Page 1

Introduction 1

Turning On,

SINUMERIK 802D

SINUMERIK 802D base line

Programming and Operating

Turning

Reference−Point Approach

Setting Up 3

Manually Controlled Mode 4

Automatic Mode 5

Part Programming 6

System 7

Programming 8

2

Valid for

Control system Software version

SINUMERIK 802D 2

SINUMERIK 802D base line 1

Cycles 9

08/05 Edition

Page 2

Safety information

This Manual contains information which you should carefully observe to ensure your own personal safety

and the prevention of material damage. The notices are highlighted by a warning triangle and, depending on

the degree of hazard, represented as shown below:

Danger

!

indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

!

indicates that death or severe personal injury can result if proper precautions are not taken.

Caution

!

with a warning triangle indicates that minor personal injury can result if proper precautions are not taken.

Caution

without a warning triangle means that material damage can occur if the appropriate precautions are not

taken.

Attention

indicates that an undesired event or status can occur if the appropriate note is not observed.

If several hazards of different degrees occur, the hazard with the highest degree must always be given preference. If a warning note with a warning triangle warns of personal injury, the same warning note can also

contain a warning of material damage.

Qualified personnel

Start−up and operation of the device/equipment/system in question must only be performed using this documentation. The start−up and operation of a device/system must only be performed by qualified personnel.

Qualified personnel as referred to in the safety guidelines in this documentation are those who are authorized to start up, earth and label units, systems and circuits in accordance with the relevant safety standards.

Proper use

Please note the following:

Warning

!

The device may only be used for the applications described in the Catalog and only in combination with the

equipment, components and devices of other manufacturers as far as this is recommended or permitted by

Siemens. It is assumed that this product be transported, stored and installed as intended and maintained

and operated with care to ensure that the product functions correctly and properly.

Trademarks

All designations marked with the copyright notice ® are registered trademarks of Siemens AG. Other names

in this publication might be trademarks whose use by a third party for its own purposes may violate the rights

of the registered holder.

Disclaimer of liability

Although we have checked the contents of this publication for agreement with the hardware and software

described, since differences cannot be totally ruled out. Nonetheless, differences might exist and therefore

we cannot guarantee that they are completely identical. The information given in this publication is reviewed

at regular intervals and any corrections that might be necessary are made in the subsequent editions.

Siemens AG

Automation and Drives

Postfach 4848

90437 NÜRNBERG

GERMANY

Copyright (E) Siemens AG 2005.

6FC5698−2AA00−1BP4

Siemens AG 2005

Subject to change without prior notice.

Page 3

Preface

SINUMERIK Documentation

The SINUMERIK Documentation is organized in 3 levels:

S General Documentation:

S User Documentation

S Manufacturer/Service Documentation:

For detailed information regarding further publications about SINUMERIK 802D, as well as

for publications that apply for all SINUMERIK control systems (e.g. Universal Interface, Measuring Cycles...), please contact your Siemens branch office.

A monthly overview of publications with specification of the available languages can be found

on the Internet at:

http://www.siemens.com/motioncontrol

Follow the menu items ”Support”/”Technical Documentation”/”Overview of Publications”.

The Internet edition of DOConCD − DOConWEB − can be found at:

http://www.automation.siemens.com/doconweb

Addressees of the documentation

Standard scope

Hotline

The present documentation is aimed at the machine tool manufacturer. This publication provides detailed information required for the machine tool manufacturer to start up the SINUMERIK 802D control system.

The present Instruction Manual describes the functionality of the standard scope. Any

amendments made by the machine manufacturer are documented by the machine manufacturer.

Other functions not described in this documentation can possibly also be performed on the

control system. However, the customer is not entitled to demand these functions when the

new equipment is supplied or servicing is carried out.

If you have any questions, do not hesitate to call our hotline:

A&D Technical Support

Tel.: +49 (0) 180 / 5050 − 222

Fax: +49 (0) 180 / 5050 − 223

Internet: http://www.siemens.de/automation/support−request

If you have any questions (suggestions, corrections) regarding the Documentation, please

send a fax to the following number or an e−mail to the following address:

Fax: +49 (0) 9131 / 98 − 63315

E−mail: motioncontrol.docu@siemens.com

Fax form: see return fax form at the end of this publication

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

iii

Page 4

Preface

Internet address

http://www.siemens.com/motioncontrol

iv

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 5

Contents

1 Introduction 1-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Screen layout 1-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Operating areas 1-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Accessibility options 1-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Calculator 1-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Editing Chinese characters 1-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Hotkeys 1-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 The help system 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Coordinate systems 1-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Turning On and Reference Point Approach 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Setting Up 3-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Entering the tools and the tool offsets operating area”# 3-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Use this softkey to create a new tool. 3-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Determining the tool offsets (manually) 3-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Determining tool compensations using a probe 3-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Determining the tool offsets using optical measuring instruments 3-37 . . . . . . . . . . . . . . . . . . . . .

3.1.5 Probe settings 3-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Tool monitoring 3-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Entering/modifying a work offset 3-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Determining the work offset 3-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Programming setting data - ”Parameter” operating area 3-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 R parameters − ”Offset/Parameter”operating area 3-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

4 Manually Controlled Mode 4-49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Mode Jog - ”Position” operating area 4-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Assigning handwheels 4-53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 MDA mode (Manual input) - ”Machine” operating area 4-54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Face turning 4-57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Automatic Mode 5-61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Selecting / starting a part program - ”Machine” operating area 5-66 . . . . . . . . . . . . . . . . . . . . . . .

5.2 Block search - ”Machine” operating area 5-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Stopping / canceling a part program 5-68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Reapproach after cancellation 5-69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Repositioning after interruption 5-69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Program execution from external source (RS232 interface) 5-70 . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Part Programming 6-71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Entering a new program - ”Program” operating area 6-74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Editing part programs - ”Program” operating area 6-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Blueprint programming 6-77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Simulation 6-95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Data transfer via the RS232 interface 6-96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

v

Page 6

Contents

7 System 7-99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 PLC diagnosis represented as a ladder diagram 7-120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Screen layout 7-120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Operating options 7-121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Programming 8-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Fundamentals of NC programming 8-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Program names 8-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Program structure 8-131 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Word structure and address 8-132 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Block structure 8-133 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Character set 8-134 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.6 Overview of the instructions 8-136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Positional data 8-148 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Absolute / incremental dimensioning: G90, G91, AC, IC 8-148 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Dimensions in metric units and inches: G71, G70, G710, G700 8-149 . . . . . . . . . . . . . . . . . . . . . .

8.2.3 Radius / diameter dimensional notation: DIAMOF, DIAMON 8-150 . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.4 Programmable work offset: TRANS, ATRANS 8-151 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.5 Programmable scaling factor: SCALE, ASCALE 8-152 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.6 Workpiece clamping − settable work offset:

G54 to G59, G500, G53, G153 8-154 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.7 Programmable working area limitation:

G25, G26, WALIMON, WALIMOF 8-155 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Axis movements 8-157 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Linear interpolation with rapid traverse: G0 8-157 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Linear interpolation with feedrate: G1 8-158 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Circular Interpolation: G2, G3 8-159 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Circular interpolation via intermediate point: CIP 8-162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.5 Circle with tangential transition: CT 8-162 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.6 Thread cutting with constant lead: G33 8-163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.7 Thread cutting with variable lead: G34, G35 8-166 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.8 Thread Interpolation: G331, G332 8-167 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.9 Fixed point approach: G75 8-168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.10 Reference point approach: G74 8-168 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.11 Measuring with touch−trigger probe: MEAS, MEAW 8-169 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.12 Feedrate F 8-170 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.13 Exact stop / continuous−path control mode: G9, G60, G64 8-171 . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.14 Acceleration pattern: BRISK, SOFT 8-173 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.15 Percentage acceleration override: ACC 8-174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.16 Traversing with feedforward control: FFWON, FFWOF 8-175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.17 3rd and 4th axes 8-176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.18 Dwell Time: G4 8-176 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.19 Travel to fixed stop 8-177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Spindle movements 8-181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Spindle speed S, directions of rotation 8-181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Spindle speed limitation: G25, G26 8-181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Spindle positioning: SPOS 8-182 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.4 Gear stages 8-183

8.4.5 2nd spindle 8-183 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Special turning functions 8-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Constant cutting rate: G96, G97 8-185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Rounding, chamfer 8-187 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.3 Blueprint programming 8-188 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Tool and tool offset 8-191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 General notes 8-191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Tool T 8-191 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Tool offset number D 8-192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 7

8.6.4 Selecting the tool radius compensation: G41, G42 8-196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.5 Corner behavior: G450, G451 8-197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.6 Tool radius compensation OFF: G40 8-199 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.7 Special cases of the tool radius compensation 8-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.8 Example of tool radius compensation 8-201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.9 Use of milling cutters 8-202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.10 Special handling of tool compensation 8-204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Miscellaneous function (M) 8-205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 H function 8-206 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Arithmetic parameters R, LUD and PLC variables 8-207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.1 Arithmetic parameters R 8-207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.2 Local User Data (LUD) 8-208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.3 Reading and writing PLC variables 8-210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10 Program jumps 8-211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.1 Jump destination for program jumps 8-211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.2 Unconditional program jumps 8-211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.3 Conditional program jumps 8-212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.4 Program example for jumps 8-214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 Subroutine technique 8-215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11.1 General 8-215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11.2 Calling machining cycles 8-217 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12 Timers and workpiece counters 8-218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12.1 Runtime timer 8-218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.12.2 Workpiece counter 8-219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.13 Language commands for tool monitoring 8-221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.13.1 Tool monitoring overview 8-221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.13.2 Tool life monitoring 8-222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.13.3 Workpiece count monitoring 8-223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.14 Milling on turning machines 8-226 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.14.1 Milling of the front face − TRANSMIT 8-226 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.14.2 Milling of the peripheral surface − TRACYL 8-228 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.15 G functions equivalent to the SINUMERIK 802S − Turning 8-233 . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

9 Cycles 9-235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Overview of cycles 9-235 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Programming cycles 9-236 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Graphical cycle support in the program editor 9-238 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Drilling cycles 9-240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 General 9-240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Prerequisites 9-241 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Drilling, centering – CYCLE81 9-242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.4 Drilling, counterboring – CYCLE82 9-245 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.5 Deep hole drilling – CYCLE83 9-247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.6 Rigid tapping – CYCLE84 9-251 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.7 Tapping with compensating chuck – CYCLE840 9-254 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.8 Reaming1 (boring 1) – CYCLE85 9-258 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.9 Boring (boring 2) – CYCLE86 9-261 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.10 Boring with Stop 1 (boring 3) – CYCLE87 9-264 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.11 Drilling with stop 2 (boring 4) – CYCLE88 9-267 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.12 Reaming 2 (boring 5) – CYCLE89 9-269 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.13 Row of holes – HOLES1 9-271 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.14 Circle of holes – HOLES2 9-275 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Turning cycles 9-278 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

vii

Page 8

Contents

9.5.1 Prerequisites 9-278 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Grooving – CYCLE93 9-280 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 Undercut (forms E and F to DIN) – CYCLE94 9-288 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.4 Machining with undercut – CYCLE95 9-292 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.5 Thread undercut – CYCLE96 9-305 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.6 Thread cutting – CYCLE97 9-309 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.7 Chaining of threads – CYCLE98 9-315 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Error Messages and Error Handling 9-322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 General notes 9-322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Error handling in the cycles 9-322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 Overview of cycle alarms 9-322 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 Messages in the cycles 9-324 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 9

