Sharp Carousel II R-3A54 Schematic

R-3A54

R-2CC”

SHARP

SERVICE MANUAL

S4202R3A54PJ/

MICXOWAVE OVEN

MODELS

R-3A54

Photo R-3A54

R-3E54

In interests of user-safety the oven should be restored to its original

condition and only manufacturer original spare parts must be used.

(RD16101 U)

TABLE OF CONTENTS

Page

GENERAL

IMPORTANT INFORMATION

......................................................................................................

1

CAUTION, MICROWAVE

RADIATION,WARNING

......................................................................................

1

PRODUCT

SPECIFICATIONS

.........................................................................................................................

2

APPEARANCE

VIEW

........................................................................................................................................

3

OPERATION SEQUENCE

.................................................................................................................................

4

FUNCTION

OF

IMPORTANT COMPONENTS

...............................................................................

......................................................................................................................................

...?

............. 5

SERVICING

............. 7

TEST PROCEDURE

...........................................................................................................................................

9

TOUCH

CONTROL

ASSEMBLY ..................................................................................................................

17

COMPONENT

REPLACEMENT AND ADJUSTMENT

PROCEDURE

.....................................................

22

MICROWAVE

MEASUREMENT

/ WIRING DIAGRAM

.....................................................................

..!..

.........................................

28

.......................................................................................................................................

29

PICTORIAL DIAGRAM . ..................................................................................................................................

30

CONTROL PANEL

CIRCUIT

.........................................................................................................................

31

PRlN-I-ED WIRING

DIAGRAM

.....................................................................................................................

32

PARTS LIST

....................................................................................................................................................

33

PACKlNG

AND ACCESSORIES

...................................................................................................................

38

SHARP CORPORATION

All manuals and user guides at all-guides.com

all-guides.com

R-3A54

R-3E54

Photo R-3E54W)

All manuals and user guides at all-guides.com

SERVICE MANUAL

SHARP

MICROWAVE OVEN

R-3A54/ R-3E54

GENERAL IMPORTANT INFORMATION

This Manual has been prepared to provide Sharp Corp. Service

engineers with Operation and Service Information.

It is recommended that service engineers carefully study the

entire text of this manual, so they will be qualified to render

satisfactory customer service.

(RD36106U)

CAUTION

MICROWAVE RADIATION

Service engineers should not be exposed to the micro-

wave energy which may radiate from the magnetron or

other microwave generating devices if it is improperly

used or connected. All input and output microwave

connections, waveguides, flanges and gaskets must be

secured. Never operate the device without a microwave

energy absorbing load attached. Never look into an

open waveguide or antenna while the device is ener-

gized.

(RD36203U)

WARNING

Never operate the oven until the following points are

ensured.

(A)The door is tightly closed.

(B)The door brackets and hinges are not defective.

(C)The door packing is not damaged.

(D)The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by

trained service engineers.

list are used at voltages

All the parts marked 11*11 on parts

more than 250V.

I

(RD5111 Ou)

R-3A54

R-3E54

t>

is:,

PRODUCT SPECIFICATIONS

“4 .

APPEARANCE VIEW

3

f,”

OPERATING SEQUENCE

/1 *

~ ,JF

2 1 s?r’

. “:

,^

* ,‘*y$$

FUNCTION OF IMPORTANT -“

SERVICING AND

S”

g:”

TEST PROCEDURE

,I ,*<

I Y”“-

I .

^ A

“\;

_ *

TOUCH CONT

ASSEMBLY

REPLACEMENT AND

A

“-

> *

: I‘

@) ;

p”,* ”

MICROWAVE MEASUREMENT

SHARP CORPORATION

OSAKA, JAPAN

(RD37201 U)

All manuals and user guides at all-guides.com

R-3A54

R-3E54

PRODUCT SPECIFICATIONS

SPECIFICATION

ITEM

Power Requirements

240 Volts

50 Hertz

DESCRIPTION

Power Consumption

Power Output

Case Dimensions

Single phase, 3 wire earthed

I .3kW Approx. 6.0 A

800W (IEC-705-1988), 650W (AS 2895-l 986)

Operating frequency of 2450M Hz

Width 520mm

._ Height 294mm

Depth 388mm

Cooking Cavity Dimensions

Width 350 mm

Height 197 mm

Depth 368 mm

Turntable diameter

Control Complement

325mm

Touch Control System

Clock( I:00 - 12:59 )

Timer (0 - 99 minutes 99 seconds )

Microwave Power for Variable Cooking

Repetition Rate;

HIGH

. . . . . . . . ..*...................... Full power throughout the cooking time

MEDIUM

HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

approx. 70% of Full

Power

MEDIUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

approx.

