Page 1

Diagnostics Guide 10/2002 Edition

sinumerik

SINUMERIK 802D

SINUMERIK 802D base line

Page 2

Page 3

SINUMERIK 802D

Diagnostics Guide

Alarms

Glossary /

Abbreviations

1

2

Valid for

Control Software version

SINUMERIK 802D as of 1

10.02 Edition

Page 4

SINUMERIK documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” column.

Status code in the ”Remarks” column:

A New documentation.. . . .

B Unrevized reprint with new Order No.. . . .

C Revised edition with new status. . . . .

If actual changes have been made on the page since the last edition,

this is indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

11.00 6FC5698-2AA20-0BP0 A

10.02 6FC5698-2AA20-0BP1 C

This Manual is included on the documentation on CD-ROM (DOCONCD)

Edition Order No. Remarks

11.02 6FC5298-6CA00-0BG3 C

Trademarks

SIMATICr, SIMATIC HMIr, SIMATIC NETr, SIROTECr, SINUMERIKr and SIMODRIVEr are registered

trademarks of Siemens. Third parties using for their own purposes any other names in this document which

refer to trademarks might infringe upon the rights of trademark owners.

This documentation was produced using Interleaf 7.0.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority. Offenders

will be liable for demages. All rights, including rights created by patent

grant or registration of utility model or design, are reserved.

Siemens AG 2002. All rights reserved.

Printed in the Federal Republic of Germany

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

We have checked that the contents of this document correspond to

the hardware and software described. Nonetheless, differences might

exist and therefore we cannot guarantee that they are completely

identical. The information contained in this document is, however,

reviewed regularly and any necessary changes will be included in the

next edition. We welcome suggestions for improvement.

Siemens-AktiengesellschaftOrder No. 6FC5698-2AA20-0BP1

Page 5

10.02

Preface

The present description is intended to be used as a reference manual. It

allows the operator on the machine tool to:

- access special cases in the operation of the machine correctly;

- to learn the response of the system/installation to the particular special case;

- to use the possibilities of continuing work after the special case;

- to follow notes for further references.

Scope

Object of the present description are the alarms occurring in the areas

NC kernel (NCK), Profibus, cycles and PLC.

Further alarms may occur in the HMI area (Human Machine Interface).

They are announced to the user by self-explaining alarm lines displayed

on the operator panel. These alarms are not part of this Diagnostics

Guide.

For special cases in conjunction with the integrated PLC, please refer to

the relevant SIMATIC S7-200 system documentation.

Sorting

Safety

NC alarms

The alarms are sorted in the Diagnostics Guide by ascending alarm

numbers with gaps between them.

Danger

Please always check the situation of the particular system/installation

carefully on the basis of the alarms occurred. Eliminate the causes for

the occurrence of the alarms and acknowledge them as described.

Otherwise, danger will result for machine, workpiece, saved settings

and - under certain circumstances - even for your health.

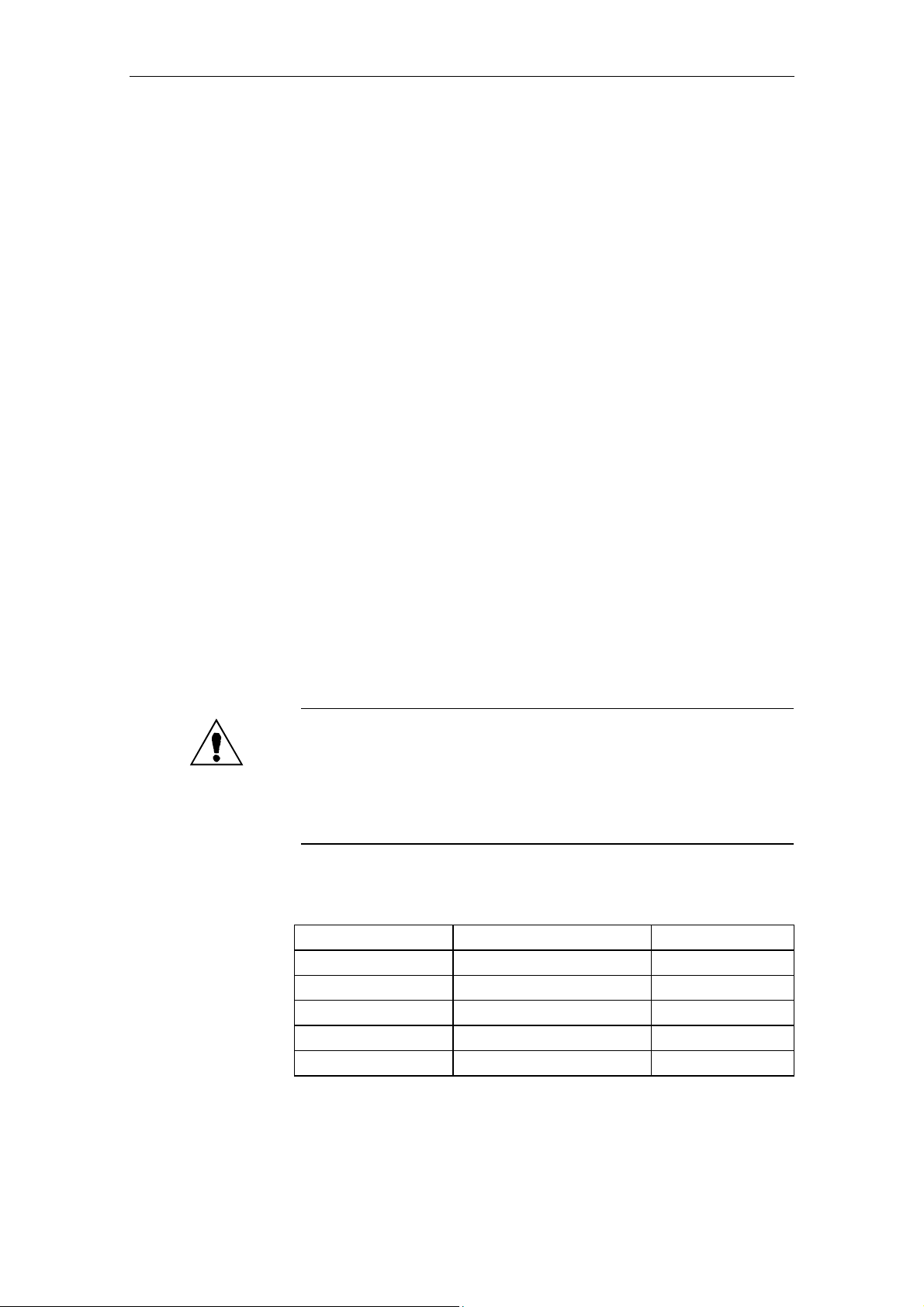

Table 1_1 Alarm number ranges

000 000 - 009 999 General alarms

010 000 - 019 999 Channel alarms

020 000 - 029 999 Axis / spindle alarms

030 000 - 099 999 Functional alarms

060 000 - 064 999 SIEMENS cycle alarms

065 000 - 069 999 User cycle alarms

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG)