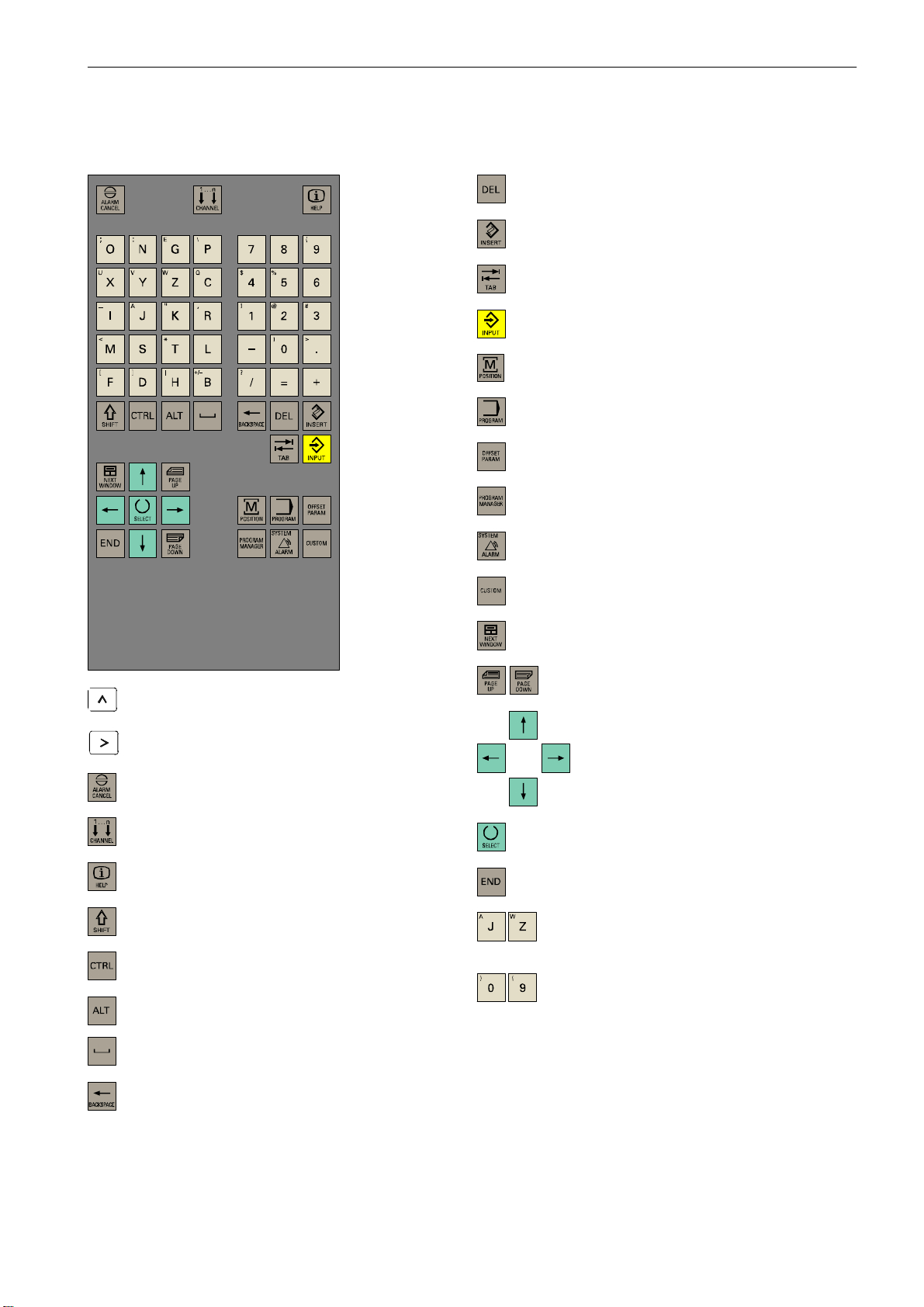

SINUMERIK 802D Key Definition

SINUMERIK 802D Key Definition

Clear key

&

Insert key

Tabulator

ENTER / Input key

”Position” operating area key

”Program” operating area key

”Parameter” operating area

”Program Manager” operating area

”Alarm/System” operating area

not assigned

”Recall” key

ETC key

”Acknowledge alarm” key

without function

Info key

Shift key

Controlkey

Altkey

SPACE

Backspace

PageUp / PageDown keys

Cursor keys

Selection key / toggle key

Alphanumeric keys

Double assignment on the Shift level

Numeric keys

Double assignment on the Shift level

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

ix

Page 10

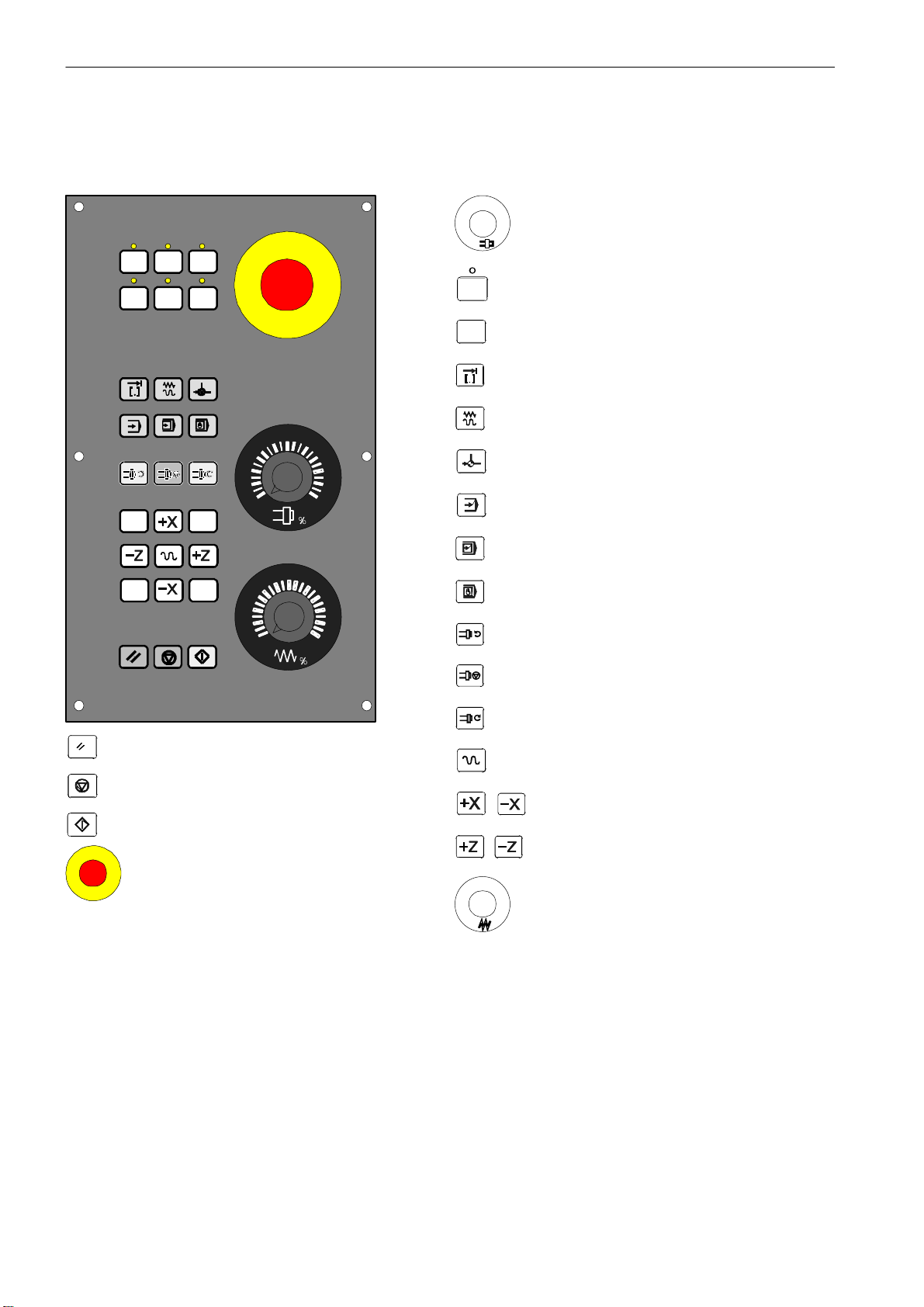

External Machine Control Panel

External Machine Control Panel

%

Spindle override

User−defined key with LED

User−defined key without LED

INCREMENT

80

70

60

90

100

110

120

JOG

REFERENCE POINT

AUTOMATIC

60

70

40

20

10

6

2

0

80

90

100

110

120

SINGLE BLOCK

MANUAL DATA

SPINDLE START LEFT

SPINDLE STOP

RESET

NC STOP

NC START

EMERGENCY STOP

X axis

Z axis

%

SPINDLE START RIGHT

RAPID TRAVERSE OVERRIDE

Feedrate override

x

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 11

Introduction

Note

The present Manual always uses ”802D bl” as an acronym for SINUMERIK 802D base line.

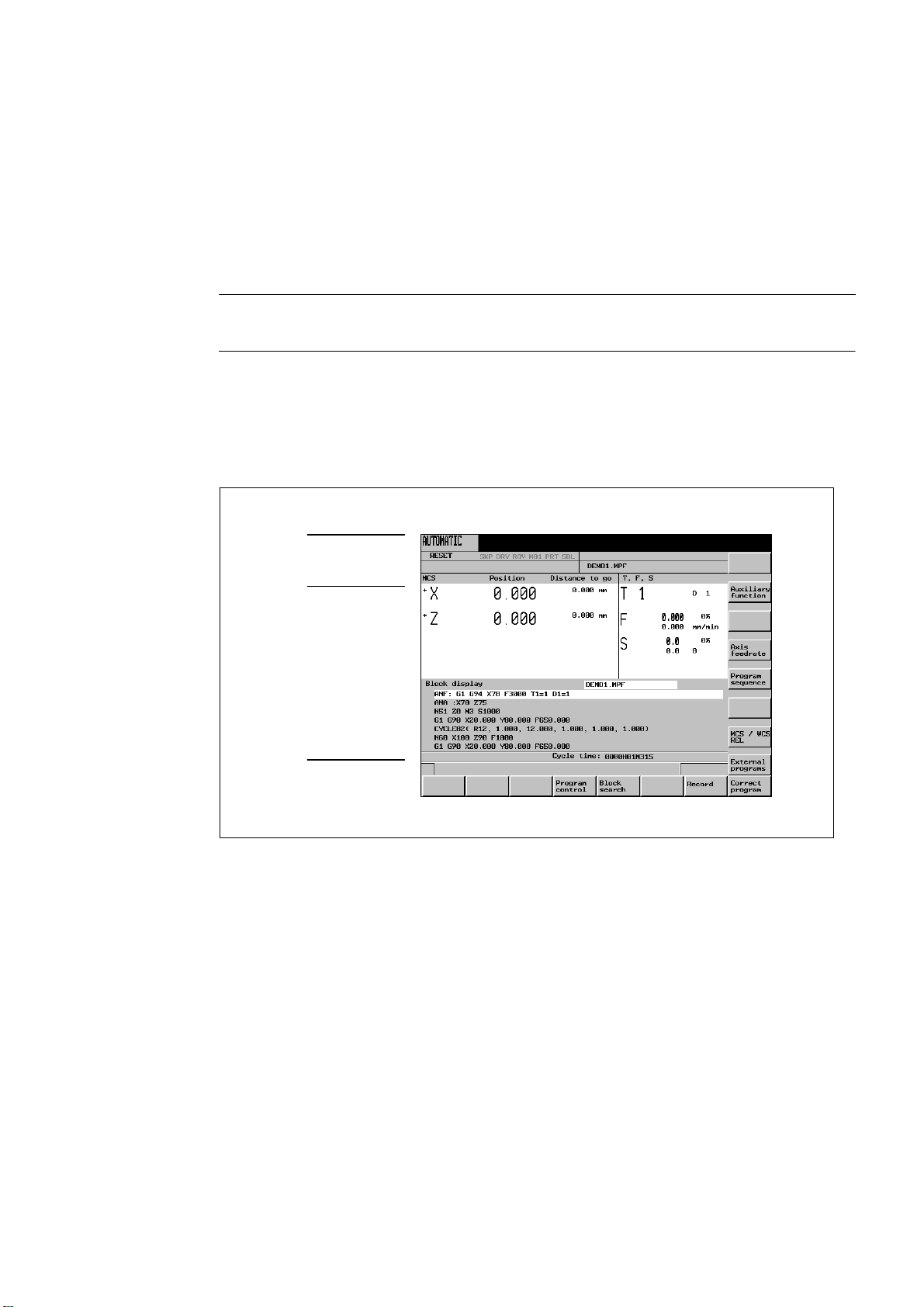

1.1 Screen layout

1

Status area

Applicationarea

Tip

and softkey area

Fig. 1-1 Screen layout

The screen is divided into the following main areas:

S Status area

S Applicationarea

S Tip and softkey area

G

function

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-11

Page 12

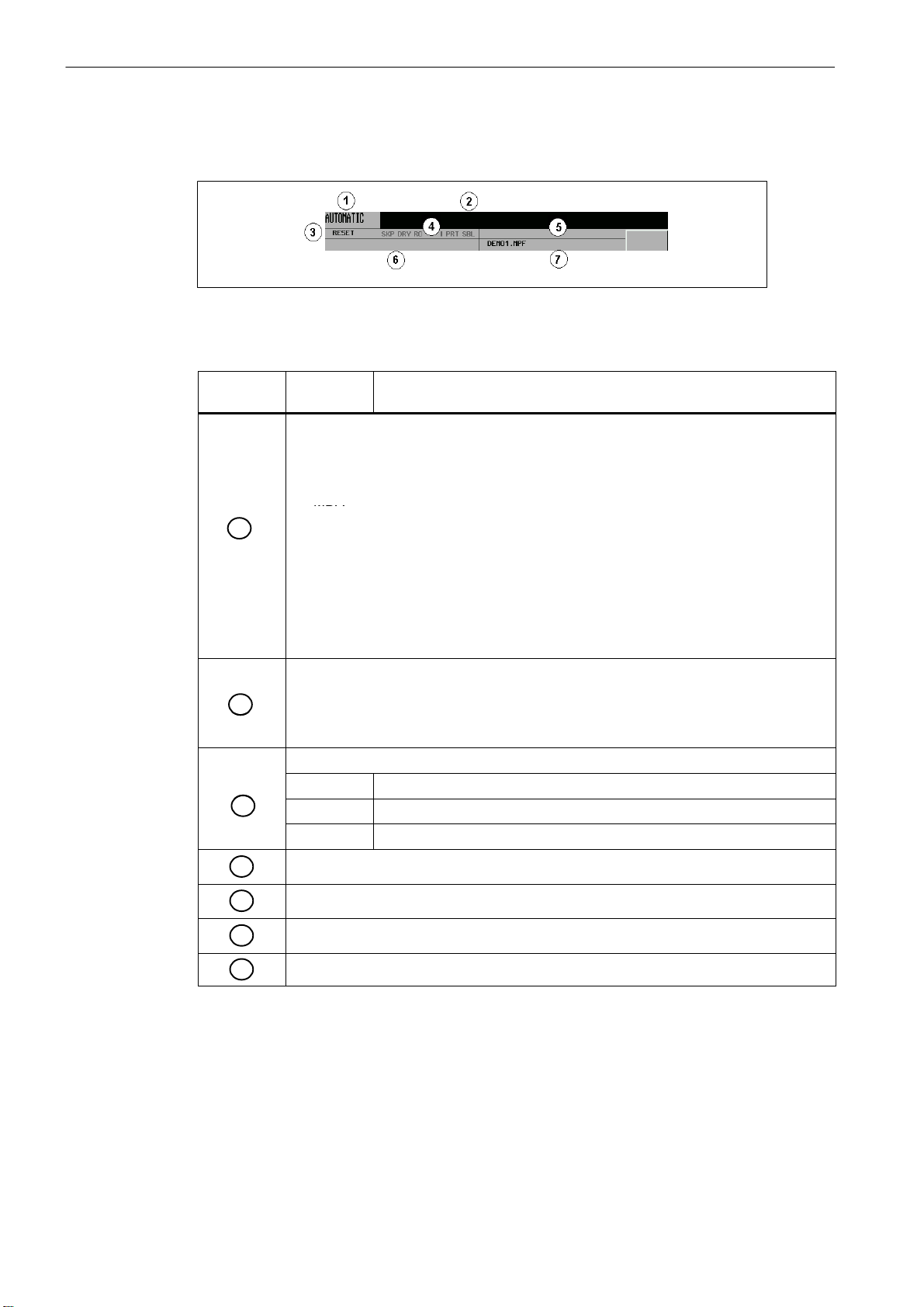

Introduction

MDA

y

System

1. Alarm number with alarm text, or

1.1 Screen layout

Status area

Fig. 1-2 Status area

Table 1-1 Explanation of the display elements in the status area

Screen Con-

trol

1

2

3

4

Display Meaning

Active operating area, active mode

Position

JOG; 1 INC, 10 INC, 100 INC, 1000 INC, VAR INC (evaluation by increments in the

JOG mode)

MDA

AUTOMATIC

Offset

Program

Program Manager

S

stem

Alarm

Marked as an ”external language” using G291

Alarm and message line

In addition, the following is displayed:

1. Alarm number with alarm text, or

2. Message text

Program status

RESET Program canceled / default status

RUN Program running

STOP Program stopped

Program controls in the AUTOMATIC mode

1-12

5

6

7

Reserved

NC messages

Selected part program (main program)

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 13

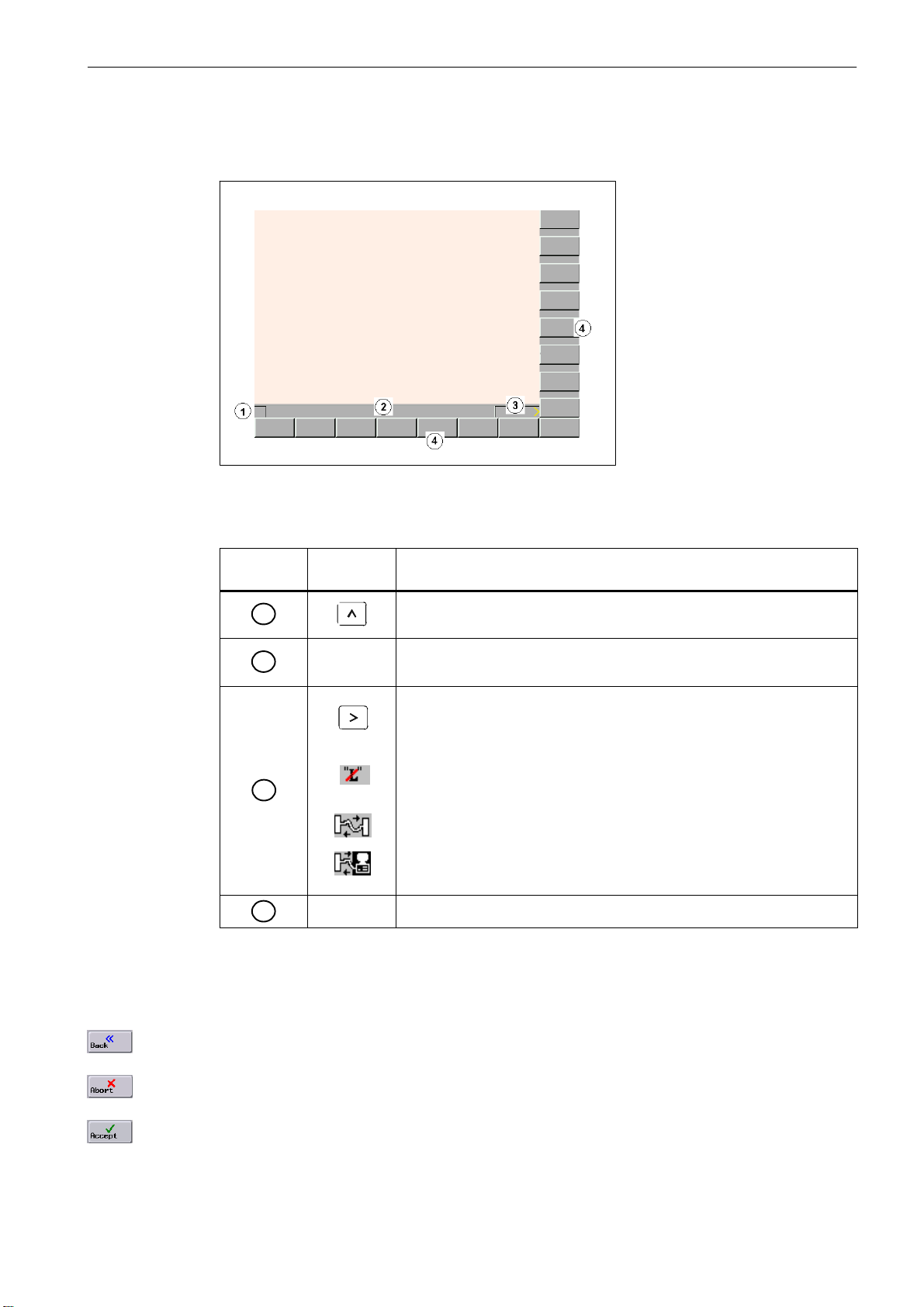

Tip and softkey area

Fig. 1-3 Tip and softkey area

Introduction

1.1 Screen layout

Table 1-2 Explanation of the screen elements in the tip and softkey area

Screen Con-

trol

1

2

3

4

Display Meaning

Recall symbol

Pressing the Recall key lets you return to the next higher menu level.

Tip line

Displays tips for the operator

MMCstatus information

ETC is possible (Pressing this key displays the horizontal softkey bar

providing further functions.)

Mixed notation active

Data transfer running

Connection to the PLC programming tool active

Softkey bar vertical and horizontal

Standard softkeys

Use this softkey to quit the screenform.

Use this softkey to cancel the input; the window is closed.

Selecting this softkey will complete your input and start the calculation.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-13

Page 14

Introduction

1.2 Operating areas

Selecting this softkey will complete your input and accept the values you have entered.

This function is used to switch the screenform from diameter programming to radius programming.

1.2 Operating areas

The functions of the control system can be carried out in the following operating areas:

Position Machine operation

Offset/Parameters Input of offset values and setting data

Program Creation of part programs

Protection levels

Program Manager Part program directory

System Diagnosis, start−up

Alarm Alarm and message lists

To switch the operating area, use the relevant key (hard key).

The input and modification of vital data in the control system is protected by passwords.

In the menus listed below the input and modification of data depends on the protection level

set:

S Tool offsets

S Work offsets

S Setting data

S RS232 settings

S Program creation / program correction

1-14

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 15

1.3 Accessibility options

1.3.1 Calculator

The calculator function can be activated from any operating area using ”SHIFT” and ”=”.

To calculate terms, the four basic arithmetic operations can be used, as well as the functions

”sine”, ”cosine”, ”squaring” and ”square root”. A bracket function is provided to calculate

nested terms. The bracket depth is unlimited.

If the input field is already occupied by a value, the function will accept this value into the

input line of the calculator.

When you press the Input key, the result is calculated and displayed in the calculator.

Selecting the Accept softkey enters the result in the input field at the current cursor position

of the part program editor and closes the calculator automatically.

Introduction

1.3 Accessibility options

Note

If an input field is in the editing mode, it is possible to restore the original status using the

”Toggle” key.

Fig. 1-4 Calculator

Characters permitted for input

+, −, *, / Basic arithmetic operations

S Sine function

The X value (in degrees) in front of the input cursor is replaced by the sin(X) value.

O Cosine function

The X value (in degrees) in front of the input cursor is replaced by the cos(X) value.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-15

Page 16

Introduction

1.3 Accessibility options

Q Square function

The X value in front of the input cursor is replaced by the X

R Square root function

The X value in front of the input cursor is replaced by the √⎮ value.

( ) Bracket function (X+Y)*Z

Calculation examples

100 + (67*3) 100+67*3 −> 301

sin(45_) 45 S −> 0.707107

cos(45_) 45 C −> 0.707107

2

4

√4 4 R −> 2

(34+3*2)*10 (34+3*2)*10 −> 400

To calculate auxiliary points on a contour, the calculator offers the following functions:

S Calculating the tangential transition between a circle sector and a straight line

S Moving a point in the plane

2

value.

Task Input −> Result

4 Q −> 16

Softkeys

S Converting polar coordinates to Cartesian coordinates

S Adding the second end point of a straight line/straight line contour section given from an

angular relation

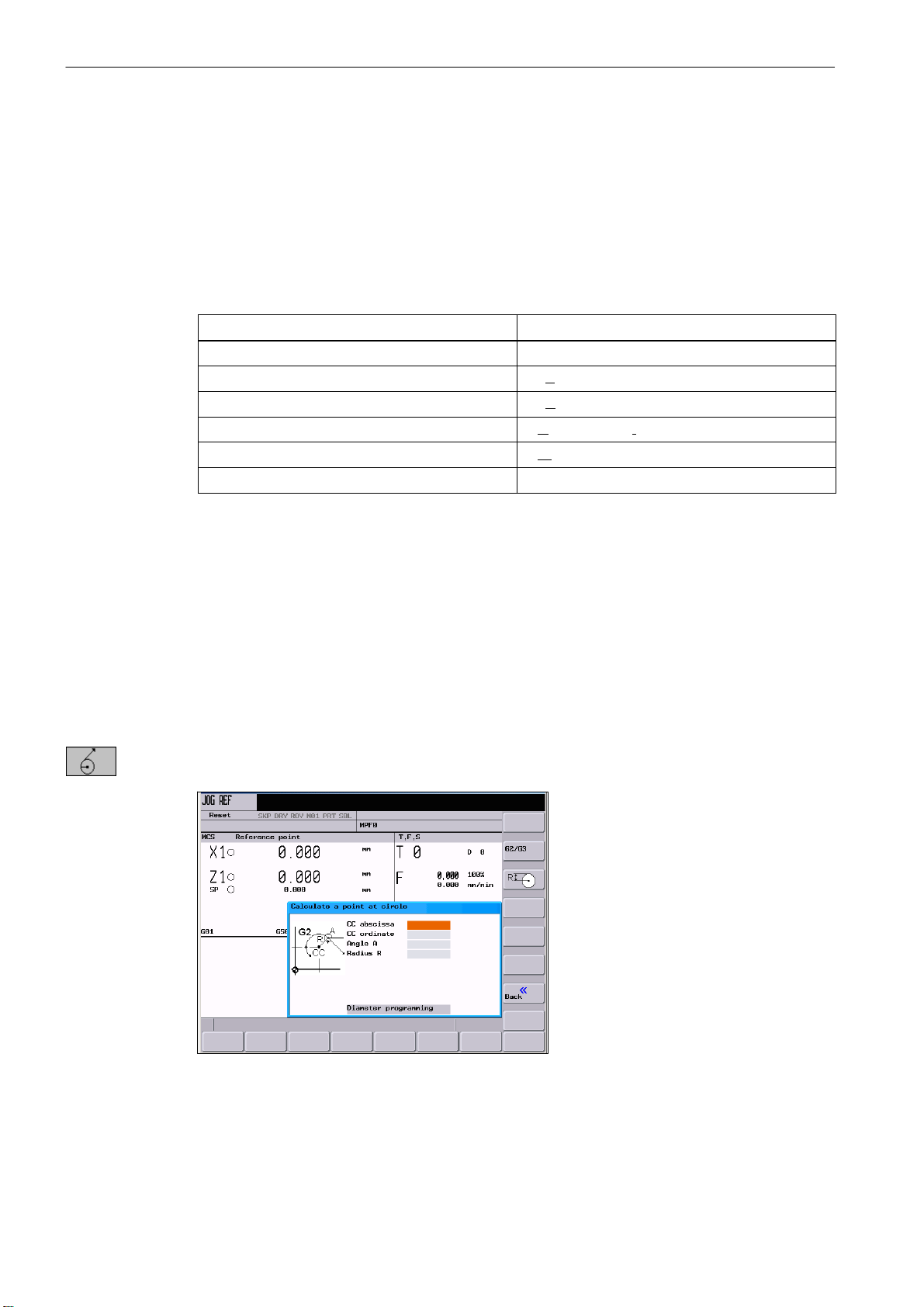

This function is used to calculate a point on a circle. The point results from the angle of the

tangent created, as well as from the radius and the direction of rotation of the circle.