50% of Full Power

MEDIUM LOW . . ..*...............*........*.......... approx. 30% of Full Power

LOW

*..................,.................................,.... approx. 10% of Full Power

AUTO COOK (R-3A54 only)

EASY DEFROST

Set Weight

INSTANT COOK/START

LESS/MORE (R-3A54 only)

AUTO START/CLOCK

POWER LEVEL

INSTANT ACTION (8 menu)

NUMBER”

STOP/CLEAR

Approx. 16.0 kg

,PnA*,n, 1 I

L

,.l”v-rl”I u)

GENERAL INFORMATION

WARNING

THIS APPLIANCE MUST BE EARTHED

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN-AND-YELLOW

: EARTH

BLUE

: NEUTRAL

BROWN

: LIVE

i

NOTE: Numbers and letters shown after sentences such as “RD44101 U” are for factory use only.

2

All manuals and user guides at all-guides.com

R-3A54

R-3E54

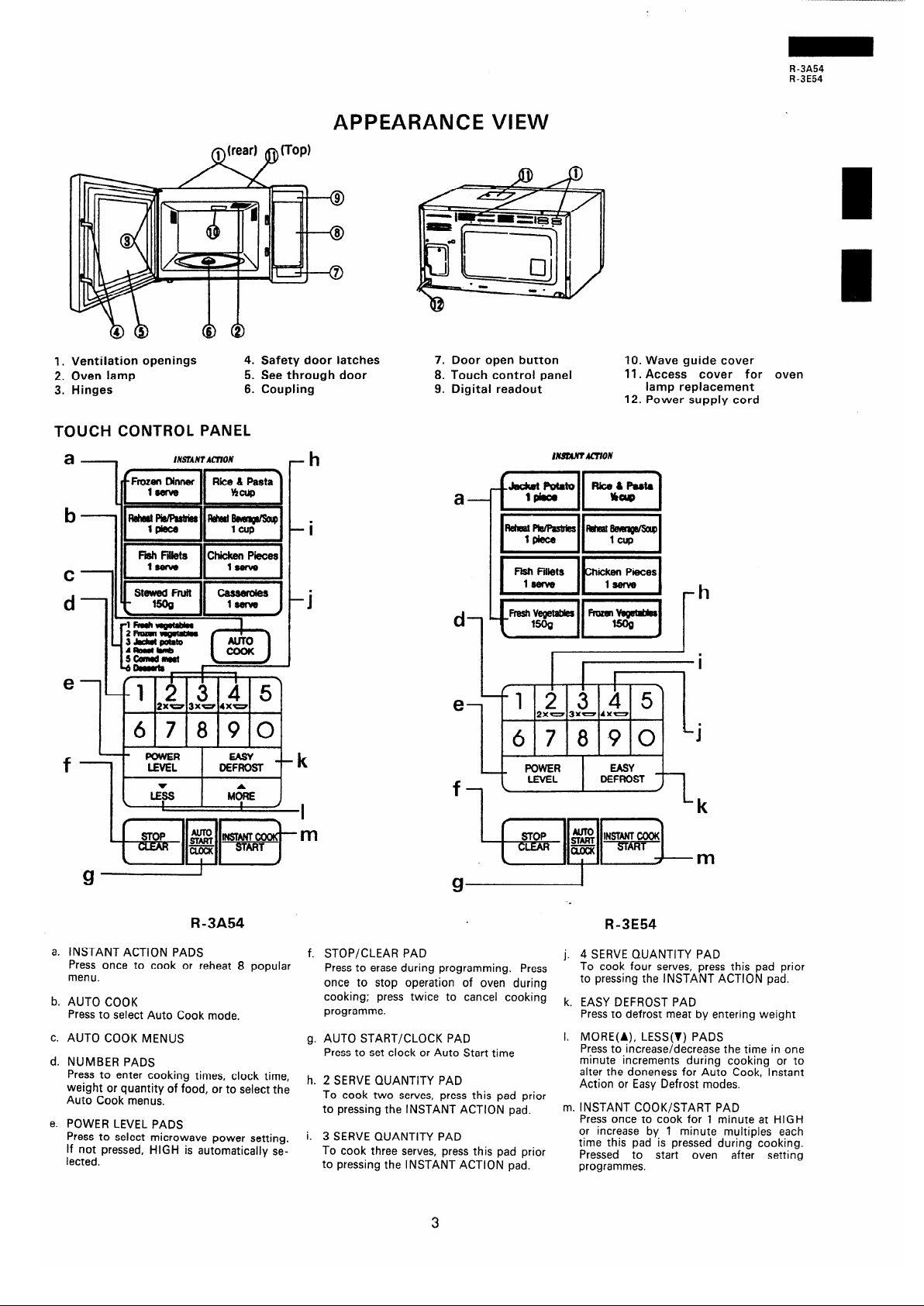

APPEARANCE VIEW

1.

Ventilation

openings 4.

Safety door

latches

2.

Oven lamp

5. See through

door

3.