v

Page 6

10.02

HMI alarms/messages

PLC alarms/messages

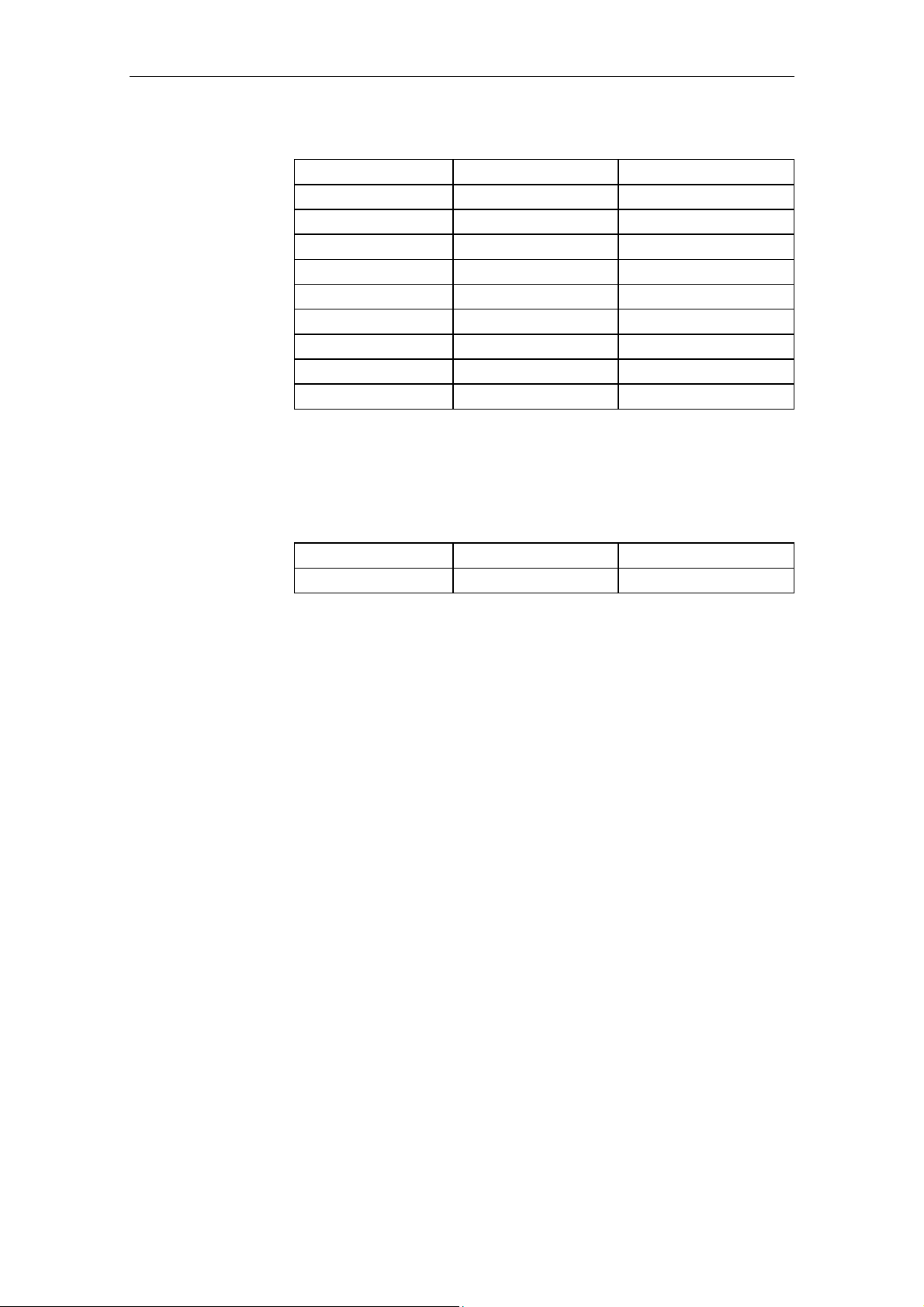

Table 1_2 Alarm number ranges (cont'd.)

100 000 - 100 999 Basic system HMI0

101 000 - 101 999 Diagnosis

102 000 - 102 999 Services

103 000 - 103 999 Machine

104 000 - 104 999 Parameters

105 000 - 105 999 Programming

106 000 - 106 999 Reserve

107 000 - 107 999 OEM

110 000 - 110 999 Reserved

120 000 - 120 999 Reserved

Table 1_4 Alarm number ranges (cont'd.)

400 000 - 499 999 General alarms

700 000 - 799 999 User area

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

vi 802D (DG)

Page 7

10.02

Contents

Alarms .......................................................................................................................................... 9

1.1

1.2

13

1.4

15

1.6

Glossary / Abbreviations ........................................................................................................ 209

2.1

2.2

Overview of NC alarms ...................................................................................... 10

Profibus Alarms................................................................................................ 180

Cycle Alarms|................................................................................................... 187

ISO Alarms....................................................................................................... 197

PLC Alarms...................................................................................................... 199

Action List ........................................................................................................ 202

Abbreviations ................................................................................................... 209

Glossary........................................................................................................... 213

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG)

vii

Page 8

10.02

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

viii 802D (DG)

Page 9

10.02 1 Alarms

Alarms

1

Alarms with alarm number 1xxx are system errors that indicate internal

error states. The internal error number transmitted provides the devel-

oper important information with regard to the error cause and the error

location.

These system errors are not described in detail. If they occur with the

supplied control systems at all, please contact the following hotline,

specifying the alarm number, the alarm text and the internal system

error number contained therein:

Hotline Germany

Siemens AG, A&D MC

Tel. +49 (0) 180 525 80 08

Fax +49 (0) 180 525 80 09

Hotline China

Siemens Numerical Control Ltd.

Development & Engineering Division

Tel. (025) 2 18 18 88 (Ext. 305)

Fax (025) 2 18 16 66

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-9

Page 10

10.02 1 Alarms

10.02

1.1 Overview of NC alarms

2000

Explanation

Reaction

Remedy

Program continuation

by

2001

Explanation

Reaction

Remedy

Program continuation

by

Sign-of-life monitoring PLC

The PLC must provide a sign of life within a defined period of time. If not, this

alarm is generated.

NC Start inhibited.

NC not ready.

NC Stop at alarm.

Alarm display.

Interface signals are set.

This alarm also occurs as a consequence of PLC Stop.

(PLC Stop via Programming Tool,

PLC Stop from start-up switch,

PLC Stop caused by an alarm)

If none of the above mentioned cases exists, please contact the hotline indicated in the beginning of this publication and specify the operating system

error number.

Power ON

PLC not booted

The PLC must provide at least one sign of life within the defined period of time

after POWER ON.

NC Start inhibited.

NC not ready.

NC Stop at alarm.

Alarm display.

Interface signals are set.

Contact the hotline indicated in the beginning of this publication.

Power ON

2140

Explanation

Reaction

Remedy

Program continuation

by

3000

Explanation

Reaction

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-10 802D (DG)

The current position of the service switch will clear the SRAM with the

next POWER ON (general reset active)

The initialization switch is currently set to "General reset". As a consequence,

the SRAM of the module is cleared with the next module reset; as a result, the

NC data memory is lost.

Alarm display.

Interface signals are set.

NC not ready.

Reset the initialization switch back to "1".

Use the "Cancel" key to cancel the alarm. No further operation required.

EMERGENCY STOP

The EMERGENCY STOP request is present at the NC/PLC interface

(V 26000000.1).

NC Start inhibited.

NC not ready

Page 11

10.02 1 Alarms

NC Stop at alarm

Alarm display

Interface signals are set.

Remedy

Program continuation

by

Check whether an EMERGENCY STOP cam has been approached or an

EMERGENCY STOP button has been tripped. Check the PLC user program.

Correct the EMERGENCY STOP cause and acknowledge EMERGENCY

STOP via the PLC/NC user interface (V 26000000.2).

Use the RESET key to cancel the alarm. Restart the part program.

4000

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 machine data %2 contains a gap in the axis assignment

%1 = channel number

%2 = string: MD identifier

The assignment of a machine axis to a channel using the MD 20070

AXCONF_MACHAX_USED must be carried out without gaps. Any gaps will be

detected when the system boots (POWER ON) and be displayed as an alarm.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Configure MD 20070 AXCONF_MACHAX_USED for the axis assignment of

the channel without gaps, i.e. with ascending axis indices, a machine axis has

to be assigned until zero (no machine axis) is entered for the first time. In this

case, all MDs that have higher indices must also be loaded with zero.

The sequence order of the machine numbers is not relevant.

