Page 1

Description of Functions 11.2003 Edition

sinumerik

SINUMERIK 802D

SINUMERIK 802D base line

Page 2

Page 3

SINUMERIK 802D

Description of Functions

Preface, Table of Contents

EMERGENCY STOP (N2)

Axis Monitoring (A3)

Velocities, Setpoint/Actual -Value

Systems, Closed-Loop Control

(G2)

Acceleration (B2)

Spindle (S1)

Rotary Axes (R2)

Transverse Axes (P1)

Reference Point Approach (R1)

1

2

3

4

5

6

7

8

Manual Traversing and Handwheel Traversing (H1)

Operating Modes, Program Mode

(K1)

Feed (V1)

Continous Path Mode, Exact Stop

and LookAhead (B1)

Output of Auxiliary Functions to

the PLC (H2)

Tool Compensation (W1)

Measuring (M5)

Compensation (K3)

Traversing to Fixed Stop (F1)

9

10

11

12

13

14

15

16

17

11.03 Edition

18

Kinematic Transformations (M1)

19

Various Interface Signals (A2)

20

PLC User Interface

21

Various Machine Data

Glossary, Index

Page 4

3ls

SINUMERIKDocumentation

Printing history

Brief details of this edition and previous edition are listed below.

The status of each edition is shown by the code in the “Remarks” column.

Status code in the “Remarks” column:

A New documentation.. . . . .

B Unrevised reprint with new Order No.. . . . .

C Revised edition with new status. . . . . .

If actual changes have been made on the page since the last edition, this is indicated by

a new edition coding in the header on that page.

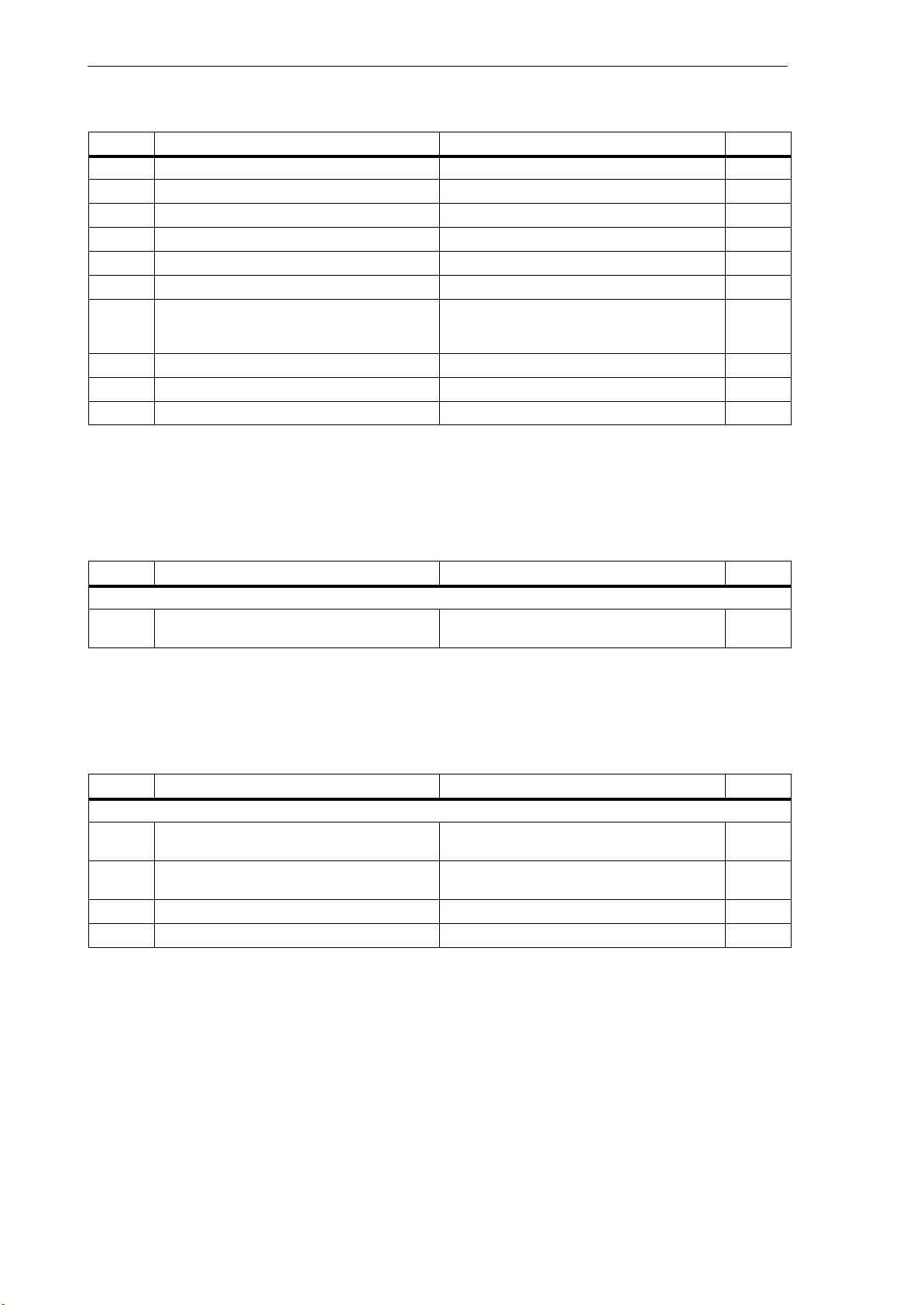

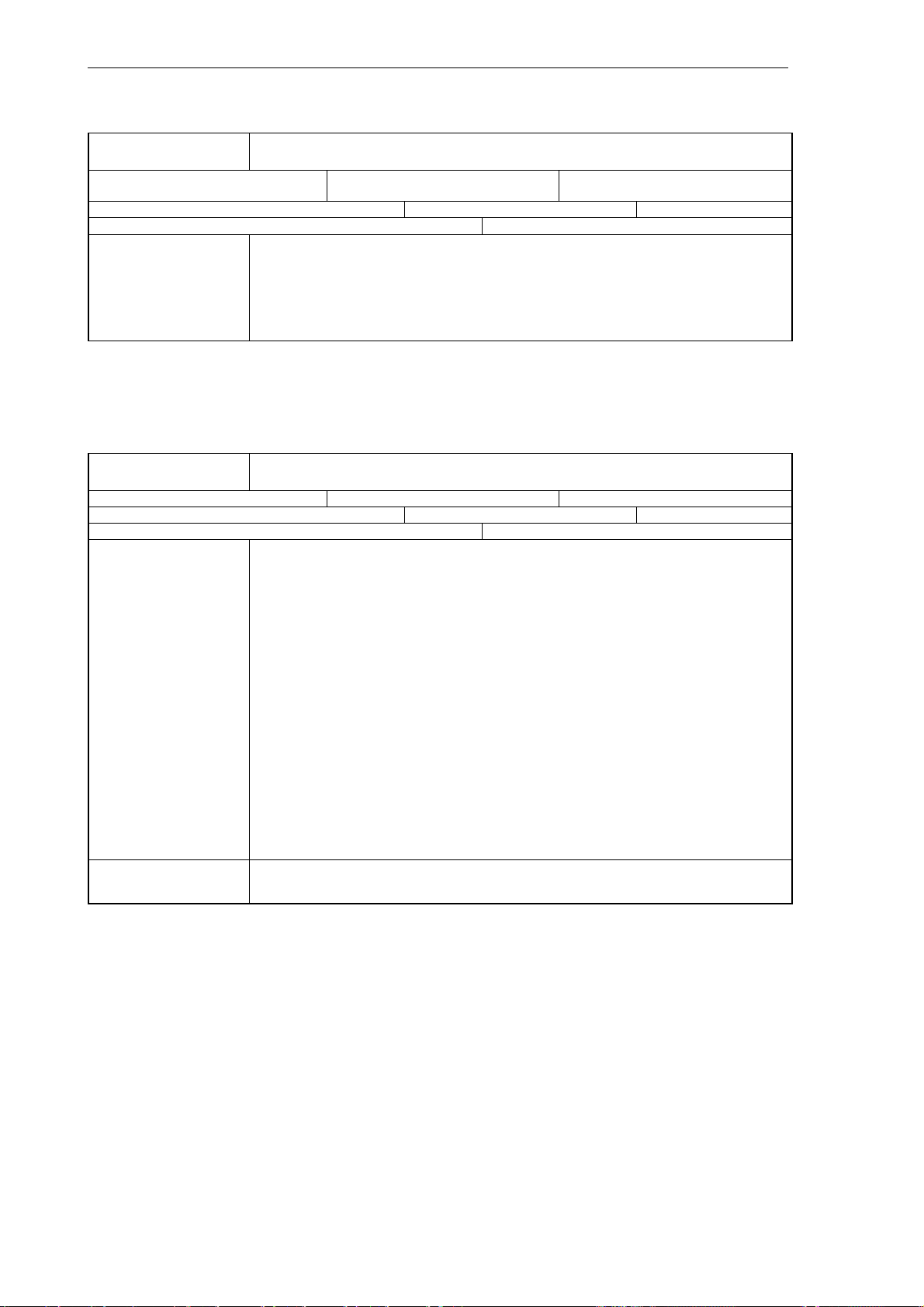

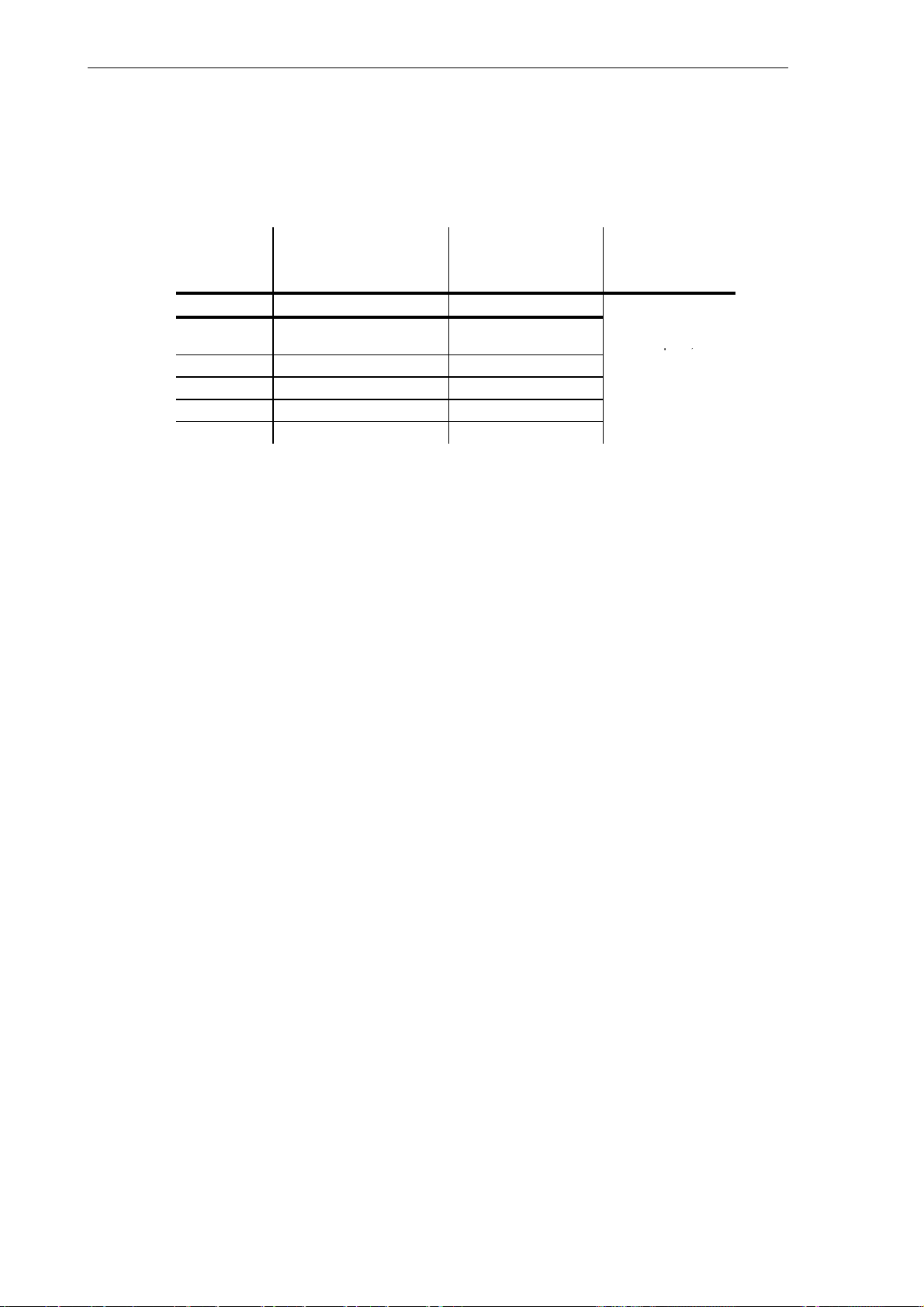

Edition Order No. Remarks

11.00 6FC5 697-2AA10-0BP0 A

10.02 6FC5 697-2AA10-0BP1 C

11.03 6FC5 697-2AA10-0BP2 C

This Manual is included on the documentation on CD ROM (DOCONCD)

E

Trademarks

SIMATIC, SIMATIC HMI, SIMATIC NET, SIROTEC, SINUMERIK and SIMODRIVE are registered

trademarks of Siemens. Third parties using for their own purpose any other names in this document which

refer to trademarks might infringe upon the rights of trademark owners.