Hinges

6. Coupling

TOUCH CONTROL PANEL

a-

INSTANT ACnON

-h

d-

e

1

2xw 3xw 4xw

67890

I

-i

4

f--=J-=: I

lE!Ev

t-k

R-3A54

7. Door open button

8. Touch control panel

9. Digital readout

10. Wave guide cover

11. Access cover for oven

lamp replacement

12. Power supply cord

a-

d

1

INSN.NT.UTION

h

I

i

I

2xw 3xw 4xw

67800 “j

R-3E54

a. INSTANT ACTION PADS f. STOP/CLEAR PAD

Press once to cook or reheat 8 popular

j. 4 SERVE QUANTITY PAD

Press to erase during programming. Press

To cook four serves, press this pad prior

menu.

once to stop operation of oven during

to pressing the INSTANT ACTION pad.

b. AUTO COOK

Press to select Auto Cook mode.

c. AUTO COOK MENUS

cooking; press twice to cancel cooking

k. EASY DEFROST PAD

programme.

Press to defrost meat by entering weight

AUTO START/CLOCK PAD

Press to set clock or Auto Start time

d. NUMBER PADS

Press to enter cooking times, clock time,

weight or quantity of food, or to select the

Auto Cook menus.

e. POWER LEVEL PADS

Press to select microwave power setting.

If not pressed, HIGH is automatically se-

lected.

g.

h.

2 SERVE QUANTITY PAD

To cook two serves, press this pad prior

to pressing the INSTANT ACTION pad.

3 SERVE QUANTITY PAD

To cook three serves, press this pad prior

to pressing the INSTANT ACTION pad.

I. MORE(A), LESS(v) PADS

Press to increase/decrease the time in one

minute increments during cooking or to

alter the doneness for Auto Cook, Instant

Action or Easy Defrost modes.

m. INSTANT COOK/START PAD

Press once to cook for 1 minute at HIGH

or increase by 1 minute multiples each

time this pad is pressed during cooking.

Pressed to start oven after setting

programmes.

3

All manuals and user guides at all-guides.com

R -3A54

R-3E54

OPERATING SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches

(1 st latch switch, 2nd latch switch and stop switch).

IMPORTANT

When the oven door is closed, the monitor switch

contacts (COM -

NC) rnust be open.

When the microwave oven is plugged in a wall outlet.

Rated voltage is supplied to the point A3+ A5 in the

control unit.

1.

3

L.

3.

Figure O-l on page 29

The display flashes “88:88”. -

To set any programmes or set the clock, you must

first touch the STOP/CLEAR key.

11 .

. II appears in the display and the time counts

up every minute.

NOTE: When the oven door is opened, the oven

lamp comes on at this time.

MICROWAVE COOKING CONDITION

HIGH COOKING

Enter a desired cooking time with the touching Number

key and start the oven with touching START key.

Function sequence

1.

2.

3.

4.

5.

Figure O-2 on page 29

CONNECTED COMPONENTS

RELAY

Oven lamp, Fan motor, Turntable motor

RYl

Power transformer

RY2

Rated voltage is supplied to the primary winding of

the power transformer. The voltage is converted to

about 3.3 volts A.C. output on the filament winding

and high voltage of approximately 2000 volts A.C.

on the secondary winding.

The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000

volts) is sent to the voltage doubling circuit, where

it is doubled to negative voltage of approximately

4000 volts D.C..

The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm.

This energy is channeled through the waveguide

(transport channel) into the oven cavity, where the

food is placed to be cooked.

When the cooking time is up, a signal tone is heard

and the relays RYI + RY2 go back to their home

position. The circuits to the oven lamp, power

transformer, fan motor and turntable motor are cut

off.

When the door is opened during a cook cycle, the

switches come to the following condition.

CONDITION

DURING

DOOR OPEN

SWITCH

CONTACT

COOKING (NO COOKING)

1st latch switch

COM - NO

Closed

Open

Monitor switch

COM -NC

Open

Closed

2nd latch switch COM - NO

Closed

Open

Stop switch COM - NO

Closed

Open

The circuits to the power transformer, fan motor and

turntable motor are cut off when the 1st latch

switch, 2nd latch switch and stop switch are made

open.

The oven lamp remains on even if the oven door is

opened after the cooking cycle has been inter-

rupted, because the relay RYI stays closed. Shown

in the display is the remaining time.

6. MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by

oven door, and monitors the operation of the 1 st

and 2nd latch switches.

6-l

When the oven door is opened during or after the

cycle of a cooking program, the 1 st latch, 2nd

latch and stop switches must open their contacts

first. After that the contacts (COM - NC) of the

monitor switch can be closed.

6-2

When the oven door is closed, the contacts

(COM -NC) of the monitor switch must be

opened. After that the contacts of the 1st latch,

2nd latch and stop switches are closed.

6-3. When the oven door is opened and the contacts

of the 1st and 2nd latch switches remain closed,

the fuse M8A will blow because the monitor

switch is closed and a short circuit is caused.

