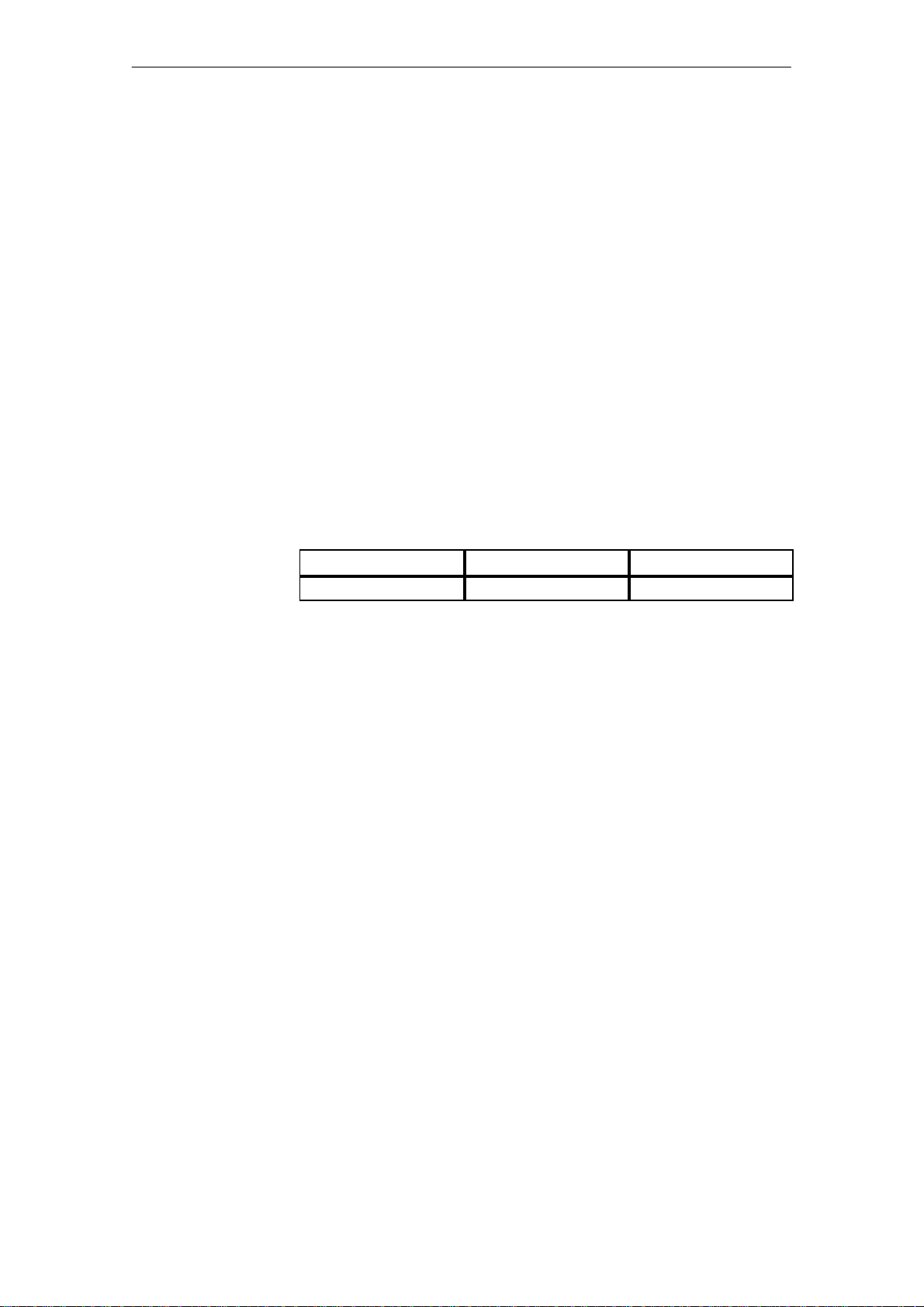

The modules IM 328–N and IM 329–N differ as follows

IM 328–N IM 329–N

Functionality Slave Slave and master

For information on the IM 328–N see:

Reference: /6/, Description

Link to SINEC L2–DP with IM 328–N Module

Trademarks

SIMATIC

, SINEC and SINUMERIK are registered trademarks of

SIEMENS AG.

vi

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 10

04.95 Description

Contents

1 General 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Hardware 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Module IM 329–N, master and slave 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Jumper settings 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Jumper settings on the slave 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Jumper settings on the master 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Elements on the front plate 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Elements for the slave 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Elemente für Master 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Technical data 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 COM ET 200 for IM 329–N 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Installation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 COM ET 200 parameterization software 3-2. . . . . . . . . . . . . . . . . . . . . . . . .

4 Description of the Slave Functionality 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Notes on parameterization of the slaves 4-1. . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Configuration example for slave 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Procedure for installation and startup 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Example of application 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Status display messages 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Normal operating state 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Fault during data transmission 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.3 Fault on the module (system error message) 4-11. . . . . . . . . . . . . . . . . . . . .

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B 4-12

4.6.1 Example: Diagnostics overview 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 Example: PLC STOP in the slave station 4-17. . . . . . . . . . . . . . . . . . . . . . . .

5 Description of the Master Functionality 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 General information about the master interface of the

IM 329–N 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Information about configuring the master interface 5-1. . . . . . . . . . . . . . . .

5.3 Sequence for start–up 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Signals and the status display 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Normal operating state 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Faults and signals 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Application example 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Abbreviations A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B References B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C Index Index-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

vii

Page 11

04.95 Description

1 General

1

General

SINEC L2–DP

field bus

Distributed I/O

system ET 200

Master stations

1

The SINEC L2–DP (DP = Distributed Peripherals) field bus is a distributed

I/O version of the SINEC L2 and is designed for minimum response times in

the communication with distributed I/O devices.

The ET 200 distributed I/O system (ET = Electronic Terminator) for SIMA-

TIC S5 uses the SINEC L2–DP field bus. The system is based on the PROFIBUS communications standard (DIN 19245, Part 1) and works on the master/

slave principle with the distributed I/O devices being the slaves.

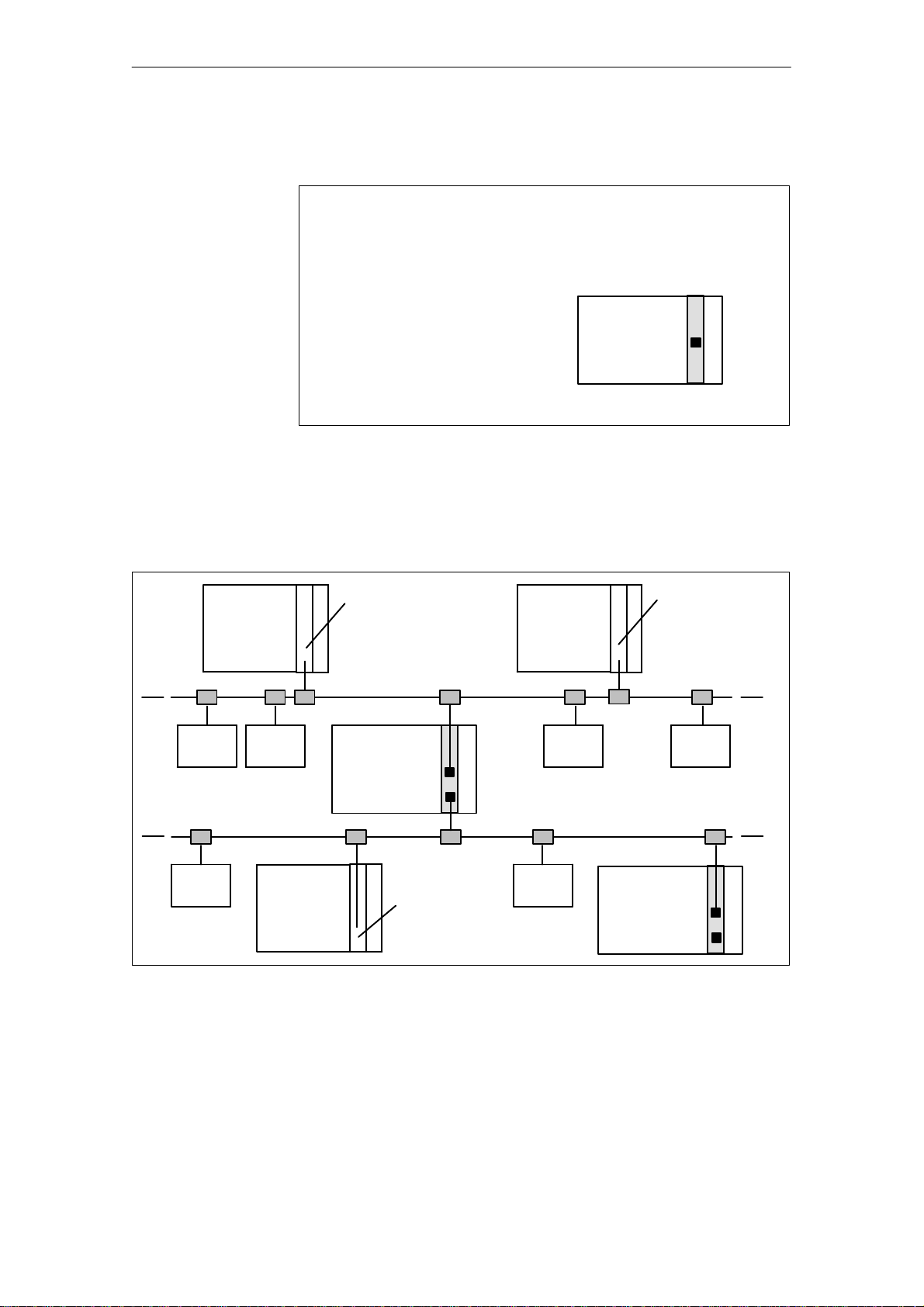

The following devices can be master stations:

SIMATIC S5 control

115U

135U

155U

with IM 308–B,

IM 308–C interface

Programming device

PG 730, PG 750 or PG 770

with CP 5410–S5DOS/ST

interface

SINUMERIK 805SM

SINUMERIK 840C

SIROTEC ACR 20

with module IM 329–N, master

or other master stations with PROFIBUS–DP

Fig. 1-1 Master stations

SINUMERIK

SIROTEC

+

or

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

1-1

Page 12

1 General

04.95Description

1

Slave stations

Example

The following can be slave stations:

Distributed I/O devices

e. g.