This publication was produced with Interleaf V 7.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.Offenders

will be made liable for damages. All rights, including rights created by

patent grant or registration of utility model or design, are reserved.

Siemens AG 2003. All rights reserved.

Printed in the Federal Republic of Germany

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist and therefore we cannot guarantee that they are completely

identical. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

Subject to change without prior notice.

Siemens - AktiengesellschaftOrder No.: 6FC5 697-2AA10 -0BP2

Page 5

Preface

Notes for the reader

The descriptions of functions are only valid for or up to the specified software release. When

new software releases are issued, the relevant descriptions of functions must be requested.

Old descriptions of functions can only partially be used for new software releases.

Note

Other functions not described in this documentation might be executable in the control. This

does not, however, represent an obligation to supply such functions with a new control or

when servicing.

Technical notes

Notations

The following notations and abbreviations are used in this Documentation:

PLC interface signals -> IS ”Signal name” (signal data)

Example: IS ”Feed override“ (VB380x 0000)

The variable byte is in the range “at axis“, “x” stands for the axis: 0 axis 1

Machine data -> MD MD_NR: MD_NAME

Setting data -> SD SD_NR: SD_NAME

The headlines of the individual chapters/sections are added by a code designation in brak-

kets (e.g. Chapter 1: EMERGENCY STOP (N2)). This code designation is used in references to individual Chapters/Sections.

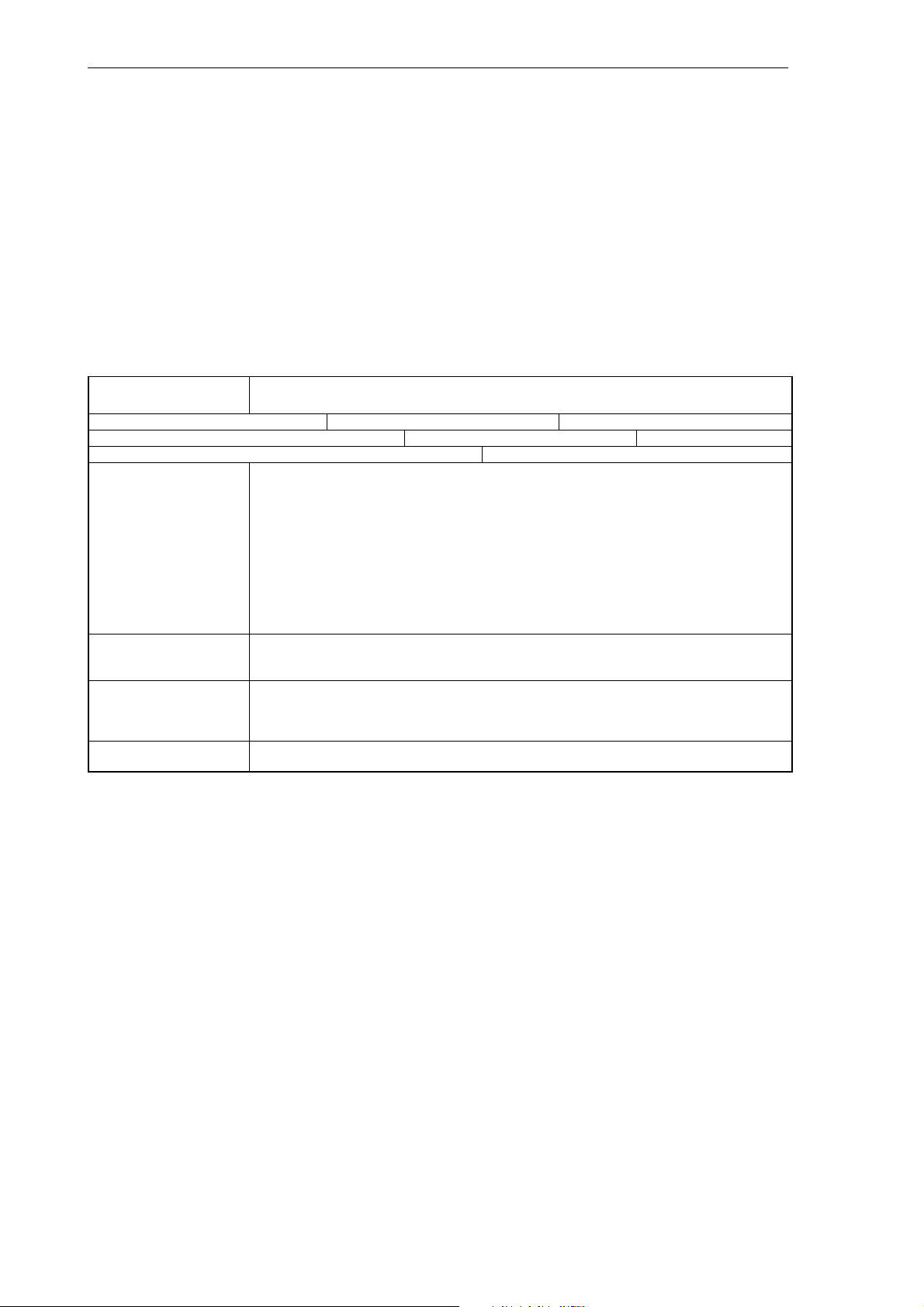

Explanation of the code designations

In the chapters/sections of each Description of Functions, the data and/or signals are explained which are important for the function discussed. Within these explanations provided in the

form of tables, some terms and abbreviations are used, which are explained here.

Default value:

This is the default value of the machine/setting data when loading the standard machine data.

Range of values (minimum/maximum values):

specifies the input limits. If no range of values is specified, the data type defines the input limits, and the field is marked with ”***”.

1 aixs 2

n axis n+1.

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

v

Page 6

Preface

Activation of changes:

Changes in machine data, setting data or the like come not immediately into effect in the control system. The conditions for activation are therefore always specified. The possibilities used

are listed below by their priority:

POWER ON (po) Turning off/turning on the power supply

or softkey “StartUp/Normal” on HMI

NEW_CONF (cf) ”RESET” key on the control unit

RESET (re) ”RESET” key on the control unit

immediately (im) after input of a value

Protection level:

There are the protection levels 0 to 7 whereby the interlock for protection levels 1 to 3 can be

canceled by setting a password and the interlock for protection levels 4 to 7 via the IS “Protection level” (e.g.: keyswitch position). Protection level 0 cannot be accessed (see Chapter “Various Interface Signals”).

The operator has only access to information that corresponds to this particular protection level

and the lower protection levels. The machine data are assigned different protection levels by

default and are marked by a Write/Read value (e.g. 4/7).

Note: In this document, the machine and setting data of protection levels 2 to 7 are documented. Notes on machine data of protection level 1 are only provided in special cases (expert

mode).

Unit:

The unit refers to the default setting (see Section “Velocities, Setpoint/Actual Value System,

Closed-Loop Control“).

If the MD has no physical unit as the basis, the field is marked with ”-”.

Data type:

The following data types are used in the control system:

DOUBLE

Floating point value (64-bit value )

Input limits from +/-4.19*10

-307

to +/-1.67*10

308

DWORD

Integer values (32-bit value)

Input limits from -2 147 483 648 to +2 147 483 648 (decimal),

as a hexadecimal value: 0000 to FFFF

BYTE

Integer values (8-bit value)

Input limits from -128 to +127 (decimal), as a hexadecimal value: 00 to FF

BOOLEAN

Boolean value: TRUE (1) or FALSE (0)

STRING

consisting of a maximum of 16 ASCII characters (uppercase letters, digits and underscore)

SINUMERIK 802D, 802D base line

vi

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 7

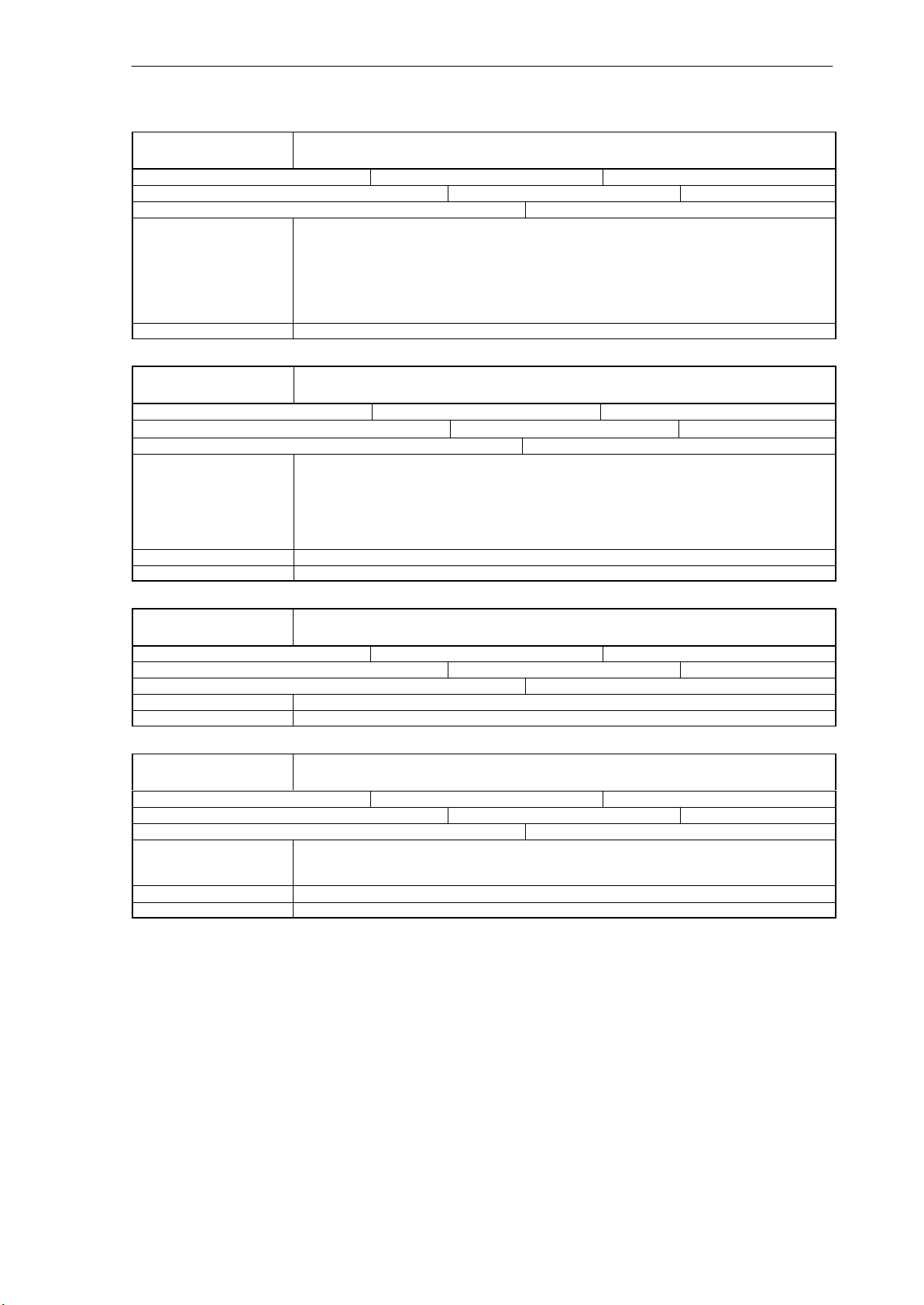

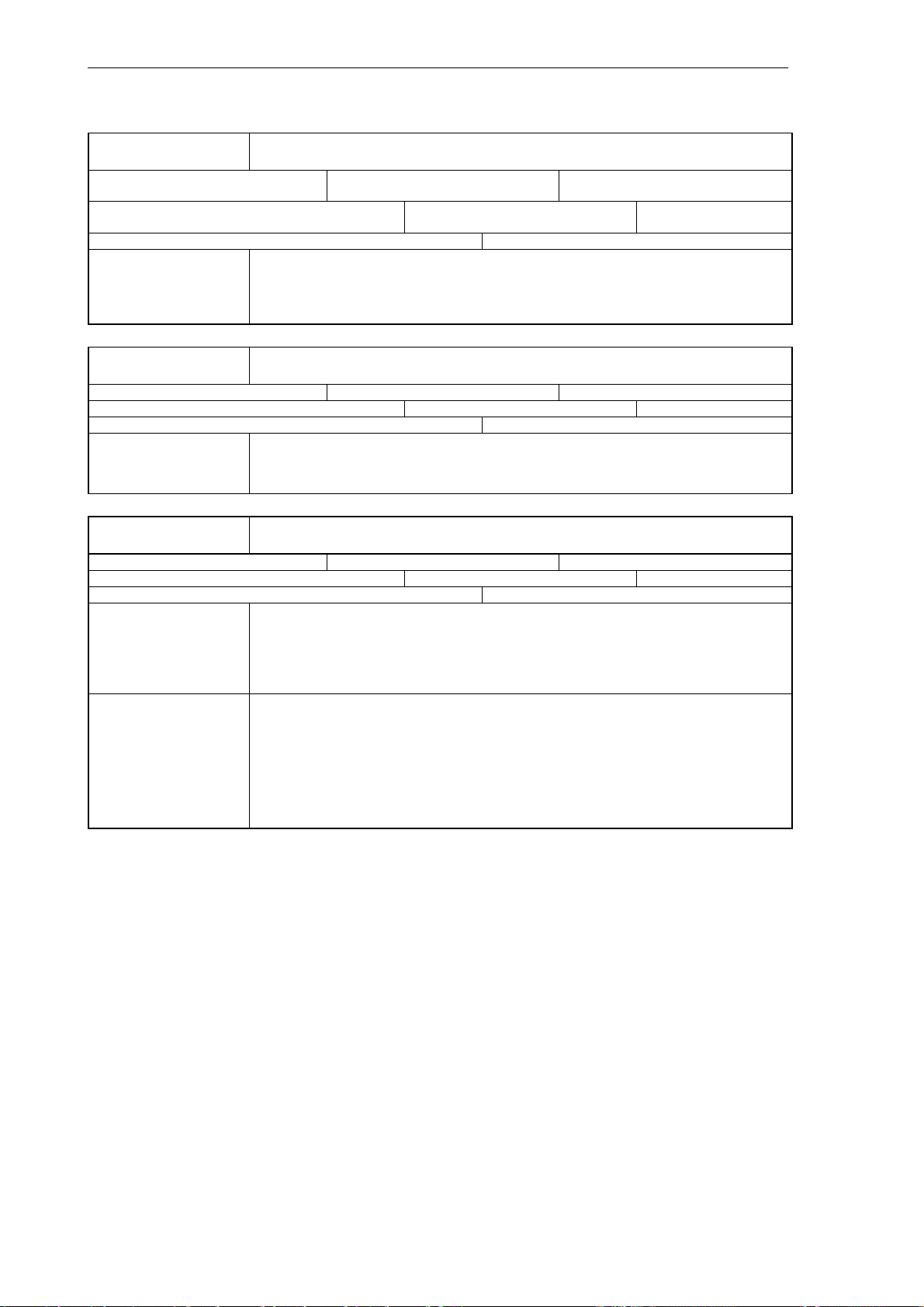

Example machine data

36210 CTRLOUT_LIMIT[0]

MD number Maximum speed setpoint

Default: 110.0 Min. input limit: 0.0 Max. input limit: 200.0

Change valid after NEW_CONF Protection level: 2/7 Unit: %

Data type: DOUBLE Valid from SW release:

Meaning:

Alarms

For detailed explanations on occurring alarms, please refer to:

References: ”Diagnostics Guide“.

Preface

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

vii

Page 8

Contents

Contents

1 EMERGENCY STOP (N2) 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Brief description 1-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 EMERGENCY STOP sequence 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EMERGENCY STOP acknowlededgement 1-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Data descriptions (MD, SD) 1-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Signal descriptions 1-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 Data fields, lists 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 Interface signals 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 Machine data 1-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Axis Monitoring (A3) 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Overview of monitoring functions 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Motion monitoring functions 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Contour monitoring 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Positioning monitoring 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Zero speed monitoring 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Clamping monitoring 2-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Speed setpoint monitoring 2-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Actual velocity monitoring 2-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Encoder monitoring functions 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Encoder limit frequency monitoring 2-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Zero mark monitoring 2-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Monitoring of static limitations 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Limit switch monitoring 2-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Working area limitation 2-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Boundary conditions 2-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Data descriptions (MD, SD) 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Channel-specific machine data 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Axis/spindle- specific machine data 2-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Axis/spindle-specific setting data 2-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Signal description 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Axis/spindle- specific signals 2-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Data fields, lists 2-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Axis/spindle- specific interface signals 2-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Axis/spindle- specific machine data 2-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.3 Channel-specific machine data 2-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.4 Axis/spindle-specific setting data 2-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Velocities, Setpoint/Actual -Value Systems, Closed- Loop Control (G2) 3-49. . . . . . . . . .

3.1 Velocities, traversing ranges, accuracies 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Velocities 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Traversing ranges 3-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Input/display resolution, computational resolution 3-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Standardization of physical quantities of machine and setting data 3-52. . . . . . . . . . . . . . . . . . .

3.2 Metric/inch scaling system 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Conversion of the scaling system using the part program 3-53. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Switching over the scaling system manually 3-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Setpoint/actual-value system 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 General 3-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

viii

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 9

Contents

3.3.2 Drives connected to Profibus DP 3-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Speed setpoint and actual- value assignment 3-59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Speed setpoint output 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.5 Actual- value processing 3-63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Closed-loop control 3-65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Data description (MD, SD) 3-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 General machine data 3-68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Channel-specific machine data 3-70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Axis-specific machine data 3-71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Signal descriptions 3-76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Data fields, data lists 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.1 Interface signals 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7.2 Machine data 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Acceleration (B2) 4-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Acceleration profiles 4-79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Jerk limitation on interpolator level 4-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Jerk limitation in JOG mode 4-81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Percentage acceleration correction, ACC 4-82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Data descriptions (MD, SD) 4-83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Data fields, lists 4-84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Spindle (S1) 5-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Brief description 5-85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Spindle modes 5-86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Spindle mode: Control mode 5-87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Spindle mode: Oscillation mode 5-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Spindle mode: Positioning mode 5-90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Spindle mode: Axis mode 5-94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Synchronizing 5-95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Gear stage change 5-96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Programming 5-101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Spindle monitoring functions 5-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Axis/spindle stopped 5-102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Spindle in set range 5-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Max. spindle speed 5-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.4 Min./max. speed of the gear stage 5-103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.5 Max. encoder limit frequency 5-104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.6 Target position monitoring 5-105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 2nd spindle / master spindle 5-106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Analog spindle 5-107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Data descriptions (MD, SD) 5-108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Channel-specific machine data 5-108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Axis/spindle- specific machine data 5-108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.3 Spindle-specific setting data 5-116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 Signal descriptions 5-118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10.1 Axis/spindle-specific signals 5-118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 Data fields, lists 5-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.1 Interface signals 5-127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11.2 Machine data 5-128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

ix

Page 10

Contents

5.11.3 Setting data 5-129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Rotary Axes (R2) 6-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 General 6-131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Modulo 360 degrees 6-133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Programming rotary axes 6-134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Rotary axis with active modulo conversion 6-134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Rotary axis without modulo conversion 6-135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Data descriptions (MD, SD) 6-136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Axis/spindle- specific machine data 6-136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Data fields, lists 6-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Machine data 6-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Setting data 6-138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Transverse Axes (P1) 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Defining a transverse axis 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Diameter programming 7-139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Constant cutting rate: G96 7-140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Reference Point Approach (R1) 8-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Fundamentals 8-141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Referencing using incremental measuring systems 8-143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Referencing using absolute encoders 8-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 General 8-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Operator- sssisted adjustment 8-146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Supplementary conditions for absolute encoders 8-148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Adjusting the absolute encoder 8-148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 Data descriptions (MD, SD) 8-149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Channel-specific machine data 8-149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Axis/spindle- specific machine data 8-149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Signal descriptions 8-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Channel-specific signals 8-157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Axis/spindle- specific signals 8-158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Data fields, lists 8-159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.1 Interface signals 8-159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 Machine data 8-159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Manual Traversing and Handwheel Traversing (H1) 9-161. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 General features when traversing in JOG mode 9-161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Continuous traversing 9-165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Incremental traversing (INC) 9-166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Handwheel traversing in JOG mode 9-167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Data descriptions (MD, SD) 9-170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 General machine data 9-170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Axis/spindle- specific machine data 9-171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 General setting data 9-172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Signal descriptions 9-174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Signals from HMI to PLC 9-174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 NCK signals and signals in the operating mode area 9-175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 Channel-specific signals 9-176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

x

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 11

Contents

9.6.4 Axis/spindle- specific signals 9-180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 Data fields, lists 9-183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.1 Interface signals 9-183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.2 Machine data 9-184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7.3 Setting data 9-184. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Operating Modes, Program Mode (K1) 10-185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Brief description 10-185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Operating modes 10-186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 Mode change 10-187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Possible functions in the individual operating modes 10-188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 Monitoring functions in the individual operating modes 10-189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.4 Interlocks in the individual operating modes 10-190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Execution of a part program 10-191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.1 Program mode and part program selection 10-191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.2 Starting the part program or part program block 10-191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.3 Part program interruption 10-192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.4 RESET command 10-193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.5 Program control 10-194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.6 Program status 10-194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.7 Channel status 10-195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.8 Reactions to operator or program actions 10-196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3.9 Example of time diagram for a program sequence 10-197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Program test 10-198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.1 General remarks on program test 10-198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.2 Program execution without axis movements (PRT) 10-198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.3 Program execution in single block mode 10-199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.4 Program execution with Dry Run Feed (DRY) 10-200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.5 Block search: Execution of certain program sections 10-201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.6 Skipping part program blocks (SKP) 10-203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4.7 Graphical simulation 10-204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Timer for program runtime 10-205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.6 Workpiece counter 10-206. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7 Data descriptions (MD, SD) 10-208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.1 Display machine data 10-208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.2 Channel-specific machine data 10-211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.7.3 Channel-specific setting data 10-213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8 Signal descriptions 10-215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.1 Mode signals 10-215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.8.2 Channel-specific signals 10-217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9 Data fields, lists 10-228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9.1 Channel machine data 10-228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9.2 Channel-specific setting data 10-229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.9.3 Interface signals 10-229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Feed (V1) 11-233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Feedrate F 11-233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.1 Feed with G33 (thread cutting) 11-234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.2 Feed with G63 (tapping with compensating chuck) 11-235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.3 Feed with G331, G332 (rigid tapping = tapping without compensating chuck) 11-235. . . . . . . . . .

11.2 Rapid traverse G0 11-236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Feed override 11-237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Overview 11-237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Feed disable and feed/spindle stop 11-237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

xi

Page 12

Contents

11.3.3 Feed override from the machine control panel 11-238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 Data descriptions (MD, SD) 11-240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 Signal descriptions 11-241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.1 Channel-specific signals 11-241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.2 Axis/spindle-specific signals 11-245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 Data fields, lists 11-248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6.1 Interface signals 11-248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6.2 Machine data/setting data 11-248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Continuous -Path Mode, Exact Stop and LookAhead (B1) 12-249. . . . . . . . . . . . . . . . . . . . . .

12.1 Brief description 12-249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 General 12-250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 Exact Stop 12-251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4 Continuous path mode 12-252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.1 General 12-252. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.2 Velocity reduction according to the overload factor 12-253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.3 Velocity reduction for jerk limitation on the path 12-254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.4.4 Machine axis-specific jerk limitation 12-255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.5 LookAhead 12-256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6 Data descriptions (MD, SD) 12-258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6.1 Channel-specific machine data 12-258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.6.2 Axis-specific machine data 12-258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7 Signal descriptions 12-259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7.1 Channel-specific signals 12-259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.7.2 Axis-specific signals 12-259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8 Data fields, lists 12-260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8.1 Interface signals 12-260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.8.2 Machine data 12-260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Output of Auxiliary Functions to the PLC (H2) 13-261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Brief description 13-261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 Programming of auxiliary functions 13-262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 Transfer of values and signals to the PLC interface 13-263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.4 Division of auxiliary functions into groups 13-264. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 Behavior on block search 13-265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6 Description of the auxiliary functions 13-266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.1 M function 13-266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.2 T function 13-266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.3 D function 13-266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.4 H function 13-267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.6.5 S function 13-267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7 Data descriptions (MD, SD) 13-268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.1 General machine data 13-268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.7.2 Channel-specific machine data 13-268. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.8 Signal descriptions 13-270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9 Data fields, lists 13-272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.1 Interface signals 13-272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.9.2 Machine data 13-273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xii

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 13

Contents

14 Tool: Compensation and Monitoring (W1) 14-275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 Overview: Tool and tool compensation 14-275. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 Tool 14-276. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 Tool compensation 14-277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 Tool monitoring 14-278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.1 Overview: Tool monitoring 14-278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.2 Tool life monitoring 14-280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.3 Workpiece count monitoring 14-281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4.4 Examples for tool life monitoring 14-282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 Special cases of tool compensations 14-284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 Data descriptions (MD, SD) 14-287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.7 Signal descriptions 14-289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8 Data fields, lists 14-290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.1 Interface signals 14-290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8.2 Machine data 14-290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Measuring (M5) 15-291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 Brief description 15-291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 Hardware requirements 15-292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2.1 Probes that can be used 15-292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2.2 Connecting the probe 15-293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 Channel-specific measuring 15-295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3.1 Measuring mode 15-295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3.2 Measurement results 15-295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 Measuring accuracy and testing 15-296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.1 Measuring accuracy 15-296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4.2 Sensing probe function test 15-296. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 Tool gauging in JOG 15-298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6 Supplementary conditions 15-301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.7 Data descriptions (MD, SD) 15-302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.8 Signal descriptions 15-303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.9 Data fields, lists 15-305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.9.1 Interface signals 15-305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.9.2 Machine data 15-305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Compensation (K3) 16-307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 Brief description 16-307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Backlash compensation 16-308. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 Interpolatory compensation 16-309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.1 General 16-309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.2 Leadscrew error compensation (LEC) 16-310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3.3 Special features of interpolatory compensation 16-313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4 Following error compensation (feedforward control) 16-314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4.1 General 16-314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.4.2 Speed feedforward control 16-315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.5 Data descriptions (MD, SD) 16-316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.6 Data fields, lists 16-318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.6.1 Interface signals 16-318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.6.2 Machine data 16-318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

xiii

Page 14

Contents

17 Traversing to Fixed Stop (F1) 17-319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.1 Brief description 17-319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.2 Functionality 17-320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.3 Behavior in case of RESET and cancellation of the function 17-326. . . . . . . . . . . . . . . . . . . . . . . . .