1-16

Fig. 1-5

Enter the circle center, the angle of the tangent and the circle radius.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 17

Introduction

1.3 Accessibility options

G2/G3

Use the G2 / G3 softkey to define the direction of rotation of the circle.

Use this softkey to calculate the abscissa and ordinate values. The abscissa is the first axis,

and the ordinate is the second axis of the plane. The abscissa value is copied into the input

field from which the calculator function has been called, and the value of the ordinate is copied into the next following input field. If the function has been called from the part program

editor, the coordinates are saved with the axis names of the selected basic plane.

Example: Calculate the intersection point between the circle sector

and the straight line

in plane G18.

Given: Radius: 10

Circle center: Z 147 X 103

Connection angle of the straight line: −455

X

XZ

Z

Result: Z = 154.071

X = 110.071

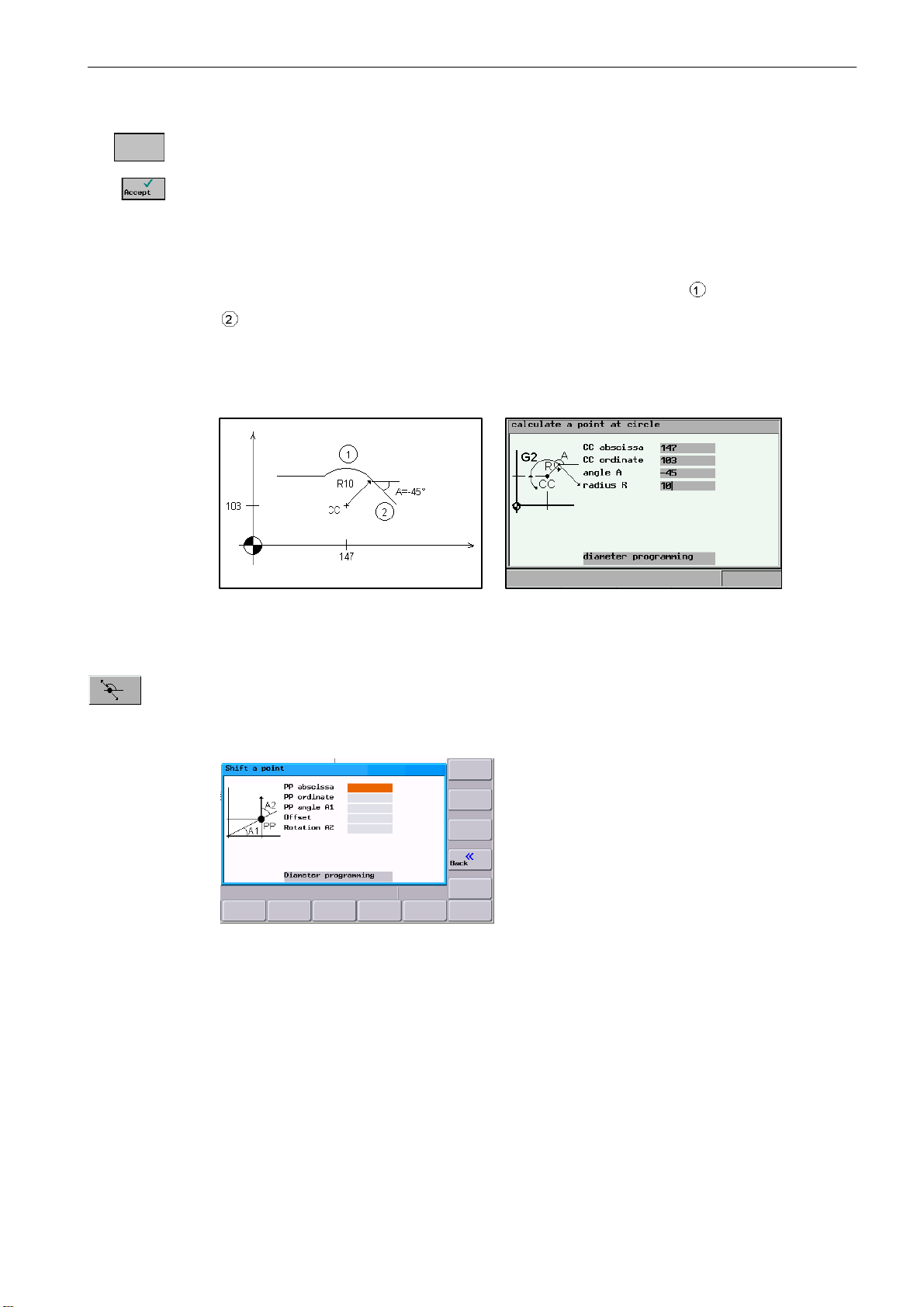

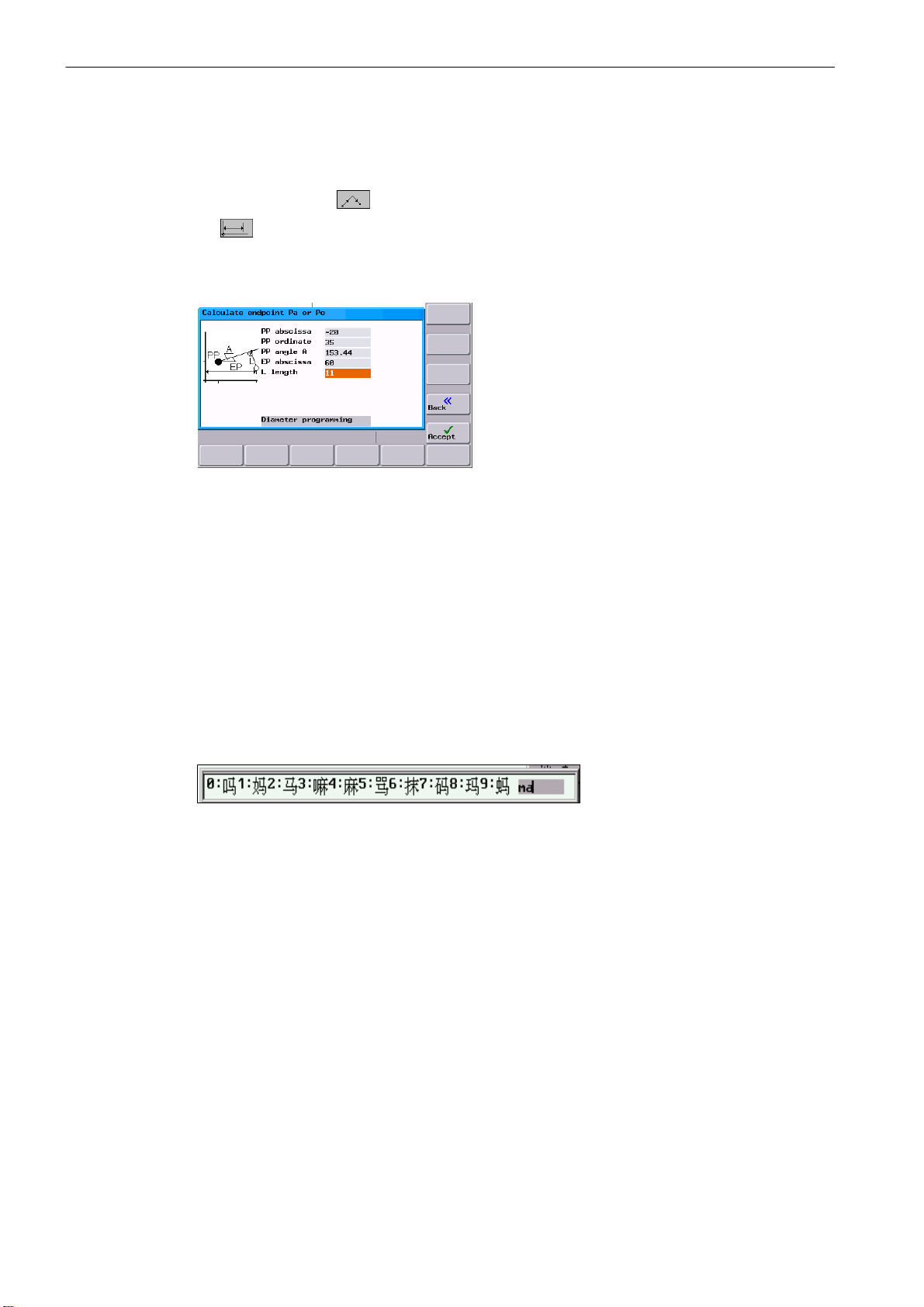

This function calculates the Cartesian coordinates of a point in the plane, which is to be connected to a point in the plane (PP) on a straight line. For calculation, the distance between

the points and the slope angle (A2) of the new straight line to be created with reference to

the slope (A1) of the given straight line must be known.

Fig. 1-6

Enter the following coordinates or angles:

S the coordinates of the given point (PP)

S the slope angle of the straight line (A1)

S the distance of the new point with reference to PP

S the slope angle of the connecting straight line (A2) with reference to A1

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-17

Page 18

Introduction

1.3 Accessibility options

Use this softkey to calculate the Cartesian coordinates which are subsequently copied into

two input fields following one after another. The abscissa value is copied into the input field

from which the calculator function has been called, and the value of the ordinate is copied

into the next following input field.

If the function has been called from the part program editor, the coordinates are saved with

the axis names of the selected basic plane.

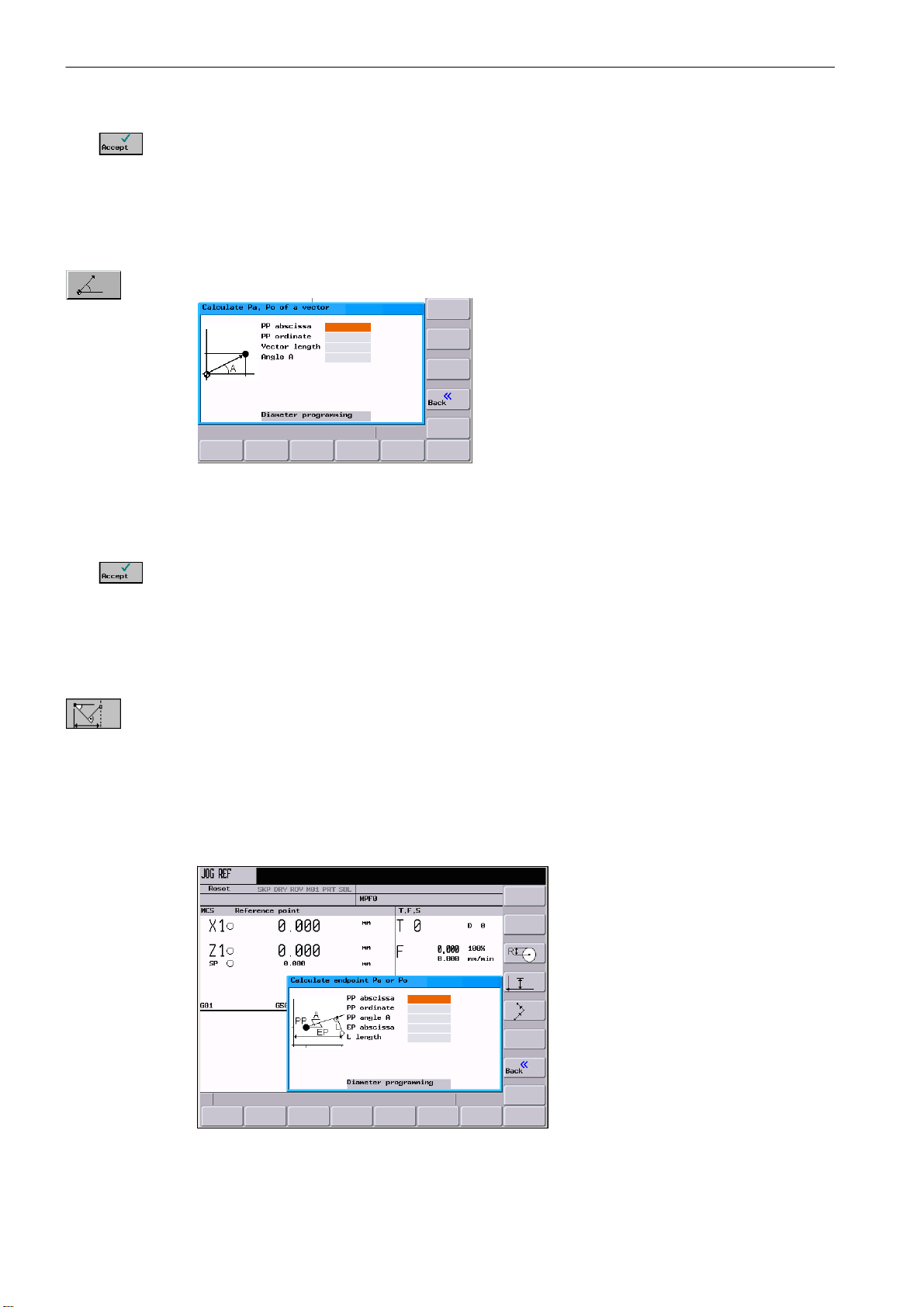

This function converts the given polar coordinates into Cartesian coordinates.

