Page 1

SINUMERIK 805

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Software Version 4

PLC Programming

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Planning Guide 11.91 Edition

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Manufacturer Documentation

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Page 2

SINUMERIK 805

Software Version 4

PLC Programming

Planning Guide 05.93 Edition

Supplement

Order No.: 6ZB5 410-0CM02-0AN3

Page 3

These sheets constitute a supplement to the edition

aaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

SINUMERIK 805

Software Version 4

PLC Programming

11.91 Edition Order No.: 6ZB5 410-0CM02-0AA3

The supplement refers to Sections 1, 3, 5, 6, 7, 8 and 9.

Please replace the following pages:

Page Replace Insert Delete

Inside title page/

Printing history page

X

1-1 and 1-2 X

1-5 and 1-6 X

1-7 and 1-8 X

1-9 and 1-10 X

1-11 X

3-3 X

3-4 to 3-8 X

5-3 and 5-4 X

5-7 and 5-8 X

6-17 and 6-18 X

7-1 and 7-2 X

7-3 and 7-4 X

8-1 and 8-2 X

9-1 and 9-2 X

Siemens AG

Automation Group

Automation Systems for Machine Tools, Robots

and Special-Purpose Machines

91050 Erlangen

Siemens Aktiengesellschaft

Subject to change without prior notice

Printed in the Fed. Rep. of Germany

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

Progress

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

in Automation.