17.4 Behavior in the case of block search 17-327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.5 Miscellaneous 17-328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.6 Data descriptions (MD, SD) 17-330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.7 Signal descriptions 17-334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8 Data fields, lists 17-336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8.1 Interface signals 17-336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.8.2 Machine data/setting data 17-336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 Kinematic Transformations (M1) 18-337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.1 Brief description 18-337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2 TRANSMIT 18-338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.1 Overview 18-338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.2.2 Configuring TRANSMIT 18-339. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3 TRACYL 18-343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3.1 Overview 18-343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3.2 Configuring TRACYL 18-346. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.3.3 Programming example for TRACYL 18-349. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.4 Special features with TRANSMIT and TRACYL 18-352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.5 Data descriptions (MD, SD) 18-353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.6 Signal descriptions 18-357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.7 Data fields, lists 18-358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.7.1 Interface signals 18-358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18.7.2 Machine data/setting data 18-358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 Various Interface Signals (A2) 19-359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.1 Brief description 19-359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.2 Signals from PLC to NCK 19-360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3 Signals from NCK to PLC 19-364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.4 Signals from PLC to HMI 19-368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.5 Signals from HMI to PLC 19-370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 PLC User Interface 20-371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.1 Address ranges 20-371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2 User data 20-373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2.1 User data 1 20-373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2.2 User Data 2 20-373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2.3 Retentive data area 20-373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3 User alarm 20-374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.1 User alarm: Enabling 20-374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.2 Variable for alarm 20-374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.3.3 Active alarm reaction 20-375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.4 Signals from/to HMI 20-375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.4.1 Program control signals from HMI (retentive area) 20-375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.4.2 General selection/status signals from MMC (retentive area) 20-377. . . . . . . . . . . . . . . . . . . . . . . . .

xiv

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 15

Contents

20.4.3 General selection/status signals to MMC (retentive area) 20-377. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5 Auxiliary function transfer from NC channel 20-378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.1 Decoded M signals (M0 - M99) 20-378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.2 T functions transferred 20-379. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.3 M functions transferred 20-379. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.4 S functions transferred 20-380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.5 D functions transferred 20-380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.5.6 H functions transferred 20-380. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.6 NCK signals 20-381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.7 Channel signals 20-383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.7.1 Signals to NC channel 20-383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.7.2 Signals from NC channel 20-385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.8 Axis/spindle signals 20-387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.8.1 Transferred M/S functions, axis-specific 20-387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.8.2 Signals to axis/spindle 20-387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.8.3 Signals from axis/spindle 20-389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9 PLC machine data 20-391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9.1 INT values (MD 14510 USER_DATA_INT) 20-391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9.2 HEX values (MD 14512 USER_DATA_HEX) 20-391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9.3 FLOAT values (MD 14514 USER_DATA_FLOAT) 20-391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.9.4 User alarm: Configuration (MD 14516 USER_DATA_PLC_ALARM) 20-392. . . . . . . . . . . . . . . . . .

20.10 Reading and writing of PLC variables 20-392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.11 Tool management functions provided by the NC channel 20-393. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.12 Axis actual values and distances to go 20-394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 Various Machine Data 21-395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.1 Display machine data 21-395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.2 General machine data 21-396. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.3 Channel-specific machine data 21-398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21.4 Axis-specific machine data 21-401. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

xv

Page 16

Contents

notice

xvi

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 17

EMERGENCY STOP (N2)

1.1 Brief description

Important

We would like to draw the machine manufacturer’s attention to his duty to observe the relevant international and national standards (see notes on standards further below in the text).

The SINUMERIK 802D supports the machine manufacturer in implementing the EMERGENCY STOP function according to the specifications in this Description of Functions. The

EMERGENCY STOP function (tripping, sequence and acknowledgement) is the sole and only

responsibility of the machine manufacturer.

Note

The following standards are relevant for the EMERGENCY STOP function:

EN 292 Part 1

EN 292 Part 2

EN 418

EN 60204 Part 1:1992 Section 10.7

1

The VDE 0113 Part 1 is only valid for a transition period and is replaced by EN 60204.

EMERGENCY STOP in the control system

The following arrangements are provided in the control system to support the machine manufacturer in implementing the EMERGENCY STOP function:

Initiation of the EMERGENCY STOP sequence in the NC via the PLC input.

The EMERGENCY STOP sequence in the NC will decelerate all axes and spindles in the

NC as fast as possible.

The EMERGENCY STOP status cannot be canceled by unlocking the EMERGENCY

STOP button. Resetting the control device will not result in a restart.

After the EMERGENCY STOP status has been canceled, it is not necessary to reference

axes or synchronize spindles (the positions are corrected).

EMERGENCY STOP button

A mushroom button (with one normally closed and normally open contact each), further referred to as EMERGENCY STOP button, is installed in the Siemens machine control panel

(MCP) for the 802D.

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

1-17

Page 18

EMERGENCY STOP (N2)

1.2 EMERGENCY STOP sequence

1.2 EMERGENCY STOP sequence

Prerequisite

The actuation of the EMERGENCY STOP button or a signal directly derived from it must be

carried to the control (PLC) as a PLC input. In the PLC user program, this PLC input must be

passed on to the NC to the IS ”EMERGENCY STOP“ (V2600 0000.1).

Resetting of the EMERGENCY STOP button or a signal directly derived from it must be carried to the control (PLC) as a PLC input. In the PLC user program, this PLC input must be

passed on the NC to the IS “Acknowledge EMERGENCY STOP” (V2600 0000.2).

Sequence in the NC

In the control system, the predetermined sequence (as per EN 418) of internal functions for

the EMERGENCY STOP status is as follows:

1. The part program execution is interrupted. All axes and spindles are stopped along defined

braking ramps according to MD 36610: AX_EMERGENCY_STOP_TIME.

2. The IS ”802-READY” (V3100 0000.3) is reset.

3. The IS ”EMERGENCY STOP active” (V2700 0000.1) is set.

4. Alarm 3000 is set.

5. The servo enable is disabled after an axis/spindle-specific time that can be set in MD

36620: SERVO_DISABLE_DELAY_TIME (servo enable cutout delay) has been elapsed.

In this context, make sure that 36620: SERVO_DISABLE_DELAY_TIME must be specified

at least as large as MD 36610: AX_EMERGENCY_STOP_TIME.

Sequence on the machine

The EMERGENCY STOP sequence on the machine is exclusively defined by the machine

manufacturer. The following must be observed in conjunction with the sequence in the NC:

The sequence in the NC is started using the IS ”EMERGENCY STOP“ (V2600 0000.1).

After the axes and spindles have been stopped, the power supply must be interrupted acc.

to EN418.

The sequence in the NC has no influence on the PLC I/Os (digital outputs). If you wish

individual outputs to have a certain status in case of EMERGENCY STOP, the machine

manufacturer must implement the appropriate functions in the PLC program.

Important

To interrupt the power supply, is the sole and only responsibility of the machine manufacturer.

1-18

If you wish the sequence in the NC in case of EMERGENCY STOP not to be carried out as

defined, the IS “EMERGENCY STOP” (V2600 0000.1) may not be set until an EMERGENCY

STOP status defined by the machine manufacturer in the PLC user program is reached. Until

the IS “EMERGENCY STOP” is not yet set and no other alarm is pending, all IS are active in

the NC. Thus, any manufacturer-specific EMERGENCY STOP status is possible.

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 19

EMERGENCY STOP (N2)

1.3 EMERGENCY STOP acknowlededgement

1.3 EMERGENCY STOP acknowlededgement

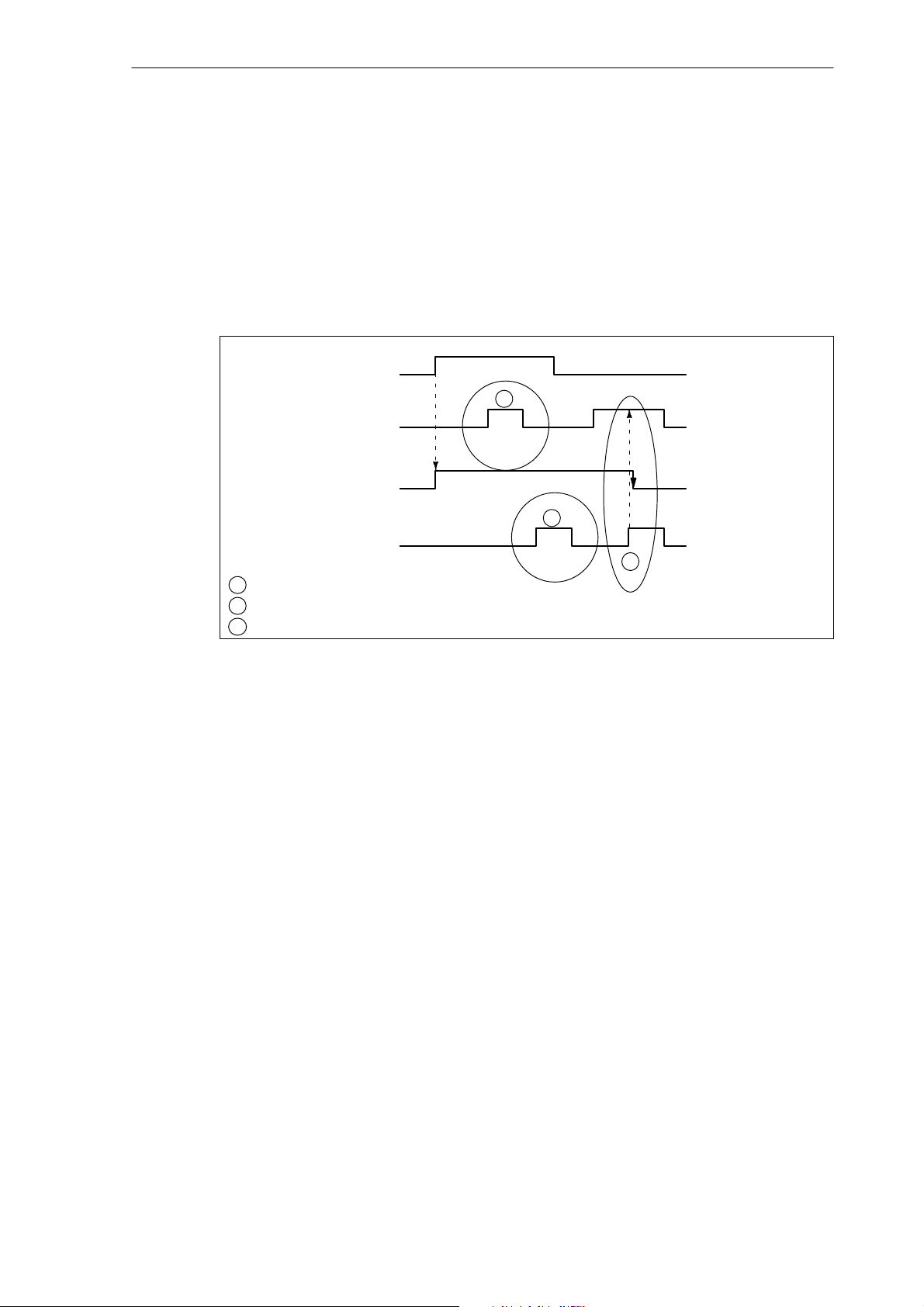

Acknowledging EMERGENCY STOP

The EMERGENCY STOP status will only be reset if first the IS “Acknowledge EMERGENCY

STOP” (V2600 0000.2) and then the IS “Reset” (V3000 0000.7) is set. When doing so, make

sure that the IS ”Acknowledge EMERGENCY STOP” and the IS ”Reset” must be set together

at least as long as the IS “EMERGENCY STOP active” (V2700 0000.1) has been reset (see

