Page 1

SINUMERIK System 800

Universal Interface

Planning Guide Edition 12.95

Manufacturer Documentation

Page 2

SINUMERIK

System 800

Universal Interface

Planning Guide

Manufacturer Documentation

Valid for:

Control Software Version

SINUMERIK 805 2

SINUMERIK 810 T / 810 TE (GA 1) 2

SINUMERIK 810 M / 810 ME (GA 1) 2

SINUMERIK 810 G 1

SINUMERIK 810 T / 810 TE (GA 2) 2

SINUMERIK 810 M / 810 ME (GA 2) 2

SINUMERIK 820 T/ TE 2

SINUMERIK 820 M/ ME 2

SINUMERIK 810 T / 810 TE (GA 3) 1

SINUMERIK 810 M / 810 ME (GA 3) 1

SINUMERIK 820 T/ TE (GA 3) 1

SINUMERIK 820 M/ ME (GA 3) 1

SINUMERIK 840T 1

SINUMERIK 840M 1

SINUMERIK 840C 5

SINUMERIK 850 T/ TE 4

SINUMERIK 850 M/ ME 4

SINUMERIK 880 T/ TE 5

SINUMERIK 880 M/ ME 5

SINUMERIK 880 N 4

December 1995 Edition

Page 3

SINUMERIK® documentation

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” column.

Status code in

”Remarks”

column

:

A . . . . New documentation B . . Unrevised reprint with new Order No.

C . . . . Revised edition with new status. If factual changes have been made on the page since

the last edition, this is indicated by a new edition coding in the header on that page.

Edition Order No. Remarks

10.86 E80210-T77-X-A3 Revised edition

10.88 6ZB5 410-0AQ02-0BA0 C

07.90 6ZB5 410-0AQ02-0BA1 C

07.90 6ZB5 410-0AQ02-0BA2 C

03.91 6ZB5 410-0AQ02-0AA3 C

12.95 6ZB5 410-0AQ02-0AA4 C

Other functions not described in this documentation might be

executable in the control. This does not, however, represent an

obligation to supply such functions with a new control or when

servicing.

This publication was produced on the Siemens 5800 Office

System.

Subject to change without prior notice.

The reproduction, transmission or use of this document or its

contents is not permitted without express written authority.

Offenders will be liable for damages. All rights, including rights

created by patent grant or registration of a utility model or

design, are reserved.

©

Siemens AG 1986, 1988, 1990, 1991, 1995 All Rights Reserved

Page 4

Preface

Notes for the reader

This documentation is intended for manufacturers of machine tools with the SINUMERIK

System 800.

It describes data exchange with input/output devices (e.g. tape reader, tape punch,

programmer, printer, magnetic tape unit, etc).

The SINUMERIK documentation is divided into three parts:

• General Documentation

• User Documentation

• Manufacturer Documentation

• Service Documentation

The manufacturer documentation for the SINUMERIK System 800 controller is divided into

the following parts:

•

Instruction Manual

•

Interface

Part 1: Signals

Part 2: Cables and Devices

• PLC Programming Guide

• Function Blocks

• Universal Interface

• Measuring Cycles

• CL - 800 Description

You can obtain more detailed information from your Siemens representative.

Page 5

1V.24 (RS232C) Interface

220 mA Current Loop Interface

3RS 422 Interface

4Interface Overview

5Adapting the Interfaces to I/O Devices

6Signal Timing for Data Transmission

7Serial Interfaces on the SINUMERIK System 800

8Connecting I/O Devices in Practice

Page 6

Contents

Page

1 V.24 (RS232) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 V.24 (RS232C) interface lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Polarity and voltage level assignment of V.24 interface signals . . . . . . . 1-3

1.4 V.24 drivers and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.1 V.24 drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4.2 V.24 receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Interface link to I/O device for V.24 . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6 Length of the transmission line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 20 mA Current Loop Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 20 mA signal level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Interface link to I/O device for 20 mA . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.1 Duplex interface active at SINUMERIK end . . . . . . . . . . . . . . . . . . . . . 2-3

2.3.2 Duplex interface passive at the SINUMERIK end . . . . . . . . . . . . . . . . . 2-4

2.4 Length of the transmission line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

3 RS 422 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Polarity and voltage level assignment of the RS 422 interface . . . . . . . . 3-2

3.3 RS 422 drivers and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 RS 422 driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 RS 422 receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4 Interface link to I/O device for RS 422 . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Length of the transmission line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.6 Level conversion from V.24 to RS 422 . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Page 7

4 Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Pin assignments of the data interfaces . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Pin assignments of the V.24/20 mA universal interface . . . . . . . . . . . . 4-1

4.1.2 Pin assignments of the RS 422 interface . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Explanation of signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Format of a serially transmitted character . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Block diagram of the data interfaces . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.4.1 Block diagram of a V.24/20 mA universal interface . . . . . . . . . . . . . . . 4-4

4.4.2 Block diagram of an RS 422 interface . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5 Adapting the Interfaces to I/O Devices . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Explanation of the setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Notes on the format of special characters . . . . . . . . . . . . . . . . . . . . . . 5-6

5.4 Notes on using the EIA code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

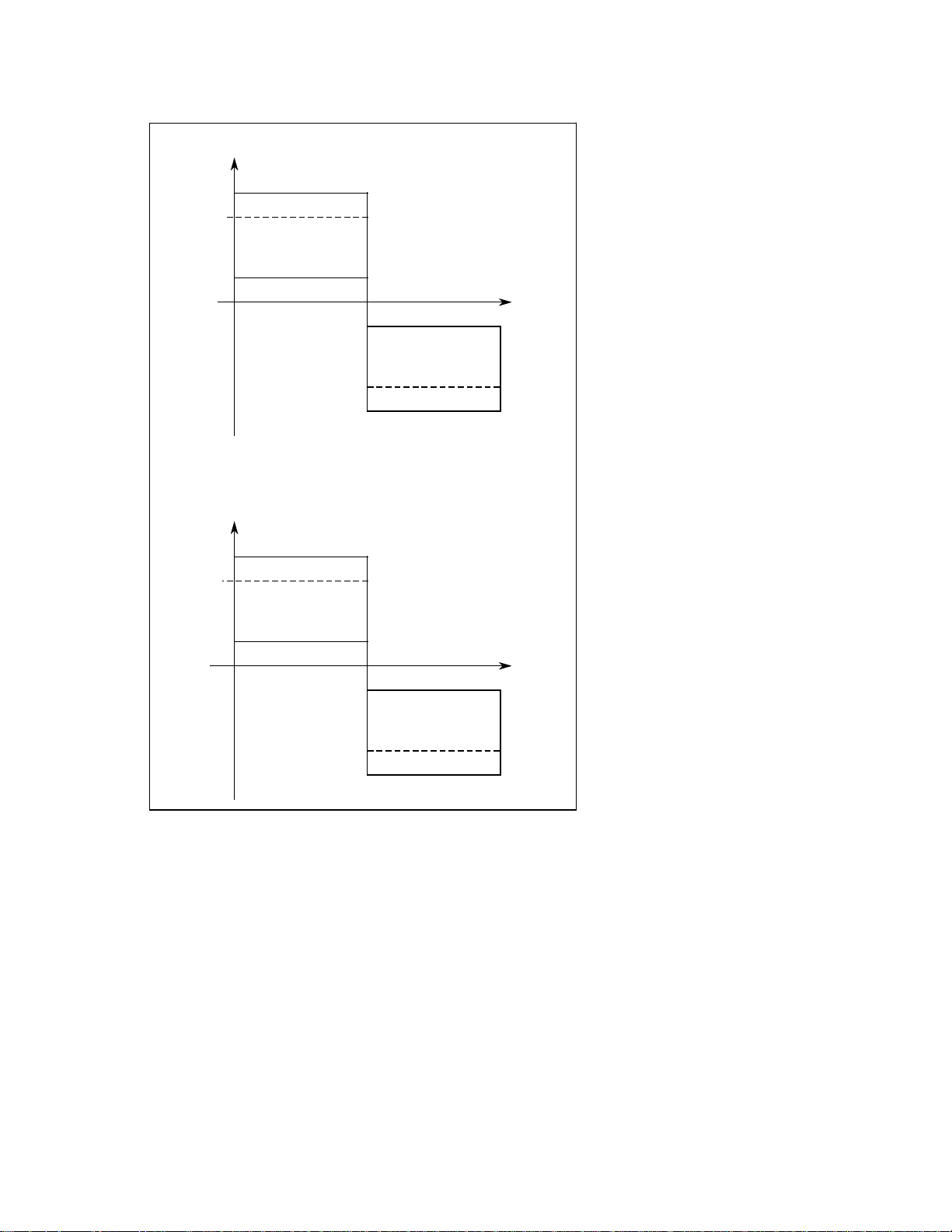

6 Signal Timing for Data Transmission . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Signal timing with line-controlled devices . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Data input (I/O device to the NC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.2 Data output (NC to I/O device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Signal timing with character-controlled devices . . . . . . . . . . . . . . . . . . 6-4

6.2.1 Data input (I/O device to NC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.2 Data output (NC to I/O device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

7 Serial Interfaces on the SINUMERIK System 800 . . . . . . . . . . . . . . 7-1

7.1 Interfaces on the various controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 SINUMERIK 805 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.2 SINUMERIK 810 GA1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.3 SINUMERIK 810GA2/820GA2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.4 SINUMERIK 810 GA3/820 GA3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.1.5 SINUMERIK 840 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.1.6 SINUMERIK 850 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.1.7 SINUMERIK 880 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.2 Setting data for the various controls . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Page 8

8 Connecting I/O Devices in Practice . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Device setting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Device connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.1 Siemens PT 80 page printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.2 Siemens PT 88 printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.3 SINUMERIK T40 and T50 tape readers . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.2.4 SINUMERIK T60 tape reader (hand-held) . . . . . . . . . . . . . . . . . . . . . . 8-7

8.2.5 Sanyo M2502U cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.2.6 ASR3320/3WE teletype . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8.2.7 Facit 4040, 4042 punch/tape reader combination. . . . . . . . . . . . . . . . . 8-9

8.2.8 Facit 4070 punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.2.9 Facit 4030 tape reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.2.10 Facit N 1000 NC Walk-Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

8.2.11 Facit N 1100 NC Walk-Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.2.12 Siemens DSG 3.5 floppy disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.2.13 Siemens DSG 2S floppy disk drive . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

8.2.14 Sommer MDC-3 SNC cartridge drive terminal . . . . . . . . . . . . . . . . . . . 8-12

8.2.15 Tekelec FDS 300, FDS 500 floppy disk drive . . . . . . . . . . . . . . . . . . . 8-13

8.2.16 Tekelec Magnetic Tape Cartridge Drive, Model CDS 1.58 . . . . . . . . . . 8-13

8.2.17 CAN NC Recorder FD/FH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.2.18 GNT 7101 NC data Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

8.2.19 GNT 4604 tape reader/punch station . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8.2.20 SINUMERIK WS 800, programming workstation . . . . . . . . . . . . . . . . . 8-15

8.2.21 SINUMERIK WS 800 A, programming workstation . . . . . . . . . . . . . . . 8-16

8.2.22 SIMATIC PG 675/685/635 programmer (PG IN) . . . . . . . . . . . . . . . . . . 8-16

8.2.23 SIMATIC 750 programmer (PC IN) . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

8.2.24 SINUMERIK System 800, RS 232 C, NC-NC link . . . . . . . . . . . . . . . . 8-17

8.2.25 SINUMERIK T30 tape reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8.2.26 Siemens T10 and T20 tape reader . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8.2.27 Siemens PD ... PG programming workstation . . . . . . . . . . . . . . . . . . . 8-19

8.2.28 SIMATIC PG 670/675/685/635/750 programmer . . . . . . . . . . . . . . . . . 8-20

8.2.29 SIMATIC PG 750 programmer (PLC progamming) . . . . . . . . . . . . . . . . 8-21

8.2.30 SIMATIC PG 615 programmer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

8.3 Ordering data of the connecting cables . . . . . . . . . . . . . . . . . . . . . . . 8-23

8.4 Device cable diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Page 9

10.88 1 V.24 (RS232C) Interface

1.1 General notes

1 V.24 (RS 232 C) Interface

1.1 General notes

The V.24 interfaces of the SINUMERIK System 800 contain V.24 receivers and V.24 senders,

conforming to DIN 66020.

DIN 66020 defines the interface between a DTE (data terminal equipment) and a DCE (data

circuit terminating equipment). It is based on recommendations V.24 and V.28 of the CCITT,

which were derived from the American EIA Standard RS 232.

The interfaces also conform to VDI guideline 2880, which specifies process and data traffic of

programmable controllers.

The interface signals used in SINUMERIK System 800 are a subset of V.24 or RS 232

standard signals and therefore possess the same electrical characteristics.