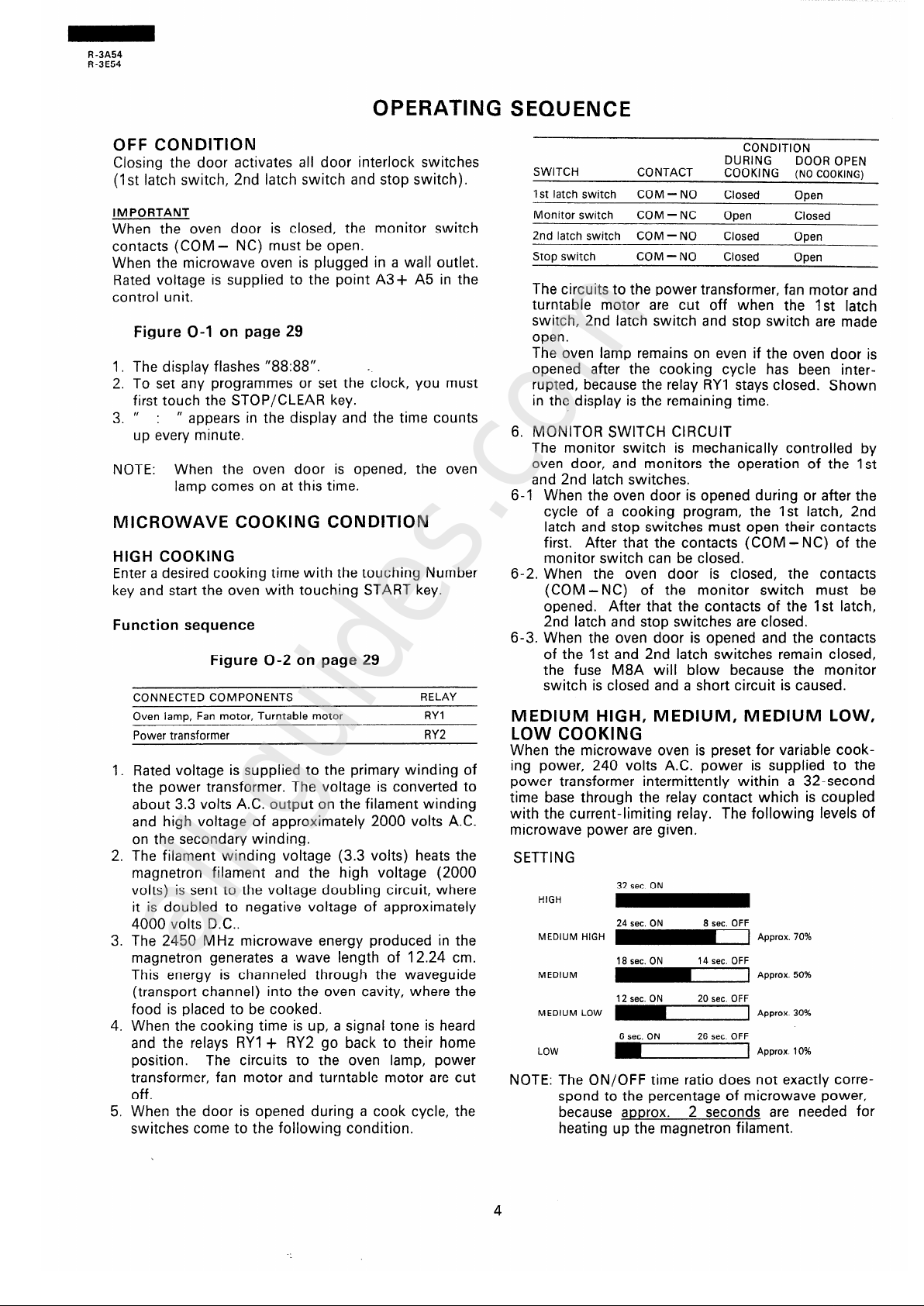

MEDIUM HIGH, MEDIUM, MEDIUM LOW,

LOW COOKING

When the microwave oven is preset for variable cook-

ing power, 240 volts A.C. power is supplied to the

power transformer intermittently within a 32-second

time base through the relay contact which is coupled

with the current-limiting relay. The following levels of

microwave power are given.

SETTING

32 sec. ON

HIGH

MEDIUM HIGH

MEDIUM

MEDIUM LOW

LOW

24 sec. ON 8 sec. OFF

18 sec. ON

14 sec. OFF

J-1 Approx. 50%

12 sec. ON 20 sec. OFF

6 sec. ON 26 sec. OFF

J-1 Approx 10%

NOTE: The ON/OFF time ratio does not exactly corre-

spond to the percentage of microwave power,

because approx. 2 seconds are needed for

heating up the magnetron filament.