ET 200B

ET 200U

ET 200C

S5–95U–DP

SINUMERIK 805SM

SINUMERIK 840C

SIROTEC ACR 20

SINUMERIK

or

SIROTEC

with IM 329–N, DP slave module

or other PROFIBUS–DP slaves

Fig. 1-2 Slave stations

The diagram below gives an example of how to connect the master and slave

stations to the SINEC L2–DP field bus:

PG

Interface module

CP 5410–S5DOS/ST

master

Field bus SINEC L2–DP

Slaves

ET 200

SINUMERIK

or

SIROTEC

with interface

module

IM 329–N

Slaves

PG

Interface module

CP 5410–S5DOS/ST

master

Fig. 1-3 Using the module IM 329–N as a slave and master

Slave

Master

ET 200ET 200

SIMATIC

S5–155U

ET 200

Field bus SINEC L2–DP

Interface module

IM 308–B/C

master

ET 200ET 200

SINUMERIK

or

SIROTEC

with interface

module

IM 329–N

J

1-2

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 13

04.95 Description

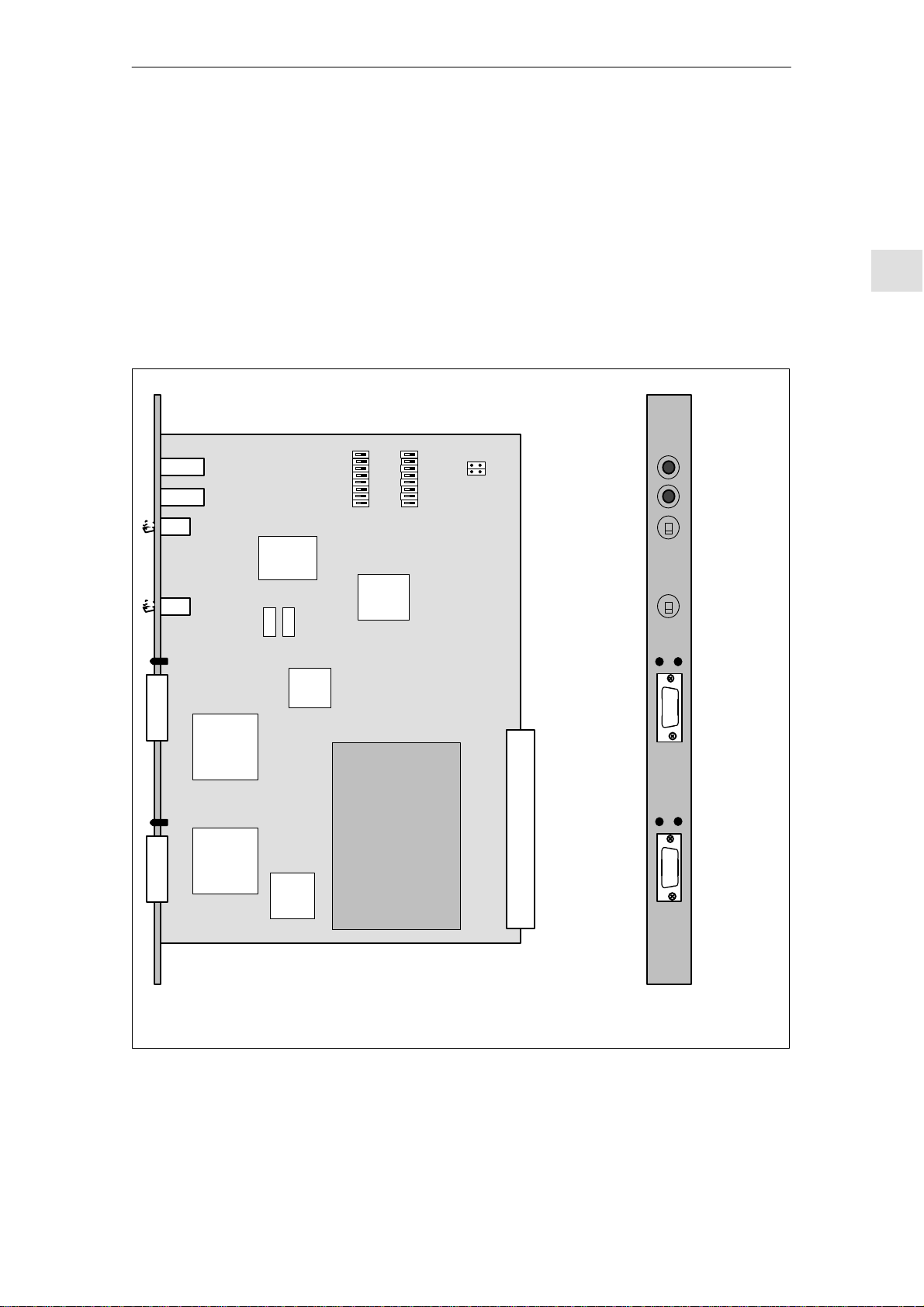

2.1 Module IM 329–N, master and slave

Hardware

2.1 Module IM 329–N, master and slave

Order No.: 6FC5 012–0CA02–0AA0

ON

S2.

8

X339

5

3

1

X21

DC/DC

converter

Slave

DC/DC

converter

Master

FEPROM

Quartz

Quartz

SPC

Dual

port

RAM

(DPR)

ON

8

5

3

1

S3.

80C32

Master

module

0

10

1

10

100–199

0–99

PARAMETERIZATION

(+ Station address slave = 0)

RUN

(+ Station address slave

between 3 and 124)

RUN

(green LED)

Slave

ACCESS

(green LED)

Bus connector

Master

2

2

Station

address

for slave

Units place

Tens place

Hundreds place

Operating

mode

master

Status display

FAULT

(red LED)

Interface

X111

Status display

FAULT

(red LED)

Interface

X112

X339: Both jumpers open

Fig. 2-1 Module IM 329–N, master and slave

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

2-1

Page 14

2.2 Jumper settings

2.2 Jumper settings

2.2.1 Jumper settings on the slave

04.95Description

2

Selecting the

control system

(S2.5, S2.6, S2.7

and S2.8)

Setting of address

range (number of

input and output

bytes) (S2.1 and

S2.2)

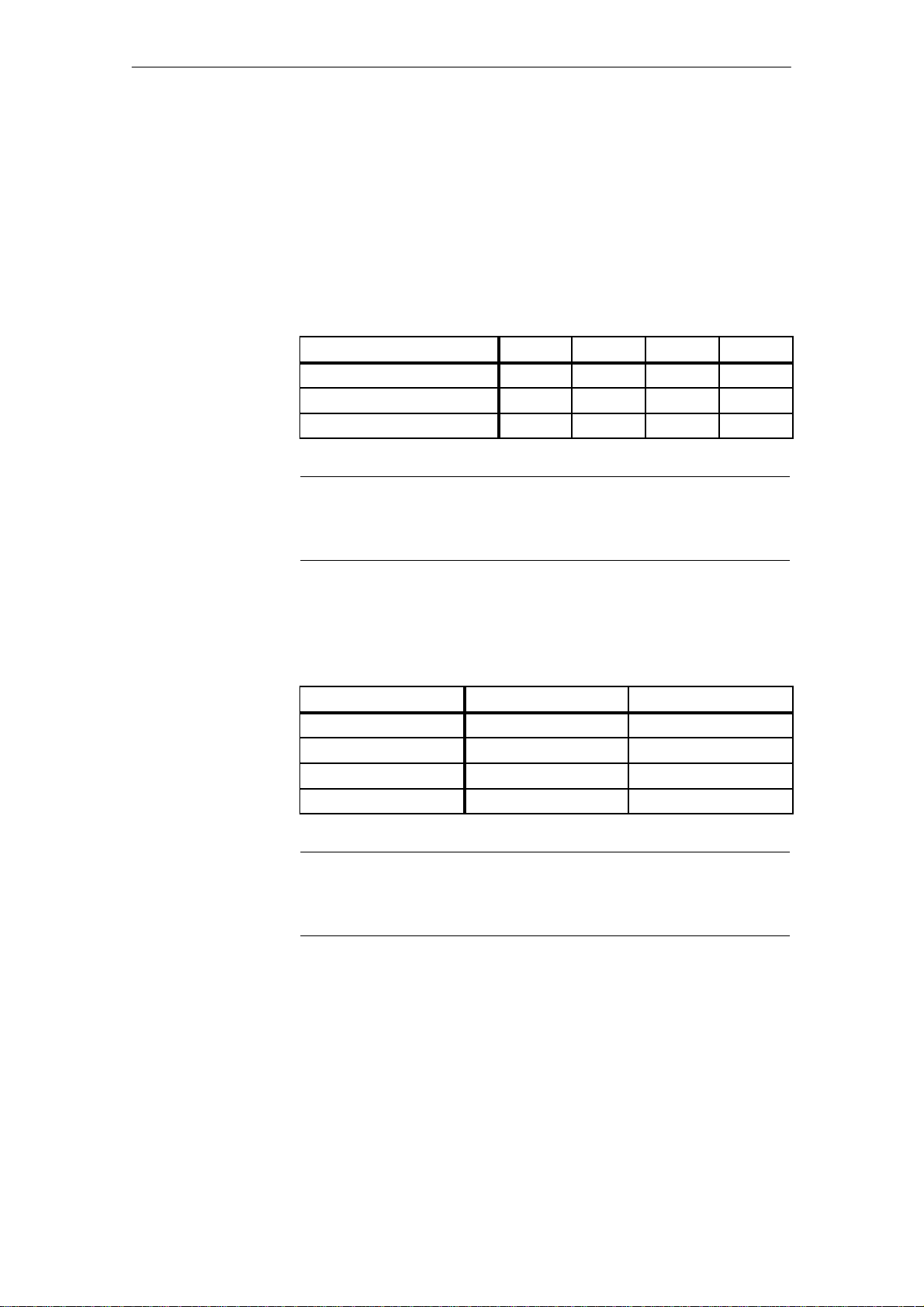

The module can be used in the control systems listed. The control type must

be set with switches S2.5, S2.6, S2.7 and S2.8 as follows:

S2.5 S2.6 S2.7 S2.8

SINUMERIK 805SM OFF ON OFF ON

SIROTEC ACR 20 ON ON ON ON

SINUMERIK 840C ON ON ON ON

Note

The IM 329–N module can only be used for SINUMERIK 805SM in the

central controller.