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaa

Siemens

aaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

Page 4

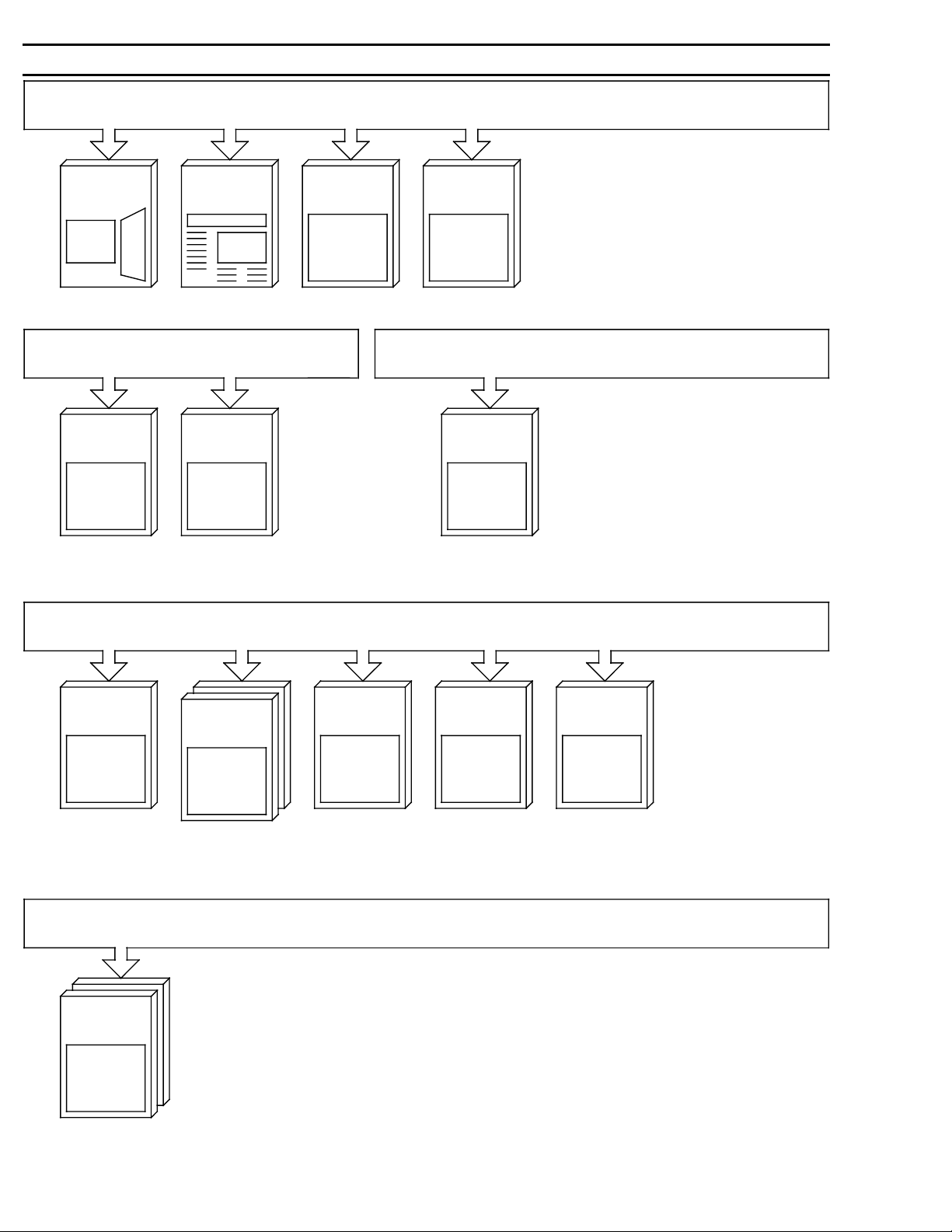

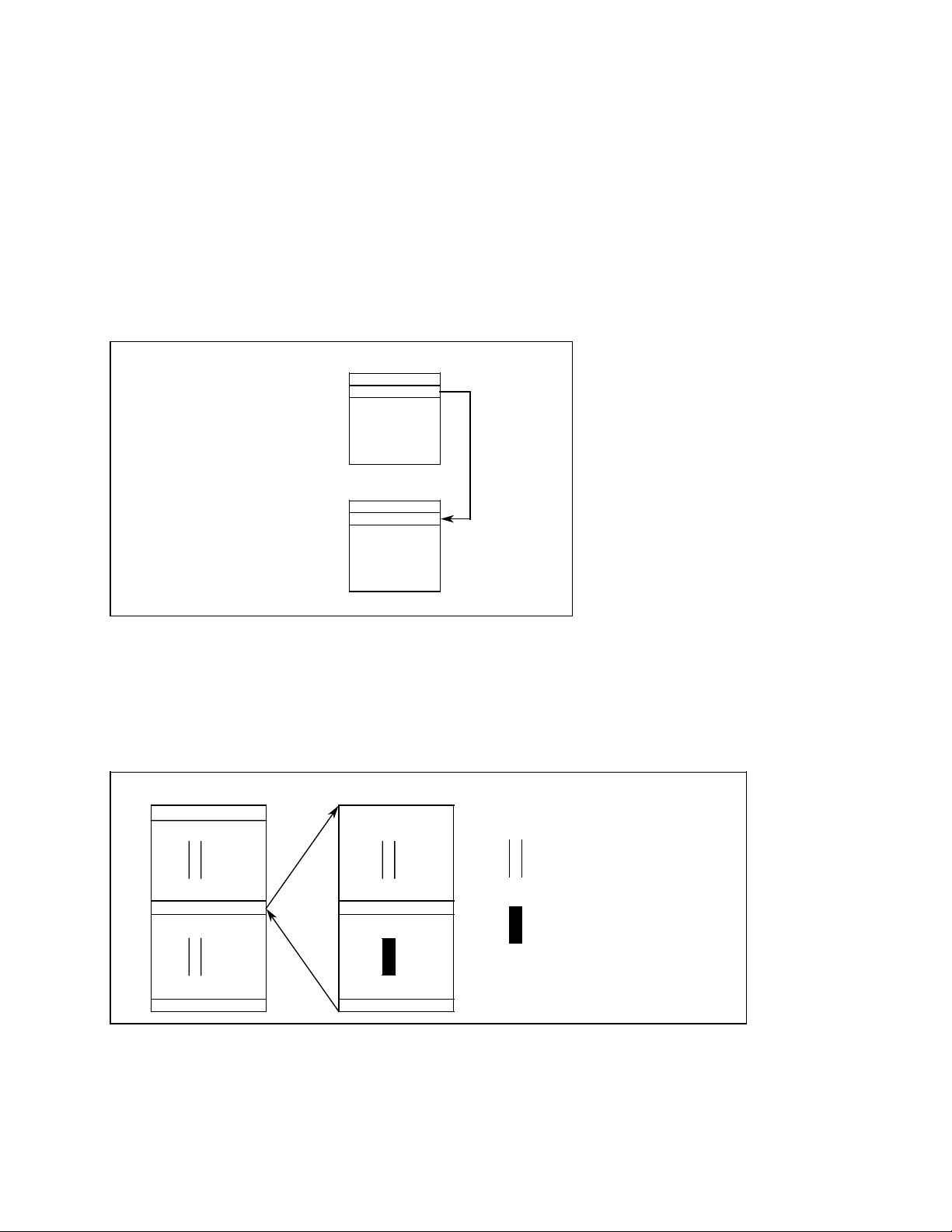

General Documentation

SINUMERIK 805

SINUMERIK

805

Sales Brochure

805

SINUMERIK

Technical Data

User Documentation

805

SINUMERIK

Operator's Guide

805

SINUMERIK

Programming Guide

Manufacturer Documentation

805

SINUMERIK

Catalog NC 34

Accessories

SINUMERIK

Catalog NC 90

User/Manufacturer and Service Documentation

805

SINUMERIK

Function Manual

SINEC L2 Interface Module

805

SINUMERIK

Instruction Manual

805

SINUMERIK

Interface:

- Signals

- Cables and

Connections

Service Documentation

805

SINUMERIK

Installation Guide

- Instructions

- Lists

805

SINUMERIK

PLC Programming

800

SINUMERIK

Universal Interface

800

SINUMERIK

CL 800 Language

Page 5

SINUMERIK 805

Software Version 4

PLC Programming

Planning Guide

Manufacturer Documentation

05.93 Edition

Page 6

SINUMERIK® documentation

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” column.

Status code in

”Remarks”

column

:

A . . . New documentation

B . . . Unrevised reprint with new Order No.

C . . . Revised edition with new status. If factual changes have been made on a page since

the last edition, this is indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

01.90 6ZB5 410-0CM02-0BA0 A

10.90 6ZB5 410-0CM02-0BA1 C

01.91 6ZB5 410-0CM02-0AA2 C

11.91 6ZB5 410-0CM02-0AA3 C

05.93 6ZB5 410-0CM02-0AN3 Supplement

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

This publication was produced on the Siemens 5800 Office

System.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

Siemens AG 1990 All Rights Reserved

©

Page 7

1Introduction

Organization, Program and Sequence Blocks

Data Blocks

Function Blocks 4

Program Organization

2

3

5

6Integral Function Blocks

Transfer Parameters and Operating System Machine

7

8Error Analysis

9STEP 5 Command Set with Programming Examples

10Rules of Compatibility between LAD, CSF and STL

Page 8

Contents

Page

1 Introductory Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Application, memory capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 STEP 5 programming language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.1 Program structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Program organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.3 Program scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.4 Influencing factor: User program size . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 Organization, Program and Sequence Blocks . . . . . . . . . . . . . . . . 2-1

2.1 Programming program blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Calling program blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

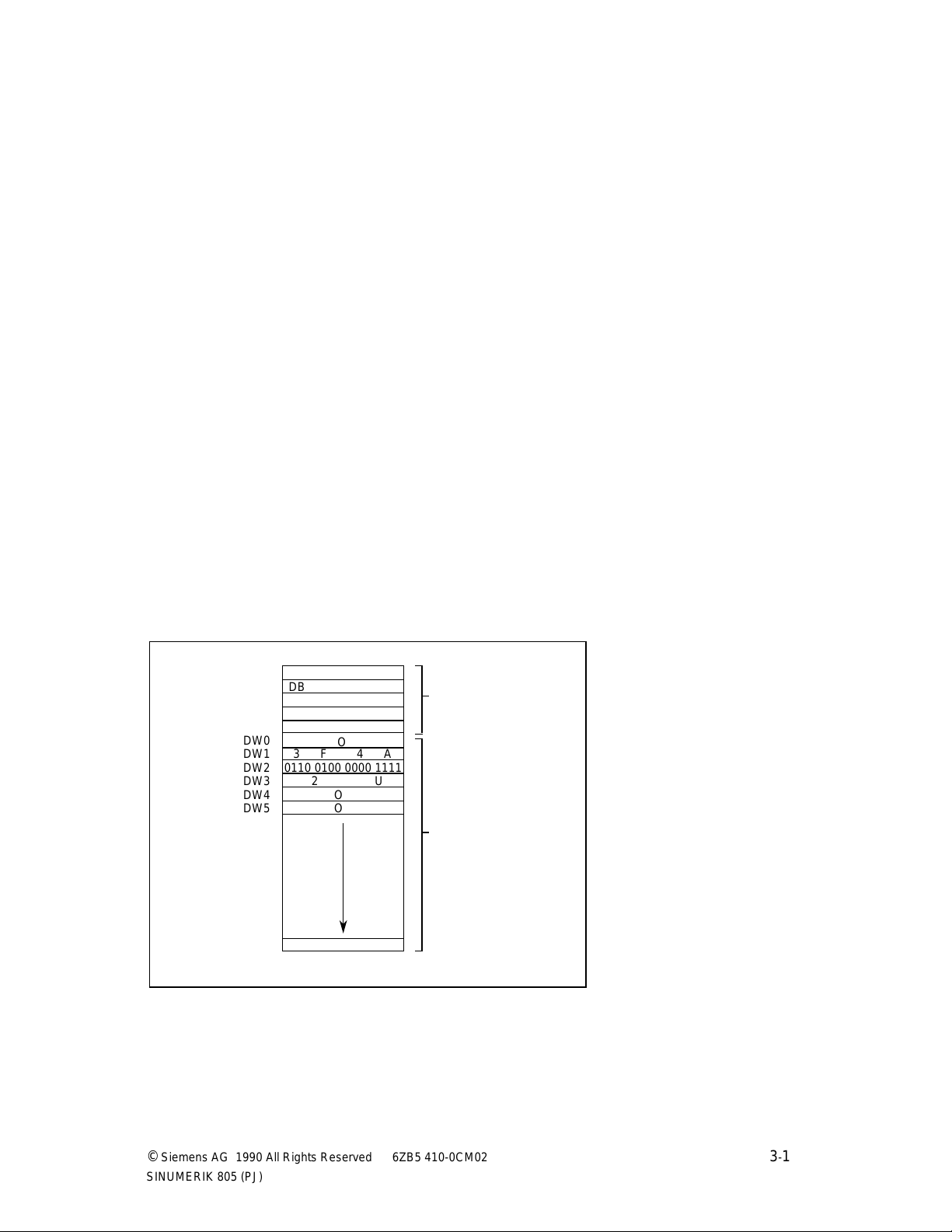

3 Data Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Programming data blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Calling data blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Data blocks created by the operating system . . . . . . . . . . . . . . . . . . . 3-4