All manuals and user guides at all-guides.com

all-guides.com

R-3A54

R-3E54

FUNCTION OF IMPORTANT COMPONENTS

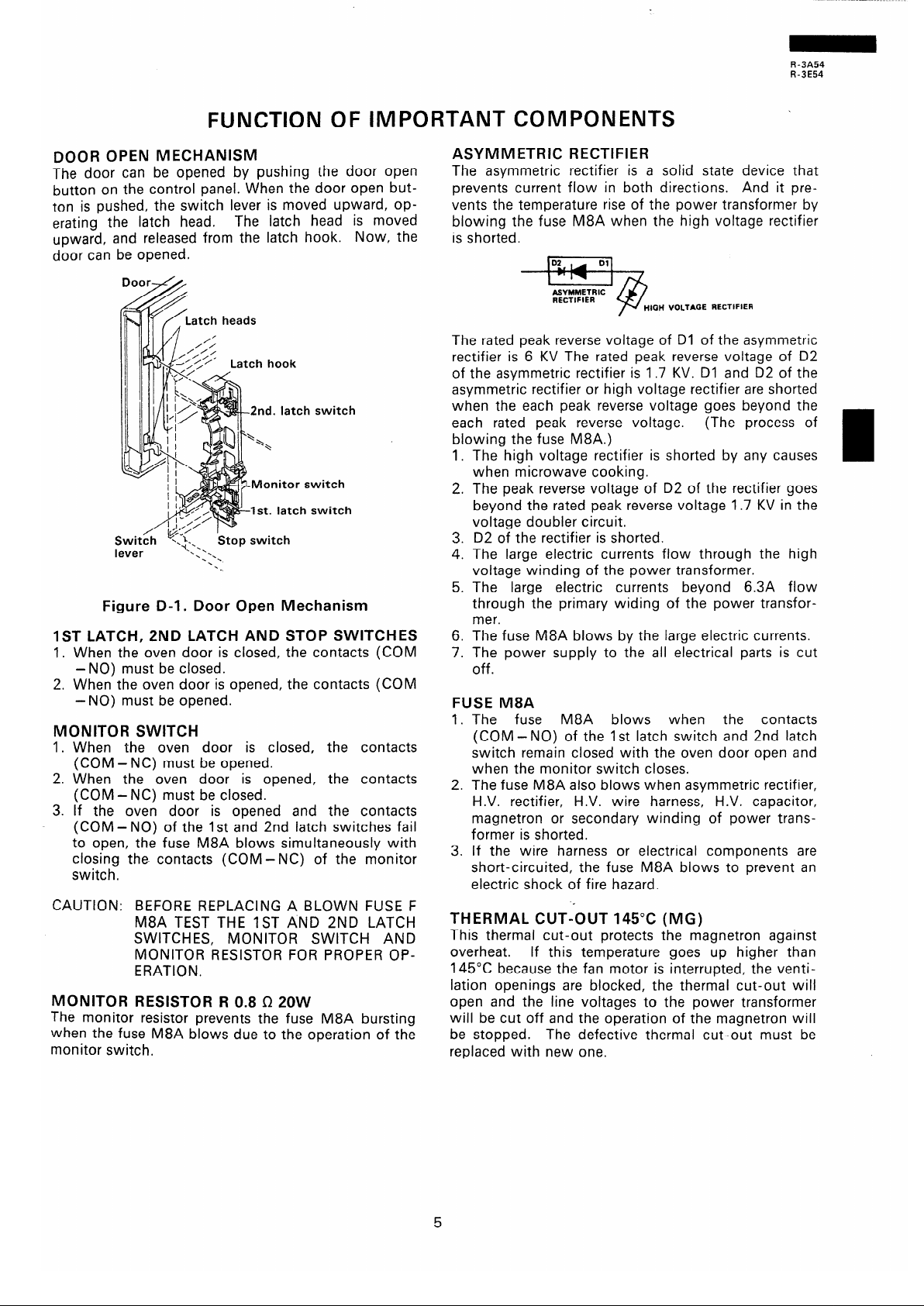

DOOR OPEN MECHANISM

The door can be opened by pushing the door open

button on the control panel. When the door open but-

ton is pushed, the switch lever is moved upward, op-

erating the latch head.

The latch head is moved

upward, and released from the latch hook. Now, the

door can be opened.

Door--&+

Switch

lever

Stop switch

‘.

‘. .\

*.

‘.

Figure D-l. Door Open Mechanism

IST LATCH, 2ND LATCH AND STOP SWITCHES

1. When the oven door is closed, the contacts (COM

2. When the oven door is opened, the contacts (COM

-NO) must be opened.

-NO) must be closed.

MONITOR SWITCH

1. When the oven door is closed, the contacts

(COM-NC) must be opened.

2. When the oven door is opened, the contacts

(COM - NC) must be closed.

3. If the oven door is opened and the contacts

(COM - NO) of the 1st and 2nd latch switches fail

to open, the fuse M8A blows simultaneously with

closing the contacts (COM -NC) of the monitor

switch.

CAUTION: BEFORE REPLACING A BLOWN FUSE F

M8A TEST THE IST AND 2ND LATCH

SWITCHES, MONITOR SWITCH AND

MONITOR RESISTOR FOR PROPER OP-

ERATION.