Switches S2.1 and S2.2 must be set according to the table below in order to

set the address range of 4, 8, 16 or 32 input or output bytes.

Address range S2.1 in position S2.2 in position

4 bytes OFF OFF

8 bytes OFF ON

16 bytes ON OFF

32 bytes ON ON

2-2

Note

Address range of, for example, 4 bytes means that 4 input bytes and 4 output

bytes are available with the same base address.

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 15

04.95 Description

2.2 Jumper settings

Setting the base

address

(S3.1 to S3.8)

Base address for

4-byte address range

The following switches are used to set the module numbers (base address)

S3.1 to S3.8 for an address range of 4 bytes

S3.2 to S3.8 for an address range of 8 bytes

S3.3 to S3.8 for an address range of 16 bytes

S3.4 to S3.8 for an address range of 32 bytes

Note

The switches not required for the 8, 16 and 32–bytes address ranges are irrelevant and any setting is permissible.

Switch S2.1 = OFF and S2.2 = OFF

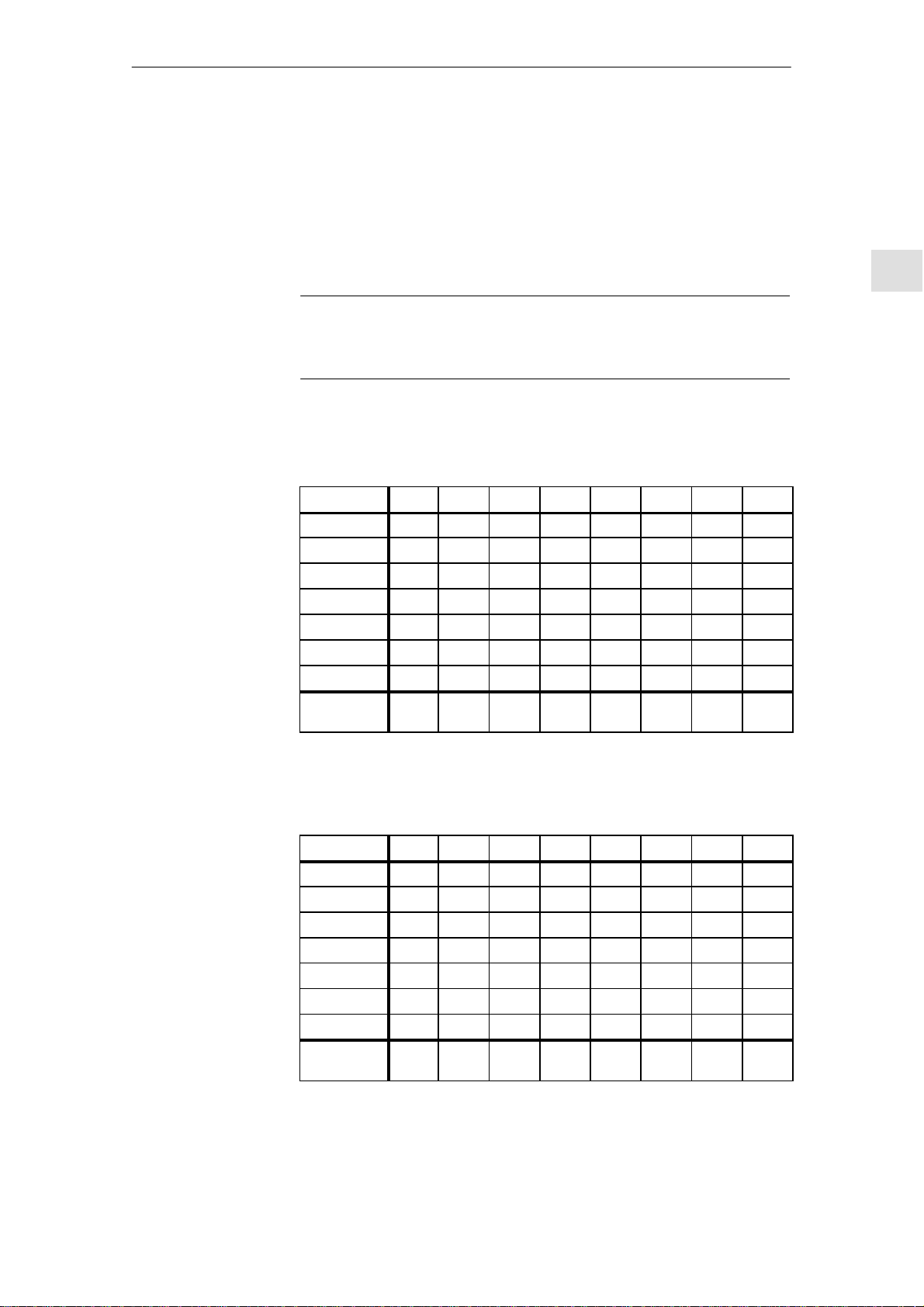

Base address S3.8 S3.7 S3.6 S3.5 S3.4 S3.3 S3.2 S3.1

0 ON ON ON ON ON ON ON ON

4 ON ON ON ON ON ON ON OFF

8 ON ON ON ON ON ON OFF ON

12 ON ON ON ON ON ON OFF OFF

16 ON ON ON ON ON OFF ON ON

: : : : : : : : :

1020 OFF OFF OFF OFF OFF OFF OFF OFF

Significance 2

=512

9

8

2

=256

7

2

=128

2

=64

6

2

=32

5

2

=16

4

2

=8

3

=4

2

2

2

Base address for

8-byte address range

Switch S2.1 = OFF and S2.2 = ON

Base address S3.8 S3.7 S3.6 S3.5 S3.4 S3.3 S3.2 S3.1

0 ON ON ON ON ON ON ON x

8 ON ON ON ON ON ON OFF x

16 ON ON ON ON ON OFF ON x

24 ON ON ON ON ON OFF OFF x

32 ON ON ON ON OFF ON ON x

: : : : : : : :