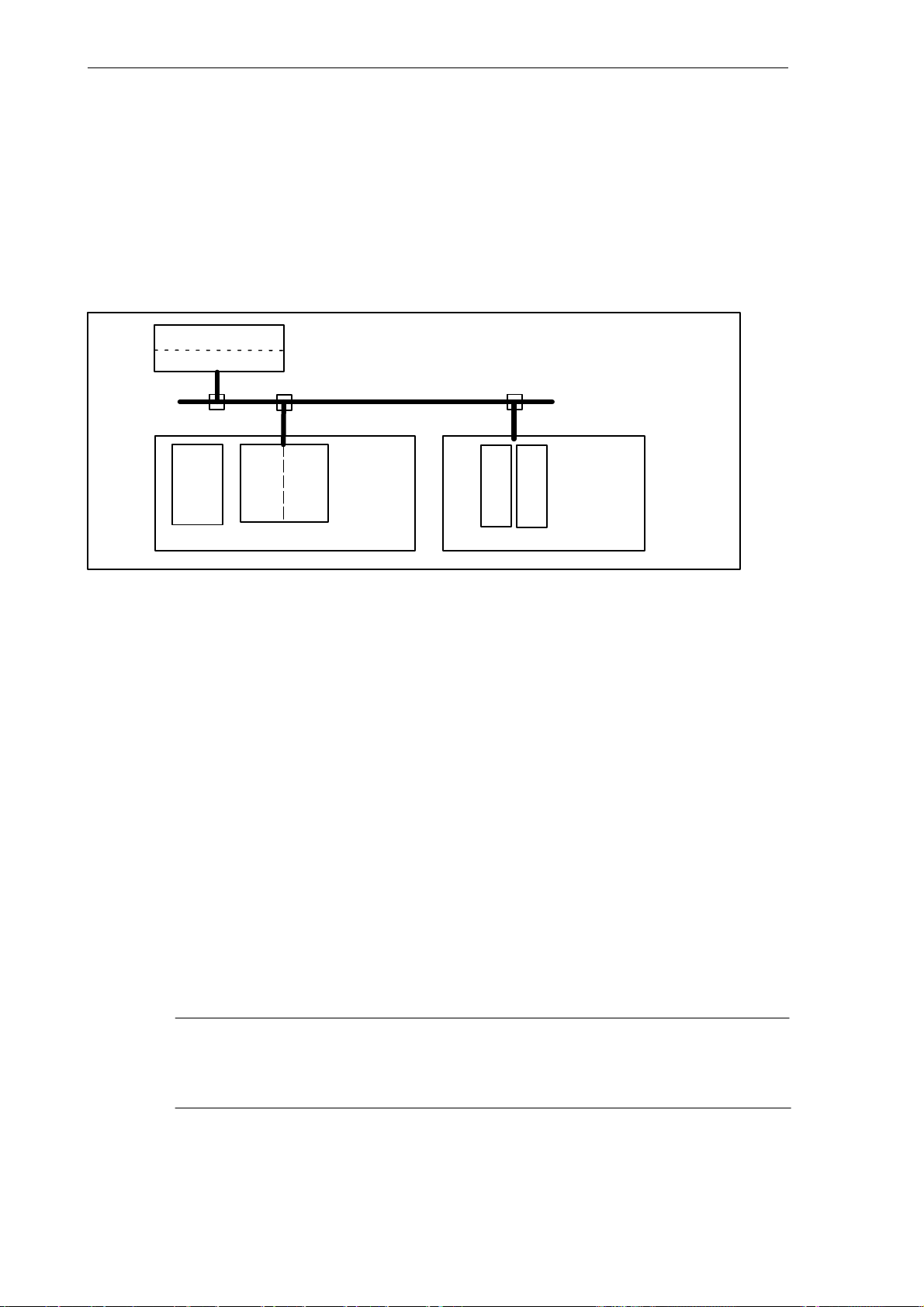

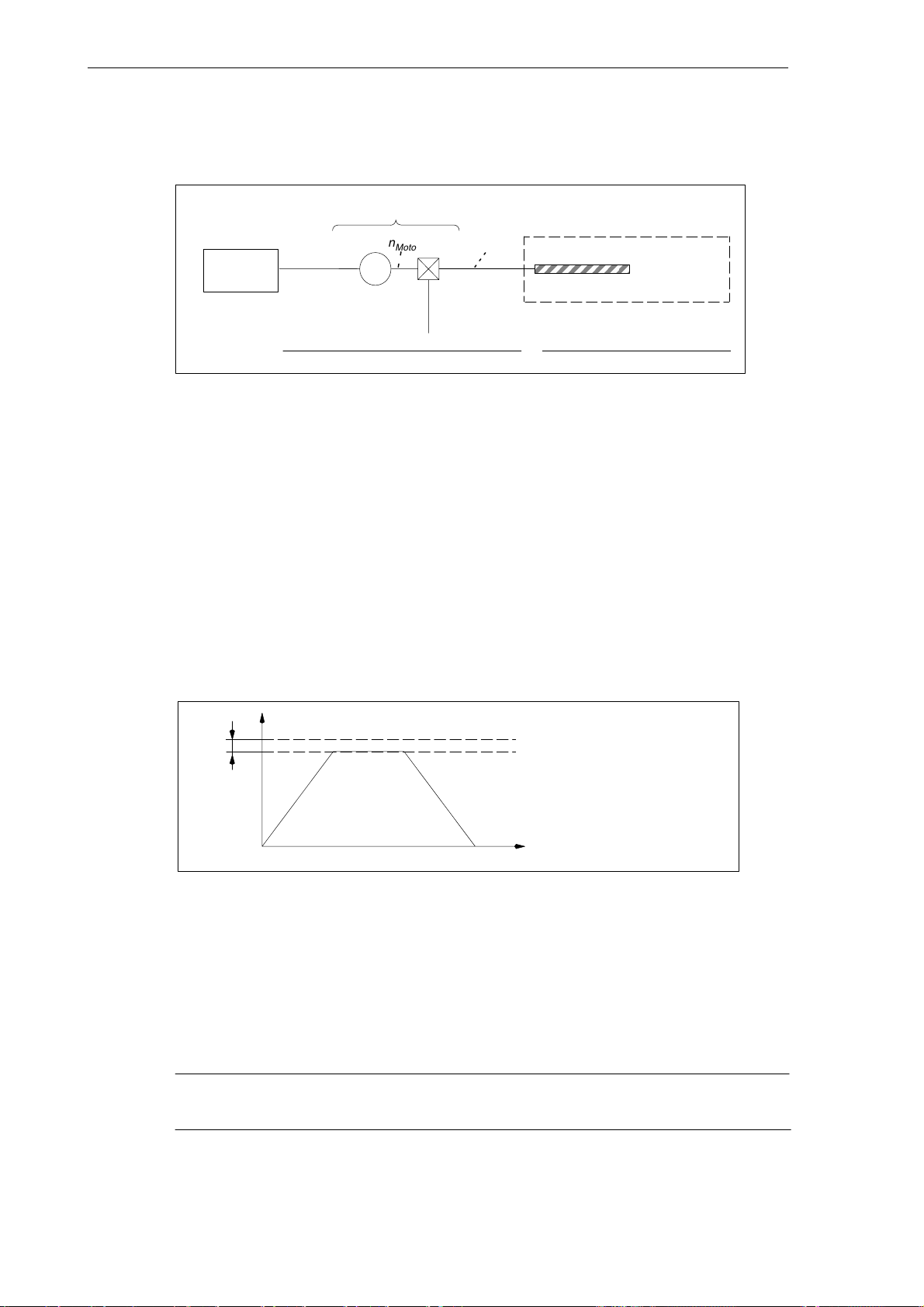

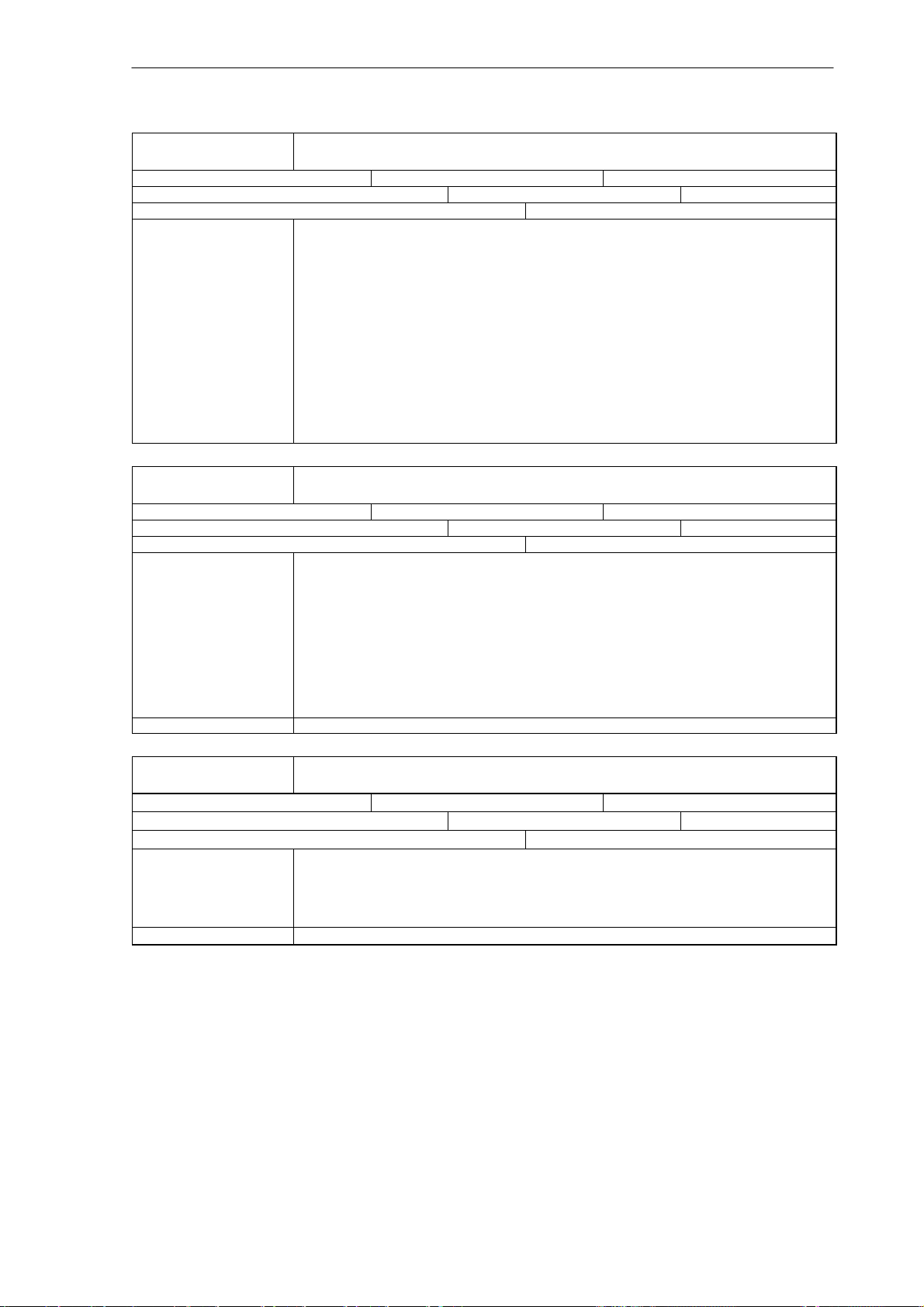

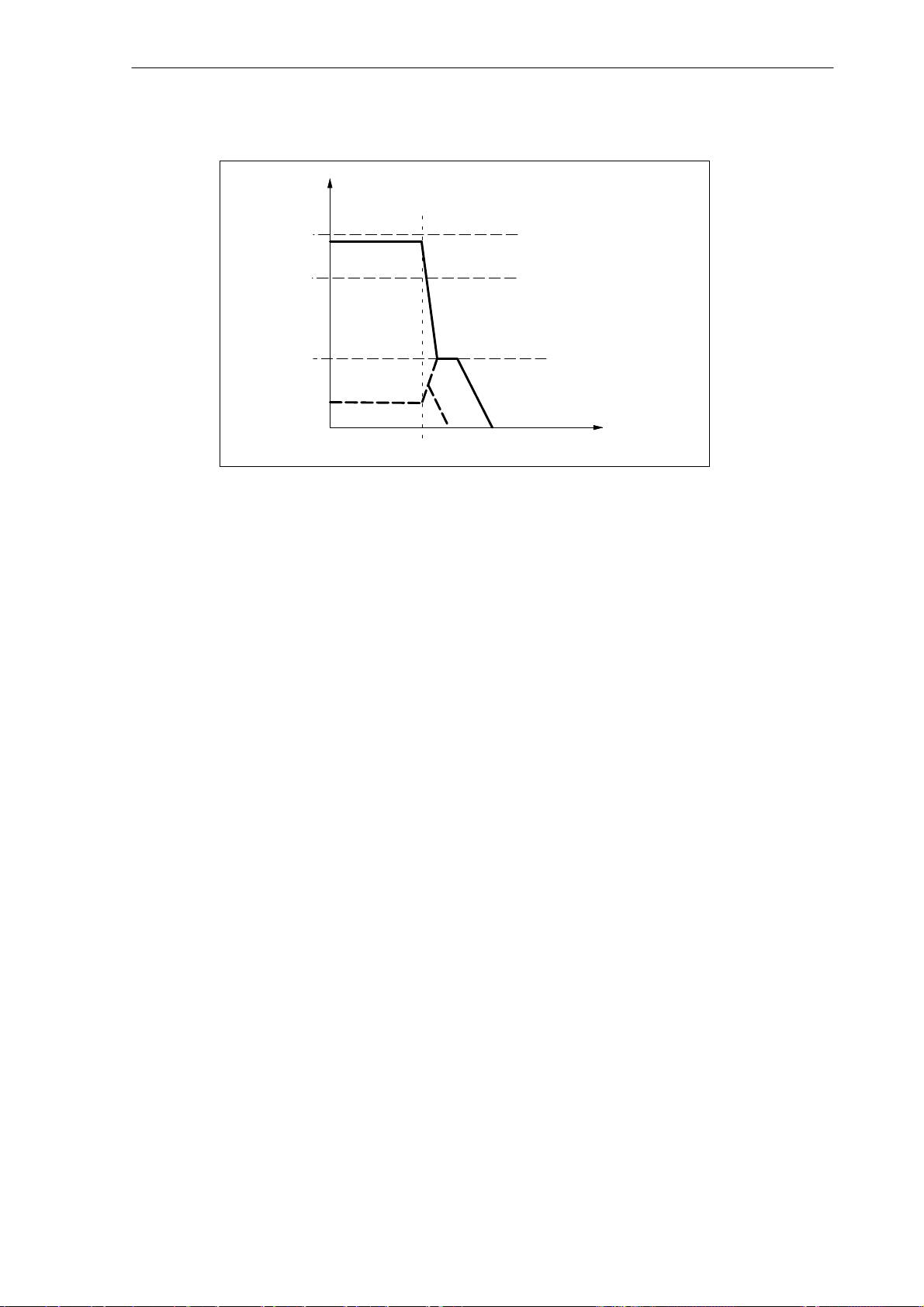

Fig. 1-1).