MONITOR RESISTOR R 0.8 I2 20W

The monitor resistor prevents the fuse M8A bursting

when the fuse M8A blows due to the operation of the

monitor switch.

ASYMMETRIC RECTIFIER

The asymmetric rectifier is a solid state device that

prevents current flow in both directions. And it pre-

vents the temperature rise of the power transformer by

blowing the fuse M8A when the high voltage rectifier

is shorted.

The rated peak reverse voltage of Dl of the asymmetric

rectifier is 6 KV The rated peak reverse voltage of D2

of the asymmetric rectifier is 1.7 KV. Dl and D2 of the

asymmetric rectifier or high voltage rectifier are shorted

when the each peak reverse voltage goes beyond the

each rated peak reverse voltage. (The process of

blowing the fuse M8A.)

1. The high voltage rectifier is shorted by any causes

when microwave cooking.

2. The peak reverse voltage of D2 of the rectifier goes

beyond the rated peak reverse voltage 1.7 KV in the

voltage doubler circuit.

6. The fuse M8A blows by the large electric currents.

7. The power supply to the all electrical parts is cut

off.

3. D2 of the rectifier is shorted.

4. The large electric currents flow through the high

voltage winding of the power transformer.

5. The large electric currents beyond 6.3A flow

through the primary widing of the power transfor-

mer.

FUSE M8A

1. The fuse M8A blows when the contacts

(COM -NO) of the 1 st latch switch and 2nd latch

switch remain closed with the oven door open and

when the monitor switch closes.

2. The fuse M8A also blows when asymmetric rectifier,

H.V. rectifier, H.V. wire harness, H.V. capacitor,

magnetron or secondary winding of power trans-

former is shorted.

3. If the wire harness or electrical components are

short-circuited, the fuse M8A blows to prevent an

electric shock of fire hazard.

THERMAL CUT-OUT 145°C (MG)

This thermal cut-out protects the magnetron against

overheat. If this temperature goes up higher than

145°C because the fan motor is interrupted, the venti-

lation openings are blocked, the thermal cut-out will

open and the line voltages to the power transformer

will be cut off and the operation of the magnetron will

be stopped.

The defective thermal cut-out must be

replaced with new one.

All manuals and user guides at all-guides.com

R-3A54

R-3E54

THERMAL CUT-OUT 145°C (OVEN)

The thermal cut-out located on the top of the oven

cavity is designed to prevent damage to the oven if the

food in the oven catch fire due to over heating

produced by upper setting of cook time or failure of

control unit. Under normal operation, the oven thermal

cut-out remain closed.

However, when abnormally

high temperatures are reached within the oven cavity,

the oven thermal cut-out will open at 145OC, causing

the oven to shut down. The defective thermal cut-out

must be replaced with new one.

TURNTABLE MOTOR

The turntable motor drives coupling to rotate the

turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool

air. This cool air is directed through the air vanes sur-

rounding the magnetron and cools the magnetron.

This air is channeled through the oven cavity to remove

steam and vapors given off from the heating foods. It

is then exhausted through the exhausting air vents at

the oven cavity.

All manuals and user guides at all-guides.com

R-3A54

R-3E54

SERVICING

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with any part

of the high voltage circuit will result in electrocuition.

REMEMBER TO CHECK 3D

1) Disconnect the supply.

2) Door opened, and wedged open.

3) Discharge high voltage capacitor.

I-

WARNING AGAINST THE CHARGE OF THE

HIGH-VOLTAGE CAPACITOR

The high-voltage capacitor remains charged

about 60 seconds after the oven has been

switched off. Wait for 60 seconds and then

short-circuit

the

connection of

the

high-voltage capacitor (that is, of the con-

necting lead of the high-voltage rectifier)

against the chassis with the use of an insu-

lated screwdriver.

Sharp

recommend

that wherever possible

fault-finding is carried out with the supply discon-

nected. It may in, some cases, be necessary to

connect the supply after the outer case has been

removed, in this event carry out 3lJ checks and then

disconnect the leads to the primary of the power

transformer. Ensure that these leads remain isolated

from other components and the oven chassis. (Use

insulation tape if necessary.) When the testing is

completed carry out 3D checks and reconnect the

leads to the primary of the power transformer.

REMEMBER TO CHECK $lJ

1) Reconnect all leads removed from components

during testing.

2) Replace the outer case (cabinet).

3) Reconnect the supply.

4) Run the oven. Check all functions.

Microwave ovens should not be run empty. To test

for the presence of microwave energy within a

cavity, place a cup of cold water on the oven

turntable, close the door and set the microwave

timer for two (2) minutes. Set the power level to

HIGH and push the START button. When the two

minutes has elapsed (timer at zero) carefully check

that the water is now hot. If the water remains cold

carry out 3lJ checks and re-examine the con-

nections to the component being tested.

When all service work is completed, and the oven is fully assembled, the microwave power output should

be checked and a microwave leakage test carried out.