1016 OFF OFF OFF OFF OFF OFF OFF x

Significance 2

=512

9

8

2

=256

2

=128

x: Switch position of no significance

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

7

2

=64

6

2

=32

5

2

=16

4

2

=8

3

2-3

Page 16

2.2 Jumper settings

04.95Description

2

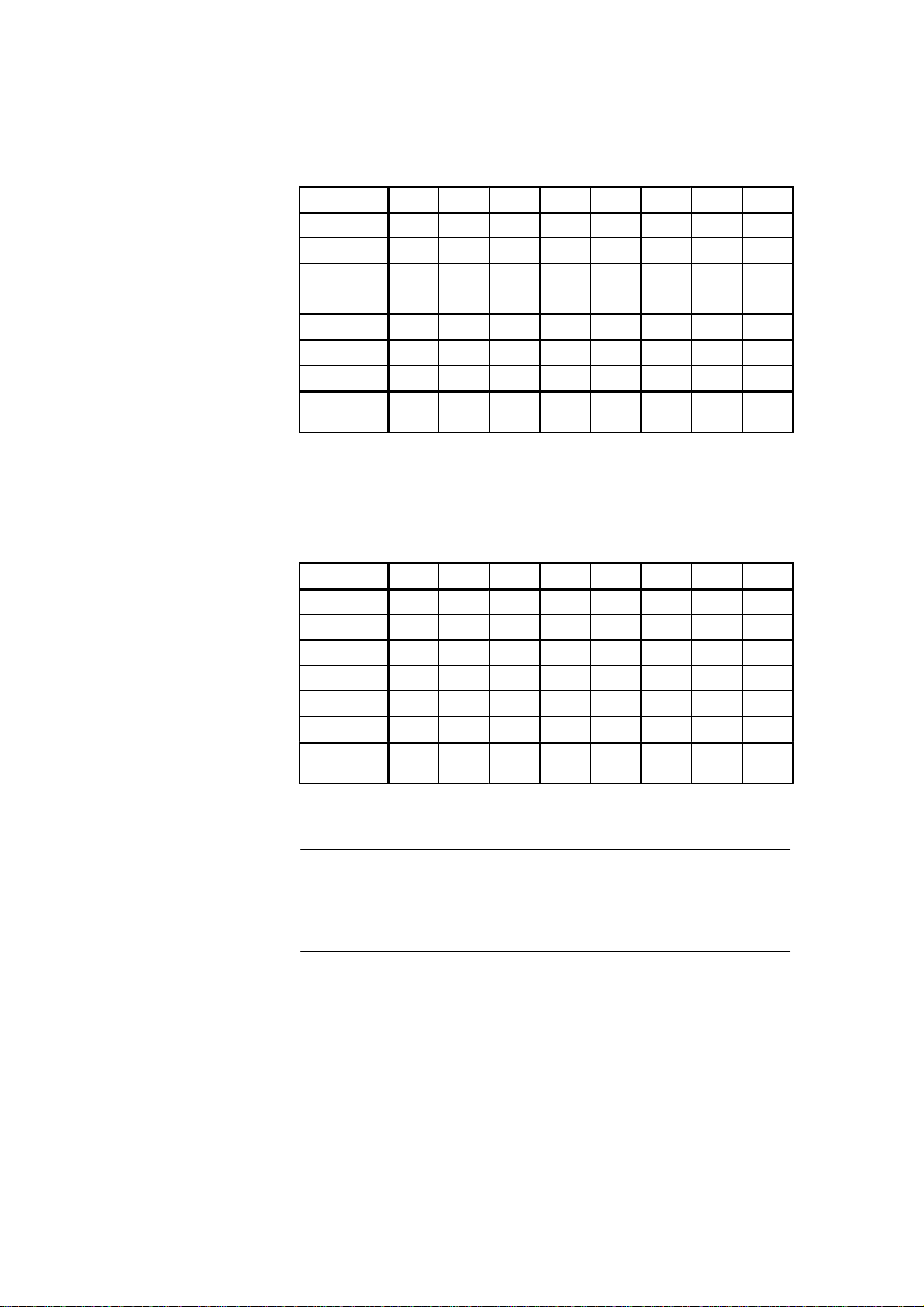

Base address for

16-byte address range

Base address for

32-byte address range

Switch S2.1 = ON and S2.2 = OFF

Base address S3.8 S3.7 S3.6 S3.5 S3.4 S3.3 S3.2 S3.1

0 ON ON ON ON ON ON x x

16 ON ON ON ON ON OFF x x

32 ON ON ON ON OFF ON x x

48 ON ON ON ON OFF OFF x x

54 ON ON ON OFF ON ON x x

: : : : : : :

1008 OFF OFF OFF OFF OFF OFF x x

Significance 2

=512

9

8

2

=256

7

2

=128

2

=64

6

2

=32

5

2

=16

4

x: Switch position of no significance

Switch S2.1 = ON and S2.2 = ON

Base address S3.8 S3.7 S3.6 S3.5 S3.4 S3.3 S3.2 S3.1

0 ON ON ON ON ON x x x

32 ON ON ON ON OFF x x x

64 ON ON ON OFF ON x x x

96 ON ON ON OFF OFF x x x

: : : : : :

992 OFF OFF OFF OFF OFF x x x

Significance 2

=512

9

8

2

=256

7

2

=128

2

=64

6

2

=32

5

Example of address

setting

2-4

x: Switch position of no significance

Note

Base addresses are only possible for 4–byte, 8–byte, 16–byte or 32–byte

steps depending on the address range. For example, an address range of 32

bytes permits only 0, 32, 64, 96 etc. as initial addresses.

Address range = 8 bytes and the base address is to be 24 ⇒

S2.1 = OFF and S2.2 = ON

S3.8, S3.7, S3.6, S3.5, S3.4 = ON and S3.3, S3.2 = OFF

The assigned input and output area is from IB 24/QB 24 to IB 31/QB 31.

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 17

04.95 Description

2.2 Jumper settings

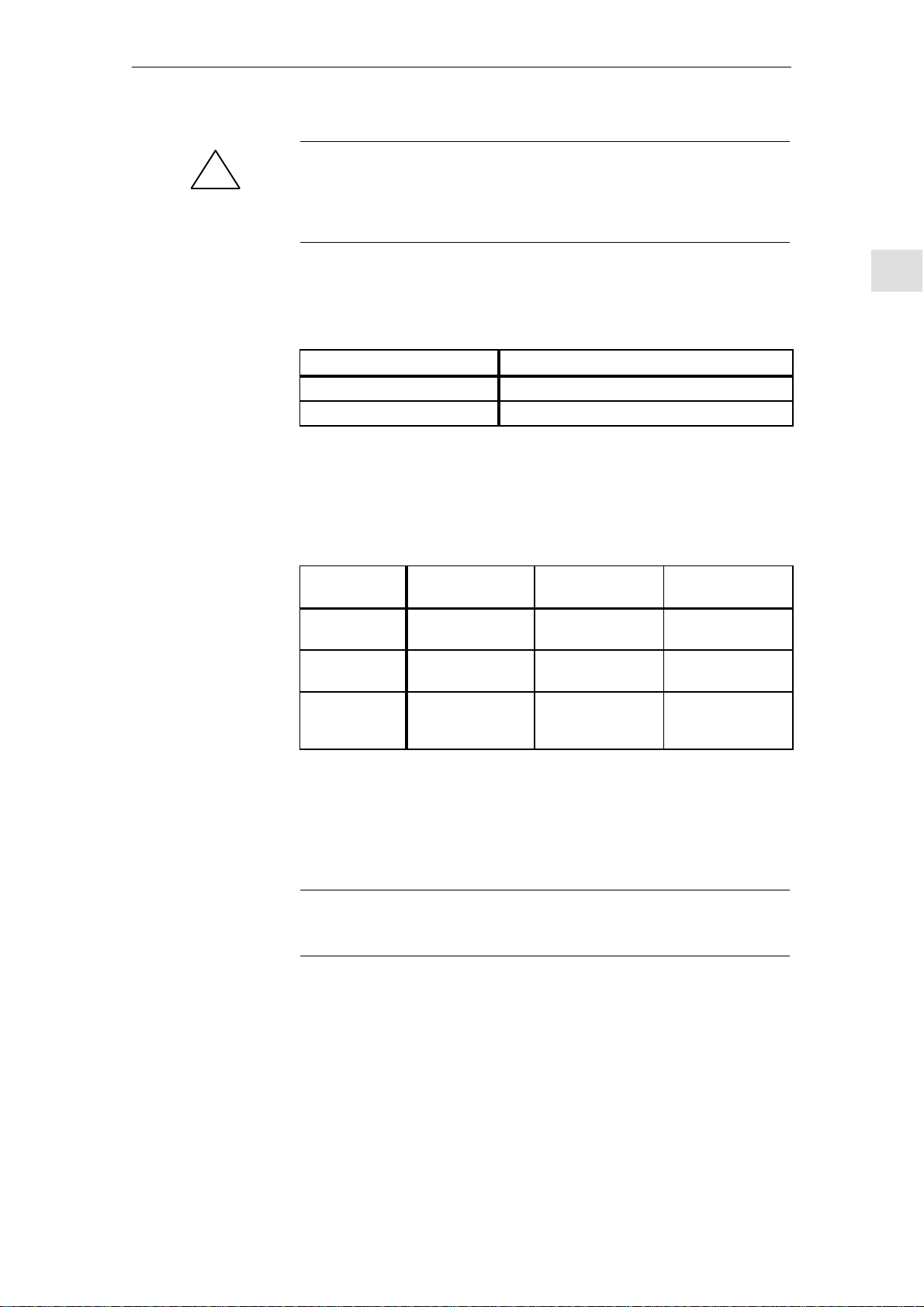

Danger

!

An incorrect setting of the base address (e.g. dual address assignment or address conflict with other I/O modules) results in “wrong signal states” and

can cause an undefined behaviour of the control and the machine!

2

Enable slave

(S2.3)

I/O ranges

S2.3 must be used to enable the slave functionality.

Switch S2.3 in position Function

OFF Slave disabled

ON Slave enabled

In assigning the slaves, please note that the following I/O ranges are available on the SIROTEC ACR 20, SINUMERIK 805SM and SINUMERIK 840C

controls:

SINUMERIK

805SM (SW4)

Inputs IB 0 to IB 47 I 1 to I 1024

Outputs QB 0 to QB 47 Q 1 to Q 1024

Physical interface without

process image

– – PB 0 to PB 255

SIROTEC ACR 20

(SW5)

(IB 0 to IB 127)

(QB 0 to QB 127)

SINUMERIK 840C

(SW4)

IB 0 to IB 127

QB 0 to QB 127

For the allocation of the I/O range for each control see:

Reference: /3/, SINUMERIK 805SM,

Interface Description, Part 2 – Connection Conditions

Reference: /4/, SIROTEC ACR 20, Configuration Instructions

Note

The I/O range must be addressed without gaps with SIROTEC ACR 20

Reference: /5/, SINUMERIK 840C

Interface Description, Part 2 – Connection Conditions

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

2-5

Page 18

2.2 Jumper settings

2.2.2 Jumper settings on the master

04.95Description

2

Enable master

(S2.4)

The master functionality must be enabled via S2.4.

Switch S2.4 in position Function

OFF Master disabled

ON Master enabled

Note

The addresses on the master are routed with the parameterization software

COM ET 200 (see Sections 3 and 5).

2-6

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 19

04.95 Description

2.3 Elements on the front plate

2.3 Elements on the front plate

2.3.1 Elements for the slave

Station address

Status display of

the slave (LEDs)

The rotary switch is used to set the units place (first switch from top) and the

tens place (second switch from top) of the station address.

The hundreds place of the station address depends on the setting of the toggle

switch (upper position = 1 x 100, lower position = 0 x 100). Valid station addresses are between 3 and 124.

Note

The software limits the station address to the range from 3 to 124.

A change in station address does not become active until after a restart of

the control.

The status display (FAULT and RUN LED) can indicate the following states

of the SINEC L2–DP slave module.

RUN

(green LED)

off on The module is being initialized

on off Normal operating state, slave in cyclic operation

Other states Fault (see Section 4.5)

FAULT

(red LED)

Remark

(this state only lasts for a short period of time)

2

Interface for slave

Via the interface X111 (SUB–D, socket, 9–way) the slave is connected to the

SINEC L2–DP field bus.