Fig. 1-7

Enter the reference point, the vector length and the slope angle.

Use this softkey to calculate the Cartesian coordinates which are subsequently copied into

two input fields following one after another. The abscissa value is copied into the input field

from which the calculator function has been called, and the value of the ordinate is copied

into the next following input field.

If the function has been called from the part program editor, the coordinates are saved with

the axis names of the selected basic plane.

Use this function to calculate the missing end point of the straight line/straight line contour

section whereby the second straight line stands vertically on the first straight line.

The following values of the straight line are known:

Straight line 1:

Starting point and slope angle

Straight line 2:

Length and one end point in the Cartesian coordinate system

1-18

Fig. 1-8

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 19

Introduction

1.3 Accessibility options

This function is used to select the given coordinate of the end point.

The ordinate value or the abscissa value is given.

The second straight line is rotated in the CW direction or in the CCW direction by 90 degrees

relative to the first straight line.

The missing end point is calculated. The abscissa value is copied into the input field from

which the calculator function has been called, and the value of the ordinate is copied into the

next following input field.

If the function has been called from the part program editor, the coordinates are saved with

the axis names of the selected basic plane.

Example

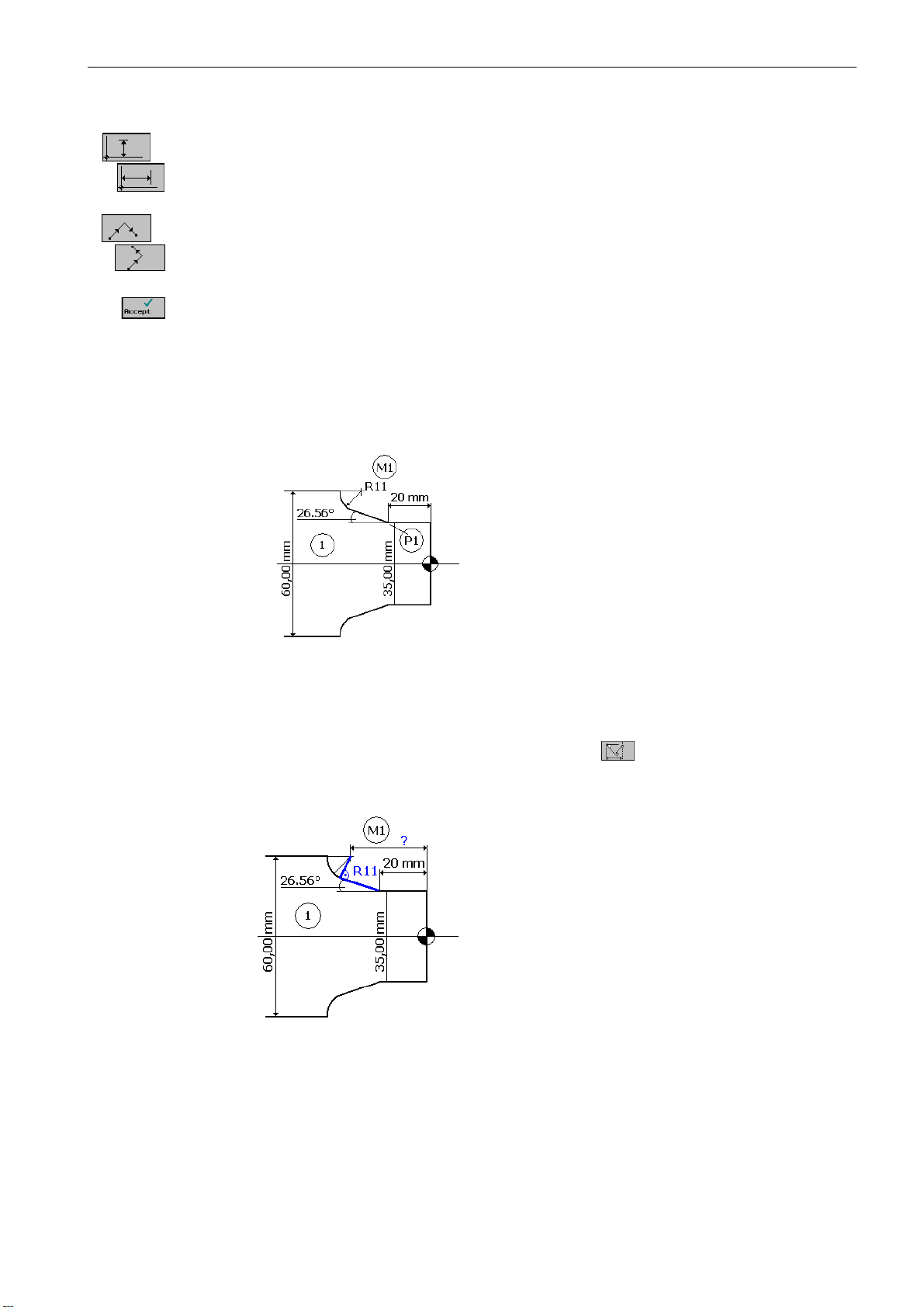

Fig. 1-9

Add the drawing above by the value of the center circle in order to be able to calculate the

intersection point between the circle sector of the straight line. The missing coordinate of the

center point is calculated using the calculator function

, since the radius in the tan-

gential transition stands vertically on the straight line.

Fig. 1-10

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-19

Page 20

Introduction

1.3 Accessibility options

Calculating M1 in section 1:

The radius stands at an angle of 90° turned CW on the straight−line defined by the angle.

Use the softkey

to select the appropriate direction of rotation. Use the softkey

to define the given end point.

Enter the coordinates of the pole, the slope angle of the straight line, the ordinate angle

of the end point and the circle radius as the length.

Fig. 1-11

Result: X = 60

Z = −44.601

1.3.2 Editing Chinese characters

This function is only available in the Chinese language version.

The control system provides a function for editing Chinese characters in the program editor

and in the PLC alarm text editor. After activation, type the phonetic alphabet of the searched

character in the input field. The editor will then offer various characters for this sound, from

which you can choose the desired one by entering either of the digits 1 to 9.

Fig. 1-12 Chinese editor

Alt S Is used to turn on / turn off the editor

1-20

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 21

1.3.3 Hotkeys

This operator control can be used to select, copy, cut and delete texts using special key

commands. These functions are available both for the part program editor and for input

fields.

CTRL C Copy

CTRL B Select

CTRL X Cut

CTRL V Paste

Alt L Is used to switch to the mixed notation

Alt H Help system

or info key

Introduction

1.3 Accessibility options

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-21

Page 22

Introduction

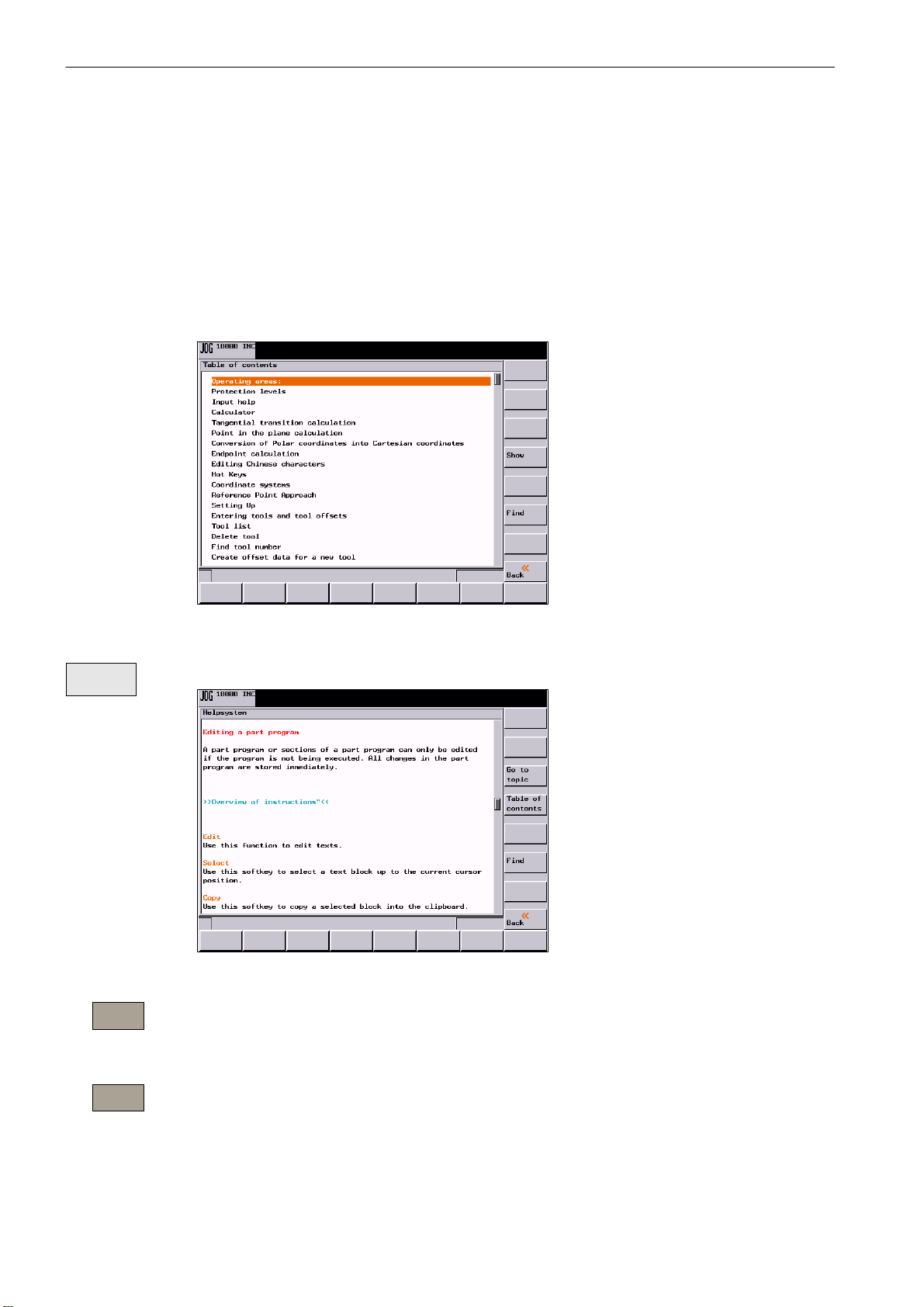

1.4 The help system

1.4 The help system

To activate the help system, use the Info key. It offers a brief description for all important operating functions.

In addition, the help offers the following topics:

S Overview of the NC commands with a brief description

S Cycle programming

S Explanation of the drive alarms

Show

Go to

topic

Fig. 1-13 Table of contents of the help system

This function opens the selected topic.

Fig. 1-14 Description for a help topic

Use this function to select cross references. A cross reference is marked by the characters

”>>....<<”. This softkey is only unhidden if a cross reference is displayed in the application

area.

1-22

Back to

topic

If you select a cross reference, in addition, the Back to topic softkey is displayed.

This function lets you return to the previous screenform.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 23

Introduction

1.4 The help system

Find

Use this function to search for a term in the table of contents. Type the term you are looking

for and start the search process.