4 Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 General remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Structure of function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.1 Block header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Block body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Calling and initializing function blocks . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.1 Call statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3.2 Parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Programming function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.1 Library number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.2 Name of the function block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.3 Formal operand (block parameter name) . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4.4 Block parameter types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4.5 Block parameters and permitted actual parameters . . . . . . . . . . . . . . . 4-7

5 Program Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Cyclic scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Interrupt capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.2 Response time and cycle time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.3 Programming the cyclic program . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.4 Interface between operating system and cyclic program . . . . . . . . . . . . 5-4

5.2.5 Basic program organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Interrupt processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.3.1 Programming the interrupt service routine . . . . . . . . . . . . . . . . . . . . . . 5-7

5.3.2 Interface between operating system and the interrupt . . . . . . . . . . . . . . 5-7

5.3.3 Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Page 9

6 Integral Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 General remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 FB identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Function macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

FB 11 EINR-DB Generate data blocks . . . . . . . . . . . . . . . . . . . . 6-4

FB 60 BLOCK-TR Block transfer . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

FB 61 NCD-LESE Read NC data

FB 62 NCD-SCHR Write NC data . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

FB 65 M STACK Transfer flags to stack . . . . . . . . . . . . . . . . . . . 6-18

FB 66 STACK M Flag stack to transfer flag area . . . . . . . . . . . . . 6-18

7 Transfer Parameters and Operating System Machine Data . . . . . . 7-1

7.1 Transfer parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 PLC machine data SINUMERIK 805 . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.3 PLC machine data bits SINUMERIK 805 . . . . . . . . . . . . . . . . . . . . . . . 7-5

8 Error Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Types of error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Interrupt stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.3 Detailed error code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3.1 Display on programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.3.2 Display on NC screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.4 Alarm List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

9 STEP 5 Command Set with Programming Examples . . . . . . . . . . . . 9-1

9.1 Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Changing the segment switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.1.2 Block lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.2.1 Numeric representation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.2.2 Condition codes of the PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.2.3 STEP 5 command representation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

9.3 Basic operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.3.1 Logic operations, binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.3.2 Storage operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.3.3 Load and transfer operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.3.4 Timing and counting operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

9.3.5 Comparison operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

9.3.6 Block calls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

9.3.7 Code operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

9.3.8 Arithmetic operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

9.3.9 Other operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.4 Supplementary operations (with function blocks only) . . . . . . . . . . . . . . 9-34

9.4.1 Logic operations, binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.4.2 Setting operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

9.4.3 Timing and counting operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.4.4 Enabling operations for timing and counting operations . . . . . . . . . . . . . 9-38

Page 10

9.4.5 Bit test operations (with function blocks only) . . . . . . . . . . . . . . . . . . . 9-39

9.4.6 Coding, load and transfer operations . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

9.4.7 Logic operations, digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

9.4.8 Shift operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

9.4.9 Conversion operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-42

9.4.10 Decrementing / Incrementing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-42

9.4.11 Jump operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

9.4.12 Processing operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-46

9.4.13 STEP 5 commands with direct memory access . . . . . . . . . . . . . . . . . . 9-48

9.4.14 Other operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-49

9.5 Command Set with Programming Examples . . . . . . . . . . . . . . . . . . . . 9-50

10 Rules of Compatibility between the LAD, CSF and

STL Methods of Representation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.2 Rules of compatibility for graphic program input

(LAD, CSF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10.3 Rules of compatibility for program input in a statement list . . . . . . . . . . 10-4

Page 11

Preliminary Remarks

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Notes for the reader

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

This manual is intended for the manufacturers of machine tools using SINUMERIK 805.

The Guide describes the program structure and the operation set of the PLC, and explains

how basic PLC software and user programs, which comprise data blocks, function blocks,

program blocks and organization blocks, are constructed.

The SINUMERIK documentation is organized in three levels:

• User documentation

• Manufacturer documentation and

• Service documentation

The Manufacturer Documentation for SINUMERIK 805 is divided into the following:

• Instruction Manual

• Description of interfaces

Part 1: Signals

Part 2: Cables and hardware

• PLC Programming

Additional SINUMERIK publications are also available for all SINUMERIK controls (e. g.

publications on the Universal Interface, Measuring Cycles, CL 800 Cycles language).

Please contact your Siemens regional office for further details.

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

Technical information

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

This documentation applies to software version 4

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Page 12

05.93 1 Introductory Remarks

1.1 Application, memory capacity

1 Introductory Remarks

1.1 Application, memory capacity

The PLC is a powerful interface controller. It has no inherent hardware, and is used as

”software PLC” in the SINUMERIK 805.

The PLC is responsible for control of machine-related functional sequences such as

• Controlling auxiliary axes

• Controlling tool-changers

• Gathering the signals generated by the machine's monitoring devices.

Special features:

On the SINUMERIK 805, all NC and PLC jobs are executed by a common processor

(Intel 80 186). A specially developed coprocessor (COP) is responsible for high-speed execution of binary operations and byte and word commands of the STEP 5 user program (e. g.

A I 3.0, L FW3, etc.).

The single-processor structure calls for strict priority scheduling of NC and PLC jobs. NC functions such as position control and block preparation, but also the PLC ”Interrupt processing”

function (OB 2), have highest priority, while scanning of the cyclic program (OB 1) is of lesser

importance.

The amount of processor time available to the PLC has been restricted to a maximum of 20%

in order to ensure that the NC can fulfill its primary objectives (positioning accuracy, short

block change times) even in extreme situations, e. g. where an exceptionally long STEP 5

program or frequent interrupt servicing is involved. It is also possible to influence the manner

in which the cyclic user program scanned via machine data (see Section 1.3.4).

PLC memory capacity of the SINUMERIK 805

User memory (OB, PB, FB, SB): 8 Kbytes

16 Kbytes (from SW 4.1, Basic Version)

32 Kbytes (from SW 4.1, in Option N46)

Data memory (DB): 4 Kbytes

6 Kbytes (from SW 4.1, Basic Version)

8 Kbytes (from SW 4.1, in Option N46)

Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02 1–1

©

SINUMERIK 805 (PJ)

Page 13

1 Introductory Remarks 11.91

1.2 STEP 5 programming language

1.2 STEP 5 programming language

The operations available in STEP 5 enable the user to program functions ranging from simple

binary logic to complex digital functions and basic arithmetic operations.

Depending on the programmer (PG) used a STEP 5 program may be written in the form of a

control system flowchart (CSF), ladder diagram (LAD) or statement list (STL) , thus enabling

the programming method to be adapted to the application. The machine code (MC5) generated

by the programmers is identical for all three. Depending on the programmer (PG) used, the

user program can be translated from one method of representation to another by conforming

to certain programming conventions (see Section10).