1.2 V.24 (RS232C) interface lines

In terms of the DIN standard, SINUMERIK is regarded as a DTE (data terminal equipment).

SINUMERIK – DTE

Transmission line – DCE

I/O devices – DTE

The abbreviations E1, E2, D1, D2, S1.2, S2, M1, M2 refer to DIN 66020, the abbreviations 101

to 108.2 refer to CCITT (V.24).

Ground lines

E1: Protective Ground

(101)

E2: Signal Ground

(102)

This is the common return cable for all interface lines

(except E1).

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 1-1

SINUMERIK System 800, (PJ)

Page 10

1 V.24 (RS232C) Interface 10.88

1.2 V.24 interface lines

Data lines

D1: T

ransmitted Data

(103 - TxD)

On this line data is transmitted from the DTE to the DCE.

Quiescent state is logic ''High''.

D2: R

eceived Data

(104 - RxD)

On this line data is transmitted to the DTE from the DCE.

Quiescent state is logic ''High''.

Control lines

S1.2: D

ata Terminal Ready

(108/2 - DTR)

The DTE signals to the DCE that it is ready for data transmission.

S2: R

equest to Send

(105 - RTS)

The DTE controls the send part of the data channel of the DCE.

Message lines

M1: D

ata Set Ready

(107 – DSR)

The DCE signals to the DTE whether or not it is ready for transmission.

M2: C

lear to Send

(106 – CTS)

The DCE signals to the DTE whether or not it is ready to send data signals through

the data channel.

1-2

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 11

10.88 1 V.24 (RS232C) Interface Lines

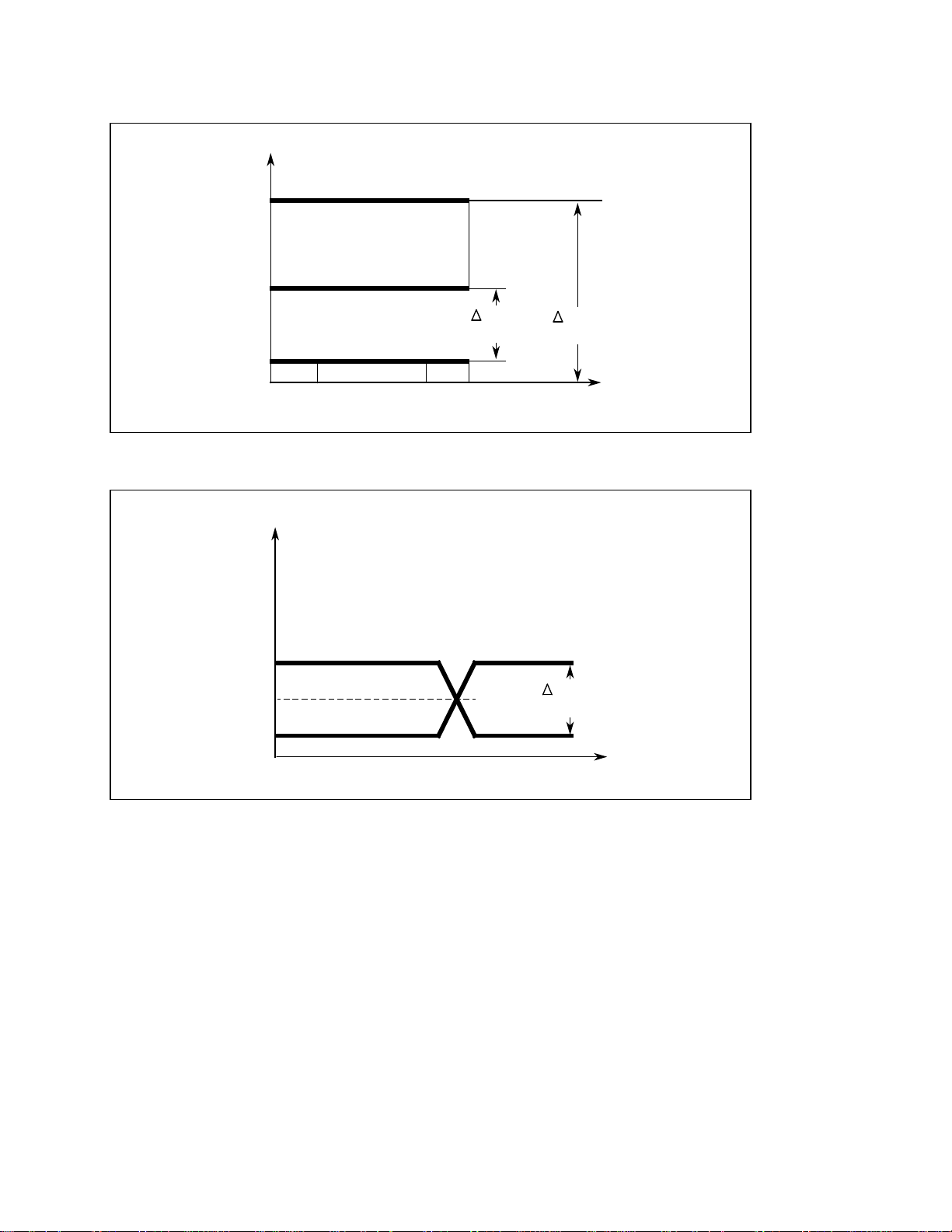

1.3 Polarity and voltage level assignment of V.24 interface signals

1.3 Polarity and voltage level assignment of V.24 interface signals

Data linesV

+15 V

+12 V

Logical ''L''

+3 V

0 V

–3 V

Logical ''H''

–12 V

–15 V

t

Control linesV

+15 V

+12 V

''On'' state

+3 V

0 V

–3 V

t

''Off'' state

–12 V

–15 V

Signal level of SINUMERIK interfaces: ±12 V

All signal levels refer to the signal ground E2 (102).

Within the transition range (+3 to –3 V) the signal state is undefined.

(Hysteresis range of the receiver circuits 75189 A)

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 1-3

SINUMERIK System 800, (PJ)

Page 12

1 V.24 (RS232C) Interface 10.88

1.4 V.24 drivers and receivers

1.4 V.24 drivers and receivers

1.4.1 V.24 drivers

The V.24 output signals *TxD, RTS and DTR are generated in the V.24 driver block 75188

from the TTL signals of the USART 8251A.

75 188

TTL level

+12 V

&

0 V

–12 V

V.24 level

Data of circuit 75188

Max. supply voltage V

Max. output current

(current limited) I

Operating voltage

and V.24 level V

± 15 V

cc

10 mA

o

± 12 V

cc

1.4.2 V.24 receivers

The V.24 input signals * RxD, CTS and DSR are put onto the receiver circuits 75189 after

passing through an RC low-pass filter.

V

c

V.24 level

3904.7 k

Data of circuit 75189A

Max. input voltage V

cc

Input resistance 390

± 30 V

75 189 A

TTL level

1-4 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 13

07.90 1 V.24 (RS232C) Interface

1.5 Interface link to I/O device for V.24

1.5 Interface link to I/O device for V.24

SINUMERIK

DTE DCE

* T x D

* R x D

RTS

CTS

DSR

2

O

3

O

4

O

5

O

6

O

Transmitted data

D1 (103)

Received data

D2 (104)

Request to send

S2 (105)

Clear to send

M2 (106)

Data set ready

M1 (107)

20

No device

DTE

3

O

* R x D

2

5

4

O

O

O

O

* T x D

CTS

RTS

DTR

DTR

MEXT

O

O

O

20

7

1

Data terminal ready

S1.2(108.2)

Signal ground

E2 (102)

Protective ground

E1 (101)

6

7

DSR

O

G

O

1

O

In all signal names and directions, the SINUMERIK is taken to be a DTE.

Which of the available control and message lines are used will depend on the I/O device. In

the simplest case, lines E2 and D1 suffice for a receiving device (printer, punch) or E2 and D2

for a sending device (reader). The specification of an I/O device determines how it is

connected.

In the interface link diagram, a device is assumed to comply with the RS232C standard. The

interfaces conform to VDI guideline 2880 with SINUMERIK as a DTE. If it is linked to an I/O

device which is also wired as a DTE, the appropriate lines must be crossed in the cable

(sender with receiver).

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 1-5

SINUMERIK System 800, (PJ)

Page 14

1 V.24 (RS232C) Interface 10.88

1.5 Interface link to I/O device for V.24

Some of the interfaces contain both the V.24 signals and the signals for 20 mA current loop

operation. A V.24 sender and a 20 mA sender may not be connected to a SINUMERIK interface at the same time.

As pins 10, 12, 13, 14, 16, 19, 21 and 24 are permanently reserved for

the 20 mA interface at the SINUMERIK end, it is important to make sure

that they are not connected to the I/O device in V.24 mode.

The interface is not set to V.24 or 20 mA operation by jumpers but by the pin assignments in

the cable plug.

1.6 Length of the transmission line

The maximum cable length for V.24 transmission is 30 m.

END OF SECTION

1-6

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 15

10.88 2 20 mA Current Loop Interface

2.1 General notes

2 20 mA Current Loop Interface

2.1 General notes

The 20 mA interface is configured to VDI guideline 2880 as a duplex interface with two pairs of

lines. At the SINUMERIK end it can be operated as an active or passive interface with the

available sources of current by changing the pin assignments in the cable connector. This

interface is also often referred to as a TTY interface.

The following is equivalent in V.24 and 20 mA interfaces (except the signal level):

20 mA

Signal V.24

+ –

Transmitted data

Received data

In the signal designations, the SINUMERIK is taken to be a DTE.

D1

D2

TTY2

TTY4

TTY1

TTY3

2.2 20 mA signal level

In the 20 mA interface, unlike the V.24 interface, information is not transmitted by the voltage

level but by impressed current.

Logical ”L”: I=0

Logical ”H”: I=20 mA

Level 1 Signal 20 mA±30 %

(max. open-circuit voltage

30 V)

0 signal 0 mA to 2 mA

Voltage for current loop source at

SINUMERIK =12 V

I=20 mA

I

Logical ”H”

( 0 V )

Logical ”L”

I= 0

(12 V)

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 2-1

SINUMERIK System 800, (PJ)

t

Page 16

2 20 mA Current Loop Interface 10.88

2.3 Interface link to I/O device for 20 mA

2.3 Interface link to I/O device for 20 mA

20 mA interfaces are duplex interfaces with two pairs of lines. They can be operated as active

or passive interfaces at the SINUMERIK end.

• Active interface:

SINUMERIK supplies the 20 mA line current.

• Passive interface:

The peripheral unit supplies the 20 mA line current.

The interface is set to ''active'' or ''passive'' at the SINUMERIK end by the wiring in the cable

connector not by jumper setting on the module.

The line current should always be checked when the loop is closed (approx. 20 mA).

Refer also to Section 1.5.