Note

T o connect up to the SINEC L2–DP field bus, the bus connectors with the

following order numbers are required:

Order number Designation

6ES5 762–2AA12 SINEC L2 bus connector (degree of protection IP 20, without

heavy–duty thread socket)

6ES5 762–2AA21 SINEC L2 bus connector (degree of protection IP 20, with

heavy–duty thread socket)

For information about the bus cable and the bus connector see:

Reference: /1/, ET 200 Distributed I/O System Manual

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

2-7

Page 20

2.3 Elements on the front plate

2.3.2 Elements for the master

04.95Description

2

Status display of

the masters (LED)

Operating mode

!

The status display (ACCESS and FAULT LED) can indicate the following

messages:

ACCESS

(green LED)

on off Normal operating state

Other states Fault or message (see Section 5.4)

The operating mode of the master can be set with this toggle switch:

(+ station address for slave = 0)

(+ station address for slave between 3 and 124)

Caution

The parameterization data on the module are deleted if

FAULT

(red LED)

Position Operating mode

Top

Bottom

Remark

PARAMETERIZATION

RUN

the PARAMETERIZATION mode is set and

Interface for

master

a RESTART of the control is performed (see Section 5.3)

Via the interface X112 (SUB–D, socket, 9–way) the master is connected to

the SINEC L2–DP field bus.

Note

T o connect up to the SINEC L2–DP field bus, the bus connectors with the

following order numbers are required:

Order number Designation

6ES5 762–2AA12 SINEC L2 bus connector (degree of protection IP 20, without

heavy–duty thread socket)

6ES5 762–2AA21 SINEC L2 bus connector (degree of protection IP 20, with

heavy–duty thread socket)

For information about the bus cable and the bus connector see:

Reference: /1/, ET 200 Distributed I/O System Manual

2-8

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 21

04.95 Description

2.4 Technical data

2.4 Technical data

Type Value

PCB format Double–height Eurocard format

(160 x 233.4 mm)

Width of front panel 1 1/3 SEP, metal (1 SEP = 15.24 mm)

Front connector 9–pin, SUB–D female connector

(bus interface)

Degree of protection IP 00 to DIN 40050

Permissible ambient temperature

during operation

Transport and storage temperature – 40 to + 70° Celsius

Humidity class F to DIN 40040

Shock resistance Class 12 to SN 29010

Mass 400 g

Power supply + 5 V (+/– 5%), 1.6 A

0 to + 55° Celsius

max

2

J

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

2-9

Page 22

04.95 Description

3.1 Installation

COM ET 200 for IM 329–N

With the COM ET 200 parameterization software, you can configure the

IM 329–N master, create the address list and analyze diagnostics data.

Version of

COM ET 200

3.1 Installation

For information

about

In this description, it is assumed you have the parameterization software

COM ET 200 Version 4.x.

Which PG/PC can be operated on the SINEC L2–DP bus?

How is the CP 5410 S5DOS/ST installed?

How is the COM ET 200 installed on the PG?

see:

Reference: /1/, ET 200 Distributed I/O System Manual

3

3

Installation of the

type file for

IM 329–N, slave

For parameterization of the slave interface of the IM 329–N with COM ET

200, the appropriate type file is required. The type files have the following

designations:

File name Designation

SI8024TD.200 German

SI8024TE.200 English

SI8024TF.200 French

SI8024TS.200 Spanish

SI8024TI.200 Italian

Note

If the appropriate type file is not contained in the directory of COM ET 200,

please contact your SIEMENS representative.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

3-1

Page 23

3.2 COM ET 200 parameterization software

3.2 COM ET 200 parameterization software

04.95Description

3

Principle

Start–up and

language selection

Function selection

With the ET 200 Distributed I/O Sysrem, the master is always configured

with the COM ET 200 configuration software. The parameters for the slaves

are then transferred during system start–up.

After start–up of the COM ET 200 package, the required language can be

selected. Five languages are available. After that, COM ET 200 branches to

the screen form FUNCTION SELECTION.

This screen form is the main screen form. Here, you are prompted to specify

a program file in which to store the parameters and data entered. Select a

name with up to 6 letters. Blanks are filled in by COM ET 200 (e.g.

“C:BEISP@ET.200”).

In this screen form, you can press one of the following softkeys:

F1: Enter the ET 200 system parameters

F2: Configuration

F3: Transfer functions

F4: Plant documentation

F5: Start–up / test

F6: Diagnostics

Selecting the

master type

ET 200

system parameters

Configuring

After input of the new program file and confirmation, e.g., of softkey F1 in

the function selection screen form, you are prompted to select the master

type.

Please select:

<F1>: DP master is an IM 308–B

<F3>: General DP master

Fig. 3-1 Selecting the master type

After you have selected the master type, the following functions are available:

Here you enter all parameters required for the correct operation of system ET

200, such as baud rate, type of addressing, CPU type, and behaviour in the

case of a station failure.

Enter the CONFIGURING data of each individual ET 200 slave station in the

configuring screen form.

3-2

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 24

04.95 Description

3.2 COM ET 200 parameterization software

TRANSFER

functions

Address assign–

ment and system

documentation

The TRANSFER FUNCTIONS screen form permits the following for a memory module:

Programming of a memory module with system parameters and configu-

ration data for the IM 308–B.

Read–in of a memory module into a program file

Comparison of the creation data from program file and memory module.

Moreover, you can transfer the configuration data created with COM ET 200

to a SINEC L2–DP master (such as the IM329–N)

This screen form gives you information about the current configuration status, e.g. via the

Set ET 200 system parameters

Assigned station numbers

Station–oriented address assignment for one station you obtain the infor-

mation:

Query:

In which slot is the module inserted?

What addresses do the inputs and outputs have?

Address assignment range–oriented for one address range each

(e.g. the P range):

Which inputs and outputs are assigned to which stations?

T o which slot and to which module type is each input and output

assigned?

3

Startup/test

Diagnostics

You can also print out the current configuration status.

This screen form enables you to verify whether the configured configuration

of a station corresponds to the actual configuration.

Form the STARTUP/TEST screen form you automatically enter the screen

form MODULE SELECTION or STATUS/FORCE.

In the STATUS/FORCE screen form, you can see the signal condition of the

inputs of all selected modules. It is also possible to force the outputs of the

modules selected.

The DIAGNOSTICS OVERVIEW screen form lists the stations for which

diagnostics data exist.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

3-3

Page 25

3

04.95Description

3.2 COM ET 200 parameterization software

In the INDIVIDUAL DIAGNOSTICS screen form, you can obtain the

following information about the required station:

S Stations number

S Station type

S Station designation

S Station status

S Device and ID–related diagnostics

Note

For operation of the software and detailed information on the functions and

parameters of the COM ET 200, please refer to

Reference: /1/, ET 200 Distributed I/O System Manual

J

3-4

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 26

04.95 Description

4.1 Notes on parameterization of the slaves

Description of the Slave Functionality

4.1 Notes on parameterization of the slaves

Here are some notes that must be observed when the IM 329–N is used as a

slave station in the ET 200 Distributed I/O System. For example, the master

IM 308–B or IM 329–N can be used.

Note

Page addressing is not possible!

Prerequisites

for slave parameterization

If the module IM 308–B is the master

PG/PC with COM ET 200 (V4.x)

If the module IM 329–N is the master

See Section 5

4

4

ET 200 system

parameters if the

master IM 308–B

is used

ET 200 system

parameter if the

master IM 329–N

is used

Note

About the system parameter BUS PROFILE:

Select the bus profile “DP standard” or

“DP/FMS operation”

About the baud rate:

Baud rates up to 1500 kBaud are possible.

Note

See Section 5

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-1

Page 27

4.1 Notes on parameterization of the slaves

04.95Description

4

Configuration

There is a separate configuration screen form to configure the slave interface

of the IM 329–N. T o make this screen form available, the appropriate type

file must be installed (see Section 3.1).

Note

Station No.:

Station numbers from 3 to 124 are allowed.

Station type:

Station type “IM 329–N slave DP” must be used to configure station type

IM 329–N, DP slave.

Station name:

Here you can enter a name for the station (all keyboard characters are

allowed).

First free address:

The address of the first free byte as seen from the master is displayed for

DI (digital inputs)

DQ (digital outputs)

The first address can also be entered and defined manually.

Configuration field:

Depending on the address range, you can enter the following address

identifiers in these input fields:

Address range Address ID 0 Address ID 1

4 bytes

8 bytes 55

16 bytes 63

32 bytes (2 16 bytes) 63

51

dec

dec

dec

dec

63

–

–

–

dec

The address IDs follow DIN E 19245 Part 3.

Pressing the ENTER softkey stores the configuration data for this station

in the specified program file.

4-2

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 28

04.95 Description

4.2 Configuration example

4.2 Configuration example for slave

The text below describes the configuration data for integrating a slave IM

329–N into an already existing ET 200 distributed I/O system.

Assumptions

The configuration data are stored in the program file C:BEISP@ET.200.

Slave stations exist with station numbers 3 and 4.

A SIMATIC S5–115U is available as master PLC (linear addressing, I/O

range =P, 256 input and output bytes).

Configuration data of a new station:

Station address and name; 5, example for IM 329–N slave

First available address: DI: 96, DQ: 96

Address range = 4 bytes ⇒ Address identifier = 51

(see Section 4.1)

Based on the above assumptions, the CONFIGURING screen form must be

parameterized as follows:

4

Program file selected C: BEISP@ET.200

CONFIGURING

Station No.: Area: Station type:

Station name:

First available address:

Configuration:

5P

Example for IM 329–N Slave

DI: DQ: AI: AQ:

96 96

Module address: I: Q:

0. 1. 2. 3. 4. 5. 6. 7.

51

8. 9. 10. 11. 12. 13. 14. 15.

16. 17. 18. 19. 20. 21. 22. 23.

24. 25. 26. 27. 28. 29. 30. 31.