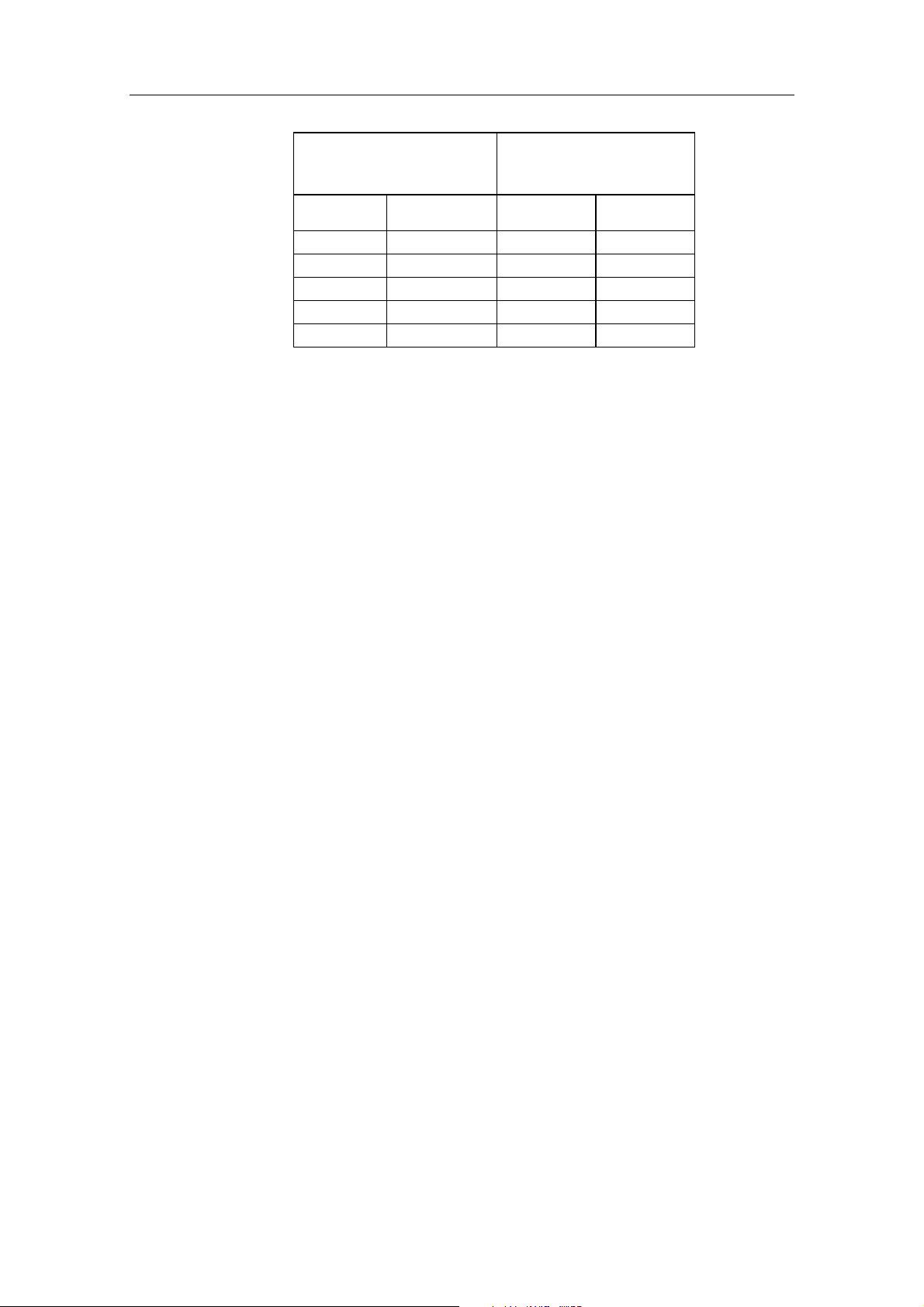

Channel

Index

0 1 AXCONF_MACHAX_USED [CH1, AX1] = 1

1 2 AXCONF_MACHAX_USED [CH1, AX2] = 2

2 3 AXCONF_MACHAX_USED [CH1, AX3] = 3

3 4 AXCONF_MACHAX_USED [CH1, AX4] = 4

4 5 AXCONF_MACHAX_USED [CH1, AX5] = 5

Assignment of the channel axes to the machine axes

Power ON

1st

Channel

Machine Axis Number

4002

Explanation

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-11

Channel %1 machine data %2[%3] contains an axis not defined in the

channel

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

Only axes activated in the channel via MD 20070

[kx]=m

may be declared geometry axes via

MD 20050 AXCONF_GEOAX_ASSIGN_TAB [gx]=k.

gx ... Geometry axis index k ... Channel axis no.

kx ... Channel axis index m ... Machine axis no.

AXCONF_MACHAX_USED

Page 12

10.02 1 Alarms

10.02

Reaction

Remedy

Program continuation

by

MD 20050

AXCONF_GEOAX_ASSIGN_TAB

(contains channel axis no. k) (contains machine axis no. m)

Geometry Axis

Index

1. Channel Channel Axis

MD 20070

AXCONF_MACHAX_USED

Index

1. Channel

0 1 0 1

1 2 1 2

2 3 2 3

3 4

4 5

Assignment of the geometry axes to the channel axes

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Check MD 20050

AXCONF_GEOAX_ASSIGN TAB

and

MD 20070 AXCONF_MACHAX_USED and correct them if necessary.

The basis is the MD array MD 20070 AXCONF_MACHAX_USED in which the

machine axis number to be controlled by this channel is entered channelspecifically. The resulting "channel axes" are assigned a name by MD 20080

AXCONF_CHANAX_NAME_TAB and assigned to a geometry axis via MD

20050 AXCONF_GEOAX_ASSIGN_TAB by entering the relevant channel axis

in this MD array for each geometry axis.

Power ON

4004

Explanation

Reaction

Remedy

Program continuation

by

4010

Explanation

Channel %1 machine data %2 axis %3 defined as a geometry axis repeatedly

%1 = channel number

%2 = string: MD identifier

%3 = axis index

An axis may be defined as a geometry axis only once.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Correct MD 20050

AXCONF_GEOAX_ASSIGN_TAB

.

Power ON

Power ON

Machine data %1[%2] contains an illegal identifier

%1 = string: MD identifier

%2 = index: MD array index

When defining the names for: machine axes, one of the following syntax rules

has been violated for the identifier to be entered:

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-12 802D (DG)

Page 13

10.02 1 Alarms

1. The identifier must be an NC address letter (A, B, C, I, J, K, U, V, W, X, Y,

Z), possibly with a numerical extension.

2. The identifier must start with 2 random uppercase letters, but not with the

$ character (reserved).

3. The identifier must not be a vocabulary word of the NC language (e.g.

SPOS).

Reaction

Remedy

Program continuation

by

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Enter the identifier for user-defined names in the displayed MD using the correct syntax.

Machine axes: MD 10000 AXCONF_MACHAX_NAME_TAB

Power ON

4011

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 Machine data %2[%3] contains an illegal identifier

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

When defining the names in the channel-specific tables for geometry axes and

channel axes, one of the following syntax rules has been violated for the identifier to be entered:

1. The identifier must be an NC address letter (A, B, C, I, J, K, U, V, W, X, Y,

Z), possibly with a numerical extension.

2. The identifier must start with 2 random uppercase letters, but not with the

$ character (reserved for system variables).

3. The identifier must not be a vocabulary word of the NC language (e.g.

SPOS).

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Enter the identifier for user-defined names in the displayed MD using the correct syntax.

Geometry axes: MD 20060 AXCONF_GEOAX_NAME_TAB

Channel axes: MD 10000

Power ON

AXCONF_MACHAX_NAME_TAB

4020

Explanation

Reaction

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-13

Identifier %1 used repeatedly in machine data %2

%1 = string: identifier

%2 = string: MD identifier

When defining the names in the NC tables (arrays) for machine axes, an

identifier was used which already exists in the control system.

Alarm display.

Interface signals are set.

NC not ready.

Page 14

10.02 1 Alarms

10.02

NC Start inhibited.

NC Stop at alarm.

Remedy

Program continuation

by

Please inform the authorized personnel/customer service.

Select a string for the identifier to be entered which is not yet used in the system (max. 32 characters).

The RESET key must be used in all channels of this mode group to cancel this

alarm.

4021

Explanation

Reaction

Remedy

Program continuation

by

4030

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 Identifier %2 used repeatedly in machine data %3

%1 = channel number

%2 = string: Identifier

%3 = string: MD identifier

When defining the names in the channel-specific tables for geometry axes

and channel axes, an identifier was used which already exists in the control

system.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Select a string for the identifier to be entered which is not yet used in the system (max. 32 characters).

Power ON

Channel %1 Missing identifier in machine data %2[%3]

%1 = channel number

%2 = string: MD identifier

%3 = index: MD array index

Due to the axis configuration in MD 20070 AXCONF_

MACHAX_USED and MD 20050 AXCONF_GEOAX_ASSIGN_TAB,

an axis identifier is expected for the MD displayed.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Check the axis configuration and enter the missing axis identifier in the MD or if you wish the axis to be omitted - specify machine axis 0 for this channel axis

in MD 20070 AXCONF_MACHAX_USED. If the axis is a geometry axis which

will not be used (with exclusively 2-axis machining, e.g. with turning machines),

the channel axis 0 must additionally entered in MD 20050

AXCONF_GEOAX_ASSIGN_TAB for the appropriate geometry axis.

Power ON

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-14 802D (DG)

Page 15

10.02 1 Alarms

4032

Explanation

Reaction

Remedy

Program continuation

by

4040

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 Wrong identifier for transverse axis in %2

%1 = channel number

%2 = string: MD identifier

Due to the axis configuration in MD 20150 GCODE_RESET_VALUES or MD

DIAMETER_AX_DEF

20100

specified place.

Alarm display

Interface signals are set

NC Stop at alarm

NC not ready

NC Start inhibited

Please inform the authorized personnel/customer service.

Add the correct identifier.

Power ON

Channel %1 axis identifier %2 inconsistent with machine data %3

%1 = channel number

%2 = string: Axis identifier

%3 = string: MD identifier

The use of the axis identifier specified in the displayed MD is not consistent

with the axis configuration of the channel specified in MD 20070

AXCONF_MACHAX_USED

MD 20050 AXCONF_GEOAX_ASSIGN_TAB.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

Check the identifiers used in MD 10000 AXCONF_

MACHAX_NAME_TAB, MD 20080 AXCONF_CHANAX_NAME_TAB and/or

MD 20050 AXCONF_GEOAX_NAME_TAB and correct them if necessary.

Power ON

, a transverse axis identifier is expected in the

and

4050

Explanation

Reaction

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-15

NC code identifier %1 was not reconfigured to %2

%1 = string: Old identifier

%2 = string: New identifier

The NC code could not be renamed for one of the following reasons:

• The old identifier does not exist any more.

• The new identifier is assigned to a different type area.

NC codes/vocabulary words can be reconfigured via machine data provided

that the type area is not left.

Type 1: "Real" G codes: G02, G17, G33, G64, ...

Type 2: Known G codes: CIP, TRANS, ...