2-2

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 17

07.90 2 20 mA Current Loop Interface

2.3.1 Duplex interface

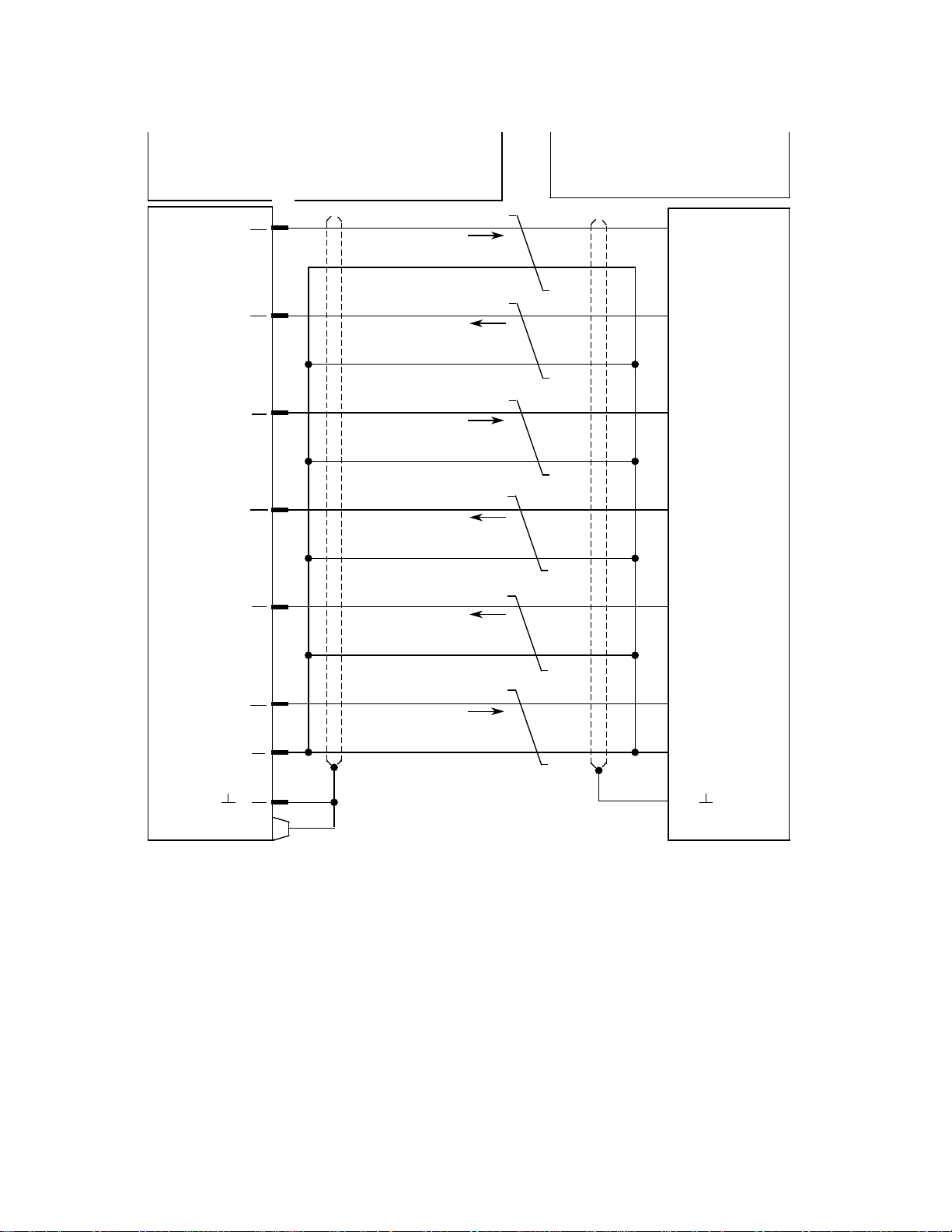

2.3.1 Duplex interface Active at SINUMERIK end

SINUMERIK

DTE DCE

0 V (R)

TTY 3

–

+

TTY 4

R 20 mA

0 V (T)

TTY 1

–

O

O

O

O

O

O

24

14

13

16

21

19

Received data –

Received data +

19

10

I/O device

DTE

O

O

+

TTY 2

T 20 mA

O

O

O

10

12

1

Transmitted data –

Transmitted data +

14

13

O

O

1

O

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 2-3

SINUMERIK System 800, (PJ)

Page 18

2 20 mA Current Loop Interface 10.88

2.3.2 Duplex interface

2.3.2 Duplex interface Passive at the SINUMERIK end

SINUMERIK

DTE DCE

24

O

–

+

TTY 3

TTY 4

O

O

O

14

13

16

21

Received data –

Received data +

O

Transmitted data +

–

TTY 1

O

19

19

12

10

24

21

I/O device

DTE

O

O

–

O

+

O

O

+

TTY 2

O

O

O

10

12

1

Transmitted data –

16

14

13

O

O

O

1

O

In all signal names and directions, the SINUMERIK is taken to be a DTE.

The specification of the I/O device determines how it is connected.

In the interface link diagram, the I/O device is assumed to comply with the VDI 2880

specification.

2.4 Length of the transmission line

The maximum cable length for the 20 mA current loop interface is 1 km.

–

+

2-4

END OF SECTION

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 19

10.88 3 RS 422 Interface

3.1 General notes

3 RS 422 Interface

3.1 General notes

The function of the signals in the RS 422 interface is identical to those of the V.24 interface.

However, instead of the V.24 signal level, transmission is via two-wire cables using differential

drivers and receivers.

The RS 422 interface combines the advantages of the V.24 interface (modem capability by

control signals) with those of the 20 mA interface (large transmission distances).

The following signals are the same for the V.24 interface and the RS 422 interface (except

signal level):

Data signals

Signal V.24 RS 422

Transmitted data

Receive data

Control signals

Signal V.24 RS 422

Data terminal ready

Request to send

Data set ready

Clear to send

D1

D2

S1.2

S2

M1

M2

TxD

RxD

DTR

RTS

DSR

CTS

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 3-1

SINUMERIK System 800, (PJ)

Page 20

3 RS 422 Interface 10.88

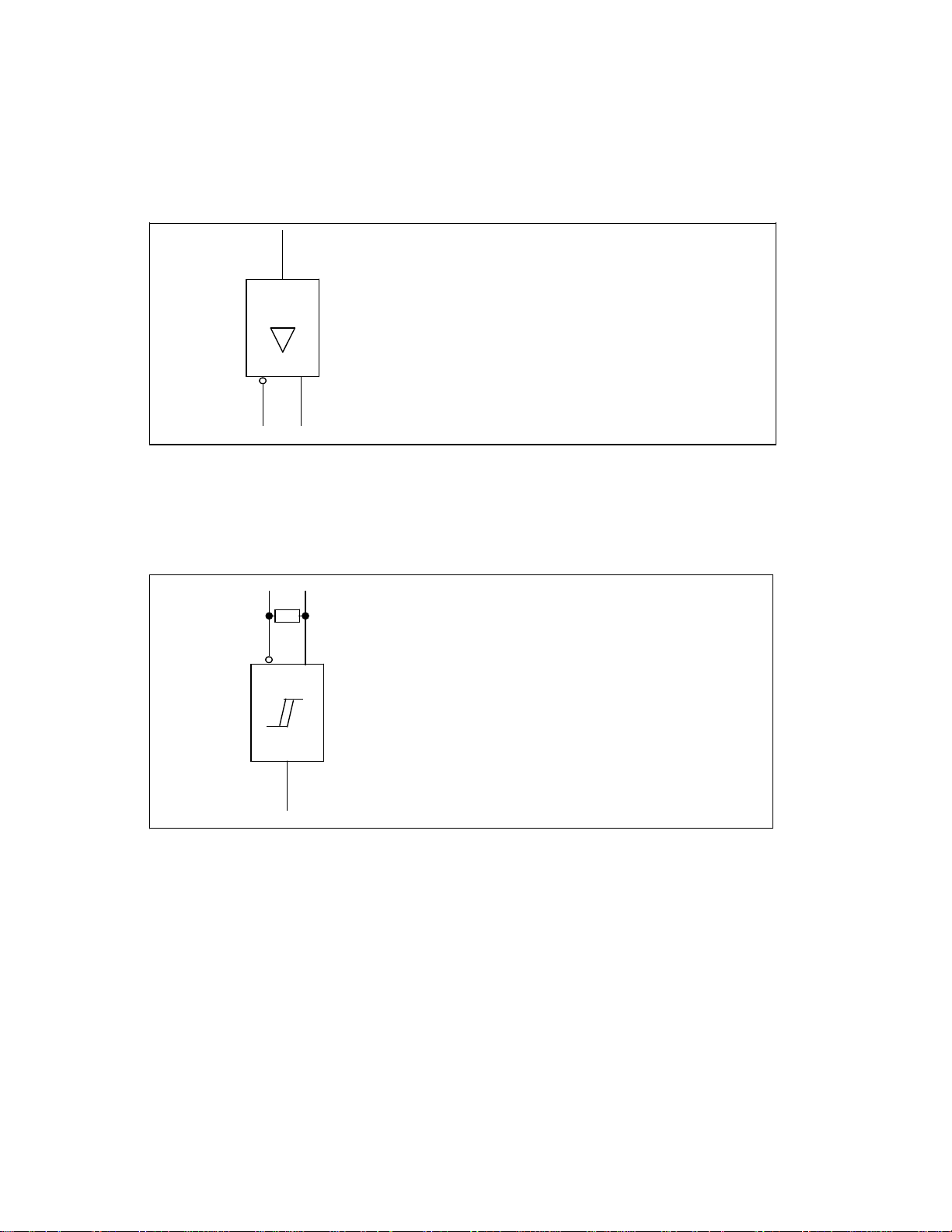

3.2 Polarity and voltage level assignment of the RS 422 interface

3.2 Polarity and voltage level assignment of the RS 422 interface

V

5 V

Logical ”H”

2.5 V

0.5 V

0 V

VOH 2.5 V

1.5 V

VOL 0.5 V

Logical ”L”

V

min.

=2V

V

max.

=5V

t

V

Output Y

V

min.

=2V

Output Z

t

The voltage levels refer to the reference voltage of the driver circuit AM 26 LS 31.

The voltage between the differential lines is

min

max

= 2 V

= 5 V

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

V

V

3-2

Page 21

10.88 3 RS 422 Interface

3.3.1 RS 422 drivers

3.3 RS 422 drivers and receivers

3.3.1 RS 422 drivers

The RS 422 output signals are generated from the TTL signals of the USART 8251 via the AM

26 LS 31 line drivers.

TTL level

Data of the AM 26 LS 31 circuit

cc

oL

oH

= 5 V

= 0.5 V

= 2.5 V

AM 26 LS 31

Supply voltage V

Max. output voltage V

Min. output voltage V

Differential voltage 2 ... 5 V

RS 422 level

Z Y

3.3.2 RS 422 receivers

The RS 422 input signals are converted to TTL signals via the AM 26 LS 33 line receivers.

150

RS 422 level

AM 26 LS 33

Data of the AM 26 LS 33 circuit

Supply voltage V

= 5 V

cc

Input parallel

resistance 150 Ohm

Differential operation

voltage 2 ... 5 V

TTL level

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 3-3

SINUMERIK System 800, (PJ)

Page 22

3 RS 422 Interface 07.90

3.4 Interface link to I/O device for RS 422

3.4 Interface link to I/O device for RS 422

SINUMERIK

DTE DCE

2

* T x D

T x D

* R x D

R x D

R

S

4

2

* RTS

2

s

i

g

n

* CTS

a

l

s

* DSR

* DTR

RTS

CTS

DSR

DTR

O

15

O

3

O

16

O

4

O

17

O

5

O

18

O

6

O

19

O

20

O

8

O

1

O

Transmitted data

D1 (103)

Received data

D2 (104)

Request to send

S2 (105)

Clear to send

M2 (106)

Data set ready

M1 (107)

Data terminal ready

S1.2 (108.2)

Protective ground

E1 (101)

I/O device

DTE

3

O

16

O

2

O

15

O

5

O

18

O

4

O

17

O

20

O

8

O

6

O

19

O

1

* R x D

R x D

* T x D

T x D

CTS

* CTS

RTS

* RTS

DTS

* DTR

DSR

* DSR

O

In all signal names and directions, the SINUMERIK is taken to be a DTE.

Which of the control and message lines are used will depend on the I/O device. The speci-

fication I/O device peripheral unit determines how it is connected.

In the interface link diagram, a device is assumed to comply with the SINUMERIK specifica-

tion. The RS 422 interface is on a special connector.

3.5 Length of the transmission line

The maximum cable length for RS 422 transmission is 1 km.

3.6 Level conversion from V.24 to RS 422

With the SINUMERIK System 800 the V.24 level of the V.24 interfaces can be converted into a

RS 422 level with a special cable. The converter electronics are integrated into the specific

SINUMERIK cable connector (housing of fibre glass conductor).

The adjustable interfaces are listed in Section 7.1 corresponding to the controls.

END OF SECTION

3-4

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 23

10.88 4 Interface Overview

4.1 Pin assignments of the data interfaces

4 Interface Overview

4.1 Pin assignments of the data interfaces

4.1.1 Pin assignments on the V.24/20 mA universal interface

D-Sub, 25-pin, socket on SINUMERIK.

Pin Signal name Interface Signal name to DIN 66020

SINUMERIK assignment VDI 2880

(English from CCITT recommendation)

(referring to SINUMERIK as a DTE)

1 Protective ground E1 (101)

2 *TxD V.24 Transmitted data D1 (103)

3 *RxD V.24 Received data D2 (104)

4 RTS V.24 Request to send S2 (105)

5 CTS V.24 Clear to send M2 (106)

6 DSR V.24 Data set ready M1 (107)

7 MEXT V.24 Signal ground E2 (102)

8

9

10 TTY2 20 mA Transmitted data+

11

12 T 20 mA 20 mA Transmit source

13 TTY4 20 mA Received data +

14 TTY3 20 mA Received data –

15

16 R 20 mA 20 mA Receive source

17

18

19 TTY1 20 mA Transmitted data –

20 DTR V.24 Data terminal ready S1.2 (108.2)

21 0V (T) 20 mA Current return

22

23

24 0V (R) 20 mA Current return

25

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 4-1

SINUMERIK System 800, (PJ)

Page 24

4 Interface Overview 10.88

4.1.2 Pin assignments of the RS 422 interface

4.1.2 Pin assignments of the RS 422 interface

D-Sub, 25-pin, socket on SINUMERIK

Pin Signal name Interface Signal name to DIN 66020

SINUMERIK assignment (English from CCITT recommendation)

(referring to SINUMERIK as a DTE)

1 Protective ground E1 (101)

2 *TxD RS 422 Transmitted data D1 (103)

3 *RxD RS 422 Received data D2 (104)

4 RTS RS 422 Request to send S2 (105)

5 CTS RS 422 Clear to send M2 (106)

6 DSR RS 422 Data set ready M1 (107)

7

8 *DTR RS 422 Data terminal ready S1.2 (108.2)

9

10

11

12

13

14

15 TxD RS 422 Transmitted data D1 (103)

16 RxD RS 422 Received data D2 (104)

17 *RTS RS 422 Request to send S2 (105)

18 *CTS RS 422 Clear to send M2 (106)

19 *DSR RS 422 Data set ready M1 (107)

20 DTR RS 422 Data terminal ready S1.2 (108.2)

21

22

23

24

25

4-2 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 25

07.90 4 Interface Overview

4.2 Explanation of signal names

4.2 Explanation of signal names

CTS Clear to Send

DSR Data Set Ready

DTR Data Terminal Ready

MEXT External Ground

RTS Request to Send

RxD Receive Data V.24

R20mA Receive Source 20 mA

TxD Transmit Data V.24

TTY1 Teletype (– 20 mA) Transmit Data

TTY2 Teletype (+20 mA) Transmit Data

TTY3 Teletype (– 20 mA) Receive Data

TTY4 Teletype (+20 mA) Receive Data

T20mA Transmit Source 20 mA

0V(R) 0V – Receive 20 mA

0V(T) 0V – Transmit 20 mA

4.3 Format of a serially transmitted character

T x D

R x D

Quiescent

state

Start

element

21

Data bits

6 87543

Stop

elements

Parity

bit (optional)

In the SINUMERIK universal interface the 8th bit of a character, which is normally the parity

bit, is designated as 8th data bit.