F1

STATION

+

Fig. 4-1 CONFIGURING screen form

F2 F3 F4 F5 F6 F7 F8

STATION

–

DELETE

STATION

NEW

STATION

SIMATIC S5 / COM ET 200

IM 329–N slave DP

ADDRESS

ASSIGNM. ENTER HELP EXIT

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-3

Page 29

4

04.95Description

4.3 Procedure for installation and startup

4.3 Procedure for installation and startup

The following procedure is recommended for installation and startup of a

station with an IM 329–N, DP slave:

Set and check the following data on the module in accordance with Sec-

tion 2.2.1 :

– Control type

– Address range (number of input and output bytes)

– Base address

– Enable slave functionality

Install the module in the control:

– Switch off the control

– Plug the module into a valid slot, see information for the relevant con-

trol in

Reference: /3/, SINUMERIK 805SM,

Interface Description, Part 2 – Connection Conditions

Reference: /4/, SIROTEC ACR 20, Configuration Instructions

Reference: /5/, SINUMERIK 840C

Interface Description, Part 2 – Connection Conditions

– Set the station address on the front panel in accordance with Section

2.3.1.

– Connect the module to the SINEC L2–DP field bus

– Switch on the control (POWER ON) and perform a RESTART of the

PLC if required

Note

On the SINUMERIK 840C, I/O modules that have just been slotted in are

not recognized until a cold RESTART of the control is performed.

Modify the configuration of the master (e.g. IM 308–B):

– Add the configuration data of the new station to the existing program

file

– For the IM 308–B: Write to the memory module

For the IM 329–N, master: perform DOWNLOAD (see Section 5)

– Program and activate monitoring and diagnostics functions on the ma-

ster and slave sides.

4-4

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 30

04.95 Description

4.4 Example of application

4.4 Example of application

The SINUMERIK 805SM, SINUMERIK 840C and SIROTEC ACR 20 controls are to be linked via the ET 200 distributed I/O system and via a master

control, such as the SIMATIC S5–115U (master PLC link).

Master

SIMATIC

S5–115U

SINEC L2–DP

Slaves

SINUMERIK

805SM

Fig. 4-2 Example of application: Master PLC link

Assumptions for

the example

The following assumptions are made for the example:

The configuration data are stored in the BEISP@ET.200 program file.

SINUMERIK

A SIMATIC S5–115U is used as master PLC (linear addressing,

I/O area = P, 256 input and output bytes, first available address is IB 96 /

QB 96.

The station addresses 3, 4 and 5 are to be set on the IM 329–N slave inter-

face modules of the individual controls.

The address range for the stations 3, 4, 5 is to be 4 bytes, 8 bytes, 32 bytes

and the base addresses for the input and output bytes are to be IB 16/

QB 16, IB 40/QB 40 und IB 64 (I 513 to I 520)/QB 64 (Q 513 to Q 520).

The ET 200 system parameters have been determined for this application

and entered in the program file.

840C

SIROTEC

ACR 20

4

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-5

Page 31

4.4 Example of application

04.95Description

4

Hardware

settings

For use in the controls, the individual SINEC L2–DP slave interface modules

are to be set as follows:

Selection of the control system

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

ON

S2.8

S2.7

S2.6

S2.5

ON

S2.8

S2.7

S2.6

S2.5

ON

S2.8

S2.7

S2.6

S2.5

Setting of address range

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

ON S2.1

S2.2

ON S2.1

S2.2

ON S2.1

S2.2

4 byte 8 byte 32 byte

Setting of base address

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

S3.8

ON

S3.1

IB 16/QB 16

ON S3.2

IB 40/QB 40 IB 64/QB 64

S3.8

ON S3.4

(I 513/Q 513)

Enable slave

Master disabled

ON S2.3

S2.4

Slave enabled

Station address for slave (to be set on the front panel)

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

Units place = 3 Units place = 4 Units place = 5

T ens place = 0 Tens place = 0 T ens place = 0

Hundreds place = 0 Hundreds place = 0 Hundreds place = 0

S3.8

4-6

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 32

04.95 Description

4.4 Example of application

Configuring

(configuration

Based on the assumptions for the individual stations, the CONFIGURING

screen form is to be parameterized as follows:

data)

Program file selected C:BEISP@ET.200

CONFIGURING

Station No.: Area: Station type:

Station name:

First available address:

Configuration:

3P

IM 329–N slave interface module SINUMERIK 805SM

DI: DQ: AI: AQ:

96 96

Module address: I: Q:

0. 1. 2. 3. 4. 5. 6. 7.

51

8. 9. 10. 11. 12. 13. 14. 15.

16. 17. 18. 19. 20. 21. 22. 23.

24. 25. 26. 27. 28. 29. 30. 31.

Fig. 4-3 Configuration of the slave in SINUMERIK 805SM

SIMATIC S5 / COM ET 200

IM 329–N slave DP

4

Program file selected BEISP@ET.200

CONFIGURING

Station No.:

Station name:

First available address:

Configuration:

Area

4P

IM 329–N–slave interface module SINUMERIK 840C

DI: DQ: AI: AQ:

100

Station type:

100

Module address:

0. 1. 2. 3. 4. 5. 6. 7.

55

8. 9. 10. 11. 12. 13. 14. 15.

16. 17. 18. 19. 20. 21. 22. 23.

24. 25. 26. 27. 28. 29. 30. 31.

Fig. 4-4 Configuration of the slave in SINUMERIK 840C

SIMATIC S5 / COM ET 200

IM 329–N slave DP

I: Q:

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-7

Page 33

4.4 Example of application

04.95Description

4

Program file selected: C:BEISP@ET.200

CONFIGURING

Station number: Area: Station type:

Station name:

First available address:

Configuration:

5P

IM 329–N slave interface module in the SIROTEC ACR 20

DI: DQ: AI: AQ:

108

108

Module address: I: Q:

0. 1. 2. 3. 4. 5. 6. 7.

63

63

8. 9. 10. 11. 12. 13. 14. 15.

16. 17. 18. 19. 20. 21. 22. 23.

24. 25. 26. 27. 28. 29. 30. 31.

Fig. 4-5 Configuration of the slave in SIROTEC ACR 20

SIMATIC S5 / COM ET 200

IM 329–N slave DP

4-8

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 34

04.95 Description

4.4 Example of application

Data transfer

diagram

The diagram below illustrates the data transfer of the input and output signals

between the master (SIMATIC S5–115U) und the slaves

(SINUMERIK 805SM, SINUMERIK 840C and SIROTEC ACR 20).

SIMATIC S5–115U

IB 96

:

IB 99

IB 100

:

IB 107

IB 108

:

IB 139

QB 96

:

QB 99

QB 100

:

QB 107

QB 108

:

QB 139

4

IB 16

:

IB 19

QB 16

:

QB 19

IB 40

:

IB 47

QB 40

:

QB 47

IB 64

(I 513

to

I 520)

:

IB 95

(I 753

to

I 760)

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

Fig. 4-6 Overview of data transfer

QB 64

(Q 513

to

Q 520)

:

QB 95

(Q 753

to

Q 760)

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-9

Page 35

4.5 Status display messages

4.5 Status display messages

4.5.1 Normal operating state

Normal operation is displayed via the status display as follows:

04.95Description

4

RUN

(green LED)

on off Normal operation, slave is in cyclic mode

FAULT

(red LED)

4.5.2 Fault during data transmission

The following faults are possible in data transmission:

Slave disconnected from the bus (e.g. bus connector unplugged)

Master broken down or switched off

Configuration of the slave does not correspond to the configuration data

of the master

Status display

slave

If threshold monitoring (system parameter) is activated, a fault in data transmission (i.e. a bus fault) is displayed by the STATUS DISPLAY SLAVE as

follows:

RUN

(green LED)

on on Fault during data transmission

FAULT

(red LED)

Meaning

Meaning

Effects of fault

!

4-10

Reset of the inputs implemented by the slave in the slave station.

Cyclic attempt of the module to link to the SINEC L2-DP bus.

Warning

If no response monitoring is activated, the inputs of the station concerned are

also not reset if a fault occurs but they remain unchanged.

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 36

04.95 Description

module

4.5 Status display messages

Monitoring of

cyclic operation on

the slave side by

The user can detect a fault in data transmission, that is, a fault of the cyclic

operation between master and slave on the slave side by means of a userdefined sign-of-life bit (pre-condition: threshold monitoring activated).

the user

Example

An output bit of the slave to be monitored is set on the master side and the

signal state of the corresponding input bit is read on the slave side and it is

evaluated as follows:

1 signal: Cyclic operation between master and slave running

0 signal: Fault during cyclic operation, data transmission fault.

Based on the signal state of this input bit, the user can have a suitable error

message displayed and can program the behaviour of the control in the case

of this fault.

4.5.3 Fault on the module (system error message)

System error messages are indicated by the flashing of the slave status

indicator (FAULT, red LED).

Possible faults

4

Consequences

Slave status indicator

FAULT LED, red

1 time on, pause, 1 time on, ... Slave functionality and

2 times on, pause, 2 times on, ..

3 times on, pause, 3 times on, ..

4 times on, pause, 4 times on, ..

Error message Comment

Slave must be enabled

master functionality

disabled

Hardware fault on

module

via S2.3, master must be

enabled via S2.4

(see Section 2.2.1)

Replace module

Interface to the local bus of the control is disabled. When the module is

accessed, the control reacts with acknowledgement delay (TO).

Cyclic data transmission between master and slave is terminated.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-11

Page 37

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

4.6 Diagnostics functions in the STEP 5 program of the

master IM 308–B

04.95Description

4

General notes on

diagnostics

The STEP 5 program of the IM 308–B master can request and evaluate the

following diagnostics messages via the IM 329–N slave:

Diagnostics type Request Description

Diagnostics “Overview” 127,0 Records all the stations for which

diagnostics data exist

Diagnostics “Parameter assignment and addressability”

Station status n,0

Device–related diagnostics

(stations diagnostics)

Identifier–related diagnostics

(module diagnostics)

n: Station number

126,n Records all stations that can be para-

meterized and addressed

Provides information about the status

n,1

n,2

n,3 Provides information about the status

n,4 Not used by slave IM 329–N

of the slave station

of the PLC in which slave IM 329–N

is slotted (PLC in RUN or in STOP?)