IS ”EMERGENCY STOP”

V2600 0000.1

IS ”Acknoweledge

EMERGENCY STOP“

V2600 0000.2

IS ”EMERGENCY STOP

active“

V2700 0000.1

1

2

PLC I/Os

IS ”RESET”

V3000 0000.7

1

The IS ”Acknowledge EMERGENCY STOP” has no effect.

2

The IS ”RESET” has no effect.

The IS ”Acknowledge EMERGENCY STOP” and ”RESET” will reset ”EMERGENCY STOP active.

3

Fig. 1-1 Resetting EMERGENCY STOP

3

Resetting the EMERGENCY STOP status:

resets the IS ”EMERGENCY STOP active”;

connect servo enable;

set the IS ”Position control active“;

set the IS ”802-READY”;

clear alarm 3000;

cancel the part program execution.

The PLC I/Os must be brought again by the PLC user program to the appropriate status required to operate the machine.

Reset

It is not possible to reset the EMERGENCY STOP status with the IS ”Reset” (V3000 0000.7)

alone (see diagram above).

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

1-19

Page 20

EMERGENCY STOP (N2)

1.4 Data descriptions (MD, SD)

Power ON

Power ON (turning off/turning off the power supply) will clear the EMERGENCY STOP status,

except the IS ”EMERGENCY STOP” (V2600 0000.1), which remains set.

1.4 Data descriptions (MD, SD)

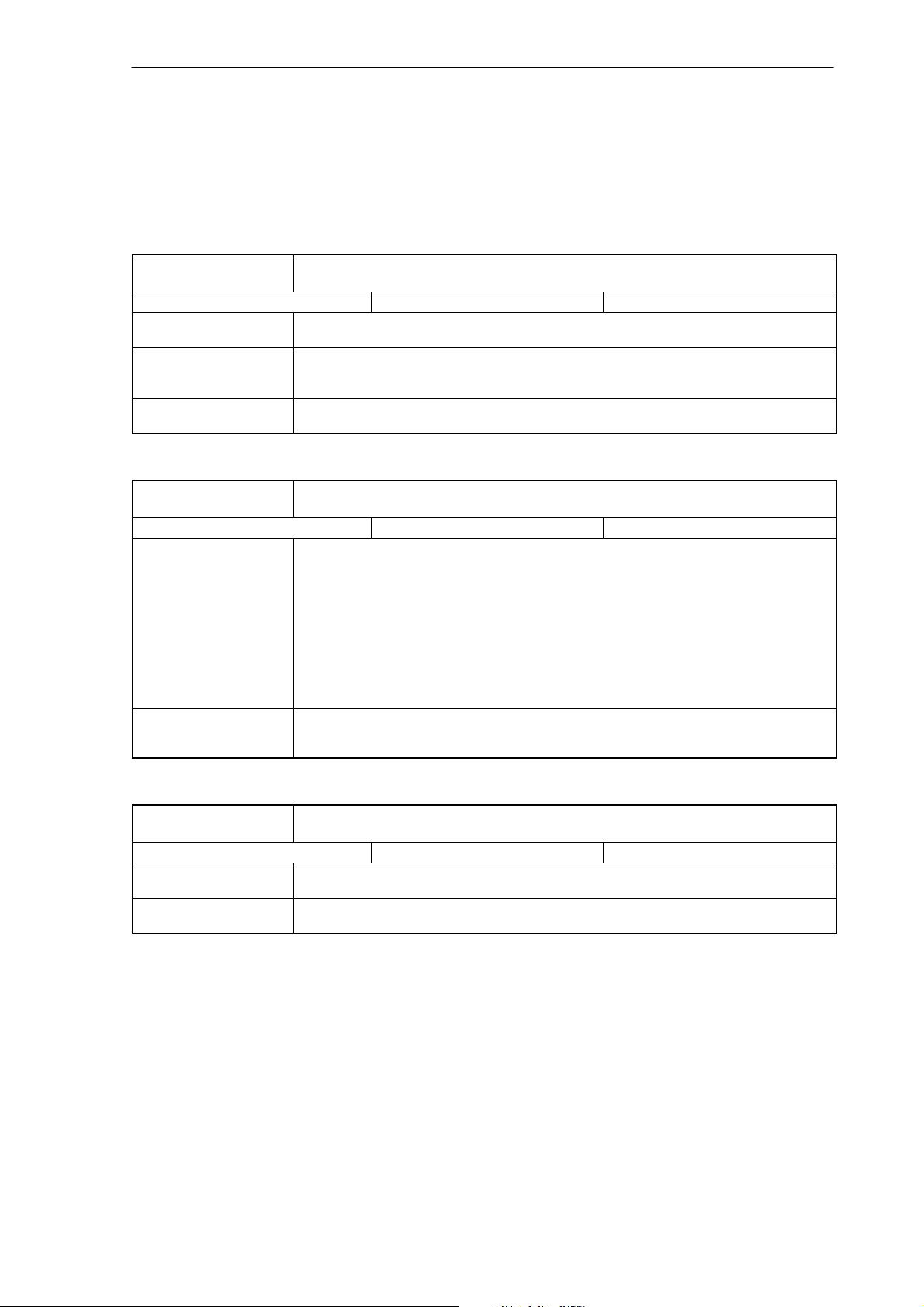

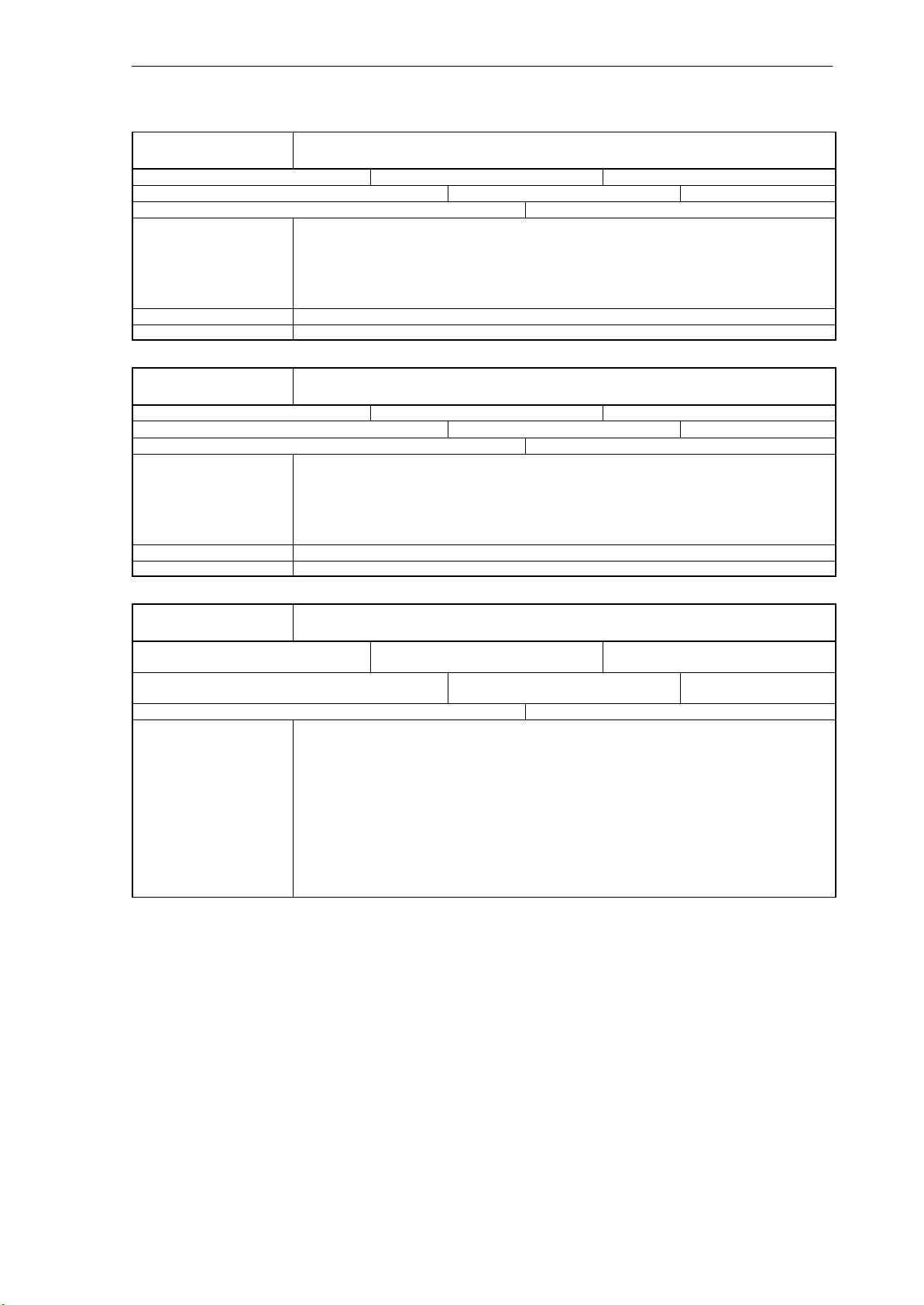

Axis-specific machine data

36620 SERVO_DISABLE_DELAY_TIME

MD number Servo enable cutout delay

Default: 0.1 Min. input limit: 0.02 Max. input limit: ***

Change valid after NEW_CONF Protection level: 2/2 Unit: s

Data type: DOUBLE Valid from SW release:

Meaning: Maximum time delay for cancellation of “Servo enable” after faults.

Application example(s) The speed control of the drive should be maintained for this time to make sure that the axis/spindle

Special cases, errors, ...... CAUTION: If the servo enable cutout delay is set too small, the “Servo enable” is already canceled

Related to .... IS ”Servo enable” (V380x 0002.1)

The speed enable (servo enable) of the drive is canceled internally in the control system at the

latest after a set delay time if the axis / spindle is moving.

The entered delay time acts due to the following events:

in case of errors resulting in immediate axis stop

if the IS “Servo enable” is canceled from the PLC.

Once the actual speed reaches the zero speed range (MD 36060: STANDSTILL_VELO_ TOL),

“Servo enable” is disabled for the drive.

The time should be set as large as the axis / spindle needs to come to a standstill from maximum

traversing velocity or speed.

If the axis / spindle is already at a standstill, “Servo enable” is disabled for the drive immediately.

can come to a standstill from maximum traversing velocity or speed. For this time, the cancellation

of “Servo enable” should be delayed for an axis/spindle moving.

even if the axis/spindle is still traversing. In this case, it is suddenly stopped with setpoint 0.

The time set in this MD should therefore be greater than the time of the braking ramp in case of

error statuses (MD 36610: AX_EMERGENCY_STOP_TIME).

MD 36610: AX_EMERGENCY_STOP_TIME (time of braking ramp in case of error statuses)

1-20

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 21

EMERGENCY STOP (N2)

1.5 Signal descriptions

1.5 Signal descriptions

General signals

V2600 0000.1 EMERGENCY STOP

Interface signal Signal(s) to NC (PLC - - -> NC)

Edge evaluation: no Signal(s) updated: cyclically Signal(s) valid from SW release:

Signal state 1 or edge

change 0 - - >1

Signal state 0 or edge

change 1 - - >0

Related to .... IS ”Acknowledge EMERGENCY STOP” (V2600 0000.2)

V2600 0000.2 Acknowledge EMERGENCY STOP

Interface signal Signal(s) to NC (PLC - - -> NC)

Edge evaluation: no Signal(s) updated: cyclically Signal(s) valid from SW release:

Signal state 1 or edge

change 0 - - >1

Related to .... IS ”EMERGENCY STOP” (V2600 0000.1)

The NC is set to the EMERGENCY STOP status and the EMERGENCY STOP sequence in the

NC is started.

The NC is not in the EMERGENCY STOP status.

The EMERGENCY STOP status is (still) active, but can be reset using the IS ”Acknowledge

EMERGENCY STOP” and IS ”Reset”.

IS ”EMERGENCY STOP active” (V2700 0000.1)

The EMERGENCY STOP status will only be reset if first the IS ”Acknowledge EMERGENCY

STOP“ and then the IS ”Reset” (V3000 0000.7) are set. When doing so, make sure that the IS

“Acknowledge EMERGENCY STOP” and the IS ”Reset” must be set together at least as long

as the IS ”EMERGENCY STOP active” (V2600 0000.1) has been reset.

Resetting the EMERGENCY STOP status:

resets the IS ”EMERGENCY STOP active”;

connects “Servo enable”;

sets the IS ”Position control”;

sets the IS ”802-Ready”;

lcears alarm 3000;

aborts the part program execution.

IS ”EMERGENCY STOP active” (V2700 0000.1)

IS ”Reset” (V3000 0000.7)

V2700 0000.1 EMERGENCY STOP active

Interface signal Signal(s) to NC (PLC - - -> NC)

Edge evaluation: no Signal(s) updated: cyclically Signal(s) valid from SW release:

Signal state 1 or edge

change 0 - - >1

Related to .... IS ”EMERGENCY STOP” (V2600 0000.1)

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

The NC is in the EMERGENCY STOP status.

IS ”Acknowledge EMERGENCY STOP” (V2600 0000.2)

1-21

Page 22

EMERGENCY STOP (N2)

1.6 Data fields, lists

1.6 Data fields, lists

1.6.1 Interface signals

Number .Bit Name Ref.

General

V2600 0000 .1 EMERGENCY STOP

V2600 0000 .2 Acknowledge EMERGENCY STOP

V2700 0000 .1 EMERGENCY STOP active

Mode signal range

V3000 0000 .7 Reset K1

1.6.2 Machine data

Number Identifier Name Ref.