The parity bit is an optional 9th bit added to an ASCII character on even, and to an EIA

character on odd bit combinations. The 8th bit is always part of the data.

An additional parity bit (9th. bit) may be generated via setting data if desired for adaptation to

certain I/O devices.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 4-3

SINUMERIK System 800, (PJ)

Page 26

4 Interface Overview 10.88

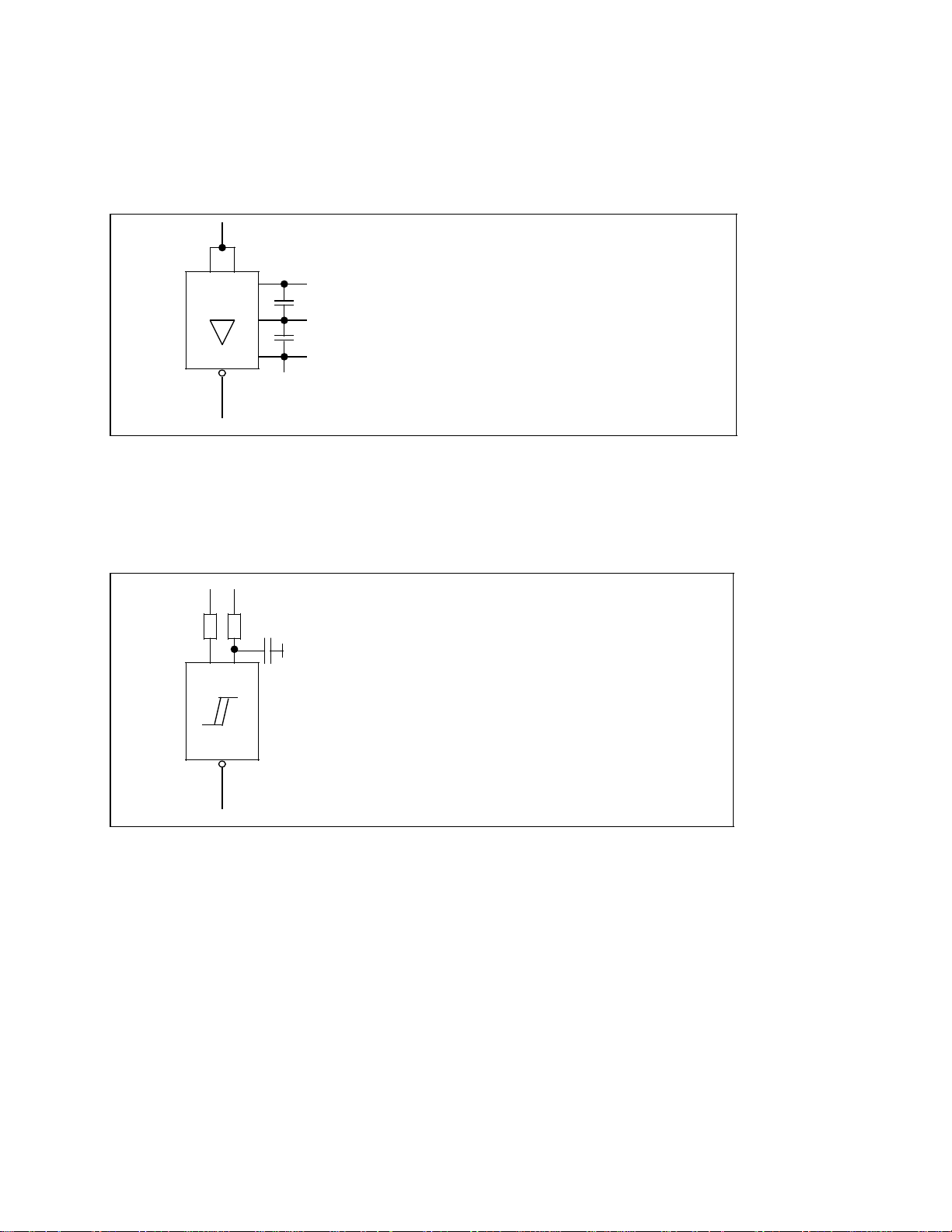

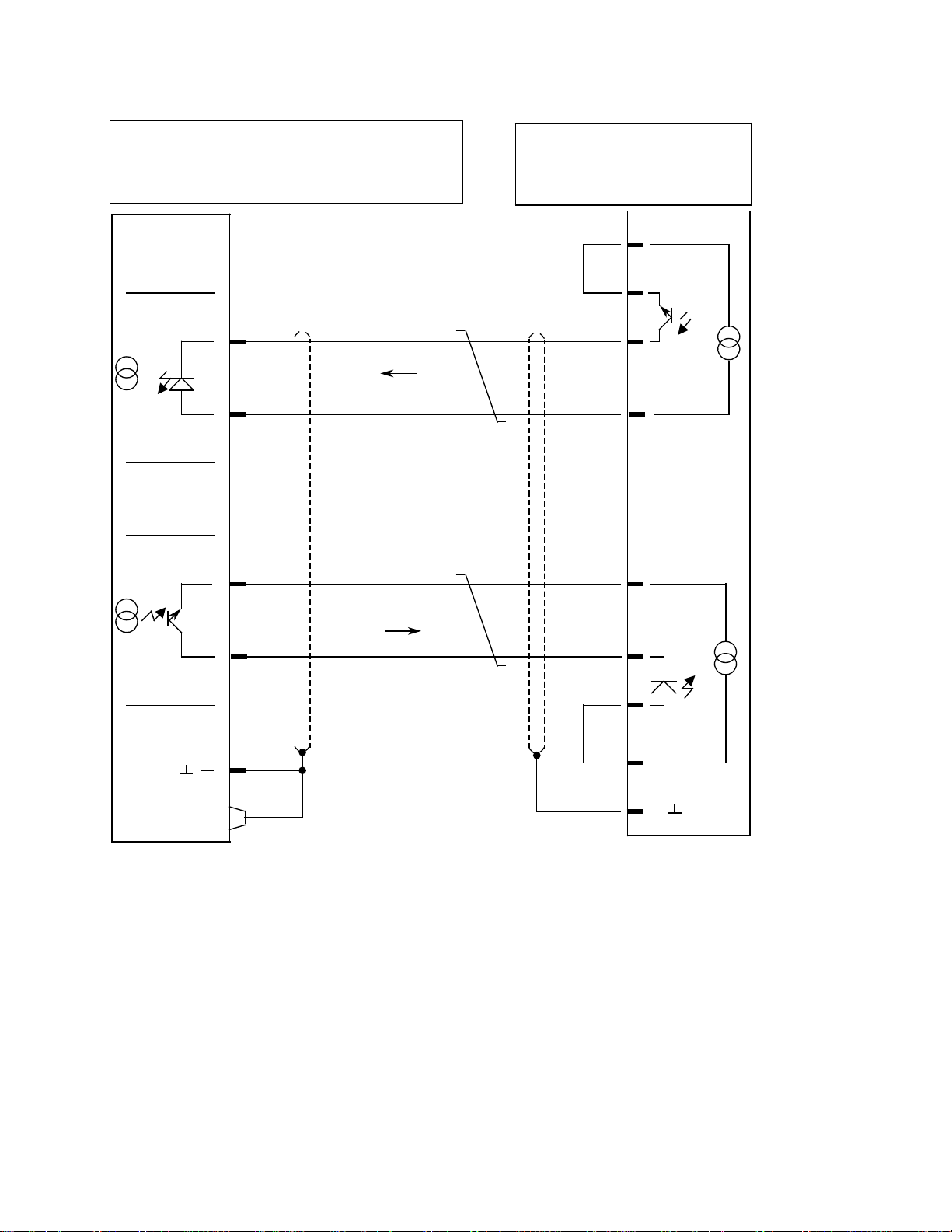

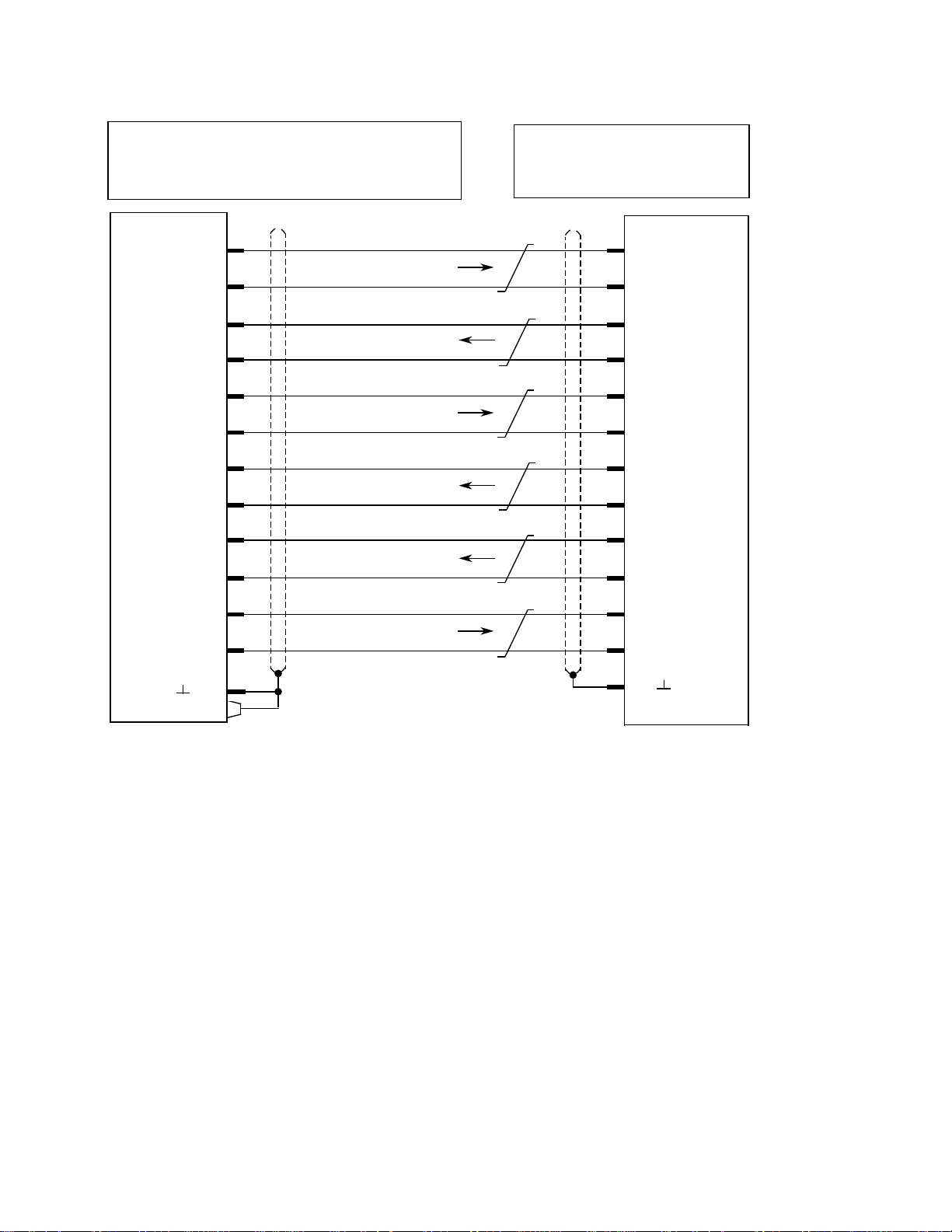

4.4 Block diagrams of the data interfaces

4.4 Block diagrams of the data interfaces

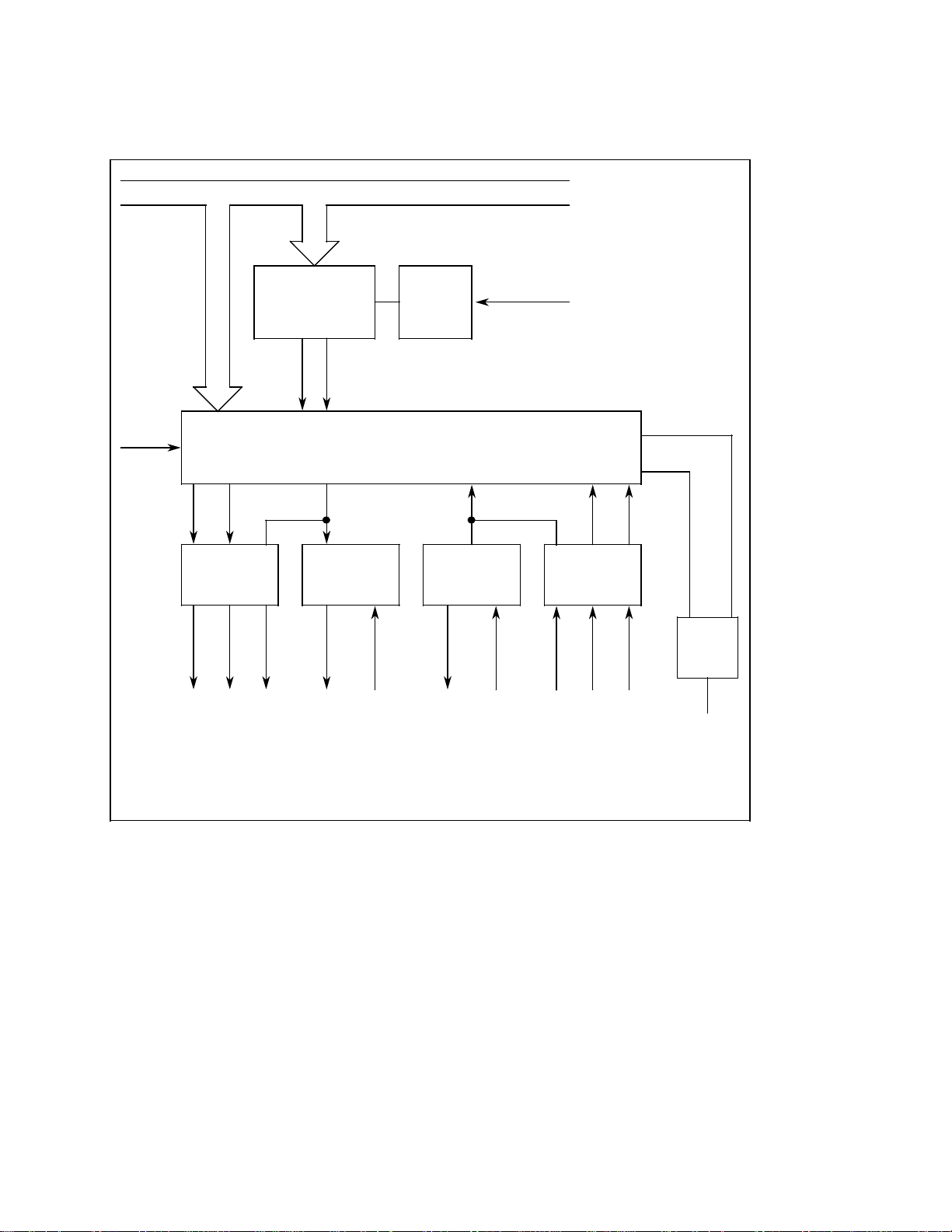

4.4.1 Block diagram of V.24/20 mA universal interface

Data bus DB

Select (1)

Baud rate

generator

DTRRTS

V.24

driver

RTS DTR * T x D

V.24

Output

Scaler

T x C

R x C

U SART

20 mA

driver

TTY 2 TTY 1 TTY 4 TTY 3 CTS DSR

20 mA

Transmit

1)

20 mA

receiver

Duplex

Receive

CPU frequency

R x DT x D

* R x D

V.24

receiver

V.24

Input

DSRCTS

R x RDYT x RDY

1

IR

Interrupt

1)

USART = Universal Synchronous Asynchronous Receiver Transmitter

Its tasks are:

• Conversion of 8 bits parallel to 8 bits serial

• Transmitting and receiving at different baud rates (possibly simultaneously)

• Error detection

• Define and check parity

4-4

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 27

07.90 4 Interface Overview

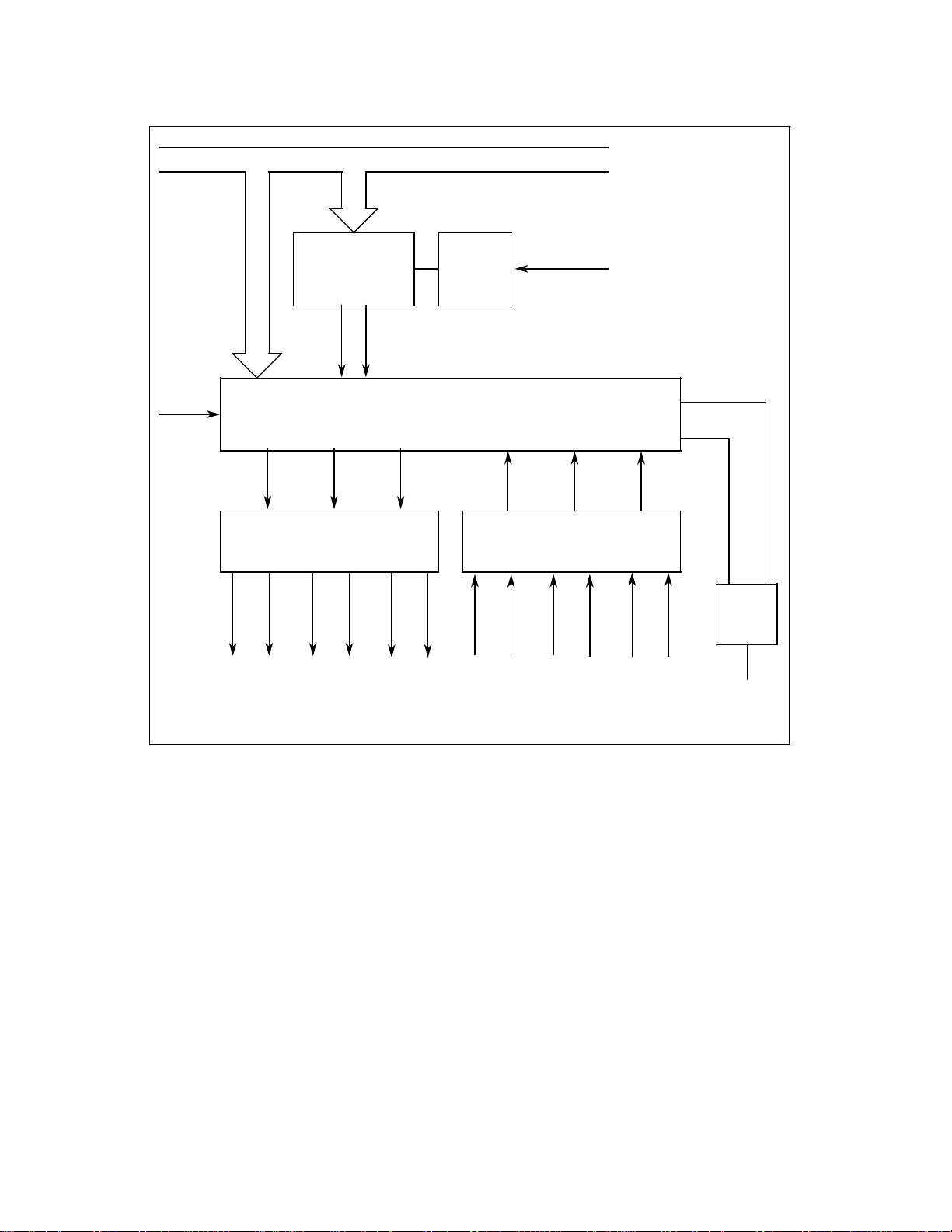

4.4.2 Block diagram of an RS 422 interface

4.4.2 Block diagram of an RS 422 interface

Data bus DB

Select (1)

Baud rate

generator

T x C

R x C

U SART

RTS DTR T x D DSRCTSR x D

RS 422

driver

RTS * RTS DTR

* DTR

* Tx D

Tx D

RS 422 Output RS 422 Input

Scaler

* R x D

CPU frequency

RS 422

receiver

R x D CTS

1

* CTS DSR *DSR

IR

Interrupt

END OF SECTION

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 4-5

SINUMERIK System 800, (PJ)

Page 28

10.88 5 Adapting the Interfaces to I/O Devices

5.1 General notes

5 Adapting the Interfaces to I/O Devices

5.1 General notes

Peripheral devices are subdivided according to the type of data transmission:

• Line-controlled devices:

– Control via the control lines DSR, DTR, CTS, RTS

• Uncontrolled devices:

– Asynchronous transmission without control

• Character-controlled devices:

– Control using control characters on the data lines

Each interface and data direction is defined at the SINUMERIK end for the I/O device using

setting data (see selection tables). The control lines are activated by connecting them.

On startup the default values of the machine data and setting data adapt the interface to the

Siemens PT 80 page printer (universal device).

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 5-1

SINUMERIK System 800, (PJ)

Page 29

5 Adapting the Interfaces to I/O Devices 03.91