Diagnostics “Overview” and “Parameter assignment and addressability”

are described in

Reference: /1/, ET 200 Distributed I/O System Manual

Enabling

diagnostics

because they can be used on all slave stations.

The diagnostics function must first be enabled in the ET 200 SYSTEM PARAMETER screen form (Y) and a diagnostics address must be specified (default diagnostics address: 252).

Diagnostics:

Y

Diagnostics address: 252

The diagnostics address is the address of the diagnostics word. The diagnostics data area of the master can be accessed with the diagnostics word. If an

error occurs, the slave stations send the diagnostics data to the master.

The two diagnostics bytes of the diagnostics word will be referred to as

DIAGNOSTICS ADDRESS (default: I/O byte 252) and DIAGNOSTICS

ADDRESS +1 (default: I/O byte 253).

By combining different diagnostics, appropriate conclusions can be drawn

such as, for example, station with fault and can be contacted.

4-12

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 38

04.95 Description

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

Immediately after diagnostics is called in the STEP 5 program, the

diagnostics data are accessed and the diagnostics message is given in the

diagnostics word.

.

.

.

Diagnostics dataDiagnostics word

Call

diagnostics

Read

diagnostics

.

.

.

Fig. 4-7 Request and read diagnostics

4

Important

diagnostics for

IM 329-N, slave

Structure and

requesting

diagnostics

For the slave IM 329–N the following diagnostics are of considerable

importance:

Station status

Device–oriented diagnostics (station diagnostics)

The diagnostics are loaded and transferred with the following instructions:

L KY (station number), (code) Station number 3 to 124

Code: 0 to 7

T PW 252 After that, the station diagnostics are

transferred to the diagnostics word

Eight words in each slave station are reserved for station status, device–

oriented (station diagnostics) and ID–oriented diagnostics (module

diagnostics).

Code Diagnostics address Diagnostics address + 1

0 Station status 1 Station status 2

1 Station status 3 Master address

2 Manufacturer ID

3 Header Device–oriented diagnostics

(station diagnostics)

4 Header ID–oriented diagnostics

(module diagnostics)

5 Unused Unused

6 Unused Unused

7 Unused Unused

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-13

Page 39

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

04.95Description

4

Requesting station

status and

evaluating

Code = 0 and

Code = 1

The bytes “Station status 1 to 3” provide information about the station. The

byte “Master address” contains the address of the master station that the slave

station has parameterized.

L KY n, 0 Load diagnostics for Code 0 (n=station number)

T PW 252 and transfer the diagnostics words

L KH 0004 Load the comparison word

L PW 252 Read the diagnostics word

!=F If the diagnostics word is not equal to the comparison word

BEB then

SPB FBx evaluate fault in FBx

L KY n, 1 Load diagnostics for Code 1 (n = station number)

T PW 252 and transfer the diagnostics word

L PW 252 Read and evaluate the diagnostics word

Code = 0 Station status 1 Station status 2

7654321076543210

Bit:

Slave station has been parameterized by another master

Slave station is not an

IM 329–N (parameter error)

Bit is always “0”

Function is not supported

Device–oriented or

ID–oriented diagnostics exists

The configuration data sent from the master to

the slave station does not match the structure

of the slave station

Slave station is not ready for

data exchange

Must be reparameterized

Slave station cannot continue

until fault is remedied

Bit is always “1”

Response monitoring is activated

Slave station is in

“FREEZE” mode

Slave station is in “SYNC” mode

Bit is always “0”

Slave station is deactivated

Slave station cannot be addressed

Note: Description of bits refers to the bit set.

Fig. 4-8 Structure of the diagnostics word after request with Code = 0

Code = 1 Station status 3 Master address

7654321076543210

Bit:

Without meaning

Fig. 4-9 Structure of the diagnostics word after request with Code = 1

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

4-14

Address of the master

that has parameterized

the slave station

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 40

04.95 Description

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

Requesting

manufacturer ID

Code = 2

The byte “Manufacturer ID” describes the type of slave station.

L KY n, 2 Load diagnostics for Code 2 (n = station number)

T PW 252 and transfer the diagnostics words

L PW 252 Read and evaluate the diagnostics word

Code = 2 Manufacturer ID

7654321076543210

Bit:

The manufacturer ID for IM 329–N, DP slave is 8024

Fig. 4-10 Structure of the diagnostics word after request with Code = 2

Requesting and

reading deviceoriented

diagnostics

Code = 3

With the device–oriented diagnostics (station diagnostics) you can ascertain

whether the PLC is in RUN or STOP state.

L KY n, 3 Load diagnostics for Code 3 (n = station number)

T PW 252 and transfer the diagnostics words

L KH 0200 Read and evaluate the diagnostics word

L PW 252 Read the diagnostics word

!=F If the diagnostics word is not equal to the comparison word

BEB then

SPB FBx evaluate fault in FBx

hex

4

Code = 3 Header

Bit:

7654321076543210

Code for

device–

oriented

diagnostics

Fig. 4-11 Structure of the diagnostics word after request with Code = 3

Length of the device–

oriented diagnostics

incl. “Header”

(length = 2 bytes)

Station diagnostics

Always “0”

Bit = 1:

PLC STOP in the slave station

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

4-15

Page 41

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

4.6.1 Example: Diagnostics overview

04.95Description

4

.

.

.

L KY 127,n

T PW 252

L KH 0000

L PW 252

!=F

BEB

SPB FBx

.

.

.

Request diagnostics OVERVIEW:

Transfer value 127 for call of the diagnostics “Overview” in the “Diagnostics

address” byte (here I/O byte 252). The number of the station group

n = 0, 1, 2, ...7) is specified in the “Diagnostics address + 1” byte

(here I/O byte 253). The diagnostics OVERVIEW comprises station (n 16)

to station (n 16 + 15) for each station group.

The master writes the diagnostics message in the I/O word 252.

Read diagnostics OVERVIEW

If no station has sent

diagnostics message,

then end of block,

otherwise evaluate error

in FB x.

Diagnostics word from diagnostics OVERVIEW

Diagnostics address Diagnostics address + 1

Bit 7 6 5 4 3 2 1 0 Bit 7 6 5 4 3 2 1 0

Station Station

n16+7n16+6n16+5n16+4n16+3n16+2n16+1n16 n16

has sent a diagnostics message has sent a diagnostics message

+15

n16

+14

n16

+13

n16

+12

n16

+11

n16

+10

n16+9n16

You can use the following programming steps to check station 5 with

diagnostics OVER VIEW:

.

.

.

L KY 127,0

T PW 252

L PW 252

T MW 252

U M 252.5

SPB FBx

Call diagnostics OVERVIEW with station group 0

(stations 0 to 15) and

transfer into a

flagword.

If station 5 has sent a diagnostics message,

then evaluate error in FB x.

.

.

.

+8

4-16

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 42

04.95 Description

4.6 Diagnostics functions in the STEP 5 program of the master IM 308–B

Note

For detailed information on the diagnostics possibilities in the STEP 5

program of the master, please refer to

Reference: /1/, ET 200 Distributed I/O System Manual

4.6.2 Example: PLC STOP in the slave station

If it is found from the diagnostics that the station to be checked has an error

and can be contacted, the device-related diagnostics (station diagnostics) can

be used to detect the cyclic operation of the slave control:

.

.

.

L KY 5,3

T PW 252

L PW 252

L KH 0001

UW

L KH 0000

> < F

SPB FBy

.

.

.

Consequences of

a fault

Monitoring of

cyclic operation of

the slave station

by the user

Call station diagnostics from the SINEC L2-DP slave interface module.

Enter station number (here: 5; can be between 3 and 124) in the “diagnostics

address” byte. The byte “diagnostics address + 1” always has the value 3.

Read station diagnostics from the SINEC L2-DP slave interface module.

Load diagnostics word.

Is bit 0 of the “diagnostics address” byte

set?

If so,

then

no cyclic operation of the slave control (evaluate in FBy

correspondingly).

Reset of the inputs implemented by the slave in the master station.

A self-defined sign-of-life bit can enable the user to detect a fault in cyclic

operation of the slave station on the master side.

4

Example

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

An output bit of the slave to be monitored is set on the slave side and on the

master side the signal state of the corresponding signal bit is read and

evaluated as follows:

1 signal: Cyclic operation of slave control running

0 signal: Fault during cyclic operation of slave control

Based on the signal state of this input bit, the user can have a suitable error

message displayed and can program the behaviour of the control should this

fault occur.

J

4-17

Page 43

04.95 Description

5.2 Information about configuring the master interface

Description of the Master Functionality

5

5.1 General information about the master interface of the IM 329–N

This section provides information about the use of the IM 329–N as a master

(master type: general DP master) in an ET 200 Distributed I/O System.

Note

For technical data, settings and operating elements of the module see

Section 2.

The structure of the SINEC L2–DP field bus (cable laying, shielding,

attenuation of interference voltage etc.) see:

Reference: /1/, ET 200 Distributed I/O System Manual

5

5.2 Information about configuring the master interface

Preconditions for

parameterizing the

master

The following preconditions must have been fulfilled before you can parameterize the master interface of the IM 329–N:

PG/PC with COM ET 200 (V4.x)

CP 5410 S5DOS/ST interface

Cable to connect PG/PC (CP 5410 S5DOS/ST interface) and IM 329–N

(X112 interface)

With length 1.5 m: 6XV 1830–1BH–15

With length 3 m: 6XV 1830–1BH–30

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

5-1

Page 44

5.2 Information about configuring the master interface

04.95Description

5

Master type

ET 200 parameters

Bus parameters

During configuration you are prompted to select the master type.