Help in the ”Program editor” area

The system offers an explanation for each NC instruction. To display the help text directly,

position the cursor after the appropriate instruction and press the Info key.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

1-23

Page 24

Introduction

1.5 Coordinate systems

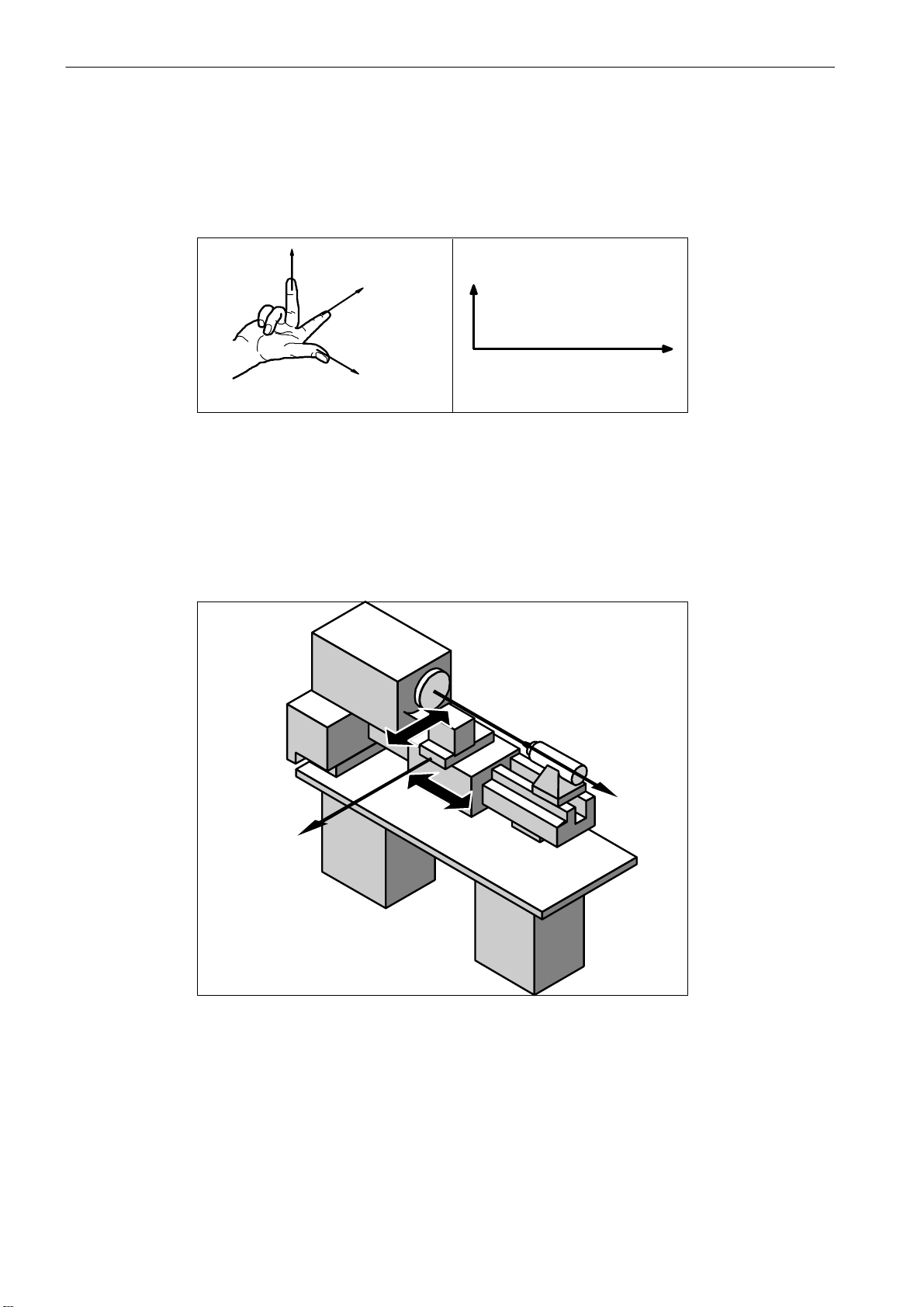

1.5 Coordinate systems

For machine tools, right−handed, right−angled coordinate systems are used. The movements on the machine are described as a relative movement between tool and workpiece.

+Z

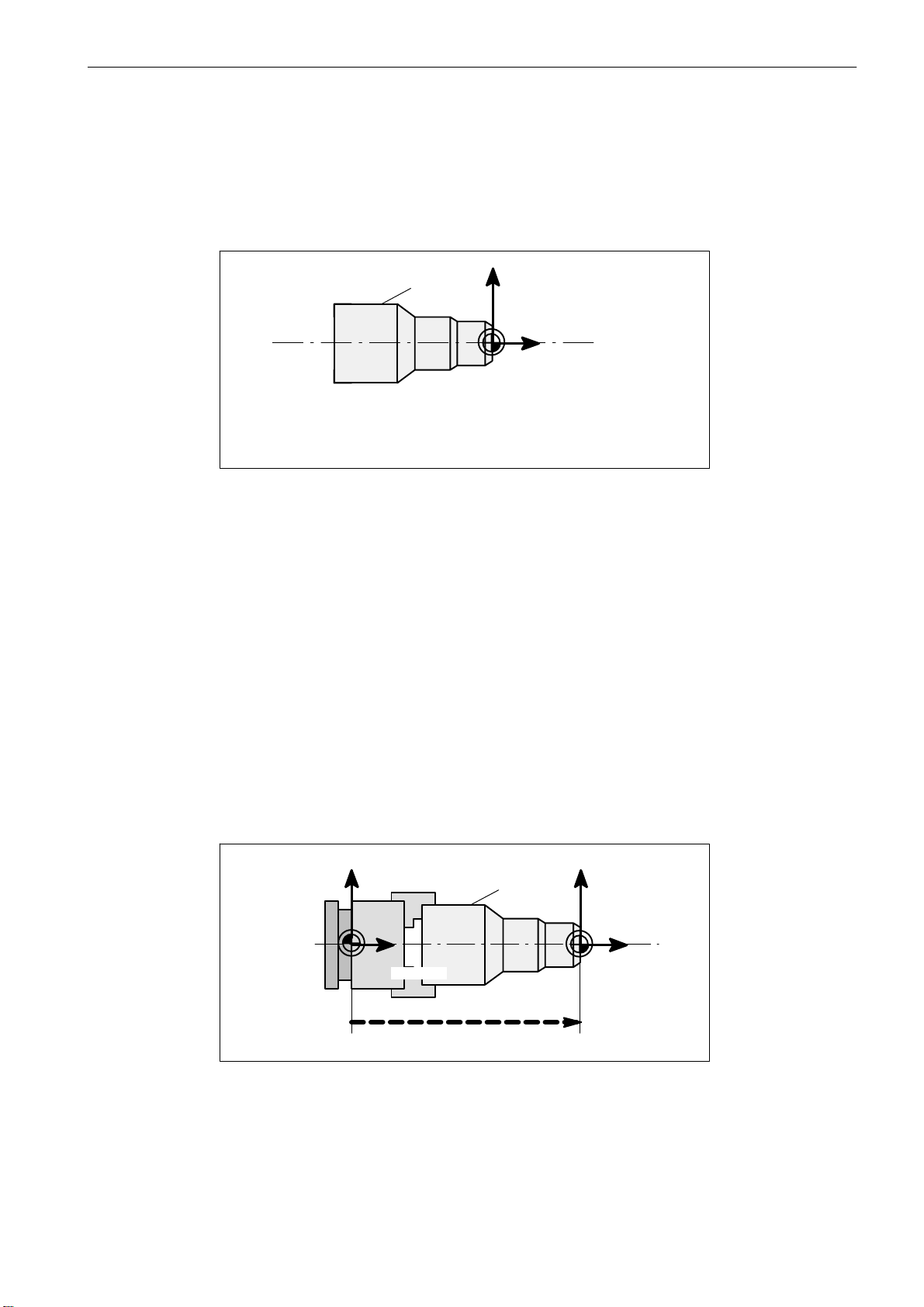

Fig. 1-15 Determination of the axis directions another to one; coordinate system for programming

when turning

Machine coordinate system (MCS)

How the coordinate system is located with reference to the machine, depends on the machine type concerned. It can be rotated in different positions.

+X

+Y

+X

+Z

+Z

+X

Fig. 1-16 Machine coordinates/machine axes using the example of a turning machine

The origin of the coordinate system is the machine zero.

This point only represents a reference point defined by the machine manufacturer. It need

not be approachable.

The traversing range of the machine axes can by in the negative range.

1-24

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 25

Workpiece coordinate system (WCS)

The coordinate system described above (see Fig. 1-15) is also used to describe the geometry of a workpiece in the workpiece program.

The workpiece zero can be freely selected by the programmer in the Z axis. In the X axis, it

lies in the turning center.

Introduction

1.5 Coordinate systems

Fig. 1-17 Workpiece coordinate system

Relative coordinate system

In addition to the machine and workpiece coordinate systems, the control system provides a

relative coordinate system. This coordinate system is used for setting freely selected reference points which have no influence on the active workpiece coordinate system. All axis

movements are displayed relative to these reference points.

Clamping the workpiece

For machining, the workpiece is clamped on the machine. The workpiece must be aligned

such that the axes of the workpiece coordinate system run in parallel with those of the machine. Any resulting offset of the machine zero with reference to the workpiece zero is determined along the Z axis and entered in a data area intended for the settable work offset. In

the NC program, this offset is activated, e.g. using a programmed G54 (see also Section

8.2.6).

Workpiece

W -workpiece zero

X

Workpiece

W

Z

Workpiece

X

Machine

M

Z

Machine

Fig. 1-18 Workpiece on the machine

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

e.g.

Workpiece

G54

X

Workpiece

W

Z

Workpiece

1-25

Page 26

Introduction

1.5 Coordinate systems

Current workpiece coordinate system

The programmed work offset TRANS can be used to generate an offset with reference to

the workpiece coordinate system resulting in the current workpiece coordinate system (see

Section ”Programmable work offset: TRANS”).

1-26

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 27

Turning On and Reference Point Approach

Note

When you turn on the SINUMERIK 802D and the machine, please also observe the Machine Documentation, since turning on and reference point approach are machine−dependent functions.

This documentation assumes an 802D standard machine control panel (MCP). Should you

use a different MCP, the operation may be other than described herein.

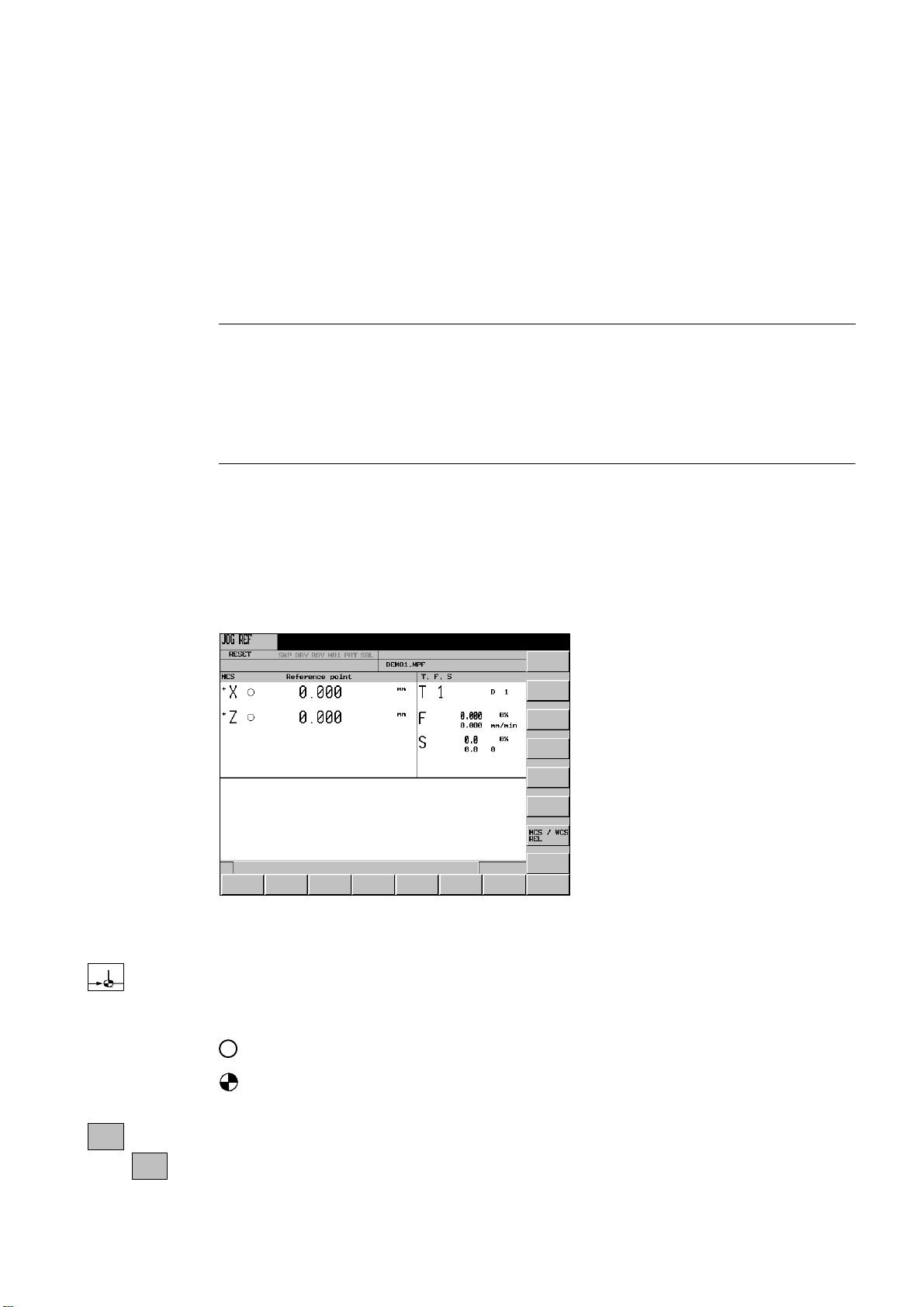

Operating sequence

First, turn on the power supply of CNC and machine. After the control system has booted,

you are in the ”Position” operating area, in the Jog mode.

The ”Reference point approach” window is active.

2

Fig. 2-1 The ”Jog−Ref” start screen

Use the Ref key on the machine control panel to activate ”reference point approach”.

The ”Reference point approach” window (Fig. 2-1) displays whether the axes are referenced

(approached to their reference points).

Axis must be referenced

Axis has reached its reference point

+X

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

...

-Z

Press a direction key.

2-27

Page 28

Turning On and Reference Point Approach

If you select the wrong approach direction, no motion will be carried out.

Approach the reference points for each axis one after the other.

Quit the function by switching the mode (MDA, AUTOMATIC or Jog).

Note

”Reference point approach” is only possible in the Jog mode.