5.2 Setting data

5.2 Setting data

SINUMERIK System 800 has one set of 8 bytes per interface for adapting the I/O devices. The

input and output directions are set separately.

The setting of the EIA code for special characters ”@”, ”:”, ”=”, ”[”, ”]” and ”,” and the

definition for the character ”End of transmission” is entered in 7 additional bytes for two

interfaces.

Byte

No.

1

2

3

4

5

6

7

8

Function

Bit

7 6 5 4 3 2 1 0

Device coding - input-

Transmission format - input -

Type of

parity

Parity

bit

Baud rateStop elements

Device coding - output -

Transmission format - output -

Stop elements

Type of

parity

Xon character (e.g. DC1 = 11

Xoff character (e.g. DC3 = 93

Parity

bit

hex

hex

Baud rate

)

)

Special bits

Output

without

1st Xon

character

Program

start

with LF

End of

block

CR LF

Output in

EIA

code

Stop at

character

end of

trans-

mission

Evaluate

data set

ready

DSR

Output

without

leader

and

trailer

Delete

program

without

reorgan.

Read-in

progr. of

systems

3, 8

Switch off

time

watchdog

9

10

11

12

13

14

15

EIA code for ”@” (e.g. 6D

EIA code for ”:” (e.g. 46

Code for ”End of transmission” (e.g. ETX=03

EIA Code for ”=” (e.g. 1C

EIA code for ”[”

EIA code for ”]”

EIA code for ”,”

hex

hex

Hex

)

)

in ISO)

hex

)

5-2 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 30

07.90 5 Adapting the Interfaces to I/O Devices

5.2.1 Explanation of the setting data

5.2.1 Explanation of the setting data

Specific data per interface

Byte 1, 3: Device code

00

= Line controlled devices

Hex

(data traffic according to standard)

= Xon/Xoff character-controlled devices

01

Hex

= SINUMERIK reader T10 and T20

02

Hex

= Siemens PLC programmer

04

Hex

PG 670/675/685/635/750/615

Device setting data are listed in the selection table in Section 8.1.

Byte 2, 4: Transmission format

– Bit 3 ... 0: Baud rate

0000 = 110 baud

0001 = 150 baud

0010 = 300 baud

0011 = 600 baud

0100 = 1200 baud

0101 = 2400 baud

0110 = 4800 baud

0111 = 9600 baud

– Bit 4: Parity bit

0 = without parity

1 = with parity

Determines whether after the 8th data bit a 9th bit should be generated and transmitted as a

parity bit.

– Bit 5: Type of parity

0= even

1= odd

Determines whether the additionally generated parity bit should complement the 8-bit data

on even or odd bit combinations.

If bit 4 is 0, bit 5 has no meaning.

– Bit 7 and 6: Number of stop elements

00=1 stop element

01=1 stop element

10=1 1/2 stop elements

11=2 stop elements

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 5-3

SINUMERIK System 800, (PJ)

Page 31

5 Adapting the Interfaces to I/O Devices 10.88

5.2.1 Explanation of the setting data

Byte 5: Xon character

Sets the Xon character for character-controlled transmission.