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Page 16

10.02 1 Alarms

10.02

Remedy

Program continuation

by

4060

Explanation

Reaction

Remedy

Program continuation

by

Please inform the authorized personnel/customer service.

Correct MD 10712 NC_USER_CODE_CONF_NAME_TAB (protection level 1).

The list must be structured as follows:

Even address: Identifier to be changed

followed by an odd address: New identifier

e.g.: NC_USER_CODE_CONF_NAME_TAB [10] = "ROT"

NC_USER_CODE_CONF_NAME_TAB [11] = " "

will cancel the ROT function in the control system

Power ON

Default machine data have been loaded

Booting with the default values by:

• operator action (e.g. start-up switch)

• MD 11200 INIT_MD

• loss of the retentive data

• operator action - booting with saved data, without saving the data first

Alarm display.

After the default machine data have been loaded, the particular MD for your

particular system/installation must be entered/loaded.

Use the "Cancel" key to cancel the alarm. Reload your own machine data.

4062

Explanation

Reaction

Remedy

Program continuation

by

4065

Explanation

Reaction

Remedy

Program continuation

by

Data backup copy has been loaded

The used data saved to flash have been loaded into the SRAM.

Alarm display.

Reload your own machine data.

Use the RESET key to cancel the alarm.

Battery-backed memory is restored from backup copy (risk of data loss !)

When booting, a possible inconsistency has been detected in the batterybacked memory.

The battery-backed memory was initialized using the last backup copy. As a

result, the changes in the battery-backed memory carried out since the last

update of the backup copy are lost. The cause of this procedure is to be

searched for in exceeding of the buffer time. Please make sure that the required on-time of the control system, which is specified in your Start-up Guide,

is not exceeded.

The current backup copy of the battery-backed memory was created using the

internal data backup carried out last using the softkey "Save data" in the HMI.

Alarm display

Interface signals are set.

NC Start inhibited

Restart the control system.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-16 802D (DG)

Page 17

10.02 1 Alarms

4070

Explanation

Reaction

Remedy

Program continuation

by

Unit machine data changed

The control system uses internal physical units (mm, degrees, s, for distances

to go, velocities, accelerations and the like). With programming or data backup, some of these values are input/output using other units (rpm, m/s2, etc.).

The conversion is carried out using scaling factors which can be entered (system-specific MD array 10230 SCALING_FACTORS USER_DEF[n] (n ... index

numbers 0 ... 10) if the relevant masking bit is set to "1".

If the masking bit is set to "0", the scaling is carried out using the internal default factors.

The following machine data influence the scaling of other MDs:

MD 10220

MD 10230 SCALING_FACTORS_USER_DEF

MD 10240 SCALING_SYSTEM_IS_METRIC

MD 10250

MD 30300 IS_ROT_AX

After these data have been changed, the NC must be rebooted. Only then the

input of dependent data will be executed correctly.

Alarm display.

Please inform the authorized personnel/customer service.

If the alarm has been displayed after downloading a consistent MD file, the

download operation must be repeated and the NC is rebooted. (Scalingdependent machine data in the file are always put in front of the scaling factors).

Use the "Cancel" key to cancel the alarm. No further operation required.

SCALING_USER_DEF_MASK

SCALING_VALUE_INCH

4075

Explanation

Reaction

Remedy

Program continuation

by

4076

Explanation

Machine data %1 (and possible further) not changed due to missing access rights %2

%1 = string: MD identifier

%2 = write protection level of the MD

When executing a TOA file, it has been tried to program a data whose protection level is higher than the access authorization currently set at the control

system.

The relevant data has not been programmed.

This alarm is only generated with the first write access violation detected.

Alarm display.

Either set the required access level via the password or delete the appropriate

machine data from the MD file.

Use the "Cancel" key to cancel the alarm. No further operation required.

%1 Machine data could not be changed with access right %2

%1 = number of MD

%2 = set access right

When executing a TOA file, it has been tried to program a data whose protection level is higher than the access authorization currently set at the control

system.

The appropriate data have not been programmed.

This alarm is issued when acknowledging alarm 4075. It can only be canceled

with POWER ON.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-17

Page 18

10.02 1 Alarms

10.02

Reaction

Remedy

Program continuation

by

4077

Explanation

Reaction

Remedy

Program continuation

by

Alarm display.

Either set the required access level via the password or using the keyswitch or

delete the appropriate machine data from the MD file.

Power ON

New value %1 of MD %2 not set; requests %3 bytes too much %4 memory.

%1 = new value of the machine data

%2 = machine data number

%3 = number of bytes requested in excess

%4 = type of memory

It was tried to assign the specified memory-configuring machine data a new

value.

The change will not be executed, since it would result in deleting the user

memory. The change requires more user memory than provided.

The third parameter specifies the number of bytes by which the maximum user

memory has been exceeded.

The fourth parameter specifies the type of the memory whose limit is exceeded:

"D" stands for the dynamic or non-backed user memory (there are, e.g. the

LUD variables, this also includes the IPO buffer size). The size of this memory

type is defined by the current memory configuration and by the value of

MD18210

"S" stands for the static or battery-backed user memory (typically, there are the

part programs, but also the compensation data, R parameters, tool data); this

memory type is also defined by the current memory configuration and by the

value of MD 18230 MM_USER_MEM_BUFFERED.

Alarm display.

If the change was not desired, then simply continue.

In this case, the alarm will not have any negative influence.

How this error is corrected depends on the access right and on the current NC

memory configuration:

The change as planned to be done is not possible in this way -> try once more

using a smaller value. When doing so, watch how the value of the byte number

changes.

Buying more memory? This possibility depends on the model you are using.

The NC user memory is possible set smaller than possible. Provided the appropriate access right, the MD (see above) can be changed.

Use the "Cancel" key to cancel the alarm. No further operation required.

MM_USER_MEM_DYNAMIC

.

4090

Explanation

Reaction

Remedy

Program continuation

by

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-18 802D (DG)

Too many errors when booting

More than <n> errors have occurred when the control system has booted.

Alarm display.

NC Start inhibited

Set the machine data correctly.

Page 19

10.02 1 Alarms

4110

Explanation

Reaction

Remedy

Program continuation

by

4111

Explanation

Reaction

Remedy

Program continuation

by

IPO cycle factor increased to %1 ms

%1 = string (new IPO cycle)

The IPO cycle divider was set to a value which was no integer

multiple of the position control divider.

The divider (MD 10070 IPO_SYSCLOCK_TIME_RATIO ) was increased.

In the case of systems working with Profibus DP,

IPO_SYSCLOCK_TIME_RATIO has been modified due to the changed DP

cycle (MD 10050 SYSCLOCK_CYCLE_TIME ) in SDB1000.

Alarm display.

The machine data 10070 IPO_SYSCLOCK_TIME_RATIO was adapted accordingly.

Use the RESET key to cancel the alarm. Restart the part program.

Increase PLC clock to %1 ms

The PLC clock divider was set to a value which was no integer multiple of the

IPO clock divider.

The divider (MD

Alarm display.

Adapt the machine data accordingly.

Power ON

10 074 PLC_IPO_TIME_RATIO

) was increased.

4112

Explanation

Reaction

Remedy

Program continuation

by

4113

Explanation

Reaction

Remedy

Program continuation

by

4114

Explanation

Reaction

Servo clock changed to %1 ms

%1 = string (new servo cycle)

In the case of systems working with Profibus DP, IPO10060

_SYSCLOCK_TIME_RATIO has been modified in SDB1000 due to the

changed DP cycle (MD 10050 SYSCLOCK_CYCLE_TIME ).

Alarm display.

The machine data 10060 POSCTRL_SYSCLOCK_TIME_RATIO was adapted

accordingly.

Use the RESET key to cancel the alarm. Restart the part program.

Sysclock changed to %1 ms

%1 = string (new PLC cycle)

The MD 10050 SYSCLOCK_CYCLE_TIME has been modified due to the

changed DP clock in SDB1000.

Alarm display.

The machine data 10050 IPO_SYSCLOCK_CYCLE_TIME was adapted accordingly.

Use the RESET key to cancel the alarm. Restart the part program.

Error in DP clock of SDB1000

%1 = string (new PLC cycle)

The DP clock in SDB1000 is faulty and can no longer be set.

The default value of $MN_SYSCLOCK_CYCLE_TIME will be set.

Alarm display.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-19

Page 20

10.02 1 Alarms

10.02

Remedy

Program continuation

by

4150

Explanation

%1=channel number

Reaction

Remedy

Program continuation

by

4152

Explanation

Reaction

Remedy

Program continuation

by

Correct SDB1000 accordingly.

Power ON

Channel %1 Invalid M function subroutine call configured

In MD 10715

function, an M function was specified which is occupied by the system and

cannot be replaced by a subroutine call (M0 to M5, M17, M19, M30, M40 to

M45, M70). With the external language active, M96 – M99 are also disabled

Alarm display.