TROUBLESHOOTING GUIDE

When troubleshooting the microwave oven, it is

helpfull to follow the Sequence of Operation in per-

forming the checks.

Many of the possible causes of

trouble will require that a specific test be performed.

These tests are given a procedure letter which will be

found in the “Test Procedure”section.

IMPORTANT: If the oven becomes inoperative be-

cause of a blown fuse (M8A) in the

1 st latch switch - 2nd latch switch -

monitor switch

- monitor resisitor cir-

cu-it, check the 1st latch switch, 2nd

latch switch, monitor switch and

monitor resistor before replacing the

fuse (M8A).

All manuals and user guides at all-guides.com

R-3A54

R-3E54

RE = Replace / CK = Check

TEST PROCEDURE

P

ii

ii

ii

F

9

-

-

-

-

-

-

-

-

-

-

C

-

-

-

P

L

ONOITION

IFF

:ONDITION

IN

:ONDITION

POSSIBLE

CASE AND

&Xl;ECTIVE

PROBLEM

iome fuse blows when power supply cord is

slugged into wall outlet.

-USE M8A blows when power supply cord is

slugged into wall outlet.

‘88:88” does not appear in display but power

jupply cord is plugged into wall outlet.

3isplay does not operate properly when

STOP/CLEAR key is touched.

3ven lamp does not light at door opened.

: Display appears.)

3ven does not start when the START pad is

ouched. (Display appears)

3ven lamp does not light

:Display appears.)

-an motor does not operate.

(Display appears.)

Turntable motor assembly does not operate.

(Display appears.)

Oven or any electrical parts does not stop

But cooking time is 0 or STOP/CLEAR key

touched

Oven seems to be operating but little or no heat

is produced in oven load. (Microwave power level

is set at HIGH)

-

Oven does not seems to be operating properly

when MEDIUM HIGH, MEDIUM, MEDIUM LOW

or LOW is set. (Oven operates properly at HIGH

and then the STOP/CLEAR pad is touched the

oven stops.)

Oven goes into cook cycle but shuts down before

end of cooking cycle.

Oven stops as soon as when the START pad is

touched.

E

-

E

I

a

i?

+

2

-

-

,

-

-

-

-

-

-

-

-

-

-

-

-

F

-

ii

E

p/1

k

ci

1

ii

1

z

C

-

5

-

-

-

-

-

-

-

-

c

-

3

2

::

E

T

i

:

i!

g

-

c

-

-

-

-

-

-

-

-

-

-

-

T

3

0

;

!i

Y

ER

ii

!i

:

-

-

”

-

v

-

2

-

-

m

-

c

c

-

-

C

-

-

-

3E

c

E

k

F

;

:

5

-

-

-

-

-

-

c:

-

-

-

-

-

-

-

8

All manuals and user guides at all-guides.com

R -3A54

I?-3E54

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

A

MAGNETRON TEST

’ NEVER TOUCH ANY PART IN THE CIRCUIT WITH YOUR HAND OR AN INSULATED

TOOL WHILE THE OVEN IS IN OPERATION.

____-- -----_____-_.. __ _____ _ _

CARRY OUT 3D CHECKS

Isolate the magnetron from the high voltage circuit by removing all leads connected to the filament

terminal.

To test for an open circuit filament use an ohmmeter to make a continuity test between the

magnetron filament terminals, the meter should show a reading of less than 1 ohm.

To test for a short circuit filament to anode condition, connect ohmmeter between one of the fil-

ament terminals and the case of the magnetron (ground). This test should be indicated an infinite

resistance. If a low or zero resistance reading is obtained then the magnetron should be re

laced.

(R g 82AOl U)