Byte 6: Xoff character

Sets the Xoff character for character-controlled transmission.

Byte 7: Special bits

– Bit 0 Read in subroutines of Systems 3 and 8

0 = Read in main programs and subroutines to System 800 format

1 = Read in main programs and subroutines to System 3, 8 format

When subroutines are read in to System 3, 8 format the identifier 00 of the subroutine no. is

eliminated.

– Bit 1 Output without leader and trailer

0 = Data output with leader and trailer (as punched tape)

1 = Data output without leader and trailer (in memory)

– Bit 2 Evaluate data set ready DSR

0 = Line ”DSR” (pin 6) is not evaluated

1 = Line ”DSR” (pin 6) is evaluated

– Bit 3 Stop at ”End of transmission” character

0=Read-in stop at M02/M30

1=Read-in stop at end of transmission character

Allows several programs to be read in en bloc (e.g. the main programs, subroutines, tool

data and blocks belonging to a workpiece)

– Bit 4 Output in the EIA code

0 = Output in ISO code

1 = Output in EIA code

– Bit 5 End of block CR LF

0 = End of block when output with LF CR CR

1 = End of block when output with CR LF

– Bit 6 Program start with LF

0 = Read-in begin with %

1 = Read-in begin with LF

Allows part program to be read in. The next LF read is interpreted as the beginning of a

program and this program is stored in the part program memory as %0.

– Bit 7 Output without 1st Xon character

0 = Output begin after request via Xon character

1 = Output begin without request

When character control devices are connected, data output is initiated with data start

without waiting for the Xon character from the external unit. Further starts and stops use

the Xon, Xoff characters.

5-4

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 32

07.90 5 Adapting the Interfaces to I/O Devices

5.2.1 Explanation of the setting data

Byte 8: Special bits

– Bit 0 Time watchdog switched off

0 = Time watchdog active

If on transmission no character is sent for 60 s, the NC interrupts the transmission line

and sets interrupt 22.

1 = Time watchdog switched off

– Bit 1 Delete program without reorganizing

0 = Reorganize

After a program has been deleted via V.24, automatic reorganization is activated.

1 = No reorganizing

After a program has been deleted via V.24, automatic reorganization is suppressed.

Data common to both interfaces

Byte 9

EIA code for ”@”

Byte 10 EIA code for ”:”

Definition of substitute characters for the”@” and ”:” characters missing in the EIA code.

Byte 11 Code for

Definition of character for end of transmission in ISO code (e.g. ETX = 03

Byte 12 EIA code for

”End of transmission”

”=”

) or in EIA code.

Hex

Definition of substitute character for the ”=” character missing in the EIA code.

Byte 13

EIA code for ” [ ”

Definition of substitute character for the ” [ ” character missing in the EIA code.

Byte 14 Code for

” ] ”

Definition of substitute character for the ” ] ” character missing in the EIA code.

Byte 15 EIA code for

”,”

Definition of substitute character for the ”,” character missing in the EIA code.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 5-5

SINUMERIK System 800, (PJ)

Page 33

5 Adapting the Interfaces to I/O Devices 10.88

5.3 Notes on the format of special characters

5.3 Notes on the format of special characters

Special characters and substitute characters must always be entered in the setting data

including the paraity bit (8th data bit).

It is important to note that the bit combination is even when using the ISO code and odd when

using the EIA code.

Example:

The Xoff character DC 3 with ASCII code 13

item of setting data in ISO code as 93

HEX

.

is odd and must therefore be entered as an

HEX

5.4 Notes on using the EIA code

Not all ISO characters can be represented in the EIA code. For this reason, interrupt 33

(program read in program stored) can occur when a program written in ISO code and

stored in the NC is compared with its equivalent converted into EIA code.

Example:

Block in NC memory

N 10 ... (... =

....)*

Block output in EIA code

N 10 ... (...

....)*

END OF SECTION

5-6

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 34

10.88 6 Signal Timing for Data Transmission

6.1 Signal timing with line-controlled devices

6 Signal Timing for Data Transmission

6.1 Signal timing with line-controlled devices

6.1.1 Data input (I/O device to NC)

Switch off NC

End of reading

in

ETX

Data

DTR

DSR

CTS

RTS

RxD

TxD

Switch on NC

I/O device ready No longer ready

NC buffer free

Data

Data Start

NC buffer full

When the NC is switched on, DTR of all interfaces goes to High = ”1”. If the readiness of the

device is to be evaluated, the DSR line must be connected.

Reading in the data is started with ”Data Start” and controlled with ”RTS”. With data start,

RTS goes to ”1” and the I/O device can send data.

If the NC cannot keep up with data input, transmission is stopped by cancelling RTS. When

the NC buffer becomes free again RTS is reset to ”1” and transmission is again enabled.

If the NC reads the ”End of Transmission” character (M02 or M30 or ETX), transmission is

stopped by cancelling of RTS.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 6-1

SINUMERIK System 800, (PJ)

Page 35

6 Signal Timing for Data Transmission 12.95

6.1.2 Data output (NC to I/O device)

6.1.2 Data output (NC to I/O device)

DTR

DSR

CTS

RTS

RxD

TxD

Data

Data Start

Data

Data End

When the NC is switched on, DTR of all interfaces goes to ”1”. If the readiness of the I/O

device is to be evaluated the DSR line must be connected.

If the external device is to control data transmission, the CTS line must be connected.

Data read-out is started with Data Start, when CTS is ”1” (if connected). If the device cannot

keep up with data input it stops transmission by cancelling CTS. If its buffer is free again, CTS

is reset to ”1” and transmission restarted. The NC terminates data transmission when the

end of program has been output or ETX and a trailer.

In the SINUMERIK 805/810/820/840/850/880, the RTS signal stays at ”0” during data output.

6-2

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 36

12.95 6 Signal Timing for Data Transmission

6.1.2 Data output (NC to I/O device)

DTR

DSR

CTS

RTS

RxD

TxD

Data

Data Start

Data

Data End

In the SINUMERIK 840C Basic Version and SINUMERIK 840C OEM Version for Windows, the

signal chart is slightly different from that above.

The RTS signal is reset to ”0” on activating the interface for data output, i.e. with Data Start

on ”1” and at the end of data transfer.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 6-3

SINUMERIK System 800, (PJ)

Page 37

6 Signal Timing for Data Transmission 10.88

6.2.1 Data input (I/O device to NC)

6.2 Signal timing with character-controlled devices

6.2.1 Data input (I/O device to NC)

Switch on NC

Switch off NC

DTR

I/O device ready No longer ready

DSR

(CTS)

(RTS)

RxD

TxD

DC Start

Data Start

Data Stop

DataData

Data Start

ETX

When the NC is switched on, the DTR of all signals goes to ”1”. If the readiness of the I/O

device is to be evaluated the DSR line must be connected.

With ”Data Start” the NC sets the RTS signal to ”1”. RTS is only cancelled at the end of

transmission or if an error occurs.

The NC enables reading in data by transmitting the character ”Xon” (setting byte no. 5). The

I/O device then transmits data to the NC. If the NC cannot keep up with data input it stops

transmission by transmitting the character ”Xoff” (setting byte no. 6).

As the I/O device generally cannot stop at a precise character the NC is able to read a few

more characters. If the NC is ready to receive again, transmission is again enabled by ”Xon”.

If the NC reads the ”End of Transmission” character (M02 or M30 or ETX), it transmits the

character ”Xoff” and sets RTS to ”0”.

If the CTS line is connected it must already be ”1” at Data Start and may only be set to ”0”

after the end of transmission.

In character-controlled transmission, the RTS and CTS lines do not normally have to be

connected to the external device.

6-4

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 38

10.88 6 Signal Timing for Data Tranmission

6.2.2 Data output (NC to I/O device)

6.2.2 Data output (NC to I/O device)

DTR

DSR

(CTS)

(RTS)

RxD

TxD

Switch on NC

I/O device ready No longer ready

)(

Data

Data Start

Switch off NC

Data

Daten End

When the NC is switched on, the DTR of all interfaces goes to ”1”. If the readiness of the I/O

device is to be evaluated the DSR line must be connected.

With ”Data Start” the NC sets the RTS signal to ”1”. RTS is only withdrawn at the end of

transmission or if an error occurs.

The NC starts reading out data after it has received the ”Xon” character. If bit 7 of setting

data 7 (output without 1st Xon character) is set, the NC starts reading out data with Data Start.

If the I/O device cannot keep up data input, it stops transmission by sending the control

character ”Xoff”. The NC can then send two more characters before transmission is

terminated. If the I/O device is ready again it restarts transmission by sending the control

character Xon.

The NC terminates transmission after output of end of program or ETX (and a trailer) by

cancelling RTS.

If the CTS line is connected this must already be ”1” at Data Start and may only be set to

”0” after end of transmission.

For character-controlled transmission, RTS and CTS do not normally need to be connected to

the external device.

END OF SECTION

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 6-5

SINUMERIK System 800, (PJ)

Page 39

07.90 7 Serial interfaces on the SINUMERIK System 800

7.1.1 SINUMERIK 805

7 Serial Interfaces on the SINUMERIK

System 800

7.1 Interfaces on the various controls

7.1.1 SINUMERIK 805

1st interface: PCB 6FX1144-4BA, connector X122 central controller

V.24 and 20 mA interface

25-way connector, D-subminiature, socket

Housing of the cable connector

SINUMERIK type, position 1 below

optional: slide latch type

2nd interface (option): PCB 6FX1144

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector

SINUMERIK type, position 1 below

optional: slide latch type

-4BA, connector X132 central controller

7.1.2 SINUMERIK 810 GA1

1st interface: Operator panel front

V.24 and 20 mA interface

(Connected within the SINUMERIK by cable on PCB

6FX1125-8AB, connector X111

Slot A6, X111)

25-way connector, D-subminiature, socket

Housing of the cable connector:

slide latch type, position 1 below

2nd interface (option): PCB 6FX1125

Slot A6, X121

-8AB, connector X121 operator panel rear

V.24 interface

25-way connector , D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 7-1

SINUMERIK System 800, (PJ)

Page 40

7 Serial interfaces on the SINUMERIK System 800 07.90

7.1.3 SINUMERIK 810 GA2/820 GA2

7.1.3 SINUMERIK 810 GA2/820 GA2

1st interface: Operator panel front

V.24 and 20 mA interface

(Connected within the SINUMERIK by cable on PCB

6FX1132-8BB, connector X121

Slot A6, X121)

25-way connector, D-subminiature, socket

Housing of the cable connector:

slide latch type, position 1 below

2nd interface (option): PCB 6FX1132

-8BB, connector X131 operator panel rear

Slot A6, X131

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

7.1.4 SINUMERIK 810 GA3/820 GA3

1st interface: Operator panel, front

V.24 and 20 mA interface

(Connected within the SINUMERIK by cable on

PCB 6FX1138-5BA, connector X121

slot A6, X121)

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

2nd interface (option): PCB 6FX1138

slot A6, X131

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

7-2

-5BA, connector X131 operator panel, rear

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 41

07.90 7 Serial interfaces on the SINUMERIK System 800

7.1.5 SINUMERIK 840

7.1.5 SINUMERIK 840

1st interface: Maschine control panel front

V.24 and 20 mA interface

(Connected within the SINUMERIK by 6FC9344-1F cable on

PCB 6FC1123-3CA, connector X131 central controller

Slot B1, X131)

25-way connector , D-subminiature, socket

Housing of the cable connector:

slide latch type, position 1 below

2nd interface (option): PCB 6FX1120

Slot A4, X131

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

-4BA, connector X131operator panel rear

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 7-3

SINUMERIK System 800, (PJ)

Page 42

7 Serial interfaces on the SINUMERIK System 800 07.90

7.1.6 SINUMERIK 850

7.1.6 SINUMERIK 850

1st interface: Machine control panel front

V.24 and 20 mA interface

(Connected within the SINUMERIK by cable on PCB

6FX1120-4BA, connector X121

Slot A4, X121)

25-way connector , D-subminiature, socket

Housing of the cable connector:

slide latch type, position 1 below

2nd interface (option): PCB 6FX1120

Slot A4, X131

V.24 interface

can be used for adaptation of RS 422 special cable from

PCB 6FX1120-4BA02

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

3rd interface: PCB 6FX1120

Slot B3, X121

V.24 und 20 mA interface

can be used for adaptation of RS 422 special cable from

PCB 6FX1120-4BA02

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

4th interface (option): PCB 6FX1120

Slot B3, X131

-4BA, connector X131 operator panel rear

-4BA, connector X121 central controller

-4BA, connector X131 central controller

7-4

V.24 interface

can be used for adaptation of RS 422 special cable from

PCB 6FX1120-4BA02

25-way connector, D-subminiature, socket

Housing of the cable connector:

slide latch type, position 1 below

optional: slide latch type

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 43

07.90 7 Serial interfaces on the SINUMERIK System 800

7.1.7 SINUMERIK 880

7.1.7 SINUMERIK 880

1st interface: Operator panel front

V.24 and 20 mA interface

(Connected within the SINUMERIK by cable on

PCB 6FX1120-4BB, connector X121

Slot A4, X121)