NC Start inhibited

Interface signals are set

NC not ready

NC Stop at alarm

Configure an M function in MD 10715 M_NO_FCT_CYCLE, which is not occupied by the system (M0 to M5, M17, M19, M30, M40 to M45, M70).

Illegal configuration of the function "Block display with absolute values"

The function "Block display with absolute values" was configured illegally:

- An illegal block length was set via $MC_MM_ABSBLOCK:

When booting, the machine data is checked for the following range of values:

0, 1, 128 ... 512

- An illegal display range was set via

$MC_MM_ABSBLOCK_BUFFER_CONF[]. When booting, the machine data is

checked for the following upper/lower limits:

0 <= $MC_MM_ABSBLOCK_BUFFER_CONF[0] <= 8

0 <= $MC_MM_ABSBLOCK_BUFFER_CONF[1] <=

($MC_MM_IPO_BUFFER_SIZE + $MC_MM_NUM_BLOCKS_IN_PREP).

In case of violation of the limits, alarm 4152 is issued.

Alarm display.

Interface signals are set.

Channel not ready.

NC Stop at alarm.

NC Start inhibited.

M_NO_FCT_CYCLE

for configuring the subroutine call via M

Dimension the block length/display range within the permitted limits.

Power ON

4160

Explanation

Reaction

Remedy

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-20 802D (DG)

Channel %1 Invalid M function number configured for spindle switching

%1=channel number

In MD 20094 SPIND_RIGID_TAPPING_M_NR for configuring the M function

number for switching the spindle to the axis mode, an M function was specified

which is occupied by the system and cannot be used for switching (M1 ... M5,

M17, M30, M40 ... M45).

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited

NC Stop at alarm

Configure an M function in MD 20094 SPIND_RIGID_TAPPING_M_NR, which

is not occupied by the system (M1 to M5, M17, M19, M30, M40 to M45, M70).

Page 21

10.02 1 Alarms

Program continuation

by

4182

Explanation

Reaction

Remedy

Program continuation

by

4183

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 Illegal M auxiliary function number in %2%3; MD reset

%1 = channel number

%2 = machine axis identifier

%3 = MD index if necessary

A number which is occupied by the system and cannot be used for an assignment was specified for configuring an M function.

(M0 ... M5, M17, M30, M40 ... M45 and - when working with ISO dialect - also

M98,M99).

The value used by the user has been reset by the system to the default value.

Alarm display.

Interface signals are set.

Channel not ready.

NC Start inhibited in this channel

NC Stop at alarm.

Configure an M function in the specified machine data, which is not occupied

by the system (M0 ... M5, M17, M30, M40 ... M45 and - when working with ISO

dialect - also M98,M99).

Use the RESET key to cancel the alarm. Restart the part program.

Channel %1 M auxiliary function number %2 used repeatedly (%3 and %4)

%1 = channel number

%2 = M auxiliary function number

%3 = machine axis data identifier

%4 = machine data identifier

A number in the specified machine data was used repeatedly for configuring an

M function.

Alarm display.

Interface signals are set.

Mode group not ready.

Channel not ready.

NC Start inhibited in this channel

NC Stop at alarm.

Check the specified machine data and provide for an unambiguous assignment of the M auxiliary function numbers.

Power ON

4200

Explanation

Reaction

Remedy

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-21

Channel %1 Geometry axis %2 may not declared a rotary axis

%1 = channel number

%2 = axis name:

The geometry axes constitute a Cartesian coordinate system; therefore, the

declaration of a geometry axis as a rotary axis will result in a definition conflict.

NC not ready.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/customer service.

Remove the rotary axis declaration of this machine axis.

Page 22

10.02 1 Alarms

10.02

To do so, determine the geometry axis index for the displayed geometry axis

via the machine data array 20060 AXCONF_GEOAX_NAME_TAB. The channel axis number is stored in the MD array 20050

AXCONF_GEOAX_ASSIGN_TAB via the same index. The channel axis number minus 1 results in the channel axis index under which the machine axis

number is found in the MD array 20070 AXCONF_MACHAX_USED.

Program continuation

by

Power ON

4210

Explanation

Reaction

Remedy

Program continuation

by

4215

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 spindle %2 Rotary axis declaration missing

%1 = channel number

%2 = axis name, spindle number

If you wish to operate a machine axis as a spindle, this machine axis must be

declared as a rotary axis.

NC not ready.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/customer service.

Set the rotary axis declaration for this machine axis in the axis-specific

MD 30300 IS_ROT_AX.

Power ON

Channel %1 spindle %2 Modulo axis declaration missing

%1 = channel number

%2 = axis name, spindle number

The spindle functionality requires a modulo axis (positions in [deg]).

NC not ready.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/customer service.

Set MD 30310 ROT_IS_MODULO.

Power ON

4220

Explanation

Reaction

Remedy

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-22 802D (DG)

Channel %1 spindle %2 declared repeatedly

%1 = channel number

%2 = axis name, spindle number

The spindle exists in the channel repeatedly.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Please inform the authorized personnel/customer service.

The spindle axis number is stored in the axis-specific MD array 35000

SPIND_ASSIGN_TO_MACHAX. Which channel this machine axis / spindle will

be assigned can be seen from the machine axis index. (The machine axis

number is to be found in the MD array 20070 AXCONF_MACHAX_USED).

Page 23

10.02 1 Alarms

Program continuation

by

4225

Explanation

Reaction

Remedy

Program continuation

by

4230

Explanation

Reaction

Remedy

Program continuation

by

Power ON

Channel %1 axis %2 Rotary axis declaration missing

%1 = channel number

%2 = axis name, axis number

The modulo functionality requires a rotary axis (positions in [deg]).

NC not ready.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/customer service.

Set MD 30300 IS_ROT_AX.

Power ON

Channel %1 In current channel status, data cannot be changed from external source

%1=channel number

This data may not be entered during part program execution (e.g. setting data

for the spindle speed limitation or for the dry run feed).

Alarm display.

Change the data to be entered before starting the part program.

Use the "Cancel" key to cancel the alarm. No further operation required.

4240

Explanation

Reaction

Remedy

Program continuation

by

Computation time overflow on the IPO or position controller level, IP %1

%1 = program position

The settings for the interpolation and position control clock have been modified

prior to the last booting such that now too few computation time is available for

the cyclic tasks to be performed.

The alarm occurs immediately after booting if too few computing time is available for a task even with standing axes and the NC program not started. The

task overflow, however, may also only occur if computation-time intensive NC

functions are called during the program execution.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

The NC switched to the follow-up mode.

Alarm display.

Interface signals are set.

Please inform the authorized personnel/customer service.

Optimize the clock time in NC MD 10050 SYSCLOCK_CYCLE_TIME,

MD 10060 POSCTRL_SYSCLOCK_TIME_RATIO and/or

MD 10070 IPO_SYSCLOCK_TIME_RATIO more cautiously.

The test should be carried out using an NC program which constitutes a maximum possible load for the control system. For reasons of safety, the ties determined in this way should be provided with a safety reserve of 15 ... 25%.

Power ON

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-23

Page 24

10.02 1 Alarms

10.02

4310

Explanation

Reaction

Remedy

Program continuation

by

4340

Explanation

Reaction

Remedy

Program continuation

by

Illegal declaration in MD %1 index %2

%1 = string: MD identifier

%2 = index in the MD array

The values of the machine data must be written in the ascending sequence

order.

NC not ready.

NC Stop at alarm.

NC Start inhibited.

Alarm display.

Interface signals are set.

Correct the MD accordingly.

Use the RESET key to cancel the alarm. Restart the part program.

Channel %1 Invalid transformation type in transformation no. %2.

%1 = channel number

%2 = transformation name

An invalid number, i.e. a number not defined was entered in one of the machine data TRAFO_TYPE_1 ... TRAFO_TYPE_8.

This alarm will also occur if a certain transformation type is not possible for the

control system type specified.

Alarm display

Interface signals are set

NC stop at alarm

Channel not ready

Mode group not ready

NC Start inhibited

Enter a valid transformation type.

Power ON

4343

Explanation

Reaction

Remedy

Program continuation

by

4346

Explanation

Channel %1 It was tried to change the machine data of an active transformation.

%1=channel number

It was tried to change the machine data of an active transformation in order to

enable them via RESET or NEWCONFIG.

Alarm display

Interface signals are set

NC Stop at alarm at the end of the block

Interpreter stop

Set valid machine data.

Use the RESET key to cancel the alarm. Restart the part program.

Channel %1 Faulty geometry axis assignment in machine data %2[%3]

%1=channel number

%2 = name of the machine data

%3 = transformation number

The machine data TRAFO_GEOAX_ASSIGN_TAB_1/2 contains an invalid

entry.

The following error causes are possible:

- The entry refers to a channel axis not existing.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-24 802D (DG)

Page 25

10.02 1 Alarms

- The entry is zero (no axis) although the transformation requires the appropri-

ate

axis as a geometry axis.

Reaction

Remedy

Program continuation

by

Alarm display.

Interface signals are set.

Reorganize also the correction block.