2-28

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 29

Setting Up

Preliminary remarks

Before you can work with the CNC, set up the machine, the tools, etc. on the CNC as follows:

S Enter the tools and the tool offsets

S Enter/modify the work offset

S Enter the setting data

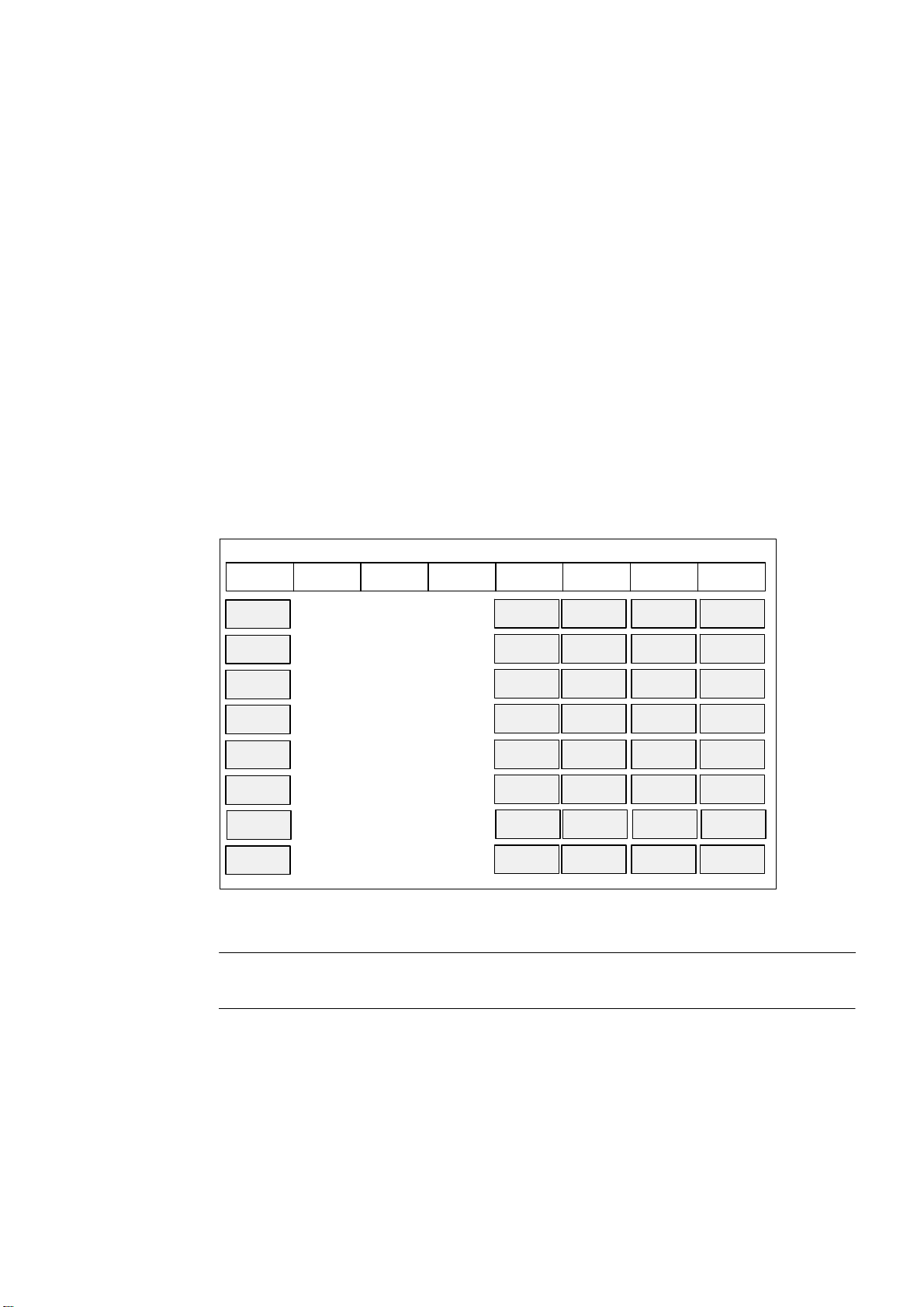

Menu tree

3

Tool

List

Tool

measure

Delete

tool

Extend

Edges

Find

New

tool

Tool

life

:

Work

offset

Measure

workpiece

R vari−

able

Find

Setting

data

Work area

limit.

Tim e

counter

Misc.

User

data

To o l

measure

Delete

tool

Extend

Edges

Find

New

tool

:

Fig. 3-1 Menu tree ”Parameters” operating area

Note

The softkeys marked in Fig. 3-1 with an asterisk (”:”) are missing in the 802D bl.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-29

Page 30

Setting Up

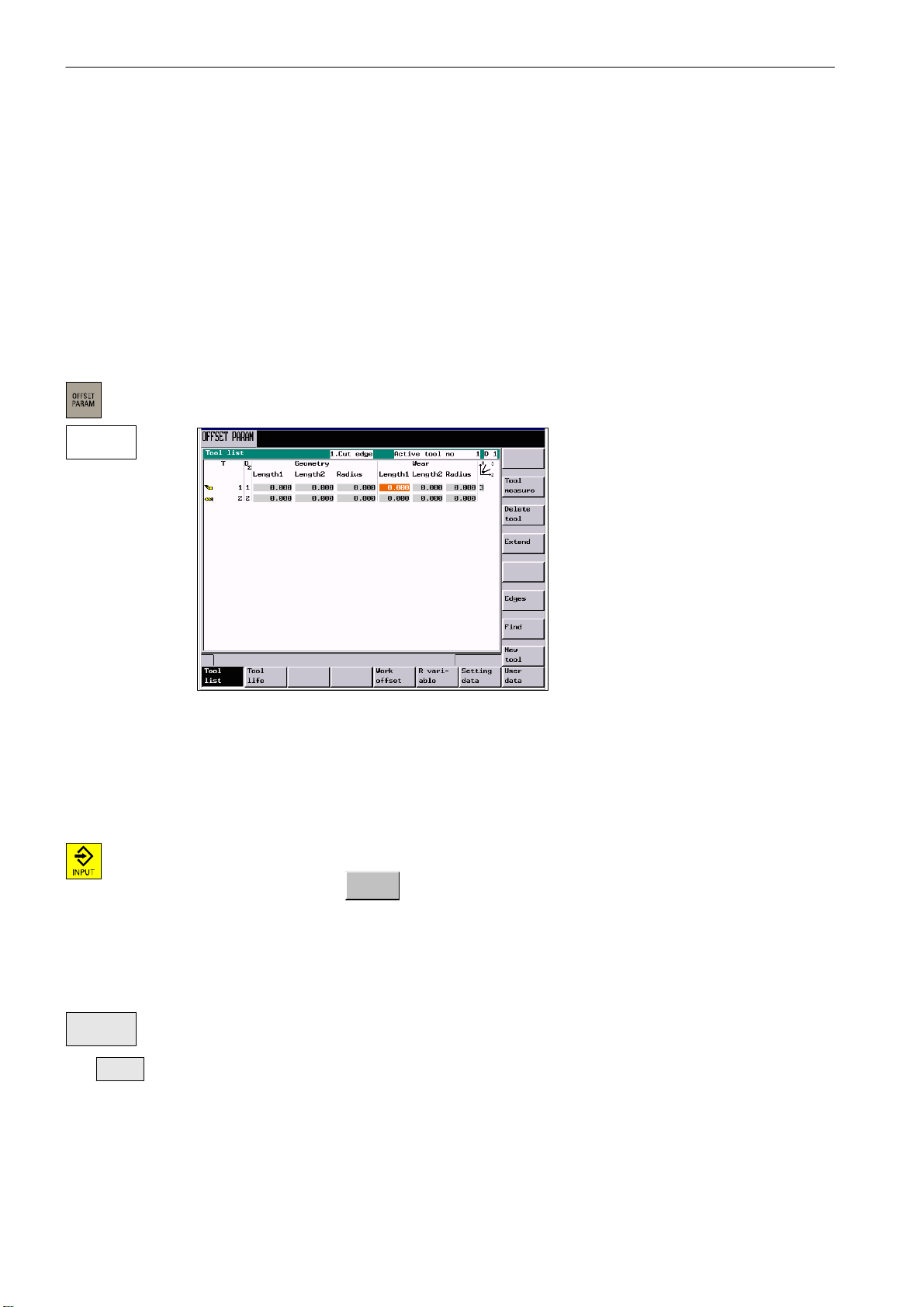

3.1 Entering the tools and the tool offsets operating area”#

3.1 Entering the tools and the tool offsets operating area”#

Functionality

The tool offsets consist of several data describing the geometry, the wear and the tool type.

Depending on the tool type, each tool is assigned a defined number of parameters. Tools are

identified by a number (T number).

See also Section 8.6 ”Tool and tool compensation”

Operating sequences

Use this softkey to open the ”Tool offset data” window which contains a list of the tools

created. Use the cursor keys and the Page Up / Page Down keys to navigate in this list.

Tool

List

Softkeys

Tool

measure

Measure

manual

Fig. 3-2 Tool list

Enter the offsets by positioning the

S cursor bar on the input field to be changed,

S enter the value(s)

and either press Input or use a cursor key to confirm.

Extend

For special tools, the

softkey function is provided which offers a complete parameter

list which can be filled out.

Use this softkey to determine the tool compensation data.

Determining the tool offset data manually (see Section 3.1.2)

3-30

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 31

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

Delete

tool

Extend

Measure

auto

Calibrate

probe

Determining the tool offset data semi−automatically (see Section 3.1.3)

Use this softkey to calibrate the sensing probe.

Note

With the 802D bl, the Tool measur softkey opens the “Measure tool” window directly.

Use this softkey to delete the tool.

Use this function to display all parameters of a tool. For the meanings of the parameters,

please refer to the Section ”Programming”.

Activate

change

Edges

Find

D >>

<< D

New

tool edge

Reset

edge

Change

type

Fig. 3-3 Input screen for special tools

Selecting this softkey activates the compensation values of the cutting edge.

Opens a lower−level menu bar offering all functions required to create and display further

edges.

Use this softkey to select the next higher edge number.

Use this softkey to select the next lower edge number.

Use this softkey to create a new edge.

Use this softkey to reset all compensation values of the edge to zero.

This function is intended to change the tool type. select the tool type using the appropriate

softkey.

Use this function to search for a tool by its number.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-31

Page 32

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

New

tool

Use this softkey to create tool offset data for a new tool.

Max. 48 tools can be created with the 802D, and 18 tools with the 802D bl. For the 802D bl,

no milling tools are offered.

3.1.1 Use this softkey to create a new tool.

Operating sequence

New

tool

This function offers another two softkey functions to select the tool type. After selecting the

tool type, type the desired tool number (max. 3 digits) in the input field.

OK

Fig. 3-4 The ”New tool” window Input of the tool number

For milling and drilling tools, the machining directions must be selected.

Fig. 3-5 Selection of the machining direction for a milling tool

Select OK to confirm your input. A data record loaded with zero will be included in the tool

list.

3-32

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 33

3.1 Entering the tools and the tool offsets operating area”#

3.1.2 Determining the tool offsets (manually)

Functionality

This function can be used to determine the unknown geometry of a tool T.

Prerequisite

The relevant tool is loaded. In the JOG mode, you will approach the edge of the tool to a

machine point whose machine coordinate values are known. This can be a workpiece with

a known geometry.

Procedure

Enter the reference point in the appropriate field Ø or Z0.

Please observe: The assignment of length 1 or 2 to the axis depends on the tool type (turn-

ing tool, drill).

With a turning tool, the reference point for the X axis is a diameter dimension.

Setting Up

Using the actual position of the point F (machine coordinate) and the reference point, the

control system can calculate the offset value assigned to length 1 or length 2 for the axis.

Note: You can also use a zero already determined (e.g value of G54). In this case, use the

edge of the tool to approach the workpiece zero point. If the edge is positioned directly at

workpiece zero, the reference point is zero.

F − toolholder reference point

M − machine zero

W - workpiece zero

The offset value in the X axis is a diameter value.

X

Machine

M

Fig. 3-6 Determination of the length offsets using the example of a cutting tool

Xactual position

Workpiece

Length 1=?

W

Diameter

Length 2=?

e.g. G54

F

Zactual position

Z

Machine

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-33

Page 34

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

F − toolholder reference point

M − machine zero

W - workpiece zero

X

Machine

Workpiece

Zactual position

Fig. 3-7 Determination of the length offset using the example of a drill: Length 1 / Z axis

Note

The diagram 3-7 only applies if the variables are the machine data MD 42950

TOOL_LENGTH_TYPE and MD 42940 TOOL_LENGHT_CONST00; otherwise, length tool 2

will apply for the milling and drilling tools (see also Manufacturer Documentation ”SINUMERIK

802D Start−up”)

Operating sequence

Measure

tool

Use this softkey to open the list box for manual and semiautomatic measuring.

M

e.g. G55

W

Length 1=?

F

Z

Machine

.

3-34

Measure

manual

Fig. 3-8 Selecting manual or semiautomatic measuring

Use this softkey to open the Measure tool window.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 35

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

Fig. 3-9 The ”Measure tool” window

S Either type the workpiece diameter in the ”Ø” field or the workpiece length in the ”Z0”

field. The machine coordinates and the values from the work offsets will apply.

When using a spacer, it is also possible to enter the thickness of the spacer for taking

into account.