25-way connector, D-subminiature, socket

Housing of the cable connector:

Slide latch type, position 1 below

2nd interface (option): PCB

6FX1120-4BB, connector X131 operator panel rear

Slot A4, X131

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

3rd interface: PCB 6FX1120

Slot B2, X121 (types 1, 2, 3, 7)

Slot B3, X121 (types 4, 5, 6)

V.24 and 20 mA interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

4th interface (option): PCB 6FX1120

Slot B2, X131 (types 1, 2, 3, 7)

Slot B3, X131 (types 4, 5, 6)

-4BB, connector X121 central controller

-4BB, connector X131 central controller

V.24 interface

can be used for adaptation of RS 422 special cable

25-way connector, D-subminiature, socket

Housing of the cable connector:

SINUMERIK type, position 1 below

optional: slide latch type

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 7-5

SINUMERIK System 800, (PJ)

Page 44

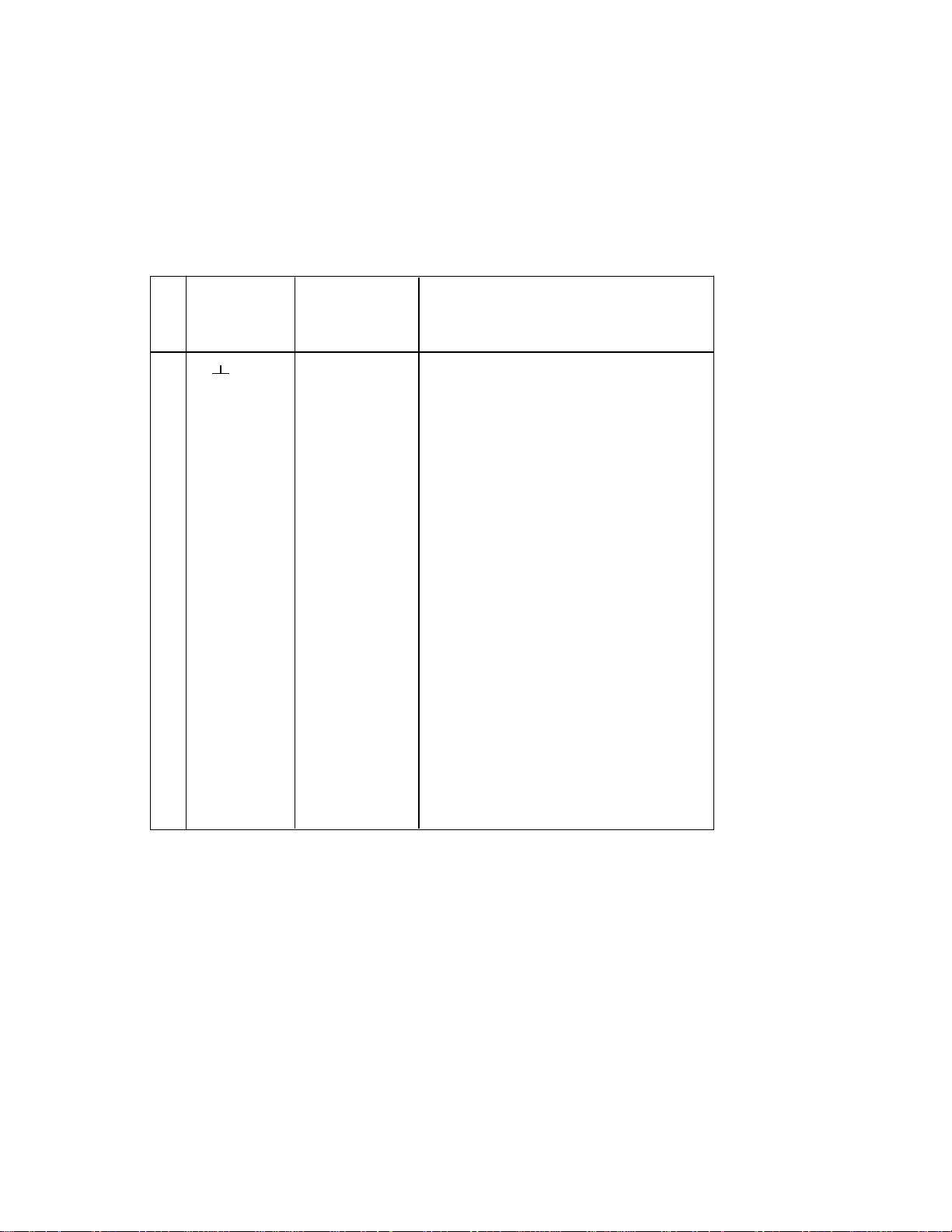

7 Serial interfaces on the SINUMERIK System 800 07.90

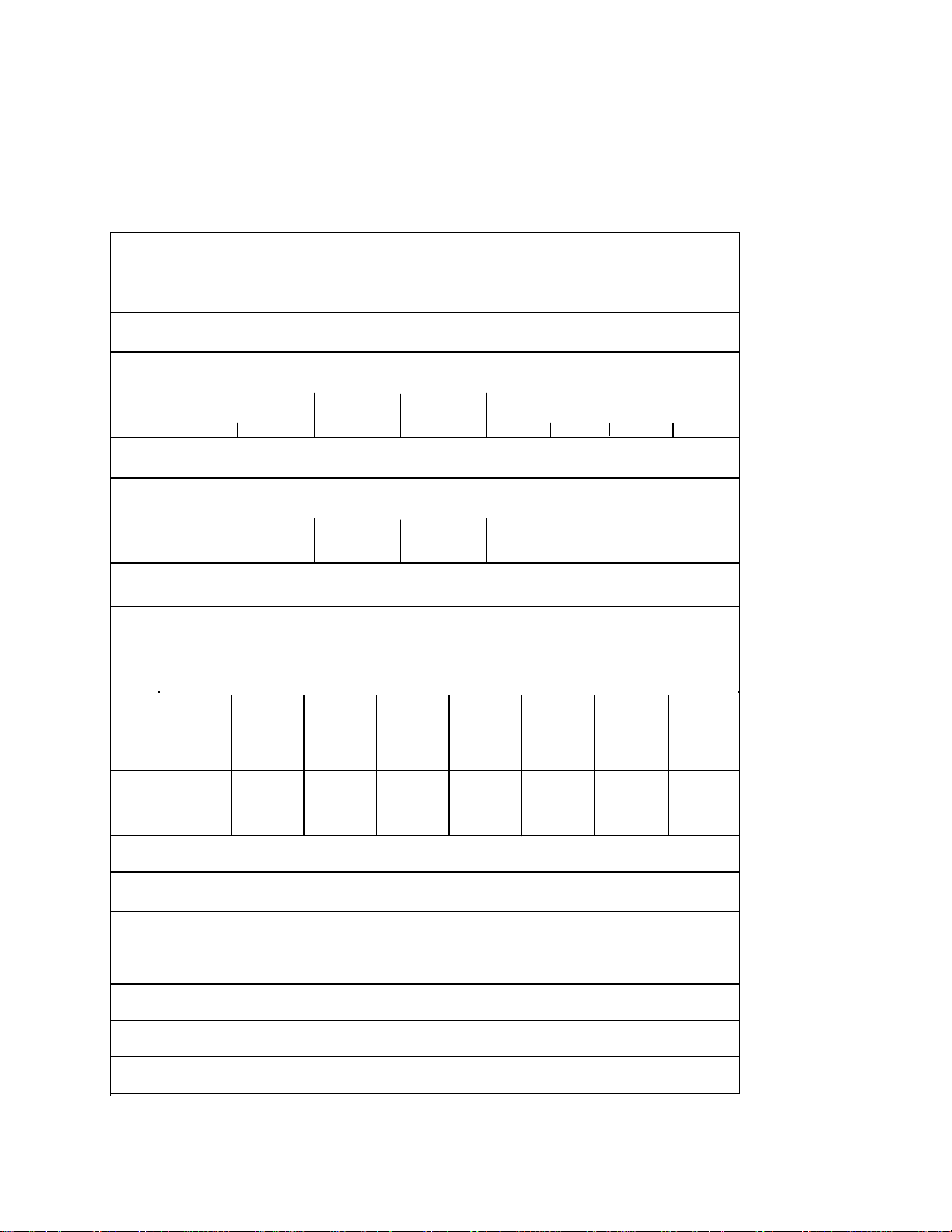

7.2 Setting data for the various controls

7.2 Setting data for the various controls

SINUMERIK

Type

Interface No.

805

810

820

840

850

880

1

2

3

4

5

6

7

8

1

1

1

1

1

1

5010

5011

5012

5013

5014

5015

5016

5017

2

2

2

–

2

2

5018

5019

5020

5021

5022

5023

5024

5025

–

–

–

2

3

3

–

–

–

–

4

4

Setting dataByte No.

5030

5031

5032

5033

5034

5035

5036

5037

5038

5039

5040

5041

5042

5043

5044

5045

10

11

12

13

14

15

9

1)

1)

1)

5026

5027

5028

5029

5050

5051

5052

END OF SECTION

1) only for:

SINUMERIK 840 and SINUMERIK 880 from software version 4

5046

5047

5048

5049

5060

5061

5062

7-6 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 45

10.88 8 Connecting I/O Devices in Practice

8.1 Device setting data (selection table)

8 Connecting I/O Devices in Practice

The following examples describing how to connect certain devices are based on their state of

development at the time of printing. We cannot guarantee that the same information will apply

to devices developed beyond this stage, so the examples can only be regarded as recommendations.

8.1 Device setting data (selection table)

––––––––––––––––––––––––––––––––––––

Flag

Device type

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

Setting data

1 Device code - input 2 Transmission format - input 3 Device code - output 4 Transmission format - output 5 DC - Start character

6 DC - Stop character

7 Special bits

11 Code for end of transmission

Byte Binary code HEX code

0000 0000

2

3

4

1100 0010

0000 0000

1100 0010

00

C2

00

C2

Hex

Hex

Hex

Hex

–

2

3

4

0000 0000

1100 0111

0000 0000

2

1100 0111

3

4

00

C7

00

C7

–

Hex

Hex

Hex

Hex

–

–

Device

Siemens PT 80 page printer

20 mA

V.24, 300 baud

Siemens PT 88 printer

V.24, 9600 baud

SINUMERIK T40

tape readers T50

T60

V.24, 9600 baud

RTS-LINE 1

2

3

4

RTS-LINE 1

2

3

4

RTS-LINE 1

2

3

4

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-1

SINUMERIK System 800, (PJ)

0000 0000

0000 0100

0000 0000

0000 0100

0000 0000

1100 0000

0000 0000

1100 0000

0000 0000

1100 0100

0000 0000

1100 0100

00

04

00

04

00

C0

00

C0

00

C4

00

C4

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Sanyo Cassette

M2502U-ZE601

V.24, 1200 baud

Teletype, ASR33

Duplex

20 mA, 110 baud

Facit 4040, 4042

tape reader/punch

V.24, 1200 baud

Page 46

8 Connecting I/O Devices in Practice 03.91

8.1 Device setting data (selection table)

––––––––––––––––––––––––––––––––––––

Flag

Device type

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

Setting data

1 Device code - input 2 Transmission format - input 3 Device code - output 4 Transmission format - output 5 DC - Start character

6 DC - Stop character

7 Special bits

11 Code for end of transmission

Byte Binary code HEX code

–

2

3

4

2

3

4

2

3

4

7

11

2

3

4

7

11

2

3

4

2

3

4

7

11

2

3

4

7

11

0000 0000

1100 0011

0000 0000

1100 0100

0000 0000

1100 0111

0000 0000

1100 0111

0010 1000

0000 0011

0000 0000

1100 0111

0000 0000

1100 0111

0010 1010

0000 0011

0000 0000

1100 0111

0000 0000

1100 0111

0000 0000

1100 0111

0000 0000

1100 0111

0010 1010

0010 0011

0000 0000

1100 0111

0000 0000

1100 0111

0010 1010

0000 0011

00

C3

00

C4

00

C7

00

C7

28

03

00

C7

00

C7

2A

03

00

C7

00

C7

00

C7

00

C7

2A

03

00

C7

00

C7

2A

03

–

Hex

Hex

Hex

Hex

–

–

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Device

Facit tape punch

4070/MI77

V.24, 600 baud

Facit tape reader

4030

V.24, 1200 baud

Facit N 1000

Facit N 1100

NC-Walk Disk

V.24, 9600 baud

Siemens

Floppy disk drive

DSG 3.5 disk drive

DSG 2S disk drive

V.24, 9600 baud

Sommer terminal

MDC-3 SNC

Cassette drive

V.24, 9600 baud

Tekelec

Floppy disk drive

FDS 300, FDS 500

V.24, 9600 baud

Tekelec magnetic tape

Cartridge drive

CDS 1.58

V.24, 9600 baud

8-2 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 47

03.91 8 Connecting I/O Devices in Practice

8.1 Device setting data (selection table)

––––––––––––––––––––––––––––––––––––

Flag

Device type

RTS-LINE 1

RTS-LINE 1

Setting Data

1 Device code - input 2 Transmission format - input 3 Device code - output 4 Transmission format - output 5 DC - Start character