NC Stop at alarm at the end of the block.

Correct the entry in TRAFO_GEOAX_ASSIGN_TAB_1/2 or

TRAFO_AXES_IN_1/2.

Use the RESET key to cancel the alarm. Restart the part program.

4347

Explanation

Reaction

Remedy

Program continuation

by

4400

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 Faulty channel axis assignment in machine data %2[%3]

%1 = channel number

%2 = name of the machine data

%3 = transformation number

The machine data TRAFO_AXIS_IN_1/2 contains an invalid entry.

The following error causes are possible:

- The entry refers to a channel axis not existing.

- The entry is zero (no axis) although the transformation requires the appropri-

ate

axis as a channel axis.

Alarm display.

Interface signals are set.

Reorganize also the correction block.

NC Stop at alarm at the end of the block.

Correct the entry in TRAFO_AXES_IN_1/2.

Use the RESET key to cancel the alarm. Restart the part program.

MD change results in reorganization of the battery-backed memory (loss

of data!)

An MD configuring the battery-backed memory was changed. Booting the NC

with the changed data will reorganize the battery-backed memory, resulting in

a loss of all battery-backed user data (part programs, tool data, GUD, LEC, ...).

Alarm display.

If the control system contains user data that have not been saved, a data

backup must be carried out before the NC is next booted. The reorganization of

the memory can be avoided by resetting the altered MD to the value during the

last booting manually.

Use the "Cancel" key to cancel the alarm. No further operation required.

4502

Explanation

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-25

Channel %1 Anachronism: %2(%3) -> %4

%1 = channel number

%2 = string: MD identifier

%3 = string: MD identifier

%4 = string: MD identifier

The reset behavior of the 6th or 8th G group has been defined in MD 20110

RESET_MODE_MASK, bit4 and bit5 to date; now, this setting is made in MD

20152 GCODE_RESET_MODE.

Page 26

10.02 1 Alarms

10.02

To be able to handle "old" data backups with full compatibility, the "old" values

are taken from MD 20110 RESET_MODE_MASK and entered in MD 20152

GCODE_RESET_MODE.

Reaction

Program continuation

by

Alarm display.

Use the "Cancel" key to cancel the alarm. No further operation required.

5000

Explanation

Reaction

Remedy

Program continuation

by

6000

Explanation

Reaction

Remedy

Program continuation

by

Communication job cannot be executed

The communication job (data exchange between NC and HMI,

such as loading of an NC part program) cannot be carried out due to insufficient memory. Cause: Too many parallel communication jobs.

Alarm display.

No remedial action possible - the operator action that resulted in the alarm

message must be repeated. Use "Cancel" to cancel the alarm.

Use the "Cancel" key to cancel the alarm. No further operation required.

Memory mapping was carried out using the default machine data

The memory management was not able to carry out the mapping of the NC

user memory using the values in the machine data. The reason is that the

entire memory is used by the NC user both as a dynamic memory and a static

memory (e.g., for: number of tool offsets, number of directories and files, etc.).

Alarm display.

Interface signals are set.

NC Start inhibited.

NC Stop at alarm.

Redefine the memory mapping.

It is not possible to specify a certain MD as an alarm cause for the NC user

memory mapping. Therefore, the MD that has caused the alarm must be determined on the base of the default values in the machine data and by modifying the user-specific memory mapping step by step.

In most cases, not only an individual MD is selected too large, and it is therefore recommended to reduce the memory area in several MDs correspondingly.

Use the RESET key to cancel the alarm. Restart the part program.

6010

Explanation

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-26 802D (DG)

Channel %1 data block %2 was not or only partially created, error number

%3

%1 = channel number

%2 = string (block name)

%3 = internal error identifier

The data management has detected an error in the boot sequence. A possible

reason is that the specified data block was not created. The type of the error

can be derived from the error number. An error number >100000 indicates to a

persisting system error. Otherwise, the user memory area has been dimensioned too small. In this case, the (user) error numbers have the following

meaning:

Page 27

10.02 1 Alarms

Error number Explanation

1 No more memory capacity

2 Number of maximum possible symbols exceeded

3 Index 1 outside the valid range of values

4 Name already exists in the channel

5 Name already exists in the NC

If the alarm occurs after loading cycle programs, macro definitions or definitions for global user data (GUD), the machine data for the user memory configuration have been dimensioned not correctly. In all the other cases, modifications to machine data that are already correct result in errors in the user

memory configuration.

The following block names (2nd parameter) are known in the NC (both system

and user data blocks in total; if problems occur only in the user data blocks, as

a rule, these can be eliminated by user intervention)

_N_NC_OPT - system-internal: Option data, NC-global

_N_NC_SEA - system-internal: Setting data, NC global

_N_NC_SEA - system-internal: Machine data, NC global

_N_NC_SEA - system-internal: 'cross error compensation'

_N_NC_PRO - system-internal: Protection areas, NC-global

_N_NC_GD1 - user: 1st GUD block defined by

_N_SGUD_DEF, NC-global

_N_NC_GD2 - user: 2nd GUD block defined by

_N_MGUD_DEF, NC-global

_N_NC_GD3 - user: 3rd GUD block defined by

_N_UGUD_DEF, NC-global

_N_NC_GD4 - user: 4th GUD block defined by

_N_GUD4_DEF, NC-global

_N_NC_GD5 - user: 5th GUD block defined by

_N_GUD5_DEF, NC-globally

_N_NC_GD6 - user: 6th GUD block defined by

_N_GUD6_DEF, NC-globally

_N_NC_GD7 - user: 7th GUD block defined by

_N_GUD7_DEF, NC-globally

_N_NC_GD8 - user: 8th GUD block defined by

_N_GUD8_DEF, NC-globally

_N_NC_GD9 - user: 9th GUD block defined by

_N_GUD9_DEF, NC-globally

_N_NC_MAC - user: Macro definitions

_N_NC_FUN - user: Cycle programs

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-27

Page 28

10.02 1 Alarms

10.02

_N_CHc_OPT - system-internally: Option data, channel-specific

_N_CHc_SEA - system-internal: Setting data, channel-specific

_N_CHc_SEA - system-internal: Machine data, channel-specific

_N_CHc_SEA - system-internal: Protection areas, channel-specific

_N_CHc_SEA - system-internal: Frames, channel-specific

_N_CHc_RPA - system-internal: Arithmetic parameters, channel-specific

_N_CHc_GD1 - user: 1st GUD block defined by

_N_SGUD_DEF, channel-specific

_N_CHc_GD2 - user: 2nd GUD block defined by

_N_MGUD_DEF, channel-specific

_N_CHc_GD3 - user: 3rd GUD block defined by

_N_UGUD_DEF, channel-specific

_N_CHc_GD4 - user: 4th GUD block defined by

_N_GUD4_DEF, channel-specific

_N_CHc_GD5 - user: 5th GUD block defined by

_N_GUD5_DEF, channel-specific

_N_CHc_GD6 - user: 6th GUD block defined by

_N_GUD6_DEF, channel-specific

_N_CHc_GD7 - user: 7th GUD block defined by

_N_GUD7_DEF, channel-specific

_N_CHc_GD8 - user: 8th GUD block defined by

_N_GUD8_DEF, channel-specific

_N_CHc_GD9 - user: 9th GUD block defined by

_N_GUD9_DEF, channel-specific

_N_AXa_OPT - system-internal: Option data, axial

_N_AXa_SEA - system-internal: Setting data, axial

_N_AXa_SEA - system-internal: Machine data, axial

_N_AXa_EEC - system-internal:

Leadscrew error compensation data, axial

_N_AXa_QEC - system-internal: Quadrant error compensation data, axial

_N_TOt_TOC - system-internal: Toolholder data, TOA-specific

_N_TOt_TOA - system-internal: Tool data, TOA-specific

_N_TOt_TMA - system-internal: Magazine data, TOA-specific

c = channel number

a = machine axis number

t = TOA unit number

Reaction

Remedy

There are further internal system data blocks with identifiers.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

NC Stop at alarm.

Either correct the machine data or undo the changes.

Please inform the authorized personnel/customer service.

• There are two decisive machine data for cycle programs:

MD 18170 MM_NUM_MAX_FUNC_NAMES = max. number of all

cycle programs

Error number = 2 indicates that the value concerned is too small

MD 18180 MM_NUM_MAX_FUNC_PARAM = max. number of all

parameters defined in the cycle programs

Error number = 2 indicates that the value concerned is too small

(if this MD is changed, the data contained in the battery-backed memory

remain stored)

• The following applies to macro definitions:

MD 18160 MM_NUM_USER_MACROS = max. number of all

macro definitions

Error number = 2 indicates that the value concerned is too small

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-28 802D (DG)

Page 29

10.02 1 Alarms

(if this MD is changed, the data contained in the battery-backed memory

remain stored)

• The following applies to GUD variables:

MD 18118 MM_NUM_GUD_MODULES = max. number of

GUD data blocks per area (NC/channel)

(if GD1, GD2, GD3, GD9 are to be defined, the value must be =9

and not =4)

MD 18120 MM_NUM_GUD_NAMES_NCK = max. number of all NC-

global GUD variables

Error number = 2 indicates that the value concerned is too small

MD 18130 MM_NUM_GUD_NAMES_CHAN = max. number of all

channel-specific GUD variables in the channel

Error number = 2 indicates that the value concerned is too small

MD 18150 MM_GUD_VALUES_MEM = entire value memory

of all GUD variables together

Error number = 1 indicates that the value concerned is too small

Power ON

Program continuation

by

Use the RESET key to cancel the alarm. Restart the part program.