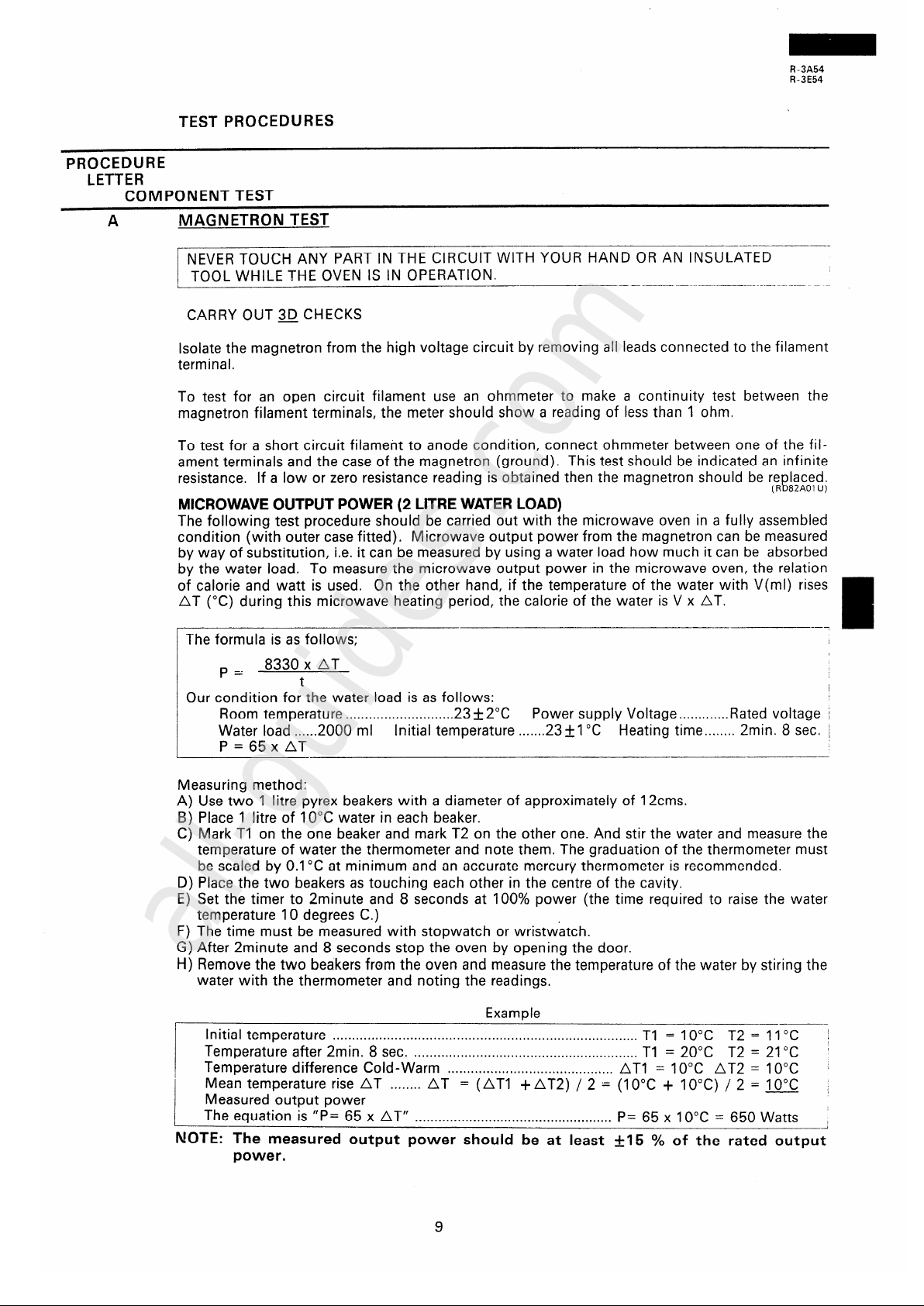

MICROWAVE OUTPUT POWER (2 LITRE WATER LOAD)

The following test procedure should be carried out with the microwave oven in a fully assembled

condition (with outer case fitted). Microwave output power from the magnetron can be measured

by way of substitution, i.e. it can be measured by using a water load how much it can be absorbed

by the water load. To measure the microwave output power in the microwave oven, the relation

of calorie and watt is used. On the other hand, if the temperature of the water with V(ml) rises

AT (“C) during this microwave heating period, the calorie of the water is V x AT.

The formula is as follows;

p=

8330 x AT

t

Our condition for the water load is as follows:

/

Room temperature

. . . . ..*..................... 23 + 2°C Power supply Voltage . . . . . . . . . . . . . Rated voltage /

Water load

. . . ...2000 ml Initial temperature

. . . . ...23&1 “C Heating time . . . . . . . . 2min. 8 sec. j

P=65xAT

Measuring method:

A) Use two 1 litre Pyrex beakers with a diameter of approximately of 12cms.

B) Place 1 litre of 10°C water in each beaker.

C) Mark Tl on the one beaker and mark T2 on the other one. And stir the water and measure the

temperature of water the thermometer and note them. The graduation of the thermometer must

be scaled by 0.1 “C at minimum and an accurate mercury thermometer is recommended.

D) Place the two beakers as touching each other in the centre of the cavity.

E) Set the timer to 2minute and 8 seconds at 100% power (the time required to raise the water

temperature 10 degrees C.)

F) The time must be measured with stopwatch or wristwatch.

G) After 2minute and 8 seconds stop the oven by opening the door.

H) Remove the two beakers from the oven and measure the temperature of the water by stiring the

water with the thermometer and noting the readings.

Example

Initial temperature

Tl = 10°C

T2 =

...............................................................................

11 “C

Temperature after 2min.

8 sec. ..........................................................

Tl =

20°C T2 = 21 “C

Temperature difference Cold-Warm

........................................... AT1 = 10°C

AT2 = 10°C

Mean temperature rise AT ........

AT = (AT1 +AT2) / 2 - (IOOC + IO’C) / 2 = 10°C

Measured output power

The equation is “P= 65 x AT”

...................................................

P= 65 x 10°C = 650 Watts

NOTE: The measured output power should be at least +I5 % of the rated output

power.

All manuals and user guides at all-guides.com

all-guides.com

Loading...

Loading...