Axis-specific

36610 AX_EMERGENCY_STOP_TIME Duration of braking ramp in case of error statuses A3

36620 SERVO_DISABLE_DELAY_TIME Servo enable cutout delay

1-22

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 23

Axis Monitoring (A3)

2.1 Overview of monitoring functions

Motion monitoring functions

- Contour monitoring

- Positioning monitoring

- Zero speed monitoring

- Clamping position monitoring

- Speed setpoint monitoring

- Actual velocity monitoring

- Encoder monitoring functions

Monitoring of static limitations

- Limit switch monitoring

- Work area monitoring

2

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

2-23

Page 24

Axis Monitoring (A3)

2.2 Motion monitoring functions

2.2 Motion monitoring functions

2.2.1 Contour monitoring

Function

The principle of functioning of the contour monitoring is based on the permanent comparison

of measured actual position value and the actual position value calculated from the NC position setpoint. To calculate the following error in advance, a model is used which simulates the

dynamic properties of the position control including feedforward control.

To make sure that the monitoring system does not respond already in the case of slight

speed variations (caused by load changes), a tolerance band is permitted for the maximum

contour deviation.

If the permissible actual value deviation entered in MD 36400: CONTOUR_TOL (contour monitoring tolerance band) is exceeded, an alarm is output, and the axes are stopped.

Activation

Effect

Remedy

The contour monitoring is active for axes and a position-controlled spindle.

If the contour error is too large, the following will occur:

Alarm 25050 ”Contour monitoring” is output.

The axis/spindle concerned is stopped with rapid stop (with open position feedback loop)

via a speed setpoint ramp.

The duration of the braking ramp is defined in the MD 36610: AX_EMERGENCY_STOP_TIME (duration of braking ramp in case of error statuses).

If the axis/spindle interpolates with other axes/spindles, these are stopped by rapid stop

with reduction of the following error (position setpoint = constant).

Increase tolerance band of monitoring function in MD 36400.

The real servo gain factor must correspond to the desired servo gain factor set in

MD 32200: POSCTRL_GAIN (servo gain factor).

With an analog spindle, check

MD 32260: RATED_VELO (rated motor speed) and

MD 32250: RATED_OUTVAL (rated output voltage).

2-24

Check optimization of speed controller.

Check smooth running of axes.

Check machine data for traversing movements (feedoverride, acceleration, max. veloci-

ties, ... )

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

Page 25

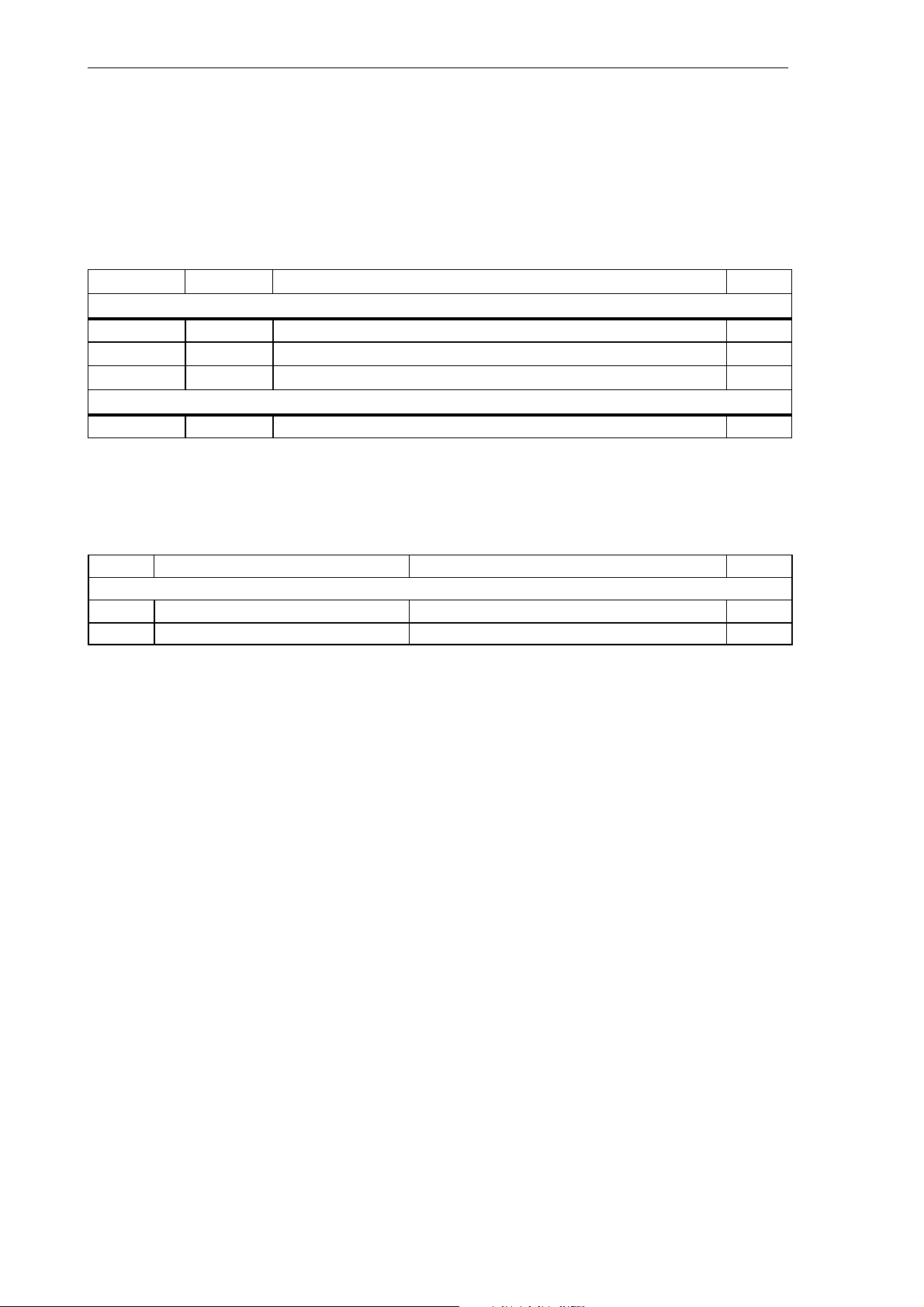

2.2.2 Positioning monitoring

Function

To make sure that an axis is positioned within a specified time, the time configured in MD

36020: POSITIONING_TIME (exact stop fine time delay) is started after a motion block has

been ended (set point has reached the target), and after this time has elapsed, it is checked

whether the axis has reached its set position within the tolerance of MD 36010: STOP_LIMIT_FINE (exact stop fine).

”Exact stop coarse and fine“ see:

References: Chapter ”Continuous -Path Mode, Exact Stop and LookAhead”

Axis Monitoring (A3)