6 DC - Stop character

7 Special bits

11 Code for end of transmission

Byte Binary code HEX code

11

11

0000 0000

2

3

4

7

1100 0111

0000 0000

1100 0111

0010 1010

0000 0011

0000 0000

2

3

4

7

1100 0111

0000 0000

1100 0111

0010 1010

0000 0011

00

C5

00

C5

2A

03

00

C7

00

C7

2A

03

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Device

CAN NC recorder

FD/FH

V.24, 9600 baud

GNT 7101

NC data carrier

V.24, 9600 baud

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

RTS-LINE 1

11

11

0000 0000

2

3

4

7

1100 0110

0000 0000

1100 0110

0010 1000

0000 0011

0000 0000

2

3

4

1100 0111

0000 0000

1100 0111

0000 0000

2

3

4

7

1100 0111

0000 0000

1100 0111

0010 1000

0000 0011

0000 0000

2

3

4

7

1100 0111

0000 0000

1100 0111

0010 0010

00

C6

00

C6

28

03

00

C7

00

C7

00

C7

00

C7

28

03

00

C7

00

C7

22

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

Hex

GNT 4604

Tape reader/punch station

V.24, 4800 baud

NC workstation

SINUMERIK WS800/WS800A

V.24, 20 mA

9600 baud

SIMATIC programmer

PG 675/685/635 (PG IN)

PC 750 (PC IN)

V.24, 9600 baud

Printer interface

COM 1 interface (PG 750)

SINUMERIK System 800

NC-NC link

V.24, 9600 baud

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-3

SINUMERIK System 800, (PJ)

Page 48

8 Connecting I/O Devices in Practice 03.91

8.1 Device setting data (selection table)

––––––––––––––––––––––––––––––––––––

1 Device code - input 2 Transmission format - input 3 Device code - output -

Flag

Device type

4 Transmission format - output 5 DC - Start character

6 DC - Stop character

7 Special bits

11 Code for end of transmission

XON/XOFF 1

PTR 1

Setting data

Byte Binary code HEX code

0000 0001

2

1100 0110

3

4

5

6

0001 0001

1001 0011

0000 0010 02

2

3

4

01

C6

11

93

Hex

Hex

–

–

Hex

Hex

Hex

–

–

–

5

6

Device

SINUMERIK

T30 tape reader

V.24, 4800 baud

SINUMERIK

T10, T20 tape readers

V.24, 9600 baud

RTS-LINE 1

PLC-PROG 1

PLC-PROG 1

0000 0000

2

3

4

7

1100 0111

0000 0000

1100 0111

0010 0010

0000 0100

2

0000 0111

3

4

00

C7

00

C7

22

04

07

Hex

Hex

Hex

Hex

Hex

Hex

Hex

–

–

Siemens

PD...PG

programming station

V.24, 9600 baud

SIMATIC PG

670/675/685/635/615

programmer

20 mA, 9600 baud

interface AG S5

0000 0100

2

0000 0111

3

4

04

07

Hex

Hex

–

–

SIMATIC PG 750

programmer

V.24, 9600 baud

COM 1 interface

8-4 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 49

10.88 8 Connecting I/O Devices in Practice

8.2 Device connection data

8.2 Device connection data

8.2.1 Siemens PT80 page printer

Cable order no. 6FC9 340-8C (V.24)

6FC9 340-8T (20 mA)

Device data

Transmission rate 300 baud

Character format 1 start element

8 data bits

2 stop elements

Order no. for PT 80 to SINUMERIK specification:

V.24: L22751-A80-D442

(Interface PCB STT104)

20 mA: L22751-A80-D441

(Interface PCB SST104 + LAT101)

Additional cable for terminal connection:

6FC9 340-4KA

On the unit with the 20 mA interface, no NC-controlled (start/stop) reader mode is possible.

8.2.2 Siemens PT88 printer

Cable order no.: 6FC9 340-8D

Device data

Interface adapter SAP-S1 (V.24)

Mode switch settings

Switch S1

123456

ON ON ON OFF OFF OFF

Transmission rate 9600 baud

Switch S2

123456

OFF ON OFF ON OFF ON

Line BUSY (X2.10) connected to BUSY line (X1.25) and negative potential.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-5

SINUMERIK System 800, (PJ)

Page 50

8 Connecting I/O Devices in Practice 10.88

8.2.3 SINUMERIK T40 and T50 tape readers

8.2.3 SINUMERIK T40 and T50 tape readers

Type GNT 28 and GNT 27

Cable order no. 6FC9 340-8S

Device data

Transmission rate 9600 baud

Character format 1 start element

8 data bits

2 stop elements

Settings on the T40 printer

Switch row A:

12345678

ON ON - OFF OFF OFF OFF OFF

Switch row B:

12345678

ON OFF OFF OFF OFF OFF OFF OFF

Settings on the T50 tape reader

Jumpering 27 P01 not assigned

Jumpering 27 P02 Jumpers 2 + 5 closed

Jumpering 27 S02 Jumpers 1, 2, 3, 4 open

Operating notes

To perform an automatic start from the SINUMERIK, the tape reader must be ready, i.e. the

”Reader start” LED must be lit. It is not possible to stop at a precise character. If several programs are punched onto one tape they must be separated by approx. 20 blanks.

If the programs are punched from SINUMERIK these blanks are generated automatically

provided the ”Output without trailer and leader” setting data (byte 7, bit 1) is not set.

8-6

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 51

10.88 8 Connecting I/O Devices in Practice

8.2.4 SINUMERIK T60 tape reader (hand-held)

8.2.4 SINUMERIK T60 tape reader (hand-held)

Type GNT 2910

Cable order no. 6FC9 344-2C

Device data

Transmission rate 9600 baud

Character format 1 Start element

8 Data bits

2 Stop elements

Settings

DIP switch in the unit:

12345678

OFF OFF OFF OFF OFF OFF ON OFF

Operating notes

Before switching on the device, the punched tape must be inserted. If an error occurs the

green LED flashes, acknowledgement by switching the device off and on. The start of reading

is controlled from the SINUMERIK.

Special operating conditions

The device stops at precise characters.

8.2.5 Sanyo M2502U cassette

with ZE601 (V.24) interface

Cable order no. -

Device data

Transmission rate 1200 baud

Character format 1 start element

8 data bits

1 stop element

Special operating conditions of the Sanyo cassette

– No controlled (start/stop) operation from the NC possible.

(To achieve this the RTS signal from the NC would have to be logical ”H” on both reading

and writing. This does not conform to the standard. RTS is ”H” on reading and ”L” on

writing.)

– The tape cannot stop at precise characters.

(This could lead to USART interrupts from the NC especially in the case of ”Program start

with LF”.)

– Leave enough space on the tape between two programs, possibly put some speech

between them.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-7

SINUMERIK System 800, (PJ)

Page 52

8 Connecting I/O Devices in Practice 10.88

8.2.5 Sanyo M2502U cassette

–If spoken text lasts longer than 60 seconds, a time monitoring alarm will occur on reading.

Supplier

Indexim GmbH

Schweidnitzer Straße 6

1000 Berlin 31

Tel. 030/8926000

8.2.6 ASR3320/3WE teletype

Duplex mode

Cable order no. -

Device data

Interface 20 mA duplex

Transmission rate 110 baud

Character format 1 start element

8 data bits

2 stop elements

Connection data

The teletype interface receives data via the TTY1/TTY2 current loop and transmits data via the

TTY3/TTY4 current loop.

Terminal block on the teletype

Receive Transmit

++– –

987654321

Terminal block

151411

Duplex

Brown and white White and blue

8-8 © Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 53

10.88 8 Connecting I/O Devices in Practice

8.2.7 Facit 4040, 4042 punch/reader combination

8.2.7 Facit 4040, 4042 punch/tape reader combination

with PI81 interface

Cable order no. 6FC9 340-8V

Device data

Interface V.24

Transmission rate 1200 baud

Character format 1 start element

8 data bits

2 stop elements

Switch settings on the PI81 Interface

1 = Switch position ON

0 = Switch position OFF

Switch 1 (S1) 1.1 1.2 1.3 1.4 1.5 1.6 1.7

0011100

Switch 2 (S2) 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9

000001000

Switch 3 (S3) 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9

000001000

Switch 4 (S4) 4.1 4.2 4.3 4.4 4.5 4.6

110000

Transmission controlled via RTS, CTS

8.2.8 Facit 4070 punch

with MI77 Interface

Cable order no. 6FC9 340-8J

Device data

Interface V.24

Transmission rate 600 baud

Character format 1 start element

8 data bits

2 stop elements

Switch settings on the MI77 Interface

Switch for mode selection

Right position: serial

Switch S1 S1-1 to S1-8 OFF

Switch S2 S2-1 2345678

OFF OFF ON OFF OFF OFF OFF OFF

Switch S3 Position V.24/TTY

Switch S4 Position 6: 600 baud

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-9

SINUMERIK System 800, (PJ)

Page 54

8 Connecting I/O Devices in Practice 07.90

8.2.9 Facit 4030 tape reader

8.2.9 Facit 4030 tape reader

Cable order no. Device data

Interface V.24

Transmission rate 1200 Baud

Character format 1 start element

8 data bits

2 stop elements

Settings on the interface PCB

Jumper Function Jumper name

A V.24 or current loop W1

E Protective ground on chassis W2

G V.24 W3

O 1200 baud W4

U All baud rates except 110 baud W6

All jumpers open.

8.2.10 Facit, N1000 NC-Walk-Disk

Floppy disk drive

Cable order no. 6FC9 344-2M

Device data

GRP1 Parameters

1-1 INPUT = V.24

1-2 OUTPUT = V.24

1-3 INPUT CODE = ASC

1-4 OUTPUT CODE = ASC

1-5 PRG MARK = OFF

1-7 DC TRANSMIT = OFF

1-8 LRC = OFF

GRP2 parameters

2-1 V.24 = 9600 BPS

2-2 V.24 WORD LENGTH = 7

2-3 V.24 STOP ELEMENT = 2

2-4 V-PARIT = EVEN

2-5 V-XON/XOFF = OFF

2-6 V-READY/BUSY = P 19

Save parameters on diskette!

8-10

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02

SINUMERIK System 800, (PJ)

Page 55

07.90 8 Connecting I/O Devices in Practice

8.2.11 Facit, N1100 NC-Walk-Disk

8.2.11 Facit, N1100 NC-Walk-Disk

Floppy disk drive

Cable order no.: 6FC9 344-2M

Device data

Parameters GRP1

1-1 INPUT = V.24/1

1-2 OUTPUT = V.24/2

1-3 free

1-4 INPUT CODE = ISO

1-5 OUTPUT CODE = ISO

1-6 INPUT PRG MARK = ON

1-7 INPUT PRG MARK PM = c (Ctrl C ETX)

1-8 OUTPUT PRG MARK = OFF

1-10 LRC = OFF

1-11 SUBROUTINE = OFF

1-13 SAVE PRG MARK = ON

Parameters GRP2

2-1 V.24/1 BAUD RATE = 9600 BPS

2-2 V.24/1 WORD LENGTH = 7 BITS

2-3 V.24/1 STOP ELEMENT = 2

2-4 V.24/1 PARIT = EVEN

2-5 V.24/1 XON/XOFF = OFF

Save parameters on diskette!

Supplier of Facit devices

Facit GmbH

Willstätter Str. 11

4000 Düsseldorf 11

Tel. 0211/5286-131

8.2.12 Siemens DSG 3.5 floppy disk drive

Panel-mounted unit, free-standing unit

Cable order no.: 6FC9 344-2P

Device data

Interface V.24

Transmission rate 9600 baud

Character format 1 start element

8 data bits

2 stop elements

The device is equipped with 3 interface connectors for simultaneous linking of 3 SINUMERIK

controls.

The device works with automatic interface generation. Operation is as described in the user

guide accompanying the device.

© Siemens AG 1990 All Rights Reserved 6ZB5 410-0AQ02 8-11

SINUMERIK System 800, (PJ)

Page 56

8 Connecting I/O Devices in Practice 07.90

8.2.13 Siemens DSG 2S floppy disk drive

8.2.13 Siemens DSG 2S floppy disk drive

Panel mounted unit

Cable order no.: 6FM1 590-7B 00

Device for ”JOB-List” and ”Program sequential operation” function