Please select:

<F1>: DP master is an IM 308–B

<F3>: General DP master

Fig. 5-1 Select the master type

Note

T o create a program file with the IM 329–N module as the master select the

type “General DP master”.

Set the ET 200 parameters as follows:

Station number DP master: 1 (permissible: 1 to 5)

Highest station number of an active station: 1 (permissible: 1 to 124)

Baud rate: Max. permissible setting

1500 kbaud

Bus profile: DP standard (see note)

Host parameters

Response monitoring Y 0.7 sec (usually)

Diagnostics Y/N (see note)

Start–up delay N (obligatory)

Host access as for S5 CPU Y (obligatory)

Note

About the bus parameter Bus profile:

You can set the bus profile for the whole bus as follows:

Bus profile Remark

DP to V3.x No DP standard slaves and no FMS stations (e.g. only IM 328–N)

DP standard DP Siemens slaves, standard slaves but no FMS stations

DP/FMS DP Siemens slaves, standard slaves and FMS slaves

About the host parameter Diagnostics:

Diagnostics Y (yes) Diagnostics N (no)

Failure of a slave station or a bus interruption

does not cause PLC stop

(diagnostics can be performed with

COM ET 200)

causes PLC stop

(ack. timeout)

5-2

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 45

04.95 Description

5.2 Information about configuring the master interface

Configuration

How are the data

transferred from

the PG/PC to the

master

The slaves must be configured as described in the corresponding

documentation.

Note

If the IM 329–N is used as the slave, then proceed as described in

Section 4.

If the IM 328–N slave is used the following applies:

Reference: /6/, Description

Link to SINEC L2–DP with IM 328–N Module

If the ET 200U, ET 200B, ET 200C slaves are used:

Reference: /2/, Distributed I/O System Manual

If other slaves are used, observe the description for them.

The data created during configuration of the system are transferred to the

IM 329–N master with the function “DOWNLOAD”.

T o transfer the data, a direct link must be set up between the

CP5410 S5DOS/ST interface and the IM 329–N master (X112).

5

T o transfer parameterization data, the master must be disconnected from the

SINEC L2–DP bus.

IM 329–N

PG/PC with

CP 5410 S5DOS/ST

X111

X112

Fig. 5-2 Transmission of the parameterization data to the master

Transmission rate

19.2 kbaud

Cable

6XV 1830–1BH–15 or

6XV 1830–1BH–30

interface

Note

During data transmission, the sequence described in Section 5.3 must be

observed.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

5-3

Page 46

5.3 Sequence for start-up

5.3 Sequence for start–up

This section describes what to look out for and what to do during start–up of

the IM 329–N master and what sequence to follow.

Preconditions

The ET 200 Distributed I/O System is set up and the slaves are set

accordingly.

One PG/PC is present (e.g. PG 750)

The CP 5410–S5DOS/ST interface is mounted and the COM ET software

(V4.x) is installed.

The system configuration with COM ET 200 is performed, i.e. all slaves

are parameterized.

The module has not yet been inserted.

04.95Description

5

Sequence

During start–up of the master, please observe the following sequence:

1. Enable master (put switch S2.4 in the ON position, see Section 2.2.2)

2. Plug in the IM 329–N module

3. Set PARAMETERIZATION mode

– Put the toggle switch MASTER MODE on the front panel in the

PARAMETERIZATION position (see Section 2.3.2)

– Set the station address for the slave to address 0 (see Section 2.3.1)

4. Switch on the control with IM 329–N (restart)

The status display of the master indicates the readiness for parameterization as follows:

ACCESS

(green LED)

on Once, pause, once, ... Ready for parameterization

Caution

!

The parameterization data on the module are deleted, if

FAULT

(red LED)

Meaning

PARAMETERIZATION mode is set and

A COLD RESTART has been performed by the control

5-4

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 47

04.95 Description

5.3 Sequence for start-up

5. Connect the PG/PC with the IM 329–N

Plug in the cable 6XV 1830–1BH–15 or 6XV 1830–1BH–30 between the

PG/PC (CP5410 S5DOS/ST interface) and the IM 329–N (X112 interface)

to transmit the parameterization data (see Section 5.2).

6. Transmit the parameterization data with COM ET 200

– Start the transmission module from COM ET 200 with the softkey

F3 (TRANSFER)

– Select the DP master as the remote station for transfer with the softkey

F6 (TRANSFER REMOTE)

The parameterization data must be transmitted at 19.2 kbaud.

– Select the BAUDRATE field with the cursor, press F7 (HELP) and set

the baud rate 19.2 kbaud.

– Start the DOWNLOAD with softkey F1 (DOWNLOAD)

After transmission, the parameterization data must be activated.

– Press softkey F4 (ACTIVATE DOWNLOAD)

After activation, the red LED of the status display of the master stops

blinking and is lit continuously. The data are now stored in the non–

volatile memory on the IM 329–N module.

Note

If the red LED does not stop blinking, trigger a COLD RESTART of the control; the data must be transferred again.

For questions about COM ET 200 see:

Reference: /1/, ET 200 Distributed I/O System Manual

7. Set RUN mode

– Put the toggle switch MASTER MODE on the front panel into the

RUN position (lower position)

– Set the station address for slave to an address between 3 and 124.

8. Disconnect the PG/PC from the IM 329–N

9. Connect the IM 329–N to the SINEC L2–DP field bus

10.Trigger a COLD RESTART of the control

Note

With the SINUMERIK 840C newly inserted modules are only detected after

a COLD RESTART.

5

11.Check data transmission and monitoring between the master and the

slave(s) and activate them if necessary.

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

5-5

Page 48

5.5 Application example

5.4 Signals and the status display

5.4.1 Normal operating state

Normal operation is indicated on the status display as follows:

04.95Description

5

ACCESS

(green LED)

on off Normal operation

5.4.2 Faults and signals

Faults and signals are indicated on the status display as follows:

ACCESS

(green LED)

on Once, pause, once, ... Ready for parameterization

on Twice, pause, twice, ... Bus interruption or slave(s) cannot be

off 3 times, pause, 3 times, ... Not ready for parameterization

off 4 times, pause, 4 times, ... Master does not start the bus

FAULT

(red LED)

FAULT

(red LED)

Meaning

Meaning

controlled

(station address for slave is not 0)

(no valid station address set for slave

(valid: 3 to 124))

5.5 Application example

Structure

Link

5-6

A structure consists of the following machining lines and stations:

Machining line 1 Machining stations with

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

Machining line 2 Machining stations with

SINUMERIK 805SM SINUMERIK 840C SIROTEC ACR 20

The link between the stations and the individual lines is implemented via the

ET 200 Distributed I/O System and the IM 329–N interfaces (master and

slaves). The first interface is used as a master and the others are slaves.

6ZB5 430–0BH02–0AA1 Siemens AG 1995 All Rights Reserved

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

Page 49

04.95 Description

5.5 Application example

A SIMATIC S5–115U is used as the host control for the machining lines. The

lines are also linked via an ET 200 distributed I/O system. The IM 308–B

interface is used as the master and the IM 329–N of the first station of each

line is used as the slave.

IM 329–N

SINUMERIK

805SM

Master for

machining

lines 1 and 2

IM 329–N

SINUMERIK

805SM

Fig. 5-3 Application example: link between the machining stations and lines

Slave

Master for the

stations of

machining line 1

IM 308–B

SIMATIC

S5–115U

Slave

Master for the

stations of

machining line 2

SINUMERIK

840C

SINUMERIK

840C

SIROTEC

ACR 20

Slave

SIROTEC

ACR 20

Slave Slave

Slave

5

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

J

5-7

Page 50

04.95 Description

Abbreviations

COM

COM ET 200

CPU

CP 5410–

S5DOS/ST

DB

DI

Download

DP

DP master

Communication

Communications software for configuring the master interface module

Central Processing Unit

PG interface module for connection to SINEC L2 and/or SINEC L2–DP

Data block

Digital inputs

Loading the master configuration onto the DP master via SINEC L2–DP bus

Distributed I/Os

e.g. IM 308–B, IM 329–N

A

A

DP standard

DPR

DQ

DW

ET 200

ET 200B

ET 200C

ET 200U

Procedure acc. to PROFIBUS–DP (DIN E 19245, Part 3)

DUAL PORT RAM, memory that can be accessed both ways (read and write

access)

Digital outputs

Data word

Electronic T erminator 200, distributed I/O system 200

Distributed I/O device to degree of protection IP 20, small and compact,

therefore suitable if only a few inputs/outputs are required or if available

mounting depth is small.

Distributed I/O device, compact design to degree of protection IP 65, for use

in an industrial environment

Distributed I/O device, modular design to degree of protection IP 20, for universal applications especially in intelligent modules

Siemens AG 1995 All Rights Reserved 6ZB5 430–0BH02–0AA1

SIROTEC ACR 20, SINUMERIK 805SM / 840C (BS)

A-1

Page 51

04.95Description

A

FB

FEPROM

FMS

GND

HEX

IB

IM 308–B

IM 318–B

IM 328–N

IM 329–N

LED

OB

Function block

Flash EPROM: read and write memory (non–volatile memory)

Field bus Message Specification

Signal ground, reference point

Abbreviation for a hexadecimal number

Input byte

Master interface module

Interface module for slave station ET 200U

Slave module for field bus SINEC L2–DP

Slave and master module for field bus SINEC L2–DP

Light emitting diode

Organization block

QB

PG

PIQ

PII

PLC

PROFIBUS

PROFIBUS–DP

PW

PY

RAM

Output byte

Programming unit

Process output image

Process input image

Programmable Logic Controller

PROcess Field BUS, German process and field bus standard defined in the

PROFIBUS standard (DIN 19245).