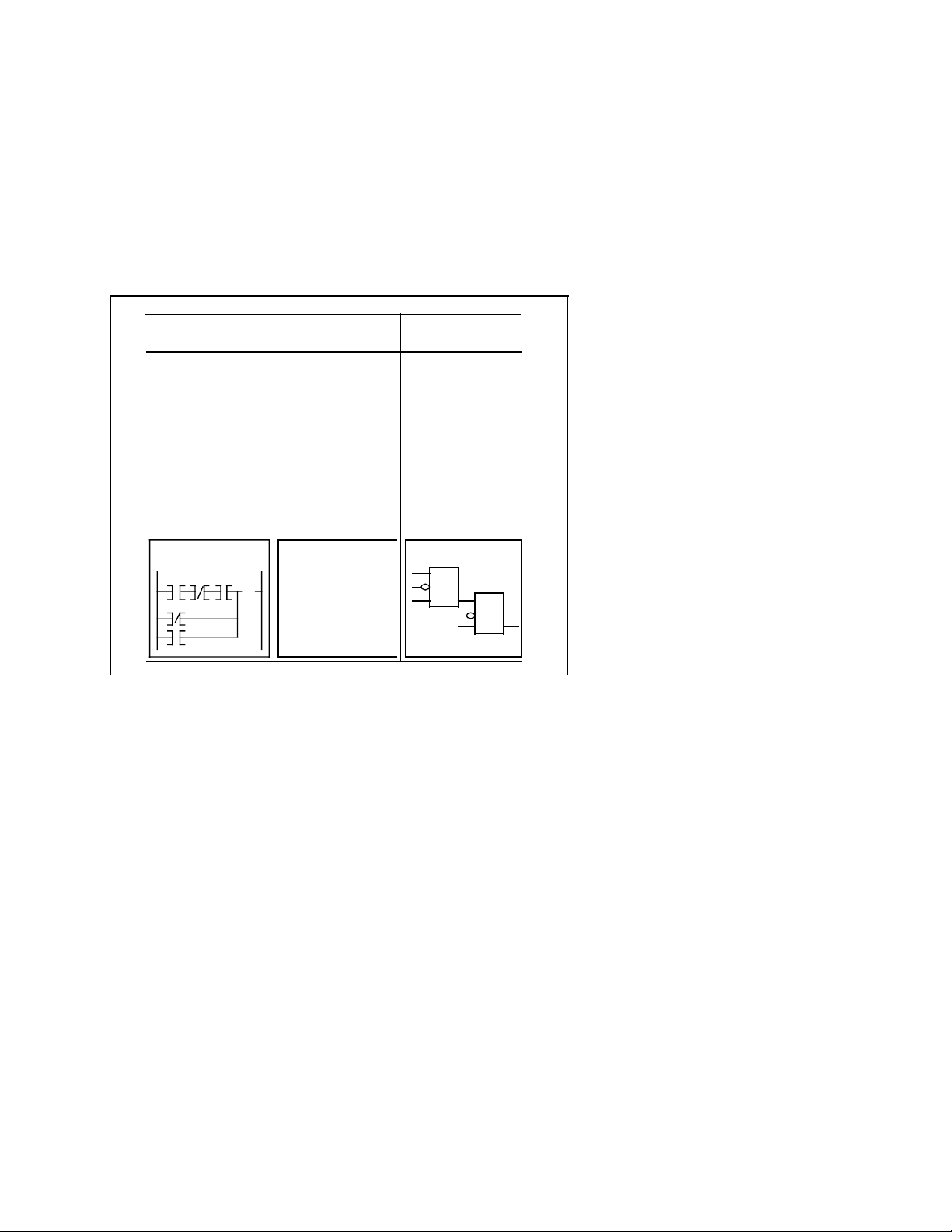

Ladder diagram Statement list Control system

Programming with Programming with Programming

symbols similar to using mnemonics with graphic

those used in sche- designating symbols

matic circuit dia- functions

grams

Complies with Complies with Complies with

DIN 19239 DIN 19239 IEC 117 - 15

(draft) (draft) DIN 40700

LAD STL

AI

( )

AN I

AI

ON I

OI

=Q

flowchart

DIN 40719

DIN 19239

(draft)

CSF

Methods of representing the STEP 5 programming language

&

>=1

1-2© Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02

SINUMERIK 805 (PJ)

Page 14

10.90 1 Introductory Remarks

1.3 Programming

1.3 Programming

1.3.1 Program structure

The PLC software comprises the operating system, the basic software and the user program.

The operating system contains all statements and declarations for internal system functions.

The basic software has a flexible interface to the operating basic functions (e. g. generation of

data blocks, NC-PLC interface initialization, signal interchange with the peripherals). The basic

software also contains pretested function blocks written in STEP 5 and assembled to form

function macros.

The operating system and the basic software are integral components of the PLC; they are

supplied on EPROMs together with the NC system program, and may not be modified in any

way.

The user program is the total of all statements and declarations/data programmed by the user.

The PLC structure makes structured programming essential, i. e. the program must be divided

into individual, self-contained sections called blocks. This method offers the following

advantages:

• Easy, lucid programming, even of large programs

• Easy standardization of program sections

• Simple program organization

• Fast, easy modification

• Simple program testing

• Easy start-up

A number of block types, each of which is used for different tasks, is available for structuring

the user program:

• Organization blocks (OBs)

The OBs serve as interface between operating system and user program.

• Program blocks (PBs)

The PBs are used to break the user program down into technologically oriented sections.

• Function blocks (FBs)

The FBs are used to program frequently recurring complex functions (such as individual

controls, reporting, arithmetic and PID control functions).

• Sequence blocks (SBs)

SBs are special forms of program blocks used primarily for processing sequencers.

• Data blocks (DBs)

DBs are used for storing data or texts, and differ in both function and structure from all

other block types.

With the exception of the organization blocks, the maximum number of programmable blocks

of each type is 255. The number of organization blocks may not exceed 64; of these, only OB

20, PB 1 and OB 2 are serviced by the operating system (cf. Section 5).