6020

Explanation

Reaction

Remedy

Program continuation

by

6030

Explanation

Reaction

Remedy

Program continuation

by

6035

Explanation

Machine data changed - memory remapped

Machine data defining the NC user memory have been changed. The data

management has remapped the memory according to the changed machine

data.

Alarm display.

No remedial action required. Re-enter the required user data.

Use the RESET key to cancel the alarm. Restart the part program.

User memory limit has been adapted

When booting, the data management checks the really existing, physical user

memory (DRAM, DPRAM and SRAM) against the values in the system-specific

machine data MD 18210

MM_USER_MEM_DPR and MD 18230 MM_USERMEM_BUFFERED.

Alarm display.

No remedial action required. The new, maximum permissible value can be

read from the reduced machine data.

Use the RESET key to cancel the alarm. Restart the part program.

System has only %2 kB free user memory of the type "%3" instead of only

%1 kB

%1 = free memory capacity in kB defined for the control system model concerned

%2 = real maximum capacity of free memory in kB

%3 = memory type, "D" = not battery-backed, "S" = battery-backed

This alarm may only occur after a 'cold restart' (= NCK booting with the default

machine data). The alarm is only a note; the NCK functions are not affected.

This alarm indicates that the NCK has fewer user memory than intended by

Siemens for this control system variant. The value of the really free user memory can also be taken from the machine data

$MN_INFO_FREE_MEM_DYNAMIC, $MN_INFO_FREE_MEMS_TATIC.

MM_USER_MEM_DYNAMIC

, MD 18220

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-29

Page 30

10.02 1 Alarms

10.02

Siemens delivers the NCK with default settings which depending on the particular model provide a certain (free) memory for the specific settings of the

particular applications. Original NCK systems are set by default such that this

alarm does not occur in cold restart.

Reaction

Remedy

Program continuation

by

Alarm display.

- This message may have the following possible causes:

- The NCK is run on a hardware that is not intended for this NCK release (in

other words, that has insufficient memory capacity).

- If the particular application can manage with the remaining free user memory

(in other words, can be started up without errors), the message can also simply be ignored.

Use the RESET key to cancel the alarm.

6410

Explanation

Reaction

Remedy

Program continuation

by

TO unit %1 tool "%2" / duplo no. %3 has reached prewarning

limit with D= %4

%1 = TO unit

%2 = tool identifier (name)

%3 = duplo number

%4 = D number

Tool monitoring:

The operator is referred to the fact the specified D compensation of the

tool monitored with reference to the time or count has reached its prewarning limit.

If possible, the D number is specified; if not, the 4th parameter will be 0.

The particular type of the tool monitoring is a property of the tool (see

$TC_TP9).

If you do not work with replacement tools,

the specification of the duplo number has no further meaning.

The alarm is triggered either via MMC or PLC (= OPI). The channel

context is not defined. For this reason, the TO unit is specified.

Alarm display.

Interface signals are set.

only intended for information; the user will decide what to do.

Use the "Cancel" key to cancel the alarm. No further operation required.

6411

Explanation

Channel %1 tool "%2" / duplo no. %3 has reached prewarning

limit with D= %4

%1 = TO unit

%2 = tool identifier (name)

%3 = duplo number

%4 = D number

Tool monitoring:

The operator is referred to the fact the specified D compensation of the tool

monitored with reference to the time or count has reached its prewarning limit.

If possible, the D number is specified; if not, the 4th parameter will be 0.

The particular type of the tool monitoring is a property of the tool (see

$TC_TP9).

If you do not work with replacement tools,

the specification of the duplo

number has no further meaning.

This alarm is caused within the framework of the NC program execution.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-30 802D (DG)

Page 31

10.02 1 Alarms

Reaction

Remedy

Program continuation

by

6412

Explanation

Reaction

Remedy

Program continuation

by

Alarm display.

Interface signals are set.

only intended for information; the user will decide what to do.

Use the "Cancel" key to cancel the alarm. No further operation required.

TO unit %1 tool "%2" / duplo no. %3 has reached monitoring

limit with D= %4

%1 = TO unit

%2 = tool identifier (name)

%3 = duplo number

%4 = D number

Tool monitoring:

The operator is referred to the fact the specified D compensation of the

tool monitored with reference to the time or count has reached its monitoring limit.

If possible, the D number is specified; if not, the 4th parameter will be 0.

The particular type of the tool monitoring is a property of the tool (see

$TC_TP9).

If you do not work with replacement tools, the specification of the duplo number

has no further meaning.

The alarm is triggered either via MMC or PLC (= OPI). The channel context is

not defined. For this reason, the TO unit is specified.

Alarm display.

Interface signals are set.

only intended for information; the user will decide what to do.

Use the "Cancel" key to cancel the alarm. No further operation required.

6413

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 tool %2 / duplo no. %3 has reached monitoring

limit with D= %4

%1 = TO unit

%2 = tool identifier (name)

%3 = duplo number

%4 = D number

Tool monitoring:

The operator is referred to the fact the specified D compensation of the

tool monitored with reference to the time or count has reached its monitoring limit.

If possible, the D number is specified; if not, the 4th parameter will be 0.

The particular type of the tool monitoring is a property of the tool (see

$TC_TP9).

If you do not work with replacement tools, the specification of the duplo

number has no further meaning.

This alarm is caused within the framework of the NC program execution.

Alarm display.

Interface signals are set.

only intended for information; the user will decide what to do.

Use the "Cancel" key to cancel the alarm. No further operation required.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-31

Page 32

10.02 1 Alarms

10.02

6430

Explanation

Reaction

Remedy

Program continuation

by

Workpiece counter: Overflow of table of monitored cutting edges

No further cutting edges can be entered in the workpiece counter table.

You can store as many cutting edges for the workpiece counter as totally possible in the NCK.

In other words: If each cutting edge of every tool is used for a workpiece exactly once, the limit is reached.

If at the same time several workpieces are machined at several toolholders/spindles, cutting edges can be stored for the workpiece counter for the

whole range of workpieces using

MD18100 MM_NUM_CUTTING_EDGES_IN_TOA.

If the alarm occurs, this means that cutting edges which will be used as of now

are no longer monitored for their count; this applies until the table is emptied,

e.g. via the NC language command SETPIECE or the relevant job from the

MMC, PLC (PI service).

Alarm display.

Interface signals are set.

NC Start inhibited.

- Decrementing workpiece counter forgotten?

If so, program SETPIECE in the part program or include the appropriate

command in the PLC program.

- If the part program or the PLC program is correct, more memory should be

freed for the cutting edges using the machine data

$MN_MM_NUM_CUTTING_EDGES_IN_TOA (this can only be done by persons who have the appropriate access rights).

Use the "Cancel" key to cancel the alarm. No further operation required.

6431

Explanation

Reaction

Remedy

Program continuation

by

Illegal function; tool management / monitoring not activated

A function of the data management has been called which is not available due

to the tool management or tool monitoring not enabled; this may pertain, e.g. to

the language commands GETT, SETPIECE, GETSELT, NEWT, DELT.

Alarm display.

Interface signals are set.

Interpreter stop.

NC Start inhibited.

• Please inform the authorized personnel/customer service.

• Check the desired configuration of the CNC. Are tool management or tool

monitoring necessary, but not activated?

• Is a part program used what is designed for a CNC with tool management/

tool monitoring? And even this program is started on a CNC not providing

tool management/tool monitoring. This is not possible! Either run the part

program on an appropriate CNC or modify the part program.

• Activate the tool management/tool monitoring by setting the appropriate

machine data; see $MN_MM_TOOL_MANAGEMENT_MASK,

$MC_TOOL_MANAGEMENT_MASK.

• Check whether the required option is set.

Use the "Cancel" key to cancel the alarm. No further operation required.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-32 802D (DG)

Page 33

10.02 1 Alarms

6432

Explanation

Reaction

Remedy

Program continuation

by

6500

Explanation

Reaction

Remedy

Program continuation

by

6510

Explanation

Reaction

Remedy

Program continuation

by

Function cannot be executed; no tool is mounted on the spindle;

channel %1

%1=channel number

You have probably tried to carry out an operation in the part program of the

appropriate channel, which requires a tool mounted on the toolholder/spindle.

This can be, e.g. the workpiece count monitoring function.

Alarm display.

Interface signals are set.

• Select a different function, a different toolholder/spindle or mount a tool on

the toolholder/spindle.