2.2 Motion monitoring functions

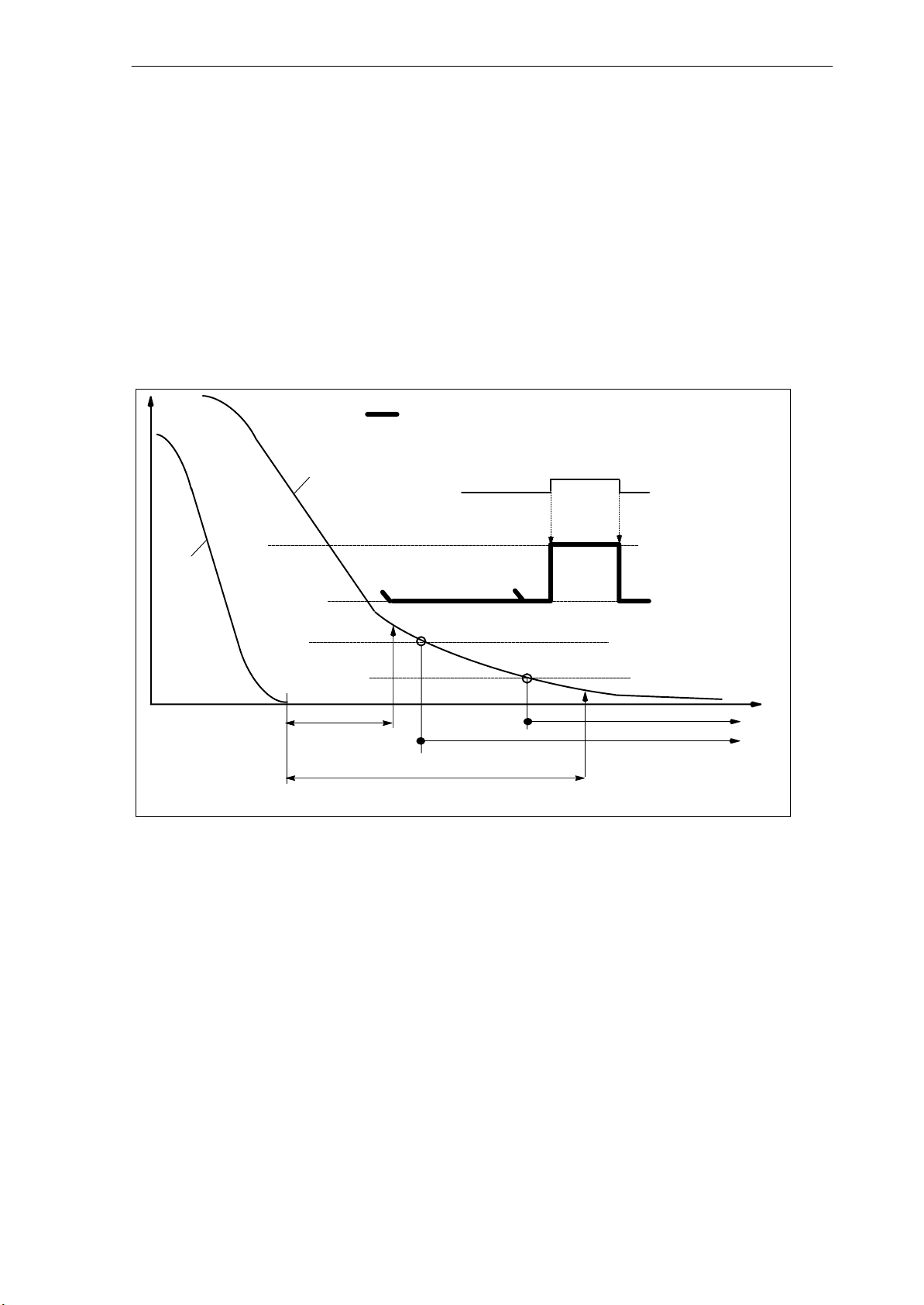

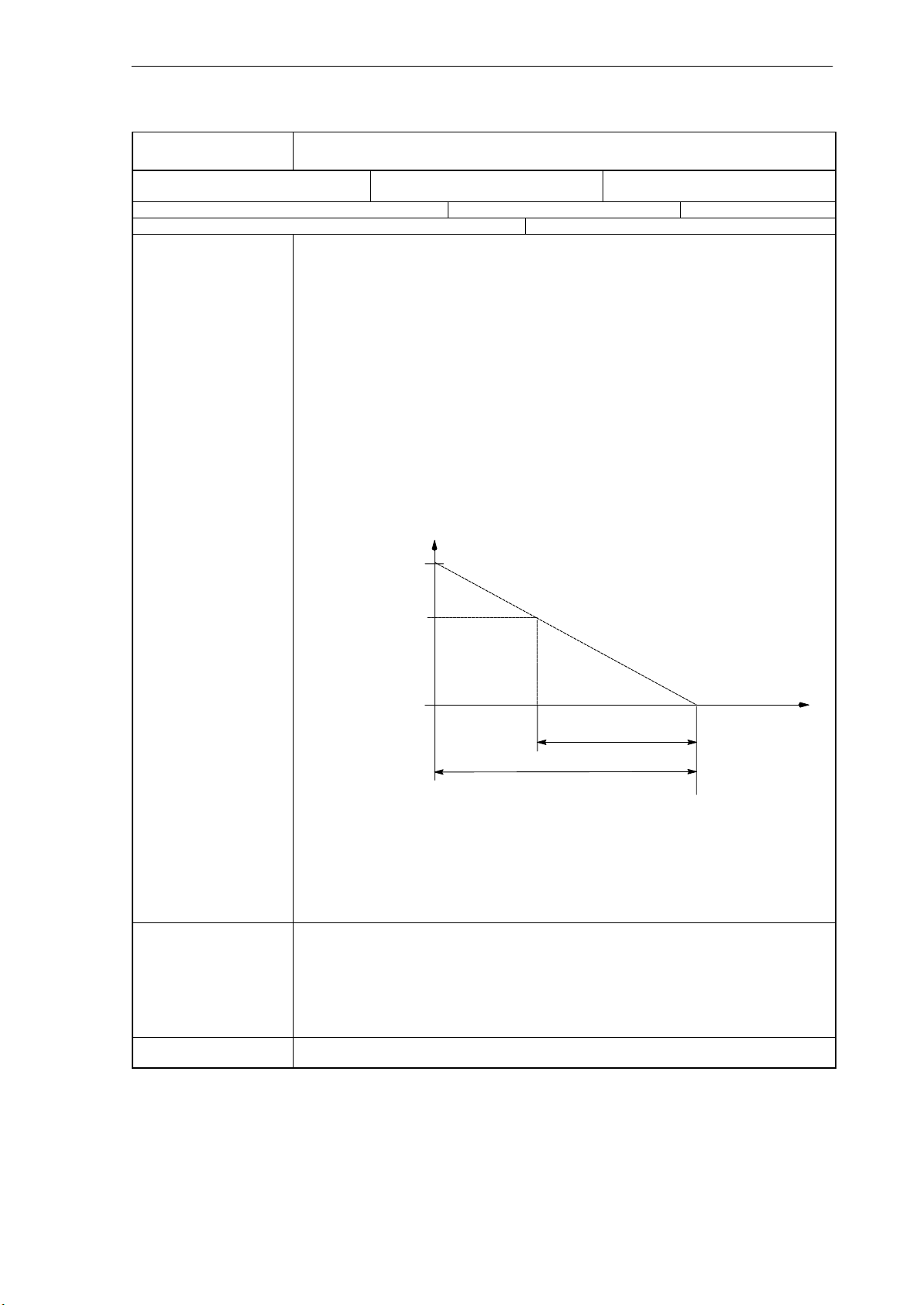

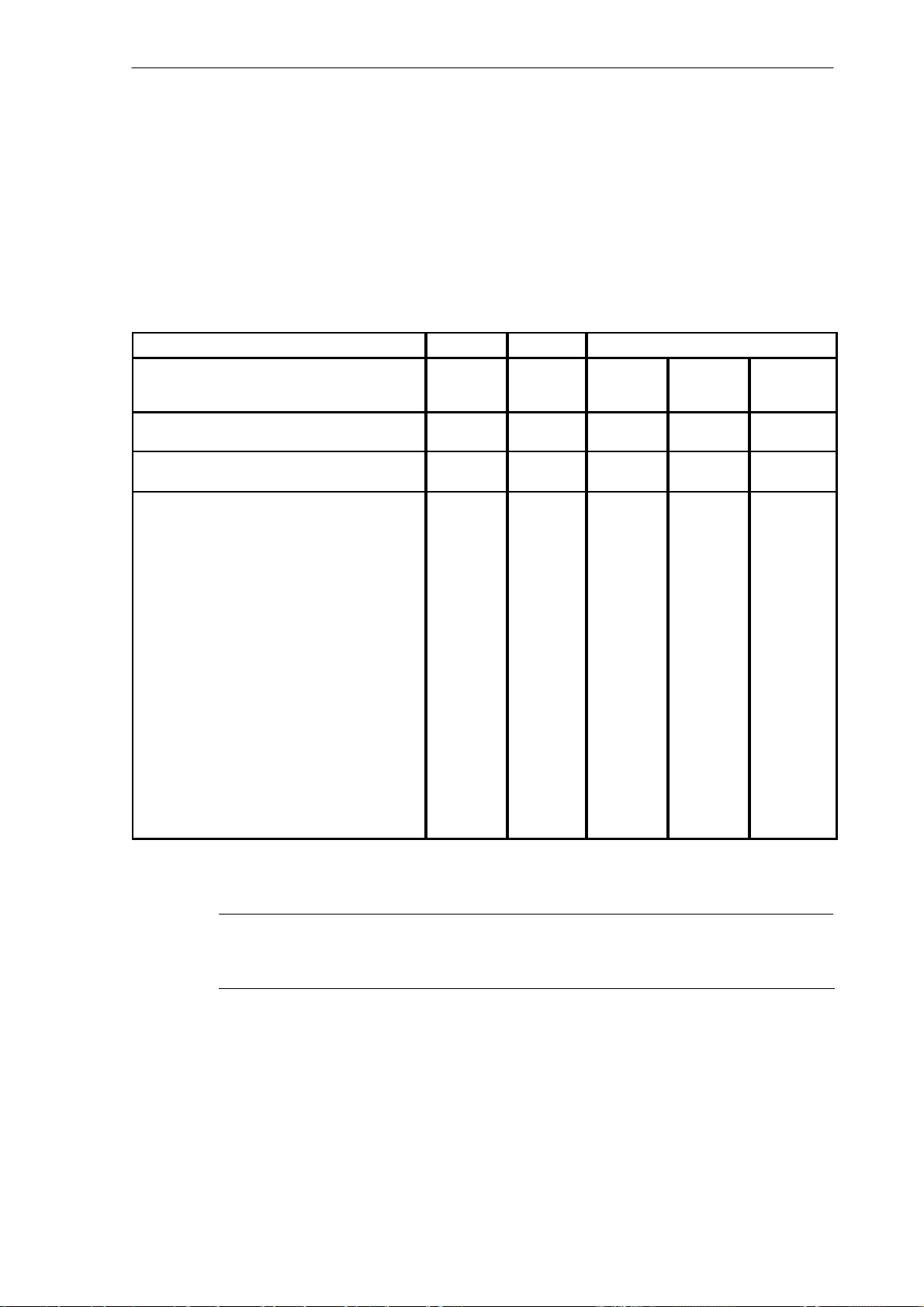

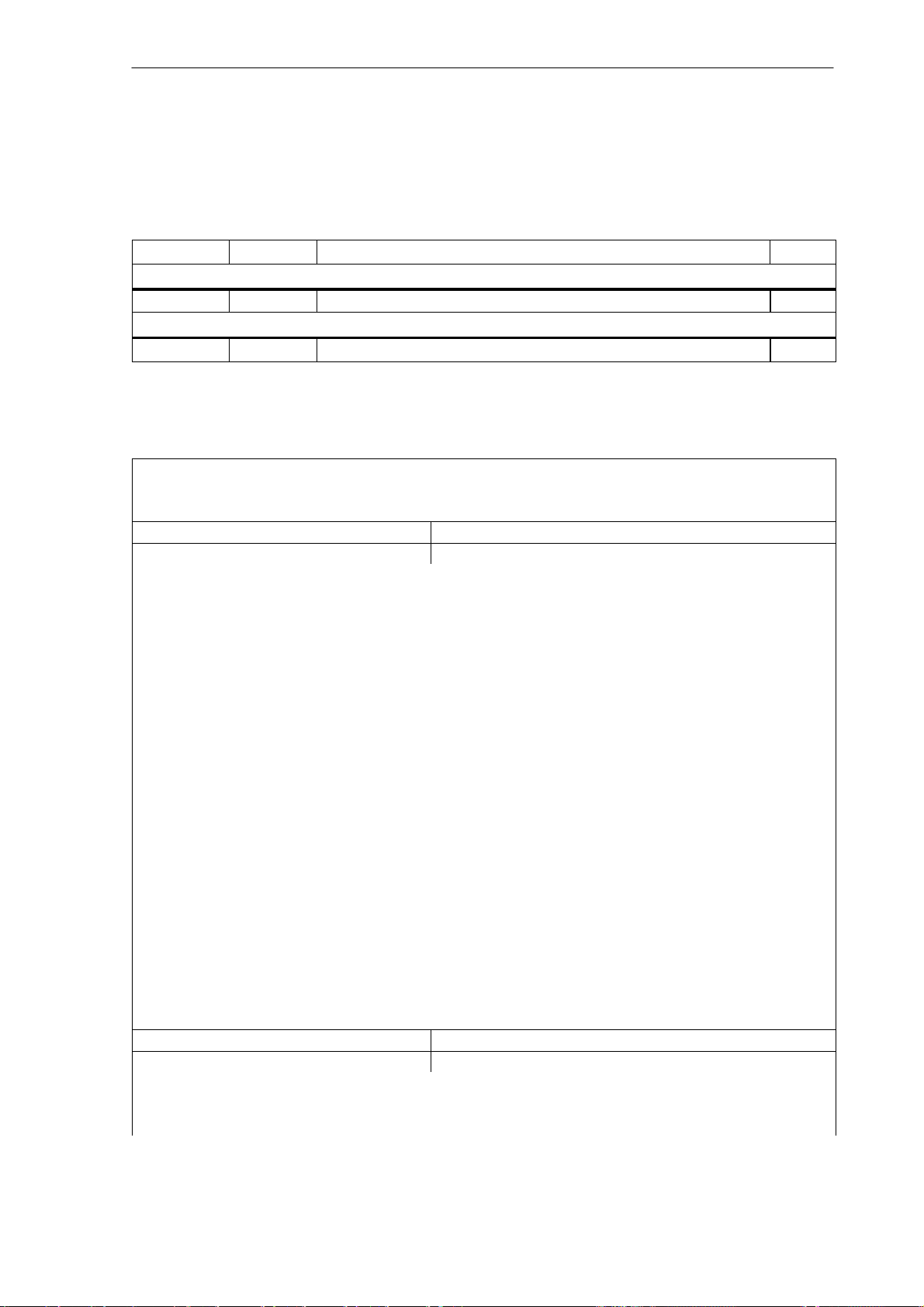

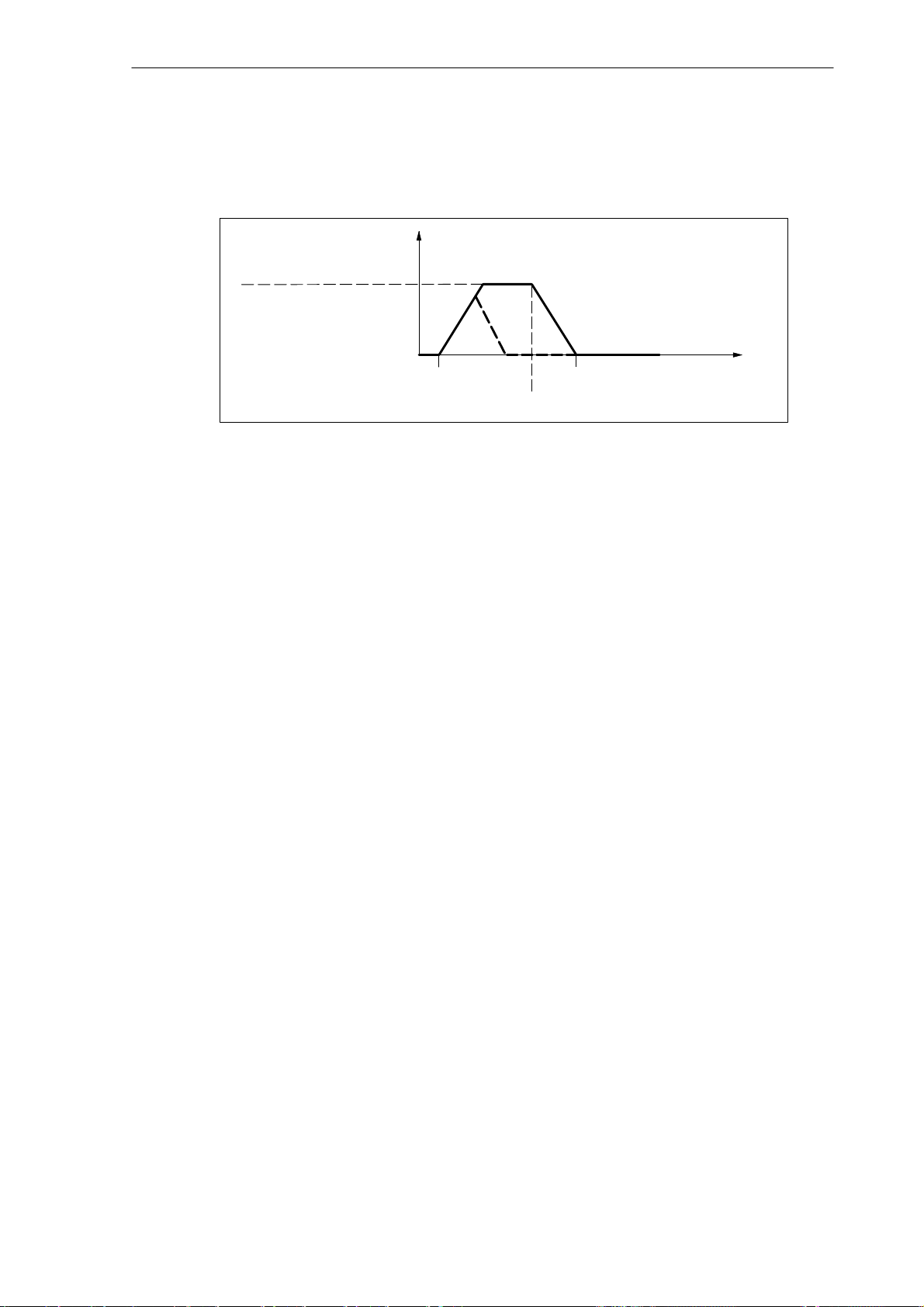

V or s

active tolerance in case of zero

speed or clamping monitoring

Actual value

Setpoint

MD:

STANDSTILL_

DELAY_TIME

MD: POSITIONING_TIME

Fig. 2-1 Interrelation between positioning, zero speed and clamping monitoring

Interface signal

”Clamping process

running“ (V380x

0002.3)

MD: CLAMP_POS_TOL

MD:

STANDSTILL_POS_T

OL

MD: STOP_LIMIT_COARSE

MD: STOP_LIMIT_FINE

“Exact stop fine” - interface signal

“Exact stop coarse“ - interface signal

t

Enabling

The positioning monitoring is always enabled after a “setpoint-dependent” completion of motion blocks (setpoint has reached the target).

The positioning monitoring is active for axes and a position-controlled spindle.

Disabling

The positioning monitoring is disabled after the specified ”Exact stop limit fine” has been reached or after output of a new setpoint position (e.g. when positioning to ”Exact stop coarse“

followed by a block change).

SINUMERIK 802D, 802D base line

6FC5 697-2AA10-0BP2 (11.03) (DF)

2-25

Page 26

Axis Monitoring (A3)

2.2 Motion monitoring functions

Effect

If the limit value for “Exact stop fine” has not yet been reached after the positioning monitoring time has elapsed, the following action is carried out:

Alarm 25080 ”Positioning monitoring” is output.