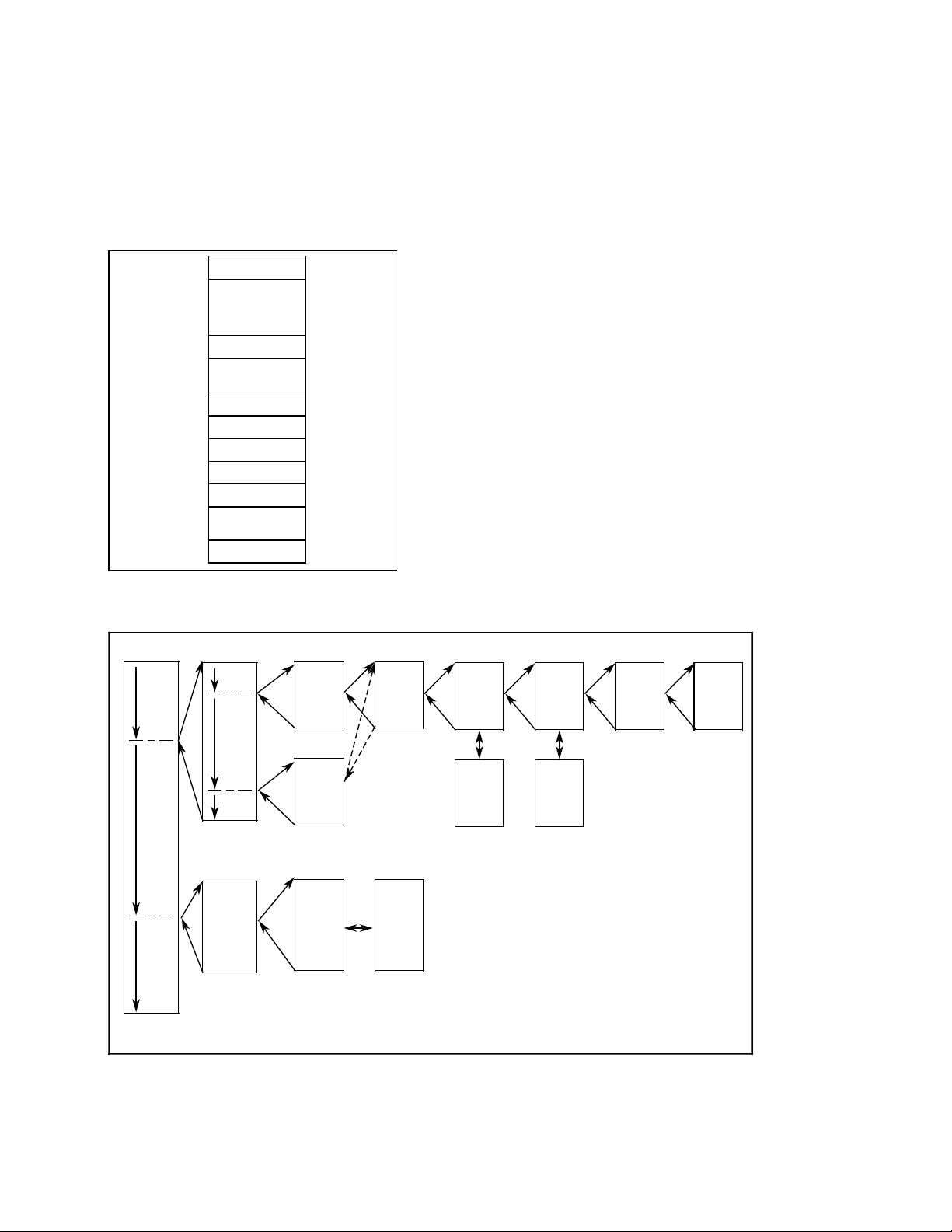

The programmer stores all programmed blocks in arbitrary order in program memory

(Fig. 1.2).

Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02 1-3

©

SINUMERIK 805 (PJ)

Page 15

1 Introductory Remarks 10.90

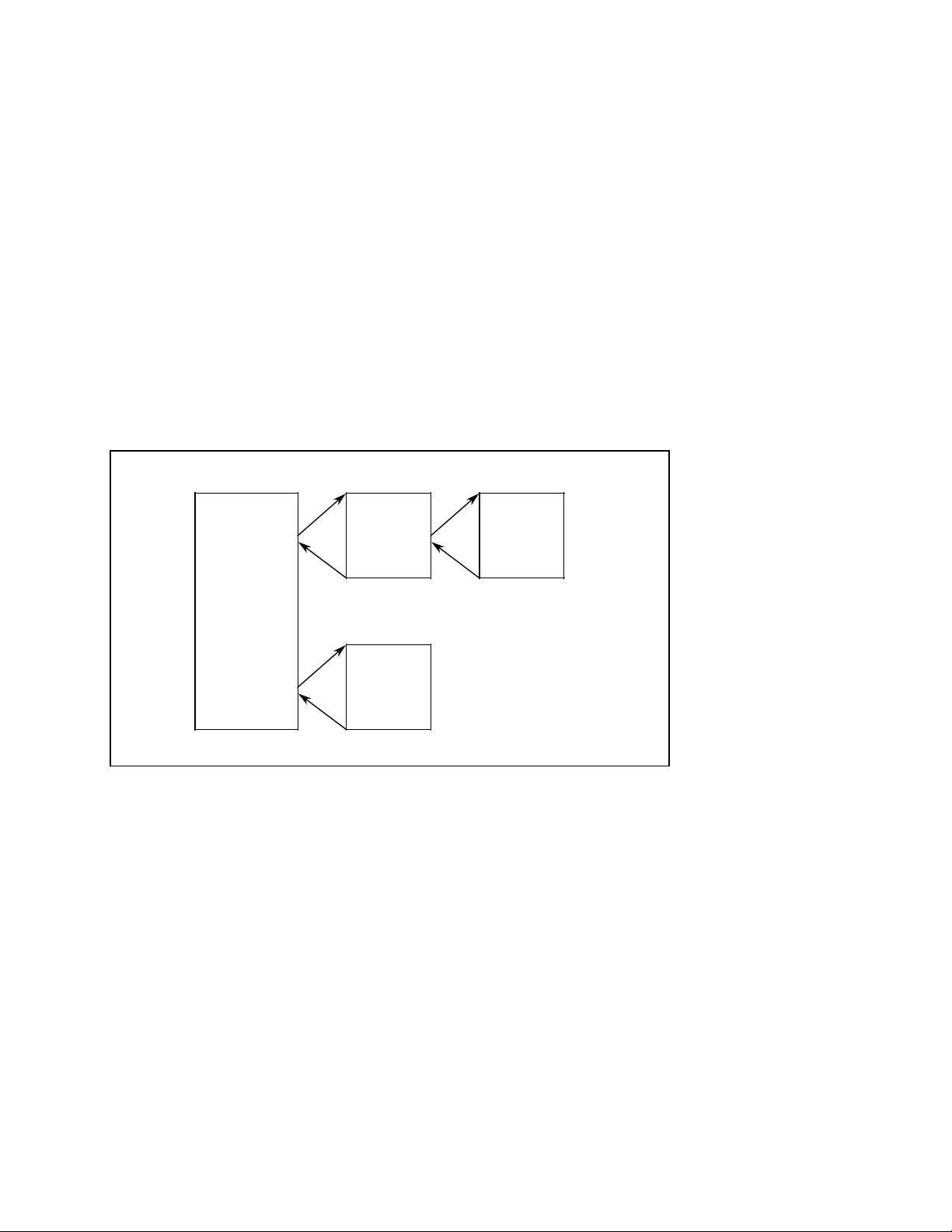

1.3.2 Program organization

1.3.2 Program organization

The manner in which the program is organized determines whether and in what order the

program, function and sequence blocks are executed. The order in which these blocks are

involved is stipulated by programming the relevant calls (conditional or unconditional) in

organization blocks (see Section 5.4, ”Cyclic program”).

Like the other blocks, the organization blocks are stored in user memory.

PB1

PB2

•

•

FB1

•

•

DB1

•

SB10

•

FX1

•

•

OB1

Storing the blocks in arbitrary order in program

memory

OB

PB

Different organization blocks are provided for

various methods of program execution (cf.