S After selecting the Set length 1 or Set length 2 softkey, the control system will deter-

mine the searched length 1 or length 2 of the preselected axis. The offset value determined will be stored.

Save

position

Selecting this softkey will save the X position. Thereafter, you can traverse in the X direction.

Thus, it is possible to determine, for example, the workpiece diameter. The stored value of

the axis position will then be used for calculating the length offset.

The activation of the softkey is dependent on the display machine data 373

MEAS_SAVE_POS_LENGTH2 (see also Manufacturer Documentation ”SINUMERIK 802D

Start−up”)

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-35

Page 36

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

3.1.3 Determining tool compensations using a probe

Note

This function is only offered by the 802D.

Operating sequence

Tool

Measur.

Measure

auto

Use this softkey to open the Measure tool window.

Fig. 3-10 The ”Measure tool” window

In this screenform, you can enter tool and cutting edge numbers. In addition, the tool tip

position is displayed after symbol.

After the screenform has been opened, the input fields are filled with the data of the tool currently working.

The tool can be either

S the currently active tool of the NC (loaded via a part program) or

S a tool loaded by the PLC.

If the tool was loaded by the PLC, the tool number in the input screenform can be different

than that in the T, F,S window.

If you change the tool number, no automatic tool change will be performed using this function. The entered tool, however, are assigned measurement results.

Measuring process

Approach the probe using either the traversing keys or the handwheel.

After the ”Probe triggered” has

measuring process is completed. During the automatic measurement, a dial appears

symbolizing the active measuring process.

3-36

appeared, release the traversing key and wait until the

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 37

3.1 Entering the tools and the tool offsets operating area”#

Note

To create the measuring program, the parameters ”Safety clearance” from the Settings screenform and the feedrate from the Probe data screenform are used (see Section 3.1.5).

If several axes are moved simultaneously, no offset data can be calculated.

3.1.4 Determining the tool offsets using optical measuring instruments

Note

This function is only offered by the 802D.

Setting Up

Fig. 3-11 Measuring using an optical measuring instrument (for the T and D input fields, please refer

Measuring process

For measuring, traverse the tool until its tip appears in the crosshair. With a milling tool, use

the highest point of the cutting edge to determine the tool length.

Subsequently, select the Set length softkeys to calculate the offset values.

to ”Measuring using a probe”)

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-37

Page 38

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

3.1.5 Probe settings

Note

This function is only offered by the 802D.

Settings

Data

probe

The screenform below is used to store the coordinates of the probe and to set the axis feedrate for the automatic measuring process.

All position values refer to the machine coordinate system.

Fig. 3-12 The ”Probe data” interactive screenform

Table 3-1

Absolute position P1 Absolute position of the probe in the Z− direction

Absolute position P2 Absolute position of the probe in the X+ direction

Absolute position P3 Absolute position of the probe in the Z+ direction

Absolute position P4 Absolute position of the probe in the X− direction

Feedrate Feedrate with which the tool approaches the probe

Calibrating the probe

Calibrate

probe

The calibration of the probe can be carried out either in the Settings menu or in the Mea-

sure tool menu.

Approach the four points of the probe.

For calibration, use a tool of the type 500 with tool tip position 3 or 4.

Parameters

Meaning

3-38

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 39

Setting Up

3.1 Entering the tools and the tool offsets operating area”#

The offset parameters required to determine the four probe positions can be written to the

data records of two cutting edges.

Fig. 3-13 Calibrating the probe

After the screenform has appeared, an animation signaling the step to be executed is displayed next to the current positions of the probe. This point must be approached with the

appropriate axis.

After the ”Probe triggered” has

appeared, release the traversing key and wait until the

measuring process is completed. During the automatic measurement, a dial appears

symbolizing the active measuring process.

The positions delivered by the measuring program serve to calculate the real probe position.

The measuring function can be quit without approaching all positions. The points already

sensed are stored.

Note

To create the measuring program, the parameters ”Safety clearance” from the ”Settings”

screenform and feedrate from the ”Probe data” screenform are used.

If several axes are moved simultaneously, no offset data can be calculated.

Use the Next Step function to skip a point if this is not needed for measuring.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-39

Page 40

Setting Up

3.2 Tool monitoring

3.2 Tool monitoring

Note

This function is only offered by the 802D.

Toollife

Each monitoring type is represented in 4 columns.

S Setpoint

S Prewarning limit

S Residual value

S active

Use the checkbox element of the 4th column to activate/deactivate the monitoring type.

life

Fig. 3-14 Tool monitoring

Reset

monitor

Symbols in the T column provide information on the tool status.

Prewarning limit reached

Tool disabled

Tool is monitored

Use this softkey to reset the monitoring values of the selected tool.

3-40

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 41

Fig. 3-15

Setting Up

3.2 Tool monitoring

After

enable

Use this softkey to change the enable of the selected tool.

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-41

Page 42

Setting Up

3.3 Entering/modifying a work offset

3.3 Entering/modifying a work offset

Functionality

After the reference point approach, the actual−value memory and thus also the actual−value

display are referred to the machine zero. A machining program, however, is always referred

to the workpiece zero. This offset must be entered as the work offset.

Operating sequences

Use Offset Parameter and Work Offset to select the work offset.

An overview of all settable work offsets will appear on the screen. The screenform addition-

Work

offset

ally contains the values of the programmed work offset, of the active scaling factors, the status display and the total of all active work offsets.

Change

activated

Fig. 3-16 The ”Work offset” window

Position the cursor bar on the input field to be changed

and enter the value(s). Either move the cursor a press the Input key to accept the values

from the input fields into the work offsets.

The compensation values of the cutting edge come into effect immediately.

3-42

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 43

3.3.1 Determining the work offset

Prerequisite

You have select the window with the relevant work offset (e.g. G54) and the axis you want to

determine for the offset.

Setting Up

3.3 Entering/modifying a work offset

Procedure

Measure

workpiece

F − toolholder reference point

M − machine zero

W - workpiece zero

X

Machine

Workpiece

F

Zactual position

M

W

Length 2

Work offset Z=?

Z

Machine

Fig. 3-17 Determining the work offset for the Z axis

Select the ”Measure workpiece” softkey. The control system will switch to the ”Position” operating area and will open the dialog box for measuring the work offsets. The selected axis

will appear as a softkey with a black background.

Then scratch the workpiece with the tool tip. Enter the position for the workpiece in the workpiece coordinate system in the ”Set position to:” field.

Fig. 3-18 The Determine work offset in X” screenform The ”Determine work offset in Z” screenform

Set work

offset

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Selecting this softkey will calculate the offset and display the result in the ”Offset” field.

3-43

Page 44

Setting Up

3.4 Programming setting data - ”Parameter” operating area

3.4 Programming setting data - ”Parameter” operating area

Functionality

The setting data are used to define the settings for the operating states. These can be

changed as necessary.

Operating sequences

Select Setting data using the Offset Parameter and Setting data keys.

Setting

data

The Setting data softkey branches to another menu level where various control options can

be set.

Fig. 3-19 The Setting datastart screen

JOG feedrate

Feedrate in the Jog mode

If the feedrate value is zero, the control system will use the value stored in the machine

data.

Spindle

Spindle speed

Minimum / maximum

A limitation of the spindle speed in the ”Max.” (G26) / ”Min.” (G25) fields can only be performed within the limit values defined in the machine data.

Programmed (limitation)

Programmable upper speed limitation (LIMS) at constant cutting rate (G96).

Dry run feed (DRY)

The feedrate which can be entered here will be used instead of the programmed feedrate

in the AUTOMATIC mode if the ”Dry run feed” function is selected.

3-44

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 45

Softkeys

Setting Up

3.4 Programming setting data - ”Parameter” operating area

Start angle for thread cutting (SF)

For thread cutting, a start position for the spindle is displayed as the start angle. If the

thread cutting operation is repeated, a multiple thread can be cut by modifying the angle.

Position the cursor bar on the input field you want to change and enter the value(s).

Either press the Input key or move the cursor to confirm.

Work area

limit.

Time

counter

The working area limitation is active with geometry and additional axes. If you want to use a

working area limitation, its values can be entered in this dialog box. Selecting the Set Active

softkey will activate / deactivate the values for the axis highlighted by the cursor.

Fig. 3-20

Timers Counters

Fig. 3-21

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-45

Page 46

Setting Up

3.4 Programming setting data - ”Parameter” operating area

Meaning:

S Parts total: Number of workpieces produced in total ( actual total )

S Parts required: Number of workpieces required ( require number of workpieces )

S Part count: This counter registers the number of all workpieces produced since the start-

ing time.

S Run time: Total runtime of NC programs in the AUTOMATIC mode

In the AUTOMATIC mode, the runtimes of all programs between NC START and end of

program / RESET are summed up. The timer is zeroed with each power−up of the control

system.

S Cycle time: Tool action time

The runtime between NC START and end of program / RESET is measured in the selected NC program. The timer is reset with starting a new NC program.

S Cutting time

The runtime of the path axes is measured in all NC programs between NC START and

end of program / RESET without rapid traverse active and with the tool active. The measurement is interrupted when a dwell time is active.

Misc

The timer is automatically reset to zero in the case of a ”Control power−up with default values”.

Use this function to display all setting data for the control system in the form of a list. The

data are divided into

S general

S axis−specific and

S channel setting data.

3-46

Fig. 3-22

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 47

3.5 R parameters − ”Offset/Parameter”operating area

3.5 R parameters − ”Offset/Parameter”operating area

Functionality

The R parameters start screen displays all R parameters existing in the control system in the form of a list (see also Section 8.9 ”R parameters”). These can be changed as necessary.

Setting Up

Fig. 3-23 The ”R parameters” window

Operating sequence

Use the Parameters and the R parameterssoftkeys

R vari−

able

Position the cursor bar on the input field to be changed

and enter the value(s).

Either press the Input key or move the cursor to confirm.

Find

Find R parameters

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

3-47

Page 48

Setting Up

3.5 R parameters − ”Offset/Parameter”operating area

This sheet has been left empty for your notes

3-48

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 49

Manually Controlled Mode

The manually controlled mode is possible in the Jog and MDA modes.

4

The softkeys marked with an asterisk (”

Set

base

x=0

z=0

Set rel

Delete

base W0

All

to zero

Back <<

Fig. 4-1 The ”Jog” menu tree

Measure

workpiece

Work

offset

X

Z

Set work

offset

Back <<

Tool

measure

Measure

manual

Measure

auto

Calibrate

probe

Back <<

:”) are not available with the 802D bl.

Settings

Data

:

probe

:

Switch

mm>inch.

:

:

Back <<

:

Set

basis

x=0

z=0

Set rel

Delete

base W0

All

to zero

Back <<

Fig. 4-2 The MDA menu tree

Face

Peripher.

surface

Abort

OK

Settings

Data

probe

Switch

mm>inch.

Back <<

:

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

4-49

Page 50

Manually Controlled Mode

4.1 Mode Jog - ”Position” operating area

4.1 Mode Jog - ”Position” operating area

Operating sequences

Use the Jog key on the machine control panel to select the Jog mode.

+X

-Z

...

To traverse the axes, press the appropriate key of the X or Z axis.

The axes will traverse continuously at the velocity stored in the setting data until the key is

released. If the value of the setting data is zero, the value stored in the machine data is

used.

If necessary set the velocity using the override switch.

%

If you press additionally the Rapid traverse override key, the selected axis will be traversed

at rapid traverse speed until both keys are released.

In the Jog mode, you can traverse the axes by adjustable increments using the same operating sequence. The set number of increments is displayed in the Status area. To deselect

the Jog mode, press Jog once more.

The Jog start screen displays the position, feedrate and spindle values, as well as the current tool.

4-50

Fig. 4-3 The ”Jog” start screen

SINUMERIK 802D, 802D bl Operartion and Programming Turning (BP−D), 08/05 Edition

6FC5 698−2AA00−1BP4

Page 51

Parameters

Manually Controlled Mode

4.1 Mode Jog - ”Position” operating area

Table 4-1 Description of the parameters in the JOG start screen

Parameter

MCS

X

Z

+X

-Z

Position

mm

REPOS offset If the axes are traversed in the ”Program interrupted” condition in the Jog mode, the distance tra-

G function Displays important G functions

Spindle S

r.p.m.

Feed F

mm/min

Tool Displays the currently active tool with the current edge number

Displays the axes existing in the machine coordinate system (MCS) or in the workpiece coordinate

system (WCS)

If you traverse an axis in the positive (+) or negative (-) direction, a plus or minus sign will appear in

the relevant field.

If the axis is already in the required position, no sign is displayed.

These fields display the current position of the axes in the MCS or WCS.

versed by each axis is displayed referred to the interruption point.

Displays the actual value and the setpoint of the spindle speed

Displays the path feedrate actual value and setpoint

Explanation

Note

If a second spindle is integrated into the system, the workspindle will be displayed using a smaller font.

The window will always display the data of only one spindle.

Softkeys

Set

base

The control system displays the spindle data according to the following aspects

:

The master spindle (large display) is displayed:

− in the idle condition;

− when starting the spindle;

− if both spindles are active.

The workspindle (small display) is displayed:

− when starting the workspindle.

The power bar applies to the spindle currently active.

This softkey is used to set the base work offset or a temporary reference point in the relative