Use either the "Cancel" key or press NC START to cancel the alarm.

NC memory limit reached

Too many programs have been loaded. The job cannot be executed.

During the commissioning, this may pertain to files of the NC file system (part

of the NC memory), such as initialization files, NC programs etc.

Alarm display.

Delete or unload files (e.g. part programs).

Use the "Cancel" key to cancel the alarm. No further operation required.

Too many part programs in NC memory

The number of the files in the NC file system (part of the NC memory) has

reached the maximum.

Alarm display.

Delete or unload files (e.g. part programs).

Use the "Cancel" key to cancel the alarm. No further operation required.

6530

Explanation

Reaction

Remedy

Program continuation

by

6540

Explanation

Reaction

Remedy

Program continuation

by

Too many files in directory

The number of files in a directory of the NC memory has reached the maximum.

Alarm display.

Delete or unload files (e.g. part programs) from the directory concerned.

Use the "Cancel" key to cancel the alarm. No further operation required.

Too many directories in NC memory

The number of the directories in the NC file system (part of the NC memory)

has reached the maximum.

Alarm display.

Delete or unload directories not needed (e.g. workpiece).

Use the "Cancel" key to cancel the alarm. No further operation required.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-33

Page 34

10.02 1 Alarms

10.02

6550

Explanation

Reaction

Remedy

Program continuation

by

6560

Explanation

Reaction

Remedy

Program continuation

by

6570

Explanation

Reaction

Remedy

Program continuation

by

Too many subdirectories

The number of subdirectories in a directory of the NC has reached the maximum.

Alarm display.

Please inform the authorized personnel/customer service.

Delete or unload subdirectories from the directory concerned.

Use the "Cancel" key to cancel the alarm. No further operation required.

Illegal data format

Illegal data are entered in a file of the NC; this may occur, e.g. if binary data

are loaded into the NC as an ASCII file.

Alarm display.

Mark the file as binary data (e.g. via the extension .BIN)

Use the "Cancel" key to cancel the alarm. No further operation required.

NC memory limit reached

The DRAM file system of the NC is full. The job cannot be executed. Too many

system files have been created in the DRAM.

Alarm display.

Start fewer "Program execution from an external source" processes.

6600

Explanation

Reaction

Remedy

Program continuation

by

6610

Explanation

Reaction

Remedy

Program continuation

by

6620

Explanation

Reaction

Remedy

Program continuation

by

NC card memory limit reached

The NC card file system of the NC is full. No further data can be stored on the

NC card.

Alarm display.

Delete data from the PCMCIA card.

Use the "Cancel" key to cancel the alarm. No further operation required.

Too many files opened on the NC card

Too many files on the NC card are accessed at the same time.

Alarm display.

Repeat the action later.

Use the "Cancel" key to cancel the alarm. No further operation required.

Invalid NC card format

The NC card cannot be accessed because of the invalid NC card format.

Alarm display.

Replace the NC card.

Use the "Cancel" key to cancel the alarm. No further operation required.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-34 802D (DG)

Page 35

10.02 1 Alarms

6630

Explanation

Reaction

Remedy

Program continuation

by

6640

Explanation

Reaction

Remedy

Program continuation

by

6650

Explanation

Reaction

Remedy

Program continuation

by

NC card hardware defective

The NC card cannot be accessed because the card is defective.

Alarm display.

Replace the PCMCIA card.

Use the "Cancel" key to cancel the alarm. No further operation required.

NC card not plugged

The NC card cannot be accessed because no card is inserted.

Alarm display.

Insert the NC card.

Use the "Cancel" key to cancel the alarm. No further operation required.

Write protection of NC card active

Writing to the NC card is not possible since the write protection is active.

Alarm display.

Deactivate the write protection.

Use the "Cancel" key to cancel the alarm. No further operation required.

6660

Explanation

Reaction

Remedy

Program continuation

by

6670

Explanation

Reaction

Remedy

Program continuation

by

6671

Explanation

Reaction

Remedy

Program continuation

by

Flash File System option not set

Writing to the NC card is not possible since the relevant option is not set.

Alarm display.

Buy the option.

Use the "Cancel" key to cancel the alarm. No further operation required.

Data are being read from NC card

This alarm is issued while the contents of the NC card are being read.

During this time, the FFS cannot be accessed.

Alarm display.

Wait until reading is finished.

The alarm display will disappear with the alarm cause. No further operation

required.

Data are being written to NC card

This alarm is issued while the contents of the NC card are being written.

During this time, the flash file system (FFS) cannot be accessed.

If POWER OFF is provided during the time when the alarm exists, the contents

of the NC card are destroyed!

Alarm display.

Wait until writing is finished.

The alarm display will disappear with the alarm cause. No further operation

required.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-35

Page 36

10.02 1 Alarms

10.02

6693

Explanation

Reaction

Remedy

Program continuation

by

6698

Explanation

Reaction

Remedy

Program continuation

by

8040

Explanation

Reaction

Remedy

Program continuation

by

File %1 is lost

%1 = file name

The file change could not correctly be completed due to power failure. The file

is lost.

Alarm display.

Interface signals are set.

NC not ready.

NC Start inhibited.

Reload the file.

Power ON

Unknown NC card (%1/%2). Writing not possible.

Writing to the NC card is not possible since no valid

writing algorithm exists for the flash memory.

Alarm display.

Either install a compatible NC card or, after consultation of SIEMENS, enter the

new manufacturer code/device code in MD 11700 PERMISSIVE_FLASH_TAB.

Use the "Cancel" key to cancel the alarm. No further operation required.

MD %1 reset; appropriate option not set

%1 = string: MD identifier

A machine data was set which is interlocked via an option.

Alarm display.

Please inform the authorized personnel/customer service.

Please contact your machine manufacturer or a sales representative from A&D

MC of SIEMENS AG for ordering the required option.

Use the "Cancel" key to cancel the alarm. No further operation required.

8041

Explanation

Reaction

Program continuation

by

10203

Explanation

Axis %1: MD %2 reset; appropriate option not sufficient

%1 = axis number

%2 = string: MD identifier

The number of axes selected in the relevant option machine data is exhausted.

In the specified machine axial machine data, functions for too many functions

belonging to the option have been selected.

Alarm display.

Interface signals are set.

NC Start inhibited.

NC Stop at alarm.

NC not ready.

Under certain circumstances, it can be switched across all channels via MD.

Power ON

Channel %1 NC start not possible without reference point

%1=channel number

NC START has been pressed either in MDA or AUTOMATIC mode, and at

least one axis to be referenced has not reached its reference point.

6FC5698-2AA20-0BP1 © Siemens AG 2002 All Rights Reserved

1-36 802D (DG)

Page 37

10.02 1 Alarms

Reaction

Remedy

Program continuation

by

10208

Explanation

Reaction

Remedy

Program continuation

by

Alarm display.

Referencing start can be initiated either channel or axis-specifically.

1. Channel-specific reference-point approach: The rising edge of the

interface signal "Activate referencing" (V 32000001.0) starts an automatic

cycle that starts the axes of the channel in the order specified in the axisspecific MD 34 110 REFP_CYCLE_NR (axis order for channel-specific

referencing).

-1:

0: Axis is not involved in channel-specific referencing, but must be

1-4: Starting order for channel-specific referencing (axes/channels with

2. Axis-specific referencing:

Press NC START to cancel the alarm and continue the program execution.

Channel %1 Press NC START to continue the program

%1=channel number

After block search with calculation, the control system is in the desired state.

The program can now be started with NC Start or in the state first changed by

Overwrite/Jog.

Alarm display.

NC Stop at alarm.

Press NC START.

Press NC START to cancel the alarm and continue the program execution.

Axis is not involved in channel-specific referencing, but has to be

referenced for NC start

referenced for NC start.

the same number are started simultaneously)

Press the direction key corresponding to the

approach direction specified in the axis-specific MD 34 010

_CAM_DIR_IS_

REFP

rection).

MINUS (Approach reference point in the minus di-

10225

Explanation

Reaction

Remedy

Program continuation

by

10299

Explanation

Reaction

Remedy

Program continuation

by

Channel %1:Command % 2 denied

%1 = channel number

%2 = string (event name)

The channel has received a command which cannot be executed.

Alarm display.

Press RESET.

Use the "Cancel" key to cancel the alarm. No further operation required.

Channel %1 Auto Repos function not enabled

%1 = channel number

The Auto Repos function (mode) which is not implemented was selected in the

channel.

Alarm display.

This is only a note.

Use the "Cancel" key to cancel the alarm. No further operation required.

© Siemens AG 2002 All Rights Reserved 6FC5698-2AA20-0BP1

802D (DG) 1-37

Page 38

10.02 1 Alarms

10.02

10601

Explanation

Reaction

Remedy

Program continuation

by

Channel %1 block %2 End-of-block velocity when thread cutting is zero

%1 = channel number

%2 = block number, label

This alarm occurs only if several blocks with G33 follow one after another. The