Section 5.2).

Organization, program, function and

sequence blocks can invoke other program,

function and sequence blocks. The user

program cannot call organization blocks. The

maximum permissible nesting depth for

organization blocks is 12, not including an

accompanying data block, if any.

FBFB

FBFBPBPB

PB

PB

1

Typical program organization in STEP 5 (nesting depth 8) (max. nesting depth 12)

2

3 4

DBFB

DB

5 6 7 8

DB

OB Organization block

PB Program block

FB Function block

DB Data block

1-4© Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02

SINUMERIK 805 (PJ)

Page 16

05.93 1 Introductory Remarks

1.3.3 Program scanning

1.3.3 Program scanning

The user program can be scanned in three ways:

• One-shot scan

One-shot scan in the controller's restart routine following ”Power up” or ”Hardware reset”.

The statements to be executed must be programmed in OB 20.

• Cyclic scanning

For cyclic scanning 0B1 is available. This block is passed at intervals of 48 ms (up to

SW4.1: 60 ms) and calls the programmed blocks.

• Interrupt scan

Event-driven, one-shot execution of the statements in OB 2, e. g. in response to an

interrupt. Prerequisites for event-driven execution are as follows:

• Normal termination of the controller's restart routine

• Interrupt enable via PLC-MD 2002, bit 0=”0”.

• A change in the interrupt input byte specified per PLC-MD 0.

Cyclic scanning can be interrupted by the high-priority NC functions' interrupt service routine

or delayed pending termination of OB 2 following execution of each STEP 5 command.

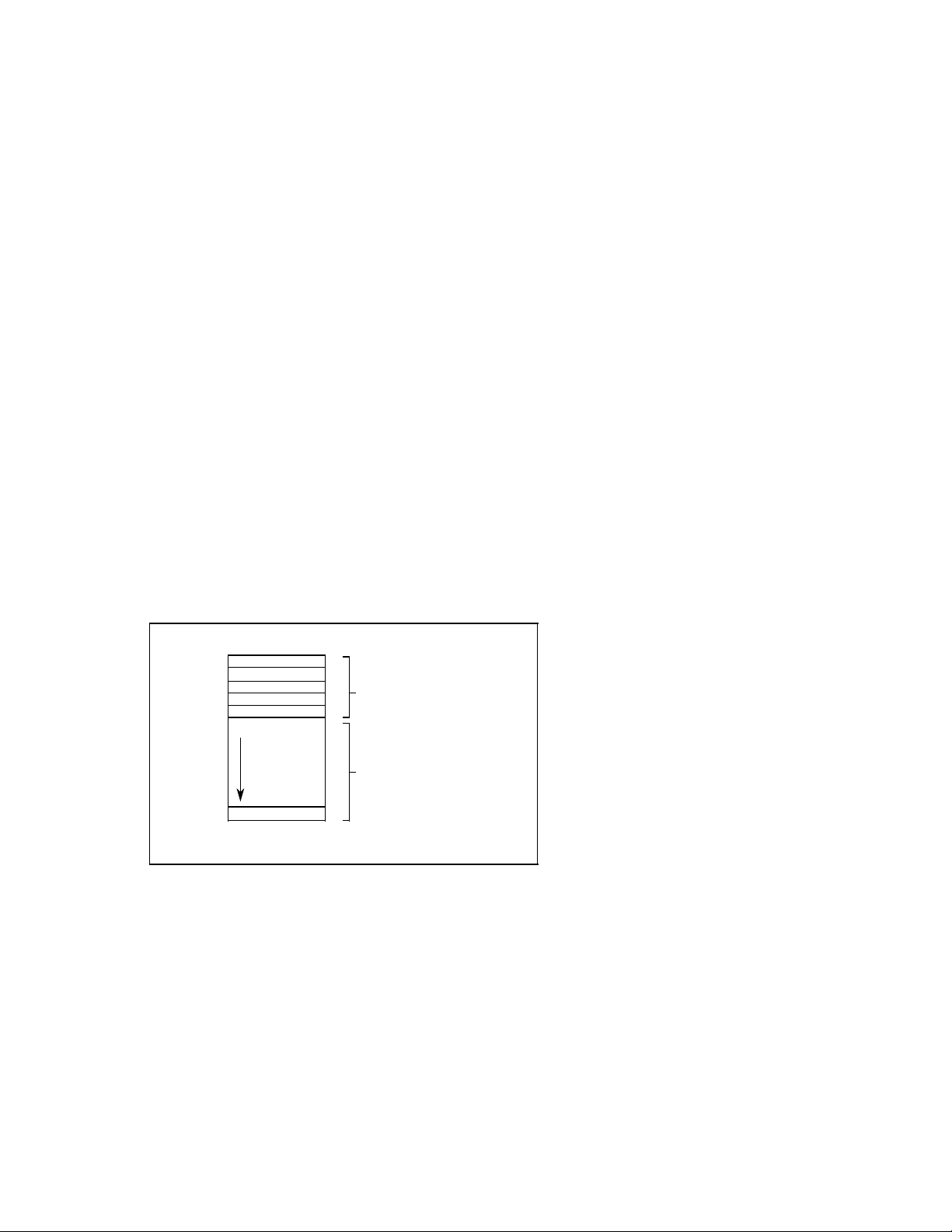

Execution of a PLC cycle; cyclic program scanning

Before OB 1 is called and started, the basic program loads the momentary state of all

peripheral inputs into working memory. All input scans in the cycle which follows refer to this

loaded status image. It is also known as ”Process Input Image” or PII for short.

OB 1 is now called. This executes the blocks that have been called one after the other. This

process can be interrupted by one or several interrupt scans (OB 2).

When OB 1 has been worked through completely, the system program transferss the statuses

of the outputs (resulting from program execution) from the working memory to the peripheral

outputs (MDP submodules, for example).

Load Process Input Image

PB 1

A I 3.1

= Q 2.0

BE

FB 1

A F 0.1

= Q 3.6

BE

PLC cycle

48 (60 )ms

time base

OB 1 scan

OB 1

SPA PB 1

SPA FB 1

BE

Write Process Output Image

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02 1–5

SINUMERIK 805 (PJ)

Page 17

1 Introductory Remarks 05.93

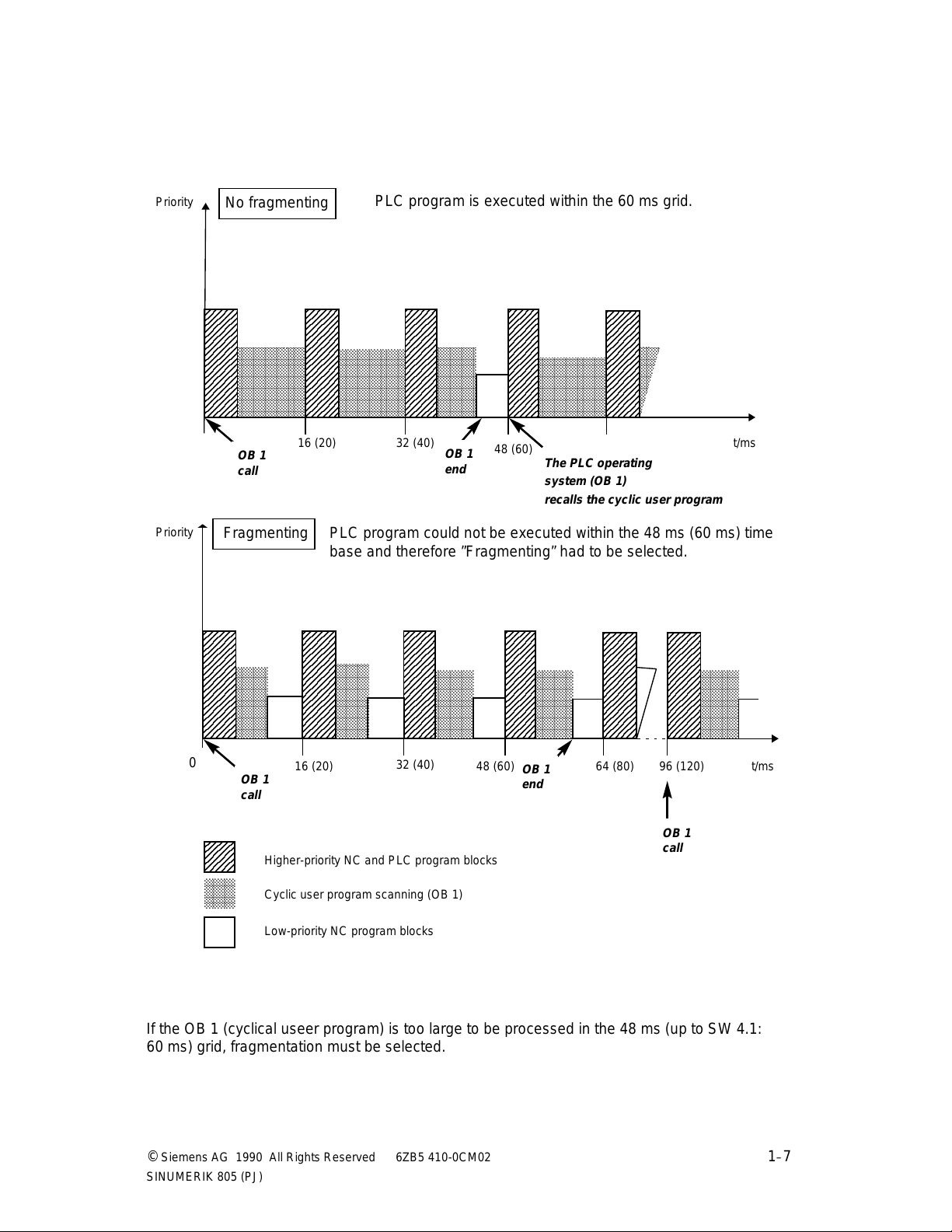

1.3.4 Influencing factor: User program size

1.3.4 Influencing factor: User program size

As mentioned in Section 1.1, execution of the STEP 5 program should not take up more then

15 % of the total available CPU time, nor should the interrupt service routine in OB 2 take up

more time than necessary because of its high priority, as this would delay execution of

important NC functions.

For this purpose, the execution times of both the cyclic user program and the interrupt service

routine are monitored at the hardware level. The permissible runtimes can be set in PLC MD 1

and 3, whereby confirmation of the defaults ensures that the ”integrated PLC” will not take up

more than the admissible amount of CPU time. When these values are exceeded, the PLC

goes to the state specified in bit 0 or 1 of PLC MD 2003; when the defaults are used, the

”integrated PLC” always enters the Stop mode.

When the user programs exceed the permissible execution times only slightly, program

scanning can be upheld by modifying these machine data bits, but this may adversely affect

the NC functions.

There are two ways of ensuring the executability of large cyclic user programs without placing

an excessive load on the CPU:

• Fragmenting cyclic execution through autonomous interrupts

• Allowing cyclic execution to be interrupted by higher-priority program blocks only

The mode is set in PLC MD 2003, bit 6. The percentage in PLC MD thus assumes the

following meaning as regards the scan time:

• No fragmenting (bit 6 of MD 2003 = 0 ˆ= default):

15% of the cyclic program's timing grid (48 ms) results in a permissible runtime of 7.2 ms.

• Fragmenting (bit 6 of MD 2003 = 1)

15% of 1/3 of the cyclic program's timing grid (48 ms) results in a runtime of 2.4 ms. The

cyclic program then interrupts itself autonomously, and resumes execution in the next

third.

–6© Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02

1

SINUMERIK 805 (PJ)

Page 18

05.93 1 Introductory Remarks

aaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

a

a

a

a

a

a

a

a

a

a

a

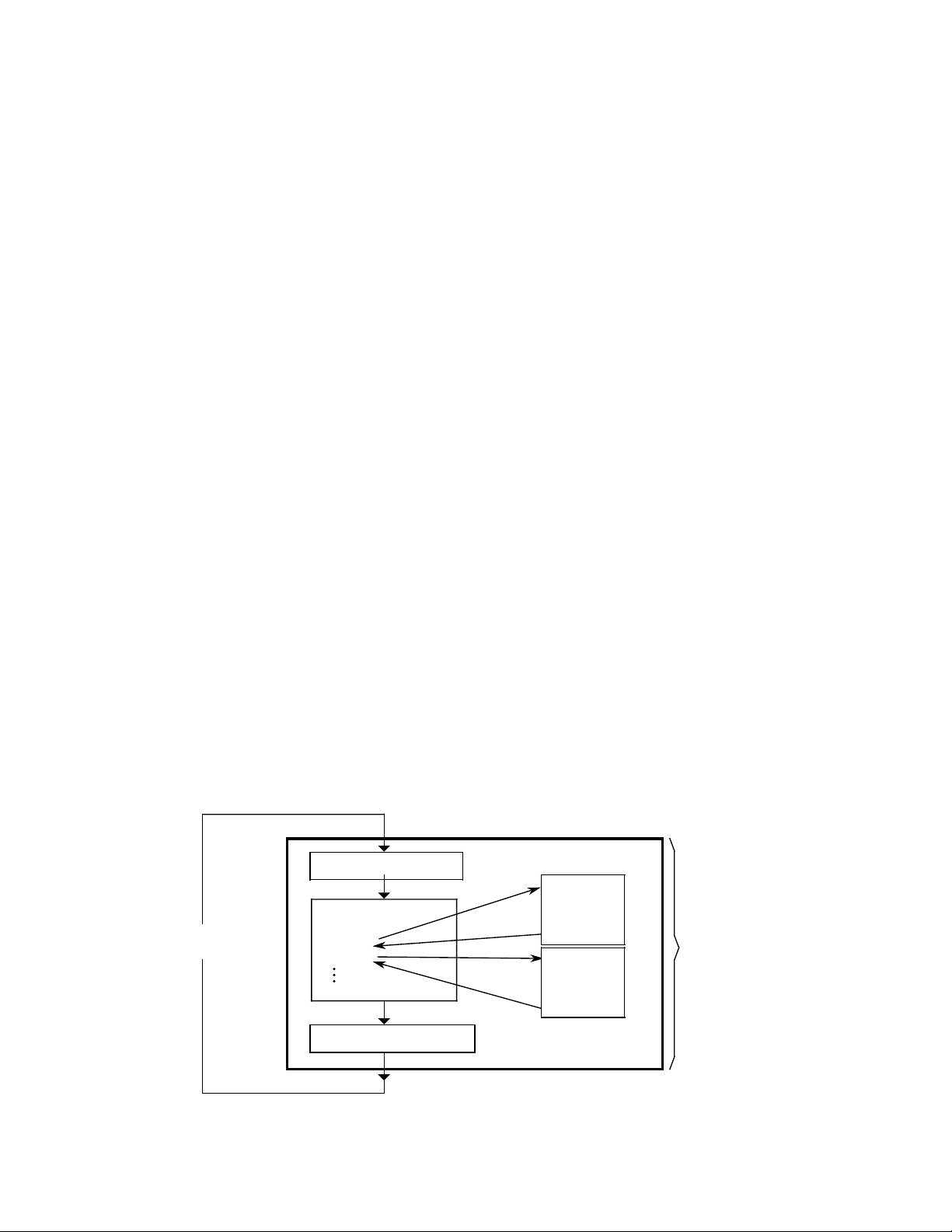

1.3.4 Influencing factor: User program size

Grafic overview of the two methods for cyclic program scanning

Note: OB 1 (cyclical user program) can only be called up in the 48 ms grid (up to SW 4.1:

60 ms).

Priority

Priority

No fragmenting

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

aaaaa

aaaaa

aaaaaaaaa

0

OB 1

call

Fragmenting

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

aaaaa

aaa

a

aaa

a

PLC program is executed within the 60 ms grid.

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

aaaaaaaaaaa

aaaaa

aaaaa

a

16 (20) 32 (40)

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

PLC program could not be executed within the 48 ms (60 ms) time

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

base and therefore ”Fragmenting” had to be selected.

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

OB 1

end

a

a

a

a

a

a

a

a

a

a

a

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

48 (60)

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

aaaaaaaaa

The PLC operating

system (OB 1)

recalls the cyclic user program

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

aaaaa

t/ms

a

a

a

a

a

0

16 (20)

32 (40)

OB 1

call

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

a

aaa

aaa

aaa

aaa

aaa

aaa

Higher-priority NC and PLC program blocks

a

a

a

a

a

Cyclic user program scanning (OB 1)

a

Low-priority NC program blocks

If the OB 1 (cyclical useer program) is too large to be processed in the 48 ms (up to SW 4.1:

60 ms) grid, fragmentation must be selected.

Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02 1–7

©

SINUMERIK 805 (PJ)

48 (60) t/ms

OB 1

64 (80) 96 (120)

end

OB 1

call

Page 19

1 Introductory Remarks 05.93

1.3.4 Influencing factor: User program size

The timing grid,of cyclic program scanning is 12 x the scanning time of the position control

(12 x 4 ms = 48 ms; up to SW 4.1: 12 x 5 = 60 ms).

The admissible execution time of the cyclic program for both variants can also be increased by

augmenting PLC MD 1 (CPU load in %).

The admissible runtime for the interrupt service routine (PLC MD 3), regardless of the cyclic

execution mode, may not exceed 2000 us in an interval of 4 * scanning time (4 x 4 ms =

16 ms; up to SW 4.1: 4 x 5 = 20 ms).

The entire runtime may either be used for one-shot execution of the statements in OB 2 or, in

an extreme situation, for 4-shot execution of OB 2, as the interrupt input byte is scanned for an

edge change on the basis of the scanning time. If the default runtime for OB 2 proves

µ

insufficient, PLC-MD 3 must either be incremented (to max. 2500

s) or the PLC set to the

Stop mode when OB 2 exceeds the allotted time by modifying bit 1 in PLC MD 2003. The

example on the next page emphasizes the difference between the two variants for a cyclic

user program with a runtime time of 25 ms.

No fragmentation:

The cyclic user program may be interrupted by higher-priority NC and PLC program blocks

only ( e. g. position control, interpolation, monitoring functions, programming and test

functions, interrupt service routine (OB 2)). It is otherwise continued until it has terminated and

all signals it generated habe been forwarded to their destinations (NC, I/Os). Only then can the

low-priority functions execute.

Depending on the size of the STEP 5 program in OB 1, the remaining interval may be quite

shorte, as the operating system recalls the cyclic program when 48 ms (up to SW 4.1: 60 ms)

have passed. The consequence is that too little time is available for the low-priority functions, a

fact which becomes immediately apparent in a sluggish ”operator interface”. Display

construction is extremely slow, as is the controller's reaction to keyboard entries. In extreme

situations, the low-priority functions are allatted almost no time at all to execute.

In the example, (runtime of cyclic user program = 25 ms, SW 4.2 installed) the CPU load

caused by the STEP 5 program alone would escalate to value x, where

x =

25 ms

48 ms

.

100 % =

52 % , assuming that cyclic execution

is terminated within 48 ms. In the example, no regard was paid to the 5% basic load resulting

from data transfers prior to and following the OB 1 call.

It is obvious that a CPU load of almost 57% for the controller alone is not acceptable.

–8© Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02

1

SINUMERIK 805 (PJ)

Page 20

05.93 1 Introductory Remarks

1.3.4 Influencing factor: User program size

Fragmenting:

When this variant is used, the cyclic program interrupts itself autonomously. If the default is

used (values for SW 4.2), the CPU load, referred to the cyclic program timing grid, would be:

x =

2.4 ms . 3

48 ms

.

100 %=15 %

The basic load for the cyclic program, about 5%, must be added to this, so that the cyclic

program load on the CPU would always be 20 %. It is less than 20% when cyclic execution

is not terminated within one timing period. Extremely long cyclic user programs may cause the

cycle time monitor to response (default: 300 ms).

Note:

By selecting the diagnostics function (PLC MD 2003, bit 7 = 1), the user can obtain a general

view of the anticipated run time for STEP 5 programs as well as the required cycle time. On

the basis of these data, he can optimize the configuration of his MD as regards his job

requests and the purpose for which the controller is to be used (cf. section 8 ”Error Analysis”).

Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02 1–9

©

SINUMERIK 805 (PJ)

Page 21

1 Introductory Remarks 11.91

1.4 Block overview

1.4 Block overview

Organization data blocks

OB No. OB designation OB name

1

2

20

OB for cyclic scanning

OB for interrupt scanning

OB for one-shot scan after starting

Program data blocks

PB No. PB designation PB name

0

User assignable

255

Function data blocks

FB No. FB designation PB name

0

10

11

12

EINR-DB

Reserved

Reserved

Generate data blocks

Reserved

User

assignable

59

60

61

62

63

64

65

66

70

104

105

106

199

200

255

BLOCK-TR

NCD-LESE

NCD-SCHR

M-STACK

STACK-M

SEND

RECEIVE

CONTROL

Reserved

Blocktransfer

Read NC data

Write NC data

Reserved

Reserved

Transfer flags to stack

Flag stack to transfer flag area

Reserved

SINEC L2

Reserved

User assignable

User assignable

1–10 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0CM02

SINUMERIK 805 (PJ)

Page 22

05.93 1 Introductory Remarks

1.4 Block overview

Data blocks

DB No. DB designation DB name

0

1

2

27

28

29

35

36

37

38

70

71

255